A Method for Optimizing the Precision of a Five-Axis Machine Tool Based on Tolerance

Abstract

1. Introduction

2. Methodology

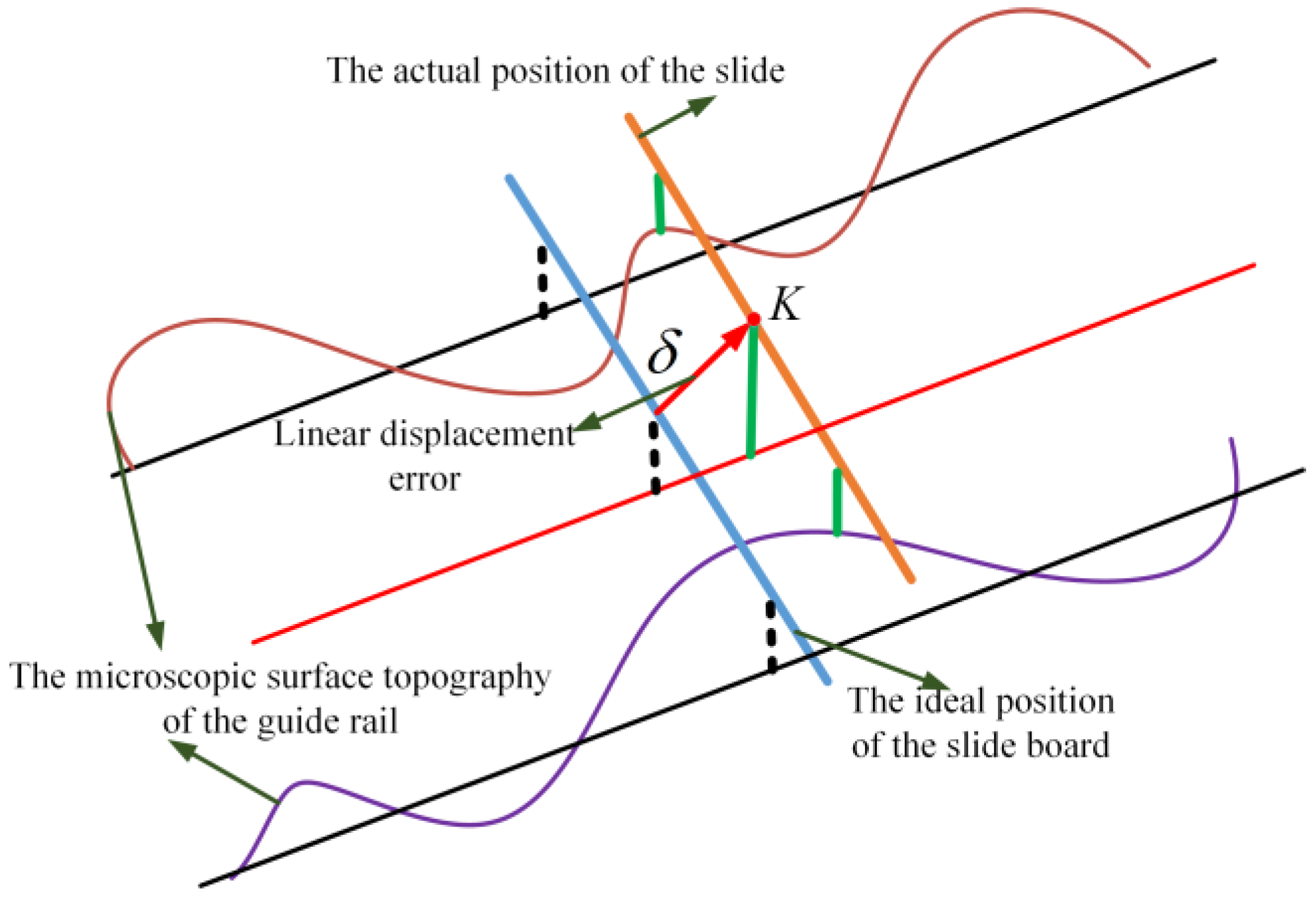

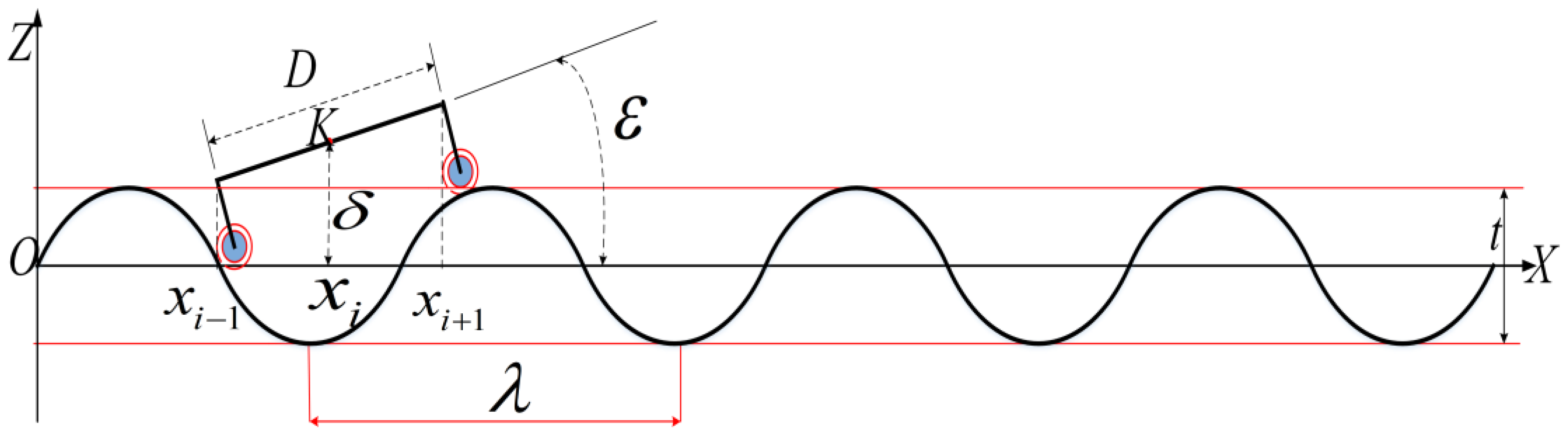

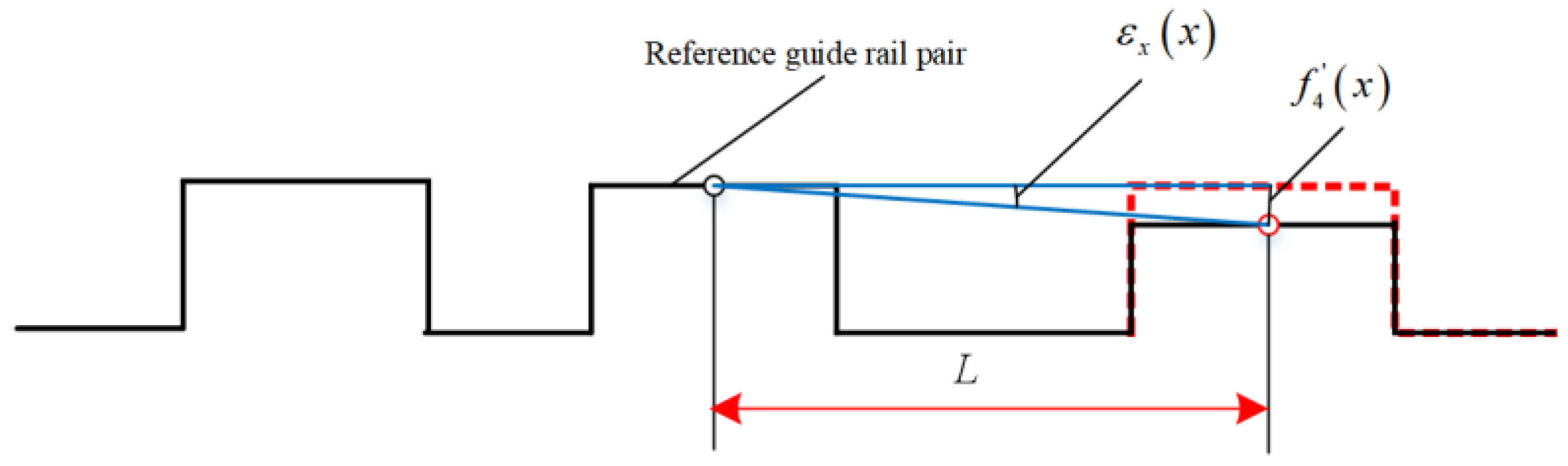

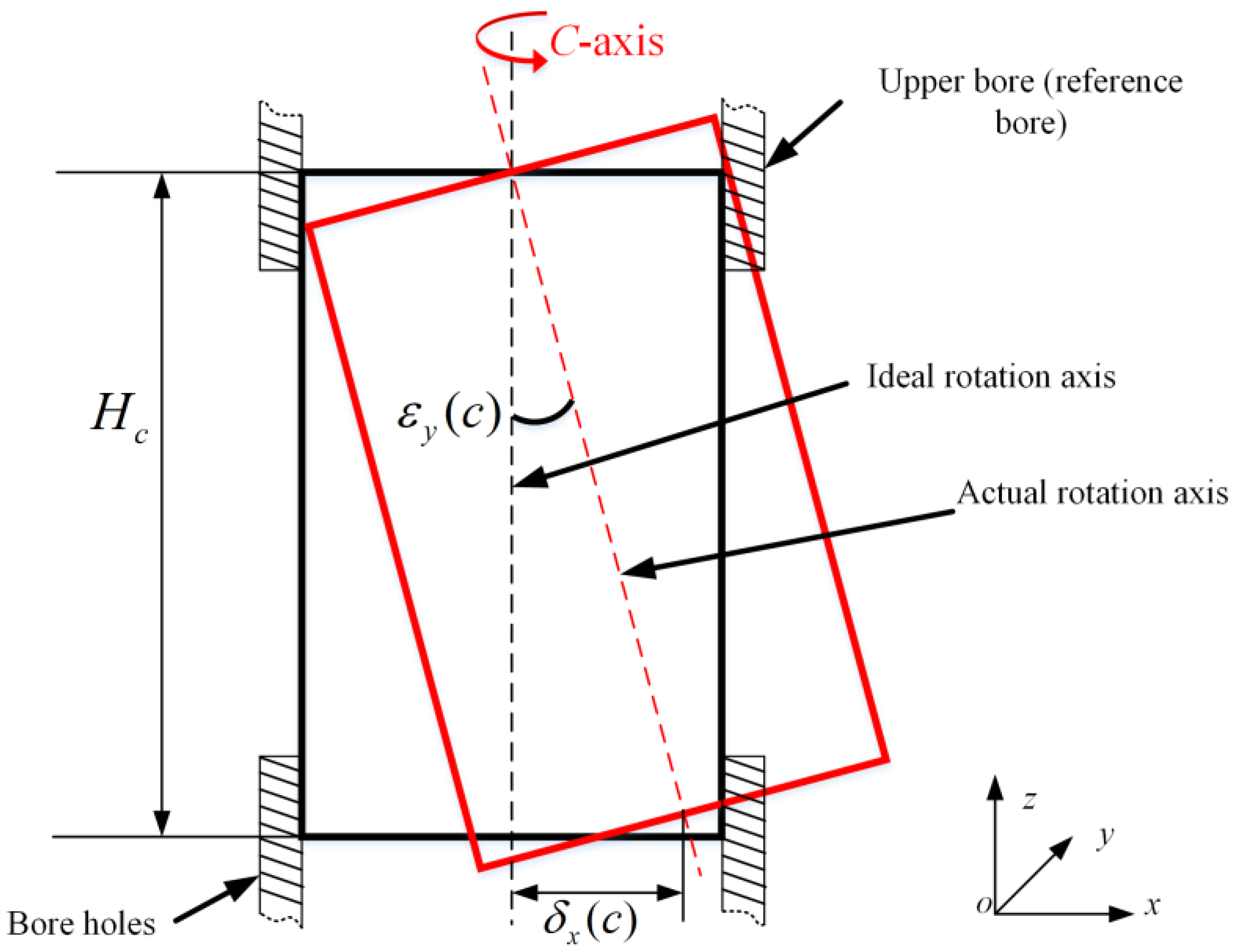

2.1. Geometric Error Prediction Model Based on Machine Tool Tolerance

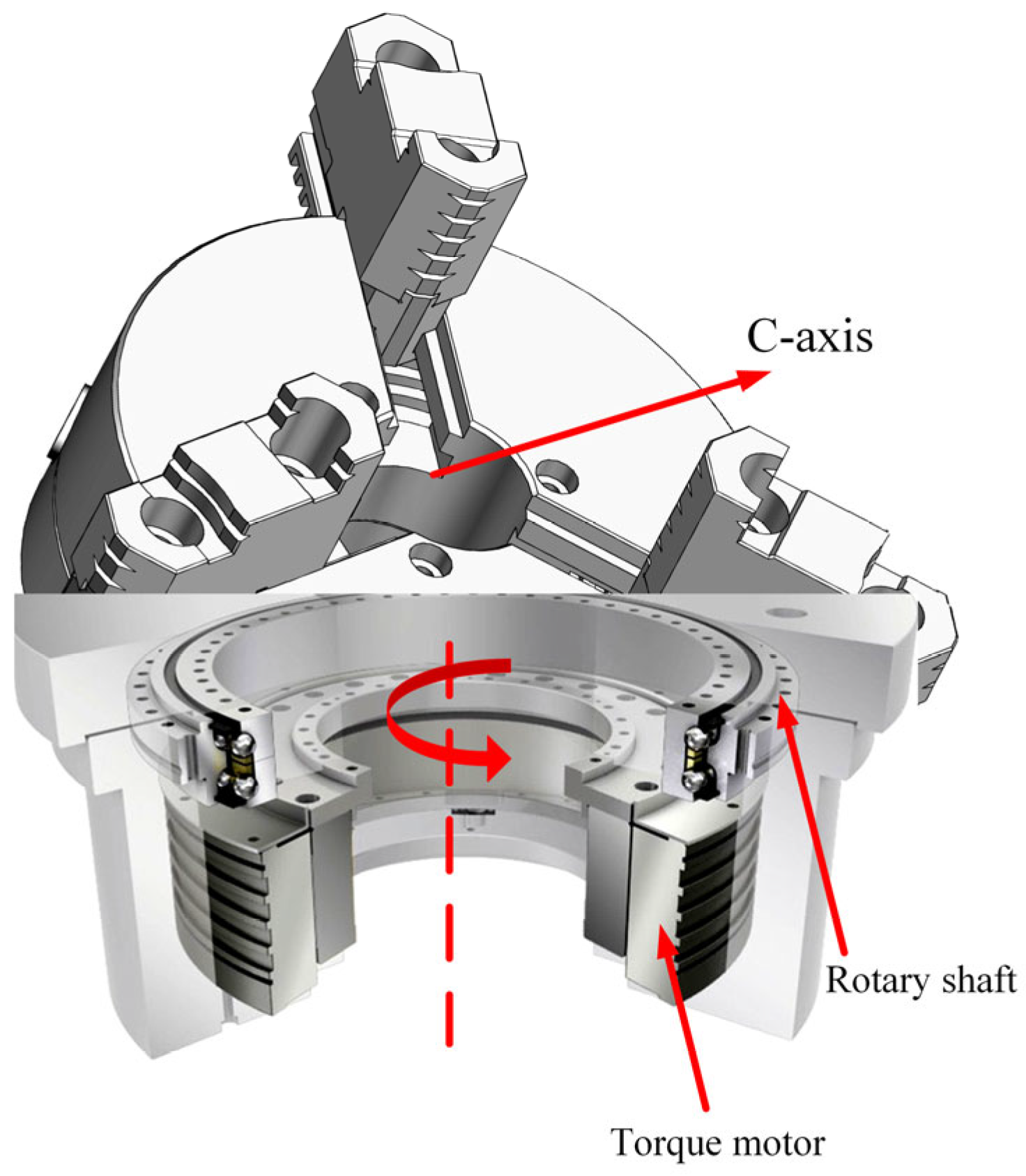

2.1.1. Machine Tool Structure

2.1.2. Geometric Error Measurement

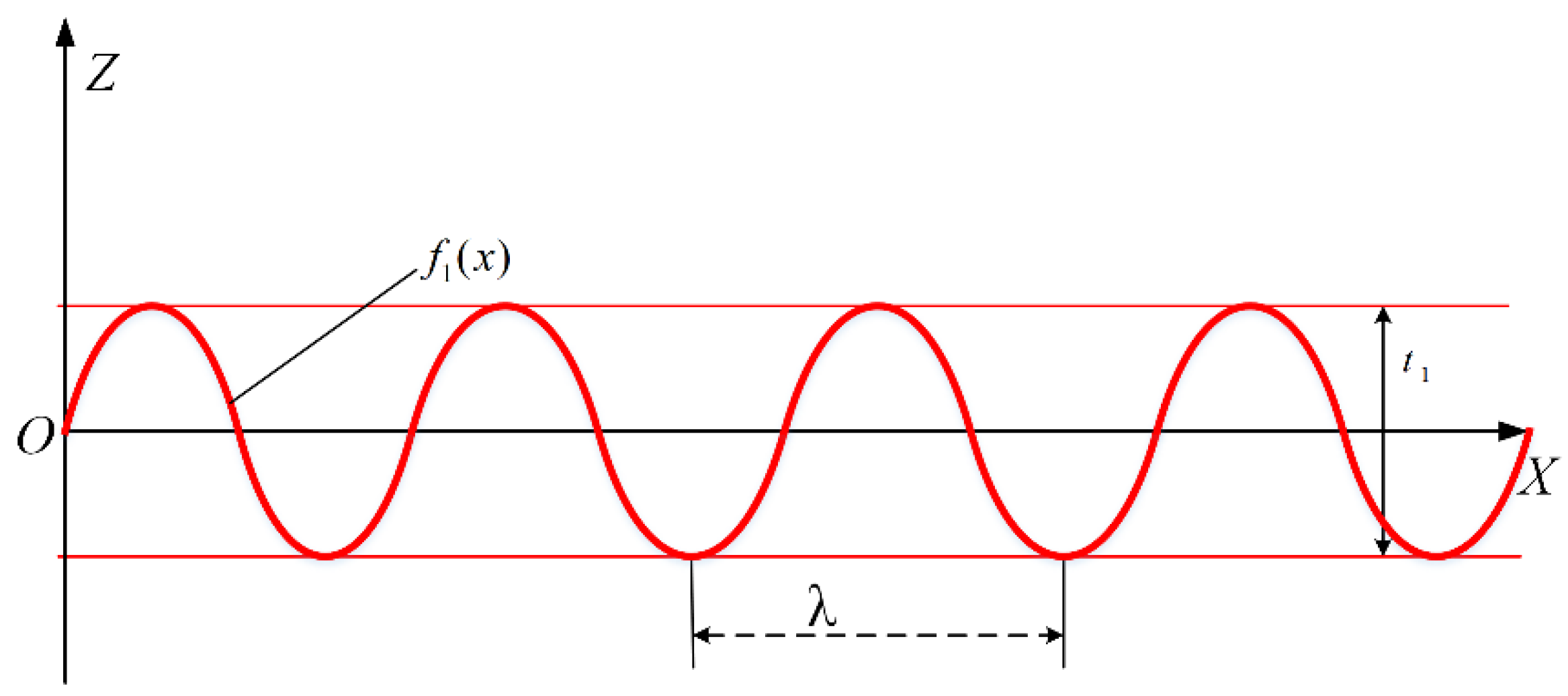

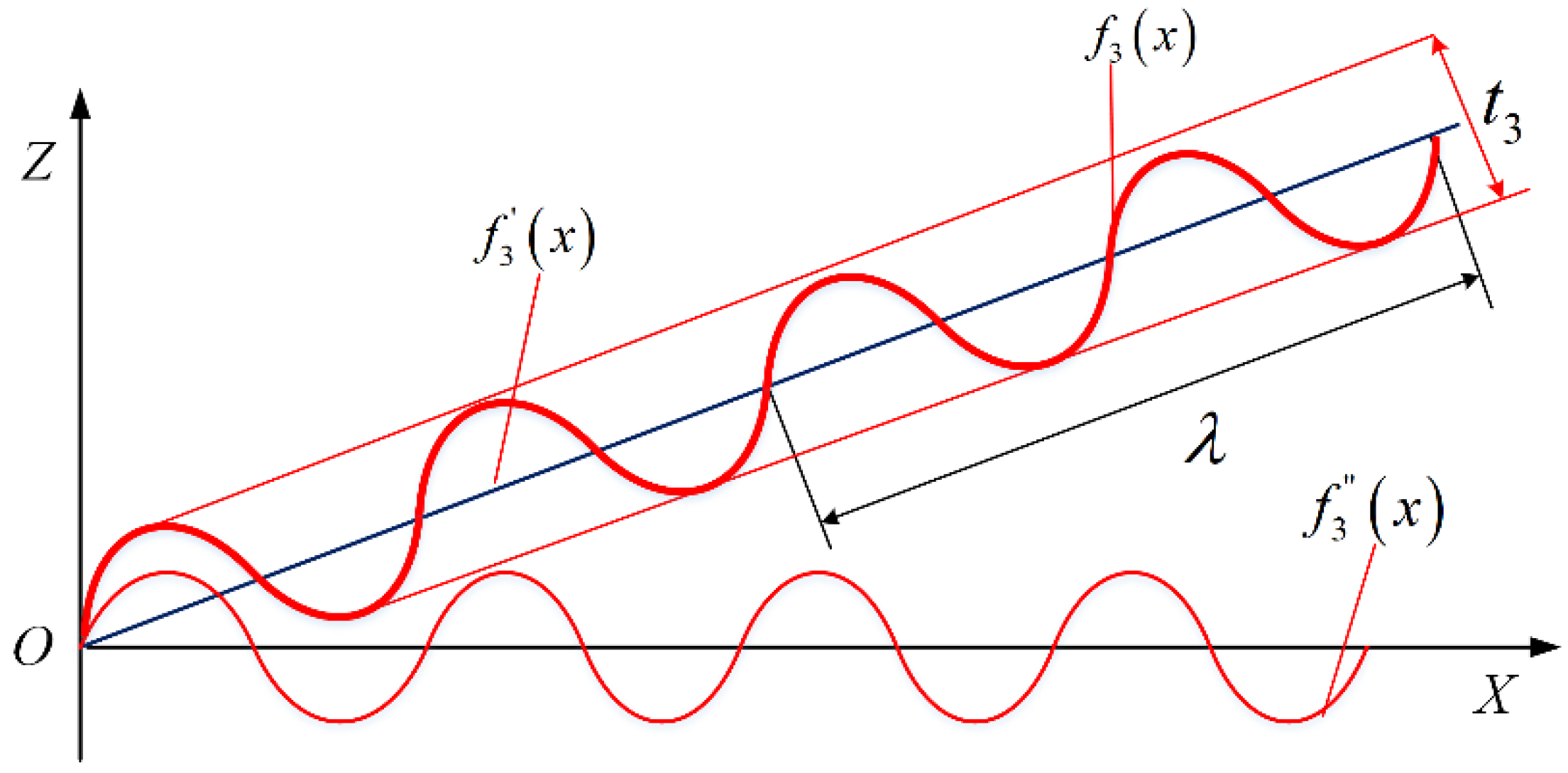

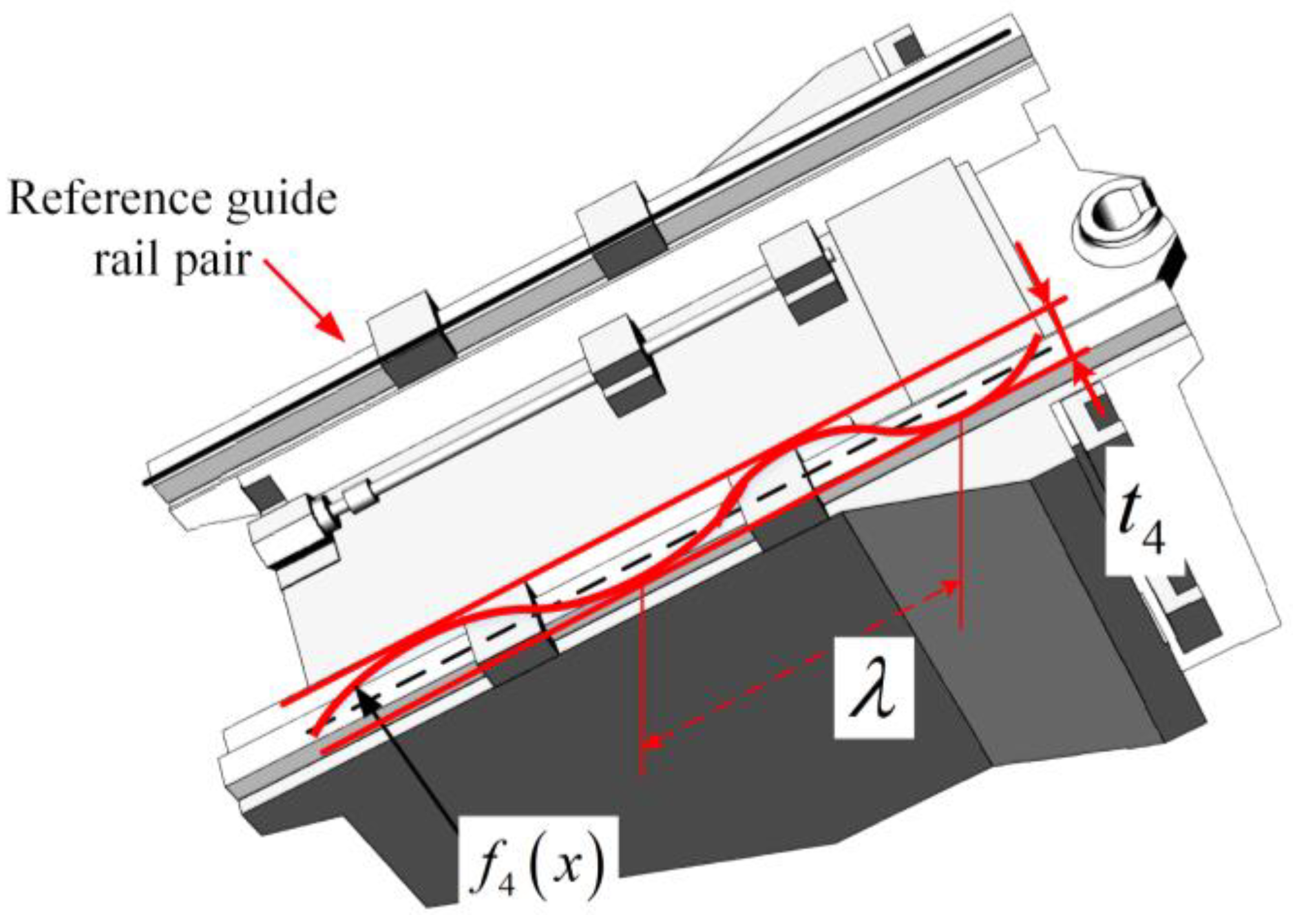

2.1.3. Fourier Series Model for Characterizing Surface Microtopography

- represents the surface microtopography of a component;

- denotes the tolerance parameter for a component;

- is the index term of the Fourier series;

- is the wavelength;

- is the kinematic position variable for a component.

2.2. Spatial Motion Error Model

- is the position matrix of point P in the workpiece coordinate system ;

- is the J body relative to the I body ideal static homogeneous transformation matrix between the bodies;

- is the actual static homogeneous transformation matrix between the J body and the I body;

- is the homogeneous transformation matrix for the ideal inter-body motion between the J body and the I body;

- is the homogeneous transformation matrix for the actual inter-body motion of the J body relative to the I body.

- is the position matrix of point P in the tool coordinate system .

- is the position matrix of point P in the tool coordinate system .

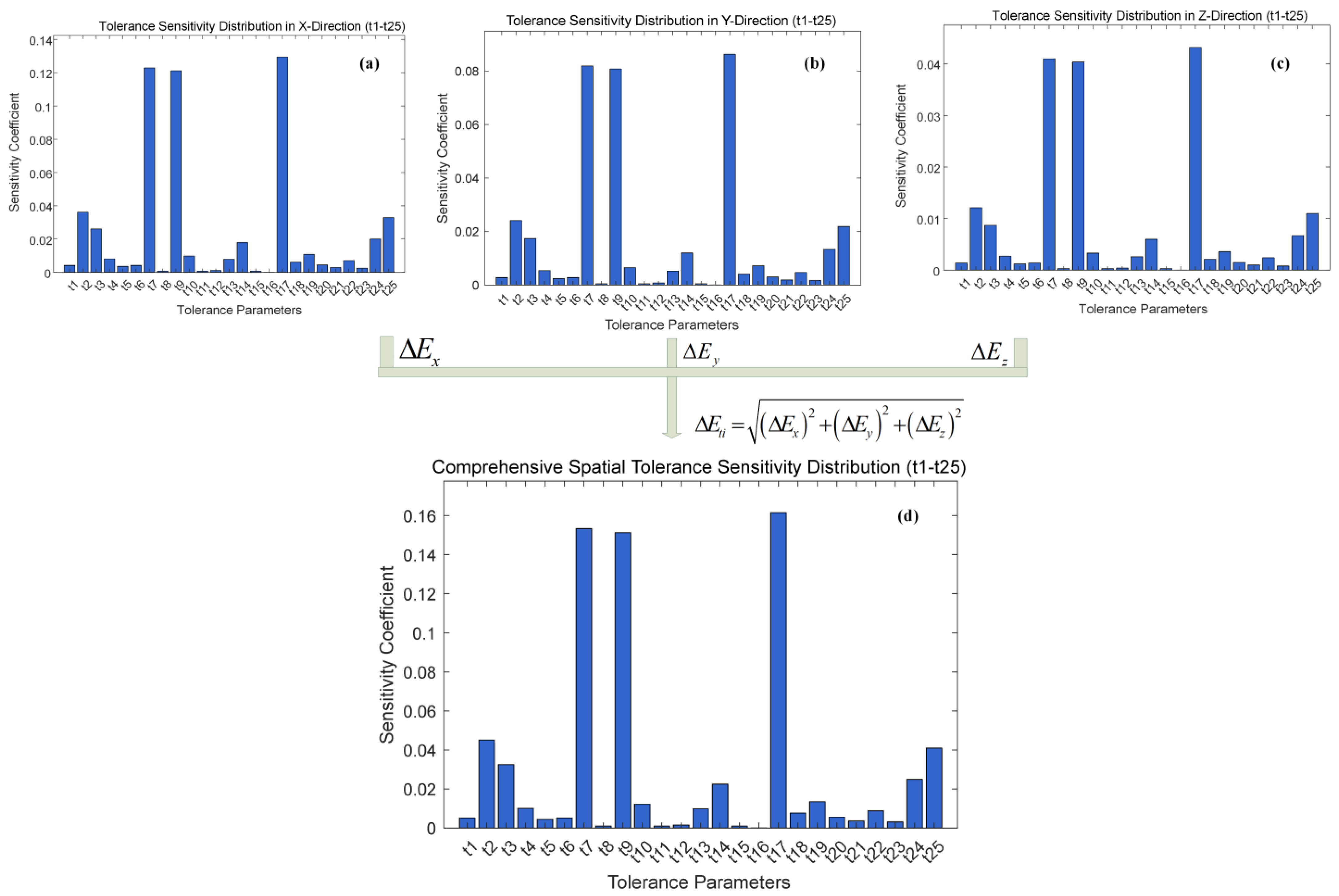

2.3. Tolerance Sensitivity Analysis

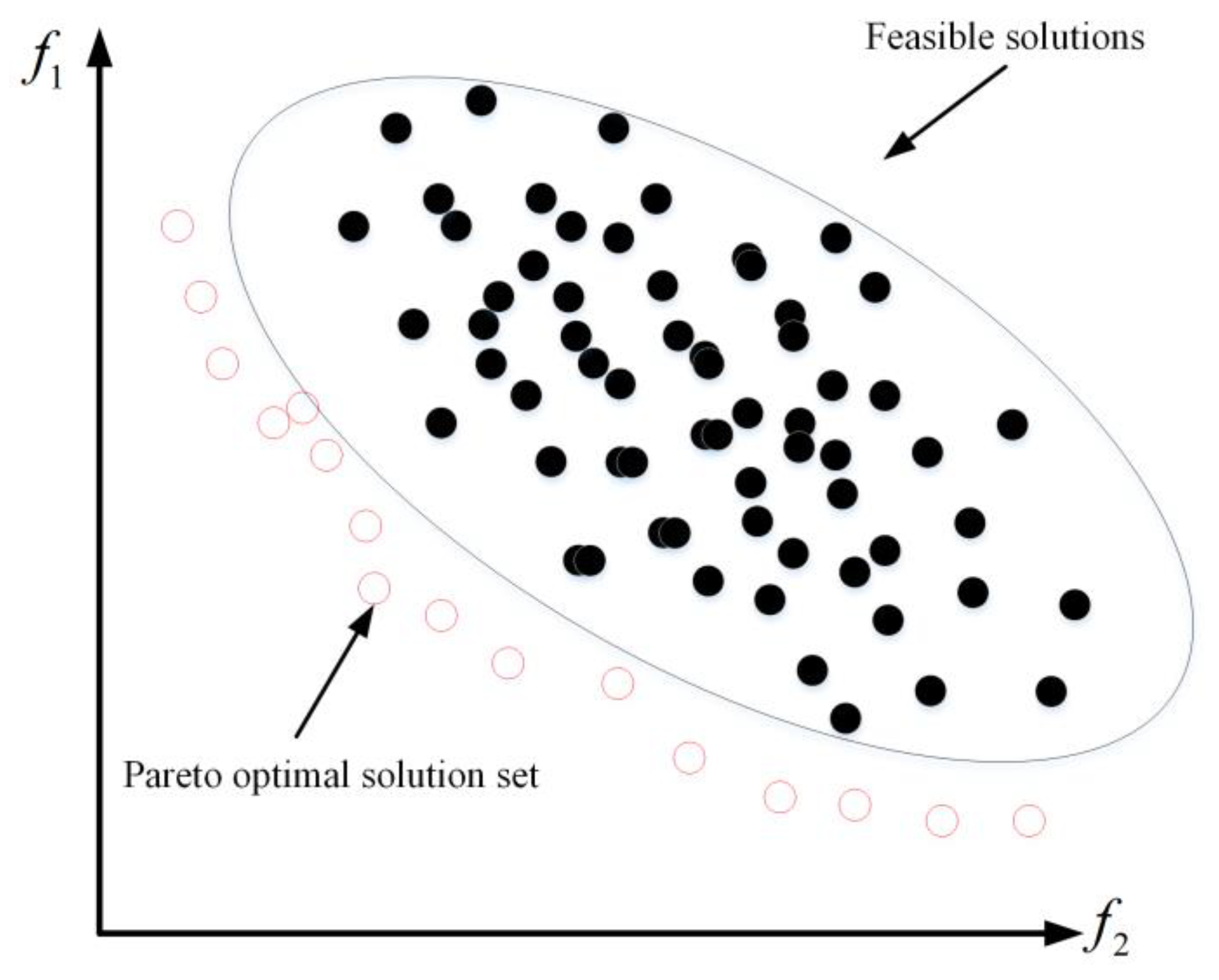

2.4. NSGA-II

2.4.1. Algorithm Principle and Improvement

Standard NSGA-II Core Mechanism

- Count the number of times each individual is dominated and the set of dominated individuals;

- Individuals with zero dominance constitute the first-level non-dominant front;

- Perform iterative calculation of non-dominant fronts for the remaining individuals until all individuals have been sorted.

Improvements Made to the NSGA-II

2.4.2. Parameter Configuration and Experimental Determination

2.4.3. Design Standards and Constraints of Machine Tool Spatial Motion Error

2.4.4. Multi-Objective Optimization Model Construction

Objective Function Definition

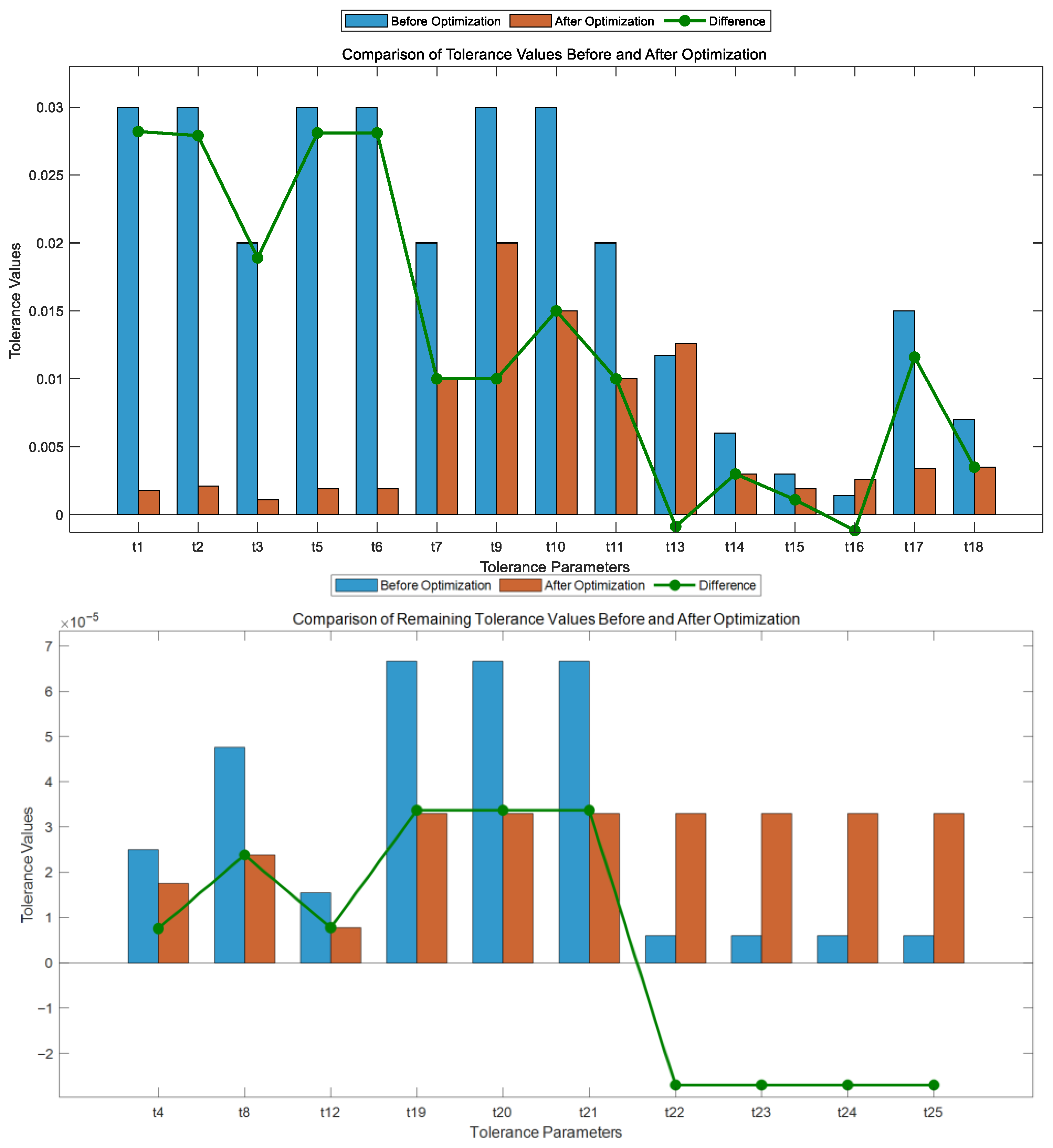

3. Simulation Results and Discussion

3.1. Geometric Error Measurement Results

3.2. Tolerance Sensitivity Results

3.3. Multi-Objective Optimization Results

3.4. Optimization Results and Convergence Analysis of NSGA-II

4. Conclusions

- (1)

- A mapping model of tolerance–surface topography–geometric error was established. The microscopic topography features were characterized using the Fourier series, enabling the prediction of geometric errors in the design stage.

- (2)

- A tolerance-driven prediction model of the overall machining error was constructed based on the multi-body system theory.

- (3)

- A gradient-based sensitivity index was innovatively proposed to quantify the influence weight of tolerances on the spatial error. This index effectively identifies the tolerance parameters that have the most significant impact on the peak value of the machining error.

- (4)

- A multi-objective tolerance optimization model was established. With 25 tolerance bandwidths as variables, under the constraint of spatial error, the NSGA-II algorithm was used to simultaneously optimize the minimization of machining error and the tolerance control cost (the weighted sum of tolerance parameters).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, Z.; Zhang, S.; Shi, J.; Sun, J. A modified method for measuring geometric errors of rotary axes based on sensitivity analysis and error simulation. Measurement 2025, 242, 115968. [Google Scholar] [CrossRef]

- Guevel, F.; Viprey, F.; Euzenat, C.; Fromentin, G.; Masciantonio, U. Geometric error compensation through position feedback modification and comparison of correction strategies in 3-axis machine-tool. J. Manuf. Process. 2025, 150, 213–223. [Google Scholar] [CrossRef]

- Vázquez, E.; Gomar, J.; Ciurana, J.; Rodríguez, C.A. Evaluation of machine-tool motion accuracy using a CNC machining center in micro-milling processes. Int. J. Adv. Manuf. Technol. 2015, 76, 219–228. [Google Scholar] [CrossRef]

- Švéda, J.; Chládek, Š.; Hornych, T.; Kozlok, T.; Smolík, J. Increasing Machining Accuracy Based on CNC Machine Tool Correction Data by Using Ad Hoc Modification. Machines 2022, 10, 288. [Google Scholar] [CrossRef]

- Jedrzejewski, J.; Kwasny, W. Development of machine tools design and operational properties. Int. J. Adv. Manuf. Technol. 2017, 93, 1051–1068. [Google Scholar] [CrossRef]

- Zimmermann, N.; Müller, E.; Lang, S.; Mayr, J.; Wegener, K. Thermally compensated 5-axis machine tools evaluated with impeller machining tests. CIRP J. Manuf. Sci. Technol. 2023, 46, 19–35. [Google Scholar] [CrossRef]

- Chen, H.; Tang, Q.; Li, X.; Yang, Y.; Qiao, P. Optimization of five-axis tool grinder structure based on BP neural network and genetic algorithm. Int. J. Adv. Manuf. Technol. 2024, 133, 2565–2582. [Google Scholar] [CrossRef]

- Song, L.; Sun, T.; Jia, R.; Liu, H.; Zhao, X. An error allocation method for five-axis ultra-precision machine tools. Int. J. Adv. Manuf. Technol. 2024, 130, 2601–2616. [Google Scholar] [CrossRef]

- Wei, B.; Zhu, S.; Xie, R.; Bi, Q. Identification of geometric errors of five-axis machine tool through volumetric error measurement. J. Phys. Conf. Ser. 2025, 3091, 012001. [Google Scholar] [CrossRef]

- Nojehdeh, M.V.; Arezoo, B. Functional accuracy investigation of work-holding rotary axes in five-axis CNC machine tools. Int. J. Mach. Tools Manuf. 2016, 111, 17–30. [Google Scholar] [CrossRef]

- Zhang, S.; He, C.; Liu, X.; Xu, J.; Sun, Y. Kinematic Chain Optimization Design Based on Deformation Sensitivity Analysis of a Five-Axis Machine Tool. Int. J. Precis. Eng. Manuf. 2020, 21, 2375–2389. [Google Scholar] [CrossRef]

- Wu, H.; Li, X.; Sun, F.; Zhao, Y. A status review of volumetric positioning accuracy prediction theory and static accuracy design method for multi-axis CNC machine tools. Int. J. Adv. Manuf. Technol. 2022, 122, 2139–2159. [Google Scholar] [CrossRef]

- Fan, J.; Wang, P.; Ren, X. A novel sensitivity analysis of translational axis operation considering key component tolerances. Int. J. Adv. Manuf. Technol. 2022, 118, 1255–1268. [Google Scholar] [CrossRef]

- Kim, K.; Kim, M.K. Volumetric accuracy analysis based on generalized geometric error model in multi-axis machine tools. Mech. Mach. Theory 1991, 26, 207–219. [Google Scholar] [CrossRef]

- Ma, W.; Tai, C.; Zhang, L.; He, G.; Xie, Q.; Sun, G.; Qu, L. Multi-stage error compensation with closed-loop quality control in five-axis flank milling of sculptured surface. Int. J. Adv. Manuf. Technol. 2024, 133, 2891–2906. [Google Scholar] [CrossRef]

- Wu, H.; Zheng, H.; Wang, W.; Xiang, X.; Rong, M. A method for tracing key geometric errors of vertical machining center based on global sensitivity analysis. Int. J. Adv. Manuf. Technol. 2020, 106, 3943–3956. [Google Scholar] [CrossRef]

- Liu, Y.; Wan, M.; Xiao, Q.-B.; Zhang, W.-H. Identification and compensation of geometric errors of rotary axes in five-axis machine tools through constructing equivalent rotary axis (ERA). Int. J. Mech. Sci. 2019, 152, 211–227. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, F.; Li, D.; Wu, Y.; Xue, J.; Wang, W.; Qiao, Z.; Wang, B. Machining accuracy improvement for a dual-spindle ultra-precision drum roll lathe based on geometric error analysis and calibration. Precis. Eng. 2020, 66, 401–416. [Google Scholar] [CrossRef]

- Gao, W.; Ibaraki, S.; Donmez, M.A.; Kono, D.; Mayer, J.R.R.; Chen, Y.-L.; Szipka, K.; Archenti, A.; Linares, J.-M.; Suzuki, N. Machine tool calibration: Measurement, modeling, and compensation of machine tool errors. Int. J. Mach. Tools Manuf. 2023, 187, 104017. [Google Scholar] [CrossRef]

- Khan, A.W.; Wuyi, C. Systematic Geometric Error Modeling for Workspace Volumetric Calibration of a 5-axis Turbine Blade Grinding Machine. Chin. J. Aeronaut. 2010, 23, 604–615. [Google Scholar] [CrossRef]

- Fan, J.; Tao, H.; Pan, R.; Chen, D. An approach for accuracy enhancement of five-axis machine tools based on quantitative interval sensitivity analysis. Mech. Mach. Theory 2020, 148, 103806. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Z.; Li, B.; Hong, J. Optimal tolerance allocation for precision machine tools in consideration of measurement and adjustment processes in assembly. Int. J. Adv. Manuf. Technol. 2015, 80, 1625–1640. [Google Scholar] [CrossRef]

- Wu, H.; Zheng, H.; Li, X.; Wang, W.; Xiang, X.; Meng, X. A geometric accuracy analysis and tolerance robust design approach for a vertical machining center based on the reliability theory. Measurement 2020, 161, 107809. [Google Scholar] [CrossRef]

- Liu, H.; Ling, S.; Wang, L.; Yu, Z.; Wang, X. An optimized algorithm and the verification methods for improving the volumetric error modeling accuracy of precision machine tools. Int. J. Adv. Manuf. Technol. 2021, 112, 3001–3015. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Mou, W.; Hao, X.; Li, Z.; Jin, Y. Sculptured surface-oriented machining error synthesis modeling for five-axis machine tool accuracy design optimization. Int. J. Adv. Manuf. Technol. 2017, 89, 3285–3298. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Li, P.; Hu, H.; Sui, X. Structural Design and Optimization of the Crossbeam of a Computer Numerical Controlled Milling-Machine Tool Using Sensitivity Theory and NSGA-II Algorithm. Int. J. Precis. Eng. Manuf. 2021, 22, 287–300. [Google Scholar] [CrossRef]

- Sun, G.; He, G.; Zhang, D.; Sang, Y.; Zhang, X.; Ding, B. Effects of geometrical errors of guideways on the repeatability of positioning of linear axes of machine tools. Int. J. Adv. Manuf. Technol. 2018, 98, 2319–2333. [Google Scholar] [CrossRef]

- Fan, J.; Wang, P.; Ren, X. A novel global sensitivity analysis method for vital geometric errors of five-axis machine tools. Int. J. Adv. Manuf. Technol. 2021, 117, 3515–3527. [Google Scholar] [CrossRef]

- Li, Q.; Wang, W.; Jiang, Y.; Li, H.; Zhang, J.; Jiang, Z. A sensitivity method to analyze the volumetric error of five-axis machine tool. Int. J. Adv. Manuf. Technol. 2018, 98, 1791–1805. [Google Scholar] [CrossRef]

- Jiang, X.; Cui, Z.; Wang, L.; Liu, C.; Li, M.; Liu, J.; Du, Y. Critical geometric errors identification of a five-axis machine tool based on global quantitative sensitivity analysis. Int. J. Adv. Manuf. Technol. 2022, 119, 3717–3727. [Google Scholar] [CrossRef]

- Tian, W.; Liu, S.; Liu, X. Accuracy design of high precision machine tools using error sensitivity analysis methodology. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 3401–3413. [Google Scholar] [CrossRef]

- Chen, G.; Ding, S.; Xu, G. Novel method for identifying sensitive geometric errors of CNC machine tools oriented to cylindricity in flank milling. J. Manuf. Process. 2024, 126, 370–381. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, Y. A novel methodology for predicting and identifying geometric errors of rotary axis in five-axis machine tools. Int. J. Adv. Manuf. Technol. 2020, 108, 705–719. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multi objective genetic algorithm: NSGA-II. IEEE Trans. Evol. Computat. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Cheng, Q.; Qi, Y.; Cai, L. An approach of comprehensive error modeling and accuracy allocation for the improvement of reliability and optimization of cost of a multi-axis NC machine tool. Int. J. Adv. Manuf. Technol. 2017, 89, 561–579. [Google Scholar] [CrossRef]

- Demir, G.; Acar Vural, R. Non-Cutting Moving Toolpath Optimization with Elitist Non-Dominated Sorting Genetic Algorithm-II. Appl. Sci. 2024, 14, 4471. [Google Scholar] [CrossRef]

- Hallmann, M.; Schleich, B.; Wartzack, S. From tolerance allocation to tolerance-cost optimization: A comprehensive literature review. Int. J. Adv. Manuf. Technol. 2020, 107, 4859–4912. [Google Scholar] [CrossRef]

- ISO 13041-1:2020; Test Conditions for Numerically Controlled Turning Machines and Turning Centres—Part 1: Geometric Tests for Machines with a Horizontal Workholding Spindle. International Organization for Standardization: Geneva, Switzerland, 2020.

| Geometric Error | Tolerance Parameter | Geometric Error | Tolerance Parameter | Geometric Error | Tolerance Parameter |

|---|---|---|---|---|---|

| — | — | ||||

| — | — |

| Tolerance Parameter | Definition | Tolerance Parameter | Definition |

|---|---|---|---|

| Linear tolerance of X-axis guide rail in XOZ plane | Radial runout tolerance of upper and lower bores of B-axis | ||

| Linear tolerance of X-axis guide rail in XOY plane | Axial run-out tolerance of B-axis | ||

| Positioning tolerance of X-axis screw | Tolerance of C-axis rotation angle | ||

| Parallelism tolerance between X-axis guide pairs | Tolerance of radial circular run-out of upper and lower bores of C-axis | ||

| Linear tolerance of Y-axis guide in YOZ plane | Axial run-out tolerance of C-axis | ||

| Linear tolerance of Y-axis guide rail in XOY plane | Squareness tolerance between X- and Z-axes | ||

| Positioning tolerance of Y-axis screw | Squareness tolerance between X- and Y-axes | ||

| Parallelism tolerance between Y-axis guide pairs | Squareness tolerance between Y- and Z-axes | ||

| Linear tolerance of Z-axis guide rail in XOZ plane | Squareness tolerance between X- and B-axes | ||

| Linear tolerance of Z-axis guide rail in YOZ plane | Squareness tolerance between Z- and B-axes | ||

| Z-axis screw positioning tolerance | Squareness tolerance between X- and C-axes | ||

| Parallelism tolerance between Z-axis guide pairs | Squareness tolerance between Y- and C-axes | ||

| Tolerance of B-axis rotation angle | — | — |

| Parameter | Symbol | Value | Determination Basis |

|---|---|---|---|

| Population size | 150 | Balance calculation efficiency and solution diversity determined via 20 repeated experiments | |

| Maximum number of iterations | 300 | Ensure convergence of algorithm; HV value tends to stabilize after 200 generations | |

| Crossover probability | Adaptive (0.8–1.0) | Dynamic adjustment based on normal distribution; mean is 0.9 | |

| Mutation probability | Approximately 0.04 ( = 25 tolerance parameters) | ||

| Cross-distribution index | 28 | Compared with the standard value, it enhances the local search ability | |

| Variation distribution index | 20 | Adaptive adjustment range of 15–25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Fan, J. A Method for Optimizing the Precision of a Five-Axis Machine Tool Based on Tolerance. Machines 2025, 13, 870. https://doi.org/10.3390/machines13090870

Yan H, Fan J. A Method for Optimizing the Precision of a Five-Axis Machine Tool Based on Tolerance. Machines. 2025; 13(9):870. https://doi.org/10.3390/machines13090870

Chicago/Turabian StyleYan, Hongxia, and Jinwei Fan. 2025. "A Method for Optimizing the Precision of a Five-Axis Machine Tool Based on Tolerance" Machines 13, no. 9: 870. https://doi.org/10.3390/machines13090870

APA StyleYan, H., & Fan, J. (2025). A Method for Optimizing the Precision of a Five-Axis Machine Tool Based on Tolerance. Machines, 13(9), 870. https://doi.org/10.3390/machines13090870