Abstract

Modern production systems face the challenges of increasing personalization of products, growing structural complexity, and the need for sustainability. In this context, it is necessary to include the human dimension in the optimization of production processes, especially in line with the principles of Industry 5.0 and the circular economy. In this paper, a complexity index is proposed that integrates the objective characteristics of the product and the subjectively perceived workload of the operator during assembly. The proposed index was used in the assembly line optimization process using linear programming to find a compromise solution between two often-conflicting objectives: maximizing output and minimizing complexity. In the analysis, two approaches to the initial balance of the assembly line were considered—by assembly time and by complexity of work elements—which were used as inputs to the optimization model. The results show that an approach that considers complexity from the operator’s point of view contributes to a more even load distribution but also can lead to higher overall performance. Such an approach confirms the importance of integrating the human factor into optimization processes and thus contributes to the creation of efficient, sustainable, and human-centric production systems of the future.

1. Introduction

Increasing customer demand for personalized, functional, and readily available products in the modern manufacturing environment has a strong influence on the way products are designed and developed. These demands, as well as the rapid introduction of new technologies, are increasing the structural and dynamic complexity of manufacturing systems [1]. Therefore, in order to remain competitive while maintaining or increasing market share and profitability, manufacturing companies need to develop systems that are more flexible and efficient. On the other hand, there is a growing awareness of sustainable development in the world, and as part of the industrial transition to a circular economy, it is becoming increasingly important to optimize production processes so that they are not only efficient and flexible but also sustainable in the long term. With its strategic documents European Green Deal and Europe Fit for the Digital Age, the European Union is intensively promoting the implementation of the Industry 5.0 concept [2]. At the heart of this concept is a green and digital transformation that places people and their well-being at the center of the production process. In Industry 4.0, the focus was on technical progress and efficiency, while the well-being of operators and the human factor were neglected [3]. In this sense, Industry 5.0 complements the previous industrial paradigm and promotes sustainability and resilience [4]. In Industry 5.0, people are not just subjects with a specific task to fulfill, but they are the main drivers of innovation and an essential factor in achieving adaptability in a complex production environment.

One of the biggest challenges for manufacturing companies in a dynamic market environment is coping with the complexity resulting from the ever-increasing demands and wishes of customers for products that meet their individual needs and desires. In most cases, the increasing variety of products leads to an increase in the variety of components and production processes, which contributes to additional difficulties in planning, scheduling, and resource management. In order to maintain the efficiency of the production system, the industry tries to diversify products as late as possible, most commonly on assembly lines, which has proven to be one of the most effective methods of achieving high product variety. The assembly process is defined as a series of sequential activities in which parts, components, or software are assembled into a functional product [5] so that products can be adapted to changing market requirements. Despite the increasing automation in modern production systems, manual assembly is still widely used due to its flexibility, precision, and ability to adapt the operator to a wide variety of products [6,7,8]. It means that humans continue to occupy a central position in manufacturing systems, as they have considerable authority in decision-making and monitoring execution [9]. With increasing complexity, the flexibility of assembly systems decreases and their control and monitoring becomes significantly more complex [10]. In the scientific literature, many measures have been used to define assembly complexity. These measures differ primarily in the sources of complexity considered and the techniques used. On the one hand, many measures are based on information theory, i.e., the application of Shannon entropy. These approaches assume that the complexity of the assembly process results from the degree of uncertainty within the observed system. The degree of uncertainty is related to the amount of information required to describe the state of the system. The more complex the system is, the more information is needed to describe it [11]. In the context of assembly, this means that the complexity of the assembly system increases with increasing variability of products and components, with increasing interdependence of components and with an increasing number of possible sequences of assembly operations. The observed state of the system can be defined differently depending on the author and can represent the variety of components, tools, assembly sequences, etc. The work that served as inspiration for a large number of papers proposing assembly complexity measures via Shannon entropy is certainly the work of Zhu et al. [12]. Zhu et al. [12] proposed a measure called “Operator Choice Complexity”, in which the conditions that lead to uncertainty in the assembly process are defined as the difficulty of operator choice at a workstation due to product variety. The more choices the operator has, the longer it takes to make a decision. A similar model is used by Hu et al. [13] to define assembly complexity for supply chains and by Wang et al. [14,15], who extended Zhu’s model and proposed the concept of relative complexity, which allows designers to compare different design alternatives for assembly systems, as well as a measure of complexity in hybrid assembly systems that relates choice complexity to operator response time and system reliability. Busogi et al. [16] also used Zhu’s complexity model as a basis and integrated the concept of component similarity into it. Similarly, Park and Okudan [17] used information theory and the concept of commonality of processes and products to define a complexity measure for a product family, while Zeltzer et al. [18] defined a complexity entropy workstation measure in a mixed-model assembly that accounts for the variability in task duration resulting from different product model requirements. Samy and ElMaraghy [19] defined a measure of product complexity by combining information theory with the principles of design for assembly, in particular the Boothroyd method, to capture the complexity arising from the number and variety of components and their geometric features.

The second main stream of research relates the complexity of product assembly to the physical characteristics of the product to be assembled or the flow of the assembly process; i.e., they quantify the complexity taking into account the technical difficulties of the assembly process. The most notable work in this area is the work of Alkan et al. [10], who define complexity through the concept of structural complexity of product design; i.e., they focus on the geometric, dimensional, and structural characteristics of the product by applying the principle of design for assembly (DFA). Alkan et al. [10] focused their work on defining the complexity of the product assembly based on the application of the DFA principle (Lucas method) and the adaptation of Huckle’s molecular orbital theory. These models [10,19] have been applied in various contexts in the literature to assess the structural complexity of products and understand their impact on human perception [20,21] and manufacturing performance (defects, assembly time, productivity, quality) [22,23] and accordingly make informed decisions in the early design stages and in newer manufacturing environments such as those involving human–robot collaboration. In addition to DFA, strategies such as modularization and product platform are recognized as architectural approaches for coping with product complexity [24,25]. While DFA approaches quantify and model the inherent structural challenges of assembly, modularization and platform-based design provide practical strategies to mitigate these challenges by redistributing or limiting complexity within modules and across product families. Modularization allows a system to be decomposed into relatively independent modules with high internal cohesion and limited external interfaces, reducing integration difficulties and making the structural complexity of the product more manageable. Similarly, a product platform strategy enables the development of product families derived from common components and processes, which ensures variability and adaptability while maintaining control over structural complexity [23].

The model presented by Akan et al. [10] is used in this research to define the complexity of product assembly and is explained in more detail in Section 2.1 accordingly. All of these measures are very important to the assembly process as they allow complexity to be quantified in a repeatable and unambiguous way, the root causes of complexity to be identified, and various aspects of complexity to be proactively managed. This is critical for engineers and managers to make timely decisions to optimize assembly processes that directly impact production efficiency and its costs and to improve human performance and well-being.

The management and design of assembly lines is crucial for the flexibility and sustainability of the production system, and one of the most important problems to be solved is assembly line balancing (ALB) [26]. Assembly line balancing refers to the problem of optimally assigning tasks to workstations to achieve desired goals such as reducing cycle time, minimizing downtime, increasing resource utilization, and the like. However, the principles of the new industrial paradigm make it necessary to consider human factors in addition to operational efficiency [27,28]. Indeed, as product variety increases, the complexity of product assembly increases [10,19], which has a negative impact on both economic parameters and human factors. Previous studies [1,20,21,23,29,30] confirm that product complexity is an important factor for higher assembly costs, longer delivery times, productivity losses, and various operational problems within the system. In addition, higher complexity extends assembly times and increases the likelihood of human error [16,18,31]. From the operator’s perspective, higher complexity means more cognitive resources, knowledge, skills, and time required for assembly [21,32]. From a physical perspective, product complexity can lead to increased physical strain and fatigue. Ghorbani et al. [28] emphasize in their review that an imbalance between cognitive and physical load can lead to ergonomic risks and musculoskeletal disorders. Katiraee et al. [33] state that lack of attention to operators, including failure to address perceived physical workload, can lead to increased worker fatigue and accidents. Therefore, understanding and managing the impact of complexity on the operator is essential in the context of Industry 5.0, which focuses on operator well-being and creating a human-centered and human-friendly environment. Ignoring the impact of product assembly complexity on the operator can lead to longer assembly times, more errors and rework, reduced operator well-being, and a decrease in the quality of the assembly system [34].

In addition to these insights, complexity theory has also been applied to solve the assembly line balancing problem in the presence of product variety, i.e., to solve the mixed-model assembly line (MMAL) balancing problem. To the authors’ knowledge, the paper by Zeltzer et al. [18] is the first paper to directly incorporate assembly complexity into the balancing process. Zeltzer et al. [18] observed the negative impact of product variability and the associated amount of information on the operator’s work and the performance of the assembly system. Therefore, as part of their research, they proposed a measure of complexity that links the entropy of the workstation to the distribution of tasks and pointed out that the goal of MMAL balancing should not only be to balance the line but also to level the complexity along the entire line during the balancing process. The complexity theory for solving mixed-model assembly line balancing problems was also applied by Liu et al. [35,36]. In [35], the authors defined three types of complexity related to assembly line balancing of a mixed model and buffer allocation and presented an integrated optimization framework for this problem. The goal of their integrated framework was to maximize productivity, minimize complexity, and minimize total buffer capacity. In a later paper by Liu et al. [36], they focused on the optimization of balancing a mixed-model assembly line under conditions of uncertain demand. Accordingly, the uncertainty of demand was expressed using information theory as a measure of uncertainty, i.e., fuzzy entropy. Although the above works introduce complexity theory to solve MMAL balancing problems and optimize system performance, they do not explicitly consider human perception of task complexity in their quantitative complexity models. Although they are aware of human factors and the impact of complexity on them, their measurements focus primarily on objective, information-theoretic aspects of system complexity rather than the subjective perceptions of operators. In recent years, there has been a clear and increasing trend towards incorporating the operator’s subjective experience. This shift is part of a broader shift towards the Industry 5.0 paradigm. A significant step in this direction is the work of Katiree et al. [33], in which the authors integrate the operator’s subjective experience directly into the assembly line rebalancing model. The authors explicitly incorporate perceived physical effort, as measured by the Borg scale, into their bi-objective model of assembly line rebalancing and operator assignment. They showed that this approach can lead to an increase in cycle times but significantly reduces operators’ physical effort, fatigue, and accident risk, while increasing operators’ motivation through their involvement in the evaluation process.

The balancing of assembly lines can no longer be viewed through the prism of strictly objective parameters. Understanding and incorporating the perception dimension is crucial, especially in the context of Industry 5.0 and the focus on people to create more robust, efficient, and human production systems [3,37]. In the field of assembly line optimization, there is a recognizable trend towards actively bridging the gap between objective complexity measurements and the subjective experience of operators. These two measurements are interdependent and complement each other. Separating these dimensions leads to an incomplete knowledge base. In order to better understand the relationship between the task and the performer, it is necessary to consider them together [21,32]. Therefore, this paper proposes a way to integrate measures of product complexity and operator-perceived workload into a single measure that can be used to optimize assembly process using linear programming. This approach is applied to manual product assembly and it supports the dual goals of improving operational efficiency and achieving maximum productivity within a given time frame. We investigated whether applying the proposed integrated complexity measure compared to traditional balancing methods based solely on task execution time produces any advantages and if so, what these are. Although the focus of this work is on manual assembly, the principles and methods are also applicable to more complex assemblies where equipment such as robots are used or their collaboration with humans is observed. The reasons for this lie in the nature of the measures used to propose an integrated measure of complexity. The proposed integrated index is based on measures that can be used to evaluate both the structural complexity of products and the operator-perceived workload in different production environments. The results of this study, in which complexity was systematically analyzed, can serve as a basis for optimizing workflows, reducing operator effort, increasing the overall efficiency of the assembly process, and implementing a human-centered assembly line.

2. A Human-Oriented Linear Programming Approach to Assembly Optimization

Recent research has shown that the complexity of product assembly has a significant impact on operator performance and the performance of the assembly process. Product assembly complexity has been shown to impact key performance indicators such as assembly time, product quality, production costs, etc. Complex assembly tasks tend to have a longer assembly time due to the additional steps or complex procedures they require [23]. This increases the likelihood of quality defects occurring and has far-reaching negative effects on other assembly performance indicators. Therefore, it is important to recognize and manage complexity not only in terms of product complexity but also in terms of operator experience to create an optimal, operator-friendly environment.

In order to analyze the structural complexity of a product, its impact on the operator, and consequently, its impact on the productivity of the assembly line, the assembly of Lego cars was used in this study. Lego sets allow the use of similar components to assemble highly personalized products that differ in the degree of complexity of assembly. Despite their simplicity, Lego models simulate certain characteristics of industrial assembly processes, including the need for correct sequencing of steps, cognitive effort, and attention to detail and, therefore, provide a relevant experimental framework for this type of research. For the purposes of this research, structural product complexity is assessed using the approach of Alkan et al. [10], while operator-perceived workload is assessed using the NASA TLX questionnaire. By combining these two instruments, a new index was defined that determines the complexity of the work elements. This index determines how much a particular work element contributes to the overall perceived workload during assembly in relation to the structural complexity of product assembly. The proposed index was used in the optimization process to achieve an optimal trade-off between the complexity and the number of outputs through linear programming. This approach is in line with the principles of Industry 5.0, which places humans at the center of the process. Instead of the operator adapting to the system, the system is optimized taking into account the operators’ perspective. This not only increases productivity but also contributes to the sustainability of work, safety, and employee satisfaction, which are important determinants of the human-centered manufacturing system design.

2.1. Model of Product Assembly Complexity

The approach used to assess structural complexity presented in the work [10] has been validated and implemented in numerous studies to define the structural or objective complexity of the product. The analogy underlying the proposed model is the combination of molecular orbital theory with the principles of design for assembly to express the complexity of product assembly as a function of the complexity of the individual components , the interaction between them , and the overall topology of the product . According to Alkan et al. [10], the overall product assembly complexity is defined as:

The proposed model can also be used to calculate the complexity of more complex systems that include different elements such as subsystems, modules, and components. In this case, the whole system is considered as a network of interconnected elements at different levels, where each component, module, or subsystem is treated as an element of the system with its own complexity.

is defined as the complexity of the individual components of product . It can be calculated as follows:

where is the total number of components that make up the product , and is the complexity of handling an individual component . The higher the value of the index, the more difficult it is to handle this part. This index refers to the technical difficulty of handling and interacting with the component and is estimated without taking into account how it fits into the assembled product or interacts with other parts, i.e., in an isolated state. It is quantified using the normalized handling index of the Lucas method [38], which depends on the physical characteristics of the part that causes difficulties in handling the component, such as size, weight, handling difficulty, and orientation.

The complexity of the connections (or liaisons or dependencies), , shows the overall complexities of pairwise connections that exist within the product structure. It can be calculated as follows:

where is the complexity of achieving connections expressed by the normalized fitting index of the Lucas method [38], while is a binary symmetric adjacency matrix of size representing the connectivity structure of the product . Fitting index represents the estimated difficulty of assembly and is usually calculated by considering seven attributes: part placement, part fastening, direction of fitting, insertion, restricted visibility, alignment difficulty, and insertion resistance.

is related to the structural architecture of the products, and it is referred to as topological complexity. It describes the complexity of the structural dependencies between the product components. It can be expressed as the ratio of the matrix energy to the observed number of components:

where is the adjacency energy of the matrix for product , that is, the sum of the singular values, , of the adjacency matrix where all diagonal elements are equal to zero.

2.2. Workload Perceived by the Operator

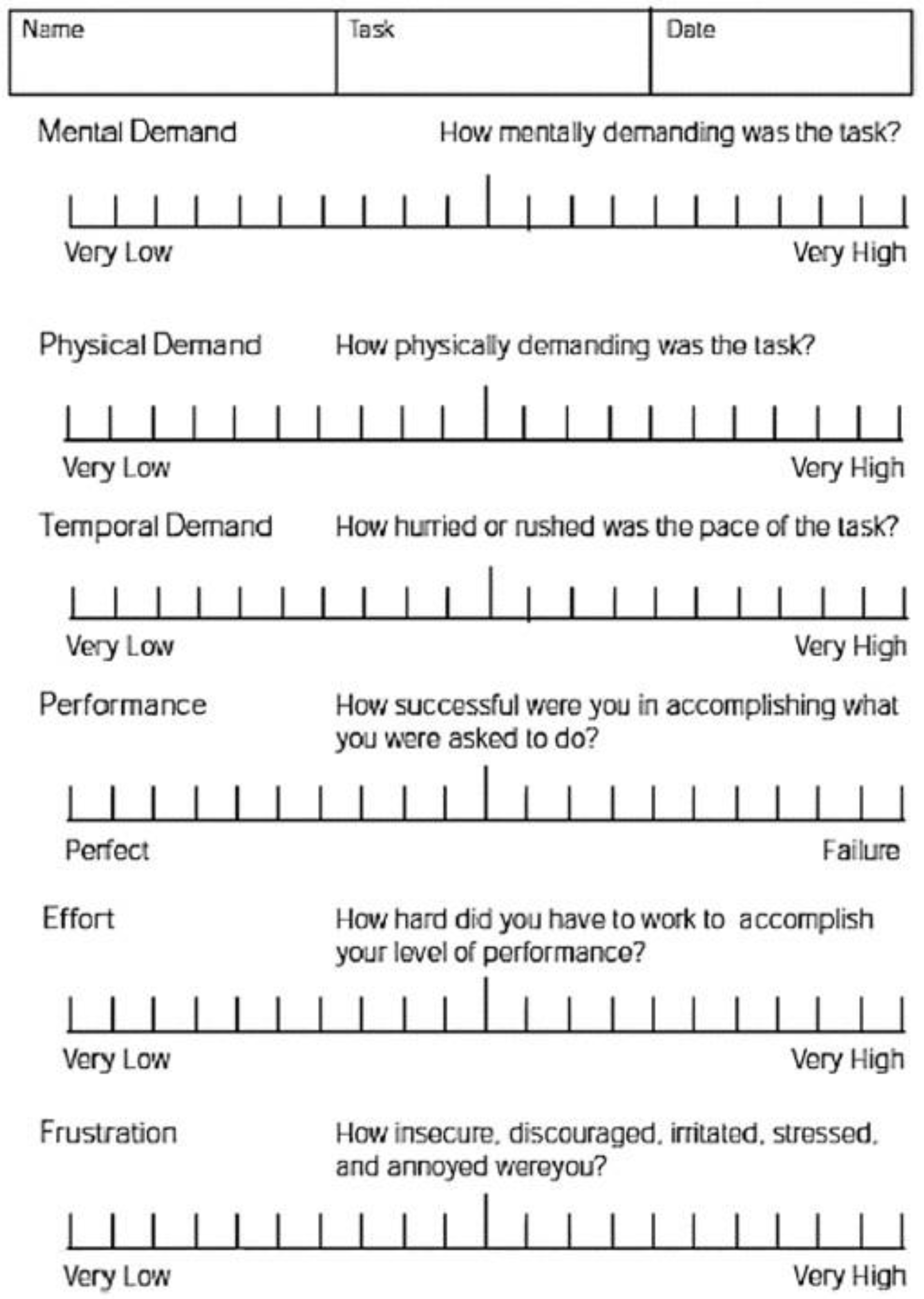

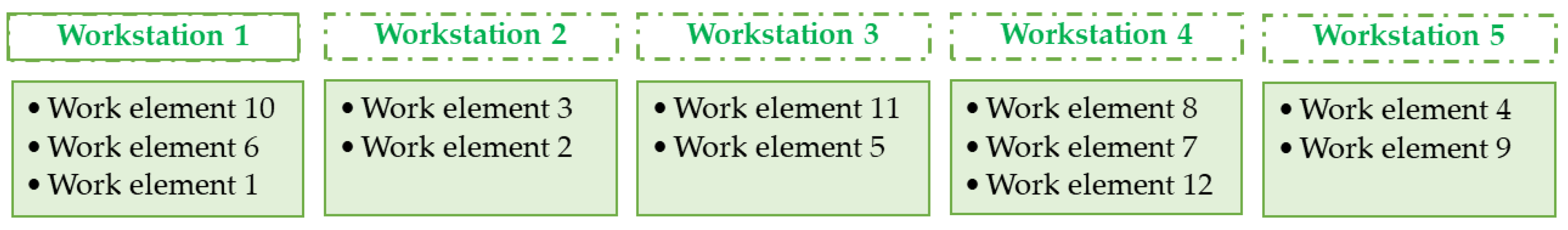

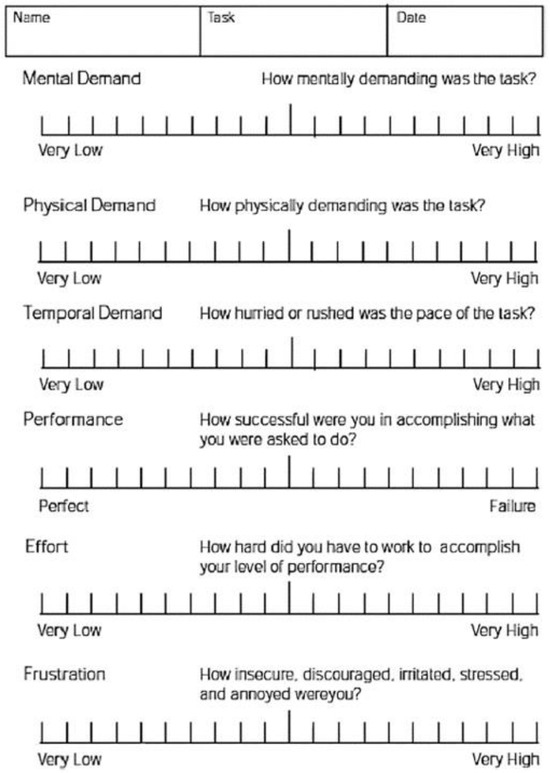

The NASA TLX questionnaire was used to assess the workload subjectively perceived by operators. The NASA TLX is one of the best known and most widely used subjective assessment techniques for evaluating perceived workload [39]. It is illustrated in Figure 1. This instrument expresses perceived workload considering six dimensions that potentially influence it [40]:

Figure 1.

NASA TLX questionnaire [41].

- Mental demand represents the amount of cognitive and perceived workload required to perform the task. This means that the operator estimates how much thinking, decision-making, calculation, and memory the task requires. A higher value means that the task requires a higher level of cognitive activity;

- The physical demand describes the amount of physical effort the task requires;

- Temporal demand expresses the perception of time pressure when performing the task;

- Performance indicates the self-assessed performance (e.g., how well and how satisfied the participant is with the results achieved);

- Effort expresses how much effort the participants had to exert (mentally and physically) to reach the level of performance they achieved;

- Frustration reflects the operator’s emotional response, i.e., the degree of irritation, stress, anxiety, or dissatisfaction felt by the operator during the task.

Each dimension is expressed on a 100-point scale from 0 to 100 with a gradation of 5 points. In this study, the final rating of perceived workload is calculated as the average of the six dimensions observed. However, in addition to the approach in which the average score of all six dimensions is taken into account, it is also possible to use an approach in which the dimensions are considered in terms of their weighting, i.e., the relative importance of the dimension. The weighting can be estimated using, for example, the AHP method or questionnaires to obtain a subjective assessment of the weighting of the dimensions or using, for example, the entropy-weighted method to assign an objective weight to each observed dimension.

Ignoring the subjectively perceived workload means ignoring the invisible overload of workers, their cognitive effort, the risk of burnout, and human failure due to overload. Using tools like NASA TLX allows the designer to quantify the effort perceived (or experienced) by operators and optimize assembly lines based on time and perceived stress, creating a more human-centered, sustainable process. The NASA TLX questionnaire was completed after the assembly of each product to determine the workload perceived by the operators.

2.3. Product Assembly Complexity from the Operator’s Perspective

This paper proposes a work element complexity index that integrates subjectively perceived workload, as determined by the NASA TLX questionnaire, and objective measures of product assembly complexity. This index quantifies the relative contribution of each work element to the overall workload from the perspective of the operator performing the assembly process. That is, it shows how much of the total perceived workload of the product “belongs” to a particular work element, given the technical complexity of the product and the assembly tasks. For the purpose of this study and the construction of the proposed index, a linear relationship between the variables was assumed, which facilitates interpretation and application of the model in practice. The proposed index results from the following expression:

where is the assembly complexity of the work element for the observed product , is the perceived assembly workload value of the observed product obtained from the NASA TLX questionnaire, and is the structural assembly complexity of the work element for the product , while is the total structural assembly complexity of the product obtained from Equation (1). The structural assembly complexity of a work element, , is also calculated according to Equation (1); however, not all product components and their interactions are considered but only those components and interactions that are required for the assembly of this work element according to the assembly sequence. This expression can be represented as follows:

where represents the complexity of the individual components that make up the work element for product , while represents the complexity of the interactions for this work element.

According to Equation (6), it follows that:

where is the total number of work elements for product .

2.4. Product Structure and Assembly Processes

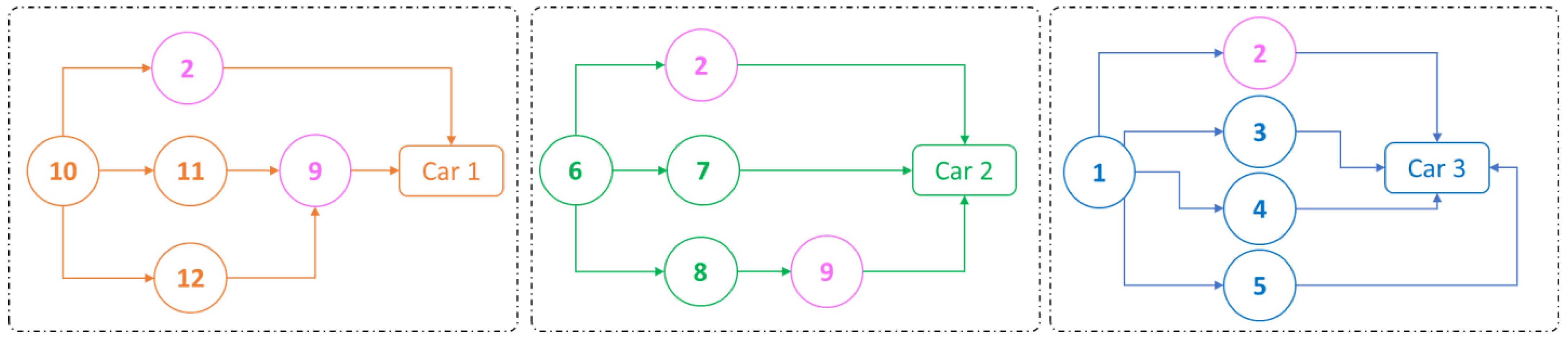

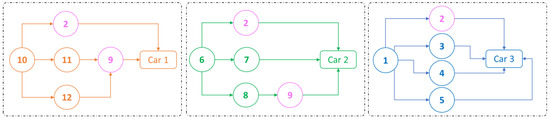

In this study, three different products were used to carry out the assembly process: Car 1, Car 2, and Car 3. These products are illustrated in Figure 2. The case study concerns the manual assembly of these products.

Figure 2.

Products for assembly.

As can be seen in Figure 2, these products consist of similar or identical components. Their assembly process is divided into work elements, i.e., a predefined set of assembly tasks. Work elements refer to a set of logically related and predefined basic steps that the operator must perform in order to assemble the product correctly. Each product consists of five work elements, with some work elements being the same for all products. In total, there are 12 different work elements for the products under consideration. The precedence diagrams of the work elements for the products under consideration are shown in Figure 3. They show the sequential and parallel assembly steps in the product assembly process. In Figure 3, the different work elements are shown with nodes numbered from 1 to 12, while the work elements that are common to two or three products are shown in purple. The observed products consist of approximately a similar number of components (30 or 31 parts).

Figure 3.

Precedence diagram of products.

Each product was assembled individually at the workstation, and the assembly times of the associated work elements were recorded. The assembly experiments were carried out by a group of five different operators (students). Each operator repeated the assembly of each product 30 times, which allowed a sufficient number of repetitions to ensure the reliability of the measurements. The times for each work element were recorded, and the final values used in the analysis represent the average times of the work element calculated for all operators. These values are shown in Table 1. The assembly time for the same work element may vary depending on the characteristics of the product and the previous operations that influence the conditions and complexity of execution.

Table 1.

Average assembly time of the work elements.

2.5. Linear Programming Model for Assembly Process Optimization

A linear programming model (simplex method) was applied to the assembly process. The solution of linear programming problems requires the definition of the objective function; the variables, i.e., the components that are optimized and influence the objective function; and the constraints or conditions that must be met for the observed solution to be acceptable. In this research, the focus is on the complexity of the product assembly from the operator’s point of view, which is quantified by the proposed complexity index of the work elements, Equation (6), and the goal is to minimize this value. A lower value means a lower perceived workload for the operator. In the example studied, the objective function is designed to simultaneously aim to reduce the complexity of product assembly from the operator’s point of view and maximize the number of components that can be assembled within the available time frame. For this reason, the objective function is formulated as an aggregate objective function, i.e., a single-objective optimization problem containing multiple interrelated criteria. This is achieved by introducing a penalty function that indirectly penalizes solutions that contain too few components:

In the analyzed objective function equation, the internal sum represents the overall complexity of the product assembly, while the variable indicates the number of assembled units of product , and indicates the total number of different products that are assembled (). Accordingly, the first part of the expression refers to the total perceived workload of the operator. The greater the number of products, the greater the total effort (workload) of the operator, especially if the products are more complex. The second part of the expression, in the form of the penalty factor , represents the “reward” for the largest number of units produced; i.e., it is used to encourage the assembly of a larger number of products. The penalty factor introduced makes it possible to modify the objective function so that it becomes less favorable for unrealizable or unbalanced solutions; e.g., if too few simple products are assembled or the total number of complex products is too large. This penalty lowers the value of the objective function for solutions that do not fulfill the specified conditions or disturb the balance of the production system. In this way, unfeasible solutions are removed from the set of competing options, and the focus of the model remains on those that are feasible and realistic under real production conditions. A higher value of means that the model favors a larger number of assembled products; i.e., a higher value of can lead to a higher overall throughput of the line but at the expense of a higher operator workload, as the model is less “afraid” of complex tasks. On the other hand, a larger value of means that the model favors complexity reduction and operator protection more strongly so that solutions with fewer products are more favorable.

The set of values of the variables that fulfill all given constraints is called a feasible solution. For a solution to be considered feasible, it must fulfill a series of defined constraints. In this case, the constraints result from the time capacities of the assembly workstations. As each workstation only has a limited amount of time available to carry out assembly tasks, it must be ensured that the total time required to assemble all the products assigned to it does not exceed its available working time. This can be expressed mathematically as follows:

where is the time required to assemble the product at the workstation , is the total time available at workstation , and is the total number of workstations. To ensure that the number of assembled units cannot be less than zero, an additional variable non-negative condition is introduced:

These constraints define a set of feasible solutions and, together with the objective function, form the basis for solving the observed optimization problem.

3. Results

3.1. Assembly Complexity of the Observed Products and Their Perceived Workload

3.1.1. Product Assembly Complexity

The assembly complexity of the observed product was assessed according to the method described in Section 2.1. Table 2 contains the values calculated for three products.

Table 2.

Product assembly complexity of the observed products.

The complexity of handling and connection of the individual work elements depending on the product for which the work element is considered is shown in Table 3.

Table 3.

Handling and connection complexity of work elements.

The topological complexity associated with the interactions between components is calculated by considering all direct connections between parts (components) within the product. Due to the structure of the product, a component may be directly connected to several other components, which influences the overall complexity of the system. For the products Car 1 and Car 2, the connectivity matrix has the dimensions 30 × 30; for the product Car 3, the dimensions are 31 × 31. These dimensions correspond to the total number of parts that make up the products. In this study, only direct connections between components are considered, while indirect connections are not included in the analysis. This approach allows an objective quantification of the topological complexity at the level of the whole product.

3.1.2. Assessment of Perceived Workload and Assembly Complexity

In order to obtain data on the assembly complexity of the work elements from the operator’s point of view depending on the product to be assembled, the NASA-TLX questionnaire was carried out for all three products after their assembly. Each of the five operators completed NASA-TLX questionnaire after performing 30 repetitions of the assembly of each product. The values of perceived workload for the products, were calculated as the average of all six observed dimensions for all operators. These values for the observed products are shown in Table 4.

Table 4.

Average perceived workload.

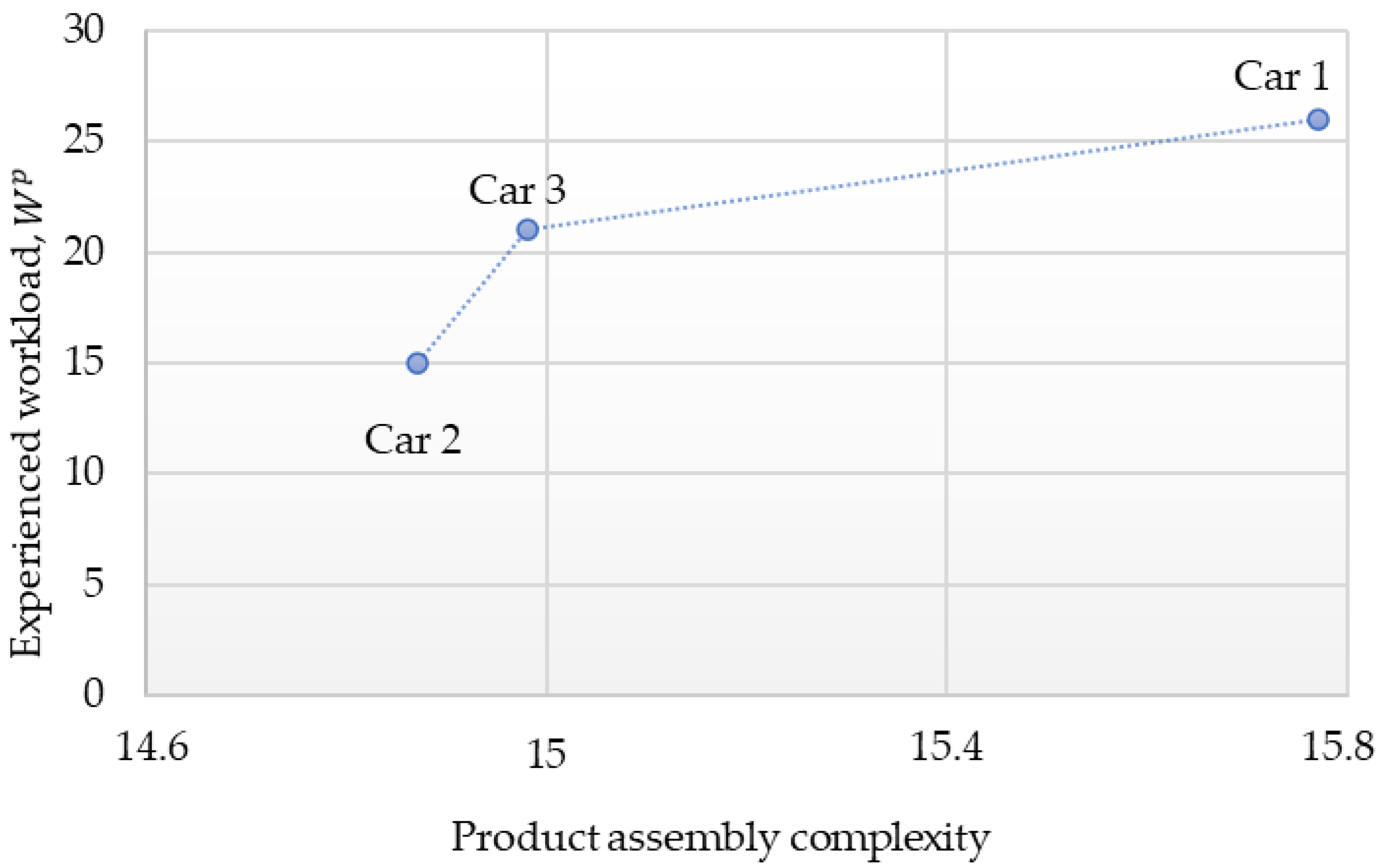

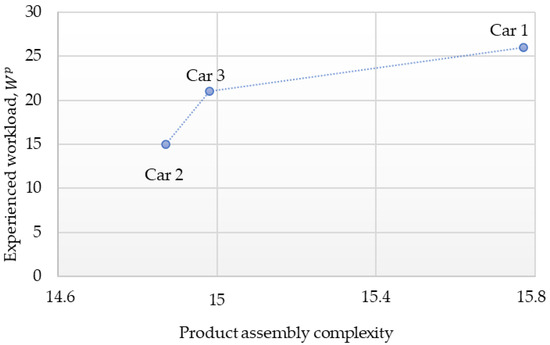

The relationship between the perceived workload and the objective complexity of product assembly is shown in Figure 4. For this sample, the results show that there is a preliminary growth trend between the two observed values. Nevertheless, it is important to extend the analysis to larger data sets to ensure a more reliable validation of the relationship. This conclusion is in line with the conclusion of Capponi et al. [34], who state that a general correspondence (increasing trend) between perceived and objective complexity can be observed in a small sample but also point out that such results should be interpreted with caution, as they may not capture the full variability of the observed phenomenon. To allow for more robust conclusions, such comparisons will therefore be the focus of future research.

Figure 4.

Product assembly complexity and experienced workload by operator (NASA TLX).

Once these values have been determined, the values for the assembly complexity of the work elements are determined for each work element according to Equation (6). These values are listed in Table 5.

Table 5.

Assembly complexity of the work elements.

The determined complexity indices were used as input parameters in the creation of the initial feasible solution for line balancing and in the further optimization of the assembly line with the linear programming model.

3.2. Initial Feasible Solution of Line Balancing

In order for the proposed complexity index to be used as an input value in the linear programming model, with the aim of a more even distribution of more complex and less complex tasks among the workstations from the operator’s point of view, the assembly line was first balanced using the heuristic method of the largest candidate rule (LCR). The solution obtained served as the initial feasible solution, i.e., as a basis for further optimization using the linear programming model with the aim of further reducing the perceived assembly complexity, i.e., to achieve a more even distribution of the workload across the stations while maximizing throughput. Linear programming optimizes within a certain framework and on the basis of an initial distribution; therefore, the quality of this initial solution has a direct impact on the final optimization results. Therefore, two initial solutions were generated.

The LCR method is carried out in four steps. In the first step, the work elements are sorted in descending order according to the criterion under consideration (e.g., assembly time). Then, these tasks are assigned to the first workstation one after the other, taking into account the precedence conditions, until the specified cycle time is reached. The process is continued for each further workstation, taking into account the same precedence conditions, until all tasks have been assigned.

Since the fact that the LCR method addresses standard simple assembly line balancing (SALB) and multiple product variants are not directly taken into account, the average values of the observed criterion were used for the work elements that occur in multiple products. If, for example, work element 2 occurs in all three products and the assembly time is used as a distribution criterion, the values for the assembly time are added together and divided by three.

In the case of the assembly of the Lego car models under consideration, a simple assembly line balancing of type II was considered, the aim of which is to minimize the cycle time for a given number of workstations—five in this study.

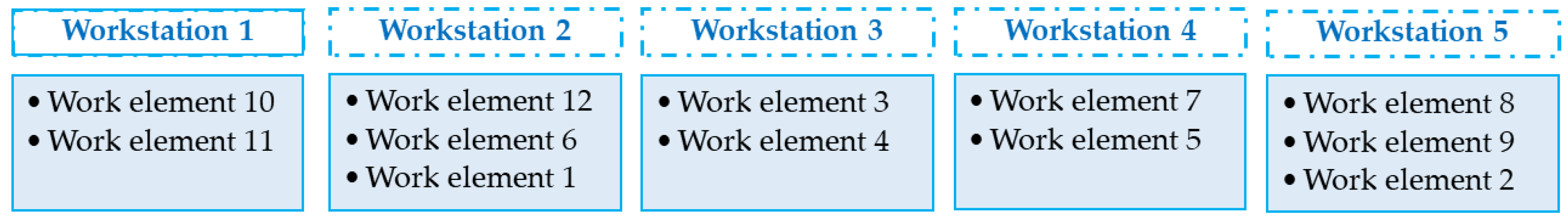

The initial balancing was performed in two ways. In the first case, the assembly time values of the work elements were used as the criterion for balancing the assembly line, while in the second case the complexity values of the work elements () were used as the criterion for balancing the assembly line.

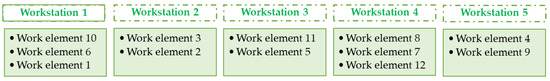

Figure 5.

Distribution of work element when assembly time is criterion (Case 1).

Figure 6.

Distribution of work element when complexity is criterion (Case 2).

3.3. Results of Linear Programming

This section presents the formation of the linear programming model and its results for both cases analyzed. Linear programming was used in this context to find the optimal combination of the production of different models, taking into account the complexity and the time available at the workstations. The Excel solver was used to solve the linear programming problem. The objective function was the same in both cases and was defined as follows:

Equation (12) is the application of the general Equation (9) using the values given in Table 4. The parameter was selected for both cases using the sensitivity analysis method. Different effects of the value of this parameter on the objective function were found. The first case showed that for a value , the penalty function is so strong that only the solutions that fulfill the given constraints and ensure a higher output are competitive. This means that the penalty function in this range steers the optimization procedure towards feasible and acceptable solutions. In the second case, the same effect is achieved with a value of . If the value of the parameter is greater than or equal to 37 in the first case and greater than or equal to 41 in the second case, the penalty function strongly favors solutions with a higher output. In this case, the objective function behaves almost exactly as in a classical linear problem, where the only objective is to maximize the number of products produced. Therefore, the solutions obtained for the value of the parameter between 23 and 36 in the first case and the solutions obtained for the value of the parameter between 22 and 40 can be considered as compromise solutions, i.e., solutions that strike a balance between increasing the output and controlling the perceived complexity of the assembly.

The data listed in Table 6 and Table 7 were used to determine the constraints of the linear programming model. The values in these tables result from the distribution of the work elements and their assembly time (Table 1). In the context of this study, the constraints of the model refer to the time availability of each workstation. It is assumed that each workstation has a total of 28,800 s available, which corresponds to a full working time of eight hours.

Table 6.

Workstations, complexity, and assembly times for first feasible solution (Case 1).

Table 7.

Workstations, complexity and assembly times for first feasible solution (Case 2).

For the value of the parameter of 23, the total quantity of assembled products is 100 for Car 1, 259 for Car 2, and 429 for Car 3; i.e., a total of 788 products were assembled.

With a value of the parameter of 22, the total quantity of assembled products amounts 100 for Car 1, 325 for Car 2, and 385 for Car 3; i.e., a total of 810 units were assembled.

This research has shown that by applying an approach that includes the integration of the proposed measure of complexity of the work element, a balanced trade-off between the observed key objectives can be achieved. By introducing the complexity index as an input variable in the linear programming model and by applying a penalty function that encourages a larger number of units produced, an optimization that does not neglect the human dimension of the assembly process is made possible. Such an approach is in line with the principles of Industry 5.0, as it places the operator at the center of optimization efforts. This contributes to a more even distribution of the workload across the individual workstations, reduces the risk of overload and monotony, and improves the ergonomics and sustainability of the work.

This approach creates a surplus of free time at certain workstations. Employees can use this excess free time to clean up their workplace, perform additional quality checks on assemblies, and make improvements to their workplace or the entire assembly line. Improvements can be made to processes, tools, fixtures, and ultimately, the design of the product itself. All leisure activities can be purposeful, even if they are not measurable.

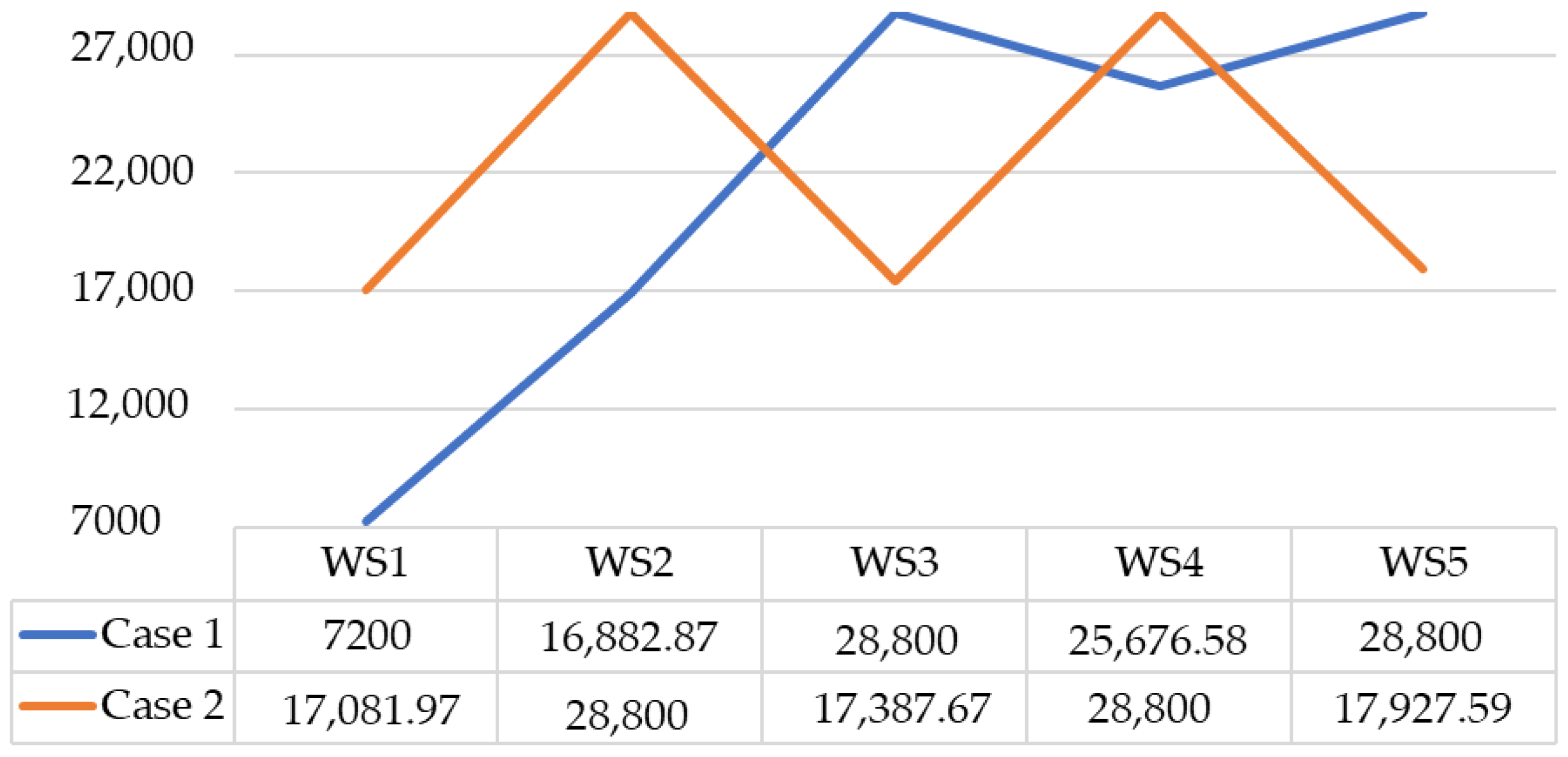

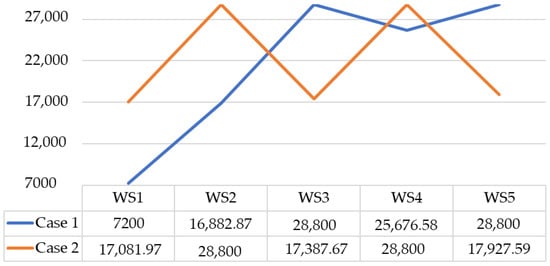

Comparing the two linear programming cases analyzed, which differ in the initial solution, Figure 7, it can be seen how the initial solution influences the final optimization results.

Figure 7.

Comparison of the total assembly time for workstations in both observed cases in [s].

In Case 1, the values of the total assembly time per workstation vary considerably, from 7200 s at the first workstation (WS1) to 28,800 s for workstations 3 (WS3) and 5 (WS5), which indicates a large discrepancy in workstation capacity utilization. In Case 2, although there are also fluctuations, the values are closer to the maximum capacity, and the differences are not so pronounced. It can therefore be seen that balancing according to the complexity criterion (Case 2) creates a more even basis for optimization, which leads to a higher overall output and a more even distribution of the workload across the workstations. Balancing by assembly time (Case 1), on the other hand, led to greater load differences between workstations and to smaller total production quantities after optimization. This confirms the importance of carefully defining the initial solution in the optimization process, especially in a human-centric context.

4. Discussion

In this study, a new complexity index is proposed that integrates the objective structural complexity of the product and the subjectively perceived workload of the operator. The aim of the index defined in this way was to quantify the contribution of a single work element to the overall perceived workload of the worker during assembly in the context of the structure and requirements of the product. This enables a better understanding of the influence of product design features and assembly requirements on working conditions, process duration, and overall productivity. The proposed index was implemented in the optimization model through linear programming, which allows a compromise solution to be found between two often-conflicting objectives: maximizing output and minimizing complexity. For the initial balancing of the assembly line, two different approaches were observed and used as input for the optimization process through linear programming. In the first case, the balancing was based on the assembly times of the individual work elements. In the second case, the balancing was based on the proposed integrated index. These two approaches allowed a comparative analysis of the impact of the initial balancing on the final result of the optimization, highlighting the importance of the human factor in achieving balanced and efficient production solutions.

The results of the analysis show that a complexity-based approach to balance can lead to a more even distribution of workload across workstations and an increase in the number of units produced compared to an approach based solely on assembly times. Such an approach strongly supports the fundamental postulates of Industry 5.0, which shifts the focus from exclusively technological efficiency (Industry 4.0) to people, sustainability, and resilience. This paper thus provides empirical confirmation of the theoretical positions of authors such as Kinzel [37], who emphasize the need to include human needs in the design of production systems and warn that neglecting them leads to worker frustration and exclusion. By appreciating complexity from the operator’s point of view, this model simultaneously improves working conditions and contributes to higher productivity.

The main contribution of this paper is the development and implementation of an integrated complexity index that combines both aspects of complexity in a single index. In contrast to previous research that focused exclusively on objective [10,19,22,23] or subjective [21,34] complexity, this approach closes this gap by providing a holistic assessment that encompasses both the technical and human dimensions of assembly. This enables a comprehensive quantification of the contribution of each work element to the operator’s perceived workload. The proposed model recognizes the operator as a central element of the production system and incorporates dimensions such as mental and physical demands, effort, frustration, and self-assessment of performance. The paper thus goes beyond traditional Industry 4.0 approaches, which have only focused on technical efficiency, and contributes to the development of systems that put people at the center. By incorporating the index into the optimization model for assembly line balancing through linear programming, the research demonstrates not only its conceptual novelty but also its potential practical utility.

Although the case study in this paper is performed on a relatively simple example of a Lego assembly, the proposed methodology is much more broadly applicable, as it is based on the structural complexity model presented by Alkan et al. [10]. This model results from the adaptation of Hückel’s orbital theory to the engineering domain and can be applied to determine the complexity of any networked engineering system, regardless of the number of elements. This is also confirmed by studies in which the same approach was applied to complex industrial systems with several hundred components, such as train chassis [24] or families of electronic boards [23].

It is important to emphasize that in this study, for methodological and practical reasons, the relationship between objective complexity and perceived workload was analyzed for a small sample. The results indicate a preliminary increasing trend between the two observed values. This observation is consistent with the findings of the [34], which reported that such a correspondence (increasing trend) between perceived and objective complexity can be observed in small samples. However, other studies (e.g., [20,21]) indicate a super-linear relationship with a “stagnation point” where operators no longer perceive a further increase in complexity. This difference opens up areas for further research that could model the relationship between objective and perceived complexity more accurately with larger samples and other conditions.

In summary, the proposed model and approach represent an important contribution to the development of advanced strategies for the planning and optimization of assembly processes. They form the basis for productive, sustainable, and human-centered systems, thus supporting the transition to Industry 5.0. Optimization that incorporates the human dimension of assembly processes becomes an important step in creating work environments that do not neglect operators but recognize them as active participants in the process of designing, planning, and continuously improving production systems.

Author Contributions

Conceptualization, A.A.M. and M.C.Ž.; methodology, A.A.M.; validation, M.C.Ž. and N.G.; formal analysis, A.A.M. and N.B.; investigation, A.A.M. and M.C.Ž.; resources, N.G. and A.A.M.; writing—original draft preparation, A.A.M.; writing—review and editing, N.G. and N.B.; visualization, N.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

Author Nikola Banduka was employed by the company DigitaLLeather LLC. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Myrodia, A.; Hvam, L.; Sandrin, E.; Forza, C.; Haug, A. Identifying variety-induced complexity cost factors in manufacturing companies and their impact on product profitability. J. Manuf. Syst. 2021, 60, 373–391. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0, Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Briken, K.; Moore, J.; Scholarios, D.; Rose, E.; Sherlock, A. Industry 5 and the Human in Human-Centric Manufacturing. Sensors 2023, 23, 6416. [Google Scholar] [CrossRef]

- Moraes, A.; Carvalho, A.M.; Sampaio, P. Lean and Industry 4.0: A Review of the Relationship, Its Limitations, and the Path Ahead with Industry 5.0. Machines 2023, 11, 443. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human–robot collaborative assembly. CIRP Annals 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Brolin, A.; Thorvald, P.; Case, K. Experimental study of cognitive aspects affecting human performance in manual assembly. Prod. Manuf. Res. 2017, 5, 141–163. [Google Scholar] [CrossRef]

- Ozdemir, R.; Sarigol, I.; AlMutairi, S.; AlMeea, S.; Murad, A.; Naqi, A.; AlNasser, N. Fuzzy multi-objective model for assembly line balancing with ergonomic risks consideration. Int. J. Prod. Econ. 2021, 239, 108188. [Google Scholar] [CrossRef]

- Calzavara, M.; Battini, D.; Bogataj, D.; Sgarbossa, F.; Zennaro, I. Ageing workforce management in manufacturing systems: State of the art and future research agenda. Int. J. Prod. Res. 2020, 58, 729–747. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, P.; Yin, Y.; Shih, A.; Wang, L. Toward human-centric smart manufacturing: A human-cyber-physical systems (HCPS) perspective. J. Manuf. Syst. 2022, 63, 417–490. [Google Scholar] [CrossRef]

- Alkan, B.; Vera, D.; Ahmad, B.; Harrison, R. A Method to Assess Assembly Complexity of Industrial Products in Early Design Phase. IEEE Access 2017, 6, 989–999. [Google Scholar] [CrossRef]

- Modrak, V.; Soltysova, Z. Novel complexity indicator of manufacturing process chains and its relations to indirect complexity indicators. Complexity 2017, 2017, 9102824. [Google Scholar] [CrossRef]

- Zhu, X.; Hu, S.J.; Koren, Y.; Marin, S.P. Modeling of manufacturing complexity in mixed-model assembly lines. J. Manuf. Sci. Eng. Trans. ASME 2008, 130, 051013. [Google Scholar] [CrossRef]

- Hu, S.J.; Zhu, X.; Wang, H.; Koren, Y. Product variety and manufacturing complexity in assembly systems and supply chains. CIRP Ann.-Manuf. Technol. 2008, 57, 45–48. [Google Scholar] [CrossRef]

- Wang, H.; Hu, S.J. Manufacturing complexity in assembly systems with hybrid configurations and its impact on throughput. CIRP Ann.-Manuf. Technol. 2010, 59, 53–56. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, X.; Wang, H.; Hu, S.J.; Lin, Z.; Chen, G. Multi-objective optimization of product variety and manufacturing complexity in mixed-model assembly systems. J. Manuf. Syst. 2011, 30, 16–27. [Google Scholar] [CrossRef]

- Busogi, M.; Ransikarbum, K.; Oh, Y.G.; Kim, N. Computational modelling of manufacturing choice complexity in a mixed-model assembly line. Int. J. Prod. Res. 2017, 55, 5976–5990. [Google Scholar] [CrossRef]

- Park, K.; Okudan Kremer, G.E. Assessment of static complexity in design and manufacturing of a product family and its impact on manufacturing performance. Int. J. Prod. Econ. 2015, 169, 215–232. [Google Scholar] [CrossRef]

- Zeltzer, L.; Aghezzaf, E.H.; Limère, V. Workload balancing and manufacturing complexity levelling in mixed-model assembly lines. Int. J. Prod. Res. 2017, 55, 2829–2844. [Google Scholar] [CrossRef]

- Samy, S.N.; Elmaraghy, H. A model for measuring products assembly complexity. Int. J. Comput. Integr. Manuf. 2010, 23, 1015–1027. [Google Scholar] [CrossRef]

- Alkan, B. An experimental investigation on the relationship between perceived assembly complexity and product design complexity. Int. J. Interact. Des. Manuf. 2019, 13, 1145–1157. [Google Scholar] [CrossRef]

- Verna, E.; Genta, G.; Galetto, M. A new approach for evaluating experienced assembly complexity based on Multi Expert-Multi Criteria Decision Making method. Res. Eng. Des. 2023, 34, 301–325. [Google Scholar] [CrossRef]

- Verna, E.; Genta, G.; Galetto, M.; Franceschini, F. Defect prediction for assembled products: A novel model based on the structural complexity paradigm. Int. J. Adv. Manuf. Technol. 2022, 120, 3405–3426. [Google Scholar] [CrossRef]

- Puttero, S.; Verna, E.; Genta, G.; Galetto, M. Impact of product family complexity on process performance in electronic component assembly. Int. J. Adv. Manuf. Technol. 2024, 132, 2907–2922. [Google Scholar] [CrossRef]

- Kim, G.; Kwon, Y.; Suh, E.S.; Ahn, J. Analysis of Architectural Complexity for Product Family and Platform. J. Mech. Des. 2016, 138, 071401. [Google Scholar] [CrossRef]

- Sinha, K.; Suh, E.S. Pareto-optimization of complex system architecture for structural complexity and modularity. Res. Eng. Des. 2018, 29, 123–141. [Google Scholar] [CrossRef]

- Sancı, E.; Azizoğlu, M. Rebalancing the assembly lines: Exact solution approaches. Int. J. Prod. Res. 2017, 55, 5991–6010. [Google Scholar] [CrossRef]

- Boysen, N.; Schulze, P.; Scholl, A. Assembly line balancing: What happened in the last fifteen years? Eur. J. Oper. Res. 2022, 301, 797–814. [Google Scholar] [CrossRef]

- Ghorbani, E.; Keivanpour, S.; Sekkay, F.; Imbeau, D. Ergonomic Assembly Line Balancing Problems Evolution and Future Trends with Insights into Industry 5.0 Paradigm; Bureau de Montreal, Université de Montreal: Montreal, QC, Canada, 2023. [Google Scholar]

- Verna, E.; Genta, G.; Galetto, M. Effects of product complexity on human learning in assembly and disassembly operations. J. Manuf. Technol. Manag. 2023, 34, 139–162. [Google Scholar] [CrossRef]

- Trattner, A.; Hvam, L.; Forza, C.; Herbert-Hansen, Z.N.L. Product complexity and operational performance: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2019, 25, 69–83. [Google Scholar] [CrossRef]

- Zeltzer, L.; Limère, V.; Van Landeghem, H.; Aghezzaf, E.H.; Stahre, J. Measuring complexity in mixed-model assembly workstations. Int. J. Prod. Res. 2013, 51, 4630–4643. [Google Scholar] [CrossRef]

- Capponi, M.; Mastrogiacomo, L.; Franceschini, F. Empirical comparison of assembly complexity assessment approaches in manufacturing. Int. J. Interact. Des. Manuf. (IJIDeM) 2025, 19, 3219–3243. [Google Scholar] [CrossRef]

- Katiraee, N.; Calzavara, M.; Finco, S.; Battaïa, O.; Battini, D. Assembly line balancing and worker assignment considering workers’ expertise and perceived physical effort. Int. J. Prod. Res. 2023, 61, 6939–6959. [Google Scholar] [CrossRef]

- Capponi, M.; Gervasi, R.; Mastrogiacomo, L.; Gervasi, R.; Mastrogiacomo, L. Assessing perceived assembly complexity in human-robot collaboration processes: A proposal based on Thurstone’s law of comparative judgement. Int. J. Prod. Res. 2024, 62, 5315–5335. [Google Scholar] [CrossRef]

- Liu, X.; Lei, M.; Zeng, Q.; Li, A. Integrated optimization of mixed-model assembly line balancing and buffer allocation based on operation time complexity. Procedia CIRP 2019, 81, 1040–1045. [Google Scholar] [CrossRef]

- Liu, X.; Yang, X.; Lei, M. Optimisation of mixed-model assembly line balancing problem under uncertain demand. J. Manuf. Syst. 2021, 59, 214–227. [Google Scholar] [CrossRef]

- Kinzel, H. Industry 4.0-Where Does This Leave the Human Factor? J. Urban Cult. Res. 2017, 15, 70–83. [Google Scholar] [CrossRef]

- Chan, V.; Salustri, F.A. DFA: The Lucas Method. Available online: https://ebrary.net/191720/business_finance/lucas_evaluation_method (accessed on 29 January 2020).

- Arana-De las Casas, N.I.; Maldonado-Macías, A.A.; De La Riva-Rodríguez, J.; Sáenz-Zamarrón, D.; Alatorre-Ávila, J.F.; García-Grajeda, E. Mental Workload Management and Evaluation: A Literature Review for Sustainable Processes and Organizations. In New Perspectives on Applied Industrial Ergonomics; Springer: Berlin/Heidelberg, Germany, 2021; pp. 55–78. [Google Scholar]

- Hart, S.G.; Staveland, L.E. Development of NASA-TLX (Task Load Index): Results of Empirical and Theoretical Research. Adv. Psychol. 1988, 52, 139–183. [Google Scholar] [CrossRef]

- Gervasi, R.; Capponi, M.; Mastrogiacomo, L.; Franceschini, F. Manual assembly and Human–Robot Collaboration in repetitive assembly processes: A structured comparison based on human-centered performances. Int. J. Adv. Manuf. Technol. 2023, 126, 1213–1231. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).