Abstract

The emergence of mass personalized production has increased the adaptability and intelligence requirements of welding robots. To address the challenges associated with mass personalized production, this paper proposes a novel knowledge-driven framework for intelligent welding process planning in cloud robotics systems. This framework integrates cloud-edge-end collaborative computing with ontology-based knowledge representation to enable efficient welding process optimization. A hierarchical knowledge-based architecture was developed using the SQLite 3.38.0, Redis 5.0.4, and HBase 2.1.0 tools. The ontology models formally define the welding tasks, resources, processes, and results, thereby enabling semantic interoperability across heterogeneous systems. A hybrid knowledge evolution method that combines cloud-based welding simulation and transfer learning is presented as a means of achieving inexpensive, efficient, and intelligent evolution of welding process knowledge. Experiments demonstrated that, with respect to pure cloud-based solutions, edge-based knowledge bases can reduce the average response time by 86%. The WeldNet-152 model achieved a welding parameter prediction accuracy of 95.1%, while the knowledge evolution method exhibited a simulation-to-reality transfer accuracy of 78%. The proposed method serves as a foundation for significant enhancements in the adaptability of welding robots to Industry 5.0 manufacturing environments.

1. Introduction

In recent years, significant emphasis has been placed on mass personalized production [1], which allows customers to personalize multiple configurable attributes of fabricated parts, which can include dimensions, material, appearance, and performance. This production pattern requires machine tools and robots that are capable of managing complex and variable production tasks. The escalating complexity of robotic task execution presents significant challenges due to inherent computational and memory limitations that are characteristic of embedded hardware architectures. As the implementation of Industry 4.0 progresses, these limitations should be overcome. Industry 4.0 [2] represents an integration of physical industrial assets with digital technologies [3], and it encompasses many types of applications, such as digital twins (DTs) [4], artificial intelligence (AI), the Internet of Things (IoT) [5], robotics, additive manufacturing (AM), and cloud computing.

The rapid technological advancements that have occurred in emerging domains have the potential to enhance the efficiency and performance capabilities of existing robotic systems. Cloud robotics, which has emerged as a new paradigm, exhibit a great potential to revolutionize the field of robotics [6,7]. The convergence of diverse computing paradigms offers substantial advantages for cloud-connected robotic systems, particularly because it leads to enhanced memory capacities with scalable data storage solutions and remote processing capabilities [8].

In recent years, the significant advantages associated with cloud robotics have driven the implementation and deployment of cloud robotic systems [9]. DAvinCi, a software framework that was implemented around the Apache Hadoop framework, was proposed by Arumugam et al. to provide the scalability and parallelism advantages of cloud computing for service robots [10]. Rapyuta, which was the first commercial cloud robotics platform, was developed by Mohanarajah et al. to support robots that needed to offload heavy computational tasks by providing cloud computing environments [11]. These computing environments also facilitate seamless robotic access to the RoboEarth knowledge repository, which is a worldwide platform that was developed by Riazuelo et al. to help robots to share and reuse knowledge and data [12]. A robot operating system (ROS)-based framework for robot–cloud communication was proposed by Mello et al. to ease the integration of robotics and remote cloud platforms [13]. A deep reinforcement learning-based framework was proposed by Chinchali et al. [14] to solve the problems associated with robots offloading to the cloud.

Beyond its applications in the service-robotics field, cloud robotics has expanded into industrial manufacturing domains, where it has revolutionized production processes and operational efficiency. A cloud-based cyber–physical system (CPS) architecture was presented by Zhang to solve the problems associated with the massive data processing that is required by industrial robots [15]. The Open Platform Communications Unified Architecture (OPC UA) communication protocol has been used for robot data integration. A DT-based control framework was proposed by Xu et al. to enable fine sensing control in industrial cloud robotics applications [16]. A cloud-based system and methods of integrating physical resources were developed by Wang et al. for manufacturing processes, and they were evaluated for both machining and robotics applications [17]. Their evaluation results showed that the system was an effective tool by which robots could achieve optimized energy consumption.

The geographic distribution of robotic systems and cloud data centers typically requires multiple network hops, which results in increased latency and significant data transmission delays due to the extended communication pathways. Therefore, edge computing [18], which decentralizes computational resources and uses cloudlets [19,20] and fog computing nodes [21] to enable the deployment of infrastructure, platform, and software services in closer proximity to the robots, has emerged as a crucial way to mitigate this limitation. A cloud-edge-device collaborative framework for cloud manufacturing was developed by Yang et al. to meet the computational and operational demands of deep learning models that are implemented in smart robotic systems for mass personalized production [22]. A solution was proposed by Stan et al. to increase the dependability of information exchange and processing in systems with cloud-edge-device architectures [23].

Welding robots fulfill important functions in industrial production and are widely used in the manufacture of large equipment, such as ships, automobiles, engineering machinery, and agricultural machinery, among others [24]. Therefore, research regarding information technology-driven welding robots and welding manufacturing has gradually attracted significant attention. An intelligent welding manufacturing system combined with an IoT technique was proposed by Liu et al. for feature extraction during welding processes and welding quality predictions [25]. Romero-Hdz et al. implemented a reinforcement learning framework in which empirical welding expertise is combined with algorithmic exploration mechanisms to enhance the optimization efficiency of robotic welding sequences [26].

Knowledge engineering has great potential to improve the intelligence levels and capabilities of robots. A knowledge-based framework for object searching was proposed by Liu et al. to improve the searching efficiency and rationality of home service robots [27]. Multi-domain knowledge was built into a multi-layered and interconnected knowledge structure in which properties are described according to the ontology in the framework. A general information–theoretic framework was developed by Krzysiak et al. to control multiple autonomous robots during search and rescue missions [28]. In this framework, prior human knowledge about location was modeled as an initial target distribution so that the target location and dynamics could be captured.

Knowledge representation, reasoning, storage, management, sharing, and interoperability are key problems that must be solved when knowledge engineering is applied. An approach in which knowledge is stored and represented in a cognitive architecture was proposed by Russo et al. to improve human–machine and machine–machine interactions [29]. They used an unsupervised machine learning technique to distinguish semantic clusters from visual features provided by robots. A blockchain-based knowledge inference framework for edge-assisted multi-robot systems was presented by Li et al. to support trusted edge collaborative inference in the presence of malicious nodes [30]. A knowledge management framework was proposed by Liau et al. to manage the human–robot collaboration knowledge in a mold assembly domain [31].

Although notable achievements have been reported in cloud robotics, robotic welding, and knowledge-based research, there remains a lack of research regarding the efficient management of heterogeneous welding knowledge, the low-latency response requirements of welding process planning, and the sustainable evolution of welding knowledge. Therefore, the primary objective of this paper is to propose a cloud-based solution that can achieve intelligent process planning for robotic welding.

This paper is organized into six principal sections, beginning with this introductory section (Section 1). Section 2 delineates the architectural framework of the cloud-based welding process planning system. The methodological implementation of the proposed knowledge-driven welding process planning approach is elaborated upon in Section 3. Section 4 presents the experimental results associated with the performance evaluation of the cloud-edge-end collaborative welding process knowledge base, as well as those that concern the evolutionary optimization of the welding process parameters. A comprehensive discussion of the proposed method is provided in Section 5. Finally, Section 6 concludes the paper.

2. Framework of the Cloud-Based Welding Process Planning System

2.1. Requirements Analysis

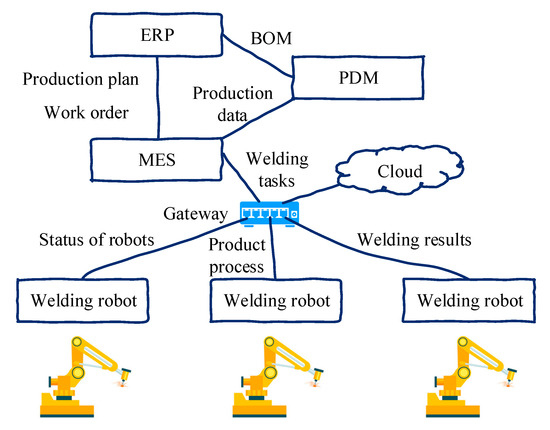

As shown in Figure 1, enterprise resource planning (ERP) systems, product data management (PDM) systems, and manufacturing execution systems (MESs) retrieve information from the cloud-based welding process planning system. This information includes the welding robot resource status, the operational status, and the welding results. Conversely, the cloud-based welding process planning system acquires the welding tasks, production data, and welding process knowledge from the MES and the PDM system, as well as from other robotic systems. Automatically triggered events occur within the cloud-based welding process planning system; these include welding task parsing, welding knowledge acquisition, welding parameter planning, and welding sequence planning.

Figure 1.

Operational process of the cloud-based welding process planning system.

The operational process of the cloud-based welding process planning system is briefly described next.

First, the ERP system retrieves the product bill of materials (BOM), which is based on customer orders, from the PDM system. The ERP then issues production plans and work orders to the MES. Subsequently, the MES assigns welding tasks to the welding robots using production data obtained from the PDM system.

Next, the cloud-based welding process planning system performs knowledge-driven welding process planning, which includes welding parameter planning and welding sequence planning. This planning procedure relies on three key processes: welding resource information parsing, welding task information parsing, and welding knowledge acquisition. The welding knowledge acquisition process is dependent upon welding process knowledge parsing and welding knowledge evolution. Furthermore, welding knowledge evolution is supported by welding process simulations as well as by machine learning algorithms.

Finally, the welding robot system completes the welding process planning, performs the actual product welding, and returns the welding results to the MES.

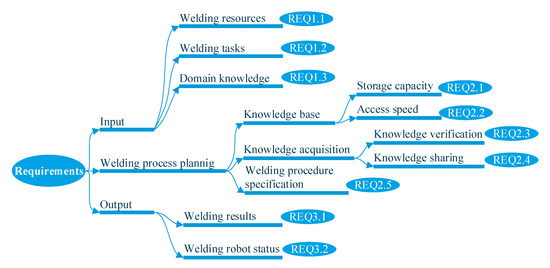

The requirements for the cloud-based welding process planning system were analyzed. The results are shown in Figure 2. The system requirements consist of three key components: input requirements, welding process planning requirements, and output requirements. The input requirements include the welding resources, welding tasks, and domain knowledge. The welding process planning requirements encompass the knowledge base, knowledge acquisition, and welding process specifications. The knowledge base requirements are focused on the storage capacity and the access speed. The knowledge acquisition requirements involve knowledge verification and knowledge sharing. The output requirements consist of the welding results and the welding robot status.

Figure 2.

Requirements for the cloud-based welding process planning system.

2.2. Overall Structure

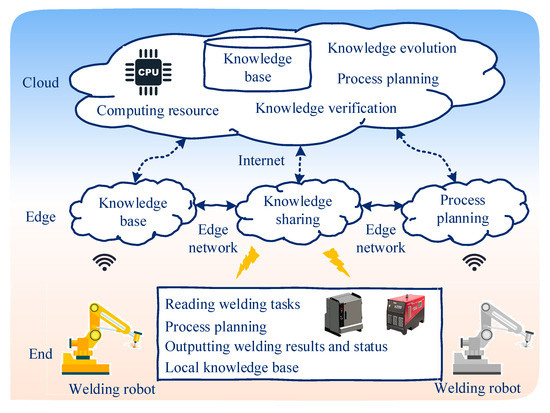

Based on the requirements analysis of the cloud-based welding process planning system, the results of which are presented in Section 2.1, a cloud-edge-end collaborative framework for the intelligent welding process planning system was constructed. This framework is illustrated in Figure 3. The cloud-edge-end collaborative intelligent welding process planning system primarily consists of a cloud system, an edge system, and an end system.

Figure 3.

Cloud-edge-end collaborative framework for the intelligent welding process planning system.

The sub-functional modules of the cloud system include a cloud knowledge base module, a knowledge evolution module that is based on elastic computing resources, a knowledge verification module, and a process planning module. These modules fulfill the “REQ1.2 Welding tasks,” “REQ1.3 Domain knowledge,” “REQ2.1 Storage capacity,” “REQ2.3 Knowledge verification,” and “REQ2.5 Welding process specifications” system requirements.

The sub-functional modules of the edge system include an edge knowledge base module, a knowledge sharing module, and a process planning module. These modules fulfill the “REQ2.2 Access speed,” “REQ2.4 Knowledge sharing,” and “REQ2.5 Welding process specifications” system requirements.

The sub-functional modules of the end system include a reading welding tasks module, a process planning module, a local knowledge base module, and welding result output and status modules. These modules address the “REQ1.1 Welding resources,” “REQ1.2 Welding tasks,” “REQ2.2 Access speed,” “REQ3.1 Welding results,” and “REQ3.2 Welding robot status” system requirements.

To ensure the reliability of this collaborative system, the cloud and edge systems, which connect to the end system, are not fixed; rather, they are dynamically selected and linked according to the availability and load capacity of the network, computing, storage, and service resources. This elastic connectivity enhances the resilience and reliability of the cloud-edge-end collaborative intelligent welding process planning system. For instance, when specific cloud or edge systems experience excessive network latency or connectivity disruptions, the end system can flexibly switch to alternative cloud or edge systems. This function can be implemented by determining network latency or network connection status of the end system. As the dynamic configuration of computing resources is not the primary focus of the present work, it has not been subjected to case verification.

3. Materials and Methods

According to the cloud-edge-end collaborative framework for the intelligent welding process planning system, as described in Section 2, a method of implementing the knowledge-driven welding process planning procedure was developed. This method is presented in the sub-sections of the current section (Section 3). Section 3.1 proposes a method of representing the welding process knowledge. Subsequently, Section 3.2 introduces the method that was used to construct the cloud knowledge base. Section 3.3 elaborates upon the welding process knowledge evolution method. Finally, Section 3.4 presents the knowledge-driven welding process planning methodology.

3.1. Representation of the Welding Process Knowledge

The method by which the welding process knowledge is represented directly influences the approach that is used to construct both the welding knowledge bases and the knowledge utilization efficiency. A welding process case knowledge model can represent the symbolic, formalized, or modeled abstraction of welding tasks, welding resources, welding processes, and welding results.

Common knowledge representation methods include logical representation, production rule representation, frame representation, semantic network representation, object-oriented representation, concept map-based representation, rough set-based representation, and ontology representation. Of these, ontology representation enables the understanding, sharing, and reuse of knowledge by both humans and machines. It does this by abstracting domain concepts and establishing hierarchical systems to express the semantic relationships between concepts. Therefore, ontology representation was used to represent the welding process knowledge during this study.

Welding process knowledge is represented by definitions of the welding tasks, welding resources, welding processes, and welding results. Specifically, the welding tasks encompass the weld features, base materials, and welding requirements for the workpiece. The welding resources include the welding equipment and their performance characteristics. The welding processes consist of the welding methods, process parameters, and welding sequences. The welding results include the weld quality and the workpiece deformation.

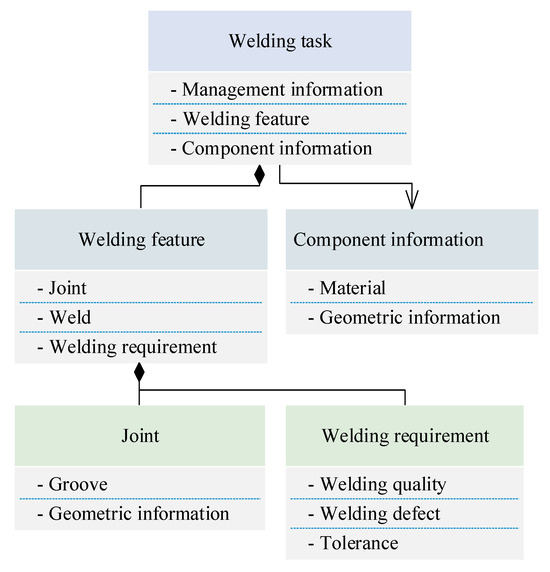

3.1.1. Ontology Model for the Welding Tasks

The ontology model for the welding tasks is depicted in Figure 4. In this model, a Unified Modeling Language (UML) class diagram is used to define the classes, attributes, and ontological relationships. The connecting lines that contain solid diamond shapes represent composition relationships. The connecting lines with arrows represent association relationships. The connecting lines containing triangles represent generalization relationships. The attributes of the welding tasks include the management information, welding features, and component information. Specifically, the component-information attributes include the material properties and geometric data. The welding-feature attributes consist of the joint characteristics, weld details, and welding requirements. The joint attributes include the groove specifications and geometric parameters. The welding requirements consist of the weld quality standards, defect criteria, and tolerance specifications.

Figure 4.

Ontology model for the welding tasks.

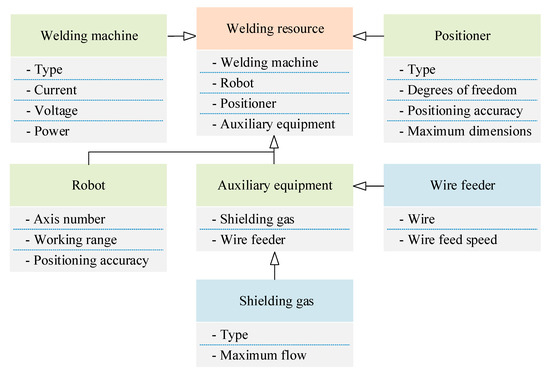

3.1.2. Ontology Model for the Welding Resources

The welding resource model characterizes the performance of the welding equipment in order to ensure that the welding processes are properly executed and the desired welding results are achieved. In the welding resource ontology model, which is shown in Figure 5, the subtypes of the welding resources include the welding machine, robots, positioners, and auxiliary equipment. The detailed attribute specifications are discussed next.

Figure 5.

Ontology model for the welding resources.

The welding-machine attributes encompass the weld type (e.g., MIG, TIG, SAW), current range, voltage range, and power capacity. The robot attributes consist of the number of axes, working envelope dimensions, and positioning accuracy. The positioner attributes include the type, degrees of freedom, positioning accuracy, and maximum workpiece dimensions. Finally, the subtypes of the auxiliary equipment include the shielding-gas system (gas type and maximum flow rate) and the wire-feeder (wire specifications and feed-speed range).

3.1.3. Ontology Model for the Welding Process

The ontology model for the welding process is illustrated in Figure 6. This model comprehensively describes the pre-weld treatment, post-weld treatment, welding process parameters, and welding sequences.

Figure 6.

Ontology model for the welding process.

Specifically, the pre-weld treatment attributes include the pre-heat temperature and the displacement constraints (which define the degree-of-freedom restrictions imposed by fixtures or positioners on the workpiece). The displacement constraints are characterized by the constraint locations (which are defined by the reference coordinate system and coordinates) and the constraint directions. The post-weld treatment attributes consist of the heat treatment and the weld-seam grinding. The subtypes of the welding process parameters include the welding-machine power parameters (current and voltage), torch travel speed, and shielding-gas parameters. The welding sequences are defined by the welding features.

3.1.4. Ontology Model for the Welding Results

As indicated by the welding results ontology model depicted in Figure 7, the subtypes of the welding results include both the joint quality and the workpiece deformation after the welding process is complete. The subtypes of joint quality include quality standards, joint defect classification, weld bead size, and joint performance (which includes the mechanical strength and the fatigue life). The welding-induced deformation is specified through the deformation type (longitudinal shrinkage, transverse shrinkage, angular distortion, misalignment, buckling distortion, bending deformation, or helical distortion) and the deformation degree.

Figure 7.

Ontology model for the welding results.

3.2. Construction of the Cloud-Edge-End Collaborative Knowledge Base

The knowledge-driven welding process planning system has two primary requirements for the knowledge base:

(1) Storage capacity. The data types stored in the knowledge base include welding knowledge instances, 3D models of welded components, and various raw-data documents. As the amount of stored welding knowledge increases, the amount of available local storage may become insufficient to meet the demands of the welding knowledge base.

(2) Low-latency access and high reliability. Welding robots that access the cloud knowledge base must rely on stable network connectivity and remote servers. To achieve personalized mass production, the welding robots must rapidly plan welding processes and execute welding tasks; thus, efficient access to relevant welding knowledge is necessary.

To meet these requirements, a cloud-edge-end collaborative welding process knowledge base was constructed according to the welding process knowledge ontology model. This knowledge base enables the representation, storage, sharing, and evolution of the welding process knowledge, as shown in Figure 8.

Figure 8.

Cloud-edge-end collaborative welding process knowledge base.

The cloud-based knowledge base stores welding process knowledge, which is composed of welding tasks, welding resources, welding processes, and welding results. The model base maintains welding quality prediction models and welding sequence planning models. The cloud platform functions include welding knowledge retrieval, knowledge updating, knowledge sharing, and process model training.

The edge system functions include personalized adaptation of the welding process models, welding process planning, and knowledge updating. Personalized adaptation of welding process models involves the retraining of generic process models according to the welding knowledge so that the models would be better suited to individualized welding tasks. The key distinction between the edge-based welding knowledge base and the cloud-based welding knowledge base lies in the focus of each: the edge-based welding knowledge base prioritizes low-latency responses to end devices, while the cloud-based welding knowledge base emphasizes the management of large amounts of welding knowledge.

The end-based welding knowledge base primarily stores welding knowledge that is downloaded from both the edge-based and cloud-based welding knowledge bases. When it receives a welding task, a welding robot first queries its locally cached welding knowledge. If no matching knowledge is found, it sends a request to either the edge system or the cloud systems. Through edge–end collaboration, cloud–end collaboration, and cloud–edge collaboration, the system can achieve low-latency, high-reliability access to a massive storage capacity, as well as privacy security for welding knowledge.

3.3. Evolution of the Welding Process Knowledge

The accumulation of welding process knowledge is heavily reliant upon extensive welding experiments, which require significant human, material, and time resources. Rapidly increasing the amount of process knowledge in welding knowledge bases remains a critical challenge for intelligent welding process planning. To address this issue, a cloud-edge-end collaborative welding process knowledge evolution method was developed. Unlike the time-consuming and resource-intensive physical welding experiments, welding simulations can substantially reduce both the temporal and economic costs of acquiring welding knowledge. By integrating deep learning-based welding parameter generation and reinforcement learning-based welding sequence generation, this approach enables inexpensive, efficient, and intelligent evolution of welding process knowledge.

As shown in Figure 9, the welding process knowledge evolution method consisted of three primary processes: cloud-based welding simulation, deep learning-based welding parameter generation, and reinforcement learning-based welding sequence generation. The details of these processes are provided in the following list.

Figure 9.

Welding process knowledge evolution method.

(1) Cloud-based welding simulation. By leveraging the advantages of cloud computing, this approach enables the parallel computation of welding tasks by means of cloud-based simulation. It can be used to rapidly acquire welding simulation results, which provide new welding process knowledge for the welding knowledge base.

(2) Deep learning-based welding parameter generation. Using existing welding process knowledge from the knowledge base, a deep neural network is trained in the cloud. Then, transfer learning of the personalized network is performed in the edge system. Finally, the personalized network generates optimized welding parameters.

(3) Reinforcement learning-based welding sequence generation. Utilizing existing welding sequence knowledge, an agent for welding sequence generation is trained in the cloud. This agent can generate the required welding sequences by employing a Q-value table or a deep neural network. After it is trained, the agent is deployed to the edge system, where it generates new welding process sequences.

3.4. Utilization of the Welding Process Knowledge

As shown in Figure 10, the welding knowledge matching process includes four primary steps:

Figure 10.

Welding knowledge matching process.

(1) Input of the welding-task and welding-resource instances. The welding-resource instance describes the welding-related resource information.

(2) Local knowledge matching. When it receives the welding-task instance, the welding robot retrieves relevant welding process case knowledge (which includes parameter matching and sequence matching) from the end-based knowledge base according to the task and resource instances. Then, the similarity between the retrieved knowledge and the input requirements is calculated.

(3) Hierarchical knowledge search. If no suitable welding knowledge is found in the end-based knowledge base, the edge-based and cloud-based knowledge bases are searched sequentially.

(4) Welding process adaptation and output. If welding process knowledge is successfully retrieved, then welding process adaptation is performed. Finally, an appropriate welding process plan is output.

4. Results

As described in Section 3, welding process parameters and welding sequences are both welding process. Both joint quality and workpiece deformation are welding results. In our previous work [32], we developed a knowledge-driven approach for welding sequence planning and analyzed its impact on workpiece deformation. This method was evaluated through a case study on bracket welding, which validated its effectiveness in sequencing laser-welding tasks for such structures.

The primary objective of this study is to validate the efficacy of the proposed method in the planning of welding process parameters. Welding process parameters include the welding-machine power parameters, welding speed, and shielding-gas parameters.

In laser welding, the primary parameters influencing the welding results are power and welding speed. For welding medium-thickness metal plates, high power is generally preferred to maximize efficiency, after which the appropriate welding speed is determined through commissioning. Conversely, for thin-thickness metal plates, the welding process parameter planning typically involves first fixing the welding speed and then gradually increasing the power from low to high until a sufficient penetration depth and a sound weld bead are achieved. This study was exclusively conducted on medium-thickness plates. With the objective of achieving a target weld bead area and profile, the welding power was held constant, while the corresponding welding speed was predicted using the developed model.

Both weld bead size and joint performance are subsets of joint quality. Among these, weld bead size is a more commonly used and is intuitive indicator of joint quality. Therefore, in this study, weld bead size was selected as the metric for evaluating welding results.

4.1. Cloud-Edge-End Collaborative Knowledge Base

4.1.1. Knowledge-Base Composition

The proposed cloud-edge-end collaborative welding process knowledge base has a three-tier architecture that consists of end-based, edge-based, and cloud-based knowledge bases. These knowledge bases synergistically provide intelligent welding process planning by means of coordinated storage and computational capabilities.

Frequently accessed welding process knowledge was stored in the end-based knowledge base, which was built using the SQLite 3.38.0 database engine. Meanwhile, the edge-based knowledge base, which was implemented using Redis 5.0.4 software, provided low-latency caching for frequently matched welding process knowledge. In contrast, the cloud-based knowledge base, which leveraged HBase 2.1.0 software for scalable storage, served as the central repository for comprehensive welding process knowledge.

The welding process knowledge base includes three key technical features. First, it possesses a hierarchical storage architecture that utilizes SQLite 3.38.0 (lightweight end-based storage), Redis 5.0.4 (high-performance edge-based caching), and HBase 2.1.0 (distributed cloud storage). Second, network connectivity is achieved by the utilization of LANs (for end-edge communication) and public networks (for edge-cloud communication). Third, cross-tier computing coordination enables the retrieval of distributed knowledge across all the architectural layers.

4.1.2. Performance Testing

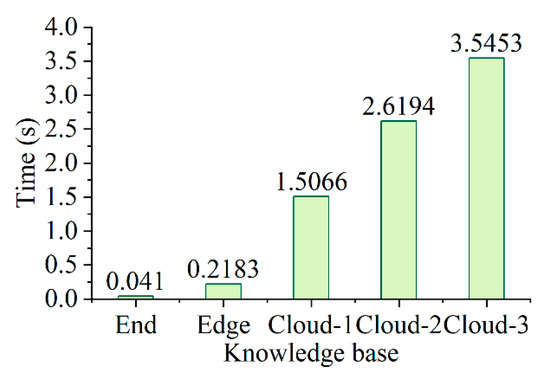

The geographic locations of the knowledge bases are provided in Table 1. The nodes of the cloud-based knowledge base are located in Beijing (Alibaba Cloud, Beijing, China), London (Alibaba Cloud, London, UK), and Silicon Valley (Alibaba Cloud, San Francisco, CA, USA). Both the edge-based and end-based knowledge bases are located in Jinan city.

Table 1.

Geographic locations of the knowledge bases.

The knowledge-matching efficiency of the end-based, edge-based, and cloud-based knowledge bases was tested with a workflow. In this test, the end system sent a welding task, then the knowledge base received the task, performed knowledge matching, and returned the results. Finally, the end system received the results. The average matching latency was obtained after 10 tests of the workflow. As shown in Figure 11, the average matching latency was very small for both the end-based and edge-based knowledge bases, which was 0.041 s and 0.2183 s. This result demonstrates their suitability for real-time operations. The cloud-based knowledge base had significantly longer matching times of 1.5066 s, 2.6194 s, and 3.5453 s due to the network and computational overhead. The average response time of the edge-based knowledge base was reduced from that of pure cloud-based solutions by 86%, .

Figure 11.

Knowledge-matching efficiencies of the knowledge bases.

A comparative latency analysis revealed distinct performance characteristics across the architectural tiers. The low-latency response of the edge layer confirms the critical role of this layer in time-sensitive welding process planning. The cloud-based knowledge base leverages its multi-node architecture to store vast amounts of welding knowledge. The cloud-edge-end collaboration combines the advantages of high matching efficiencies and strong storage capacities.

4.2. Evolution of the Welding Process Parameters

The welding process parameters are optimized by utilizing deep learning and transfer learning. First, a cloud-based welding simulation method is used to generate a dataset of welding process cases. A deep learning model is then pre-trained using a public dataset, after which it is fine-tuned with the generated dataset to achieve personalized adaptation. Finally, a deep learning model that is capable of generating welding process parameters is obtained. The results of this process are described in detail below.

(1) Figure 12 presents the results of a laser-welding temperature simulation after Gaussian filtering and edge detection were performed. The resulting edge detection profiles for welds produced at different welding speeds are depicted in these plots. The simulated temperature field from the laser-welding process was processed using a Gaussian filter to reduce high-frequency noise. Subsequently, as illustrated in Figure 12, edge detection techniques were applied to accurately identify the distinct thermal regions, namely the weld zone and the other zone. The final obtained weld profile represented the weld shape of the welding task.

Figure 12.

Laser-welding simulation results for various welding speeds.

ANSYS 19.0 was used to numerically simulate the laser-welding process. Two medium-thickness plates that were made of 06Cr19Ni10 steel were joined by using a fillet weld. Each plate had a thickness of 5 mm. 06Cr19Ni10 steel contains chromium (Cr) at 18.0–20.0%, nickel (Ni) at 8.0–10.5%, carbon (C) 0.08%, manganese (Mn) 2.0%, silicon (Si) 1.0%, phosphorus (P) 0.045%, sulfur (S) 0.03%, and the rest is iron (Fe).

The initial condition for the laser-welding simulation was set such that the plates temperature was equal to the room temperature of 20 °C. To simplify the calculation, the heat exchange between the plates and the surrounding environment was uniformly treated as convective heat transfer and represented by an overall heat transfer coefficient with a value of 25 W/(m2·°C). The element type used in the simulation model was SOLID 70. The minimum mesh size was 0.5 mm.

The welding simulation was conducted with a power of 2800 W and a laser incidence angle of 30°, while the welding speed consisted of 100 unique randomized values generated within the range of 10 to 30 mm/s. Using a cloud-based welding simulation approach, a dataset of 100 welding process cases was then generated. Of these, 70 cases were used to train the deep neural network, while the remaining 30 cases served as test data for an evaluation of the network performance.

(2) The ResNet deep neural network model was initially pre-trained using the public ImageNet dataset [33]. All the ResNet parameters were frozen except for those in the output layer. The number of variables in the output layer of the network was then modified, and the loss function was replaced with a mean squared error loss. This adapted model was designated as WeldNet.

(3) The WeldNet model was fine-tuned using the dataset of welding process cases, after which its accuracy was tested by performing welding-speed predictions and comparing the results with those in the test set. As shown in Figure 13, the training process exhibited progressive convergence. The WeldNet models with varying numbers of hidden layers (18, 34, 50, 101, and 152) successfully converged within 15 epochs and consistently maintained a stable prediction accuracy for welding speed.

Figure 13.

WeldNet model training process.

The input of the WeldNet models was the area and shape of the weld bead as depicted in Figure 12. The WeldNet models predicted the welding speed required to achieve the target weld bead profile. Welding-speed prediction accuracy is defined as follows:

where n (n = 30) denotes the number of cases in the test dataset, represents the predicted welding speed, and corresponds to the true welding speed.

The test results, as presented in Table 2, revealed that the welding-speed prediction accuracy improved with an increase in the number of hidden layers in the WeldNet. The WeldNet-152 model with 152 hidden layers achieved the highest welding-speed prediction accuracy of 95.10%.

Table 2.

Prediction accuracies of various WeldNet models.

4.3. Experimental Results

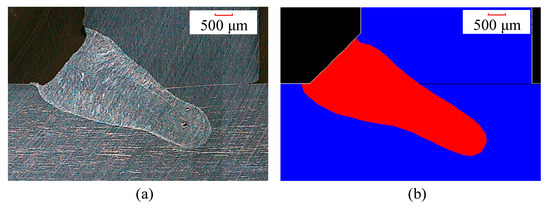

Figure 14 illustrates the weld profile requirements for the welding task of two 06Cr19Ni10 plates that have a thickness of 5 mm. Figure 14 was used as the input for the WeldNet-152 model, and the output parameter of the WeldNet-152 model was 14.9 mm/s.

Figure 14.

Weld profile requirements for the welding task of two 06Cr19Ni10 plates.

A welding simulation (ANSYS 19.0) and a welding experiment were conducted with a power of 2800 W, a laser incidence angle of 30°, and a welding speed of 14.9 mm/s. Figure 15 depicts the cross-sections of the welds obtained from the experiment and the simulation.

Figure 15.

Weld cross-sections: (a) experimental results and (b) simulation results.

Table 3 presents the weld-size results obtained from the experiment and the simulation. These results include the deep-penetration weld thickness, s, and the nominal weld thickness, a. The maximum error of the weld-size results was 22%. In other words, the simulation-to-reality transfer accuracy was 78% for parameter-optimization tasks. The observed relative error aligns with well-established benchmarks for welding prediction using simulation [34,35], accounting for imperfect boundary conditions and acceptable computational time.

Table 3.

Weld-size results from the experiment and the simulation.

Table 4 presents the requirements for the welding task and the weld-size results obtained from the experiment. The maximum error of the deep-penetration weld thickness (s) was 21%. The maximum error of the nominal weld thickness (a) was 11%. The experimental results demonstrated that the method proposed in this study and the developed model were feasible for the laser-welding process planning of plates with medium thickness.

Table 4.

Experimental results and requirements for the welding task.

5. Discussion

The proposed cloud-edge-end collaborative framework partially addresses three critical challenges associated with intelligent welding process planning for mass personalized production: (1) efficient management of heterogeneous welding knowledge across distributed systems, (2) low-latency response requirements for welding process planning, and (3) the sustainable evolution of welding process knowledge. An ontological model was established to enable automated knowledge sharing between heterogeneous systems and welding robots. A hierarchical framework achieved a lower knowledge query latency than conventional cloud-only systems. A simulation-driven learning approach exhibited a 78% prediction accuracy when used for evolution of the welding process knowledge.

The study results revealed multiple important insights. First, the hierarchical knowledge-based architecture utilized during this study achieved a balance between the storage capacity and access efficiency. Specifically, the average response time of the edge-based knowledge base was reduced from that of pure cloud-based solutions by 86%. Second, the knowledge evolution method demonstrated a simulation-to-reality transfer accuracy of 78% during parameter-optimization tasks. Notably, the transfer learning approach achieved a prediction accuracy of 95.1% with only 70 training samples; thus, it demonstrated effective knowledge transfer from general computer-vision tasks to welding parameter optimization.

6. Conclusions

This paper presents a novel knowledge-driven framework for intelligent welding process planning in cloud robotics environments. The main contributions of this study can be summarized into three points:

(1) Ontology-based welding knowledge representation. An ontological model that unifies welding tasks, resources, processes, and outcomes is established. This formalized representation enables automated knowledge sharing between heterogeneous systems and welding robots.

(2) Cloud-edge-end collaborative architecture for intelligent welding process planning systems. A hierarchical framework that integrates cloud computing, edge processing, and end execution is developed. It achieved a lower knowledge query latency than conventional cloud-only systems.

(3) Hybrid welding knowledge evolution method. A simulation-driven learning approach that combined cloud-based thermal–structural analysis with transfer learning exhibited a 78% prediction accuracy when used for parameter optimization; thus, it can reduce the experimental costs from those of physical trial-and-error methods.

To advance the proposed intelligent welding framework, future research will be conducted in these directions: knowledge-driven welding process parameter planning for thin-plate welding, high-precision simulation of solid–liquid thermal coupling for multi-layer welding processes, and the integration of multi-modal sensor data for real-time knowledge-base updating. The proposed framework serves as a foundation for next-generation intelligent welding systems that can adapt to evolving Industry 5.0 requirements while maintaining production efficiency in mass customization environments.

Author Contributions

Conceptualization, K.S. and W.S.; methodology, W.S.; validation, W.S.; formal analysis, W.S.; writing—original draft preparation, K.S. and W.S.; writing—review and editing, K.S. and W.S.; project administration, W.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundamental Research Program of Shanxi Province, grant number 202203021222123.

Data Availability Statement

Data will be available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, Y.; Ma, H.S.; Yang, J.H.; Wang, K.S. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. Adv. S 2022, 11, 40. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Tao, F.; Xiao, B.; Qi, Q.; Cheng, J.; Ji, P. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- Simoens, P.; Dragone, M.; Saffiotti, A. The Internet of Robotic Things: A review of concept, added value and applications. Int. J. Adv. Robot. Syst. 2018, 15, 1729881418759424. [Google Scholar] [CrossRef]

- de Araujo, P.R.M.; Lins, R.G. Cloud-based approach for automatic CNC workpiece origin localization based on image analysis. Robot. Comput. Integr. Manuf. 2021, 68, 102090. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Yan, H.; Li, D.; Wang, S.; Vasilakos, A.V. Cloud robotics: Current status and open issues. IEEE Access 2016, 4, 2797–2807. [Google Scholar] [CrossRef]

- Afrin, M.; Jin, J.; Rahman, A.; Rahman, A.; Wan, J.; Hossain, E. Resource Allocation and Service Provisioning in Multi-Agent. Cloud Robotics: A Comprehensive Survey. IEEE Commun. Surv. Tutor. 2021, 23, 842–870. [Google Scholar] [CrossRef]

- Dawarka, V.; Bekaroo, G. Building and evaluating cloud robotic systems: A systematic review. Robot. Comput. Integr. Manuf. 2022, 73, 102240. [Google Scholar] [CrossRef]

- Arumugam, R.; Enti, V.R.; Bingbing, L.; Xiaojun, W.; Baskaran, K.; Kong, F.F.; Kumar, A.S.; Meng, K.D.; Kit, G.W. DAvinCi: A cloud computing framework for service robots. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 3084–3089. [Google Scholar] [CrossRef]

- Mohanarajah, G.; Hunziker, D.; D’Andrea, R.; Waibel, M. Rapyuta: A cloud robotics platform. IEEE Trans. Autom. Sci. Eng. 2014, 12, 481–493. [Google Scholar] [CrossRef]

- Riazuelo, L.; Tenorth, M.; Di Marco, D.; Salas, M.; Galvez-Lopez, D.; Mosenlechner, L.; Kunze, L.; Beetz, M.; Tardos, J.D.; Montano, L.; et al. RoboEarth semantic mapping: A cloud enabled knowledge-based approach. IEEE Trans. Autom. Sci. Eng. 2015, 12, 432–443. [Google Scholar] [CrossRef]

- Mello, R.C.; Scheidegger, W.M.; Múnera, M.C.; Cifuentes, C.A.; Ribeiro, M.R.; Frizera-Neto, A. The PoundCloud framework for ROS-based cloud robotics: Case studies on autonomous navigation and human-robot interaction. Robot. Auton. Syst. 2022, 150, 103981. [Google Scholar] [CrossRef]

- Chinchali, S.; Sharma, A.; Harrison, J.; Elhafsi, A.; Kang, D.; Pergament, E.; Cidon, E.; Katti, S.; Pavone, M. Network offloading policies for cloud robotics: A learning-based approach. Auton. Robot. 2021, 45, 997–1012. [Google Scholar] [CrossRef]

- Zhang, N. A Cloud-Based Platform for Big Data-Driven CPS Modeling of Robots. IEEE Access 2021, 9, 34667–34680. [Google Scholar] [CrossRef]

- Xu, W.; Cui, J.; Li, L.; Yao, B.; Tian, S.; Zhou, Z. Digital twin-based industrial cloud robotics: Framework, control approach and implementation. J. Manuf. Syst. 2021, 58, 196–209. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L.; Mohammed, A.; Givehchi, M. Ubiquitous manufacturing system based on Cloud: A robotics application. Robot. Comput. Int. Manuf. 2017, 45, 116–125. [Google Scholar] [CrossRef]

- Cao, K.; Liu, Y.; Meng, G.; Sun, Q. An overview on edge computing research. IEEE Access 2020, 8, 85714–85728. [Google Scholar] [CrossRef]

- Xu, Z.; Liang, W.; Xu, W.; Jia, M.; Guo, S. Efficient algorithms for capacitated cloudlet placements. IEEE Trans. Parallel Distrib. Syst. 2015, 27, 2866–2880. [Google Scholar] [CrossRef]

- Jia, M.; Cao, J.; Liang, W. Optimal cloudlet placement and user to cloudlet allocation in wireless metropolitan area networks. IEEE Trans. Cloud Comput. 2015, 5, 725–737. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, T.; Shi, W. Fog computing. IEEE Internet Comput. 2017, 21, 4–6. [Google Scholar] [CrossRef]

- Yang, C.; Wang, Y.; Lan, S.; Wang, L.; Shen, W.; Huang, G.Q. Cloud-edge-device collaboration mechanisms of deep learning models for smart robots in mass personalization. Robot. Comput. Int. Manuf. 2022, 77, 102351. [Google Scholar] [CrossRef]

- Stan, O.P.; Enyedi, S.; Corches, C.; Flonta, S.; Stefan, I.; Gota, D.; Miclea, L. Method to Increase Dependability in a Cloud-Fog-Edge Environment. Sensors 2021, 21, 4714. [Google Scholar] [CrossRef]

- Kovarikova, Z.; Duchon, F.; Trebula, M.; Nagy, F.; Dekan, M.; Labat, D.; Babinec, A. Prototyping an intelligent robotic welding workplace by a cyber-physic tool. Int. J. Adv. Manuf. Tech. 2023, 125, 4855–4882. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, C.; Chen, S. Key technology of intelligentized welding manufacturing and systems based on the internet of things and multi-agent. J. Manuf. Mater. Process. 2022, 6, 135. [Google Scholar] [CrossRef]

- Romero-Hdz, J.; Saha, B.N.; Tstutsumi, S.; Fincato, R. Incorporating domain knowledge into reinforcement learning to expedite welding sequence optimization. Eng. Appl. Artif. Intel. 2020, 91, 103612. [Google Scholar] [CrossRef]

- Liu, S.; Tian, G.; Zhang, Y.; Zhang, M.; Liu, S. Service planning oriented efficient object search: A knowledge-based framework for home service robot. Expert Syst. Appl. 2022, 187, 115853. [Google Scholar] [CrossRef]

- Krzysiak, R.; Butail, S. Information-Based Control of Robots in Search-and-Rescue Missions With Human Prior Knowledge. IEEE Trans. Hum. Mach. Syst. 2022, 52, 52–63. [Google Scholar] [CrossRef]

- Russo, C.; Madani, K.; Rinaldi, A.M. An Unsupervised Approach for Knowledge Construction Applied to Personal Robots. IEEE Trans. Cogn. Dev. Syst. 2021, 13, 6–15. [Google Scholar] [CrossRef]

- Li, J.; Wu, J.; Li, J.; Bashir, A.K.; Piran, J.; Anjum, A. Blockchain-Based Trust Edge Knowledge Inference of Multi-Robot Systems for Collaborative Tasks. IEEE Commun. Mag. 2021, 59, 94–100. [Google Scholar] [CrossRef]

- Liau, Y.Y.; Ryu, K. Framework of knowledge management for human-robot collaborative mold assembly using heterogeneous cobots. J. Intell. Manuf. 2024, 35, 3713–3729. [Google Scholar] [CrossRef]

- Shen, W.; Wang, X.; Li, J.; Wang, Y.; Qiao, X. A self-learning method with domain knowledge integration for intelligent welding sequence planning. Sci. Rep. 2025, 15, 24902. [Google Scholar] [CrossRef] [PubMed]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar] [CrossRef]

- Prajadhiana, K.P.; Manurung, Y.H.; Bauer, A.; Adenan, M.S.; Syahriah, N.I.; Mohamed, M.A.; Awiszus, B.; Graf, M.; Haelsig, A. Experimental verification of computational and sensitivity analysis on substrate deformation and plastic strain induced by hollow thin-walled WAAM structure. Rapid Prototyp. J. 2022, 28, 559–572. [Google Scholar] [CrossRef]

- Manurung, Y.H.P.; Prajadhiana, K.P.; Adenan, M.S.; Awiszus, B.; Graf, M.; Haelsig, A. Analysis of material property models on WAAM distortion using nonlinear numerical computation and experimental verification with P-GMAW. Arch. Civ. Mech. Eng. 2021, 21, 32. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).