2.1. Problem Statement

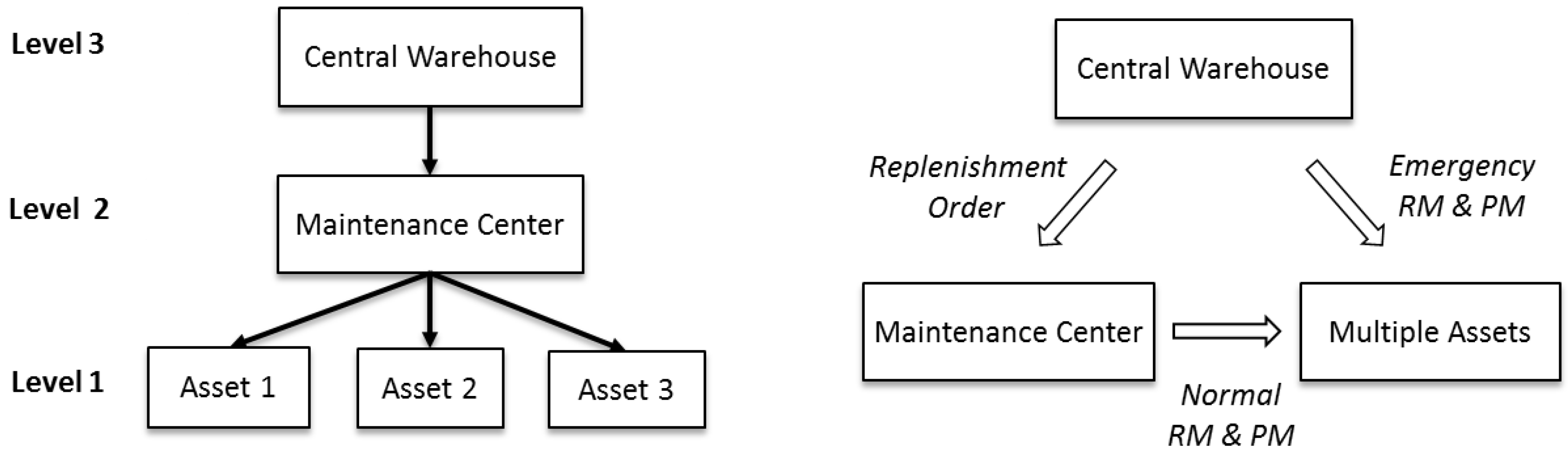

As illustrated in

Figure 1, the topology of the SPL system considered in this paper is a three-level logistic network, consisting of a

central warehouse, a

maintenance center, and a set of multiple

assets. Furthermore, the assets are assumed to have multi-part structure, each consisting of multiple independent

working parts. These entities are explained in more detail below.

A

central warehouse is the primary source for all new spare parts and plays two roles in the spare part inventory flow—replenishing spare parts for the maintenance centers following a (

s,

S) replenishment policy [

25], or providing spare parts directly to the assets as emergency orders when the maintenance order could not be satisfied from a maintenance center. Infinite inventory levels of spare parts are assumed for the central warehouse.

A maintenance center fulfills maintenance orders from the nearby assets by shipping new undegraded spare parts to their operating sites. It is assumed to have finite inventory levels of spare parts and any maintenance order that cannot be immediately fulfilled by the maintenance center is serviced via an emergency order to the central warehouse.

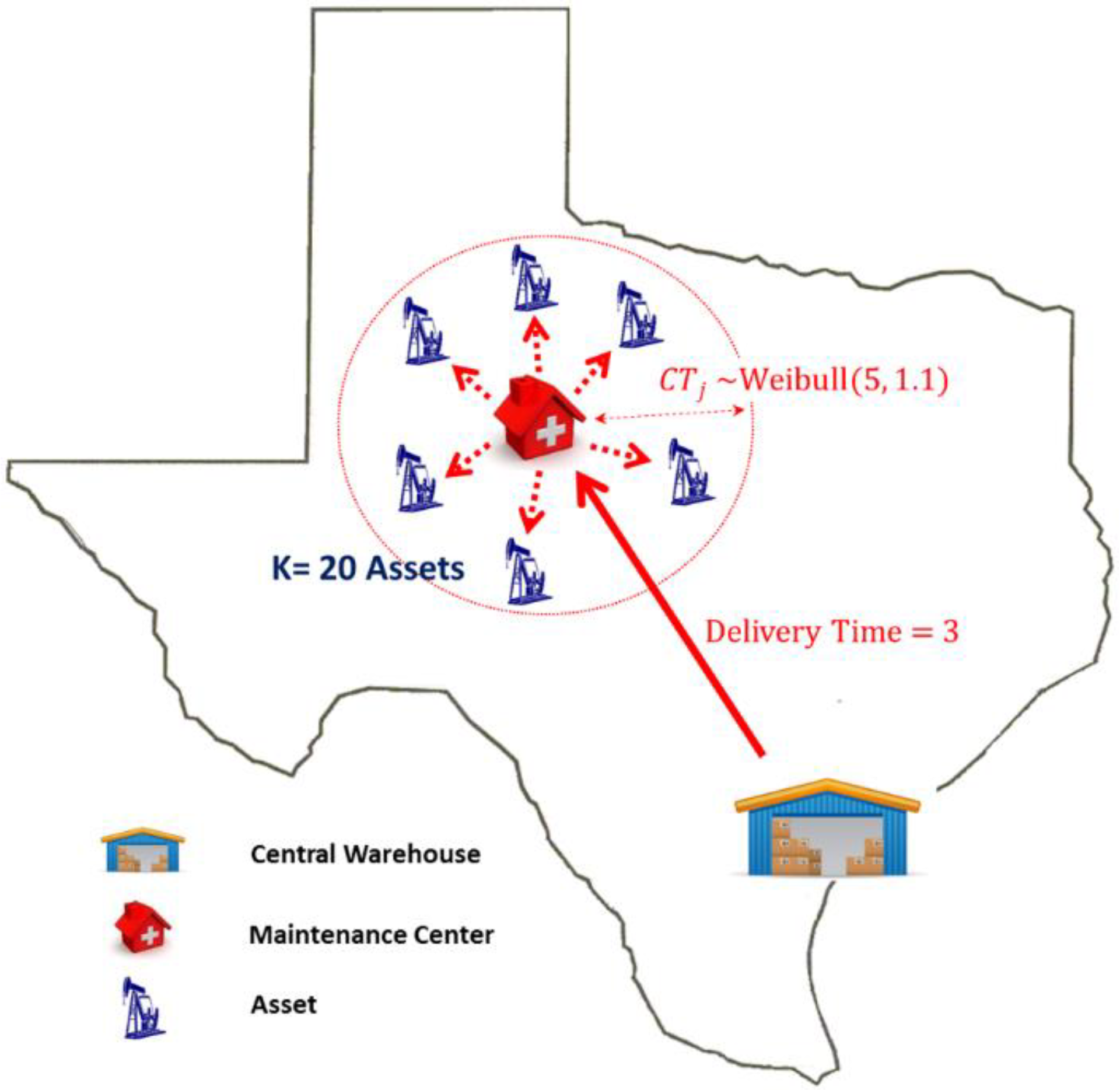

The term asset is used to refer to a machine that can be operated independently to generate revenue. It is assumed that there is a fleet of geographically dispersed assets in the system, labeled . An asset consists of multiple independent working parts and can only operate properly if all its parts behave properly.

The term working part is used to refer to a basic unit of an asset. An asset () is assumed to be made up of serially connected parts, labeled . Degradation process of a part is characterized by a reliability function, , representing the distribution of that part’s usage time to failure. From the point of view of logistics, a working part on an asset corresponds to a certain type of a spare part that needs to be stored in the maintenance center. During a preventive or reactive maintenance intervention, a new spare part should be shipped either from the maintenance center or directly from the central warehouse to replace the degraded working part.

In this paper, a continuous-review inventory system is considered and an (

s,

S) replenishment policy is followed to manage spare part inventories in the maintenance centers. Let

denote all spare parts needed to be stocked in a maintenance center. For a spare part

, the re-order inventory level

(corresponding to

s in the replenishment policy) indicates the critical level of this spare part that triggers a replenishment order with batch size

(corresponding to

s-

S in the replenishment policy), indicating the number of the spare parts to be shipped from the central warehouse to that maintenance center. Furthermore, the replenishment cost per order (

) is assumed to be a linear function of the batch size (

), or more formally,

where

denotes the fixed replenishment handling cost and

denotes the additional cost to have one more spare part added to the replenishment order.

From the side of maintenance decisions, the so-called reactive maintenance policy is assumed [

1], that is to say, both PM and reactive (unscheduled) maintenance (RM) intervention involve a new spare part replacing the broken or severely degraded working part on the asset. Moreover, a

usage-based PM triggering policy is considered, which means that a PM triggering usage level

is set for each working part

, indicating the part’s critical usage level at which a PM operation is initiated.

Once initialized, a complete maintenance order consists of two phases: transportation and execution.

(1) Transportation consists of shipping the ordered spare part to the asset from the maintenance center as a normal order, or from the central warehouse as an emergency order, with the lead times following the distributions and , respectively.

During RMs, a significant portion of the asset downtimes are caused by the waiting times for the new spare part. Therefore, several expedited shipping options will be considered, with faster ones incurring more costs. More formally, decision variable will be used to denote the relative acceleration of the expedited shipping option compared with normal delivery to the asset , with its influence on the lead time distributions (though we do not explicitly model holding costs accrued for parts in transport, these costs are present in the model via the transport costs associated with each transport option) and expedited shipping costs as follows:

Lead time from the maintenance center to following the distribution .

Lead time from the central warehouse to following the distribution .

Expedited shipping cost to accelerate an RM delivery to the asset given by .

Obviously, decision variable scales the delivery times, with, for example, corresponding to no acceleration in deliveries, doubling the speed of deliveries, tripling that speed, and so on.

(2) Execution is essentially the process in which the target part on the asset is replaced with the newly delivered spare part, resulting in a maintenance intervention. The times needed to execute maintenance interventions will be referred to as repair times.

It is assumed that an RM always restores the part to as-good-as-new condition, or, in other words, RM operations are assumed to be so-called perfect maintenance operations. However, it is assumed that PM operations of various performance qualities are available, with different costs and repair times. The character of a PM on an asset will be described by the PM recovery rate , representing its relative quality compared with a perfect PM. The decision variable is assumed to take discrete values between 0 and 1 ( indicates a perfect PM and indicates a minimal repair), influencing the PM-related parameters as follows:

Usage to failure of the part after PM following the distribution .

PM cost per order on the part given by .

PM repair time on the part given by .

In the above, denotes the relative quality of a minimal repair compared to a perfect operation, () denotes the fixed PM cost (time), and () denotes the additional cost (time) to improve PM performance.

2.2. Stochastic Optimization Formulation

In this paper, we will seek an integrated decision-making policy for the usage levels triggering PMs for working parts (please note that we here evaluate just a purely usage-based PM policy, without considerations of other options, such as, e.g., opportunistic maintenance. Such additional maintenance options can be incorporated into the same simulation-based framework, though such considerations remain outside the scope of this paper.) (

−

s), re-order and target inventory levels for spare parts being stocked in the maintenance centers (

−

s and

−

s), the expedited delivery rates for RMs (

−

s), and the recovery rates of PMs (

−

s). More formally, the integrated decision-making policy will be pursued through the following stochastic optimization,

where the terms are explained in

Table 1.

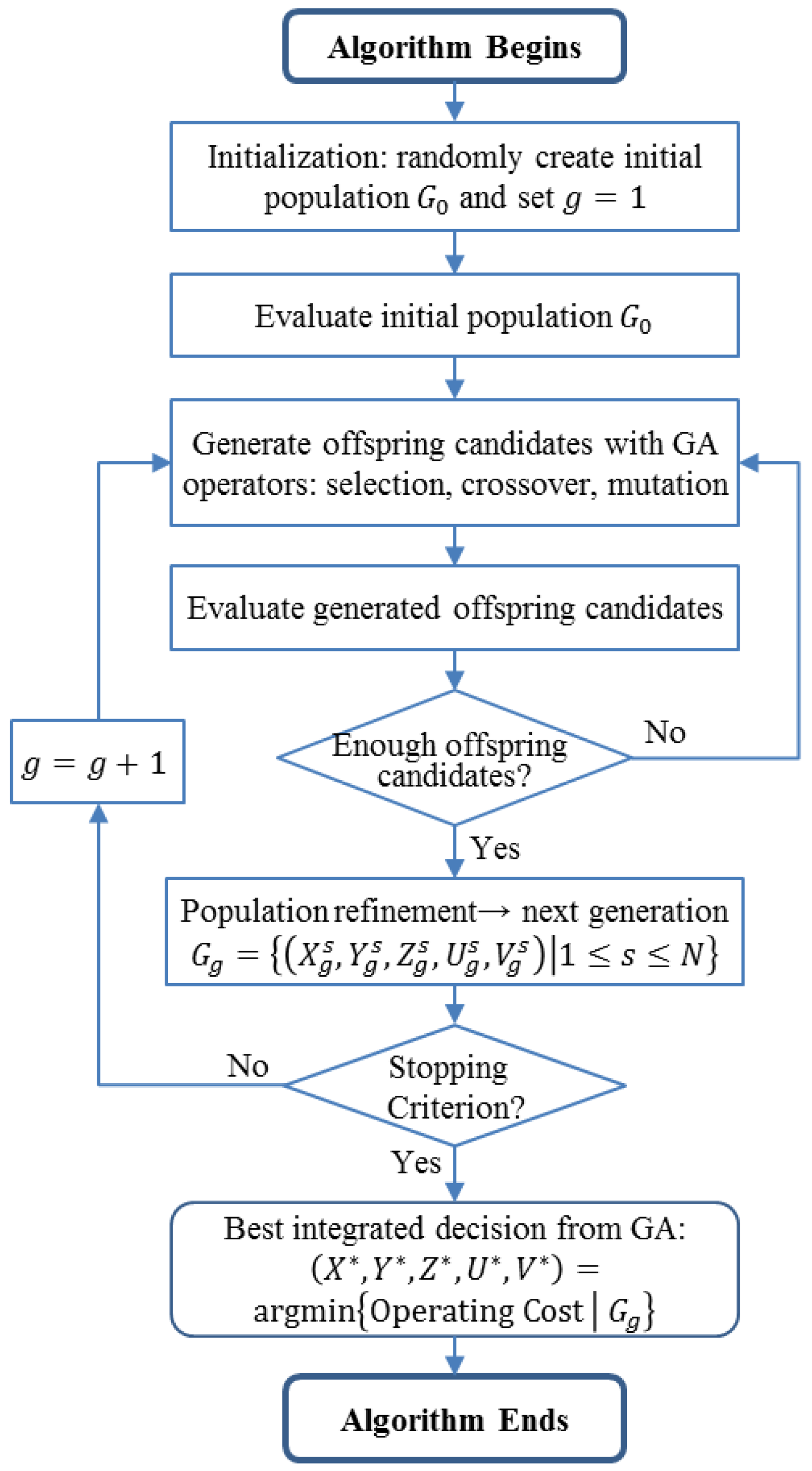

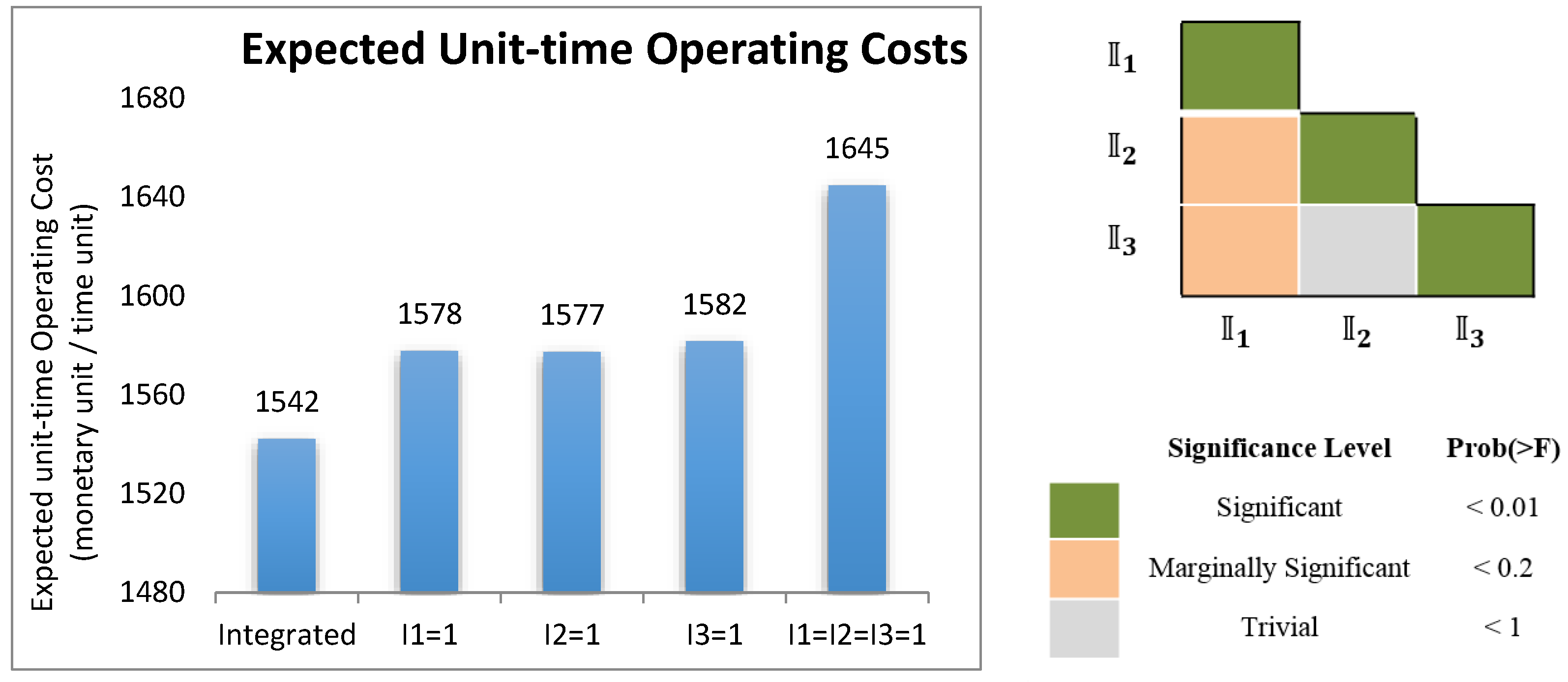

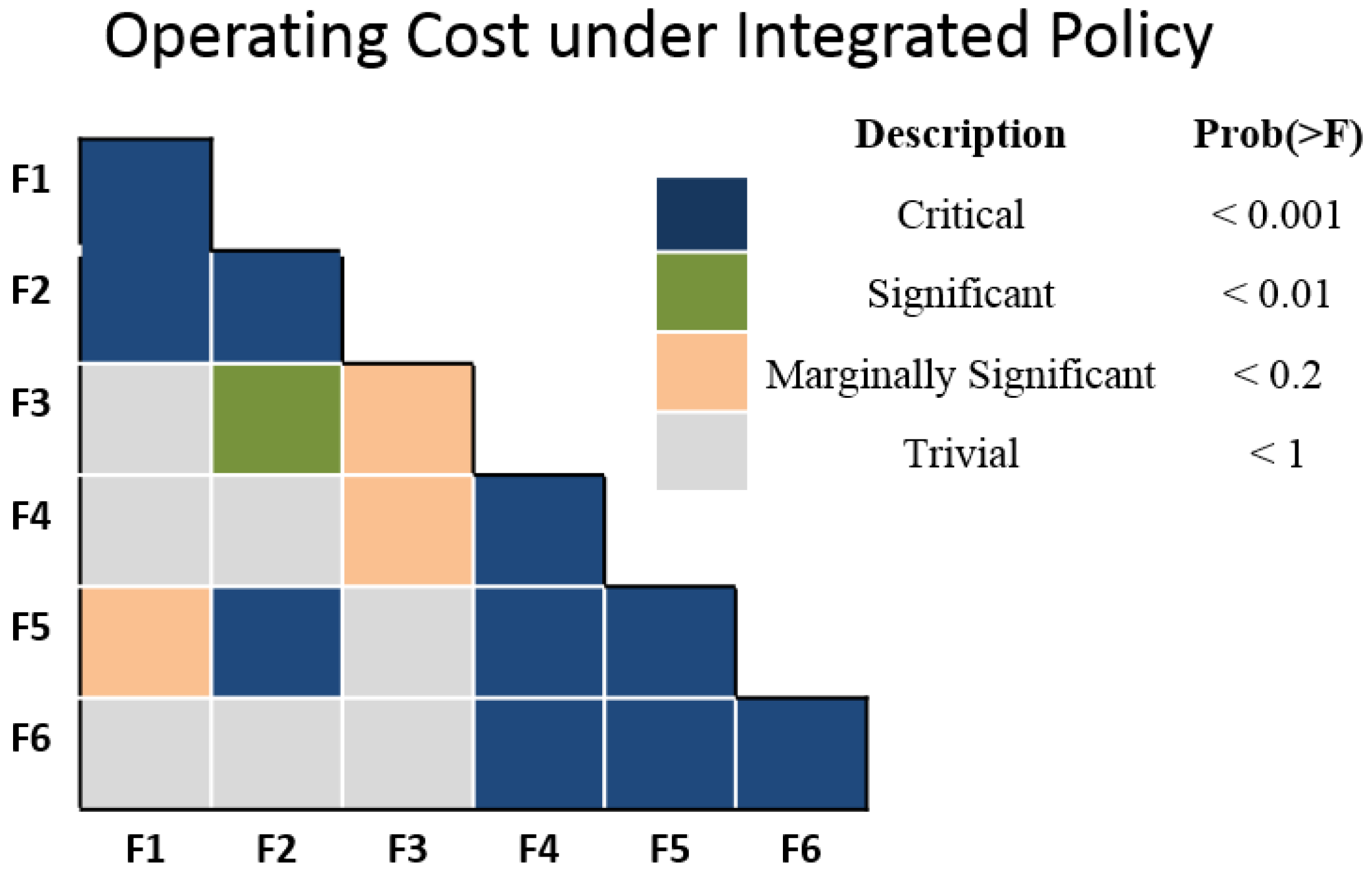

The objective function in (1) represents the expected unit-time operating cost of the system. The expectation operator is applied because of the random effects induced by the reliability of working parts and the delivery delays of spare parts. For each integrated decision, these random effects are captured by discrete-event simulation and the expected operating costs are estimated through averaging of the objective function values obtained from multiple replications of simulations.

One can see that the cost function in (1) consists of three groups of costs: (i) inventory-related costs, including the cost to hold spare parts inventories in the maintenance center and the cost to order replenishment for the maintenance center; (ii) penalties for the asset downtimes; and (iii) maintenance costs incurred by execution of PM and RM operations. This objective function penalizes the consumption of maintenance and logistic resources, while rewarding the asset availability. Obviously, this is a relatively simple cost function and one may likely need to choose cost parameters and/or incorporate other potential operating costs, such as emergency ordering costs and unfulfilled contract penalties. In effect, different companies, and often different parts of the same company, operate with different cost functions and cost parameters, necessitating adequate changes in the optimization Formulation (1). A simulation-based meta-heuristic optimization approach to solving the optimization problem (1), which will be elaborated in the next section, allows such alterations to the objective function, and was one of the main reasons for choosing such an optimization approach.