Coordinated Motion Pattern of Dual Forging Manipulators Based on Forging Deformation Behavior and Press Kinematics

Abstract

1. Introduction

2. Materials and Methods

2.1. Analysis of Compliance Motion Requirements for Dual-Manipulator Forging Systems

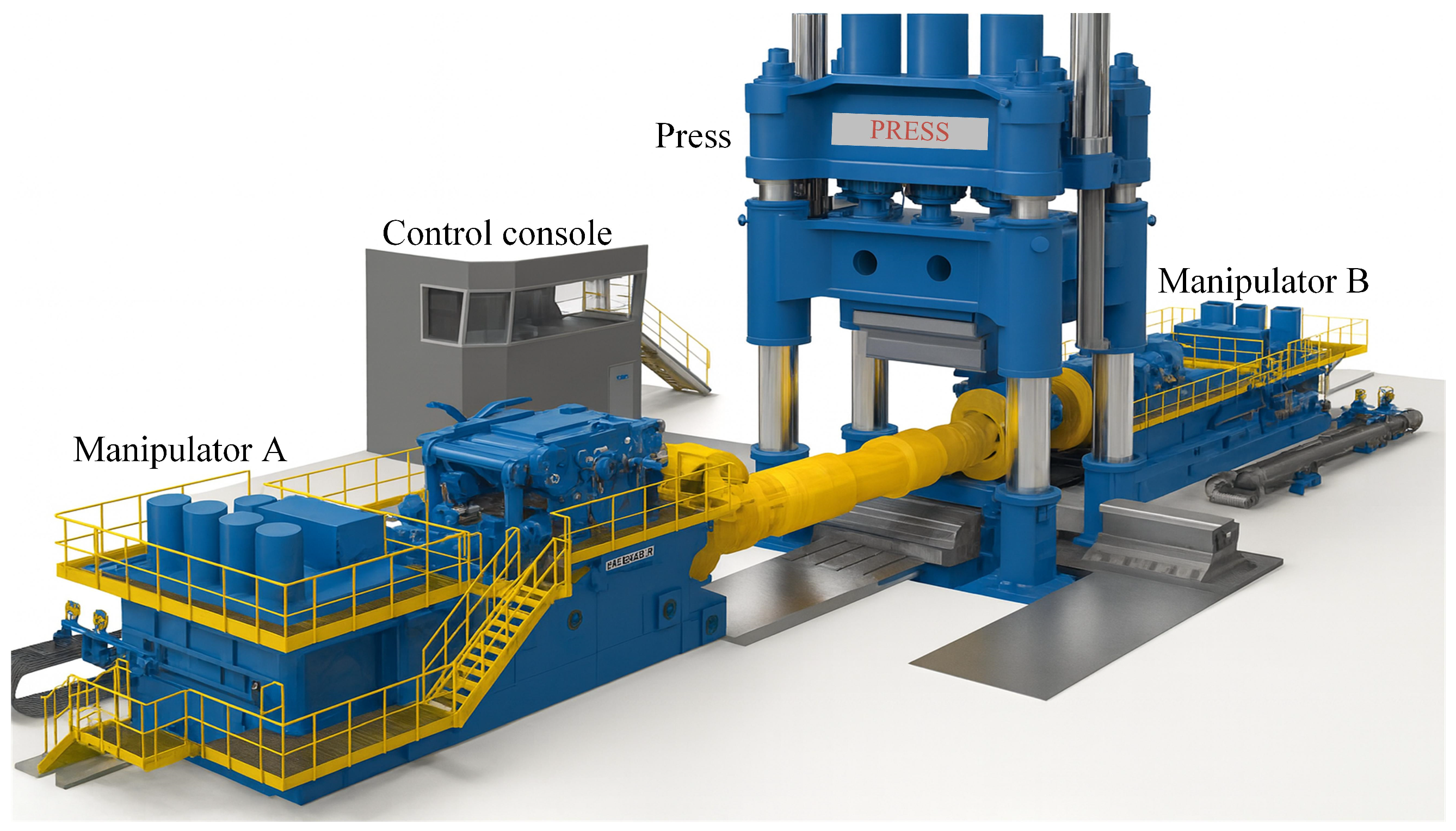

2.1.1. Structural Composition of the Dual-Manipulator Forging System

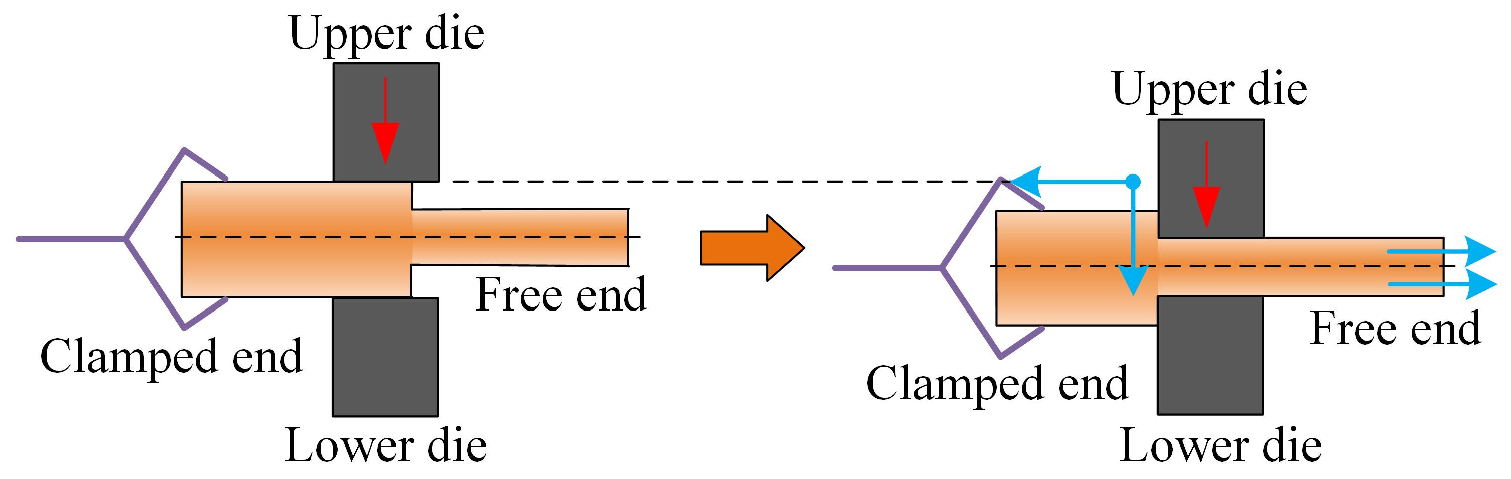

2.1.2. Compliance Modes of the Manipulator

2.2. Classification and Deformation Simulation of Forged Components

2.2.1. Classification of Typical Large Long-Shaft Forgings

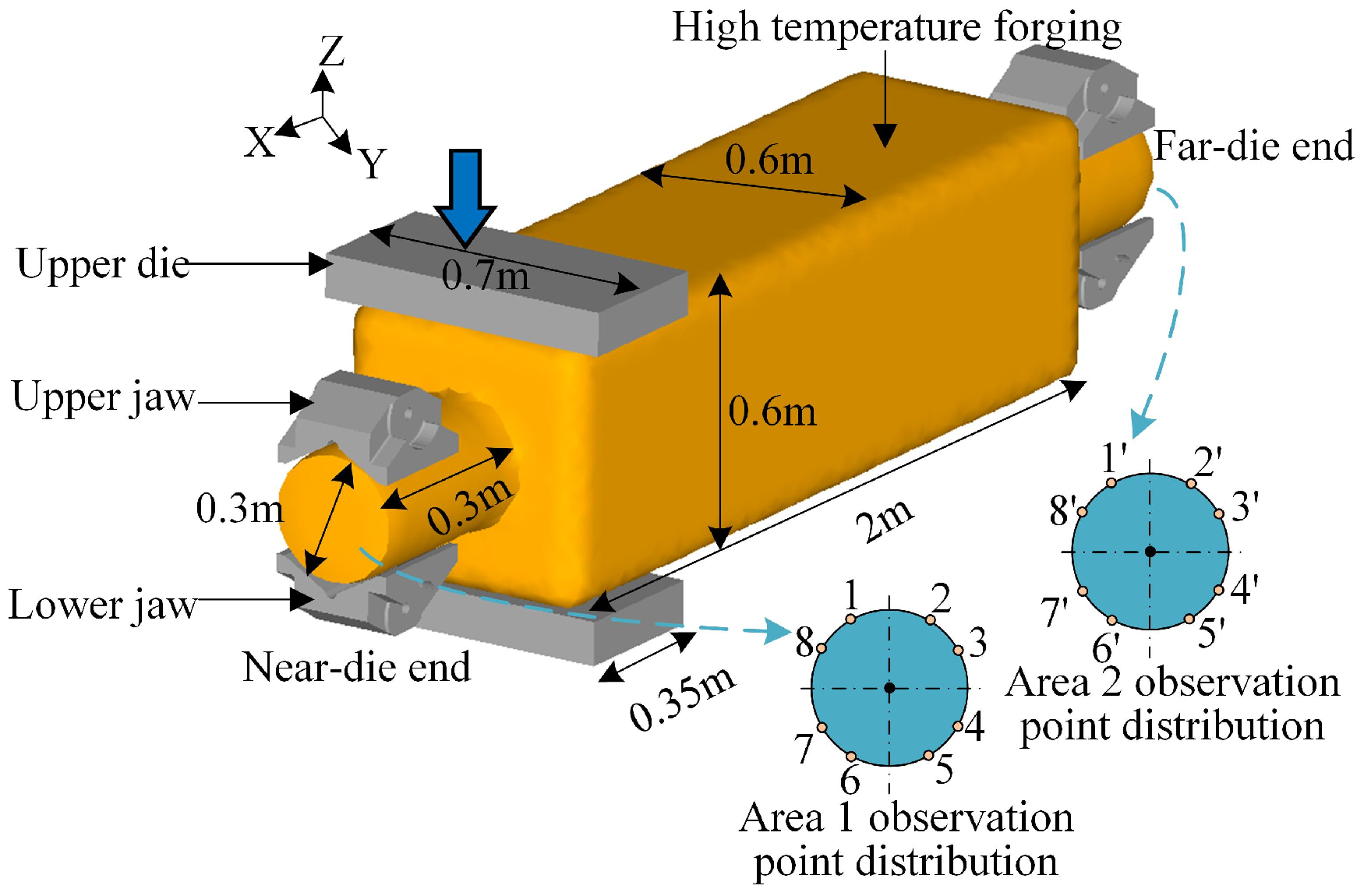

2.2.2. Finite Element Model

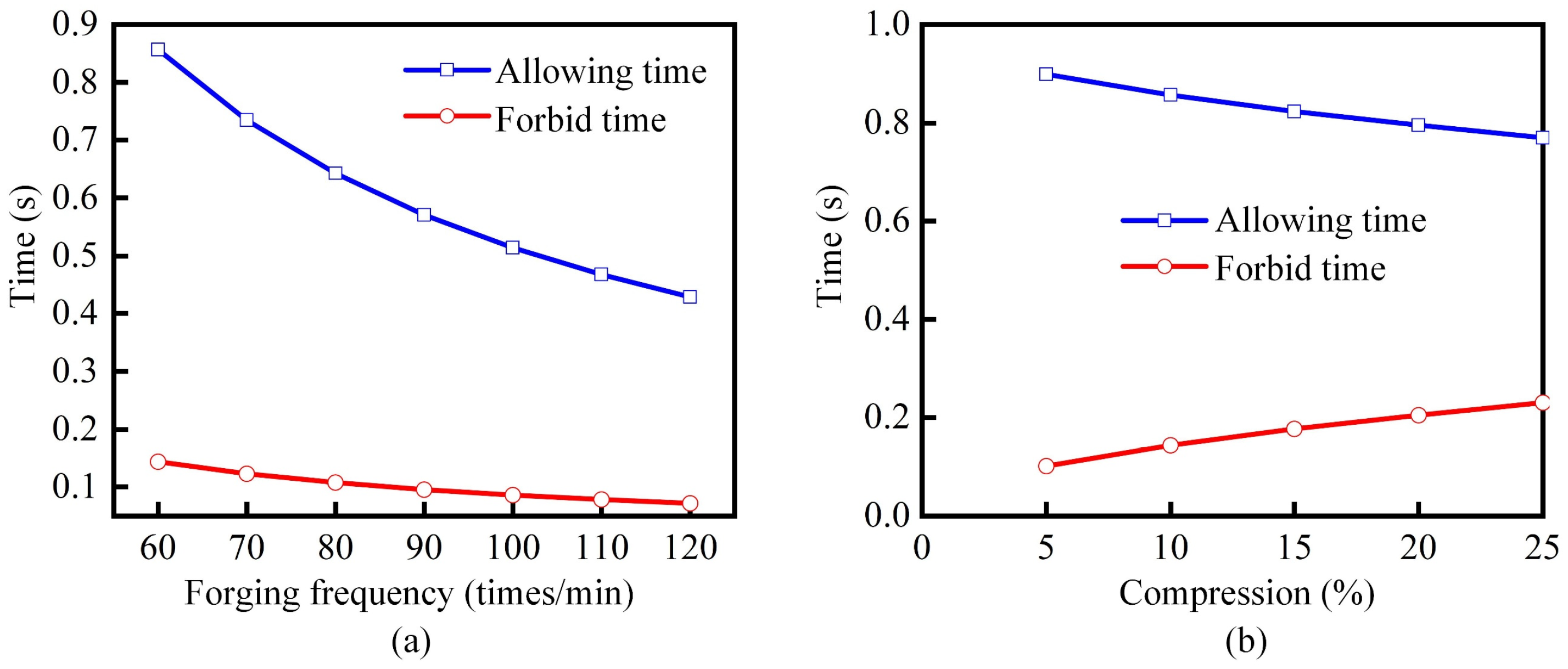

2.3. Calculation of Manipulator Motion Time

3. Results

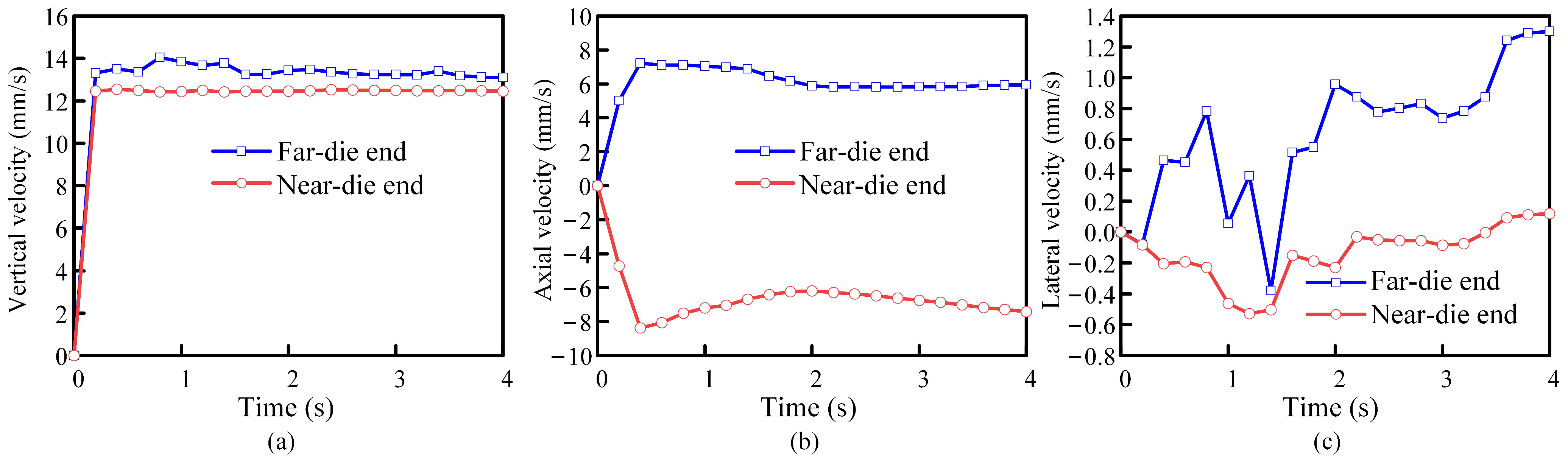

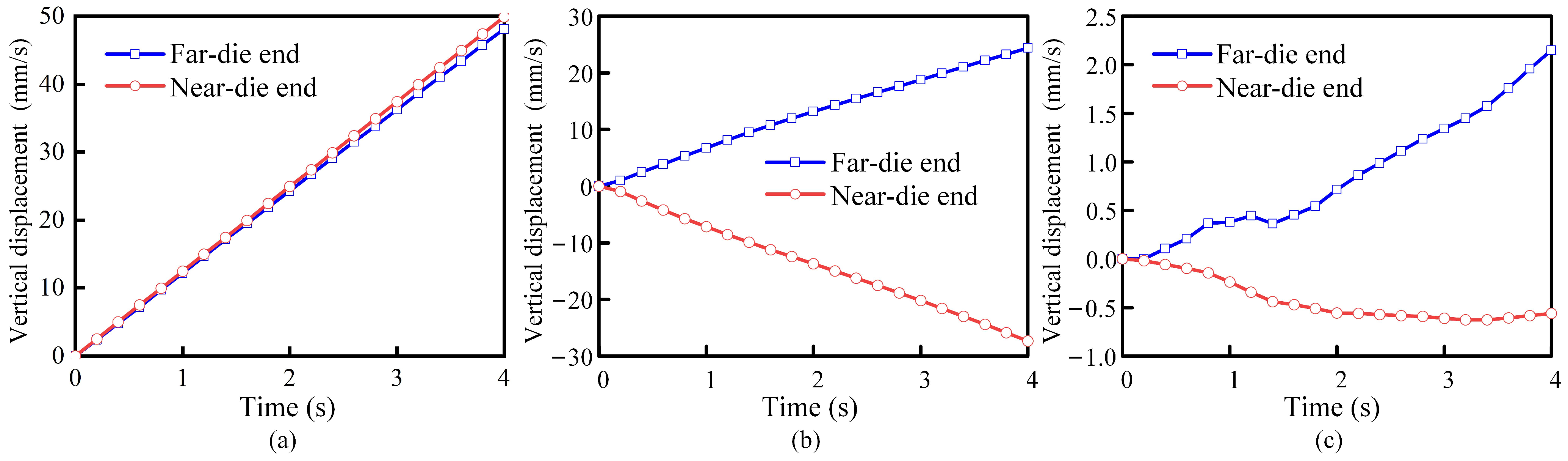

3.1. Forging Deformation Velocity and Displacement

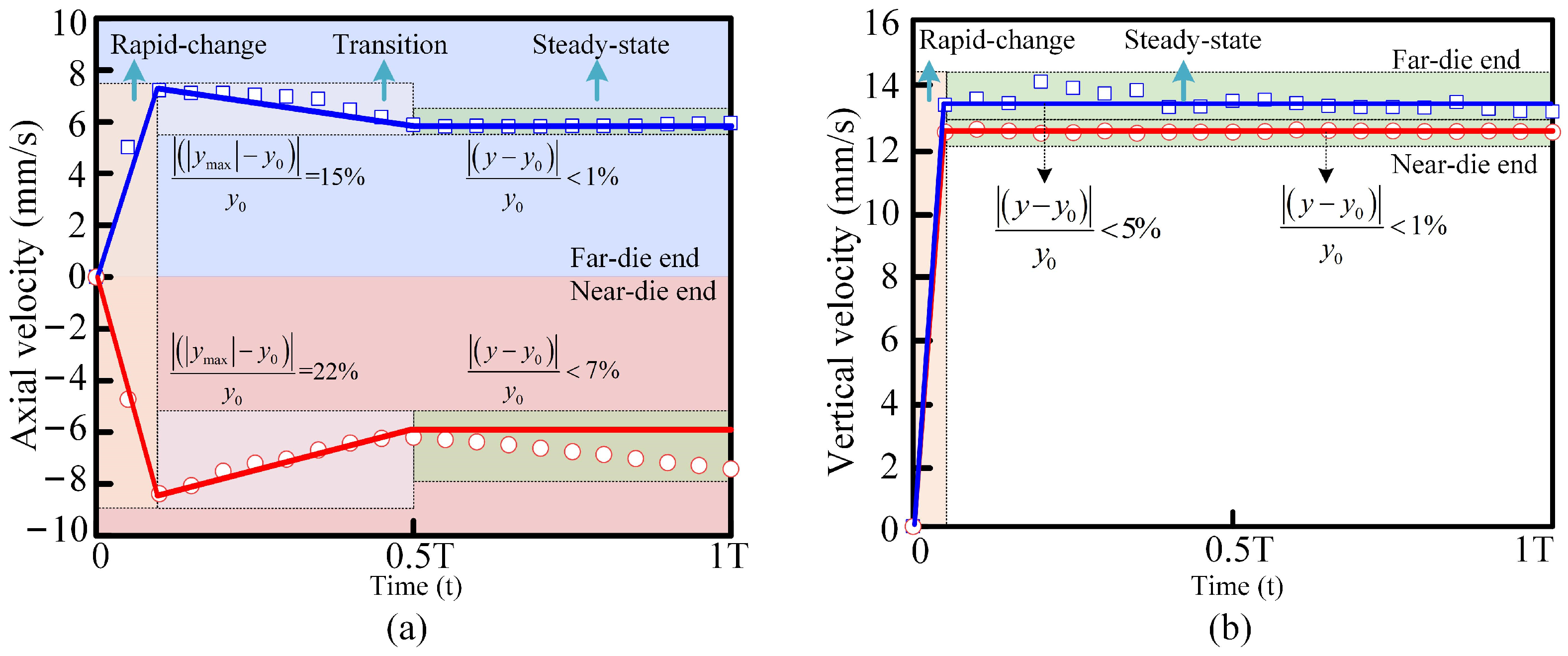

3.2. Compliant Motion of Manipulators

- (1)

- Axial Compliant Velocity

- (2)

- Vertical Compliant Velocity

- (3)

- Axial Compliant Displacement

- (4)

- Vertical Compliant Displacement

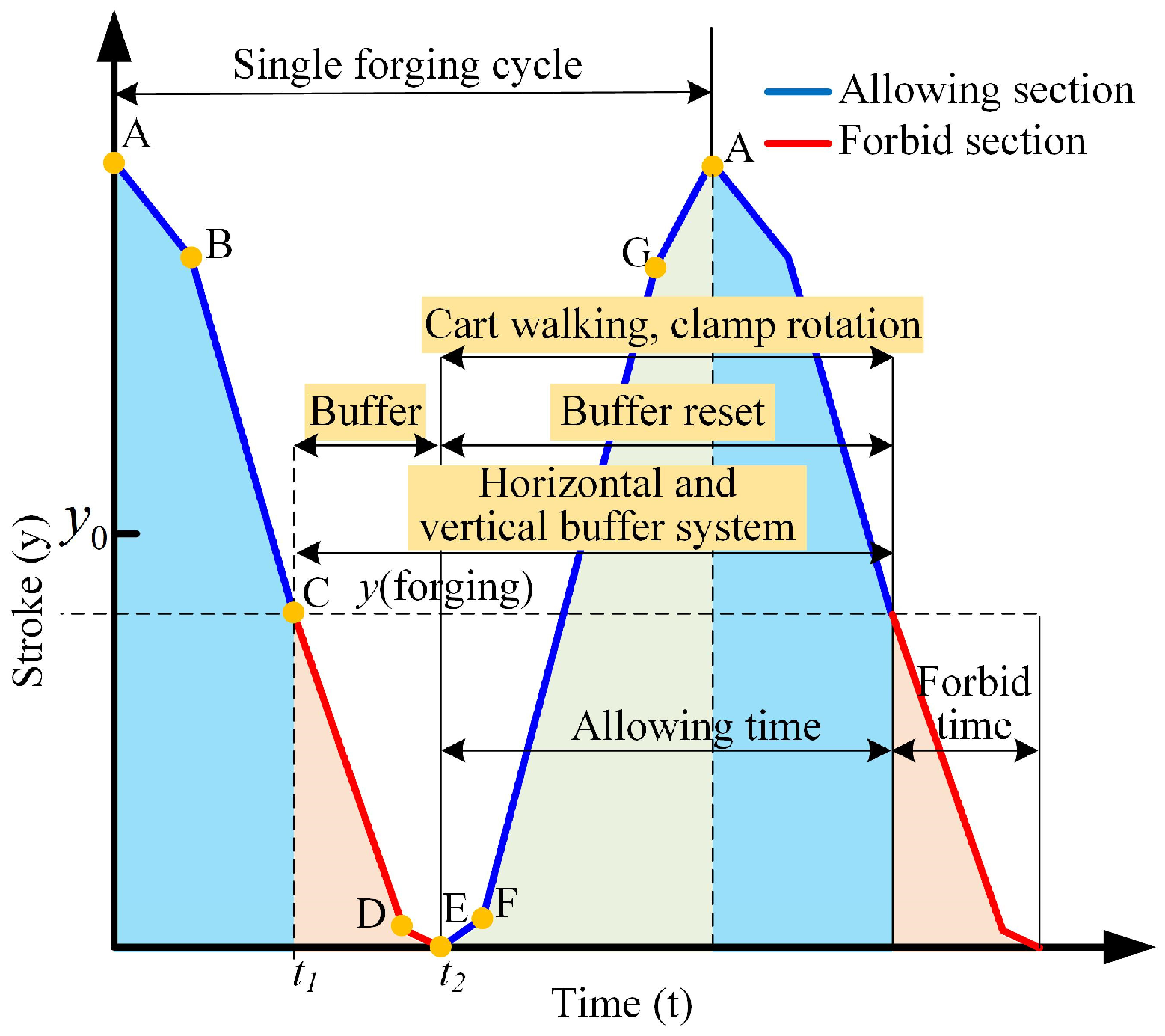

3.3. Manipulator Motion Planning

3.4. Dynamic Characterization Test of Dual-Manipulator Forging System

3.4.1. Test Bench Configuration

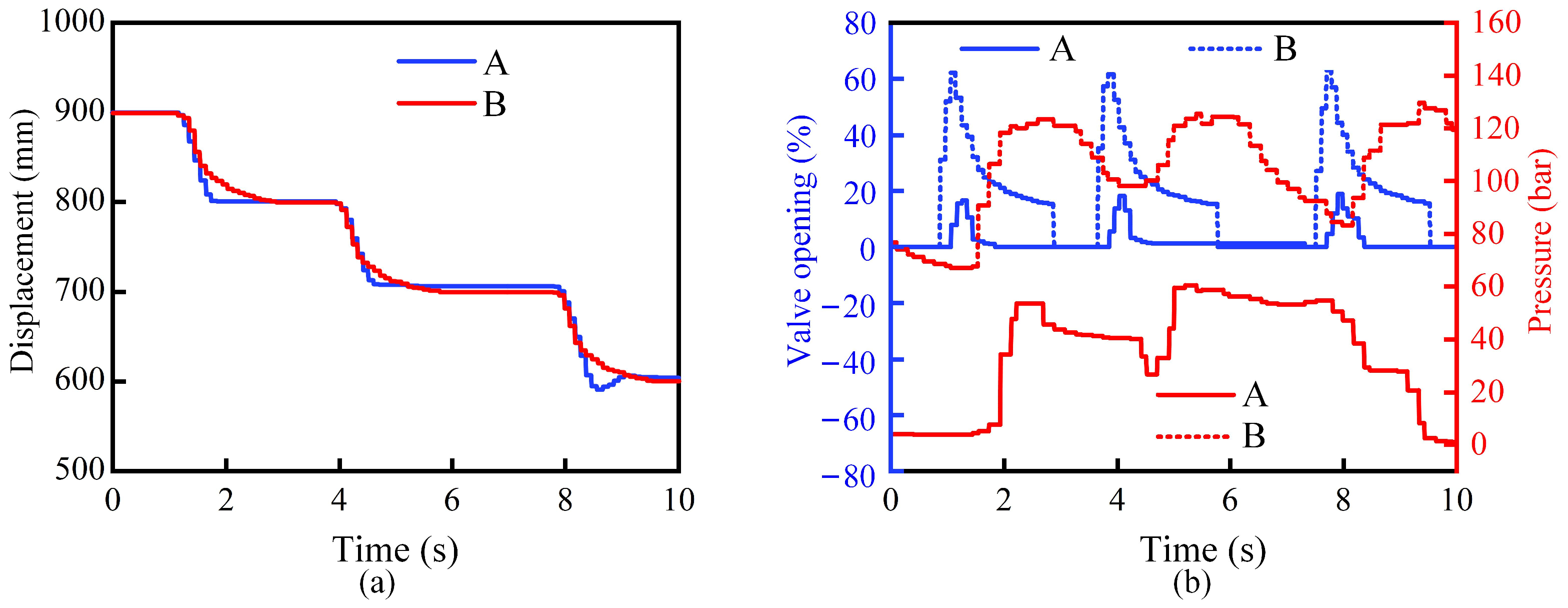

3.4.2. Synchronized Trolley Feed Test of Dual Manipulators

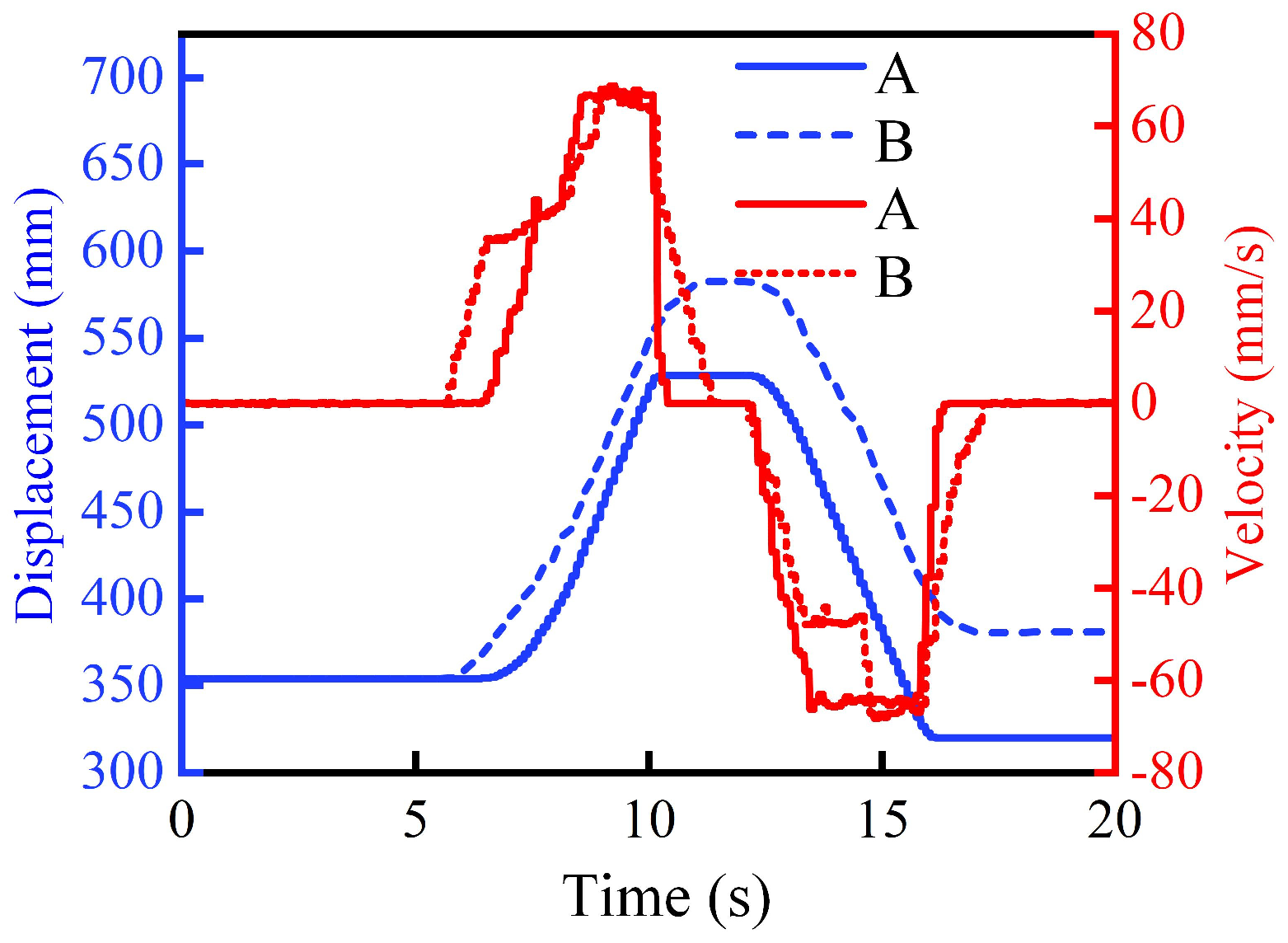

3.4.3. Synchronized Lifting and Gripper Rotation Tests of Dual Manipulators

3.5. Operational Mode of Dual Forging Manipulators

- (1)

- Pre-Forging Adjustment Stage

- (2)

- Inter-Pass Compliance Stage

- (3)

- Execution Stage

- (4)

- Forging Completion Stage

4. Conclusions

- (1)

- Based on industry requirements and the characteristics of the forging process, the properties of typical shaft-type forgings were systematically classified. Six representative material models were developed by considering key parameters such as Young’s modulus, Poisson’s ratio, and forging temperature. Finite element simulations using DEFORM-3D (V11.0) were performed to analyze the deformation behaviors at both ends of the forgings under single-stroke loading. From these simulations, characteristic velocity and displacement profiles were extracted, along with their response relationships to key press parameters for each material.

- (2)

- A three-phase segmentation method was proposed to describe the end-deformation velocity curves of the forgings, consisting of a rapid-change zone, a transition zone, and a steady-state zone. By coupling these deformation characteristics with press motion parameters, a compliant motion demand model for dual forging manipulators was established. This model lays the theoretical foundation for accurate motion profile planning and velocity control of the manipulators.

- (3)

- A segmented timing model was developed based on the downward stroke profile of the press, enabling the reconstruction and optimization of the manipulators’ allowable motion windows. Under typical forging conditions (5% press stroke depth with forging frequencies of 60 and 30 strokes per minute), the allowable motion time was improved by 112.5% and 42.85%, respectively, demonstrating the method’s effectiveness in enhancing the timing coordination between the press and manipulators.

- (4)

- Experimental validation was performed on a dual-manipulator system to evaluate its dynamic response and confirm the feasibility of the compliant motion strategy. By analyzing the sequence, timing, and functional phases of manipulator actions, a four-phase coordinated motion pattern—pre-forging adjustment, inter-pass compliance, execution phase, and forging completion—was summarized. This framework provides not only a practical reference for the coordinated control of dual manipulators but also a theoretical basis for advancing intelligent, high-precision forging operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Sun, W.; Liu, D. Investigation of the dynamic bending moment transmitted to the forging manipulator due to press motion. J. Mech. Sci. Technol. 2013, 27, 2435–2443. [Google Scholar] [CrossRef]

- He, X. Effects of manipulator compliant movements on the quality of free forgings based on FEM simulation. Int. J. Adv. Manuf. Technol. 2011, 56, 905–913. [Google Scholar] [CrossRef]

- Ding, W.H.; Deng, H.; Zhang, Y.; Ren, Y.Q. Optimum design of the jaw clamping mechanism of forging manipulators based on force transmissibility. Appl. Mech. Mater. 2012, 157, 737–742. [Google Scholar] [CrossRef]

- Cao, X.; Yao, J.; Sha, T.; Song, Y. Pressure-Relief Impact Control of Open Circuit Hydraulic Pump-Controlled Forging Press System. Processes 2019, 7, 638. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, W.; Deng, H. Reduced dynamic modeling for heavy-duty hydraulic manipulators with multi-closed-loop mechanisms. IEEE Access 2020, 8, 101708–101720. [Google Scholar] [CrossRef]

- He, Z.; Zhai, F.; Xing, Y.; Wang, X.; Zhao, R.; Chang, R. Research on the perception capability and characteristics based on the full-attitude indirect sensing model of forging force. Mech. Based Des. Struct. Mach. 2025, 53, 5513–5533. [Google Scholar] [CrossRef]

- Xing, Y.; Zhai, F.; He, Z.; Wang, X.; Zhao, R. Enhanced Force Sensing Method Using BP Neural Network and Sensitive Point Analysis for Forging Manipulator Clamping Mechanism in Operational Conditions. Machines 2025, 13, 226. [Google Scholar] [CrossRef]

- Wang, G.; Li, X.; Ding, M.; Chen, W.; Tian, C.; Gu, G.; Lu, Y. Study on deformation uniformity of mandrel forging process and control measures of inner hole eccentricity. J. Manuf. Process. 2020, 58, 75–91. [Google Scholar] [CrossRef]

- Cai, J.; Guo, M.; Peng, P.; Han, P.; Yang, X.; Ding, B.; Qiao, K.; Wang, K.; Wang, W. Research on hot deformation behavior of as-Forged TC17 titanium alloy. J. Mater. Eng. Perform. 2021, 30, 7259–7274. [Google Scholar] [CrossRef]

- Rahul, M.R.; Samal, S.; Venugopal, S.; Phanikumar, G. Experimental and finite element simulation studies on hot deformation behaviour of AlCoCrFeNi2. 1 eutectic high entropy alloy. J. Alloys Compd. 2018, 749, 1115–1127. [Google Scholar] [CrossRef]

- Yan, C.; Gao, F.; Guo, W. Coordinated kinematic modelling for motion planning of heavy-duty manipulators in an integrated open-die forging centre. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 1299–1313. [Google Scholar] [CrossRef]

- Pinto, B.A.M.B. Polylactic Acid-Based Stent Manufacturing Using Fused Deposition Modeling from a Biomedical Perspective. Master’s Thesis, Universidade do Porto, Porto, Portugal, 2019. [Google Scholar]

- Şimşir, C.; Duran, D. A flow stress model for steel in cold forging process range and the associated method for parameter identification. Int. J. Adv. Manuf. Technol. 2018, 94, 3795–3808. [Google Scholar] [CrossRef]

- Sciavicco, L.; Siciliano, B. Modelling and Control of Robot Manipulators; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Yao, J.; Li, Y.; Zhai, F.; Zhu, H.; Zhang, Y. Energy Dissipation Analysis of Forging Manipulator Hydraulic Systems in Stretching Processes. China Mech. Eng. 2019, 30, 385–392. [Google Scholar]

- Gaikwad, S.D.; Dabhade, V.V.; Murty, S.N.; Manwatkar, S. Mechanical properties and deformation mechanism at elevated temperatures of IN718 superalloy processed by powder forging. Mater. Sci. Eng. A 2025, 924, 147803. [Google Scholar] [CrossRef]

- Fang, X.; Liu, H.; Liu, J.; Li, H.; Yang, F. Dynamic design and application on Ti-6Al-4V of novel hybrid forging system. J. Mech. Sci. Technol. 2025, 39, 201–212. [Google Scholar] [CrossRef]

- Zhao, Q.; Wu, G.; Sha, W. Deformation of titanium alloy Ti–6Al–4V under dynamic compression. Comput. Mater. Sci. 2010, 50, 516–526. [Google Scholar] [CrossRef]

- Prabhu, T.R. Modelling studies on effects of deformation speed, preform shape, and upset ratio on the forging characteristics of the aerospace structural Al alloys. Int. J. Mater. Prod. Technol. 2017, 54, 291–305. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, L.; Ma, H.; Lu, G. Superimposed liquid supply energy-saving technology on fast forging hydraulic press. Forg. Technol. 2023, 48, 199–203. [Google Scholar]

- Ma, Q.; Lin, Z.Q.; Yu, Z.Q. Prediction of deformation behavior and microstructure evolution in heavy forging by FEM. Int. J. Adv. Manuf. Technol. 2009, 40, 253–260. [Google Scholar] [CrossRef]

| Application Fields | Materials | Application Range | Young’s Modulus (GPa) | Poisson’s Ratio | Forging Temperature (°C) |

|---|---|---|---|---|---|

| Automobiles and heavy machinery | 42CrMo4 | High load | 210 | 0.28 | 900–1100 |

| 42CrMo | High stress | 205 | 0.29 | 900–1150 | |

| 20CrMnTi | Shock load | 200 | 0.27 | 850–950 | |

| Aerospace | 34CrNiMo6 | High strength | 210 | 0.29 | 850–1050 |

| GH4169 | High temperature | 200 | 0.31 | 980–1150 | |

| Ti-6Al-4V | Corrosion resistance | 114 | 0.34 | 930–980 | |

| Energy and chemical industry | 15CrMo | High temperature and high pressure | 206 | 0.3 | 900–1050 |

| GH4169 | High-temperature corrosion resistance | 200 | 0.31 | 980–1150 | |

| General machinery | 45 steel | Moderate load | 200 | 0.29 | 800–1050 |

| Medical devices | Ti-6Al-4V | Corrosion resistance | 114 | 0.34 | 930–980 |

| High | Middle | Low | |

|---|---|---|---|

| Temperature (°C) | 800–900 | 850–1000 | 1000–1150 |

| Young’s modulus (Gpa) | 200–210 | 150 | 100–120 |

| Poisson’s ratio | 0.3–0.34 | 0.28–0.29 | 0.27 |

| Number | Young’s Modulus (GPa) | Poisson’s Ratio | Temperature (°C) | Material |

|---|---|---|---|---|

| 1 | High (210) | Middle (0.28) | Middle (900) | 42CrMo4 |

| 2 | High (210) | High (0.31) | High (1100) | GH4169 |

| 3 | Middle (150) | Middle (0.29) | Middle (900) | 42CrMo |

| 4 | Middle (150) | Low (0.27) | Middle (850) | 20CrMnTi |

| 5 | Low (120) | High (0.34) | Middle (950) | Ti-6Al-4V |

| 6 | Low (120) | Middle (0.28) | Low (800) | 45 steel |

| Number | Direction | Near-Die End Velocity | Far-Die End Velocity | Near-Die End Displacement | Far-Die End Displacement | Near-Die End Maximum Velocity | Far-Die End Maximum Velocity |

|---|---|---|---|---|---|---|---|

| 1 | Horizontal | 28.77 | 27.91 | 26.64 | 29.76 | 35.21 | 27.63 |

| Vertical | 49.35 | 47.40 | 49.83 | 53.59 | —— | —— | |

| 2 | Horizontal | 28.85 | 25.13 | 26.71 | 26.63 | 33.55 | 29.56 |

| Vertical | 50.00 | 53.52 | 49.93 | 53.88 | —— | —— | |

| 3 | Horizontal | 28.77 | 24.94 | 26.86 | 27.08 | 37.22 | 30.01 |

| Vertical | 49.80 | 51.70 | 49.89 | 53.44 | —— | —— | |

| 4 | Horizontal | 28.08 | 26.73 | 23.13 | 28.46 | 31.22 | 28.44 |

| Vertical | 49.70 | 51.30 | 49.93 | 53.86 | —— | —— | |

| 5 | Horizontal | 29.69 | 24.74 | 27.38 | 26.95 | 36.22 | 28.45 |

| Vertical | 49.80 | 52.35 | 49.85 | 53.54 | —— | —— | |

| 6 | Horizontal | 28.49 | 26.12 | 23.26 | 28.09 | 35.66 | 27.98 |

| Vertical | 49.45 | 50.20 | 49.85 | 53.70 | —— | —— |

| Forging Process | Manipulator Action | Motion Time | Press Action |

|---|---|---|---|

| Pre-Forging Adjustment Stage | Pitching, clamp opening and closing clamping, clamp lifting, cart walking | Allowing time | —— |

| Inter-Pass Compliance Stage | Horizontal and vertical buffering | Forbid time | Extrusion forging deformation |

| Execution Stage | Cart walking, clamp rotation, buffer reset | Allowing time | No-load return Accelerated pressing |

| Forging Completion Stage | —— | Allowing time | —— |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Y.; Shi, J.; Chang, R.; Wang, Y.; Han, X.; Wang, Z.; Zhai, F. Coordinated Motion Pattern of Dual Forging Manipulators Based on Forging Deformation Behavior and Press Kinematics. Machines 2025, 13, 816. https://doi.org/10.3390/machines13090816

Xing Y, Shi J, Chang R, Wang Y, Han X, Wang Z, Zhai F. Coordinated Motion Pattern of Dual Forging Manipulators Based on Forging Deformation Behavior and Press Kinematics. Machines. 2025; 13(9):816. https://doi.org/10.3390/machines13090816

Chicago/Turabian StyleXing, Yangtao, Junqiang Shi, Ruihao Chang, Yanzhe Wang, Xuefeng Han, Zhuo Wang, and Fugang Zhai. 2025. "Coordinated Motion Pattern of Dual Forging Manipulators Based on Forging Deformation Behavior and Press Kinematics" Machines 13, no. 9: 816. https://doi.org/10.3390/machines13090816

APA StyleXing, Y., Shi, J., Chang, R., Wang, Y., Han, X., Wang, Z., & Zhai, F. (2025). Coordinated Motion Pattern of Dual Forging Manipulators Based on Forging Deformation Behavior and Press Kinematics. Machines, 13(9), 816. https://doi.org/10.3390/machines13090816