Classification of Design Methodologies to Minimize Vibrations in Gears and Bearings in the 21st Century: A Review

Abstract

1. Introduction

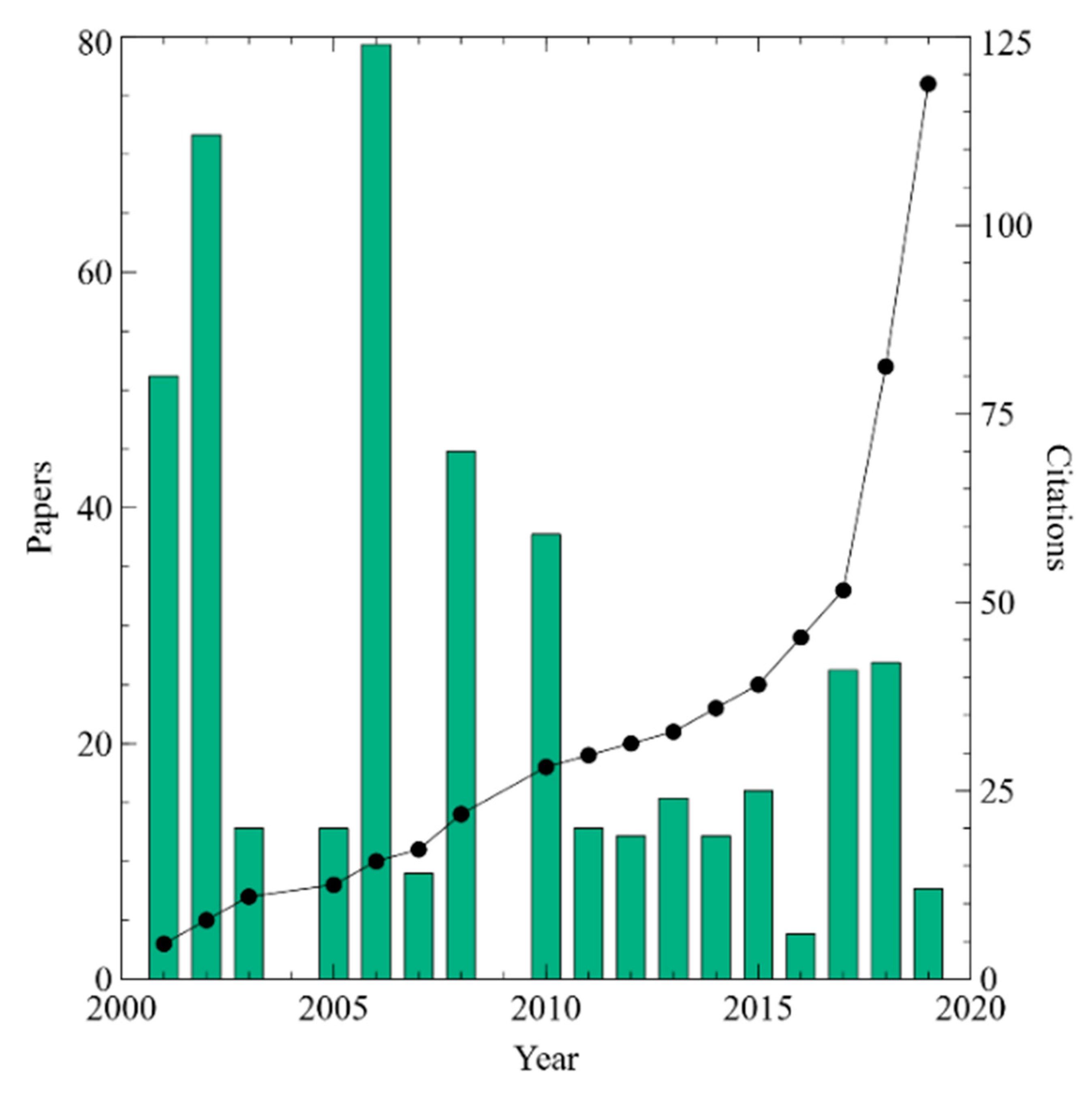

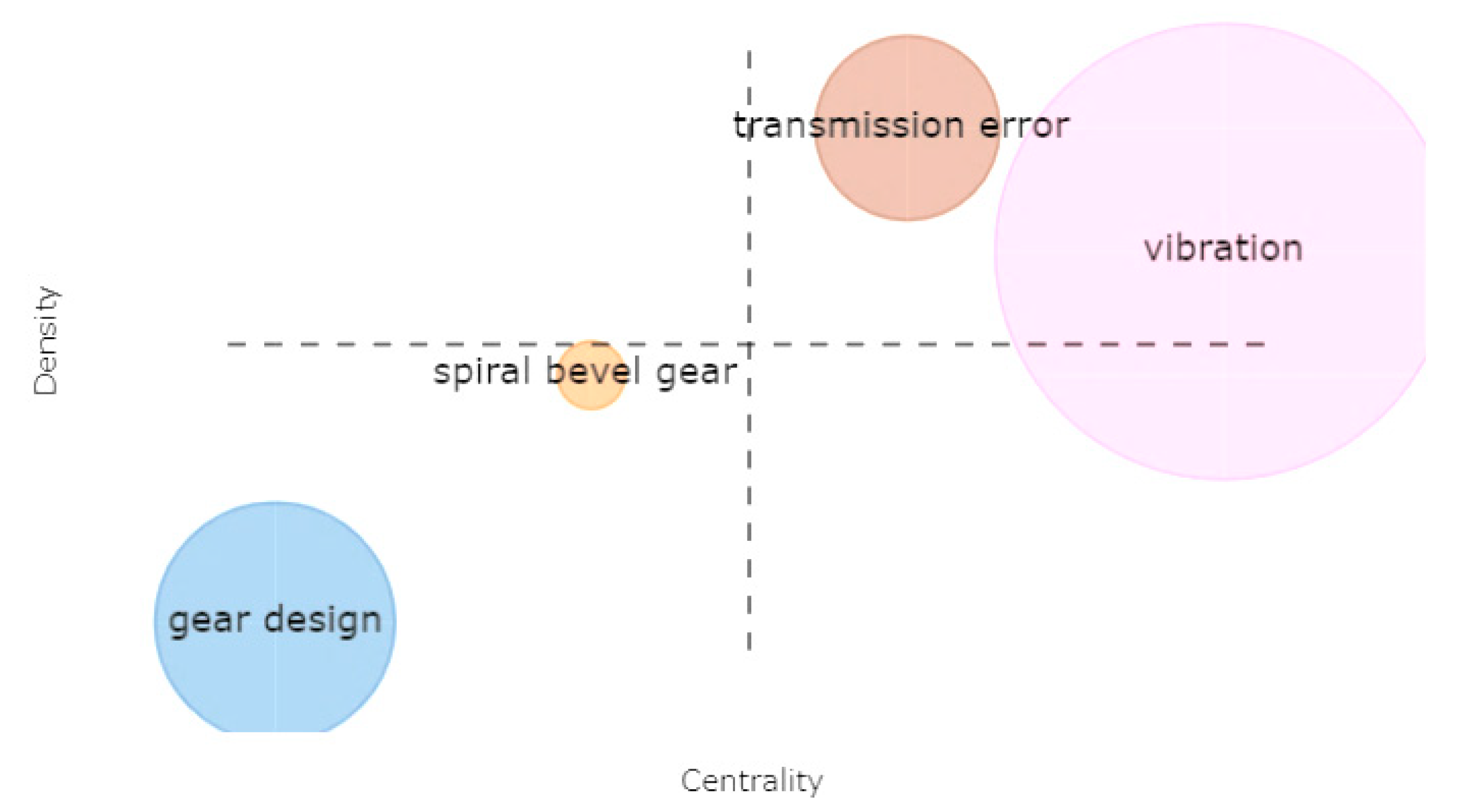

2. Science Mapping Method

3. Analysis of Reviews

| Principal Topic | Applications | Works |

|---|---|---|

| Fault Diagnosis | Bearings, motor bearings, wind turbine planetary gearboxes, solar photovoltaic, rolling element bearings, gears, rotors, rotating machinery, active magnetic bearings, high-speed railway bridges, internal combustion engines, rotating shafts, squirrel-cage induction motors, low-speed bearings, heavy-load slewing bearings, fixed axis gearboxes, power equipment, gerotor pumps, micro-vibration detection, rolling/sliding bearings, hybrid electric vehicles, engines, turbines and motors, gear transmission systems, wind turbine bearings, wind turbines, offshore wind turbines, machinery, planetary gearboxes, induction machines and drive trains in offshore applications, rotating electrical machinery and helicopter transmissions. | [1,18,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72] |

| Dynamic characterization | Mechanical structures, landing gear shock absorbers, gearbox, carbody vibrations, rolling element bearings, rolling bearing rotor systems, rotating machinery, gearboxes, rotating laminated shafts, spur gear pairs, transmission lines, beams, shafts, plates, aircrafts, gears, journal bearings, drive train systems in wind turbines, journal bearings, flexible rotor-bearing systems, planetary gears, epicyclic gears, mounting elements of rotating machinery, tilting-pad journal bearings, aerostatic bearing films, magnetic bearings, and out-of-round wheels. | [21,22,24,25,27,42,59,65,67,70,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88] |

| Math tools or signal processing methods | Bearings, vehicles, ships, aviation, and other transportation engineering fields, complex elastic multibodies, low-speed slew bearings, magnetic bearing systems, joined structures, wind turbine drive trains, marine power transmission systems, rotating machines, mechanical structures with cyclic symmetry, rotary machines, structures coupled with elastic media, gears, and gear drives. | [16,17,18,19,20,30,34,36,38,43,44,45,46,49,50,58,66,67,80,89,90,91,92] |

| Vibration control or noise control | Long shafts, flexible rotors, hybrid magnetic bearings, sliding bearings, dampers, wind turbines, rotors, ergonomic, magnetic bearings, plate-like structures, air bearing systems and shafts of highspeed tooling spindles, automotive components, machine tool transmission housings, nonlinear vibration isolations, aerospace vehicles, and ultralight structures. | [22,51,52,62,76,93,94,95,96,97,98] |

| Design | Aerostatic bearings, internal combustion engines, vehicles, and dynamic vibration neutralizers. | [21,22,23,24,25,26,27,99] |

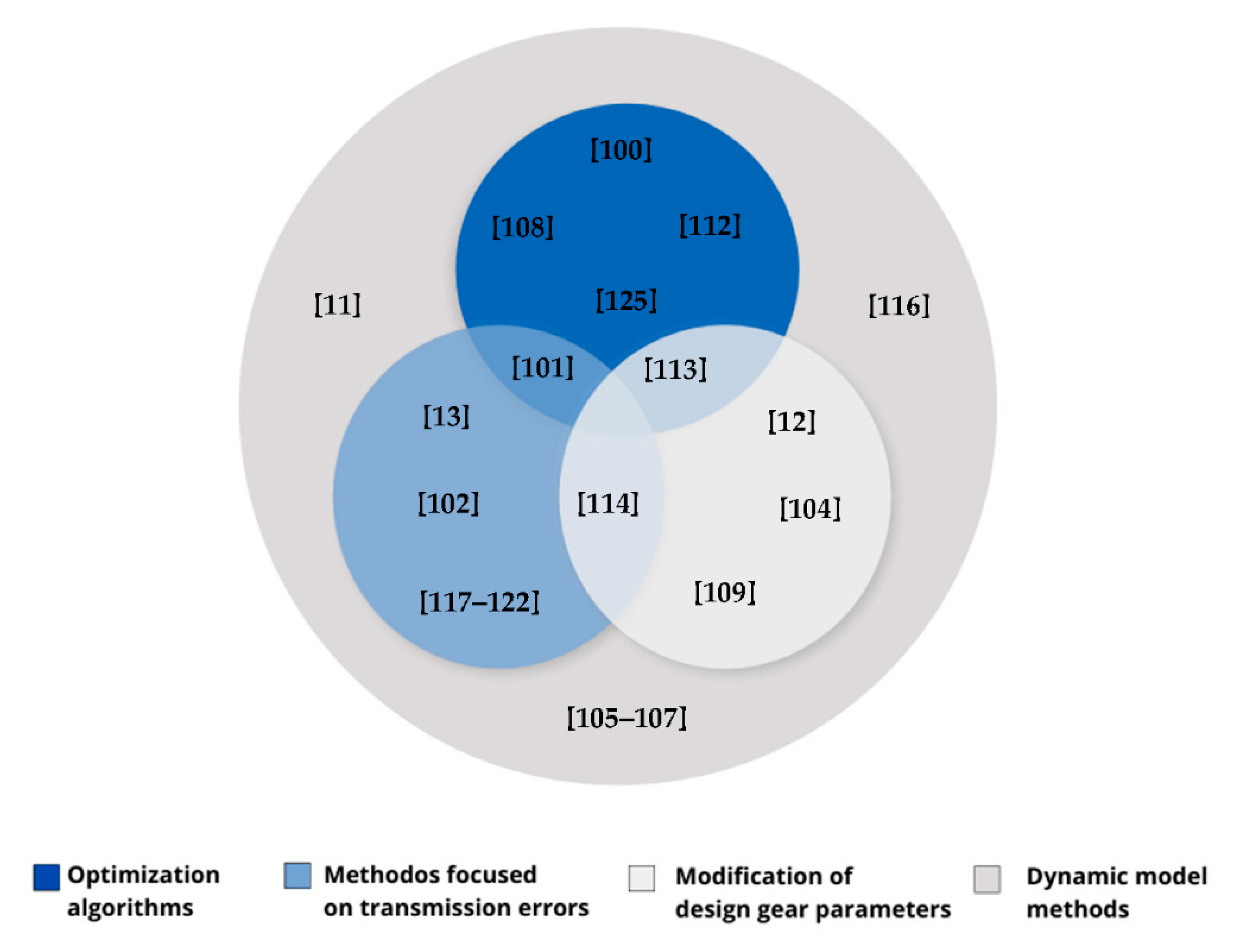

4. Design and Vibration

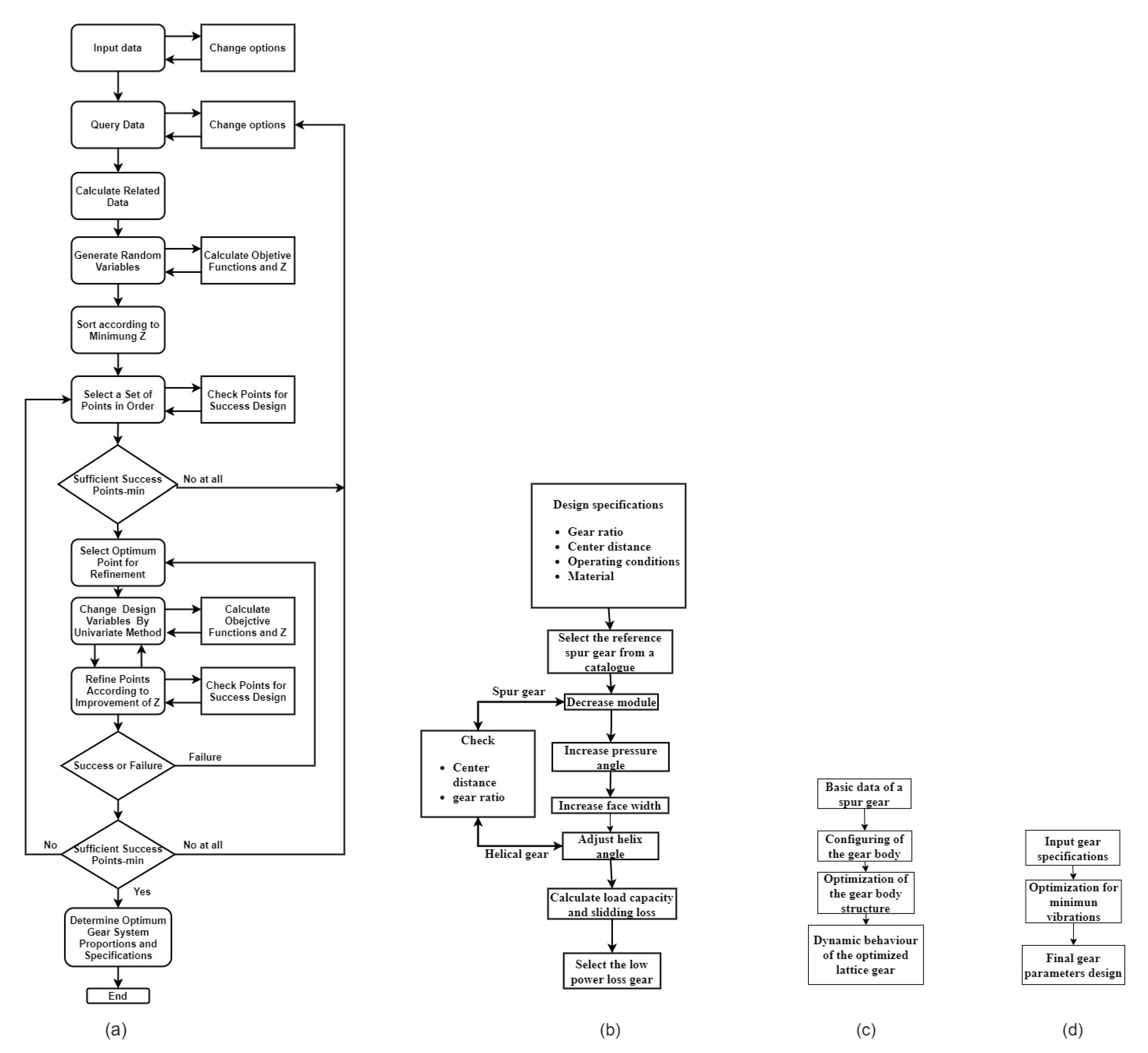

4.1. Gears

4.1.1. Spur Gears

4.1.2. Helical Gears

4.1.3. Spiral Bevel Gears

4.2. Bearings

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Henriquez, P.; Alonso-Hernández, J.B.; Ferrer, M.A.; Travieso-González, C.M. Review of Automatic Fault Diagnosis Systems Using Audio and Vibration Signals. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 642–652. [Google Scholar] [CrossRef]

- Sheng, S.; NREL (National Renewable Energy Laboratory). Gearbox Typical Failure Modes, Detection, and Mitigation Methods (Presentation). In Proceedings of the AWEA Operations & Maintenance and Safety Seminar, San Diego, CA, USA, 15–16 January 2014. [Google Scholar]

- Parker, R.G.; Vijayakar, S.M.; Imajo, T. Non-Linear Dynamic Response of a Spur Gear Pair: Modelling and Experimental Comparisons. J. Sound Vib. 2000, 237, 435–455. [Google Scholar] [CrossRef]

- Lin, J.; Parker, R. Structured Vibration Characteristics of Planetary Gears With Unequally Spaced Planets. J. Sound Vib. 2000, 233, 921–928. [Google Scholar] [CrossRef]

- Kahraman, A. Free torsional vibration characteristics of compound planetary gear sets. Mech. Mach. Theory 2001, 36, 953–971. [Google Scholar] [CrossRef]

- Inalpolat, M.; Kahraman, A. A theoretical and experimental investigation of modulation sidebands of planetary gear sets. J. Sound Vib. 2009, 323, 677–696. [Google Scholar] [CrossRef]

- Richard, G.; Budynas, J.; Keith, N. Mechanical Engineering Design, 10th ed.; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Velex, P.; Ajmi, M. On the modelling of excitations in geared systems by transmission errors. J. Sound Vib. 2006, 290, 882–909. [Google Scholar] [CrossRef]

- Tavakoli, M.S. Optimization of Spur Gear Transmission Error Using Profile Modifications. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 1983. [Google Scholar]

- Andersson, A. An Analytical Study of the Effect of the Contact Ratio on the Spur Gear Dynamic Response. J. Mech. Des. 1999, 122, 508–514. [Google Scholar] [CrossRef]

- Hedlund, J.; Lehtovaara, A. A parameterized numerical model for the evaluation of gear mesh stiffness variation of a helical gear pair. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 1321–1327. [Google Scholar] [CrossRef]

- Wu, Y.-J.; Wang, J.-J.; Han, Q.-K. Static/dynamic contact FEA and experimental study for tooth profile modification of helical gears. J. Mech. Sci. Technol. 2012, 26, 1409–1417. [Google Scholar] [CrossRef]

- Marafona, J.D.; Marques, P.; Martins, R.; Seabra, J.H. Towards constant mesh stiffness helical gears: The influence of integer overlap ratios. Mech. Mach. Theory 2019, 136, 141–161. [Google Scholar] [CrossRef]

- Ingeniería Concurrente: Una Metodología Integradora; Riba, C., Molina, A., Eds.; Catalunya, Spain, 2006. Available online: https://upcommons.upc.edu/bitstream/handle/2117/7851/Riba-Molina-2006-Ingenier%C3%ADa%20concurrente...secci%C3%B3n%20V-v5.pdf (accessed on 15 September 2021).

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods 2014, 18, 429–472. [Google Scholar] [CrossRef]

- Lin, H.-C.; Ye, Y.-C. Reviews of bearing vibration measurement using fast Fourier transform and enhanced fast Fourier transform algorithms. Adv. Mech. Eng. 2019, 11, 1–12. [Google Scholar] [CrossRef]

- Olson, B.J.; Shaw, S.W.; Shi, C.; Pierre, C.; Parker, R.G. Circulant Matrices and Their Application to Vibration Analysis. Appl. Mech. Rev. 2014, 66, 040803. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X.; Chen, X. Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Process. 2014, 96, 1–15. [Google Scholar] [CrossRef]

- Prášil, L.; Mackerle, J. Finite element analyses and simulations of gears and gear drives. Eng. Comput. 2008, 25, 196–219. [Google Scholar] [CrossRef]

- Su, J.; Zheng, L.; Deng, Z.; Jiang, Y. Research Progress on High-Intermediate Frequency Extension Methods of SEA. Shock. Vib. 2019, 2019, 1–16. [Google Scholar] [CrossRef]

- Li, F.; Qin, Y.; Ge, L.; Pang, Z.; Liu, S.; Lin, D. Influences of planetary gear parameters on the dynamic characteristics—A review. J. Vibroeng. 2015, 17, 574–586. [Google Scholar]

- Mohan, K.M.; Srinivasan, K.; Ramamurti, V. Dynamics of machine tool drive housings. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1619–1630. [Google Scholar] [CrossRef]

- Gao, Q.; Chen, W.; Lu, L.; Huo, D.; Cheng, K. Aerostatic bearings design and analysis with the application to precision engineering: State-of-the-art and future perspectives. Tribol. Int. 2019, 135, 1–17. [Google Scholar] [CrossRef]

- Al-Bender, F. On the modelling of the dynamic characteristics of aerostatic bearing films: From stability analysis to active compensation. Precis. Eng. 2009, 33, 117–126. [Google Scholar] [CrossRef]

- Hong, S.-W.; Tong, V.-C. Rolling-element bearing modeling: A review. Int. J. Precis. Eng. Manuf. 2016, 17, 1729–1749. [Google Scholar] [CrossRef]

- Mahdisoozani, H.; Mohsenizadeh, M.; Bahiraei, M.; Kasaeian, A.; Daneshvar, A.; Goodarzi, M.; Safaei, M.R. Performance Enhancement of Internal Combustion Engines through Vibration Control: State of the Art and Challenges. Appl. Sci. 2019, 9, 406. [Google Scholar] [CrossRef]

- Sharma, S.; Coetzee, E.; Lowenberg, M.; Neild, S.; Krauskopf, B. Numerical continuation and bifurcation analysis in aircraft design: An industrial perspective. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140406. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration based condition monitoring and fault diagnosis of wind turbine planetary gearbox: A review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Tse, C.K.; Tan, S.-C.; Lai, Y.M. Sliding mode voltage controller for basic DC-DC converter in discontinuous conduction mode. IET Electr.Power Appl. 2001, 67, 263–270. [Google Scholar] [CrossRef]

- Lei, Y.; Lin, J.; Zuo, M.; He, Z. Condition monitoring and fault diagnosis of planetary gearboxes: A review. Measurement 2014, 48, 292–305. [Google Scholar] [CrossRef]

- Smith, W.; Randall, R. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64–65, 100–131. [Google Scholar] [CrossRef]

- Liu, W.; Tang, B.; Han, J.; Lu, X.; Hu, N.; He, Z. The structure healthy condition monitoring and fault diagnosis methods in wind turbines: A review. Renew. Sustain. Energy Rev. 2015, 44, 466–472. [Google Scholar] [CrossRef]

- Antoniadou, I.; Dervilis, N.; Papatheou, E.; Maguire, E.; Worden, K. Aspects of structural health and condition monitoring of offshore wind turbines. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140075. [Google Scholar] [CrossRef]

- El-Thalji, I.; Jantunen, E. A summary of fault modelling and predictive health monitoring of rolling element bearings. Mech. Syst. Signal Process. 2015, 60-61, 252–272. [Google Scholar] [CrossRef]

- Babu, T.N.; Raj, T.M.; Lakshmanan, T. A Review on Application of Dynamic Parameters of Journal Bearing for Vibration and Condition Monitoring. J. Mech. 2015, 31, 391–416. [Google Scholar] [CrossRef]

- Gómez, M.J.; Castejón, C.; García-Prada, J.C. Review of Recent Advances in the Application of the Wavelet Transform to Diagnose Cracked Rotors. Algorithms 2016, 9, 19. [Google Scholar] [CrossRef]

- Goyal, D.; Pabla, B.S. The Vibration Monitoring Methods and Signal Processing Techniques for Structural Health Monitoring: A Review. Arch. Comput. Methods Eng. 2016, 23, 585–594. [Google Scholar] [CrossRef]

- Wang, Y.; Xiang, J.; Markert, R.; Liang, M. Spectral kurtosis for fault detection, diagnosis and prognostics of rotating machines: A review with applications. Mech. Syst. Signal Process. 2016, 66–67, 679–698. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S.H. A review on signal processing techniques utilized in the fault diagnosis of rolling element bearings. Tribol. Int. 2016, 96, 289–306. [Google Scholar] [CrossRef]

- Samuel, P.D.; Pines, D.J. A review of vibration-based techniques for helicopter transmission diagnostics. J. Sound Vib. 2005, 282, 475–508. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, Y.; Hu, C.; Peng, Z. Recent progress on decoupling diagnosis of hybrid failures in gear transmission systems using vibration sensor signal: A review. Measurement 2016, 90, 4–19. [Google Scholar] [CrossRef]

- de Azevedo, H.D.M.; Araújo, A.M.; Bouchonneau, N. A review of wind turbine bearing condition monitoring: State of the art and challenges. Renew. Sustain. Energy Rev. 2016, 56, 368–379. [Google Scholar] [CrossRef]

- Caesarendra, W.; Tjahjowidodo, T. A Review of Feature Extraction Methods in Vibration-Based Condition Monitoring and Its Application for Degradation Trend Estimation of Low-Speed Slew Bearing. Machines 2017, 5, 21. [Google Scholar] [CrossRef]

- Javorskyj, I.; Kravets, I.; Matsko, I.; Yuzefovych, R. Periodically correlated random processes: Application in early diagnostics of mechanical systems. Mech. Syst. Signal Process. 2017, 83, 406–438. [Google Scholar] [CrossRef]

- Liu, C.; Wang, F.; Su, W.; Xue, Z.; Li, H.; Han, Q. Condition monitoring and fault diagnosis methods for low-speed and heavy-load slewing bearings: A literature review. J. Vibroeng. 2017, 19, 3429–3444. [Google Scholar] [CrossRef]

- Tong, X.; Palazzolo, A.; Suh, J. A Review of the Rotordynamic Thermally Induced Synchronous Instability (Morton) Effect. Appl. Mech. Rev. 2017, 69, 060801. [Google Scholar] [CrossRef]

- Sabato, A.; Niezrecki, C.; Fortino, G. Wireless MEMS-Based Accelerometer Sensor Boards for Structural Vibration Monitoring: A Review. IEEE Sens. J. 2017, 17, 226–235. [Google Scholar] [CrossRef]

- Liu, Y.; Bazzi, A.M. A review and comparison of fault detection and diagnosis methods for squirrel-cage induction motors: State of the art. ISA Trans. 2017, 70, 400–409. [Google Scholar] [CrossRef]

- Xu, X.; Wang, H.; Zhang, N.; Liu, Z.; Wang, X. Review of the Fault Mechanism and Diagnostic Techniques for the Range Extender Hybrid Electric Vehicle. IEEE Access 2017, 5, 14234–14244. [Google Scholar] [CrossRef]

- Goyal, D.; Vanraj; Pabla, B.S.; Dhami, S.S. Condition Monitoring Parameters for Fault Diagnosis of Fixed Axis Gearbox: A Review. Arch. Comput. Methods Eng. 2016, 24, 543–556. [Google Scholar] [CrossRef]

- Sekhar, A.S. Multiple cracks effects and identification. Mech. Syst. Signal Process. 2008, 22, 845–878. [Google Scholar] [CrossRef]

- Li, S.; Li, J. Condition monitoring and diagnosis of power equipment: Review and prospective. High Volt. 2017, 2, 82–91. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Liang, X.; Zuo, M.J.; Feng, Z. Dynamic modeling of gearbox faults: A review. Mech. Syst. Signal Process. 2018, 98, 852–876. [Google Scholar] [CrossRef]

- Xu, S.; Xing, F.; Wang, R.; Li, W.; Wang, Y.; Wang, X. Vibration sensor for the health monitoring of the large rotating machinery: Review and outlook. Sens. Rev. 2018, 38, 44–64. [Google Scholar] [CrossRef]

- Delvecchio, S.; Bonfiglio, P.; Pompoli, F. Vibro-acoustic condition monitoring of Internal Combustion Engines: A critical review of existing techniques. Mech. Syst. Signal Process. 2018, 99, 661–683. [Google Scholar] [CrossRef]

- Srinivas, R.S.; Tiwari, R.; Kannababu, C. Application of active magnetic bearings in flexible rotordynamic systems—A state-of-the-art review. Mech. Syst. Signal Process. 2018, 106, 537–572. [Google Scholar] [CrossRef]

- Touret, T.; Changenet, C.; Ville, F.; Lalmi, M.; Becquerelle, S. On the use of temperature for online condition monitoring of geared systems—A review. Mech. Syst. Signal Process. 2018, 101, 197–210. [Google Scholar] [CrossRef]

- Ding, Y.; Ren, P.; Zhao, H.; Miao, C. Structural health monitoring of a high-speed railway bridge: Five years review and lessons learned. Smart Struct. Syst. 2018, 21, 695–703. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Liu, Z.; Liang, X.; Si, S. The Entropy Algorithm and Its Variants in the Fault Diagnosis of Rotating Machinery: A Review. IEEE Access 2018, 6, 66723–66741. [Google Scholar] [CrossRef]

- Qiao, Z.; Lei, Y.; Li, N. Applications of stochastic resonance to machinery fault detection: A review and tutorial. Mech. Syst. Signal Process. 2019, 122, 502–536. [Google Scholar] [CrossRef]

- Patil, M.S.; Mathew, J.; Rajendrakumar, P.K. Bearing Signature Analysis as a Medium for Fault Detection: A Review. J. Tribol. 2007, 130, 014001. [Google Scholar] [CrossRef]

- Zai, B.A.; Khan, M.; Khan, K.A.; Mansoor, A.; Shah, A.; Shahzad, M. The role of dynamic response parameters in damage prediction. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4620–4636. [Google Scholar] [CrossRef]

- Malla, C.; Panigrahi, I. Review of Condition Monitoring of Rolling Element Bearing Using Vibration Analysis and Other Techniques. J. Vib. Eng. Technol. 2019, 7, 407–414. [Google Scholar] [CrossRef]

- Lu, S.; Yan, R.; Liu, Y.; Wang, Q. Tacholess Speed Estimation in Order Tracking: A Review With Application to Rotating Machine Fault Diagnosis. IEEE Trans. Instrum. Meas. 2019, 68, 2315–2332. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, R. Role of Signal Processing, Modeling and Decision Making in the Diagnosis of Rolling Element Bearing Defect: A Review. J. Nondestruct. Eval. 2019, 38, 5. [Google Scholar] [CrossRef]

- Poompavai, T.; Kowsalya, M. Control and energy management strategies applied for solar photovoltaic and wind energy fed water pumping system: A review. Renew. Sustain. Energy Rev. 2019, 107, 108–122. [Google Scholar] [CrossRef]

- Wang, D.; Tsui, K.-L.; Miao, Q. Prognostics and Health Management: A Review of Vibration Based Bearing and Gear Health Indicators. IEEE Access 2017, 6, 665–676. [Google Scholar] [CrossRef]

- Vieira, A.; De Moura, E.P.; Gonçalves, L.L. Fluctuation Analyses for Pattern Classification in Nondestructive Materials Inspection. EURASIP J. Adv. Signal Process. 2010, 2010, 262869. [Google Scholar] [CrossRef]

- Randall, R.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Cibulka, J.; Ebbesen, M.K.; Hovland, G.; Robbersmyr, K.G.; Hansen, M.R. A Review on Approaches for Condition Based Maintenance in Applications with Induction Machines located Offshore. Model. Identif. Control. A Nor. Res. Bull. 2012, 33, 69–86. [Google Scholar] [CrossRef]

- Feng, Z.; Liang, M.; Chu, F. Recent advances in time–frequency analysis methods for machinery fault diagnosis: A review with application examples. Mech. Syst. Signal Process. 2013, 38, 165–205. [Google Scholar] [CrossRef]

- Cao, H.; Niu, L.; Xi, S.; Chen, X. Mechanical model development of rolling bearing-rotor systems: A review. Mech. Syst. Signal Process. 2018, 102, 37–58. [Google Scholar] [CrossRef]

- Liu, J.; Shao, Y. Overview of dynamic modelling and analysis of rolling element bearings with localized and distributed faults. Nonlinear Dyn. 2018, 93, 1765–1798. [Google Scholar] [CrossRef]

- Jang, J.Y.; Khonsari, M.M. On the Characteristics of Misaligned Journal Bearings. Lubricants 2015, 3, 27–53. [Google Scholar] [CrossRef]

- Singh, S.; Howard, C.Q.; Hansen, C.H. An extensive review of vibration modelling of rolling element bearings with localised and extended defects. J. Sound Vib. 2015, 357, 300–330. [Google Scholar] [CrossRef]

- Aboshosha, H.; Elawady, A.; El Ansary, A.; El Damatty, A. Review on dynamic and quasi-static buffeting response of transmission lines under synoptic and non-synoptic winds. Eng. Struct. 2016, 112, 23–46. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, J.; Feng, R.; Pang, X.; Wang, Q.; Wen, B. Review on dynamics of cracked gear systems. Eng. Fail. Anal. 2015, 55, 224–245. [Google Scholar] [CrossRef]

- Ji, J.; Hansen, C.H.; Zander, A.C. Nonlinear Dynamics of Magnetic Bearing Systems. J. Intell. Mater. Syst. Struct. 2008, 19, 1471–1491. [Google Scholar] [CrossRef]

- Bovsunovsky, A.; Surace, C. Non-linearities in the vibrations of elastic structures with a closing crack: A state of the art review. Mech. Syst. Signal Process. 2015, 62-63, 129–148. [Google Scholar] [CrossRef]

- Cooley, C.G.; Parker, R. A Review of Planetary and Epicyclic Gear Dynamics and Vibrations Research. Appl. Mech. Rev. 2014, 66, 040804. [Google Scholar] [CrossRef]

- Wang, Q.; Zeng, J.; Wei, L.; Zhu, B. Carbody vibrations of high-speed train caused by dynamic unbalance of underframe suspended equipment. Adv. Mech. Eng. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- del Campo, V.; Ragni, D.; Micallef, D.; Diez, F.J.; Ferreira, C.J.S. Estimation of loads on a horizontal axis wind turbine operating in yawed flow conditions. Wind. Energy 2015, 18, 1875–1891. [Google Scholar] [CrossRef]

- Sharma, A.; Upadhyay, N.; Kankar, P.K.; Amarnath, M. Nonlinear dynamic investigations on rolling element bearings: A review. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Papadopoulos, C.A. The strain energy release approach for modeling cracks in rotors: A state of the art review. Mech. Syst. Signal Process. 2008, 22, 763–789. [Google Scholar] [CrossRef]

- Barke, D.W.; Chiu, W.K. A Review of the Effects of Out-Of-Round Wheels on Track and Vehicle Components. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2005, 219, 151–175. [Google Scholar] [CrossRef]

- Hori, Y.; Kato, K. Studies on tribology. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 2008, 84, 287–320. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, R. Recent advances in nonlinear passive vibration isolators. J. Sound Vib. 2008, 314, 371–452. [Google Scholar] [CrossRef]

- Clouteau, D.; Cottereau, R.; Lombaert, G. Dynamics of structures coupled with elastic media—A review of numerical models and methods. J. Sound Vib. 2013, 332, 2415–2436. [Google Scholar] [CrossRef]

- Maheswari, R.U. Trends in non-stationary signal processing techniques applied to vibration analysis of wind turbine drive train—A contemporary survey. Mech. Syst. Signal Process. 2017, 85, 296–311. [Google Scholar] [CrossRef]

- Braun, S. The synchronous (time domain) average revisited. Mech. Syst. Signal Process. 2011, 25, 1087–1102. [Google Scholar] [CrossRef]

- Lei, Y.; Lin, J.; He, Z.; Zuo, M. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2013, 35, 108–126. [Google Scholar] [CrossRef]

- Ben-Brahim, L.; Gastli, A.; Yoshino, T.; Yokoyama, T.; Kawamura, A. Review of Medium Voltage High Power Electric Drives. IEEJ J. Ind. Appl. 2019, 8, 1–11. [Google Scholar] [CrossRef]

- Gardonio, P. Review of Active Techniques for Aerospace Vibro-Acoustic Control. J. Aircaft. 2002, 39, 206–214. [Google Scholar] [CrossRef]

- Hanselka, H. Adaptronics as a Key Technology for Intelligent Lightweight Structures. Adv. Eng. Mater. 2001, 3, 205–215. [Google Scholar] [CrossRef]

- Santos, I.F. Controllable Sliding Bearings and Controllable Lubrication Principles—An Overview. Lubricants 2018, 6, 16. [Google Scholar] [CrossRef]

- Aridogan, U.; Basdogan, I. A review of active vibration and noise suppression of plate-like structures with piezoelectric transducers. J. Intell. Mater. Syst. Struct. 2015, 26, 1455–1476. [Google Scholar] [CrossRef]

- Liu, W. A review on wind turbine noise mechanism and de-noising techniques. Renew. Energy 2017, 108, 311–320. [Google Scholar] [CrossRef]

- Abouel-seoud, S. Review Papers Tire and Engine Sources Contribution to Vehicle Interior Noise and Vibration Exposure Levels. Arch. Acoust. 2019, 44, 201–214. [Google Scholar] [CrossRef]

- Abuid, B.A.; Ameen, Y.M. Procedure for Optimum Design of a Two-Stage Spur Gear System. JSME Int. J. Ser. C 2003, 46, 1582–1590. [Google Scholar] [CrossRef]

- Fonseca, D.J.; Shishoo, S.; Lim, T.C.; Chen, D.S. A genetic algorithm approach to minimize transmission error of automotive spur gear sets. Appl. Artif. Intell. 2005, 19, 153–179. [Google Scholar] [CrossRef]

- Jiang, J.; Fang, Z. Design and analysis of modified cylindrical gears with a higher-order transmission error. Mech. Mach. Theory 2015, 88, 141–152. [Google Scholar] [CrossRef]

- Wang, Y. Optimized tooth profile based on identified gear dynamic model. Mech. Mach. Theory 2007, 42, 1058–1068. [Google Scholar] [CrossRef]

- Yildirim, N.; Gasparini, G.; Sartori, S. An improvement on helicopter transmission performance through use of high contact ratio spur gears with suitable profile modification design. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2008, 222, 1193–1210. [Google Scholar] [CrossRef]

- Karpat, F.; Ekwaro-Osire, S.; Cavdar, K.; Babalik, F.C. Dynamic analysis of involute spur gears with asymmetric teeth. Int. J. Mech. Sci. 2008, 50, 1598–1610. [Google Scholar] [CrossRef]

- Ouyang, T.; Huang, H.; Zhang, N.; Mo, C.; Chen, N. A model to predict tribo-dynamic performance of a spur gear pair. Tribol. Int. 2017, 116, 449–459. [Google Scholar] [CrossRef]

- Ouyang, T.; Huang, H.; Zhou, X.; Pan, M.; Chen, N.; Lv, D. A finite line contact tribo-dynamic model of a spur gear pair. Tribol. Int. 2018, 119, 753–765. [Google Scholar] [CrossRef]

- Ramadani, R.; Belsak, A.; Kegl, M.; Predan, J.; Pehan, S. Topology Optimization Based Design of Lightweight and Low Vibration Gear Bodies. Int. J. Simul. Model. 2018, 17, 92–104. [Google Scholar] [CrossRef]

- Xu, L.; Chen, N. Nonlinear dynamic study and vibration reduction of a power turret gear train with modified design parameters. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 229, 1745–1759. [Google Scholar] [CrossRef]

- Liou, C.-H.; Lin, H.H.; Oswald, F.B.; Townsend, D.P. Effect of Contact Ratio on Spur Gear Dynamic Load With No Tooth Profile Modifications. J. Mech. Des. 1996, 118, 439–443. [Google Scholar] [CrossRef]

- Theerarangsarit, K.; Ratanasumawong, C. Parallel-Axis Gear Design Methodology for Minimization of Power Loss and Its Effect on Vibration Characteristics. Eng. J. 2017, 21, 427–439. [Google Scholar] [CrossRef][Green Version]

- Chong, T.H.; Bae, I.; Kubo, A. Multiobjective Optimal Design of Cylindrical Gear Pairs for the Reduction of Gear Size and Meshing Vibration. JSME Int. J. Ser. C 2001, 44, 291–298. [Google Scholar] [CrossRef][Green Version]

- Komori, M.; Kubo, A.; Suzuki, Y. Simultaneous Optimization of Tooth Flank Form of Involute Helical Gears in Terms of Both Vibration and Load Carrying Capacity. JSME Int. J. Ser. C 2003, 46, 1572–1581. [Google Scholar] [CrossRef][Green Version]

- Fuentes, A.; Nagamoto, H.; Litvin, F.L.; Gonzalez-Perez, I.; Hayasaka, K. Computerized design of modified helical gears finished by plunge shaving. Comput. Methods Appl. Mech. Eng. 2010, 199, 1677–1690. [Google Scholar] [CrossRef]

- Wang, C.; Cui, H.Y.; Zhang, Q.P.; Wang, W.M. Modified optimization and experimental investigation of transmission error, vibration and noise for double helical gears. J. Vib. Control. 2016, 22, 108–120. [Google Scholar] [CrossRef]

- Tanaka, E.; Houjoh, H.; Mutoh, D.; Motoshiromizu, H.; Ohno, K.; Tanaka, N. Vibration and Sound-Radiation Analysis for Designing a Low-Noise Gearbox with a Multi-Stage Helical Gear System. JSME Int. J. Ser. C 2003, 46, 1178–1185. [Google Scholar] [CrossRef]

- Wang, F.; Xu, X.; Fang, Z.; Chen, L. Design and analysis of herringbone gear with sixth-order transmission error based on meshing vibration optimization. Adv. Mech. Eng. 2017, 9, 1–8. [Google Scholar] [CrossRef]

- Litvin, F.L.; Fuentes, A.; Hayasaka, K. Design, manufacture, stress analysis, and experimental tests of low-noise high endurance spiral bevel gears. Mech. Mach. Theory 2006, 41, 83–118. [Google Scholar] [CrossRef]

- Su, J.; Fang, Z.; Cai, X. Design and analysis of spiral bevel gears with seventh-order function of transmission error. Chin. J. Aeronaut. 2013, 26, 1310–1316. [Google Scholar] [CrossRef]

- Astoul, J.; Mermoz, E.; Sartor, M.; Linares, J.; Bernard, A. New methodology to reduce the transmission error of the spiral bevel gears. CIRP Ann. 2014, 63, 165–168. [Google Scholar] [CrossRef]

- Mu, Y.; Fang, Z. Design and analysis of high contact ratio spiral bevel gears by modified curvature motion method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 3396–3409. [Google Scholar] [CrossRef]

- Mu, Y.; Li, W.; Fang, Z.; Zhang, X. A novel tooth surface modification method for spiral bevel gears with higher-order transmission error. Mech. Mach. Theory 2018, 126, 49–60. [Google Scholar] [CrossRef]

- Argyris, J.; Fuentes, A.; Litvin, F.L. Computerized integrated approach for design and stress analysis of spiral bevel gears. Comput. Methods Appl. Mech. Eng. 2002, 191, 1057–1095. [Google Scholar] [CrossRef]

- Fuentes-Aznar, A.; Orzáez, R.R.; Gonzalez-Perez, I. Computational approach to design face-milled spiral bevel gear drives with favorable conditions of meshing and contact. Meccanica 2018, 53, 2669–2686. [Google Scholar] [CrossRef]

- Yang, B.; Choi, S.; Kim, Y. Vibration reduction optimum design of a steam-turbine rotor-bearing system using a hybrid genetic algorithm. Struct. Multidiscip. Optim. 2005, 30, 43–53. [Google Scholar] [CrossRef]

- Ohta, H.; Kato, S.; Matsumoto, J.; Nakano, K. A Design of Crowning to Reduce Ball Passage Vibrations of a Linear Guideway Type Recirculating Linear Ball Bearing. J. Tribol. 2005, 127, 257–262. [Google Scholar] [CrossRef]

- Kirk, R.G.; Mondschein, B.; AlSaeed, A.A.; Gallimore, D.; Frank, A.; Crouch, J.; Tiller, M.; Vo, T.; Thrush, K.; Lloyd, R. Influence of Turbocharger Bearing Design on Observed Linear and Nonlinear Vibration. In Proceedings of the STLE/ASME 2010 International Joint Tribology Conference, San Francisco, CA, USA, 17–20 October 2010; pp. 175–177. [Google Scholar]

- Chasalevris, A.; Dohnal, F. A journal bearing with variable geometry for the suppression of vibrations in rotating shafts: Simulation, design, construction and experiment. Mech. Syst. Signal Process. 2015, 52–53, 506–528. [Google Scholar] [CrossRef]

- Cao, J.; Allaire, P.; Dimond, T. Reduction of vibration and power loss in industrial turbochargers with improved tilting pad bearing design. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; pp. 1–9. [Google Scholar]

| Transmission Element | Method | Application | Results |

|---|---|---|---|

| Spur gear | Refined min–max technique and direct min/max search method [100] | Two-stage spur gear system | Reduction of dynamic factor by 22% and 53% in the first and second teeth meshing zone, respectively |

| Genetic algorithm [101] | Two mating gears | 22,1 microns of TE | |

| H-TE [102] | Gear pair | High effective contact ratio with the higher-order TE | |

| HCR and profile modification [104] | Two-stage helicopter transmission | Vibration decrease of three to four times compared with regular design | |

| Dynamic behavior of spur gears with asymmetric teeth [105] | Involute spur gear pairs | Design rules for spur gears with asymmetric teeth | |

| Tribo-dynamic model [106] | Spur gear pair | Conclusions about dynamic mesh force and load ratio | |

| Unified tribo-dynamic model [107] | Spur gear of ink vibrator | Optimal range of the crown radius and round corner radius for reducing maximum pressure | |

| Topology optimization [108] | Titanium alloy’s gear | Lower frequency ranges in some dominating frequency components in the lattice structure proposed | |

| Optimization of the dynamic response of the turret gear system by improving the modulus and the pressure angle [109] | Three-stage gear train | Reduction of vibration of 28–60% | |

| Helical gear | Multi-objective optimization technique through goal programming method [112] | Gear pair used in an elevator reduction drive | Reduction of the vibrational excitation force (N/mm) by 60% |

| Optimization of tooth flank form [113] | Gear pair | Reduction of the vibrational excitation force (N/mm) in the range of 16–50% | |

| Model for excitation calculation [11] | Gear pair | Mesh stiffness variation in the frequency domain and reasonable computational time | |

| Computerized method for geometry modification [114] | Gear pair | Reduction on the TE | |

| Tooth profile modification [12] | Gear pair | Vibration reduction for the studied load conditions | |

| Modification of different gear parameters [111] | Gear pair | Maximum vibration reduction of 85% for the studied load condition | |

| Constant mesh stiffness [13] | Gear pair | Lowest RMS of the Dynamic TE for the evaluated gears | |

| Analysis of dynamic behavior to add ribs in helical gearbox [116] | Second-stage helical reduction gears | Concordance with experimental measurements and the proposed method | |

| Optimization design method for six order TE [117] | Herringbone gear coupling | Reduction of RMS acceleration of 40% in resonance velocity of sixth-order TE compared with second-order TE | |

| Spiral bevel gear | Local synthesis algorithm for reducing TE [118] | Gear pair | Reduced level of TE for prototypes of optimized gear drives studied |

| Seventh-order polynomial function of TE [119] | Gear pair | Advantages in load sharing curves and tensile stress | |

| Optimization process to reduce the TE [120] | Gear pair | 30% reduction in the quasi-static TE | |

| Seventh-order TE for HCR spiral bevel gears [121] | Gear pair | Improvements in the dynamics meshing quality of spiral bevel gears | |

| H-TE for HCR spiral bevel gears [122] | Gear pair | Reduction of TE for different load conditions | |

| Synthesis, TCA, and stress analysis [123] | Gear pair | Reduction of the shift of bearing contact caused by misalignment | |

| Integrated computerized approach of design through a five-cut process [124] | Gear pair | Uniform evolution of contact and bending stresses | |

| Bearing | Hybrid genetic algorithm [125] | Two journal bearings | Optimum values of bearing length and bearing clearance |

| Design of crowning [126] | Linear ball bearing | Reduction of 33% in the amplitude of displacement for the maximum linear velocity tested | |

| Design of VGJB [128] | Journal bearings | Decrease in the vibration amplitude at resonance by up to 70% compared to a conventional journal bearing |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuirán Villalba, R.; Maury Ramírez, H.; Águila Estrada, H. Classification of Design Methodologies to Minimize Vibrations in Gears and Bearings in the 21st Century: A Review. Machines 2021, 9, 212. https://doi.org/10.3390/machines9100212

Tuirán Villalba R, Maury Ramírez H, Águila Estrada H. Classification of Design Methodologies to Minimize Vibrations in Gears and Bearings in the 21st Century: A Review. Machines. 2021; 9(10):212. https://doi.org/10.3390/machines9100212

Chicago/Turabian StyleTuirán Villalba, Rafael, Heriberto Maury Ramírez, and Héctor Águila Estrada. 2021. "Classification of Design Methodologies to Minimize Vibrations in Gears and Bearings in the 21st Century: A Review" Machines 9, no. 10: 212. https://doi.org/10.3390/machines9100212

APA StyleTuirán Villalba, R., Maury Ramírez, H., & Águila Estrada, H. (2021). Classification of Design Methodologies to Minimize Vibrations in Gears and Bearings in the 21st Century: A Review. Machines, 9(10), 212. https://doi.org/10.3390/machines9100212