Stating Diagnosis of Current State of Electric Furnace Transformer on the Basis of Analysis of Partial Discharges

Abstract

1. Introduction

2. Problem Statement

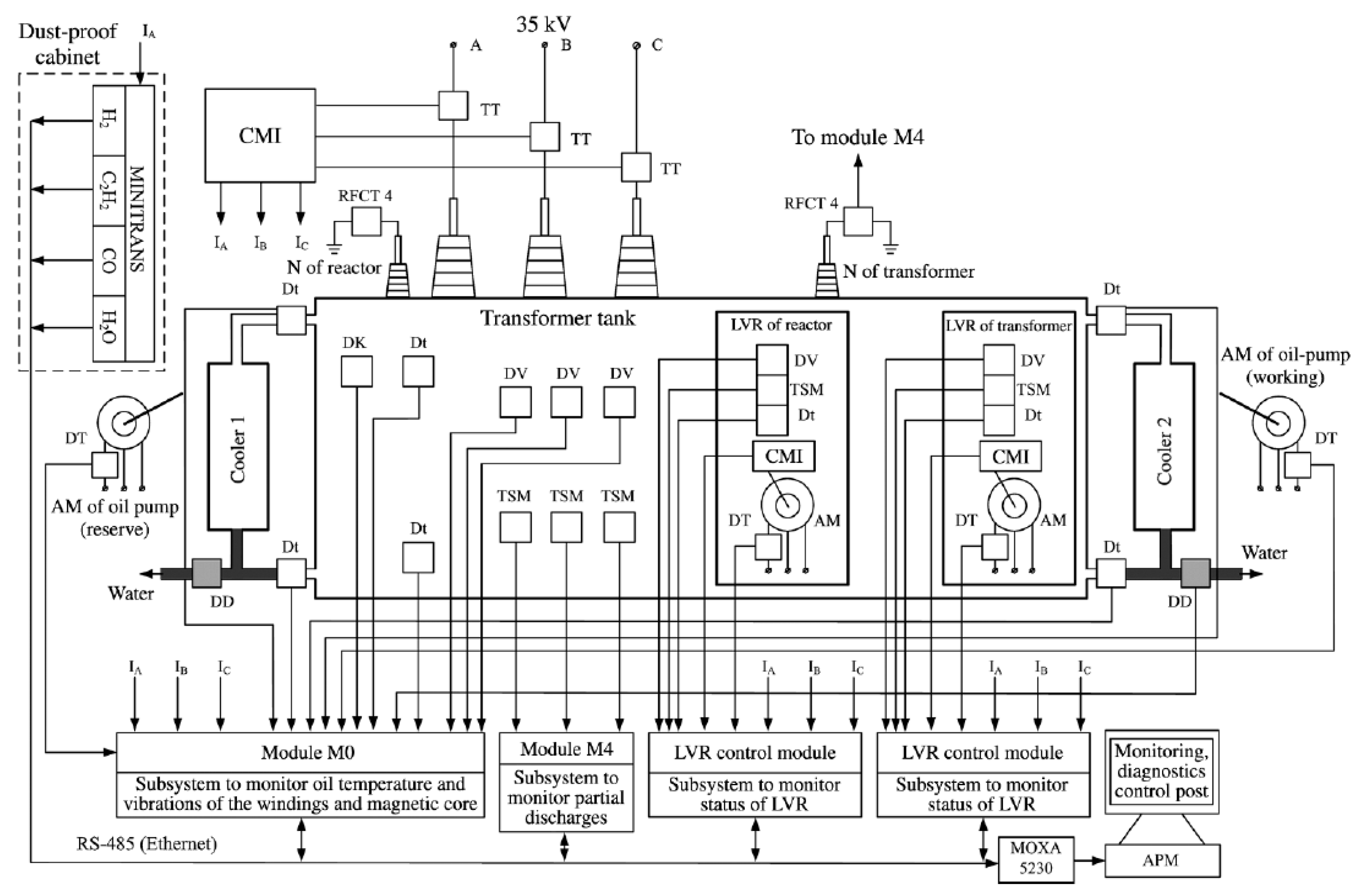

Characteristics of the Developed Monitoring System

- highest possible integration of all functions related to monitoring, control, and diagnosing the separate transformer subsystem into the single module;

- adding a module to or removing it from the system bears changes to functional capabilities of the system, but it does not have any impact on the capabilities of other modules;

- reconfiguring the operational algorithms of the entire monitoring system after changing the number of modules can be easily conducted through changing the configuration parameters;

- adding the new module to the system automatically connects it to the central monitoring module. Integration of data acquired from all the modules is conducted through the single digital and analog buses. Such a configuration allows for implementing the structure required for each object.

3. Materials and Methods

3.1. Partial Discharges (PD) Occurrence in the Transformer Insulation

3.2. Integral Properties of Partial Discharges

- Apparent Charge, Q02 (nC), proportional to max pulse amplitude. The operating system was set so that the duration of a pulse would be no longer than 640 ns, while during the consequent 2560 ns, there should be no pulses with the amplitude higher than 30% of the initial pulse. In case these conditions are not met, the pulse is considered a distorting action and not registered. Pulses of partial discharges are considered to be regularly repeating if their frequency equals to 0.2 of the pulse value per power network period. When registering partial discharges using almost all known devices, the amplitude (pulse voltage, U02 (mV)) is measured. The apparent charge is found by the following formula: Q02 = 10∙U02 (in relative units), which simplifies system configuration.

- Partial Discharge Power, in most cases presented in the form of PDI. This parameter characterizes the power and intensity of partial discharges, found by the following formula:where m stands for the number of pulses registered during observation time T; Ud—stands for the effective voltage.

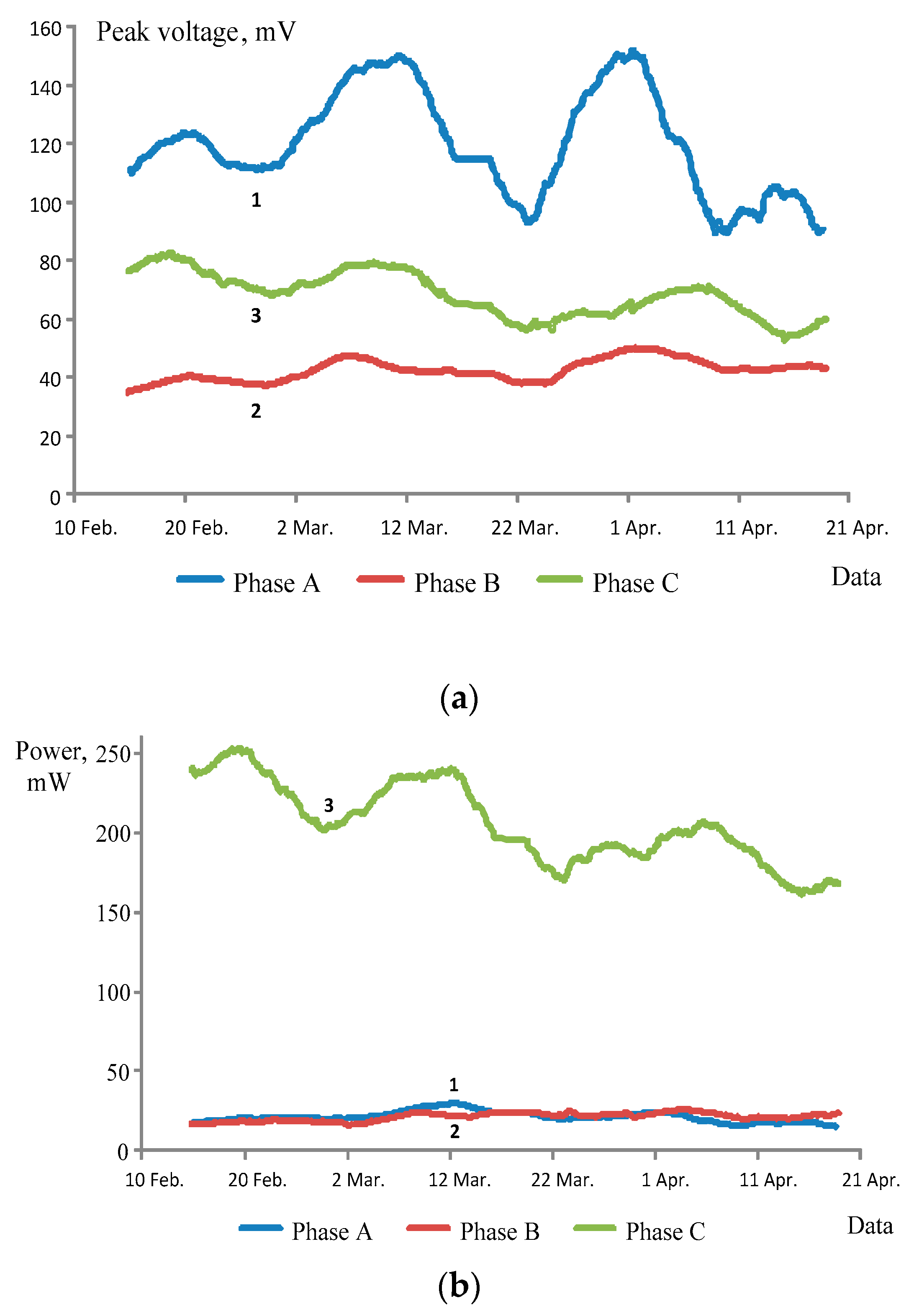

- Worsened State: Q02 > Qg1 = 2.5 nC, U02 > Ug1 = 80 mV; PDI > PDIg1 = 60 mW;

- Pre-Fault State: Q02 > Qg2 = 5 nC, U02 > Ug2 = 160 mV; PDI > PDIg2 = 80 mW.

4. Time-Series Data Processing Methods

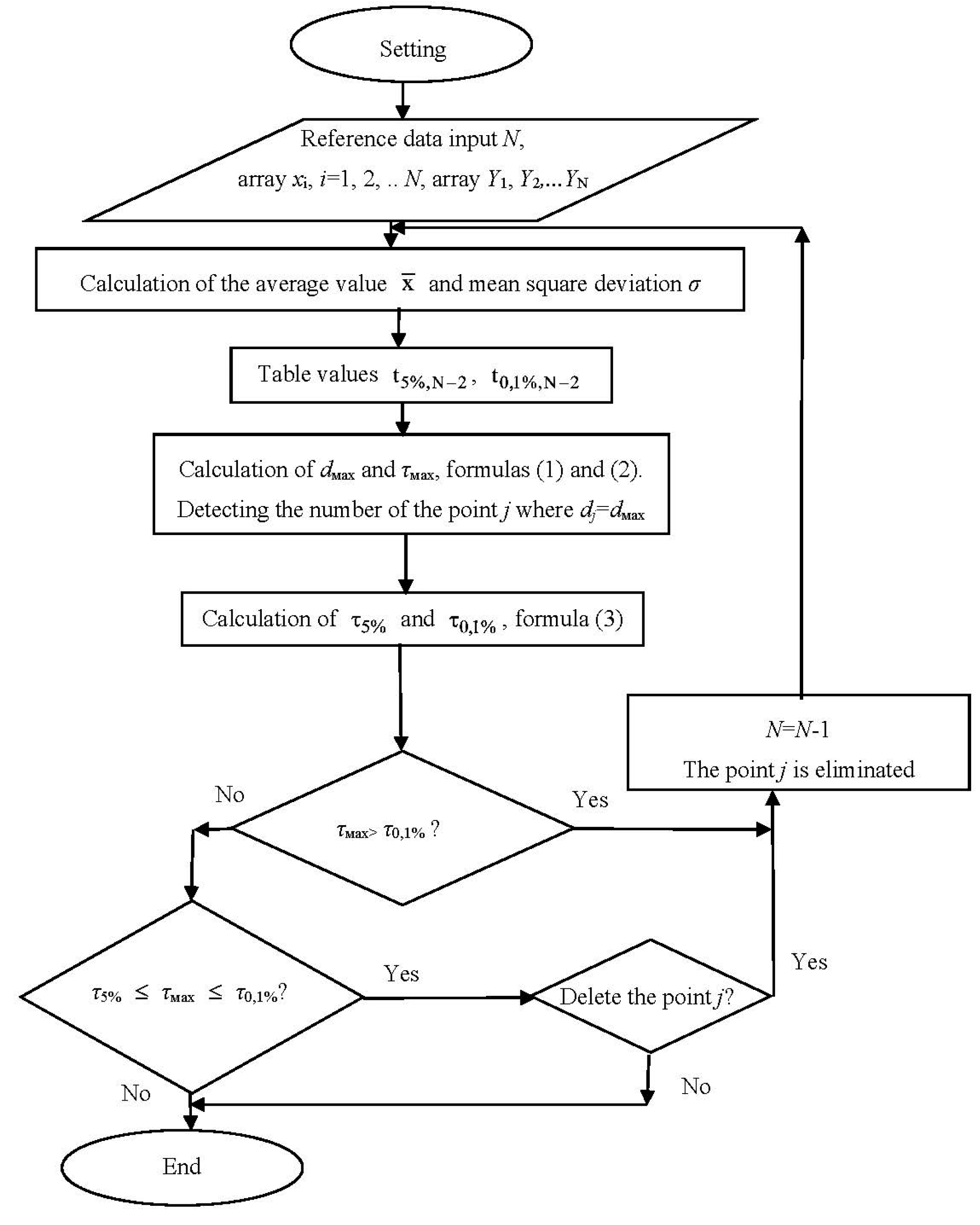

4.1. Elimination of Observation Errors

- at —xi not eliminated;

- at —xi eliminated;

- at —elimination xi by the user’s preference.

4.2. Distribution Law Checking

4.3. Adjusting Time Series

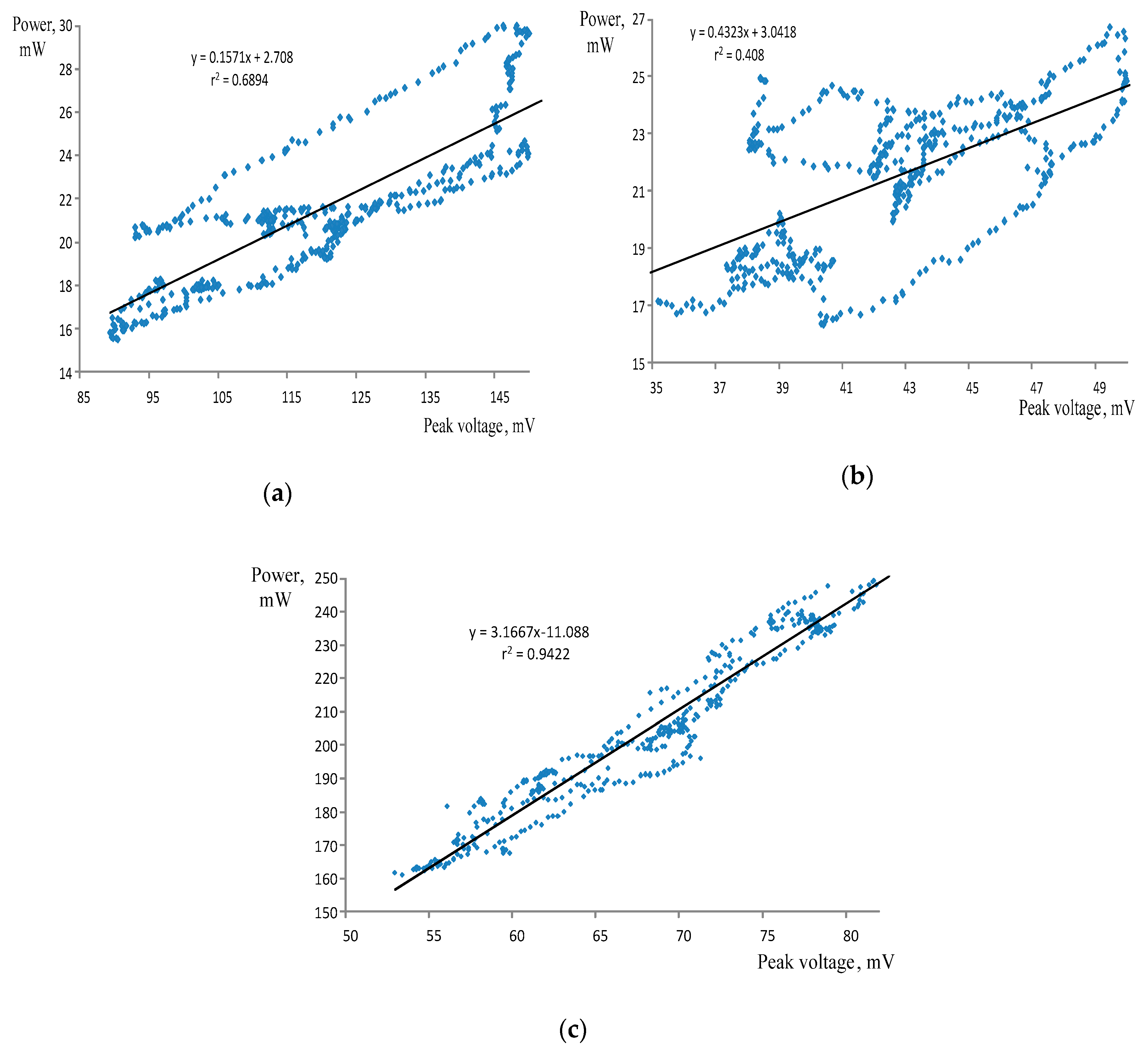

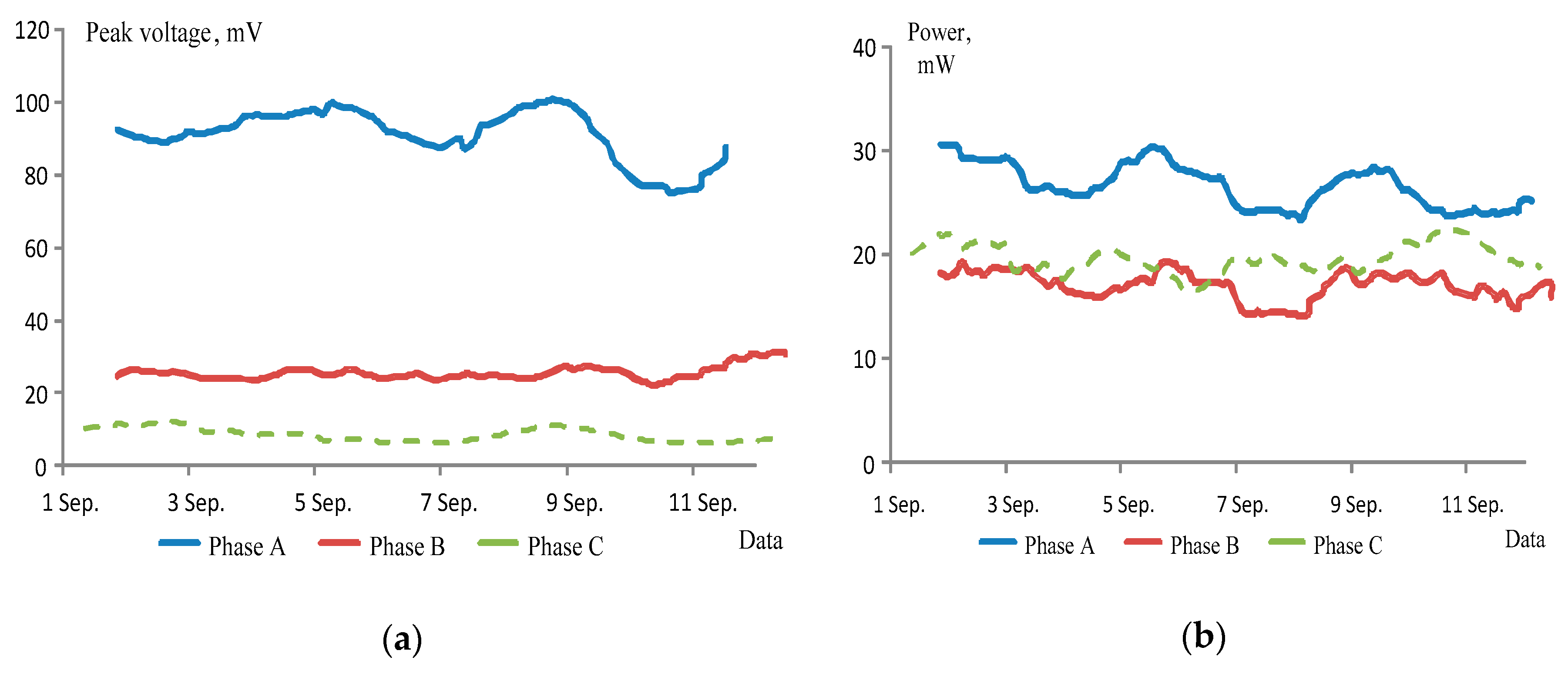

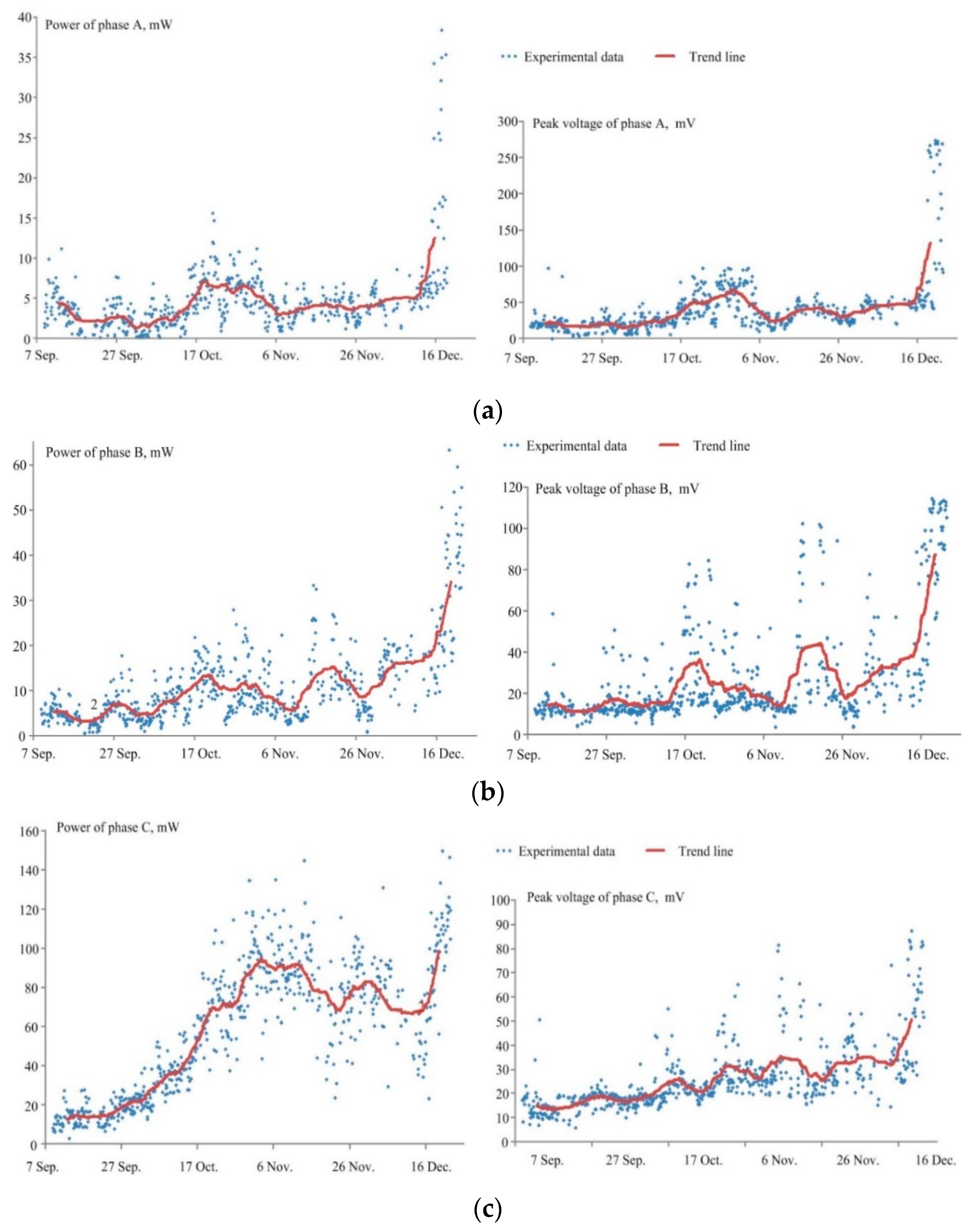

5. Practical Diagnosis of Furnace Transformer Technical State

5.1. Detecting Transformer Insulation Issues with the Time Series of Partial Discharge Parameters

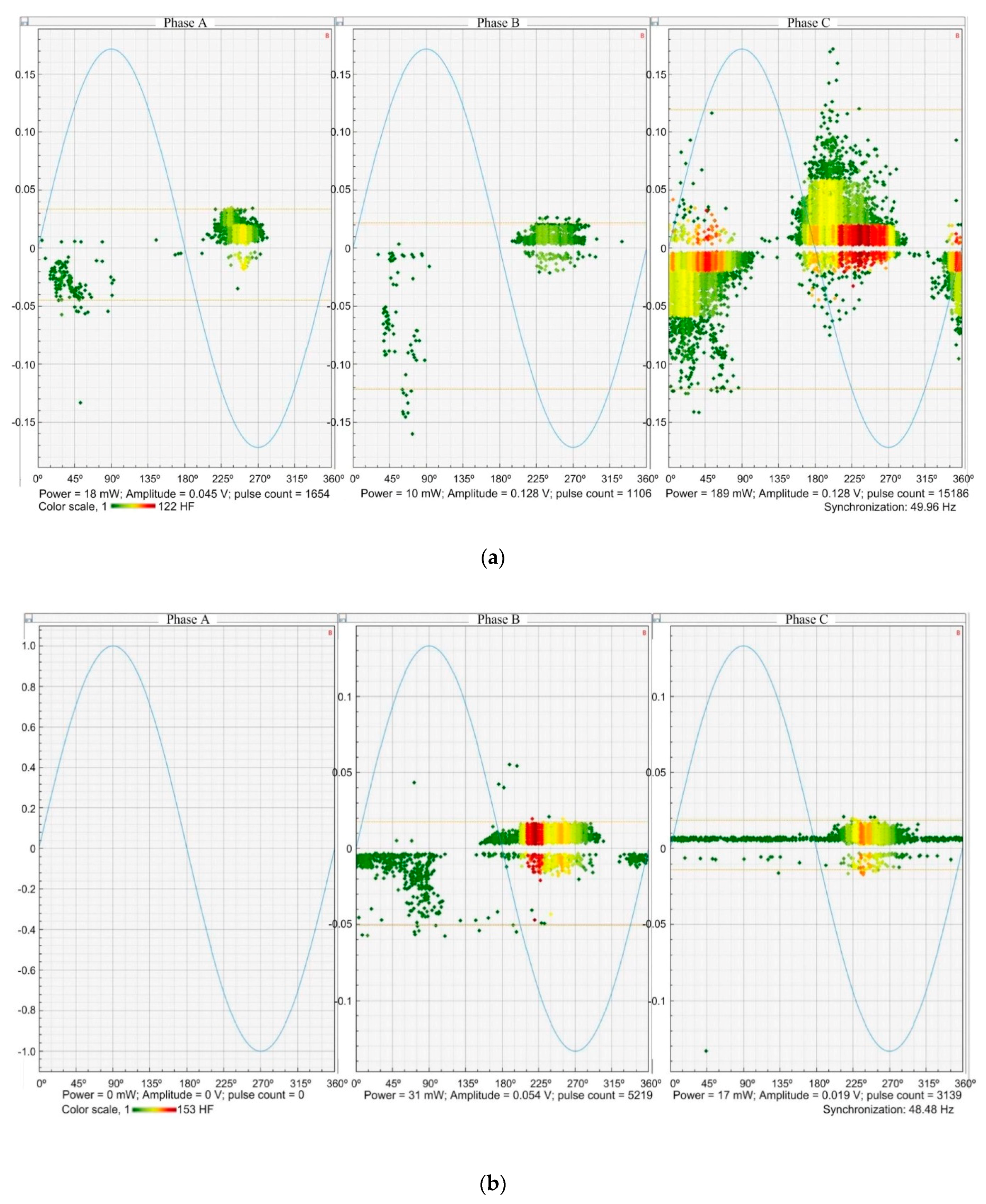

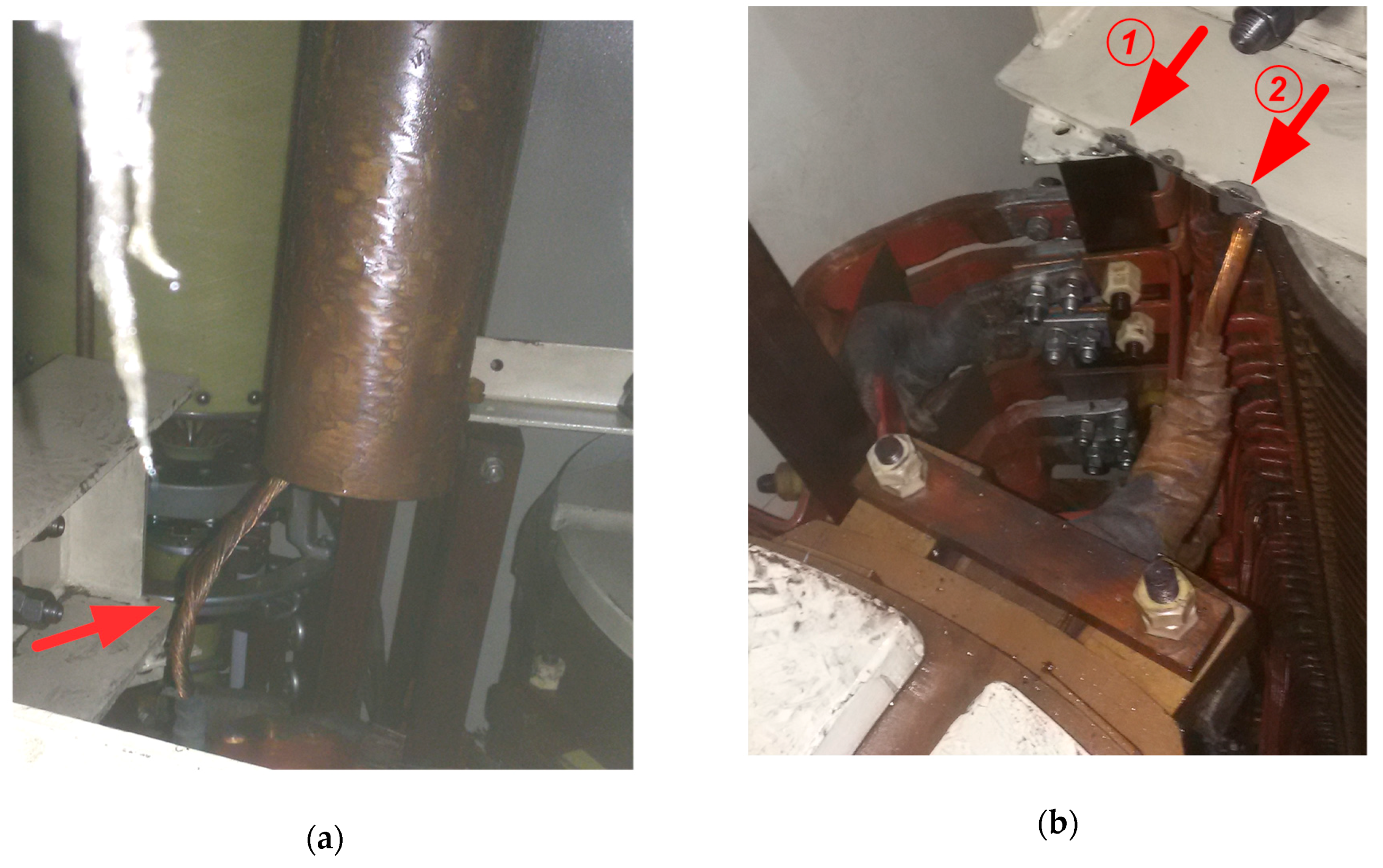

5.2. Comparing Data before and after Repair

6. Result Discussion

6.1. Analysis of Research Results

6.2. Research Prospects

7. Conclusions

Author Contributions

Conflicts of Interest

References

- Khramshin, V.R.; Nikolayev, A.A.; Evdokimov, S.A.; Kondrashova, Y.N.; Larina, T.P. Validation of Diagnostic Monitoring Technical State of Iron and Steel Works Transformers. In Proceedings of the 2016 IEEE NW Russia Young Researchers in Electrical and Electronic Engineering Conference, St. Petersburg, Russia, 2–3 February 2016; pp. 596–600. [Google Scholar] [CrossRef]

- Karandaev, A.S.; Evdokimov, S.A.; Khramshin, V.R.; Lednov, R.A. Diagnostic Functions of a System for Continuous Monitoring of the Technical Condition of the Transformers of Arc Steelmaking Furnaces. Metallurgist 2014, 58, 655–663. [Google Scholar] [CrossRef]

- Transformer Monitoring and Diagnostic Systems—GE Energy. Available online: http://www.geindustrial.com/publibrary/checkout/GEA-18000?TNR=Service%20and%20Maintenance|GEA-18000|generic (accessed on 9 September 2019).

- Kuzmin, O.A. ABB Expertize in Development and Application of Smart Transformers. Key Principles and Examples of New Solutions Application. Science to Practice Conference IV “Control of Technical State of Equipment of Power Engineering Objects” 2017. Available online: http://www.ti-ees.ru/fileadmin/f/Conference/2017/report/15._Kuzmin_O.A.pdf (accessed on 9 September 2019).

- Jonsson, L. Advanced Transformer Control and Monitoring with TEC. Available online: https://library.e.abb.com/public/5b56967bbeb58b84c1257b130057df40/TEC%20ABB%20Review.pdf (accessed on 9 September 2019).

- Zhivodernikov, S.V. Foreign Expertise in Monitoring Oil-Filled Equipment State. Available online: https://megaom.ucoz.ru/nornativ/vv_oborudovanie/statja_zarubezhnyj_opyt_monitoringa_oborudovanija.pdf (accessed on 9 September 2019).

- Legacy Transformer Monitoring and Diagnostic System (TMDS 2000 L). Available online: https://new.siemens.com/us/en/products/energy/product-support/t-d-guardian-articles/legacy-transformer-monitoring-diagnostic-system.html (accessed on 9 September 2019).

- Gill, P. Electrical Power Equipment Maintenance and Testing; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- MS 3000 The Expert Solution. Available online: http://www.gegridsolutions.com/products/brochures/AlstomEnergy/PTR/Grid-PTR-L3-MS3000-0203-2015_10-EN.pdf (accessed on 9 September 2019).

- Dolata, B.; Wagner, L. On-line condition monitoring and expert system for power transformers—Integration into protection and control system by using of IEC 61850. In Proceedings of the 21st International Conference on Electricity Distribution, Frankfurt, Germany, 6–9 June 2011; pp. 1–4. [Google Scholar]

- Akbari, A.; Setayeshmehr, A.; Borsi, H. Software Modules for Monitoring and Diagnosis of Power Transformers. In Proceedings of the 19th International Power System Conference (PSC 2004), Tehran, Iran, 22–24 November 2004; Available online: https://docplayer.net/24603244-49-e-trn-752-software-modules-for-monitoring-and-diagnosis-of-power-transformers-callinstr-25-a-d-hannover-germany.html (accessed on 9 September 2019).

- Rodrigo, A.; Castro, L.C.; Muñoz, F.A. Effect of acquisition parameters on equivalent time and equivalent bandwidth algorithms for partial discharge clustering. Electr. Power Energy Syst. 2017, 8, 141–149. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture Migration in an Oil-Paper Insulation System in Relation to Online Partial Discharge Monitoring of Power Transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Karandaev, A.S.; Khramshin, V.R.; Evdokimov, S.A.; Larina, T.P.; Yachikov, I.M. Practical Diagnostics of Power Transformers with Acoustic Radar Method of Partial Discharge Determination. In Proceedings of the 2016 IEEE NW Russia Young Researchers in Electrical and Electronic Engineering Conference, St. Petersburg, Russia, 2–3 February 2016; pp. 576–580. [Google Scholar] [CrossRef]

- Kunicki, M.; Cichon, A. Statistics based method for partial discharge identification in oil paperinsulation systems. Electr. Power Energy Syst. 2018, 163, 559–571. [Google Scholar] [CrossRef]

- Warren, V.; Stone, G.; Sedding, H. Partial Discharge Testing: A Progress Report. Available online: https://irispower.com/wp-content/uploads/2017/06/14-Sedding-Comparison-Test-IRMC-2017.pdf (accessed on 9 September 2019).

- Radionov, A.A.; Karandaev, A.S.; Yachikov, I.M.; Karandaeva, O.I.; Gasyarov, V.R. Power Transformer Condition Forecast with Time-series Extrapolation. In Proceedings of the 9th International Conference on Computer and Automation Engineering, Sydney, Australia, 18–21 February 2017; pp. 326–330. [Google Scholar] [CrossRef]

- Fofana, I. Power Transformer Diagnostics, Monitoring and Design Features; MDPI: Basel, Switzerland, 2018; Available online: https://www.mdpi.com/journal/energies (accessed on 9 September 2019).

- Evdokimov, S.A.; Kondrashova, Y.N.; Karandaeva, O.I.; Gallyamova, M.S. Stationary System for Monitoring Technical State of Power Transformer. Procedia Eng. 2016, 150, 18–25. [Google Scholar] [CrossRef][Green Version]

- System of Transformer Oil Monitoring KELMAN Minitrans. Available online: http://granat-e.ru/kelman_minitrans.html (accessed on 9 September 2019).

- Karandaev, A.S.; Evdokimov, S.A.; Khramshin, V.R.; Sarlybaev, A.A. System for Real-Time Monitoring of the Technical State of a Transformer on an Ultrahigh-Power Electric-Arc Steelmaking Furnace. Metallurgist 2014, 58, 872–879. [Google Scholar] [CrossRef]

- Karandaev, A.S.; Evdokimov, S.A.; Khramshin, V.R.; Karandaeva, O.I. Information and Measuring System for Electric Arc Furnace Transformer Monitoring. In Proceedings of the 2014 12th International Conference on Actual Problems of Electronic Instrument Engineering, Novosibirsk, Russia, 2–4 October 2014; Volume 1, pp. 273–279. [Google Scholar] [CrossRef]

- Sarlybaev, A.A. Description of systems for continuous condition control of furnace transformers. Russ. Internet J. Electr. Eng. 2016, 3, 24–35. [Google Scholar]

- Sensors for Portable and Stationary High Voltage Equipment Monitoring Systems. Available online: https://dimrus.ru/manuals/sensors.pdf (accessed on 9 September 2019).

- Karandaev, A.S.; Yachikov, I.M.; Khramshin, V.R. Methods of Multi-Parameter Diagnostics of Electric Equipment Condition within On-line Monitoring Systems. Procedia Eng. 2016, 150, 32–38. [Google Scholar] [CrossRef][Green Version]

- Radionov, A.A.; Evdokimov, S.A.; Sarlybaev, A.A.; Karandaeva, O.I. Application of subtractive clustering for power transformer fault diagnostics. Procedia Eng. 2015, 129, 22–28. [Google Scholar] [CrossRef]

- Dhaval, S.; Jay, A. Simulation and Mathematical Analysis of Partial Discharge Measurement in Transformer. Int. J. Eng. Res. Technol. 2018, 7, 125–132. [Google Scholar]

- Radionov, A.A.; Karandaeva, O.I.; Evdokimov, S.A.; Gallyamova, M.S.; Kondrashova, Y.N. Monitoring Partial Discharges in Stationary Condition Monitoring System of Furnace Transformer. In Proceedings of the IEEE NW Russia Young Researchers in Electrical and Electronic Engineering Conference, St. Petersburg, Russia, 1–3 February 2017; pp. 1571–1575. [Google Scholar] [CrossRef]

- Rusov, V.A. Measurement of Partial Discharges in Insulation of High-Voltage Equipment; Dimrus: Yekaterinburg, Russia, 2011. [Google Scholar]

- Methodical Directions for to Diagnostic of Mains Transformers, the Autotransformers, Bypassing Chokes and Their Feedings into МУ 0634-2006. Concern «ROSENERGOATOM». Available online: http://leg.co.ua/knigi/oborudovanie/diagnostika>-transformatorov-i-shuntiruyuschih-reaktorov.htm (accessed on 9 September 2019).

- Guidelines RD EO 0069–97. NPP Maintenance and Repair Guidelines. Concern «ROSENERGOATOM». Available online: https://files.stroyinf.ru/Data2/1/4293777/4293777767.pdf (accessed on 9 September 2019).

- Brockwell, P.J. Introduction to Time Series and Forecasting, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Grubbs, E. Sample Criteria for Testing Outlying Observations. Ann. Math. Statist. 1950, 21, 27–58. Available online: https://projecteuclid.org/download/pdf_1/euclid.aoms/1177729885 (accessed on 9 September 2019). [CrossRef]

- Lothar, S. Applied Statistics: A Handbook of Techniques (Springer Series in Statistics), 2nd ed.; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Malkin, V.S. Technical Diagnostics: Study Guide; Lan: St. Petersburg, Russia, 2013. [Google Scholar]

- AR700—Tool for Localization of Defects High-Voltage Equipment Insulation by Means of Acoustic Sensors. Available online: https://dimrus.ru/manuals/ar700.pdf (accessed on 9 September 2019).

- Khramshin, V.R.; Evdokimov, S.A.; Nikolaev, A.A.; Karandaev, A.S. Monitoring Technical State of the Power Transformers Is a Necessary Condition of the Smart-Grid Technology Introduction within the Industrial Electric Networks. In Proceedings of the IEEE NW Russia Young Researchers in Electrical and Electronic Engineering Conference, St. Petersburg, Russia, 2–4 February 2015; pp. 214–220. [Google Scholar] [CrossRef]

- Nikolayev, A.A. Introducing System of Monitoring Technical State of Transformer 80 MVA of Power Block of Thermal Plant of “MMK”, JSC. Electrotech. Syst. Complexes 2016, 52–57. [Google Scholar] [CrossRef]

- Hoek, S.; Ranninger, U. Acoustic localization of partial discharge in power transformers. Practical experiences with and without the help of UHF measurement technology. Transform. Mag. 2015, 4, 88–95. Available online: https://www.transformers-magazine.com/tm-issues-pdf-download/10-transformers-magazine-digital-edition-vol-2-issue-4/file.html (accessed on 9 September 2019).

- Giscard, F.; Cintra, V. A Strategy to Locate Partial Discharges in Power Transformers using Acoustic Emission. RE&PQJ 2007, 1, 596–600. [Google Scholar] [CrossRef]

- Markalous, S.M.; Feser, K. All-acoustic pd measurements of oil/paper-insulated Transformers for pd-localization. Sci. Works Inst. Electr. Eng. Electrotechnol. Wrocław Univ. Technol. 2004, 40, 106–112. [Google Scholar]

- Dhole, P.; Sinha, T.; Nayak, S. Analysis of Propagation Paths of Partial Discharge Acoustic Emission Signals. In Proceedings of the Fifteenth National Power Systems Conference, Bombay, India, 16–18 December 2008; pp. 345–350. [Google Scholar]

- Sikorski, W.; Ziomek, W.; Siodla, K.; Moranda, H. Location of Partial Discharge Sources in Power Transformers Based on Advanced Auscultatory Technique. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1948–1956. [Google Scholar] [CrossRef]

- Sikorski, W.; Ziomek, W.; Kuffel, E. Location and Recognition of Partial Discharge Sources in a Power Transformer Using Advanced Acoustic Emission Method. Electr. Rev. 2008, 10, 20–23. [Google Scholar]

- Agamalov, O.N. Cluster analysis of partial discharges for estimation of condition of electric machine insulations. Electricity 2006, 6, 56–62. [Google Scholar]

| Type | Rated Capacity, kVA | Rated Coil Voltage, V | Diagram and Group of Coil Connection | Number of OLTC Positions | Cooling System | Mass, Tons | Length × Width × Height, mm |

|---|---|---|---|---|---|---|---|

| ETCNKV -40000/110-UHL-4 | 20,282–26,000 | 110,000 HV 289.5–421 LV | Y/Δ-11 | 9 | Suspended | 80 | 4840 × 3540 × 6200 |

| Measurement Conditions | Phase | Capacity, mW | Amplitude, V | Number of Pulses |

|---|---|---|---|---|

| Before repair (Figure 2a) | A | 18 | 0.045 | 1654 |

| B | 10 | 0.128 | 1106 | |

| C | 189 | 0.12 | 15,186 | |

| After repair (Figure 2b) | A | 0 | 0 | 0 |

| B | 33 | 0.054 | 5219 | |

| C | 17 | 0.019 | 3130 |

| Classification in Compliance with [31] | Classification of Technical State | Extent of Defect Propagation in Compliance with [31] | Values of Maximum PD Amplitudes, Ampere-Second | ||

|---|---|---|---|---|---|

| In Windings and between Coils | Main Insulation, Barriers, in Compliance with [31] | Inputs in Compliance with [31] | |||

| Faulty state | PRE-FAULT | Limit state | more than 5 nC | more than 100 nC | more than 10 nC |

| WORSENED | Critical defect | to 2.5 nC | 5–25 nC | 0.5–2.5 nC | |

| NORM with significant deviations | Significant defect | to 500 pC | 1–5 nC | to 500 pC | |

| Operating state | NORM with deviations | Minor defect | to 100 pC | to 1000 pC | to 100 pC |

| NORM | Absence of obvious defects | – | to 100 pC | – | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karandaeva, O.I.; Yakimov, I.A.; Filimonova, A.A.; Gartlib, E.A.; Yachikov, I.M. Stating Diagnosis of Current State of Electric Furnace Transformer on the Basis of Analysis of Partial Discharges. Machines 2019, 7, 77. https://doi.org/10.3390/machines7040077

Karandaeva OI, Yakimov IA, Filimonova AA, Gartlib EA, Yachikov IM. Stating Diagnosis of Current State of Electric Furnace Transformer on the Basis of Analysis of Partial Discharges. Machines. 2019; 7(4):77. https://doi.org/10.3390/machines7040077

Chicago/Turabian StyleKarandaeva, Olga I., Ivan A. Yakimov, Alexandra A. Filimonova, Ekaterina A. Gartlib, and Igor M. Yachikov. 2019. "Stating Diagnosis of Current State of Electric Furnace Transformer on the Basis of Analysis of Partial Discharges" Machines 7, no. 4: 77. https://doi.org/10.3390/machines7040077

APA StyleKarandaeva, O. I., Yakimov, I. A., Filimonova, A. A., Gartlib, E. A., & Yachikov, I. M. (2019). Stating Diagnosis of Current State of Electric Furnace Transformer on the Basis of Analysis of Partial Discharges. Machines, 7(4), 77. https://doi.org/10.3390/machines7040077