Semantic-Based Assembly Precision Optimization Strategy Considering Assembly Process Capacity

Abstract

:1. Introduction

- (1)

- By combining the empirical knowledge, the research on assembly precision optimization can quickly establish the assembly precision optimization strategy, which can be used to guide the assembly precision optimization.

- (2)

- In the literature, the influence of multiple alternative assembly processes on precision optimization was rarely considered. The proposed method can be used to balance the cost and assembly accuracy of multiprocess complex assembly parts, and it is an effective precision optimization method.

- (3)

- Manufacturing deviation in the process of parts machining is characterized by uncertainty and randomness. Tolerances of parts are gradually accumulated in mechanical assembly. The traditional analysis method did not consider the tolerance stack. The problem of tolerance stack is solved by the Monte Carlo simulation in the section of case study.

2. Assembly Precision Optimization Based on Process Capability

2.1. Assembly Precision Optimization Principle

- (1)

- An assembly precision optimization semantic model depicting the terminology and data structure for assembly precision optimization.

- (2)

- A reasoning mechanism based on Cp inferring the underlying relations among the existing data.

2.2. Assembly Precision Optimization Procedure

- Determination of key characteristics

- Parsing the assembly model

- Assembly precision analysis

3. An Ontology-Based Assembly Precision Optimization Model

3.1. Assembly Precision Optimization Semantic Model

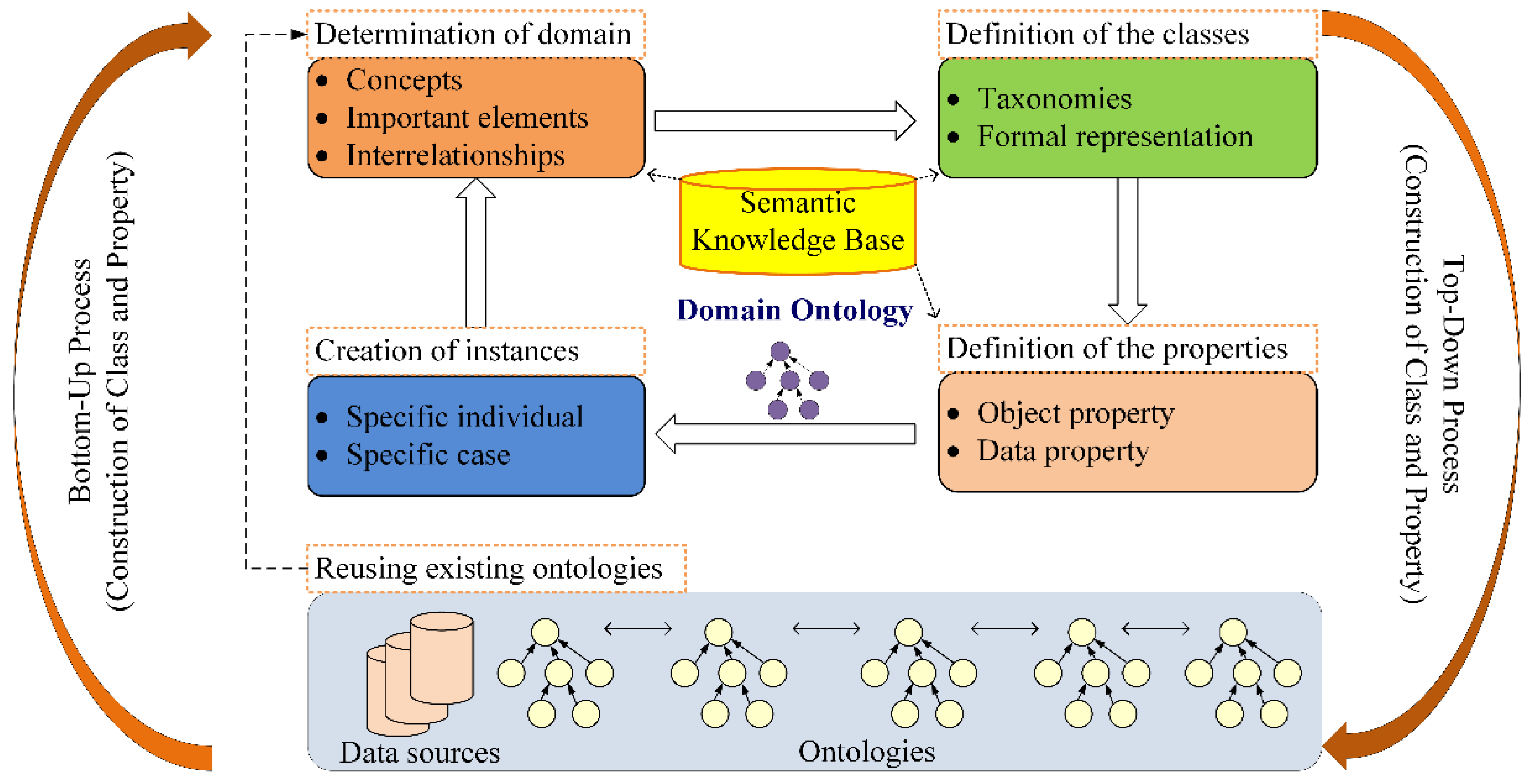

- Step 1. Determining the domain and scope of the ontology application. In the first stage, some basic problems and concepts in the research field are determined, which help to understand the scope, definition domain, and comprehensiveness of ontology construction. Under the background of ensuring assembly precision in the product design stage, the established ontology application domain is to optimize assembly precision.

- Step 2. Considering the reusing of existing ontologies. Although ontology theory and technology have been applied in the design and manufacturing fields, such as assembly sequence planning, tolerance specification design, etc., it has not been applied in any assembly precision optimization-related domain. Therefore, no appropriate ontology can be reused.

- Step 3. Enumerating important terms in the ontology. In order to standardize this step, the main terms and their meanings are international standards and integrated scientific publications. Important terms include (1) terms related to assembly precision optimization, such as assembly precision optimization object, assembly precision optimization strategy, and (2) terms related to the assembly precision analysis result, such as assembly capacity level, assembly capacity level description, contributor, sensitivity, process capability index, and out-of-tolerance and within-design requirements. The listed terms above are used to semantically represent assembly precision analysis and optimization-related contents that constitute the application method of this study.

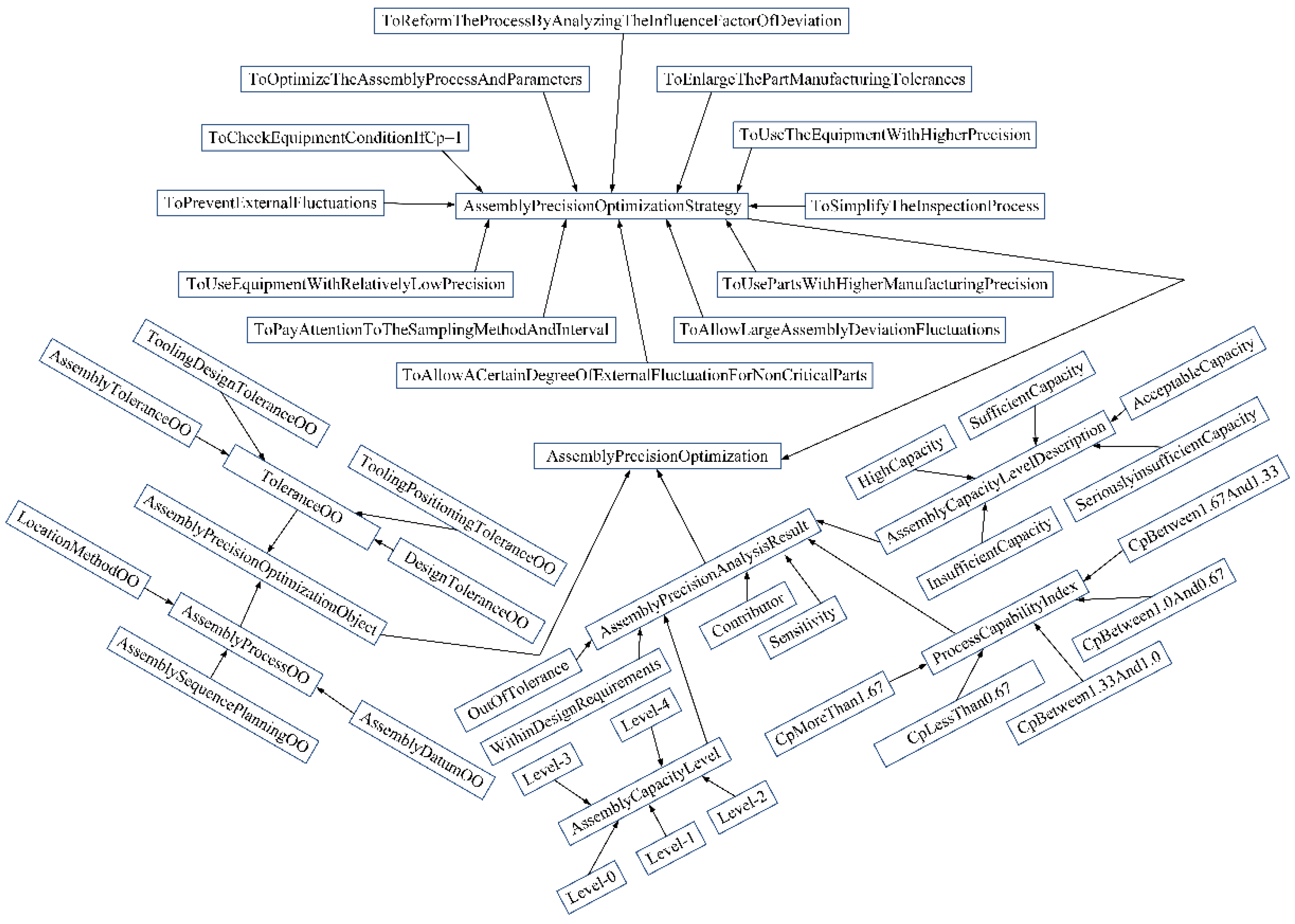

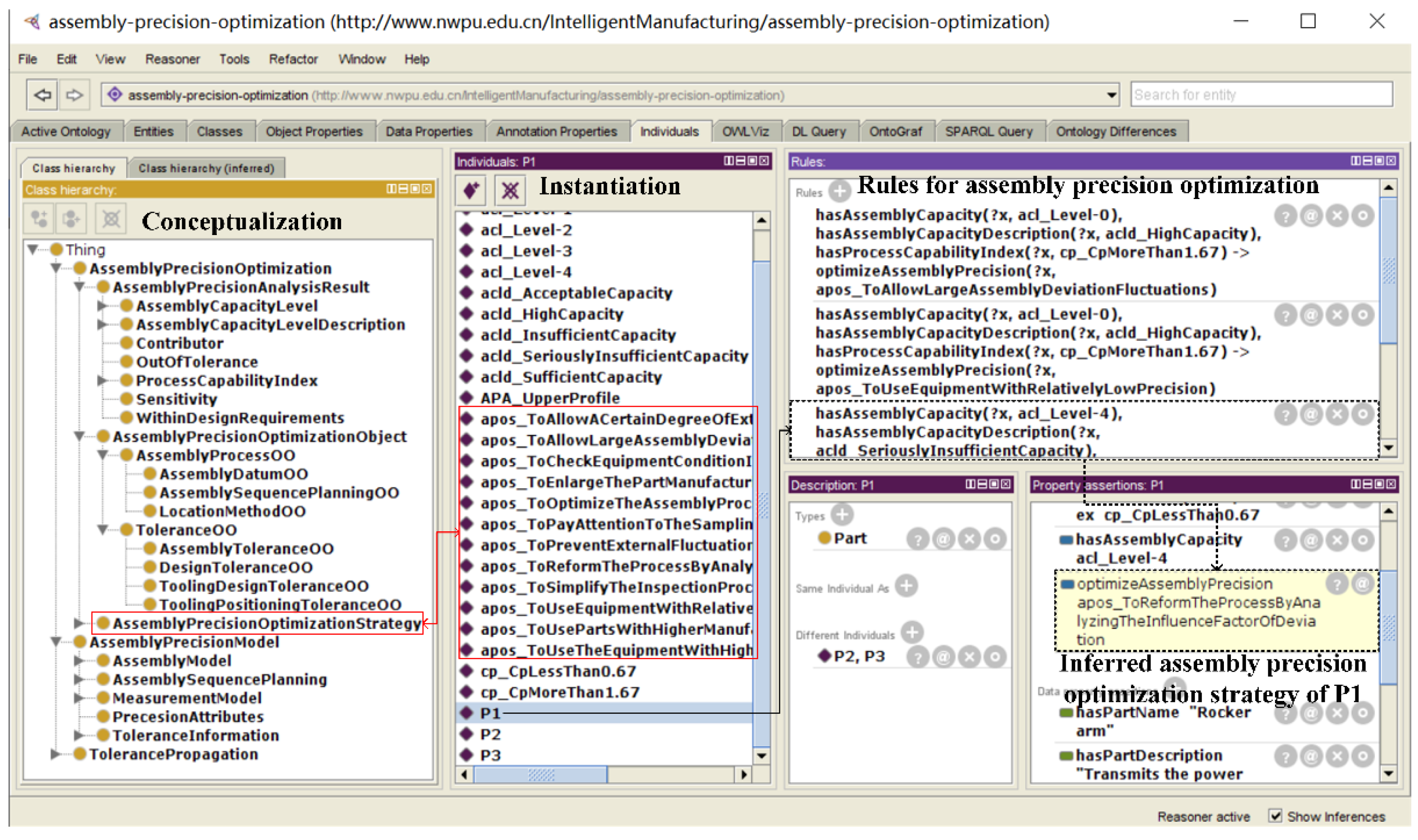

- Step 4. Definition of the classes and the class hierarchy. A composite development procedure is a combination of the top-down and bottom-up class construction approaches, the more salient concepts firstly being defined and then being generalized and specialized appropriately. A few top-level concepts such as assembly precision optimization and assembly precision analysis result are established and then related to a middle-level concept, such as assembly capacity level, assembly capacity level description, process capability index, assembly precision optimization object, and assembly precision optimization strategy. As shown in Figure 4, the hierarchy of the first- to fourth-level classes of assembly precision optimization ontology is presented.

- Step 5. Definition of the properties of the classes. In the process of assembly precision optimization ontology construction, it is also necessary to describe the internal structure of concepts (classes) and their mutual relations for classes with defined top-level framework properties. As shown in Table 1, the object properties, their corresponding meanings, and their domain and range are listed. As the class definitions are refined and concretized, more property definitions (such as data property definitions) are added to the lower nonframework classes. The construction of classes and the definition of properties between classes are closely related, and the two processes occur interactively.

| No. | Object Property | Meaning | Domains | Ranges |

|---|---|---|---|---|

| 1 | hasAssemblyPrecisionAnalysis | Assembly precision simulation is carried out | AssemblyModel | AssemblyPrecisionAnalysisResult |

| 2 | hasProcessCapabilityIndex | Process capability index in the results of assembly precision analysis | AssemblyModel | ProcessCapabilityIndex |

| 3 | hasSensitivity | The sensitivity of deviation source in the results of assembly precision analysis | AssemblyModel | Sensitivity |

| 4 | hasContributor | The contributor of deviation source in the results of assembly precision analysis | AssemblyModel | Contributor |

| 5 | hasKeyCharacteristicsOutOfTolerance | Key characteristics out of tolerance in assembly precision analysis | AssemblyModel | KeyCharacteristics |

| 6 | determineRangeOfAssemblyPrecisionOptimizationObjects | According to the results of assembly precision analysis, the target range of assembly precision optimization is determined | AssemblyModel | Subassembly |

| 7 | adjustAssemblyProcessOutOfTolerance | According to the determined optimization object range, assembly process of the key characteristics out of tolerance is adjusted | AssemblyModel | AssemblyProcess |

| 8 | adjustDesignTolerance | According to the determined optimization object range, design tolerance of the key characteristics out of tolerance is adjusted | AssemblyModel | ToleranceInformation |

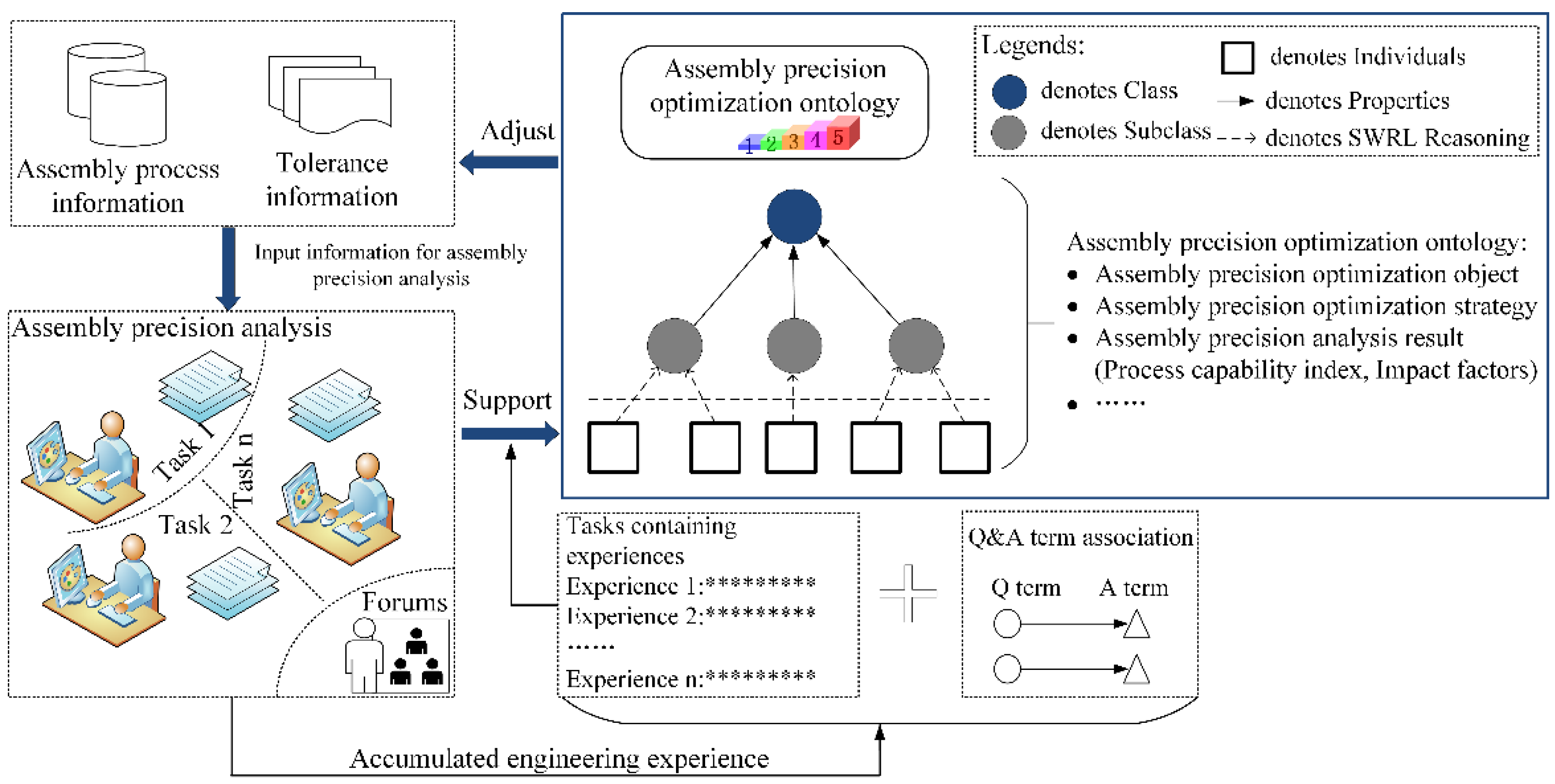

- Step 6. The last step of the assembly precision optimization ontology model is creating instances (also known as an object, value, or individual). The instances of classes are used to represent the specific problem of assembly precision optimization. The relationships between instances, classes, and properties are illustrated in Figure 5.

3.2. Assembly Precision Optimization SWRL Rules Based on Cp

4. Case Study

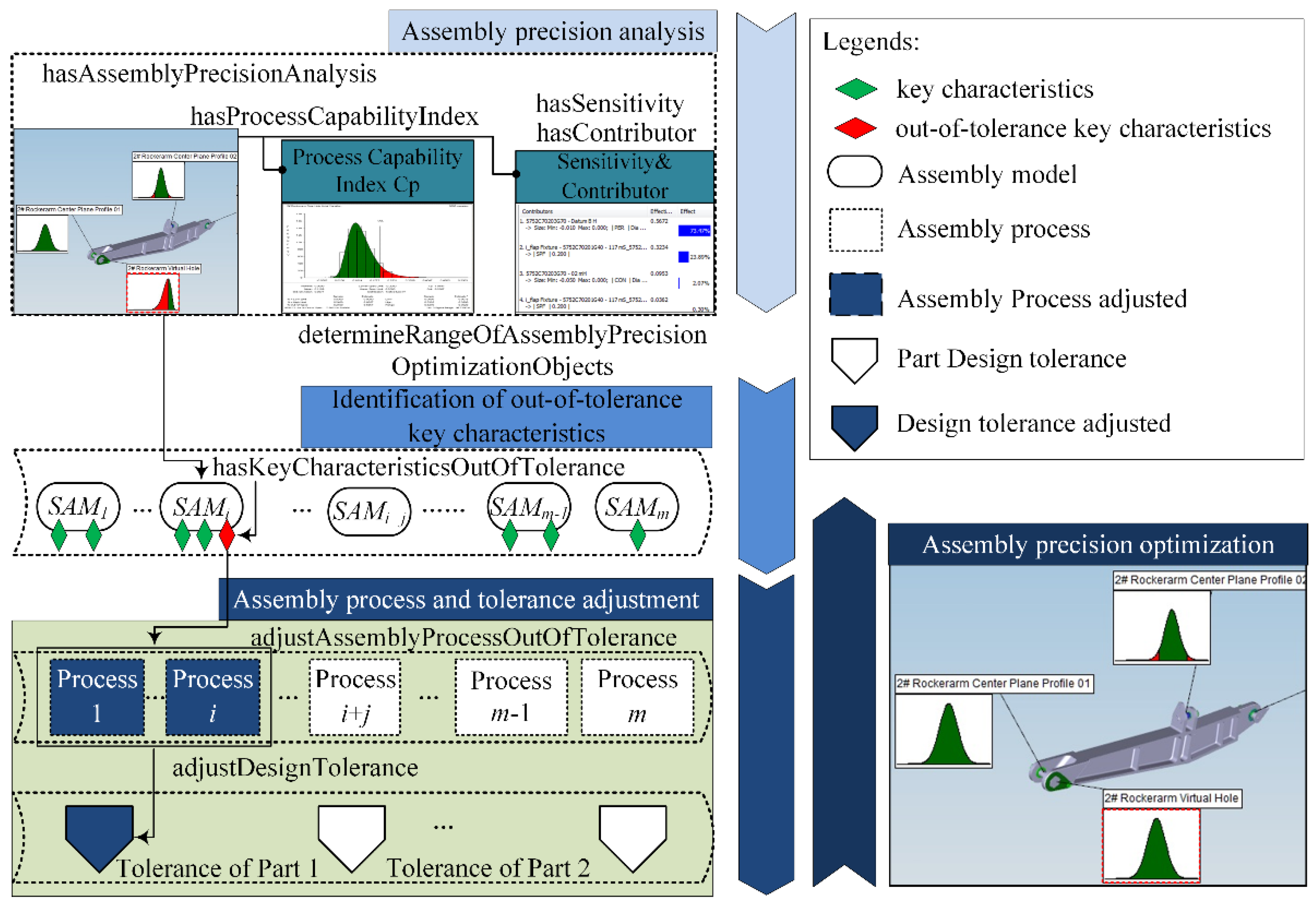

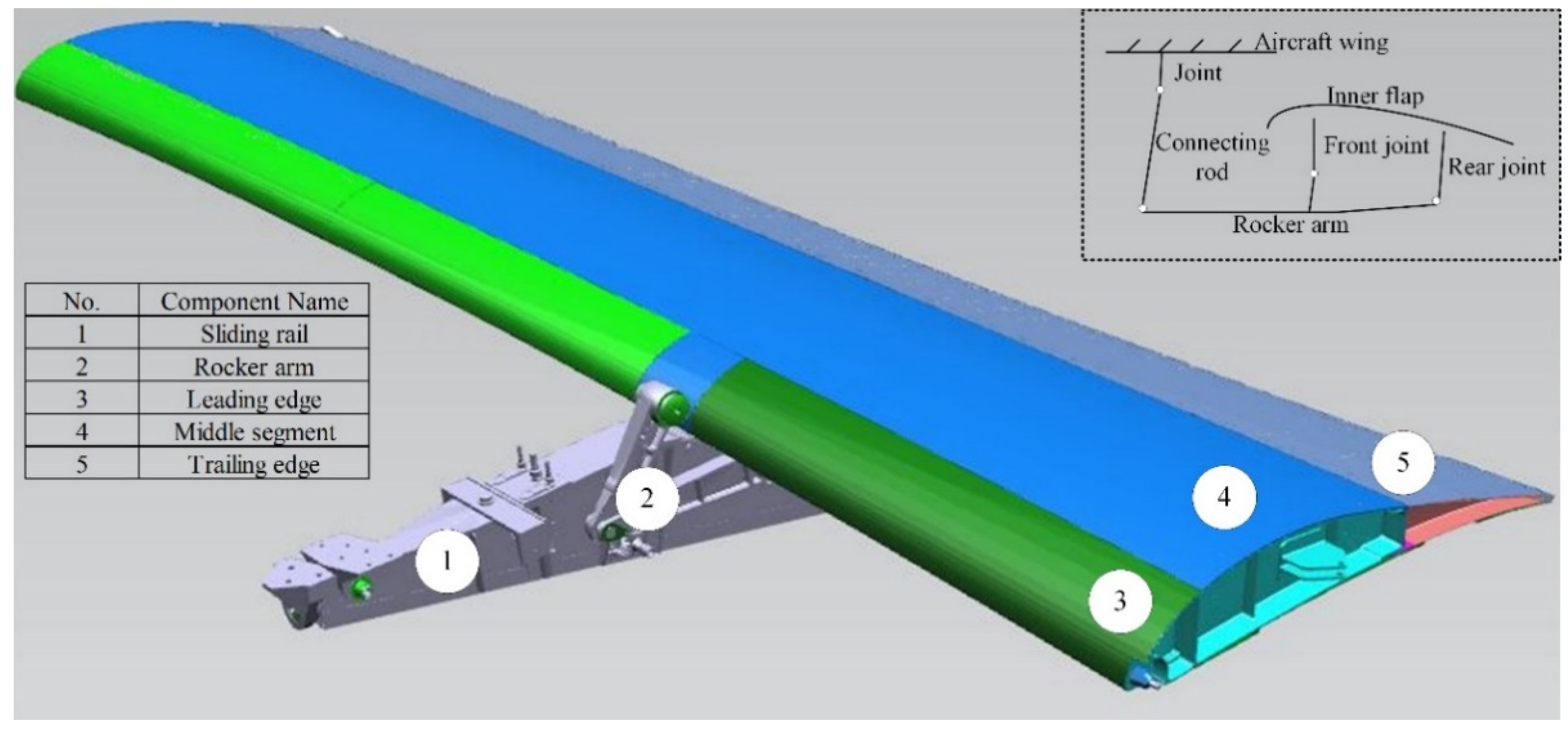

- The Monte Carlo algorithm is used to calculate the cumulative results of assembly deviation. In order to make the statistical result closer to the true value, 5000 groups of random deviation values are taken for assembly precision analysis. The final assembly precision analysis result is shown in Figure 8. According to the result of the inner flap assembly precision analysis, the axis deviation of the rocker arm front intersection hole is out of tolerance, and the distribution of axis deviation is shown in Figure 8, in which the Cp of the key characteristic is 0.13. According to Table 3, the process capacity level of the key characteristic is seriously insufficient. The optimized assembly process information should be determined according to assembly deviation source impact factors so as to realize the assembly precision optimization of the front intersection hole axis deviation of the rocker arm. According to Figure 8, it can be seen that the main influencing factors of the front intersection hole axis deviation are: the floating of the rocker arm and front and rear joints caused by bolt assembly, deviation of the rocker arm rear joint assembling hole, deviation of the rocker arm rear joint assembly tooling, and deviation of the rocker arm assembly datum B.

- According to the inference machine Hermit of Protege software, the results show that the assembly process needs to be reformed for achieving assembly precision optimization and meeting the requirements of assembly precision, as shown in Figure 9. The positioning mode of the front and rear joints and the deviation of the front and rear joints positioning tooling are the first targets to be optimized. The upper semantic framework of the proposed method is established through conceptualization. Next, concrete instances are built based on the defined concepts for semantic instance modeling of the analyzed products. The inference rules applicable to Protégé are established according to the SWRL rules mentioned in the third section. Finally, the inference result is obtained by running the inference machine, and the strategy for assembly precision optimization is obtained.

- Before the optimization of the assembly process, the rocker arm and inner flap are assembled directly through the front and rear joints, which is conducive to the interchangeability of parts, as shown in Figure 10 (Scheme 1). In order to ensure assembly precision of the front intersection hole of the rocker arm, the front and rear joints of the rocker arm are assembled with tooling to directly locate the intersection hole of the parts and the surface where the intersection hole is located. The rocker arm positioning mode is changed to the front and rear intersection holes and rocker arm plane positioning, as shown in Figure 10 (Scheme 2). Through the optimization of the assembly process, the ±3σ value and Cp value are, respectively, 0.05 and 1.35, which are within the target range of assembly process optimization, indicating that assembly process optimization has realized the precision optimization target of the front intersection hole axis deviation. A comparison between the original assembly process scheme (Scheme 1) and the assembly process optimization scheme (Scheme 2) is shown in Figure 10.

5. Conclusions

- (1)

- Aiming at the problem that the product key characteristics are out of tolerance in the simulation results of assembly precision, the ontology theory and technology are introduced into the research of assembly precision optimization, and an assembly precision optimization technology based on process capability is proposed, which lays the foundation for subsequent computer-aided tolerance allocation and assembly process scheme optimization. The principle of assembly precision optimization based on process capability is analyzed, and the process of assembly precision optimization is explained. The corresponding relationship between process capability index and assembly precision optimization is summarized.

- (2)

- The semantic model of assembly precision optimization, which has multilevel features of the assembly precision analysis results, out-of-tolerance key characteristics, and assembly process and design tolerance adjustment, is introduced as the bridge between product the CAD model and assembly precision guarantee. The class module and instance module of ontology are used to integrate the high-level semantic concepts of the assembly precision analysis system and the assembly precision analysis data of specific products into a model framework. The semantic model of assembly precision optimization is composed of several layers and elements. The semantic model of assembly precision optimization is extended according to different granularity, and it is used as the link of CAT and CAPP integration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Demoly, F.; Yan, X.T.; Eynard, B.; Rivest, L.; Gomes, S. An assembly oriented design framework for product structure engineering and assembly sequence planning. Robot Comput. Integr. Manuf. 2011, 27, 33–46. [Google Scholar] [CrossRef] [Green Version]

- Ou, L.M.; Xu, X. Relationship matrix based automatic assembly sequence generation from a CAD model. Comput. Aided Des. 2013, 45, 1053–1067. [Google Scholar] [CrossRef]

- Masehian, E.; Ghandi, S. Assembly sequence and path planning for monotone and nonmonotone assemblies with rigid and flexible parts. Robot Comput. Integr. Manuf. 2021, 72, 102180. [Google Scholar] [CrossRef]

- Li, R.K.; Hwang, C.L. A framework for automatic DFA system-development. Comput. Ind. Eng. 1992, 22, 403–413. [Google Scholar] [CrossRef]

- Desai, A. Ease of product assembly through a time-based design methodology. Assem. Autom. 2019, 39, 881–903. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, Q.J.; Zhang, J.; Gu, P.H. Planning for automatic product assembly using reinforcement learning. Comput. Ind. 2021, 130, 103471. [Google Scholar] [CrossRef]

- Ni, J.; Liu, R.; Sun, Y. Algorithm for Accumulating Part Mating Gaps to Evaluate Solid and Fluid Performances. J. Mech. Des. 2021, 143, 043501. [Google Scholar] [CrossRef]

- Su, Q.; Lai, S.J. 3D geometric constraint analysis and its application on the spatial assembly sequence planning. Int. J. Prod. Res. 2010, 48, 1395–1414. [Google Scholar] [CrossRef]

- Goka, E.; Homri, L.; Beaurepaire, P.; Dantan, J.Y. Statistical Tolerance Analysis of Over-Constrained Mechanical Assemblies with Form Defects Considering Contact Types. J. Comput. Inf. Sci. Eng. 2019, 19, 021010. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, G.; Hui, J.; Hou, W.; Evans, R.D. A precision analysis method for the kinematic assembly of complex products based on equivalence of deviation source. Assem. Autom. 2020, 40, 447–460. [Google Scholar] [CrossRef]

- Li, J.; Ran, Y.; Wang, H.W.; Mu, Z.Y.; Zhang, G.B. A tolerance analysis method for complex mechanical products based on meta-action unit. Int. J. Adv. Manuf. Technol. 2021, 117, 1377–1393. [Google Scholar] [CrossRef]

- Wang, K.; Liu, D.; Liu, Z.Y.; Wang, Q.; Tan, J.R. An assembly precision analysis method based on a general part digital twin model. Robot Comput. Integr. Manuf. 2021, 68, 102089. [Google Scholar] [CrossRef]

- McKenna, V.; Jin, Y.; Murphy, A.; Morgan, M.; Fu, R.; Qin, X.D.; McClory, C.; Collins, R.; Higgins, C. Cost-oriented process optimisation through variation propagation management for aircraft wing spar assembly. Robot Comput. Integr. Manuf. 2019, 57, 435–451. [Google Scholar] [CrossRef]

- Mei, B.; Zhu, W.D. Accurate positioning of a drilling and riveting cell for aircraft assembly. Robot Comput. Integr. Manuf. 2021, 69, 102112. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Z.; Li, B.; Hong, J. Optimal tolerance allocation for precision machine tools in consideration of measurement and adjustment processes in assembly. Int. J. Adv. Manuf. Technol. 2015, 80, 1625–1640. [Google Scholar] [CrossRef]

- Sun, W.; Mu, X.K.; Sun, Q.C.; Sun, Z.Y.; Wang, X.B. Analysis and optimization of assembly precision-cost model based on 3D tolerance expression. Assem. Autom. 2018, 38, 497–510. [Google Scholar] [CrossRef]

- Cao, Y.J.; Li, X.; Zhang, Z.X.; Shang, J.Z. Dynamic prediction and compensation of aerocraft assembly variation based on state space model. Assem. Autom. 2015, 35, 183–189. [Google Scholar] [CrossRef]

- Li, H.; Zhu, H.P.; Li, P.G.; He, F. Tolerance analysis of mechanical assemblies based on small displacement torsor and deviation propagation theories. Int. J. Adv. Manuf. Technol. 2014, 72, 89–99. [Google Scholar] [CrossRef]

- Speckhart, F.H. Calculation of tolerance based on a minimum cost approach. J. Eng. Ind. 1972, 94, 447–453. [Google Scholar] [CrossRef]

- Singh, P.K.; Jain, P.K.; Jain, S.C. Simultaneous optimal selection of design and manufacturing tolerances with different stack-up conditions using genetic algorithms. Int. J. Prod. Res. 2003, 41, 2411–2429. [Google Scholar] [CrossRef]

- Wang, G.D.; Yang, Y.; Wang, W.; Si-Chao, L.V. Variable coefficients reciprocal squared model based on multi-constraints of aircraft assembly tolerance allocation. Int. J. Adv. Manuf. Technol. 2016, 82, 227–234. [Google Scholar] [CrossRef]

- Sanz-Lobera, A.; Gomez, E.; Perez, J.; Sevilla, L. A proposal of cost-tolerance models directly collected from the manufacturing process. Int. J. Prod. Res. 2016, 54, 4584–4598. [Google Scholar] [CrossRef]

- Dong, Z.; Hu, W. Optimal process sequence identification and optimal process tolerance assignment in computer-aided process planning. Comput. Ind. 1991, 17, 19–32. [Google Scholar] [CrossRef]

- Jeang, A.; Leu, E. Robust tolerance design by computer experiment. Int. J. Prod. Res. 1999, 37, 1949–1961. [Google Scholar] [CrossRef]

- Lu, C.; Fuh, J.Y.H.; Wong, Y.S. Evaluation of product assemblability in different assembly sequences using the tolerancing approach. Int. J. Prod. Res. 2006, 44, 5037–5063. [Google Scholar] [CrossRef]

- Hallmann, M.; Schleich, B.; Wartzack, S. Process and machine selection in sampling-based tolerance-cost optimisation for dimensional tolerancing. Int. J. Prod. Res. 2021, 59, 1–16. [Google Scholar] [CrossRef]

- Wu, H.R.; Li, X.X.; Sun, F.C.; Zheng, H.L.; Zhao, Y.X. Optimization design method of machine tool static geometric accuracy using tolerance modeling. Int. J. Adv. Manuf. Technol. 2021, 116, 1–17. [Google Scholar] [CrossRef]

- Lee, K.K.; Ro, Y.C.; Han, S.H. Tolerance Optimization of a Lower Arm by using Genetic Algorithm and Process Capability Index. Int. J. Precis. Eng. Manuf. 2014, 15, 1001–1007. [Google Scholar] [CrossRef]

- Prabhaharan, G.; Asokan, P.; Rajendran, S. Sensitivity-based conceptual design and tolerance allocation using the continuous ants colony algorithm (CACO). Int. J. Adv. Manuf. Technol. 2005, 25, 516–526. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Ji, S.T.; Zhao, J.; Xiang, L.J. Tolerance analysis and allocation of special machine tool for manufacturing globoidal cams. Int. J. Adv. Manuf. Technol. 2016, 87, 1597–1607. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Hartman, N.W.; Sutherland, J.W. Allocation of assembly tolerances to minimize costs. CIRP Ann. Manuf. Technol. 2019, 68, 13–16. [Google Scholar] [CrossRef]

- Kumar, D.V.; Ravindran, D.; Lenin, N.; Kumar, M.S. Tolerance allocation of complex assembly with nominal dimension selection using Artificial Bee Colony algorithm. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 18–38. [Google Scholar] [CrossRef]

- Kumar, M.S.; Kannan, S.M.; Jayabalan, V. A new algorithm for optimum tolerance allocation of complex assemblies with alternative processes selection. Int. J. Adv. Manuf. Technol. 2009, 40, 819–836. [Google Scholar] [CrossRef]

- Forouraghi, B. Optimal tolerance allocation using a multiobjective particle swarm optimizer. Int. J. Adv. Manuf. Technol. 2009, 44, 710–724. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.P. Integrated tolerance optimisation with simulated annealing. Int. J. Adv. Manuf. Technol. 1993, 8, 167–174. [Google Scholar] [CrossRef]

- Coelho, L.D. Self-organizing migration algorithm applied to machining allocation of clutch assembly. Math. Comput. Simul. 2009, 80, 427–435. [Google Scholar] [CrossRef]

- Kumar, L.R.; Padmanaban, K.P.; Kumar, S.G.; Balamurugan, C. Design and optimization of concurrent tolerance in mechanical assemblies using bat algorithm. J. Mech. Sci. Technol. 2016, 30, 2601–2614. [Google Scholar] [CrossRef]

- Wu, Z.J.; Liu, T.; Gao, Z.B.; Cao, Y.L.; Yang, J.X. Tolerance design with multiple resource suppliers on cloud-manufacturing platform. Int. J. Adv. Manuf. Technol. 2016, 84, 335–346. [Google Scholar] [CrossRef]

- Balamurugan, C.; Saravanan, A.; Babu, P.D.; Jagan, S.; Narasimman, S.R. Concurrent optimal allocation of geometric and process tolerances based on the present worth of quality loss using evolutionary optimisation techniques. Res. Eng. Des. 2017, 28, 185–202. [Google Scholar] [CrossRef]

- Kumar, L.R.; Padmanaban, K.P.; Balamurugan, C. Optimal tolerance allocation in a complex assembly using evolutionary algorithms. Int. J. Simul. Model 2016, 15, 121–132. [Google Scholar] [CrossRef]

- Sanfilippo, E.M.; Belkadi, F.; Bernard, A. Ontology-based knowledge representation for additive manufacturing. Comput. Ind. 2019, 109, 182–194. [Google Scholar] [CrossRef]

- Xing, X.J.; Zhong, B.T.; Luo, H.B.; Li, H.; Wu, H.T. Ontology for safety risk identification in metro construction. Comput. Ind. 2019, 109, 14–30. [Google Scholar] [CrossRef]

- He, W.; Wang, F.K.; Akula, V. Managing extracted knowledge from big social media data for business decision making. J. Knowl. Manag. 2017, 21, 275–294. [Google Scholar] [CrossRef]

- Gao, J.; Bernard, A. An overview of knowledge sharing in new product development. Int. J. Adv. Manuf. Technol. 2018, 94, 1545–1550. [Google Scholar] [CrossRef] [Green Version]

- France-Mensah, J.; O’Brien, W.J. A shared ontology for integrated highway planning. Adv. Eng. Inform. 2019, 41, 100929. [Google Scholar] [CrossRef]

- Peng, G.Z.; Wang, H.W.; Zhang, H.M.; Zhao, Y.W.; Johnson, A.L. A collaborative system for capturing and reusing in-context design knowledge with an integrated representation model. Adv. Eng. Inform. 2017, 33, 314–329. [Google Scholar] [CrossRef] [Green Version]

- Sanfilippo, E.M.; Borgo, S. What are features? An ontology-based review of the literature. Comput. Aided Des. 2016, 80, 9–18. [Google Scholar] [CrossRef] [Green Version]

- Sudarsan, R.; Fenves, S.J.; Sriram, R.D.; Wang, F. A product information modeling framework for product lifecycle management. Comput. Aided Des. 2005, 37, 1399–1411. [Google Scholar] [CrossRef]

- Barbau, R.; Krima, S.; Rachuri, S.; Narayanan, A.; Fiorentini, X.; Foufou, S.; Sriram, R.D. OntoSTEP: Enriching product model data using ontologies. Comput. Aided Des. 2012, 44, 575–590. [Google Scholar] [CrossRef]

- Sarigecili, M.I.; Roy, U.; Rachuri, S. Interpreting the semantics of GD&T specifications of a product for tolerance analysis. Comput. Aided Des. 2014, 47, 72–84. [Google Scholar] [CrossRef]

- Zhong, Y.R.; Qin, Y.C.; Huang, M.F.; Lu, W.L.; Gao, W.X.; Du, Y.L. Automatically generating assembly tolerance types with an ontology-based approach. Comput. Aided Des. 2013, 45, 1253–1275. [Google Scholar] [CrossRef]

- Qin, Y.C.; Lu, W.L.; Qi, Q.F.; Li, T.K.; Huang, M.F.; Scott, P.J.; Jiang, X.Q. Explicitly representing the semantics of composite positional tolerance for patterns of holes. Int. J. Adv. Manuf. Technol. 2017, 90, 2121–2137. [Google Scholar] [CrossRef] [Green Version]

- Lu, W.L.; Qin, Y.C.; Liu, X.J.; Huang, M.F.; Zhou, L.P.; Jiang, X.Q. Enriching the semantics of variational geometric constraint data with ontology. Comput. Aided Des. 2015, 63, 72–85. [Google Scholar] [CrossRef]

| Cp | 0.33 | 0.67 | 1.00 | 1.33 | 1.67 |

| Assembly Success Rate | 68.27% | 95.45% | 99.73% | 99.993% | 99.999943% |

| Cp | Level | Capacity | Distribution of the Sample | Relevant Methods |

|---|---|---|---|---|

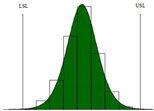

| Cp > 1.67 | Level 0 | High capacity |  | (1) Allow large deviation fluctuation in assembly to improve efficiency; (2) use less accurate equipment to reduce manufacturing cost. |

| 1.67 ≥ Cp > 1.33 | Level 1 | Sufficient capacity |  | (1) Magnify part manufacturing tolerance; (2) allow some degree of external fluctuation for noncritical part; (3) simplify inspection process. |

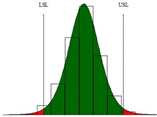

| 1.33 ≥ Cp > 1.0 | Level 2 | Acceptable capacity |  | (1) Protection against external fluctuation; (2) pay attention to sampling method and interval for product sampling inspection; (3) equipment condition should be checked when Cp = 1. |

| 1.0 ≥ Cp > 0.67 | Level 3 | Insufficient capacity |  | (1) Optimize assembly process and parameter; (2) use higher accurate equipment to improve assembly precision; (3) assembly with higher manufacturing precision part. |

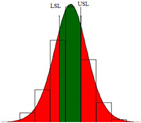

| 0.67 ≥ Cp | Level 4 | Seriously insufficient capacity |  | (1) Analyze deviation contributor to reform assembly process. |

| NO. | SWRL Rules |

|---|---|

| 1–1 | hasAssemblyCapacity(?x,acl_Level-0), hasAssemblyCapacityDescription(?x,acld_HighCapacity), hasProcessCapabilityIndex(?x,cp_CpMoreThan1.67) ->optimizeAssemblyPrecision(?x,apos_ToAllowLargeAssemblyDeviationFluctuations) |

| 1–2 | hasAssemblyCapacity(?x,acl_Level-0), hasAssemblyCapacityDescription(?x,acld_HighCapacity), hasProcessCapabilityIndex(?x,cp_CpMoreThan1.67) ->optimizeAssemblyPrecision(?x,apos_ToUseEquipmentWithRelativelyLowPrecision) |

| 2–1 | hasAssemblyCapacity(?x,acl_Level-1), hasAssemblyCapacityDescription(?x,acld_SufficientCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.67And1.33) ->optimizeAssemblyPrecision(?x,apos_ToEnlargeThePartManufacturingTolerances) |

| 2–2 | hasAssemblyCapacity(?x,acl_Level-1), hasAssemblyCapacityDescription(?x,acld_SufficientCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.67And1.33) ->optimizeAssemblyPrecision(?x,apos_ToAllowACertainDegreeOfExternalFluctuationForNonCriticalParts) |

| 2–3 | hasAssemblyCapacity(?x,acl_Level-1), hasAssemblyCapacityDescription(?x,acld_SufficientCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.67And1.33) -> optimizeAssemblyPrecision(?x,apos_ToSimplifyTheInspectionProcess) |

| 3–1 | hasAssemblyCapacity(?x,acl_Level-2), hasAssemblyCapacityDescription(?x,acld_AcceptableCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.33And1.0) ->optimizeAssemblyPrecision(?x,apos_ToPreventExternalFluctuations) |

| 3–2 | hasAssemblyCapacity(?x,acl_Level-2), hasAssemblyCapacityDescription(?x,acld_AcceptableCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.33And1.0) ->optimizeAssemblyPrecision(?x,apos_ToPayAttentionToTheSamplingMethodAndInterval) |

| 3–3 | hasAssemblyCapacity(?x,acl_Level-2), hasAssemblyCapacityDescription(?x,acld_AcceptableCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.33And1.0) ->optimizeAssemblyPrecision(?x,apos_ToCheckEquipmentConditionIfCp = 1) |

| 4–1 | hasAssemblyCapacity(?x,acl_Level-3), hasAssemblyCapacityDescription(?x,acld_InsufficientCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.0And0.67) ->optimizeAssemblyPrecision(?x,apos_ToOptimizeTheAssemblyProcessAndParameters) |

| 4–2 | hasAssemblyCapacity(?x,acl_Level-3), hasAssemblyCapacityDescription(?x,acld_InsufficientCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.0And0.67) ->optimizeAssemblyPrecision(?x,apos_ToUseTheEquipmentWithHigherPrecision) |

| 4–3 | hasAssemblyCapacity(?x,acl_Level-3), hasAssemblyCapacityDescription(?x,acld_InsufficientCapacity), hasProcessCapabilityIndex(?x,cp_CpBetween1.0And0.67) ->optimizeAssemblyPrecision(?x,apos_ToUsePartsWithHigherManufacturingPrecision) |

| 5–1 | hasAssemblyCapacity(?x,acl_Level-4), hasAssemblyCapacityDescription(?x,acld_SeriouslyInsufficientCapacity), hasProcessCapabilityIndex(?x,cp_CpLessThan0.67) ->optimizeAssemblyPrecision(?x,apos_ToReformTheProcessByAnalyzingTheInfluenceFactorOfDeviation) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Tian, X.; Wang, G.; Zhao, D. Semantic-Based Assembly Precision Optimization Strategy Considering Assembly Process Capacity. Machines 2021, 9, 269. https://doi.org/10.3390/machines9110269

Shi X, Tian X, Wang G, Zhao D. Semantic-Based Assembly Precision Optimization Strategy Considering Assembly Process Capacity. Machines. 2021; 9(11):269. https://doi.org/10.3390/machines9110269

Chicago/Turabian StyleShi, Xiaolin, Xitian Tian, Gangfeng Wang, and Dongping Zhao. 2021. "Semantic-Based Assembly Precision Optimization Strategy Considering Assembly Process Capacity" Machines 9, no. 11: 269. https://doi.org/10.3390/machines9110269

APA StyleShi, X., Tian, X., Wang, G., & Zhao, D. (2021). Semantic-Based Assembly Precision Optimization Strategy Considering Assembly Process Capacity. Machines, 9(11), 269. https://doi.org/10.3390/machines9110269