Enhanced Voltage Stability and Fault Ride-Through Capability in Wind Energy Systems Using FACTS Device Integration

Abstract

1. Introduction

- (i)

- A grid-connected wind system comprising six FSWGs is systematically examined under diverse operating conditions, including both ideal and turbulent wind profiles, as well as multiple grid fault scenarios. This provides new insights into the dynamic challenges faced by conventional FSWG-based wind farms, which are often overlooked in favour of modern variable-speed systems.

- (ii)

- The study investigates the integration and performance of FACTS devices to improve voltage stability, enhance fault ride-through (FRT) capability, and strengthen the overall reliability of modern power systems. The work highlights how FACTS-based compensation offers a more flexible and robust alternative compared to traditional fixed capacitor methods.

- (iii)

- The article develops and evaluates control strategies specifically tailored for the optimal operation of FACTS devices within wind farm systems. These strategies demonstrate superior performance across various operational scenarios, establishing their practical application value in improving system stability, reducing downtime, and supporting large-scale wind energy integration into power grids.

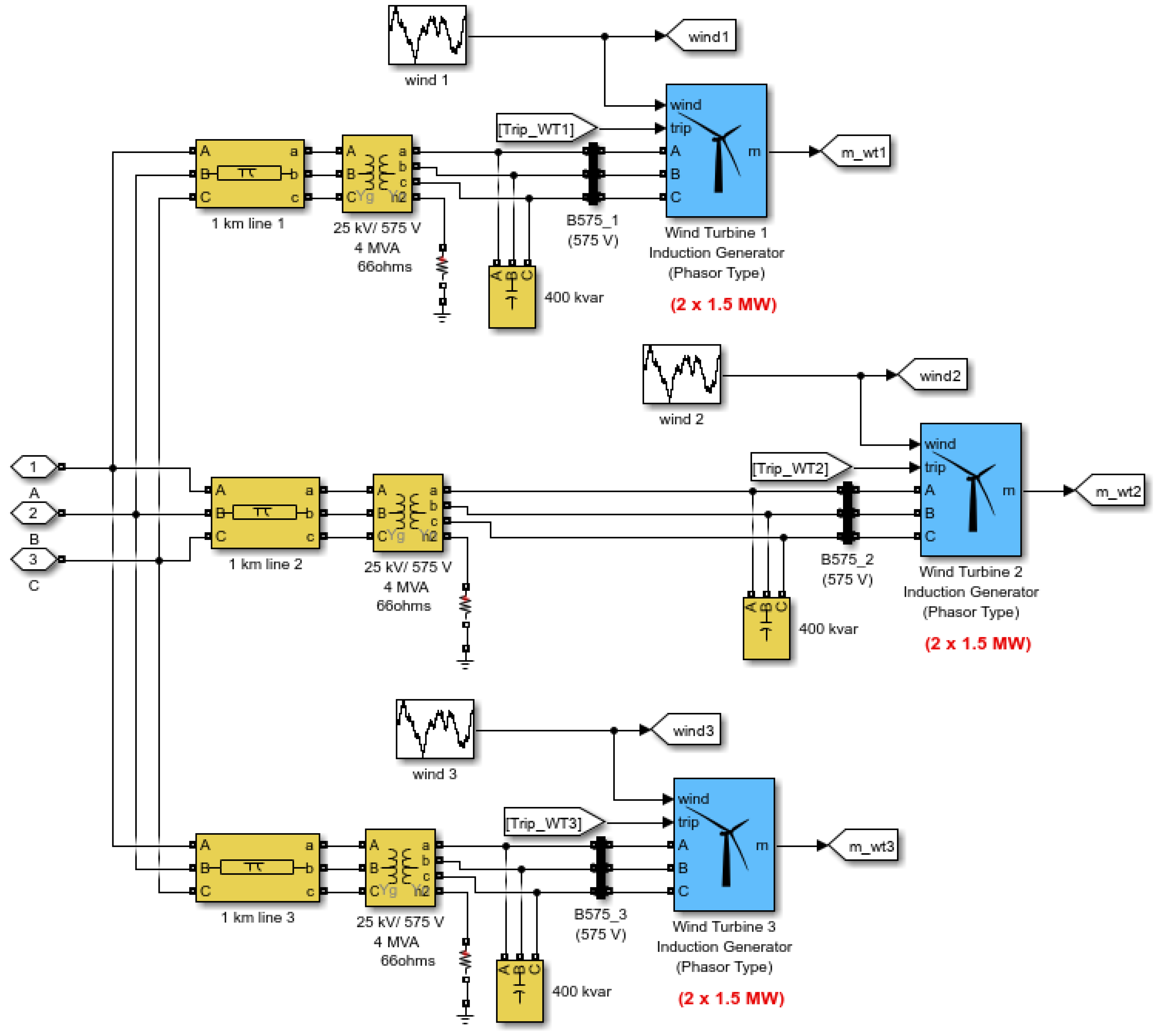

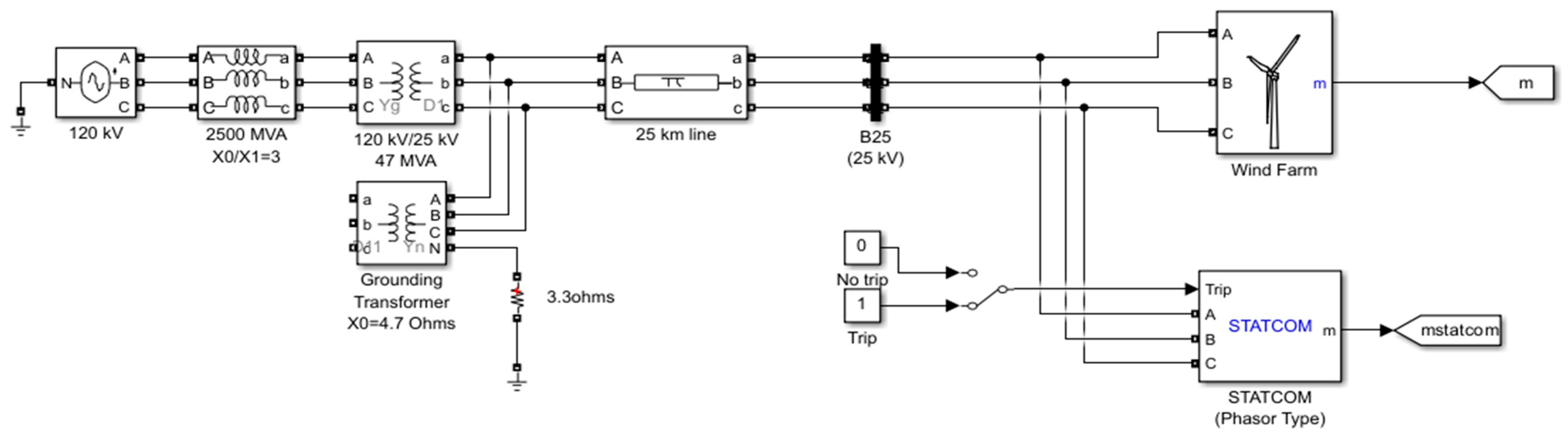

2. Description of the Wind Farm

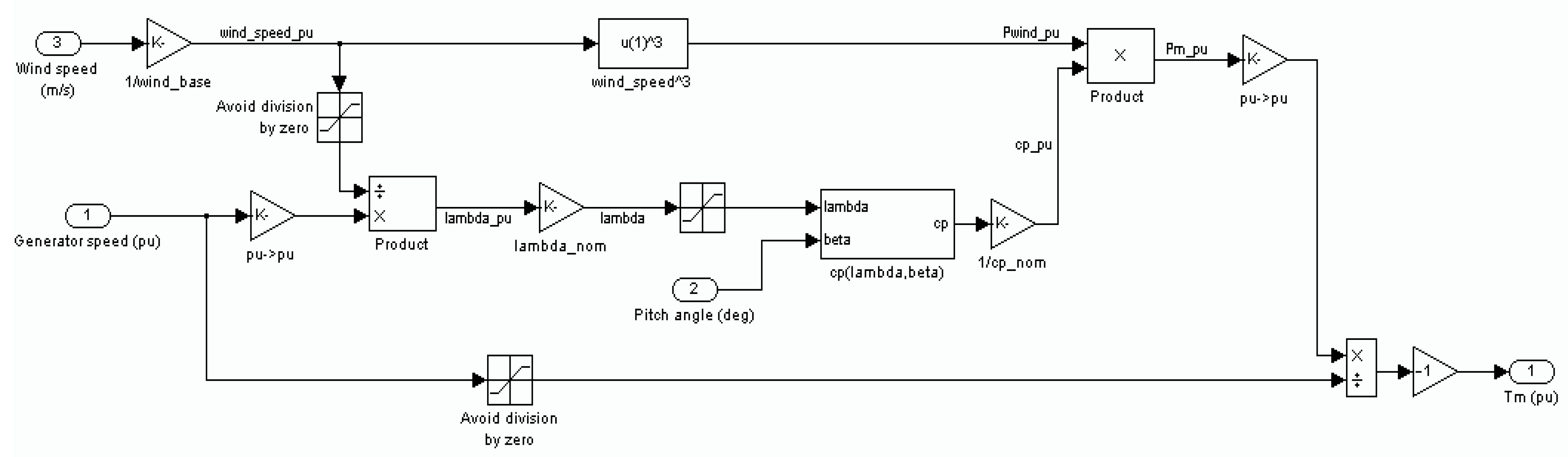

2.1. Modelling of Wind Generated Energy System (WGES)

- (1)

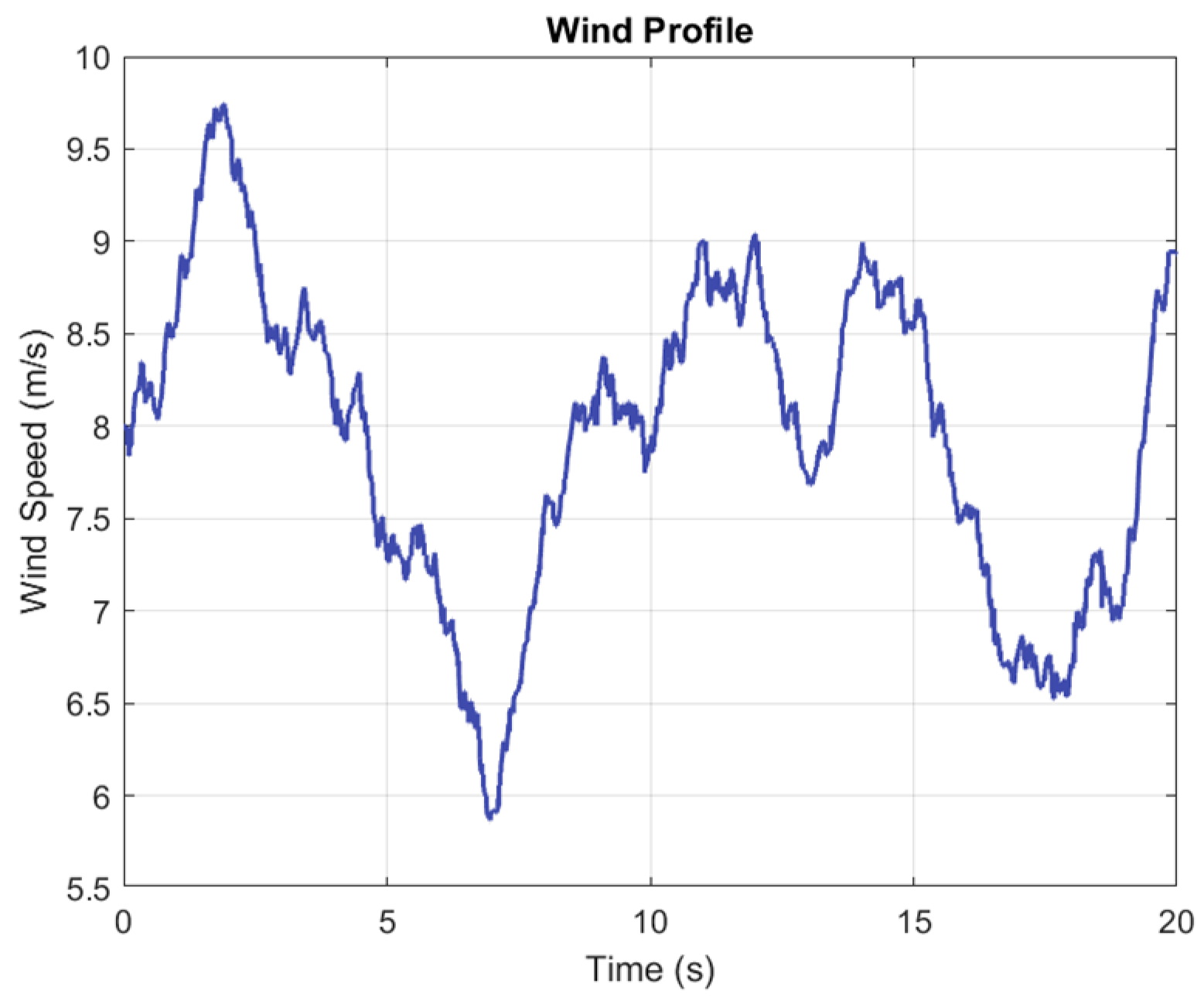

- Wind speed is simulated by combining turbulence and average wind.

- (2)

- Wind speed is simulated by combining step wind, average wind, random wind, and gust wind.

- (1)

- The influence of temperature and frequency on the corresponding parameter values of the motor is not taken into account, and spatial harmonics, magnetic saturation, and core loss are ignored.

- (2)

- The stator and rotor windings are symmetrically distributed, using Y-type connection and fixed values of self-inductance and mutual inductance.

- (3)

- The rotor side is converted to the stator side, and the ratio of the number of turns of the converted winding is 1.

2.2. Modelling of Squirrel Cage Induction Generator (SCIG)

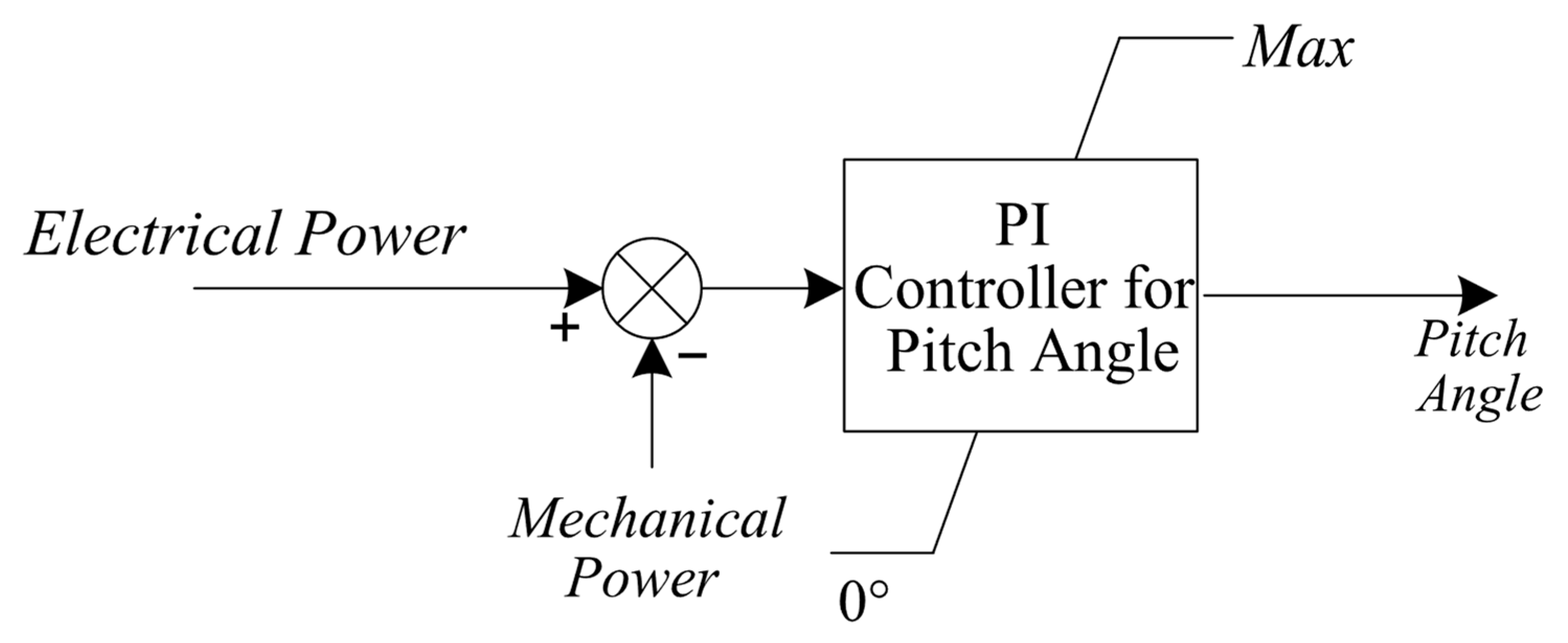

3. Modelling of FACTS

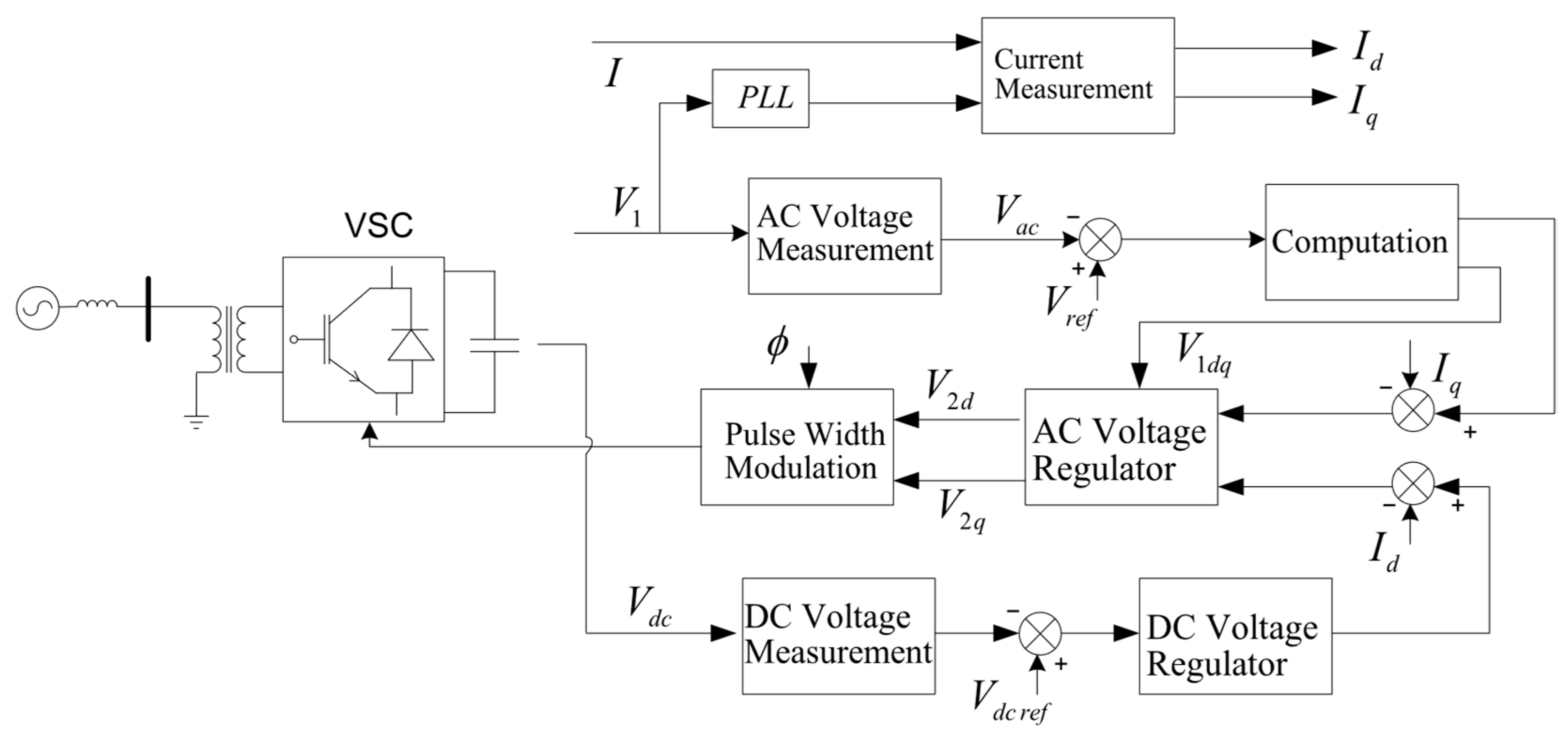

3.1. Modelling of STATCOM

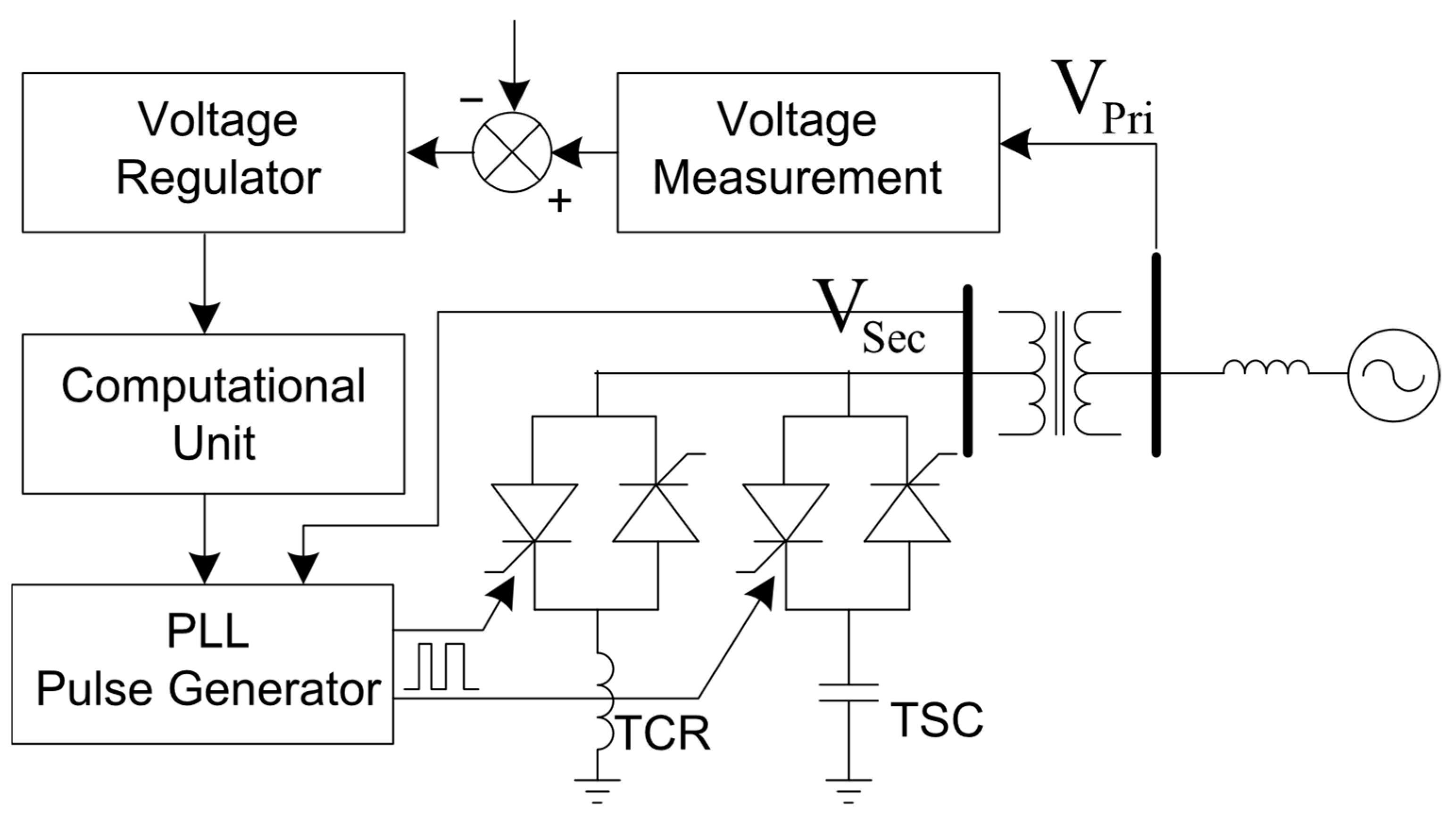

3.2. SVC Modelling

3.3. Cost-Efficient FACTS Study

4. Results & Discussion

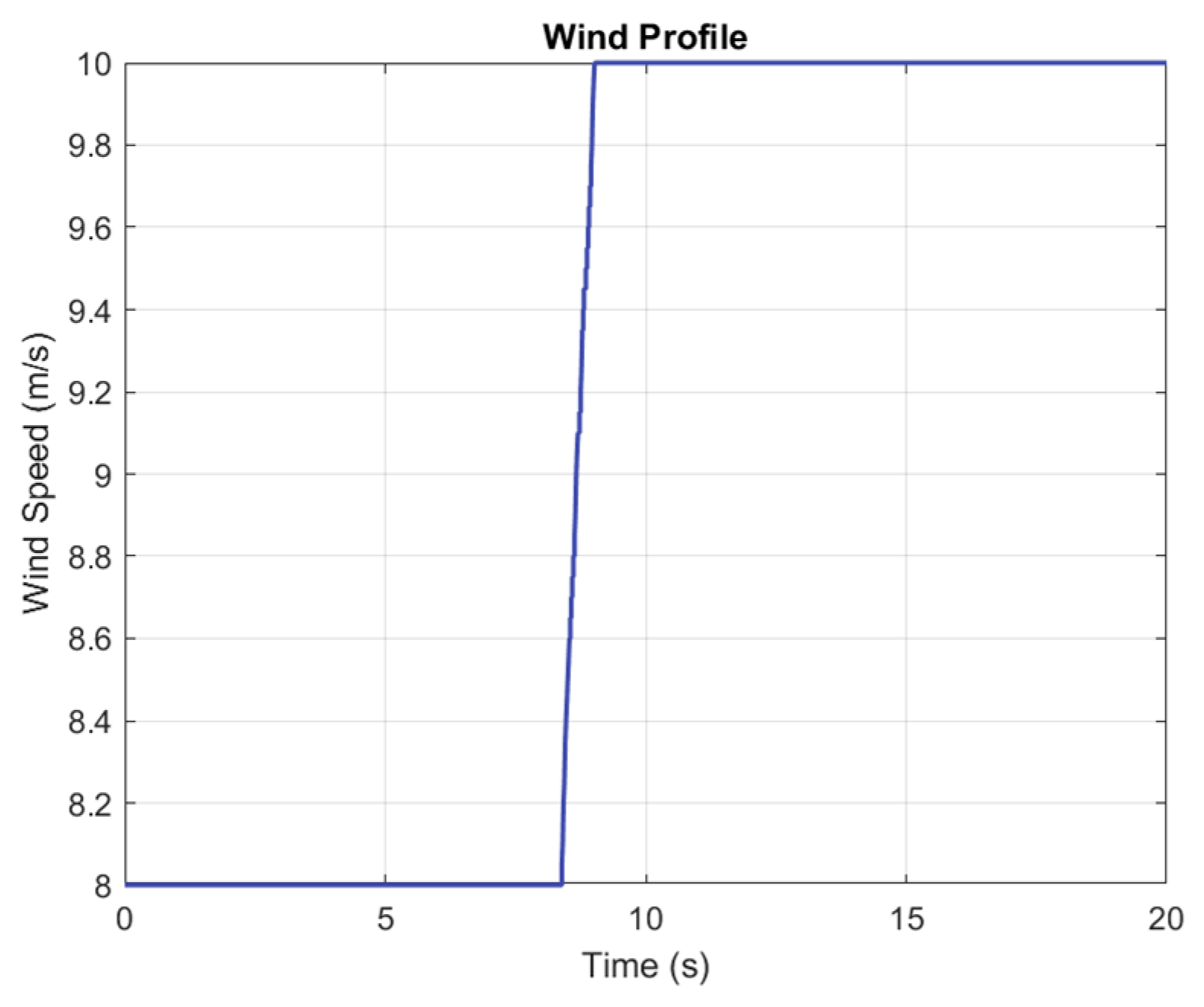

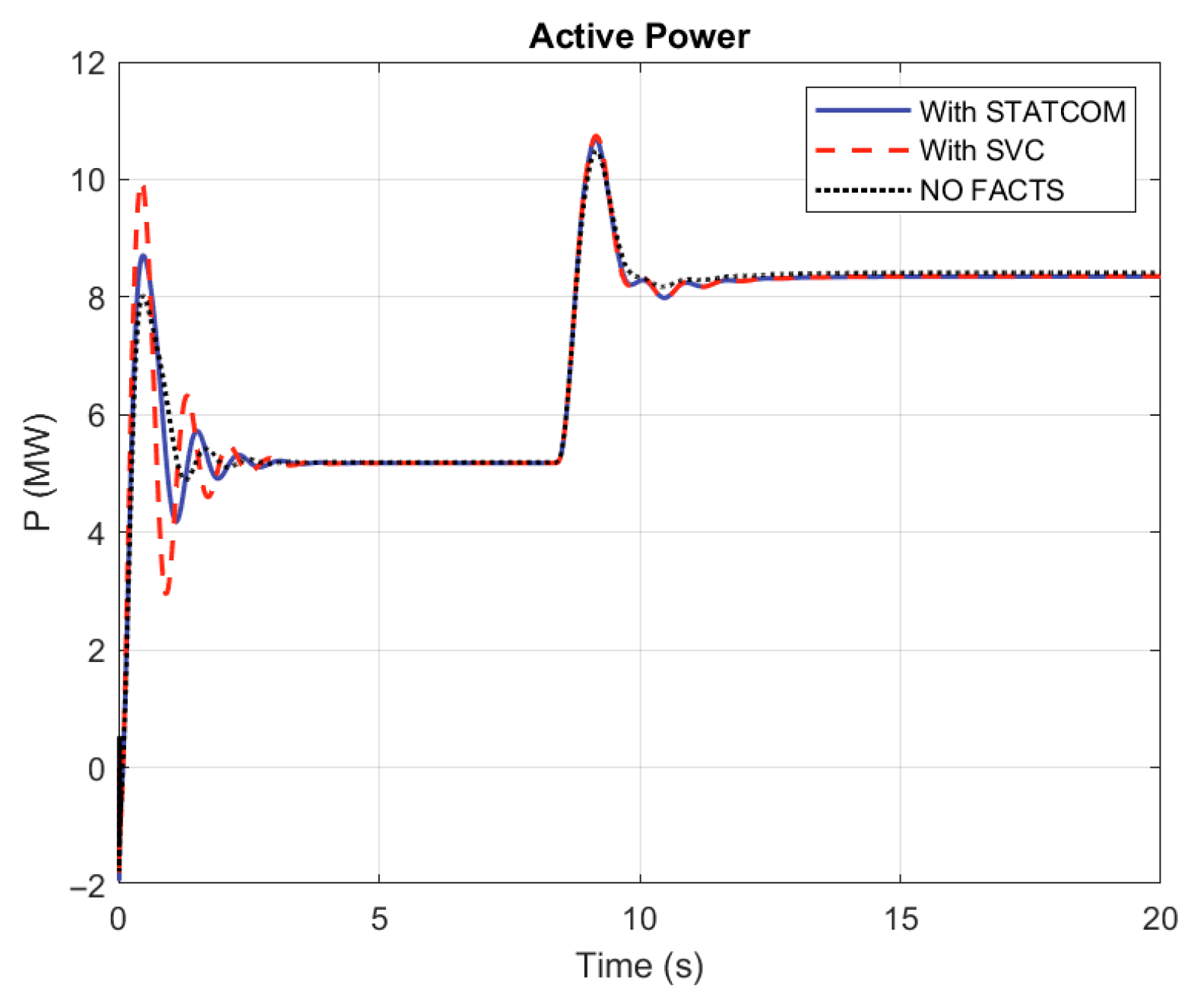

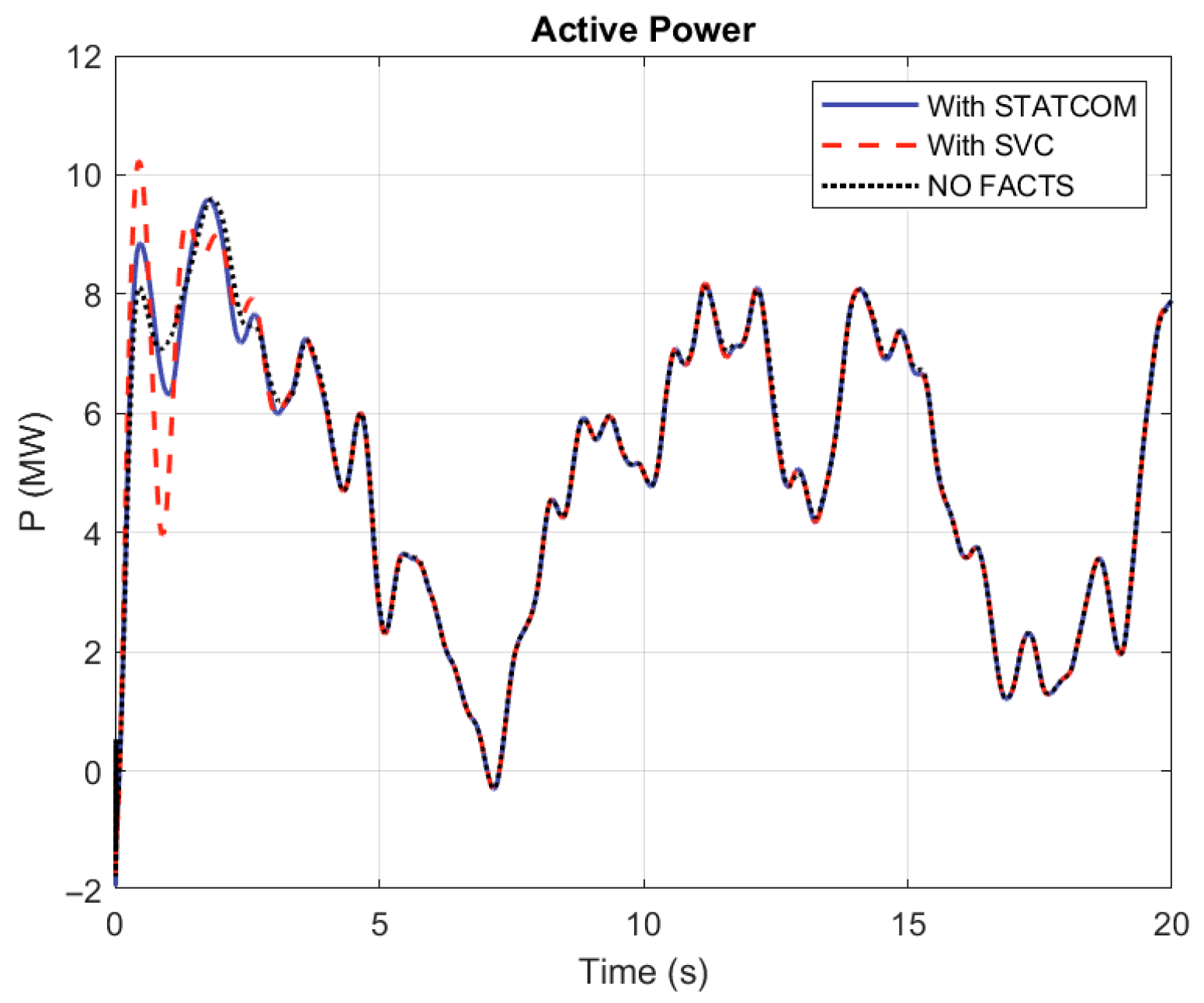

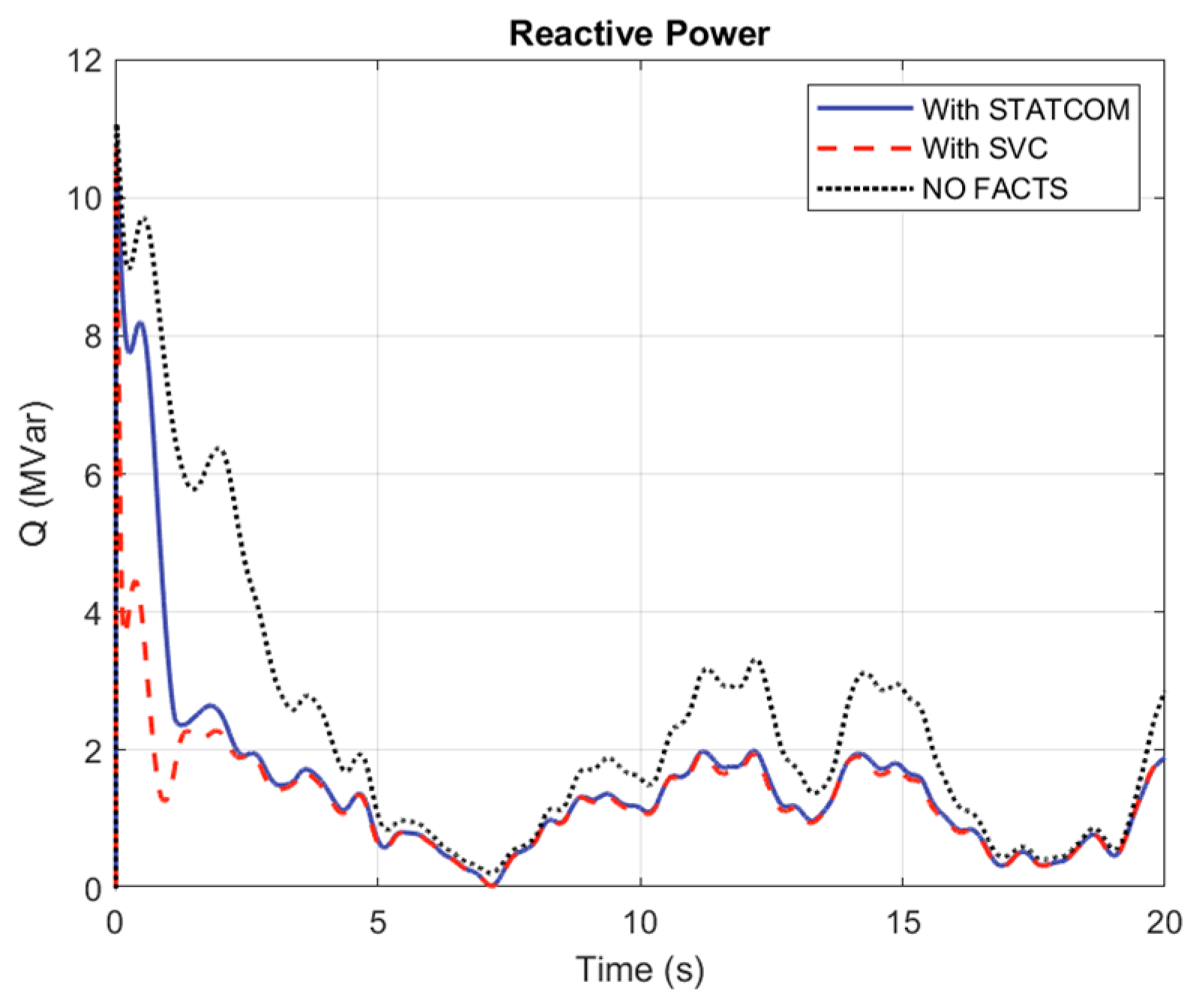

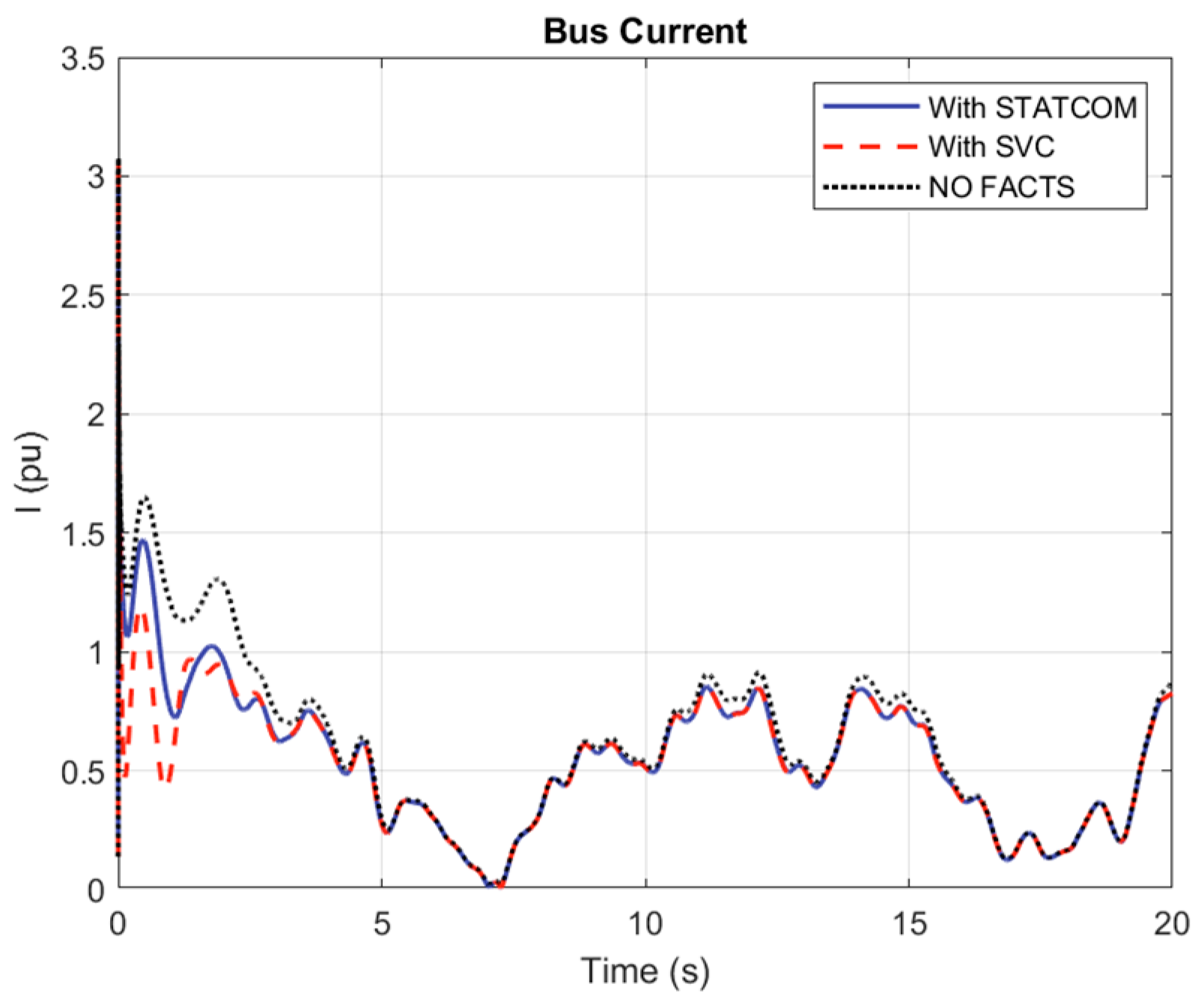

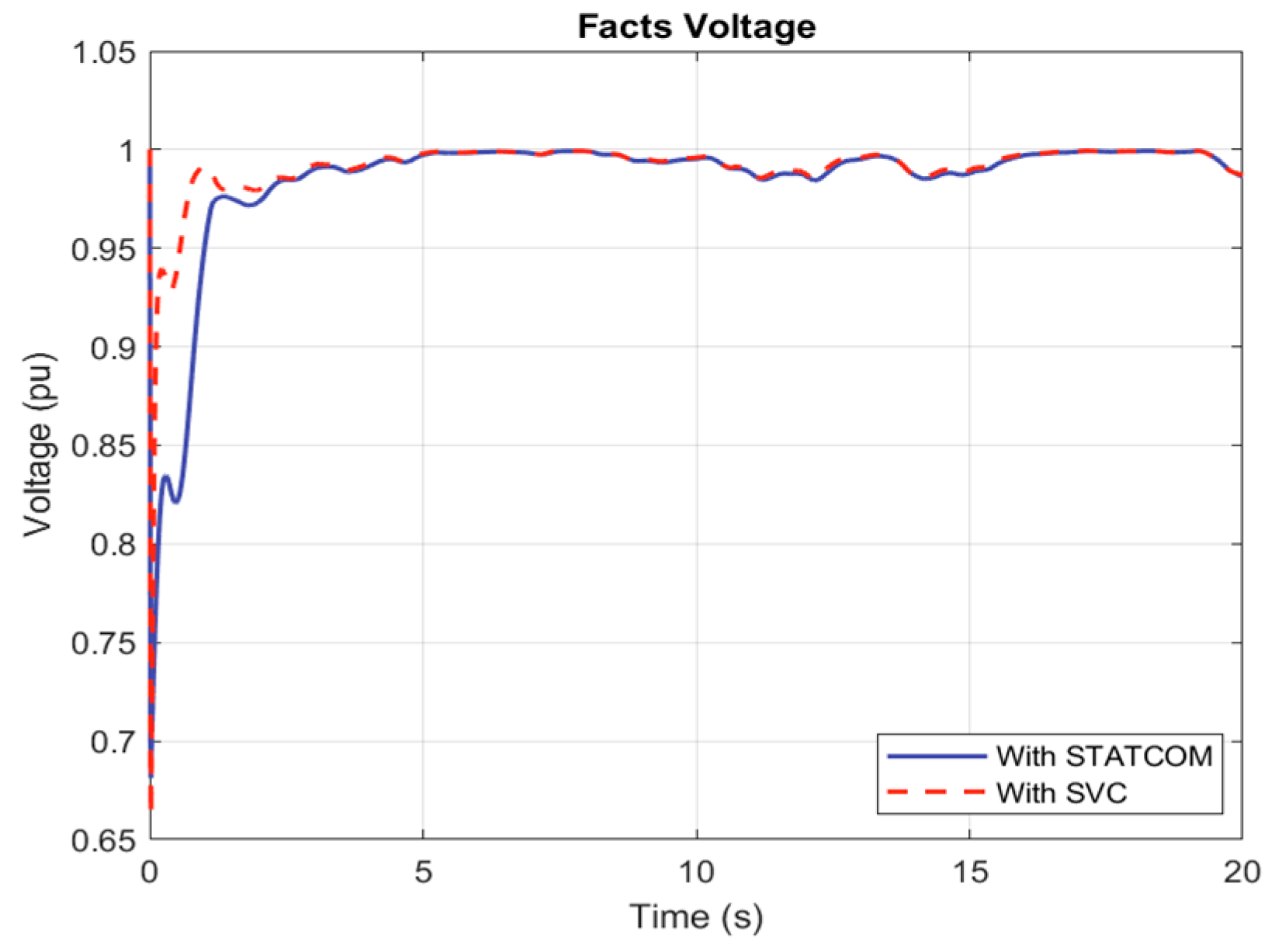

- Case 1: Ideal Wind Speed Profile

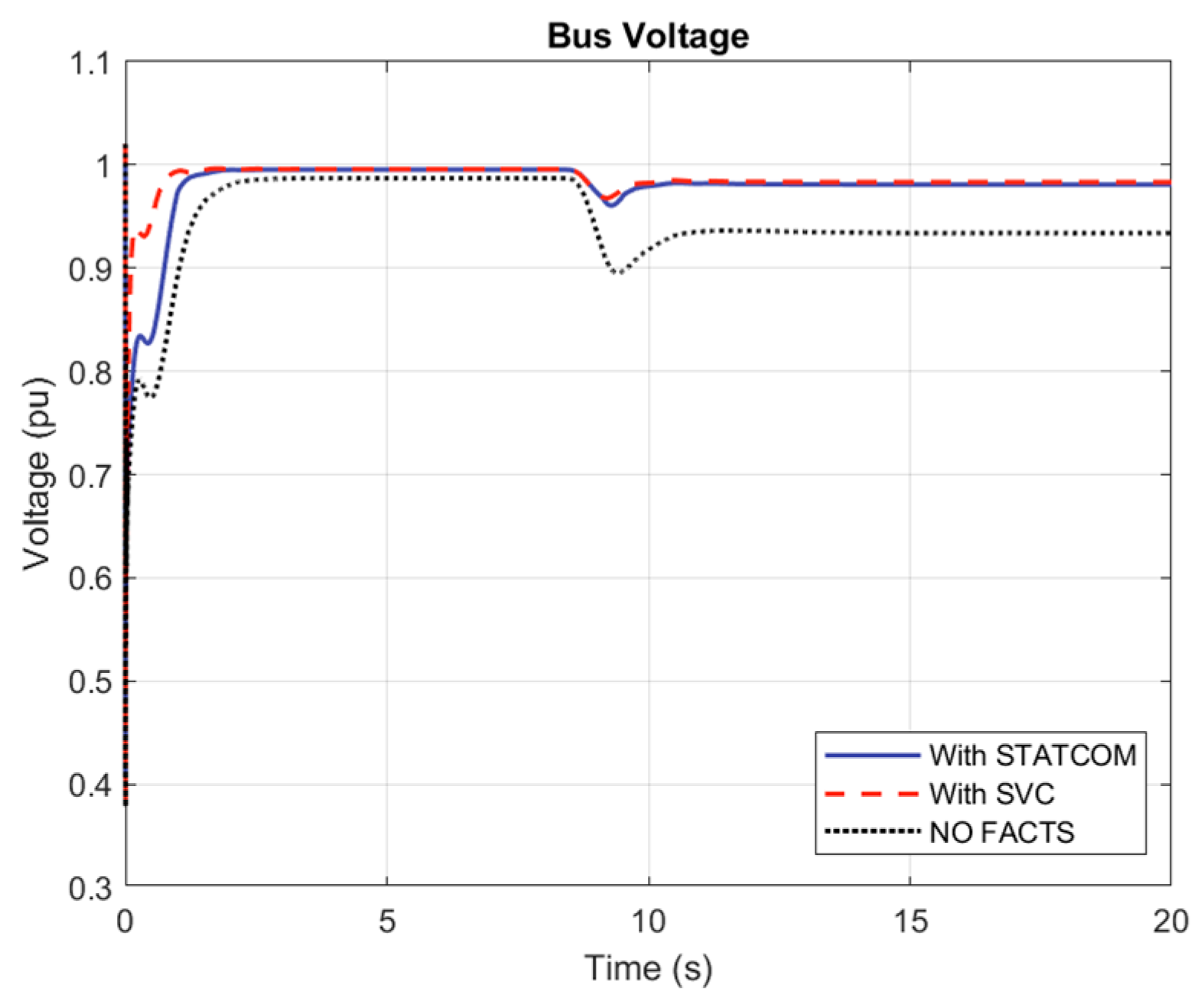

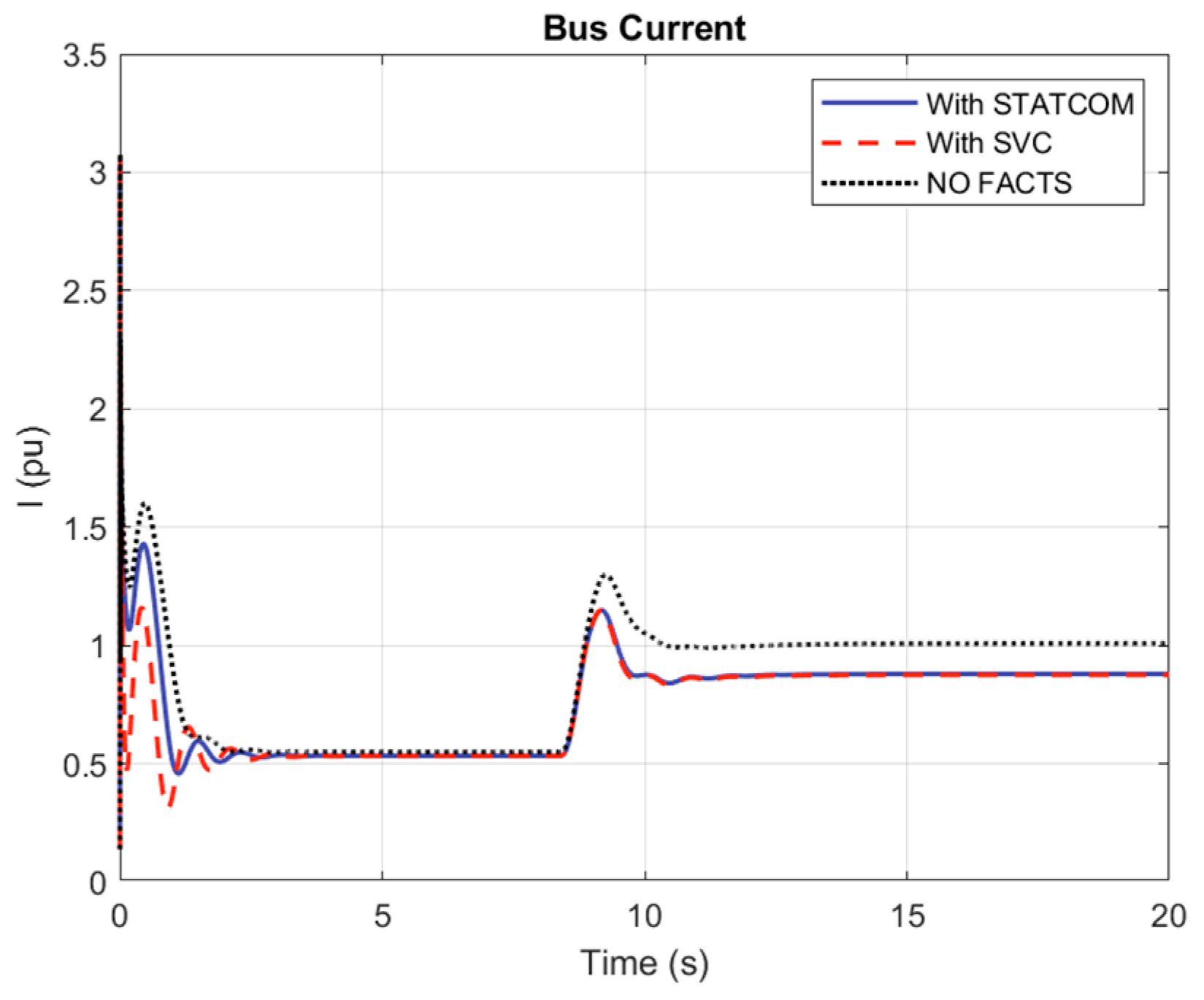

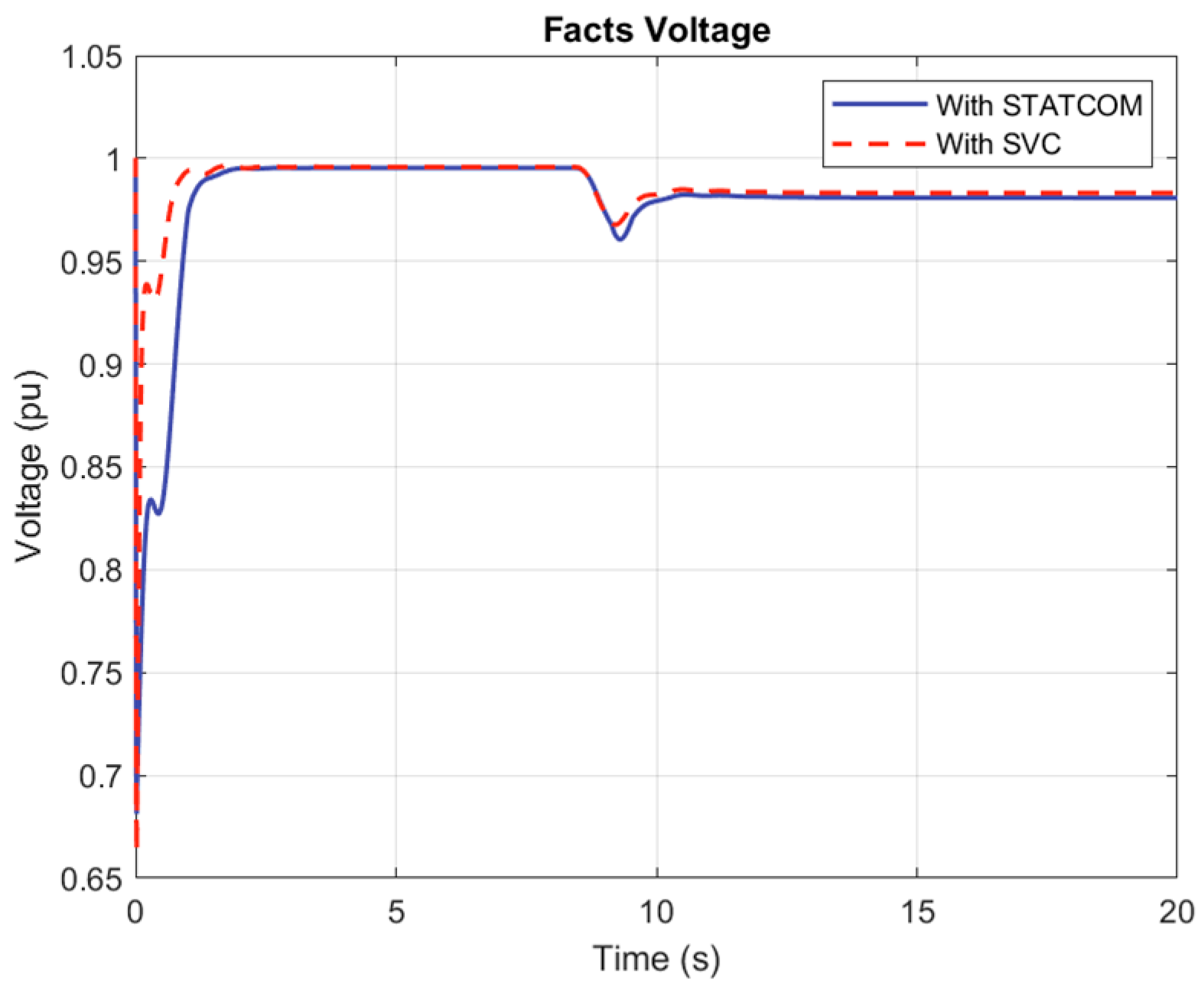

- Case 2: Turbulent Wind Speed Profile

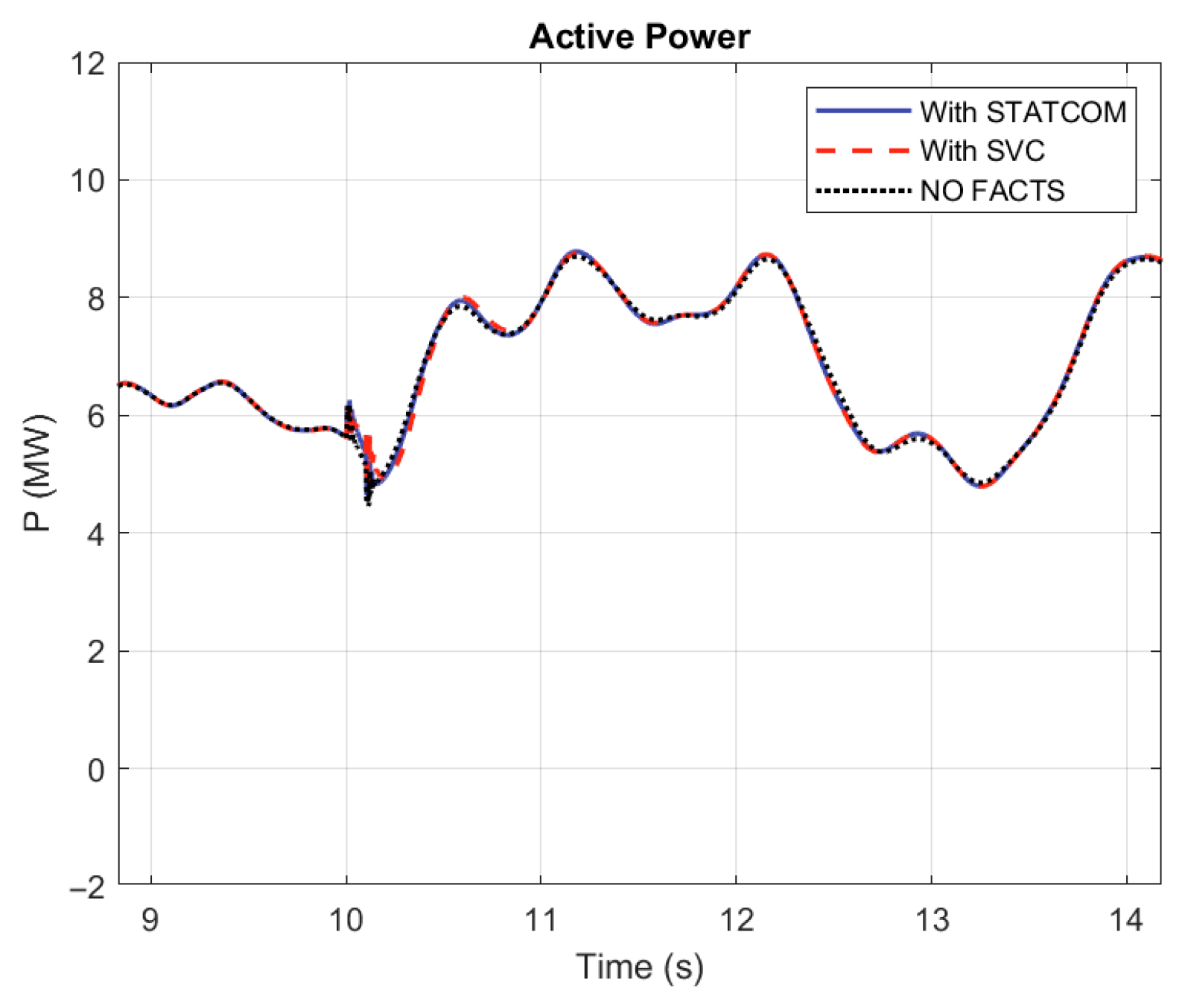

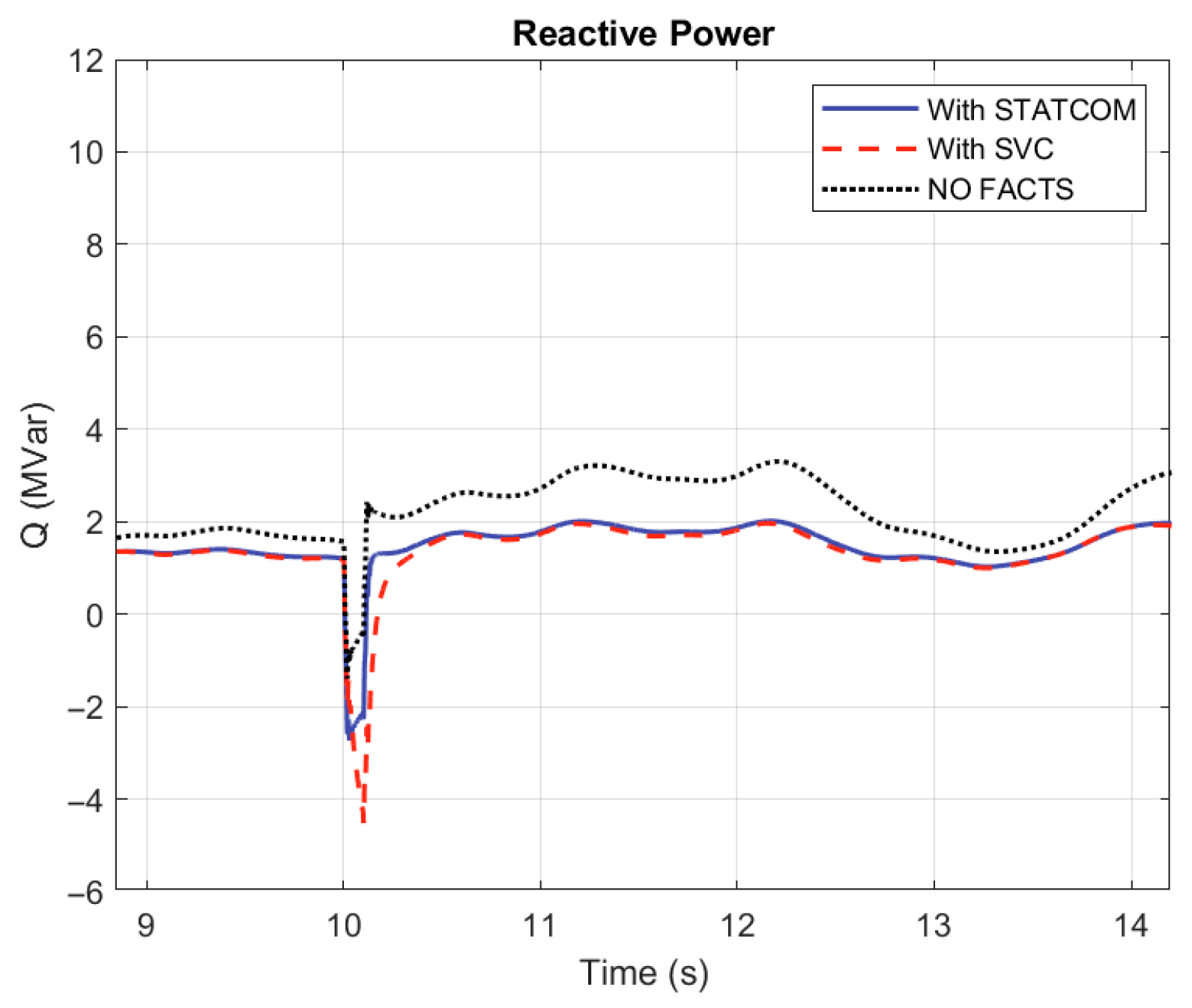

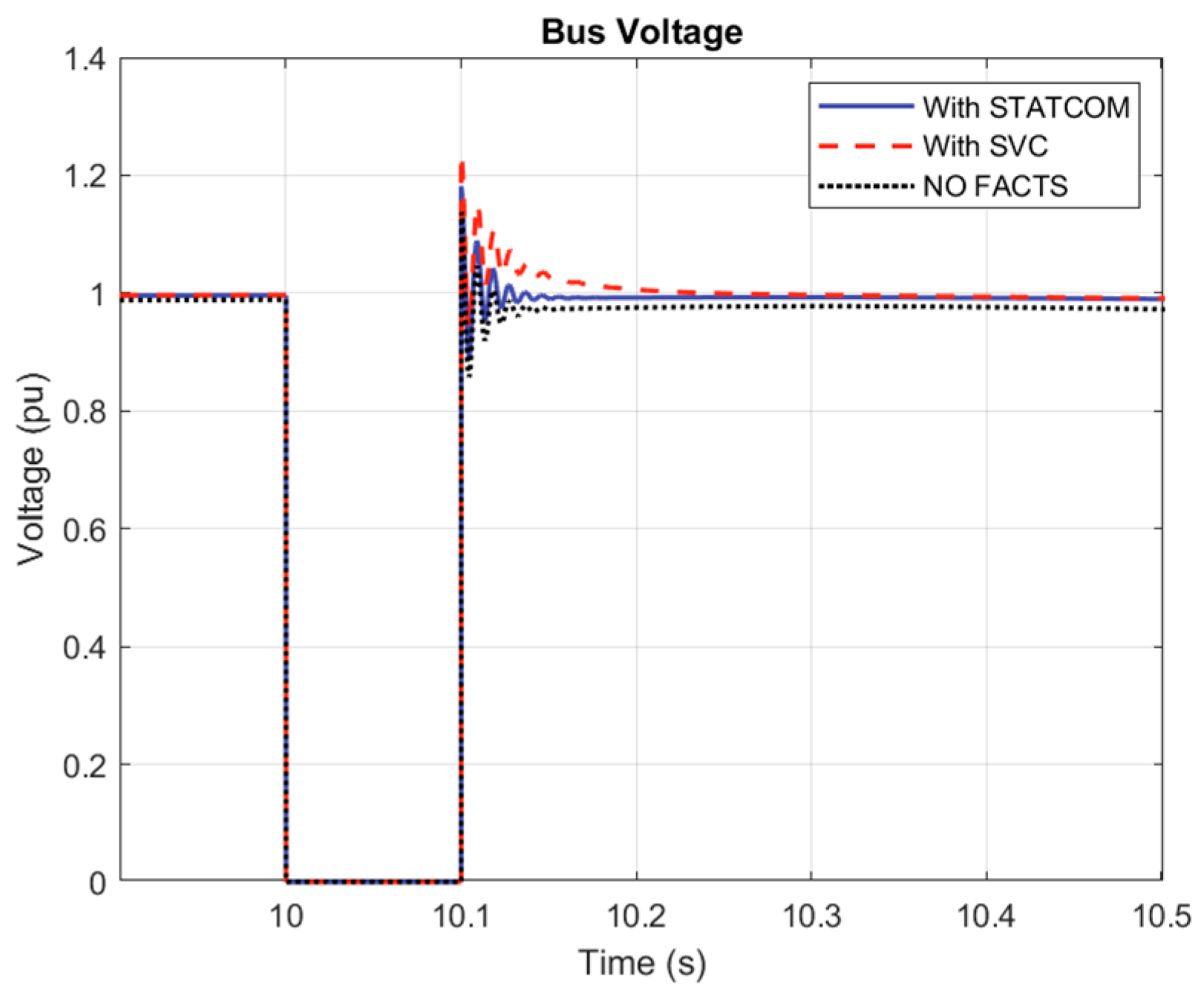

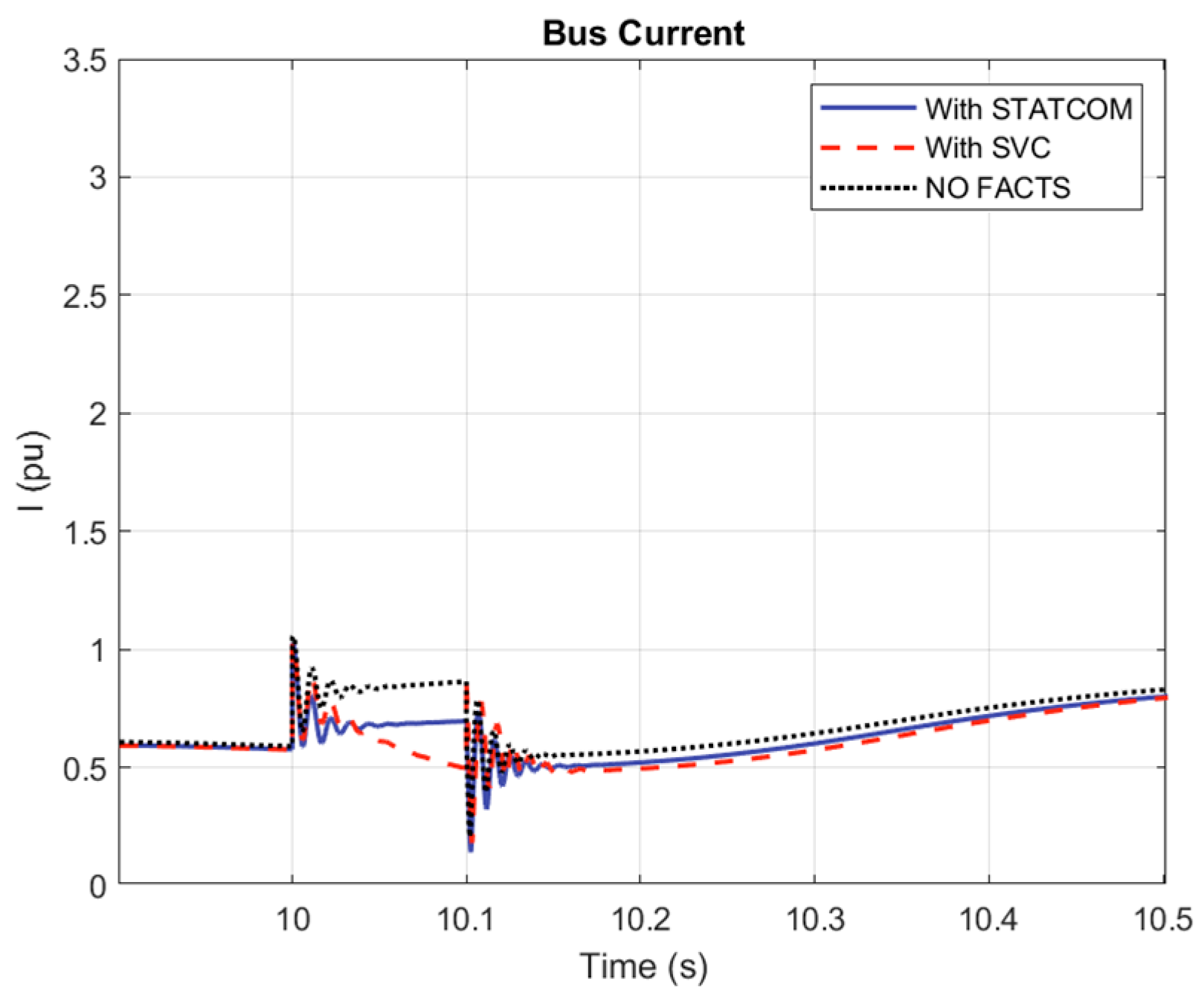

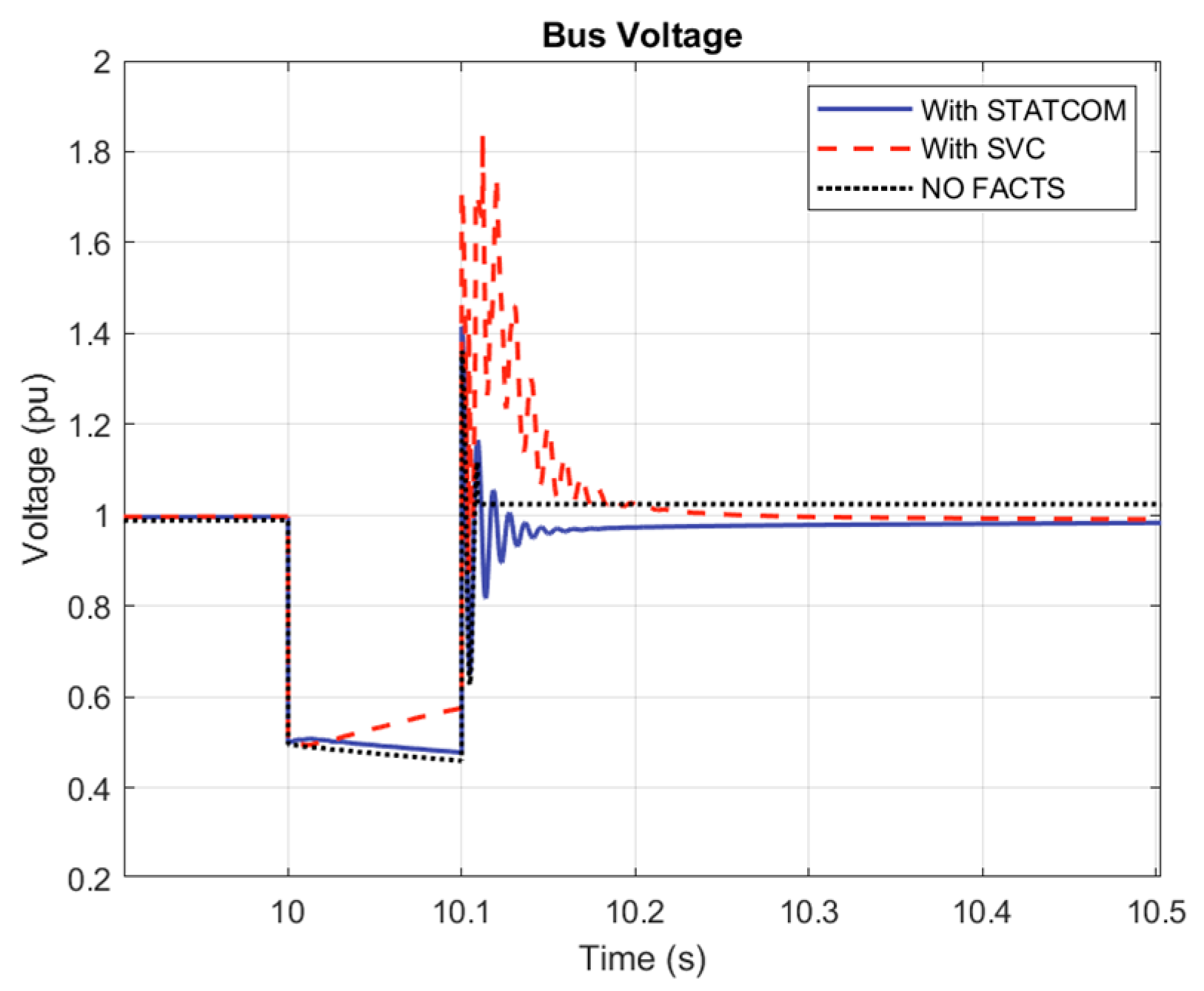

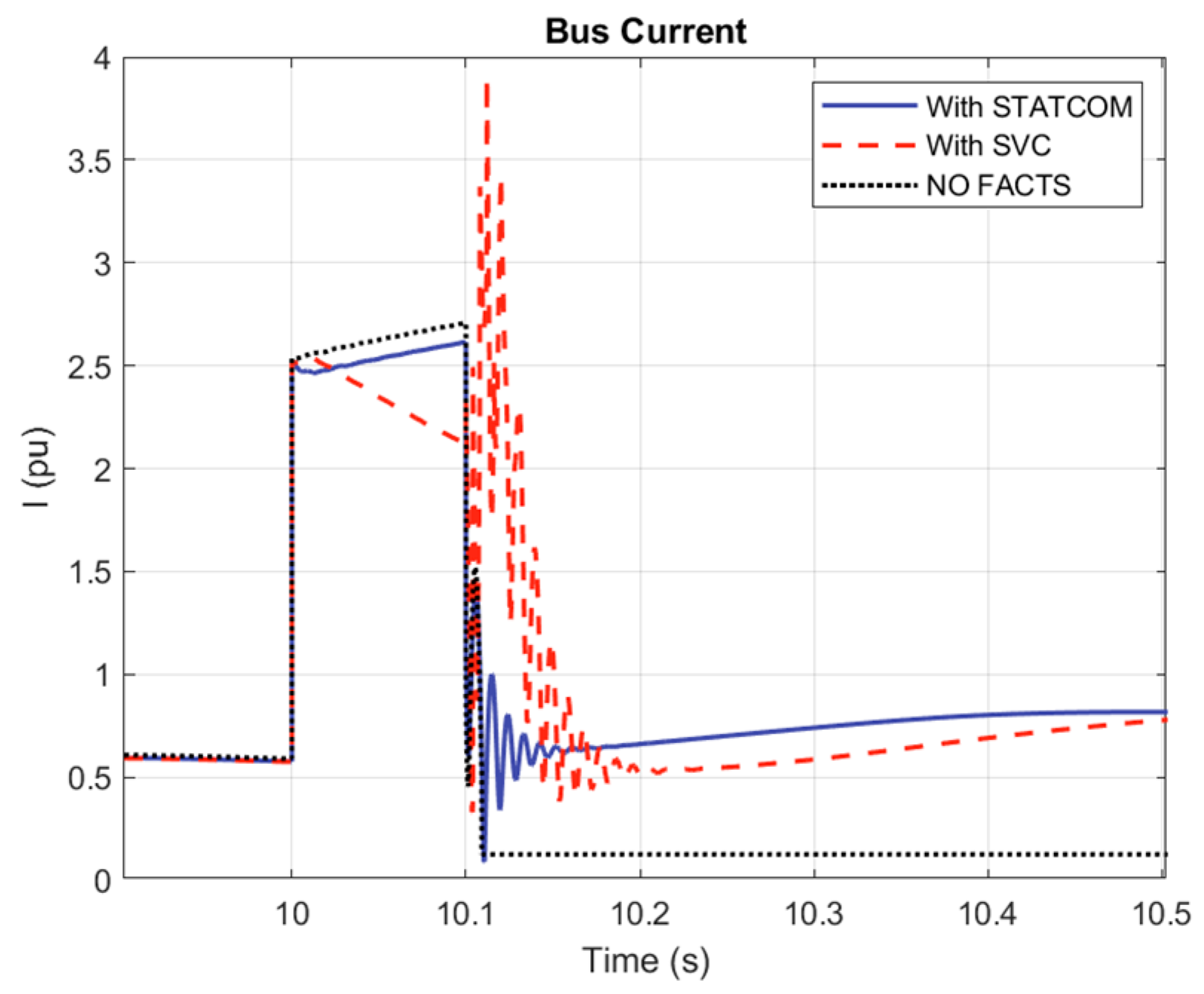

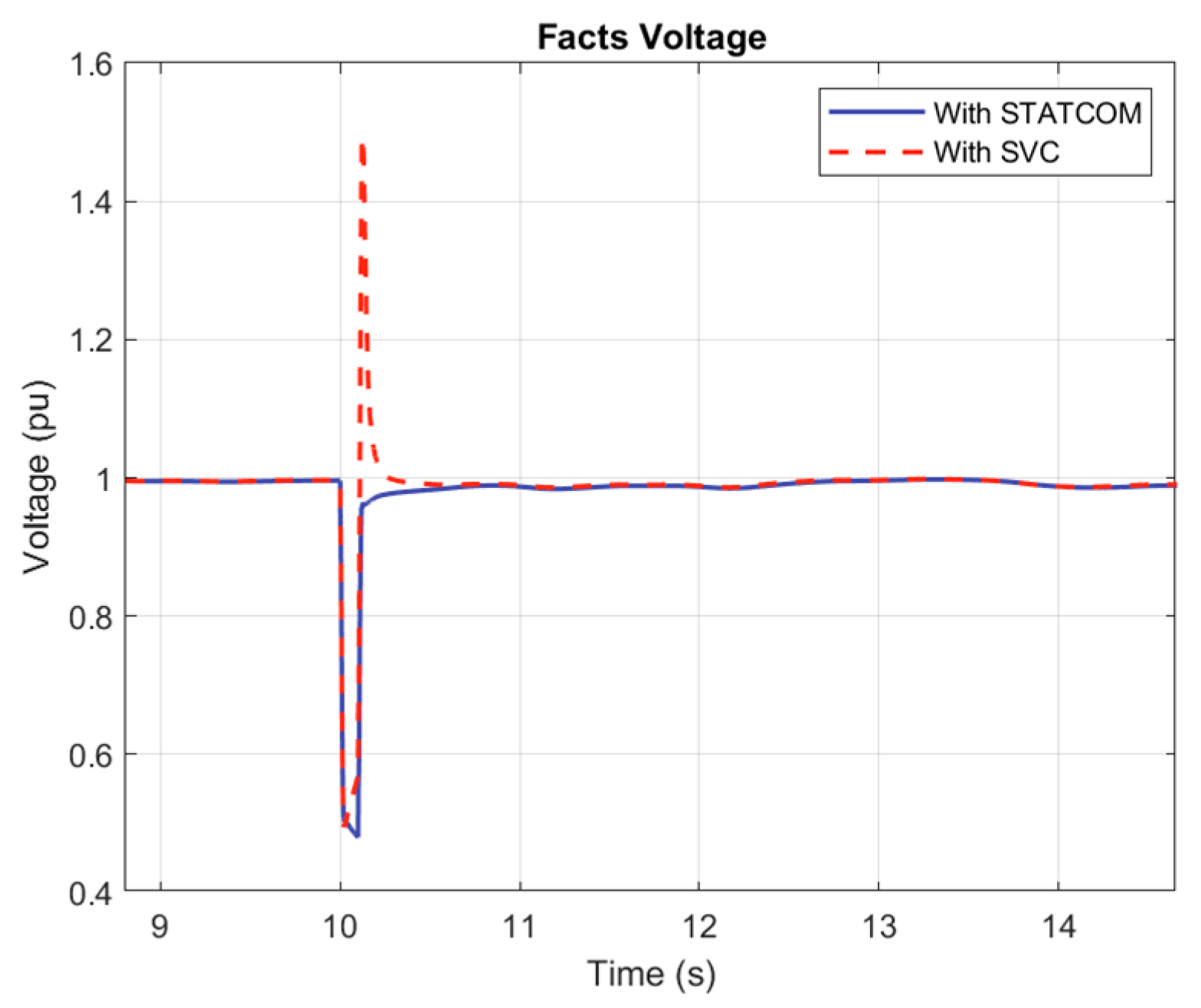

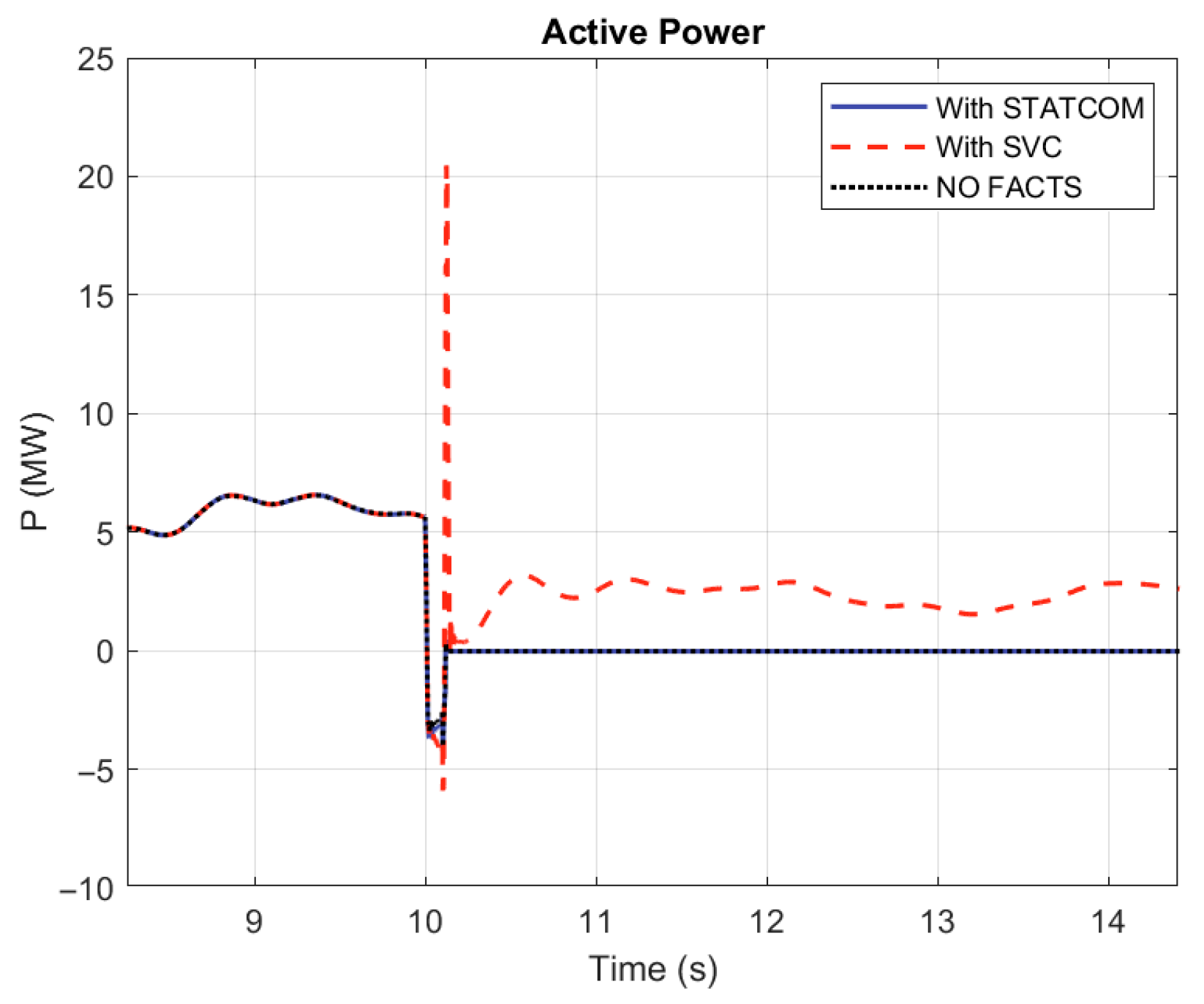

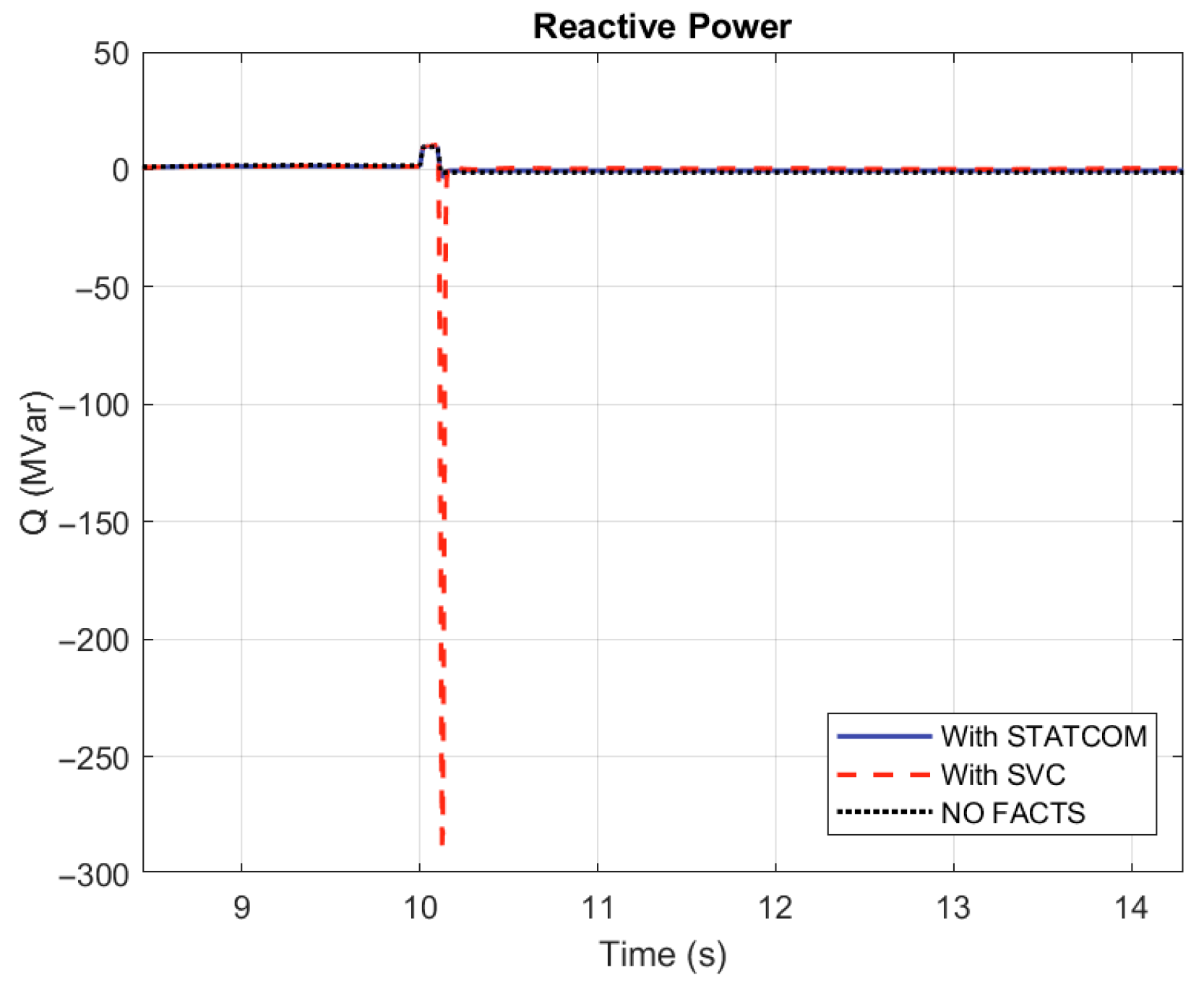

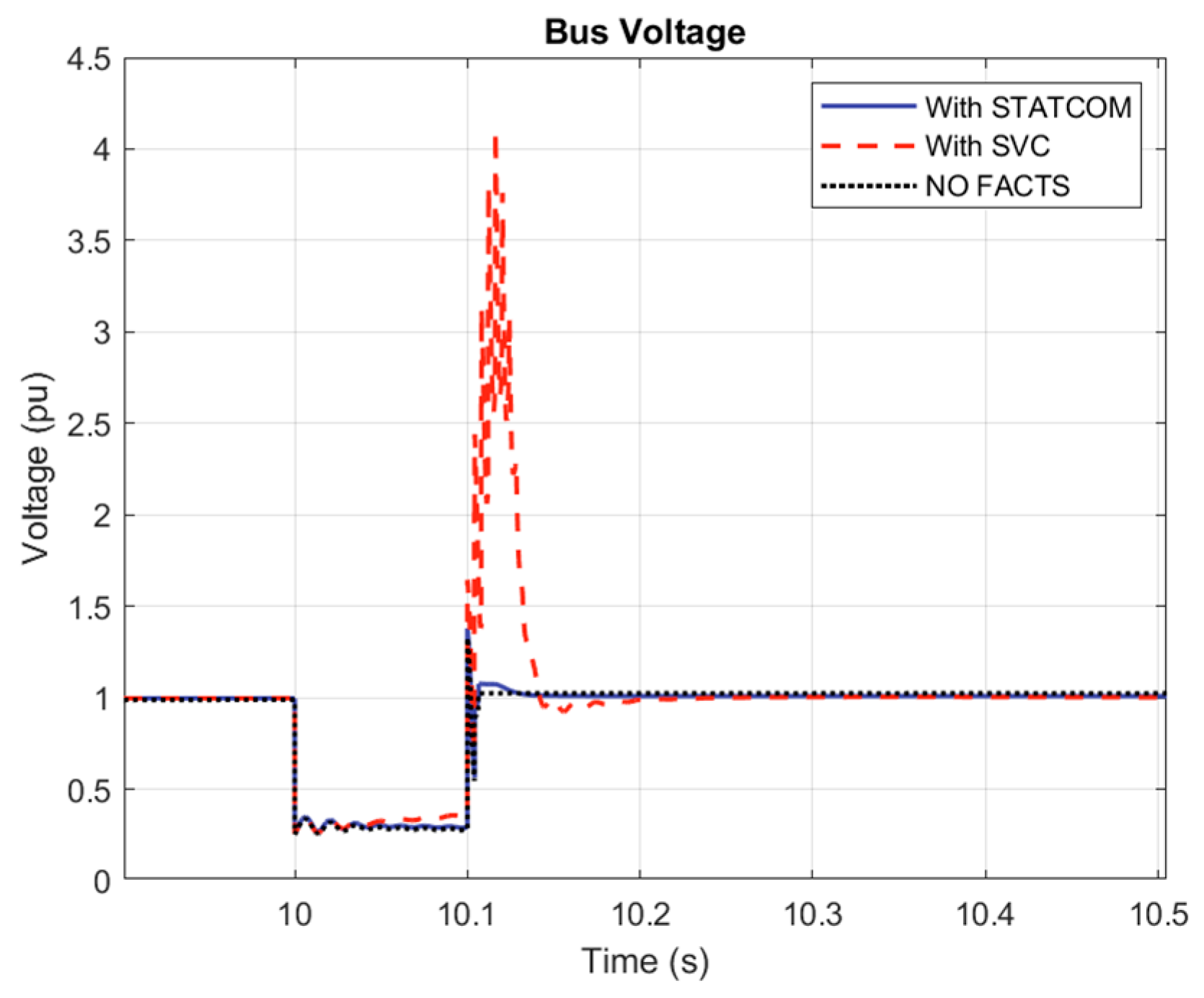

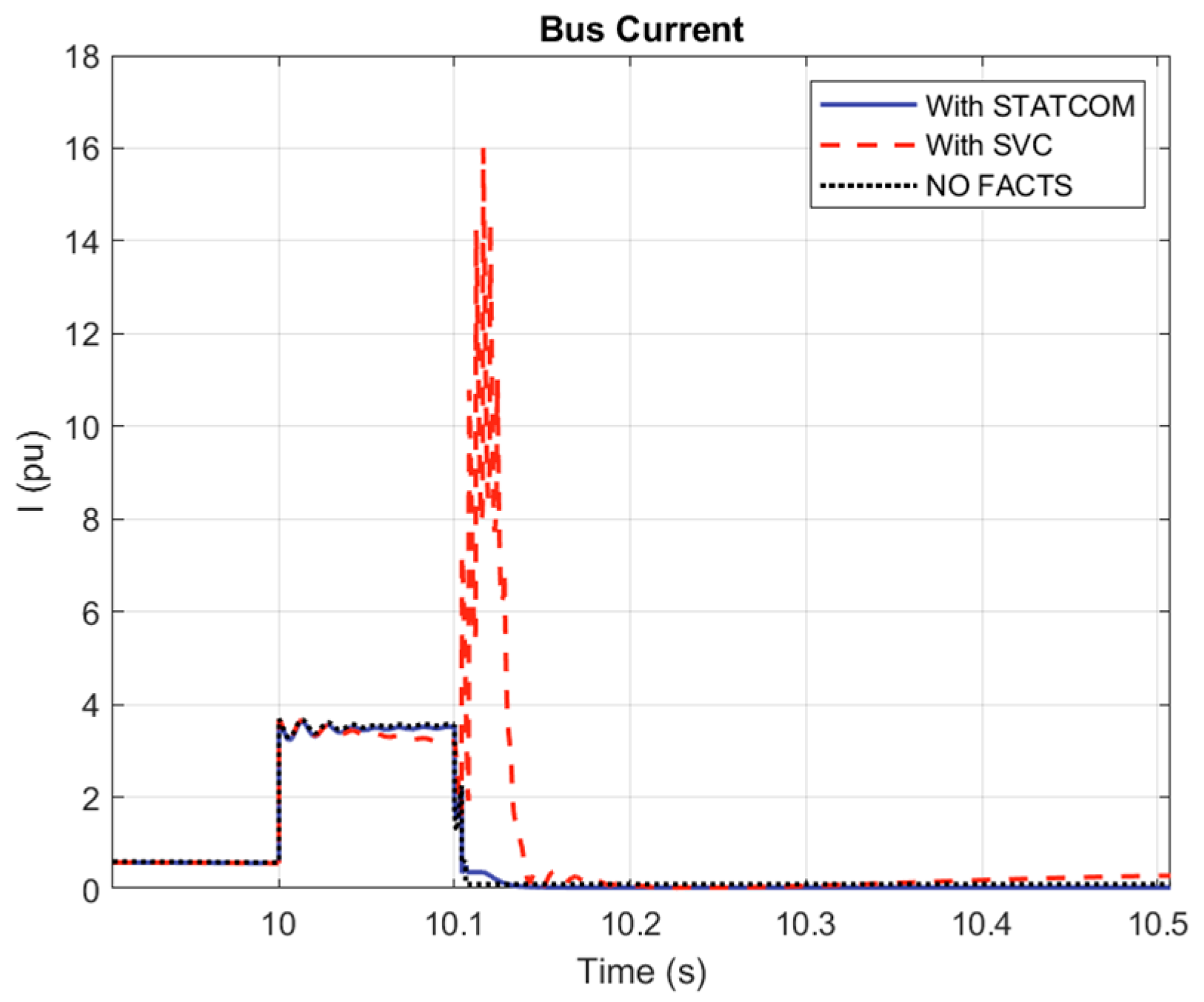

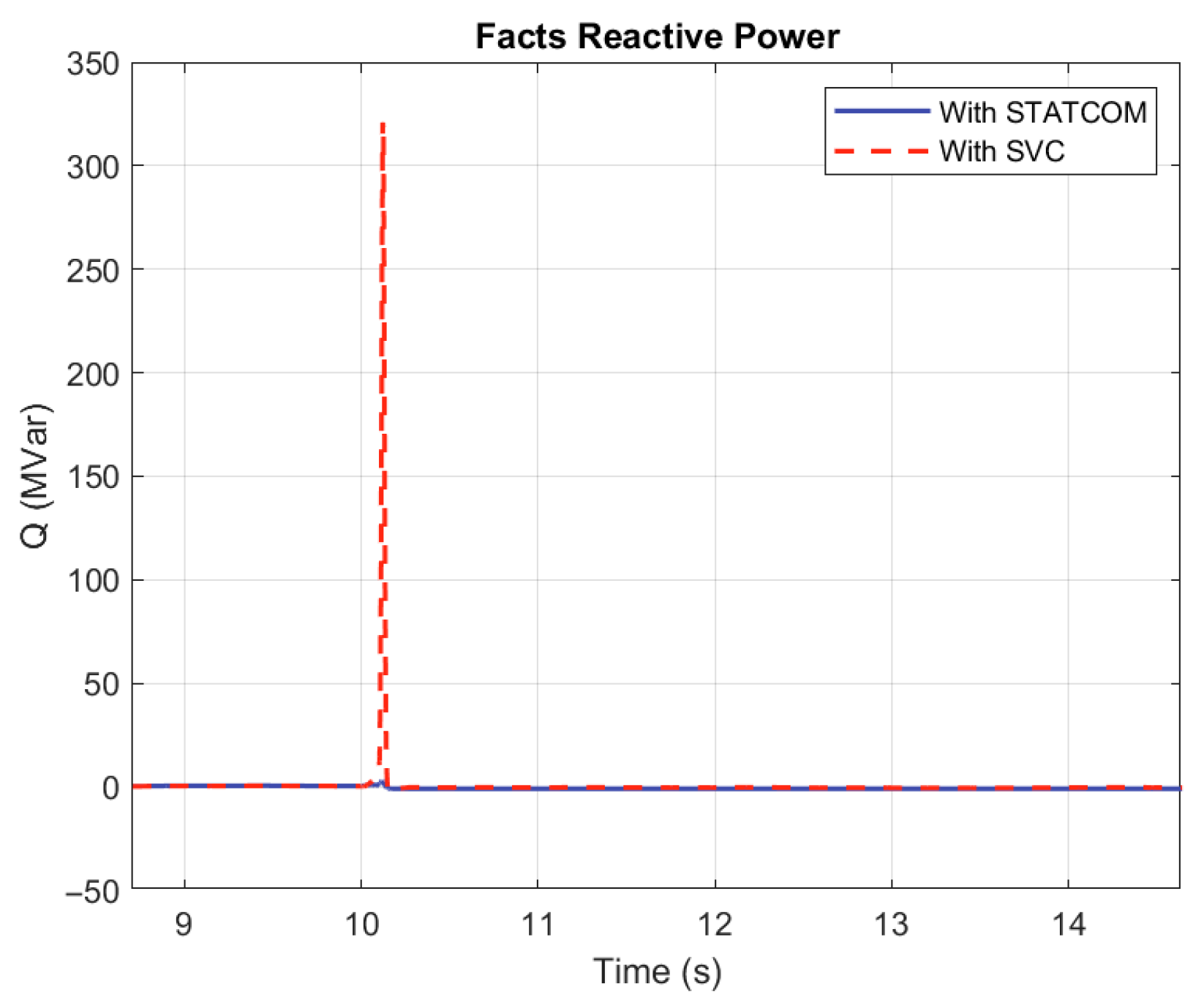

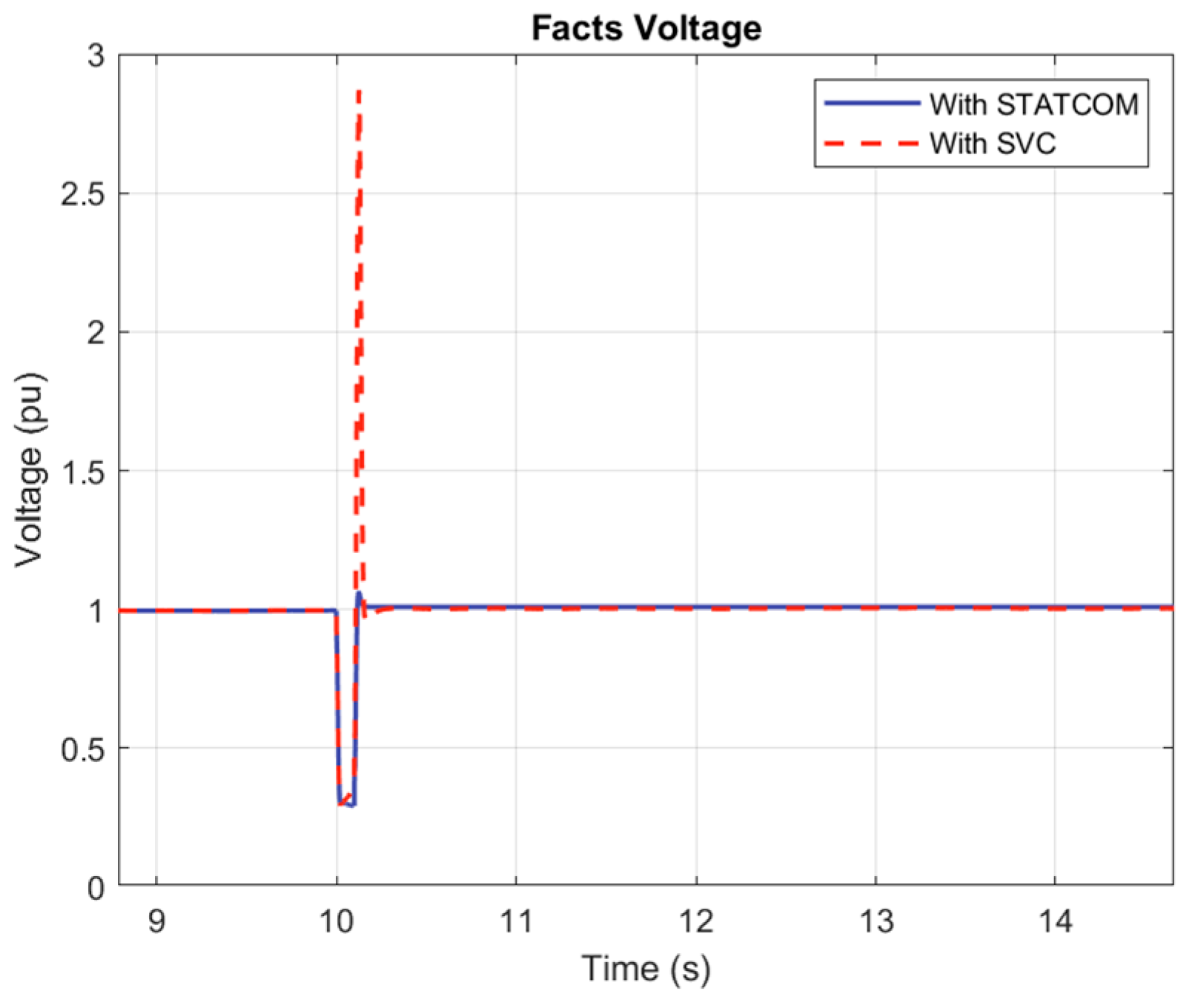

- Case 3: Single-Phase Fault at PCC

- Case 4: Two-Phase Fault at PCC

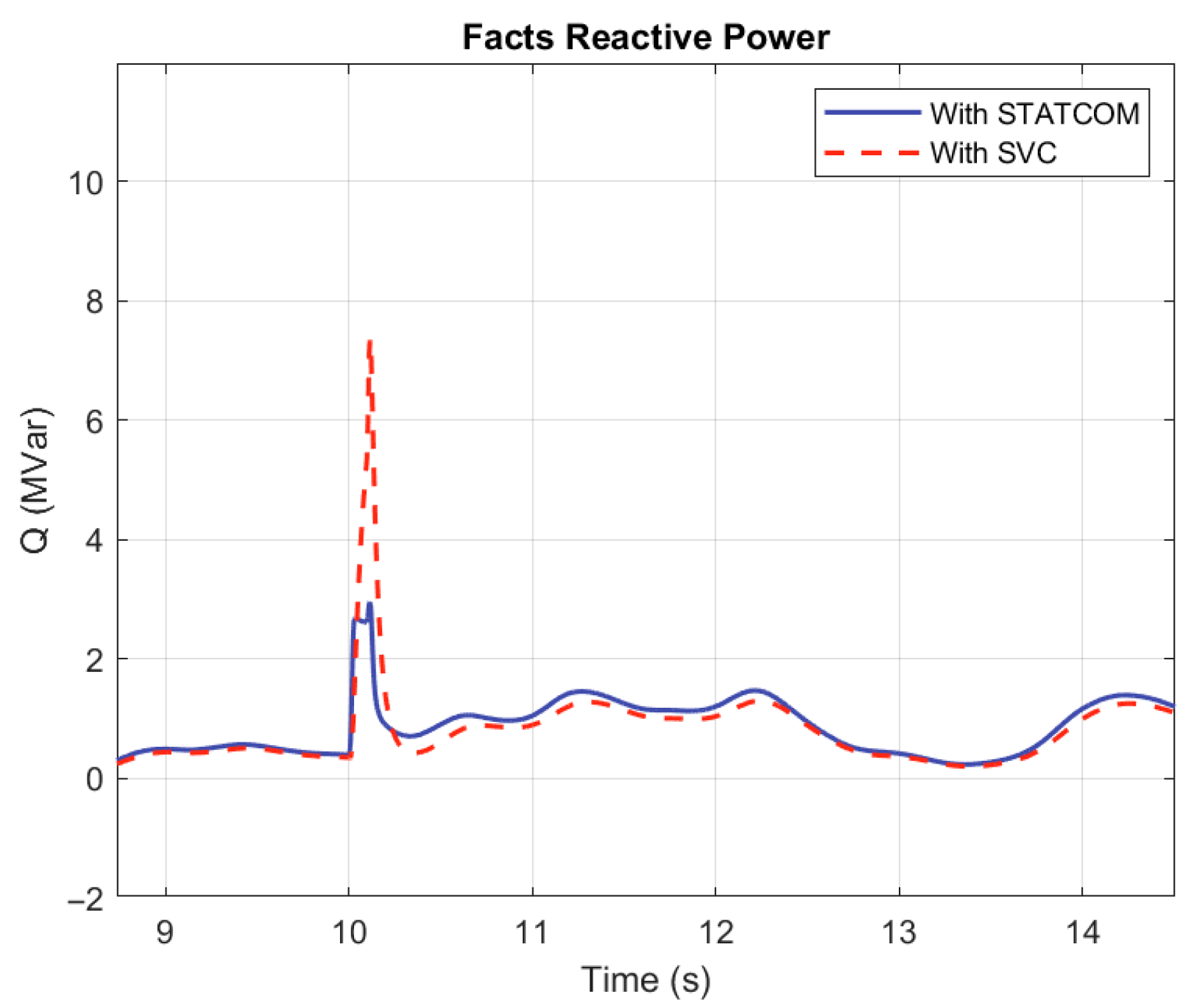

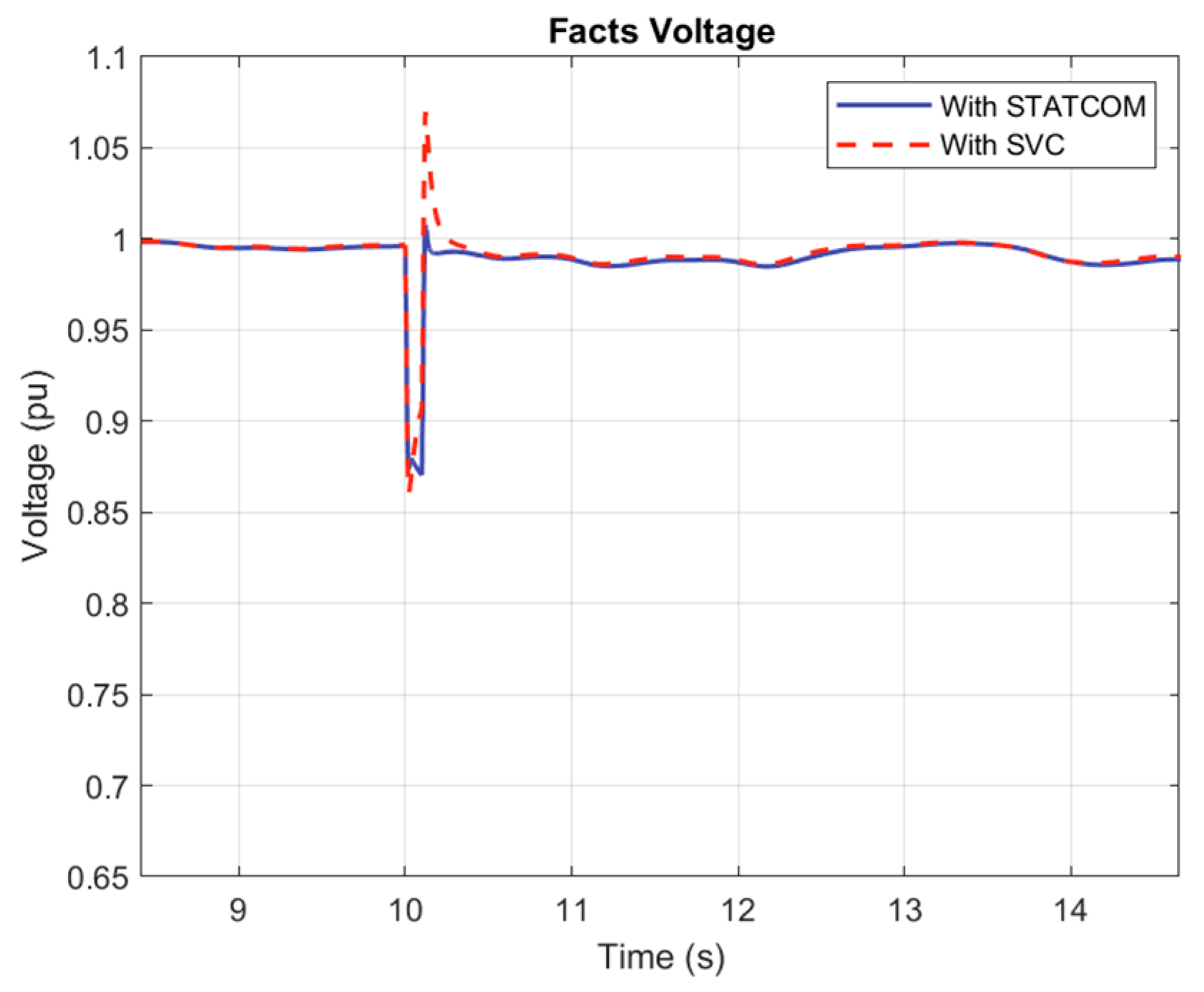

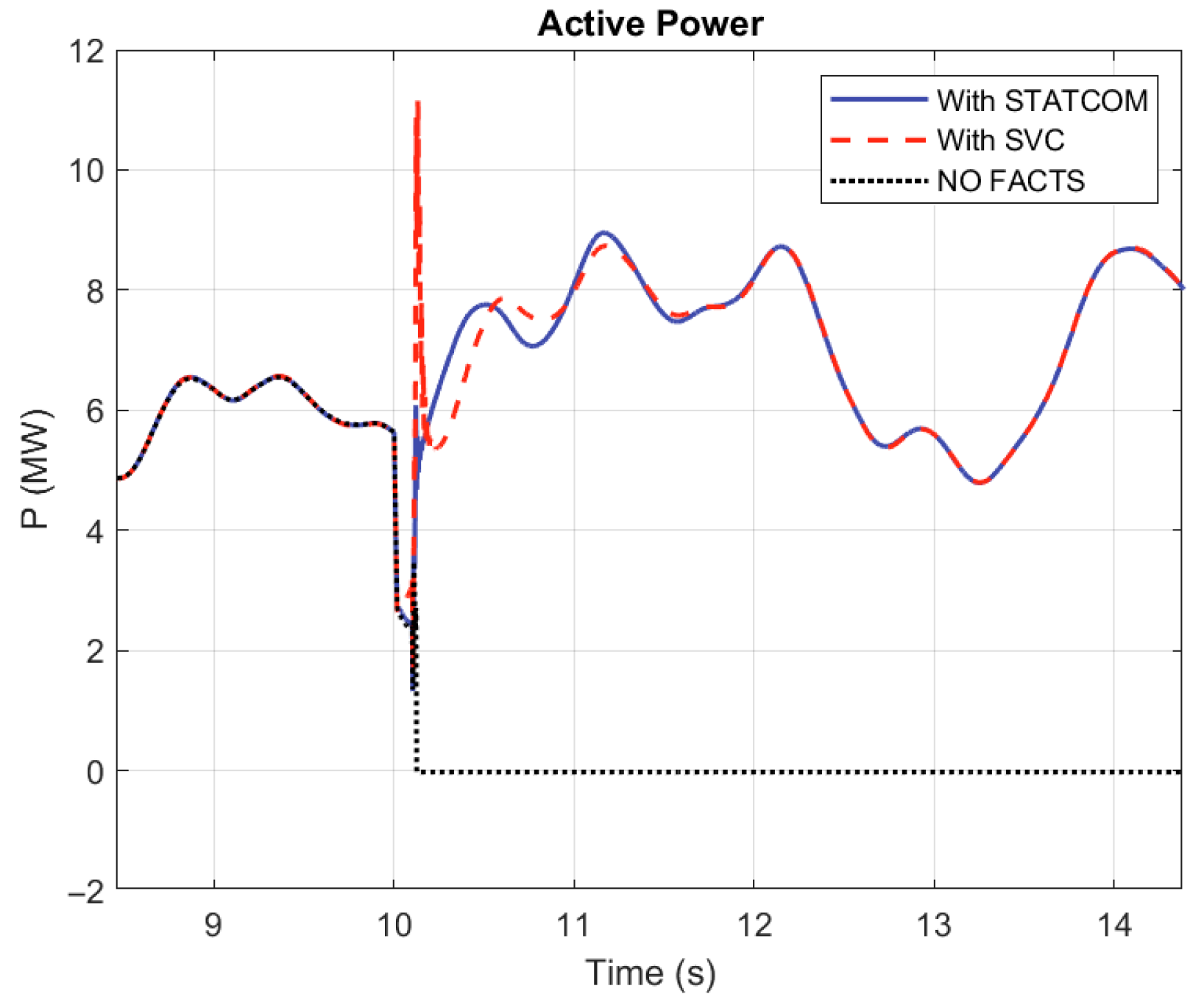

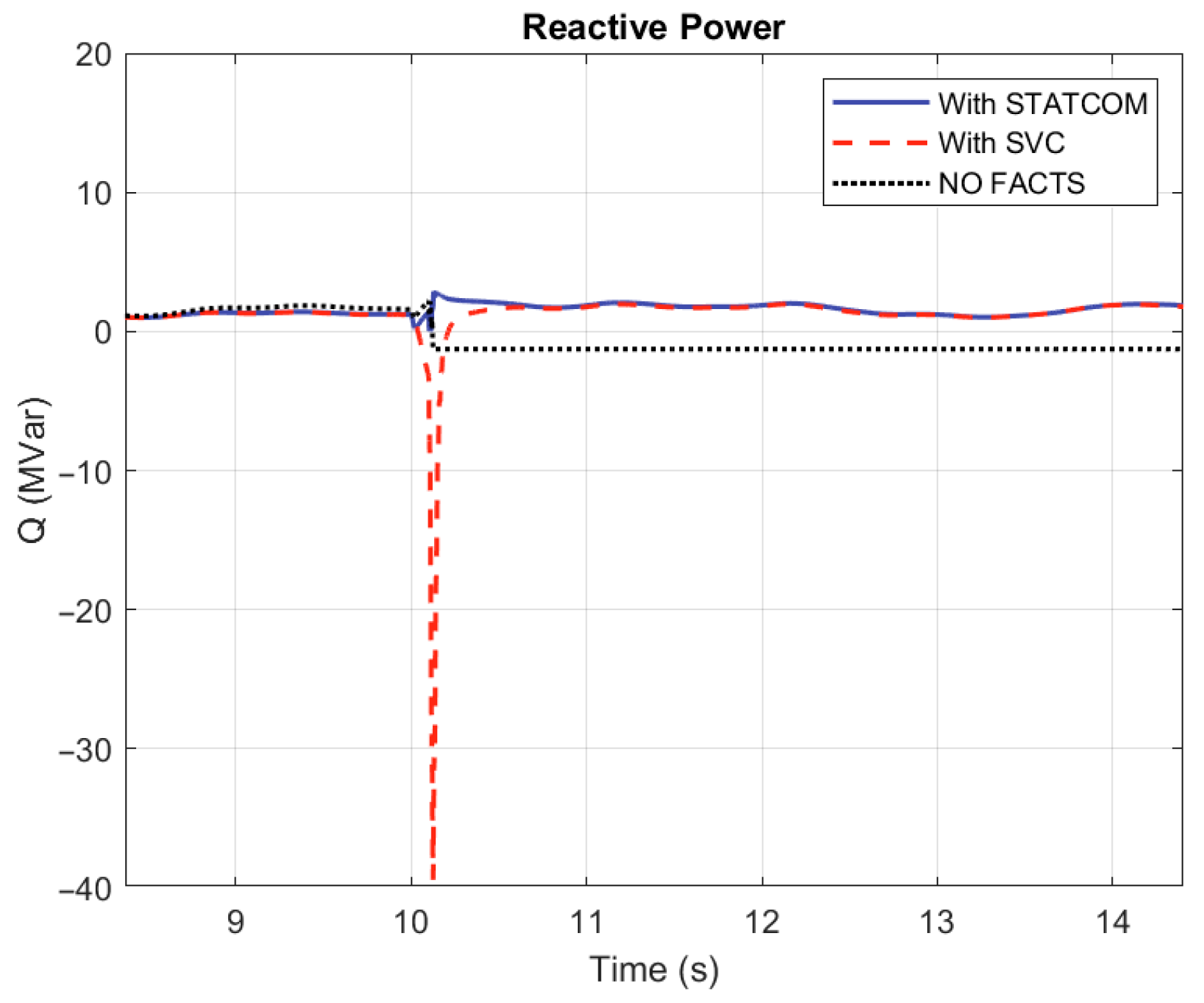

- Case 5: Three-Phase Fault at any two branches of Wind Farm

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thapar, S. Energy and Climate Change. In Renewable Energy: Policies, Project Management and Economics: Wind and Solar Power (India); Springer Nature Singapore: Singapore, 2024; pp. 1–11. [Google Scholar] [CrossRef]

- IRENA. Renewable Capacity Statistics 2023; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023.

- Shao, H.; Henriques, R.; Morais, H.; Tedeschi, E. Power quality monitoring in electric grid integrating offshore wind energy: A review. Renew. Sustain. Energy Rev. 2024, 191, 114094. [Google Scholar] [CrossRef]

- Malik, F.H.; Khan, M.W.; Rahman, T.U.; Ehtisham, M.; Faheem, M.; Haider, Z.M.; Lehtonen, M. A Comprehensive Review on Voltage Stability in Wind-Integrated Power Systems. Energies 2024, 17, 644. [Google Scholar] [CrossRef]

- Alnasir, Z.; Kazerani, M. A small-scale standalone wind energy conversion system featuring SCIG, CSI, and a novel storage integration scheme. Renew. Energy 2016, 89, 360–370. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, F.; Gu, L.; Chen, J. Research on Grid Integration of Wind Power Generation with Power Quality Control Functions. In Proceedings of the 2021 4th International Conference on Energy, Electrical and Power Engineering (CEEPE), Chongqing, China, 23–25 April 2021. [Google Scholar] [CrossRef]

- Kazemi, Y.; Rezaei, M.M. A grid forming control strategy for STATCOM-assisted isolated SCIG-based wind energy conversion systems. Energy Syst. 2023, 9, 2016–2026. [Google Scholar] [CrossRef]

- Saxena, N.K.; Kumar, A.; Gupta, V. Enhancement of system performance using STATCOM as a dynamic compensator with squirrel cage induction generator (SCIG) based microgrid. Int. J. Emerg. Electr. Power Syst. 2021, 22, 177–189. [Google Scholar] [CrossRef]

- Goudarzi, N.; Zhu, W.D. A review on the development of wind turbine generators across the world. Int. J. Dyn. Control 2013, 1, 192–202. [Google Scholar] [CrossRef]

- Rather, Z.; Flynn, D. Impact of voltage dip induced delayed active power recovery on wind integrated power systems. Control Eng. Pract. 2017, 61, 124–133. [Google Scholar] [CrossRef]

- Qiao, W.; Harley, R.G.; Venayagamoorthy, G.K. Dynamic Modeling of Wind Farms with Fixed-Speed Wind Turbine Generators. In Proceedings of the 2007 IEEE Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007. [Google Scholar] [CrossRef]

- Vegunta, S.C.; Xu, X.; Bishop, M.; Kamalinia, S. The Impact of Grid Code Requirements on Efficient Wind Generation Integration. In Proceedings of the 2020 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Chicago, IL, USA, 12–15 October 2020. [Google Scholar] [CrossRef]

- Elyaalaoui, K.; Ouassaid, M.; Cherkaoui, M. Reactive capability limits for wind turbine based on SCIG for optimal integration into the grid. In Renewable Energy Systems; Academic Press: Cambridge, MA, USA, 2021; pp. 567–587. [Google Scholar] [CrossRef]

- Tingyi, H.; Shengnan, L.; Shuijun, W.; Zhen, P.; Ran, O.; Zixuan, Z. Adaptability of Wind Power Integration and Comparison Study on Grid Code Technical Requirements. In Proceedings of the 2018 China International Conference on Electricity Distribution (CICED), Tianjin, China, 17–19 September 2018. [Google Scholar] [CrossRef]

- Hussen, M.; Rajaram, T. A Comprehensive Review of Voltage Source Converters-Based FACTS Controllers in Hybrid Microgrids. IEEE Access 2025, 13, 62961–62999. [Google Scholar] [CrossRef]

- Patel, N.A.; Patel, K.N. SSR Mitigation in Power System by LQR Control of nearby DFIG. In Proceedings of the 15th International Conference on Advances in Computing, Control, and Telecommunication Technologies, ACT 2024, Hyderabad, India, 21–22 June 2024; GRENZE Scientific Society: Thiruvananthapuram, India, 2024; Volume 1, pp. 70–79. [Google Scholar]

- Patel, N.; Patel, K.; Keya, P. Analysis and Mitigation of SSR in a Doubly Fed Induction Generator (DFIG) Based Wind Farm by Employing a STATCOM Controller. J. Electr. Syst. JES 2024, 20, 2379–2384. [Google Scholar] [CrossRef]

- Esterhuizen, R.; Giraneza, M.; Abo-Al-Ez, K. An Approach to Voltage Quality Enhancement in Wind Energy Conversion Systems. In Proceedings of the 2022 International Conference on Electrical, Computer and Energy Technologies (ICECET), Prague, Czech Republic, 20–22 July 2022. [Google Scholar] [CrossRef]

- Qi, J.; Zhao, W.; Bian, X. Comparative Study of SVC and STATCOM Reactive Power Compensation for Prosumer Microgrids With DFIG-Based Wind Farm Integration. IEEE Access 2020, 8, 209878–209885. [Google Scholar] [CrossRef]

- Upadhyai, R.P.; Garg, L. An Integration of the SVC and STATCOM Technologies into Wind-Based Power Systems. In Proceedings of the 2022 International Conference on Futuristic Technologies (INCOFT), Belgaum, India, 24–26 November 2022. [Google Scholar] [CrossRef]

- Belhamidi, M.; Lakdja, F.; Boumediene, L.; Guentri, H. Analysis of D-SVC and D-STATCOM in Microgrids with Wind Farm Integration. In Proceedings of the 2022 IEEE International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Tunis, Tunisia, 26–28 October 2022. [Google Scholar] [CrossRef]

- Cherkaoui, N.; Haidi, T.; Belfqih, A.; El Mariami, F.; Boukherouaa, J. A comparison study of reactive power control strategies in wind farms with SVC and STATCOM. Int. J. Electr. Comput. Eng. 2018, 8, 4836. [Google Scholar] [CrossRef]

- Faraji, H.; Beigvand, N.Y.; Hemmati, R. Multi-objective and resilient control on hybrid wind farms under healthy/faulty and off-grid/grid-tied states. Electr. Power Syst. Res. 2023, 215, 109004. [Google Scholar] [CrossRef]

- Karaagac, U.; Kocar, I.; Mahseredjian, J.; Cai, L.; Javid, Z. STATCOM integration into a DFIG-based wind park for reactive power compensation and its impact on wind park high voltage ride-through capability. Electr. Power Syst. Res. 2021, 199, 107368. [Google Scholar] [CrossRef]

- Heier, S. Grid Integration of Wind Energy Conversion Systems; John Wiley & Sons Ltd.: Chichester, UK, 1998; ISBN 0-471-97143-X. [Google Scholar]

- Hingorani, N.G.; Gyugyi, L. Understanding FACTS; Concepts and Technology of Flexible AC Transmission Systems; IEEE® Press: Piscataway, NJ, USA, 2000. [Google Scholar]

| References | System Used | Methodology | Limitations | Outcomes of Study |

|---|---|---|---|---|

| [16] | IEEE FBM test system with additional DFIG | Linear Quadratic Regulator (LQR) applied to DFIG rotor converter for SSR damping | High complexity; scalability for large farms uncertain | LQR–DFIG control damped multimodal SSR oscillations effectively |

| [17] | DFIG-based wind farm | Employed STATCOM controller for subsynchronous resonance (SSR) mitigation | Focused only on SSR, not overall voltage/reactive power issues | STATCOM effectively damped SSR oscillations and improved stability |

| [18] | Wind Energy Conversion System (WECS) with SVC & STATCOM | MATLAB/Simulink study on IEC 61400-21 grid codes and voltage quality issues | Did not cover economic feasibility; only short-term simulation results | STATCOM showed slightly faster transient response and higher reactive power support than SVC |

| [19] | Prosumer microgrid with DFIG wind farm | Proposed coordinated STATCOM–DFIG control; compared SVC vs. STATCOM at PCC under faults | Coordination tested only in simulation; no real-time controller implementation | STATCOM required lower capacity than SVC for same performance; coordination reduced investment costs |

| [20] | Wind farm with DFIG connected to grid | Simulation of 10 MVAr SVC & STATCOM devices in MATLAB/Simulink under static & dynamic load | Limited to DFIG-based systems; economic cost analysis not considered | STATCOM outperformed SVC in improving transient stability and damping oscillations |

| [21] | Microgrid with wind integration | Studied voltage stability using Distributed FACTS (D-SVC and D-STATCOM) via MATLAB/Simulink | Considered only distribution-level simulation; not tested under large-scale wind penetration | D-STATCOM showed superior performance in stabilizing microgrid voltage compared to D-SVC |

| [22] | Wind farms with SVC and STATCOM | MATLAB/Simulink simulation to compare voltage stability and reactive power compensation | Limited to simulation results; real-time hardware implementation not considered | STATCOM provided faster voltage support and stability enhancement compared to SVC |

| Proposed work | Grid-connected SCIG with Fixed Capacitor, SVC, and STATCOM | MATLAB/Simulink study under ideal & turbulent wind profiles; symmetrical & unsymmetrical faults; compared Fixed Capacitor, SVC, STATCOM | Earlier works lacked SCIG focus, real-world turbulent wind & multiple fault cases, and broader benchmark devices | Demonstrated STATCOM superiority in FRT and voltage stability; highlighted limits of fixed capacitor; provided holistic benchmark across devices |

| Studied Cases | Voltage Profile at PCC | Reactive Power Supply from the Grid | FRT Capability Achieved | |

|---|---|---|---|---|

| Ideal Wind Speed | No FACTS | Worst | High | - |

| STATCOM | Close to Best | Similar to SVC | - | |

| SVC | Best | Low | - | |

| Turbulent Wind Speed | No FACTS | Worst | High | - |

| STATCOM | Close to Best | Similar to SVC | - | |

| SVC | Best | Low | - | |

| Single Phase Fault at PCC | No FACTS | Worst | High | Yes |

| STATCOM | Best | Similar to SVC | Yes | |

| SVC | Very good | Low | Yes | |

| Two Phase Fault at PCC | No FACTS | Shutdown | Shutdown | No |

| STATCOM | Best | Similar to SVC | Yes | |

| SVC | Very good | Low | Yes | |

| Three Phase Fault at any two branches of WF | No FACTS | Shutdown | Shutdown | No |

| STATCOM | Shutdown | Shutdown | No | |

| SVC | Very good | Low | Yes | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, K.N.; Patel, N.A.; Patel, J.; Sarda, J.; Sain, M. Enhanced Voltage Stability and Fault Ride-Through Capability in Wind Energy Systems Using FACTS Device Integration. Machines 2025, 13, 805. https://doi.org/10.3390/machines13090805

Patel KN, Patel NA, Patel J, Sarda J, Sain M. Enhanced Voltage Stability and Fault Ride-Through Capability in Wind Energy Systems Using FACTS Device Integration. Machines. 2025; 13(9):805. https://doi.org/10.3390/machines13090805

Chicago/Turabian StylePatel, Khush N., Nilaykumar A. Patel, Jignesh Patel, Jigar Sarda, and Mangal Sain. 2025. "Enhanced Voltage Stability and Fault Ride-Through Capability in Wind Energy Systems Using FACTS Device Integration" Machines 13, no. 9: 805. https://doi.org/10.3390/machines13090805

APA StylePatel, K. N., Patel, N. A., Patel, J., Sarda, J., & Sain, M. (2025). Enhanced Voltage Stability and Fault Ride-Through Capability in Wind Energy Systems Using FACTS Device Integration. Machines, 13(9), 805. https://doi.org/10.3390/machines13090805