Abstract

Recent advances in manufacturing technology, such as cyber–physical systems, industrial Internet, AI (Artificial Intelligence), and machine learning have driven the evolution of manufacturing architectures into integrated networks of automation devices, services, and enterprises. One of the resulting challenges of this evolution is the increased need for interoperability at different levels of the manufacturing ecosystem. The scope ranges from shop–floor software, devices, and control systems to Internet-based cloud-platforms, providing various services on-demand. Successful implementation of interoperability in smart manufacturing would, thus, result in effective communication and error-prone data-exchange between machines, sensors, actuators, users, systems, and platforms. A significant challenge to this is the architecture and the platforms that are used by machines and software packages. A better understanding of the subject can be achieved by studying industry-specific communication protocols and their respective logical semantics. A review of research conducted in this area is provided in this article to gain perspective on the various dimensions and types of interoperability. This article provides a multi-faceted approach to the research area of interoperability by reviewing key concepts and existing research efforts in the domain, as well as by discussing challenges and solutions.

1. Introduction

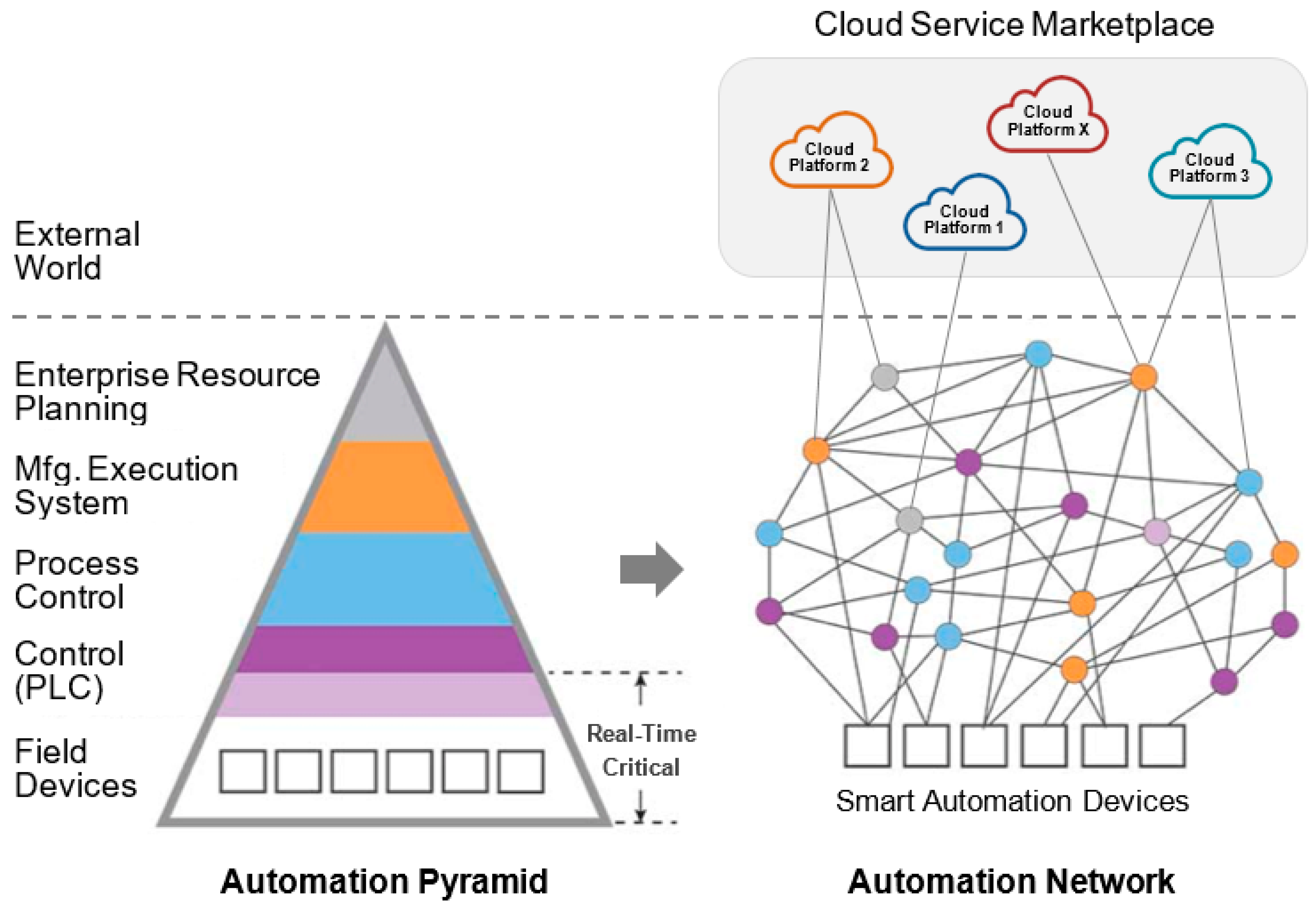

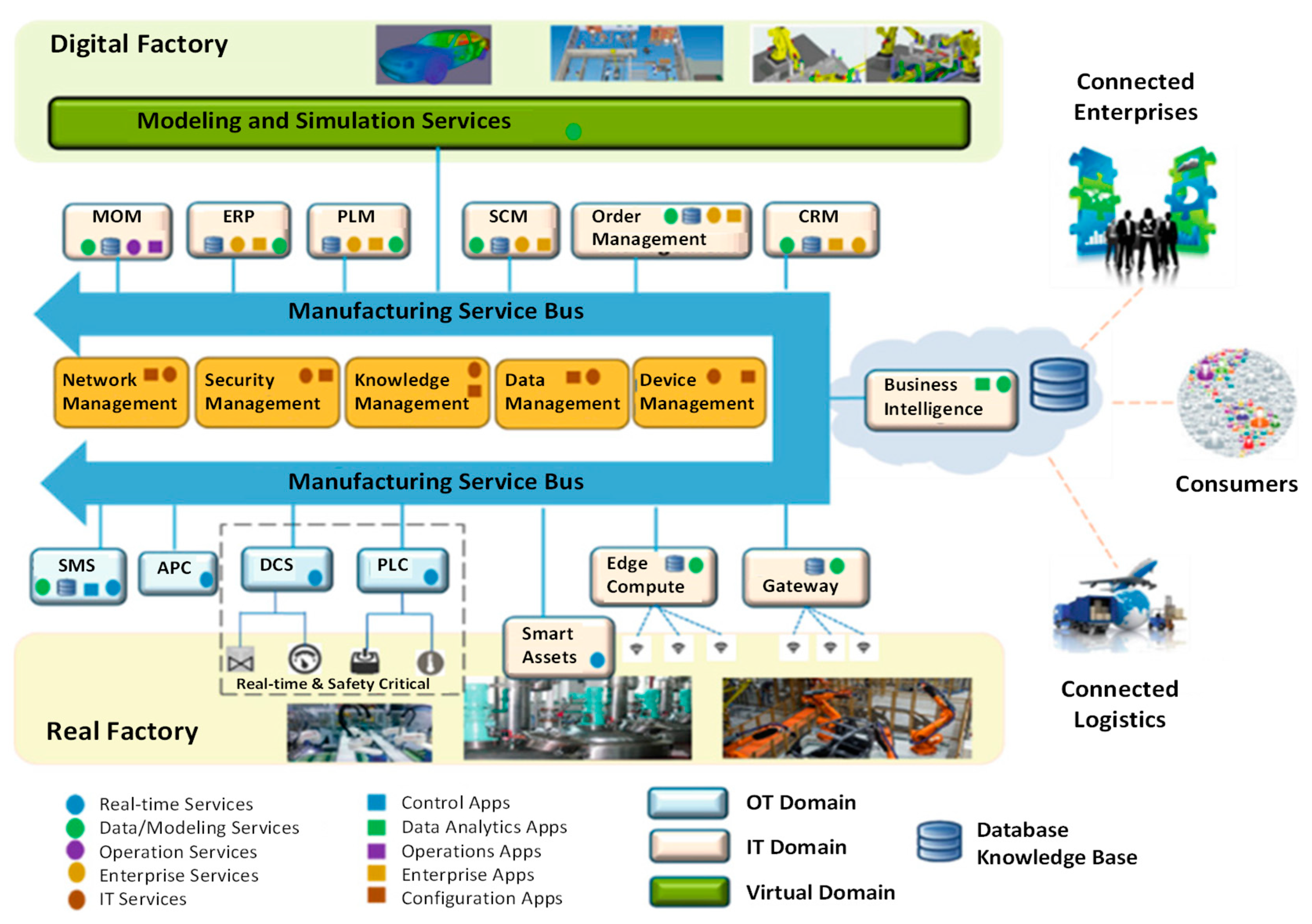

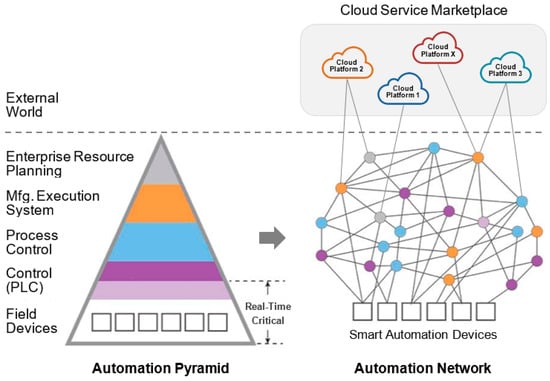

The manufacturing industry has always been driven by the evolution of technology—from steam engines to electricity, microprocessors, computers, automation, and recently, artificial intelligence, Internet of things and cyber–physical systems. Several initiatives have been launched globally over the past few years (e.g., Industry 4.0 in Europe [1]; Made in China 2025 [2]; U.S. Advanced Manufacturing [3]) to address the global needs for higher efficiency, lower costs, and mass-personalization of products and services. The synergetic effect between emerging technologies and needs has led to the creation of new manufacturing paradigms characterized by [4]: (1) digitalization and integration of manufacturing resources on cloud-based platforms as adaptive, secure, and on-demand services, and (2) smart and connected objects capable of real-time and autonomous decision-making via embedded electronics and analytical/cognitive capabilities (Figure 1). Examples of recent paradigms include smart manufacturing [5], cyber–physical production systems (CPPS) [6], Industry 4.0 [1], and cloud manufacturing [7], among others. We henceforth refer to these new paradigms as smart manufacturing.

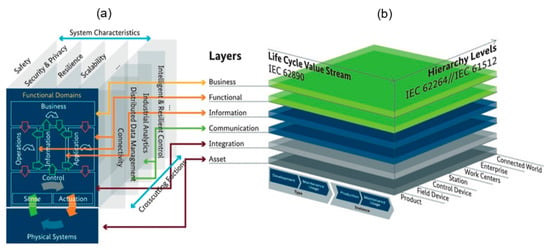

Figure 1.

Evolution of the hierarchical model of enterprise control system integration toward an integrated network of smart automation devices, cloud services, cloud platforms, and enterprises. Different types of interoperability problems may arise, due to the diverse nature of interactions in the emerging automation networks. (Adapted from Reference [6]).

Smart manufacturing involves networking of heterogenous components and services that reside within the boundaries of a factory (e.g., integration of smart shop–floor devices) or beyond (e.g., integration of a manufacturing cell with a cloud-based service). These two types of integration are sometimes referred to as vertical and horizontal, respectively [1]. Thus, unlike the traditional “automation pyramid” for manufacturing control where integration problems would arise in intra-enterprise hierarchical structures (i.e., Enterprise Resource Planning (ERP)–Manufacturing Execution Systems (MES)–shop-floor), smart manufacturing calls for the integration of diverse and distributed cloud-based services, enterprises, smart factories, smart devices, and processes. The required integration in turn calls for a seamless exchange of information between these heterogenous systems which operate under a wide variety of communication standards [8]. This phenomenon has introduced an unprecedented challenge known as interoperability.

This article conducts a review of the notion of interoperability in the context of smart manufacturing. First, an overview of the emerging concepts and paradigms in manufacturing is provided, along with their detailed characteristics and elements, comparative analysis, and common vernacular (Section 2). Next, different definitions and dimensions of interoperability are introduced, and the interoperability problems associated with vertical and horizontal integration are differentiated and formalized with respect to the interoperability stack model [8] (Section 3). Finally, several reference architectures for smart manufacturing and their approaches to interoperability are evaluated and compared, followed by a summary of challenges and recommendations for future research and development.

2. Overview of Key Concepts and Paradigms

To better understand and formalize different definitions and dimensions of interoperability, it is necessary to provide an overview of its enabling concepts and technologies (e.g., cyber–physical systems; Internet of things; data analytics), along with the emerging paradigms that drive the need for it. This section provides an overview of some of the major concepts and paradigms in manufacturing.

2.1. Cyber–Physical Systems

Cyber–physical systems (CPS) are systems that integrate physical processes with computation through embedded computers, feedback loops, and computer networks used to control the desired process [6]. The CPS framework usually consists of a central control unit (e.g., a microcontroller) which controls the sensors and actuators that perform the desired task and generate data [9]. CPS as designed consists of interacting elements with input and output layers, unlike standalone devices in traditional systems. CPS has been defined by the National Science Foundation (NSF) as “systems that consist of physical and software components that are deeply intertwined, each operating on different spatial and temporal scales, exhibiting multiple and distinct behavioral modalities, and interacting with each other in a myriad of ways that change with context” [10]. With continuous improvements in technologies involving CPS, there has been an exponential growth of its applications in the manufacturing industry.

2.2. Internet of Things

The Internet of things (IoT) enables access to a full-fledged network of smart devices, systems and products, cloud-based services, humans, and enterprises [11], which are connected to each other over a secure Internet. The devices can be smart devices that consist of sensors and actuators or legacy devices that record some form of information that can be shared on the cloud. The IoT provides the capability to connect legacy devices and systems to the Internet, which in turn allows for systematic data collection and decision-making. In the industrial setting, the IoT has aided in the growth of smart manufacturing through integration of machines, processes, and systems. The IoT is bringing about fundamental transformations to the manufacturing and supply networks through the integration of physical manufacturing processes with cloud-based services [12]. A service, in this context, refers to “a logical representation of a set of activities that has specified outcomes, is self-contained, may be composed of other services and is a black box to consumers of the service” [13]. The encapsulation of knowledge and capabilities in cloud-based services allow users to shift their focus from reinventing those capabilities to utilizing them. Examples of cloud-based services in the context of smart manufacturing include analytics, security, visualization, machine learning, and cognitive services [14], sourced from a variety of platforms, such as Amazon Web Services, Microsoft Azure, and IBM Cloud, among others.

2.3. Data Analytics and Machine Learning

The integration of distributed and formerly-siloed devices, systems, and enterprises through CPS and the IoT has led to the generation of massive data—from the data generated by sensors-actuators and automation devices on the shop-floor to the transaction data generated by cloud marketplaces and the life cycle data generated by smart products. These data revolution demands new techniques and technologies for efficient collection, storage, retrieval, communication, and real-time analysis of large and diverse datasets. On the other hand, the fast-paced growth of machine learning algorithms and compute capabilities has provided unprecedented potentials to support manufacturing operations and decisions with further insights from their available datasets. Examples of such capabilities include, but are not limited to, processing high-dimensional data, reducing the complexity of data, adapting to new processes and environments, identifying relations, correlations, and causality [15]. In the manufacturing setting, data analytics and machine learning techniques have been extensively applied in various areas, such as quality management, preventive maintenance, fault diagnosis and prognosis, decision-making, sequencing and production scheduling [16].

2.4. Emerging Paradigms in Manufacturing

Over the past decade, several new paradigms have emerged to represent the various requirements and characteristics of next-generation manufacturing systems. Some common examples are introduced below (see Reference [4] for further details). The common theme of all of these paradigms, as pointed out earlier, revolves around service-orientation through digitalization and integration of resources on the cloud (i.e., horizontal integration) as well as smart reconfigurable shop-floor operations through integrated and collaborative automation devices and systems (i.e., vertical integration).

2.4.1. Smart Manufacturing

The U.S. National Institute of Standards and Technology defines smart manufacturing as “fully-integrated, collaborative manufacturing systems that respond in real time to meet changing demands and conditions in the factory, in the supply network, and in customer needs” [5]. The Smart Manufacturing Leadership Coalition provides a complementary definition for smart manufacturing as “the ability to solve existing and future problems via an open infrastructure that allows solutions to be implemented at the speed of business while creating advantaged value”. The characteristics of smart manufacturing include digitalization and service-orientation, smart and connected automation devices, collaborative supply networks enabled by advanced analytics [5], with the goal of enabling cost-efficient, flexible, and personalized mass-production [17].

2.4.2. Cyber–Physical Production Systems

Cyber–physical production systems (CPPS) consist of automated components that communicate with each other across multiple levels of a manufacturing or production facility, including the shop-floor, warehouse and logistics networks [6]. The characteristics of CPPS include intelligent and autonomous interactions of CPS objects, responsiveness to changes [6], integration of manufacturing resources on the cloud as adaptive and secure services [18], predictive and prescriptive operations through data analytics, and product life cycle support through digital twin technologies [19].

2.4.3. Industry 4.0

Vertical integration of automation devices, horizontal integration of inter-factory operations throughout value networks, and end-to-end engineering of smart products are the three major characteristics of Industry 4.0 [1]. This paradigm represents a model of a fully-integrated industry where “products and services are flexibly connected via the Internet or other network applications like the blockchain. The digital connectivity enables an automated and self-optimized production of goods and services including the delivering without human interventions. The value networks are controlled decentralized while system elements are making autonomous decisions” [20].

2.4.4. Cloud Manufacturing

Cloud manufacturing is defined as “a new networked manufacturing paradigm that organizes manufacturing resources over networks (manufacturing clouds) according to consumers’ needs and demand to provide a variety of on-demand manufacturing services via networks (e.g., the Internet) and cloud manufacturing service platforms” [7]. A derivative of this paradigm is cloud-based design and manufacturing, “a service-oriented networked product development model in which service consumers are enabled to configure, select, and utilize customized product realization resources and services ranging from Computer Aided Engineering (CAE) software to reconfigurable manufacturing systems” [21]. Another derivative of cloud manufacturing is social manufacturing, “a new cyber-physical-social-connected and service-oriented manufacturing paradigm that drives distributed Prodcution Service Providers (PSPs)to self-organize into dynamic resource communities (DRCs) through social network, provide the production- and product-related services to prosumers [producers + consumers], and collaborate with prosumers through cyber-physical-social systems/network (CPSS) [22]. Accordingly, the main theme of the cloud manufacturing paradigm and its derivatives is horizontal integration through service-orientation with emphasis on design and manufacturing services.

3. Interoperability in Manufacturing

The integration and networking of smart manufacturing components and services within and beyond the boundaries of the factory, as characterized by the aforementioned paradigms, call for seamless exchanging of information with syntax and semantics understandable by all the heterogeneous systems involved. This ability is referred to as interoperability. In shop–floor operations, for example, manufacturing equipment must update each other and the control systems about the process updates and potential errors or conflicts. They also need to interact with cloud-based platforms to receive required services. In general, the software that these components and services are based on must be able to interact by developing an understanding of the common language or syntax that each uses to interact with the external world.

3.1. Definitions of Interoperability

Several definitions of interoperability have been proposed by different standard organizations and institutions. In general terms, interoperability can be defined as the ability of two or more entities to interact and cooperate. ISO 16100 defines interoperability as “the ability to share and exchange information using a common syntax and semantics to meet an application specific functional relationship across a common interface” [23]. The IEEE Standard Computer Dictionary defines interoperability as “the ability of two or more systems or components to exchange information and to use the information that has been exchanged” [24]. There are many other definitions of interoperability that are used in different contexts. The most relevant ones have been compiled and listed below.

- The ability of one system to receive and process intelligible information of mutual interest transmitted by another system [25].

- Interoperability means the ability of two or more parties, machine or human, to make a perfect exchange of content. Perfect means no perceptible distortions or unintended delays between content origin, processing and use [26].

- Interoperability among components of large-scale, distributed systems is the ability to exchange services and data with one another [27].

- The condition achieved between systems when information or services are exchanged directly and satisfactorily between the systems and/or their users [28].

- The ability to integrate data, functionality and processes with respect to their semantics [29].

- Interoperability, in a broad sense, refers to the use of computer-based tools that facilitate coordination of work and information flow across organizational boundaries, focusing mainly on inter-enterprise distributed BPs and flows [30].

- The ability of systems, units, or forces to provide services to and accept services from other systems, units, or forces and to use the services so exchanged to enable them to operate effectively together [31].

In smart manufacturing, interoperability takes two general forms. The first form corresponds with vertical integration, e.g., interoperability between the manufacturing software, the shop–floor departments, the processes performed by different equipment, the various shop–floor systems, and so forth [32]. The second form corresponds with horizontal integration; the interoperability between smart automation devices, cloud services, cloud platforms, and enterprises (see Figure 1). Successful implementation of enterprise-wide interoperability would result in effective and smooth operations of the manufacturing industry, thus cutting costs, increasing production and product quality.

3.2. Challenges in Implementation of Interoperability

The factors that affect interoperability are bound to be multivariate considering the complexity of the processes. The Manufacturing Interoperability Program at NIST (the National Institute of Standards and Technology) list several factors that impact the effectiveness of interoperability [33]:

- Transfer of data between systems that may be similar or dissimilar (commercially).

- Transfer of data between software made by the same vendor (or creator) but having different versions on the systems.

- Compatibility between different versions of software (newer and older versions).

- Misinterpretation of terminology used or in the understanding of the terminology used for exchange of data or information.

- The use of non-standardized documentation on which the exchange of data is processed or formatted.

- Not testing the applications that are deemed conformant, due to the lack of means to do so between systems.

Other barriers to interoperability include inconsistent data formats or standards, connectivity in the IoT realm, and the wide variety of commercially available products.

3.3. Generic Approaches to Implement Interoperability

Over the years, there have been many approaches to successfully implement interoperability. The IEEE Guide to Enterprise IT Body of Knowledge (EITBOK) has categorized the approaches mainly into two types: Syntactic and semantic [34].

3.3.1. Syntactic Interoperability

The European Telecommunications Standards Institute (ETSI) defines syntactic interoperability as follows: “Syntactical Interoperability is usually associated with data formats. Certainly, the messages transferred by communication protocols need to have a well-defined syntax and encoding, even if it is only in the form of bit-tables. However, many protocols carry data or content, and this can be represented using high-level transfer syntaxes such as Hypertext Markup Language (HTML), Extensible Markup Language (XML) or Abstract Syntax Notation One (ASN.1)” [35]. Syntactic interoperability merely considers the format of the data—it does not take into account the meaning of the data to be transferred. Standardization of data formats, as well as the mode of communication can greatly improve this type of interoperability.

3.3.2. Semantic Interoperability

The ETSI offers a concrete definition for semantic interoperability as follows: “Semantic Interoperability is usually associated with the meaning of content and concerns the human rather than machine interpretation of the content. Thus, interoperability on this level means that there is a common understanding between people of the meaning of the content (information) being exchanged” [35]. Semantic interoperability not only looks into the meaning of the content, it also applies logic to the fact being transferred and used [36]. XML and Resource Definition Framework (RDF) are widely used as standards for semantic interoperability. Nevertheless, RDF is proven more effective due to providing models extendable to multiple techniques that are represented by unique ontologies [37]. A thorough list of ontologies by the devices that use them has been published by Lelli [38] in which they discuss and compare World Wide Web Consortium (W3C) Semantic Sensor Network, Fiesta-IoT, Smart Energy Aware Systems (SEASD), Machine-to-Machine (M2M) solutions (http://www.onem2m.org), and Schema.org technologies, to name a few.

3.4. Factory Interoperability (Vertical Integration)

The term manufacturing interoperability refers to the capability of manufacturing enterprises to exchange information that maybe technical or enterprise related in a coherent manner within and between each other [8]. A recent study conducted on the U.S. automotive industry reports an annual economic loss of $1 billion due to the lack of interoperability throughout the supply network [39], which reveals the significant impact of interoperability on the manufacturing sector in terms of both cost and performance quality. Jones and Ray [8] suggest three approaches to tackle the high cost problem associated with manufacturing interoperability. The first is machine-to-machine solution. The idea behind this approach is making each individual machine interoperable with every other machine it is linked to or integrated with. The challenge is that each of these machines may communicate based on their own manufacturer-specified communication protocol. Achieving interoperability under this scenario requires a thorough understanding of their unique semantics along with translation of their syntax. This approach is clearly not effective and is likely to impose significant cost.

The second approach is industry-wide standardization solution. The idea here is to ensure that all the manufacturing industry service partners follow a single solution. For example, a manufacturing unit may be integrated and interoperable until the period of production. However, if further processes have to be performed on the product in later stages, it may have to move to another plant to complete those operations. In this case, not only is a common protocol required for operations within the manufacturing setup, there is also a need for another protocol between different manufacturing units. This approach can be extended to various industries. The drawback of this approach, however, is that the manufacturing units used to process a given product may belong to different enterprises with different integration/communication protocols. The third, and the most effective approach is the application of open standards or platforms to achieve interoperability. See Reference [40] for a review of recent developments in the area.

3.5. Cloud-Manufacturing Interoperability (Horizontal Integration)

The ISO/IEC 19941 standard [41] specifies a facet-based model to approach both interoperability and portability in cloud computing. Extending the notion of cloud computing to cloud manufacturing [7], it is imperative to generalize the interoperability definitions and approaches to the domain of cloud manufacturing. In addition to syntactic and semantic interoperability, cloud-based platforms must address three additional types of interoperability:

- Transport interoperability. This type makes the transfer and exchange of data interoperable by the use of protocols such as REpresentational State Transfer (REST) [42] over HyperText Transfer Protocol (HTTP), and Message Queuing Telemetry Transport (MQTT) [43].

- Behavioral interoperability. This type selects from a list of anticipated responses when requests are received for our services. By setting conditions on the requests, computer simulations with the help of human responses can anticipate the outcomes of the service request and be ready to offer a solution.

- Policy interoperability. This type ensures that all the systems in the cloud follow and conform to the regulations and policies while interacting within the cloud environment.

In cloud manufacturing, the majority of operations and resources are virtualized on cloud platforms as cloud-based services supported by the IoT, cloud computing, and cyber–physical technologies. In recent years, several cloud-based platforms have emerged to provide such cloud-based manufacturing services. Common platforms include Amazon Web Services (AWS), IBM Watson, Microsoft Azure, Google Cloud Platform, Oracle, and Alibaba, among others. The users of these services can subscribe and use services remotely and on-demand, from multiple providers for their manufacturing enterprise. Database management, big data analytics, scheduling and supply-chain operations are among some of the services provided.

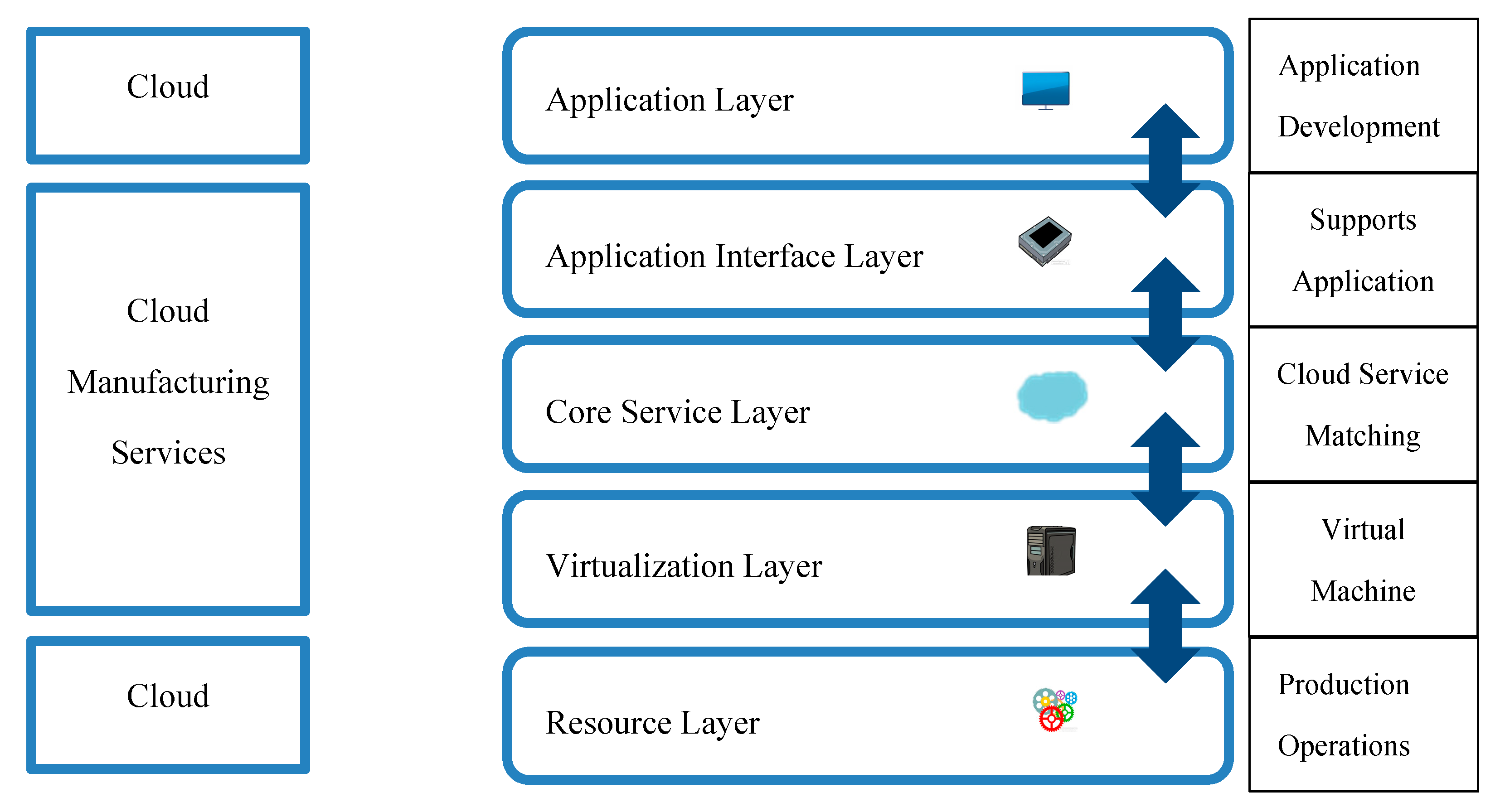

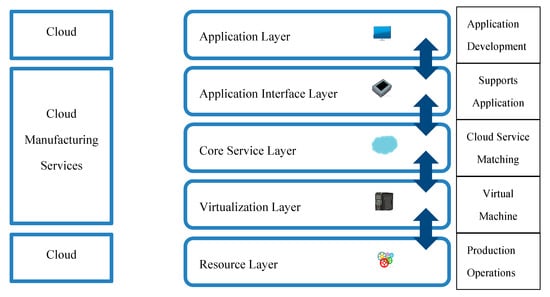

A generic cloud manufacturing architecture consists of five layers (Figure 2): Application layer, application interface layer, core service layer, virtualization layer, and physical resource layer [44]. The application layer develops applications on the cloud for a user or subscriber. These requests can be specialized in nature relative to the manufacturing enterprise that is integrating with the cloud. The next three layers, the application interface layer, the service layer, and the virtualization layer, work in tandem to ensure that cloud manufacturing services are realized with acceptable knowledge, security and virtualization. The physical resource layer or the resource layer actually implements the manufacturing service that is offered and can be initiated by the user.

Figure 2.

A generic cloud manufacturing architecture.

An example of interoperability in the domain of cloud manufacturing is the Interoperable Cloud-based Manufacturing System (ICMS) [45]. The four layers in the ICMS are the manufacturing resource layer, virtual service layer, global service layer, and application layer. The manufacturing resource layer combines the actual manufacturing systems into chunks that can be invoked by the user by incorporating STEP-NC. The virtual service layer maintains records of the services that are being requested while ensuring safety and privacy. The global service layer ensures that the enterprise has control over the services and also provides means for conducting analysis into the diagnostics of the service offered. The application layer provides an interface to the ICMS that the user or subscriber can access based on privileges granted.

Another example is the Hybrid Manufacturing Cloud (HMC) framework [46]. HMC uses different models of the cloud: Private, community, and public. This model prioritizes security and privacy of data and information by the use of a cloud management engine. Li et al. introduce a new approach to cloud architectures by the use of a New Generation Artificial Intelligence-driven Intelligent Manufacturing (NGAIIM) architecture [47]. The authors introduce the applications of artificial intelligence in the current computing habitats and compare its progress over the years. The four-layer architecture proposed consists of a resource layer, communications layer, platform layer and service layer that are integrated with the NGAIIM concept. The resource layer is analogous to the resource layer seen in other architectures, i.e., the base layer consists of the physical elements of the manufacturing unit. The communication layer uses IoT based network models to interconnect the layers, thus providing interoperability. The platform layer provides access for the user to be a part of the system and also provides application support. The service layer provides intelligent services for manufacturing. Chai et al. introduce a platform called INDICS, which is China’s Internet-based platform operating on IoT and other technologies [48]. This platform architecture consists of five layers: Resource layer, industrial IoT layer, access layer, cloud layer and the APP layer. The resource layer is again analogous to other architectures. The industrial IoT layer supports and integrates wireless networks and Object Linking and Embedding for Process Control Unified Architecture (OPC-UA) protocol to name a few. The access layer and cloud layer handle the communications and application development with other related tasks respectively. The APP layer provides intelligent services that are supported by the INDICS platform.

Various other frameworks and architectures have been proposed by researchers and industry professionals that are yet to be tested and deployed in the cloud manufacturing environment. With the advancements in the smart manufacturing domain, however, open communication standards and platforms that are shared across by enterprises are starting to attract more research interests.

4. Reference Architectures for Interoperable Manufacturing

A number of reference models and architectures have been developed in recent years to address the issues of integration and interoperability in the context of smart manufacturing. Reference architectures have been categorized into types of architectures [49]:

- (a)

- The physical architecture of the components of a system (e.g., automation devices, machines, software, departments).

- (b)

- The functional architecture representing the set of functions and processes to be accomplished by the systems.

- (c)

- The allocated architecture describing the mapping between the functional architecture and the physical architecture.

The most widely discussed architecture models have been proposed by Platform Industrie 4.0 and Industrial Internet Consortium (IIC), two of the largest organizations that research on topics related to Industry and the Industrial Internet respectively. Platform Industrie 4.0’s Reference Architecture Model for Industry 4.0 (RAMI 4.0) is an architecture that was designed primarily for applications in the manufacturing industry, and IIC’s Industrial Internet Reference Architecture (IIRA) was designed for all industries related to the Industrial Internet of Things (IIoT) [50]. Other prominent architecture models in this context are IBM’s Industry 4.0 architecture and the NIST service-oriented architecture. For the purpose of this paper, we consider these architecture models and describe them in the context of manufacturing interoperability.

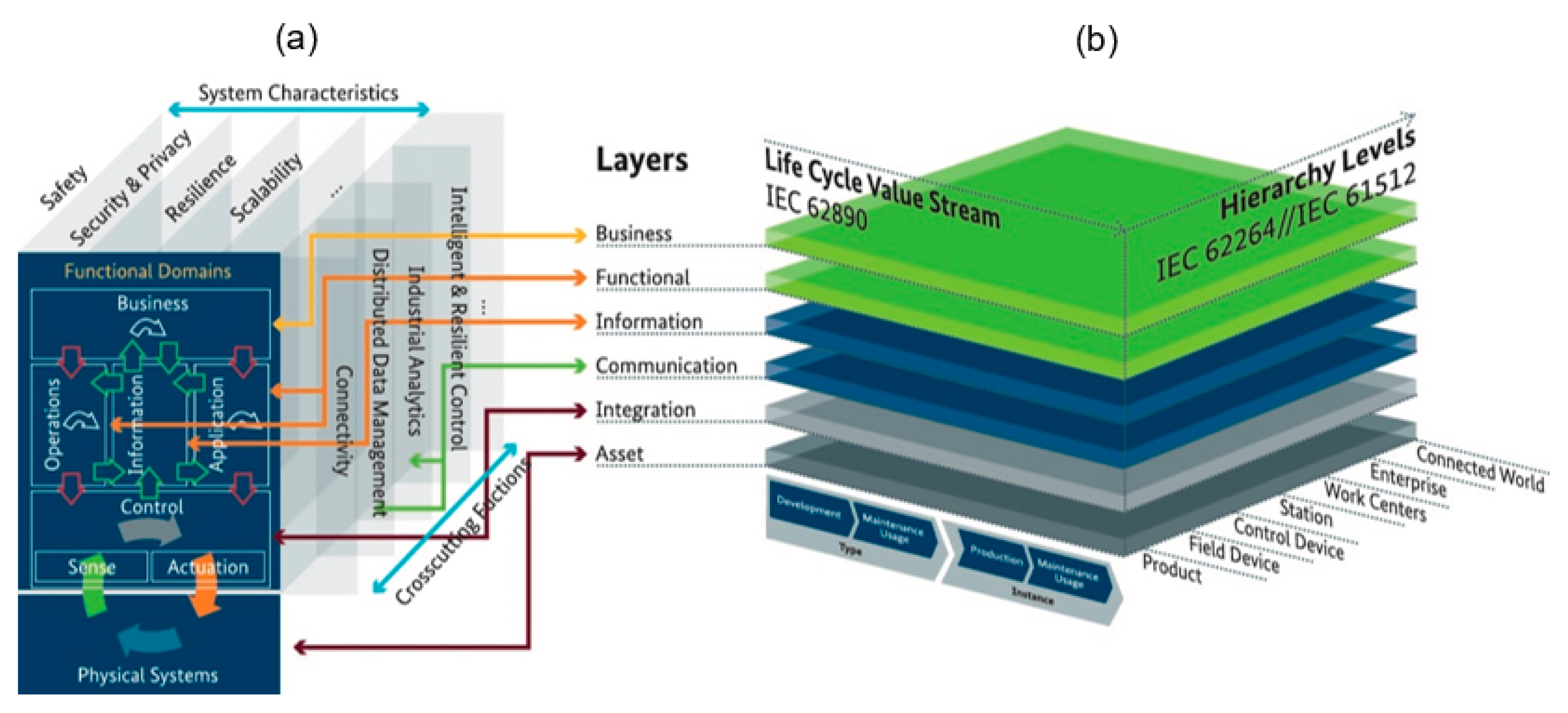

4.1. RAMI 4.0

The RAMI 4.0 was developed by several industry partners based out of Germany. RAMI 4.0 addresses interoperability by proposing a set of abstract interoperability layers for the manufacturing industry, as seen in Figure 3b [1]. Those layers are better explained as follows:

Figure 3.

(a) The Functional Viewpoint of IIRA. (b) RAMI 4.0 ©Plattform Industrie 4.0 and Zentralverband Elektrotechnik-und Elektronikindustrie e.V. (ZVEI) (Reprint with permission).

- (a)

- Business layer. This layer consists of the business models and information about the business’s components, such as the service and or the products that it offers. The business rules and practices are pre-defined and serve for governing the manner in which business processes are executed.

- (b)

- Functional layer. The functions of the architecture model are characterized and detailed and their relationships are established. The functions are designed and rendered and are autonomous, not dependent upon the processes or its utilization in the architecture.

- (c)

- Information layer. This layer controls and governs the data and information that is used in the architecture. It also serves the purpose of analyzing the information that is being exchanged and the level of data quality.

- (d)

- Communication layer. The communication between layers, systems and all the components that are executed, while at the same time interoperable are described by this layer.

- (e)

- Integration layer. This layer provides a connection between all the layers of this architecture and the physical components. It also addresses network and software integration.

- (f)

- Asset Layer. This layer includes all the systems at the physical level such as shop floor machines, the human interaction with the systems as well as other physical objects.

The RAMI 4.0 model was built after studying existing approaches and incorporating them into the interoperability stack. Approaches such as OPC-UA: Basis IEC 62541 [51] (for the Communication layer), IEC Common Data Dictionary (for the Information layer), Field Device Integration technology (for the Functional and Information Layer) and AutomationML and ProSTEP (for design and end to end engineering) have been used in designing and building the interoperability stack [1]. The architecture also incorporated IEC 62890 functions to address life cycle improvement and value stream mapping.

4.2. IIRA

The IIRA was built as an open architecture with a wide array of applications across industries [50]. It provides a model to create systems based on IIoT without any constraint on the system’s use of any specific standards or protocol. The IIRA’s domains that are analogous to RAMI 4.0’s layers (as seen in Figure 3a are the following:

- (a)

- Business domain. This domain is at the top of the IIRA functional viewpoint and consists of business-related information at the enterprise level. It also manages systems that are used across the business such as Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) in line with objectives and goals pertinent to the business.

- (b)

- Information domain. This domain consists of functions that are tasked with the purpose of data analysis and assessment of data quality to procure knowledge of all the system’s components.

- (c)

- Application domain. This domain builds on the information logged by the information domain and applies logic to it to improve system performance and efficiency of operations.

- (d)

- Operations domain. This domain assesses the operations that are planned and ongoing, performs scheduled maintenance and diagnostics, with the end goal being ensuring optimal performance.

- (e)

- Control domain. This domain consists of functions that control the implementation of processes at the physical system with feedback.

One can see from Figure 3 that the functional layers of RAMI 4.0 and the domains of IIRA are related and have the same high-level tasks distributed amongst them. Similar to RAMI 4.0, IIRA also applies OPC-UA to model its communications and network. This enables syntactic interoperability between these two reference architectures. Although IIRA is not specifically designed for manufacturing applications, the linkage with RAMI 4.0 establishes a foundation for its application in the manufacturing domain. Not only has interoperability within these architectures been established, but interoperability between these architectures has also been mapped.

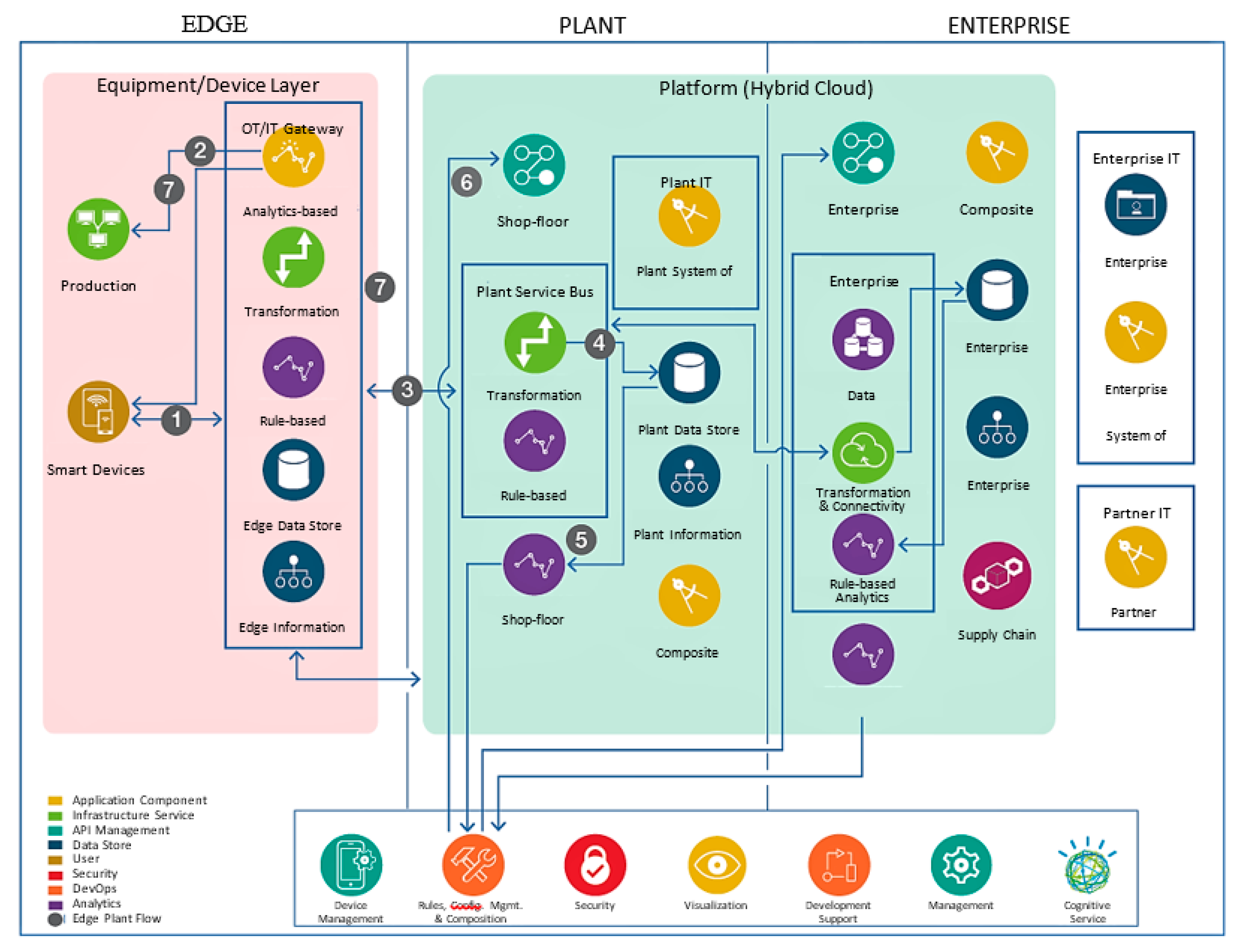

4.3. IBM Industry 4.0 Reference Architecture

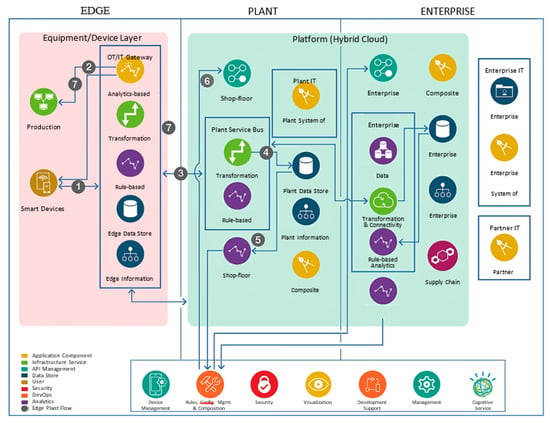

IBM introduced the Industry 4.0 Architecture (Figure 4) with a reference model that consists of two layers with functions distributed amongst them [52]:

Figure 4.

The IBM Industry 4.0 Architecture consisting of an Edge layer and Platform layer. (Reprint from Reference [49]).

- (a)

- The Edge integrates the Plant and the Enterprise layers, with the ability to connect with legacy systems and equipment and also the protocol that they follow. The Edge can work independent of the Plant and Enterprise layers, without any integration by controlling the systems components at the device level directly. Smart devices and equipment can communicate all the way up through to the Enterprise level from the Edge when integrated. The Edge undertakes the task of data analytics and transformation and communicates this information through the layers.

- (b)

- The Hybrid Cloud or the Platform consisting of the Plant and the Enterprise levels perform plant wide and enterprise wide analytics. The Plant level can direct MES to take appropriate decisions based on the analyzed data and the Enterprise level can similarly make decisions based on factories, locations, etc.

It is important to note that the architecture incorporates the OPC-UA communication standards (similar to RAMI 4.0 and IIRA) and is also designed keeping in mind the ISA-95 specifications.

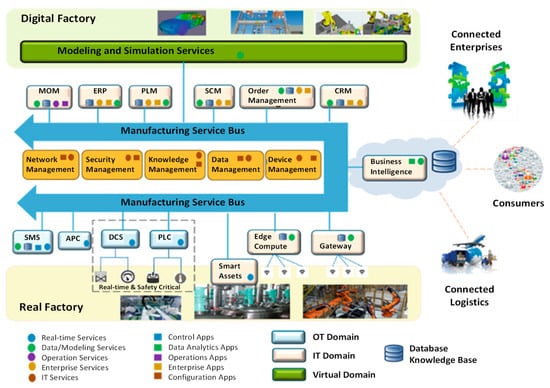

4.4. NIST Service-Oriented Architecture for Smart Manufacturing

NIST proposed a service-oriented architecture (Figure 5) that is specifically aimed at smart manufacturing [53] by linking operational technology (OT) and information technology (IT) via a manufacturing service bus. It also provides a Business Intelligence (BI) service that ensures all stakeholders are in contact. The IT domain services consist of all IT operations right from the system level to the enterprise level (ERP, MES, etc.). The OT domain services address the processes and tasks that are assigned to the physical level, the components on the shop floor. There is also another domain that addresses the virtual capabilities of the architecture, the virtual domain. This domain’s services are primarily to ensure data quality and data management are achieved at the highest level as well as simulating models for the manufacturing tasks at hand. The other high-level services such as enterprise level security, product life cycles, manufacturing value stream and information management are attended to by management or common services.

Figure 5.

NIST service-oriented architecture for smart manufacturing working on a shared manufacturing bus (Reprint from [53]). Terminology used in Figure 5: Smart Manufacturing Architecture (SMS), Distributed Control Systems (DCS), Customer Relationship Management (CRM), Manufacturing Operation Management (MOM), Supply Chain Management (SCM), Product Lifecycle Management (PLM).

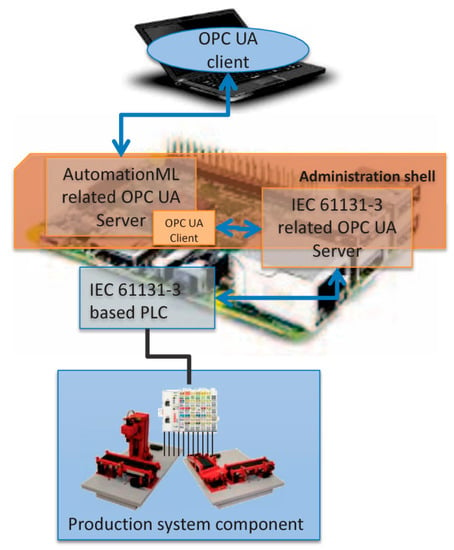

5. Real-World Implementation of Industry 4.0 Components

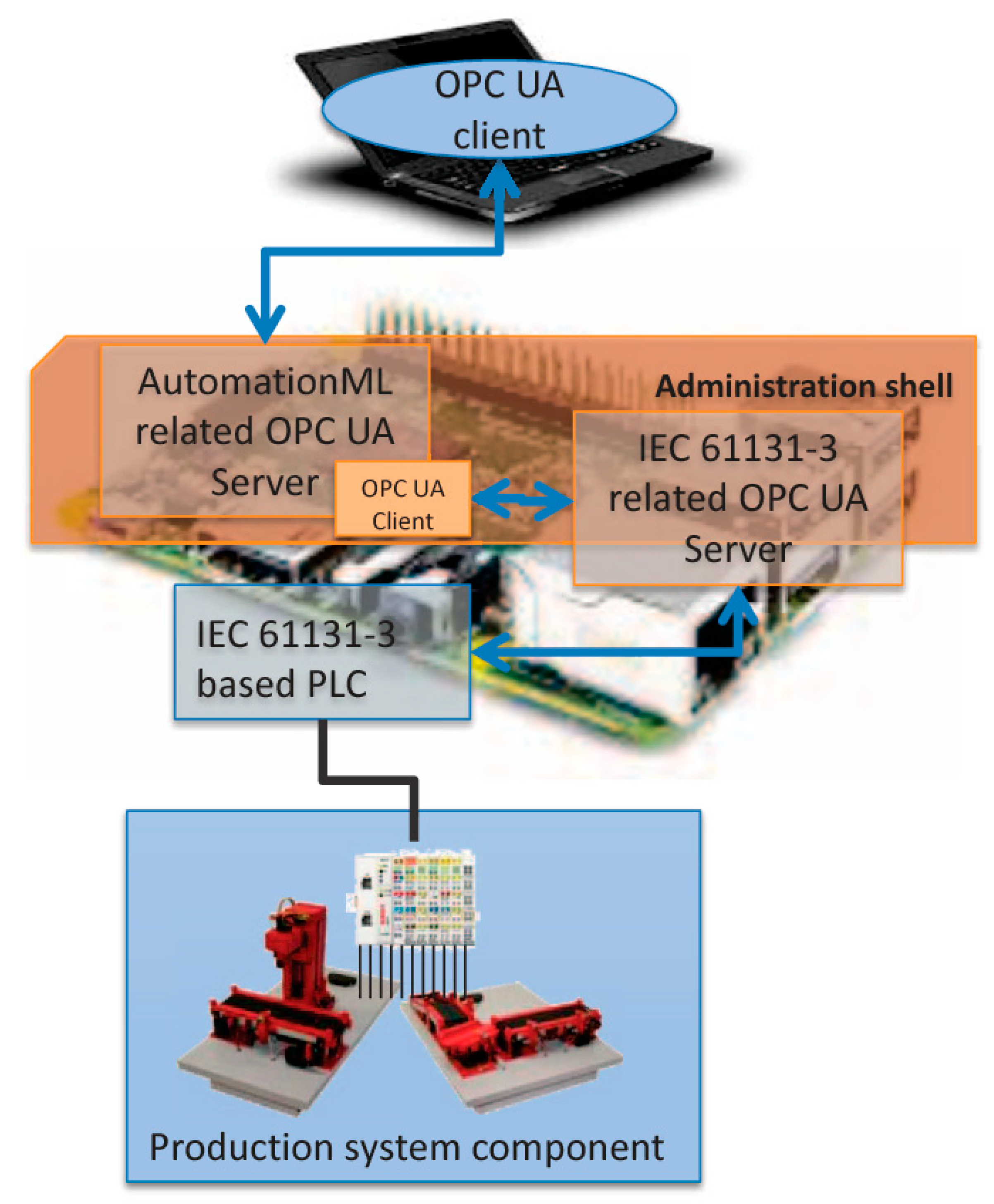

Since most of the reference architecture models are still in the conceptual phase, there are very few implementations that have been documented. A successful implementation of emerging technologies has been achieved by Lüder et al. in which they integrate a production plant model to an OPC UA client by the use of AutomationML and an administration shell that is built on IEC 61131-3 [54]. AutomationML is a neutral format for the exchange of data developed by Daimler, ABB, Siemens, Rockwell, Kuka, Zühlke, netAllied and universities of Karlsruhe and Magdeburg [55]. The model (Figure 6) uses a combination of Modbus Transmission Control Protocol (TCP) and a fieldbus to connect to the Programmable logic controller (PLC), and is controlled by a Raspberry Pi. The OPC-UA client is on the computer that is able to access the plant and make changes according to the functions provided by the PLC. The OPC UA information model is generated and the communication with the AutomationML model is set up. The information generated by the OPC UA model is transferred into the OPC UA server based on OPC standards. The network connection is configured automatically by AutomationML.

Figure 6.

AutomationML implementation (Reprint from Reference [55]).

6. Future Scope and Recommendations

With the advent of the numerous architectures that have been proposed, there are many areas of interest for research that are gaining importance. A comprehensive list of the most significant areas of focus has been compiled by researchers after interviewing seven industry experts in the area of manufacturing [4]. The results can be seen in Table 1, in which the R&D challenges are listed and corresponding to each challenge, views of experts are recorded. A check mark denotes that the expert agrees and proposes the challenge as a significant area for future research.

Table 1.

Summary of R&D Challenges Identified by the Experts. Adopted from [4].

We can see that integration of shop floor, business processes, and cloud services for plug-and-produce work received the support of four experts. Similarly, asynchronous and interoperable communication mechanisms and publish/subscribe also received four votes. Common language for standardizing object and services too received four votes. We notice that the three aforementioned propositions have one thing in common: they all address interoperability directly. Integration across the enterprise is a core for the successful implementation of interoperability. Interoperable communication mechanisms address the issue of the exchange of data and information which would include syntactic, as well as semantic interoperability. The proposition of the use of a common language for standardizing object and services also addresses the core issue of interoperability. While these are important areas of research for interoperability for the future, there are also other areas in the smart manufacturing domain that are very important. NIST has conducted workshops on enabling composable service oriented manufacturing systems [56]. The topics discussed include the setting up of messaging standards in smart manufacturing, the reference models and architectures of smart manufacturing, the applications of smart manufacturing and marketplaces that offer manufacturing services and the development of ontologies.

7. Conclusions

The evolution of the traditional hierarchical models of enterprise control system integration, or the automation pyramid, towards integrated networks of smart devices, cloud-based services, and extended enterprises demand seamless communication and information exchange between heterogeneous and traditionally-siloed systems. Thus, there is a need for both vertical interoperability between shop-floor automation devices and services as well as horizontal interoperability between enterprises and cloud service platforms. The hierarchical structure of a pyramid that often inhibits interoperability between non-adjacent layers must be transformed into an interoperable, heterarchical network that facilitates decentralized operations and decision making. CPPS, cloud manufacturing, smart manufacturing and other emerging paradigms follow a highly interoperable, hierarchy-free structure.

With new systems and manufacturing architectures being proposed and introduced, standardization is gaining importance. The need for standardization and integration in making interoperability at every level is imminent. The type of interoperability essentially depends on the systems or components of the architecture that one is trying to make interoperable. The most common type of interoperability can be observed within the manufacturing system, i.e., the physical level (Levels 2-0 of ISA-95). Other types of interoperability that the reference architecture models specifically address are between and across business units across the enterprise and between different factory locations. The reference architectures described in this paper are still at a conceptual phase and implementation has not been fully accomplished at the operational level due to the relative absence of standardization. Although syntactic interoperability has become increasingly common amongst ICT systems, semantic interoperability has yet to be developed at all levels because of the complexity in the logic applied. The future scope of research in this direction will focus on the specific interoperability challenges at each level of the network, both vertical and horizontal. Developing communication protocols built upon OPC-UA to enable an interoperable smart manufacturing environment will also be considered.

Author Contributions

Conceptualization, A.Z. and S.S.; Methodology, A.Z.; Investigation, S.S.; Resources, M.M.; Data Curation, M.M.; Writing-Original Draft Preparation, S.S. and M.M; Writing-Review & Editing, T.M.; Supervision, A.Z.; Project Administration, A.Z.; Funding Acquisition, S.K.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- DIN. DIN SPEC 91345:2016-04, Reference Architecture Model Industrie 4.0 (RAMI4.0); DIN: Berlin, Germany, 2016. [Google Scholar]

- CSIS. Made in China 2025; CSIS: Washington, DC, USA, 2015. [Google Scholar]

- Manufacturing USA. National Network for Manufacturing Innovation; A National Advanced Manufacturing Portal: Gaithersburg, MD, USA, 2011. [Google Scholar]

- Moghaddam, M.; Cadavid, M.; Kenley, C.R.; Deshmukh, A. Reference architectures for smart manufacturing: A critical review. J. Manuf. Syst. 2018, 49, 215–225. [Google Scholar] [CrossRef]

- Lu, Y.; Morris, K.C.; Frechette, S. Current Standards Landscape for Smart Manufacturing Systems; NIST: Gaitehrsburg, MD, USA, 2016; Volume 8107, ISBN 1069600690287.

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Xu, X. From cloud computing to cloud manufacturing. Robot. Comput. Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Ray, S.R.; Jones, A.T. Manufacturing interoperability. J. Intell. Manuf. 2006, 17, 681–688. [Google Scholar] [CrossRef]

- Lee, E.A. Cyber Physical Systems: Design Challenges. In Proceedings of the 2008 11th IEEE International Symposium on Object and Component-Oriented Real-Time Distributed Computing (ISORC), Orlando, FL, USA, 5–7 May 2008; pp. 363–369. [Google Scholar]

- NSF. Cyber-Physical Systems (CPS); National Science Foundation: Arlingation, VA, USA, 2010.

- Nolin, J.; Olson, N. The Internet of Things and convenience. Internet Res. 2016, 26, 360–376. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; da Xu, L.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud Computing and Internet of Things-Based Cloud Manufacturing Service System. IEEE Trans. Ind. Inf. 2014, 10, 1435–1442. [Google Scholar]

- ISO/IEC. ISO/IEC 18384: 2016, Information Technology—Reference Architecture for Service Oriented Architecture (SOA RA); International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Ivezic, N.; Kulvatunyou, B.; Brandl, D.; Machi, M.; Lu, Y.; Noller, D.; Davis, J.; Wuest, T.; Kiritsis, D.; Witherell, P. NIST Advanced Manufacturing Series 100-15—2017 NIST/OAGi Workshop: Drilling down on Smart Manufacturing—Enabling Composable Service-Oriented Manufacturing Systems. NIST AMS 2018. [Google Scholar] [CrossRef]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.-D. Machine learning in manufacturing: Advantages, challenges, and applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- Harding, J.A.; Shahbaz, M.; Kusiak, A. Data Mining in Manufacturing: A Review. J. Manuf. Sci. Eng. 2006, 128, 969–976. [Google Scholar] [CrossRef]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The Smart Factory: Exploring Adaptive and Flexible Manufacturing Solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef]

- Wang, L.; Torngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Jin, C. Introduction to cyber manufacturing. Manuf. Lett. 2016, 8, 11–15. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Wu, D.; Rosen, D.W.; Wang, L.; Schaefer, D. Cloud-based design and manufacturing: A new paradigm in digital manufacturing and design innovation. Comput.-Aided Des. 2015, 59, 1–14. [Google Scholar] [CrossRef]

- Jiang, P.; Ding, K.; Leng, J. Towards a cyber-physical-social-connected and service-oriented manufacturing paradigm: Social Manufacturing. Manuf. Lett. 2016, 7, 15–21. [Google Scholar] [CrossRef]

- ISO/IEC. ISO 16100-6:2011(E): Industrial Automation Systems and Integration—Manufacturing Software Capability Profiling for Interoperability; International Organization for Standardization: Geneva, Switzerland, 2015; Volume 2011. [Google Scholar]

- 610-1991 IEEE Standard Computer Dictionary. A Compilation of IEEE Standard Computer Glossaries; IEEE Press: Piscataway, NJ, USA, 1991; ISBN 9780738147680.

- Kasunic, M. Measuring Systems Interoperability: Challenges and Opportunities. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.464.9748&rep=rep1&type=pdf (accessed on 1 April 2019).

- Ford, T.C.; Colombi, J.M.; Graham, S.R.; Jacques, D.R. A Survey on Interoperability Measurement. Available online: http://www.dodccrp.org/events/12th_ICCRTS/CD/html/papers/096.pdf (accessed on 1 April 2019).

- Heiler, S. Sandra Semantic interoperability. ACM Comput. Surv. 1995, 27, 271–273. Available online: https://dl.acm.org/citation.cfm?doid=210376.210392 (accessed on 25 March 2019). [CrossRef]

- Curts, R.J.; Campbell, D.E. Architecture: The Road to Interoperability; Command & Control Research Technology Symposium (CCRTS): US Naval War College, Newport, RI, USA, 1999. [Google Scholar]

- Berre, A.-J.; Hahn, A.; Akehurst, D.; Bezivin, J.; Tsalgatidou, A.; Vermaut, F.; Kutvonen, L.; Linington, P.F. State-of-the Art for Interoperability Architecture Approaches—Model Driven and Dynamic, Federated Enterprise Interoperability Architectures and Interoperability for Non-Functional Aspects. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.106.9713&rep=rep1&type=pdf (accessed on 25 March 2019).

- Chituc, C.-M.; Toscano, C.; Azevedo, A. Interoperability in Collaborative Networks: Independent and industry-specific initiatives—The case of the footwear industry. Comput. Ind. 2008, 59, 741–757. [Google Scholar] [CrossRef]

- Morris, E.; Levine, L.; Meyers, C.; Place, P.; Plakosh, D. System of Systems Interoperability (SOSI): Final Report; Carnegie-Mellon University: Pittsburgh, PA, USA, 2004; Available online: https://resources.sei.cmu.edu/asset_files/TechnicalReport/2004_005_001_14375.pdf (accessed on 1 April 2019).

- Chen, D.; Vernadat, F.B. Enterprise Interoperability: A Standardisation View; Springer: Boston, MA, USA, 2003; pp. 273–282. [Google Scholar]

- Kemmerer, S.J. Manufacturing Interoperability Program: A Synopsis, National Institue of Standards and Technology; Technical Reprot for NIST Interagency/Internal Report (NISTIR)-7533: Gaithersburg, MD, USA, 2009. [Google Scholar]

- Mosley, M.; Brackett, M.H.; Earley, S.; Henderson, D.; Data Administration Management Association. DAMA Guide to the Data Management Body of Knowledge (DAMA-DMBOK Guide). 2009. Available online: http://eitbokwiki.org/Interoperability (accessed on 26 February 2019).

- van der Veer, H.; Wiles, A. Achieving Technical Interoperability-the ETSI Approach; European Telecommunications Standards Institute: Sophia Antipolis, France, 2008. [Google Scholar]

- Shukla, A.; Harris, S.; Davies, J. Semantic Interoperability in Practice. In Proceedings of the IEEE 2010 43rd Hawaii International Conference on System Sciences, Honolulu, HI, USA, 5–8 January 2010; pp. 1–10. [Google Scholar]

- Decker, S.; Melnik, S.; van Harmelen, F.; Fensel, D.; Klein, M.; Broekstra, J.; Erdmann, M.; Horrocks, I. The Semantic Web: The roles of XML and RDF. IEEE Internet Comput. 2000, 4, 63–73. [Google Scholar] [CrossRef]

- Lelli, F. Interoperability of the Time of Industry 4.0 and the Internet of Things. Futur. Internet 2019, 11, 36. [Google Scholar] [CrossRef]

- Tassey, G.; Brunnermeier, S.B.; Martin, S.A. Interoperability Cost Analysis of the U.S. Automotive Supply Chain Final Report RTI Project Numer 7007-03; Research Triangle Institute: Research Triangle Park, NC, USA, 1999. [Google Scholar]

- Chen, D.; Doumeingts, G.; Vernadat, F. Architectures for enterprise integration and interoperability: Past, present and future. Comput. Ind. 2008, 59, 647–659. [Google Scholar] [CrossRef]

- ISO/IEC. Information Technology-Cloud Computing-Interoperability and Portability; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Representational State Transfer (REST). Available online: https://www.ics.uci.edu/~fielding/pubs/dissertation/rest_arch_style.htm (accessed on 28 January 2019).

- ISO/IEC. Information Technology-Message Queuing Telemetry Transport (MQTT) v3.1.1; International Organization for Standardization: Geneva, Switzwerland, 2016. [Google Scholar]

- Mourad, M.; Nassehi, A.; Schaefer, D. Interoperability as a Key Enabler for Manufacturing in the Cloud. Procedia CIRP 2016, 52, 30–34. [Google Scholar] [CrossRef]

- Wang, X.V.; Xu, X.W. ICMS: A Cloud-Based Manufacturing System; Springer: London, UK, 2013; pp. 1–22. [Google Scholar]

- Lu, Y.; Xu, X.; Xu, J. Development of a Hybrid Manufacturing Cloud. J. Manuf. Syst. 2014, 33, 551–566. [Google Scholar] [CrossRef]

- Li, B.; Chai, X.; Hou, B.; Zhang, L.; Zhou, J.; Liu, Y. New Generation Artificial Intelligence-Driven Intelligent Manufacturing (NGAIIM). In Proceedings of the 2018 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), Guangzhou, China, 8–12 October 2018; pp. 1864–1869. [Google Scholar]

- Chai, X.; Hou, B.; Zou, P.; Zeng, J.; Zhou, J. INDICS: An Industrial Internet Platform. In Proceedings of the 2018 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), Guangzhou, China, 8–12 October 2018; pp. 1824–1828. [Google Scholar]

- Rouse, W.B.; Sage, A.P. Handbook of Systems Engineering and Management; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 9780470083536. [Google Scholar]

- Architecture Alignment and Interoperability an Industrial Internet Consortium and Plattform Industrie 4.0 Joint Whitepaper Contributors. Available online: https://www.iiconsortium.org/pdf/JTG2_Whitepaper_final_20171205.pdf (accessed on 25 March 2019).

- IEC. IEC TR 62541-2:2016—OPC Unified Architecture—Part 2: Security Model; Technical Report for International Electrotechnical Commission: Geneva, Switzerland, 2016. [Google Scholar]

- Internet of Things for Insights from Connected Devices: Industrie 4.0—IBM Cloud Garage Method. IBM. Available online: https://www.ibm.com/cloud/garage/architectures/iotArchitecture/industrie_40 (accessed on 28 January 2019).

- Lu, Y.; Riddick, F.; Ivezic, N. The Paradigm Shift in Smart Manufacturing System Architecture; Springer: Cham, Switzerland, 2016; pp. 767–776. [Google Scholar]

- Luder, A.; Schleipen, M.; Schmidt, N.; Pfrommer, J.; Hensen, R. One step towards an industry 4.0 component. In Proceedings of the 2017 13th IEEE Conference on Automation Science and Engineering (CASE), Xi’an, China, 20–23 August 2017; pp. 1268–1273. [Google Scholar]

- Drath, R.; Luder, A.; Peschke, J.; Hundt, L. AutomationML—The glue for seamless automation engineering. In Proceedings of the 2008 IEEE International Conference on Emerging Technologies and Factory Automation, Hamburg, Germany, 15–18 September 2008; pp. 616–623. [Google Scholar]

- 2018 NIST/OAGi Workshop: Enabling Composable Service-Oriented Manufacturing Systems. Available online: https://www.nist.gov/news-events/events/2018/04/2018-nistoagi-workshop-enabling-composable-service-oriented-manufacturing (accessed on 26 February 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).