Recent Advances in Fault Detection and Analysis of Synchronous Motors: A Review

Abstract

1. Introduction

1.1. Current Challenges and Research Gap in Existing Literature

1.2. Research Objectives and Main Contributions

1.3. Structure of the Paper

2. Overview of Fault Types in Synchronous Motors

2.1. Classification of Synchronous Motors

2.2. Faults in Synchronous Motors

3. Fault Diagnosis Techniques: A Methodological Classification

3.1. Model-Based Approaches—Theoretical Background

3.2. Data-Driven Approaches (ML/DL)—Theoretical Background

Drawbacks of Data-Driven Methods

- -

- -

- Attention mechanisms and saliency maps embedded in CNNs visualize critical spectral or temporal signatures, making deep models more transparent.

- -

- Federated learning enables collaborative model training across multiple sites without sharing raw data, preserving privacy while enriching training diversity [44].

- -

- Transfer learning adapts pre-trained networks from one motor family to another under scarce-label regimes, slashing annotation costs and accelerating deployment [45].

- -

- Techniques such as model pruning, weight quantization, and knowledge distillation produce compact networks that meet strict latency and memory budgets on embedded drives [46].

- -

- Autoencoder-based schemes learn nominal motor behavior without fault labels, flagging anomalies via reconstruction errors.

- -

- Contrastive learning frameworks build robust feature embeddings that better generalize across unseen operating conditions.

3.3. Hybrid Strategies and Sensor Fusion

3.4. Cross-Domain Approaches: Adapted Acoustic Techniques for Motor Fault Diagnosis

3.5. Comparative Analysis and Summary of Diagnostic Techniques

4. Comparative Analysis of Methods and Technologies

4.1. Model-Based Approaches

4.2. Data-Driven Approaches (ML/DL)

4.3. Hybrid Methods and Techniques

4.4. Cross-Domain Approaches

4.5. Semi-Quantitative Synthesis of Performance Metrics

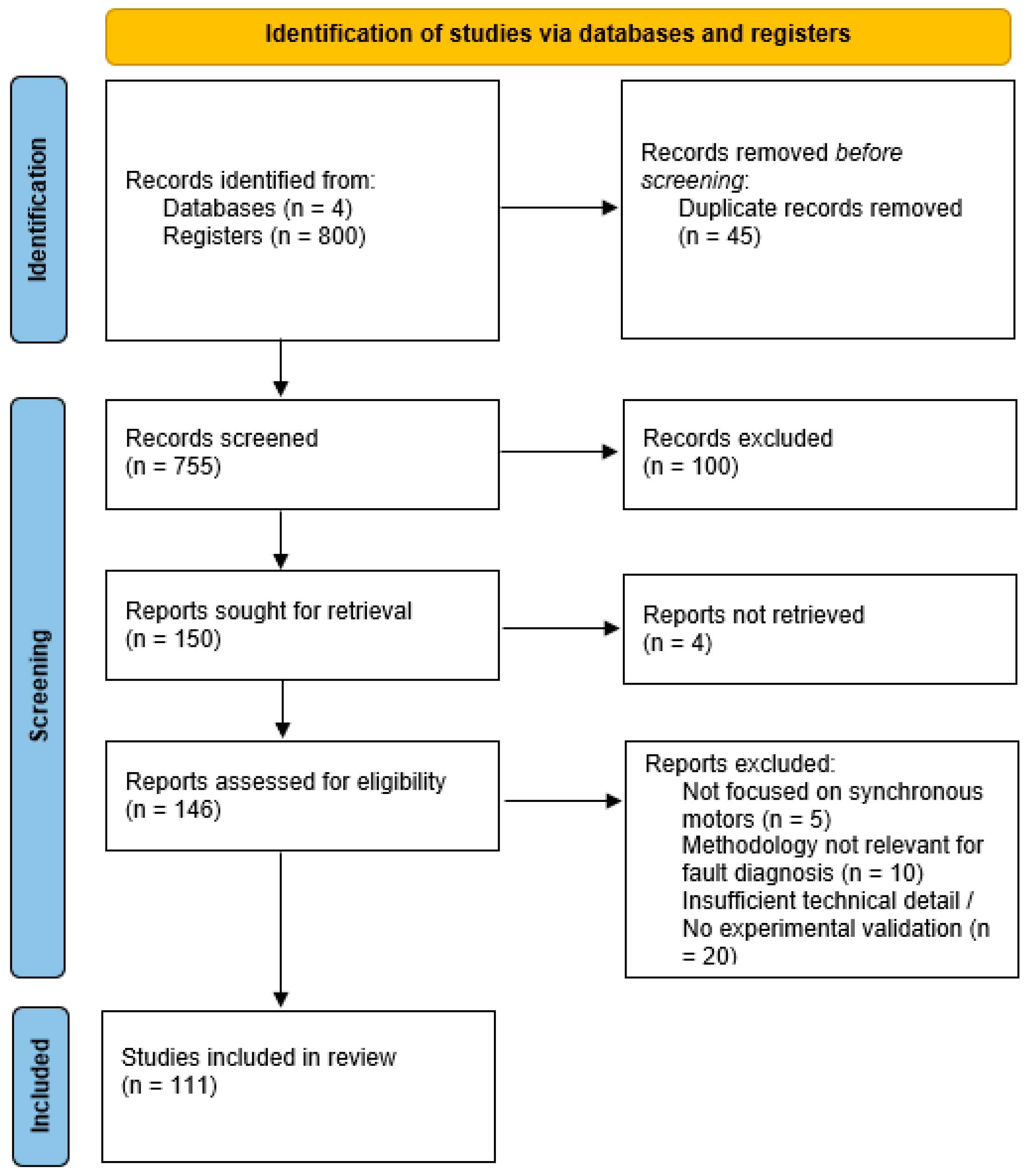

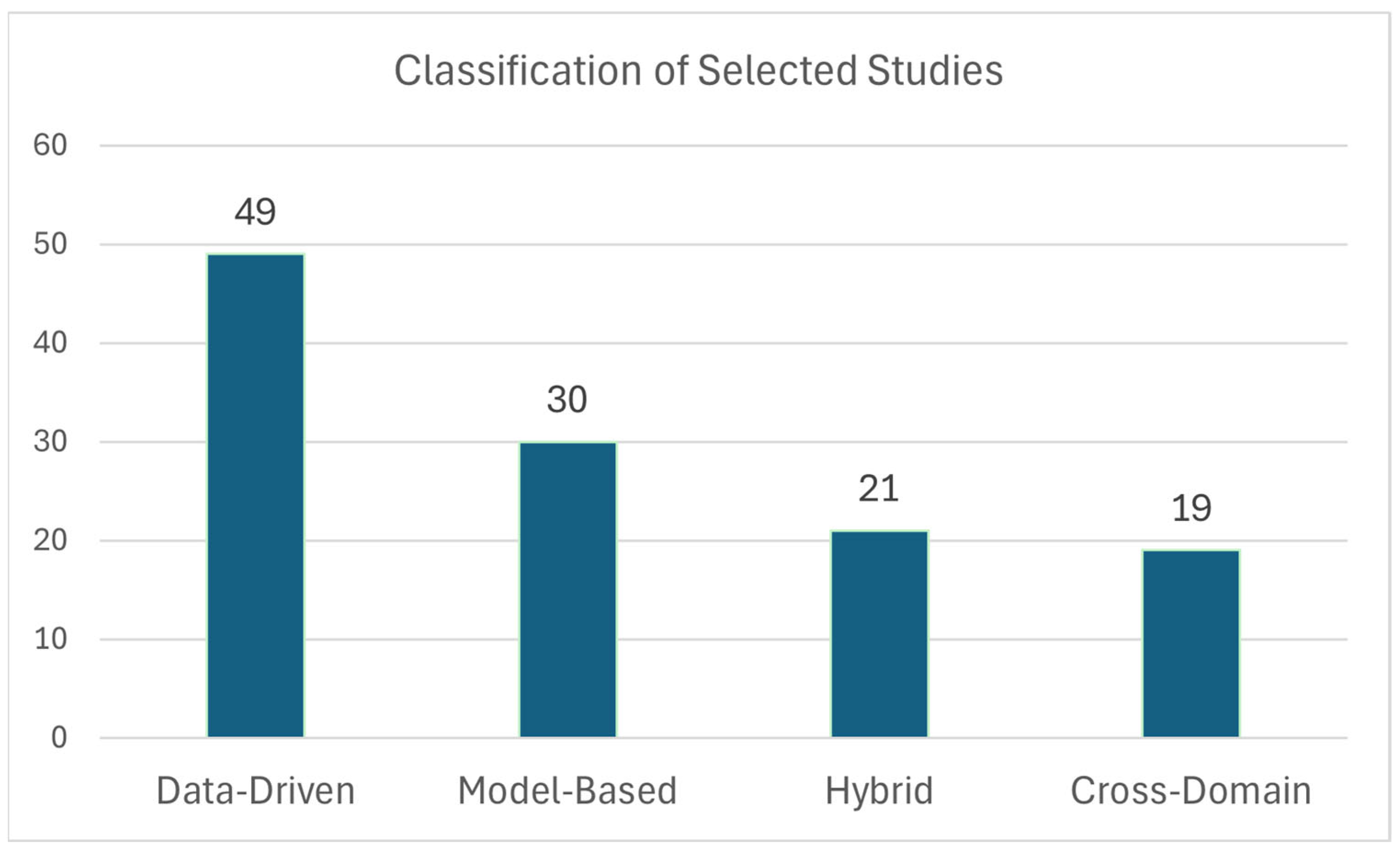

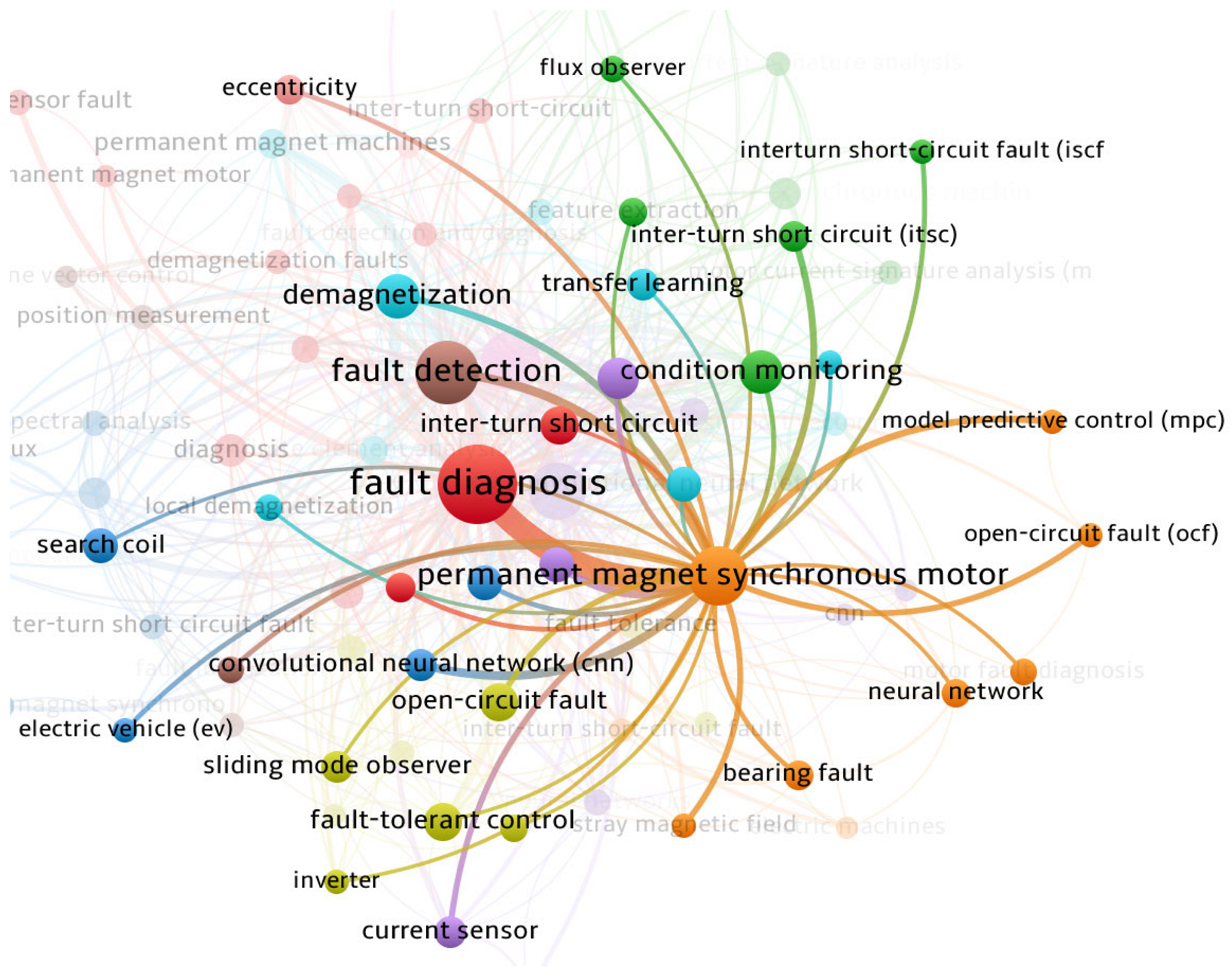

5. Scientometric Analysis and Research Trends

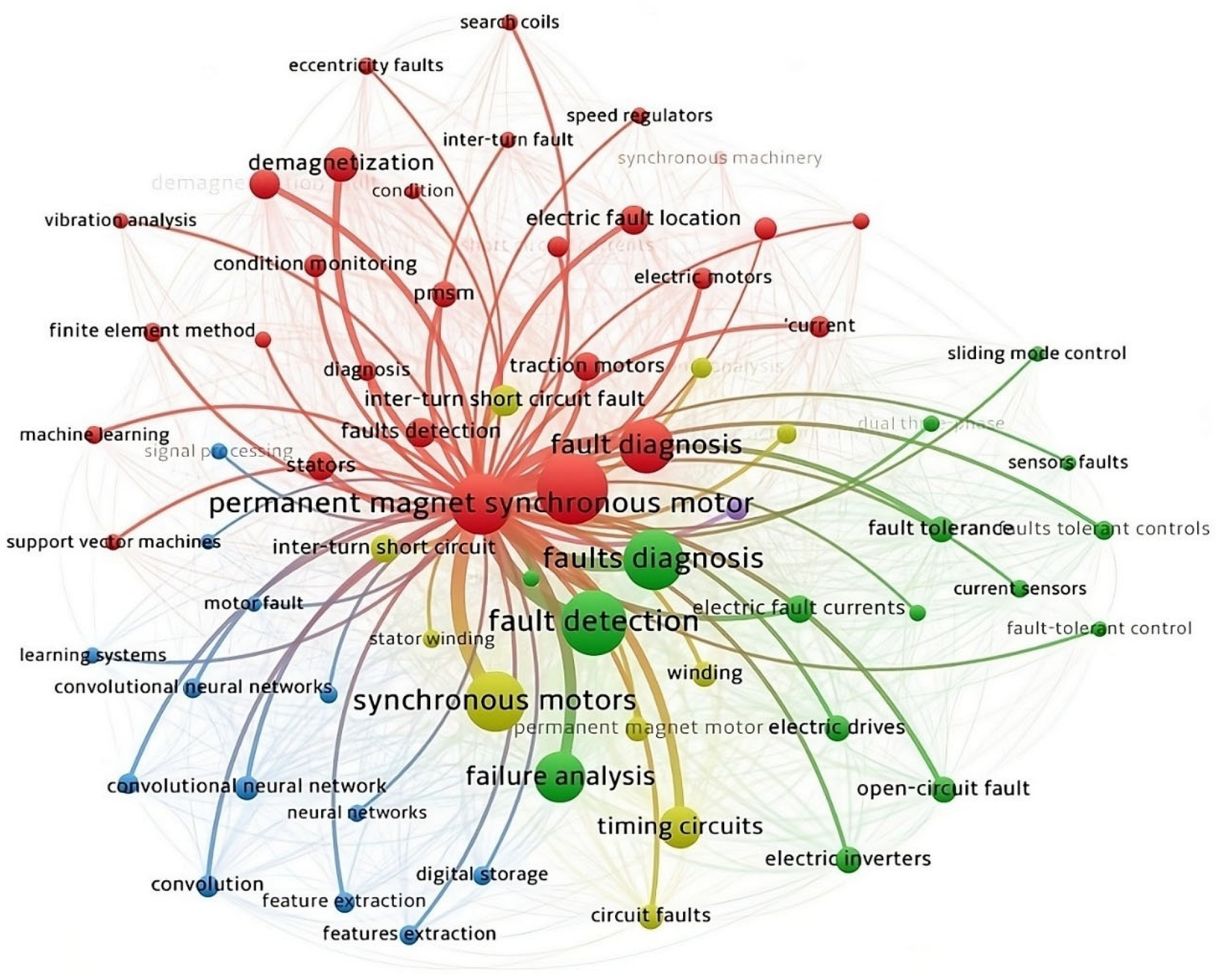

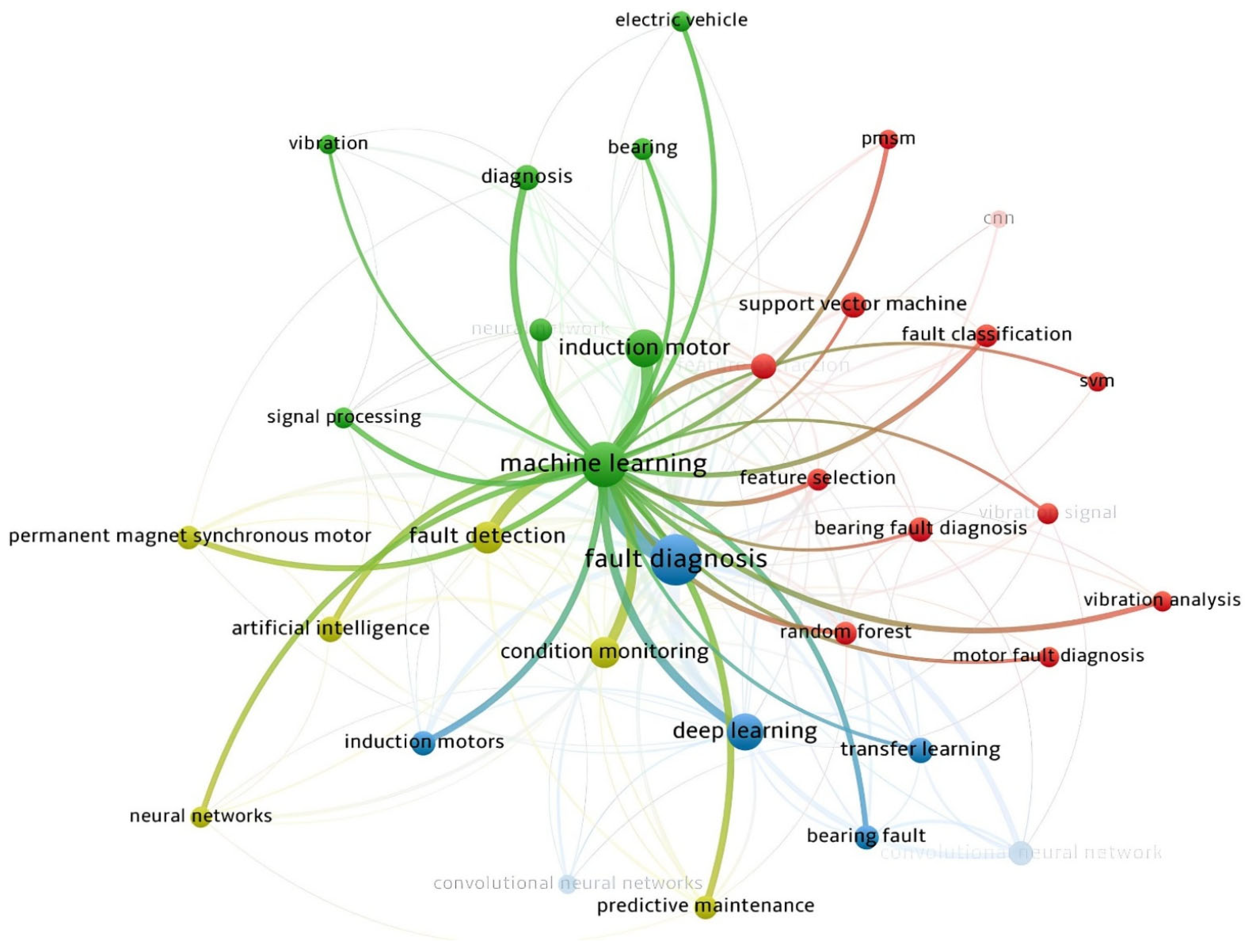

5.1. Results of VOSviewer Analysis

5.2. Concluding Remarks on Scientometric Trends

6. Discussion

6.1. Methodological Landscape and Trends

6.2. Challenges and Gaps in Current Research

6.3. Review Limitations and Scope Constraints

6.4. Practical Implications and Future Research Directions

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abid, A.; Khan, M.T.; Iqbal, J. A review on fault detection and diagnosis techniques: Basics and beyond. Artif. Intell. Rev. 2021, 54, 3649–3707. [Google Scholar] [CrossRef]

- Lin, Q.; Zhou, X.; Hong, W.; Wang, K. A Comprehensive Survey of Multi-View Intelligent Fault Diagnosis Tailored to the Sensor, Machinery Equipment, and Industrial System Faults. J. Vib. Eng. Technol. 2025, 13, 335. [Google Scholar] [CrossRef]

- Krishna, M.S.R.; Seshadrinath, J. Model Based Stator Interturn Fault Analysis in Synchronous Reluctance Motor Drives. IEEE Trans. Ind. Appl. 2024, 60, 8878–8887. [Google Scholar] [CrossRef]

- Yakhni, M.F.; Cauet, S.; Sakout, A.; Assoum, H.; Etien, E.; Rambault, L.; El-Gohary, M. Variable speed induction motors’ fault detection based on transient motor current signatures analysis: A review. Mech. Syst. Signal Process. 2023, 184, 109737. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Wolkiewicz, M.; Pietrzak, P.; Skowron, M.; Ewert, P.; Tarchala, G.; Krzysztofiak, M.; Kowalski, C.T. Fault Diagnosis and Fault-Tolerant Control of PMSM Drives—State of the Art and Future Challenges. IEEE Access 2022, 10, 59979–60035. [Google Scholar] [CrossRef]

- El Abdi, R.; Benjemaa, N. Mechanical Wear of Automotive Connectors During Vibration Tests. UPB Sci. Bull. Ser. C 2009, 71, 167–178. [Google Scholar]

- Khan, M.A.; Asad, B.; Kudelina, K.; Vaimann, T.; Kallaste, A. The Bearing Faults Detection Methods for Electrical Machines—The State of the Art. Energies 2023, 16, 296. [Google Scholar] [CrossRef]

- Rehman, A.U.; Jiao, W.; Jiang, Y.; Wei, J.; Sohaib, M.; Sun, J.; Rehman, K.U.; Chi, Y. Deep learning in industrial machinery: A critical review of bearing fault classification methods. Appl. Soft Comput. 2025, 171, 112785. [Google Scholar] [CrossRef]

- Kudelina, K.; Asad, B.; Vaimann, T.; Rassõlkin, A.; Kallaste, A.; Khang, H.V. Methods of Condition Monitoring and Fault Detection for Electrical Machines. Energies 2021, 14, 7459. [Google Scholar] [CrossRef]

- Sergakis, A.; Salinas, M.; Gkiolekas, N.; Gyftakis, K.N. A Review of Condition Monitoring of Permanent Magnet Synchronous Machines: Techniques, Challenges and Future Directions. Energies 2025, 18, 1177. [Google Scholar] [CrossRef]

- Du, G.; Zhang, G.; Li, H.; Hu, C. Comprehensive Comparative Study on Permanent-Magnet-Assisted Synchronous Reluctance Motors and Other Types of Motor. Appl. Sci. 2023, 13, 8557. [Google Scholar] [CrossRef]

- Krishna, M.S.R.; Seshadrinath, J. Modeling Analysis and Tolerant Capability for Stator Winding Interturn Fault in Synchronous Reluctance Motor with Series and Parallel Connected Windings. IEEE Trans. Ind. Electron. 2025, 72, 3136–3147. [Google Scholar] [CrossRef]

- Tawfiq, K.B.; Ibrahim, M.N.; El-Kholy, E.E.; Sergeant, P. Performance Improvement of Synchronous Reluctance Machines—A Review Research. IEEE Trans. Magn. 2021, 57, 8107811. [Google Scholar] [CrossRef]

- Murataliyev, M.; Degano, M.; Di Nardo, M.; Bianchi, N.; Gerada, C. Synchronous Reluctance Machines: A Comprehensive Review and Technology Comparison. Proc. IEEE 2022, 110, 382–406. [Google Scholar] [CrossRef]

- Bozkurt, A.; Baba, A.F.; Oner, Y. Design of Outer-Rotor Permanent-Magnet-Assisted Synchronous Reluctance Motor for Electric Vehicles. Energies 2021, 14, 3739. [Google Scholar] [CrossRef]

- López-Torres, C.; Riba, J.-R.; Garcia, A.; Romeral, L. Detection of Eccentricity Faults in Five-Phase Ferrite-PM Assisted Synchronous Reluctance Machines. Appl. Sci. 2017, 7, 565. [Google Scholar] [CrossRef]

- Kazakbaev, V.; Paramonov, A.; Dmitrievskii, V.; Prakht, V.; Goman, V. Indirect Efficiency Measurement Method for Line-Start Permanent Magnet Synchronous Motors. Mathematics 2022, 10, 1056. [Google Scholar] [CrossRef]

- Ould Lahoucine, Y.; Raute, R.; Caruana, C. Line-Start Permanent Magnet Synchronous Motors: Evolution, Challenges, and Industrial Prospects. Energies 2025, 18, 4545. [Google Scholar] [CrossRef]

- Gong, H.; Yang, Y.; Zhang, Y.; Shi, T.; Yang, Y.; Zhang, Y. Digital twin model of a permanent magnet synchronous motor via a multiphysics-informed deep operator network. IEEE Trans. Ind. Electron. 2024, 71, 5022–5032. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, J.; Geng, Q. Noninvasive Prognostic and Health Management for Permanent Magnet of PMSM Drive System Through Comprehensive Parameter Identification. IEEE Trans. Transp. Electrif. 2025, 11, 10498–10510. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, H.; Orviz, M.; Lee, S.B.; Reigosa, D.; Briz, F. Detection of Trailing Edge PM Demagnetization in Surface PM Synchronous Motors. IEEE Trans. Ind. Appl. 2023, 59, 3390–3399. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, D.; Jia, S.; Yang, L.; Yang, S. Incipient Interturn Short-Circuit Fault Diagnosis of Permanent Magnet Synchronous Motors Based on the Data-Driven Digital Twin Model. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 3514–3524. [Google Scholar] [CrossRef]

- Xiao, L.; Li, S.; Liu, C.; Zou, J. Inter-Turn Short-Circuit Fault Diagnosis Method for Dual Three-Phase PMSM Based on Voltage Demodulation. IEEE Trans. Magn. 2025, 61, 1–5. [Google Scholar] [CrossRef]

- Huang, F.; Chen, C.; Wang, Z.; Fu, H. Research on vibration characteristics of permanent magnet synchronous motor rotor parallel eccentricity and bearing inner ring radial misalignment coupling fault. Electr. Eng. 2025, 107, 7909–7931. [Google Scholar] [CrossRef]

- Kang, J.-K.; Heo, J.-H.; Lee, S.-W.; Hur, J. A New Eccentricity Fault Diagnosis Method for IPMSM Using Variable Reluctance Resolver. IEEE Trans. Ind. Appl. 2025, 61, 7117–7128. [Google Scholar] [CrossRef]

- Romdhane, M.; Naoui, M.; Mansouri, A. PMSM Inter-Turn Short Circuit Fault Detection Using the Fuzzy-Extended Kalman Filter in Electric Vehicles. Electronics 2023, 12, 3758. [Google Scholar] [CrossRef]

- Guo, X.; Sun, W.; Jiang, D.; Qu, R. Application of the Luenberger Observer for Rotor Resistance Estimation in Induction Motor Drives. In Proceedings of the 2023 IEEE 6th International Electrical and Energy Conference (CIEEC), Wuhan, China, 19 July 2023. [Google Scholar] [CrossRef]

- Rodriguez-Blanco, M.A.; Golikov, V.; Osorio-Sánchez, R.; Samovarov, O.; Ortiz-Torres, G.; Sanchez-Lara, R.; Vazquez-Avila, J.L. Fault Diagnosis of Induction Motor Using D-Q Simplified Model and Parity Equations. Energies 2022, 15, 8372. [Google Scholar] [CrossRef]

- De Souza, D.A.; Batista, J.G.; Vasconcelos, F.J.S.; Dos Reis, L.L.N.; Machado, G.F.; Costa, J.R.; Junior, J.N.N.; Silva, J.L.N.; Rios, C.S.N.; Junior, A.B.S. Identification by Recursive Least Squares With Kalman Filter (RLS-KF) Applied to a Robotic Manipulator. IEEE Access 2021, 9, 63779–63789. [Google Scholar] [CrossRef]

- Dehnavi, V.S.; Shafiee, M. Fault Diagnosis of Induction Motors Using Novel Measurement Techniques and Data Fusion. Measurement 2025, 256, 118135. [Google Scholar] [CrossRef]

- Yang, G. State filtered disturbance rejection control. Nonlinear Dyn. 2025, 113, 6739–6755. [Google Scholar] [CrossRef]

- Xu, J.; Wei, Z.; Hu, L.; Zhang, M. Active Disturbance Rejection Resonant Control with Decoupling Extended Observation Branch for Current Harmonic Suppression of DTP-PMSM. IEEE J. Emerg. Sel. Top. Power Electron. 2025, Early Access. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, Y.; Gui, X.; Chai, J. Sliding-Mode Speed Control Based on Active-Disturbance-Rejection for Permanent-Magnet Synchronous Motors. In Proceedings of the 7th International Electrical and Energy Conference (CIEEC), Beijing, China, 10–12 May 2024; pp. 724–729. [Google Scholar] [CrossRef]

- Tahami, H.; Saberi, S.; Ali, B.M.; AbdulAmeer, S.; Abdul Hussein, A.H.; Chaoui, H. A Robust H∞-Based State Feedback Control of Permanent Magnet Synchronous Motor Drives Using Adaptive Fuzzy Sliding Mode Observers. Actuators 2024, 13, 307. [Google Scholar] [CrossRef]

- Kawady, T.A.; Khater, W.M.; Abu-Faty, H.G.; Izzularab, M.A.; Ibrahim, M.E. AI Driven Fault Diagnosis Approach for Stator Turn-to-Turn Faults in Induction Motors. Sci. Rep. 2025, 15, 20125. [Google Scholar] [CrossRef]

- Shih, K.-J.; Hsieh, M.-F.; Chen, B.-J.; Huang, S.-F. Machine Learning for Inter-Turn Short-Circuit Fault Diagnosis in Permanent Magnet Synchronous Motors. IEEE Trans. Magn. 2022, 58, 8204307. [Google Scholar] [CrossRef]

- Kasap, M.; Çınar, E.; Yazıcı, A.; Özkan, K. An Experimental Evaluation of Intelligent Fault Detection and Classification for Induction Motors Utilizing Machine Learning Approaches. J. ESOGU Engin. Arch. Fac. 2021, 29, 126–136. [Google Scholar] [CrossRef]

- Mohammad-Alikhani, A.; Jamshidpour, E.; Dhale, S.; Akrami, M.; Pardhan, S.; Nahid-Mobarakeh, B. Fault Diagnosis of Electric Motors by a Channel-Wise Regulated CNN and Differential of STFT. IEEE Trans. Ind. Appl. 2025, 61, 3066–3077. [Google Scholar] [CrossRef]

- Huang, T.; Zhang, Q.; Tang, X.; Zhao, S.; Lu, X. A Novel Fault Diagnosis Method Based on CNN and LSTM and Its Application in Fault Diagnosis for Complex Systems. Artif. Intell. Rev. 2021, 54, 1289–1315. [Google Scholar] [CrossRef]

- Baharvand, A.H.; Beigi Fard, S.H.; Poursaeed, A.H.; Doostizadeh, M. An Optimized Classifier Chains-Based Deep Learning Framework for Inter-Turn Fault Diagnosis in Permanent Magnet Synchronous Motors. Appl. Soft Comput. 2025, 180, 113482. [Google Scholar] [CrossRef]

- Presciuttini, A.; Cantini, A.; Costa, F.; Portioli-Staudacher, A. Machine Learning Applications on IoT Data in Manufacturing Operations and Their Interpretability Implications: A Systematic Literature Review. J. Manuf. Syst. 2024, 74, 477–486. [Google Scholar] [CrossRef]

- Kim, K.J.; Park, J.H.; Min, D.H.; Min, S.G. Data-Driven Optimization of Aspect Ratio in Permanent Magnet Machines Using Deep Learning and SHAP Analysis. IEEE Access 2025, 13, 122164–122176. [Google Scholar] [CrossRef]

- Iwata, K.; Sasaki, H. Design-LIME: An Interpretable Visualization Method for Electric Motor Design Based on Deep Learning. IEEE Access 2025, 13, 73697–73707. [Google Scholar] [CrossRef]

- Vlachou, V.I.; Karakatsanis, T.S.; Efstathiou, D.E.; Vlachou, E.I.; Vologiannidis, S.D.; Balaska, V.E.; Gasteratos, A.C. Condition Monitoring and Fault Prediction in PMSM Drives Using Machine Learning for Elevator Applications. Machines 2025, 13, 549. [Google Scholar] [CrossRef]

- Sung, M.-H.; Park, S.-H.; Cha, K.-S.; Sim, J.-H.; Lim, M.-S. Deep Transfer Learning-Based Performance Prediction Considering 3-D Flux in Outer Rotor Interior Permanent Magnet Synchronous Motors. Machines 2025, 13, 302. [Google Scholar] [CrossRef]

- Yu, H.; Li, S.; Xu, Y.; Zhang, Z.; Mu, H.; Han, W. Time-Frequency Domain Lightweight Dual-Branch MSCFormer for PMSM ITSC Fault Diagnosis. IEEE Trans. Ind. Electron. 2025, Early Access. [Google Scholar] [CrossRef]

- Lee, S.K.; Kim, H.; Chae, M.; Oh, H.J.; Yoon, H.; Youn, B.D. Self-Supervised Feature Learning for Motor Fault Diagnosis under Various Torque Conditions. Knowl.-Based Syst. 2024, 288, 111465. [Google Scholar] [CrossRef]

- Wu, X.; Li, M.; Geng, Y.; Qian, H. Unsupervised Diagnosis of Interturn Short Circuit of Permanent Magnet Synchronous Motor Guided by Density-Based Clustering and Deep Learning. IEEE Trans. Instrum. Meas. 2025, 74, 3503811. [Google Scholar] [CrossRef]

- Drakaki, M.; Karnavas, Y.L.; Tziafettas, I.A.; Linardos, V.; Tzionas, P. Machine Learning and Deep Learning Based Methods Toward Industry 4.0 Predictive Maintenance in Induction Motors: A State of the Art Survey. J. Ind. Eng. Manag. 2022, 15, 31–57. [Google Scholar] [CrossRef]

- Kohtz, S.; Zhao, J.; Renteria, A.; Lalwani, A.; Xu, Y.; Zhang, X.; Haran, K.S.; Senesky, D.; Wang, P. Optimal Sensor Placement for Permanent Magnet Synchronous Motor Condition Monitoring Using a Digital Twin-Assisted Fault Diagnosis Approach. Reliab. Eng. Syst. Saf. 2024, 242, 109714. [Google Scholar] [CrossRef]

- Weddington, J.; Niu, G.; Chen, R.; Yan, W.; Zhang, B. Lithium-Ion Battery Diagnostics and Prognostics Enhanced with Dempster-Shafer Decision Fusion. Neurocomputing 2021, 458, 440–453. [Google Scholar] [CrossRef]

- Chelmiah, E.T.; Madigan, C.D.; Kavanagh, D.F. An Acoustic Sensor Array Approach for Localising Partial Discharges in Electric Machines. Mech. Syst. Signal Process. 2024, 214, 111354. [Google Scholar] [CrossRef]

- Athisayam, A.; Kondal, M. Noise-Resilient Bearing Fault Diagnosis Using DTW-Based IMF Selection and Wavelet-Fused Features with the Bat Algorithm. Signal Image Video Process. 2025, 19, 607. [Google Scholar] [CrossRef]

- Xie, F.; Li, G.; Fan, Q.; Xiao, Q.; Zhou, S. Optimizing and Analyzing Performance of Motor Fault Diagnosis Algorithms for Autonomous Vehicles via Cross-Domain Data Fusion. Processes 2023, 11, 2862. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, G.; Zhao, W.; Zhou, H.; Chen, Q.; Wei, M. Online Diagnosis of Slight Interturn Short-Circuit Fault for a Low-Speed Permanent Magnet Synchronous Motor. IEEE Trans. Transp. Electrif. 2021, 7, 104–113. [Google Scholar] [CrossRef]

- Zeng, C.; Huang, S.; Lei, J.; Wan, Z.; Yang, Y. Online Rotor Fault Diagnosis of Permanent Magnet Synchronous Motors Based on Stator Tooth Flux. IEEE Trans. Ind. Appl. 2021, 57, 2366–2377. [Google Scholar] [CrossRef]

- Dan, H.; Yue, W.; Xiong, W.; Liu, Y.; Su, M.; Sun, Y. Open-Switch and Current Sensor Fault Diagnosis Strategy for Matrix Converter-Based PMSM Drive System. IEEE Trans. Transp. Electrific. 2022, 8, 875–885. [Google Scholar] [CrossRef]

- Huang, S.; Aggarwal, A.; Strangas, E.G.; Li, K.; Niu, F.; Huang, X. Robust Stator Winding Fault Detection in PMSMs with Respect to Current Controller Bandwidth. IEEE Trans. Power Electron. 2021, 36, 5032–5042. [Google Scholar] [CrossRef]

- Wei, D.; Liu, K.; Hu, W.; Peng, X.; Chen, Y.; Ding, R. Short-Time Adaline Based Fault Feature Extraction for Inter-Turn Short Circuit Diagnosis of PMSM via Residual Insulation Monitoring. IEEE Trans. Ind. Electron. 2023, 70, 3103–3114. [Google Scholar] [CrossRef]

- Shi, P.; Wang, X.; Meng, X.; He, M.; Mao, Y.; Wang, Z. Adaptive Fault-Tolerant Control for Open-Circuit Faults in Dual Three-Phase PMSM Drives. IEEE Trans. Power Electron. 2023, 38, 3676–3688. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, J.; Cui, P.; Lu, Y.; Lu, M.; Yu, Y. A Fast and Robust Open-Switch Fault Diagnosis Method for Variable-Speed PMSM System. IEEE Trans. Power Electron. 2021, 36, 2598–2610. [Google Scholar] [CrossRef]

- Wang, W.; Tian, W.; Wang, Z.; Hua, W.; Cheng, M. A Fault Diagnosis Method for Current Sensors of Primary Permanent-Magnet Linear Motor Drives. IEEE Trans. Power Electron. 2021, 36, 2334–2345. [Google Scholar] [CrossRef]

- Xu, S.; Chen, X.; Liu, F.; Wang, H.; Chai, Y.; Zheng, W.X.; Chen, H. A Novel Adaptive SMO-Based Simultaneous Diagnosis Method for IGBT Open-Circuit Faults and Current Sensor Incipient Faults of Inverters in PMSM Drives for Electric Vehicles. IEEE Trans. Instrum. Meas. 2023, 72, 3526915. [Google Scholar] [CrossRef]

- Heidari, H.; Rassolkin, A.; Kallaste, A.; Vaimann, T.; Andriushchenko, E.; Belahcen, A.; Lukichev, D.V. A Review of Synchronous Reluctance Motor-Drive Advancements. Sustainability 2021, 13, 729. [Google Scholar] [CrossRef]

- Attaianese, C.; D’Arpino, M.; Di Monaco, M.; Di Noia, L.P. Model-Based Detection and Estimation of DC Offset of Phase Current Sensors for Field Oriented PMSM Drives. IEEE Trans. Ind. Electron. 2023, 70, 6316–6325. [Google Scholar] [CrossRef]

- Geng, Q.; Li, Z.; Wang, H.; Zhang, G.; Zhou, Z. Natural Fault-Tolerant Control with Minimum Copper Loss in Full Torque Operation Range for Dual Three-Phase PMSM Under Open-Circuit Fault. IEEE Trans. Power Electron. 2024, 39, 1279–1291. [Google Scholar] [CrossRef]

- Yu, K.; Wang, Z.; Gu, M.; Wang, X. Universal Control Scheme of Dual Three-Phase PMSM Drives with Single Open-Phase Fault. IEEE Trans. Power Electron. 2022, 37, 14034–14039. [Google Scholar] [CrossRef]

- Alimardani, R.; Rahideh, A.; Hedayati Kia, S. Mixed Eccentricity Fault Detection for Induction Motors Based on Time Synchronous Averaging of Vibration Signals. IEEE Trans. Ind. Electron. 2024, 71, 3173–3181. [Google Scholar] [CrossRef]

- Rafaq, M.S.; Lee, H.-J.; Park, Y.; Lee, S.B.; Zapico, M.O.; Fernandez, D.; Reigosa, D.; Briz, F. Airgap Search Coil Based Identification of PM Synchronous Motor Defects. IEEE Trans. Ind. Electron. 2022, 69, 6551–6560. [Google Scholar] [CrossRef]

- Krzysztofiak, M.; Skowron, M.; Orlowska-Kowalska, T. Analysis of the Impact of Stator Inter-Turn Short Circuits on PMSM Drive with Scalar and Vector Control. Energies 2021, 14, 153. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, H.; Shi, P.; Zhou, Y.; Xiao, D.; Wang, Z. Adaptive Fault-Tolerant Control-Based Fault Diagnosis of Dual Three-Phase PMSM Drives. IEEE J. Emerg. Sel. Top. Power Electron. 2025, 13, 2556–2564. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M. Comparison of Selected Methods for the Stator Winding Condition Monitoring of a PMSM Using the Stator Phase Currents. Energies 2021, 14, 1630. [Google Scholar] [CrossRef]

- Cen, J.; Yang, Z.; Liu, X.; Xiong, J.; Chen, H. A Review of Data-Driven Machinery Fault Diagnosis Using Machine Learning Algorithms. J. Vib. Eng. Technol. 2022, 10, 2481–2507. [Google Scholar] [CrossRef]

- Parvin, F.; Faiz, J.; Qi, Y.; Kalhor, A.; Akin, B. A Comprehensive Interturn Fault Severity Diagnosis Method for Permanent Magnet Synchronous Motors Based on Transformer Neural Networks. IEEE Trans. Ind. Inform. 2023, 19, 10923–10933. [Google Scholar] [CrossRef]

- Luo, P.; Yin, Z.; Yuan, D.; Gao, F.; Liu, J. An Intelligent Method for Early Motor Bearing Fault Diagnosis Based on Wasserstein Distance Generative Adversarial Networks Meta Learning. IEEE Trans. Instrum. Meas. 2023, 72, 3517611. [Google Scholar] [CrossRef]

- Park, C.H.; Kim, H.; Suh, C.; Chae, M.; Yoon, H.; Youn, B.D. A Health Image for Deep Learning-Based Fault Diagnosis of a Permanent Magnet Synchronous Motor Under Variable Operating Conditions: Instantaneous Current Residual Map. Reliab. Eng. Syst. Saf. 2022, 226, 108715. [Google Scholar] [CrossRef]

- Wang, X.-B.; Luo, L.; Tang, L.; Yang, Z.-X. Automatic Representation and Detection of Fault Bearings in In-Wheel Motors Under Variable Load Conditions. Adv. Eng. Inform. 2021, 49, 101321. [Google Scholar] [CrossRef]

- Lang, W.; Hu, Y.; Gong, C.; Zhang, X.; Xu, H.; Deng, J. Artificial Intelligence-Based Technique for Fault Detection and Diagnosis of EV Motors: A Review. IEEE Trans. Transp. Electrific. 2022, 8, 384–406. [Google Scholar] [CrossRef]

- Guo, Z.; Yang, M.; Huang, X. Bearing Fault Diagnosis Based on Speed Signal and CNN Model. Energy Rep. 2022, 8, 904–913. [Google Scholar] [CrossRef]

- Dybkowski, M.; Kołodziej, A.; Klimkowski, K.; Orłowska-Kowalska, T. Application of Simplified Convolutional Neural Networks for Initial Stator Winding Fault Detection of the PMSM Drive Using Different Raw Signal Data. Energies 2022, 15, 8051. [Google Scholar] [CrossRef]

- Cai, B.; Hao, K.; Wang, Z.; Yang, C.; Kong, X.; Liu, Z.; Ji, R.; Liu, Y. Data-Driven Early Fault Diagnostic Methodology of Permanent Magnet Synchronous Motor. Expert Syst. Appl. 2021, 177, 115000. [Google Scholar] [CrossRef]

- Liu, Z.; Fang, L.; Jiang, D.; Qu, R. A Machine-Learning-Based Fault Diagnosis Method with Adaptive Secondary Sampling for Multiphase Drive Systems. IEEE Trans. Power Electron. 2022, 37, 8767–8772. [Google Scholar] [CrossRef]

- Kao, I.-H.; Wang, W.-J.; Lai, Y.-H.; Perng, J.-W. Analysis of Permanent Magnet Synchronous Motor Fault Diagnosis Based on Learning. IEEE Trans. Instrum. Meas. 2025, 74, 310–324. [Google Scholar] [CrossRef]

- Karabacak, Y.E.; Gürsel Özmen, N. Common Spatial Pattern-Based Feature Extraction and Worm Gear Fault Detection Through Vibration and Acoustic Measurements. Measurement 2022, 187, 110366. [Google Scholar] [CrossRef]

- Bacha, A.; El Idrissi, R.; Janati Idrissi, K.; Lmai, F. Comprehensive Dataset for Fault Detection and Diagnosis in Inverter-Driven Permanent Magnet Synchronous Motor Systems. Data Brief 2025, 58, 111286. [Google Scholar] [CrossRef]

- Jankowska, K.; Dybkowski, M. Design and Analysis of Current Sensor Fault Detection Mechanisms for PMSM Drives Based on Neural Networks. Designs 2022, 6, 18. [Google Scholar] [CrossRef]

- Skowron, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Detection of Permanent Magnet Damage of PMSM Drive Based on Direct Analysis of the Stator Phase Currents Using Convolutional Neural Network. IEEE Trans. Ind. Electron. 2022, 69, 13665–13675. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Zhang, Y.; Zhang, J. Diagnosis of Inter-Turn Short Circuit of Permanent Magnet Synchronous Motor Based on Deep Learning and Small Fault Samples. Neurocomputing 2021, 442, 348–358. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhu, K.; Zhang, Y.; Li, Y. Diagnosis of Interturn Short-Circuit Faults in Permanent Magnet Synchronous Motors Based on Few-Shot Learning Under a Federated Learning Framework. IEEE Trans. Ind. Inform. 2021, 17, 8495–8504. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M. Demagnetization Fault Diagnosis of Permanent Magnet Synchronous Motors Based on Stator Current Signal Processing and Machine Learning Algorithms. Sensors 2023, 23, 1757. [Google Scholar] [CrossRef]

- Morales-Perez, C.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Rangel-Magdaleno, J.; Cerezo-Sanchez, J.; Leon-Bonilla, A. ITSC Fault Detection in Induction Motor using a Cosine Filter and a CNN Architecture. In Proceedings of the 2024 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 11–13 November 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, C.-S.; Kao, I.-H.; Perng, J.-W. Fault Diagnosis and Fault Frequency Determination of Permanent Magnet Synchronous Motor Based on Deep Learning. Sensors 2021, 21, 3608. [Google Scholar] [CrossRef]

- Ewert, P.; Orlowska-Kowalska, T.; Jankowska, K. Effectiveness Analysis of PMSM Motor Rolling Bearing Fault Detectors Based on Vibration Analysis and Shallow Neural Networks. Energies 2021, 14, 712. [Google Scholar] [CrossRef]

- Pasqualotto, D.; Zigliotto, M. Increasing Feasibility of Neural Network-Based Early Fault Detection in Induction Motor Drives. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 2042–2051. [Google Scholar] [CrossRef]

- Lv, W.; Xu, S.; Xie, H.; Chen, L.; Wu, S.; Zhu, T. Detection and Discrimination of Interturn Short and High-Resistance Connection Faults in PMSM Based on Multi-Channel CNN. In Proceedings of the 2025 IEEE 8th International Electrical and Energy Conference (CIEEC), Changsha, China, 16–18 May 2025; pp. 1586–1591. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M.; Orlowska-Kowalska, T. PMSM Stator Winding Fault Detection and Classification Based on Bispectrum Analysis and Convolutional Neural Network. IEEE Trans. Ind. Electron. 2023, 70, 5192–5202. [Google Scholar] [CrossRef]

- Song, Q.; Wang, M.; Lai, W.; Zhao, S. On Bayesian Optimization-Based Residual CNN for Estimation of Inter-Turn Short Circuit Fault in PMSM. IEEE Trans. Power Electron. 2023, 38, 2456–2467. [Google Scholar] [CrossRef]

- Mohammad-Alikhani, A.; Nahid-Mobarakeh, B.; Hsieh, M.-F. One-Dimensional LSTM-Regulated Deep Residual Network for Data-Driven Fault Detection in Electric Machines. IEEE Trans. Ind. Electron. 2024, 71, 3083–3092. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M. On-line Detection and Classification of PMSM Stator Winding Faults Based on Stator Current Symmetrical Components Analysis and the KNN Algorithm. Electronics 2021, 10, 1786. [Google Scholar] [CrossRef]

- Yan, H.; Peng, Y.; Shang, W.; Kong, D. Open-Circuit Fault Diagnosis in Voltage Source Inverter for Motor Drive by Using Deep Neural Network. Eng. Appl. Artif. Intell. 2023, 120, 105866. [Google Scholar] [CrossRef]

- Khan, M.U.I.; Pathan, M.I.H.; Rahman, M.M.; Islam, M.M.; Chowdhury, M.A.R.; Anower, M.S.; Rana, M.; Alam, M.S.; Hasan, M.; Sobuj, M.S.I.; et al. Securing Electric Vehicle Performance: Machine Learning-Driven Fault Detection and Classification. IEEE Access 2024, 12, 71566–71584. [Google Scholar] [CrossRef]

- Guo, H.; Guo, S.; Xu, J.; Tian, X. Power Switch Open-Circuit Fault Diagnosis of Six-Phase Fault Tolerant Permanent Magnet Synchronous Motor System Under Normal and Fault-Tolerant Operation Conditions Using the Average Current Park’s Vector Approach. IEEE Trans. Power Electron. 2021, 36, 2641–2660. [Google Scholar] [CrossRef]

- Hang, J.; Shu, X.; Ding, S.; Huang, Y. Robust Open-Circuit Fault Diagnosis for PMSM Drives Using Wavelet Convolutional Neural Network with Small Samples of Normalized Current Vector Trajectory Graph. IEEE Trans. Ind. Electron. 2023, 70, 7653–7663. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, X.; Zhai, Y.; Qin, G.; Song, D.; Huang, S.; Long, Z. Rotating Machine Systems Fault Diagnosis Using Semisupervised Conditional Random Field-Based Graph Attention Network. IEEE Trans. Instrum. Meas. 2021, 70, 3521010. [Google Scholar] [CrossRef]

- Saucedo-Dorantes, J.J.; Jaen-Cuellar, A.Y.; Delgado-Prieto, M.; Romero-Troncoso, R.J.; Osornio-Rios, R.A. Condition Monitoring Strategy Based on an Optimized Selection of High-Dimensional Set of Hybrid Features to Diagnose and Detect Multiple and Combined Faults in an Induction Motor. Measurement 2021, 178, 109404. [Google Scholar] [CrossRef]

- Huang, W.; Du, J.; Hua, W.; Bi, K.; Fan, Q. A Hybrid Model-Based Diagnosis Approach for Open-Switch Faults in PMSM Drives. IEEE Trans. Power Electron. 2022, 37, 3728–3732. [Google Scholar] [CrossRef]

- Cai, B.; Wang, Z.; Zhu, H.; Liu, Y.; Hao, K.; Yang, Z.; Ren, Y.; Feng, Q.; Liu, Z. Artificial Intelligence Enhanced Two-Stage Hybrid Fault Prognosis Methodology of PMSM. IEEE Trans. Ind. Inform. 2022, 18, 7262–7273. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Zhu, K.; Bai, C.; Zhang, J. An Effective Federated Learning Verification Strategy and Its Applications for Fault Diagnosis in Industrial IoT Systems. IEEE Internet Things J. 2022, 9, 16835–16849. [Google Scholar] [CrossRef]

- Wang, X.; Lu, S.; Chen, K.; Wang, Q.; Zhang, S. Bearing Fault Diagnosis of Switched Reluctance Motor in Electric Vehicle Powertrain via Multisensor Data Fusion. IEEE Trans. Ind. Inform. 2022, 18, 2452–2463. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, Z.; Wu, H.; Chen, X.; Xiao, Q.; Yu, Y. Fault Anomaly Detection of Synchronous Machine Winding Based on Isolation Forest and Impulse Frequency Response Analysis. Measurement 2022, 188, 110531. [Google Scholar] [CrossRef]

- Zhang, Y.; Mao, Y.; Wang, X.; Wang, Z.; Xiao, D.; Fang, G. Current Prediction-Based Fast Diagnosis of Electrical Faults in PMSM Drives. IEEE Trans. Transp. Electrif. 2022, 8, 4622–4632. [Google Scholar] [CrossRef]

- Huang, F.; Zhang, X.; Qin, G.; Xie, J.; Peng, J.; Huang, S.; Long, Z.; Tang, Y. Demagnetization Fault Diagnosis of Permanent Magnet Synchronous Motors Using Magnetic Leakage Signals. IEEE Trans. Ind. Inform. 2023, 19, 6105–6116. [Google Scholar] [CrossRef]

- Zhang, M.; Li, W.; Tang, H. Demagnetization Fault Diagnosis of the Permanent Magnet Motor for Electric Vehicles Based on Temperature Characteristic Quantity. IEEE Trans. Transp. Electrif. 2023, 9, 759–770. [Google Scholar] [CrossRef]

- Wang, X.; Lu, S.; Huang, W.; Wang, Q.; Zhang, S.; Xia, M. Efficient Data Reduction at the Edge of Industrial Internet of Things for PMSM Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2021, 70, 3508612. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, J.; Xiang, J. Online Bearing Fault Diagnosis Using Numerical Simulation Models and Machine Learning Classifications. Reliab. Eng. Syst. Saf. 2023, 234, 109142. [Google Scholar] [CrossRef]

- Gmati, B.; Jlassi, I.; El Khil, S.K.; Marques Cardoso, A.J. Open-Switch Fault Diagnosis in Voltage Source Inverters of PMSM Drives Using Predictive Current Errors and Fuzzy Logic Approach. IET Power Electron. 2021, 14, 1059–1072. [Google Scholar] [CrossRef]

- Zhou, Y.; Shang, Q.; Guan, C. Three-Phase Asynchronous Motor Fault Diagnosis Using Attention Mechanism and Hybrid CNN-MLP by Multi-Sensor Information. IEEE Access 2023, 11, 98402–98414. [Google Scholar] [CrossRef]

- Huang, W.; Du, B.; Li, T.; Sun, Y.; Cheng, Y.; Cui, S. Interturn Short-Circuit Fault Diagnosis of Interior Permanent Magnet Synchronous Motor for Electric Vehicle Based on Search Coil. IEEE Trans. Power Electron. 2023, 38, 2506–2515. [Google Scholar] [CrossRef]

- Hang, J.; Ding, S.; Ren, X.; Hu, Q.; Huang, Y.; Hua, W.; Wang, Q. Integration of Interturn Fault Diagnosis and Torque Ripple Minimization Control for Direct-Torque-Controlled SPMSM Drive System. IEEE Trans. Power Electron. 2025, 36, 11124–11134. [Google Scholar] [CrossRef]

- Chen, H.; Gao, C.; Si, J.; Nie, Y.; Hu, Y. A Novel Method for Diagnosing Demagnetization Fault in PMSM Using Toroidal-Yoke-Type Search Coil. IEEE Trans. Instrum. Meas. 2022, 71, 7501012. [Google Scholar] [CrossRef]

- Shaikh, M.F.; Park, J.; Lee, S.B. A Non-Intrusive Leakage Flux Based Method for Detecting Rotor Faults in the Starting Transient of Salient Pole Synchronous Motors. IEEE Trans. Energy Convers. 2021, 36, 1262–1270. [Google Scholar] [CrossRef]

- Rafaq, M.S.; Lee, H.; Park, Y.; Lee, S.B.; Fernandez, D.; Diaz-Reigosa, D.; Briz, F. A Simple Method for Identifying Mass Unbalance Using Vibration Measurement in Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2022, 69, 6441–6444. [Google Scholar] [CrossRef]

- Gurusamy, V.; Bostanci, E.; Li, C.; Qi, Y.; Akin, B. A Stray Magnetic Flux-Based Robust Diagnosis Method for Detection and Location of Interturn Short Circuit Fault in PMSM. IEEE Trans. Instrum. Meas. 2021, 70, 3500811. [Google Scholar] [CrossRef]

- Bostanci, E.; Akin, B. Recent Trends in Magnetic Sensors and Flux-Based Condition Monitoring of Electromagnetic Devices. IEEE Trans. Ind. Electron. 2021, 68, 4052–4063. [Google Scholar] [CrossRef]

- Im, J.-H.; Kang, J.-K.; Hur, J. Static and Dynamic Eccentricity Faults Diagnosis in PM Synchronous Motor Using Planar Search Coil. IEEE Trans. Ind. Electron. 2023, 70, 9291–9300. [Google Scholar] [CrossRef]

- Glowacz, A. Thermographic Fault Diagnosis of Electrical Faults of Commutator and Induction Motors. Eng. Appl. Artif. Intell. 2023, 121, 105962. [Google Scholar] [CrossRef]

- Luo, P.; Yin, Z.; Zhang, Z.; Zhang, Y.; Zhang, P.; Liu, J. Diversified Diagnosis Strategy for PMSM Inter-Turn Short-Circuit Fault via Novel Sliding Mode Observer. IEEE Trans. Power Electron. 2024, 39, 4149–4160. [Google Scholar] [CrossRef]

- Xu, S.; Chen, X.; Yang, W.; Liu, F.; Chai, Y. Current Sensor Incipient Fault Diagnosis in PMSM Drive Systems Using Novel Interval Sliding Mode Observer. IEEE Trans. Instrum. Meas. 2024, 73, 3508211. [Google Scholar] [CrossRef]

- Hang, J.; Qiu, G.; Hao, M.; Ding, S. Improved Fault Diagnosis Method for Permanent Magnet Synchronous Machine System Based on Lightweight Multisource Information Data Layer Fusion. IEEE Trans. Power Electron. 2024, 39, 13808–13817. [Google Scholar] [CrossRef]

- Wei, D.; Liu, K.; Wang, J.; Zhou, S.; Li, K. ResNet-18-Based Interturn Short-Circuit Fault Diagnosis of PMSMs with Consideration of Speed and Current Loop Bandwidths. IEEE Trans. Transp. Electrific. 2024, 10, 5805–5818. [Google Scholar] [CrossRef]

- Lang, W.; Hu, Y.; Zhang, Z.; Gan, C.; Si, J.; Wen, H. Few-Shot Learning with Residual Current for EV Inverter Fault Diagnosis of EV Powertrain. IEEE Trans. Transp. Electrific. 2024, 10, 9316–9326. [Google Scholar] [CrossRef]

- Bacha, A.; El Idrissi, R.; Lmai, F.; El Hassani, H.; Janati Idrissi, K.; Benhra, J. Advanced Deep Learning Approaches for Fault Detection and Diagnosis in Inverter-Driven PMSM Systems. Int. J. Adv. Comput. Sci. Appl. 2024, 15, 912. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Jaber, A.A.; Hamzah, M.N.; Fayad, M.A. Vibration-Current Data Fusion and Gradient Boosting Classifier for Enhanced Stator Fault Diagnosis in Three-Phase Permanent Magnet Synchronous Motors. Electr. Eng. 2024, 106, 3253–3268. [Google Scholar] [CrossRef]

- Huang, F.; Zhang, X.; Deng, X.; Qin, G.; Xie, J. Denoising Universal Domain Adaptation Method for PMSM Fault Diagnosis Under Category Inconsistency. IEEE Sens. J. 2025, 25, 15642–15652. [Google Scholar] [CrossRef]

- Meng, Q.; Shahvali, M.; Vrachimis, S.; Polycarpou, M.M. Fault-Tolerant Safe Control for Water Networks: A Backstepping Neural Control Barrier Function Approach. J. Process Control 2025, 145, 103344. [Google Scholar] [CrossRef]

| Ref. | Research Objectives | Main Contributions | Limitations |

|---|---|---|---|

| [4] | To review and assess transient motor current signature analysis (TMCSA) for fault detection in variable-speed induction motors. | Detailed taxonomy of fault types and TMCSA methods; comparative evaluation of spectral and bispectral analysis; identification of frequency estimation techniques for non-stationary conditions. | Lack of experimental validation across diverse motor types; most techniques assume idealized operating conditions; computational complexity for real-time analysis not addressed. |

| [5] | To summarize current methods for fault diagnosis and fault-tolerant control (FTC) in PMSM drives and identify future research directions. | Comprehensive classification of model-based and data-driven techniques for PMSM diagnosis; highlights role of control strategies in FTC. | Lack of integration between diagnosis and control in real-time applications; absence of standardized datasets; limited experimental validation in industrial settings. |

| [7] | To provide a comprehensive review of state-of-the-art bearing fault detection methods for electrical machines. | Categorization of bearing fault types, sources, and detection methods; overview of vibration, current, and hybrid signal-based diagnostics. | Focus is broad and general; lacks focus on synchronous machines; limited discussion on real-time deployability and data requirements. |

| [8] | To critically review deep learning-based approaches for bearing fault classification in industrial machinery. | Comparison of conventional and deep learning models; identifies performance of CNN, RNN, and hybrid networks for classification tasks. | Dependence on large, labeled datasets; insufficient discussion on explainability and interpretability; industrial generalization remains limited. |

| [9] | To review intelligent techniques and signal-based methods used in condition monitoring and fault detection of electrical machines. | Provides a comprehensive overview of AI algorithms (e.g., ANN, SVM, PCA, fuzzy logic) used in diagnostics; analyzes major fault types and their signatures. | The review lacks detailed experimental comparisons; limited emphasis on practical real-time deployment; focuses more on theoretical capabilities than industrial constraints. |

| Fault Type | Cause | Typical Symptoms | Detection Signal | Impact on Operation | Common Detection Methods |

|---|---|---|---|---|---|

| Stator winding short-circuits | Insulation failure, overheat | Unbalanced current, temperature rise | Stator current, temperature | Torque pulsations, possible burnout | MCSA, thermal sensors, FFT, wavelet |

| Rotor demagnetization [21] | Aging, high temp, corrosion, mechanical | Symmetrical flux weakening | Airgap flux distortion | Reduced torque and efficiency | GA-SVM, FFT, airgap flux monitoring |

| Inter-turn short-circuit fault [22,23] | Local insulation breakdown | Slight imbalance in current, noise | Stator current | Early-stage degradation | CNN-BiLSTM, spectral analysis |

| Bearing defects | Wear, contamination, misalignment | Vibration, noise, harmonics | Vibration, current | Severe mechanical damage | Vibration analysis, envelope analysis |

| Eccentricity [24,25] | Shaft misalignment, wear | Harmonic patterns in current | Current, flux, resolver output variation | Noise, energy losses, reduced stability, bearing wear | Signal pattern analysis + ANN, FEM modeling, spectral analysis |

| Open-circuit fault | Broken wire, connector failure | Missing current phase | Stator current | Severe performance degradation | Observer-based, current residual analysis |

| Magnetic unbalance | Partial magnet damage, unequal field | Torque pulsation, speed oscillations | Back-EMF, flux | Motor instability | Flux estimation, field-oriented control |

| Voltage unbalance | Power grid fault, faulty inverter | Overheating, torque reduction | Voltage input | Stress on stator and control unit | Monitoring supply parameters |

| Approach | Interpretability | Data Dependency | Robustness to Noise | Computational Complexity | Industrial Applicability |

|---|---|---|---|---|---|

| Model-Based | High (physics-based) | Low to Moderate (model parameters) | Moderate (sensitive to mismatch) | Low to Moderate | High (for known systems) |

| Data-Driven (ML/DL) | Low to Moderate (black-box models) | High (requires large datasets) | High (if trained properly) | High (especially DL models) | High (when data available) |

| Hybrid + Sensor Fusion | Moderate to High (combined reasoning) | Moderate to High (fusion and training) | High (through redundancy and fusion) | High (due to integration and fusion layers) | Very High (supports multiple faults) |

| Cross-Domain | Moderate (requires domain adaptation) | Moderate (depends on sensor type) | Moderate to High (beamforming improves SNR) | High (real-time processing requirements) | Emerging (needs further validation) |

| Ref. | Method Used | Application Context | Advantages | Limitations |

|---|---|---|---|---|

| [55] | Zero-sequence voltage vector decomposition and PWM control voltage extraction | Online diagnosis of slight inter-turn short-circuit fault (ISCF) in low-speed PMSM |

|

|

| [56] | Mathematical modeling of stator tooth flux with fault feature extraction using search coils | Online rotor fault diagnosis (demagnetization, eccentricity) in PMSM, using stator tooth flux sensors |

|

|

| [57] | FCS-MPC (Finite Control Set—Model Predictive Control) with model-based residual analysis for open-switch and current sensor faults | Matrix converter-based PMSM drives (airplanes, electric ships, military vehicles) |

|

|

| [58] | Rayleigh quotient-based fault indicator (combining 2nd harmonics in voltage and current) | Detection of inter-turn short-circuit (ITSC) in PMSMs, robust to controller bandwidth |

|

|

| [59] | Short-Time Adaline-based 2nd harmonic extraction from axis currents (Residual Insulation Monitoring) | Real-time ITSC diagnosis in PMSM (steady and dynamic conditions), residual insulation monitoring |

|

|

| [68] | Time Synchronous Averaging (TSA) of vibration signals (plus TSA-difference, TSA-regular, and wavelet decomposition) | Detection of mixed eccentricity faults in induction motors (can be extended to PMSM) under variable load |

|

|

| [69] | Airgap search coil flux monitoring and analysis of esc peak patterns for each pole | Online detection and classification of rotor and load faults (demagnetization, dynamic eccentricity, load unbalance) in PMSMs |

|

|

| [70] | Mathematical modeling and experimental validation (simulation and real PMSM); spectral analysis (FFT), phase current envelope; model-based fault indicators | Analysis of stator inter-turn short-circuits impact on PMSM with scalar and vector control |

|

|

| [71] | Adaptive fault-tolerant control + data matching | Dual three-phase PMSM drives (open-phase and open-switch faults) |

|

|

| [72] | Comparative stator current-based techniques: FFT spectral analysis, current envelope, Discrete Wavelet Transform (DWT) | Early detection of inter-turn short-circuit faults in PMSMs using stator current measurements |

|

|

| Ref. | Method/Algorithm | Application Context | Strengths | Limitations |

|---|---|---|---|---|

| [91,92] | SVM and CNN (1D/2D, multi-scale feature extraction) for ITSC, demagnetization, bearing faults | Early and multi-level fault detection in PMSM (variable speed/load) | High accuracy (~99%), robust to varying conditions, minimal manual feature engineering, early/multiclass diagnosis | Large data and computational needs (CNN); SVM depends on feature selection, minor fault data may be scarce |

| [93] | Shallow NNs (MLP, RBF, SOM) with FFT-based features | Bearing fault detection/classification in PMSM | Simple, fast, effective for limited data, low complexity | Sensitive to parameter/feature selection, less robust for complex/noisy signals, not end-to-end |

| [94] | CNN on CWT images; data augmentation (FEA + ANN) | Early broken bar fault detection (IM/PMSM), digital twin/virtual scenarios | Works with few/no real faulty samples, enables digital/virtual training | Needs simulation validation, CNN resource intensive, may not generalize to unseen cases |

| [95] | Multi-channel CNN with data normalization and overlap sampling | Inter-turn short fault and High-Resistance Connection (HRC) |

|

|

| [96] | Hybrid method: Bispectrum (BS) feature extraction + CNN classification | Stator winding inter-turn short circuit (ITSC) detection and classification in PMSMs | Very high classification accuracy (up to 99.4%); robust to load and speed variation; reduced training time and network size; only current sensors required; effective even for incipient faults | Requires BS computation; preprocessing step needed; generalization to other types of faults requires further testing |

| [97] | Residual dilated CNN with Bayesian Optimization (BO) for hyperparameter tuning | Early-stage ITSC detection and severity estimation in PMSM under various operating conditions | Learns from raw current signals; no manual feature engineering needed; BO automates tuning; achieves high accuracy across multiple fault severities; robust to variable conditions; only uses current measurements | Network complexity increases with depth; BO adds computational overhead during tuning; data-driven nature requires representative fault samples |

| [98] | 1D ResNet with ConvLSTM regulator and multi-filter approach | Detecting ITSC and bearing faults (PMSM and CWRU dataset), using current and vibration signals | Generalizes to multiple fault types and signals; achieves 100% test accuracy even with small datasets; converges faster; robust to lower sampling rates; lower complexity than other deep variants | LSTM regulator increases model complexity; computational time still higher than traditional methods; may require adaptation for very noisy environments |

| [99] | Spectral analysis of symmetrical current components + K-Nearest Neighbors (KNN) classifier | On-line detection and classification of stator winding ITSC in PMSM | Simple hardware/software; fast training; sensitive even to a single shorted turn; robust to variable speed/load, explainable output | KNN less efficient for high-dimensional/large data; requires careful selection of features and K value |

| [100] | Deep feedforward neural network (DNN) using feature-engineered current signals | Detection and classification of single/double open-circuit faults in PWM-VSI (motor drives) | High diagnostic accuracy (>95%); strong generalization, effective for multiple fault types; no extra sensors required; scalable for multi-fault detection | Relies on extracted features, not end-to-end; DNN requires tuning; performance may be sensitive to data representativeness and sensor quality |

| [101] | Ensemble ML classifiers (Voting, KNN, Decision Tree, XGBoost, AdaBoost, Logistic Regression, SGD); uses current, voltage, speed, Hall sensor data | BLDC motor and inverter line fault detection/classification in EVs (simulation, real data, variable operating modes) | Real-time capability; high accuracy (>98% with voting classifier); covers multiple fault types; robust comparison with other ML methods | Relies on a rich dataset (simulated + measured); practical deployment may need sensor integration and computational resources |

| [102] | Average Current Park’s Vector (ACPV) analysis; threshold-based fault detection and localization | Six-phase FTPMSM (aerospace/industrial, including open/short-circuit and fault-tolerant modes) | No extra hardware/sensors needed; robust to speed/load variations; real-time; low computational burden | Limited to open-circuit power switch faults; relies on accuracy of current measurements; extension to other fault types may require adaptations |

| [103] | Wavelet CNN (WCNN) using normalized current vector trajectory as feature; DWT pooling for noise robustness | PMSM inverter open-circuit fault diagnosis (covers 22 fault types; validated in simulation and experiment, under noise and varying loads/speeds) | High accuracy with very small datasets; excellent noise immunity; robust to changing operating conditions; fast inference | Only open-circuit faults addressed; requires construction of current vector trajectory; network design (depth, pooling) impacts performance |

| [104] | Semi-supervised CRF-GAT (graph neural network + conditional random field); combines labeled/unlabeled data; learns label dependencies | Fault diagnosis in rotating machines (PMSM and IM); identifies status, severity, and working condition, including demagnetization, BRB, bearing, short-circuit faults | >97% accuracy with <10% labeled data; robust to limited labels; models both data and label relationships; scalable to many fault types and conditions | Complexity of graph/network construction; needs design/tuning for new datasets; interpretability may be challenging for practitioners |

| Ref. | Hybrid Solution Composition | Data and Sensors | Fault Types Addressed | Hybrid Advantage |

|---|---|---|---|---|

| [105] | Hybrid statistical features + AI/ML optimizer | Vibration, current | Multiple and combined faults (IM) | Diagnoses simultaneous faults, robust, real-time. |

| [106] | MPC + MLD model + data-driven indicators | Motor currents | Open-switch faults (PMSM) | Fast, accurate, robust to parameter variations. |

| [107] | Bayesian networks + ARMA time series | Multi-sensor degradation data | Prognosis, multi-stage degradation | Tracks stage changes, improves prognosis accuracy. |

| [108] | Federated stacking (NSAE + DAE) + PSO | Distributed, edge current data | ITSC, imbalanced IIoT data | Privacy, robust to imbalance, scalable, low comm. Cost. |

| [109] | Sensor fusion + ML classifier | Vibration, current (fusion) | Bearing faults (SRM, EV) | Enhanced discrimination, robust for EV, multi-sensor. |

| [110] | Isolation Forest + IFRA features | Vibration/IFRA | Winding anomaly (SM) | Accurate for rare/unlabeled data, robust, fast. |

| [111] | Model current prediction + signal analysis | Motor currents | Open-phase/open-switch (PMSM) | Rapid, phase/type localization, no extra sensors. |

| [112] | WSCN + SSDRB classifier | Magnetic leakage, SDP images | Demagnetization (PMSM) | Non-contact, few labels, noise-robust, high accuracy. |

| [113] | Data fusion + BP neural network | Temp, current, torque, speed | Demagnetization (EV PMSM) | Multi-signal, sensitive to fault, easy signals. |

| [114] | Edge data reduction + ML classifier | Vibration, current (edge/IIoT) | Bearing faults (PMSM) | Low bandwidth, scalable, preserves accuracy. |

| [115] | Digital twin simulation model + ML classifier | Vibration (measured and simulated) | Bearing faults (single, mixed) | Overcomes real data scarcity, adapts simulation model to real machine via PCC correction, improves classification and prognosis accuracy. |

| [116] | Predictive current error analysis + Fuzzy Logic | Open-switch faults in voltage source inverters for PMSM drives | Current sensors only; no extra hardware | Can detect both single and multiple faults, robust to parameter and load variations, and capable of identifying both permanent and intermittent faults. Simple implementation and real-time suitability. |

| [117] | Attention-based hybrid CNN-MLP with multi-sensor fusion | Fault diagnosis for three-phase asynchronous motors | Vibration and current signals | Simultaneous processing of different data types enables complementary diagnosis of electrical and mechanical faults; achieves >99% accuracy, high robustness, and cost-effectiveness; dynamic weighting improves performance over single-modality approaches. |

| [118] | Search coil-based voltage analysis + signal processing (coordinate transformations, LPF) | Inter-turn short-circuit faults in IPMSMs for EVs | Specially arranged search coils in stator | Very high sensitivity to ISCF; method amplifies high-frequency fault signatures, robust to speed/load changes, suitable for online real-time diagnosis. Reduced cost due to optimized SC placement. |

| [119] | Integration of inter-turn fault diagnosis and torque ripple minimization via advanced control | Inter-turn short-circuit faults in SPMSM with DTC | Current sensors, control system data | Joint approach for diagnosis and real-time control improvement; reduces torque ripple while maintaining accurate fault detection under varying loads. |

| Ref. | Technique/Cross-Domain Approach | Application Context | Key Advantages | Limitations |

|---|---|---|---|---|

| [120] | Toroidal-yoke-type search coil flux analysis | PMSM demagnetization fault localization | Multi-pole, non-invasive, precise location | Needs additional coils; limited to flux faults |

| [121] | Non-intrusive leakage flux (search coil) + STFT | Rotor fault detection in salient-pole SM | Differentiates damper/field faults, no disassembly | Requires startup transient; sensitivity drop in steady state |

| [122] | Vibration analysis for unbalance | PMSM unbalance detection | Simple, highly effective for mechanical issues | Only mechanical faults; not generalizable |

| [123] | Stray magnetic flux monitoring (using both fundamental and third harmonic components) for detection and location of inter-turn short circuit faults in PMSM | Early-stage detection and localization of stator winding faults in PMSMs | Can detect and locate faulty winding; third harmonic analysis provides robust fault indication regardless of fault severity and operating point | Requires fluxgate sensor installation; fundamental component alone can miss faults at low speeds or with low severity |

| [124] | Review and comparative analysis of magnetic sensors (Hall, search coil, fluxgate, TMR, etc.) for internal and stray flux monitoring, with discussion of flux-based diagnostic techniques for various faults (stator, bearing, rotor, eccentricity, demagnetization, transformer faults, etc.) | Broad range of AC machines (induction, PMSM, synchronous machines, transformers) | Highlights versatility and advantages of flux-based methods; potential for location detection and improved reliability; many sensor options for non-invasive measurement | Some sensor types (search coil, Hall) are invasive; cost and complexity if multiple sensors required; practical implementation can be challenging for some fault types |

| [125] | Planar Search Coil (PSC) for direct detection of static and dynamic eccentricity in PMSMs via analysis of airgap flux linkage and inductance deviation | Eccentricity fault diagnosis in PMSM drives (static, dynamic, mixed eccentricity) | Detects and differentiates between static and dynamic eccentricity; flexible PCB sensor is easy to install and minimally invasive; robust against noise with proper signal processing | Requires sensor placement on stator teeth; less suitable for motors with very small airgaps; extra hardware compared to purely current-based methods |

| [126] | Infrared thermography for fault diagnosis using thermal signatures, combined with image processing and pattern recognition | Non-intrusive detection of electrical faults in commutator and induction motors | Enables remote, non-contact diagnosis; can visualize and classify multiple fault types using thermal patterns | Limited by camera resolution and sensitivity; affected by ambient conditions; less effective for incipient (early-stage) faults with low heat signature |

| Fault Type | Dataset Type | Accuracy (%) | Detection Latency (ms) | Key Notes |

|---|---|---|---|---|

| ITSC (5% and 10% shorted turns, Rf = 0 Ω) [127] | Experimental (2 kW PMSM test bench, DSP28335 @150 MHz, 5 kHz switching) | >95% (robust under steady, dynamic, and load perturbations) | <1000 ms (fault diagnosis), current calculation in 100 ms | Accurate fault localization; superior to LPF-SMO; slight performance degradation at very low/zero speed |

| Current sensor incipient (phase-c, >5% amplitude), disconnection, drift [128] | HIL experimental setup (dSPACE + DSP TMS320F28335, PMSM) | >95% (validated by robust detection under disturbances) | 36 ms (incipient), 1 ms (disconnection and drift) | Novel interval SMO with adaptive thresholds; robust to DC voltage fluctuation, inductance unbalance, and load torque variation |

| OC inverter faults + ITSC (10–30% shorted turns) [129] | Multisource dataset (3 phase currents + 3 line voltages), Simulink + PMSM experimental platform | 100% | ~1036 ms (full testing set inference time) | Lightweight 1D-LKCNN with multisource data fusion; fewer parameters and FLOPs than MobileNetV2/ShuffleNetV2; real-time capable for embedded drives |

| ITSC (early-stage, 1–4 Ω residual insulation resistance) [130] | Experimental test bench (IPMSM, dSPACE, 20 kHz) + FEM simulations | 97.8–99% (avg 97.81%, max 98.97%), false alarm rate 0.66% | <1000 ms (online monitoring) | ResNet-18 CNN robust to controller bandwidth variation; superior to CNN, AE, RNN; effective on close fault degrees |

| Inverter open-circuit faults (T1, T1 and T3, T1 and T4) [131] | Experimental PMSM drive (DSP TMS320F28335, 10 kHz sampling, 400 sets) | 92.85% (30-step adaptation); >89% consistently | <30 ms (per diagnostic run) | Hybrid method combining Luenberger observer residuals + Siamese ViT network; robust to load variation; effective with few-shot datasets |

| Inverter open/short-circuit, thermal faults (HB1–HB3) [132] | Experimental dataset (10,892 samples, multisensor fusion: currents, voltages, temps) | 98.6% overall, F1 = 0.9786; per-class up to 100% | 3.2 ms (GPU inference) | Transformer + Physics-Informed NN (PINN); robust across load/speed/temp variations; physics-based constraints reduce false alarms (0.43%) |

| Stator inter-turn short-circuit faults [133] | Experimental PMSM test rig (currents + vibration, 1000 samples, 50/50 split) | 90.7% (fusion), 74.5% (vibration), 43.4% (current) | N/A (offline ML) | Gradient boosting with vibration-current fusion; AUC 95.1%, F1 = 0.878; data fusion greatly improves accuracy |

| ISCF, demagnetization (10%, 30%, 100%) [134] | Experimental PMSM datasets, cross-domain (multi-speed, multi-load, label noise, category inconsistency) | 95–96% avg (DUDAN); CNN ~62%; DAN ~69%; UAN ~91%; CMU ~86%; DANCE ~82 | ~1000 ms (1 s sample window, 10 kHz) | DUDAN (denoising universal domain adaptation); robust to noisy labels and fault category inconsistency; H-score > 90% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gherghina, I.-S.; Bizon, N.; Iana, G.-V.; Vasilică, B.-V. Recent Advances in Fault Detection and Analysis of Synchronous Motors: A Review. Machines 2025, 13, 815. https://doi.org/10.3390/machines13090815

Gherghina I-S, Bizon N, Iana G-V, Vasilică B-V. Recent Advances in Fault Detection and Analysis of Synchronous Motors: A Review. Machines. 2025; 13(9):815. https://doi.org/10.3390/machines13090815

Chicago/Turabian StyleGherghina, Ion-Stelian, Nicu Bizon, Gabriel-Vasile Iana, and Bogdan-Valentin Vasilică. 2025. "Recent Advances in Fault Detection and Analysis of Synchronous Motors: A Review" Machines 13, no. 9: 815. https://doi.org/10.3390/machines13090815

APA StyleGherghina, I.-S., Bizon, N., Iana, G.-V., & Vasilică, B.-V. (2025). Recent Advances in Fault Detection and Analysis of Synchronous Motors: A Review. Machines, 13(9), 815. https://doi.org/10.3390/machines13090815