Investigation on Finishing Characteristics of Magnetic Abrasive Finishing Process Using an Alternating Magnetic Field

Abstract

1. Introduction

2. Processing Principle and Experimental Setup

2.1. Processing Principle

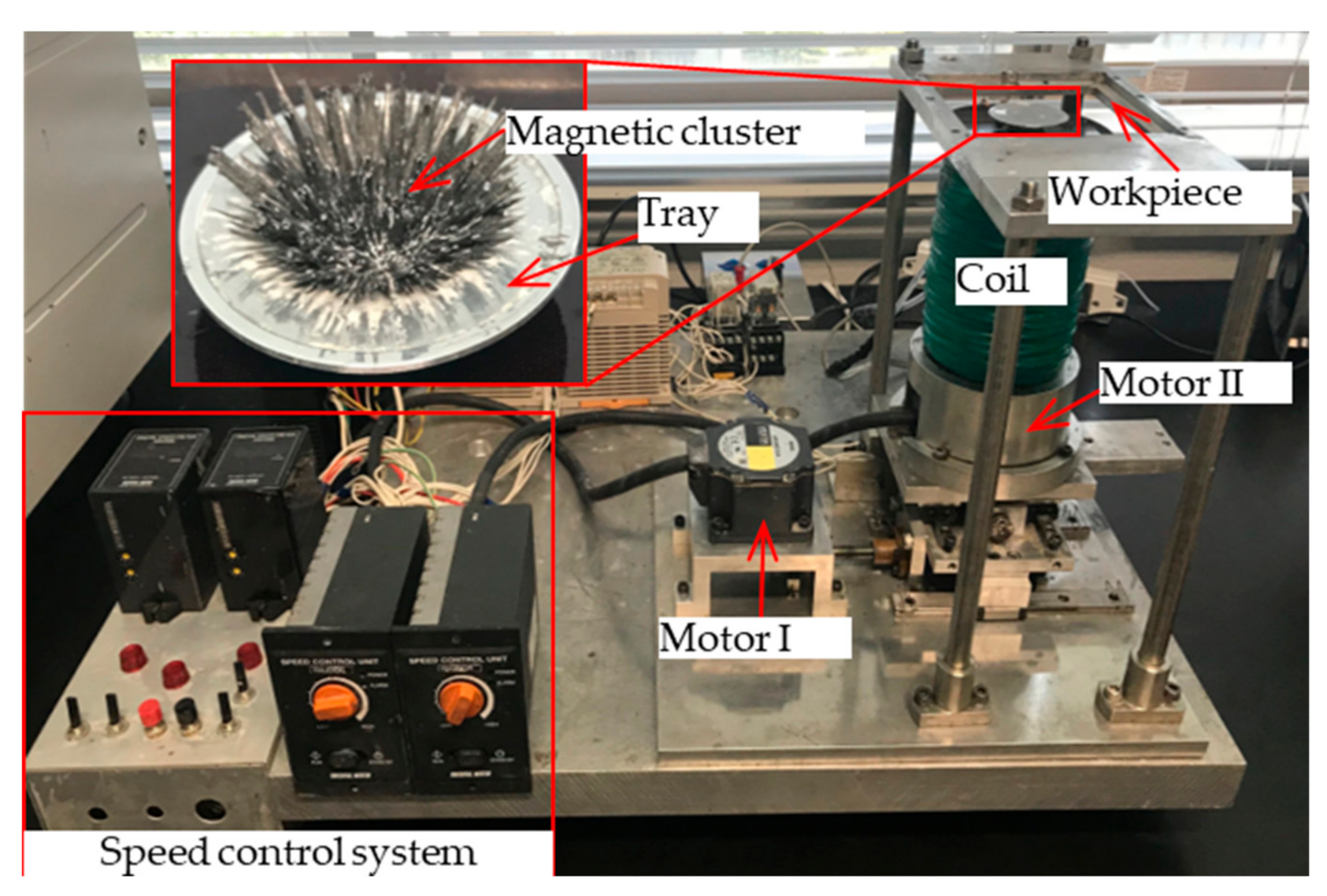

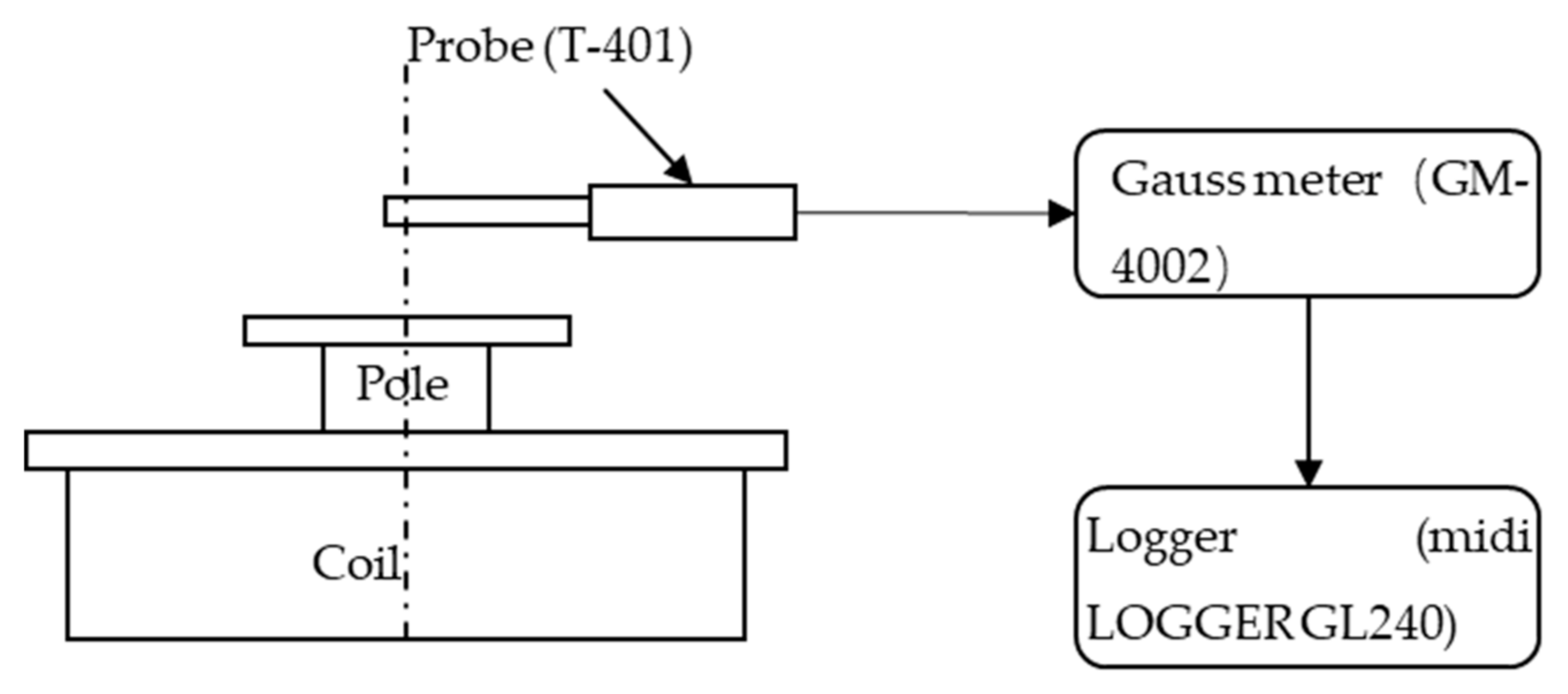

2.2. Experimental Setup

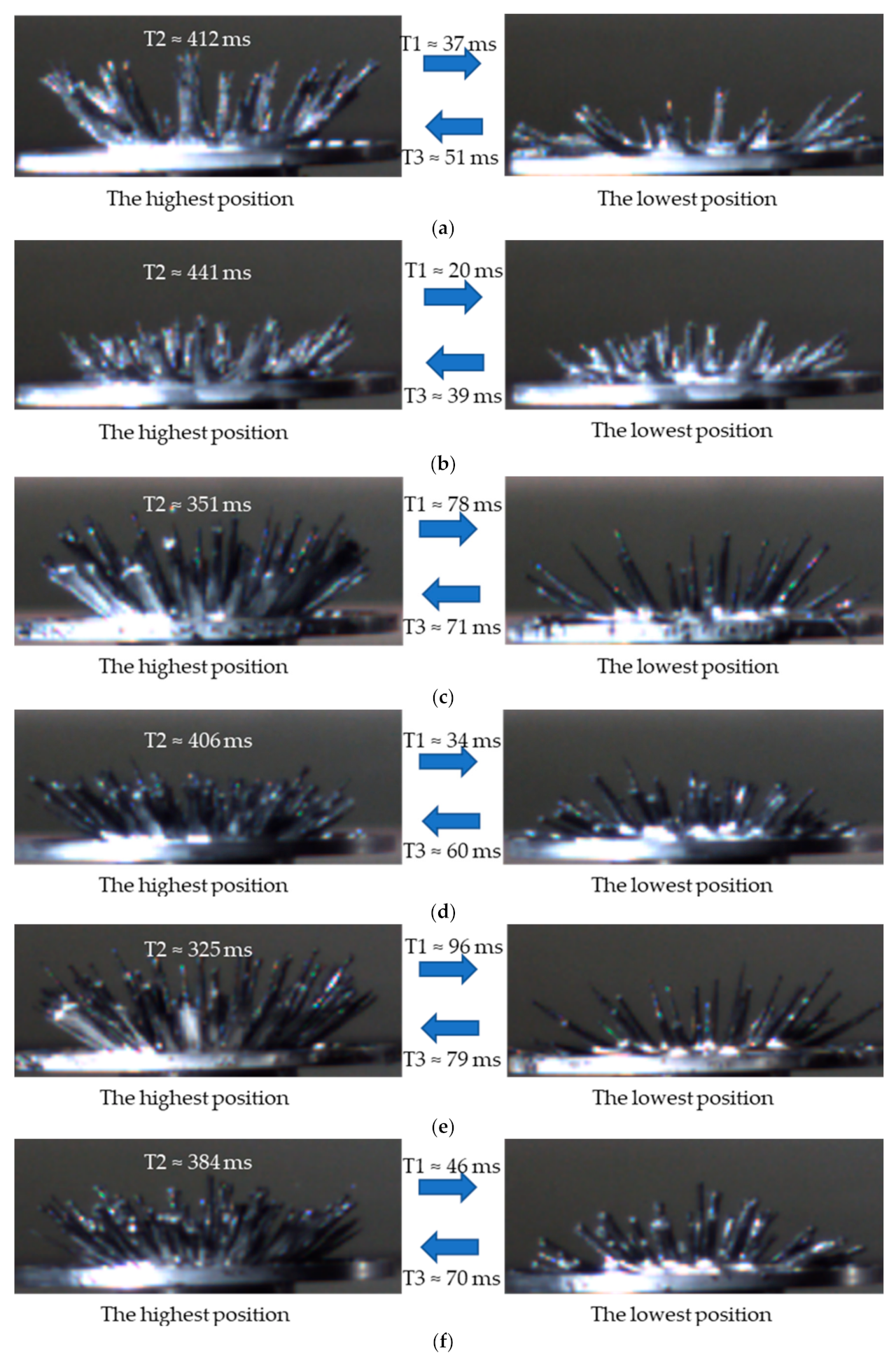

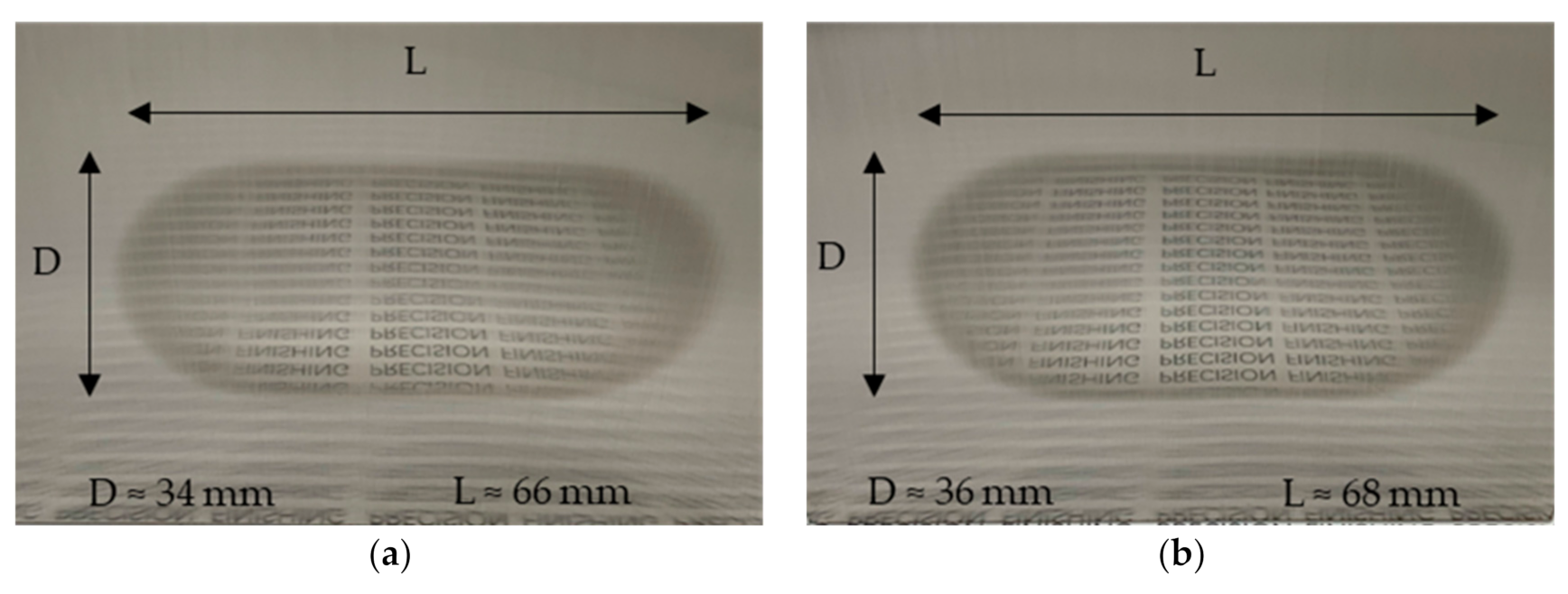

2.3. Magnetic Cluster Observation

3. Experimental Conditions and Method

4. Experimental Results and Discussion

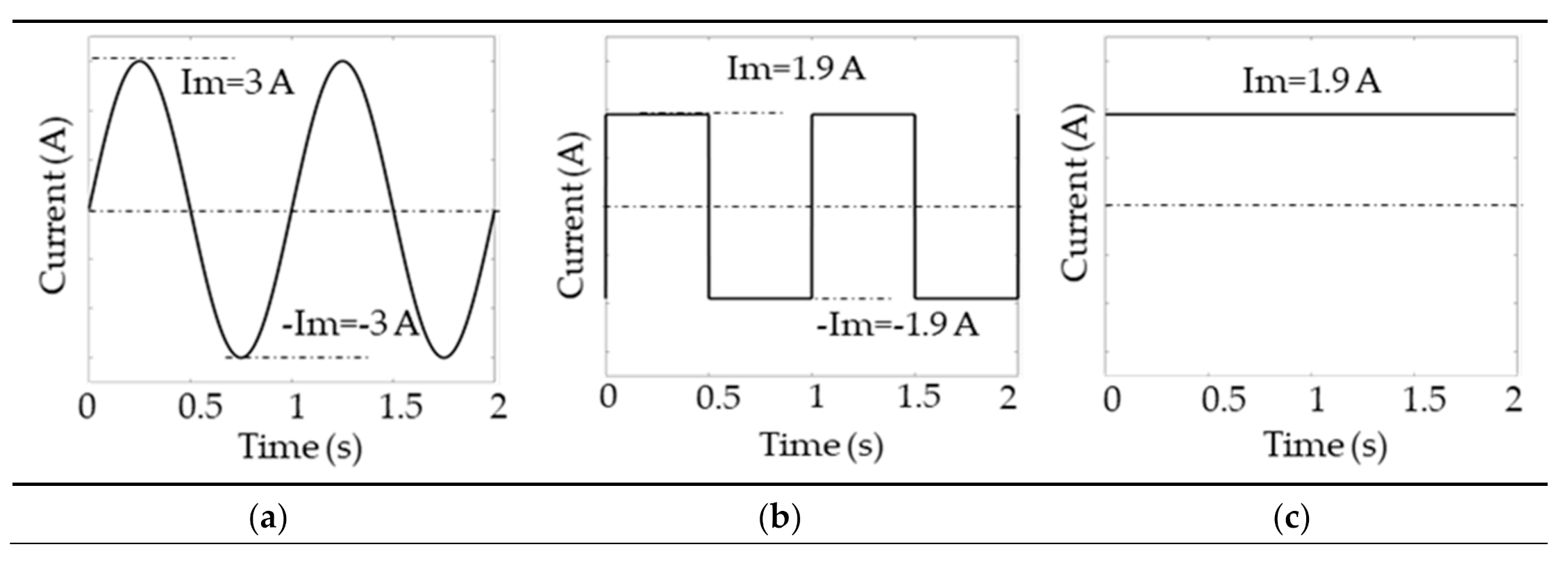

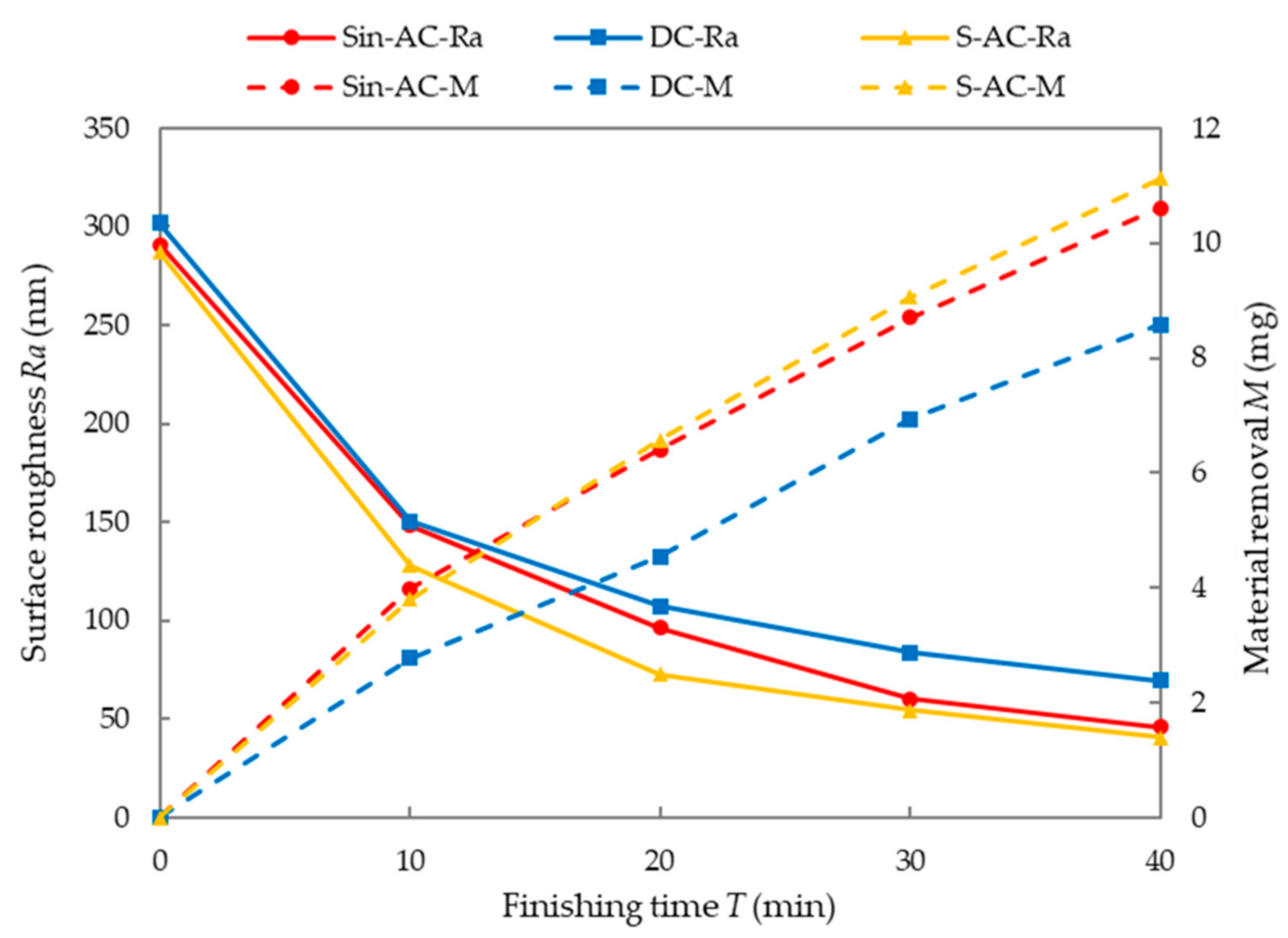

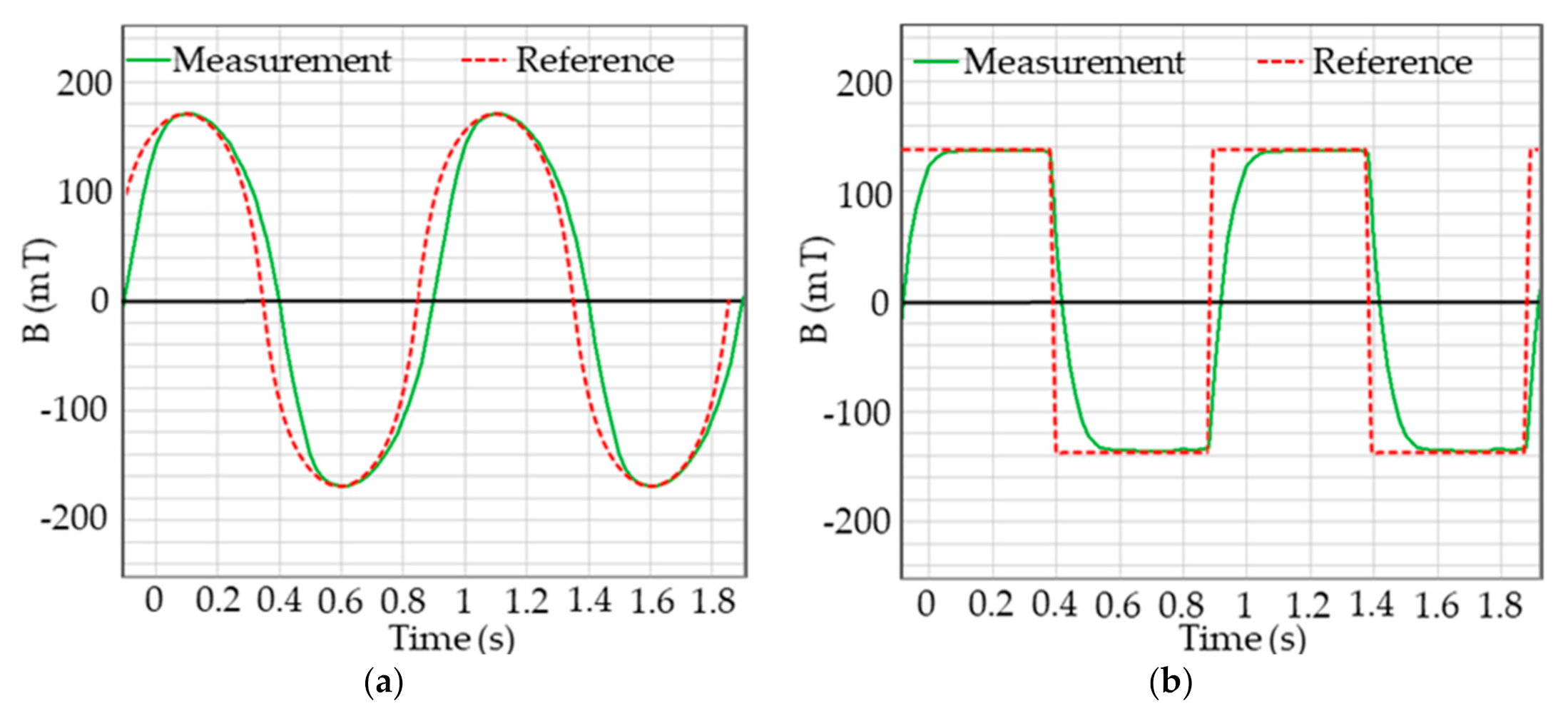

4.1. Current Waveform

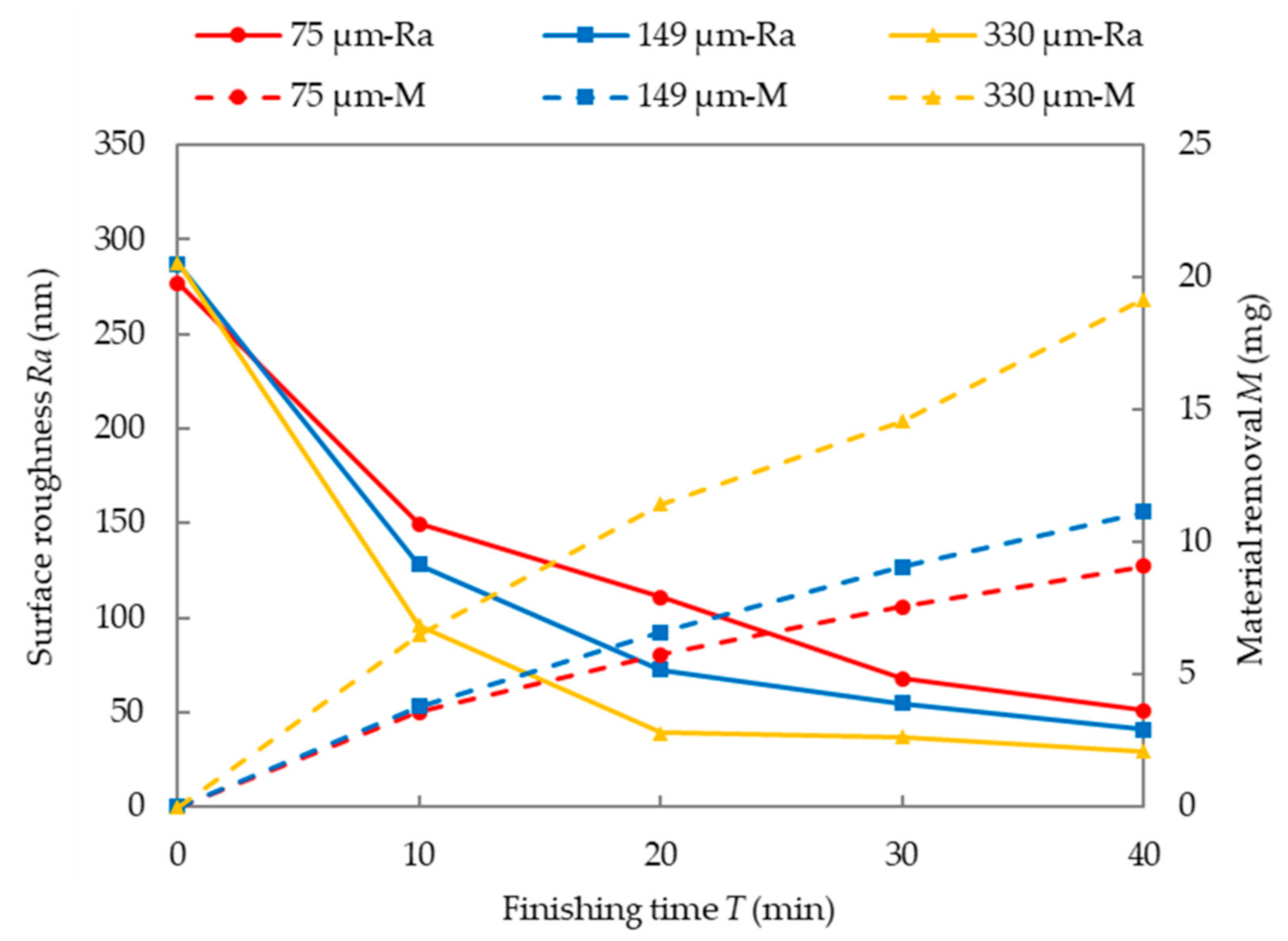

4.2. Magnetic particle size

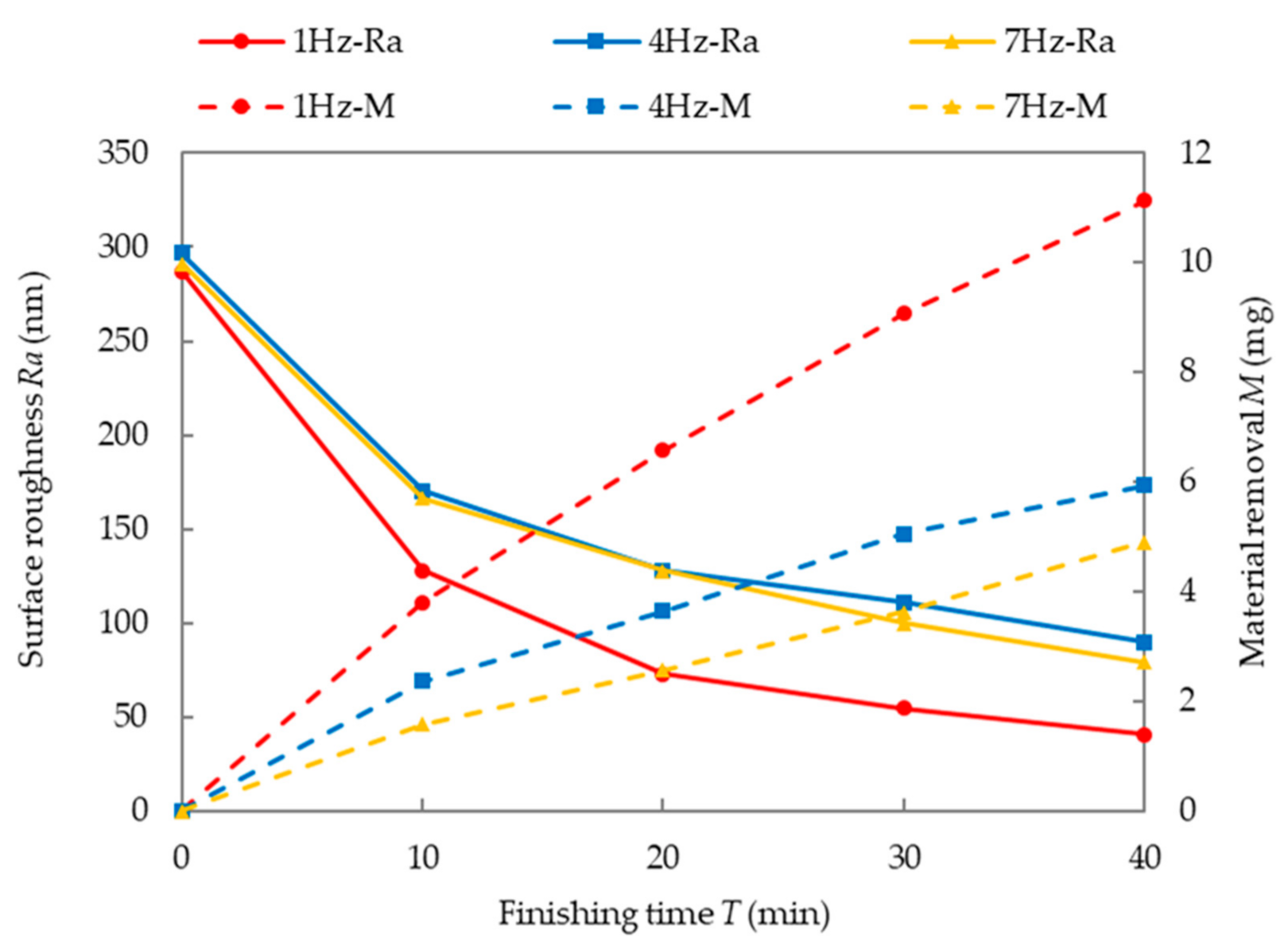

4.3. Frequency

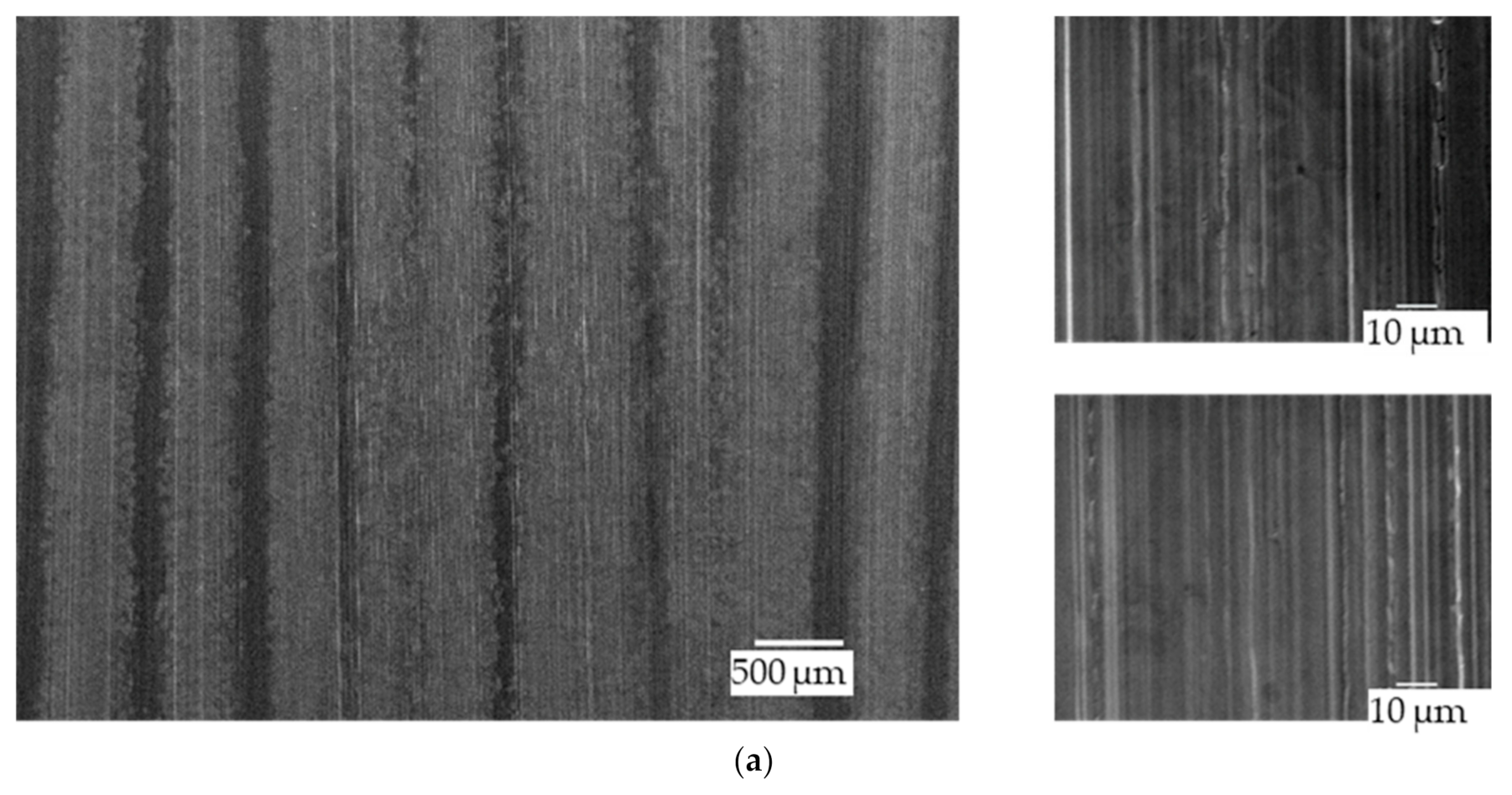

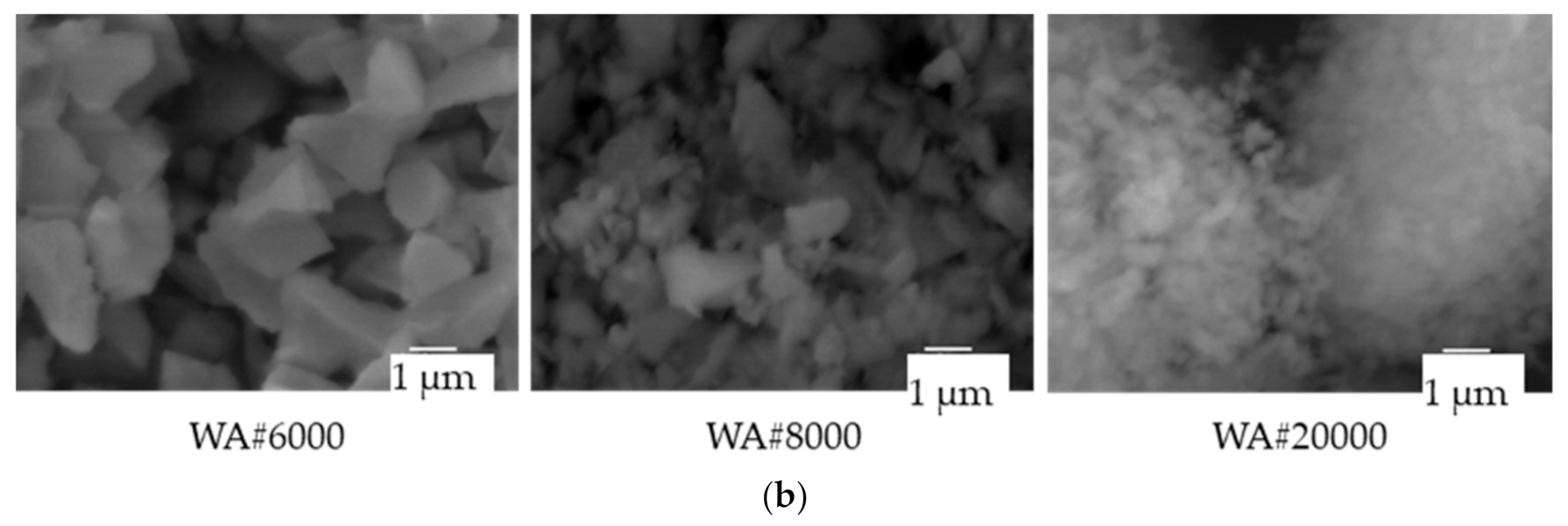

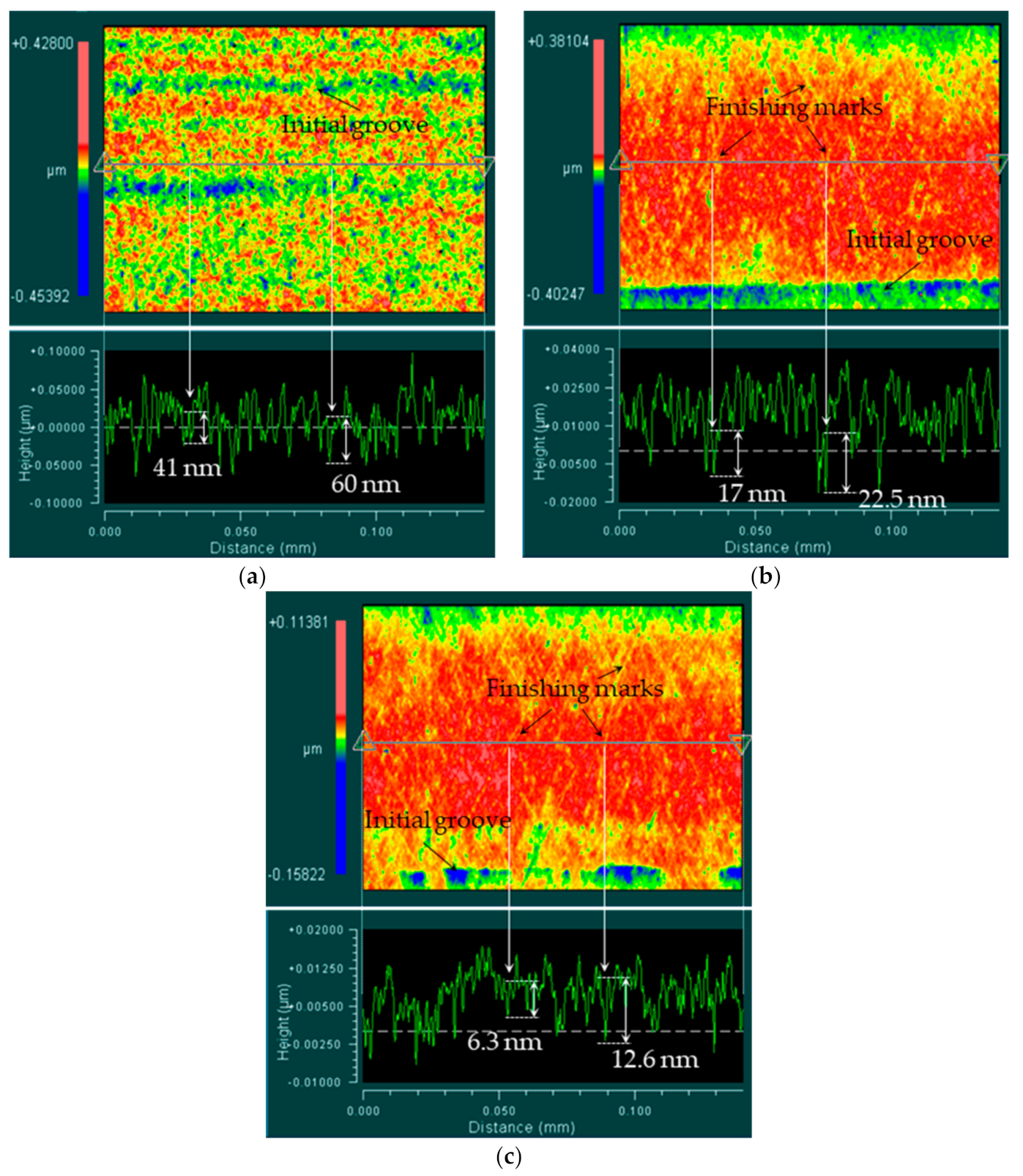

4.4. Abrasive Particle Size

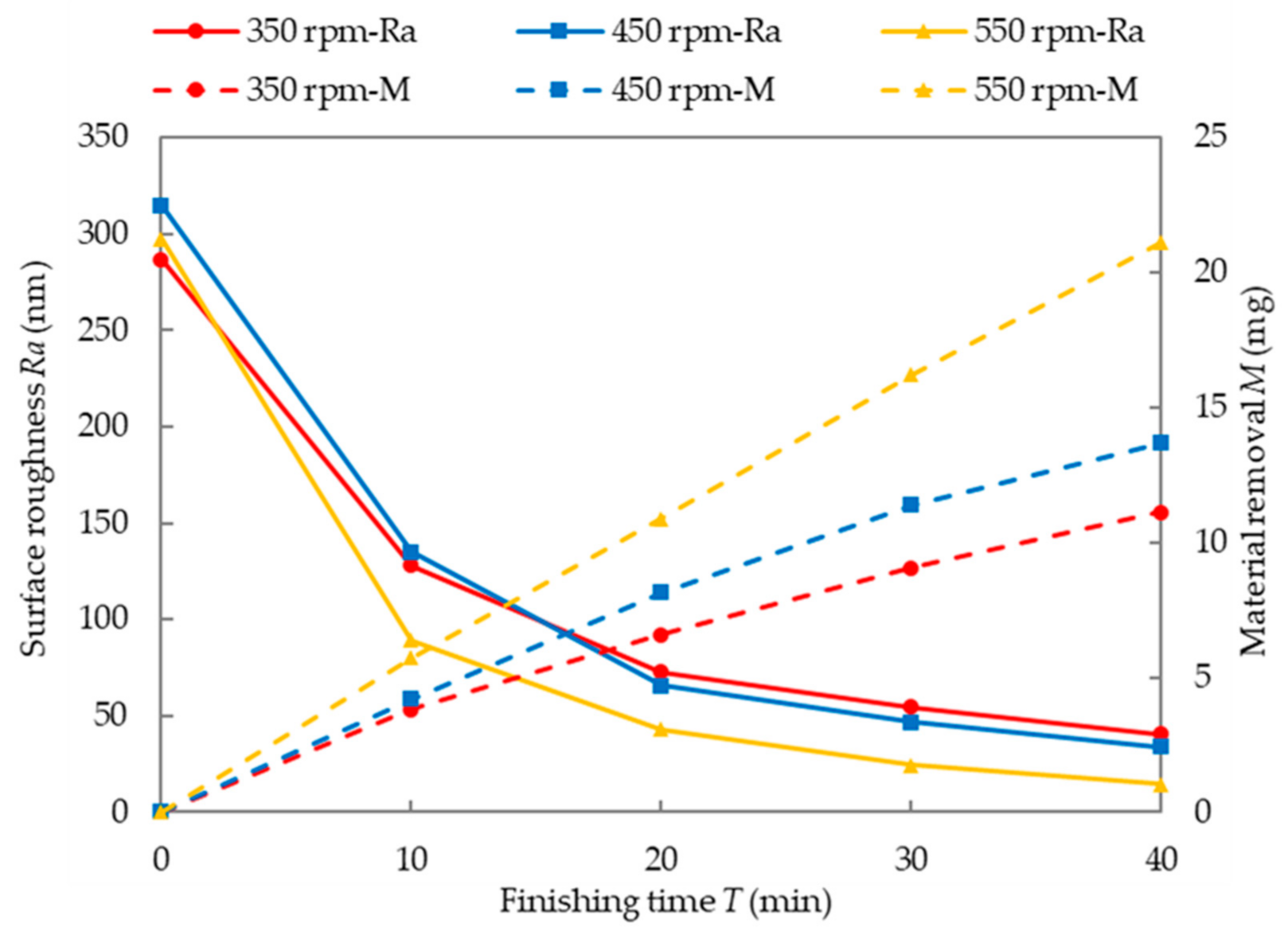

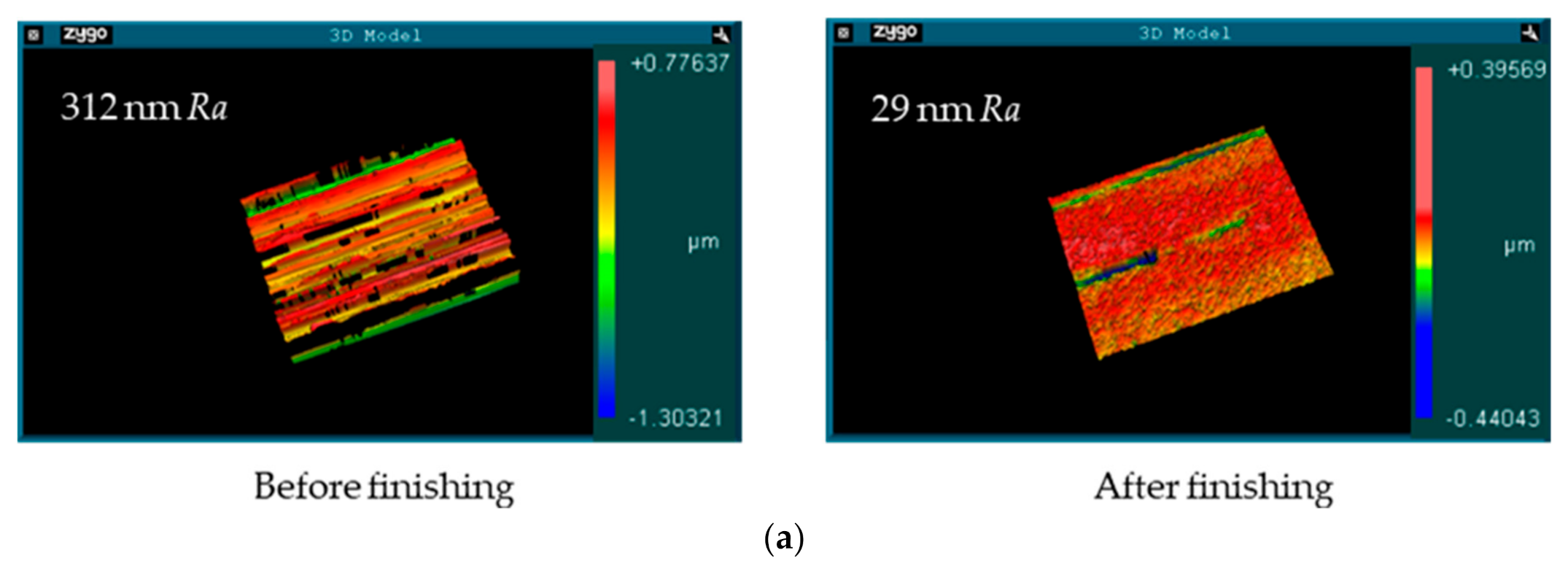

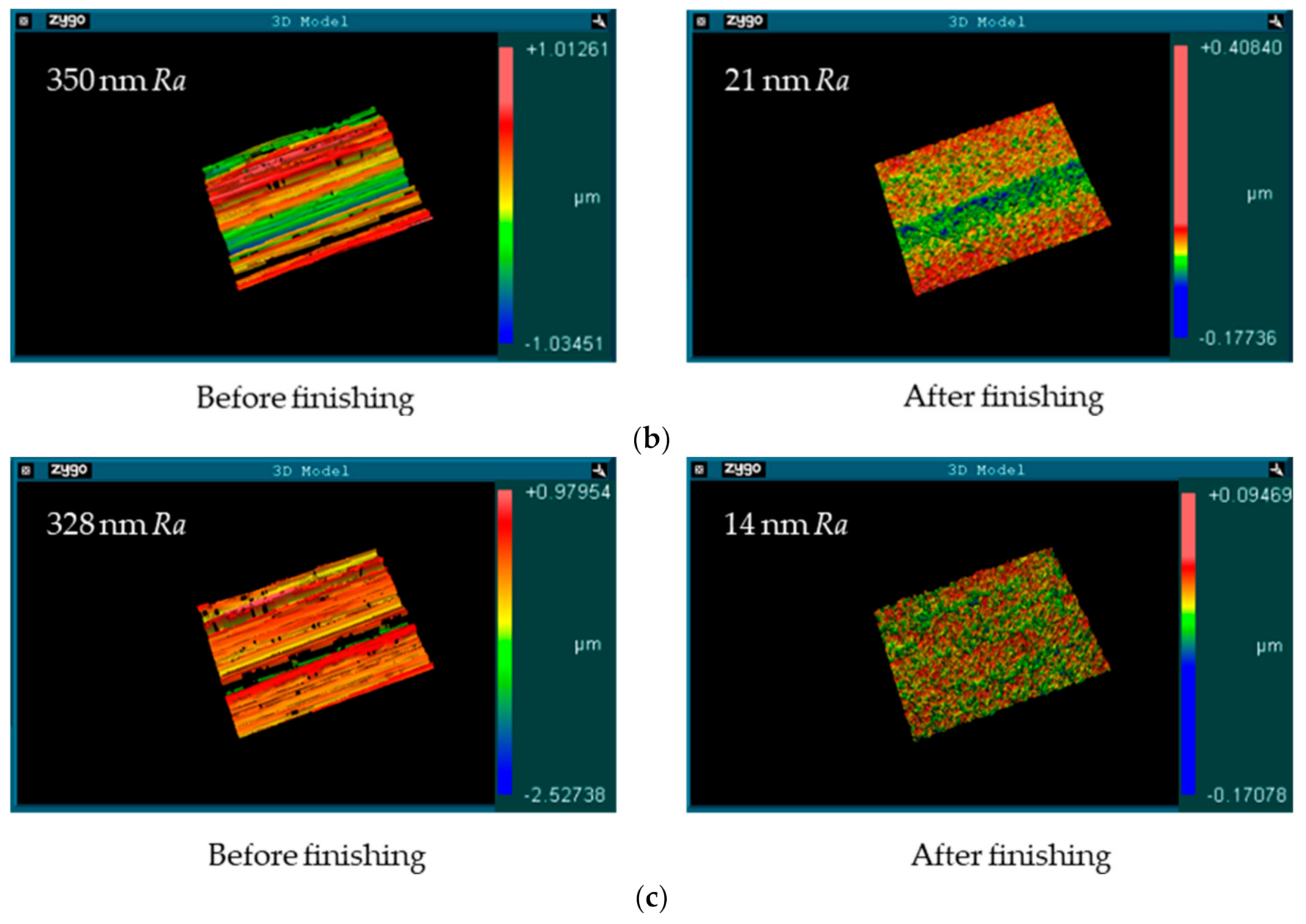

4.5. Rotational Speed

5. Conclusions

- When using a square wave, a higher magnetic cluster fluctuation speed can be obtained, and as the size of the MPs decreases, the difference between the magnetic cluster fluctuation speed of the two waveforms is greater.

- Under this experimental condition, when the current waveform is a square wave, the finishing efficiency is improved.

- When the waveform of the alternating current is a square wave, as the size of the MPs increases and the frequency of the magnetic field decreases, the finishing efficiency increases. At the same time, when the APs are WA#8000, the finishing efficiency is higher. In addition, the increase in the rotation speed of the magnetic pole significantly improves the finishing efficiency.

- According to the experimental results, when the current waveform is a square wave, the average diameter of MPs is 149 μm, the current frequency is 1 Hz, the APs are WA#8000, and the rotation speed is 550 rpm, the surface roughness of the SUS304 stainless steel plate is improved from 328 nm Ra to 14 nm Ra within 40 min.

Author Contributions

Funding

Conflicts of Interest

References

- Konefal, K.; Korzynski, M.; Byczkowska, Z.; Korzynska, K. Improved corrosion resistance of stainless steel X6CrNiMoTi17-12-2 by slide diamond burnishing. J. Mater. Process. Technol. 2013, 213, 1997–2004. [Google Scholar] [CrossRef]

- Bagehorn, S.; Wehr, J.; Maier, H.J. Application of mechanical surface finishing processes for roughness reduction and fatigue improvement of additively manufactured Ti-6Al-4V parts. Int. J. Fatigue 2017, 102, 135–142. [Google Scholar] [CrossRef]

- Jain, N.K.; Jain, V.K.; Jha, S. Parametric optimization of advanced fine-finishing processes. Int. J. Adv. Manuf. Technol. 2007, 34, 1191–1213. [Google Scholar] [CrossRef]

- Khalaj Amineh, S.; Fadaei Tehrani, A.; Mohammadi, A. Improving the surface quality in wire electrical discharge machined specimens by removing the recast layer using magnetic abrasive finishing method. Int. J. Adv. Manuf. Technol. 2013, 66, 1793–1803. [Google Scholar] [CrossRef]

- Uddin, M.S.; Santos, V.; Marian, R. Interplay of Process Variables in Magnetic Abrasive Finishing of AISI 1018 Steel Using SiC and Al2O3 Abrasives. J. Manuf. Mater. Process. 2019, 3, 29. [Google Scholar] [CrossRef]

- Wang, R.; Lim, P.; Heng, L.; Mun, S.D. Magnetic Abrasive Machining of Difficult-to-Cut Materials for Ultra-High-Speed Machining of AISI 304 Bars. Materials 2017, 10, 1029. [Google Scholar] [CrossRef]

- Zou, Y.; Shinmura, T.; Wang, F. Study on a Magnetic deburring method by the application of the plane magnetic abrasive machining process. Adv. Mater. Res. 2009, 76–78, 276–281. [Google Scholar] [CrossRef]

- Lin, C.; Yang, L.; Chow, H. Study of magnetic abrasive finishing in free-form surface operations using the Taguchi method. Int. J. Adv. Manuf. Technol. 2007, 34, 122–130. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Nomura, M. A novel magnetic field-assisted polishing method using magnetic compound slurry and its performance in mirror surface finishing of miniature V-grooves. AIP Adv. 2016, 6, 056602. [Google Scholar] [CrossRef]

- Shinmura, T.; Takazawa, K.; Hatano, E.; Aizawa, T. Study on magnetic abrasive process (finishing characteristics). Bull. Jpn. Soc. Precis. Eng. 1984, 18, 347–348. [Google Scholar]

- Shinmura, T.; Takazawa, K.; Hatano, E.; Aizawa, T. Study on magnetic abrasive process (Process principles and finishing possibility). Bull. Jpn. Soc. Precis. Eng. 1985, 19, 54–55. [Google Scholar]

- Zou, Y.; Xie, H.; Zhang, Y. Study on surface quality improvement of the plane magnetic abrasive finishing process. Int. J. Adv. Manuf. Technol. 2020, 109, 1825–1839. [Google Scholar] [CrossRef]

- Jiao, A.; Quan, H.; Li, Z.; Zou, Y. Study on improving the trajectory to elevate the surface quality of plane magnetic abrasive finishing. Int. J. Adv. Manuf. Technol. 2015, 80, 1613–1623. [Google Scholar] [CrossRef]

- Zou, Y.; Xing, B.; Sun, X. Study on the magnetic abrasive finishing combined with electrolytic process—Investigation of machining mechanism. Int. J. Adv. Manuf. Technol. 2020, 108, 1675–1689. [Google Scholar] [CrossRef]

- Sun, X.; Zou, Y. Study on Electrolytic Magnetic Abrasive Finishing for Finishing Stainless Steel SUS304 Plane with a Special Compound Machining Tool. J. Manuf. Mater. Process. 2018, 2, 41. [Google Scholar] [CrossRef]

- Yin, S.; Shinmura, T. Vertical vibration-assisted magnetic abrasive finishing and deburring for magnesium alloy. Int. J. Mach. Tool. Manuf. 2004, 44, 1297–1303. [Google Scholar] [CrossRef]

- Yin, S.; Shinmura, T. A comparative study: Polishing characteristics and its mechanisms of three vibration modes in vibration-assisted magnetic abrasive polishing. Int. J. Mach. Tool. Manuf. 2004, 44, 383–390. [Google Scholar] [CrossRef]

- Jain, V.K.; Kumar, P.; Behera, P.K.; Jayswal, S.C. Effect of working gap and circumferential speed on the performance of magnetic abrasive finishing process. Wear 2001, 250, 384–390. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Shinmura, T.; Kobayashi, A. Development of an internal magnetic abrasive finishing process for nonmagnetic complex shaped tubes. JSME Int. J. Ser. C 2001, 44, 275–281. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Shinmura, T. Internal finishing process for alumina ceramic components by a magnetic field assisted finishing process. Precis. Eng. 2004, 28, 135–142. [Google Scholar] [CrossRef]

- Kala, P.; Pandey, P.M.; Verma, G.C.; Sharma, V. Understanding flexible abrasive brush behavior for double disk magnetic abrasive finishing based on force signature. J. Manuf. Process 2017, 28, 442–448. [Google Scholar] [CrossRef]

- Mulik, R.S.; Pandey, P.M. Experimental Investigations and Modeling of Finishing Force and Torque in Ultrasonic Assisted Magnetic Abrasive Finishing. ASME J. Manuf. Sci. Eng. 2012, 134, 051008. [Google Scholar] [CrossRef]

- Lee, Y.H.; Wu, K.L.; Jhou, J.H.; Tsai, Y.H.; Yan, B.H. Two-dimensional vibration-assisted magnetic abrasive finishing of stainless steel SUS304. Int. J. Adv. Manuf. Technol. 2013, 69, 2723–2733. [Google Scholar] [CrossRef]

- Lee, Y.H.; Wu, K.L.; Bai, C.T.; Liao, C.Y.; Yan, B.H. Planetary motion combined with two-dimensional vibration-assisted magnetic abrasive finishing. Int. J. Adv. Manuf. Technol. 2015, 76, 1865–1877. [Google Scholar] [CrossRef]

- Wu, J.; Zou, Y.; Sugiyama, H. Study on ultra-precision magnetic abrasive finishing process using low frequency alternating magnetic field. J. Magn. Magn. Mater. 2015, 386, 50–59. [Google Scholar] [CrossRef]

- Zou, Y.; Xie, H.; Dong, C.; Wu, J. Study on complex micro surface finishing of alumina ceramic by the magnetic abrasive finishing process using alternating magnetic field. Int. J. Adv. Manuf. Technol. 2018, 97, 2193–2202. [Google Scholar] [CrossRef]

- Xie, H.; Zou, Y.; Dong, C.; Wu, J. Study on the magnetic abrasive finishing process using alternating magnetic field: Investigation of mechanism and applied to aluminum alloy plate. Int. J. Adv. Manuf. Technol. 2019, 102, 1509–1520. [Google Scholar] [CrossRef]

- Shinmura, T.; Aizawa, T. Study on internal finishing of non-ferromagnetic tubing by magnetic abrasive machining process. Bull. Jpn. Soc. Precis. Eng. 1989, 23, 37–41. [Google Scholar]

- Jain, V.K. Magnetic field assisted abrasive based micro-/nano-finishing. J. Mater. Process. Technol. 2009, 209, 6022–6038. [Google Scholar] [CrossRef]

- Cheng, K. Abrasive micromachining and microgrinding. In Micromachining of Engineering Material; McGeough, J., Ed.; CRC Press Dekker: New York, NY, USA, 2002; pp. 85–123. [Google Scholar]

| Workpiece | SUS304 Austenitic Stainless Steel Plate with the Size of 100 mm × 100 mm × 1 mm |

|---|---|

| Grinding fluid | Oily grinding fluid (Honilo 988): 0.8 mL |

| Working gap | 1.5 mm |

| Feed speed | 260 mm/min |

| Current | 1.9 A (Average) |

| Finishing time | Single 10 min (40 min) |

| Magnetic particles | Electrolytic iron powder, 75 μm in mean dia:1.2 g |

| Electrolytic iron powder, 149 μm in mean dia:1.2 g | |

| Electrolytic iron powder, 330 μm in mean dia:1.2 g | |

| Current waveform | DC, Sine (Sin-AC), Square (S-AC) |

| Current frequency | 1 Hz, 4 Hz, 7 Hz |

| Abrasive particles | WA#6000: 0.3 g, WA#8000: 0.3 g, WA#20000: 0.3 g |

| Rotational speed | 350 rpm, 450 rpm, 550 rpm |

| Chemical Composition (%) | C | Cr | Ni | Mn | Si | P | S |

|---|---|---|---|---|---|---|---|

| ≤0.08 | 18.00–20.00 | 8.00–10.50 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.030 | |

| Hardness test (max) | HB 187, HRB 90, HV 200 | ||||||

| Proof stress (N/mm2) | 205 | ||||||

| Tensile strength (N/mm2) | 520 | ||||||

| Elongation (%) | 40 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Zou, Y. Investigation on Finishing Characteristics of Magnetic Abrasive Finishing Process Using an Alternating Magnetic Field. Machines 2020, 8, 75. https://doi.org/10.3390/machines8040075

Xie H, Zou Y. Investigation on Finishing Characteristics of Magnetic Abrasive Finishing Process Using an Alternating Magnetic Field. Machines. 2020; 8(4):75. https://doi.org/10.3390/machines8040075

Chicago/Turabian StyleXie, Huijun, and Yanhua Zou. 2020. "Investigation on Finishing Characteristics of Magnetic Abrasive Finishing Process Using an Alternating Magnetic Field" Machines 8, no. 4: 75. https://doi.org/10.3390/machines8040075

APA StyleXie, H., & Zou, Y. (2020). Investigation on Finishing Characteristics of Magnetic Abrasive Finishing Process Using an Alternating Magnetic Field. Machines, 8(4), 75. https://doi.org/10.3390/machines8040075