Abstract

This study examines the digital maturity of small- and medium-sized enterprises (SMEs) in the context of Industry 4.0. Despite growing awareness of the importance of digital transformation, many SMEs encounter structural and strategic challenges that impede their progress. Among their obstacles is the inadequacy of digital maturity models used to diagnose digital maturity levels in SMEs due to their typological, sectoral, geographical, and other specific characteristics. Using a constructivist and qualitative approach, we have developed a simplified, inclusive, and holistic assessment framework comprising six key dimensions (technology, culture, organization, people and human resources, strategic planning), associated with six progressive maturity levels. Our findings reveal that most SMEs studied in 2023 exhibit a beginner level of digital maturity. These enterprises are characterized by small-scale digital initiatives, often lacking a clear strategy, with limited or partial digitization of processes and heterogeneous technology adoption. The resulting self-assessment tool provides SMEs with practical guidance to launch, evaluate, and accelerate their digital transformation. This study contributes theoretically by proposing a practical digital maturity model and offering a tool to support SMEs and public policy. It highlights the need for tailored support, strategic alignment, and continuous training to unlock the full potential of Industry 4.0 in less urbanized and resource-constrained areas.

1. Introduction

After the First Industrial Revolution, which was defined by steam engines and mechanization, the Second Industrial Revolution ushered in the era of electricity and electronics. The Third Revolution brought computing, automation, and electronics to industrial processes, while the Fourth Industrial Revolution is distinguished by an unprecedent pace of changes in the industrial production, but also in every aspect of the society: the infusion of new advanced digital technologies (e.g., artificial intelligence, the IoT, 3D printing) creating cyber–physical systems that have no equivalent in previous industrial revolutions, making industries smarter and more intuitive for greater optimization and productivity [1]. Although the concept of the Fourth Industrial Revolution—also known as I4.0—was first introduced at the Hannover Fair in 2011 [2] and popularized by the economist Klaus Schwab [3] within the same mid-decade, SMEs have been less involved with the digital transformation than larger enterprises. Meanwhile, the concept of Industry 4.0 has evolved into a new global paradigm, characterized by an organizational philosophy based on interconnectivity, intermodality, data sharing, and intelligent processing, as well as support for informed decision-making by business leaders [4,5].

As a result of these technological shifts, organizations such as SMEs grapple with a host of new challenges [6,7]. They are compelled to adapt their processes to their business models in order to fully leverage the new capabilities introduced by Industry 4.0 [8], as digitalization has gradually become a critical determinant of their success and survival [9,10,11]. They thus need to undergo a digital transition, also referred to as digital transformation.

Digital transformation refers to the accelerated integration of I4.0 technologies across all sectors of economic and social activities [3]. However, while large enterprises are generally completing their digital transformation to the highest maturity level, SMEs, including manufacturing SMEs, are still lagging due to several barriers rooted in their size and organizational structures [12].

The challenges are both internal and external, manifesting at various levels, including inadequate skills, resources, and infrastructure, and, above all, strategic management that is ill-suited to the complexities of digital transformation [13,14,15,16,17].

At the strategic and managerial level, digital transformation is often misconceived as the mere, sporadic implementation of cutting-edge technologies [18]. However, the existing scientific literature suggests more complex and diverse patterns while providing a series of levers to guide the successful digital transformation of SMEs [17,19,20,21]. For instance, SMEs must devise a robust, continuous, and pragmatic strategy that aligns with their business goals [20,22]. Moreover, SMEs are advised to adopt a comprehensive, inclusive, skills-based, and holistic approach to foster sustainable transformation [21].

In the Quebec province of Canada, the situation mirrors that of SMEs globally. Although most Quebec SMEs have, in fact, initiated their digital transformation [23], they remain further behind larger corporations [24,25] due to ineffective strategies and inadequate support [23,26]. These asymmetric distributional mechanisms across smaller-sized companies are worrisome for productivity, competitiveness, growth, and economic development.

However, tangible and intangible support resources, such as practical tools and methods, are increasingly available to assist SMEs in initiating, accelerating, and achieving the highest maturity level in their digital transformation [24,27,28]. Notably, despite the existence of various digital maturity models (DMM) in the academic literature and practical tools in the field, no model or assessment tool is entirely suited to SMEs, particularly when considering their typological, sectoral, and geographical diversities.

Consequently, this paper aims to design a digital maturity model (DMM) that caters to the unique needs of SMEs for the purpose of assessing their digital maturity, regardless of sector, industry, or geographical location.

The key research questions guiding this study are as follows:

- (1)

- What dimensions are necessary for an all-encompassing digital transformation model for SMEs, considering their distinctive traits?

- (2)

- What is the digital maturity level of the SMEs under study in relation to these dimensions?

To answer these questions, we bridge gaps in the existing literature by creating a cross-functional digital maturity tool tailored to SMEs’ digital transformation needs [29]. This tool will provide the necessary support for businesses navigating the complexity of digital adoption, from a narrative and empirical standpoint. Our research is especially significant as it provides an integrated, multi-dimensional, and holistic digital maturity model applicable to all SME sectors, areas of activity, and types.

From a managerial perspective, this study provides valuable insights into Industry 4.0 that are likely to contribute to raising awareness of SME managers about the centrality of the digital transition. Furthermore, the model we develop and present in this paper is a tool that is part of a broader support framework designed to enhance the digital transformation strategies of SMEs in Quebec and beyond, encompassing all types of businesses.

To this end, our research is structured around five sections. Section 2 starts with the Literature Review before Section 3 highlights the Theoretical Framework. Section 4 explains in more detail the methodology of the study in Materials and Methods, while Section 5 presents the Results, and Section 6 wraps up the paper with a Discussion and Conclusion.

2. Literature Review

Industry 4.0 encompasses initiatives aimed at leveraging 4.0 technologies to enhance processes, products, and services [15,30] across organizations, regardless of their size, sector, and field of activity [8,31]. In extant research, however, Industry 4.0 technologies are often referred to in a heterogeneous manner, with their selection lacking explicit classification or a structured conceptual framework. There is no explicit characterization of I4.0 technologies based on specific criteria [32]. To address this gap, Meindl and Mendonça [32] categorized these technologies into eight (08) distinct groups, where approximately 80% of interconnections occur within the same category. Notably, the core group comprises the Industrial Internet of Things (IIoT), while seven external groups are identified—four related to information technology (i.e., algorithms, cloud platforms, management systems, sensor systems) and three to manufacturing processes (i.e., additive manufacturing, computer-aided manufacturing [CAM], human–robot systems). The application of these digital technologies is rooted in principles such as interconnection, information transparency, decentralized decision making, and technical assistance within industrial systems [33]. These principles aim to achieve mass customization, intelligent automation, system flexibility, enhanced adaptability in manufacturing and logistics, production optimization, improved decision-making, rapid prototyping, and expanded production capacity [4,14,34,35], with a high potential for adapting business models and organizational models.

Thus, digital transformation in the context of Industry 4.0 is more than adopting smart technologies; it encompasses the integration of these technologies and principles in organizational practices [36,37,38,39]. In fact, the digital transformation refers to the implementation of Industry 4.0 technologies and principles, which thus emerge as a strategic process whereby organizations, including manufacturing SMEs, adopt digital technologies to rethink their business models, operational processes, products, and customer experience in line with the Industry 4.0 paradigm [17,40,41,42].

From an entrepreneurial viewpoint, the digital transformation is regarded as an endeavor to create, deliver, and capture value through the increasing deployment of Industry 4.0 technologies driven by organizational factors such as organizational culture, change management, and the cultivation of internal digital skills [43,44,45,46].

In summary, the digital transformation constitutes a multidisciplinary approach that integrates aspects related to 4.0 technologies, performance, strategy, culture, and skills [18,47,48].

Despite the acknowledged necessity to adapt to a fast-paced changing environment, the transition toward a digital transformation presents significant challenges, especially for small- and medium-sized manufacturing enterprises (SMEs) [17,49,50]. These challenges are both internal and external, spanning several critical dimensions, including insufficient digital skills and culture (digital literacy), limited resources, inadequate infrastructure, and barriers to technology acquisition, as well as strategic and managerial obstacles.

Regarding the skills gap (digital literacy), digital transformation initiatives typically demand four types of competencies from SME owners and employees: fundamental, specialized, complementary, and generic [21]. SMEs commonly face a shortage of specialized market skills, as well as deficiencies in fundamental, generic, and complementary skills within their workforce [16,35,51]. Moreover, employee resistance to change is often attributed to these skills shortages [16,52,53,54].

In terms of limited resources, SMEs face several significant challenges, including a shortage of financial and human resources [13,55,56], restricted access to information pertaining to the fast-paced evolving market [13,57], and infrequent utilization of strategic management tools such as financial analysis and forecasting [13,58,59]. Due to their smaller size, SMEs face higher investment costs, particularly for emerging technologies such as the Internet of Things (IoT), augmented reality (AR), and artificial intelligence (AI) [16,60,61,62,63]. Moreover, the digital transformation requires the iterative redesign of business models and enhanced data management capabilities. Unfortunately, most SMEs lack the tools, data analysis skills, and access to innovative financial models to support that shift [16,17,64,65,66].

Regarding infrastructure and technology, the adoption of key technologies such as cloud computing, cybersecurity, and the IoT is often hindered by inadequate existing technological infrastructures within these SMEs [16,67,68,69]. Existing infrastructure within SMEs typically suffers from poor network connectivity with slow information dataflow [70,71], while business managers often lack the qualification and training to establish robust infrastructures built on high network connectivity and efficient data flow information [70,72]. Additionally, SMEs face high total costs for installing and maintaining technological infrastructure, which include the cost of the technology itself, installation space, energy consumption, system downtime, and the technological support required for operating hardware and software [73,74].

Strategic and managerial issues also present significant challenges. Problems related to governance, change management, and strategic alignment are often cited as critical barriers to the transformation processes of SMEs. The absence of clear standards, legal uncertainties, the near standardization of technologies, and the challenges of collaboration between the scientific community and the field complicate these transformation efforts [14,75,76].

As a result, the digital transformation of SMEs, including those in manufacturing, remains delayed. Many SMEs are significantly behind because they fail to adopt new technologies at the same rate that they emerge in the market [77]. In fact, most SMEs are still in the initial stages of digital transformation [15,17,64,65], and the situation in the Quebec province is no exception [23]. Quebecer SMEs remain just as far behind [24,25] due to inappropriate strategies and a lack of adequate support [23,26]. Consequently, these SMEs, which represent approximately 95% of Quebec’s industrial fabric, are considerably behind in their digital transformation. This delay can be attributed to recurring constraints related to financial and human resources, as well as the digital skills of all levels [24,25,78]. Additionally, the potential lack of strategic focus among entrepreneurs or little importance attributed to it exacerbates the issue [79].

In response to these findings, several levers—primarily strategic, organizational, and managerial—have been identified in the literature.

It is crucial that digital transformation processes are not only carefully planned but also embedded within a holistic and skills-based approach. This approach must be inclusive in terms of strategic decisions, but also agile and accompanied by (cyber) security measures [21].

Likewise, several authors, including Moeuf et al. [19], Orzes et al. [20], and Turkyilmaz et al. [22], emphasized that SMEs must adopt a strategy of continuous improvement supported by a long-term vision. This involves implementing a robust strategy followed by a realistic investment plan aligned with business objectives. The same authors, along with Wu et al. [17], note that SMEs must focus on developing a flexible organizational culture that promotes collaborative work and continuous training to optimize employees’ skills and expertise, enabling digital transformation.

3. Theoretical Framework

3.1. Digital Maturity

Digital maturity in an organizational context refers to the extent to which an organization has successfully implemented digital technologies into its practices and processes, enabling it to remain competitive, agile, and responsive to the evolving technological landscape. It is not only the adoption of new technologies, but also the strategic alignment of these technologies with the SMEs’ long-term goals. This alignment shapes the existing culture and employee skills, fostering transparency and data accountability across the enterprise.

In the digital transformation journey, organizations increase their capabilities over time, and as these capabilities grow, so does their level of digital maturity. It is essential to note that in specific contexts, such as IT project management maturity models, the entities being measured are fixed rather than evolving dynamically over time [80].

Thus, digital maturity is defined by Hizam-Hanafiah et al. [81] (p. 3) as the level of ability to use emerging digital technologies and means to remain competitive. It refers to a state of constant adaptation and flexibility in the face of technological innovations [10] (pp. 63–86) and measures an organization’s readiness to integrate advanced technologies, according to Basl [82] (pp. 3–6). It is a systematic means by which an organization digitally transforms itself [83] and represents the state of digital transformation within the organization [84]. According to Marcos et al. [85], it refers to a state of digitization of operational processes as well as a profound transformation of culture and ways of thinking towards an integrated digital vision that supports and guides the organization’s performance. Table 1 summarizes all these definitions:

Table 1.

Definitions of digital maturity.

We can see that the definition provided by Hizam-Hanafiah et al. [81] (p. 3) focuses on the capacity developed, while omitting the organizational process dimension. Furthermore, in another definition, Basl [82] (pp. 3–6) refers to the organization’s state of readiness. To this end, Schumacher et al. [86] clarified the difference between the concepts of readiness and maturity. According to the authors, the assessment of readiness takes place before engagement in the maturity process, while the assessment of maturity aims to capture the current state, i.e., the current digitization level of transformation in a continuous transformation process. These two definitions differ from our concept of digital maturity in the sense that both can be assessed at once, but the first level of maturity is more likely to show lower maturity factors.

Furthermore, the concepts of systematic means and state of adaptation, found in the definitions of Kane et al. [83] or Ma [10] (pp. 63–86), refer to the perspective of explicitly organized processes and regular evaluation of entities. Similarly, the concept of state of transformation found in the definition of Chanias and Hess [84] refers to the capacity development component of the concept of maturity. The definition provided by Marcos et al. [85] aligns with the same lines but is more detailed, focusing on the dimensions of digital maturity.

We therefore align ourselves with the latest concepts of digital maturity, defining it as the current state of an organization’s digital transformation, as well as the state of constant adaptation and flexibility through which the organization continuously transforms itself through an explicitly organized process.

In this sense, digital maturity is a holistic and dynamic concept that evolves in step with technological advances and is not limited to the organization’s technological situation. It extends to the organization’s managerial performance, which is measured in terms of products, services, internal processes, skills, organizational culture, and the ability to drive change [84,87].

3.2. Digital Maturity Models

From the above, digital maturity models (DMMs) serve as normative reference frameworks that enable organizations to position themselves on the path toward the highest maturity level, while allowing them to assess their current state of transformation and thereby identify critical areas for improvement [88,89]. These models provide information on how SMEs should approach their transformation, identify, and prioritize concrete measures that would promote progress from an initial level to a target level of digital maturity, and guide organizations through the process [88,90]. Such models are both descriptive and prescriptive, providing actionable insights, but can also serve as comparative tools to benchmark against industry standards [90,91,92].

Despite a plethora of digital maturity models, most are not tailored for SMEs. These models, akin to audit assessment or self-audit assessment questionnaires, are reported to be lengthy, complex, and multi-dimensional [93], which makes them difficult for SMEs to implement. They also often suggest a linear progression towards maturity without considering the different integration levels according to the diverse needs and resources of SMEs [90,94,95]. Examples include the multi-attribute digital assessment model (MAADM) by Kljajić Borštnar and Pucihar [96] and the digital transformation model (DTM) by Viloria-Núñez et al. [97], both developed with large enterprises in mind.

While some models are geographically centred [98] or focus on specific fields or sectors (e.g., retail [99,100] or manufacturing [101]), they still tend to assume significant financial and technological resources that SMEs generally lack [98]. Still, some focus on specific areas of application, such as human resources, while others are more heavy on cross-functional organization functions [102] (e.g., Industry 4.0 Maturity Index from Schuh et al. [103], Information Technology Infrastructure Library (ITIL) from Dabade [104], People Capability Maturity Model (PCMM) [105], or the Digital Operations study for energy, Oil and gas from PwC [106]).

Some models, often designed by practitioners, lack methodological rigour, validation and external references [90,94,95]. Most of the time, they tend to describe rather than prescribe [98]. Examples include the Digital Maturity Model (DMM) from Deloitte [107], the Digital Capability Model (DCM) from Ramantoko et al. [108], the Digital Operations study for energy, oil and gas by PwC [106], the Digital Assessment Model (DAM) from Trotta and Garengo [109], and the DTM from Jeansson and Bredmar [110].

Sometimes, the processes for selecting dimensions or criteria are poorly documented, which compromises the reliability and viability of these models for SMEs [90,94,95]. Examples include the DMM from Schallmo et al. [111], the DTM from Viloria-Núñez et al. [97], and the Digital Readiness Assessment (DRA) from Pirola et al. [112].

Even when they are documented, these models remain theoretical and intangible, making them difficult to implement in practice [90,94,95]. Examples include the DMM from Schallmo et al. [111] and the Digital Maturity Readiness Model (DMRM) from Yezhebay et al. [113].

Other existing models are very technology-centric and address few or none of the social and organizational dimensions necessary for SMEs to achieve balance and maintain their identity as SMEs [90,94]. Examples include the Information Technology Infrastructure Library (ITIL) from Dabade [104] and the Capability Maturity Model Integration (CMMI) from Team [114].

Some models are specifically designed for manufacturing SMEs. This is the case, for instance, with the model of Gamache [24]. Others are designed to assess readiness rather than assess digital maturity. This is the case, for example, with the Digital Readiness Assessment (DRA) from Pirola et al. [112] and the Audit Industrie 4.0 digital self-assessment from Fugère [115]. Others are designed exclusively to assess the capabilities required for the implementation and the use of 4.0 technologies. This is the case with the Capability Maturity Model Integration (CMMI), or more specifically, the Industry 4.0 Maturity Index from Schuh et al. [103]. Similarly, there are others based on specific frameworks, such as the technology–organization–environment framework from Senna et al. [98], or organization and processes from Tubis [116], which are interesting to SMEs but still need some adaptation to fit their reality within SMEs, especially in regional areas.

In addition, there are many micro-enterprises, which are just as concerned with digital transformation issues and have the potential to benefit from it despite their small size. These enterprises are generally classified as SMEs and, in addition to sharing the same characteristics as SMEs, are often characterized by atypical business processes and organizational weaknesses caused by strategic shortcomings [29,117]. Most of these businesses are involved in traditional or craft activities, sometimes innovative but generally with low turnover [29,118].

Many of these companies have strong operational and communication ties to their local area, with a structure in which the owners themselves are responsible for management, thereby significantly changing the leadership approach in management, operations, and services [29,119]. They are generally subject to models with highly technical language, featuring items on cutting-edge technologies and very high annual turnover [29,120], which does not speak to their reality.

Taking all these aspects into account, we are considering a model for assessing digital maturity that is applicable to all types of SMEs, all fields, and all sectors of activity, focusing on the core of digital transformation. Our model must be able to measure not only the state of readiness, but also the state of digital maturity of the enterprises. Our tool is designed to be both descriptive and prescriptive, simple yet flexible, balanced in its dimensions, theoretically valid, and practically actionable for SMEs.

To this end, and for a broader exploration of the dimensions and items, we have selected six (06) digital maturity assessment models based on a variety of criteria, both positive and critical. These are: the Digital Maturity Assessment Model from Omol et al. [95], the Digital Transformation Maturity Model from Bumann and Peter [121], the Digital Performance Assessment Model from Gamache [122], the Digital Readiness Model from Brozzi et al. [29], the Digital Maturity Model from Senna et al. [98], the Digital Maturity Assessment Model from Tubis [116], and the Forrester’s Digital Maturity Model from Gill [123].

3.3. Dimensions of Digital Maturity Models

The digital maturity assessment model by Omol et al. [95], based on the Capability Maturity Model Integration (CMMI), was selected due to its recent tool status, which offers both a descriptive and prescriptive approach, and its intended application for SMEs. These dimensions were selected using an occurrence matrix based on a survey of 18 dimensions from 20 maturity models. The 40% rule was applied, meaning that out of 20 maturity models, the dimensions must appear in at least eight models. The dimensions, in order of weighting, are technology (14/20), product (9/20), strategy (14/20), people (11/20), organization (8/20), and operations (9/20).

The same comparative analysis method was applied to the digital transformation maturity model developed by Bumann and Peter [121]. This is a multi-sector model designed for rapid digital adoption. The dimensions selected, following the 40% weighting rule, are strategy, organization, culture, technology, customer, and people. However, the model does not mention that it is intended for SMEs, which leads us to believe that it is a model designed for the digital maturity of large organizations, especially in manufacturing.

Next, we have the digital performance assessment model from Gamache [122]. As its name suggests, it focuses on digital performance and is aimed at manufacturing SMEs. It is a Quebec model whose dimensions vary slightly from those of the other models proposed. These include leadership, culture and organization, technology, data management, measurement systems, and customer experience.

In addition, the model digital readiness model from Brozzi et al. [29] was selected because it is a self-assessment model tailored to very small businesses, and the core of digital transformation is represented by the presence of a dimension related to data. It meets the criteria of a simple tool that can be applied in the regions. The model from Brozzi et al. [29] offers three dimensions: digitization, production and operations, and ecosystem, which could be disputable from a justice perspective.

The digital maturity model from Senna et al. [98] is a descriptive model designed for large companies. It focuses on the Technology–Organization–Environment (TOE) framework and includes sub-dimensions such as strategy, governance, culture, human resources, processes, legal and regulatory aspects, market perspective, inter-organizational aspects, and technology. This model was selected because it is a recent model, whose dimensions were chosen based on a comparative analysis of the dimensions of around fifty digital maturity models, the oldest of which dates from 2016. Although it is TOE-focused, we have retained it with a view to excluding dimension and nomenclature pertaining to large-sized organizations and reality, acting as a boundary to make it more applicable to SMEs.

With this in mind, we have adopted the digital maturity assessment model developed by Tubis [116]. Although focused on organizational and process frameworks, this model is relatively recent and has been designed using a descriptive and prescriptive approach for businesses in general. It can be used for self-assessment and comprises the following sub-dimensions: strategy, corporate culture, data, processes, business partners, employees, and technology.

Still with a view to broadening the analytical framework, we have selected a commercial tool, namely Forrester’s Digital Maturity Model 5.0 from Gill [123]. This model places a strong emphasis on interactive marketing and e-commerce but remains a tool for analyzing the digital skills and practices of businesses in general. It is correlated to an audit tool that covers the dimensions of culture, technology, organization, and insights.

Table 2 shows the occurrences of the different dimensions identified in the seven (07) digital maturity models selected.

Table 2.

Comparison of digital maturity models.

Applying the 40% rule, we retain the dimensions of technology, strategy, people or human resources, culture, and ecosystem. The technology dimension, which has a 100% occurrence rate, is the most important dimension. This is hardly surprising, given that technology remains the backbone of digital transformation, as everything that comes after it in terms of management and strategy will rely on technology.

3.4. Selection of Framework for Analyzing Digital Maturity in SMEs

To establish a robust framework for analyzing the digital maturity of SMEs in the context of Industry 4.0, it was crucial to draw on insights from existing models while simultaneously accounting for the distinctive characteristics of SMEs. Given the wide variety of digital maturity models (DMM) and the heterogeneity of approaches in the literature, the framework for this study drew from a range of models with dimensions most pertinent to the specific challenges and needs faced by SMEs. The primary goal at this stage was to examine various frameworks to identify the most suitable dimensions and sub-dimensions that would help us understand the extent of digital transformation in SMEs.

It is important to emphasize that the framework proposed at this point remains iterative and aims to guide the data collection phase by establishing a foundation that will allow for an in-depth examination of SMEs’ digital maturity across multiple dimensions. The framework will be refined based on the findings from the data collected, which will serve as the basis for evaluating the effectiveness of the selected dimensions and sub-dimensions. This ongoing refinement will ensure that the framework remains adaptable, relevant, and capable of accurately assessing the digital transformation of SMEs as it progresses throughout the study. The following paragraphs outline the five dimensions retained for our analysis.

- Technology

According to Gamache [122], this dimension refers to 4.0 technological tools, but also to all the skills, methods, processes, and techniques used to integrate, master, and optimize them. It encompasses the digital ecosystem and architecture, technological expertise, cybersecurity, and automation. For Gill [123] and Bumann & Peter [121], it represents the use and adoption of emerging technologies by enterprises. Senna et al. [98] and Tubis [116] limit it to technical infrastructure, associating it with data-based aspects, including cybersecurity, data management, data-based measurement, and decision-making systems. According to the same authors, it also refers to technical infrastructure, advanced manufacturing technologies, and automation.

We believe that mastering technology is a human resource issue, while data management, cybersecurity, measurement systems, and decision making are more managerial issues because they are strategic. The technology dimension, therefore, refers to both the presence and the use in the adoption of these 4.0 technologies by the organization. These include technical infrastructure, technologies such as the Industrial Internet of Things (IIoT), information technologies (algorithms, cloud platforms, management systems, sensor systems), and manufacturing process technologies (additive manufacturing, computer-aided manufacturing [CAM], human–robot systems). We are hereby considering automation as a maturity level rather than a dimension.

- Strategy

Once this dimension is defined, based on the model from Tubis [116], the allocation of financial resources for implementing transformation processes, communication methods within the organization, employee preparation for the digitization pathway, and establishing a roadmap for the introduced changes must be determined. According to the model developed by Senna et al. [98], this dimension boils down to the company’s digital strategic planning, the degree of its implementation, the definition of key performance indicators, investments, and the management of innovation. It also refers to change management, the creation of commercial value through digitization, and the digital production/manufacturing strategy.

We are considering the strategy dimension for SMEs, which involves assessing the existence of documented digital strategic planning, including a digital strategy and a roadmap for its implementation. It is also assessing employee involvement in the establishment of strategic planning and internal communication strategies, with a focus on transparency. Additionally, the strategy dimension also refers to the level of flexibility of this strategic planning. Elements related to performance indicators, investment, innovation, change management, resources, and so on are elements of strategic planning and are therefore defined around projects resulting from post-diagnostic recommendations.

- People and Culture

This dimension is defined by the model of Bumann & Peter [121] as the education and development of new skills among employees. Tubis [116] approach it in terms of support given to employee activities, employee behaviour with technology, and measures to develop their skills. Senna et al. [98] interpret it in terms of talent acquisition and training activities, measures contributing to employee well-being. We add change management measures, and the level of training—rather than education—for developing fundamental, specialized, complementary, and generic skills in technology. These elements are consistent with our understanding of the people and culture dimension within the context of organizational digital transformation.

Also, culture refers to the approach to digital innovation and change management methods [123]. According to Gamache [122], this dimension is associated with the organizational dimension and refers to work organization, skills acquisition and development, change management, internal communication, agility and innovation, and external openness. For Bumann & Peter [121], these are digital leadership and commitment from management. According to Senna et al. [98], the cultural dimension refers to the values, norms, beliefs, attitudes, and assumptions necessary for collaboration. It refers to the state of understanding and sharing of the company’s digital vision by all staff. Tubis [115] also associates it with organization, and define it as the common values, norms, attitudes, and assumptions that underpin internal collaboration within the company.

In this study, we distinguish the organizational dimension from the cultural dimension, as culture pertains specifically to the values, norms, beliefs, and assumptions that underpin internal collaboration around digital technologies. Culture refers precisely to the level of understanding and sharing of the enterprise’s digital vision by all employees, supported by a corporate narrative. This dimension encompasses all factors that contribute to a positive attitude and emotional commitment to the enterprise among all employees and managers. For example, the enterprise may define a trial-and-error approach as the norm.

This dimension is more important given that it accounts for 71% of the weighting, just behind technology, which accounts for 100%. Moreover, for Bettoni et al. [124] and Tubis [116], the culture dimension is of paramount importance because it is rooted in the convictions of the enterprise’s employees and management. It remains essential to the success of the expected digital transformation in terms of interconnectivity and people-to-technology.

- Organizational alignment

From all the above, the organizational dimension refers to the strategic alignment of the organization. It differs from the strategy dimension in the sense that the latter only assesses whether the company has a strategy and whether it is defined in accordance with best practice. The organizational dimension encompasses a range of work processes through information systems, including collaboration, management, organization, innovation mechanisms, leadership, investment, cybersecurity, and any strategy related to products, operations, customer experience, processes, and so on. It is in this dimension that the simplicity and cross-functionality of our model are determined, as some of these strategic elements may be relevant for one SME and not for another. For example, the product element may be relevant for a manufacturing company but not for a service company. Apart from the technological and people dimensions, the organizational alignment dimension is of paramount importance as it shows the cultural use of data within the organizational goals while adopting technology. Table 3 displays the recapitulative framework selected.

Table 3.

Digital maturity framework for SMEs.

This table organizes the dimensions of digital maturity for SMEs based on the selected framework, with each sub-item appropriately aligned to its respective dimension.

3.5. Digital Maturity Levels

Upon reviewing the dimensions of digital maturity, we defined the level of digital maturity as a set of practices—both generic and specific—structured around predefined dimensions. These practices can enhance the overall maturity of an organization. Digital maturity is a reflection of an organization's performance, serving as a pathway towards continuous improvement. As noted by Teichert [125], assessing an organization’s maturity is crucial in achieving a higher level of organizational performance. The successive stages of evolution represent higher degrees of advancement in digital transformation [88].

Our review of the digital maturity models initially reveals that there are up to six (06) levels of digital maturity, generally starting from one (1), as well as a wide variety of terminologies used to describe these stages. Table 4 summarizes the first and second designations for different levels as identified in our selected models, illustrating the variations in terminology across various frameworks.

Table 4.

Occurrences of the different digital maturity levels and their designations.

At this point of our preparation analysis, the occurrences of various maturity levels are established, though it is important to note that we will proceed with both quantitative and qualitative methods.

Table 4 shows that at level 1, the designations “Initial” and “Beginner” are the most common. The designation “Initial” refers to little or no digital initiatives according to Fraunhofer [126], Kolla et al. [93], and Hizam-Hanafiah [81]. It also refers, according to the model of Schumacher et al. [86], to a level corresponding to no digital strategy. As for the designation “Beginner”, Gill [123] interpret it as a level corresponding to limited use of digital technology. Fitzgerald et al. [127] represent it as a level of low digital maturity, while Gamache and Abdulnour [24] equate it with a level where processes are digitized. It is therefore clear that, overall, level 1 corresponds to a low level of maturity where small initiatives are taken without any strategy and generally limited to the digitization of processes. These are heterogeneous adoptions of the latest technologies. In this case, an enterprise that has not undertaken any digital initiatives, not even heterogeneous adoption, is at level 0. This corresponds to the designation “Artisanal” or “Traditional”. The designation “Beginner” is therefore best suited to level 1.

For level 2, only the designation “Basic” was appropriate. It refers to a basic adoption of technologies, according to the models in Fraunhofer [126] and Schumacher et al. [86]. It differs from the “Beginner” level in that it involves organized and planned adoption of technologies. From a strategic point of view, this is the beginning of a true digital transformation. However, it remains an intermediate level, because whether planned or not, level 1 already corresponds to the digitization of processes. Gamache and Abdulnour [24] rightly associate it with process automation. This is therefore a level at which the enterprise plans and finalizes the digitization of processes or plans and begins the automation of processes.

At level 3, the terms “Advanced” and “Defined” were used. These designations refer to a level where strategies for adopting 4.0 technologies (cutting-edge technologies) are formulated or defined [81,93], and where processes have been fully transformed. This is the logical continuation of the previous level and is an advanced intermediate level [24].

For level 4, the terms “Advanced” and “Integrated” were selected as the most common. The term “Advanced” refers to the level where digital transformation is underway and has reached the enterprise level [86,126]. There is a level of process automation [116] as well as advanced data analysis and management. Processes are fully integrated both internally and externally with business partners. Data are contextualized and shared in real time between humans, machines and products (internal and external), and planning processes are consistent and coordinated between partners [116]. Operational processes run autonomously, and the risk of cyber-attacks is well managed [116]. The designation “Integrated” is most appropriate for this level.

At level 5, the designations used are “Expert” or “Optimizing”. This refers to continuous optimization of digital processes, where business models are transformed and the company innovates continuously and disruptively, together with its partners.

In conclusion, there are six (06) levels of digital maturity, as detailed in Table 5.

Table 5.

Key characteristics of the derived maturity levels.

3.6. Sustainability Index

Reducing waste and improving energy efficiency through optimized resource and energy management [39,128,129]—which is also a performance target for Industry 4.0—is a principle of the circular economy and therefore also a sustainable development goal. To successfully navigate the digital transformation and remain innovative, they must aim for value creation and legitimacy, which integrates environmental and social considerations alongside financial outcomes [23,130,131].

Several strategies can support SMEs in achieving these sustainability objectives, including digitization [23,130], leveraging big data to enhance sustainable production and consumption [23,128], and adopting a service-oriented approach that extends to the utility of goods [23,131,132]. Collaborative models [23,133,134] also play a crucial role in enabling sustainability in SME operations. For instance, service options such as maintenance, consultancy, and training can extend product lifecycles, while usage-based models, including leasing, rental, sharing, and pooling, offer alternative ways to maximize resource efficiency [23,135].

Our approach encompasses sustainability indicators directly into the digital self-audit tool, facilitating effective digital strategic planning. This integration ensures that sustainability goals are not merely peripheral but are embedded within the overall strategy, enabling SMEs to align their digital transitions with long-term sustainability objectives. Through this framework, SMEs are empowered to track and manage their sustainability performance as part of their ongoing digital transformation efforts.

4. Materials and Methods

Our research is grounded in a constructivist–interpretative paradigm, specifically drawing from the pragmatic constructivist approach in social science. We distinguish between the pragmatic constructivist paradigm and that developed by Guba and Lincoln [136,137]. The pragmatic constructivist paradigm, which aligns with our study, is built upon three epistemic assumptions, the most relevant of which is that intellectual innovation related to a phenomenon is undeniably associated with the context of the study and the experiences of the researchers and their participants in relation to the subject. An interpretative study is based on the interpretation and description of the perceptions of the study participants, and the results are generalized by induction or abduction [137]. The knowledge developed thus expresses the researcher’s understanding of the phenomenon in the form of a symbolic construction, i.e., a representation or model, which in turn provides a framework for action in relation to the phenomenon for the researcher and their respondents, if it is appropriate to their experience. This paradigm gives the researcher methodological leeway based on existing knowledge, but the resulting knowledge is conceptually generalized [137].

This paradigm justifies the first part of our study, which focuses on the development of an innovative digital maturity model based on existing models. The dimensions and level of digital maturity will be the results of our analyses, reflecting the design process we have undertaken.

Thus, our approach to assessing the digital maturity of SMEs adopts a qualitative-inductive methodology. Data are collected from a sample of 30 SMEs from a variety of sectors, fields, and geographical locations.

4.1. Preparatory Phase

We began by reviewing the literature on Industry 4.0, digital transformation, and existing digital maturity assessment models. This comprehensive review allowed us to understand the theoretical and empirical underpinnings of digital maturity within the context of SMEs.

We then engaged in exploratory discussions with stakeholders in the regional SMEs innovation ecosystem to explore not only the key concepts and dimensions of digital maturity to be investigated, but also the scope of the study. This resulted in a preliminary interview grid.

Pilot interviews were subsequently conducted with diverse SME managers, economic development organization managers, a researcher specializing in manufacturing organization audits, and certified auditors using different models. This phase served to test the interview grid and identify emerging themes, adjust the questions based on the responses obtained and the issues raised, and refine the approach to ensure consistency of interpretation across various stakeholder perspectives.

4.2. Participants Recruitment

Participants were recruited by posting an interest survey questionnaire online via the LimeSurvey platform. With the support of socio-economic partners, a non-random snowball sampling procedure was used to recruit fifty-four (54) participants from thirty-two (32) enterprises in the secondary and tertiary sectors. Recruitment was based on the following inclusion criteria: participants had to be owners or managers directly involved in their company’s digital transformation, irrespective of their size, sector of activity, or life cycle stage.

The questionnaire (available in Appendix A) aimed to measure certain key dimensions of the respondents’ profiles, such as the assignment of an internal digital transformation, professional and employee training in digital transformation, the intention to initiate or continue the digital transformation, and digital literacy within the organization. This approach was drawn on Yin [138] (p. 10), which emphasized the managerial unit of analysis and the relevance of decision-making leadership, maximizing the diversity of perspectives [29], to ensure a rich and representative analysis of local realities.

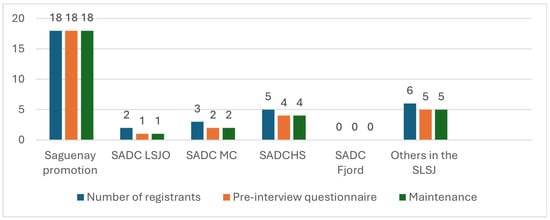

Following the analysis of the preliminary results, the sample was refined, narrowing down to thirty-two (32) participants with the most relevant profiles. Two of the participants resigned, so the sample was finally reduced to thirty (30) SMEs, broken down as shown in Table 6.

Table 6.

Breakdown of respondents by territory.

4.2.1. Breakdown by Territory

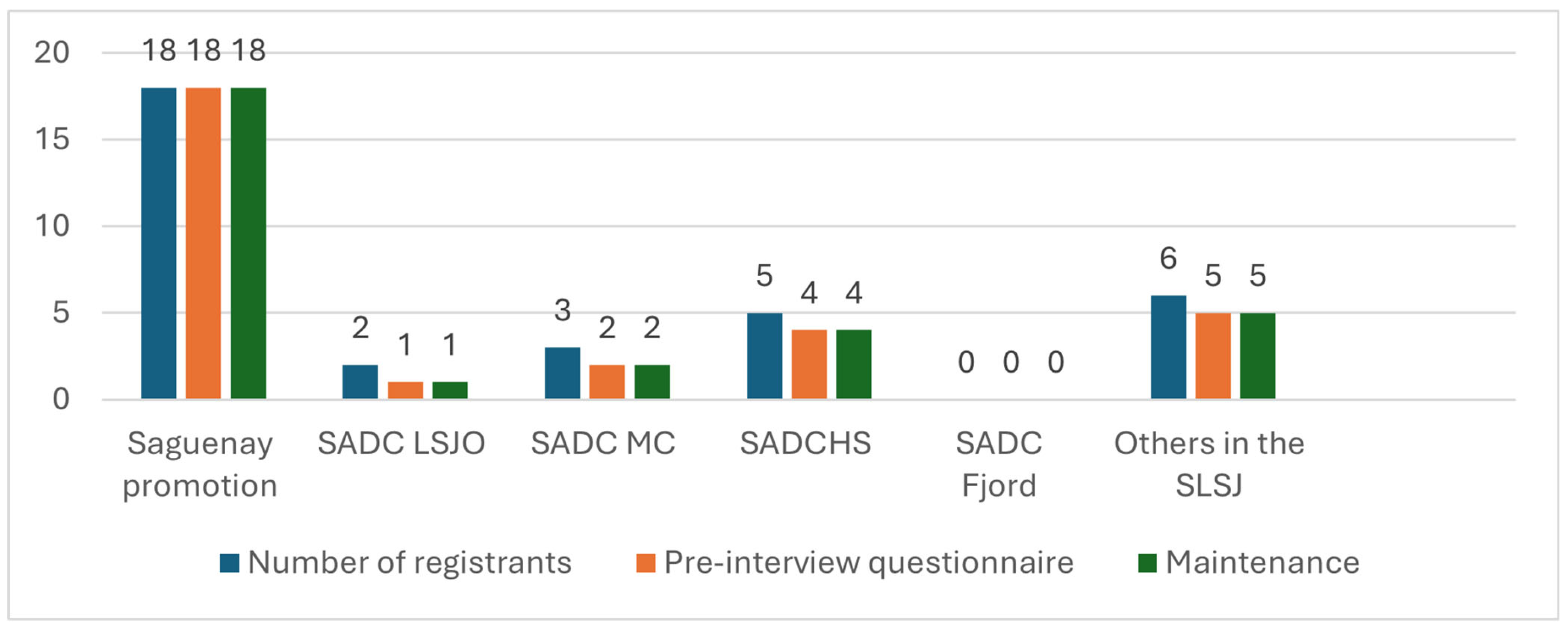

The participating enterprises represent a diverse range of sectors and come from all areas of the Saguenay–Lac-Saint-Jean region. They are distributed by economic partner as shown in Figure 1 below.

Figure 1.

Breakdown of interviews by region.

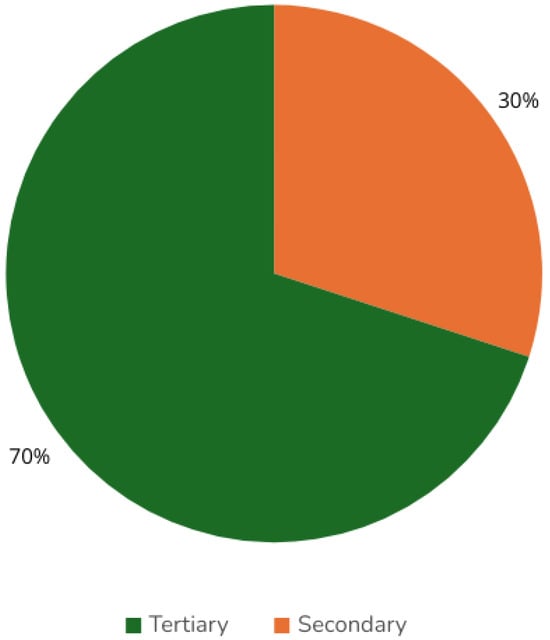

4.2.2. Breakdown by Sector and Area of Activity

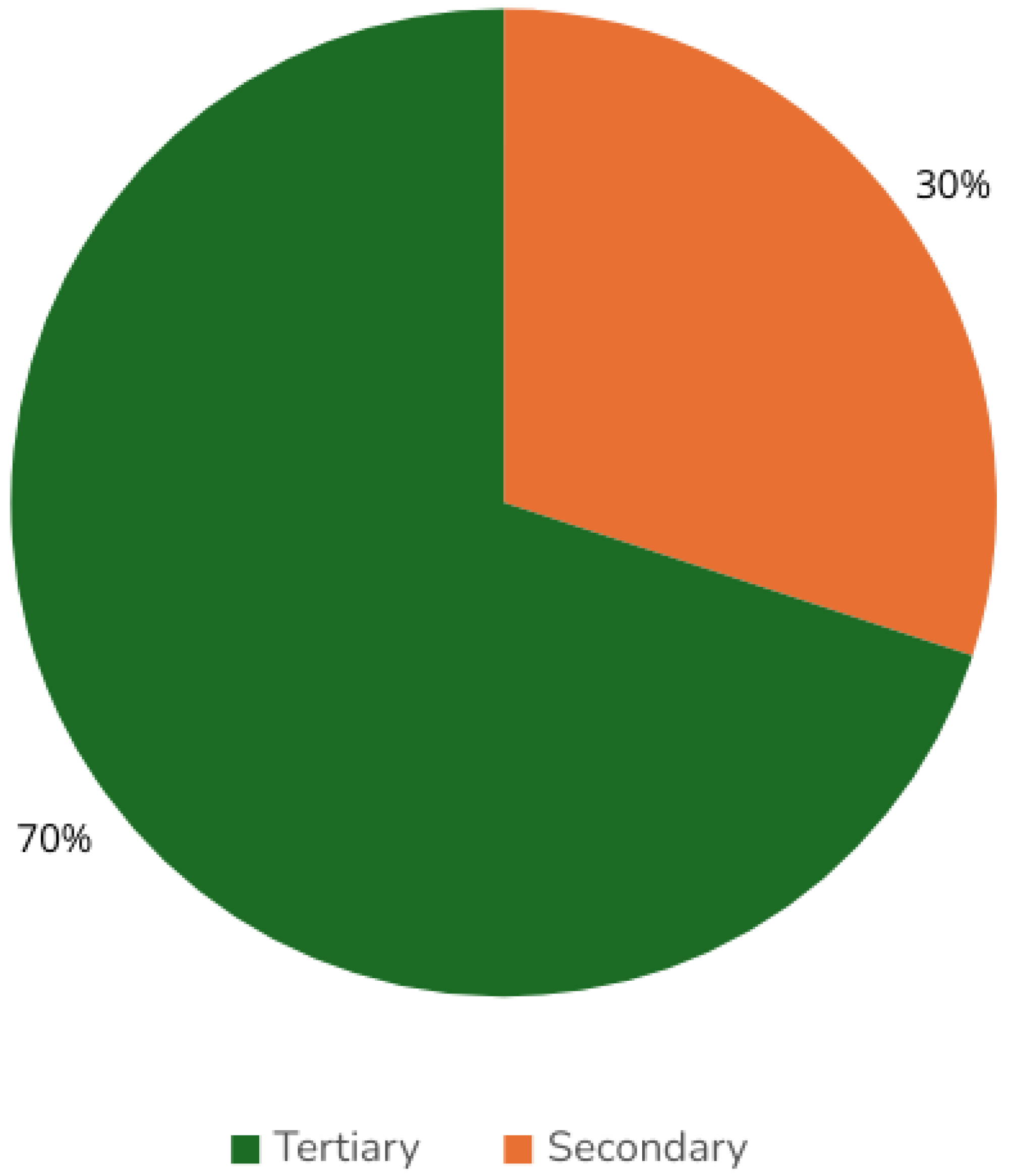

The enterprises recruited come from two sectors of activity, namely the secondary and tertiary sectors, representing the province’s distribution. They are distributed as follows in Figure 2.

Figure 2.

Breakdown by sector of activity.

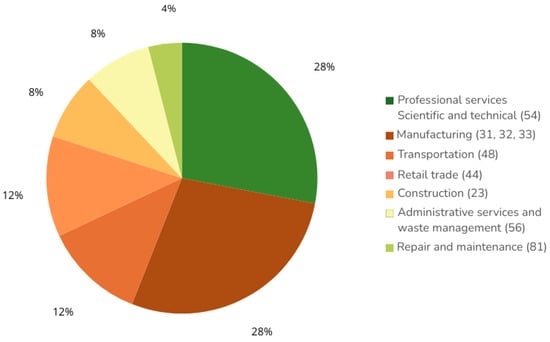

4.2.3. Breakdown by NAICS Codes

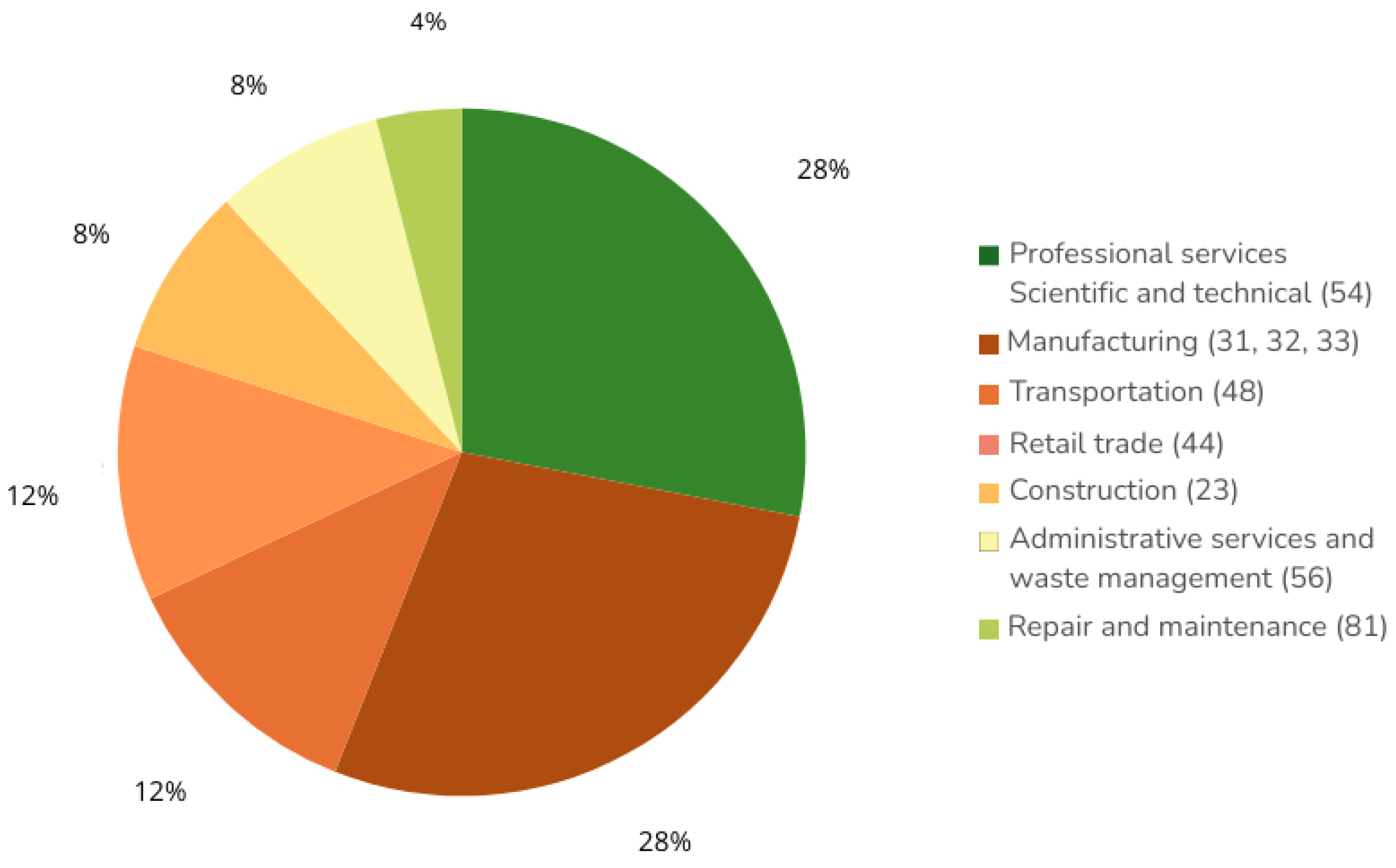

The participants selected came from eight (8) different fields of activity, commonly coded by the North American Industry Classification System (NAICS) as shown in Figure 3.

Figure 3.

Breakdown by SCIAN codes.

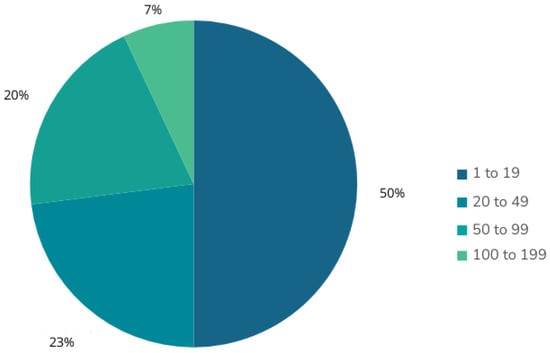

4.2.4. Breakdown by Size

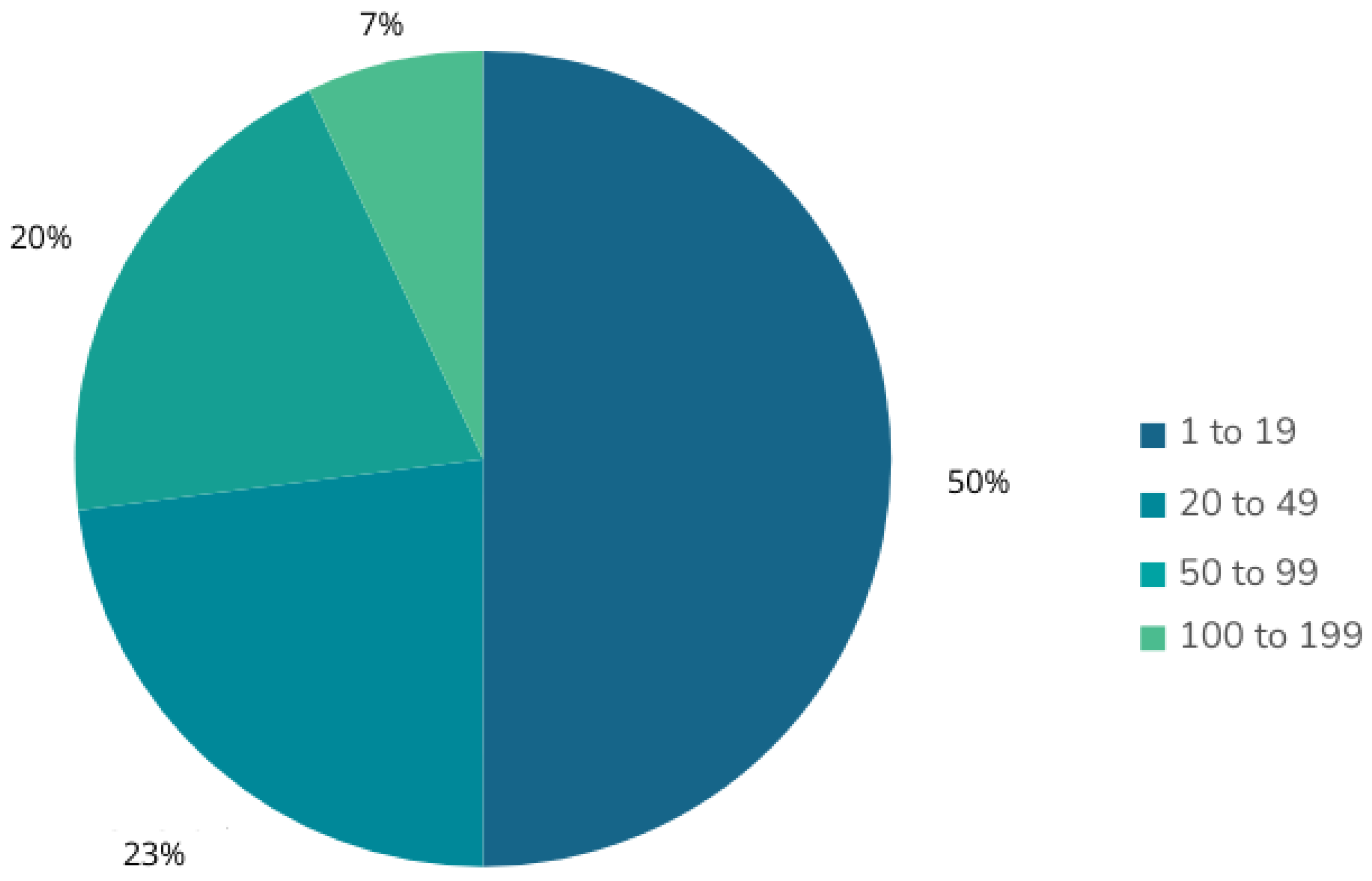

The SMEs participating in the research all have fewer than 200 employees; 50% have between 1 and 19 employees, 23% have between 20 and 49 employees, 20% have between 50 and 99 employees, and finally, 6% have between 100 and 199 employees, as shown in Figure 4.

Figure 4.

Breakdown by company size.

4.3. Data Collection and Analysis Phase

In March and May 2023, thirty (30) semi-structured individual interviews lasting from 90 to 120 min were conducted remotely via Zoom platform. We reminded each participant at the beginning of each interview of the study's context, its objectives, and the main areas on which they would be interviewed. They were reminded that the interview was not mandatory and that they could withdraw if they changed their mind about participating in the study, in accordance with the consent criteria mentioned in the pre-recruitment questionnaire. Verbal consent was obtained from each participant before the start of each interview and before recording.

All methodological procedures were therefore carried out in accordance with ethical considerations, in particular, the principles of confidentiality and the rights of participants, in accordance with the ethical certificate issued by the UQAC Research Ethics Committee (Certificate No. 2022-796).

Interviews were designed as collaborative spaces, allowing participants to reflect on their experiences, express their perceptions, motivations and challenges, and co-construct perspectives around their level of digital enterprise maturity. The data were first anonymized using an alphanumeric code consisting of the letter “E” (for “enterprise”) followed by a number corresponding to the order in which the respondents were interviewed. The data were then transcribed and cleaned up using the Amberscript application.

Verbatim transcripts were transferred to the NVivo 15.0 qualitative data analysis tool (Burlington, MA, USA). An initial thematic analysis was carried out. Inductive coding of units of meaning was performed. The coded units related to digital transformation practices (e.g., education, change management, internal collaboration) were then grouped into broad themes, such as knowledge of Industry 4.0, adoption of 4.0 technologies, and cultural approach, which correspond to the dimensions of digital maturity outlined in the theoretical framework. The analysis continued until data saturation was achieved in the 27th corpus.

To ensure triangulation, a qualitative content analysis was carried out by another researcher. The digital maturity dimensions selected in the theoretical framework were used as analytical frameworks. Units of meaning were coded deductively, and the data confirmed the digital maturity. Theoretical saturation was only observed in the thirtieth interview.

Throughout both analyses, we remained open to unexpected concerns raised by participants, which allowed us to capture new or specific dimensions that had not yet been anticipated. For example, participants spontaneously mentioned issues related to data replication, a theme that had not been explicitly anticipated in the initial theoretical framework.

There is a perfect triangular correspondence between the elements of our theoretical framework and each of the two approaches to thematic and content analysis adopted by two separate researchers.

5. Results

5.1. Knowledge of the Fourth Industrial Revolution

The data analysis reveals that most respondents, particularly those from non-manufacturing companies, have little or no knowledge of Industry 4.0. A few of them use the terms “digital shift” and “digital transformation” to describe the changes taking place within their organizations. They have a limited perception of Industry 4.0, associating it only with basic technological tools rather than a fundamental industrial paradigm. Some of them have not begun their digital transformation, continuing to operate within the Industry 3.0 paradigm while using new technologies.

“[…] No idea. No clue! We used to take orders by fax, years ago. Today, all companies have CRM systems.”—E11, owner of a recreational vehicle sales company.

“Um, no, I don’t know much about it, no. It’s Industry 4.0? It would be something completely automated and accompanied by artificial intelligence.”—E27—Solopreneur of a loyalty points company.

Some respondents believe they have started their digital transformation by installing technological infrastructure, yet their systems remain rooted in Industry 3.0 technologies. Specifically, they have adopted automation technologies that lack intelligence, which do not align with the more advanced, interconnected systems characteristic of Industry 4.0.

“[…] I bought new printers and those 4.0 printers with a belt that feeds the fabric into the printer […]”—E10—Owner and manager of a sublimation printing process company.

For other respondents, their understanding of I4.0 depends on their field of activity. For instance, some associate it with immersive technologies for teaching, while others relate it to technologies for collecting and processing big data for statistical studies. This suggests that the perception of Industry 4.0 is often shaped by the specific needs and practices within different sectors.

“[…] Industry 4.0 is really about working with technological tools, getting off the floor. Well, for us, 4.0 really means moving to one-to-one teaching, from employee to employee, really having training on an e-learning system, but […] having training systems that aren’t just videos that you can skip through, you must answer questions. […] Having something truly automated in terms of training in companies, with results tables for managers so they can see whether people have followed the training properly […] Fewer people in my management team. More automation!”—E20—Co-owner and managing director of a video production services company.

“[…] The key step in our field is data collection. I do a lot of it myself, going to the customer […] we would eventually like to provide other tools, or at least develop tools to make this data collection easier […] it would facilitate the collection of data needed to make a proposal.”—E4—Co-owner and manager of a furniture manufacturing company.

Some respondents revealed a slightly more advanced understanding of digital transformation in that they did not simply associate it with the adoption of technology, but rather with the digitization and automation of processes. They associated it with the strategic and operational use of data.

“[…] Industry 4.0, I think, is a process automation. It’s enabling a sequence to become autonomous on its own right. That’s how I would define it, I think […]”—E15—Owner of financial services businesses.

“Basically, for me, it’s about: ‘How can we computerize?’ Computerize, or at least introduce a certain level of business or artificial intelligence into our organizations’ operations to be more efficient and achieve better indicators […] we’re really trying to optimize our operations and have the right information at the right time.”—E1—Owner-manager of an agri-food processing company.

5.2. Adoption of 4.0 Technologies

In terms of technology adoption, some respondents still have traditional practices in their business processes.

“[…] Sometimes it was just written on a post-it note on a desk, which isn’t very efficient. Or telling someone not to forget to send the payment for X… It just disappears into thin air.”—E14—Owner of an electronics recycling and repair business.

“[…] We still use a lot of Excel spreadsheets, which is not something I personally like. […] When we have Excel spreadsheets lying around for reasons that we don’t develop quickly enough, it’s a personal failure.”—E16 Co-owner of a scientific technical services company.

Some respondents, especially those from non-manufacturing companies, mention the high cost of technology as a barrier to its adoption.

“[…] Then we’re also constrained by costs, and what it costs, because we can’t just throw money out the window like that without thinking about how it might impact the company. Well, I’d say it costs us around $40,000 to $50,000 a year in monthly expenses, easily.”—E11—Owner-manager of a recreational vehicle sales company.

Most respondents have begun their digital transformation, but their adoption of digital technologies remains limited to basic technologies or information technologies and is being implemented in a piecemeal fashion.

“[…] We scan all our invoices. Receipts, shipments, everything goes through barcodes.”—E1—Owner-manager of an agri-food processing company.

“[…] I’ve implemented a computer system, an online booking system. I changed the website, and now, let’s say 40% to 45% of my bookings come from online bookings during the winter. In the summer, the rest comes from walk-ins.”—E12—Owner and manager of an adventure tourism company.

Other respondents, certainly those with advanced knowledge of 4.0 technologies, plan to adopt certain cutting-edge technologies such as intelligent robots, and virtual reality for strategic advantage. Business environments are becoming increasingly competitive, and new technologies seem to be a compelling necessity to remain competitive.

“[…] We’re starting to get a lot of requests for robotization, exoskeletons, things like that. In fact, none of our competitors offer it, so it’s part of who we are, part of our strategic plan to move in that direction. We also have plans to grow by territory and into a franchise business model. […] I see that people are starting to want to integrate robotization. That’s the only thing I’ve started to see. Robotization, i.e., machines that clean on their own. […]”—E13—Owner of a cleaning services company.

Companies that have adopted technology report tangible benefits, including time savings, improved accuracy, and employee satisfaction. They mention tangible results that have not only increased efficiency and productivity but also supported hiring and expansion.

“[…] It saved a good 10 h per week to the person who does the payroll. […] Our employees are truly satisfied.”—E9—Co-owner of a waste management and recycling company.

Some respondents mention a significant return on investment and having resolved labour-related issues.

“[…] We’ve doubled the foundation’s turnover. We’ve grown to six people plus two contractors who take on about a third of the work. And now we’re looking to hire another full-time person.”—E29—Executive Director of a fundraising organization.

“[…] Right now, there are five of us, but we have a sixth person starting. Normally, we should have at least seven, seven to be exact. We’re up and running.”—E31—Co-owner of an agri-food resale business.

However, the adoption of new technologies has been a failure for some companies.

“[…] We realized that our online registration and donation platform on the first website, the first new website in 2015, wasn’t doing the job either. […] We tried lots of programming, lots of exercises, working with FileMaker in parallel, only to realize that no, it would never be powerful enough for our needs […]”—E29—Executive Director of a fundraising organization.

“[…] We wanted to integrate these systems with Lightspeed, but we quickly realized that it’s such a big company […] it was very difficult to develop and integrate with them, it took months and months, and it was very difficult to develop with them.”—E31—Co-owner of an agri-food resale business.

5.3. Organization and Strategy

These failures can be explained by a lack of strategy for adopting digital technologies at the company level. Their strategic approaches are generally improvised, which also reflects a lack of knowledge of the support ecosystem. For example, as in the following quote, some respondents have applied a technology watch strategy, but this remains unintegrated into a concrete planning perspective.

“[…] So we have a team leader who has been given time to do some research. After that, he calls us into a meeting and presents all his ideas… The last two machine purchasing cases were a bit like that. We’re kind of in a perpetual state of… not reorganizing but analyzing our industry […]”—E6—Owner and manager of an industrial maintenance company.

Moreover, most respondents stated that they did not have a documented strategic plan, or if they did, it became obsolete after a year and was not updated. This failure to update is often attributed to a lack of availability or to changes and variations that are more rapid and difficult to keep track of on paper.

“[…] So we don’t have a fixed plan, we don’t have a written plan. On the other hand, we have plans that are somewhat agile, or at least in flux. […] A written plan quickly becomes obsolete at the speed we’re moving.”—E16, scientific technical services company.

“[…] We had even exceeded our targets in the first year.”—E3, co-owner of a waste processing company.

“[…] Then we didn’t review our strategic planning often enough, so it was no longer relevant […] It’s a lot of ‘as we go along’, but some customers still come in to plan a couple of months ahead. We have to make sure we have the time slot, so to speak, to deliver the contract on time.”—E30, Co-owner and manager of a design and welding company.

In this context, digital technology implementation projects, while not failing as in the cases mentioned above, often encounter internal resistance to change. Employees develop workarounds or express uncertainty about job losses.

“[…] I have one employee […] who complains about every change, all the time, all the time. But he’s never left. […] The worst thing is that he’s the one who manages it, since he’s in purchasing, but he always finds a way to put a spoke in your wheel to do it his way. Then we must come back and say, ‘No, that’s not how we’re doing things from now on.’ Ah, it’s not that easy, you know?”—E6, Owner and manager of a company specializing in the maintenance and valorization of industrial waste materials.

This resistance can sometimes be overcome through training measures or coercive mechanisms.

“[…] First case, we put the scanners in the distribution center to sell. Obviously, it took two weeks, and someone found a way to get around the system. But hey, we all saw it on our IT reports, so we blocked it. OK, you can scan, but you scan properly or you don’t scan at all.”—E1, Owner-manager of an agri-food processing company.

“[…] At the moment, our accountant is undergoing training to set up our entire item-by-item coding structure.”—E4—Co-owner of a furniture manufacturing company.

In some cases, employee dissatisfaction led to the departure of the most discontented, while in others, it led to the dissipation of uncertainties and genuine commitment to the project. Commitment to the project can also be explained by internal support measures and improved employee well-being regarding the technologies adopted.

“[…] There have been many, many, many changes, a huge number of changes. Since then, many of those who were already there have left. Because if we hadn’t set that limit, we’d still be there.”—E5—Owner of a metal processing company.

“[…] For the person who does the payroll, it saved them a good 10 h a week. And for the supervisors, it made their work easier in terms of schedule management and planning. And our employees are really happy too […] So I think our employees really appreciate it, and everyone has their mobile phones with them all the time, so they can access it on their phones.”—E9—Co-owner of a waste management and recovery company.

5.4. People and Culture

Several respondents reported that their initial exposure to certain technologies occurred through their business network, conferences, the media, market trends, or word of mouth. Their attitude shows an openness to a new work culture around technology without specifying their skill level.

“[…] We’ll find the right people to speak the right language, and we’ll get good advice on implementing the ERP system we choose.”—E7—Co-owner of a home manufacturing company.

“[…] I heard about this software from other welders in the area. They told me it was the best.”—E30—Co-owner and manager of a design and welding company.

In terms of support, most respondents mention some kind of collaborative work with partners; however, these partnerships are primarily limited to relationships with suppliers.

“[…] In fact, when we are asked to test new features or suggest improvements (to the software provider), they don’t even charge us for these services, because we help them develop their software with the bridges, we create ourselves internally.”—E2—Co-owner of a chemical manufacturing company.

However, the results indicate that most respondents do not use support and subsidy programmes, either because they do not consider themselves eligible, because they are unaware of the existence of such programmes and confuse them with traditional business support programmes, or because they do not know which programme corresponds to their profile. Their responses reveal a considerable lack of information about existing support programmes.

“[…] Well, I didn’t look into those programmes because I always thought they were for bigger players.”—E30, Co-owner and manager of a design and welding company.

“We’ve been here for three years; we’ve done everything we could for three years. […] They paid for support with accountants, lawyers, notaries […]”—E20, Co-owner and managing director of a video production services company.

“[…] You must take your time. I know there’s a subsidy. Well, it’s not a subsidy; there’s help available in Quebec for employee training. But as for everything else related to 4.0, I’m not up to speed. I’d have to do some research.”—E8—Co-owner of a family-owned agricultural machinery manufacturing company.

Overall, most respondents did not take any initiatives related to digital culture within their company. A few, such as company E9, reported some initiatives, but these remain general and are not focused on digital transformation.

“[…] because we also have a news feed where we post a lot of things, such as security information, birthdays and appointments. I think our employees really appreciate that, and everyone has their mobile phones with them all the time, so they can access it on their phones.”—E9—Co-owner of a waste management and recovery company.

5.5. Data and Cybersecurity

Most respondents still have an inadequate approach to data management. Data are still stored in the traditional way, with little or no use of cloud computing. Some acknowledge that they have enough data but do not know how to use it.

“[…] But you know, we have a lot of stuff, but I feel like it’s too much and I’m not sure what’s essential. But at some point, we must make choices; we can’t take everything, thinking that it’ll be better.”—E11—Owner-manager of a recreational vehicle sales company.

“[…] I’d have to read through all the boxes from before 2005, and most of the customer data has been on my computer since 2005 for accounting purposes, with year-on-year tracking, so there’s a lot of information I wouldn’t know how to use right now.”—E30—Co-owner and manager of a design and welding company.

Respondents mentioned that they find many errors in this traditional approach to data management.

“[…] Where are we going to submit our bids or place our orders? We’re going to do our customers who are in there, invoicing, shipping, but they don’t talk to Trello. Everything must be transcribed again. When you transcribe, that’s when mistakes can happen.”—E10—Owner and manager of a printing company.

We note that, overall, they have a strategic vision of data management. However, the respondents who are most advanced in the adoption of digital technologies, especially those in manufacturing companies, plan to use data operationally and strategically for informed decision-making.

“[…] It must be easy because, as an entrepreneur, you need access to everything. You need access to your statistics. It helps you to have structure, analysis and statistics. And it gives entrepreneurs a more accurate and broader view of their business.”—E12—Owner and manager of an adventure tourism company.

“[…] so we accumulate an excessive amount of data, precisely to enable more automation and predictions. So, in the plans, there is the integration of data acquisition. Then, as we go along, we will also start to integrate data acquisition. Currently, data entry is still done manually, but we are looking to have more automated data acquisition pipelines at that level.”—E16—Co-owner of a scientific technical services company.

When it comes to investments in cybersecurity, most respondents highlight the high costs and lack of information about the process. They have a real understanding of their problems but remain inactive because they have no idea how to proceed.

“[…] Right now, we’re really just gathering information. I’m trying to get cyber risk insurance. It’s so complicated, the questions are so complicated. We can’t even fill out the insurance form to sign up. Our CRM is on a virtual server. Well, we have online backups. We have lots of information, but I feel like it’s too early and I’m not sure what’s essential.”—E11—Owner-manager of a recreational vehicle sales company.

“[…] We realized that silo management was a challenge because people in different offices couldn’t talk to each other. We find it inconceivable, but the fact is that you have to be willing to manage the type of team it takes to break down those silos.”—E15—Financial services business owner.

- General Conclusions

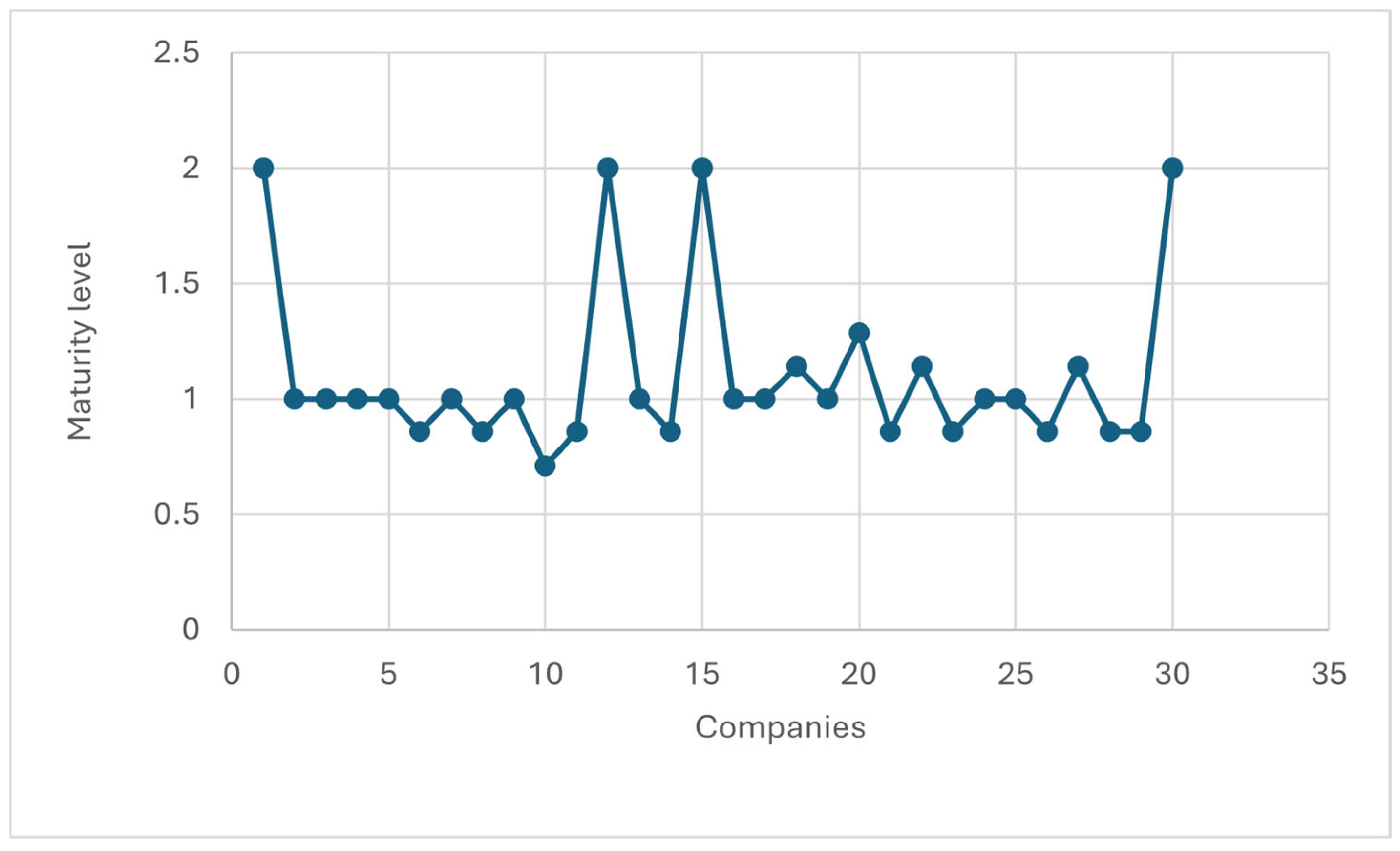

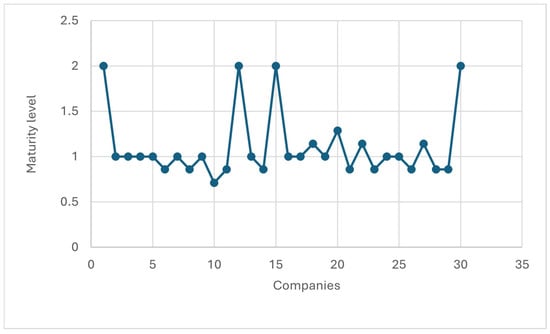

The following Figure 5 shows the average digital maturity scores of the participating companies. It was determined based on the main categories of results, i.e., the dimensions of digital maturity. A score ranging from 0 to 5 was assigned based on how each enterprise represented each dimension. The average scores correspond to the digital maturity levels previously determined in Table 5. For reference, the different levels of digital maturity are as follows: Level 0 = traditional, Level 1 = beginner, Level 2 = basic, Level 3 = advanced, Level 4 = integrated, and Level 5 = optimized.

Figure 5.

Average digital maturity scores.

The most mature companies (n = 4) have an average score of 2, which corresponds to the basic level of digital maturity according to our scale of digital maturity. The basic level of digital maturity is characterized by finalized process digitization, planned or initiated automation, employee’s awareness around digital transformation, and an intention to adopt a strategic approach (see digital maturity score matrix in the Appendix A). However, in general, most SMEs in our sample have an average score of around 1. This means that these enterprises have a digital maturity level corresponding to “beginner” level. The beginner level is characterized by a few digital initiatives without a clear strategy, partial or limited digitization of processes, and heterogeneous adoption of processes.

6. Discussion

The aim of this research was to design a cross-functional digital maturity model tailored to Quebec SMEs and to assess their level of digital maturity.

The results reveal that the key dimensions for successful digital transformation are technology, culture, and people. After these dimensions comes the organizational dimension, because this is where the full potential of the company’s digital transformation strategy lies. The people dimension is no less a human dimension, but it is more skills-oriented, which justifies its inclusion as a separate dimension in our model. However, the results obtained implicitly integrate this into the organizational dimension, as it is unplanned and constitutes an immediate response to resistance to change. The strategic planning dimension reflects the company’s strategy and the implementation of a roadmap.

It is in the organizational dimension that the cross-functional nature of our model comes into play. As proposed, enterprises have the flexibility to design their digital strategy according to whether an element of this dimension is relevant to their operations or not. For example, a digital maturity model for manufacturing SMEs would have elevated the product/operations elements to the level of a dimension. This would make the model unusable for a non-manufacturing SME that offers a service. Similarly, a model designed for manufacturing SMEs may emphasize decision-making based on big data, whereas this element may not be necessary for a micro-enterprise.

That said, the logic behind our definition of digital maturity dimensions is based on a cautious approach that allows SMEs flexibility to design their digital strategy according to their needs.

Based on these dimensions and the defined levels of digital maturity, we were able to analyze the digital maturity of a group of thirty (30) SMEs, regardless of their specific characteristics, and to refine the initial conceptual framework based on the inductive findings from the qualitative study.

The results show that business leaders still have only a rough understanding of the Fourth Industrial Revolution and the technologies it involves. The fundamental principles of Industry 4.0, namely integration, interoperability, modularity, decentralization, virtualization, real-time capability, and service orientation [139], remain unknown or poorly understood by most businesses in the Saguenay-Lac-Saint-Jean region. This situation is reflected in the results, which show that many respondents equate 4.0 with simple, isolated digital tools, such as online booking or a website, without understanding its systemic dimensions.

Furthermore, the performance benefits associated with the adoption of digital technologies—such as improved operational efficiency, reduced production costs, optimized working time, enhanced product quality, increased human resource productivity, reduced waste, and optimized energy resources, as well as informed decision-making—are still relatively unknown among SMEs. This lack of awareness can be attributed to the insufficient use of existing support resources, often due to a lack of information or clear benchmarks for accessing them. Raymond et al. [21] therefore recommend that business leaders better identify key resources, both tangible and intangible, including human resources (such as training, awareness, and information management practices) and strategic partnerships with external consultants. Although there is a significant support ecosystem in Quebec [28], these resources are still not well identified or utilized by SMEs.

Despite these knowledge gaps, most companies have already begun their digital transformation by adopting common management software (office suites, websites, ERP, CRM, social media). However, in the manufacturing sector, the adoption of more advanced technologies (computer-aided design and manufacturing, big data analytics, simulation systems, augmented reality, cyber-physical systems) remains marginal. This contrast is consistent with the literature on the low integration of advanced technologies in SMEs [15].

Although these primary technologies are generating some satisfaction—for example, time savings, improved accuracy, and employee satisfaction—the approach to digital transformation often remains improvised. Managers tend to view it as a one-off adoption of tools, without an overall vision or long-term strategy. E16 illustrates this perfectly by pointing out that fixed plans quickly become obsolete, while others, such as E32, have shelved their strategic plans due to the pandemic. These results reflect a tension between agility and strategic planning [140]

However, the literature recommends that the SMEs’ digital transformation be a part of a planned, integrated, inclusive, and skills-based approach [21] while adopting a logic of continuous improvement [22]. However, SMEs still operate largely within small networks, relying on their business circles or sectoral groupings (E24, E19), without fully utilizing structured support resources.

In terms of inclusiveness, the results show that staff are rarely involved in strategic decisions, which fuels resistance to change. Some cases report forms of “digital mutiny” where employees circumvent tools (E1, E6), while others manage to become leaders of the transition after sufficient training (E6, E3). This confirms the importance of integrating transition and training measures to support ownership [141].