Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles

Abstract

1. Introduction

2. Materials and Methods

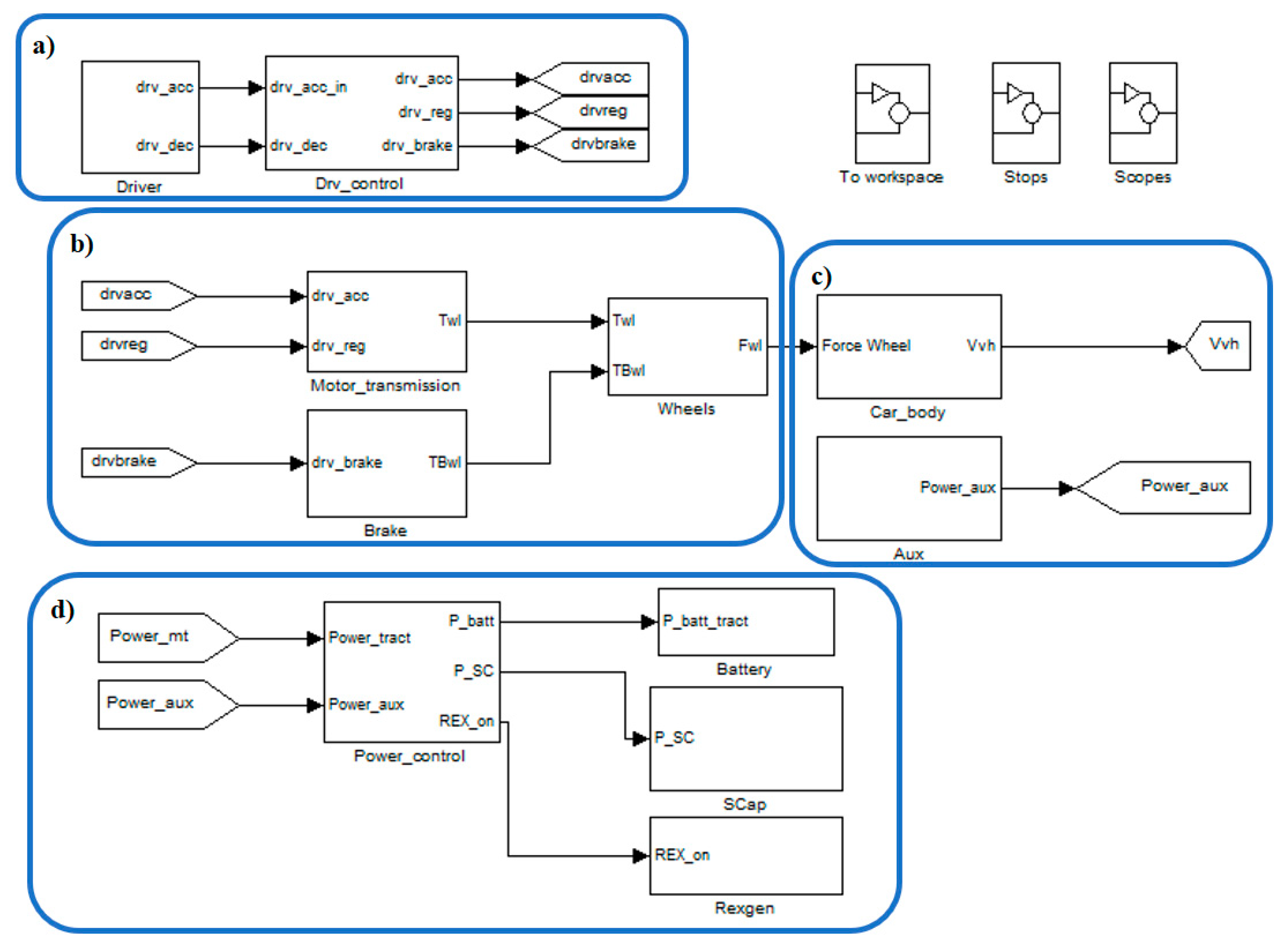

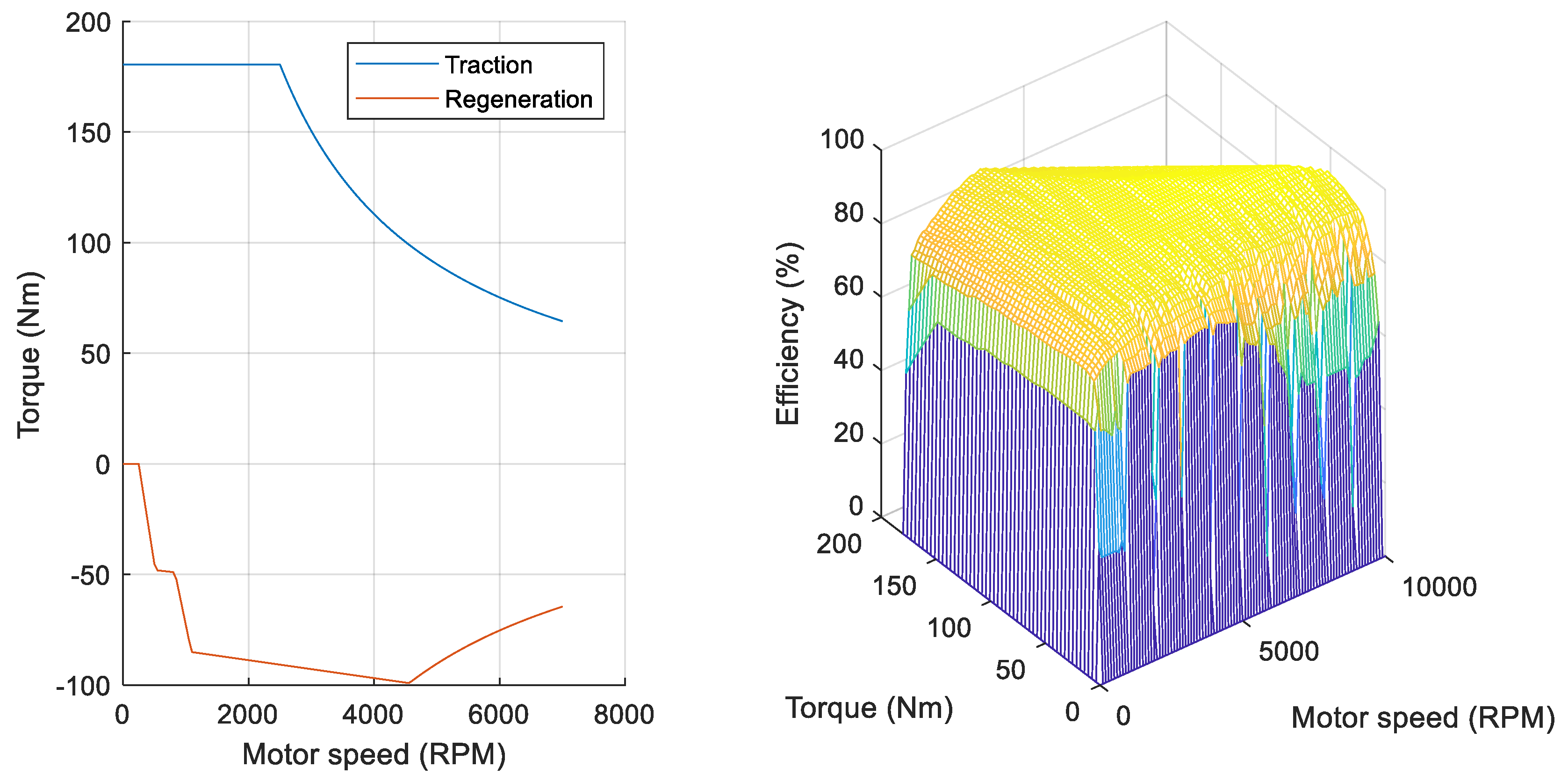

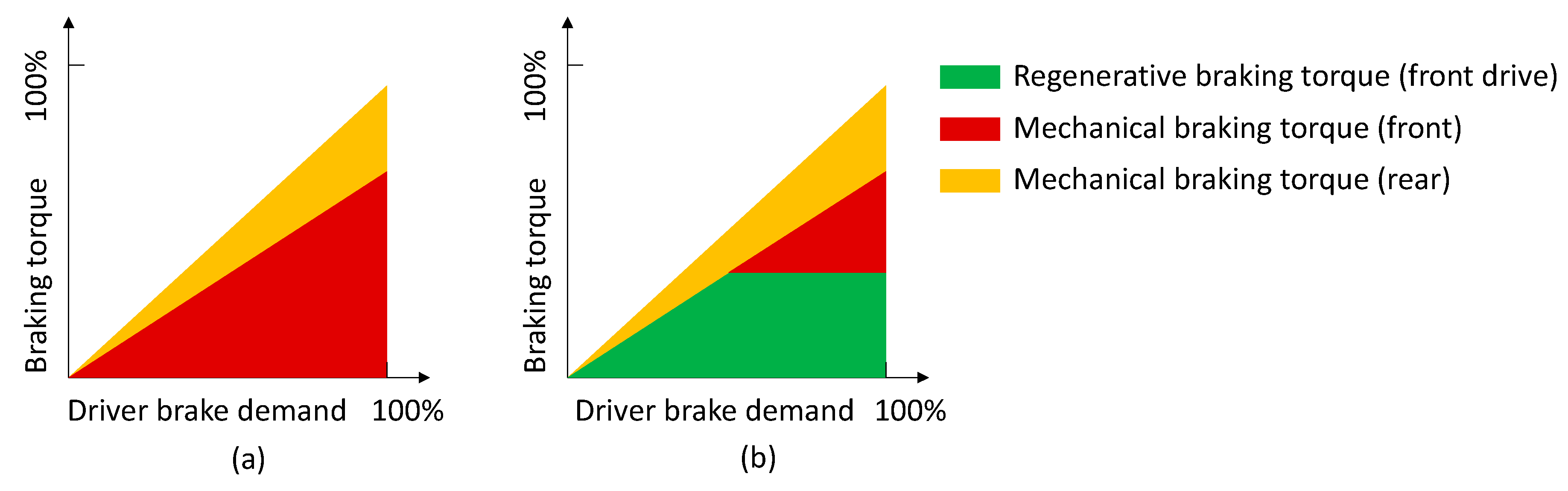

2.1. Simulation Modeling of Vehicle Consumption

2.2. Estimation of Reduction Values for Energy Consumption and Environmental Impact

3. Results

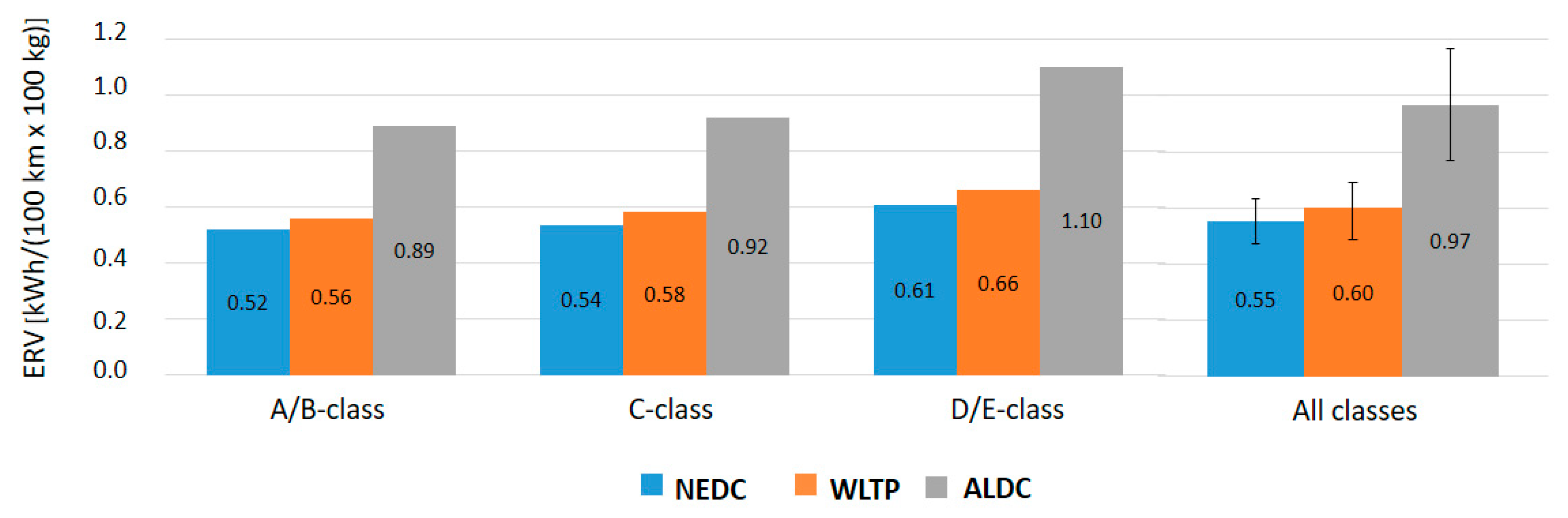

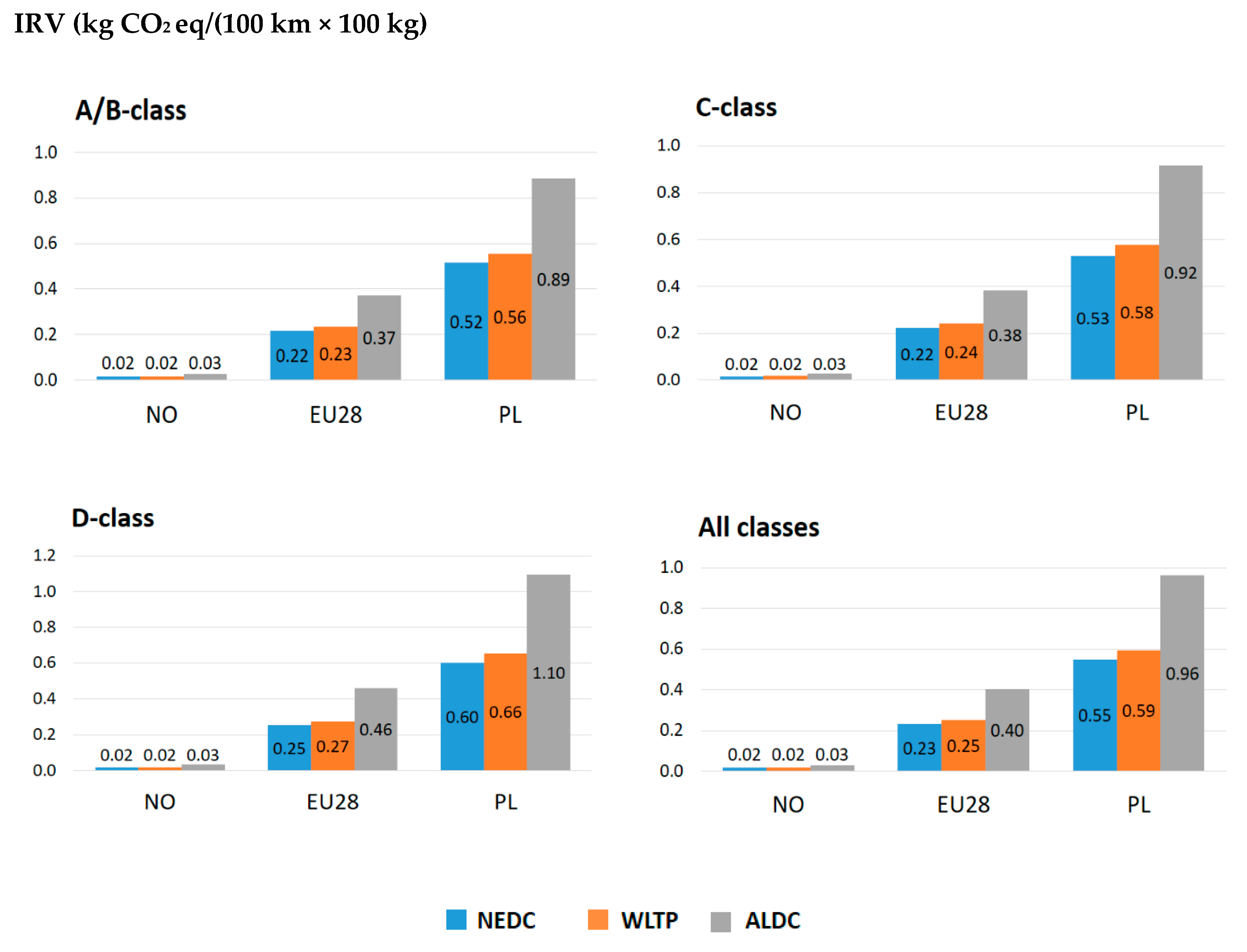

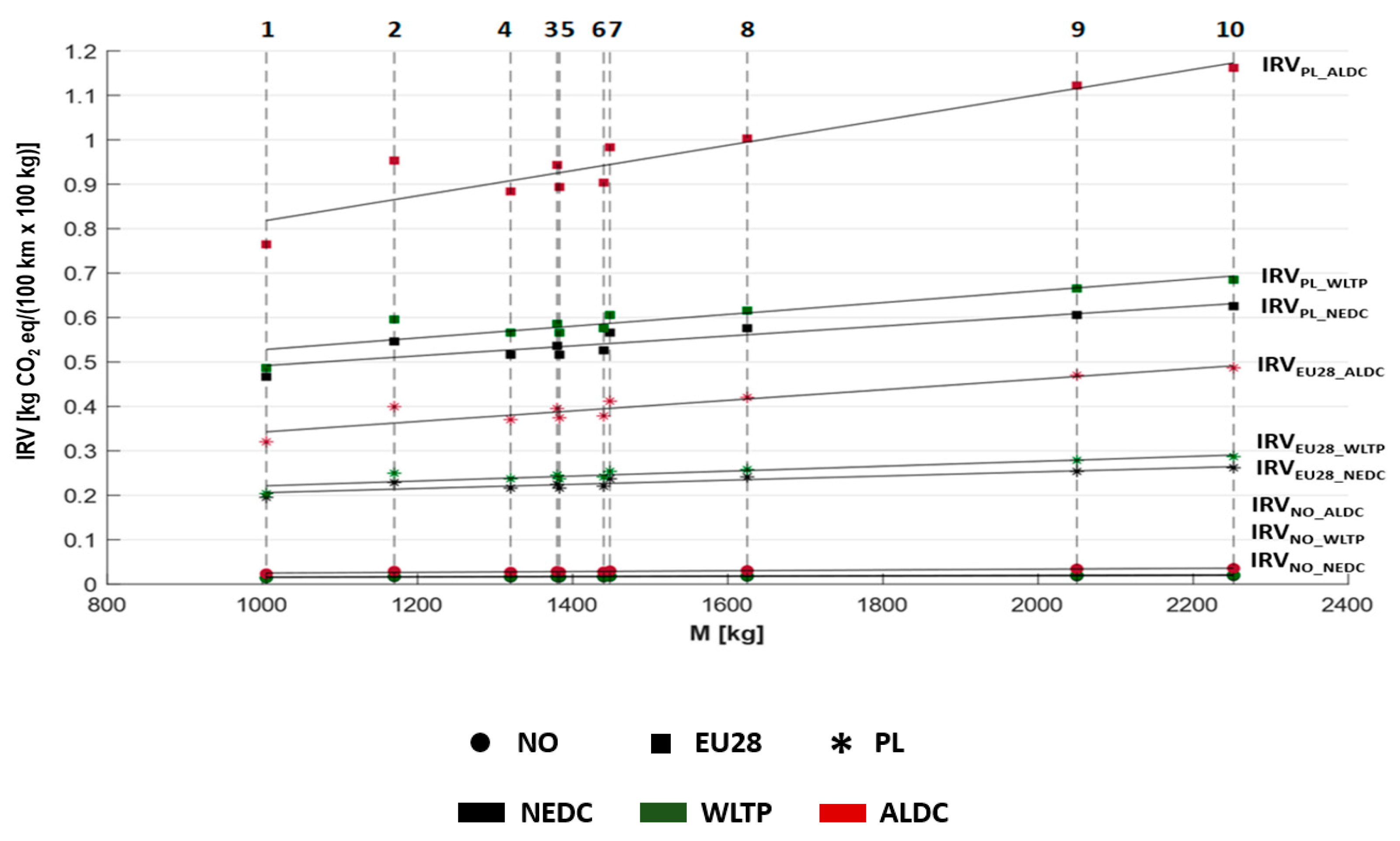

3.1. Variability of Reduction Coefficients on Use Stage Boundary Conditions

- 0.02 kg CO2 eq/(100 km × 100 kg) (IRVNEDC) and 0.03 kg CO2 eq/(100 km × 100 kg) (IRVALDC) when considering the Norwegian grid mix;

- 0.55 kg CO2 eq/(100 km × 100 kg) (IRVNEDC) and 0.96 kg CO2 eq/(100 km × 100 kg) (IRVALDC) when considering the Polish grid mix.

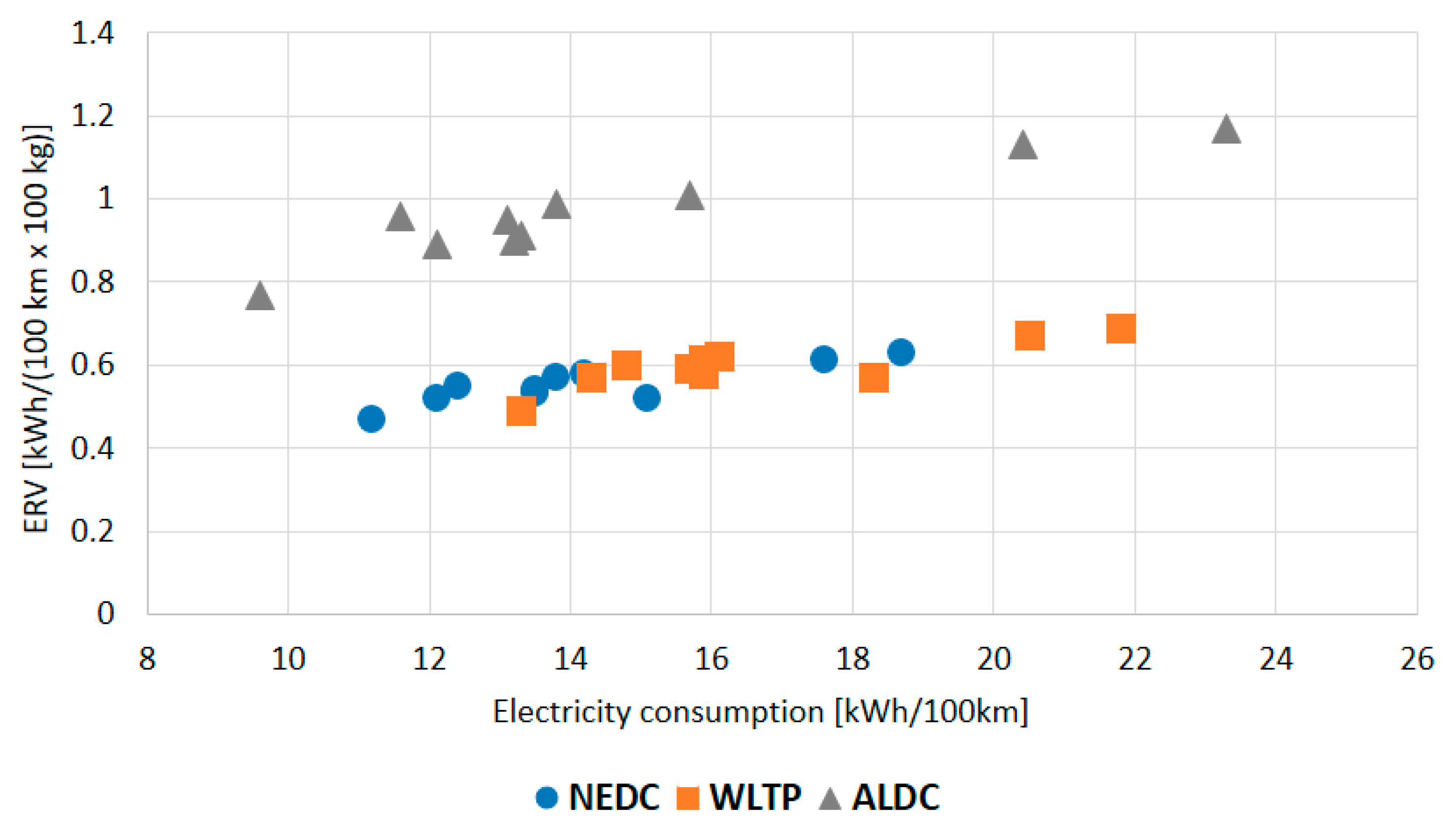

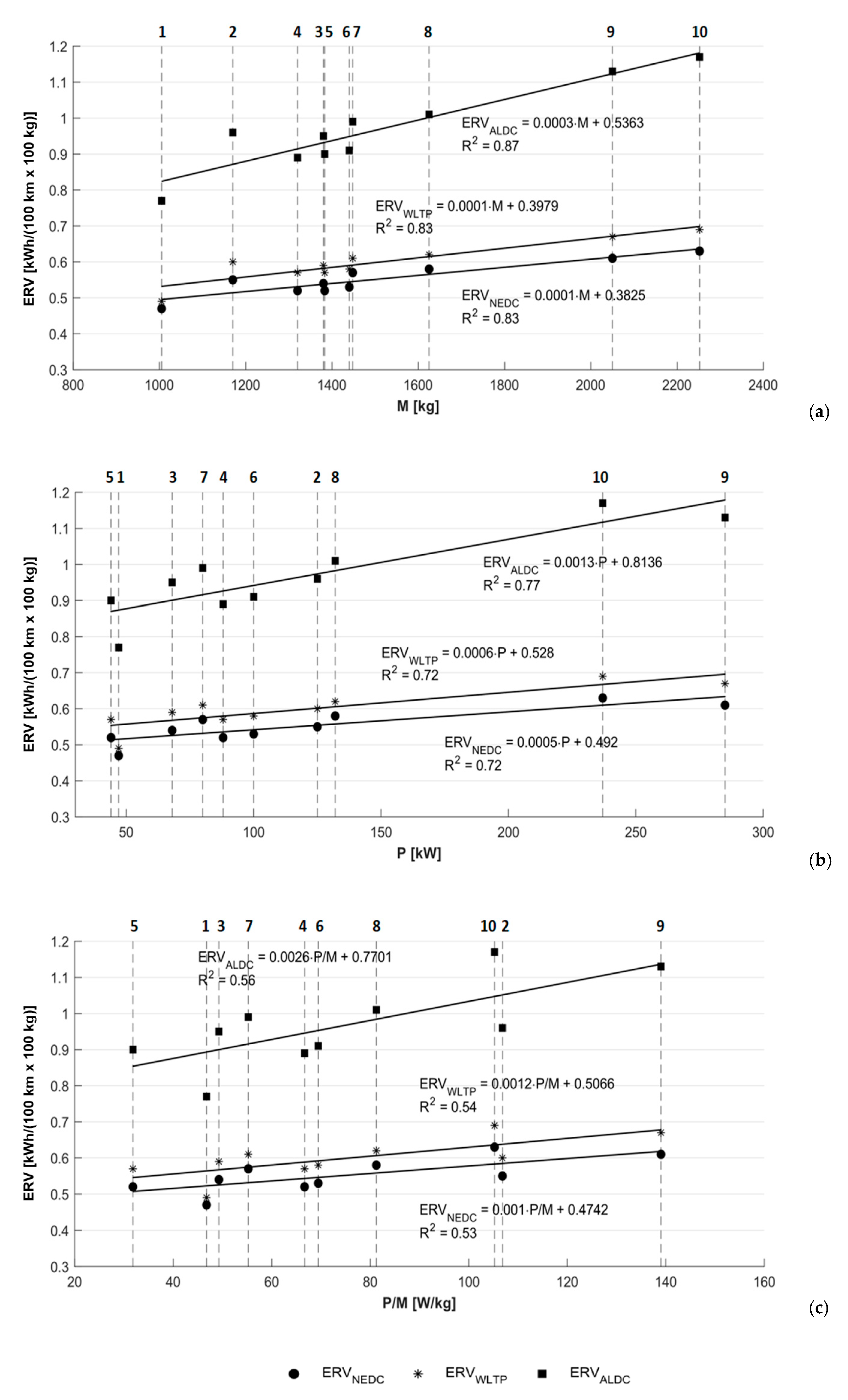

3.2. Modeling Approach for ERV and IRV Estimation

- Higher class-level case studies generally have higher M, Pmax, and P/M;

- The greater mass-dependent resistance forces in the ALDC make that the ERV increases more rapidly at car size increasing with respect to the other driving cycles.

- The NEDC had been the standardized driving cycle for European type approval tests until 2017, when it was replaced by the WLTP. However, the cycle is widely criticized to not represent the driving behavior of current real-world drivers and cars, since numerous studies show that actual on-road fuel consumption and emissions might be substantially higher than values determined through the NEDC [56,57,58,59].

- The WLTP is a global, harmonized standard for determining the levels of fuel consumption/pollutants of both conventional and hybrid cars, as well as the range of fully Electric Vehicles.

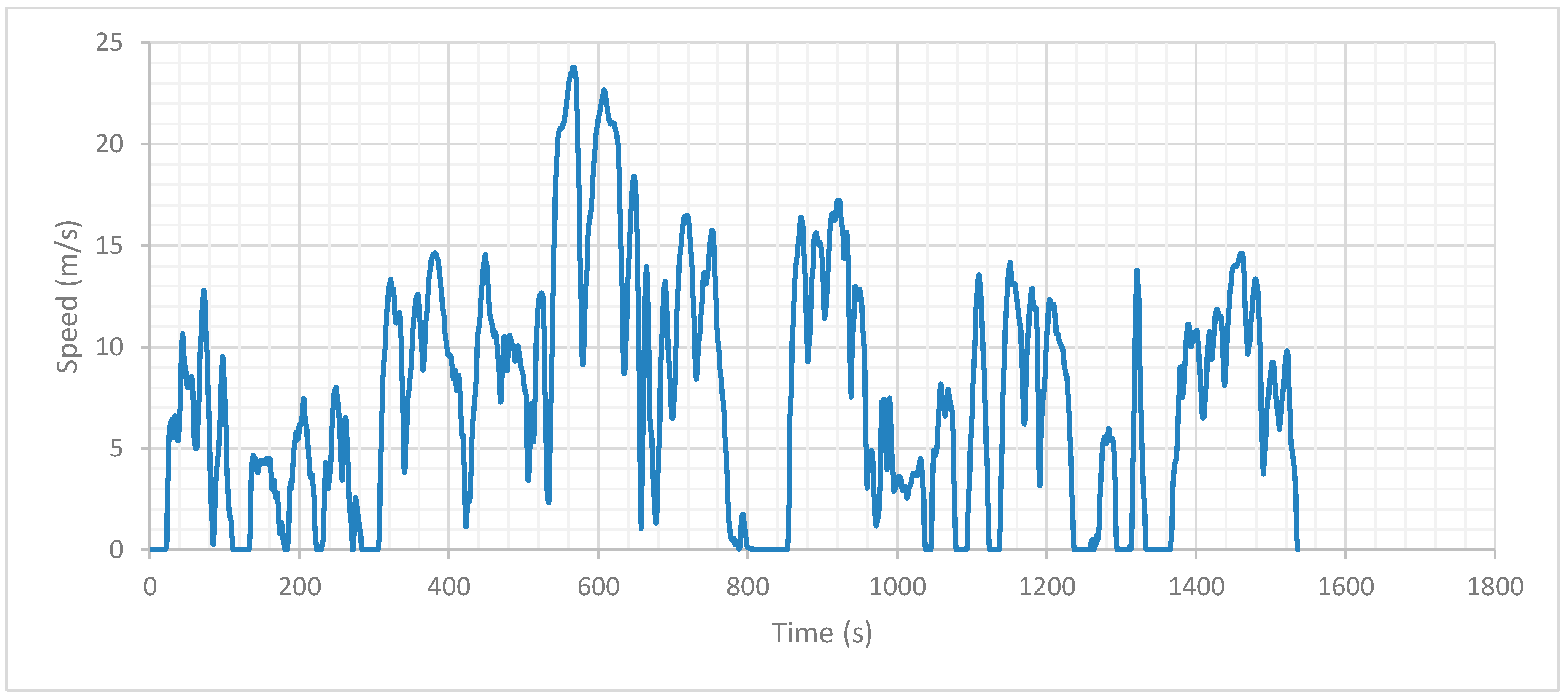

- The ALDC can be considered fully representative of actual usage conditions of current EVs, since it has been developed specifically for fully electric cars through testing campaigns carried out over urban and suburban driving routes of a large number of real vehicle users.

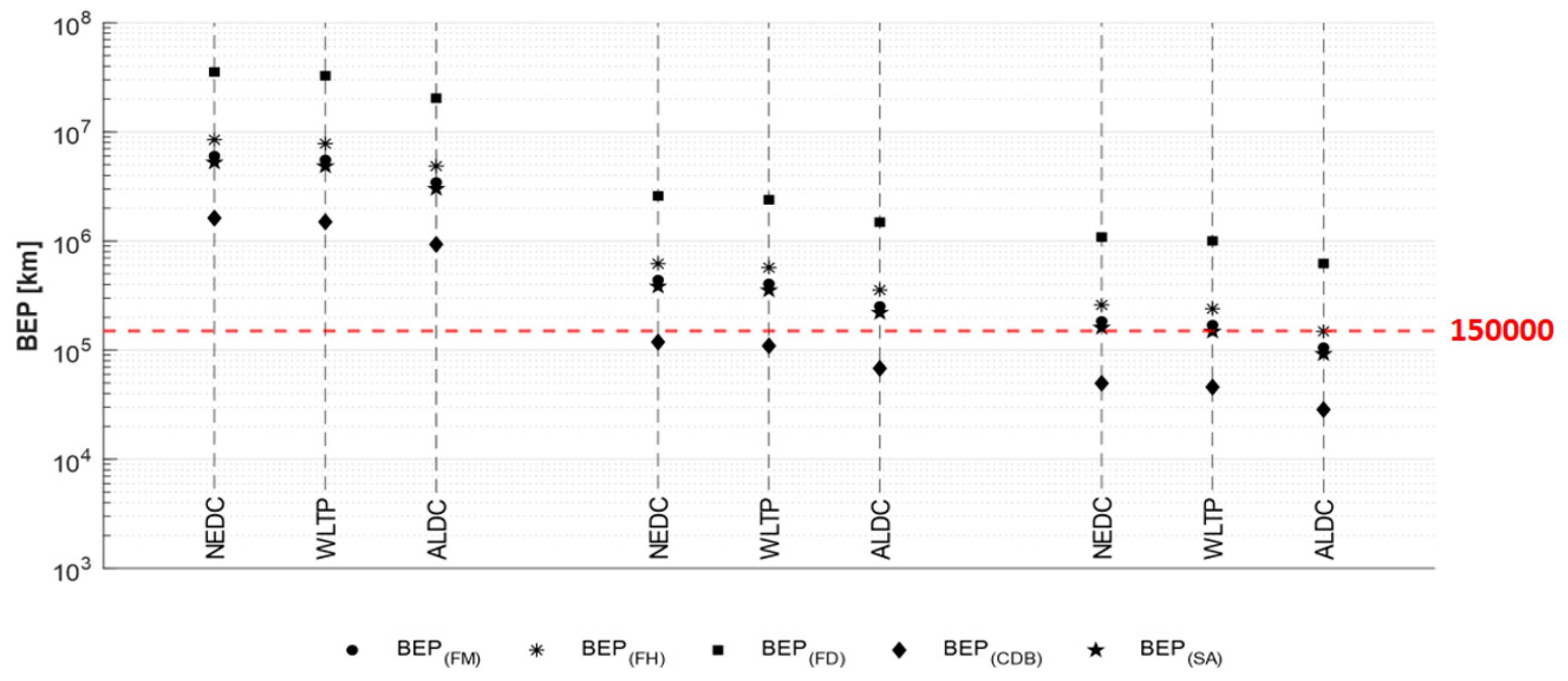

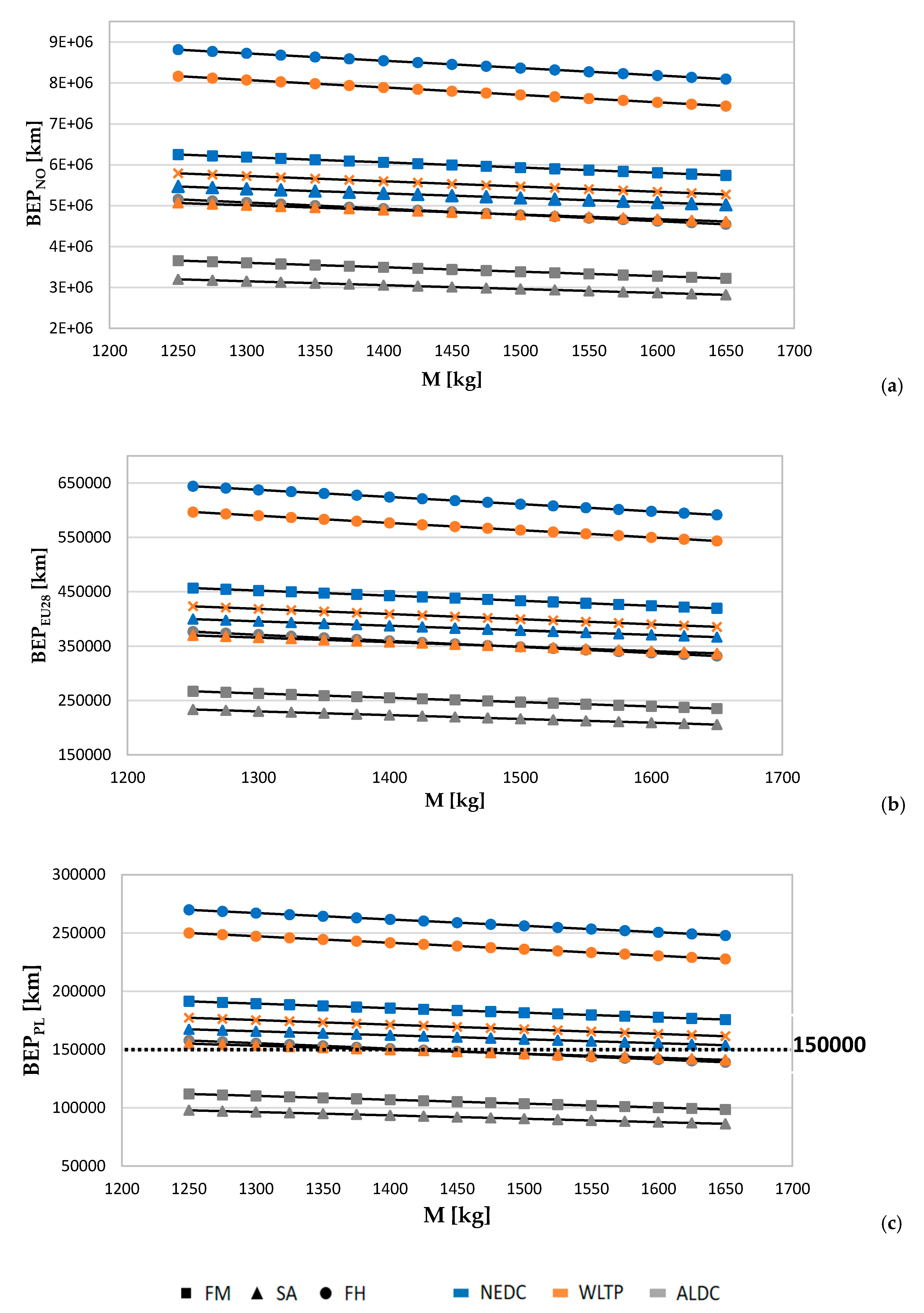

3.3. Implementation of Modeling Approach on Real-Word Case Studies

- These are comparative Life-Cycle Assessments (LCAs) of reference and innovative design solutions for different modules installed on a C-class EV;

- The lightweight components are based on composites and hybrid materials and they have been specifically developed for fully electric cars;

- The environmental analysis is carried out considering the entire Life Cycle (LC) of the modules and it is based on several impact categories, including the Global Warming Potential (GWP).

- Dealing with lightweight case studies characterized by a low mass-specific GWP increase in production and EoL (ΔGWPProd+EoL/ΔMlight);

- Assuming fossil-intensive electricity grid mixes and driving cycles with highly dynamic run.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ALDC | All-Long Driving Cycle |

| ASTERICS | “Ageing and efficiency Simulation & TEsting under Real world conditions for Innovative electric vehicle Components and Systems” |

| BEV | Battery Electric Vehicle |

| CDB | Crash Dashboard Beam |

| EoL | End-of-Life |

| ERV | Energy Reduction Value |

| EV | Electric Vehicle |

| FD | Front Door |

| FH | Front Hood |

| FM | Front Module |

| FRV | Fuel Reduction Value |

| FTP | Federal Test Procedure |

| GWP | Global Warming Potential |

| ICEV | Internal Combustion Engine |

| IRV | Impact Reduction Value |

| LC | Life Cycle |

| LCA | Life-Cycle Assessment |

| NEDC | New European Driving Cycle |

| PID | Proportional–Integral–Derivative |

| PMSM | Permanent Magnet Synchronous Motor |

| SA | Suspension Arm |

| WLTP | Worldwide Harmonized Light-Duty Test Procedure |

Appendix A

| Case Study | Vehicle Model | Mass (kg) | Power (kW) | Power-to-Mass Ratio (W/kg) |

| 1 | Mitsubishi I-MIEV | 1005 | 47 | 47 |

| 2 | BMW i3 | 1170 | 125 | 107 |

| 3 | Renault Zoe | 1380 | 68 | 49 |

| 4 | Hyundai Sonic | 1320 | 88 | 67 |

| 5 | Renault Kangoo ZE | 1383 | 44 | 32 |

| 6 | Volkswagen e-Golf | 1440 | 100 | 69 |

| 7 | Nissan Leaf | 1448 | 80 | 55 |

| 8 | Mercedes B-class | 1625 | 132 | 81 |

| 9 | Tesla model-S | 2050 | 285 | 139 |

| 10 | Tesla model-X | 2252 | 237 | 105 |

| Descriptive Parameters of Driving Cycles | ||||

|---|---|---|---|---|

| NEDC | WLTP | ALDC | ||

| General | Duration (s) | 1180 | 1800 | 1536 |

| Distance (km) | 11.03 | 23.27 | 11.57 | |

| Mean velocity (km/h) | 33.6 | 46.5 | 27.1 | |

| Max velocity (km/h) | 120.0 | 131.3 | 85.6 | |

| Stop phases (null) | 14 | 9 | 11 | |

| Durations | Stop (s) | 280 | 226 | 210 |

| Constant driving (s) | 475 | 66 | 114 | |

| Acceleration (s) | 247 | 789 | 624 | |

| Deceleration (s) | 178 | 719 | 588 | |

| Shares | Stop (%) | 23.7 | 12.6 | 13.7 |

| Constant driving (%) | 40.3 | 3.7 | 7.4 | |

| Acceleration (%) | 20.9 | 43.8 | 40.6 | |

| Deceleration (%) | 15.1 | 39.9 | 38.3 | |

| Dynamic | Mean positive acceleration (m/s2) | 0.59 | 0.41 | 0.55 |

| Max positive acceleration (m/s2) | 1.04 | 1.67 | 3.25 | |

| Mean positive “vel * acc” (acceleration phases) (m2/s3) | 4.97 | 4.54 | 4.56 | |

| Max positive “vel * acc” (m2/s) | 9.22 | 21.01 | 29.29 | |

| Mean deceleration (m/s2) | −0.82 | −0.45 | −0.58 | |

| Min deceleration (m/s2) | −1.39 | −1.50 | −4.78 | |

| Relative positive acceleration (m/s3) | 0.111 | 0.153 | 0.271 | |

| Electricity Consumption (kWh/100 km) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vehicle Class | Case Study | NEDC | WLTP | ALDC | ||||||||||||

| Reference | 5% Lightweight | 10% Lightweight | 15% Lightweight | 20% Lightweight | Reference | 5% Lightweight | 10% Lightweight | 15% Lightweight | 20% Lightweight | Reference | 5% Lightweight | 10% Lightweight | 15% Lightweight | 20% Lightweight | ||

| A/B | 1 | 11.2 | 11.0 | 10.8 | 10.7 | 10.5 | 13.3 | 13.1 | 12.9 | 12.8 | 12.6 | 9.6 | 9.3 | 9.0 | 8.7 | 8.4 |

| 2 | 12.4 | 12.2 | 12.0 | 11.7 | 11.5 | 14.8 | 14.5 | 14.2 | 14.0 | 13.7 | 11.6 | 11.2 | 10.8 | 10.4 | 10.0 | |

| 3 | 13.5 | 13.3 | 13.0 | 12.7 | 12.5 | 15.7 | 15.4 | 15.2 | 14.9 | 14.6 | 13.1 | 12.6 | 12.1 | 11.7 | 11.2 | |

| C | 4 | 12.1 | 11.9 | 11.6 | 11.4 | 11.1 | 14.3 | 14.0 | 13.7 | 13.4 | 13.1 | 12.1 | 11.6 | 11.2 | 10.7 | 10.3 |

| 5 | 15.1 | 14.8 | 14.6 | 14.3 | 14.1 | 18.3 | 18.0 | 17.7 | 17.4 | 17.2 | 13.2 | 12.7 | 12.3 | 11.8 | 11.4 | |

| 6 | 13.5 | 13.2 | 12.9 | 12.6 | 12.3 | 15.9 | 15.6 | 15.3 | 15 | 14.7 | 13.3 | 12.8 | 12.3 | 11.8 | 11.3 | |

| 7 | 13.8 | 13.5 | 13.2 | 12.9 | 12.6 | 15.9 | 15.6 | 15.3 | 14.9 | 14.6 | 13.8 | 13.2 | 12.7 | 12.2 | 11.6 | |

| D/E | 8 | 14.2 | 13.8 | 13.4 | 13.0 | 12.7 | 16.1 | 15.7 | 15.3 | 14.9 | 14.5 | 15.7 | 15.1 | 14.4 | 13.8 | 13.2 |

| 9 | 17.6 | 17.2 | 16.8 | 16.4 | 16.0 | 20.5 | 20.0 | 19.6 | 19.1 | 18.7 | 20.4 | 19.6 | 18.9 | 18.1 | 17.4 | |

| 10 | 18.7 | 18.2 | 17.7 | 17.2 | 16.7 | 21.8 | 21.2 | 20.7 | 20.2 | 19.7 | 23.3 | 22.3 | 21.5 | 20.6 | 19.7 | |

| Case Study | Materials | Technologies | ΔGWPProd+EoL (GWPRef − GWPLight) (kg CO2 eq) | ΔMlight (MRef − MLight) (kg) | |

|---|---|---|---|---|---|

| FM | Reference | Aluminum; steel | Stamping and bending; deep drawing | 130.2 | −13.1 |

| Lightweight | Aluminum; high-strength steel; PA410 Carbon Fiber reinforced; steel | Extrusion and forming; thermoforming; airborne winding; deep drawing and drilling; bending | |||

| FH | Reference | Steel | Stamping and bending | 71.6 | −5.1 |

| Lightweight | Aluminum; epoxy resin Carbon Fiber reinforced | Metal stamping; compression molding | |||

| FD | Reference | Steel; aluminum | Stamping and bending | 83.9 | −1.4 |

| Lightweight | Aluminum; Polyamide410 Carbon Fiber reinforced | Metal stamping; CF-airborne; thermoforming | |||

| CDB | Reference | Steel | Stamping and bending | 11.5 | −4.3 |

| Lightweight | Aluminum; Polyamide410 Carbon/Glass Fiber reinforced | Metal stamping; injection molding; thermoforming | |||

| SA | Reference | Steel | Forging | 19.0 | −2.2 |

| Lightweight | Aluminum; Vinyl Ester Carbon Fiber/reinforced | Forging; advanced sheet compression molding | |||

| Reference car model | Volkswagen e-Golf Mass = 1440 (kg) Power = 100 (kW) Power-to-mass ratio = 69 (W/kg) | ||||

| Break-Even Point (BEP) (km) | ||||||

|---|---|---|---|---|---|---|

| Electricity Grid Mix | Driving Cycle | Modules | ||||

| FM | FH | FD | CDB | SA | ||

| NO | NEDC | 6,005,141 | 8,468,388 | 35,432,544 | 1,623,002 | 5,252,987 |

| WLTP | 5,541,154 | 7,814,078 | 32,694,849 | 1,497,601 | 4,847,115 | |

| ALDC | 3,446,079 | 4,859,625 | 20,333,137 | 931,368 | 3,014,452 | |

| EU28 | NEDC | 438,837 | 618,844 | 2,589,301 | 118,604 | 383,872 |

| WLTP | 404,930 | 571,029 | 2,389,239 | 109,440 | 354,212 | |

| ALDC | 251,829 | 355,126 | 1,485,883 | 68,061 | 220,287 | |

| PL | NEDC | 183,843 | 259,254 | 1,084,743 | 49,687 | 160,817 |

| WLTP | 169,639 | 239,223 | 1,000,930 | 45,848 | 148,391 | |

| ALDC | 105,499 | 148,774 | 622,485 | 28,513 | 92,285 | |

| Break-Even Point (BEP) (km) | |||||||

|---|---|---|---|---|---|---|---|

| Electricity Grid Mix | Driving Cycle | Modules | |||||

| FM | FH | SA | |||||

| M = 1250 kg | M = 1650 kg | M = 1250 kg | M = 1650 kg | M = 1250 kg | M = 1650 kg | ||

| NO | NEDC | 6,250,466 | 5,931,622 | 8,814,343 | 8,364,712 | 5,467,585 | 5,188,676 |

| WLTP | 5,789,971 | 5,466,963 | 8,164,958 | 7,709,456 | 5,064,768 | 4,782,217 | |

| ALDC | 3,655,753 | 3,384,774 | 5,155,305 | 4,773,174 | 3,197,864 | 2,960,826 | |

| EU28 | NEDC | 456,765 | 433,465 | 644,125 | 611,267 | 399,554 | 379,173 |

| WLTP | 423,113 | 399,509 | 596,670 | 563,383 | 370,118 | 349,470 | |

| ALDC | 267,151 | 247,349 | 376,734 | 348,809 | 233,690 | 216,368 | |

| PL | NEDC | 191,354 | 181,592 | 269,845 | 256,080 | 167,386 | 158,848 |

| WLTP | 177,256 | 167,367 | 249,964 | 236,020 | 155,054 | 146,404 | |

| ALDC | 111,918 | 103,622 | 157,826 | 146,127 | 97,900 | 90,644 | |

References

- Intergovernmental Panel on Climate Change. Climate Change 2014: Impacts, Adaptation, and Vulnerability; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014; Volume 1. [Google Scholar]

- U.S. Environmental Protection Agency. DRAFT Inventory of U.S. Greenhouse Gas. Emissions and Sinks: 1990−2016; U.S. Environmental Protection Agency: Washington, DC, USA, 2018.

- Intergovernmental Panel on Climate Change. Climate Change 2013: The Physical Science Basis, Working Group I Contribution to the Fifth Assessment; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Mashayekh, Y.; Jaramillo, P.; Samaras, C.; Hendrickson, C.T.; Blackhurst, M.; MacLean, H.L.; Matthews, H.S. Potentials for sustainable transportation in cities to alleviate climate change impacts. Environ. Sci. Technol. 2012, 46, 2529–2537. [Google Scholar] [CrossRef] [PubMed]

- Milovanoff, A.; Kim, H.C.; De Kleine, R.; Wallington, T.J.; Posen, I.D.; MacLean, H.L. A Dynamic Fleet Model of U.S Light-Duty Vehicle Lightweighting and Associated Greenhouse Gas Emissions from 2016 to 2050. Environ. Sci. Technol. 2019, 53, 2199–2208. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Palencia, J. Energy use and CO2 emissions reduction potential in passenger car fleet using zero emission vehicles and lightweight materials. Energy 2012, 48, 548–565. [Google Scholar] [CrossRef]

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Das, S.; Graziano, D.; Upadhyayula, V.K.K.; Masanet, E.; Riddle, M.; Cresko, J. Vehicle lightweighting energy use impacts in U.S. light-duty vehicle fleet. Sustain. Mater. Technol. 2016, 8, 5–13. [Google Scholar] [CrossRef]

- Luk, J.; Kim, H.C.; De Kleine, R.; Wallington, T.J.; MacLean, H. Impact of powertrain type on potential life cycle greenhouse gas emission reduction from a real world lightweight glider. SAE Tech. Pap. Ser. 2017, 1–8. [Google Scholar] [CrossRef]

- Modaresi, R.; Pauliuk, S.; Løvik, A.N.; Muller, D.B. Global Carbon Benefits of Material Substitution in Passenger Cars until 2050 and the Impact on the Steel and Aluminum Industries. Environ. Sci. Technol. 2014, 48, 10776–10784. [Google Scholar] [CrossRef]

- Koffler, C.; Rodhe-Branderburger, K. On the calculation of fuel savings through lightweight design in automotive life cycle assessments. Int. J. Life Cycle Assess. 2010, 15, 128–135. [Google Scholar] [CrossRef]

- Sah, S.; Bawase, M.; Saraf, M. Light-weight Materials and their Automotive Applications. SAE Tech. Pap. 2014, 28, 25. [Google Scholar] [CrossRef]

- Ferreira, V. Lightweight automotive components based on nano-diamond-reinforced aluminium alloy: A technical and environmental evaluation. Diam. Relat. Mater. 2019, 2019, 92. [Google Scholar]

- Mayyas, A.T.; Qattawi, A.; Mayyas, A.R.; Omar, M.A. Life cycle assessment based selection for a sustainable lightweight body-in-white design. Energy 2012, 39, 412–425. [Google Scholar] [CrossRef]

- Poulikidou, S.; Jerpdal, L.; Bjorklund, A.; Åkermo, M. Environmental performance of self-reinforced composites in automotive applications. Case study on a heavy truck component. Mater. Des. 2016, 103, 321–329. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life-Cycle Energy and Greenhouse Gas Emission Benefits of Lightweighting in Automobiles: Review and Harmonization. Environ. Sci. Technol. 2013, 47, 6089–6097. [Google Scholar] [CrossRef]

- Lewis, A.M.; Kelly, J.C.; Keoleian, G.A. Vehicle lightweighting vs. electrification: Life cycle energy and GHG emissions results for diverse powertrain vehicles. Appl. Energy 2014, 126, 13–20. [Google Scholar] [CrossRef]

- Egede, P. Environmental Assessment of Lightweight Electric Vehicles; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Alonso, E.; Lee, T.M.; Bjelkengren, C.; Roth, R.; Kirchain, R.E. Evaluating the Potential for Secondary Mass Savings in Vehicle Lightweighting. Environ. Sci. Technol. 2012, 46, 2893–2901. [Google Scholar] [CrossRef] [PubMed]

- Egede, P. Sustainable Production, Life Cycle Engineering and Management. In Environmental Assessment of Lightweight Electric Vehicles, 1st ed.; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Vinodh, S.; Jayakrishna, K. Environmental impact minimisation in an automotive component using alternative materials and manufacturing processes. Mater. Des. 2011, 32, 5082–5090. [Google Scholar] [CrossRef]

- Raugei, M.; Morrey, D.; Hutchinson, A.; Winfield, P. A coherent life cycle assessment of a range of lightweighting strategies for compact vehicles. J. Clean. Prod. 2015, 108, 1168–1176. [Google Scholar] [CrossRef]

- Weimar, E.; Finkbeiner, M. Statistical analysis of empirical lifetime mileage data for automotive LCA. Int. J. Life Cycle Assess. 2016, 21, 215–223. [Google Scholar] [CrossRef]

- Bian, J.; Mohrbacher, H.; Zhang, J.S.; Zhao, Y.T.; Lu, H.Z.; Dong, H. Application potential of high performance steels for weight reduction and efficiency increase in commercial vehicles. Adv. Manuf. 2015, 3, 27–36. [Google Scholar] [CrossRef]

- Faßbender, S.; Broöckerhoff, D.E.; Eckstein, L.; Hartmann, B.; Urban, P. Investigation of the Trade-Off between Lightweight and Battery Cost for an Aluminum-Intensive Electric Vehicle; Report 106330; Forschungsgesellschaft Kraftfahrwesen mbH Aachen: Aachen, Germany, 2012. [Google Scholar]

- Schuh, G.; Korthals, K.; Backs, M. Environmental Impact of Body Lightweight Design in the Operating Phase of Electric Vehicles. In Proceedings of the 20th CIRP International Conference on Life Cycle Engineering, Singapore, 17–19 April 2013; Springer: Singapore. [Google Scholar]

- Wilhelm, E.; Hofer, J.; Schenler, W.; Guzzella, L. Optimal implementation of lightweighting and powertrain efficiency in passengers’ vehicles. Transport 2012, 27, 237–249. [Google Scholar] [CrossRef]

- Pagerit, S.; Sharer, P.; Rousseau, A. Fuel Economy Sensitivity to Vehicle Mass for Advanced Vehicle Powertrains. SAE Tech. Pap. 2006, 1, 665. [Google Scholar]

- Ridge, L. EUCAR—Automotive LCA Guidelines—Phase 2. SAE Tech. Pap. 1998. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. New Fuel Economy and Environment Labels for a New Generation of Vehicles; EPA-420-F-11-017; United States Environmental Protection Agency: Washington, DC, USA, 2011.

- Muttana, S.B.; Sardar, A. Lightweighting of Battery Electric Cars: An Impact Analysis Using Indian Driving Cycle. SAE Tech. Pap. Ser. 2013. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J.; Sullivan, J.L.; Keoleian, G.A. Life cycle assessment of vehicle lightweighting: Novel mathematical methods to estimate use-phase fuel consumption. Environ. Sci. Technol. 2015, 49, 10209–10216. [Google Scholar] [CrossRef]

- Kelly, J.C.; Sullivan, J.L.; Burnham, A.; Elgowainy, A. Impacts of vehicle weight reduction via material substitution on life-cycle greenhouse gas emissions. Environ. Sci. Technol. 2015, 49, 12535–12542. [Google Scholar] [CrossRef]

- Hofer, J.; Wilhelm, E.; Schenler, W. Comparing the mass, energy, and cost effects of lightweighting in conventional and electric passenger vehicles. J. Sustain. Dev. Energy Water Environ. Syst. 2014, 2, 284–295. [Google Scholar] [CrossRef]

- Del Pero, F.; Delogu, M.; Pierini, M. The effect of lightweighting in automotive LCA perspective: Estimation of mass-induced fuel consumption reduction for gasoline turbocharged vehicles. J. Clean. Prod. 2017, 154, 566–577. [Google Scholar] [CrossRef]

- Delogu, M.; Del Pero, F.; Pierini, M. Lightweight design solutions in the automotive field: Environmental modelling based on Fuel Reduction Value applied to diesel turbocharged vehicles. Sustainability 2016, 8, 1167. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life cycle assessment of vehicle lightweighting: A physics-based model of mass-induced fuel consumption. Environ. Sci. Technol. 2013, 47, 14358–14366. [Google Scholar] [CrossRef]

- An, F.; Santini, D.J. Mass Impacts on Fuel Economies of Conventional vs. Hybrid Electric Vehicles. In Proceedings of the SAE World Congress, Detroit, MI, USA, 8−11 March 2004. [Google Scholar]

- Redelbach, M.; Klotzke, M.; Friedrich, H.E. Impact of Lightweight Design on Energy Consumption and Cost Effectiveness of Alternative Powertrain Concepts. In Proceedings of the European Vehicle Congress (EEVC), Brussel, Belgium, 19–22 November 2012. [Google Scholar]

- Casadei, A.; Broda, R. Impact of Vehicle Weight Reduction on Fuel Economy for Various Vehicle Architectures; Project FB769; Ricardo Inc.: Shoreham-by-Sea, UK, 2008. [Google Scholar]

- Wohlecker, R.; Johannaber, M.; Espig, M. Determination of Weight Elasticity of Fuel Economy for ICE, Hybrid and Fuel Cell Vehicles. SAE Tech. Pap. 2007, 1, 343. [Google Scholar]

- U.S. Environmental Protection Agency. Light-Duty Automotive Technology, Carbon Dioxide Emissions, and Fuel Economy Trends: 1975 through 2016; U.S. Environmental Protection Agency: Washington, DC, USA, 2016.

- Carlson, R.; Lohse-Busch, H.; Diez, J.; Gibbs, J. The measured impact of vehicle mass on road load forces and energy consumption for a BEV, HEV and ICE vehicle. SAE Int. J. Altern. Powertrains 2013, 2, 105–114. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life Cycle Assessment of Vehicle Lightweighting: A Physics-Based Model to Estimate Use-Phase Fuel Consumption of Electrified Vehicles. Environ. Sci. Technol. 2016, 50, 11226–11233. [Google Scholar] [CrossRef] [PubMed]

- Luk, J.M.; Kim, H.C.; De Kleine, R.; Wallington, T.J.; MacLean, H.L. Review of the Fuel Saving, Life Cycle GHG Emission, and Ownership Cost Impacts of Lightweighting Vehicles with Different Powertrains. Environ. Sci. Technol. 2017, 51, 8215–8228. [Google Scholar] [CrossRef] [PubMed]

- Mathworks. Available online: https://it.mathworks.com (accessed on 5 July 2020).

- Argonne National Laboratory. GREET 2015 Model. In Transportation Research and Analysis Computing Center; Argonne National Laboratory: Argonne, IL, USA, 2015. [Google Scholar]

- Berzi, L.; Delogu, M.; Pierini, M. A comparison of electric vehicles use-case scenarios: Application of a simulation framework to vehicle design optimization and energy consumption assessment. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; pp. 1–6. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory Future Automotive Systems Technology Simulator (FASTSim). Available online: http://www.nrel.gov/transportation/fastsim.html (accessed on 10 July 2020).

- Burress, T.; Campbell, S. Benchmarking EV and HEV power electronics and electric machines. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 16–19 June 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Barlow, T.J.; Latham, S.; McCrae, I.S.; Boulter, P.G. A Reference Book of Driving Cycles for Use in the Measurement of Road Vehicle Emissions; TRL: Berks, UK, 2009. [Google Scholar]

- Marotta, A.; Tutuianu, M. Europe-centric light duty test cycle and differences with respect to the WLTP cycle. In European Commission—Joint Research Centre—Scientific and Policy Reports; Publications Office of the European Union: Brussels, Belgium, 2012. [Google Scholar]

- ASTERICS Project. Available online: https://egvi.eu/research-project/asterics/ (accessed on 15 July 2020).

- Berzi, L.; Delogu, M.; Pierini, M. Development of driving cycles for electric vehicles in the context of the city of Florence. Transp. Res. Part D Transp. Environ. 2016, 47, 299–322. [Google Scholar] [CrossRef]

- World Auto Steel. Future Steel Vehicle Overview Report; World Auto Steel: Brussels, Belgium, 2011. [Google Scholar]

- Cubito, C.; Millo, F.; Boccardo, G.; Di Pierro, G.; Ciuffo, B.; Fontaras, G.; Serra, S.; Otura Garcia, M.; Trentadue, G. Impact of Different Driving Cycles and Operating Conditions on CO2 Emissions and Energy Management Strategies of a Euro-6 Hybrid Electric Vehicle. Energies 2017, 10, 1590. [Google Scholar] [CrossRef]

- Weiss, M.B.P.; Hummel, R.; Steininger, N. A complementary emissions test for light—Duty vehicels: Assessing the technical feasibility of candidate procedures. JRC Sci. Policy Rep. 2013. [Google Scholar] [CrossRef]

- Mock, P.; Kulhwein, J.; Tietge, U.; Franco, V.; Bandivadekar, A.; German, J. The WLTP: How a New Test Procedure for Cars will Affect Fuel Consumption Values in the EU; Working paper; The International Council on Clean Transportation (ICCT): Washington, DC, USA, 2014. [Google Scholar]

- Fontaras, G.; Ciuffo, B.; Zacharofa, N.; Tsiakmakisa, S.; Marotta, S.; Pavlovica, J.; Anagnostopoulosa, K. The difference between reported and real-world CO2 emissions: How much improvement can be expected by WLTP introduction? Transp. Res. Procedia 2017, 25, 3933–3943. [Google Scholar] [CrossRef]

- Delogu, M.; Zanchi, L.; Dattilo, C.A.; Pierini, M. Innovative composites and hybrid materials for electric vehicles lightweight design in a sustainability perspective. Mater. Today Commun. 2017, 13, 192–209. [Google Scholar] [CrossRef]

| ERV (kWh/(100 km × 100 kg) | IRV (kg CO2 eq/(100 km × 100 kg)) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vehicle Class | Case Study | NEDC | WLTP | ALDC | NO Grid Mix | EU28 Grid Mix | PL Grid Mix | ||||||

| NEDC | WLTP | ALDC | NEDC | WLTP | ALDC | NEDC | WLTP | ALDC | |||||

| A/B | 1 | 0.47 | 0.49 | 0.77 | 0.01 | 0.01 | 0.02 | 0.20 | 0.20 | 0.32 | 0.47 | 0.49 | 0.76 |

| 2 | 0.55 | 0.60 | 0.96 | 0.02 | 0.02 | 0.03 | 0.23 | 0.25 | 0.40 | 0.55 | 0.60 | 0.95 | |

| 3 | 0.54 | 0.59 | 0.95 | 0.02 | 0.02 | 0.03 | 0.22 | 0.25 | 0.40 | 0.54 | 0.59 | 0.94 | |

| C | 4 | 0.52 | 0.57 | 0.89 | 0.02 | 0.02 | 0.03 | 0.22 | 0.24 | 0.37 | 0.52 | 0.57 | 0.88 |

| 5 | 0.52 | 0.57 | 0.90 | 0.02 | 0.02 | 0.03 | 0.22 | 0.24 | 0.37 | 0.52 | 0.57 | 0.89 | |

| 6 | 0.53 | 0.58 | 0.91 | 0.02 | 0.02 | 0.03 | 0.22 | 0.24 | 0.38 | 0.53 | 0.58 | 0.90 | |

| 7 | 0.57 | 0.61 | 0.99 | 0.02 | 0.02 | 0.03 | 0.24 | 0.25 | 0.41 | 0.57 | 0.61 | 0.98 | |

| D/E | 8 | 0.58 | 0.62 | 1.01 | 0.02 | 0.02 | 0.03 | 0.24 | 0.26 | 0.42 | 0.58 | 0.62 | 1.00 |

| 9 | 0.61 | 0.67 | 1.13 | 0.02 | 0.02 | 0.03 | 0.25 | 0.28 | 0.47 | 0.61 | 0.67 | 1.12 | |

| 10 | 0.63 | 0.69 | 1.17 | 0.02 | 0.02 | 0.04 | 0.26 | 0.29 | 0.49 | 0.63 | 0.69 | 1.16 | |

| A/B Class | C Class | D/E Class | All Classes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | Maximum | Range Max–Min | Arithmetic Mean | Minimum | Maximum | Range Max–Min | Arithmetic Mean | Minimum | Maximum | Range Max–Min | Arithmetic Mean | Minimum | Maximum | Range Max–Min | Arithmetic Mean | Standard Deviation | |||

| ERV (kWh/(100 km × 100 kg)) | NEDC | 0.47 | 0.55 | 0.08 | 0.52 | 0.52 | 0.57 | 0.05 | 0.54 | 0.58 | 0.63 | 0.05 | 0.61 | 0.47 | 0.63 | 0.16 | 0.55 | 0.05 | |

| WLTP | 0.49 | 0.60 | 0.11 | 0.56 | 0.57 | 0.61 | 0.04 | 0.58 | 0.62 | 0.69 | 0.07 | 0.66 | 0.49 | 0.69 | 0.20 | 0.60 | 0.06 | ||

| ALDC | 0.77 | 0.96 | 0.19 | 0.89 | 0.89 | 0.99 | 0.10 | 0.92 | 1.01 | 1.17 | 0.16 | 1.10 | 0.77 | 1.17 | 0.40 | 0.97 | 0.12 | ||

| IRV (kg CO2 eq/(100 km × 100 kg)) | NO | NEDC | 0.01 | 0.02 | 0.01 | 0.02 | 0.02 | 0.02 | 0.01 | 0.02 | 0.02 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 |

| WLTP | 0.01 | 0.02 | 0.01 | 0.02 | 0.02 | 0.02 | 0.01 | 0.02 | 0.02 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | ||

| ALDC | 0.02 | 0.03 | 0.01 | 0.03 | 0.03 | 0.03 | 0.01 | 0.03 | 0.03 | 0.04 | 0.01 | 0.03 | 0.02 | 0.04 | 0.01 | 0.03 | 0.01 | ||

| EU28 | NEDC | 0.20 | 0.23 | 0.03 | 0.22 | 0.22 | 0.24 | 0.02 | 0.22 | 0.24 | 0.26 | 0.02 | 0.25 | 0.20 | 0.26 | 0.07 | 0.23 | 0.02 | |

| WLTP | 0.20 | 0.25 | 0.05 | 0.23 | 0.24 | 0.25 | 0.02 | 0.24 | 0.26 | 0.29 | 0.03 | 0.27 | 0.20 | 0.29 | 0.08 | 0.25 | 0.02 | ||

| ALDC | 0.32 | 0.40 | 0.08 | 0.37 | 0.37 | 0.41 | 0.04 | 0.38 | 0.42 | 0.49 | 0.07 | 0.46 | 0.32 | 0.49 | 0.17 | 0.40 | 0.05 | ||

| PL | NEDC | 0.47 | 0.55 | 0.08 | 0.52 | 0.52 | 0.57 | 0.05 | 0.53 | 0.58 | 0.63 | 0.05 | 0.60 | 0.47 | 0.63 | 0.16 | 0.55 | 0.05 | |

| WLTP | 0.49 | 0.60 | 0.11 | 0.56 | 0.57 | 0.61 | 0.04 | 0.58 | 0.62 | 0.69 | 0.07 | 0.66 | 0.49 | 0.69 | 0.20 | 0.59 | 0.06 | ||

| ALDC | 0.76 | 0.95 | 0.19 | 0.89 | 0.88 | 0.98 | 0.10 | 0.92 | 1.00 | 1.16 | 0.16 | 1.10 | 0.76 | 1.16 | 0.40 | 0.96 | 0.12 | ||

| ERV (kWh/(100 km × 100 kg)) | |||

|---|---|---|---|

| NEDC | WLTP | ALDC | |

| ERVNEDC = 1.0 × 10−4 M + 0.3825 | ERVWLTP = 1.0 × 10−4 M + 0.3979 | ERVALDC = 3.0 × 10−4 M + 0.5363 | |

| IRV (kg CO2 eq/(100 km × 100 kg)) | |||

| NEDC | WLTP | ALDC | |

| NO | IRVNO_NEDC = 3.0 × 10−6 M + 0.0116 | IRVNO_WLTP = 4.0 × 10−6 M + 0.0121 | IRVNO_ALDC = 9.0 × 10−6 M + 0.0163 |

| EU28 | IRVEU28_NEDC = 4.7 × 10−5 M + 0.1591 | IRVEU28_WLTP = 5.6 × 10−5 M + 0.1655 | IRVEU28_ALDC = 1.2 × 10−4 M + 0.2231 |

| PL | IRVPL_NEDC = 1.1 × 10−4 M + 0.3798 | IRVPL_WLTP = 1.3 × 10−4 M + 0.3951 | IRVPL_ALDC = 2.8 × 10−4 M + 0.5326 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Pero, F.; Berzi, L.; Antonacci, A.; Delogu, M. Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles. Machines 2020, 8, 51. https://doi.org/10.3390/machines8030051

Del Pero F, Berzi L, Antonacci A, Delogu M. Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles. Machines. 2020; 8(3):51. https://doi.org/10.3390/machines8030051

Chicago/Turabian StyleDel Pero, Francesco, Lorenzo Berzi, Andrea Antonacci, and Massimo Delogu. 2020. "Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles" Machines 8, no. 3: 51. https://doi.org/10.3390/machines8030051

APA StyleDel Pero, F., Berzi, L., Antonacci, A., & Delogu, M. (2020). Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles. Machines, 8(3), 51. https://doi.org/10.3390/machines8030051