Kinematics Analysis and Optimization of a 3-DOF Planar Tensegrity Manipulator under Workspace Constraint

Abstract

:1. Introduction

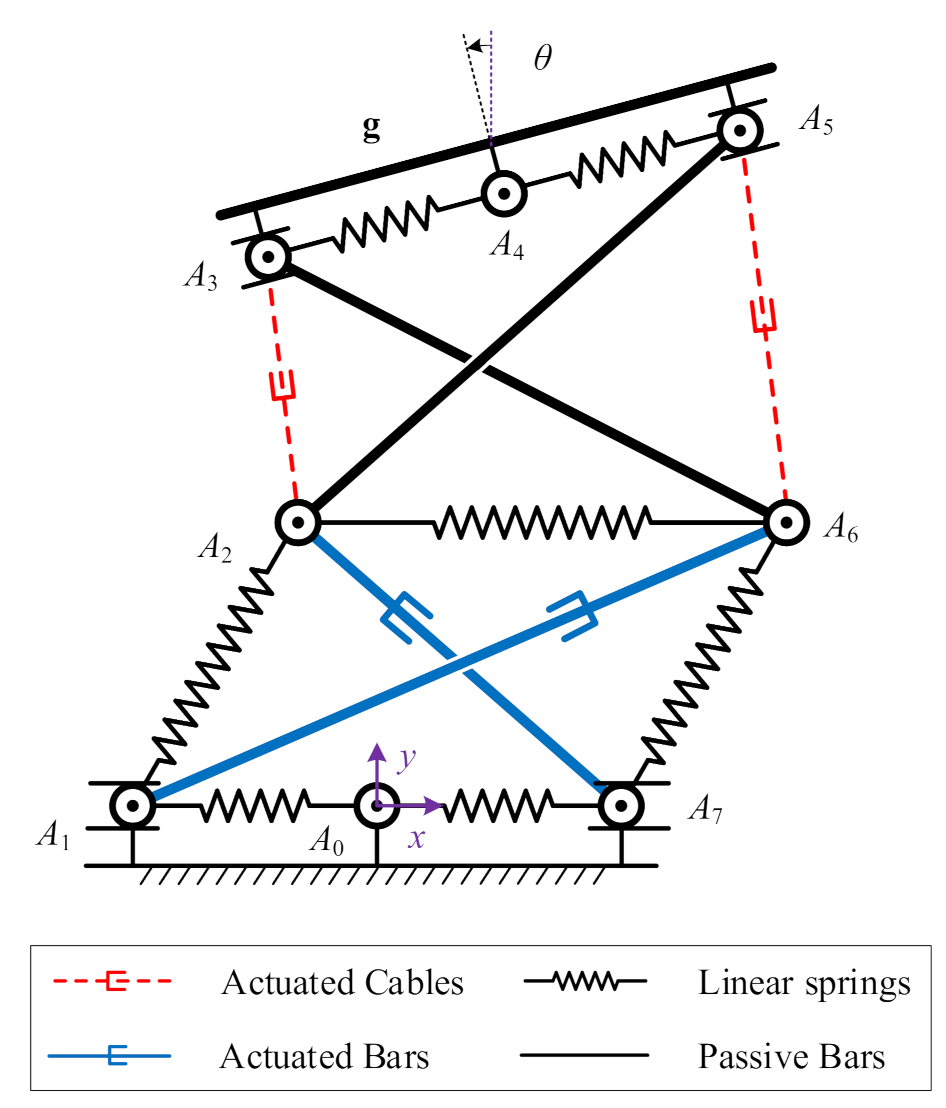

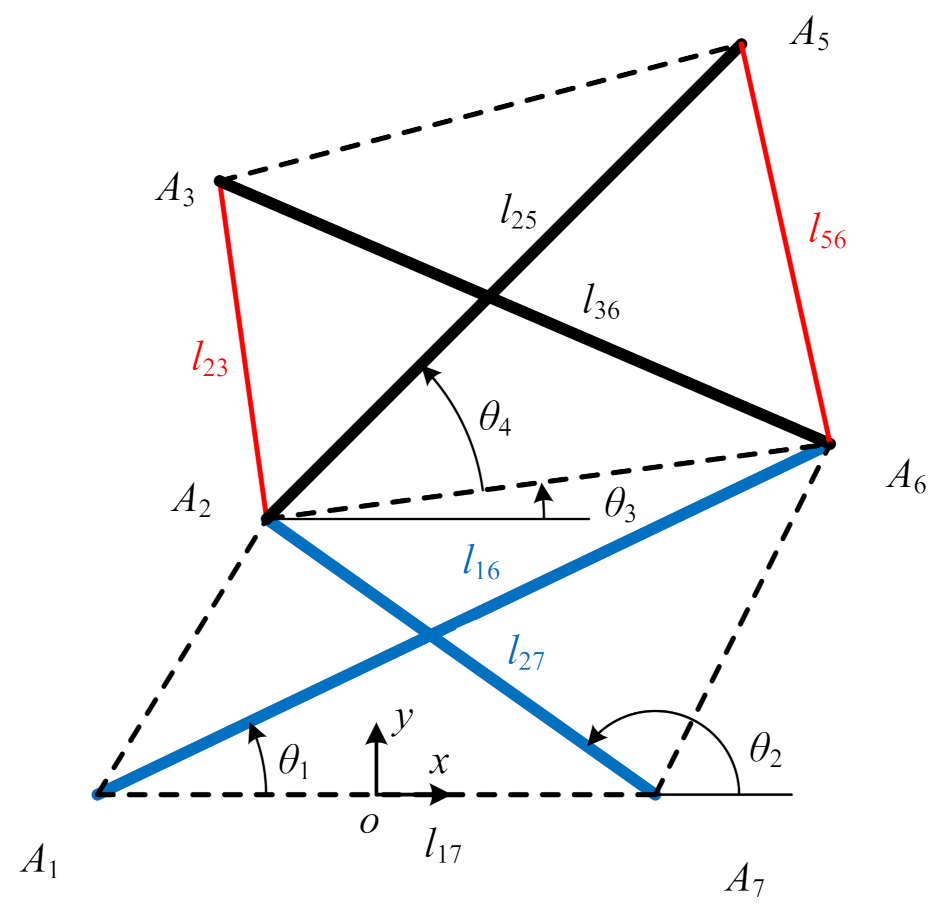

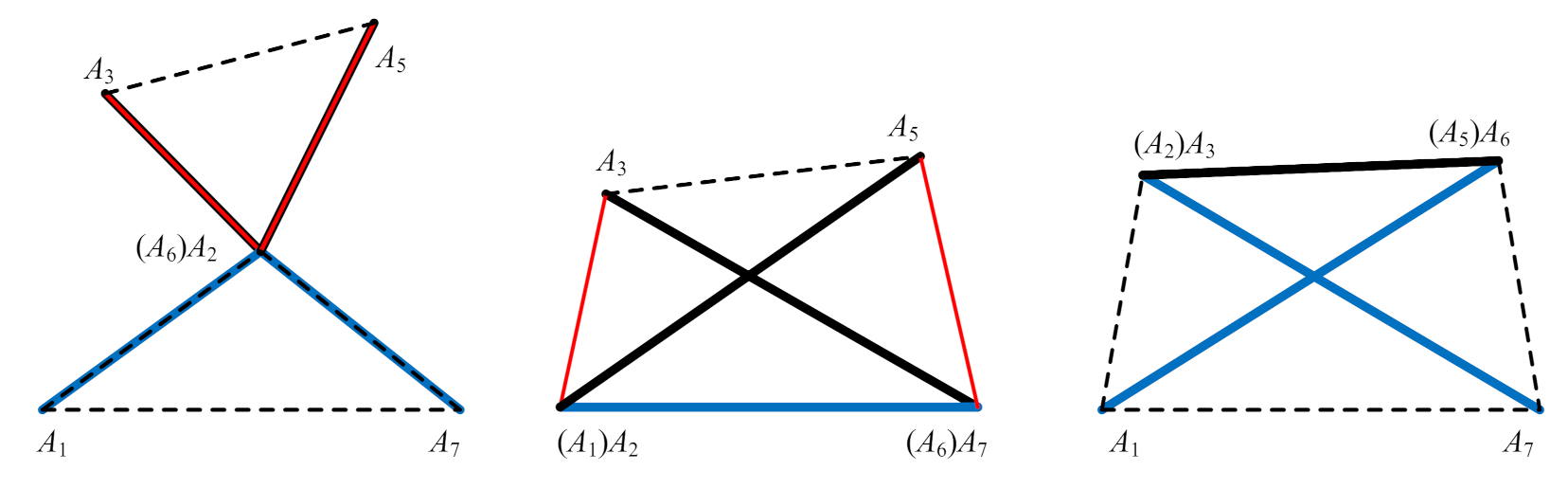

2. Configuration and Actuation Mode

3. Two-Step Kinematics Modeling

3.1. Step-1: Energy-Based Preliminary Modeling

3.2. Step-2: FDM Equilibrium Equations

3.3. Kinematics Solving Procedure

4. Performance Criteria

4.1. Stability

4.2. End-Effector Workspace

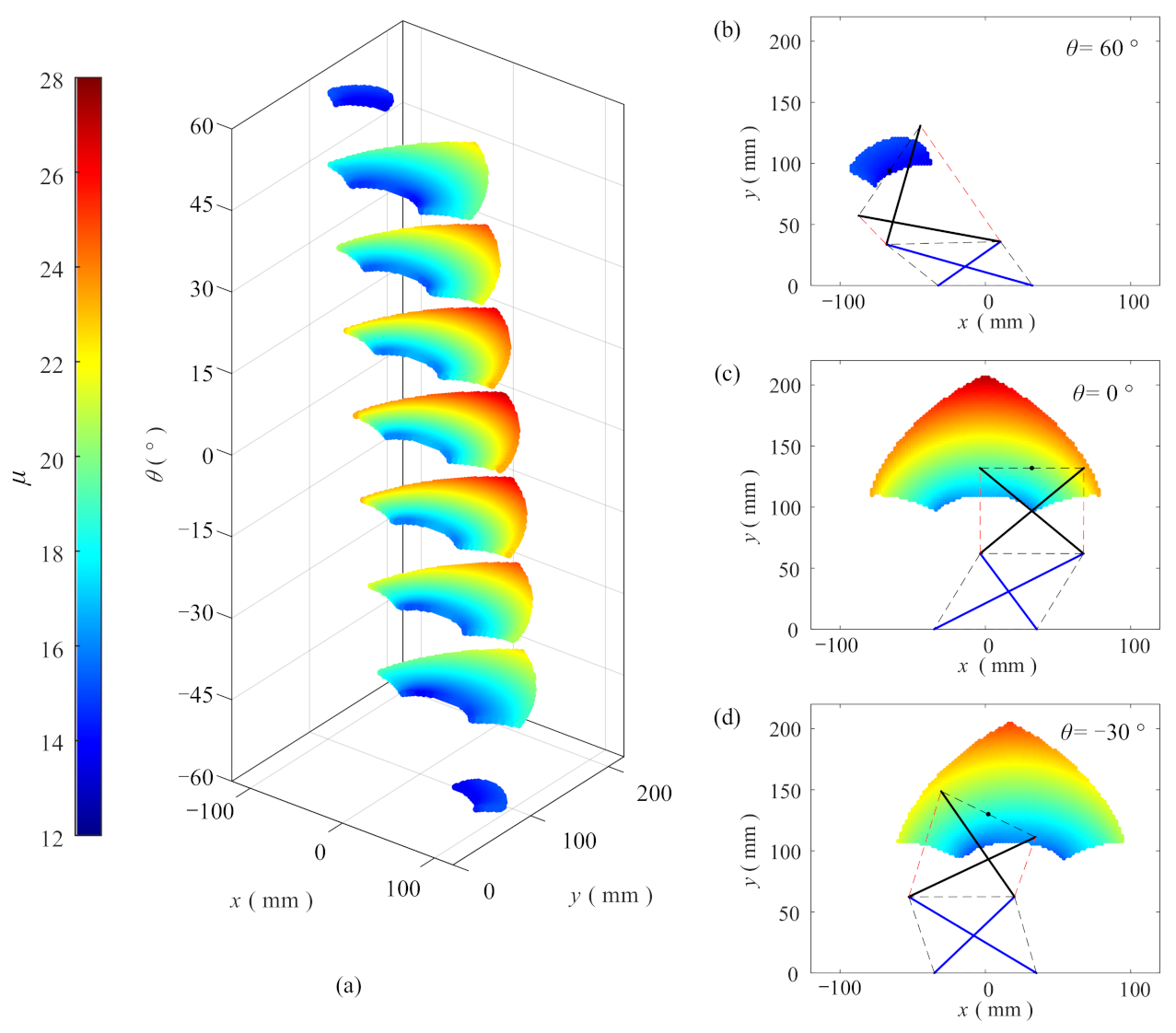

4.3. Manipulability

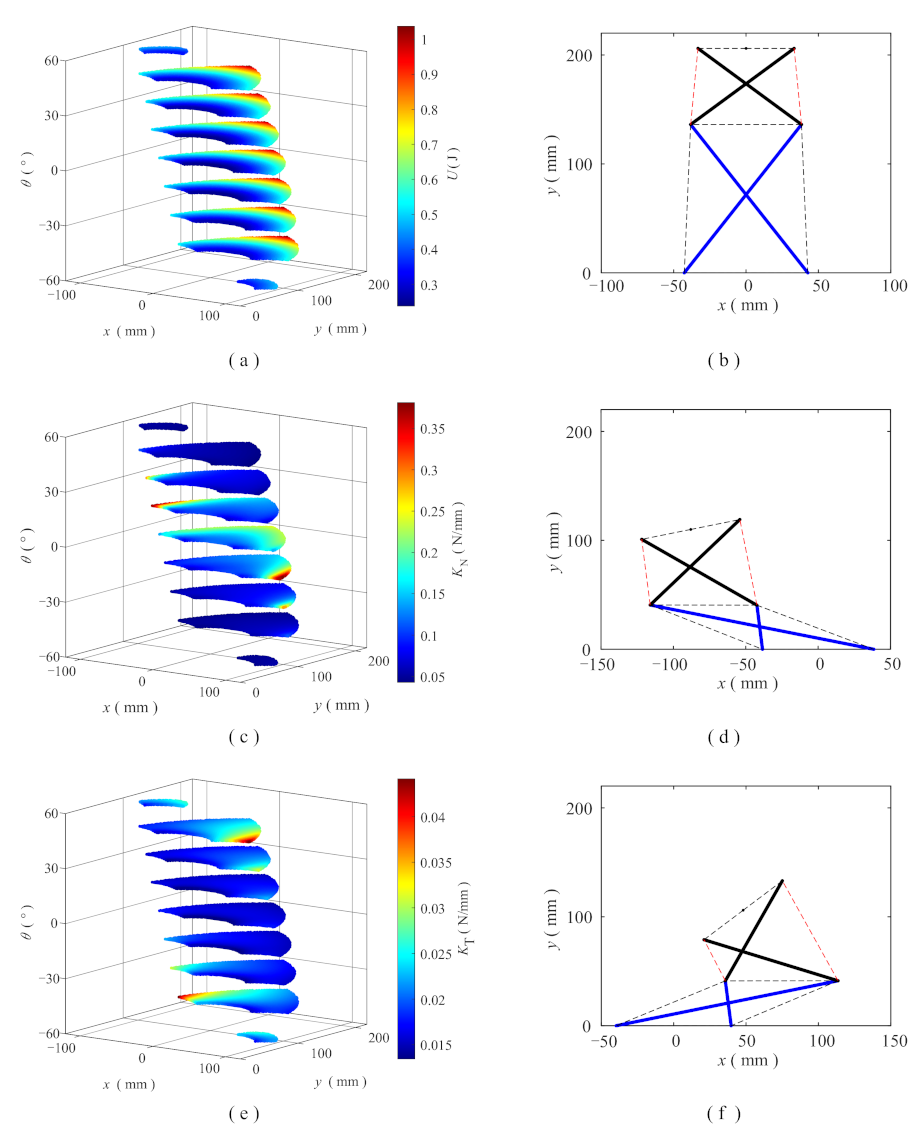

4.4. Potential Energy and Stiffness of End-Effector

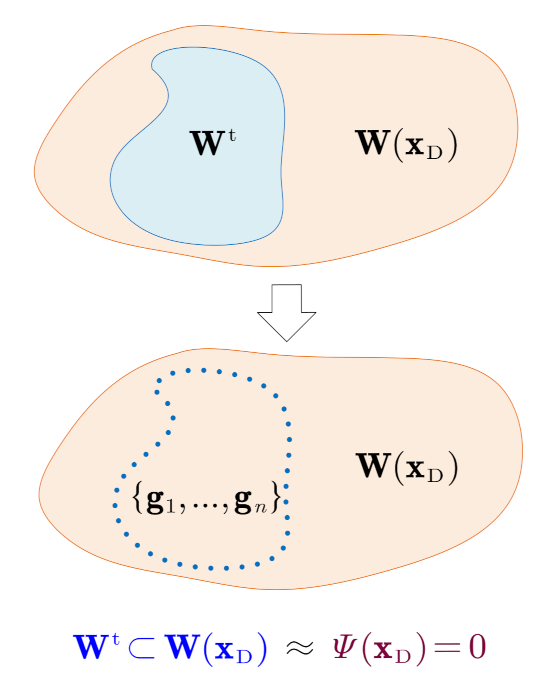

5. Optimization under Workspace Constraint

5.1. Optimization Model

5.2. Constraint Simplification

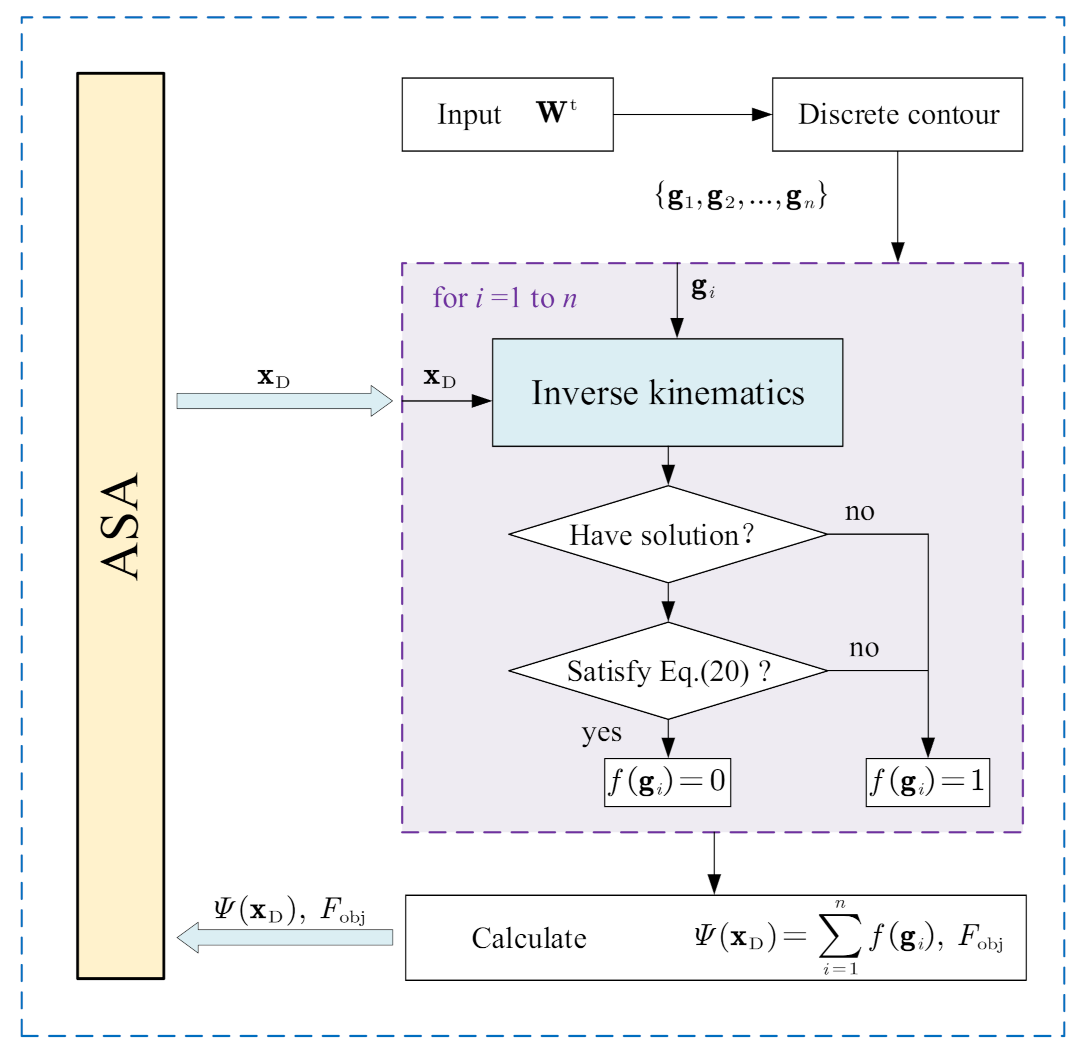

5.3. Optimization Procedure

6. Results and Discussion

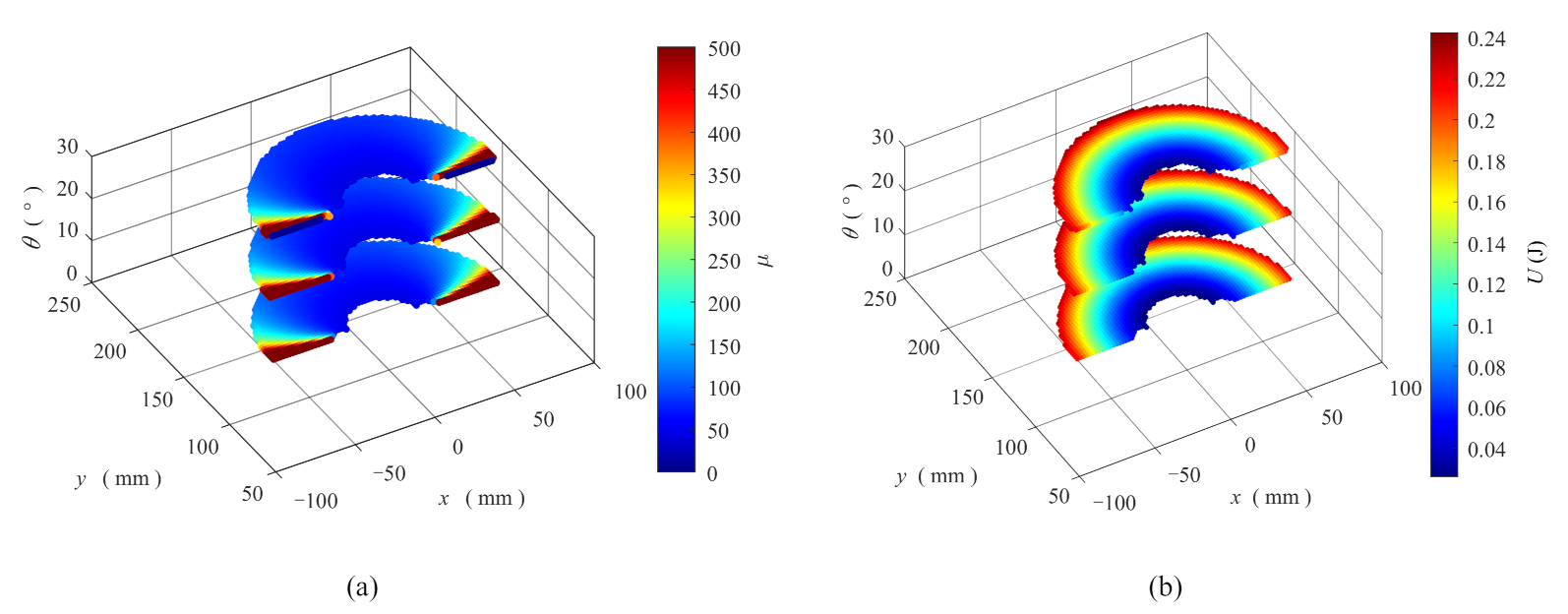

6.1. Workspace Analysis

6.2. Potential Energy and Stiffness of End-Effector

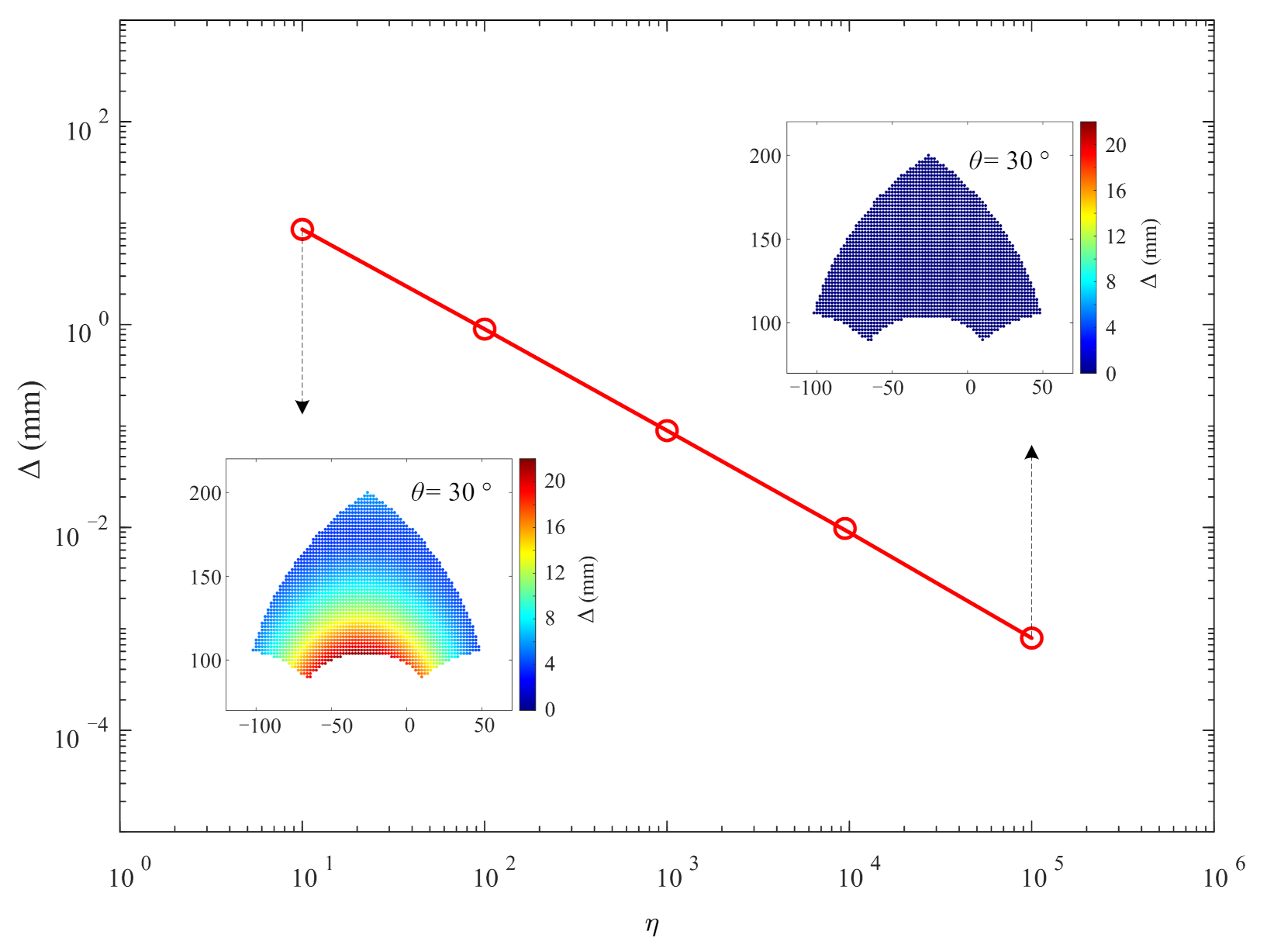

6.3. Effect of the Flexibility of Bars and Cables on Kinematics

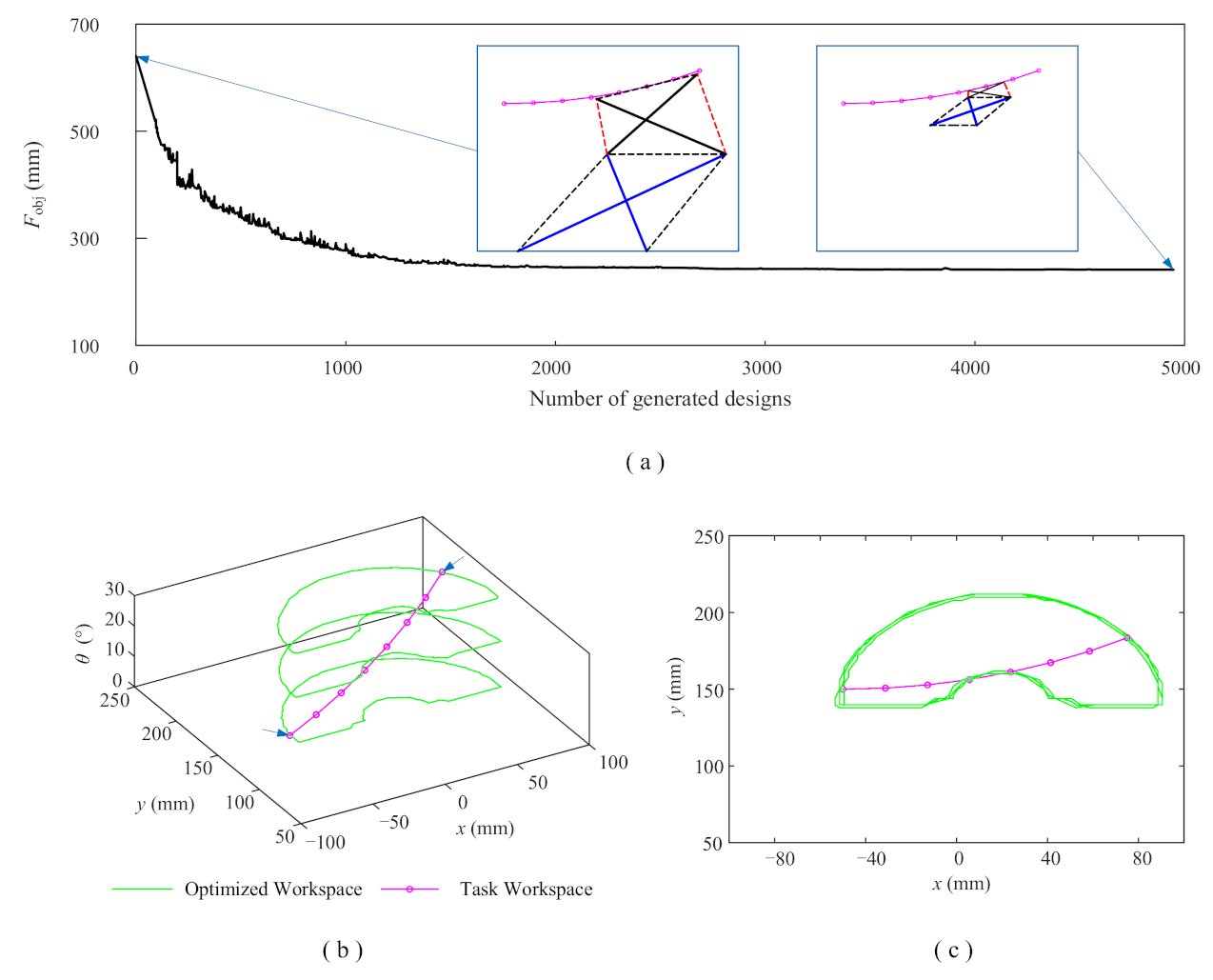

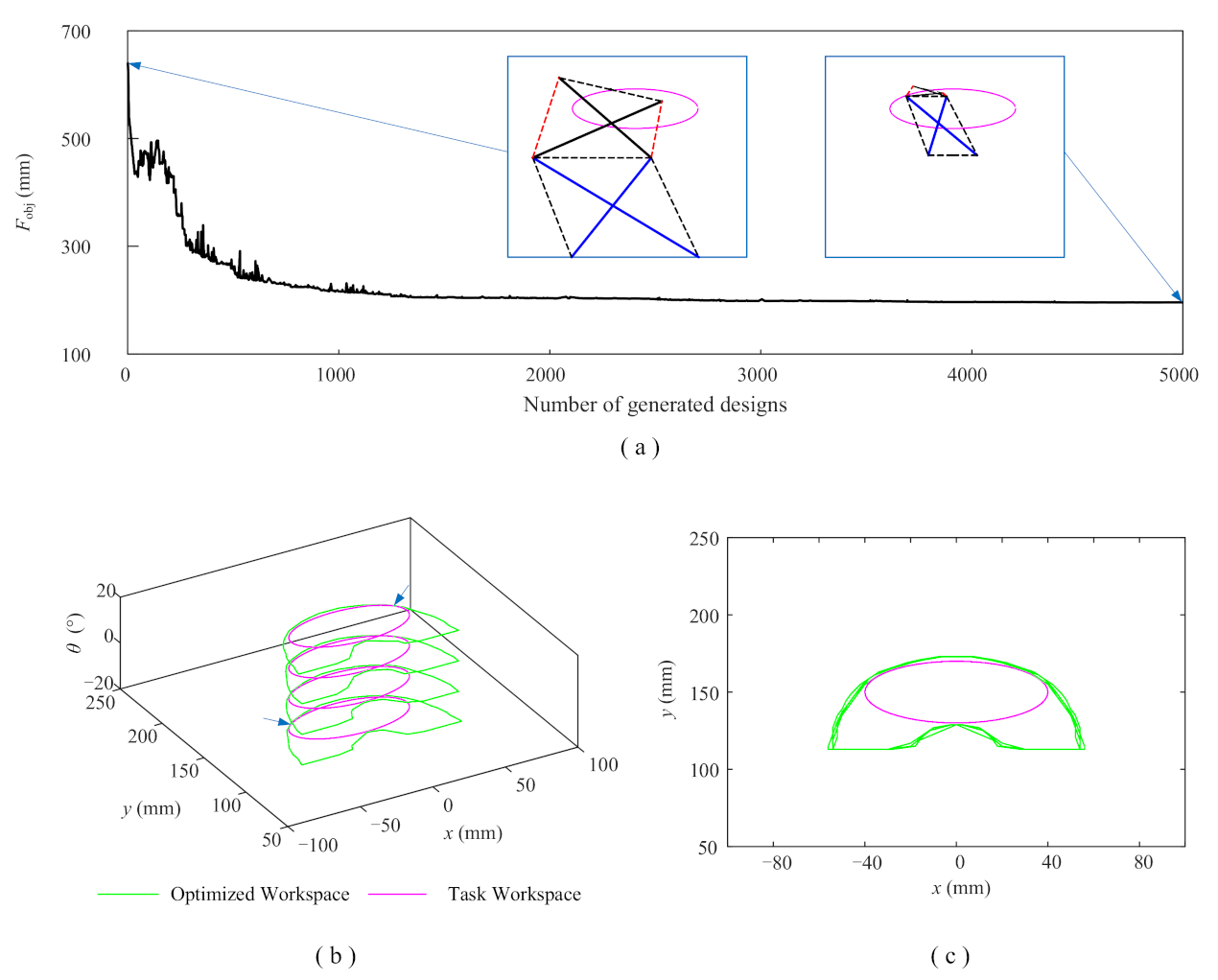

6.4. Optimization Examples

7. Conclusions

- The numerical example suggests that the TM has a relatively sizeable 3-DOF workspace and no singularity under the constraints of driving variables and spring elongation limitation;

- The stiffness of the end-effector in the tangential direction is significantly less than that in the normal direction, and excessive tangential force must be avoided during application;

- The flexibility of the bars and cables have a relatively noticeable effect on the kinematics when the bars-to-spring stiffness ratio is less than , and it is necessary to use the two-step method for accurate modeling. When the ratio is more extensive than , flexibility can be ignored.

- Two study cases are used to validate the effectiveness of the optimization method. After optimization, the objectives are reduced by 62.3% and 69.4% , respectively. Moreover, the target poses are located on and tangent to the contour of the workspace, suggesting that optimal designs considering compactness are obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Richard, B.F. Tensile-Integrity Structures. U.S. Patent 3063521, 13 November 1962. [Google Scholar]

- Castro, G.; Levy, M.P. Analysis of the georgia dome cable roof. In Proceedings of the Computing in Civil Engineering and Geographic Information Systems Symposium, Dallas, TX, USA, 7–9 June 1992; pp. 566–573. [Google Scholar]

- Zhan, W.D.; Dong, S.L. Advances in cable domes. J. Zhejiang Univ. (Eng. Sci.) 2004, 38, 1298–1307. [Google Scholar]

- Zavodszky, M.I.; Ming, L.; Thorpe, M.F.; Day, A.R.; Kuhn, L.A. Modeling correlated main-chain motions in proteins for flexible molecular recognition. Proteins-Struct. Funct. Bioinform. 2010, 57, 243–261. [Google Scholar] [CrossRef]

- Luo, Y.; Xu, X.; Lele, T.; Kumar, S.; Ingber, D.E. A multi-modular tensegrity model of an actin stress fiber. J. Biomech. 2008, 41, 2379–2387. [Google Scholar] [CrossRef] [Green Version]

- Scarr, G. A consideration of the elbow as a tensegrity structure. Int. J. Osteopath. Med. 2012, 15, 53–65. [Google Scholar] [CrossRef]

- Sultan, C. Tensegrity deployment using infinitesimal mechanisms. Int. J. Solids Struct. 2014, 51, 21–22. [Google Scholar] [CrossRef] [Green Version]

- Sychterz, A.; Smith, I. Damage mitigation of near-full-scale deployable tensegrity structure through behavior biomimetics. J. Struct. Eng. 2020, 146, 04019181. [Google Scholar] [CrossRef]

- Yıldız, K.; Lesieutre, G. Deployment of n-strut cylindrical tensegrity booms. J. Struct. Eng. 2020, 146, 04020247. [Google Scholar] [CrossRef]

- Rahmat Abadi, B.; Farid, M.; Mahzoon, M. Introducing and analyzing a novel three-degree-of-freedom spatial tensegrity mechanism. J. Comput. Nonlinear Dyn. 2014, 9, 94. [Google Scholar]

- Rovira, A.; Mirats-Tur, J. Control and simulation of a tensegrity-based mobile robot. Robot. Auton. Syst. 2009, 57, 526–535. [Google Scholar] [CrossRef]

- Caluwaerts, K.; Despraz, J.; Iscen, A.; Sabelhaus, A.P.; Bruce, J.; Schrauwen, B.; SunSpiral, V. Design and control of compliant tensegrity robots through simulation and hardware validation. J. R. Soc. Interface 2014, 11, 20140520. [Google Scholar] [CrossRef] [Green Version]

- Du, W.; Ma, S.; Li, B.; Wang, M.; Hirai, S. Force analytic method for rolling gaits of tensegrity robots. IEEE/ASME Trans. Mechatron. 2016, 21, 2249–2259. [Google Scholar] [CrossRef]

- Luo, A.; Liu, H. Analysis for feasibility of the method for bars driving the ball tensegrity robot. J. Mech. Robot. 2017, 9, 051010. [Google Scholar] [CrossRef]

- Furet, M.; Wenger, P. Workspace and Cuspidality Analysis of a 2-X Planar Manipulator. In Mechanism Design for Robotics; Springer International Publishing: Cham, Switzerland, 2019; pp. 110–117. [Google Scholar]

- Arsenault, M.; Gosselin, C. Kinematic, static and dynamic analysis of a planar 2-dof tensegrity mechanism. Mech. Mach. Theory 2006, 41, 1072–1089. [Google Scholar] [CrossRef]

- Boehler, Q.; Vedrines, M.; Abdelaziz, S.; Poignet, P.; Renaud, P. Influence of Spring Characteristics on the Behavior of Tensegrity Mechanisms. In ARK: Advances in Robot Kinematics; Springer International Publishing: Cham, Switzerland, 2014; pp. 161–169. [Google Scholar]

- Boehler, Q.; Charpentier, I.; Vedrines, M.S.; Renaud, P. Definition and computation of tensegrity mechanism workspace. J. Mech. Robot. 2015, 7, 044502. [Google Scholar] [CrossRef]

- Wenger, P.; Chablat, D. Kinetostatic analysis and solution classification of a class of planar tensegrity mechanisms. Robotica 2019, 37, 1214–1224. [Google Scholar] [CrossRef] [Green Version]

- Rahmat Abadi, B.; Shekarforoush, S.; Mahzoon, M.; Farid, M. Kinematic, stiffness, and dynamic analyses of a compliant tensegrity mechanism. J. Mech. Robot. 2014, 6, 041001. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Ohsaki, M. Tensegrity Structures; Springer: Tokyo, Japan, 2015. [Google Scholar]

- Moored, K.W.; Kemp, T.H.; Houle, N.E.; Bart-Smith, H. Analytical predictions, optimization, and design of a tensegrity-based artificial pectoral fin. Int. J. Solids Struct. 2011, 48, 3142–3159. [Google Scholar] [CrossRef] [Green Version]

- Begey, J.; Vedrines, M.; Andreff, N.; Renaud, P. Selection of actuation mode for tensegrity mechanisms: The case study of the actuated snelson cross. Mech. Mach. Theory 2020, 152, 103881. [Google Scholar] [CrossRef]

- Begey, J.; Vedrines, M.; Renaud, P. Design of tensegrity-based manipulators: Comparison of two approaches to respect a remote center of motion constraint. IEEE Robot. Autom. Lett. 2020, 5, 1788–1795. [Google Scholar] [CrossRef]

- Zorn, L.; Renaud, P.; Bayle, B.; Goffin, L.; Lebosse, C.; de Mathelin, M.; Foucher, J. Design and evaluation of a robotic system for transcranial magnetic stimulation. IEEE Trans. Biomed. Eng. 2012, 59, 805–815. [Google Scholar] [CrossRef] [PubMed]

- Bruyas, A.; Geiskopf, F.; Renaud, P. Toward unibody robotic structures with integrated functions using multimaterial additive manufacturing: Case study of an mri-compatible interventional device. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–2 October 2015; pp. 1744–1750. [Google Scholar]

| Springs | Free Length (mm) | Stiffness (N/mm) | (mm) |

|---|---|---|---|

| , | 20 | 0.05 | [40,120] |

| , , , | 10 | 0.1 | [20,60] |

| 20 | 0.1 | [40,120] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Ding, J.; Wang, C.; Liu, X. Kinematics Analysis and Optimization of a 3-DOF Planar Tensegrity Manipulator under Workspace Constraint. Machines 2021, 9, 256. https://doi.org/10.3390/machines9110256

Dong Y, Ding J, Wang C, Liu X. Kinematics Analysis and Optimization of a 3-DOF Planar Tensegrity Manipulator under Workspace Constraint. Machines. 2021; 9(11):256. https://doi.org/10.3390/machines9110256

Chicago/Turabian StyleDong, Yang, Jianzhong Ding, Chunjie Wang, and Xueao Liu. 2021. "Kinematics Analysis and Optimization of a 3-DOF Planar Tensegrity Manipulator under Workspace Constraint" Machines 9, no. 11: 256. https://doi.org/10.3390/machines9110256

APA StyleDong, Y., Ding, J., Wang, C., & Liu, X. (2021). Kinematics Analysis and Optimization of a 3-DOF Planar Tensegrity Manipulator under Workspace Constraint. Machines, 9(11), 256. https://doi.org/10.3390/machines9110256