Abstract

During voltage dips, wind turbines must remain connected to the electrical grid and contribute to voltage stabilization. This study analyzes the impact of voltage dips arising from grid faults on Doubly Fed Induction Generator (DFIG) based Wind Energy Conversion Systems (WECSs). This paper presents a review of the technical regulations for integrating the Algerian electricity grid with the Low Voltage Ride Through (LVRT) system, along with specific requirements for renewable power generation installations. Additionally, the modeling and control strategy of DFIG based WECS has been outlined. Voltage dips can induce excessive currents that threaten the DFIG rotor and may cause harmful peak oscillations in the DC-link voltage, and can lead to turbine speed increase due to the sudden imbalance between the mechanical input torque and the reduced electromagnetic torque. To counter this, a modified vector control and crowbar protection mechanism were integrated. Its role is to mitigate these risks, thereby ensuring the system remains stable and operational through grid faults. The proposed system successfully meets the stringent Algerian LVRT requirements, with voltage dipping to zero for 0.3 s and recovering gradually. Simulations confirm that rotor and stator currents remain within safe limits (peak rotor current at 0.93 , and peak stator current at 1.36 ). The DC-link voltage, despite a transient rise due to the continued power conversion from the rotor-side converter during the grid fault, was effectively stabilized and maintained within safe operating margins (with less than 14% overshoot). This stability was achieved as the crowbar ensured power balance by managing active and reactive power. Notably, the turbine rotor speed demonstrated stability, peaking at 1.28 within mechanical limits.

1. Introduction

The global energy landscape is undergoing a profound transformation, with renewable energy sources, particularly wind and solar, playing an increasingly central role in the transition toward cleaner and more sustainable energy systems [1]. The data indicate that, in 2023, approximately 30% of global electricity production originated from renewable sources [2]. In Algeria, a country traditionally dependent on fossil fuels, the government has set ambitious targets to diversify its energy mix, aiming to reach a renewable energy capacity of 15 by 2035, with a major emphasis on solar (13 ) and wind (2 ) energy [3]. With a current installed capacity of 2.3 from renewable sources, Algeria’s efforts are part of a broader strategy to reduce its carbon footprint while leveraging its significant solar and wind potential. The country’s vast solar resource, with an average of 5.5–6.5 kWh/m2/day [4,5], and wind energy potential highlight Algeria’s strong renewable energy base. Southern regions such as Adrar, Timimoun, and Tindouf show mean wind speeds of 4.3–5.9 at 10 m. In Adrar, a 30 wind farm could yield about 98,800 MWh annually (capacity factor 38%), compared to 78,100 MWh (30%) in Timimoun and 56,000 MWh (21%) in Tindouf [6]. Wind power density in the south typically ranges from 160 to 280 , with Adrar reaching up to 647 at P50 (median) and 283 at P10 (exceeded 90% of the time), indicating both high potential and reliability. In contrast, northern sites such as Constantine offer weaker resources, with wind speeds of 3.4–3.9 and densities of 53–71 . These regional contrasts emphasize the importance of site-specific planning in Algeria’s renewable energy strategy [7,8].

The integration of wind generation, characterized by non-synchronous operation, into conventional power systems poses significant challenges to grid stability, power quality, and dynamic response characteristics [9]. Within WECS, multiple topologies have emerged to mitigate these issues, spanning fixed-speed induction generators, synchronous generator configurations, and variable-speed architectures [10]. The DFIG represents a predominant variable-speed solution, distinguished by its capacity to achieve electromechanical decoupling through partial-scale power converters. This critical feature facilitates adaptive speed regulation and independent control of active/reactive power flows [11]. Consequently, DFIG-based systems enhance energy harvesting efficacy across diverse wind regimes while satisfying strict grid code mandates for fault ride-through (FRT) and dynamic voltage support. Despite these advancements, the inherent stochasticity of wind resources induces persistent output power fluctuations. Such variability manifests as voltage sags, frequency excursions, and transient instabilities, thereby complicating grid synchronization and network stability management [12].

One of the key solutions to address these challenges is the implementation of Low Voltage Ride Through (LVRT) capability [13]. LVRT ensures that wind turbines remain connected to the grid during short-term voltage sags or dips, which are typically caused by grid faults or transient disturbances [14]. The requirement for LVRT has become a fundamental aspect of modern grid codes, as it helps maintain the stability of the electrical grid by preventing the disconnection of wind turbines during such events. In the absence of LVRT, wind turbines would automatically disconnect during voltage dips, that may affect grid stability and increase the risk of cascading failures [15]. LVRT, therefore, serves not only as a protective mechanism but also as a critical enabler for higher renewable energy penetration by allowing for continuous operation of wind farms during transient disturbances [16].

In Algeria, the adoption of LVRT is becoming increasingly important as the share of renewable energy in the grid increases. The country is actively modernizing its electrical infrastructure to accommodate higher levels of intermittent generation, and as part of this effort, the Grid Code has been updated to include stringent LVRT requirements. These updated regulations, which came into effect in 2019, ensure that all new renewable energy projects, particularly wind farms utilizing DFIG technology, meet the necessary standards for voltage dip tolerance and remain operational during grid disturbances. This aligns with international best practices and supports the grid’s ability to integrate larger volumes of renewable energy without compromising system reliability [17,18].

The evolving Grid Code in Algeria, which governs the technical and operational standards for grid connections, plays a pivotal role in ensuring the successful integration of renewable energy sources. By mandating LVRT compliance, the Grid Code ensures that renewable energy producers, including wind farms with DFIG-based turbines, contribute to grid stability even during fault conditions. The integration of such requirements also aligns with global efforts to standardize grid connection rules for renewable energy systems, ensuring that they can operate harmoniously with conventional power plants and other grid resources [19].

This paper aims to examine the technical, regulatory, and operational frameworks surrounding the integration of renewable energy in Algeria, with a particular focus on the role of DFIG-equipped WECS and the implementation of LVRT standards. Whereas, the importance of these technologies in ensuring voltage dip tolerance and their contribution to grid stability will be discussed. Furthermore, the paper will explore how the updated Grid Code in Algeria is enabling the country’s transition towards a more resilient and sustainable energy system by fostering greater renewable energy integration.

Building upon this regulatory and technical framework, this study presents a novel hybrid LVRT strategy that integrates a Modified Vector Control scheme with crowbar protection for the DFIG, specifically engineered to meet the stringent Algerian grid code requirement of withstanding a voltage drop to zero.

This approach is supported by a clear techno-economic rationale: while advanced external solutions like Static Synchronous Compensators (STATCOMs), with a cost ranging from 50$ to 100$ per kVAr, or Battery Energy Storage Systems (BESS), costing over 590$ per kWh [20], involve significantly higher capital expenditure, the crowbar-based protection offers a robust and cost-effective first-line defense at an incremental cost estimated at only 10$ to 20$ per kVA of system rating [21].

Validated through a comprehensive simulation case study, the effectiveness of the proposed strategy will be assessed. Key performance indicators will be evaluated, including whether rotor and stator currents can be maintained within established safe thresholds during fault conditions. Furthermore, the DC-link voltage’s transient response will be examined to confirm it can be stabilized and kept within safe operating margins, despite the energy imbalance caused by the grid fault. This stability will be pursued by ensuring power balance through the coordinated management of active and reactive powers via the modified control scheme. Finally, the stability of the turbine rotor speed will be verified to ensure it remains within permissible mechanical limits, thereby validating the system’s overall resilience under critical grid faults.

2. LVRT Strategies

The LVRT strategies can be categorized into two main types:

Active methods that focus on enhancing control strategies using Proportional–Integral (PI) controllers to independently regulation active and reactive power [22]. However, during grid voltage dips, conventional PI controllers often face saturation problems that limit their ability to generate appropriate corrective actions. Once the controller output reaches its maximum or minimum bound, it cannot react effectively to ongoing disturbances, which delays the recovery of proper voltage regulation. This shortcoming has motivated the development of a wide range of alternative control methods. For instance, Proportional–Integral–Derivative (PID) controllers extend the basic PI structure by introducing derivative action, which improves transient performance and helps reduce overshoot during fault conditions [23]. Sliding mode control has been widely studied for its robustness against parameter variations and external disturbances, making it suitable for low-voltage ride-through requirements [24,25]. Approaches based on fuzzy logic provide a flexible means of adapting to imprecise or varying operating conditions, while Model Predictive Control (MPC) makes use of predictive models to optimize control inputs in real time, enhancing the dynamic response during voltage sags [26]. Adaptive controllers adjust their parameters on-line according to system dynamics, and other solutions such as hysteresis-based control, neural-network-based controllers, and robust designs have also shown promise in improving fault ride-through capability [27,28].

And passive methods that involve additional protective hardware such as crowbars, DC capacitors, supercapacitors, energy storage systems, and pitch angle control [29,30]. Traditional crowbar circuits feature continuous current through the thyristor, preventing turn-off, leading to the proposal of active crowbars using switches like IGBTs and GTOs to respond more efficiently [31]. To limit rotor current transients and protect the converter during grid disturbances, active crowbars typically consisting of resistors connected to the rotor circuit and controlled switching devices are commonly used. In some designs, DC-link choppers with resistors are also employed to dissipate excess energy [32]. On the other side, studies have shown that energy capacitor systems protect the IGBT from DC bus overvoltages and dissipate energy, though they do not impact rotor currents [33]. In contrast, energy storage-based methods can control the generator during faults, but long-term storage is needed to supply predefined power output, increasing cost [34,35].

After a fault, the rotor accelerates, and the pitch angles increase, which reduces mechanical power and limits both rotor speed and reactive power consumption [29,36]. To address these dynamics, some methods incorporate more nonlinearities and accurate models of system noise. As part of this response mechanism, pitch angle variations, which can range between 2° and 90° depending on wind speed, play a critical role in stabilizing turbine behavior [37,38]. These control strategies are essential for complying with grid requirements, such as the fault ride-through capability defined in different countries National Grid Codes including Algeria, as illustrated in Figure 1 [39].

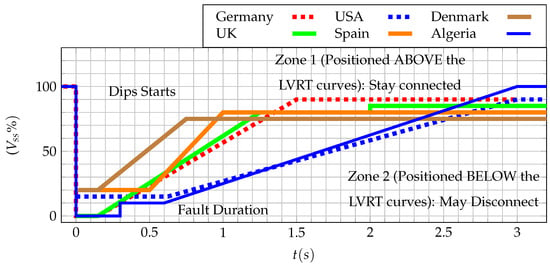

Figure 1.

LVRT requirement of different national grid codes [39].

The voltage ride-through curve of WECS requires that in Zone 1 (above the grid code curve), wind turbines must stay connected to the grid and generate active power as in conventional power generation. However, if the RMS value of the grid voltage drops below this curve, turbines can be disconnected (Zone 2). It can be noted that the algerian LVRT grid code is the most restrictive especially during the first 1300 milliseconds.

3. Technical Regulations for Connecting the Electricity System in Algeria

Power generation systems connection to the electrical grid in Algeria (WECS in particular) requires a comprehensive understanding of specific technical standards, especially regarding the injection of energy into the grid. Installers must ensure compliance with safety, quality, and energy integration standards to ensure seamless operation. The growth of wind energy and other renewable energy sources in the country hinges on close collaboration with regulatory authorities, the implementation of suitable technologies, and the optimal management of the electrical grid to ensure a successful energy transition.

3.1. Non-Synchronous Power Generation System

This refers to an electrical energy production installation that utilizes one or more generation units incorporating current converters or asynchronous machines. This includes DFIG as well as both synchronous and asynchronous machines connected to the grid through a current converter.

3.1.1. Specific Requirements for Non-Synchronous Power Generation System

Any non-synchronous production installation must have the constructive capacity to contribute to voltage regulation by supplying and absorbing reactive power. To this end, generation units and their power transformers must be designed in accordance with the following requirements [10]:

- Power Factor: Installations must be designed to achieve a power factor of 0.90 at the injection point.

- Voltage Range: The specified voltage ranges during normal operation are outlined in Table 1.

Table 1. Normal operating voltage ranges [10].

Table 1. Normal operating voltage ranges [10]. - Reactive Power: At nominal active power, the electricity generation system must be able to absorb a maximum reactive power of at nominal voltage .

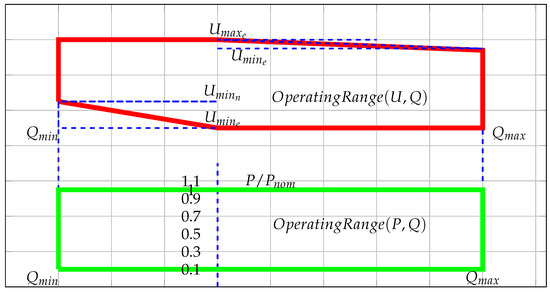

- Operating Range: For active power greater than , the installation must operate within the defined diagram, with no time limitation at any point in the normal operating range. The diagram is specified in Figure 2.

Figure 2. Operating range diagram [10].

Figure 2. Operating range diagram [10]. - Low Active Power Operation: For active power less than , non-synchronous installations must be able to operate with reactive power within the range , where and .

3.1.2. Technical Specifications for Disturbed Conditions Operation

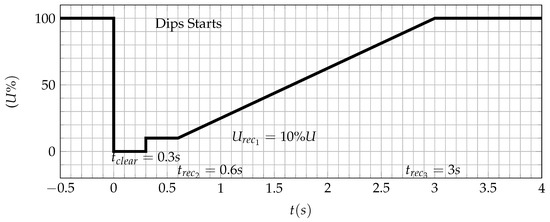

Non-synchronous power generation units are required to remain connected and synchronized with the electricity transmission network during faults. The voltage at the high-voltage transformer terminals must not be of the nominal voltage for s, and not below of the nominal voltage for s, as specified in Table 2 and Figure 3. In the case of asymmetrical faults, the lowest phase-to-phase or phase-to-ground voltage must be maintained. The system must continue operating in the case of reverse current imbalances in accordance with applicable standards. During voltage dips, the unit must provide reactive power based on the reduced voltage. After the fault is cleared, active power production must be restored to at least of the pre-fault level within one second. In the event of single-phase reclosures or consecutive multiple faults, the unit must remain connected and synchronized for up to 120 s [40].

Table 2.

Operating time under disturbed conditions [10].

Figure 3.

Voltage dip profile of a non-synchronous power generation installation in Algerian grid code [10].

3.2. Synchronous Power Generation System

This kind is related to systems generating electrical energy that utilizes one or more synchronous generators that are directly connected to the electrical grid without using power electronics converters.

3.2.1. Specific Requirements for Synchronous Power Generation Systems

Similar to asynchronous generation facilities, synchronous generation plants play a vital role in voltage regulation by supplying and absorbing reactive power. Accordingly, their generating units and associated power transformers must be engineered to comply with the following technical requirements [10]:

- Power Transformer Voltage Regulation: The power transformer should be fitted with a no-load voltage regulator, offering five adjustable tap positions (−5%, −2.5%, 0, +2.5%, +5%) on the high-voltage side for connections to a 220 kV or higher electricity transmission network. For a 60 kV network, only three positions (−5%, 0, +5%) are required. Additionally, the transformer may incorporate an on-load tap changer, with the adjustment range to be agreed upon with the System Operator.

- Voltage and Reactive Power Control: Power generation installations must be equipped with regulators to control voltage and/or reactive power. The voltage regulation system should include a manual backup regulator to ensure continuous operation in case of failure.

- Voltage Stabilization Systems: The voltage regulation system must include at least one stabilizer that adjusts to variations in power. Depending on the specific needs, additional types of stabilizers may also be used to enhance the stability and reliability of the power generation system.

3.2.2. Technical Specifications for Operating Under Disturbed Conditions

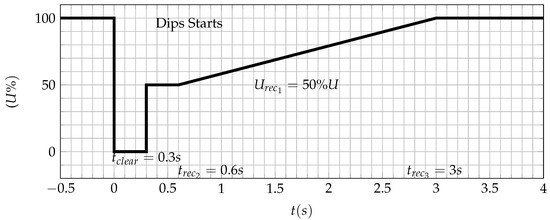

Synchronous power generation installations must remain connected and synchronized with the grid even during voltage faults, with specific requirements. In the case of a voltage drop to of the nominal voltage for 0.3 s followed by a dip voltage of 50% for 0.3 s (as shown in Figure 4), the installation must continue operating. In the case of asymmetrical faults, the minimum voltage of the three phases is considered. The installation must avoid losing synchronization and ensure that oscillations are damped, allowing the power to stabilize within 5% of its final value in less than 10 s. During single-phase reclosing or consecutive faults, the system must remain synchronized for 20 s after three consecutive events.

Figure 4.

Voltage dip profile of a synchronous power generation installation in Algerian grid code [10].

In this paper, we will focus exclusively on the section related to non-synchronous power generation installations.

4. DFIG Modeling and Control

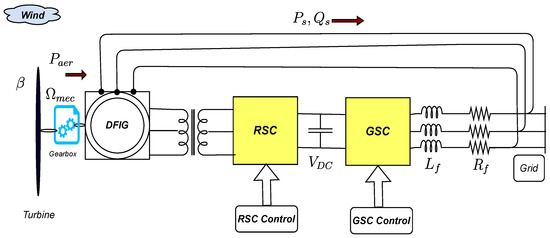

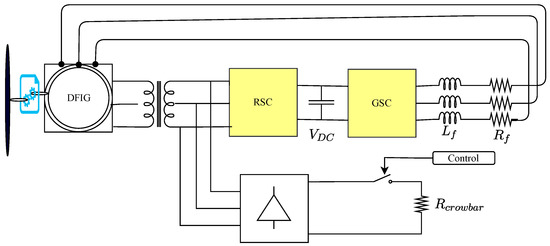

The DFIG based WECS studied in this paper is presented in Figure 5. The stator of the DFIG is directly connected to the grid and the rotor is connected to the grid through a back to back AC-DC-AC PWM converter consists of two stages: the Rotor Side Converter (RSC), which regulates rotor currents to control active and reactive power, and the Grid Side Converter (GSC), which maintains the DC-link voltage and ensures proper power exchange with the grid (see Appendix A).

Figure 5.

DFIG based Wind Energy Conversion System [41].

The available wind power passing through an area S swept by the turbine blades is expressed by the following equation [42]:

And the wind turbine captures a part of this power which depends on its power coefficient

The wind turbine studied in this paper has a power of 2 , its power coefficient is defined as follows [42]:

where is the wind power, is the aerodynamic power captured from the wind, is the air density (kg/m3), S in this case represents the area swept by the turbine blades in m2, represents the wind velocity in (m/s) and is the tip speed ratio.

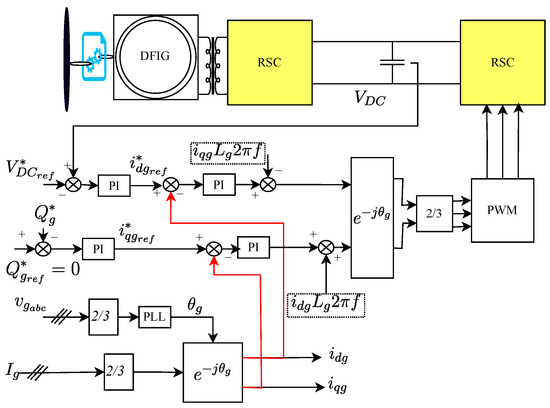

4.1. Turbine Speed Control

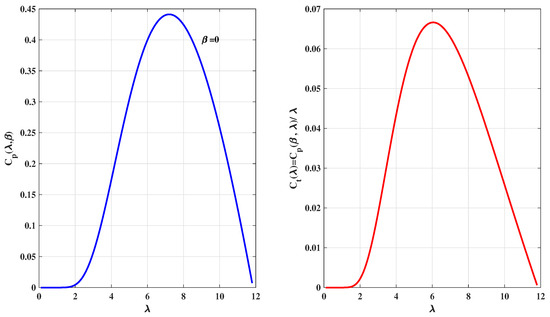

The control block of a variable-speed wind turbine (see Figure 6 and Figure 7), determines the generator torque and pitch angle references to maximize energy extraction from the wind via Maximum Power Point Tracking (MPPT) [43,44].

Figure 6.

Power coefficient and Torque Coefficient for .

Figure 7.

Wind Turbine Modeling scheama [41].

Hence, the turbine will work on the maximum power point. Then the tip speed ratio (TSR) is given by the following equation:

where is the turbine speed (/). From the turbine speed, the aerodynamic torque is expressed by:

The tip speed ratio corresponding to the maximum power coefficient, , is denoted as . This value enables the extraction of the maximum possible power from the turbine.

The gearbox is mathematically modeled by the following equation:

where is the torque output from the gearbox; is the aerodynamic torque; and G is the gearbox ratio (gain).

Accordingly, the turbine rotational speed is given by the following expression:

In addition, the aerodynamic torque () extracted by the turbine is then given by [45]:

4.2. DFIG Modelling

The machine is supposed to be symmetrical and the three-phase supply is balanced, so that the three-phase variables are described by two variables in the frame. The following stator (rotor) voltage equations are presented using the standard synchronous reference frame convention for motor modeling, where the q-axis is defined as leading the d-axis by 90° and the sign convention aligns with typical power system analysis for generator operation [46]:

Elsewhere, the active and reactive powers of the stator, rotor and those injected into the grid are expressed respectively by:

Furthermore, the stator and rotor axis fluxes are expressed as follows:

And, according to the stator field orientation condition, one can write (In this case, it is assumed that (, )):

One can write also [47]:

This power is converted electrical power and delivered at the DFIG output power with non significant stator, rotor and friction losses. So, one can write:

By combining these equations, one can find:

The fundamental dynamics equation that determines the mechanical speed evolution from the total mechanical torque applied to the rotor is given by [41,42]:

With:

where:

- J is the total moment of inertia (turbine inertia referred to generator side plus generator inertia in 2;

- is the rotor mechanical speed ();

- is the mechanical torque from the turbine ();

- is the electromagnetic torque ();

- is the viscous friction coefficient ().

The electromagnetic torque can be formulated in terms of stator fluxes and currents as follows:

With p is the number of DFIG pole pairs.

4.3. Stator and Rotor Flux Estimation

The stator voltage components expressed in the frame are given by [42]:

In addition, the stator flux components expressed in the frame are estimated by:

From the relationships between the stator and rotor fluxes and currents (Equation (13)), one can establish equations that link rotor fluxes to stator fluxes in the frame:

The term represents the total leakage factor (also known as the Blondel leakage coefficient), which is a dimensionless parameter defined as follows:

Then:

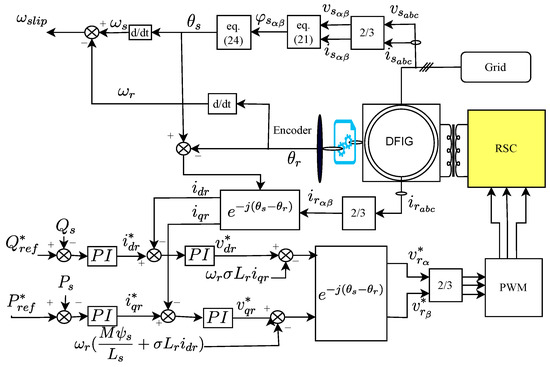

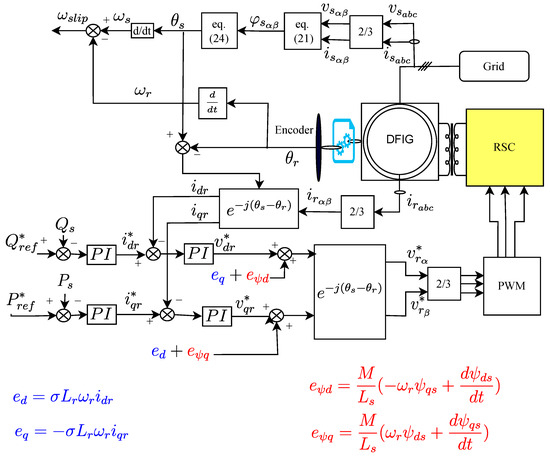

4.4. DFIG Control

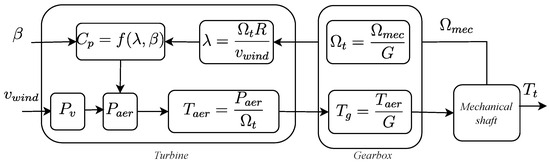

The back-to-back AC/DC/AC converter, based on and PWM, consists of a GSC (see Figure 8) and a RSC (see Figure 9). The GSC maintains a constant DC-link voltage with zero reactive current, while the RSC controls rotor currents to decouple stator active and reactive power control [42].

Figure 8.

GSC control block diagram [41].

Figure 9.

RSC control block diagram [41].

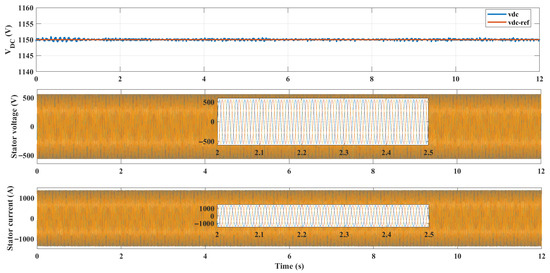

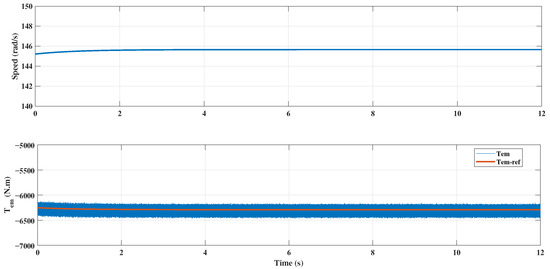

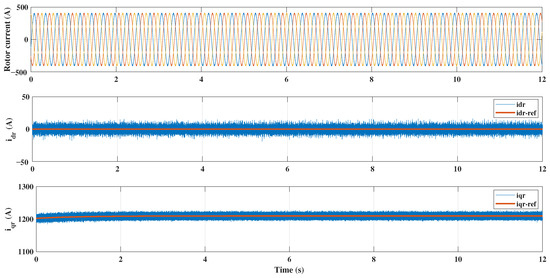

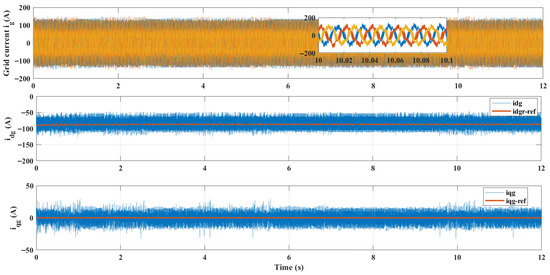

A constant wind speed profile of 8.5 was maintained throughout all simulations. The control strategy applied in this study ensure an operation in the MPPT (Maximum Power Point Tracking) mode. The results obtained are illustrated in Figure 10, Figure 11, Figure 12 and Figure 13.

Figure 10.

Simulation results of the studied DFIG-based WECS operating in the MPPT Control mode: DC-bus voltage, stator instantaneous voltages and currents (, and ).

Figure 11.

Simulation results of the studied DFIG-based WECS operating in the MPPT Control mode: Speed and Torque ( and ).

Figure 12.

Simulation results of the studied DFIG-based WECS operating in the MPPT Control mode: Instantaneous and components of rotor currents (, and ).

Figure 13.

Simulation results of the studied DFIG-based WECS operating in the MPPT Control mode: Instantaneous and components of grid currents (, and ).

In Figure 10 it can be observed that the DC bus voltage correctly tracked its reference value of 1150 V. Furthermore, the voltages () and currents () are stable and exhibit a sinusoidal waveform, indicating a proper system operation.

Regarding the speed, it remained constant at (145.65 ). The torque also reaches its reference value, reflecting the expected system performance (see Figure 11). A similar observation can be made for the rotor current (see Figure 12).

It is clearly shown (see Figure 13) that the current injected from the WECS to the grid is nearly sinusoidal owing to advanced control strategies and filtering. Note also that the very small harmonic content of the current is mainly due to the use of PWM switching to pilot power electronics converters of the WECS.

These results highlight the stability and reliability of the MPPT control strategy, with voltages and currents maintained within optimal ranges.

5. Analysis of DFIG-Based Wind Turbines During Voltage Dips

5.1. Impact of Severe Voltage Dip on a DFIG-Based WECS

In this section, the DFIG-based wind energy conversion system is deliberately subjected to a severe voltage drop on the grid side, without any protective or control measures in place.

The aim is to observe and evaluate the resulting electrical and mechanical effects on the system, thereby assessing its vulnerability under these extreme conditions. The applied voltage drop profile, shown in (Figure 14), may be invoked by a severe grid fault scenario. In this case, the voltage magnitude drops abruptly to a low level of (80%), remains there for a short duration of (0.5 s), and then returns to its nominal value.

Figure 14.

A grid severe voltage drop of (80%) applied to the studied DFIG-based WECS.

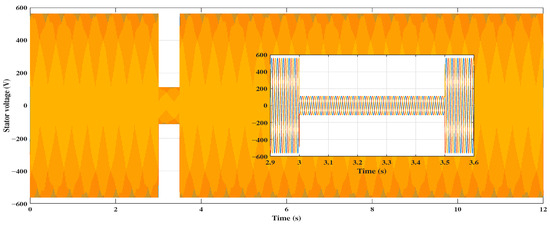

During the simulated fault, the grid-side voltage dropped by about 80% of its nominal value, causing an almost complete collapse at the generator terminals. As shown in Figure 15, the DC bus still held a substantial voltage because the rotor-side converter kept converting rotor AC power into DC power. Since the grid-side converter could not pass this energy to the grid, this latter (energy) began to accumulate in the DC bus capacitor, driving the voltage upward.

Figure 15.

DC bus voltage under 80% grid-side severe voltage drop.

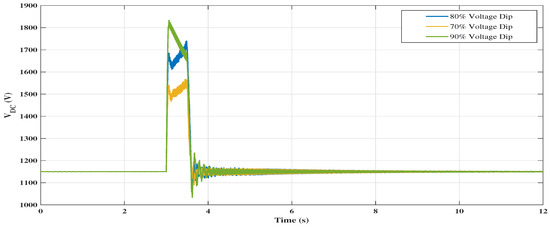

The sensitivity of the DC-link voltage to fault severity is unequivocally demonstrated by comparing the responses to 70%, 80%, and 90% sags, which produced peak voltages of 1568 V, 1740 V, and 1833 V, respectively (see Figure 16). These values critically exceed the typical maximum safe operating voltage for IGBTs and capacitors. This threshold is defined as 1.15 to 1.20 corresponding to 1322 V to 1380 V for a nominal 1150 V system a design limit that is strictly enforced to prevent immediate component failure [48,49].

Figure 16.

DC Bus Voltage Response to 70%, 80%, and 90% grid voltage drops.

The recorded overvoltage of 1833 V (1.59 ), in particular, highlights a dangerous margin of exceedance.

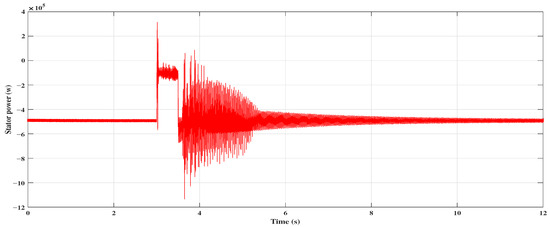

While the fault persists, the wind turbine rotor continues to be driven by the incoming wind energy, ensuring that mechanical power is still being supplied to the system. However, with the grid voltage reduced by 80%, the generator’s ability to transfer electrical power to the grid is severely impaired. As shown in Figure 17, the stator power drops almost instantly to near-zero values following the fault onset and remains negligible throughout the disturbance. This sharp reduction occurs because the stator, being directly connected to the grid, experiences the same voltage collapse.

Figure 17.

Stator power under 80% of grid severe voltage drop.

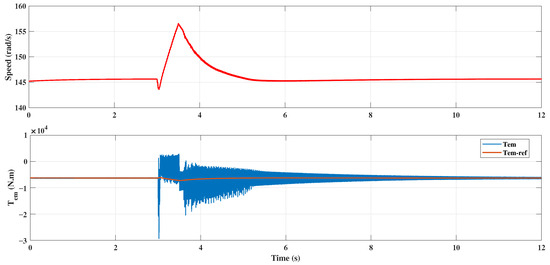

Consequently, the imbalance between the WECS input energy and the reduced electrical power (output energy) results in the accumulation of excess energy in the rotating mass of the turbine–generator set. As illustrated in Figure 18, this surplus energy manifests as an acceleration of the rotor, creating a temporary energy balance.

Figure 18.

Speed and torque under 80% grid-side severe voltage drop.

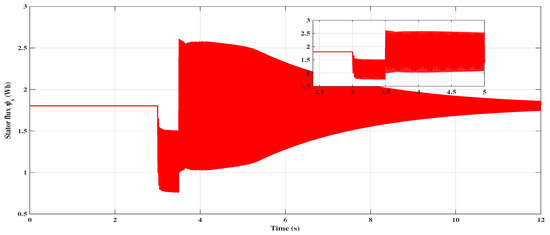

As shown in Figure 19, the sharp reduction in during the fault does not cause the stator flux to disappear instantly. Due to the DFIG electromagnetic ’inertia’, the flux decays gradually according to (Equation (9)). Given the small value of , this decay is relatively slow and contains both steady and oscillatory components. The residual flux induces significant EMFs in the rotor, leading to high transient currents and additional stress on the converter.

Figure 19.

Stator flux under 80% of grid severe voltage drop.

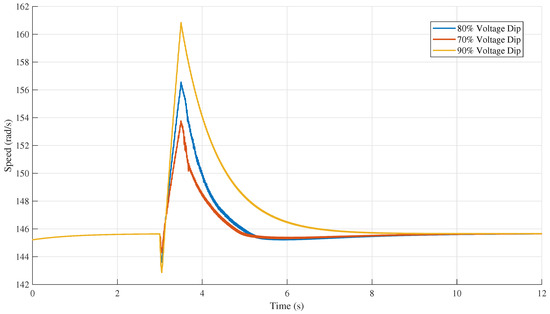

As illustrated in the accompanying Figure 20, the measured data demonstrate a direct correlation between the severity of the voltage dip and the mechanical response of the rotor speed. Recorded speeds increased to 153.8 for a 70% voltage dip, 156.55 for an 80% dip, and reached 160.8 under the most severe 90% dip condition. It is noteworthy that the system’s steady-state operating speed, both prior to the disturbance and after full recovery, remained constant at approximately 145.65 .

Figure 20.

Mechanical rotor speed response to 70%, 80%, and 90% voltage drops.

Critically, although all measured values remain within safe operational boundaries well below the established maximum threshold of approximately 175 (1.25 ) [50,51] their progressive increase underscores the high sensitivity of DFIG rotor dynamics to grid disturbances.

The analysis of Figure 21 and Figure 22 illustrates that this kind of fault causes also a significant rise in rotor current () and stator current (), risking overload of the IGBTs on the RSC and the GSC fails to transfer energy to the grid which exacerbates the DC bus overvoltage issues.

Figure 21.

Stator current under 80% of grid severe voltage drop.

Figure 22.

Rotor current under 80% grid-side severe voltage drop.

To ensure the safety of the converters and the stability of the WECS, it’s crucial for both and to stay within their rated limits between 1.2 to 1.5 () for brief intervals dip voltages [52,53]. During LVRT-type dips, brief envelopes up to 2–3 may be tolerated, but only for very short durations to protect the RSC/GSC and their IGBTs. The table below consolidates these ranges [54,55].

For clarity, the indicative magnitudes in our case are: (2 , 690 V, = 0.95), the nominal stator current is;

The determination of the nominal rotor current in a DFIG is not straightforward, as it depends on both the slip power and the actual rotor voltage. A commonly used estimate is

where is the rated apparent power of DFIG; is the maximum design slip; is the typical rotor voltage ( = 2070 V, ( = 1/3 is the stator/rotor turns ratio)).

The only way to obtain perfectly accurate values of the rotor nominal current and voltage is to rely on the manufacturer’s datasheet, which directly provides and . As highlighted in [56], the rated amplitude of the rotor phase current under nominal operating conditions.

Then:

The worst-case peak current was obtained as follows:

Then:

And

These electrical currents observed across all rotor phases within the 500 fault.

To obtain a clearer picture of heating effects and filter out rapid switching noise, we calculate a sliding RMS value updated every half-cycle of the grid ( = 0.01 s).

That captures inertial thermal effects:

And

Then:

It was found that the rotor current exhibited a peak of about 2.61 and an RMS envelope of 1.98 , while the stator current also showed excursions a peak of about 3.91 and an RMS envelope of 2.87 , indicate a potential for overheating of the components, which may lead to irreversible damage. These extreme current surges occurred in the absence of adequate protective or control measures.

To mitigate these adverse effects and enhance the fault tolerance of the DFIG-based WECS, two remedial strategies are proposed and evaluated in the following section.

5.2. LVRT of a DFIG-Based WECS

In modern wind energy conversion systems, mitigating electrical faults—particularly Low Voltage Ride-Through (LVRT) events—constitutes a critical challenge for preserving grid stability and ensuring generator as well as turbine integrity [57,58,59]. During severe voltage dips, wind turbines sustain rotational inertia, accumulating excess kinetic energy that cannot be delivered to the grid.

Unmanaged, this energy surplus poses significant risks to system components. Crowbar protection circuits have emerged as a predominant solution for rapid energy dissipation, with several advanced topologies developed to enhance efficacy [60]:

- Resistive crowbars for direct energy absorption [61];

- RL integrated circuits enabling rotor current division [62];

- Series Dynamic Resistors (SDR) reducing activation frequency and torque oscillations [63].

- Time-controlled systems triggered by current thresholds [64].

While crowbar activation necessitates temporary suspension of active/reactive power regulation, these refinements substantially improve fault ride-through capacity and reinforce voltage support at grid interfaces.

The voltage dip applied in this section is the voltage dip profile of a non-synchronous electricity generation installation required by the Algeria LVRT grid code (see Figure 3).

By analyzing the stator flux and its relationship to the voltage and current during a voltage dip, an expression for estimating the flux behavior can be derived, as shown in (Equation (9)). This understanding is crucial for assessing the response of the machine to voltage dips and mitigating potential issues, such as WECS instability or components damage [65,66,67].

Since, the q-component of the flux is not zero during a voltage dip, the stator currents are expressed as follows:

By replacing these expressions in the rotoric magnetic flux expressions, one can write:

And:

In these equations, ,, and represent the stator and rotor phase resistances and inductances, respectively, while M denotes the mutual inductance. The variables , , , , , , , , and , , , correspond to the components of the stator and rotor voltage, current, and flux linkage vectors, respectively. By substituting the stator current Equation (37) into the stator voltage expressions (Equation (9)), the following equations could be established:

On the other hand, it is useful to modify the equivalent electric circuit of the DFIG (see Figure 23), to a more compact equivalent circuit. it is possible to achieve the following Equation (42), which leads to the new circuit [42]:

Figure 23.

Modified vector control scheme of the DFIG during voltage dips faults [65].

WECS based on DFIG incorporate an additional crowbar protection connected at the rotor terminals as shown in Figure 24. This protection circuit overcomes the issue of severe voltage dips by limiting the voltage across the rotor terminals.

Figure 24.

Studied WECS equipped with 3 AC-DC crowbar protection [65].

The crowbar is composed of a diode three phase universal full-bridge and a resistance that can be calculated from the following relationship [68,69]:

To ensure proper protection of the rotor converter, the voltage must satisfy the following condition:

The application period of the crowbar protection is generally very short. This brief duration helps limit the effects of electrical disturbances while protecting the rotor converter from overcurrents and overvoltages that could otherwise damage the electronic components [70,71,72]. There are several other problems for power electronics and wind farms [73,74,75].

6. Simulation Results

In this section, the simulation results of two strategies proposed to mitigate voltage dips’ impact on the studied DFIG-based WECS are explored:

- The integration of a Modified Vector Control scheme applied to the DFIG.

- The use of an R-crowbar circuit during the fault.

The effectiveness of this proposed strategy is systematically evaluated under severe voltage sag conditions. To this end, time-domain simulations are performed in accordance with the Algeria LVRT grid code requirement enabling a detailed assessment of the system’s fault ride-through capability and dynamic response.

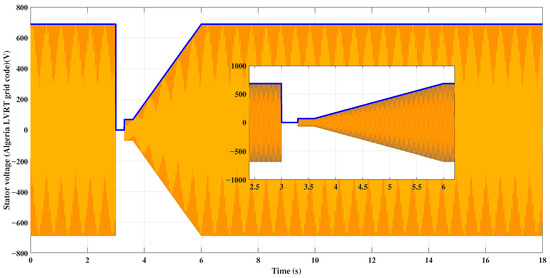

The LVRT requirement in Algerian grid is very strict system. For the first 0.3 s, the generator voltage () may drops to zero. Then, during the next 0.3 s, it remains at of the nominal value of . Finally, it gradually increases over 2.4 s until it reaches its nominal value (see Figure 25).

Figure 25.

Voltage profile of the LVRT requirement in the Algerian grid code.

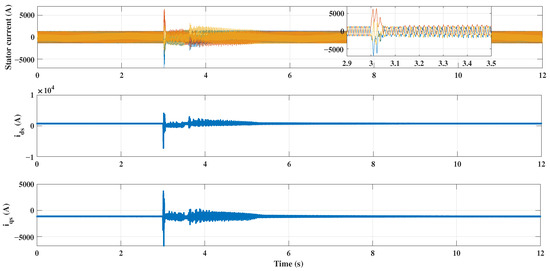

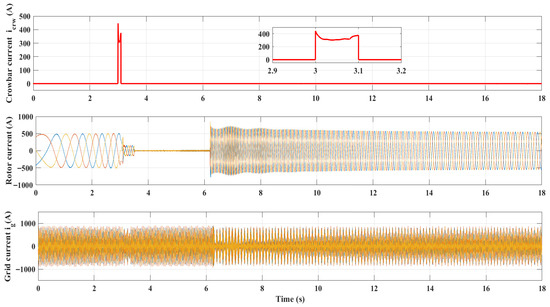

In the simulation scenario, the voltage dip fault occurs at t = 2.5 s. The rotor converter is inhibited and the crowbar is applied at that moment, keeping it safe and ensuring that the entire rotor current circulates through the crowbar as shown in Figure 26.

Figure 26.

Current, response during a three-phase fault under LVRT compliance.

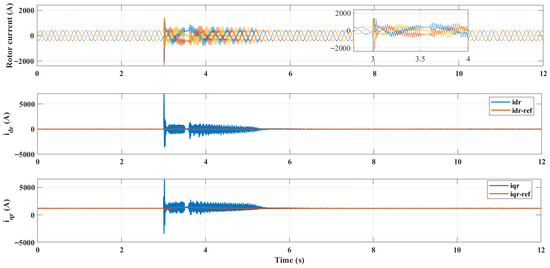

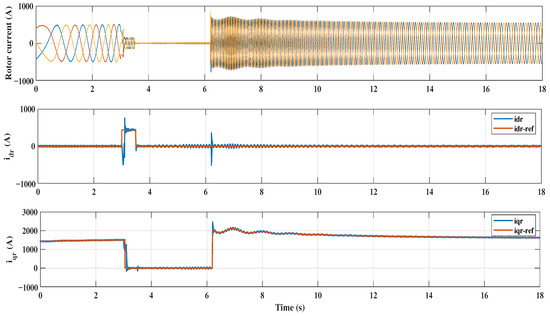

This over-current does not affect the rotor winding, because this value did not exceed the limit value (see Figure 27 and Table 3).

Figure 27.

Rotor currents response during three-phase fault under LVRT compliance.

Table 3.

Transient Current Limits for DFIG Stator and Rotor Under Normal and Faulty Conditions.

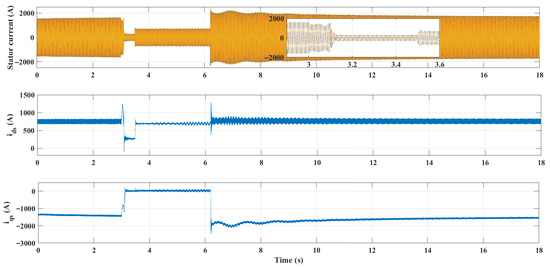

Similarly, stator currents presented in Figure 28 remain within permissible limits during the fault event.

Figure 28.

Stator currents response during three-phase fault under LVRT compliance.

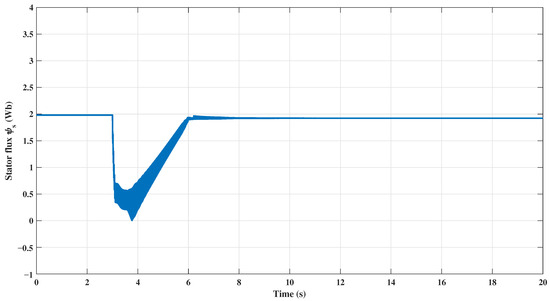

The elevated rotor voltage requirement during the fault led to a gradual decay of the stator flux, as depicted in Figure 29. This flux dynamic resulted in a surplus of energy that manifested as an electromagnetic torque transient, which, due to the rotor’s inertia, caused a temporary acceleration. Despite this, the turbine’s rotor speed demonstrated remarkable stability.

Figure 29.

Staor flux magnitude under LVRT compliance.

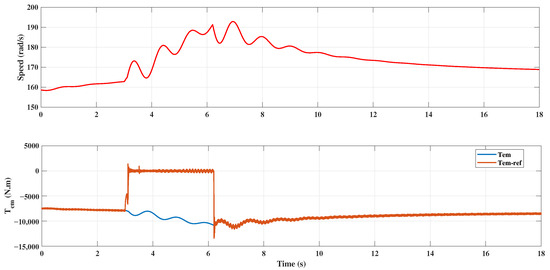

As illustrated in Figure 30, the speed exhibited a controlled transient with a recorded peak of 192.88 (1.28 ), which remains within the safe mechanical limits of the drive train. This resilience is a direct result of the robust protection system, which effectively managed the energy surplus through precise converter control, thereby preventing catastrophic runaway acceleration. The system’s ability to maintain stability under such severe grid conditions confirms the efficacy of the implemented LVRT strategy in safeguarding the integrity of the WECS.

Figure 30.

Speed and electromagnetic torque reponse under LVRT compliance.

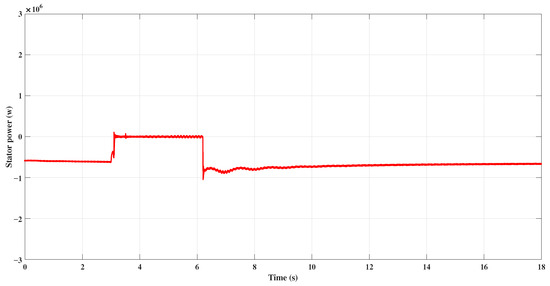

While active power is reduced during voltage dips, reactive power is called upon to stabilize the WECS (see Figure 31). The crowbar plays a crucial role in protecting the system by preventing critical failures while ensuring the balance of power is maintained under these severs disturbance conditions.

Figure 31.

Stator active and reactive powers under LVRT compliance.

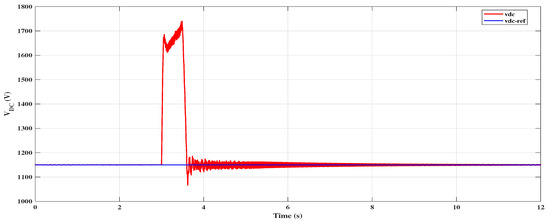

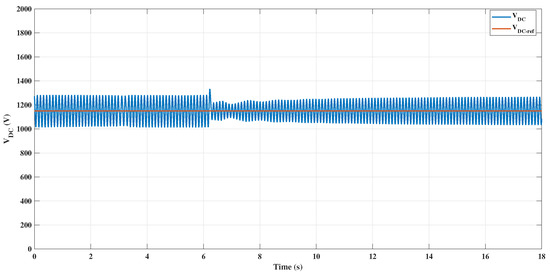

Figure 32 shows that the DC bus voltage during a three-phase voltage dip, suffers a transient because the grid-side converter is also affected by the dip.

Figure 32.

DC-link bus voltage under LVRT compliance.

7. Conclusions

The stability of the Algerian electrical grid, as with power systems globally, can be challenged by sudden voltage dips. To address this, generators (particularly Non-Synchronous Power Generation Installations from renewable sources) are required to have Low Voltage Ride-Through (LVRT) capability. This prevents them from disconnecting during minor faults, which is crucial because their sudden loss can severely impact the grid’s active and reactive power balance.

This study investigated the impact of grid voltage dips on a DFIG-based WECS. Without protection, these dips induce high currents that can damage the rotor and stator windings and may cause instability in the DC link voltage as well. To prevent this, a hybrid protection strategy integrating a Modified Vector Control scheme with a crowbar circuit was implemented and evaluated. This research evaluates this mechanism’s effectiveness in safeguarding the WECS and ensuring its stable and continuous operation during fault conditions. The proposed hybrid protection strategy demonstrates substantial improvement, reducing peak rotor currents by 64% (from 2.61 to 0.93 ) and peak stator currents by 65% (from 3.91 to 1.36 ). Furthermore, the strategy successfully managed the DC-link voltage, limiting its transient rise to a safe overshoot of less than 14%, and maintained turbine stability with a rotor speed peaking at 1.28 within mechanical limits. This proves the validity of the Modified Vector Control with crowbar protection in ensuring the stability and resilience of the studied WECS, even in the presence of significant voltage dips.

Moreover, this study has demonstrated the efficacy of an internal protection strategy for DFIGs under strict grid codes; however, certain limitations are acknowledged. The findings are based on simulation models, and thus lack the validation from experimental or hardware-in-the-loop (HIL) testing that would confirm performance in a real-world environment. Furthermore, while the proposed crowbar-based solution is recognized for its cost effectiveness compared to advanced external devices like STATCOMs and energy storage, a detailed, case-specific comparative techno-economic analysis was beyond the scope of this foundational study but is essential for a complete assessment.

Therefore, future work will be directed towards: (1) transitioning the validated simulation model to an experimental or HIL test-rig to evaluate practical performance under non-ideal conditions, and (2) conducting a thorough comparative study that benchmarks the proposed strategy’s performance, reliability, and total cost of ownership against other LVRT solutions (e.g., STATCOM, BESS) to identify the most economically efficient solutions or potential synergies in hybrid schemes for specific grid environments.

Author Contributions

Conceptualization, B.D.; Methodology, B.D., L.M., A.K., M.M., J.R. and M.A.; Software, B.D., L.M.; Validation, B.D.; Formal analysis, L.M., M.M. and M.A.; Investigation, A.K.; Writing—original draft, B.D., L.M., A.K. and M.M.; Writing—review & editing, J.R. and M.A.; Supervision, A.K., L.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

J. Rodriguez acknowledges the support of ANID through project CIA250006.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| DFIG | Doubly Fed Induction Generator |

| LVRT | Low Voltage Ride Through |

| WECS | Wind Energy Conversion System |

| MPPT | Maximum Power Point Tracking |

| TRS | Tip Speed Ratio |

| GSC | Grid Side Converter |

| RSC | Rotor Side Converter |

| PWM | Pulse Width Modulation |

| PLL | Phase Lock Loop |

| SDR | Series Dynamic Resistor |

Appendix A. WECS Parameters and Simulation Data [41]

Table A1.

WECS parameters.

Table A1.

WECS parameters.

| Value | Parameter |

|---|---|

| Rated active power () | |

| Nominal stator voltage (V) | |

| Mechanical speed () | |

| DC bus voltage ) | |

| Wind turbine radius (m) | |

| Air density at 15 °C () | |

| Gearbox gain | |

| Stator one-phase winding resistance (m) | |

| Rotor one-phase winding resistance (m) | |

| Stator leakage inductance () | |

| Rotor leakage inductance () | |

| Mutual inductance () | |

| Stator inductance () | |

| Rotor inductance () | |

| Shaft inertia () | |

| Friction coefficient of the induction machine (/) | |

| Leakage coefficient | |

| Number of pole pairs | |

| Stator time constant (s) | |

| Rotor time constant (s) |

Table A2.

Grid Connection Parameters.

Table A2.

Grid Connection Parameters.

| Value | Parameter |

|---|---|

| Power grid frequency (Hz) | |

| Grid angular frequency (rad/s) | |

| Filter resistance () | |

| Filter inductance (H) | |

| DC bus capacitance (mF) |

Table A3.

Controllers Parameters.

Table A3.

Controllers Parameters.

| Value | Parameter | |

|---|---|---|

| Proportional gain ()/() | RSC current PI controller | |

| Integral gain ()/() | ||

| = 10,160 | Proportional gain | RSC powers PI controller |

| = 406,400 | Integral gain | |

| Proportional gain ()/() | GSC current PI controller | |

| Integral gain ()/() | ||

| Proportional gain | GSC PI Controller | |

| = 30,000 | Integral gain |

References

- Bessalem, C.; Diemer, A.; Batisse, C. Les transitions énergétiques a l’horizon 2030 et 2050, le retour en grâce des scenarios et de la prospective. Rev. Francoph. Dev. Durable 2022, 19, 1–67. [Google Scholar]

- Les Énergies Renouvelables: État des Lieux des Pourcentages dans le Monde. 2025. Available online: https://www.energiesrenouvelables.org/energie-eolienne/impact-environnemental/energies-renouvelables-monde/ (accessed on 10 August 2025).

- Himri, Y.; Rehman, S.; Mostafaeipour, A.; Himri, S.; Mellit, A.; Merzouk, M.; Merzouk, N.K. Overview of the Role of Energy Resources in Algeria’s Energy Transition. Energies 2022, 15, 4731. [Google Scholar] [CrossRef]

- Africa Energy Portal. Ethiopia to Exploit Full Potential of Solar Energy to Accelerate Energy Transition. Available online: https://africa-energy-portal.org/news/ethiopia-exploit-full-potential-solar-energy-accelerate-energy-transition (accessed on 15 September 2024).

- MESIA; Middle East Energy Dubai. MENA Solar and Renewable Energy Report; Middle East Solar Industry Association (MESIA): Dubai, United Arab Emirates, 2022. [Google Scholar]

- Himri, Y.; Rehman, S.; Draoui, B.; Himri, S. Wind power potential assessment for three locations in Algeria. Renew. Sustain. Energy Rev. 2008, 12, 2495–2504. [Google Scholar] [CrossRef]

- Diaf, S.; Belhamel, M.; Haddadi, M.; Louche, A. Assessment of wind energy resource in southern Algeria. Rev. Energ. Renouvelables 2007, 10, 321–333. [Google Scholar] [CrossRef]

- Mederreg, D.; Salmi, M.; Rachid, M.; Ahmad, H.; Lorenzini, G.; Menni, Y.; Ameur, H. Assessment of the Resources of Wind Energy in Various Regions of Algeria. Int. J. Sustain. Dev. Plan. 2021, 16, 641–650. [Google Scholar] [CrossRef]

- Loza, B.; Minchala, L.I.; Ochoa-Correa, D.; Martinez, S. Grid-Friendly Integration of Wind Energy: A Review of Power Forecasting and Frequency Control Techniques. Sustainability 2024, 16, 9535. [Google Scholar] [CrossRef]

- Ministry of Energy and Mines of Algeria. National Strategy for Renewable Energy: Achievements and Prospects; Ministry of Energy and Mines of Algeria: Algiers, Algeria, 2019.

- Senapati, M.K.; Pradhan, C.; Nayak, P.K.; Padmanaban, S.; Gjengedal, T. Modified demagnetisation control strategy for low-voltage ride-through enhancement in DFIG-based wind systems. IET Renew. Power Gener. 2020, 14, 3487–3499. [Google Scholar] [CrossRef]

- Zhou, D.; Song, Y.; Blaabjerg, F. Control of Wind Turbine System. In Control of Power Electronic Converters and Systems; AALBORG Universitet Press: Aalborg, Denmark, 2018; Volume 10, pp. 269–298. [Google Scholar]

- Yadav, M.; Pal, N.; Saini, D.K. Low voltage ride through capability for resilient electrical distribution system integrated with renewable energy resources. Energy Rep. 2023, 9, 833–858. [Google Scholar] [CrossRef]

- Ntuli, W.K.; Kabeya, M.; Moloi, K. Review of Low Voltage Ride-Through Capabilities in Wind Energy Conversion System. Energies 2024, 17, 5321. [Google Scholar] [CrossRef]

- Ali, S.W.; Sadiq, M.; Terriche, Y.; Naqvi, S.A.R.; Hoang, L.Q.N.; Mutarraf, M.U. Offshore Wind Farm-Grid Integration: A Review on Infrastructure, Challenges, and Grid Solutions. IEEE Access 2021, 9, 102811–102827. [Google Scholar] [CrossRef]

- Velasco, D.; López, J. Low Voltage Ride-Through (LVRT) Capability of an enhanced DFIG System. In Proceedings of the PCIM Europe 2016 International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2016; pp. 2043–2049. [Google Scholar]

- Wang, L.; Kerrouche, K.D.E.; Mezouar, A.; Van Den Bossche, A.; Draou, A.; Boumediene, L. Feasibility Study of Wind Farm Grid-Connected Project in Algeria Under Grid Fault Conditions Using D-Facts Devices. Appl. Sci. 2018, 8, 2250. [Google Scholar] [CrossRef]

- Baccouche, G.; Saidi, A.S.; Salah, C.B.; Makhloufi, S.; Hamida, A.H. A Comparative Analysis Study of Tunisian and Algerian Grid Codes Relevant to PV Solar Energy Installations. In Proceedings of the 2021 18th International Multi-Conference on Systems, Signals & Devices (SSD), Monastir, Tunisia, 22–25 March 2021; pp. 719–724. [Google Scholar]

- Martins, H. Integration of Renewable Energy Sources in Power Systems: Challenges and Solutions. J. Electr. Electron. Syst. 2023, 12, 42. [Google Scholar]

- Yaramasu, V.; Wu, B. Model Predictive Control of Wind Energy Conversion Systems; Wiley: Hoboken, NJ, USA, 2017; ISBN 978-1-118-98858-9. [Google Scholar]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Peng, L. Research on Graphical Modeling and Low Voltage Ride-Through Control Strategies of Doubly Fed Induction Wind Generator System. Ph.D. Thesis, Central School of Lille, Villeneuve-d’Ascq, France, 17 June 2010. [Google Scholar]

- Hiremath, R.; Moger, T. Comparative Analysis of Different Controllers for Enhancing the LVRT of DFIG system. In Proceedings of the 2021 9th International Renewable and Sustainable Energy Conference (IRSEC), Tetouan, Morocco, 23–27 November 2021; ISBN 978-1-6654-1319-0/21. [Google Scholar]

- Villanueva, I.; Rosales, A.; Ponce, P.; Molina, A. Grid-Voltage-Oriented Sliding Mode Control for DFIG Under Balanced and Unbalanced Grid Faults. IEEE Trans. Sustain. Energy 2017, 9, 1090–1098. [Google Scholar] [CrossRef]

- Rezaei, M.M.; Soltani, J. Sliding Mode Control of a Grid-Connected Distributed Generation Unit under Unbalanced Voltage Conditions. Automatika 2016, 57, 89–98. [Google Scholar] [CrossRef]

- Ardjoun, S.A.E.M.; Denai, M.; Abid, M. A robust power control strategy to enhance LVRT capability of grid-connected DFIG-based wind energy systems. Wind Energy 2019, 22, 834–847. [Google Scholar] [CrossRef]

- Cakmak, F.; Meral, M.E. Comparative Analysis of PI and PR Control Strategies for Enhancing Voltage Quality in D-Statcom-Based Distribution Networks. Balk. J. Electr. Comput. Eng. 2024, 12, 282–293. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Q.; Gong, W.; Gryning, M.P.S. H∞ Robust Current Control for DFIG Based Wind Turbine subject to Grid Voltage Distortions. IEEE Trans. Sustain. Energy 2016, 8, 816–825. [Google Scholar] [CrossRef]

- Baiju, P.; Rajeev, T. Low Voltage Ride Through in DFIG Based Wind Turbines: A Review. In Proceedings of the 2015 International Conference on Control Communication & Computing India (ICCC), Trivandrum, India, 19–21 November 2015; pp. 19–21. [Google Scholar]

- Nadour, M.; Essadki, A.; Nasser, T. Improving low-voltage ride-through capability of a multimegawatt DFIG based wind turbine under grid faults. Prot. Control. Mod. Power Syst. 2020, 5, 33. [Google Scholar] [CrossRef]

- Niiranen, J. Voltage dip ride through of a doubly-fed generator equipped with an active Crowbar. In Proceedings of the Nordic Wind Power Conference NWPC 2004, Gothenburg, Sweden, 1–2 March 2004. [Google Scholar]

- Qin, B.; Li, H.; Zhou, X.; Li, J.; Liu, W. Low-Voltage Ride-Through Techniques in DFIG-Based Wind Turbines: A Review. Appl. Sci. 2020, 10, 2154. [Google Scholar] [CrossRef]

- Abdelbar, F.N.; Alaboudy, A.H.K.; El-Zohri, E.H.; Mahmoud, H.A. Improved Protection Schemes for DFIG Based Wind Turbines during the Grid Faults. IOSR J. Electr. Electron. Eng. 2016, 11, 74–84. [Google Scholar]

- Muyeen, S.M.; Takahashi, R.; Murata, T.; Tamura, J.; Ali, M.H.; Matsumura, Y.; Kuwayama, A.; Matsumoto, T. Low voltage ride through capability enhancement of wind turbine generator system during network disturbance. IET Renew. Power Gener. 2009, 3, 65–74. [Google Scholar] [CrossRef]

- Marwa, E.; Benbouzid, M.; Muyeen, S.M.; Harnefors, L. Low-Voltage Ride-Through Techniques for DFIG-Based Wind Turbines: State-of-the-Art Review and Future Trends. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 7681–7686. [Google Scholar]

- Hossain, M.J.; Pota, H.R.; Ugrinovskii, V.A.; Ramos, R.A. Simultaneous STATCOM and pitch angle control for improved LVRT capability of fixedspeed wind turbines. IEEE Trans. Sustain. Energy 2010, 1, 142–151. [Google Scholar] [CrossRef]

- Hiremath, R.; Moger, T. Comprehensive review on low voltage ride through capability of wind turbine generators. Int. Trans. Electr. Energy Syst. 2020, 30, e12524. [Google Scholar] [CrossRef]

- Badreldien, M.M.; Abouzayed, U.R.; El-Wakeel, A.S.; Abdelaziz, A.Y. Modeling, Analysis and Control of Doubly Fed Induction Generators for Wind Turbines. In Proceedings of the 9th International Conference on Electrical Engineering ICEENG-9, Military Technical College, Cairo, Egypt, 27–29 May 2014. [Google Scholar]

- Djidel, B.; Mokrani, L.; Machmoum, M.; Kouzou, A. Investigation of LVRT Capability of a DFIG Based WECS Under Different Grid Codes. In Proceedings of the 2022 19th International Multi-Conference on Systems, Signals & Devices (SSD), Sétif, Algeria, 6–10 May 2022. [Google Scholar]

- Miloševic, D.; Đurišic, Ž. Single-phase reclosing technique for reducing islanding events of distributed generators during temporary faults. Int. Trans. Electr. Energy Syst. 2020, 30, e12311. [Google Scholar] [CrossRef]

- Omaç, Z.; Erdem, İ. Rotor Field-Oriented Control of Doubly Fed Induction Generator in Wind Energy Conversion System. Gazi Univ. J. Sci. 2023, 36, 1217–1229. [Google Scholar] [CrossRef]

- Abad, G.; López, J.; Rodríguez, M.A.; Marroyo, L.; Iwanski, G. Doubly Fed Induction Machine: Modeling and Control for Wind Energy Generation; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Justo, J.J.; Mwasilu, F.; Jung, J.-W. Doubly-fed induction generator based wind turbines: A comprehensive review of fault ride-through strategies. Renew. Sustain. Energy Rev. 2015, 45, 447–467. [Google Scholar] [CrossRef]

- Arifi, E.A. Modelling & Simulation of a Wind Turbine with Doubly-Fed Induction Generator (DFIG). Ph.D. Thesis, North China Electric Power University, Beijing, China, 2020. [Google Scholar]

- Peng, L. Reconfiguration du Dispositif de Commande D’une Éolienne en cas de Creux de Tension. Ph.D. Thesis, Ecole Centrale de Lille, Villeneuve-d’Ascq, France, 17 June 2010. [Google Scholar]

- Kadri, A.; Marzougui, H.; Aouiti, A.; Bacha, F. Energy Management and Control Strategy for a DFIG Wind Turbine/Fuel Cell Hybrid System with Super Capacitor Storage System. Energy 2020, 192, 116518. [Google Scholar] [CrossRef]

- Achkar, M.E.; Mbayed, R.; Salloum, G.; Patin, N.; Ballois, S.L.; Monmasson, E. Power operating domain of a cascaded doubly fed induction machinem. Math. Comput. Simul. 2016, 130, 142–154. [Google Scholar] [CrossRef]

- IEEE Std 1566-2015; IEEE Standard for Performance of Adjustable-Speed AC Drives Rated 375 kW and Larger. IEEE: New York, NY, USA, 2015; pp. 1–74.

- López, J.; Gubía, E.; Sanchis, P.; Roboam, X.; Marroyo, L. Wind Turbines Based on Doubly Fed Induction Generator Under Asymmetrical Voltage Dips. IEEE Trans. Energy Convers. 2008, 23, 321–330. [Google Scholar] [CrossRef]

- Murad, N.S.F.M.; Kamarudin, M.N.; Hanafi, A.N.; Rozali, S.M.; Ibrahim, M.A. Exploration of Characteristic Equation Towards the Analysis of Dynamical Stability for Synchronous Generators through Swing Equation. Int. J. Electr. Eng. Appl. Sci. 2024, 7, 25–30. [Google Scholar]

- Swing Equation in Power System|Derivation. 2025. Available online: https://electricalacademia.com/electric-power/swing-equation-power-system/ (accessed on 10 December 2024).

- Saleh, M.A.H.; Eskander, M.N. Sizing of Converters Interfacing the Rotor of Wind Driven DFIG to the Power Grid. Smart Grid Renew. Energy 2011, 2, 300–304. [Google Scholar] [CrossRef]

- IEC 61400-21-1; Wind Energy Generation Systems—Part 21-1: Measurement and Assessment of Electrical Characteristics—Wind Turbines. IEC: Geneva, Switzerland, 2019.

- Wu, D.; Seo, G.S.; Xu, L.; Su, C.; Kocewiak, L.; Sun, Y. Grid Integration of Offshore Wind Power: Standards, Control, Power Quality and Transmission. IEEE Open J. Power Electron. 2024, 5, 583–604. [Google Scholar] [CrossRef]

- Nouri, B.; Göksu, Ö.; Gevorgian, V.; Sørensen, P.E. Generic characterization of electrical test benches for AC- and HVDC-connected wind power plants. Wind Energy Sci. 2020, 5, 561–575. [Google Scholar] [CrossRef]

- Zhou, D.; Song, Y.; Blaabjerg, F. Modeling and Stress Analysis of Doubly-Fed Induction Generator during Grid Voltage Swell. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 4175–4180. [Google Scholar]

- Xu, S.; Dong, Y.; Zhang, Y.; Wang, Y.; Yuan, S. Protective strategy of Crowbar circuit when network voltage drop sharply. In Proceedings of the International Conference on Information Technology and Management Innovation (ICITMI 2015), Shenzhen, China, 12–13 September 2015; pp. 377–383. [Google Scholar]

- Jing, Y.; Zhang, J.; Su, L.; Shi, G.; Zang, J.; Zhou, J. A Novel Modular DC Chopper Based on Combination of Fully and Semi-Controlled Devices for Offshore Wind VSC-HVDC Transmission System. IEEE Trans. Power Electron. 2025, 41, 1282–1296. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhu, C.; Goetz, S.M. Fault-Tolerant Multiparallel Three-Phase Two-Level Converters with Adaptive Hardware Reconfiguration. IEEE Trans. Power Electron. 2024, 39, 3925–3930. [Google Scholar] [CrossRef]

- Elabideen, S.; Helal, A.; El-Arabawy, I. Low Votage Ride though Capability Techniques for DFIG-based Wind Turbines. Int. J. Energy Power Eng. 2016, 10, 910–918. [Google Scholar]

- Morren, J.; de Haan, S.W.H. Short-Circuit Current of Wind Turbines with Doubly Fed Induction Generator. IEEE Trans. Energy Convers. 2007, 22, 174–180. [Google Scholar] [CrossRef]

- Justo, J.J.; Ro, K.-S. Control strategies of doubly fed induction generator-based wind turbine system with new rotor current protection topology. J. Renew. Sustain. Energy 2012, 4, 043123. [Google Scholar] [CrossRef]

- Yang, J.; Fletcher, J.E.; O’Reilly, J. A Series-Dynamic-Resistor-Based Converter Protection Scheme for Doubly-Fed Induction Generator During Various Fault Conditions. IEEE Trans. Energy Convers. 2010, 25, 422–432. [Google Scholar] [CrossRef]

- Pannell, G.; Atkinson, D.J.; Zahawi, B. Minimum-Threshold Crowbar for a Fault-Ride-Through Grid-Code-Compliant DFIG Wind Turbine. IEEE Trans. Energy Convers. 2010, 25, 750–759. [Google Scholar] [CrossRef]

- Abu-Rub, H.; Malinowski, M.; Al-Haddad, K. Power Electronics for Renewable Energy Systems, Transportation and Industrial Applications; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Liu, Y.; Yao, H.; Di, P.; Qin, Y.; Ma, Y.; Alkahtani, M. Region of Attraction Estimation for Power Systems with Multiple Integrated DFIG-Based Wind Turbines. IEEE Trans. Sustain. Energy 2025, 16, 3095–3109. [Google Scholar] [CrossRef]

- Gao, W.; Xiahou, K.; Liu, Y.; Li, Z.; Wu, Q.H.; Chang, D. Transient Frequency-Voltage Support Strategy for VSC-MTDC Integrated Offshore Wind Farms Based on Perturbation Observer and Funnel Control. IEEE Trans. Sustain. Energy 2025, 16, 1931–1943. [Google Scholar] [CrossRef]

- Lohde, R.; Jensen, S.; Knop, A.; Fuchs, F.W. Analysis of Three Phase Grid Failure and Doubly Fed Induction Generator Ride-through using Crowbars. In Proceedings of the 2007 European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007. [Google Scholar]

- Noureldeena, O. Behavior of DFIG Wind Turbines with Crowbar Protection under Short Circuit. Int. J. Electr. Comput. Sci. 2012, 12, 32–37. [Google Scholar]

- Wang, H.; Wang, Y.; Xiao, X.; Ma, Z.; Xu, Q. Investigation on Transformer Inrush Current in Wind Farms Connected MMC-HVDC Systems. J. Mod. Power Syst. Clean Energy 2025, 1–11. [Google Scholar] [CrossRef]

- Xu, X.; Xiahou, K.; Du, W.; Liu, Y.; Li, Z.; Liu, Z. Security Assessment of Cascading Failures in Cyber-Physical Power Systems with Wind Power Penetration. IEEE Trans. Power Syst. 2025, 40, 4480–4492. [Google Scholar] [CrossRef]

- Yang, M.; Peng, T.; Zhang, W.; Su, X.; Han, C.; Fan, F. Abnormal Data Identification and Reconstruction Based on Wind Speed Characteristics. CSEE J. Power Energy Syst. 2025, 11, 612–622. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, A.; Ma, J.; Wang, P.; Zhang, R.; Liu, T. Transient Stability Analysis for Hybrid Parallel-Connected Converters by Two-Dimensional Phase Portrait. IEEE Trans. Power Electron. 2025, 40, 7765–7776. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Xiao, X.; Ma, Z.; Xu, Q. Harmonic State Space Based Stability Analysis of LCC-HVDC System with Saturated Transformer. IEEE Trans. Power Deliv. 2025, 40, 2254–2266. [Google Scholar] [CrossRef]

- Yang, M.; Jiang, R.; Yu, X.; Wang, B.; Su, X.; Ma, C. Extraction and application of intrinsic predictable component in day-ahead power prediction for wind farm cluster. Energy 2025, 328, 136530. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.