1. Introduction

With the recent developments on silicon carbide (SiC) power electronics, new opportunities have opened for optimizing rail vehicle traction system efficiency [

1]. Its main benefits over silicon-based components are a wider range of tolerable temperatures and higher switching frequencies. For electronic converters on trains, this translates into a reduction of nearly 30% in weight and 50% in volume [

2] and reduced energy losses due to current switching, allowing more efficient motor driving. It has already been successfully tested in Japanese high-speed trains [

3,

4], where the motor and the power electronics box have been significantly reduced in size.

For power electronics, the use of SiC also enables simplifying the cooling system, reducing even more the size, weight, and complexity of these components. Instead of active cooling with a liquid coolant [

5] or forced-air cooling with fans [

6], electronics can be cooled down passively using the convection airflow below the moving train, as demonstrated on the Shinkansen [

3]. This means that effective cooling is provided without the need for fans, etc., and so such a component could be omitted along with their associated energy and volume demands. There are, however, system-dependent challenges as the cooling effect is directly dependent on the motion of the train. So, for lower-speed trains like metros, the potential cooling will be reduced. The recent success of a pilot test in the Stockholm metro [

2] encourages the research on cooling modeling for this specific application.

From an operational perspective, there is a certain lack of alignment between the traction power and speed of the vehicle for different operational scenarios. Higher speeds will enhance cooling, while high-power peaks and the subsequent high energy dissipation in the converters are arguably highest during the acceleration phase from standstill, where the speed is near-zero. The present paper investigates the temperature variations in the electronic system during train operation. Both traction power and train speed impact the temperature evolution on the converters: when the motor operates at higher power, the electronic system heats up more, whilst for larger speeds, the cooling is more efficient. A balance between the source of heating and the dissipation must be ensured at all times in order to avoid any overheating, and the transitions make it a non-steady-state problem.

Numerically, simulating this interaction is very challenging as it couples two different types of problems: the conduction of the heat generated by the drive system and the convective cooling of the air flowing past the electronic system. Computational fluid dynamics (CFD) simulations are very costly for that kind of coupling, and simple models are sought to derive new designs. There are also a limited amount of articles in the literature that deal with the modeling of this coupling.

These types of problems are known as conjugate heat transfer (CHT) problems, which are complex fluid mechanics problems that study the conduction in a solid interacting with the convection of the fluid flowing past the solid.

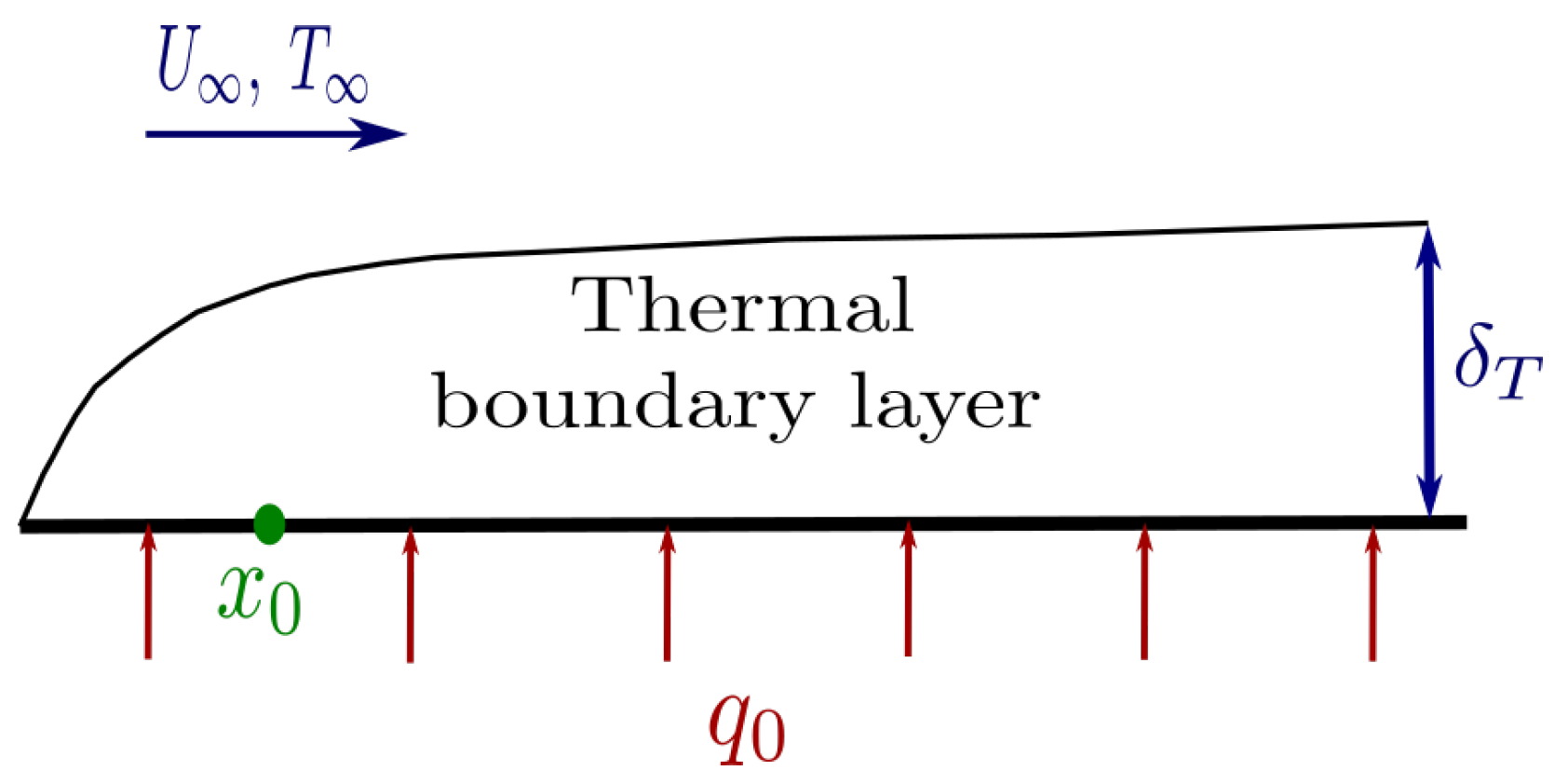

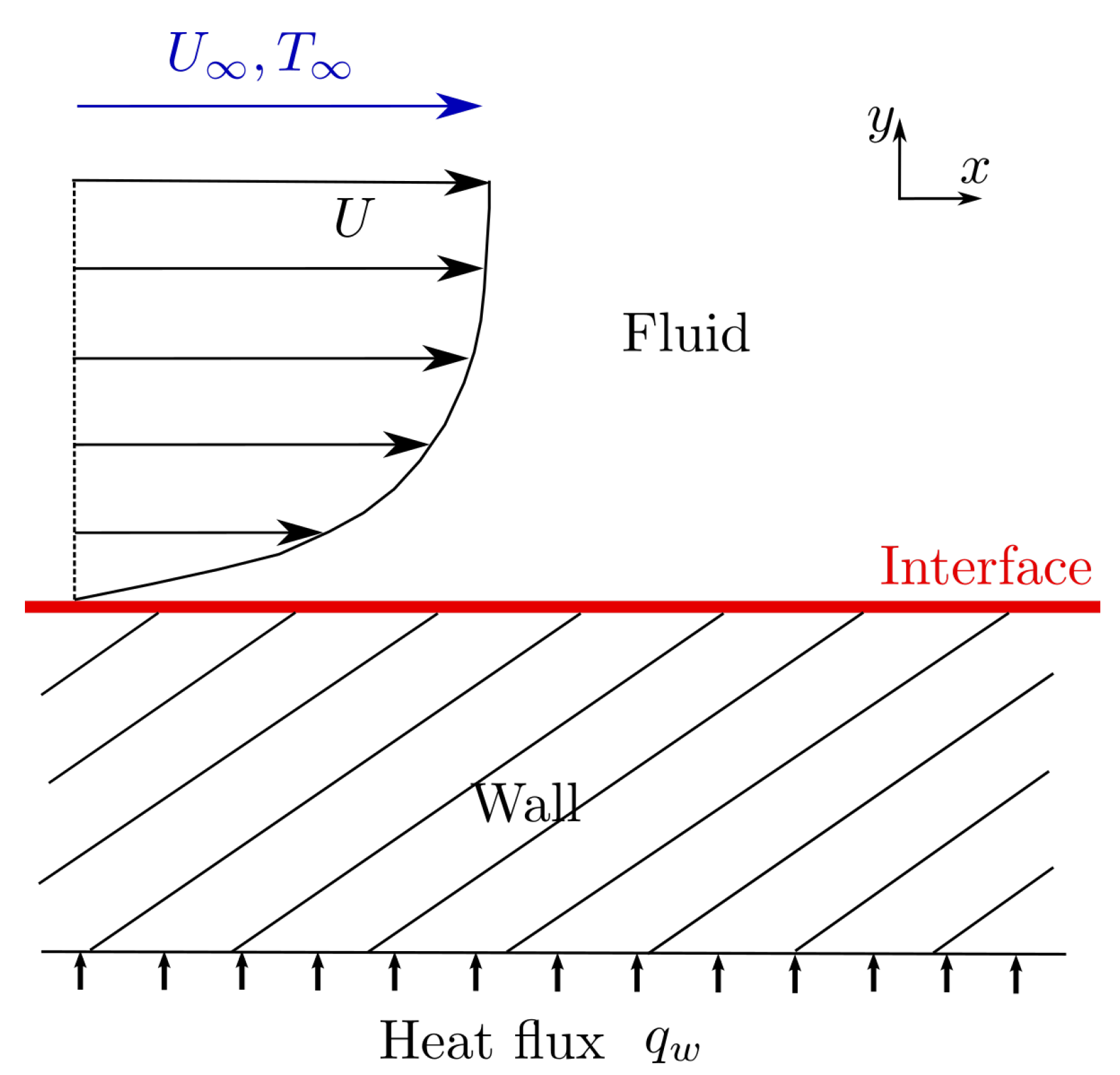

Figure 1 illustrates a classical CHT problem, the interaction between the conductive flow through the slab generated by the heat flux

from below and the airflow. Steady-state predictions can reasonably be achieved with a good level of accuracy [

7]. However, transient developments of the temperature at the interface between the solid and the fluid are usually much harder to estimate. This is crucial when applied to trains power electronics: large temperature peaks may damage the converters and potentially degrade their functioning in operation.

Due to the difference in time scales between conduction and convection processes, computational fluid dynamics (CFD) simulations are numerically challenging [

8]. The required fluid mesh needs to be refined enough to accurately capture the fluid dynamics, but the physical simulated time for the coupled solid/fluid system is much larger than the advection time. Because of the mesh refinement, some elements are very small and need to be numerically solved with a small time-step in the CFD simulation. This means that with a small time-step and a long physical simulated time, the simulation needs many iterations and a long time to converge.

The major difficulty in classical CHT problem is to capture the unsteadiness of the temperature subsequent to the variations of either or both the speed and the heat flux over time [

9].

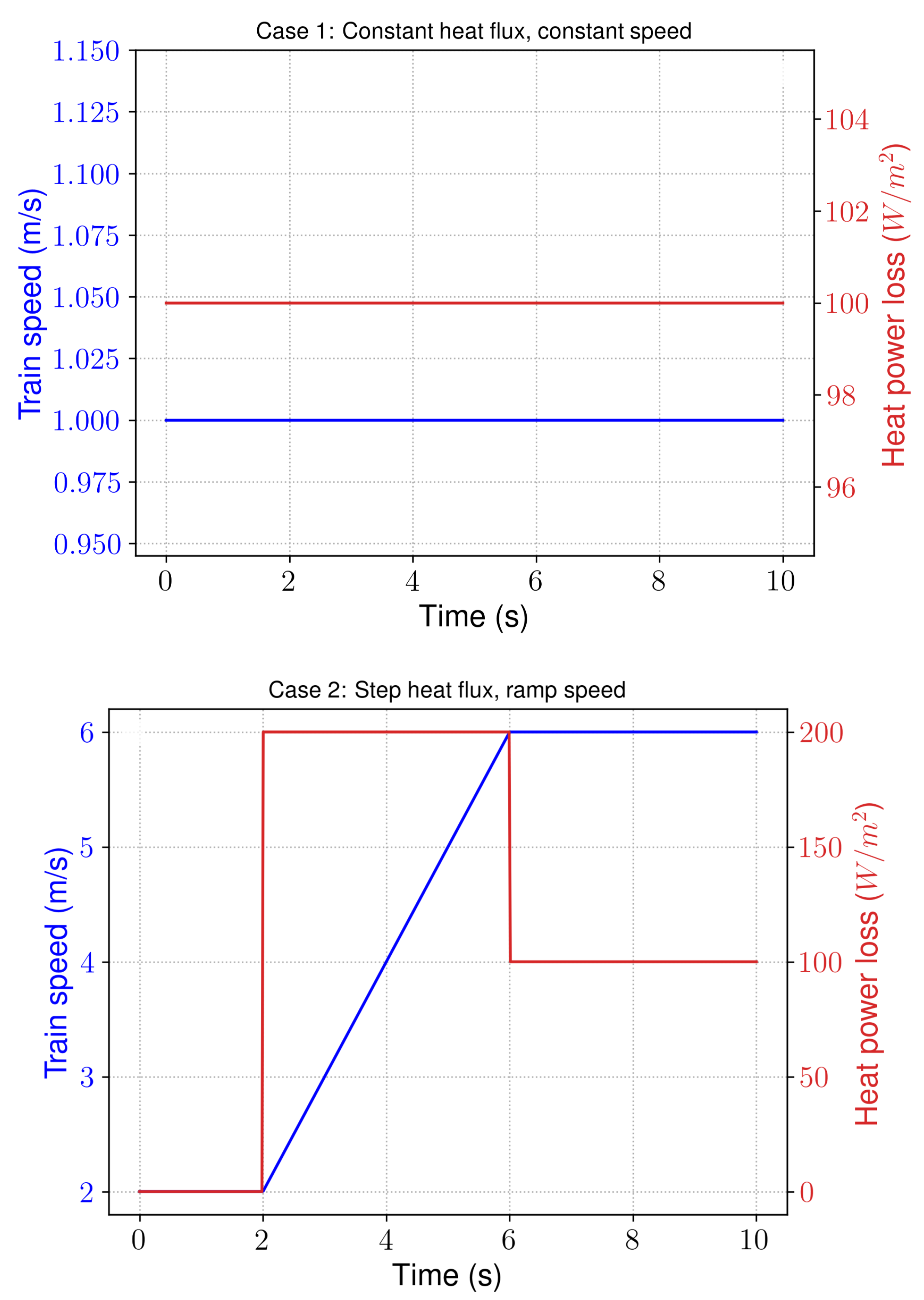

Therefore, in this article, the objective is to develop a method that captures the temperature variations at the surface of the electronic inverters by considering as many physical effects as possible with a much lower computational cost than a CFD simulation. To demonstrate the developed method, a simplistic inverter model representative of a metro train inverter is used in combination with an operational drive cycle, which provides information on track geometry, speed, the number of traction motors, and traction power.

By utilizing such simplified models, the analysis can be focused on the region where one of the most critical thermal exchanges in the inverter occur, thereby allowing the essential physics of the problem to be captured while keeping the computational complexity manageable.

The method proposed in this article to estimate the temperature evolution at the surface of electronic inverters addresses two key aspects:

The speed of the flow cooling the inverter varies over time like the train speed in real conditions;

The power loss and the heat generated by the converters are calculated simultaneously from the variations of the traction power of the motor.

An element of focus in the study is the integration of electronic and aerodynamic factors influencing the thermal behavior of the converters coupled via the operational drive cycle, thus highlighting the multidisciplinary aspect of this study. Initially, the process involved in developing a simplified passive convection cooling model is explained. Subsequently, the converter power losses are derived, and the electric motor operation is described. Finally, the complete model is coupled and tested with speed and traction power derived from a realistic operational drive cycle of a metro train to predict the temperature variations over the entire drive cycle.

3. Power Losses on the Converters

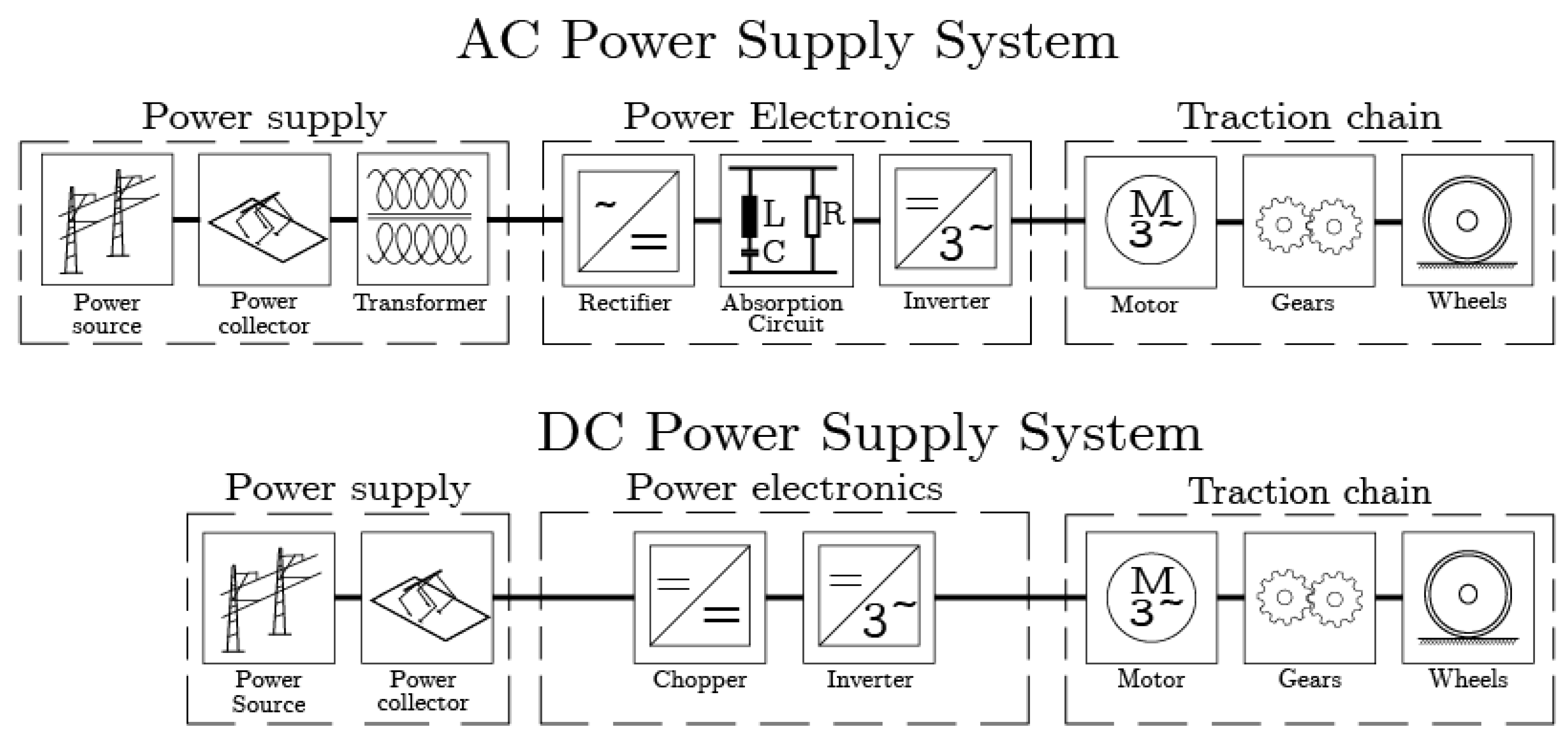

Converters are devices that convert one form of electric current to another, i.e., from Alternating Current (AC) to Direct Current (DC) or vice versa. Converters that convert the AC to DC are called rectifiers, and those converting DC to AC are called inverters. Both play a vital role in the traction chain of a rail vehicle. As represented in

Figure 7, a typical traction chain of a rail vehicle consists of three parts: the power supply, the power electronics, and the traction. The components in the power supply and the power electronics will vary depending on the supply system available. In the case of an AC supply system, both rectifiers and inverters are utilized in the traction chain. In the case of a DC supply system, only the inverters are utilized in the traction chain.

In this paper, a conceptual metro train with a DC supply system has been used as an example to illustrate the model. As depicted in

Figure 7, in the case of a DC supply system, the current from the catenary is transferred to the pantograph through a contact patch. If the line voltage is too high for the operation of the motor, a chopper may be inserted in the DC-intermediate part of the traction chain. The current from the pantograph or the chopper is then fed to the inverter. The inverter then converts the DC to a three-phase AC. The three-phase AC is finally used to operate the traction motor. The traction motor is connected to the wheelsets with the help of a gearbox.

3.1. Calculation of the Losses

It is here assumed that the electric motor operates in nominal conditions, at the peak value for the torque, for a fixed-supply frequency. In this section, the losses induced on the inverters are calculated.

3.1.1. Converter Losses

As mentioned in the introduction, the new possibilities offered by silicon carbide are changing the perspective in terms of converter designs. The history of the high-speed Japanese trains detailed by Sato et al. [

3] shows how power electronics has improved over the last thirty years and how SiC is a big breakthrough for the sector. A figure that is worth recalling is the 30% decrease in total device energy loss per phase of the converter. This reduction in losses directly implies a reduction in the heat generated, explaining why passive cooling systems have become a possibility.

By switching on and off the inverter at a high frequency, the conversion system aims at replicating a sine signal with the right frequency in order to control the revolution speed of the rotor and the torque in the electric motor.

The losses in power electronics are due to two main sources [

15]:

Switching losses : They correspond to the amount of energy wasted in the switching on/off of the transistors and diodes of the converters. The opening and closing of these components are not perfect and some energy is lost due to the latency of these components.

Conduction losses : They correspond to Joule’s law, relating the power lost due to the resistance of the system to the current passing through it.

The total loss can be written in Equation (

6):

represents the phase voltage, represents the peak current of the sine feeding the motor, represents the switching frequency of the power electronics, and and represent the respective turning-on and turning-off times. Finally, is the load resistance of the whole conversion system. The question is how to relate these different values to the actual traction provided by the motor at each instant.

3.1.2. Relation Between the Motor and the Converter Losses

The idea of the complete model is to use two inputs for predicting the temperature: the speed of the train and the traction power on the motors. With the traction power, it is possible to extract the torque and the revolution speed

of the rotor. The latter can then be used to obtain the current, voltage, and switching frequency, from

Figure 8, presented before.

The corresponding evolutions of the current and the voltage with the revolution speed enable one to calculate the total losses on the converters by using the values given by the electronics manufacturer regarding the switching frequency, the latency, and the load resistance.

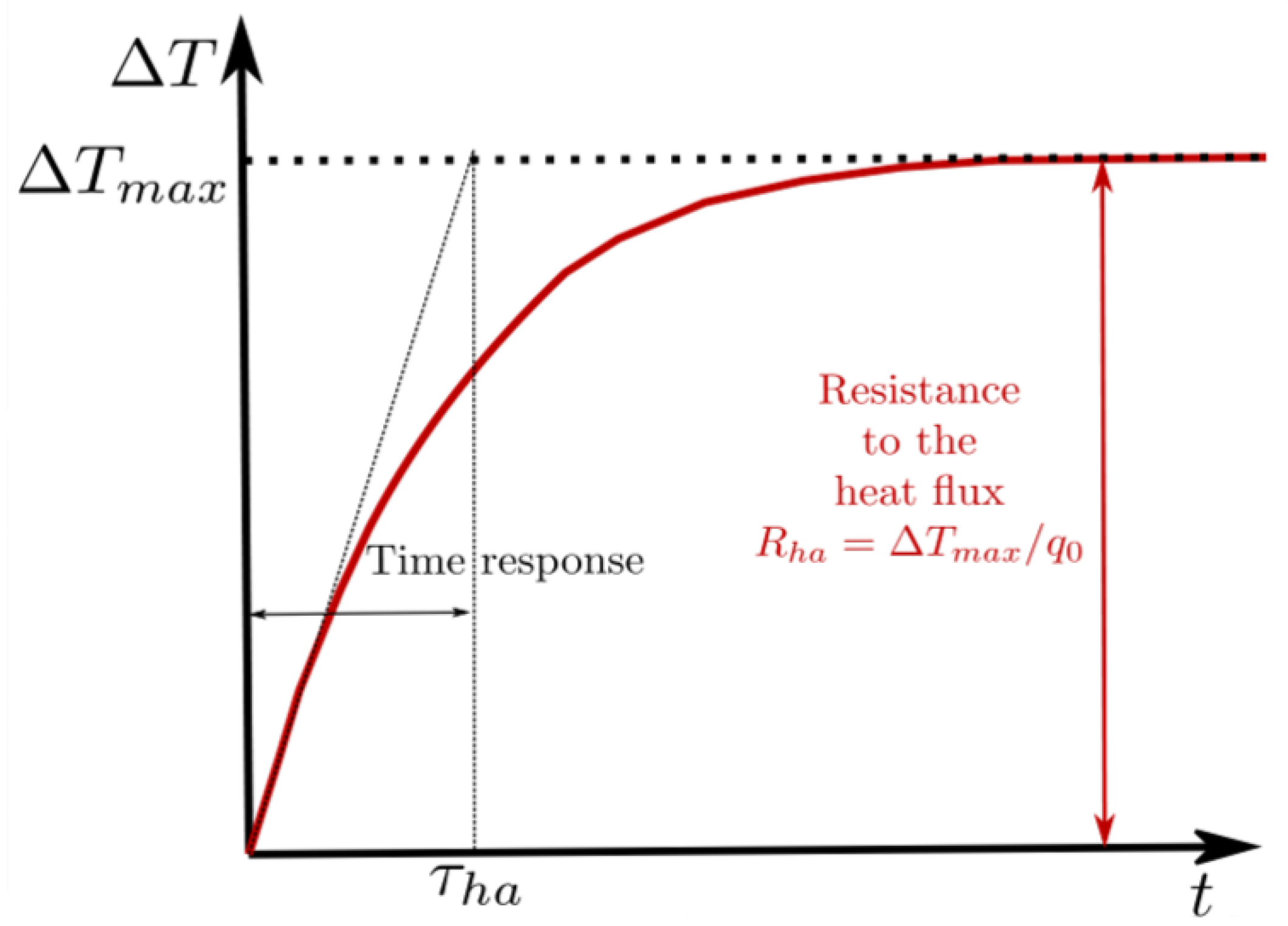

3.2. Thermal Transfer from the Converters

Based on the same idea as the one used to estimate the resistance and response time of the air interaction with the heated flat plate, in the previous section, the thermal conduction through the electronic converters can be modeled by an

network. According to Ma et al. [

16], power electronic devices such as the insulated-gate bipolar transistors (IGBTs) can basically be divided into two main parts: the inside module and the outside module. The inside module consists of the chip, the solder, and several layers of conductors down to the base. Below that is the outside module, where the heat sink is placed, to cool down the IGBT.

The construction of the current model is also based on Bahman et al. [

17]. The coupling of the cooling with the power losses generated on the converters can be illustrated by the model in

Figure 9, putting together both the power loss from the electronics and the power dissipated by convection.

The model can be summarized by the top block, representing the electronic ensemble from the conversion system to the heat sink where the temperature needs to be captured at different locations. This block has two boundary conditions:

The heat source for the power actually lost on the electronic system, as described in the previous section.

The cooling for the power dissipated by the interaction of the air with the heat sink.

The sketch is broken down into two parts, summarizing how both electronic and fluid models work. Using the traction power and the train speed as inputs, the power generated and the power dissipated can be used as inputs for the thermal RC network showed in the middle of the sketch. Thus, the temperature can be estimated over time at the different nodes, corresponding to the different locations of interest in between the control board and the heat sink.

After explaining here how to calculate the power losses on converters, a model for the induction motor is still needed. The losses indeed depend on the voltage and intensity of the motor when it is operating.

3.3. Electric Motor

In this paper, a three-phase squirrel cage induction motor is used in the conceptual metro train, consisting of two main parts, the stator and the rotor. The stator consists of two major components: the core and the windings. The stator core is made of laminated sheets with slots for accommodating the three-phase copper windings.

The core of the squirrel cage rotor is similarly made of thin laminated steel sheets with slots, accommodating longitudinal conductive bars typically made of aluminum or copper. These conductor bars are then connected to end rings at both ends, short-circuiting the rotor. The rotational motion of the rotor shaft is what powers the train (

Figure 7).

When applying a three-phase alternating current to the stator windings placed 120° apart, it generates a rotating magnetic field (RMF), which interacts with the stationary rotor conductors, inducing an alternating current in the rotor. The two alternating fluxes, from the stator and the rotor, interact with each other, the alternating flux in the rotor lagging behind, developing an electromagnetic torque that powers the rotor.

During an operation cycle of a train, there are variations in the power demand of the motor due to the nature of the drive cycle of the train. This means the current and the voltage also vary. Since the inverters supply the motor with the required current and voltage, a variation in the power demand on the motor results in a variation in the power demand on the inverters, influencing the power losses in the inverter.

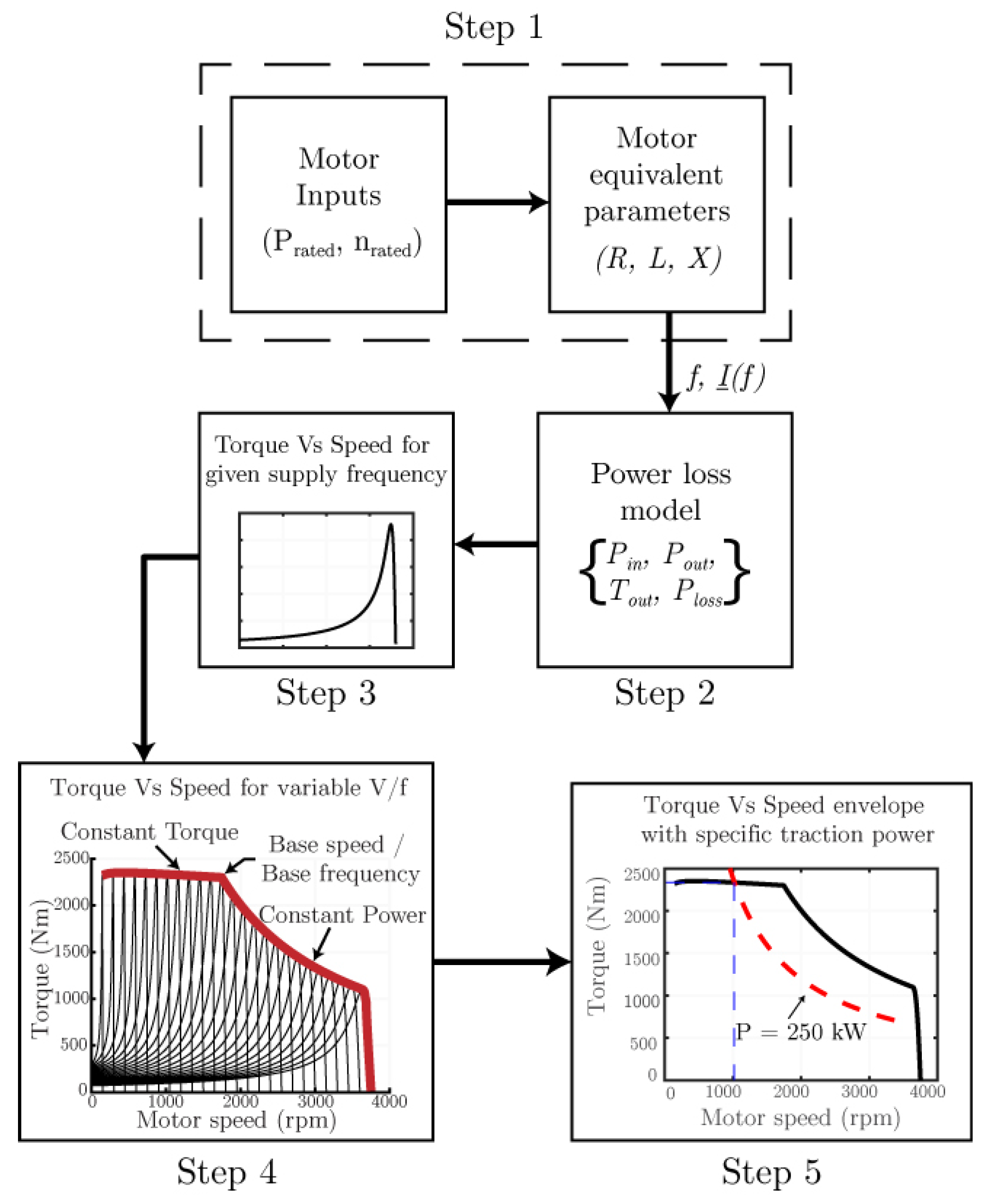

To derive these current and voltage values, an extensive motor model is developed. The method is inspired from [

18,

19]. It comprises five major steps as depicted in

Figure 8.

In the first step, the motor equivalent parameters are calculated from the input parameters. The motor equivalent parameters include the current , resistance , inductance , and reactance of both stator and rotor. In the second step, these equivalent parameters are used to calculate the power loss model of the motor. In the third step, this power loss model is then used to calculate the power and torque developed by the motor at one specific frequency. In the fourth step, a simple Variable–Voltage–Variable–Frequency (VVVF) control logic is implemented to obtain the power and torque developed by the motor across its entire operating range. This results in a typical torque–speed characteristics of the motor. In the fifth step, for a given traction power, the corresponding torque, speed, current, and voltage values are calculated using the developed torque–speed curve.

The torque–speed characteristic curve in step 4 contains information about current and voltage values at every operational point of the motor. For the sake of simplification, it is assumed that the motor would operate on the nominal region of the torque–speed curve, i.e., the envelope of the characteristic map. As depicted in

Figure 8, a specific traction power when plotted with the torque–speed curve results in a hyperbolic curve. Therefore, for any given traction power, the hyperbolic curve intersects with the nominal torque–speed curve. This allows the calculation of the torque and speed values corresponding to the given traction power

. These values of power, torque, and speed are further used to interpolate the corresponding current and the voltage values used for the calculation of power loss on the inverters for any given operational point.

5. Conclusions

With the adoption of SiC power electronics, passive cooling by train-induced airflow is becoming a realistic alternative to active systems. In such systems, however, heat generation is driven by traction power, while cooling depends on train speed, leading to critical mismatches during operation. The highest power peaks, and thus the largest thermal loads, often occur during acceleration from standstill when cooling is minimal. Predicting these transient interactions requires solving a conjugate heat transfer (CHT) problem, where computational fluid dynamics is accurate but computationally costly. As predesign tools that can address this coupling are scarce in the literature, the objective of this study was to develop an analytical method to estimate the temperature evolution at the inverter surface by incorporating the main physical effects while keeping computational costs significantly lower than CFD. To demonstrate the developed method, a simplified model of a metro train inverter and a realistic operational drive cycle are used.

An electronic model of the heat loss generated by an electronic converter of a metro train has been coupled to a fluid model aiming to predict the temperature evolution in time and space on a flat plate, depending on the flow speed and the power input on the flat plate. By predicting the heat generated and the power dissipated on that flat plate, the model is able to estimate the variations of the temperature at the surface of a converter, considering the converter as a circuit of thermal impedance.

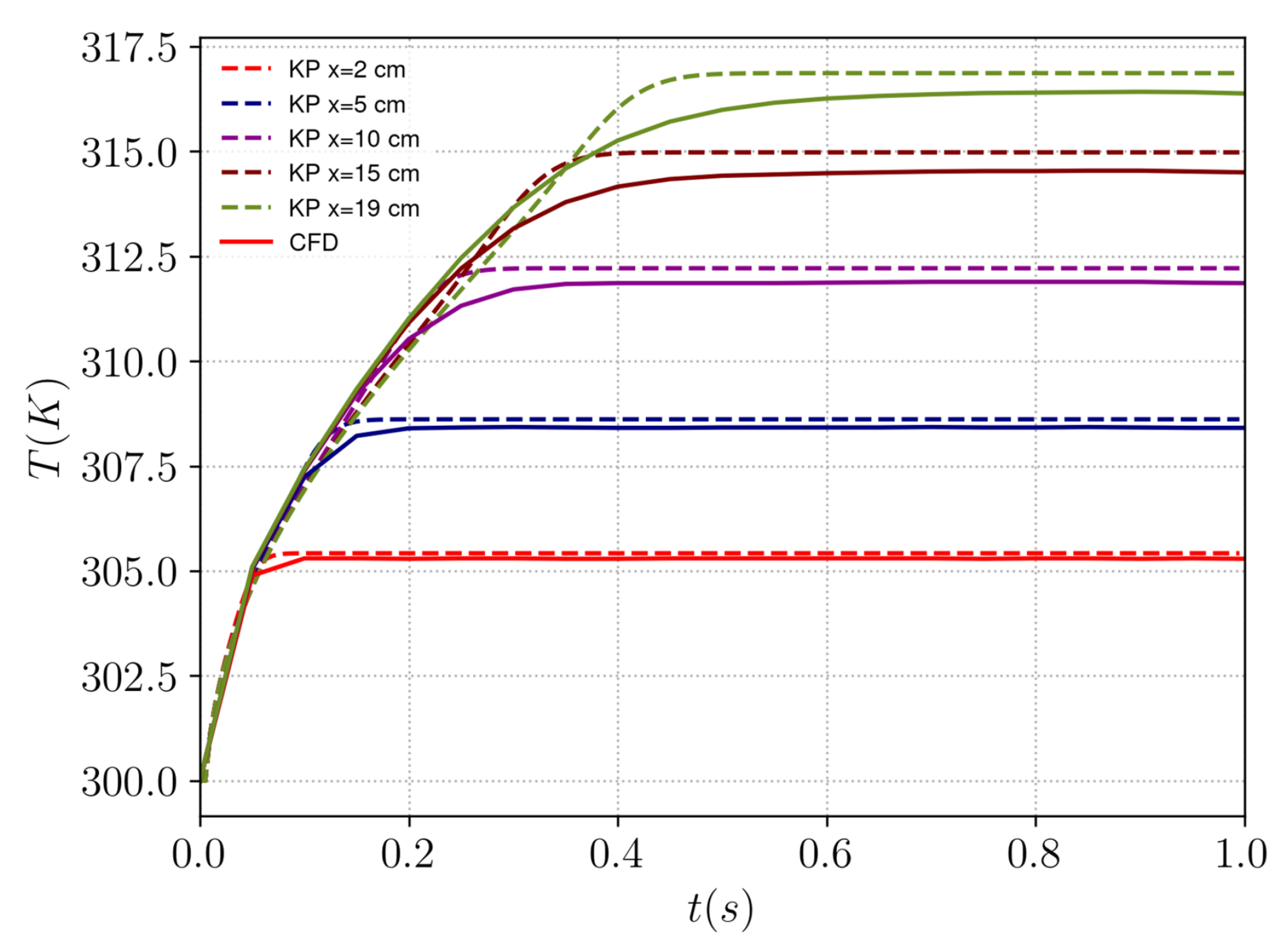

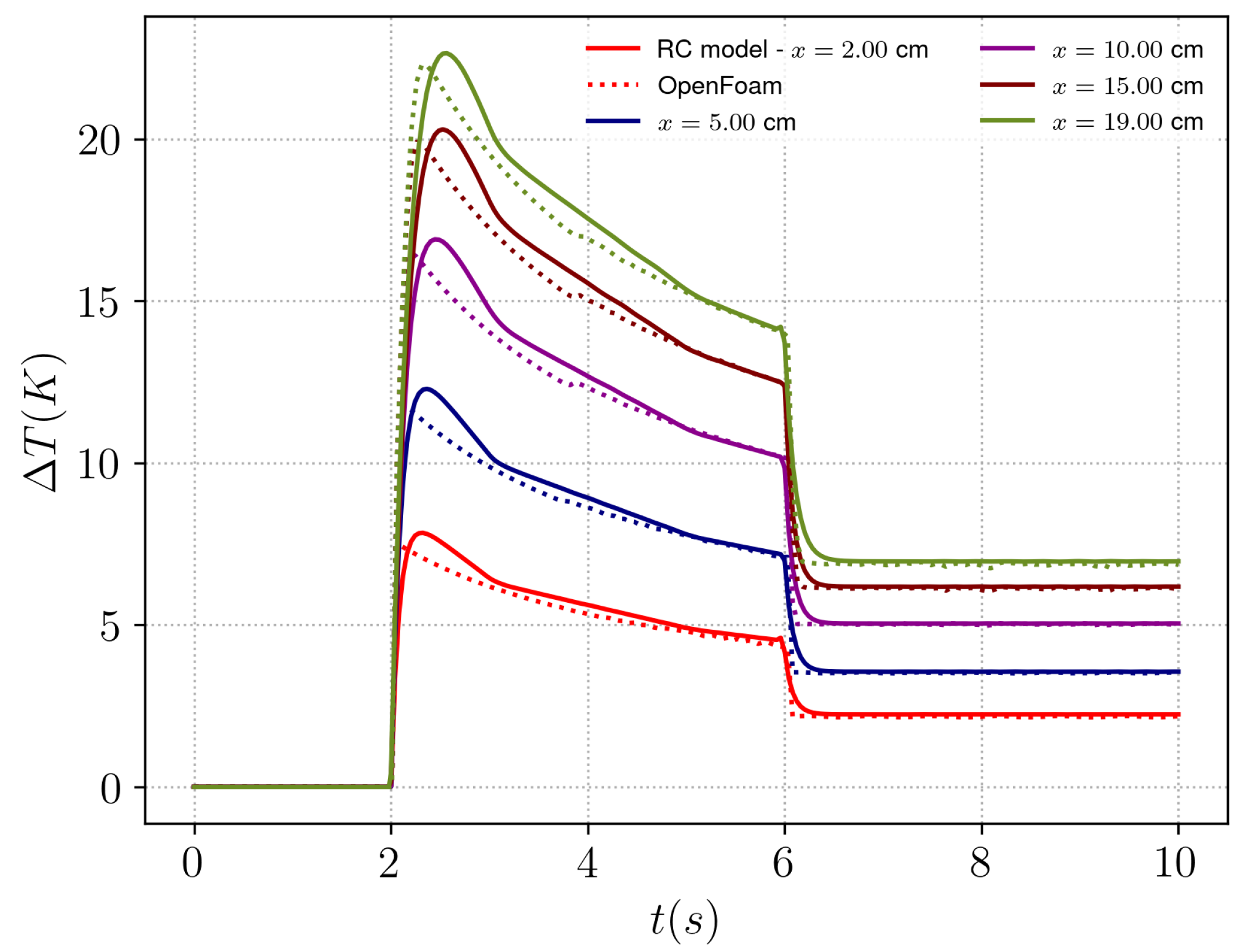

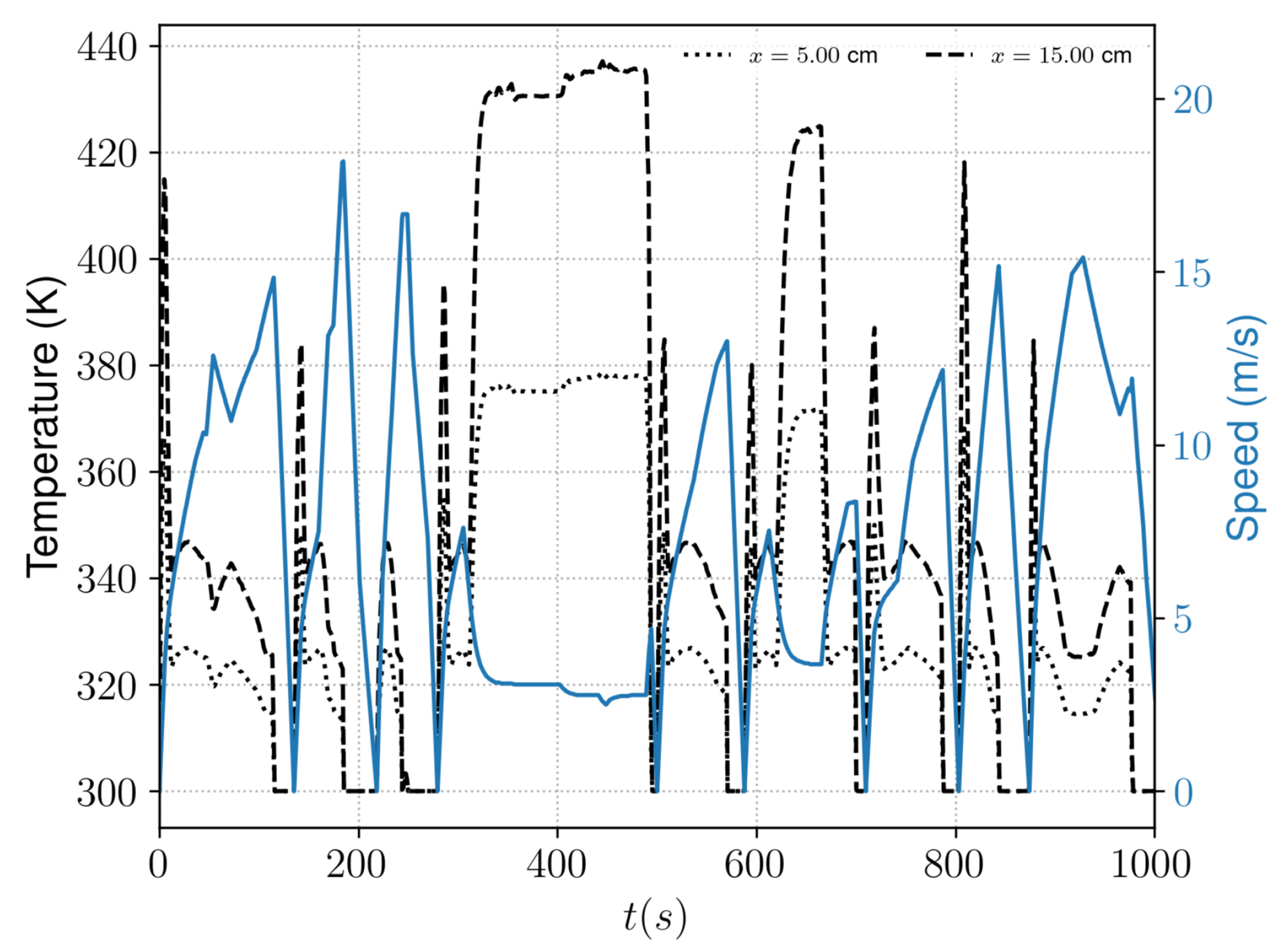

For the fluid model, an integral method has been used to calculate the variations of temperatures along a flat plate compared to CFD with a constant heat flux input and a constant airflow speed. The integral method has been used to calibrate values of an equivalent resistance and a capacitance for different speeds and heat fluxes. When the RC model is applied with the driving behavior of case 2, the results are very close to the CFD. The method has its limitations based on the assumptions made but gives promising results in terms of what can be pursued with such a method.

Such a model could be useful to state on the viability of passive cooling. The advantage of such a method is clearly its cost: if the error made on the temperature variations, particularly temperature peaks, can be properly evaluated, a possibility of adapting this type of models to assess whether passive cooling is sufficient on different designs of converters and driving configurations. Again, CFD is still very challenging in that regard for industrials.

The results depict that there are higher losses during acceleration and larger temperature surges of around 70 K at lower speeds. Additionally, the temperature variation at the junction at cm is 20 K higher than at the base position, and the junction temperature exceeds 420 K further downstream at cm. This indicates that the developed method is able to capture the temperature variations with sufficient accuracy across the flat plate configuration considering several physical effects influencing the thermal exchange at the surface of the inverter.

As further work, the temperature increase given by the model presented in the paper should be compared with actual data in the future. It should also be noticed that using a heat sink would improve the efficiency of cooling compared to a simple flat plate, but further work should be carried out on analytically modeling the interaction with the air to be used in the same perspective as in the present model (thermal impedance associated). Moreover, accounting for turbulent conditions would also impact the results in terms of cooling. If laminar flows can be seen as a worst-case scenario in terms of passive cooling efficiency, a better predesign approach could go further by modeling turbulent flows, but the problem to be solved is even more complex.