Design and Vibration Characteristics Analysis of Marine Hydraulic Pipelines Under Multi-Source Excitation

Abstract

1. Introduction

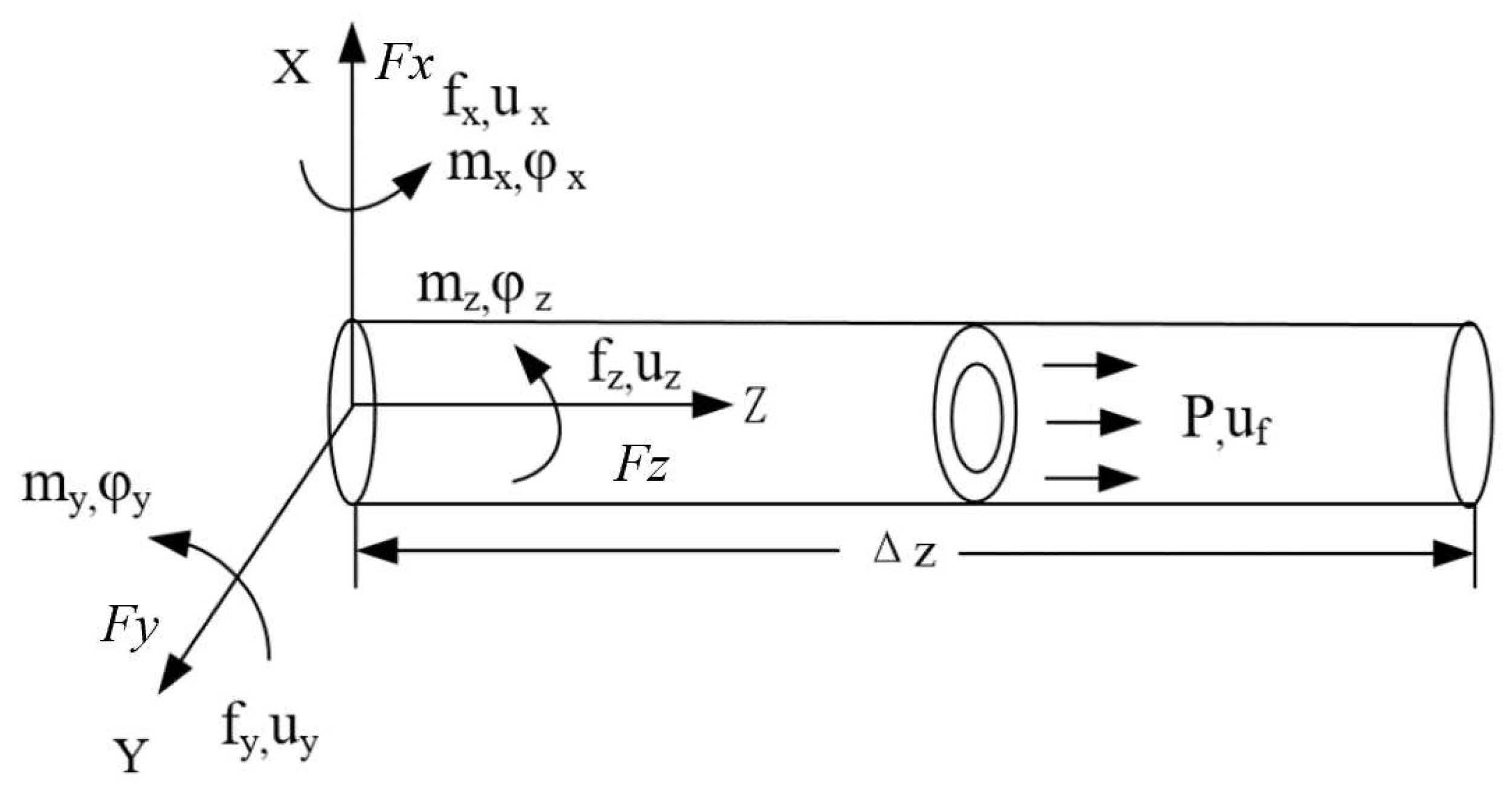

2. Dynamic Modeling of Flow Pipelines

2.1. Vibration Equation for Axial Fluid-Solid Coupling in Straight Tube

2.2. Vibration Equation of Straight Tube in Radial x-z Direction

2.3. Vibration Equation of Straight Tube in Radial y-z Direction

2.4. Torsional Vibration Equation for a Straight Tube

2.5. Model Solution

3. Impact of Piping Arrangement and Fluid Parameters on Piping System Performance

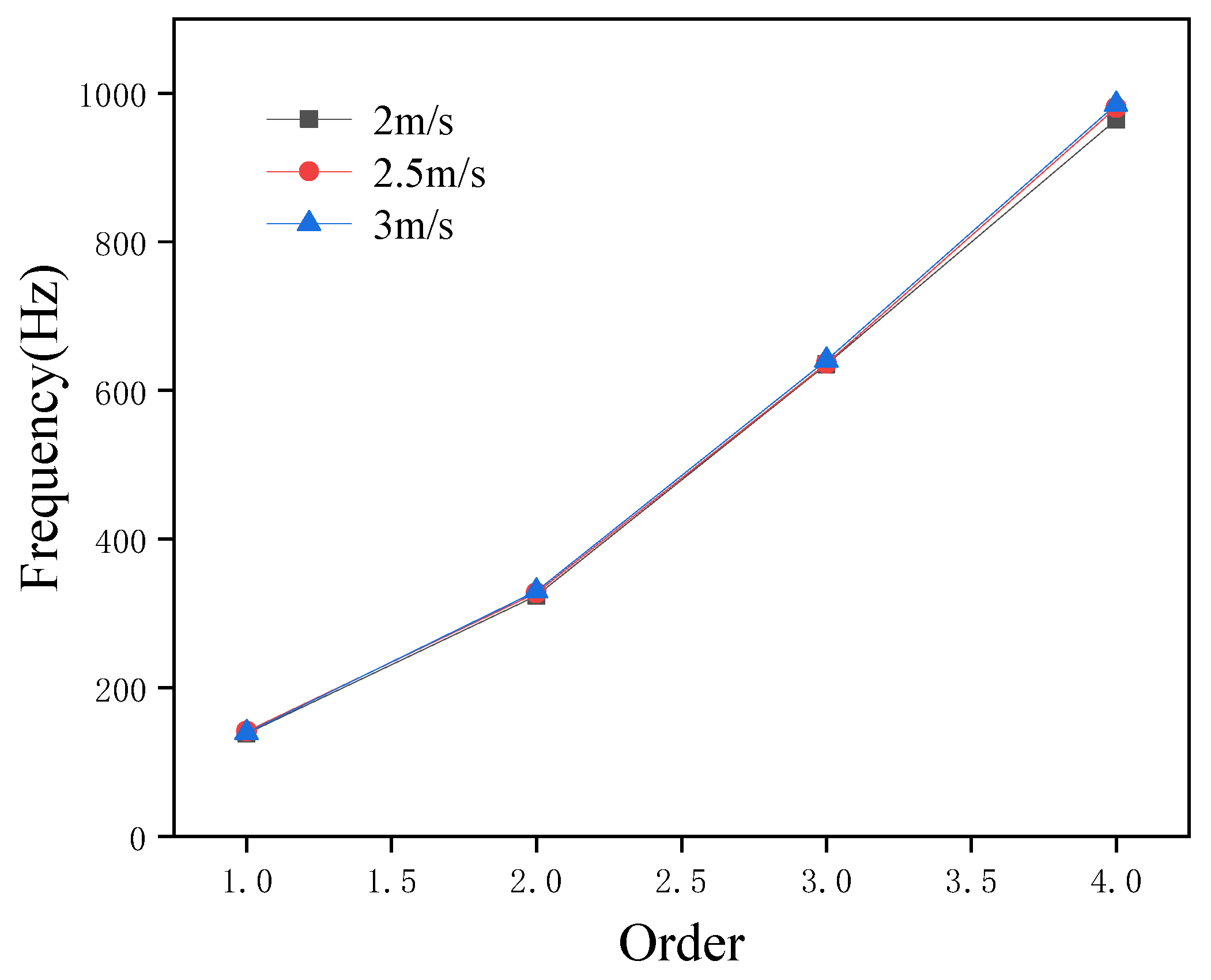

3.1. Influence of Fluid Flow Rate on the Modal State of Piping Systems

3.2. Effect of the Number of Pipeline Circuits on the Modes

3.3. Influence of Support Layout on Piping System Vibration

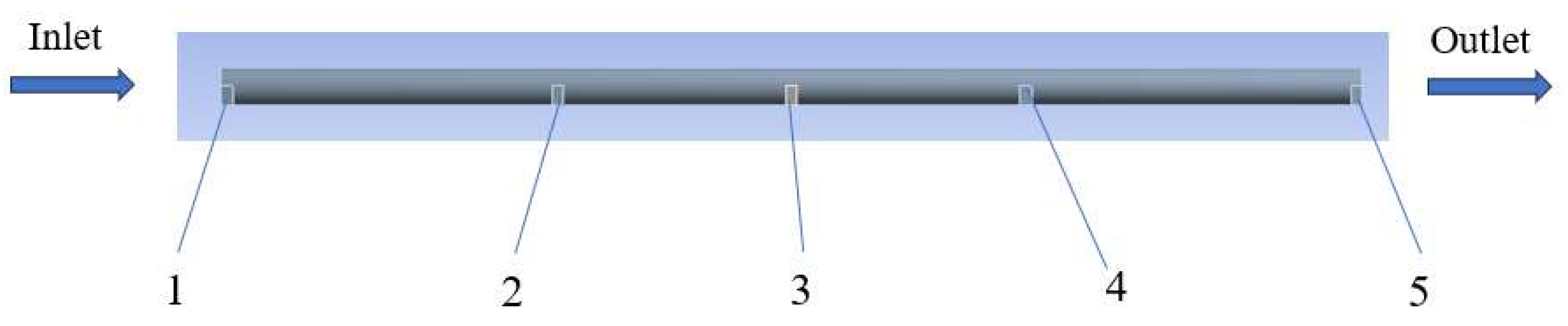

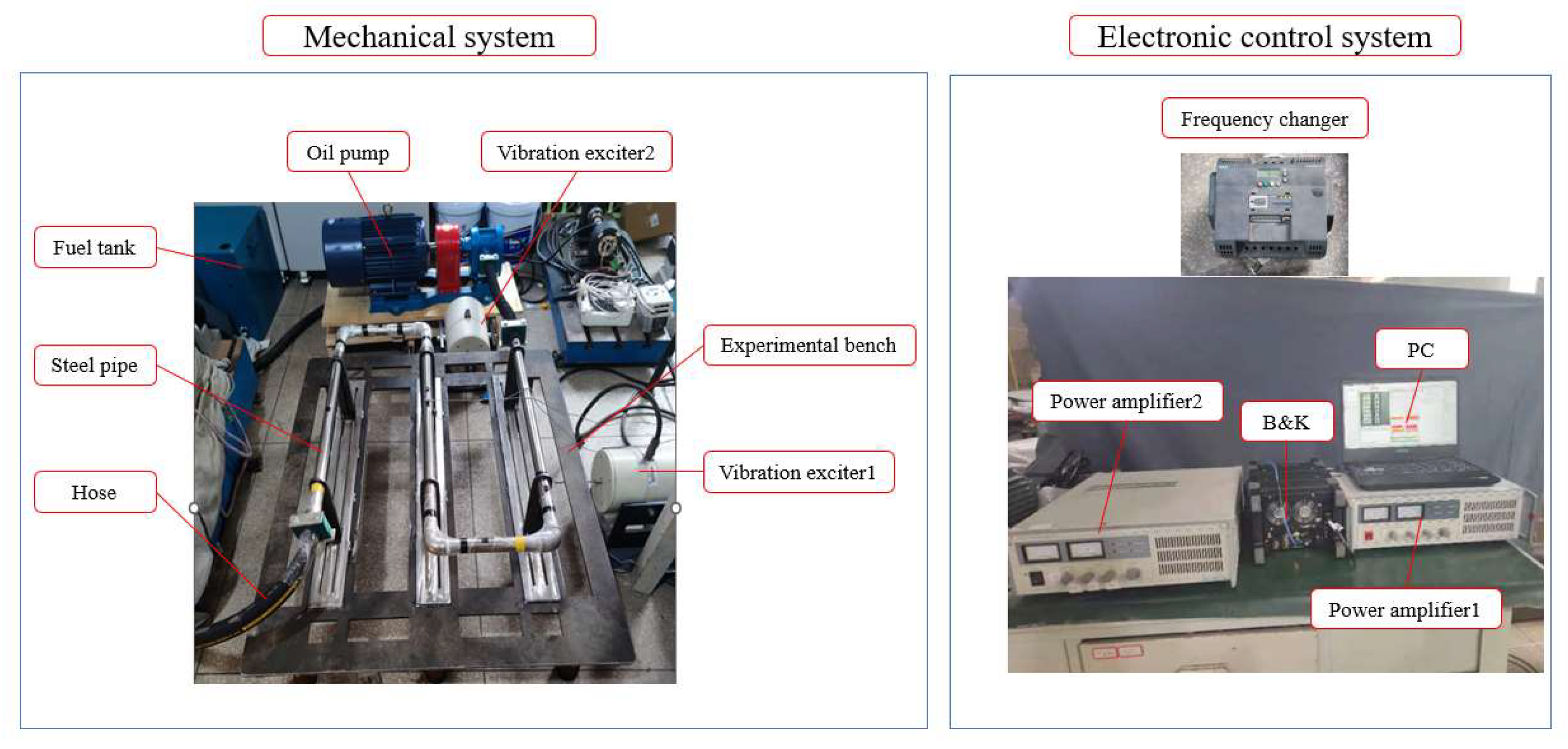

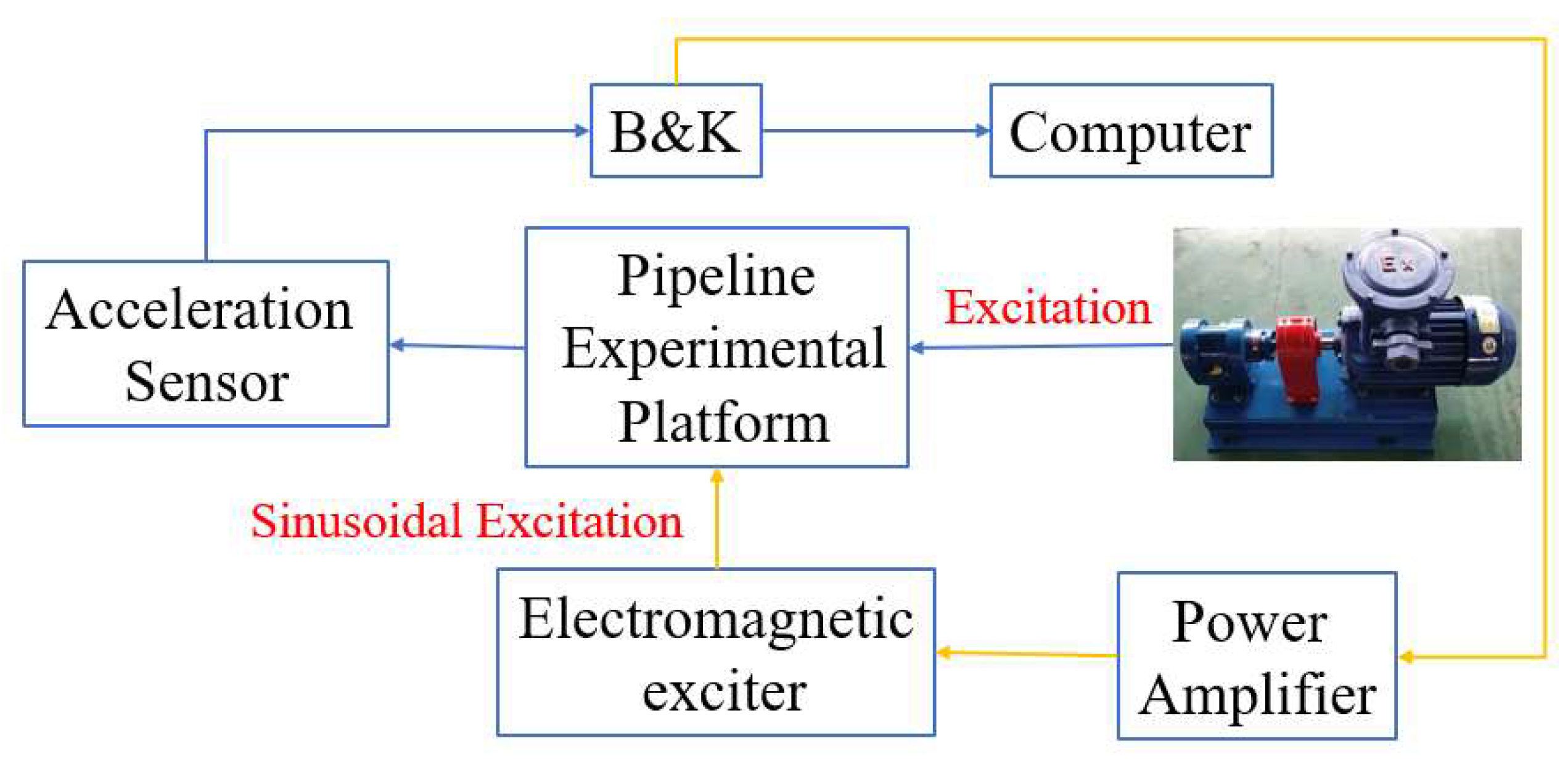

4. The Construction of Pipeline System Experimental Platform and Pipeline Vibration Experimental Analysis

4.1. Piping System Test Bench Construction

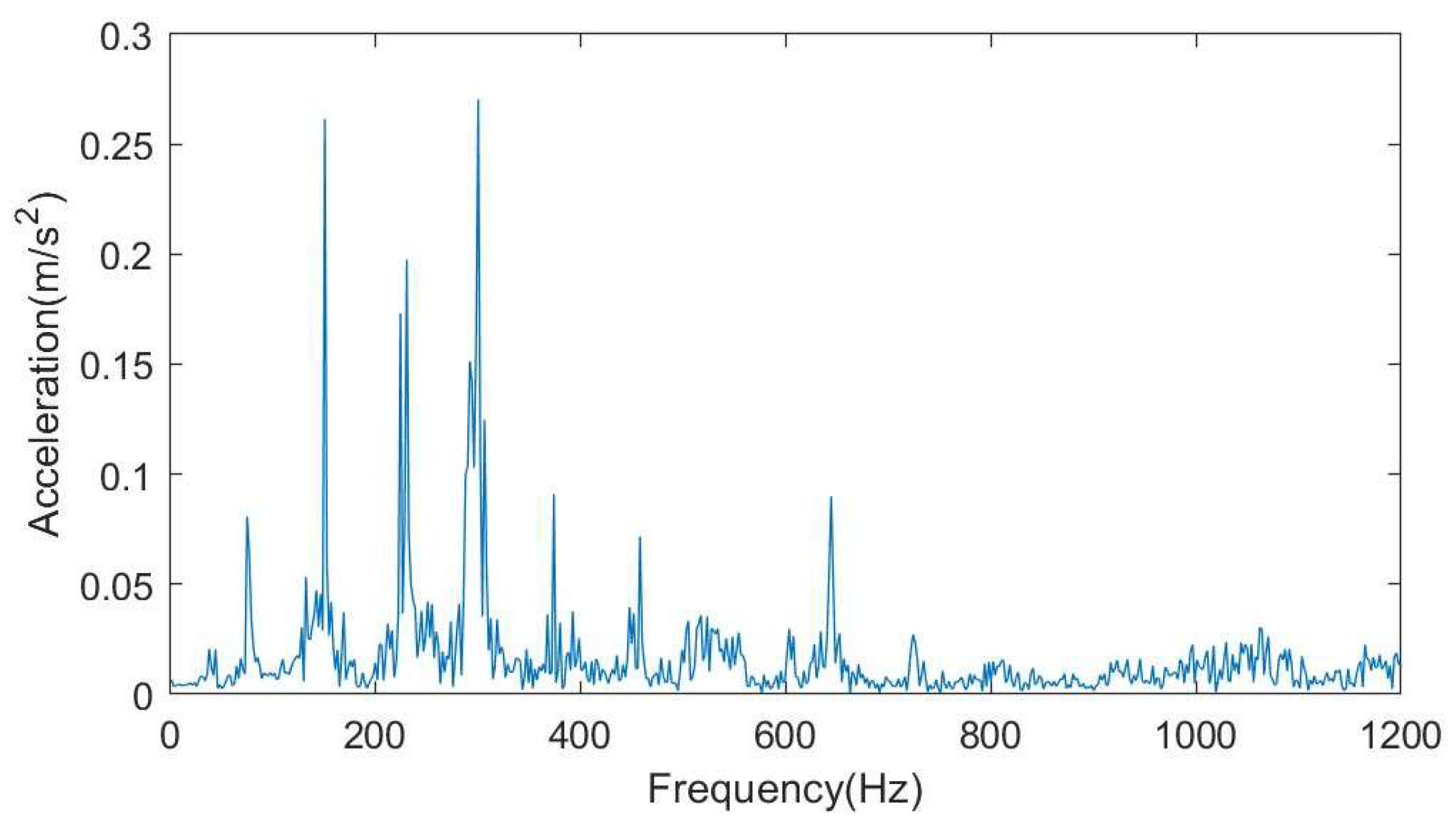

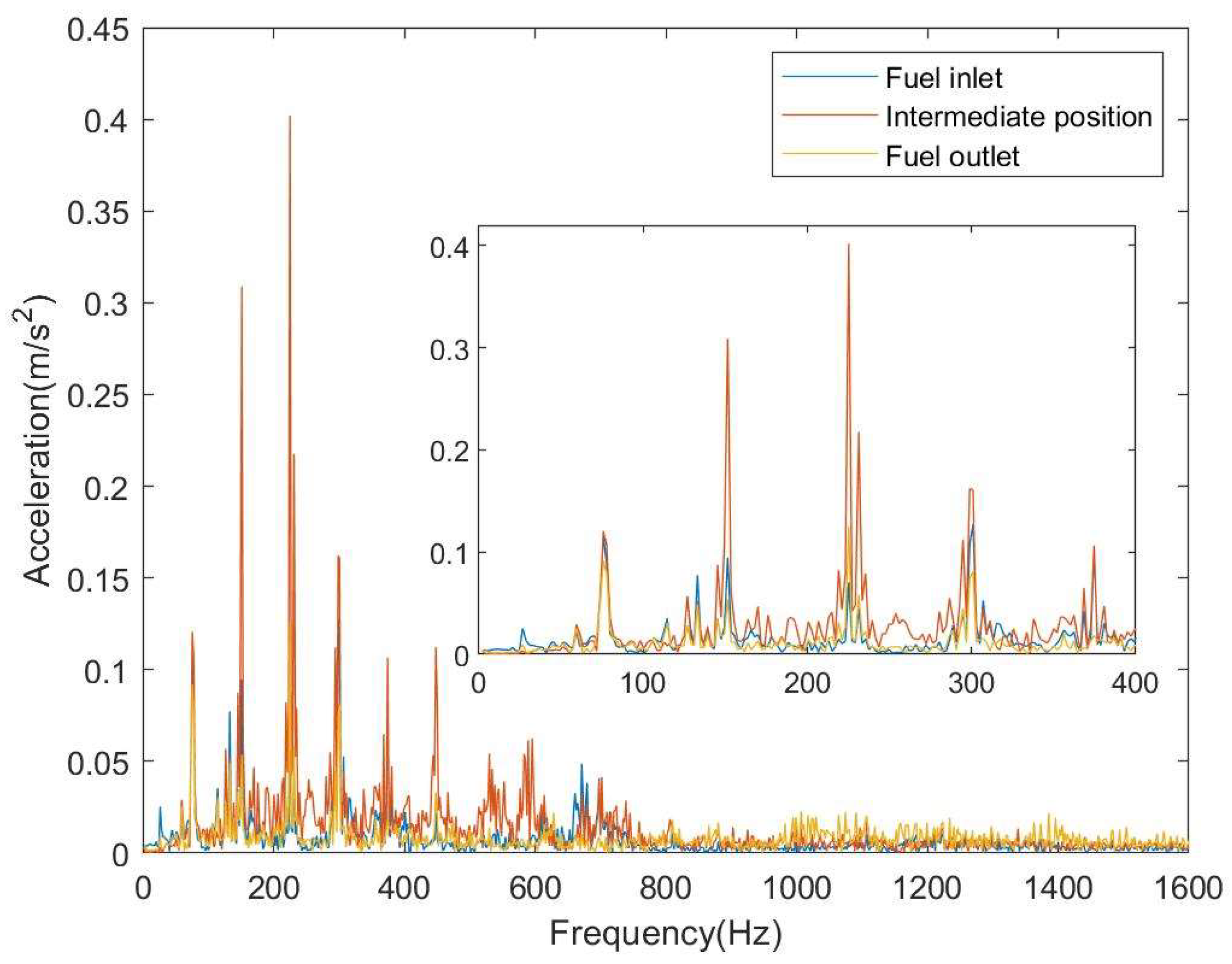

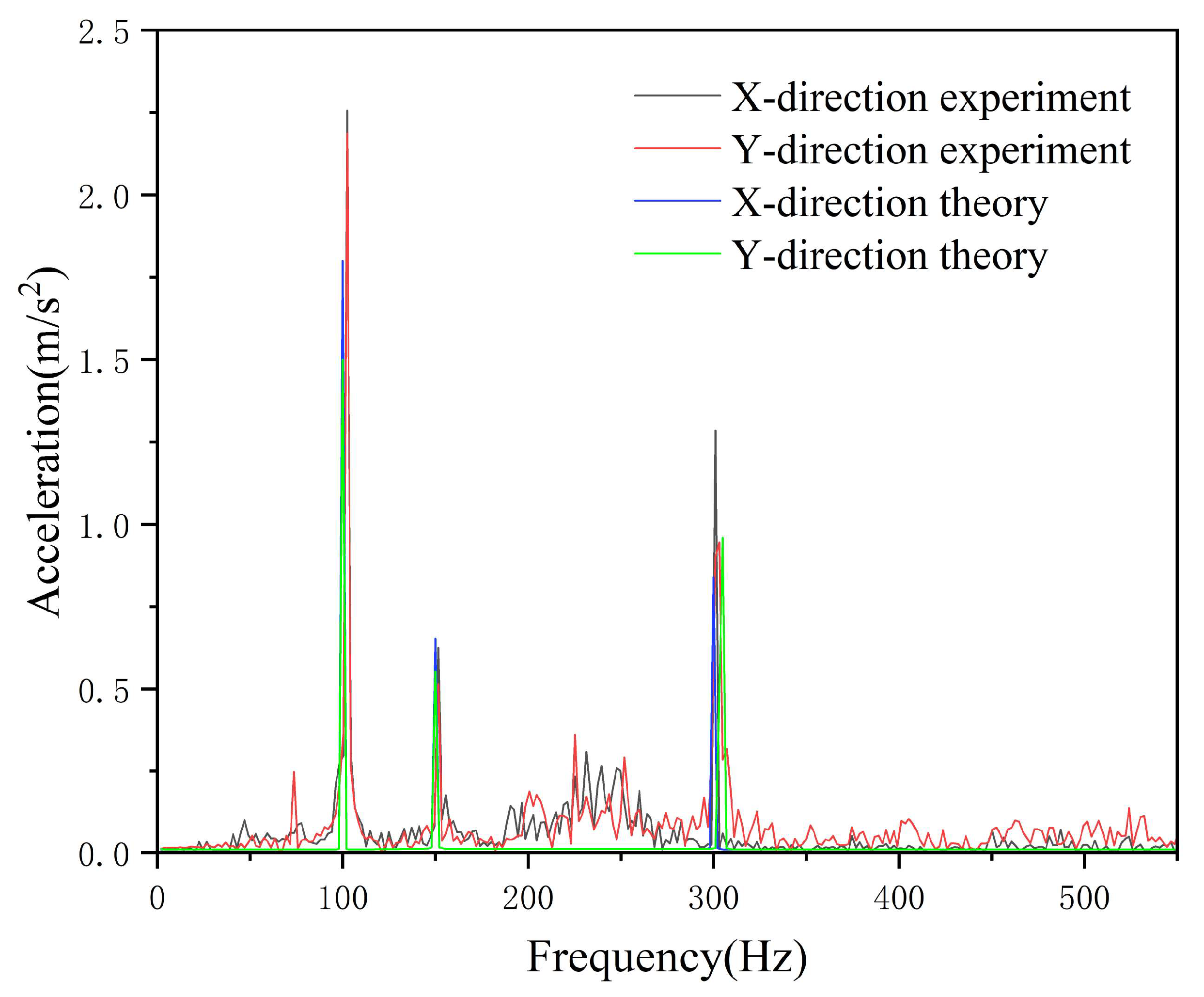

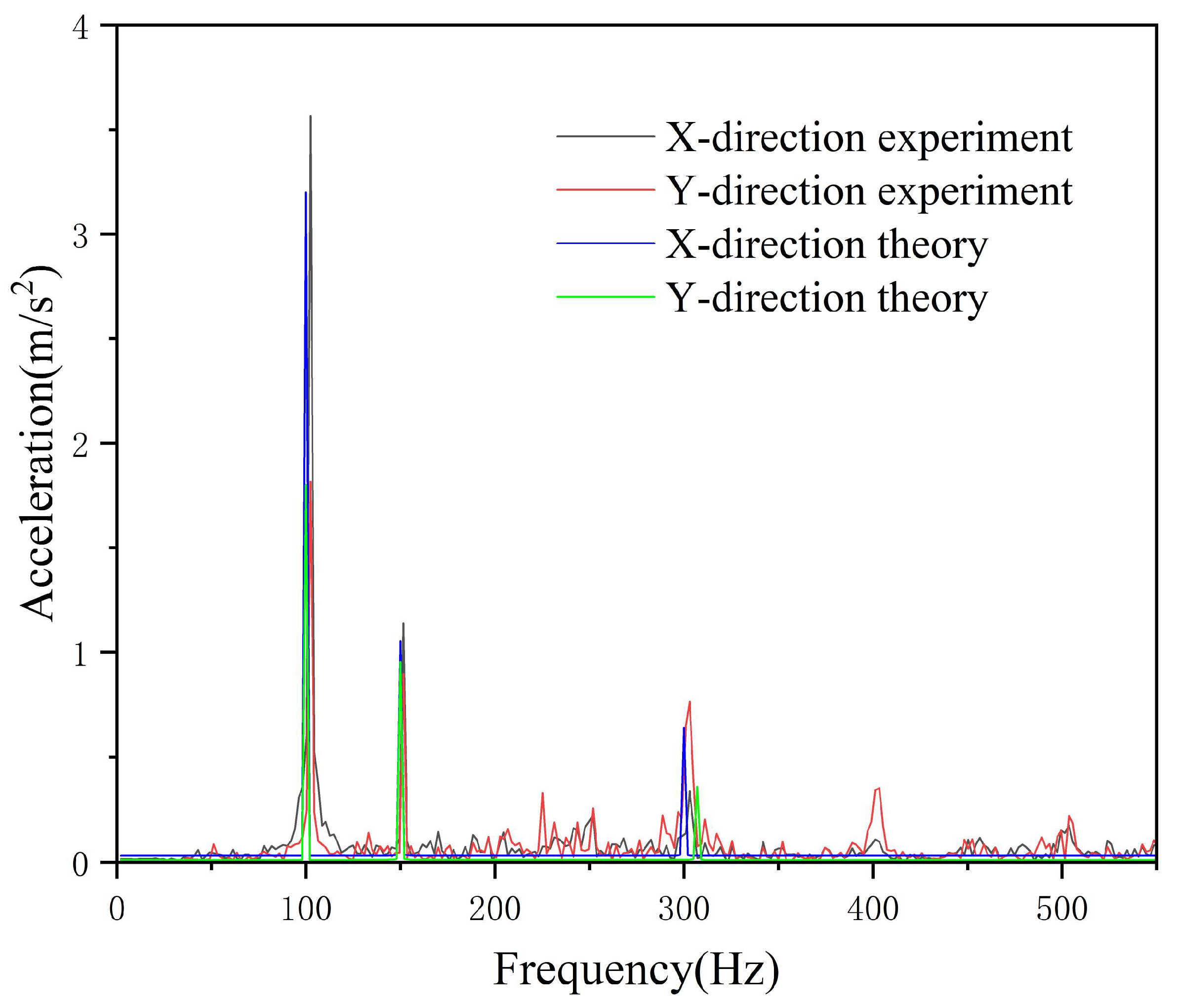

4.2. Experimental Analysis of Pipeline Vibration

5. Conclusions

- The fluid flow rate change in the pipeline has no significant effect on the modal order of the overall piping system; however, the pipeline’s vibration intensity increases with increasing flow rate. Furthermore, the pipeline loop configuration exerts a more significant influence on the system’s modal order—increasing the number of loops can effectively reduce the modal order. Additionally, as the distance from the fluid inlet increases, the vibration amplitude of each pipeline span gradually decreases.

- Increasing the number of supports can effectively reduce the overall vibration level of the piping system. It has been observed that the maximum vibration of the piping is concentrated between two supports located near the input end. Therefore, reinforcing the input end of the piping can effectively mitigate the amplitude of the maximum vibration.

- The vibration characteristics of a piping system are influenced by external excitation. Specifically, when unidirectional excitation is applied, it enhances vibration in the same direction while simultaneously weakening vibration in other directions. Bidirectional excitation further complicates the pipeline’s vibration behavior: the excitation signals from the two directions interact with each other, resulting in a degree of enhancement in pipeline vibration, but this enhancement is less pronounced than that observed under unidirectional excitation. Furthermore, the aforementioned weakening effect on non-target directions disappears, thereby achieving a certain damping effect. This finding offers a new insight for the subsequent exploration of vibration isolation techniques for marine hydraulic pipelines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, W.; Wang, X.; Wang, B.; Leong, E.-C.; Zhou, S.; Wang, B.; Wang, C. Torsional vibration of a pipeline pile in unsaturated cross-anisotropic soil based on the fractional viscoelastic model. Ocean Eng. 2024, 313, 119483. [Google Scholar] [CrossRef]

- Fabrizio, A.; Roberto, A.; Salvatore, B.O. Pipeline vibration attenuation through internal damping and optimal design of vibro-impact systems. Sci. Rep. 2023, 13, 6510. [Google Scholar]

- Aitken, M.J.; Allsop, A.L.; Bussell, G.D.; Winter, M. Archaeomagnetic intensity determination: A nineteenth century pottery kiln near Jordan, Ontario. Can. J. Earth Sci. 1987, 24, 2392–2395. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Z.; Zhou, Z.; Qu, Y.; Yu, Z.; Wei, Q.; Lu, L. Vibration response of multi-span fluid-conveying pipeline with multiple accessories under complex boundary conditions. Eur. J. Mech./A Solids 2018, 72, 41–56. [Google Scholar]

- Beatty, M.F. Stress-Softening Effects in the Vibration of a Non-Gaussian Rubber Membrane. Math. Mech. Solids 2003, 8, 481–495. [Google Scholar] [CrossRef]

- Ashley, H.; Haviland, G. Bending vibrations of a pipeline line containing flowing fluid. J. Appl. Mech. 1950, 17, 229–232. [Google Scholar] [CrossRef]

- Johnson, R.O.; Stonekin, J.E.; Carley, T.G. The stability of simply supported tubes conveying in compressible fluid. J. Sound Vib. 1987, 117, 335–350. [Google Scholar] [CrossRef]

- Askarian, A.R.; Haddadpour, H.; Firouz-Abadi, R.D.; Abtahi, H. Nonlinear dynamics of extensible viscoelastic cantilevered pipelines conveying pulsatile flow with an end nozzle. Int. J. Non-Linear Mech. 2017, 91, 22–35. [Google Scholar]

- Li, B.; Gao, X.; Liu, Y.; Yue, Z. Stability analysis of fluid-solid coupled vibration in two-ended solidly supported flow pipeline. Mech. Des. Manuf. 2010, 2, 105–107. [Google Scholar]

- Cao, J.; Liu, Y.; Liu, W. Study on wavelet finite element method for vibration in the tube surface of a flow-conveying bend. Vib. Shock 2018, 37, 256–260. [Google Scholar]

- Zhu, H.; Wang, W.; Yin, X.; Gao, C. Coupled vibration of a functional gradient-fed pipeline based on a hierarchical model. Vib. Shock 2019, 38, 203–209+259. [Google Scholar]

- Liang, Z.-j.; Guo, C.-y.; Chun, Y. Research On Mechanism of Dynamic Evolution Vibration Characteristics of Horizontal 90° Elbow Flow Pattern. J. Press. Vessel Technol. 2023, 145, 031404. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, C.; Jiang, Y. Simulation Analysis and Experimental Investigation on the Fluid–Structure Interaction Vibration Characteristics of Aircraft Liquid-Filled Pipelines under the Superimposed Impact of External Random Vibration and Internal Pulsating Pressure. Appl. Sci. 2024, 14, 8008. [Google Scholar] [CrossRef]

- Zhu, B.; Feng, J.Z.; Guo, Y.; Wang, Y.Q. Exact closed-form solution for buckling and free vibration of pipes conveying fluid with intermediate elastic supports. J. Sound Vib. 2025, 596, 118762. [Google Scholar] [CrossRef]

- Zarghami, F.; Vatankhah, R.; Hashemnia, K. Passive vibration control and stability analysis of fluid-conveying pipe with different boundary conditions under impact load employing optimized absorbers. Int. J. Dyn. Control 2025, 13, 60. [Google Scholar] [CrossRef]

- dos Reis, E.V.M.; Sphaier, L.A.; Nunes, L.C.S.; Alves, L.S.d.B. Dynamic response of free span pipelines via linear and nonlinear stability analyses. Ocean Eng. 2018, 163, 533–543. [Google Scholar] [CrossRef]

- Cao, Y.; Yan, G.; Lu, J.; Qi, W.; Zhao, T.; Yu, D.; Cai, L.; Li, Y.; Zhang, W. Vibration mitigation and dynamics of pipeline system with nonlinear soft clamp by a nonlinear energy sink. Int. J. Non-Linear Mech. 2025, 170, 104990. [Google Scholar] [CrossRef]

- Gong, S.; Xu, P.; Bao, S.; Zhong, W.; He, N.; Yan, H. Numerical modelling on dynamic behaviour of deepwater S-lay pipeline. Ocean Eng. 2014, 88, 393–408. [Google Scholar] [CrossRef]

- Arastoo, A.; Firooz, B.-N.; Zhu, W. Fractional-order control with second-order sliding mode algorithm and disturbance estimation for vibration suppression of marine riser. J. Frankl. Inst. 2021, 358, 6545–6565. [Google Scholar]

- Gaurav, S.; Adepu, K.; Sangram, R. Enhancing Structural Vibration Damping in Marine Machinery: A Comprehensive Numerical Investigation with Modal and Harmonic Analysis. Appl. Mech. Mater. 2024, 921, 39–56. [Google Scholar] [CrossRef]

- Park, M.-H.; Yeo, S.; Choi, J.-H.; Lee, W.-J. Review of noise and vibration reduction technologies in marine machinery: Operational insights and engineering experience. Appl. Ocean Res. 2024, 152, 104195. [Google Scholar] [CrossRef]

- Zhang, L.X.; Yang, K. Fluid-Structure Interaction Theory and Its Application; Science Press: Beijing, China, 2004; p. 3. [Google Scholar]

- Wang, C.-Y.; Sun, Z.-P.; Qin, M.; Xu, Y.-Q.; Lv, S.-Q.; Yi, M. Non-Markovian effect of the fractional damping environment and Newton’s second law of motion. Mod. Phys. Lett. B 2018, 32, 8. [Google Scholar] [CrossRef]

- Watzka, B.; Omarbakiyeva, Y.; Hahn, L.; Klein, P.; Krumphals, I.; Rubitzko, T. Wind as a context for Newton’s first and second law and force diagrams. Phys. Educ. 2025, 60, 015006. [Google Scholar] [CrossRef]

- Wilkinson, D.H. Acoustic and mechanical vibrations in liquid-filled pipelinework systems. In Proceedings of the BNES International Conference on Vibration in Nuclear Plant, Paper 8.5, Keswick, UK, 9–12 May 1978; pp. 863–878. [Google Scholar]

- Hutchinson, J.R. Shear Coefficients for Timoshenko Beam Theory. J. Appl. Mech. 2001, 68, 87–92. [Google Scholar] [CrossRef]

- Chen, W.; Wang, L.; Peng, Z. A magnetic control method for large-deformation vibration of cantilevered pipeline conveying fluid. Nonlinear Dyn. 2021, 105, 1459–1481. [Google Scholar] [CrossRef]

- Li, Y. Study on Vibration Noise and Characteristics of Piping System Considering Fluid-Solid Coupling. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2011. [Google Scholar]

- Gao, H. Modification of 14-Equation Model for Fluid-Structure Interaction and Vibration Characteristic Analysis of Hydraulic Pipeline. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2021. [Google Scholar]

- Li, S. Dynamic Analysis of Fluid-Structure Interaction of Pipe Systems Conveying Fluid. Doctoral Dissertation, Harbin Engineering University, Harbin, China, 2015. [Google Scholar]

- Liu, Y.; Wei, J.; Du, H.; He, Z.; Yan, F. An Analysis of the Vibration Characteristics of an Aviation Hydraulic Pipeline with a Clamp. Aerospace 2023, 10, 900. [Google Scholar] [CrossRef]

- Wu, J. Research on Coupled Vibration and Sound Radiation of Space Pipeline and Shell; China Shipbuilding Research Institute: Wuxi, China, 2023. [Google Scholar]

| Grid Size/mm | First Order/Hz | Second Order/Hz | Third Order/Hz |

|---|---|---|---|

| 15 | 151.4 | 307.5 | 638.1 |

| 20 | 150.2 | 301.7 | 622.4 |

| 25 | 149.7 | 300.2 | 617.5 |

| 30 | 147.5 | 298.6 | 611.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Song, C. Design and Vibration Characteristics Analysis of Marine Hydraulic Pipelines Under Multi-Source Excitation. Machines 2025, 13, 859. https://doi.org/10.3390/machines13090859

Ma X, Song C. Design and Vibration Characteristics Analysis of Marine Hydraulic Pipelines Under Multi-Source Excitation. Machines. 2025; 13(9):859. https://doi.org/10.3390/machines13090859

Chicago/Turabian StyleMa, Xin, and Chunsheng Song. 2025. "Design and Vibration Characteristics Analysis of Marine Hydraulic Pipelines Under Multi-Source Excitation" Machines 13, no. 9: 859. https://doi.org/10.3390/machines13090859

APA StyleMa, X., & Song, C. (2025). Design and Vibration Characteristics Analysis of Marine Hydraulic Pipelines Under Multi-Source Excitation. Machines, 13(9), 859. https://doi.org/10.3390/machines13090859