Cooling Performance Analysis of Outside Fins of the Closed Circuit Axial Piston Transmission

Abstract

1. Introduction

2. Analysis and Modeling

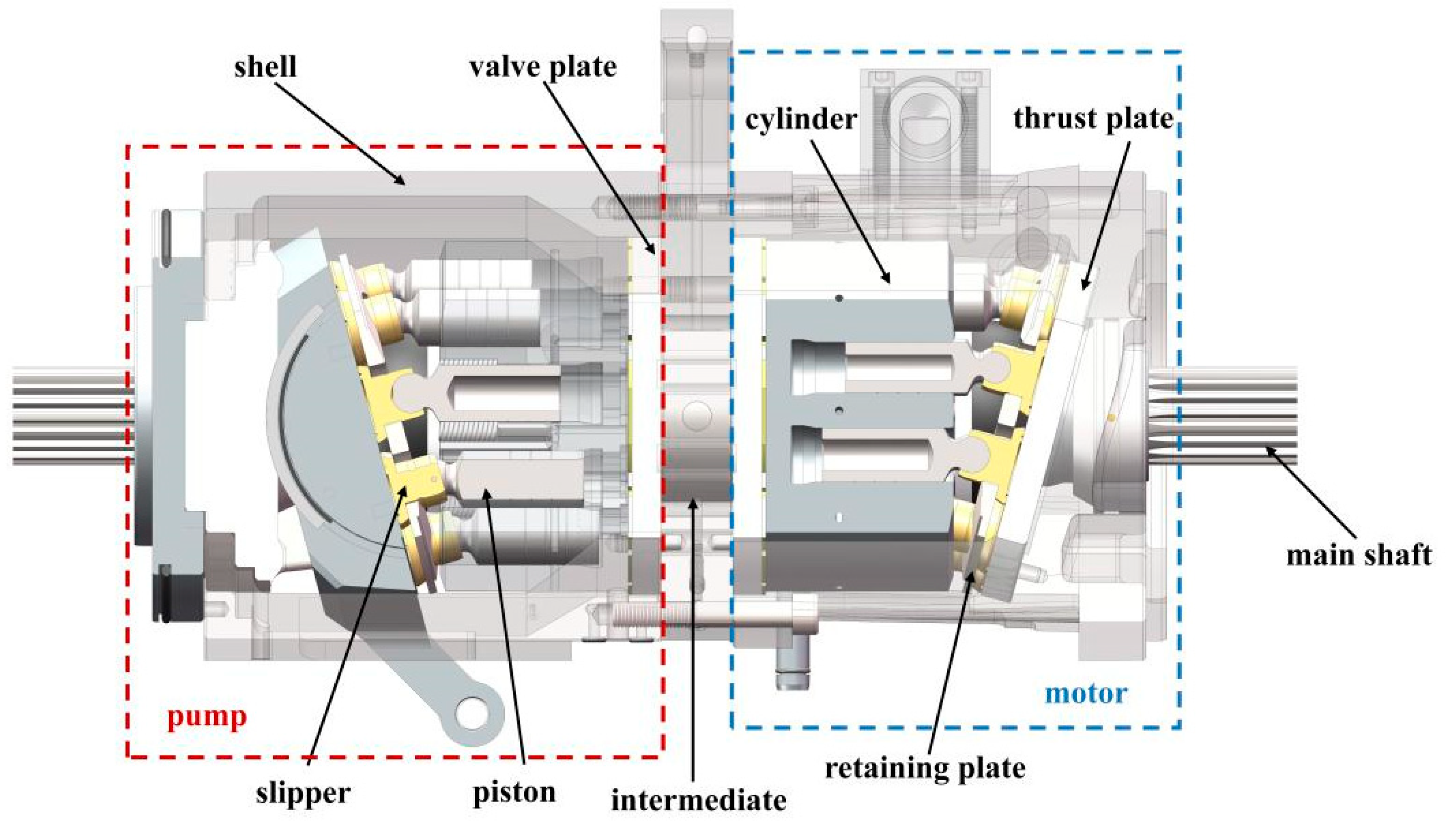

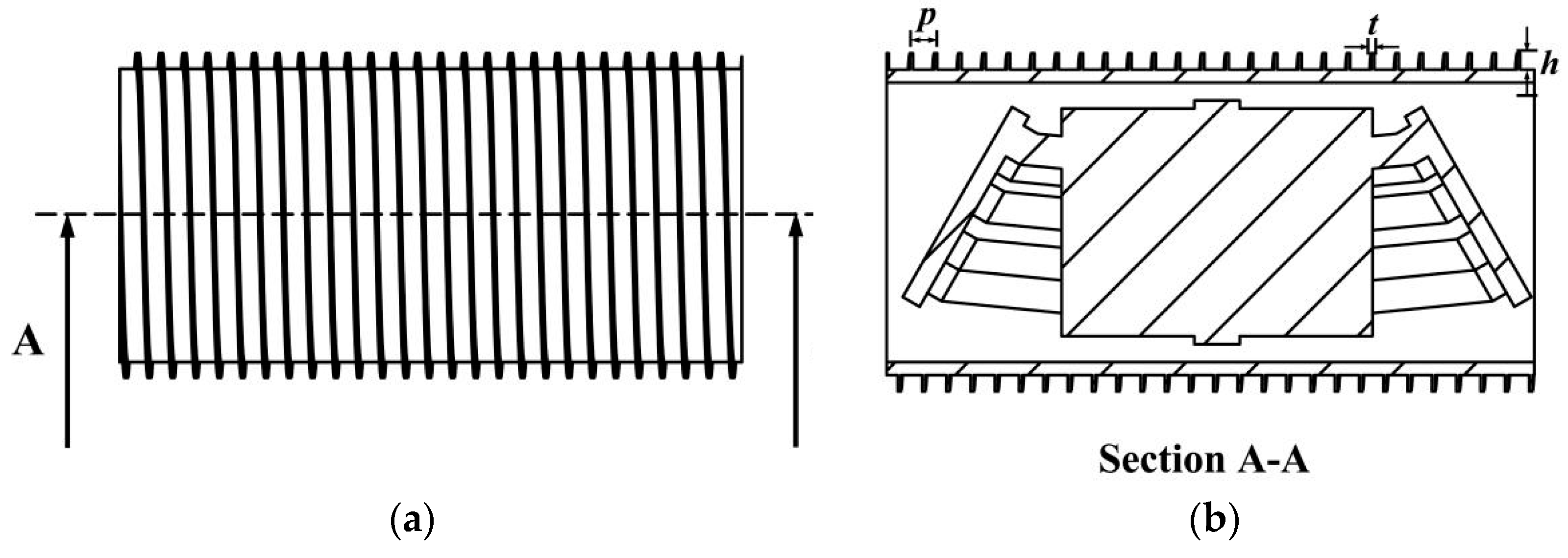

2.1. Geometrical Model

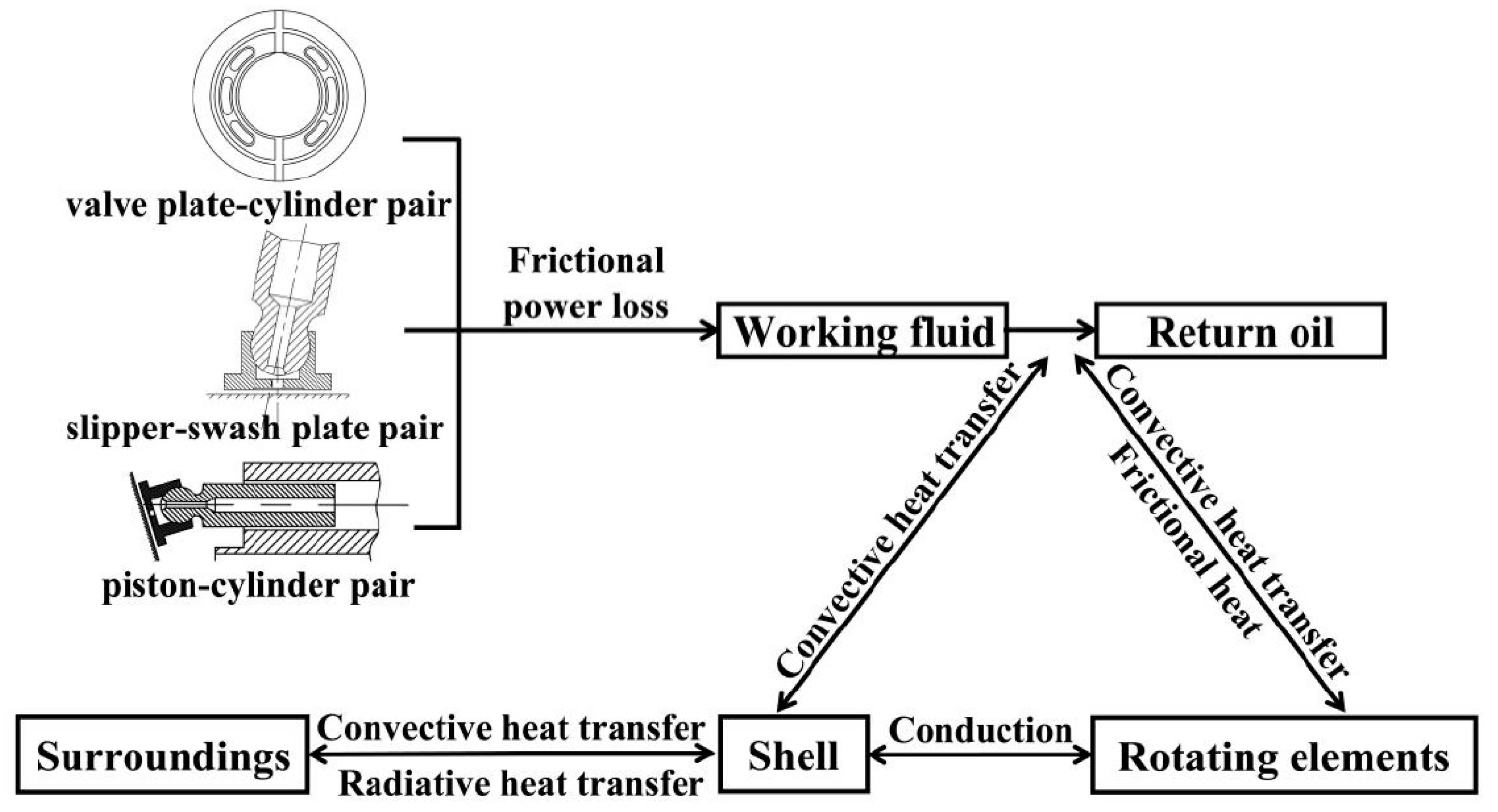

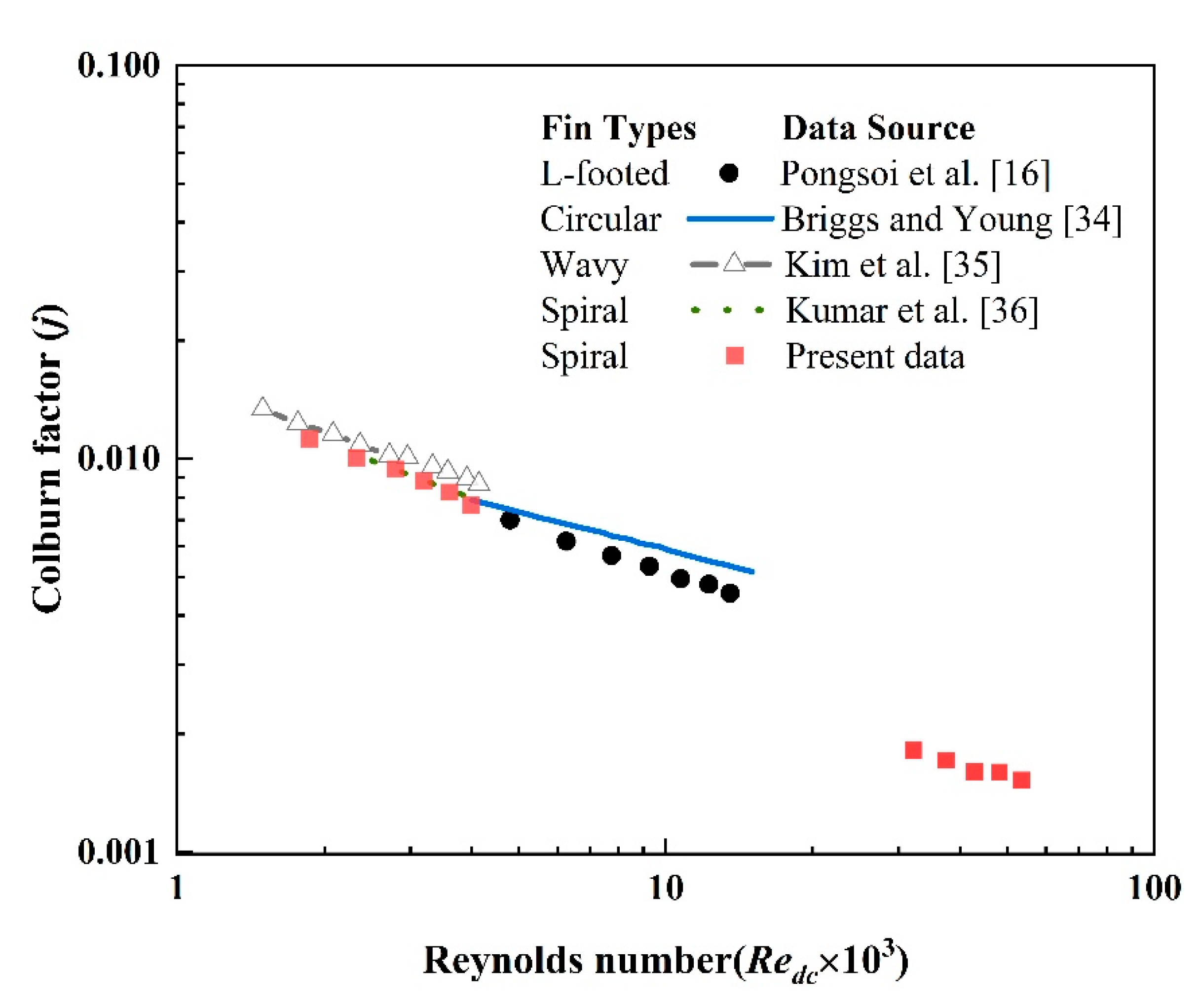

2.2. Data Reduction

2.3. Mesh and Boundary Conditions

- (1)

- The CCAPT operates under the steady state, which means the volume loss and the mechanical loss are constant during the simulation.

- (2)

- Neglect the temperature differences between the shell and the internal rotating elements.

- (3)

- Take no account of the variance of the ambient temperature.

- (4)

- Leave out the pressure pulsation inside the CCAPT.

3. Results and Discussion

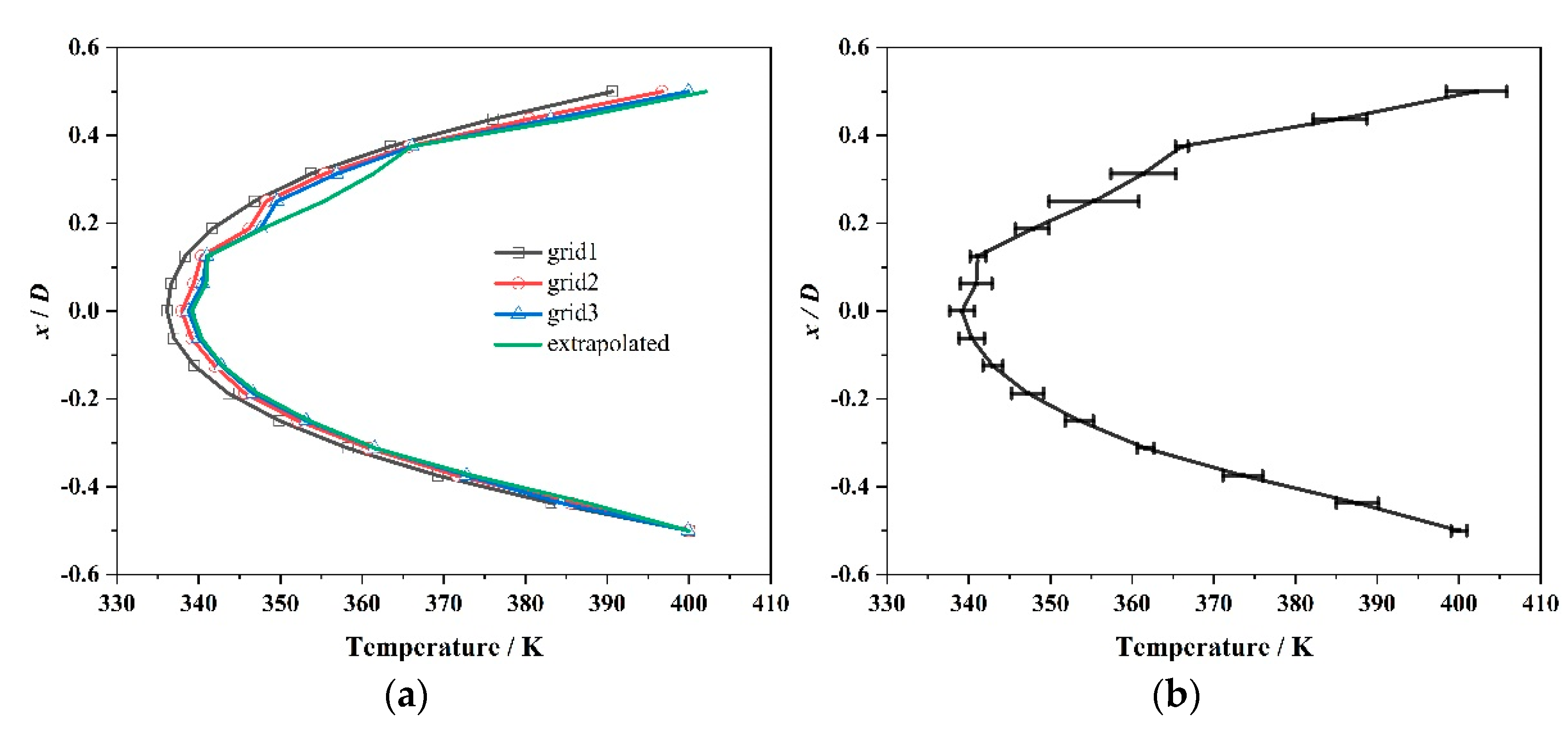

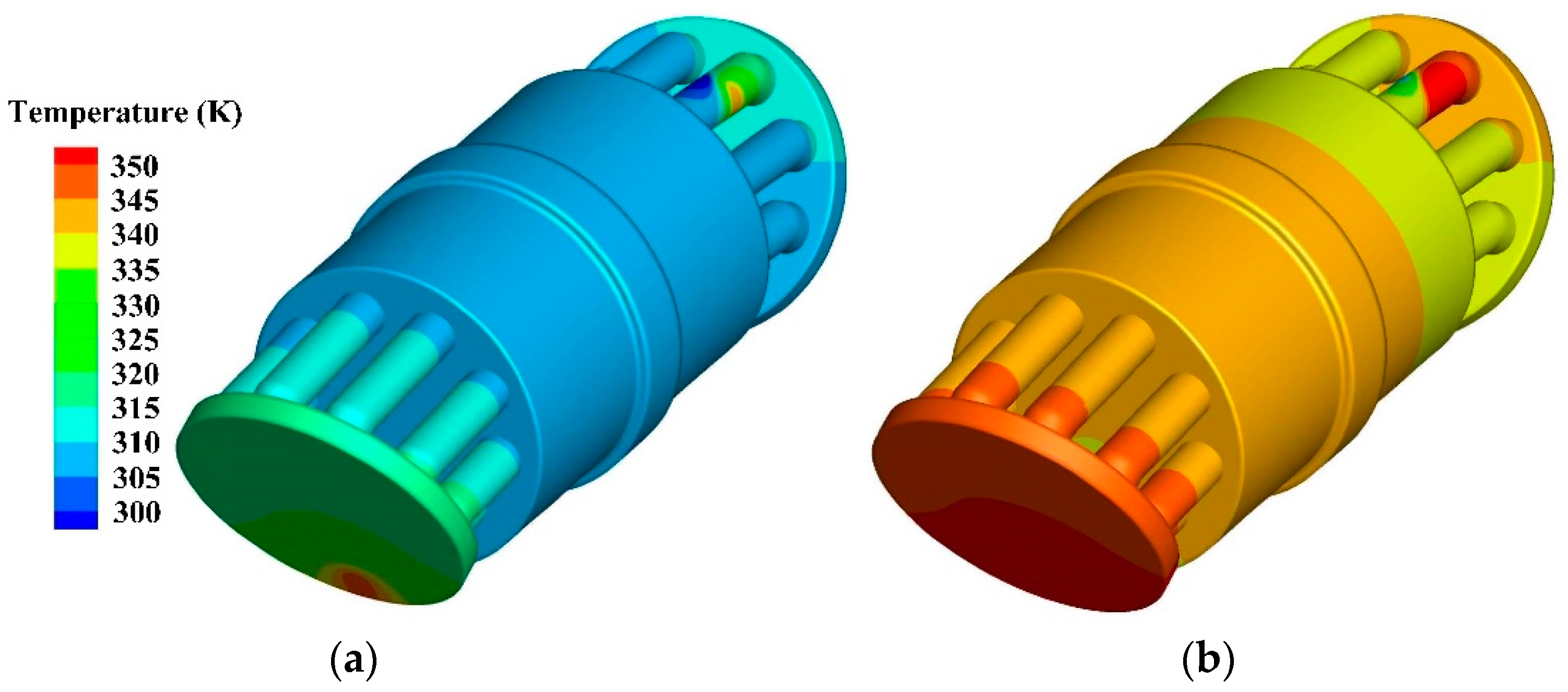

3.1. Temperature Distribution Inside the CCAPT

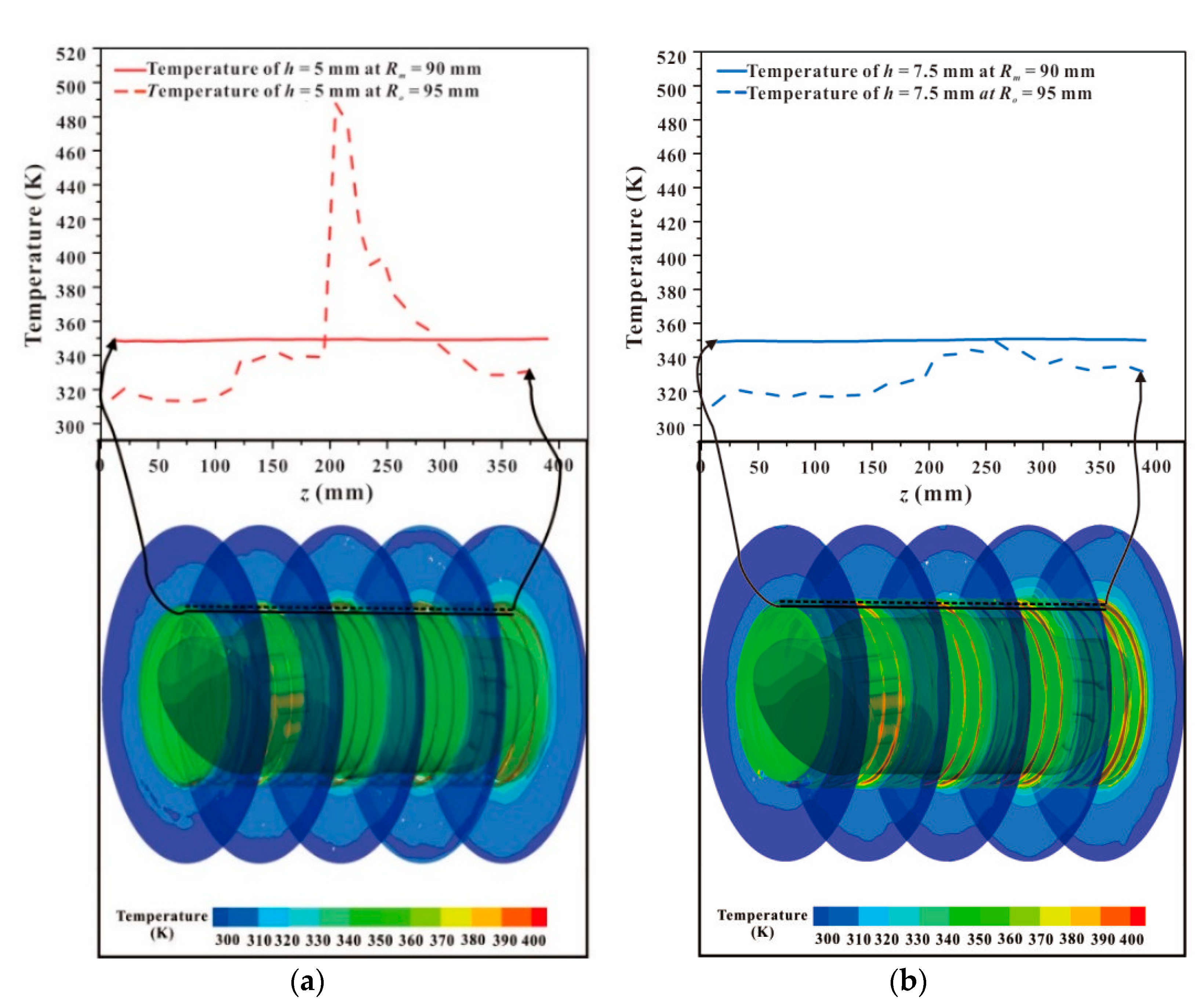

3.2. Effect of Fin Height h

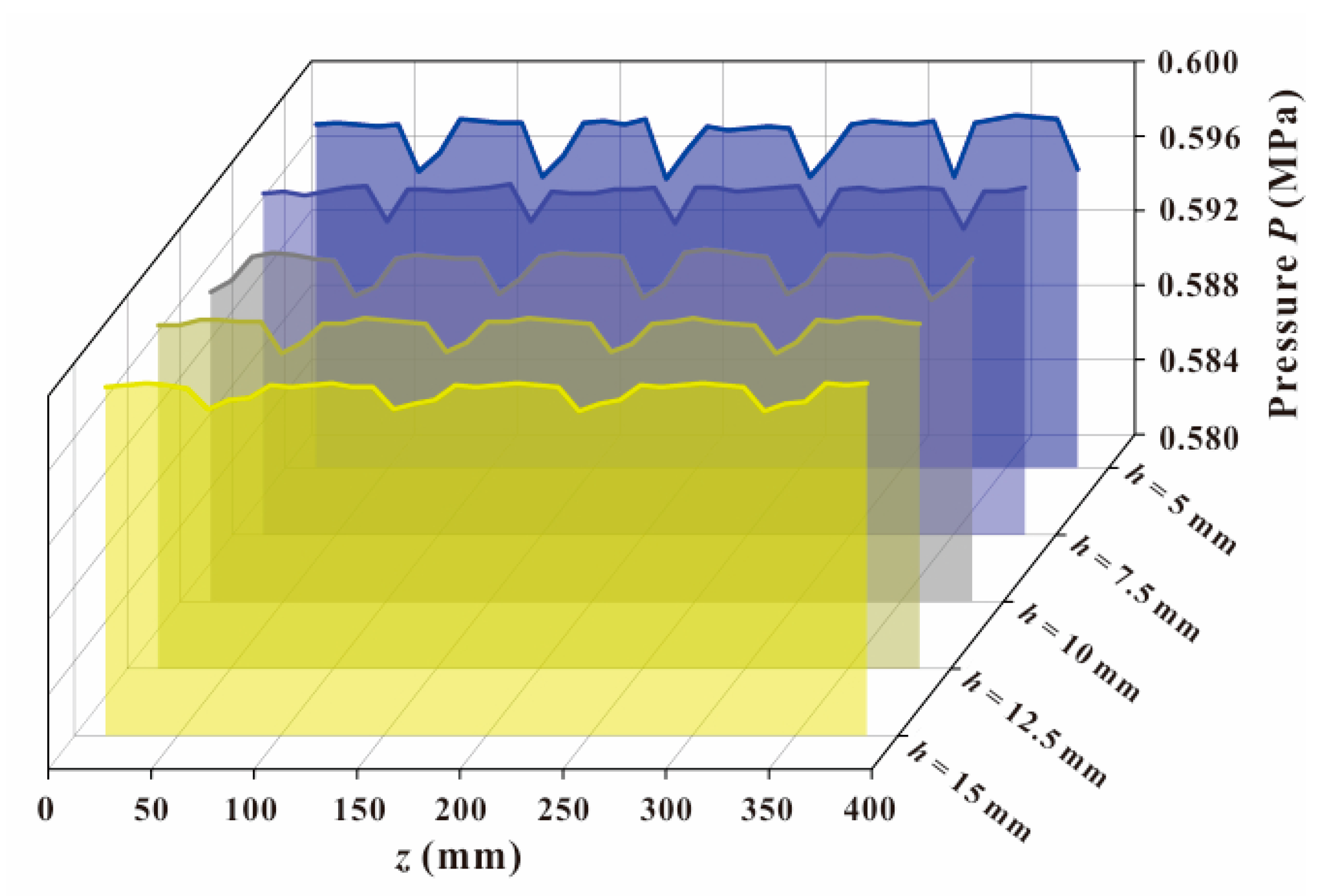

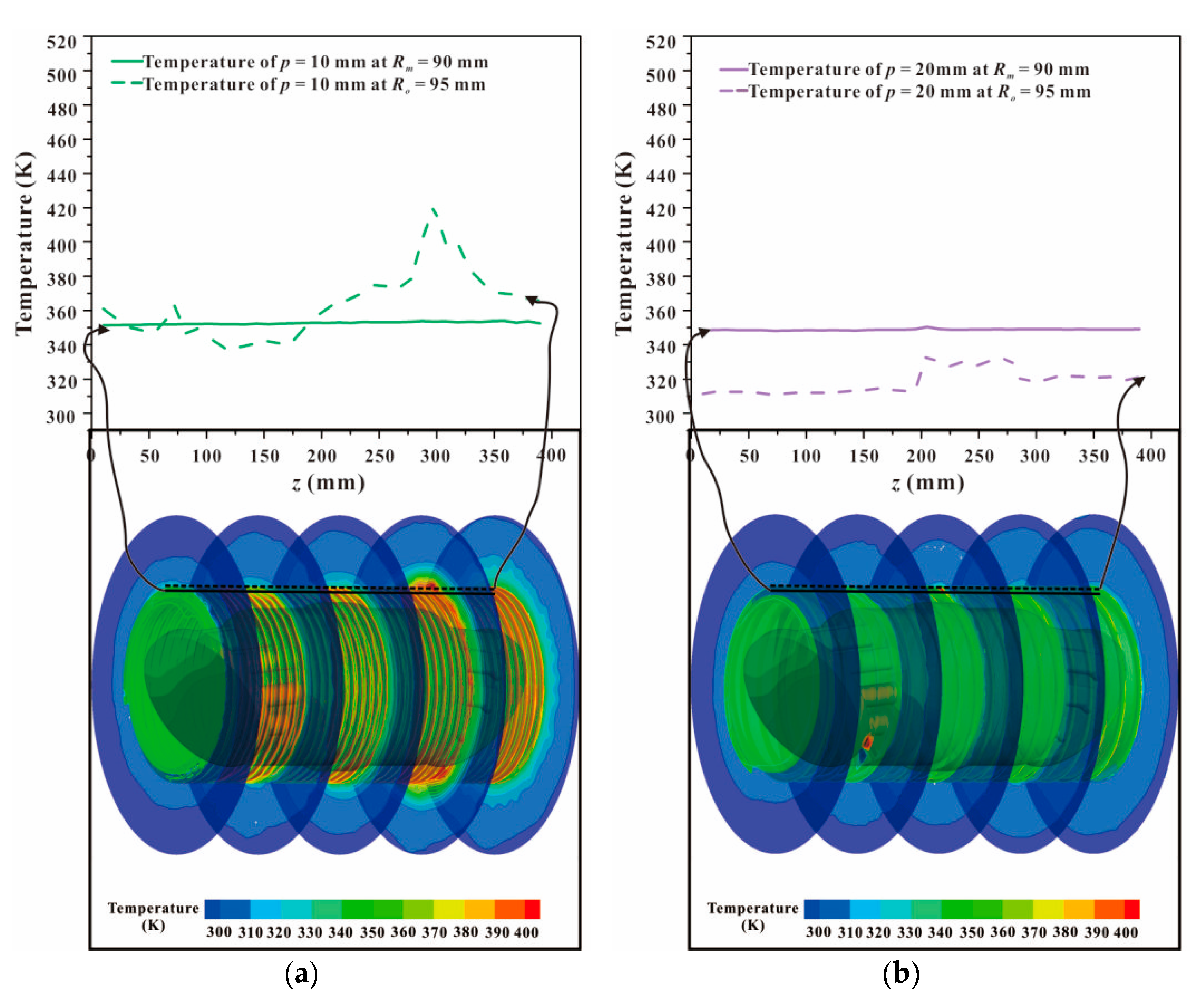

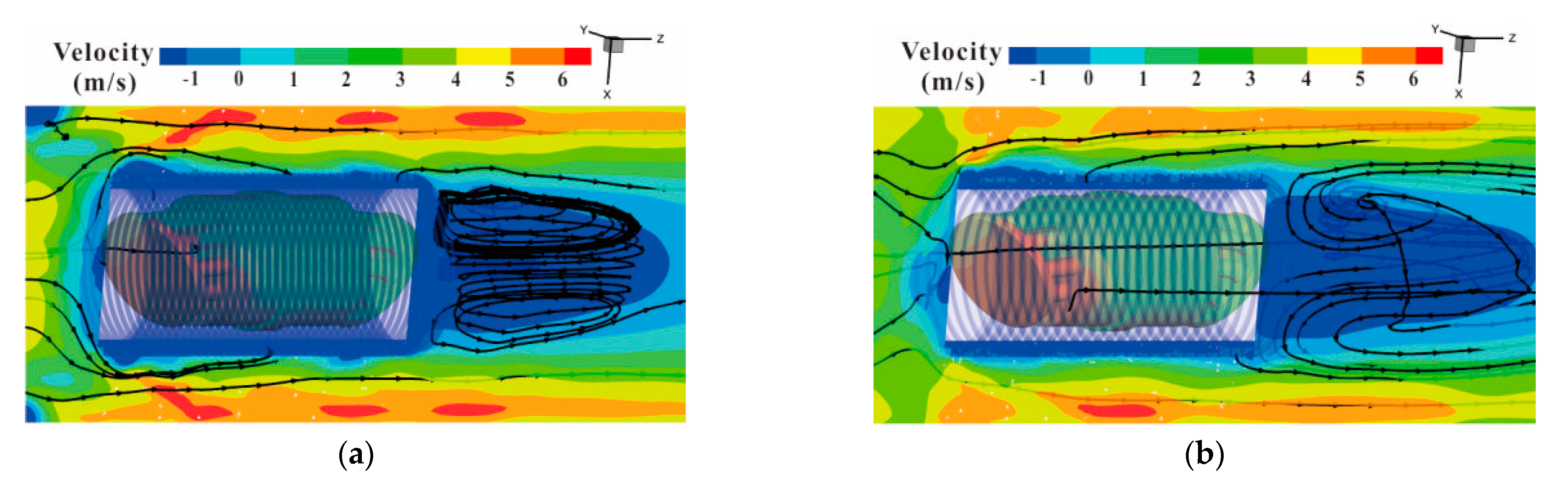

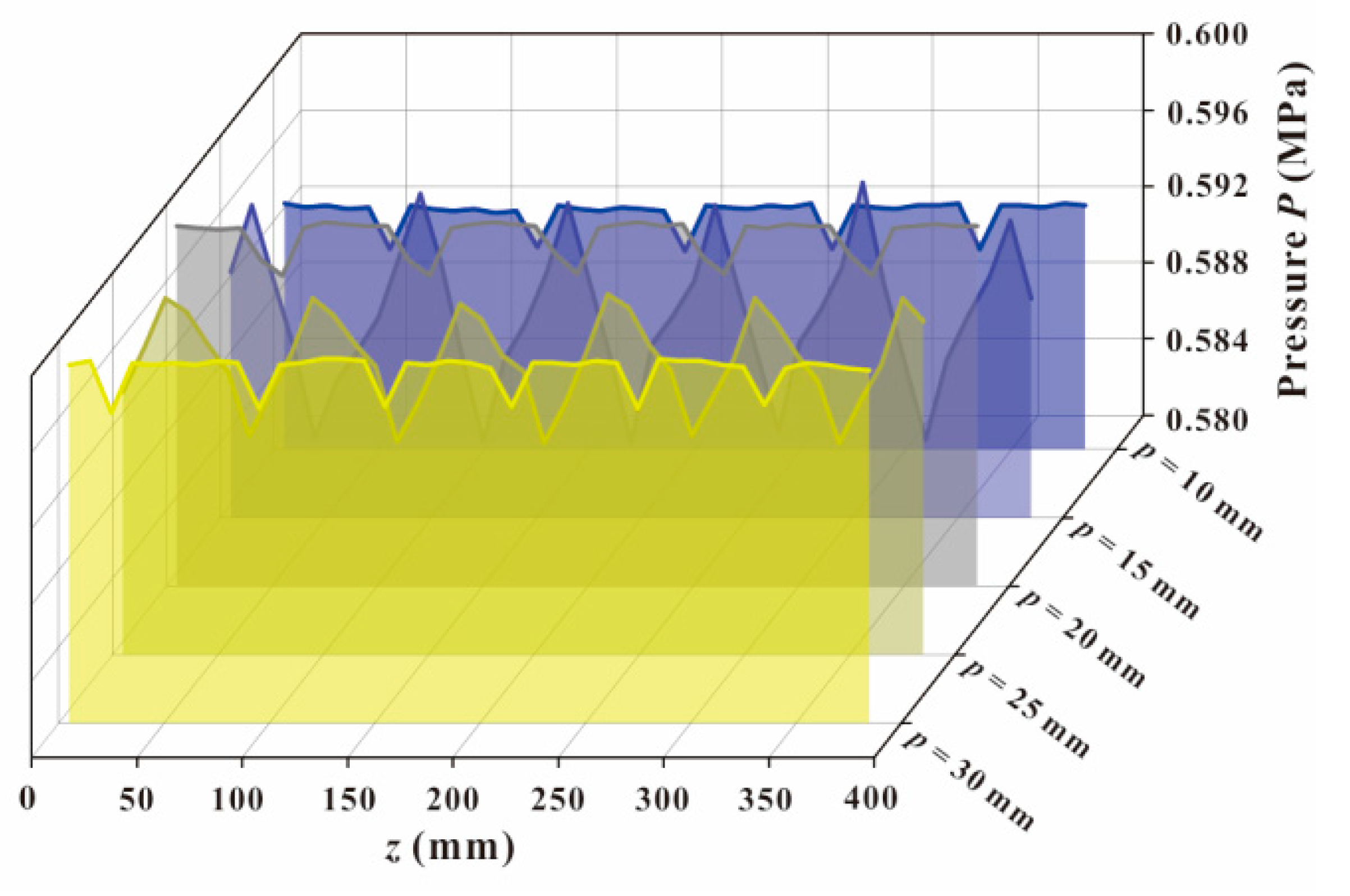

3.3. Effect of Fin Pitch p

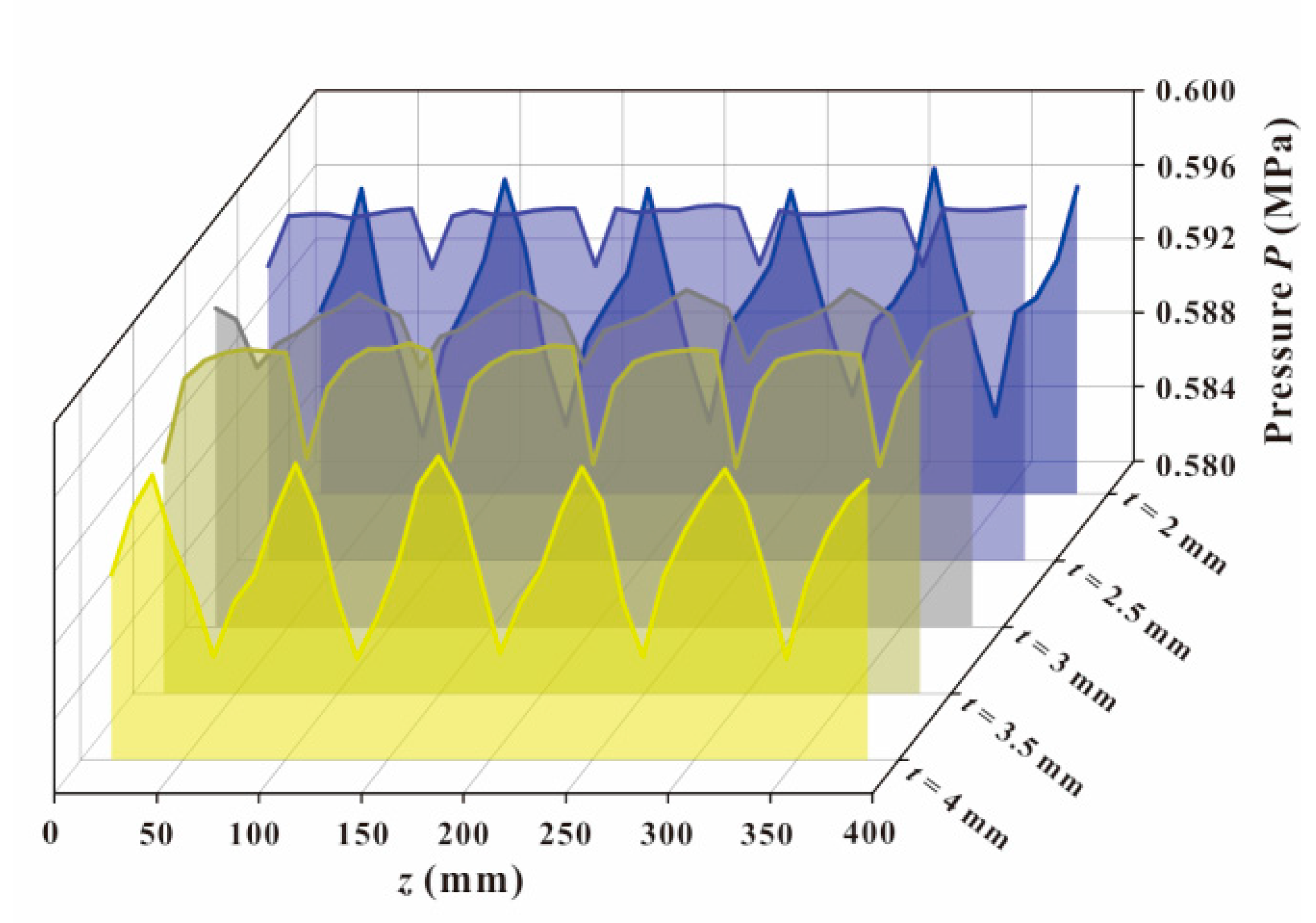

3.4. Effect of Fin Thickness t

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Aa | Total heat transfer area | mm2 |

| Acf | Heat transfer area between the shell and fluids | mm2 |

| Ach | Heat transfer area between the shell and environments | mm2 |

| Acs | Contact area between rotating area and the shell | mm2 |

| Af | Area of the fin structure | mm2 |

| Asf | Heat transfer area between rotating element and fluid | mm2 |

| Cp | Specific heat capacity | J·kg−1·K−1 |

| dcf | Characteristic diameter of the inner surface | mm |

| Gr | Grashof number | |

| h | Fin height | mm |

| hi | Heat transfer coefficient | W·m−2·K−1 |

| hc | Thickness of pump shell | mm |

| j | Colburn factor | |

| kf | Thermal conductivity of the material of the fin structure | W·m−2·K−1 |

| l | Half the length of the fin height | mm |

| Nu | Nusselt number | |

| Nux | Local Nusselt number | |

| p | Pitch | mm |

| P | Pressure | Pa |

| Pr | Prandtl number | |

| Q | Heat transfer quantity | J |

| Convective heat transfer rate between the shell and fluids | W | |

| Convective heat transfer rate between the shell and surroundings | W | |

| Heat transfer rate of thermal conduction between rotating element and system | W | |

| Radiative heat transfer rate between the shell and ambient environment | W | |

| Heat transfer rate of forced convection between the rotating element and fluid | W | |

| Re | Reynolds number | |

| Tcn | Temperature of inner surface | K |

| Tcw | Temperature of outer surface | K |

| Tf | Temperature of fluid | K |

| Th | Temperature of environment | K |

| Ts | Surface temperature of rotating element | K |

| t | Fin thickness | mm |

| u | Velocity | m·s−1 |

| Greek symbols | ||

| ε | Blackness of shell material | |

| αcf | Convection coefficient between the shell and fluids | W·m−2·K−1 |

| αchf | Convection coefficient between the shell and surroundings | W·m−2·K−1 |

| αsf | Convective heat transfer coefficient between rotating elements and fluid | W·m−2·K−1 |

| η0 | Surface coefficient of the fin | |

| ηf | Fin efficiency | |

| λ | Thermal conductivity | W·m−1·K−1 |

| ρ | Density | kg/m3 |

| σ | The Stefan-Boltzmann constant | W·m−2·K−4 |

| ΔP | Pressure difference | Pa |

| ΔTLMTD | Logarithm mean temperature difference | K |

References

- Wang, Z.W.; Wang, L.; Ma, A.H.; Liang, K.F.; Song, Z.; Feng, L.W. Performance evaluation of ground water-source heat pump system with a fresh air pre-conditioner using ground water. Energy Convers. Manag. 2019, 188, 250–261. [Google Scholar] [CrossRef]

- Sergey, A. System of energy-saving optimal control of metal heating process in heat treatment furnaces of rolling mills. Machines 2019, 7, 60. [Google Scholar]

- Harish, S.; Simone, B. A novel modelling approach for condensing boilers based on hybrid dynamical systems. Machines 2016, 4, 10. [Google Scholar]

- Muhammad, S.U.Z.; Raza, H.; Syed, B.A.B.; Hafiz, M.A.; Chul-Hwan, K. Impacts of responsive loads and energy storage system on frequency response of a multi-machine power system. Machines 2019, 7, 1–15. [Google Scholar]

- Gao, D.R.; Zhang, Z.Y.; Sun, Y.N.; Xu, S.H.; Liu, J.C.; Zhang, Y. Numerical simulation and analysis of temperature and flow field of high-speed axial piston motor pump. J. Eng. 2019, 13, 127–131. [Google Scholar] [CrossRef]

- Chen, H.; Peng, Y.H.; Wang, Y.L.; Zhang, J. Thermodynamic analysis of hybrid cooling system integrated with waste heat reusing and peak load shifting for data center. Energy Convers. Manag. 2019, 183, 427–439. [Google Scholar] [CrossRef]

- Chan, M.A.; Yap, C.R.; Ng, K.C. Modeling and testing of an advanced compact two-phase cooler for electronics cooling. Int. J. Heat Mass Transf. 2009, 52, 3456–3463. [Google Scholar] [CrossRef]

- Alexey, N.; Innokentiy, S.; Igor, S. The setup design for selective laser sintering of high-temperature polymer materials with the alignment control system of layer deposition. Machines 2018, 6, 11. [Google Scholar]

- Amber, K.P.; Akram, W.; Bashir, M.A.; Muhammad, S.K.; Anila, K. Experimental performance analysis of two different passive cooling techniques for solar photovoltaic installations. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Pongsoi, P.; Pikulkajorn, S.; Wang, C.C.; Wongwises, S. Effect of number of tube rows on the air-side performance of crimped spiral fin-and-tube heat exchangers with a multipass parallel and counter cross-flow configuration. Int. J. Heat Mass Transf. 2012, 55, 1403–S1411. [Google Scholar] [CrossRef]

- Dezan, D.J.; Yanagihara, J.I.; Jenovencio, G.; Leandro, O.S. Parametric investigation of heat transfer enhancement and pressure loss in louvered fins with longitudinal vortex generators. Int. J. Therm. Sci. 2019, 135, 533–545. [Google Scholar] [CrossRef]

- Kim, N.H. Airside performance of fin-and-tube heat exchangers having nonrepeating nonsymmetrical slit fins under wet condition. Int. J. Air-Cond. Refrig. 2019, 27, 1950033. [Google Scholar] [CrossRef]

- Shadlaghani, A.; Farzaneh, M.; Shahabadi, M. Numerical investigation of serrated fins on natural convection from concentric and eccentric annuli with different cross sections. J. Therm. Anal. Calorim. 2018, 135, 1429–1442. [Google Scholar] [CrossRef]

- Alsallami, W.; Aldamook, A.; Thompson, H.M. A numerical investigation of the thermal-hydraulic characteristics of perforated plate fin heat sinks. Int. J. Therm. Sci. 2017, 121, 266–277. [Google Scholar] [CrossRef]

- Lee, M.; Kang, T.; Kim, Y. Air-side heat transfer characteristics of spiral-type circular fin-tube heat exchangers. Int. J. Refrig. 2010, 33, 313–320. [Google Scholar] [CrossRef]

- Kim, N. An experimental investigation on the airside performance of fin-and-tube heat exchangers having radial slit fins under wet condition. Int. J. Therm. Sci. 2016, 11, 1–17. [Google Scholar] [CrossRef]

- Pongsoi, P.; Promoppatum, P.; Pikulkajorn, S.; Wongwises, S. Effect of fin pitches on the air-side performance of L-footed spiral fin-and-tube heat exchangers. Int. J. Heat Mass Transf. 2013, 59, 75–82. [Google Scholar] [CrossRef]

- Nørgård, J. Thermodynamic determination of power loss in hydraulic components. J. Fluids Eng. 1973, 95, 2–7. [Google Scholar] [CrossRef]

- Olems, L. Investigations of the Temperature behaviour of the piston cylinder assembly in axial piston pumps. Int. J. Fluid Power 2000, 1, 27–39. [Google Scholar] [CrossRef]

- Iboshi, N.; Yamaguchi, A. Characteristics of a slipper bearing for swash plate type axial piston pumps and motors: 1st report, theoretical-analysis. JSME Int. J. Ser. B-Fluids Therm. Eng. 1982, 25, 1921–1930. [Google Scholar] [CrossRef][Green Version]

- Iboshi, N. Characteristics of a slipper bearing for swash plate type axial piston pumps and motors: 2nd report, experiment. JSME Int. J. Ser. B-Fluids Therm. Eng. 1983, 26, 1583–1589. [Google Scholar] [CrossRef]

- Iboshi, N.; Yamaguchi, A. Characteristics of a slipper bearing for swash plate type axial piston pumps and motors: 3rd report, design method for a slipper with a minimum power loss in fluid lubrication. JSME Int. J. Ser. B-Fluids Therm. Eng. 1986, 29, 2529–2538. [Google Scholar] [CrossRef][Green Version]

- Xu, B.; Wang, Q.N.; Zhang, J.H. Effect of case drain pressure on slipper/swashplate pair within axial piston pump. J. Zhejiang Univ.-Sci. A 2015, 16, 1001–1014. [Google Scholar] [CrossRef]

- Wieczorek, U.; Monika, I. Computer aided optimization of bearing and sealing gaps in hydrostatic machines—the simulation tool caspar. Int. J. Fluid Power 2002, 3, 7–20. [Google Scholar] [CrossRef]

- Li, D.L.; Li, G.Q.; Han, J.H.; Liu, Y.S.; Wu, D.F. Thermodynamic characteristics research of a water lubricating axial piston pump. Proc. Inst. Mech. Eng. C-J. Mech. 2020. [Google Scholar] [CrossRef]

- Xu, B.; Hu, M.; Zhang, J.H.; Mao, Z.B. Distribution characteristics and impact on pump’s efficiency of hydro-mechanical losses of axial piston pump over wide operating ranges. Cent. South Univ. 2017, 24, 609–624. [Google Scholar] [CrossRef]

- Xu, B.; Hu, M.; Zhang, J.H.; Su, Q. Characteristics of volumetric losses and efficiency of axial piston pump with respect to displacement conditions. J. Zhejiang Univ.-Sci. A 2016, 17, 186–201. [Google Scholar] [CrossRef]

- Ye, S.; Zhang, J.; Xu, B.; Zhu, S.; Xiang, J.; Tang, H. Theoretical investigation of the contributions of the excitation forces to the vibration of an axial piston pump. Mech. Syst. Signal Process. 2019, 129, 201–217. [Google Scholar] [CrossRef]

- Ye, S.; Zhang, J.; Xu, B.; Hou, L.; Xiang, J.; Tang, H. A theoretical dynamic model to study the vibration response characteristics of an axial piston pump. Mech. Syst. Signal Process. 2021, 150, 107237. [Google Scholar] [CrossRef]

- Amiri, H.A.; Shafaghat, R.; Alamian, R.; Taheri, S.M.; Shadloo, M.S. Study of horizontal axis tidal turbine performance and investigation on the optimum fixed pitch angle using CFD. Int. J. Numer. Method Heart 2020, 30, 206–227. [Google Scholar] [CrossRef]

- Alavi, S.M.A.; Safaei, M.R.; Mahian, O.; Goodarzi, M.; Yarmand, H.; Dahari, M.; Wongwises, S. A hybrid finite-element/finite-difference scheme for solving the 3-d energy equation in transient nonisothermal fluid flow over a staggered tube bank. Numer. Heat Transf. B-Fundam. 2015, 68, 169–183. [Google Scholar] [CrossRef]

- Roberto, M. Pollutant emission validation of a heavy-duty gas turbine burner by CFD modeling. Machines 2013, 1, 81–97. [Google Scholar]

- Nemati, H.; Moghimi, M.A.; Sapin, P.; Markides, C.N. Shape optimisation of air-cooled finned-tube heat exchangers. Int. J. Therm. Sci. 2020, 150, 106233. [Google Scholar] [CrossRef]

- Briggs, D.E.; Young, E.H. Convective heat transfer and pressure drop of air flowing across triangular pitch banks of finned tubes. Chem. Prog. Eng. Symp. Ser. 1963, 59, 1–10. [Google Scholar]

- Kim, N.H.; Ham, J.H.; Cho, J.P. Experimental investigation on the airside performance of fin-and-tube heat exchangers having herringbone wave fins and proposal of a new heat transfer and pressure drop correlation. J. Mech. Sci. Technol. Convers. Manag. 2008, 22, 545–555. [Google Scholar] [CrossRef]

- Kumar, A.; Joshi, J.B.; Nayak, A.K. A comparison of thermal-hydraulic performance of various fin patterns using 3D CFD simulations. Int. J. Heat Mass Transf. 2017, 109, 336–356. [Google Scholar] [CrossRef]

| Material | Pump Housing | Motor Housing |

|---|---|---|

| 40Cr | ZL105 | |

| Density/(kg m−3) | 7820 | 2680 |

| Specific heat capacity/(J kg−1 K−1) | 460 | 837 |

| Thermal conductivity/(W m−1 K−1) | 32.6 | 163.3 |

| Fin Height (mm) | Nu | j (10−3) |

|---|---|---|

| 5.0 | 89.02 | 1.77 |

| 7.5 | 108.27 | 1.81 |

| 10.0 | 93.75 | 1.79 |

| 12.5 | 81.02 | 1.77 |

| 15.0 | 74.61 | 1.73 |

| without fin structure | 51.76 | - |

| Fin Pitch (mm) | Nu | j (10−3) |

|---|---|---|

| 10 | 83.75 | 1.72 |

| 15 | 87.13 | 1.75 |

| 20 | 93.75 | 1.79 |

| 25 | 99.42 | 1.80 |

| 30 | 105.73 | 1.83 |

| without fin structure | 51.76 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Yu, L.-j.; Zhang, J.; Qian, J.-y. Cooling Performance Analysis of Outside Fins of the Closed Circuit Axial Piston Transmission. Machines 2021, 9, 17. https://doi.org/10.3390/machines9010017

Yang C, Yu L-j, Zhang J, Qian J-y. Cooling Performance Analysis of Outside Fins of the Closed Circuit Axial Piston Transmission. Machines. 2021; 9(1):17. https://doi.org/10.3390/machines9010017

Chicago/Turabian StyleYang, Chen, Long-jie Yu, Junhui Zhang, and Jin-yuan Qian. 2021. "Cooling Performance Analysis of Outside Fins of the Closed Circuit Axial Piston Transmission" Machines 9, no. 1: 17. https://doi.org/10.3390/machines9010017

APA StyleYang, C., Yu, L.-j., Zhang, J., & Qian, J.-y. (2021). Cooling Performance Analysis of Outside Fins of the Closed Circuit Axial Piston Transmission. Machines, 9(1), 17. https://doi.org/10.3390/machines9010017