1. Introduction

An impeller is the main rotating component of a centrifugal pump. Usually, it is composed of blades and a hub, with its main function being the transfer of energy from the motor to the working fluid. Impeller blades are composed of a suction surface, a leading edge, and a pressure surface. In the relevant literature, it can be observed that there are more than 120 varieties of impellers [

1,

2]. The design and manufacturing stages of a pump impeller should comply with three separate, but equally important requirements. At first, the impeller should provide an appropriate relative velocity distribution on both the pressure and suction surfaces of the blade in order to minimize the possibility of flow separation and efficiency reduction. Moreover, the blade shape must be selected in a way that it can be manufactured with adequate precision and with relatively low cost on a computer numerical control (CNC) machine tool. Finally, the blade should be safe regarding its mechanical strength, thus reducing the possibility of excessive deformation or even fracture during its operation [

3,

4].

Machining of complex 3D geometries has been a topic of interest for several decades as it constitutes a demanding process. Such geometries are usually encountered in the aircraft industry, surgical prostheses, components with optical characteristics, and automotive and electronics industries, among others. In the manufacturing process of complex parts, one of the most important subjects is the tool path patterns, as they determine how the cutting tool processes the surfaces, whether the paths are well-planned, and if efficiency and surface quality can be increased. In the case of impellers, several works have been conducted during the past few decades. Young and Chuang [

5] were among the first to investigate the feasibility of machining of impellers on five-axis machine tools in order to overcome common problems arising when machining complex parts on three-axis machine tools, such as possibility of collision and overcut, and at the same time maintain a reasonable machining time. Thus, they designed a detailed algorithm for tool-path generation dividing the machining area into two regions, namely the blades and the hub; they successfully verified the results in simulation software and conducted a detailed analysis of machining error based on comparison with the original geometry as well. Kaino [

6] presented various methods for machining of large impellers on five-axis machining centers. He underlined the main difficulties of machining impeller blades such as the constant change of cutting depth and cutting resistance, low machine tool stiffness for rotary axes, and chattering, and proposed using a special technique for the improvement of machining efficiency, adopting contour machining, and employing a tool with variable pitch and lead angle.

The majority of scientific work on impeller manufacturing was concentrated on efficient tool-path generation strategies or optimization of the milling strategies in respect to various indicators. Wu et al. [

7] studied the effect of integral impeller stiffness on the machining process in order to determine the optimum machining path. An open impeller was machined in a five-axis vertical machining center and, for the measurements, a single blade was selected. Afterwards, the stiffness matrix of the blade in respect to other parts of the system was created and its performance relevant to the cutter movements was evaluated and validated with experiments in order to determine the optimum feed direction, reduce vibrations, and improve dimensional accuracy. Fan and Xi [

8] proposed an adaptive method for the optimization of tool-path during three-axis machining of impeller blades. Their method included the division of the blade surface into four sub-surfaces after their geometry is mathematically defined, and then the tool-paths were generated using an optimization algorithm, also taking in consideration the fluid flow requirements for the impeller. They stated that, using the proposed approach, machining costs can be reduced, tool-path generation is simplified, and geometrical characteristics are in accordance with computational fluid dynamics (CFD) analysis requirements.

Fan et al. [

9] developed a novel tool-path generation method for the case of centrifugal impellers with arbitrary surface blades using the flank milling technique. They noted that, although the point machining technique was usually used for arbitrary surfaces, it could be beneficial to combine this technique with features of flank machining in order to increase the accuracy of geometrical characteristics of the blades. Thus, they modeled the arbitrary blade as an approximate ruled blade and applied the flank machining method for rough and semi-finish machining. Finally, they concluded that this approach led to the reduction of machining time by reduction of the path-line length. Li et al. [

10] developed a method for smooth machining of ruled-surface blades represented by third-order non-uniform rational basis spline (NURBS) curves. After creating the computer-aided design (CAD) model of the blades, the machining process was programmed and verified in a CNC machine tool. Their findings indicate that the CAD model using NURBS required fewer points than other types of surfaces; the adopted interpolation method led to smoother and more precise trajectories with lower machining error. Fan and Xi [

11] presented also a new tool-path generation method for special cases of machining centrifugal impellers. At first, they noticed that the commonly employed isoparametric method for tool-path generation was not sufficient, as it led to an increase in machining time. The proposed method was based on the generation of a new type of machining layers of the final geometry and was able to produce sparser tool-paths with a shorter length, something that simplified the calculation process of the tool path curves and increased the efficiency of the machining process.

Tang et al. [

2] presented an interesting study about the tool-path generation during the clean-up stage of the impeller machining process. In order to be able to remove the unwanted material remaining after the finishing process in some regions, they developed a method related to point-searching for determining the appropriate tool paths and implemented it on computer-aided manufacturing (CAM) software to test its feasibility. Their findings showed that the method is efficient in planning the appropriate tool-paths for the clean-up process in a simple way and led to rapid and accurate determination of the clean-up regions. Fan et al. [

12] created a novel strategy of five-axis machining of centrifugal impellers based on regional milling for both roughing and finishing stages. Specifically, this approach can combine favorable features of both flank and sub-surface machining methods. For the roughing stage, the objective was to choose a cutter with relatively large diameter and achieve the shortest path length, whereas for the finishing stage, owing to the fluid flow requirements, interlinking of tool path curves in some regions as well as reduction of tool interference should be achieved. Finally, machining efficiency during roughing by reducing the required time and better distribution of machining errors along with increased aerodynamic efficiency during finishing was achieved.

Wang et al. [

13] presented a multi-parameter optimization study regarding the manufacturing of an axial impeller in a five-axis machining center. They introduced a cost-effective method for machining parameters optimization based on absolute average error and standard deviation of online measured points using grey relational theory to define a single objective optimization problem with three variables, namely, the length to diameter ratio, depth of cut, and feed rate. Arriaza et al. [

14] conducted a study regarding the compromise between machining time and energy consumption during rough machining of impellers. In their work, they conducted an optimization using the response surface methodology with four input variables, namely, spindle speed, feed rate, depth and width of cut, and two responses (consumed energy and machining time). Their findings indicated that the selection of an appropriate feed rate value can lead to reduction of the necessary spindle speed as well as the depth and width of cut; spindle speed was found to be the most important factor for controlling energy consumption and width of cut was the most important factor regarding machining time.

Chaves-Jacob et al. [

15] presented a numerical method for the optimization of the finishing process for the five-axis machining of impeller blades. In their work, they focused both on geometric and cost indicators and compared point milling and flank milling strategies using these indicators for the case of an industrial impeller. They proposed that this method can be employed to determine the optimum strategy in other cases of complex workpieces. Peng et al. [

16] compared different methods for fabrication of impellers such as conventional manufacturing, additive manufacturing, and remanufacturing, regarding their environmental impact. More specifically, they employed plunge milling, laser cladding forming, and additive remanufacturing techniques, and then a life cycle analysis was conducted for them. It was shown that remanufacturing was the better choice, followed by additive manufacturing and conventional manufacturing. However, the pure additive manufacturing processes can sometimes be less environmentally friendly than the conventional ones, owing to increased power and material consumption.

Young et al. [

17] further investigated the roughing strategies for five-axis impeller machining in order to develop a methodology especially suited for the efficient roughing of centrifugal impellers by taking into consideration the appropriate depths of cut required, the residual material thickness and surface conditions on the tool path, and the control of step-over. Tang et al. [

18] investigated the effect of the use of a varying feed rate during machining of blades in a four-axis machining center. They noted that the use of constant feed rate on four-axis machining centers results in overcutting near the leading and trailing edges of the blade, and thus they determined the appropriate lead angle and speed of each axis to overcome this problem. By controlling the lead angle, they achieved the avoidance of collisions and, by imposing limitations on the feed speed and acceleration, overcut was also avoided and precision was improved for the produced blade. Heo et al. [

19] proposed an efficient method for roughing of impellers in the case of five-axis CNC machine tools. At first, they noticed that, owing to more complex control requirements for five-axis machines, the required time for roughing was increased compared with that for three-axis machines. Thus, they developed a novel method for machining the impeller by dividing it into various unit machining regions, where machining would be performed in a similar way as in three-axis machines using a repetitive procedure. This can be achieved by fixing the rotating and tilting axes of the machine bed and then, by maintaining the cutting tool at a suitable inclination angle in respect to the blade surface, it was ensured that no collision would happen as well. Kim et al. [

20] also proposed a method for the machining of impellers by integrating techniques applied to three-axis and five-axis machines in order to reducing roughing time. They noted that five-axis machines require long machining times for producing a single product, although they can avoid collisions more easily than three-axis machines. Their approach involved two distinct steps: a first step of three-axis machining and a final step of full five-axis machining for the completion of the roughing process. The method was applied to both a splitter and non-splitter type impeller and it was shown that, in both cases, the tool-path was shorter and total machining time was reduced by 17% and 11%, respectively.

From the aforementioned studies in the relevant literature, it can be concluded that the majority of works regarding impeller manufacturing have focused on the generation of optimum tool-paths and optimization of process parameters for different machining phases. However, works on manufacturing of radial impellers were somewhat limited, as well as the studies on optimum finishing conditions using high spindle speed values. Thus, in the present work, it is intended to present a detailed study on the manufacturing of a radial pump impeller, beginning with the design of required machining operations, their actual implementation, and the evaluation of surface quality of the radial impeller after conducting an investigation regarding the optimum finishing conditions.

2. Methodology

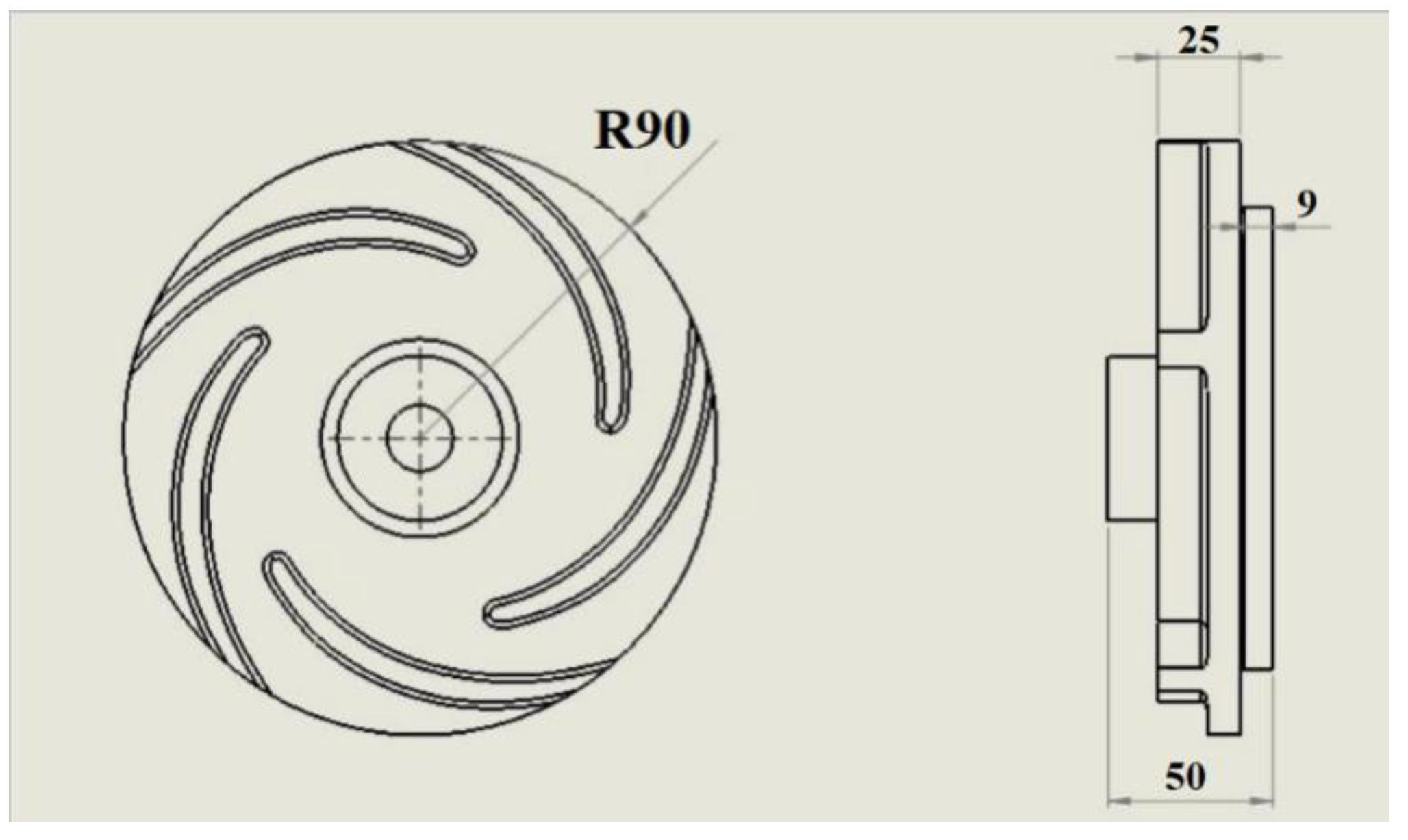

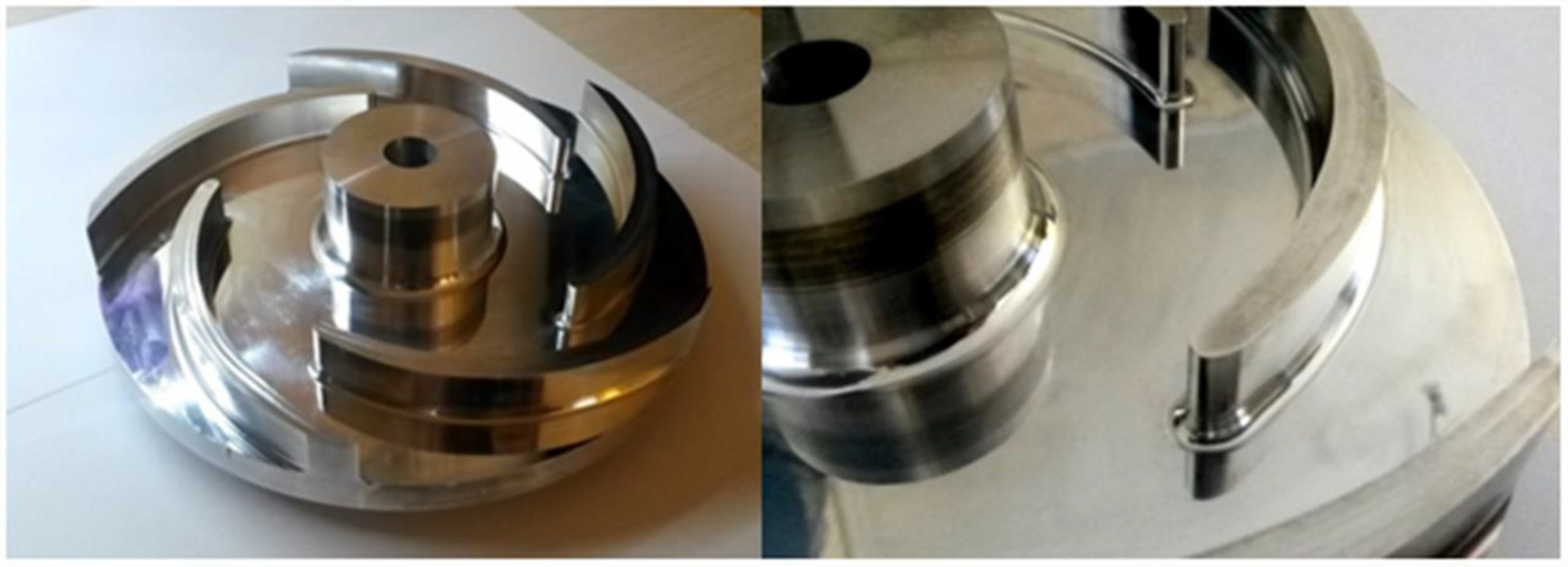

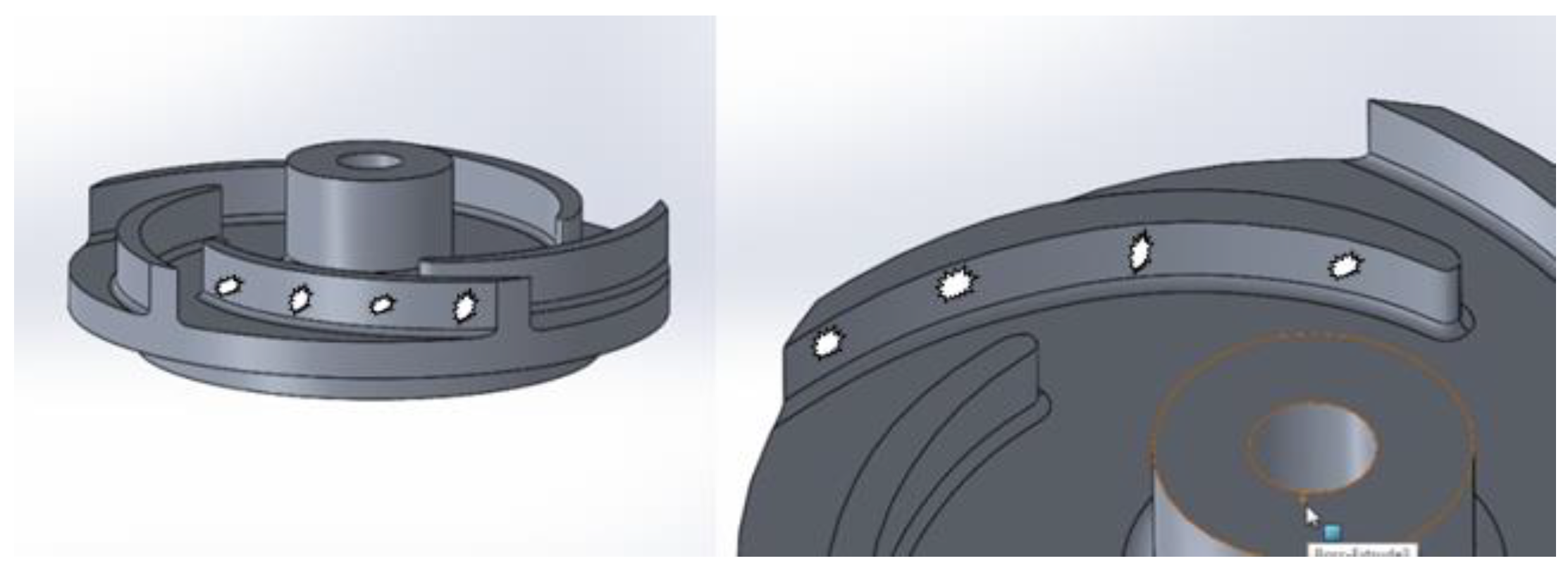

After the initial design of the appropriate geometry of the radial impeller, illustrated in

Figure 1, as well as its evaluation regarding its aerodynamic characteristics, which were investigated in a previous study [

21], the manufacturing of the actual impeller was able to be conducted. The design of the machining process of the radial impeller, which includes complex geometries, is essential to be conducted using specialized CAM software, such as NX CAM, which can be accessed through Siemens NX software. Some of the main challenges regarding the machining of complex geometries of the impeller blades or vanes and hub are the achievement of the required dimensional accuracy and surface quality, as well as the reduction of machining time. Apart from the use of cutting tools with a special geometry, the machining strategy needs to be carefully planned in order to achieve the desired geometrical features and suitable process parameters are required to be determined as well. Thus, all of these tasks need to be appropriately addressed by the use of CAM software in order to successfully perform the machining process of the impeller.

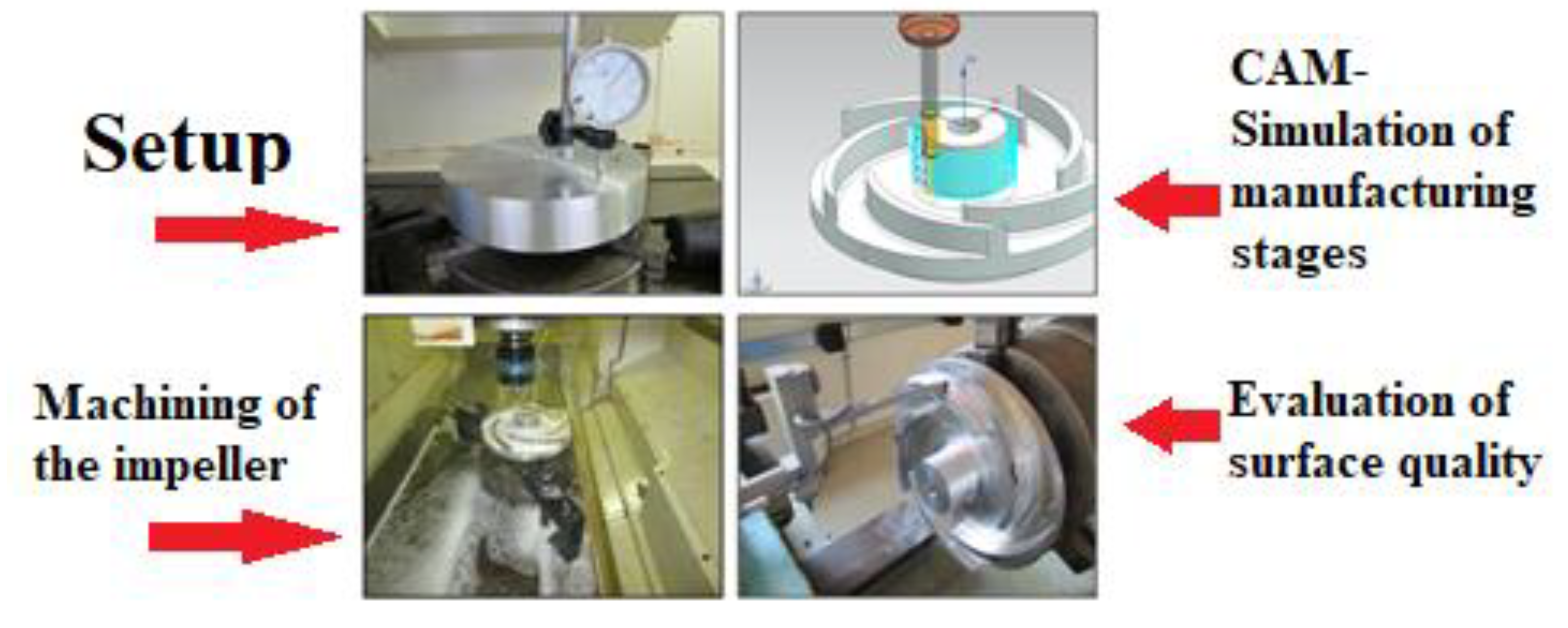

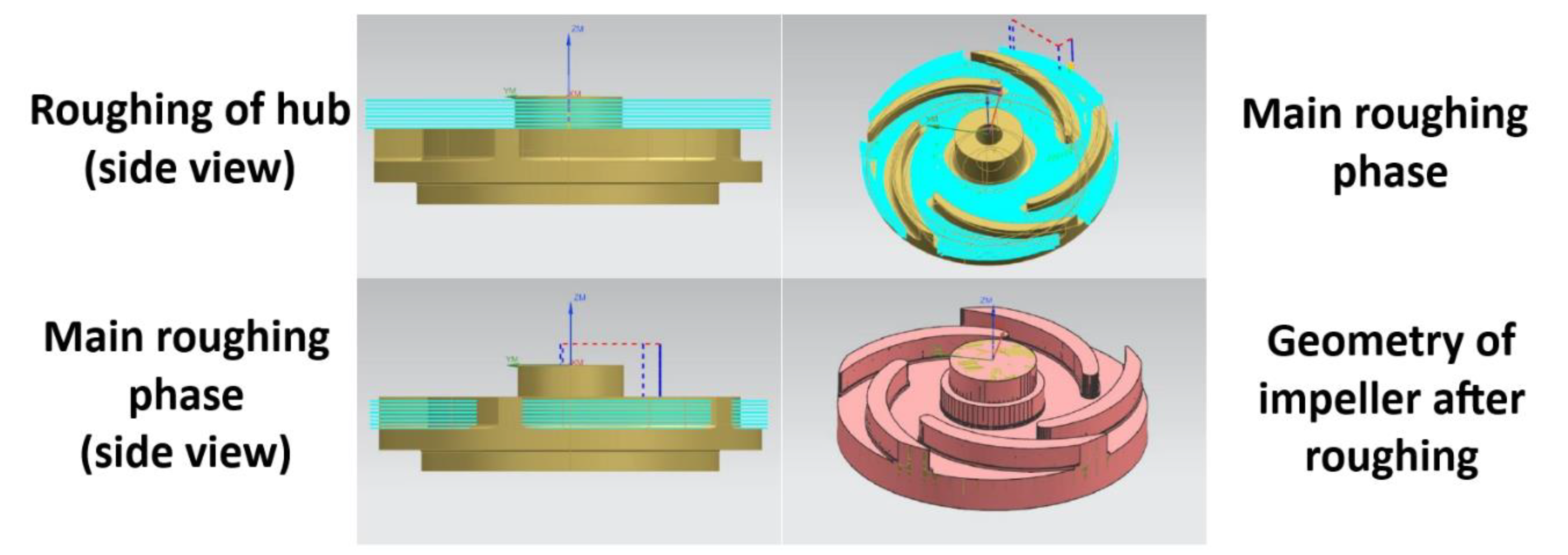

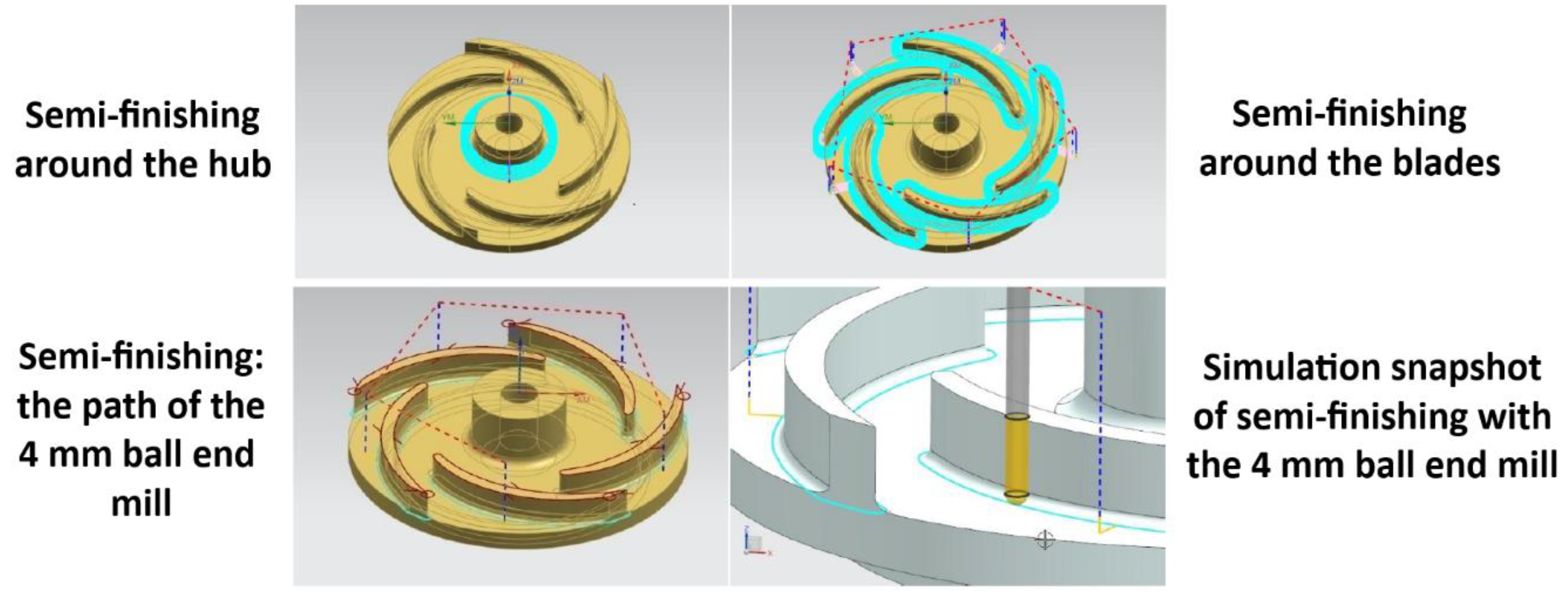

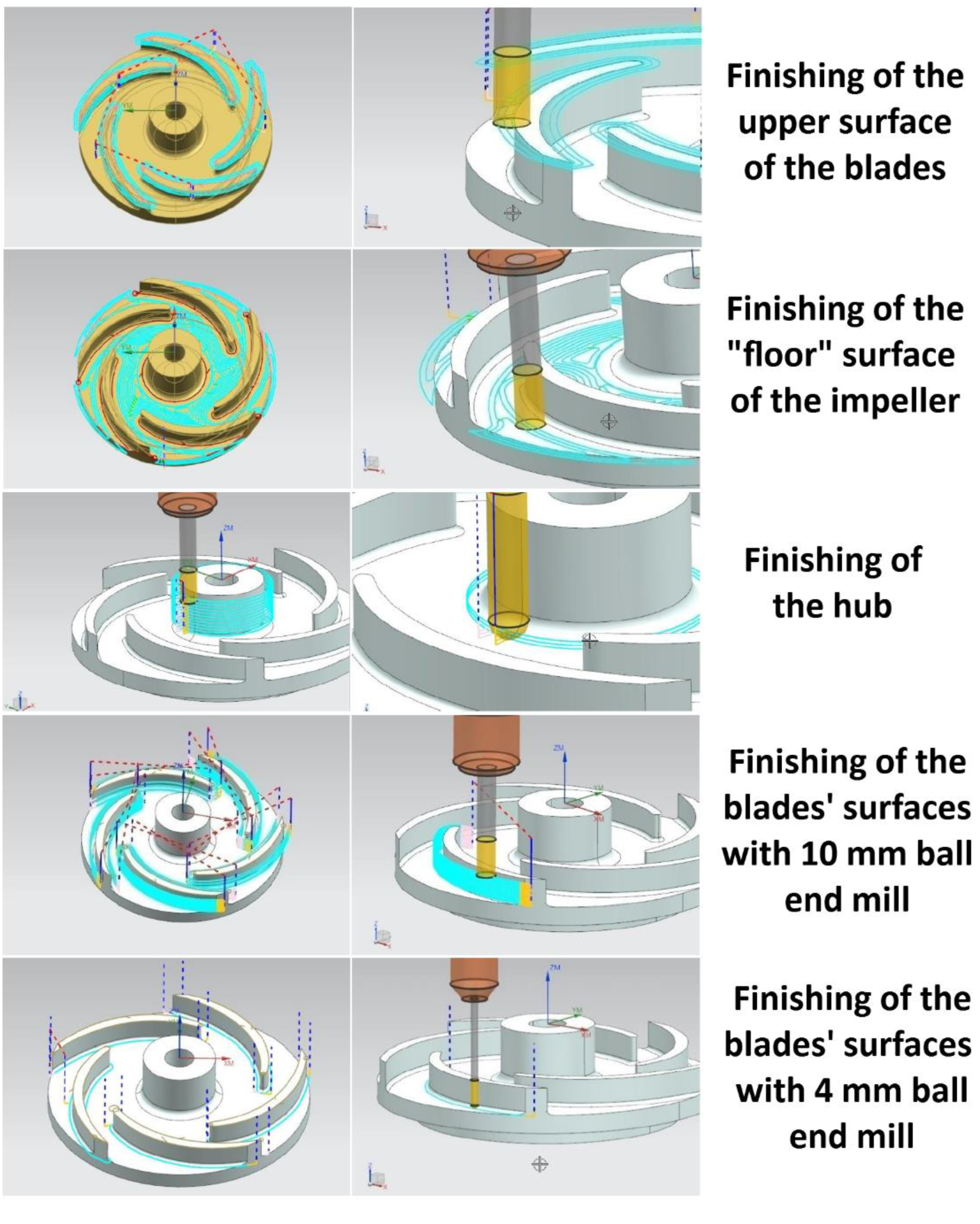

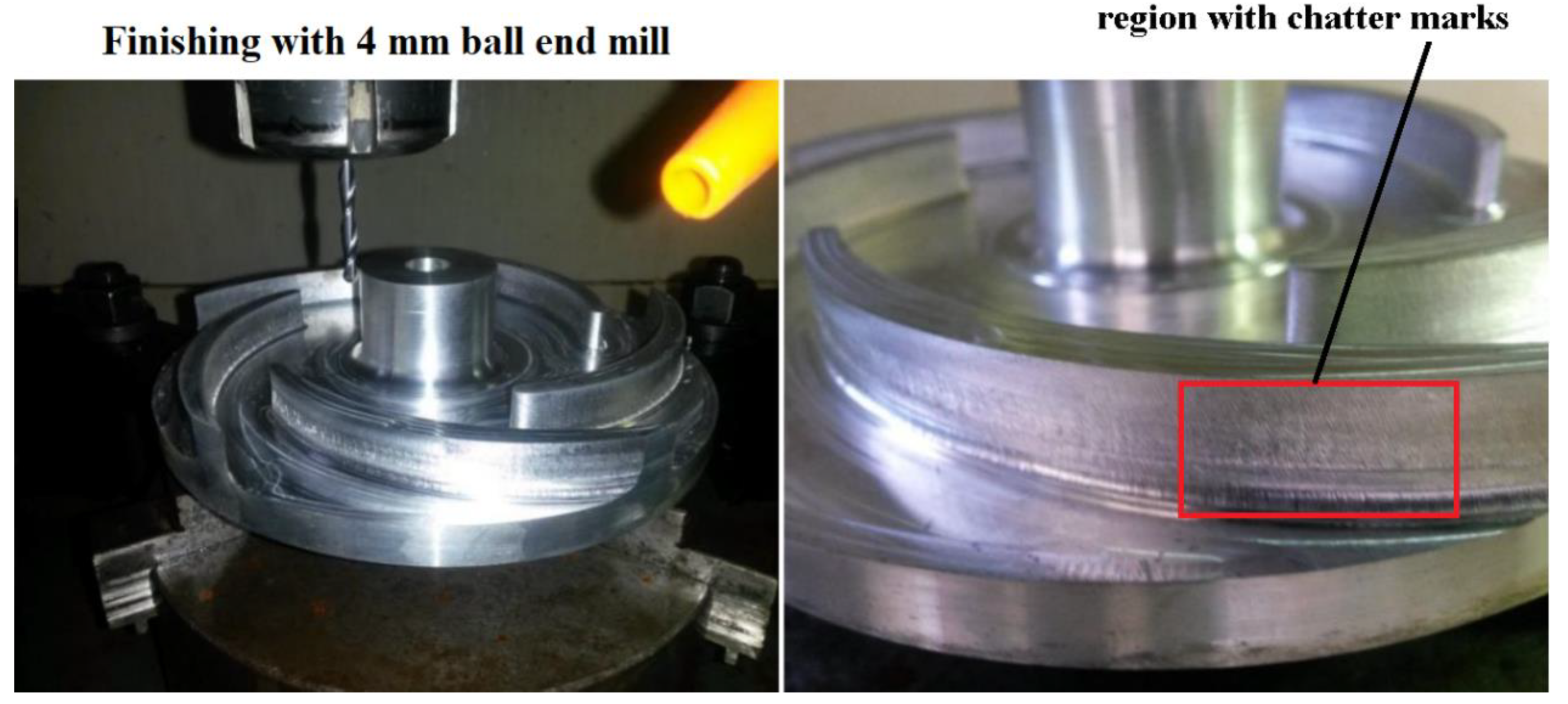

In the present work, the various stages of manufacturing of a radial pump impeller are presented in detail. At first, the machining processes required for the fabrication of the impeller are planned using dedicated CAM software. The manufacturing of the impeller is divided into three phases, namely, the roughing, semi-finishing, and finishing phase, and for each phase, the appropriate milling strategies, process parameters, cutting tools, and fixtures are determined, either using recommended values from manufacturers or the CAM software or by initial machining tests. After all phases are simulated in the environment of the CAM software, the appropriate G-code is produced and then the actual machining stage takes place in a three-axis vertical machining center. Finally, the manufactured impeller is evaluated according to its surface quality. Regarding the surface quality evaluation, a series of experiments is conducted under various spindle speed, axial depth of cut, and feed per tooth values in order to determine the optimum conditions for the finishing of the blades’ inner and outer surfaces. The stages of the manufacturing of the radial pump impeller are presented in a schematic in

Figure 2.

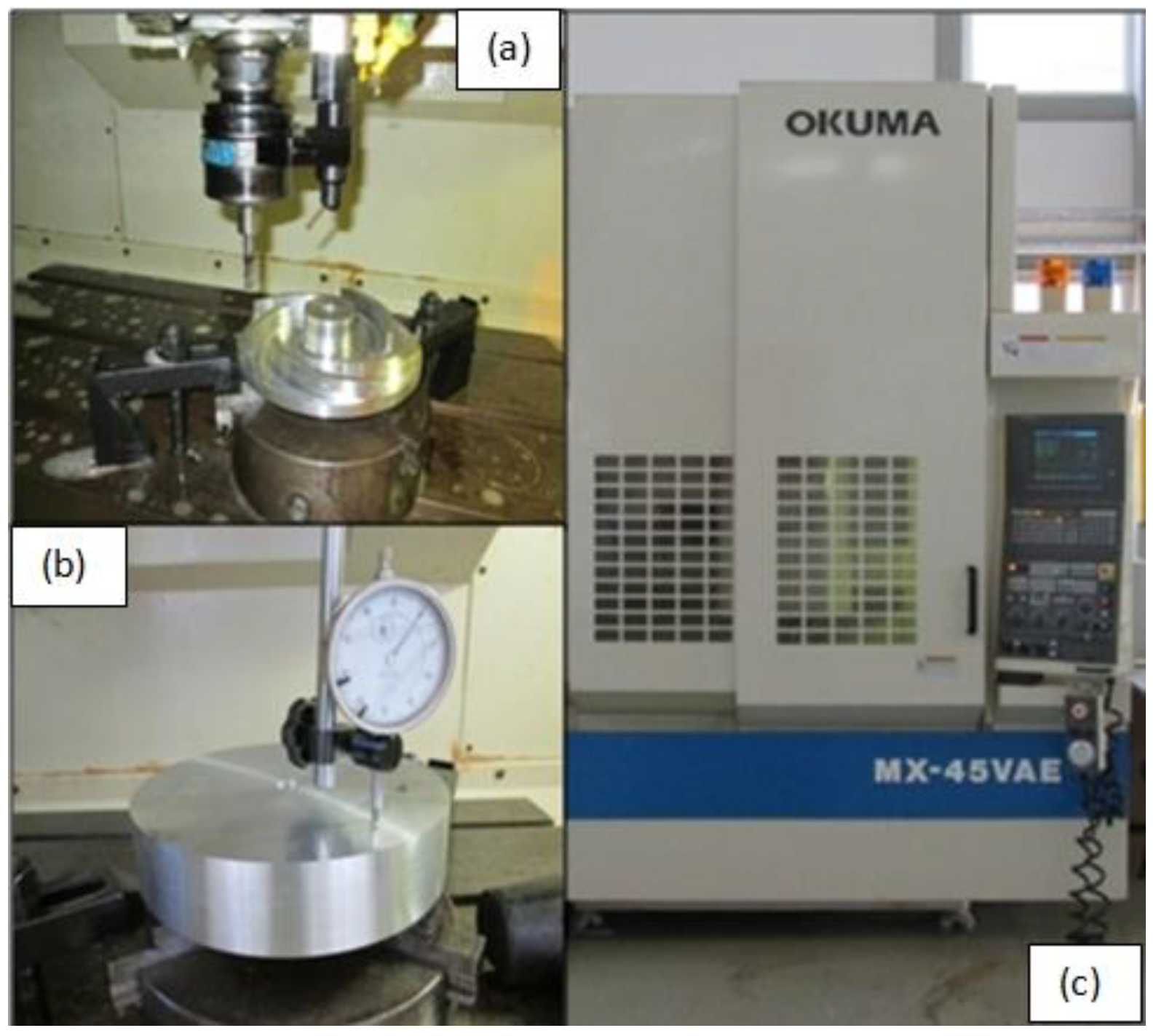

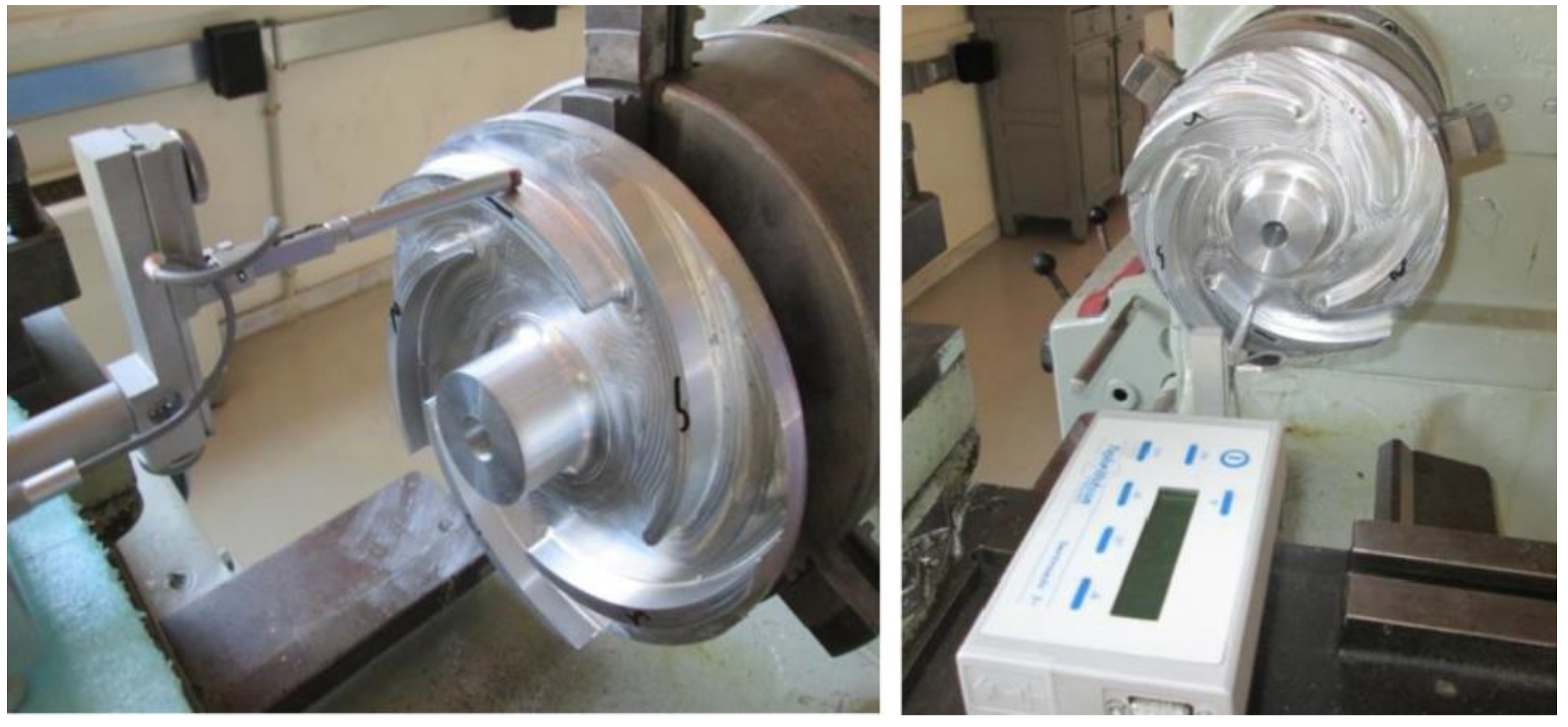

The manufacturing process of the radial pump impeller is carried out on a vertical CNC machining center; the CNC machining center, presented also in

Figure 3, is OKUMA MX-45 VAE with an OSP7000M control unit with three-axis, maximum power 7.5 kW, and 10 μm accuracy. For high speed machining, during some of the manufacturing phases of the impeller, a GERARDI GSS-10 spindle speeder was employed, with capabilities of achieving a six-fold increase of spindle speed using planetary gear mechanism. In order to fix the cutting tools on the tool holder when spindle speeder is used, ER16 type collets were employed.

As it will be explained in detail in

Section 3, four different cutting tools are employed in various phases of the machining process. The cutting tools are presented in

Figure 4 and their characteristics are summarized in

Table 1.

Cutting is performed under wet conditions by using P3 Multan S cutting fluid; this cutting fluid is semi-synthetic coolant mixed with water in a 1:3 ratio. Finally, the workpiece material for the radial impeller is Aluminum alloy 7075 (also denoted with the ISO name AlZn5.5MgCu). This aluminum alloy has zinc as the main alloying element and is of high strength and toughness, which is very frequently used in applications in the aviation industry [

22,

23]. It has low corrosion resistance with mechanical stress leading to brittle fracture—something that can be further treated with special heat treatments [

23]. It can also be hardened with precipitation after heat treatment of solubilization, quenching, and aging [

24]. The typical chemical composition of Al 7075 alloy is presented in

Table 2.

5. Conclusions

In the present work, the manufacturing process of a radial pump impeller is discussed and described, including the design of the manufacturing process, their implementation, and the evaluation of the machined product quality.

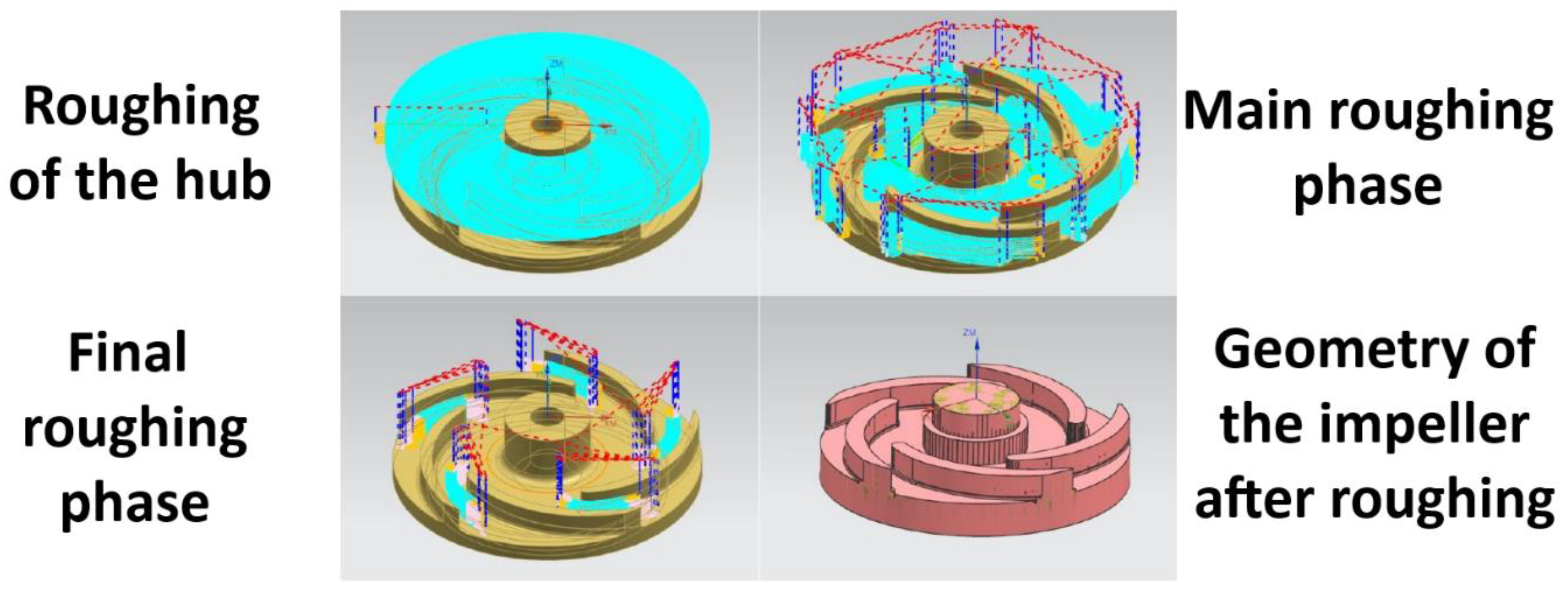

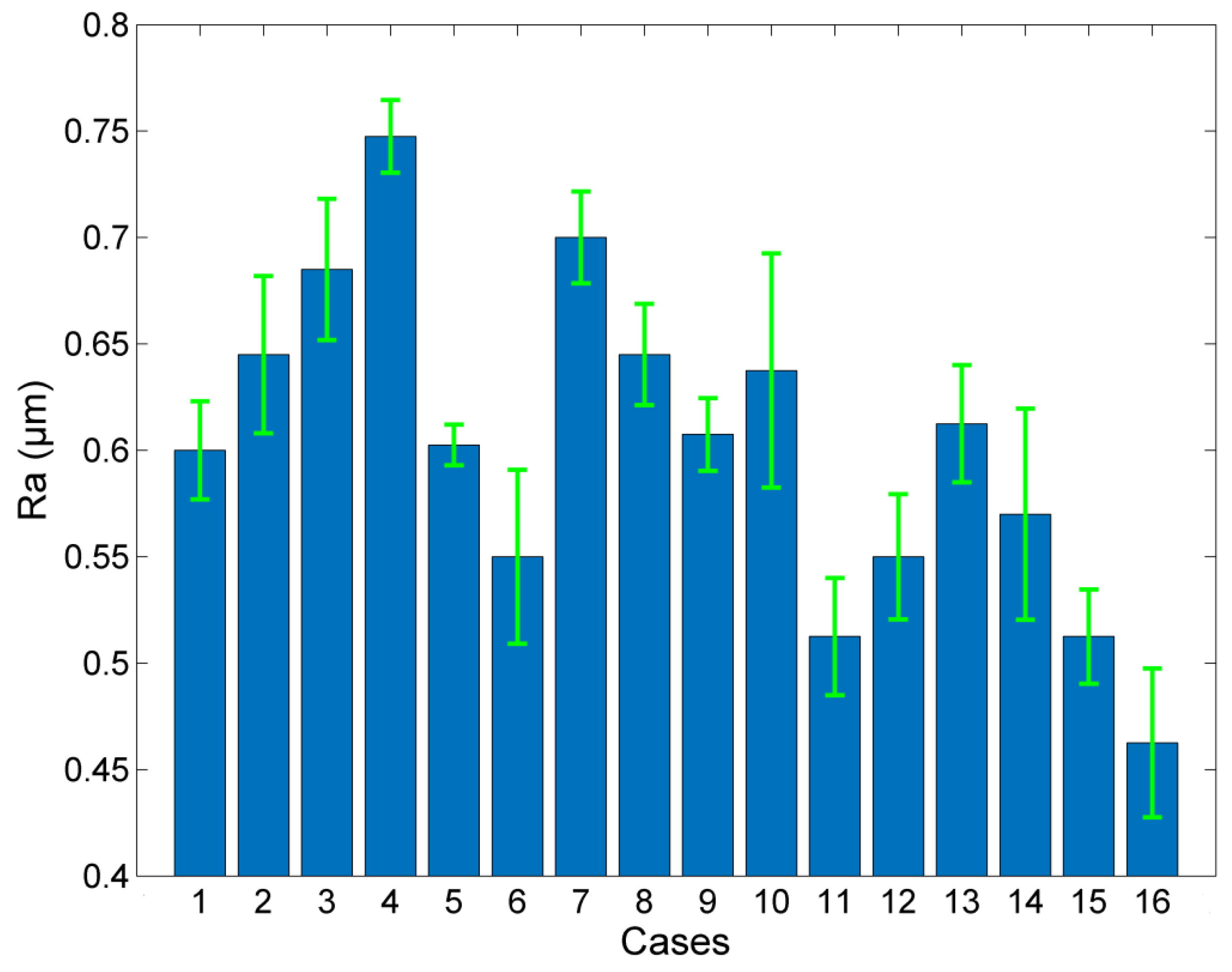

At first, the machining operations for the manufacture of the radial impeller are designed in NX CAM software. During the three main phases, namely, roughing, semi-finishing, and finishing, the milling strategies, cutting tools, and process conditions required are determined before the actual machining process is implemented in the vertical CNC machining center.

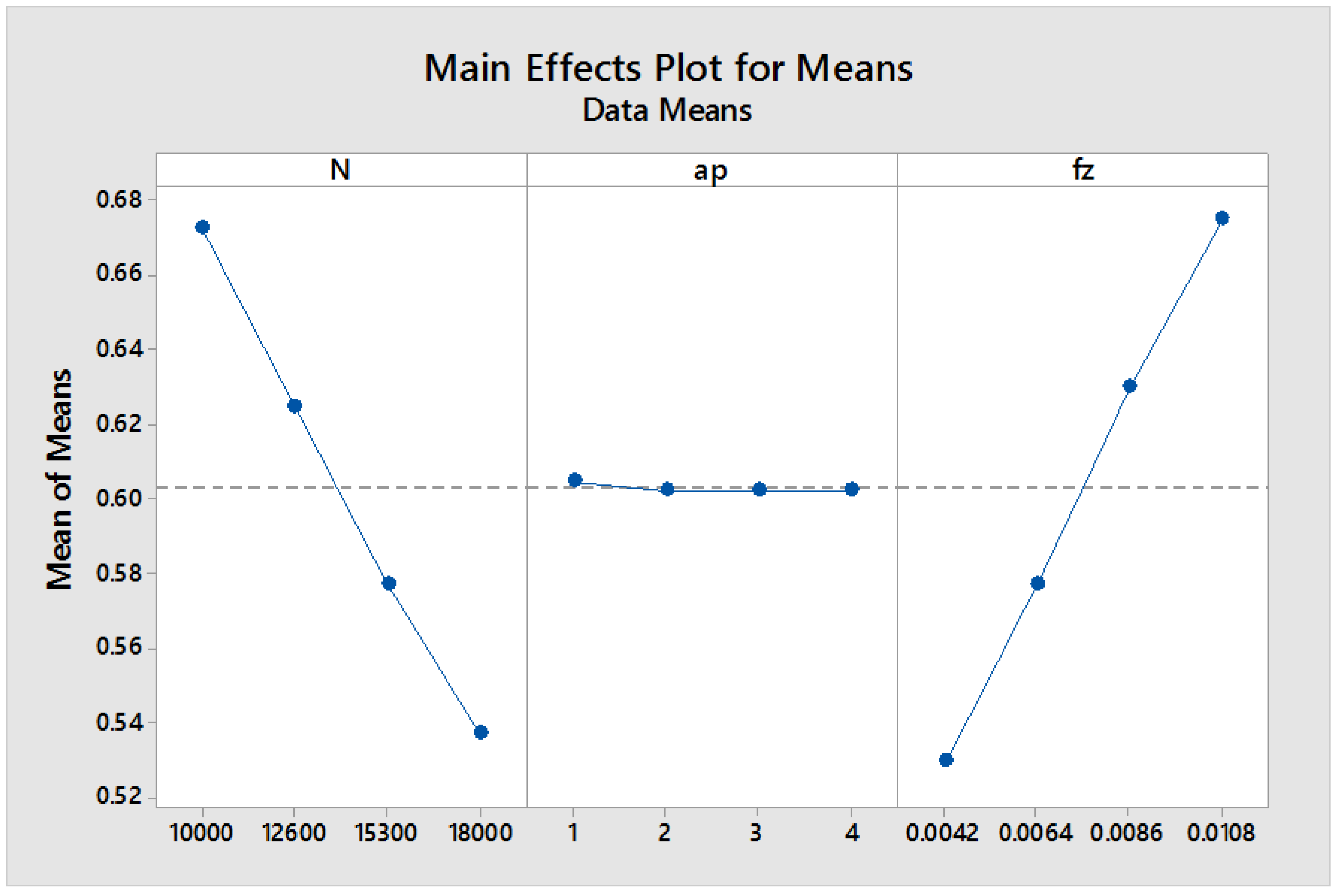

It was found that the follow periphery strategy, with a 10 mm diameter end mill with a spindle speed of 7000 rpm, feed rate of 2000 mm/min, and depth of cut of 2 mm, is the most favorable strategy during roughing, as it leads to lower machining time and minimal wear of the cutting edge. During the semi-finishing phase, the process conditions were altered in order to avoid chatter. Although when the 10 mm diameter end mill was used, the milling conditions were the same as in the design stage, namely spindle speed of 7000 rpm and feed rate of 500 mm/min, the milling conditions for the case of 4 mm diameter ball end cutting tool, the final values of spindle speed and feed rate were reduced considerably at 1200 rpm and 40 mm/min, respectively. Finally, the investigation regarding the optimum process conditions during finishing of the impeller blades, which was designed by L16 Taguchi orthogonal array, indicated that the spindle speed and feed per tooth are the most important parameters for the control of surface roughness, as anticipated, whereas the effect of axial depth of cut was insignificant. Spindle speed and feed per tooth were identified as the most important parameters. The recommended values for spindle speed, axial depth of cut, and feed per tooth determined from the investigation were 18,000 rpm, 4 mm, and 0.0042 mm/tooth, respectively, and it was shown that, in this case, the obtained surface roughness was as low as 0.46 μm. These results indicate the importance of the use of the spindle speeder, as it enabled a considerable decrease of surface roughness during the finishing process of the radial impeller.