Torque Characteristics of the Revolving Vane Air Expander

Abstract

:1. Introduction

2. Theoretical Model

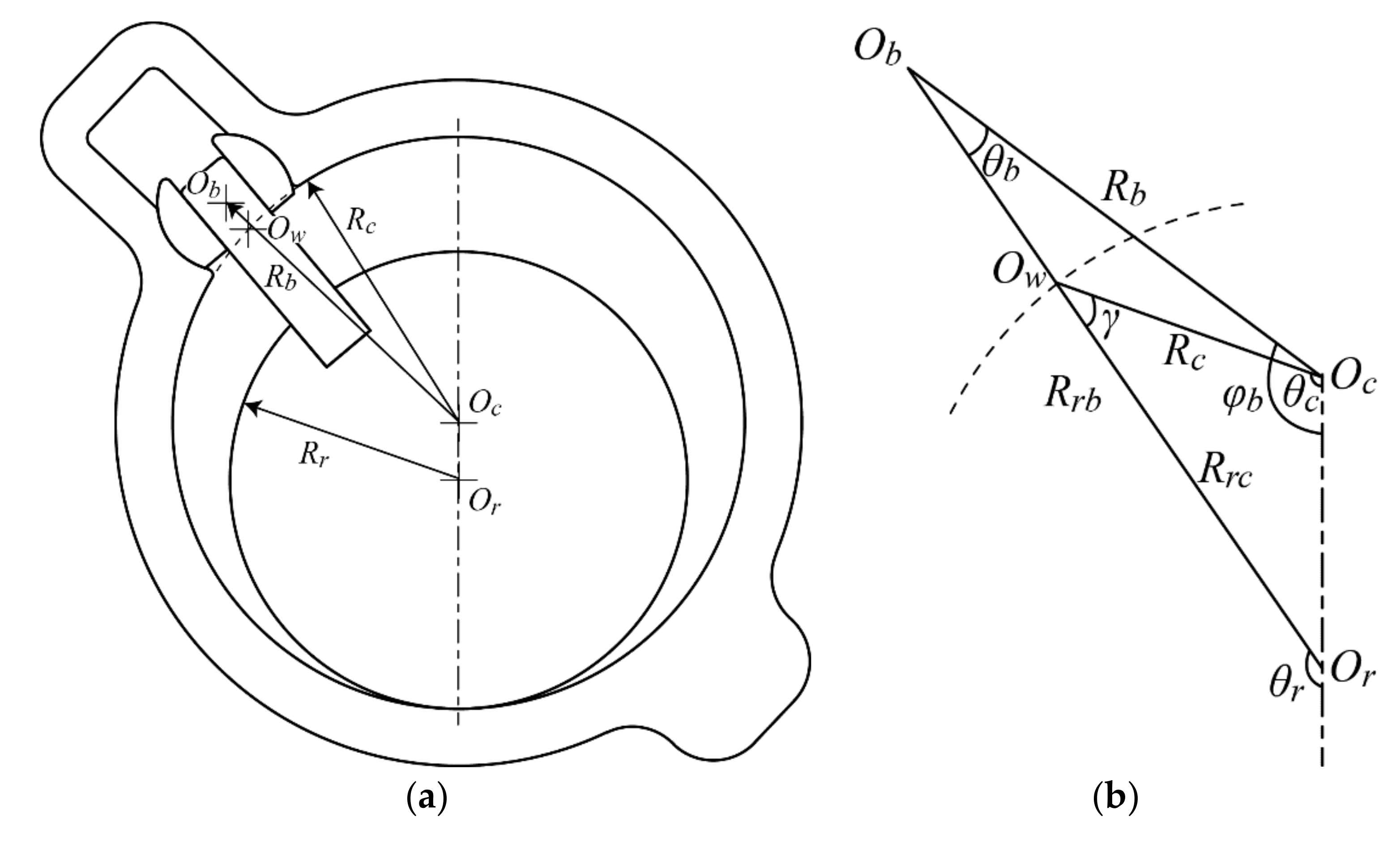

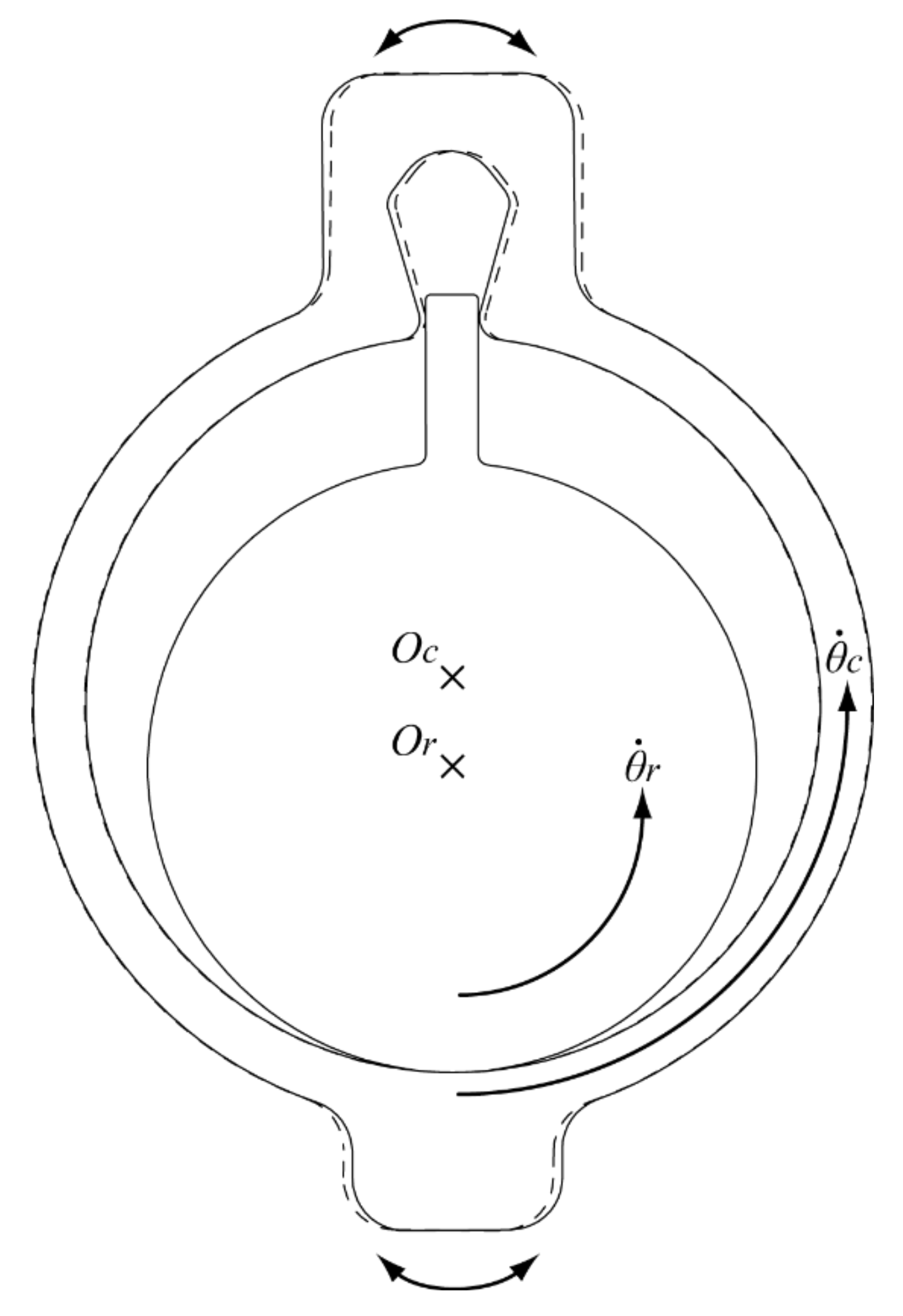

2.1. Generic Revolving Vane Mechanism

2.2. Thermodynamics Model

- Each working chamber in the expander (suction and discharge) are treated as separate control volumes, with their respective inlets and outlets.

- The properties of the fluid are homogenous throughout each entire chamber.

- Potential energy terms are negligible as changes in the heights of the control volumes, inlets and outlets are small.

2.3. Vibration Model

- The vibration of the rotor-cylinder assembly is purely rotational; i.e., no translational motion of the assembly occurs in the journal bearings.

- No manufacturing tolerance is present in the component assembly; the components are in perfect alignment with each other.

2.3.1. Geometric Model

2.3.2. Constrained Lagrange Equations

2.4. Evaulation of Torques

2.4.1. Gas Expansion Torque

2.4.2. Friction Torques

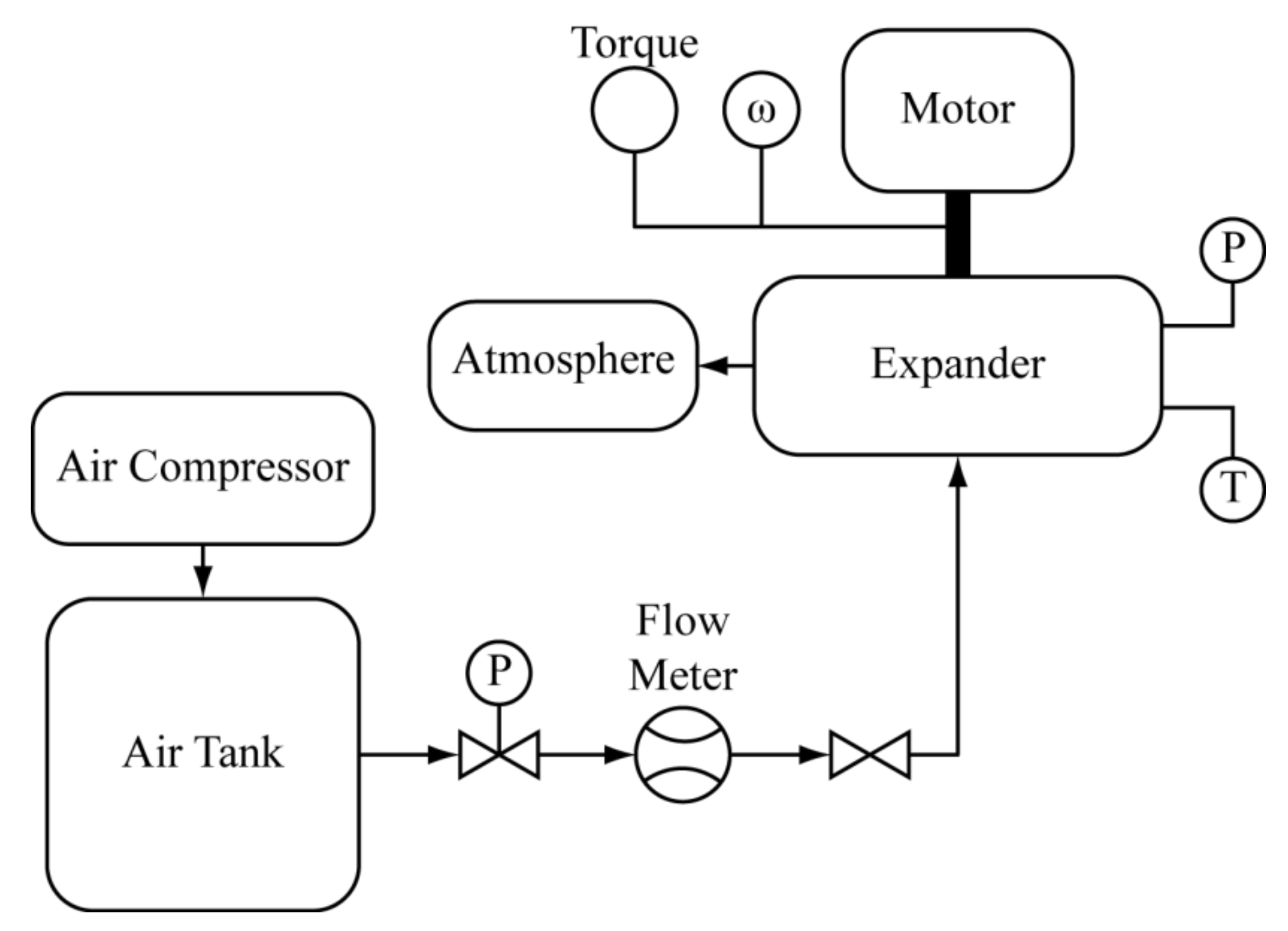

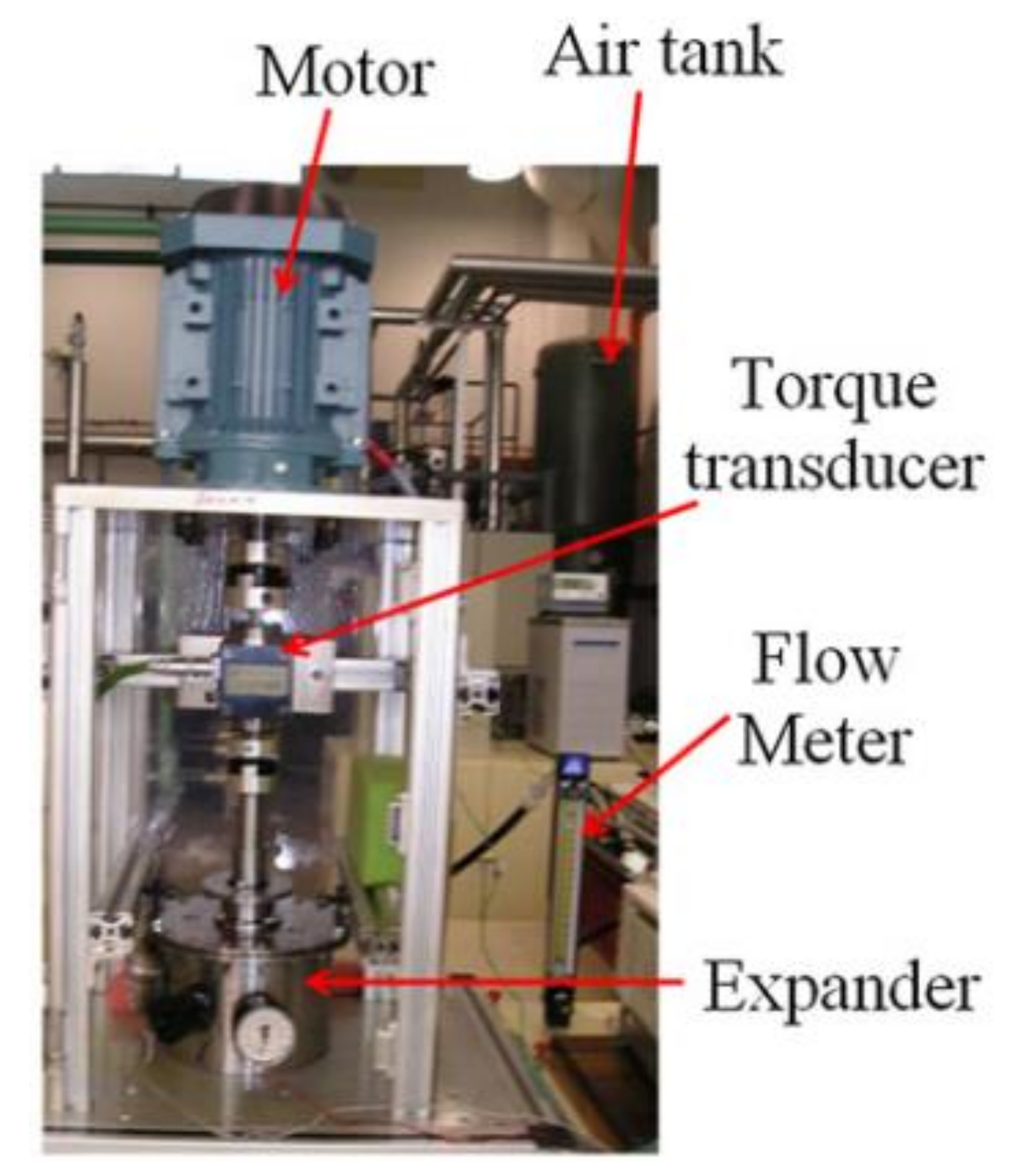

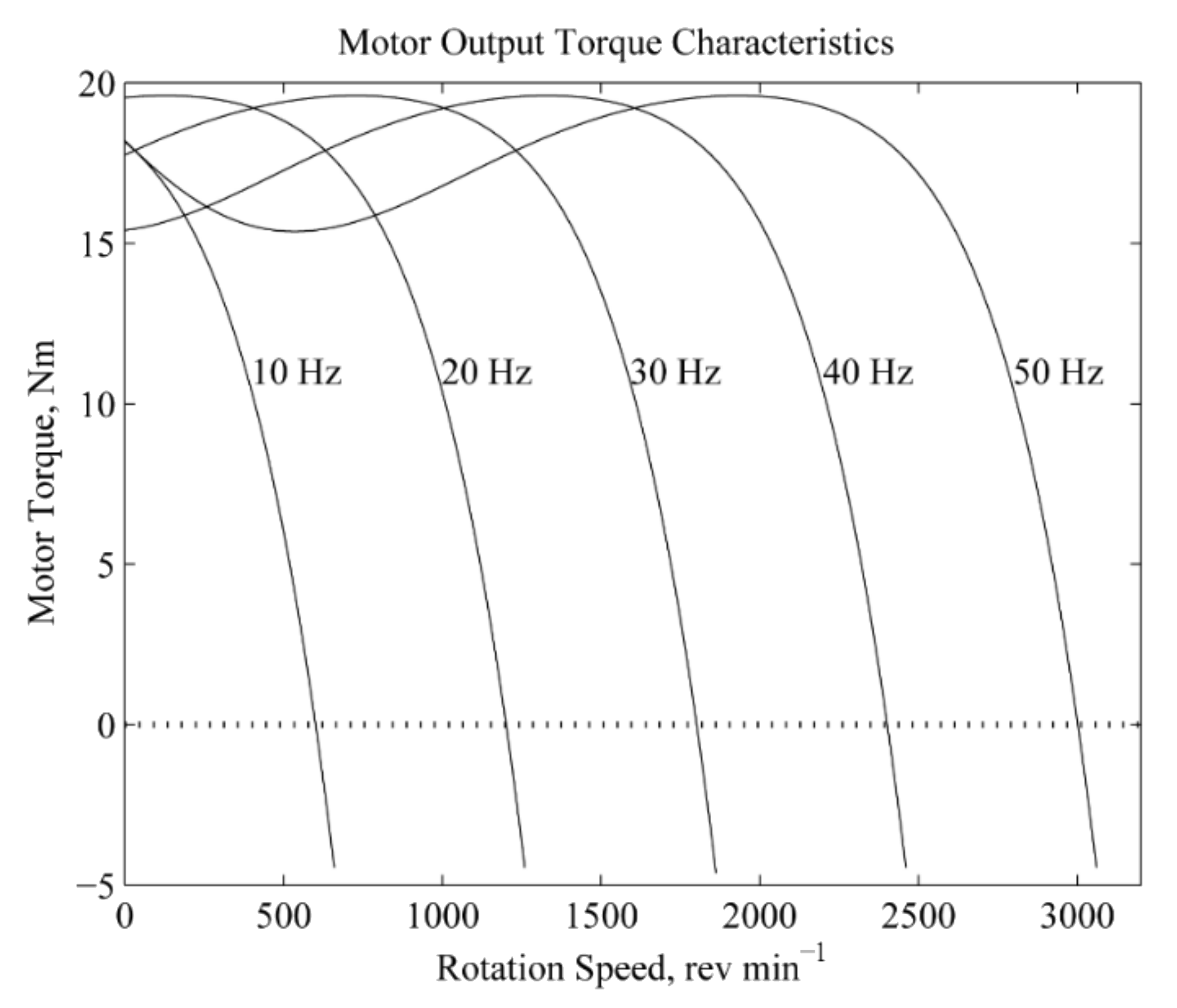

3. Experiment

4. Results and Discussion

4.1. Prototype Model

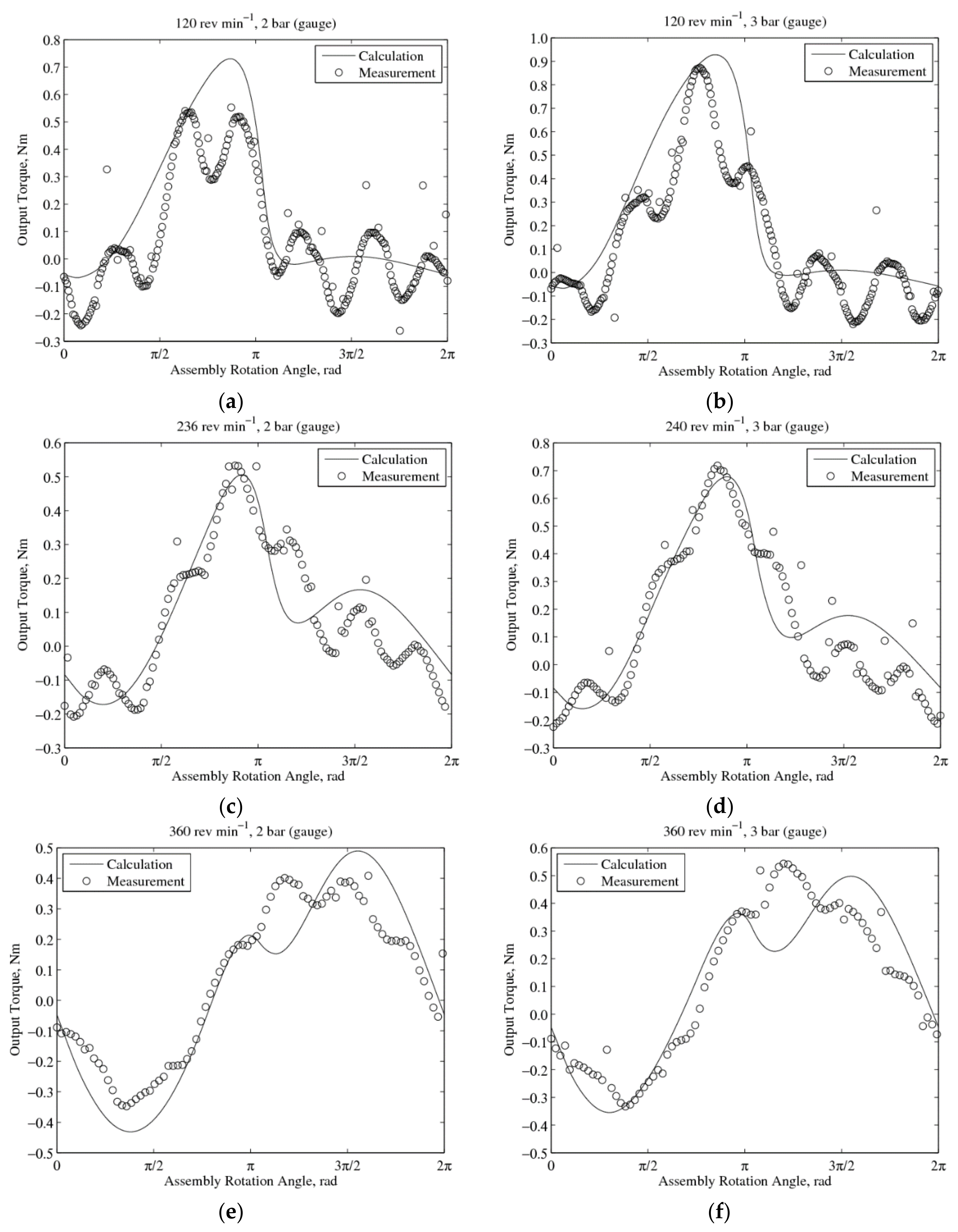

4.2. Results and Model Verification

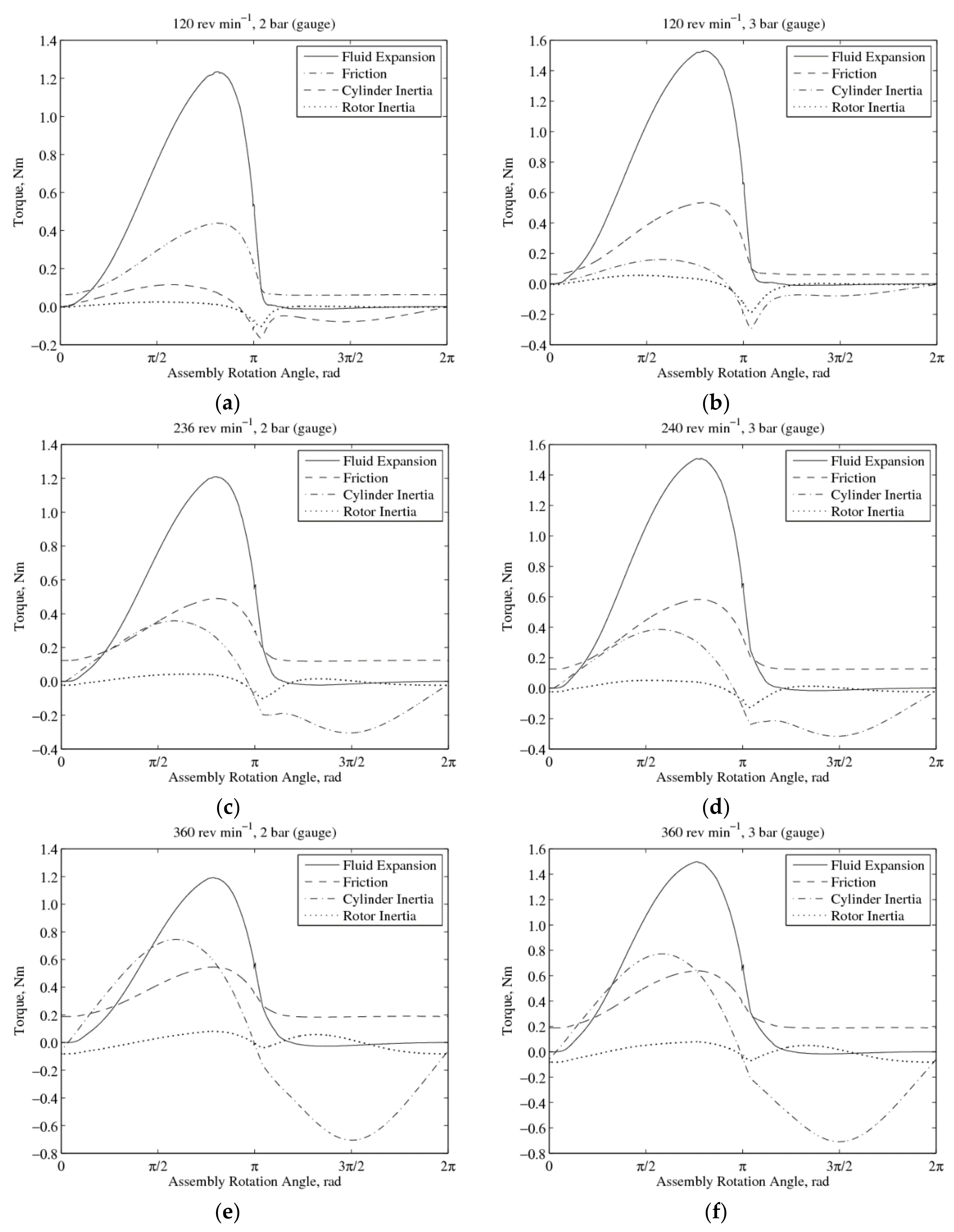

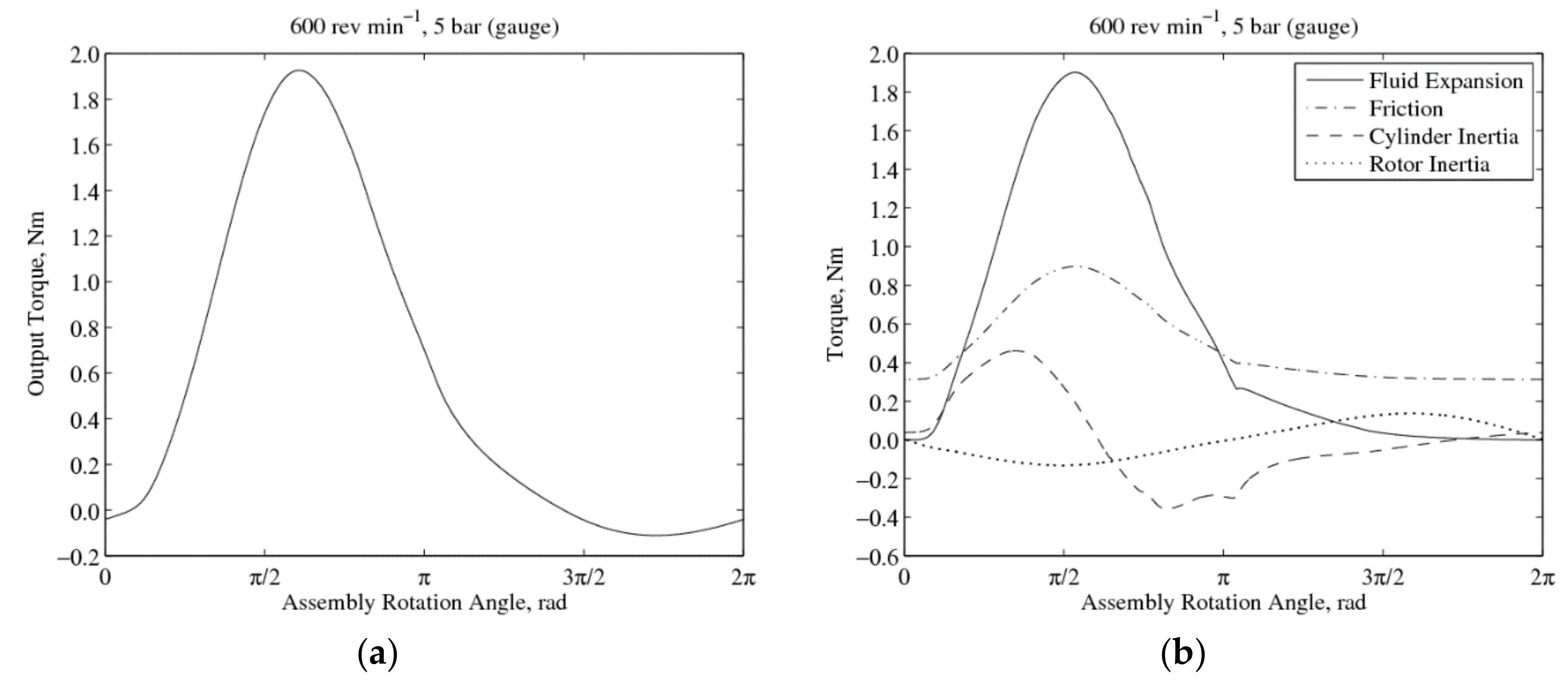

4.3. Torque Components

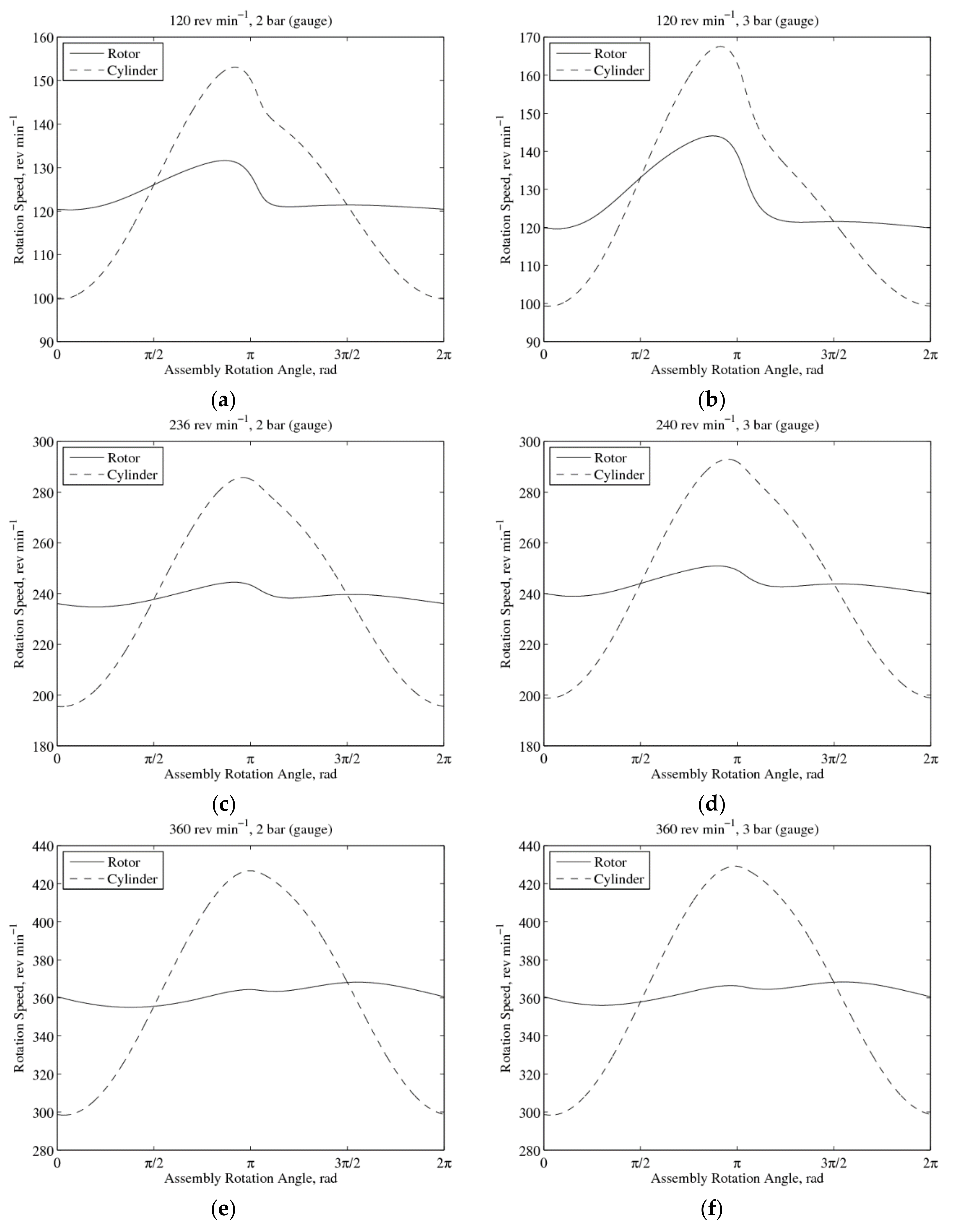

4.4. Secondary Vibration Mode

5. Operating and Design Analysis

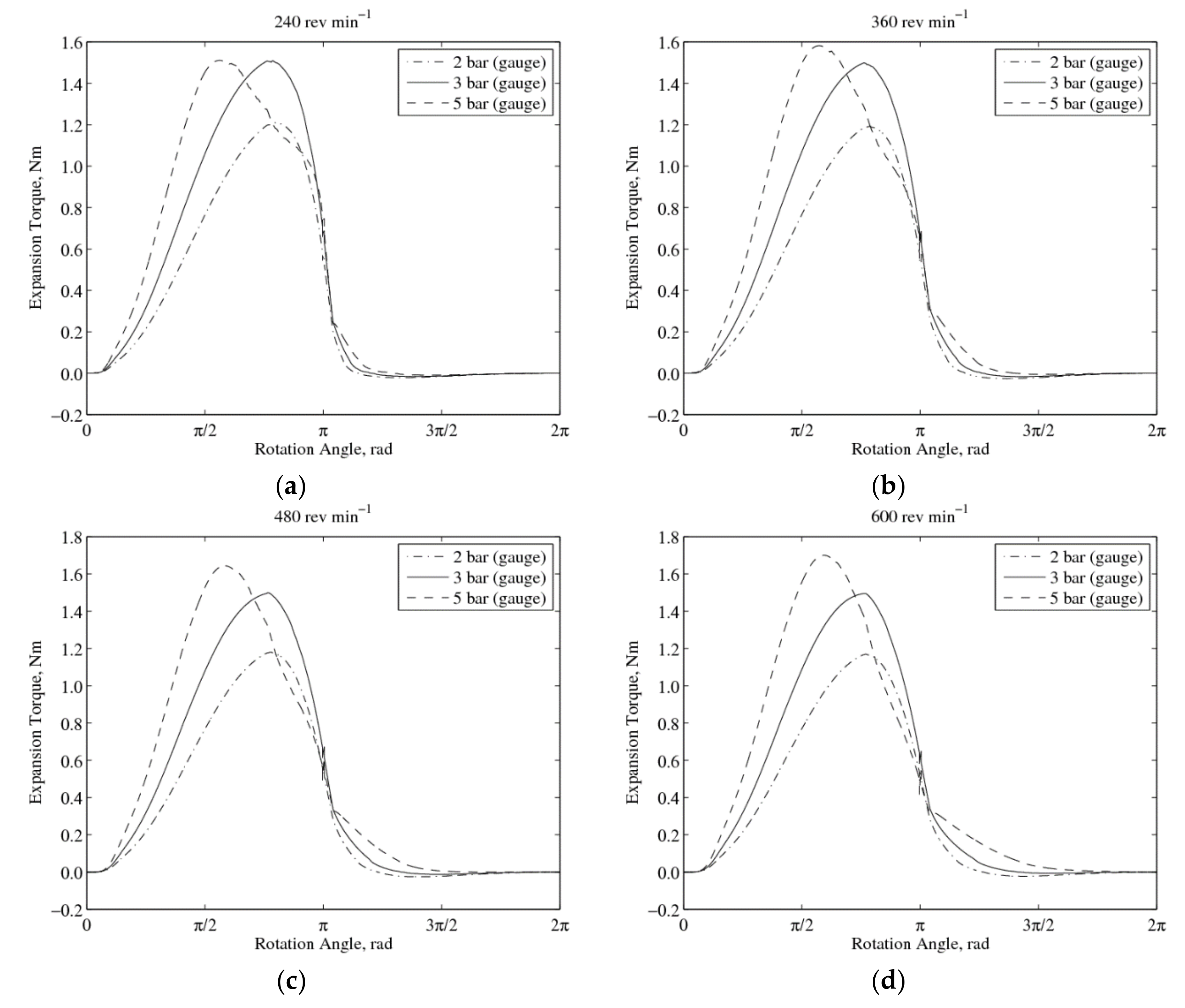

5.1. Effect of Inlet Pressures and Operating Speeds

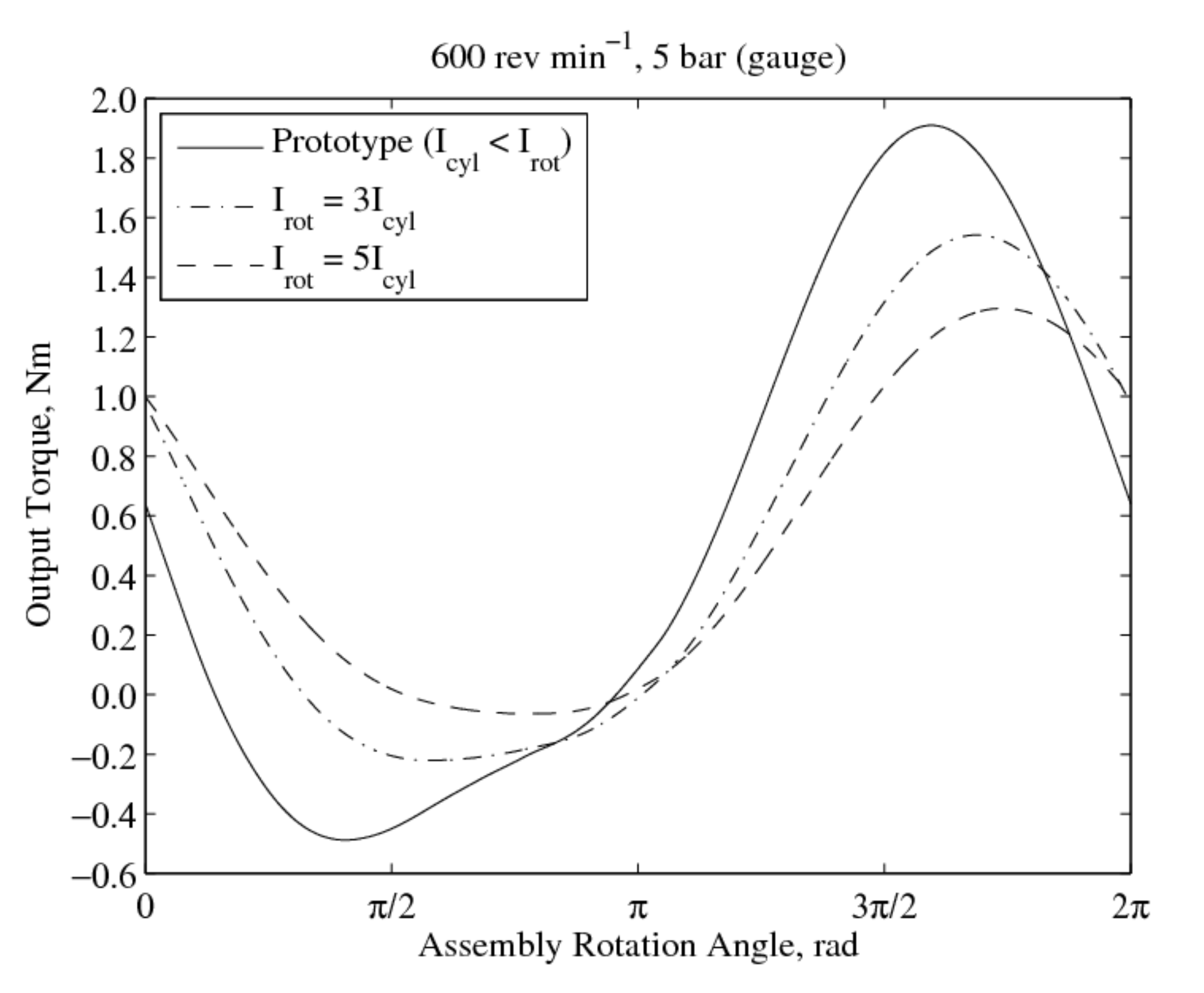

5.2. Effect of Rotor Inertia

5.3. Alternate Mechanism Design

6. Conclusions

- The vibration of the RV air expander prototype is bimodal.

- The rotor and cylinder rotate at different speeds due to eccentricity and the presence of a clearance gap between the vane and vane slot wall cause oscillations of the cylinder about the rotor, termed as ‘vane knocking’.

- The resulting impacts between the vane and vane slot wall affect the output torque of the expander especially since the cylinder possesses higher rotational inertia.

- These impacts can affect the magnitude of the peak output torque if the instances of impacts coincide with the maximum torque output.

- However, this phenomenon is less significant at high operating speeds since the oscillation time is reduced.

- For the type-I RV mechanism, since cylinder inertia increases with operating speed, high inlet pressures are required at high rotation speeds to improve performance.

- Although, high cylinder inertia causes a negative output in the first half of the cycle, the momentum of the cylinder contributes to the peak output torque in the second half of the cycle.

- Adding a flywheel to the type-I RV mechanism to increase the rotor inertia would improve the quality of the output torque but with lower peak torque values.

- When the shaft work is extracted from the cylinder instead (type-II RV mechanism), better performance is achieved as the larger cylinder inertia is now used to overcome frictional losses.

Author Contributions

Funding

Conflicts of Interest

References

- Huang, K.D.; Tzeng, S.-C. Development of a hybrid pneumatic-power vehicle. Appl. Energy 2005, 80, 47–59. [Google Scholar] [CrossRef]

- Dimitrova, Z.; Maréchal, F. Gasoline hybrid pneumatic engine for efficient vehicle powertrain hybridization. Appl. Energy 2015, 151, 168–177. [Google Scholar] [CrossRef]

- Wang, L.; Li, D.F.; Xu, H.X.; Fan, Z.P.; Dou, W.B.; Yu, X.L. Research on a pneumatic hybrid engine with regenerative braking and compressed-air-assisted cranking. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 406–422. [Google Scholar] [CrossRef]

- Huang, K.D.; Tzeng, S.-C.; Chang, W.-C. Energy-saving hybrid vehicle using a pneumatic-power system. Appl. Energy 2005, 81, 1–18. [Google Scholar] [CrossRef]

- Fang, Y.; Lu, Y.; Yu, X.; Roskilly, A.P. Experimental study of a pneumatic engine with heat supply to improve the overall performance. Appl. Therm. Eng. 2018, 134, 78–85. [Google Scholar] [CrossRef] [Green Version]

- Hung, Y.-H.; Tung, Y.-M.; Li, H.-W. A real-time model of an automotive air propulsion system. Appl. Energy 2014, 129, 287–298. [Google Scholar] [CrossRef]

- Wang, Y.-W.; You, J.-J.; Sung, C.-K.; Huang, C.-Y. The applications of piston type compressed air engines on motor vehicles. Procedia Eng. 2014, 79, 61–65. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.-T.; Hwang, Y.-R. Design and implementation of an air-powered motorcycles. Appl. Energy 2009, 86, 1105–1110. [Google Scholar] [CrossRef]

- Zhang, Y.; Nishi, A. Low-pressure air motor for wall-climbing robot actuation. Mechatronics 2003, 13, 377–392. [Google Scholar] [CrossRef]

- Lu, C.-H.; Hwang, Y.-R.; Shen, Y.-T. Backstepping sliding mode tracking control of a vane-type air motor X-Y table motion system. Isa Trans. 2011, 50, 278–286. [Google Scholar] [CrossRef]

- Fukuta, M.; Anzai, F.; Motozawa, M.; Terawaki, H.; Yanagisawa, T. Performance of radial piston type reciprocating expander for CO2 refrigeration cycle. Int. J. Refrig. 2014, 42, 48–56. [Google Scholar] [CrossRef]

- Baek, J.S.; Groll, E.A.; Lawless, P.B. Piston-cylinder work producing expansion device in a transcritical carbon dioxide cycle. Part I: Experimental investigation. Int. J. Refrig. 2005, 28, 141–151. [Google Scholar] [CrossRef]

- Baek, J.S.; Groll, E.A.; Lawless, P.B. Piston-cylinder work producing expansion device in a transcritical carbon dioxide cycle. Part II: Theoretical model. Int. J. Refrig. 2005, 28, 152–164. [Google Scholar] [CrossRef]

- Zhang, B.; Peng, X.; He, Z.; Xing, Z.; Shu, P. Development of a double acting free piston expander for power recovery in transcritical CO2 cycle. Appl. Therm. Eng. 2007, 27, 1629–1636. [Google Scholar] [CrossRef]

- Kovačević, A.; Stošić, N.; Smith, I.K. Numerical simulation of combined screw compressor–expander machines for use in high pressure refrigeration systems. Simul. Model. Pract. Theory 2006, 14, 1143–1154. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Wu, Y.; Ma, C.; Liu, L.; Yu, J. Preliminary experimental study of single screw expander prototype. Appl. Therm. Eng. 2011, 31, 3684–3688. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y.; Ma, C.; Xia, G.; Wang, J. Experimental study on the performance of single screw expanders by gap adjustment. Energy 2013, 62, 379–384. [Google Scholar] [CrossRef]

- Kovacevic, A.; Rane, S. 3D CFD Analysis of a Twin Screw Expander. In 8th International Conference on Compressors and Their Systems; Elsevier: Amsterdam, The Netherlands, 2013; pp. 417–429. [Google Scholar] [CrossRef]

- Yang, B.; Peng, X.; He, Z.; Guo, B.; Xing, Z. Experimental investigation on the internal working process of a CO2 rotary vane expander. Appl. Therm. Eng. 2009, 29, 2289–2296. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, W.; Bu, G.; Wang, Z.; Shu, P. Experimental study on a sliding vane expander in the HFC410A refrigeration system for energy recovery. Appl. Therm. Eng. 2013, 59, 559–567. [Google Scholar] [CrossRef]

- Naranjo, J.; Kussul, E.; Ascanio, G. A new pneumatic vanes motor. Mechatronics 2010, 20, 424–427. [Google Scholar] [CrossRef]

- Guangbin, L.; Yuanyang, Z.; Liansheng, L.; Pengcheng, S. Simulation and experiment research on wide ranging working process of scroll expander driven by compressed air. Appl. Therm. Eng. 2010, 30, 2073–2079. [Google Scholar] [CrossRef]

- Mendoza, L.C.; Navarro-Esbrí, J.; Bruno, J.C.; Lemort, V.; Coronas, A. Characterization and modeling of a scroll expander with air and ammonia as working fluid. Appl. Therm. Eng. 2014, 70, 630–640. [Google Scholar] [CrossRef]

- Haiqing, G.; Yitai, M.; Minxia, L. Some design features of CO2 swing piston expander. Appl. Therm. Eng. 2006, 26, 237–243. [Google Scholar] [CrossRef]

- Zhao, L.; Li, M.; Ma, Y.; Liu, Z.; Zhang, Z. Simulation analysis of a two-rolling piston expander replacing a throttling valve in a refrigeration and heat pump system. Appl. Therm. Eng. 2014, 66, 383–394. [Google Scholar] [CrossRef]

- Li, M.; Ma, Y.; Tian, H. A rolling piston-type two-phase expander in the transcritical CO2 Cycle. Hvacr Res. 2009, 15, 729–741. [Google Scholar] [CrossRef]

- Yap, K.S.; Ooi, K.T.; Chakraborty, A. Analysis of the novel cross vane expander-compressor: Mathematical modelling and experimental study. Energy 2018, 145, 626–637. [Google Scholar] [CrossRef]

- Teh, Y.L.; Ooi, K.T.; Djamari, D.W. Theoretical study of a novel refrigeration compressor—Part II: Performance of a rotating discharge valve in the revolving vane (RV) compressor. Int. J. Refrig. 2009, 32, 1103–1111. [Google Scholar] [CrossRef]

- Teh, Y.L.; Ooi, K.T. Theoretical study of a novel refrigeration compressor- Part III: Leakage loss of the revolving vane (RV) compressor and a comparison with that of the rolling piston type. Int. J. Refrig. 2009, 32, 945–952. [Google Scholar] [CrossRef]

- Subiantoro, A.; Ooi, K.T. Introduction of the revolving vane expander. Hvac R Res. 2009, 15, 801–816. [Google Scholar] [CrossRef]

- Subiantoro, A.; Ooi, K.T. Analysis of the revolving vane (RV-0) expander, Part 1: Experimental investigations. Int. J. Refrig. 2012, 35, 1734–1743. [Google Scholar] [CrossRef]

- Subiantoro, A.; Ooi, K.T. Analysis of the Revolving Vane (RV-0) expander, part 2: Verifications of theoretical models. Int. J. Refrig. 2012, 35, 1744–1756. [Google Scholar] [CrossRef]

- Subiantoro, A.; Yap, K.S.; Ooi, K.T. Experimental investigations of the revolving vane (RV-I) expander. Appl. Therm. Eng. 2013, 50, 393–400. [Google Scholar] [CrossRef]

- Naseri, A.; Norris, S.; Subiantoro, A. Experimental investigation of a prototype semi-dry revolving vane expander: Design challenges and performance criteria. Energy 2020, 205, 118063. [Google Scholar] [CrossRef]

- Aw, K.T.; Ooi, K.T. Theoretical Analysis of Revolving Vane Compressor Vibrations. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 14–17 July 2014. [Google Scholar]

- Tan, K.M.; Ooi, K.T. A novel revolving vane compressor with a fixed-vane. Int. J. Refrig. 2011, 34, 1980–1988. [Google Scholar] [CrossRef]

- Yanagisawa, T.; Shimizu, T. Leakage losses with a rolling piston type rotary compressor. I. Radial clearance on the rolling piston. Int. J. Refrig. 1985, 8, 75–84. [Google Scholar] [CrossRef]

- Liu, R.; Zhou, Z. Heat Transfer Between Gas and Cylinder Wall of Refrigerating Reciprocating Compressor. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 11–13 July 1984; pp. 110–115. [Google Scholar]

- Tan, K.M.; Ooi, K.T. Heat transfer in compression chamber of a revolving vane (RV) compressor. Appl. Therm. Eng. 2011, 31, 1519–1526. [Google Scholar] [CrossRef]

- Yanagisawa, T.; Mori, M.; Shimizu, T.; Ogi, Y. Vibration of a rolling piston type rotary compressor. Int. J. Refrig. 1984, 7, 237–244. [Google Scholar] [CrossRef]

- Thornton, S.T.; Marion, J.B. Classical Dynamics of Particles and Systems, 5th ed.; Brooks/Cole: Belmont, CA, USA, 2004. [Google Scholar]

- Subiantoro, A. Development of a Revolving Vane Expander; Nanyang Technological University: Singapore, 2012. [Google Scholar]

- Subiantoro, A.; Ooi, K.T. Comparison and performance analysis of the novel revolving vane expander design variants in low and medium pressure applications. Energy 2014, 78, 747–757. [Google Scholar] [CrossRef]

- Tan, K.M.; Ooi, K.T. Journal bearings design for a novel revolving vane compressor. Int. J. Refrig. 2011, 34, 94–104. [Google Scholar] [CrossRef]

| Coefficient | Value |

|---|---|

| ξ | 3.0 × 10−1 |

| ζ | 5.0 × 10−3 |

| Component | Dimension |

|---|---|

| Rotor radius (Rr), mm | 29.0 |

| Cylinder inner radius (Rc), mm | 35.0 |

| Chamber length (le), mm | 25.0 |

| Vane length, mm | 16.0 |

| Vane width, mm | 4.0 |

| Working volume, cm3 | 12.0 |

| Average Operating Speed, rev min−1 | Inlet Pressure, Bar (Gauge) | Measure Peak Torque, Nm | Calculated Peak Torque, Nm | Error, % |

|---|---|---|---|---|

| 120 | 2 | 0.540 | 0.731 | –35.4 |

| 120 | 3 | 0.873 | 0.928 | –6.3 |

| 236 | 2 | 0.533 | 0.506 | 5.1 |

| 240 | 3 | 0.718 | 0.678 | 5.6 |

| 360 | 2 | 0.401 | 0.490 | –22.2 |

| 360 | 3 | 0.543 | 0.498 | 8.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aw, K.T.; Subiantoro, A.; Ooi, K.T. Torque Characteristics of the Revolving Vane Air Expander. Machines 2020, 8, 58. https://doi.org/10.3390/machines8030058

Aw KT, Subiantoro A, Ooi KT. Torque Characteristics of the Revolving Vane Air Expander. Machines. 2020; 8(3):58. https://doi.org/10.3390/machines8030058

Chicago/Turabian StyleAw, Kuan Thai, Alison Subiantoro, and Kim Tiow Ooi. 2020. "Torque Characteristics of the Revolving Vane Air Expander" Machines 8, no. 3: 58. https://doi.org/10.3390/machines8030058

APA StyleAw, K. T., Subiantoro, A., & Ooi, K. T. (2020). Torque Characteristics of the Revolving Vane Air Expander. Machines, 8(3), 58. https://doi.org/10.3390/machines8030058