Review and Prospect of Integration Compatibility in Digital Vehicles: Multi-Dimensional Challenges and Industry Practice

Abstract

1. Introduction

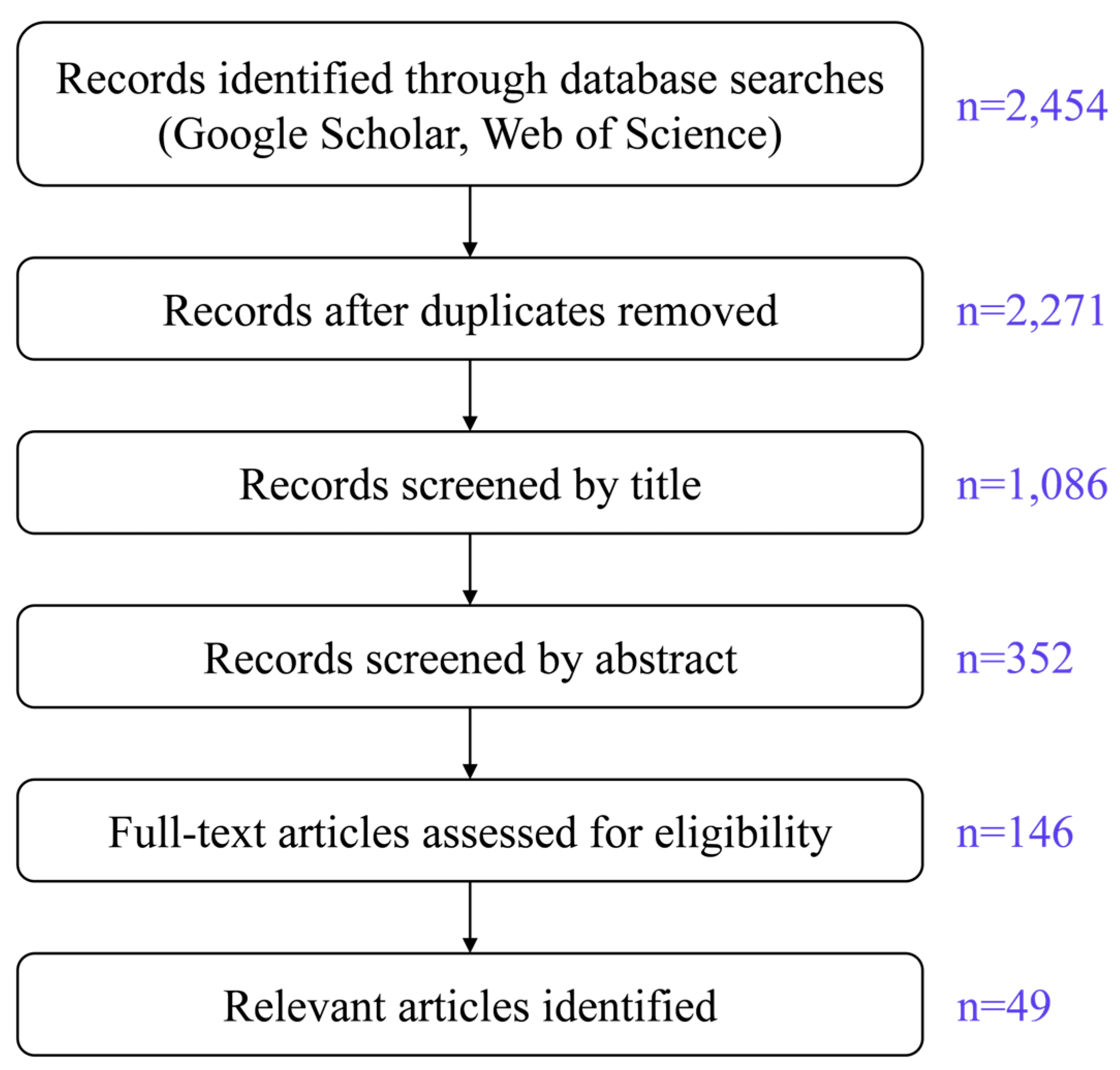

2. Materials and Methods

2.1. Literature Retrieval and Screening

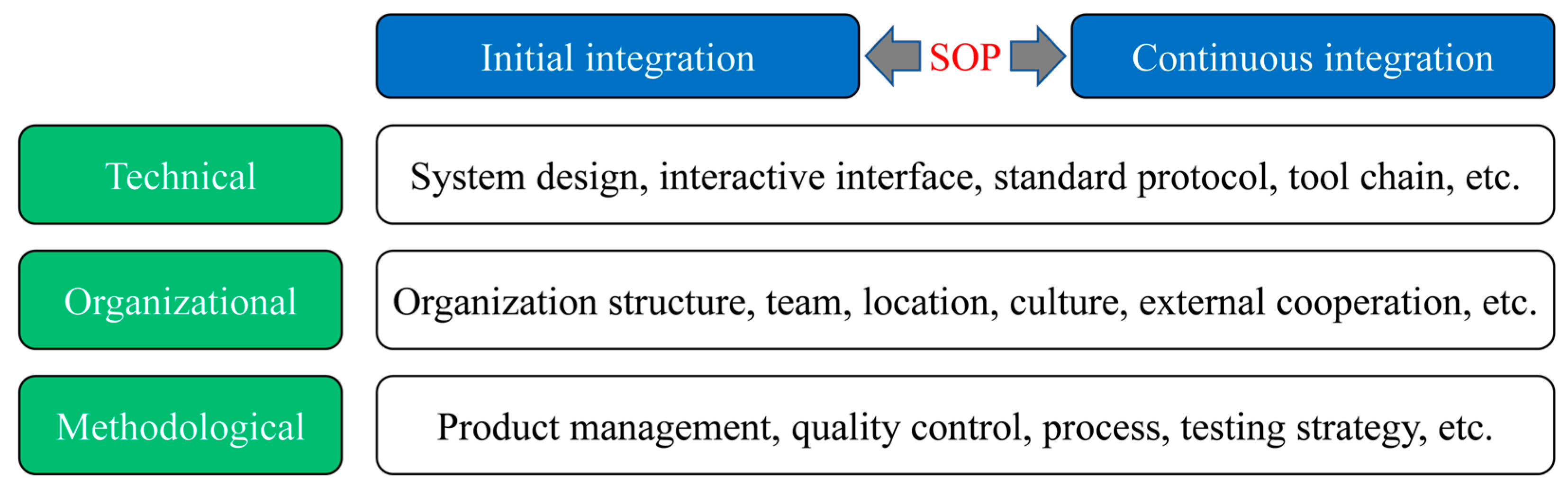

2.2. Structured Classification

- Initial integration is about building from scratch, while continuous integration involves making additions, deletions and modifications to an already stable system, which introduces more dynamic problems. For example, due to continuous software updates, the probability of system errors also dynamically changes [16].

- Initial integration focuses on the overall vehicle system, while continuous integration sometimes targets a specific component or subsystem.

- During initial integration, the versions and states of various technology stacks across different vehicles of the same model are consistent. In contrast, during continuous integration, the technology stack versions and states may vary among different vehicles of the same model. For example, two individuals may purchase the same model of computer, but due to differences in usage time and installed software updates, the two computers may gradually exhibit significant differences in terms of memory usage and software performance.

- Initial integration is typically driven by fixed and predetermined deadlines to meet product launch requirements. While the deadlines of continuous integration are often flexible and uncertain. For instance, urgent bug fixes may require completion within a week, while the integration of new functions can be adjusted flexibly based on market demands and research and development (R&D) progress [17].

- Technical dimension: There are significant differences among various software and hardware components in vehicles. Certain technical measures can facilitate communication and collaboration between components, thereby improving integration compatibility. This dimension primarily involves system design, interaction interfaces, standard protocols, toolchains, etc.

- Organizational dimension: The automotive integration work involves multiple departments, including design, research and development, engineering, operations, and supply chain management. Effective communication and collaboration mechanisms are essential to seamlessly integrate components into the vehicle system. This dimension primarily involves organizational structure, team, location, culture, external cooperation, etc.

- Methodological dimension: Cost, efficiency, and quality are considered challenging to simultaneously achieve in integration testing. Appropriate methodological strategies are widely regarded as being able to optimize this imbalanced triangle relationship [18]. This dimension primarily involves product management, quality control, processes, testing strategies, etc.

2.3. Expert Investigation

- Expert#1—Head of Integration Department at a well-known OEM: This expert has extensive management experience and a deep understanding of internal integration challenges within OEMs.

- Expert#2—OEM integration testing engineer: This expert has practical experience in integration testing, providing direct exposure and understanding of compatibility issues.

- Expert#3—Researcher specializing in digital vehicle development: This expert has conducted in-depth research on digital automotive technical trends.

- Expert#4—Partner at an automotive industry management consulting firm: This expert possesses rich consulting experience and a comprehensive understanding of the automotive industry.

- Expert#5—Product manager at an automotive software supplier: This expert has professional knowledge and experience in automotive software development and integration.

- Expert#6—Researcher focusing on automotive industry standards: This expert has a deep understanding of industry standards and specifications and has participated in the development process of related standards.

3. Compatibility Challenges of Automotive Integration

3.1. Technical Challenges of Initial Integration

3.1.1. System Design

3.1.2. Interactive Interface

3.2. Organizational Challenges of Initial Integration

3.2.1. Organization Structure

3.2.2. Team

3.2.3. Location

3.2.4. External Cooperation

- Middleware Interoperability: Middleware acts as the “glue” between hardware and software, but conflicting standards hinder cross-stack communication.

- OTA Update Standards: OTA has become a cornerstone of continuous integration, but the absence of universal protocols for update packaging, validation, and rollback creates chaos.

- Hardware–Software Co-Design: Digital vehicles demand tight hardware–software synchronization, but standards for hardware abstraction layers (HALs) and resource allocation are inconsistent.

3.3. Methodological Challenges of Initial Integration

3.3.1. Product Management

3.3.2. Quality Control

3.3.3. Development Mode

3.4. Technical Challenges of Continuous Integration

3.4.1. OTA Upgrade

3.4.2. Standard Protocol

3.5. Organizational Challenges of Continuous Integration

3.6. Methodological Challenges of Continuous Integration

3.6.1. Software Risk Management

3.6.2. Process

4. Potential Countermeasures

4.1. Countermeasures for Technical Challenges in Initial Integration

4.2. Countermeasures for Organizational Challenges in Initial Integration

4.3. Countermeasures for Methodological Challenges in Initial Integration

4.4. Countermeasures for Technical Challenges in Continuous Integration

4.5. Countermeasures for Organizational Challenges in Continuous Integration

4.6. Countermeasures for Methodological Challenges in Continuous Integration

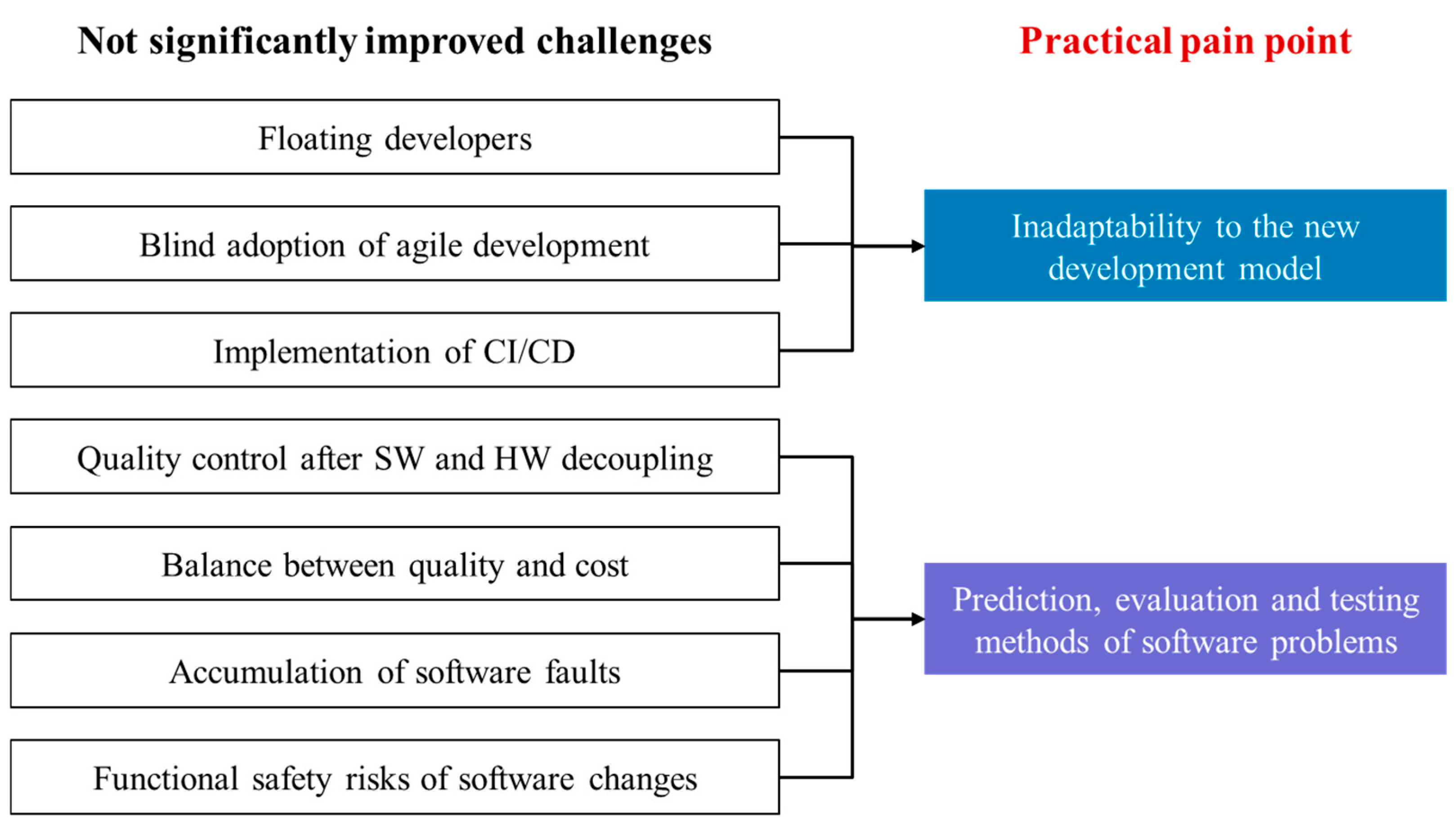

5. Practical Pain Point

5.1. Inadaptability to the New Development Model

- Agile development relies on task allocation as a prerequisite for improving efficiency [38]. Consequently, many software engineers in OEMs are not directly involved in coding but rather responsible for task allocation and outsourcing development [51]. The consequence of moving further away from the source code is a lack of knowledge when facing integration issues.

- Some development teams are forced to break down individual tasks into sub-tasks to meet the bi-weekly project milestones [51]. For software suppliers, excessively granular task packages not only introduce numerous meaningless milestones but also severely restrict the suppliers’ subjective initiative, making it challenging to address compatibility issues [79].

- Traditional automotive software development teams are accustomed to handovers and communication at project milestones after completing their own tasks, rather than engaging in proactive cross-functional communication during the development process [80]. This contradicts the communication principles of agile development and leads to many issues going unnoticed and becoming uncontrollable [81].

- The intensive agile cycles necessitate developers to anticipate the requirements of the next feature during the integration testing gap of the current feature [82]. Additionally, if there are bugs in the previous feature, developers need to find time within the current agile cycle to address them. This results in developers potentially being involved in 3–4 projects simultaneously, leading to potential quality risks.

5.2. Prediction, Evaluation and Testing Methods of Software Problems

- Many software errors are hidden at the source code level, and source code review can easily lead to intellectual property disputes [85]. Conflicts of interest prevent many methods and tools from being applied to software provided by suppliers.

- Predicting, evaluating, and testing software problems rely on a significant amount of prerequisite information, such as development requirements, architectural designs, dependencies, and coupling relationships [86]. In the real world, obtaining this information involves hundreds of teams from different companies, making it nearly impossible to acquire complete information.

- Automotive software exhibits strong heterogeneity [87]. Some software operates as black boxes based on AI networks, allowing only black box testing. Some software has complex coupling relationships with hardware, requiring highly specialized knowledge. Additionally, certain software involves extensive data exchange with the cloud, introducing unknown attack vectors. These software components also form a complex network of interactions, for which no universal approach can accommodate all components [88].

- Many academic research outcomes exist at the theoretical level, while the engineering implementations of automotive software integration testing standards, tools, and other aspects have already been solidified by industry organizations and major giant corporations [89]. This leaves OEMs with limited space for modification. The widespread application of new methods would require convincing the entire industry chain to switch.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Zhang, W.; Zhao, F. Impact, challenges and prospect of software-defined vehicles. Automot. Innov. 2022, 5, 180–194. [Google Scholar] [CrossRef]

- Pretschner, A.; Broy, M.; Kruger, I.H.; Stauner, T. Software engineering for automotive systems: A roadmap. In Proceedings of the Future of Software Engineering (FOSE’07), Minneapolis, MN, USA, 23–25 May 2007; IEEE: New York, NY, USA, 2007; pp. 55–71. [Google Scholar]

- Bandur, V.; Selim, G.; Pantelic, V.; Lawford, M. Making the case for centralized automotive E/E architectures. IEEE Trans. Veh. Technol. 2021, 70, 1230–1245. [Google Scholar] [CrossRef]

- Beckers, K.; Côté, I.; Frese, T.; Hatebur, D.; Heisel, M. A structured and systematic model-based development method for automotive systems, considering the OEM/supplier interface. Reliab. Eng. Syst. Saf. 2017, 158, 172–184. [Google Scholar] [CrossRef]

- Staron, M. Automotive Software Architectures; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Jersak, M.; Richter, K.; Ernst, R.; Braam, J.C.; Jiang, Z.Y.; Wolf, F. Formal methods for integration of automotive software. In Proceedings of the 2003 Design, Automation and Test in Europe Conference and Exhibition, Munich, Germany, 3–7 March 2003; IEEE: New York, NY, USA, 2003; pp. 45–50. [Google Scholar]

- Ayres, N.; Deka, L.; Paluszczyszyn, D. Continuous automotive software updates through container image layers. Electronics 2021, 10, 739. [Google Scholar] [CrossRef]

- Şahin, T.; Köster, L.; Huth, T.; Vietor, T. How to Upgrade Vehicles? Release Planning in the Automotive Industry. In Proceedings of the 21. Internationales Stuttgarter Symposium: Automobil-und Motorentechnik, Stuttgart, Germany, 30–31 March 2021; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2021; pp. 155–173. [Google Scholar]

- Ni, J.; Huang, X. Discovery-to-recall in the automotive industry: A problem-solving perspective on investigation of quality failures. J. Supply Chain Manag. 2018, 54, 71–95. [Google Scholar] [CrossRef]

- Zhiweidata. Analysis of Public Opinion in Automotive Industry: The Gain and Loss of Automotive Brands Behind Frequent “Recall Doors”. 2020. Available online: https://m.thepaper.cn/newsDetail_forward_8397950. (accessed on 21 January 2024).

- Vetter, A.; Sax, E. Hierarchical versioning to increase compatibility in signal-oriented vehicle networks. In Proceedings of the 27th International Conference on Systems Engineering, ICSEng 2020, Las Vegas, NV, USA, 14–16 December 2020; Springer International Publishing: Cham, Switzerland, 2021; pp. 435–444. [Google Scholar]

- Floch, J.; Carrez, C.; Cieślak, P.; Rój, M.; Sanders, R.T.; Shiaa, M.M. A comprehensive engineering framework for guaranteeing component compatibility. J. Syst. Softw. 2010, 83, 1759–1779. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, H.; Zhu, S. An incremental V-model process for automotive development. In Proceedings of the 2016 23rd Asia-Pacific Software Engineering Conference (APSEC), Hamilton, New Zealand, 6–9 December 2016; IEEE: New York, NY, USA, 2016; pp. 225–232. [Google Scholar]

- Du, B.; Azimi, S.; Moramarco, A.; Sabena, D.; Parisi, F.; Sterpone, L. An Automated Continuous Integration Multitest Platform for Automotive Systems. IEEE Syst. J. 2021, 16, 2495–2506. [Google Scholar] [CrossRef]

- Banijamali, A.; Jamshidi, P.; Kuvaja, P.; Oivo, M. Kuksa: A cloud-native architecture for enabling continuous delivery in the automotive domain. In Proceedings of the International Conference on Product-Focused Software Process Improvement, Barcelona, Spain, 27–29 November 2019; Springer International Publishing: Cham, Switzerland, 2019; pp. 455–472. [Google Scholar]

- Rana, R.; Staron, M.; Hansson, J.; Nilsson, M. Defect prediction over software life cycle in automotive domain state of the art and road map for future. In Proceedings of the 2014 9th International Conference on Software Engineering and Applications (ICSOFT-EA), Vienna, Austria, 29–31 August 2014; IEEE: New York, NY, USA, 2014; pp. 377–382. [Google Scholar]

- Mumtaz, M.; Ahmad, N.; Ashraf, M.U.; Alghamdi, A.M.; Bahaddad, A.A.; Almarhabi, K.A. Iteration causes, impact, and timing in software development lifecycle: An slr. IEEE Access 2022, 10, 65355–65375. [Google Scholar] [CrossRef]

- Huang, C.Y.; Lyu, M.R. Optimal release time for software systems considering cost, testing-effort, and test efficiency. IEEE Trans. Reliab. 2005, 54, 583–591. [Google Scholar] [CrossRef]

- Döringer, S. ‘The problem-centred expert interview’. Combining qualitative interviewing approaches for investigating implicit expert knowledge. Int. J. Soc. Res. Methodol. 2021, 24, 265–278. [Google Scholar] [CrossRef]

- Vogelsang, A. Feature dependencies in automotive software systems: Extent, awareness, and refactoring. J. Syst. Softw. 2020, 160, 110458. [Google Scholar] [CrossRef]

- Kong, S.; Lu, M.; Li, L. Fault propagation analysis in software intensive systems: A survey. In Proceedings of the 2017 Second International Conference on Reliability Systems Engineering (ICRSE), Beijing, China, 10–12 July 2017; IEEE: New York, NY, USA, 2017; pp. 1–9. [Google Scholar]

- Lee, J.; Wang, L. A method for designing and analyzing automotive software architecture: A case study for an autonomous electric vehicle. In Proceedings of the 2021 International Conference on Computer Engineering and Artificial Intelligence (ICCEAI), Shanghai, China, 27–29 August 2021; IEEE: New York, NY, USA, 2021; pp. 20–26. [Google Scholar]

- Durisic, D.; Nilsson, M.; Staron, M.; Hansson, J. Measuring the impact of changes to the complexity and coupling properties of automotive software systems. J. Syst. Softw. 2013, 86, 1275–1293. [Google Scholar] [CrossRef]

- Uddin, G.; Sabir, F.; Guéhéneuc, Y.G.; Alam, O.; Khomh, F. An empirical study of iot topics in iot developer discussions on stack overflow. Empir. Softw. Eng. 2021, 26, 121. [Google Scholar] [CrossRef]

- Akhtar, Z.B. Operating systems (OS): An insight investigative research analysis and future directions. J. Technol. Inform. 2024, 6, 58–69. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, F.; Liu, Z. Development Strategies of Intelligent Automotive Industry Under the Background of Increasing Demand for Computational Capacity. In Proceedings of the Society of Automotive Engineers (SAE)-China Congress, Nantong, China, 20–22 December 2022; Springer: Singapore, 2022; pp. 113–128. [Google Scholar]

- Nakajima, T.; Kinebuchi, Y.; Courbot, A.; Shimada, H.; Lin, T.H.; Mitake, H. Composition kernel: A multi-core processor virtualization layer for highly functional embedded systems. In Proceedings of the 2010 IEEE 16th Pacific Rim International Symposium on Dependable Computing, Tokyo, Japan, 13–15 December 2010; IEEE: New York, NY, USA, 2010; pp. 223–224. [Google Scholar]

- Oliveira, A.; Martins, J.; Cabral, J.; Tavares, A.; Pinto, S. TZ-VirtIO: Enabling standardized inter-partition communication in a trustzone-assisted hypervisor. In Proceedings of the 2018 IEEE 27th International Symposium on Industrial Electronics (ISIE), Cairns, Australia, 13–15 June 2018; IEEE: New York, NY, USA, 2018; pp. 708–713. [Google Scholar]

- Aust, S. Paving the way for connected cars with adaptive AUTOSAR and AGL. In Proceedings of the 2018 IEEE 43rd Conference on Local Computer Networks Workshops (LCN Workshops), Chicago, IL, USA, 1–4 October 2018; IEEE: New York, NY, USA, 2018; pp. 53–58. [Google Scholar]

- Sagstetter, F.; Lukasiewycz, M.; Steinhorst, S.; Wolf, M.; Bouard, A.; Harris, W.R.; Jha, S.; Peyrin, T.; Poschmann, A.; Chakraborty, S. Security challenges in automotive hardware/software architecture design. In Proceedings of the 2013 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 18–23 March 2013; IEEE: New York, NY, USA, 2013; pp. 458–463. [Google Scholar]

- Huang, C. Application Scenarios of AUTOSAR Classic Platform and Adaptive Platform. In Proceedings of the 2022 2nd International Conference on Economic Development and Business Culture (ICEDBC 2022), Dali, China, 24–26 June 2022; Atlantis Press: Dordrecht, The Netherlands, 2022; pp. 1667–1671. [Google Scholar]

- Gemlau, K.B.; Hasseln, H.; Ernst, R. Industry-track: System-Level Logical Execution Time for Automotive Software Development. In Proceedings of the 2022 International Conference on Embedded Software (EMSOFT), Shanghai, China, 7–14 October 2022; IEEE: New York, NY, USA, 2022; pp. 21–23. [Google Scholar]

- Menard, C.; Goens, A.; Lohstroh, M.; Castrillon, J. Achieving determinism in adaptive AUTOSAR. In Proceedings of the 2020 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 9–13 March 2020; IEEE: New York, NY, USA, 2020; pp. 822–827. [Google Scholar]

- Saidi, S.; Steinhorst, S.; Hamann, A.; Ziegenbein, D.; Wolf, M. Future automotive systems design: Research challenges and opportunities: Special session. In Proceedings of the International Conference on Hardware/Software Codesign and System Synthesis, Torino, Italy, 30 September–5 October 2018; pp. 1–7. [Google Scholar]

- Cabigiosu, A.; Zirpoli, F.; Camuffo, A. Modularity, interfaces definition and the integration of external sources of innovation in the automotive industry. Res. Policy 2013, 42, 662–675. [Google Scholar] [CrossRef]

- Barsalou, M.; Perkin, R. Statistical problem-solving teams: A case study in a global manufacturing organization in the automotive industry. Qual. Reliab. Eng. Int. 2024, 40, 513–523. [Google Scholar] [CrossRef]

- Bucaioni, A.; Pelliccione, P.; Wohlrab, R. Aligning architecture with business goals in the automotive domain. In Proceedings of the 2021 IEEE 18th International Conference on Software Architecture (ICSA), Stuttgart, Germany, 22–26 March 2021; IEEE: New York, NY, USA, 2021; pp. 126–137. [Google Scholar]

- Katumba, B.; Knauss, E. Agile development in automotive software development: Challenges and opportunities. In Proceedings of the Product-Focused Software Process Improvement: 15th International Conference, PROFES 2014, Helsinki, Finland, 10–12 December 2014; Proceedings 15. Springer: Cham, Switzerland, 2014; pp. 33–47. [Google Scholar]

- Deloitte. Automotive Engineering in the Software Era. 2022. Available online: https://www.199it.com/archives/1433181.html. (accessed on 10 January 2024).

- Hoeft, F. Auto makers and radical innovation: Culture, capital and talent form road blocks. J. Bus. Strategy 2021, 43, 210–221. [Google Scholar] [CrossRef]

- Doucette, R.; Hensley, R.; Kaas, H.; Rittstieg, M. Winning the Race for Talent: A Road Map for the Automotive Industry; McKinsey: New York, NY, USA, 2020. [Google Scholar]

- Yadav, V. A flexible management approach for globally distributed software projects. Glob. J. Flex. Syst. Manag. 2016, 17, 29–40. [Google Scholar] [CrossRef]

- Dakić, P.; Stupavský, I.; Todorović, V. The Effects of Global Market Changes’ on Automotive Manufacturing and Embedded Software. Sustainability 2024, 16, 4926. [Google Scholar] [CrossRef]

- Feng, K.; Karreman, B.; Zeng, D.; Pennings, E. R&D collaboration, social coordination, and standardization: Evidence from the Chinese automotive industry. J. Technol. Transf. 2022, 49, 158–190. [Google Scholar] [CrossRef]

- Burgio, P.; Bertogna, M.; Capodieci, N.; Cavicchioli, R.; Sojka, M.; Houdek, P.; Marongiu, A.; Gai, P.; Scordino, C.; Morelli, B. A software stack for next-generation automotive systems on many-core heterogeneous platforms. Microprocess. Microsyst. 2017, 52, 299–311. [Google Scholar] [CrossRef]

- Meng, T.; Li, J.; Huang, J.; Yang, D.; Zhong, Z. Study on technical system of software defined vehicles. Automot. Eng 2021, 43, 459–468. [Google Scholar]

- Antinyan, V. Revealing the complexity of automotive software. In Proceedings of the 28th Acm Joint Meeting on European Software Engineering Conference and Symposium on the Foundations of Software Engineering, Virtual Event, 8–13 November 2020; pp. 1525–1528. [Google Scholar]

- Argotti, Y.; Baron, C.; Esteban, P.; Chaton, D. Quality Quantification Applied to Automotive Embedded Systems and Software Advances with qualimetry science. In Proceedings of the Embedded Real Time Systems (ERTS) 2020, Toulouse, France, 29–31 January 2020. [Google Scholar]

- Heidrich, J.; Morgenstern, A.; Quante, J.; Grundler, T. New Framework for Measurement-based Evaluation of Quality in Automotive Software Development. ATZelectronics Worldw. 2022, 17, 8–13. [Google Scholar] [CrossRef]

- Heidrich, J.; Kläs, M.; Morgenstern, A.; Antonino, P.O.; Trendowicz, A.; Quante, J.; Grundler, T. From Complexity Measurement to Holistic Quality Evaluation for Automotive Software Development. arXiv 2021, arXiv:2110.14301. [Google Scholar] [CrossRef]

- Ågren, S.M.; Heldal, R.; Knauss, E.; Pelliccione, P. Agile beyond teams and feedback beyond software in automotive systems. IEEE Trans. Eng. Manag. 2022, 69, 3459–3475. [Google Scholar] [CrossRef]

- ISO 26262:2018; Road Vehicles—Functional Safety. International Organization for Standardization: Geneva, Switzerland, 2018.

- Zhang, Y.; Yang, J.; Jin, Z.; Sethi, U.; Rodrigues, K.; Lu, S.; Yuan, D. Understanding and detecting software upgrade failures in distributed systems. In Proceedings of the ACM SIGOPS 28th Symposium on Operating Systems Principles, Koblenz, Germany, 26–29 October 2021; pp. 116–131. [Google Scholar]

- Wiegand, N.; Imschloss, M. Do You Like What You (Can’t) See? The Differential Effects of Hardware and Software Upgrades on High-Tech Product Evaluations. J. Interact. Mark. 2021, 56, 18–40. [Google Scholar] [CrossRef]

- Bucaioni, A.; Becker, M. Enabling automated integration of architectural languages: An experience report from the automotive domain. J. Syst. Softw. 2022, 184, 111106. [Google Scholar] [CrossRef]

- Conradi Hoffmann, J.L.; Passig Horstmann, L.; Fröhlich, A.A. Transparent integration of autonomous vehicles simulation tools with a data-centric middleware. Des. Autom. Embed. Syst. 2024, 28, 45–66. [Google Scholar] [CrossRef]

- Hellwig, A.D.; Kriebel, S.; Kusmenko, E.; Rumpe, B. Component-based integration of interconnected vehicle architectures. In Proceedings of the 2019 IEEE intelligent vehicles symposium (IV), Paris, France, 9–12 June 2019; IEEE: New York, NY, USA, 2019; pp. 153–158. [Google Scholar]

- Schroeder, J. Understanding, Measuring, and Evaluating Maintainability of Automotive Software. Ph.D. Thesis, University of Gothenburg, Gothenburg, Sweeden, 2020. [Google Scholar]

- Zhang, Y.; Ning, Y.; Ma, C.; Yu, L.; Guo, Z. Empirical Study for Open Source Libraries in Automotive Software Systems. IEEE Access 2023, 11, 123717–123728. [Google Scholar] [CrossRef]

- Volker, S.; Prostean, G. Research of automotive change management and combined risk-management models. Procedia-Soc. Behav. Sci. 2016, 221, 395–404. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, L.; Liu, K.; Grundy, J. Towards automatically repairing compatibility issues in published android apps. In Proceedings of the 44th International Conference on Software Engineering, Pittsburgh, PA, USA, 25–27 May 2022; pp. 2142–2153. [Google Scholar]

- Soltanali, H.; Khojastehpour, M.; Farinha, J.T.; Pais, J.E. An integrated fuzzy fault tree model with Bayesian Network-Based maintenance optimization of complex equipment in automotive manufacturing. Energies 2021, 14, 7758. [Google Scholar] [CrossRef]

- Abazi, E. Practicing Continuous Integration in a Multi-Supplier Environment for the Development of Automotive Software. Master’s Thesis, Department of Computer Science and Engineering, Chalmers University of Technology and University of Gothenburg, Gothenburg, Sweden, 2019. Available online: https://odr.chalmers.se/items/88967ee6-3883-4930-83e3-3b7cf19212f9 (accessed on 22 January 2024).

- Guissouma, H.; Hohl, C.P.; Lesniak, F.; Schindewolf, M.; Becker, J.; Sax, E. Lifecycle management of automotive safety-critical over the air updates: A systems approach. IEEE Access 2022, 10, 57696–57717. [Google Scholar] [CrossRef]

- Guissouma, H.; Klare, H.; Sax, E.; Burger, E. An empirical study on the current and future challenges of automotive software release and configuration management. In Proceedings of the 2018 44th Euromicro Conference on Software Engineering and Advanced Applications (SEAA), Prague, Czech Republic, 29–31 August 2018; IEEE: New York, NY, USA, 2018; pp. 298–305. [Google Scholar]

- Wohlrab, R.; Pelliccione, P.; Shahrokni, A.; Knauss, E. Why and how your traceability should evolve: Insights from an automotive supplier. IEEE Software 2020, 38, 62–70. [Google Scholar] [CrossRef]

- Maro, S.; Steghöfer, J.P.; Staron, M. Software traceability in the automotive domain: Challenges and solutions. J. Syst. Softw. 2018, 141, 85–110. [Google Scholar] [CrossRef]

- Chen, C.L.; Zhu, Z.P.; Zhou, M.; Tsaur, W.J.; Wu, C.M.; Sun, H. A Secure and Traceable Vehicles and Parts System Based on Blockchain and Smart Contract. Sensors 2022, 22, 6754. [Google Scholar] [CrossRef]

- El Khalyly, B.; Belangour, A.; Banane, M.; Erraissi, A. A new metamodel approach of CI/CD applied to Internet of Things Ecosystem. In Proceedings of the 2020 IEEE 2nd International Conference on Electronics, Control, Optimization and Computer Science (ICECOCS), Kenitra, Morocco, 2–3 December 2020; IEEE: New York, NY, USA, 2020; pp. 1–6. [Google Scholar]

- Ding, Y.; Zhang, J.W.; Wang, X.T.; Li, S.; Gao, W.; Hu, S. Research on the relationship between model of middle platform and enterprise digital transformation in business field. In Proceedings of the 2021 IEEE 6th International Conference on Cloud Computing and Big Data Analytics (ICCCBDA), Chengdu, China, 24–26 April 2021; IEEE: New York, NY, USA, 2021; pp. 552–556. [Google Scholar]

- Vapiwala, F.; Pandita, D.; Choudhury, H. Strategies for Digital Innovation in Talent Management of Automotive Industry 4.0. In Proceedings of the 2023 8th International Conference on Business and Industrial Research (ICBIR), Bangkok, Thailand, 18–19 May 2023; IEEE: New York, NY, USA, 2023; pp. 200–205. [Google Scholar]

- Knieke, C.; Rausch, A.; Schindler, M.; Strasser, A.; Vogel, M. Managed Evolution of Automotive Software Product Line Architectures: A Systematic Literature Study. Electronics 2022, 11, 1860. [Google Scholar] [CrossRef]

- Aversano, L.; Grasso, C.; Tortorella, M. Managing the alignment between business processes and software systems. Inf. Softw. Technol. 2016, 72, 171–188. [Google Scholar] [CrossRef]

- Driesten, C.; Schaller, T. Overall approach to standardize AD sensor interfaces: Simulation and real vehicle. In Proceedings of the Fahrerassistenzsysteme 2018: Von der Assistenz zum automatisierten Fahren 4. Internationale ATZ-Fachtagung Automatisiertes Fahren. Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019 January 17; pp. 47–55. [Google Scholar]

- Zhang, Y.; Chen, J.; Teng, S.; Zhang, H.; Wang, F.Y. Sustainable lifecycle management for automotive development via multi-dimensional circular design framework. IEEE Trans. Intell. Veh. 2023, 8, 4151–4154. [Google Scholar] [CrossRef]

- Munten, P.; Vanhamme, J.; Maon, F.; Swaen, V.; Lindgreen, A. Addressing tensions in coopetition for sustainable innovation: Insights from the automotive industry. J. Bus. Res. 2021, 136, 10–20. [Google Scholar] [CrossRef]

- Kiklhorn, D.; Wolny, M.; Austerjost, M.; Michalik, A. Digital lifecycle records as an instrument for inter-company knowledge management. Procedia CIRP 2020, 93, 292–297. [Google Scholar] [CrossRef]

- El Safty, S.B. Critical Success Factors of Quality Culture Development in Automotive Industry. SAE Technical Paper. 2013. Available online: https://www.sae.org/publications/technical-papers/content/2013-01-1330/ (accessed on 22 January 2024).

- Roquette, J.H.; Matos, S.N.; Santos, M.M.D. On the Applicability of Behavior Driven Development for Automotive Software Testing at the Functional Model Level. J. Appl. Instrum. Control. 2022, 10, 1–8. [Google Scholar] [CrossRef]

- Gonçalves, D.; Ferreira, L.; Campos, N. Enterprise architecture for high flexible and agile company in automotive industry. Procedia Comput. Sci. 2021, 181, 1077–1082. [Google Scholar] [CrossRef]

- Anjum, S.K.; Wolff, C. Agile principles in automotive software development: Analysis of potential levers. In Proceedings of the 2021 IEEE European Technology and Engineering Management Summit (E-TEMS), Dortmund, Germany, 18–20 March 2021; IEEE: New York, NY, USA, 2021; pp. 141–147. [Google Scholar]

- Henreaux, E.; Noutcha, M.; Phan-Ngoc, T.; Suzanne, K. Design Sprints Integrating Agile and Design Thinking: A Case Study in the Automotive Industry. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, Istanbul, Türkiye, 26–30 July 2021; Springer: Cham, Switzerland, 2021; pp. 189–195. [Google Scholar]

- Noureldin, M.; Ghalwash, A.; Abd-Ellatif, L.; ElGazzar, M. Blending agile methodologies to support automotive SPICE compliance. J. Softw. Evol. Process 2022, 34, 2391. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, W.; Tan, H.; Zhao, F. Feature Identification, Solution Disassembly and Cost Comparison of Intelligent Driving under Different Technical Routes. Appl. Sci. 2023, 13, 4361. [Google Scholar] [CrossRef]

- Nagaria, B.; Hall, T. How software developers mitigate their errors when developing code. IEEE Trans. Softw. Eng. 2020, 48, 1853–1867. [Google Scholar] [CrossRef]

- Muscedere, B.J.; Hackman, R.; Anbarnam, D.; Atlee, J.M.; Davis, I.J.; Godfrey, M.W. Detecting feature-interaction symptoms in automotive software using lightweight analysis. In Proceedings of the 2019 IEEE 26th International Conference on Software Analysis, Evolution and Reengineering (SANER), Hangzhou, China, 24–27 February 2019; IEEE: New York, NY, USA, 2019; pp. 175–185. [Google Scholar]

- Milosevic, M.; Bjelica, M.Z.; Maruna, T.; Teslic, N. Software platform for heterogeneous in-vehicle environments. IEEE Trans. Consum. Electron. 2018, 64, 213–221. [Google Scholar] [CrossRef]

- Kugler, C. Systematic Derivation of Feature-Driven and Risk-Based Test Strategies for Automotive Applications. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2022. [Google Scholar]

- Roberts, A.; Marksteiner, S.; Soyturk, M.; Yaman, B.; Yang, Y. A Global Survey of Standardization and Industry Practices of Automotive Cybersecurity Validation and Verification Testing Processes and Tools. SAE Int. J. Connect. Autom. Veh. 2023, 7, 199–213. [Google Scholar] [CrossRef]

| Technology | Challenges | Related Keywords | References |

|---|---|---|---|

| System Design | Complex dependencies between features | Flexible, Scalable, Safe | [20,21] |

| Distributed deployment of software | Easy to debug, Manageable | [22,23,24] | |

| Interactive Interface | Multiple kernel integration | Safe, Open, Easy to debug | [25,26,27,28] |

| Interaction of software components | Efficient, Open, Easy to debug, Safe, Manageable | [29,30,31,32,33] |

| Organization | Challenges | Related Keywords | References |

|---|---|---|---|

| Organization structure | Cross-departmental conflict of interest | Low-cost, Efficient | [35,36] |

| Repeated work across models and brands | Low-cost, Efficient | [37] | |

| Floating developers | Efficient, High-quality | [38] | |

| Team | Lack of preparation for transformation | Efficient | [39] |

| Lack of talent | Efficient, High-quality | [40,41] | |

| Location | Distributed software projects | Low-cost, Efficient | [42,43] |

| External Cooperation | Collaboration across fragmentation standards | Low-cost, Efficient, Open | [44] |

| Method | Challenges | Related Keywords | References |

|---|---|---|---|

| Product Management | Non-uniform hardware test environment | Easy to debug, Manageable, Low-cost, Efficient, Scalable | [45,46] |

| Complexity of software variants | Low-cost, Efficient, Manageable | [47] | |

| Quality Control | Quality control after SW and HW decoupling | High-quality, Easy to debug | [48,49] |

| Balance between quality and cost | Efficient, Safe, Manageable | [50] | |

| Development Mode | Blind adoption of agile development | Efficient, High-quality, Manageable | [51] |

| Technology | Challenges | Related Keywords | References |

|---|---|---|---|

| OTA Upgrade | Cross-version upgrade | Low-cost, Efficient, Manageable | [53] |

| Matching of software and hardware | Scalable, Flexible | [54] | |

| Standard Protocol | Software changes across middleware | Low-cost, Efficient, Open, Flexible, Scalable, Easy to debug | [55,56,57] |

| Organization | Challenges | Related Keywords | References |

|---|---|---|---|

| Long-term Operation | Maintenance of third-party software | Safe, Manageable | [58] |

| Maintenance of open-source software | Safe, Manageable | [59] |

| Method | Challenges | Related Keywords | References |

|---|---|---|---|

| Software Risk Management | Functional safety risks of software changes | Efficient, Safe | [60,61,62] |

| Accumulation of software faults | Safe, High-quality, Manageable | [63,64] | |

| Process | Iteration rhythm | High-quality, safe, Easy to debug, Manageable | [65] |

| Traceability | High-quality, safe, Manageable | [66,67,68] | |

| Implementation of CI/CD | Efficient, Safe, High-quality, Easy to debug, Manageable | [63,69] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Shi, M.; Liu, X.; Ren, L. Review and Prospect of Integration Compatibility in Digital Vehicles: Multi-Dimensional Challenges and Industry Practice. Machines 2025, 13, 786. https://doi.org/10.3390/machines13090786

Zhang W, Shi M, Liu X, Ren L. Review and Prospect of Integration Compatibility in Digital Vehicles: Multi-Dimensional Challenges and Industry Practice. Machines. 2025; 13(9):786. https://doi.org/10.3390/machines13090786

Chicago/Turabian StyleZhang, Wang, Meng Shi, Xinglong Liu, and Linjie Ren. 2025. "Review and Prospect of Integration Compatibility in Digital Vehicles: Multi-Dimensional Challenges and Industry Practice" Machines 13, no. 9: 786. https://doi.org/10.3390/machines13090786

APA StyleZhang, W., Shi, M., Liu, X., & Ren, L. (2025). Review and Prospect of Integration Compatibility in Digital Vehicles: Multi-Dimensional Challenges and Industry Practice. Machines, 13(9), 786. https://doi.org/10.3390/machines13090786