Influence of Thin-Film Coatings on the Joining Process of Shaft-Hub Connections

Abstract

1. Introduction

2. Definitions

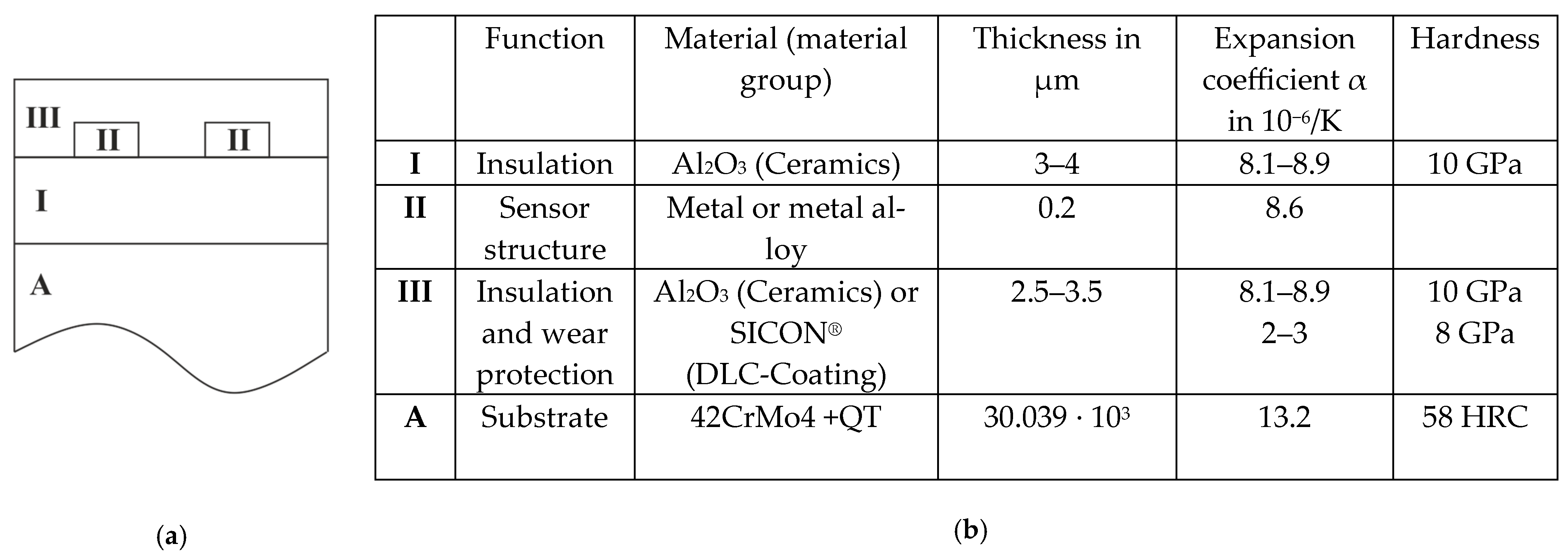

2.1. Thin-Film Sensor System

2.2. Specimen Geometry

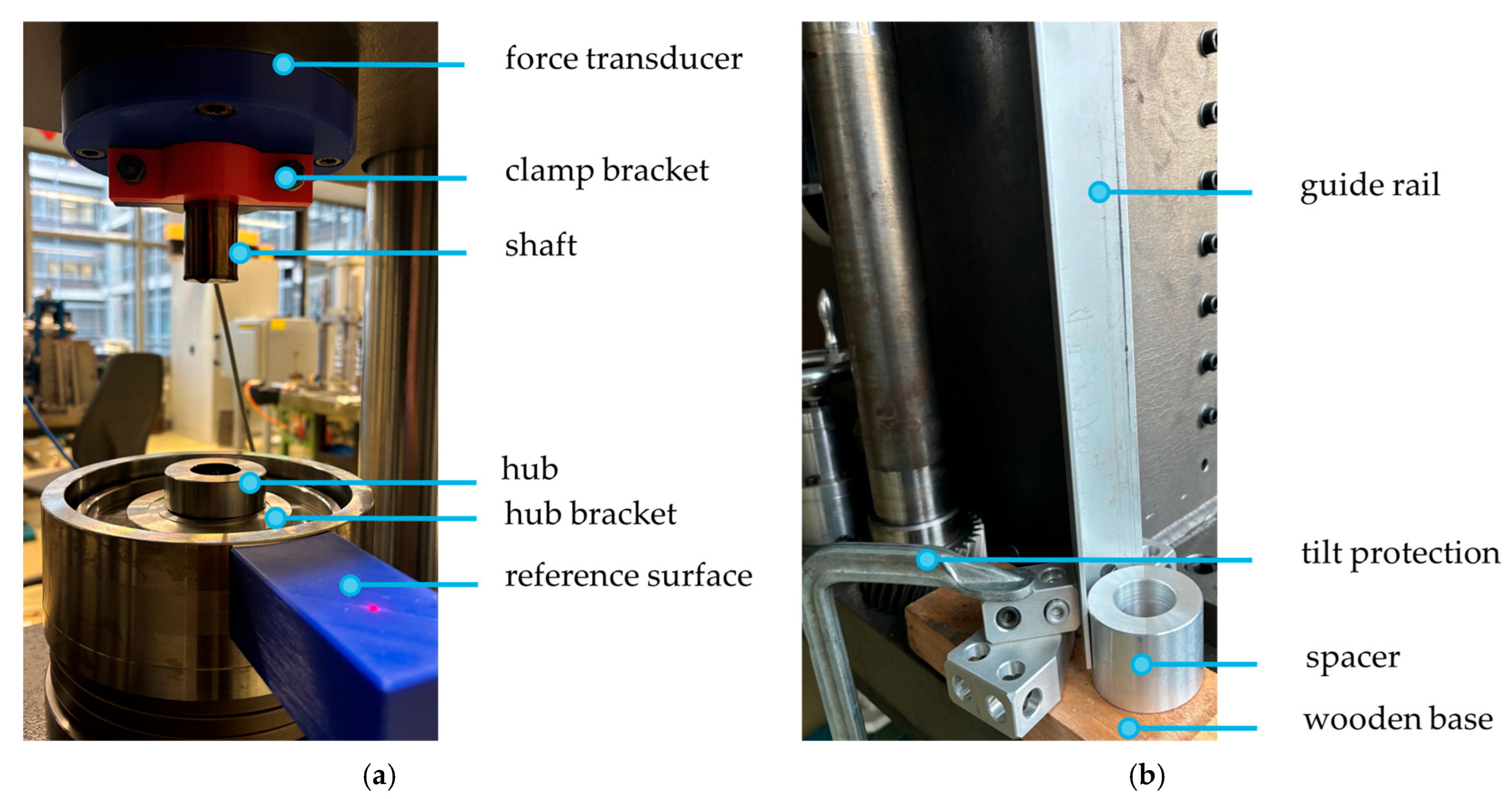

2.3. Joining Devices

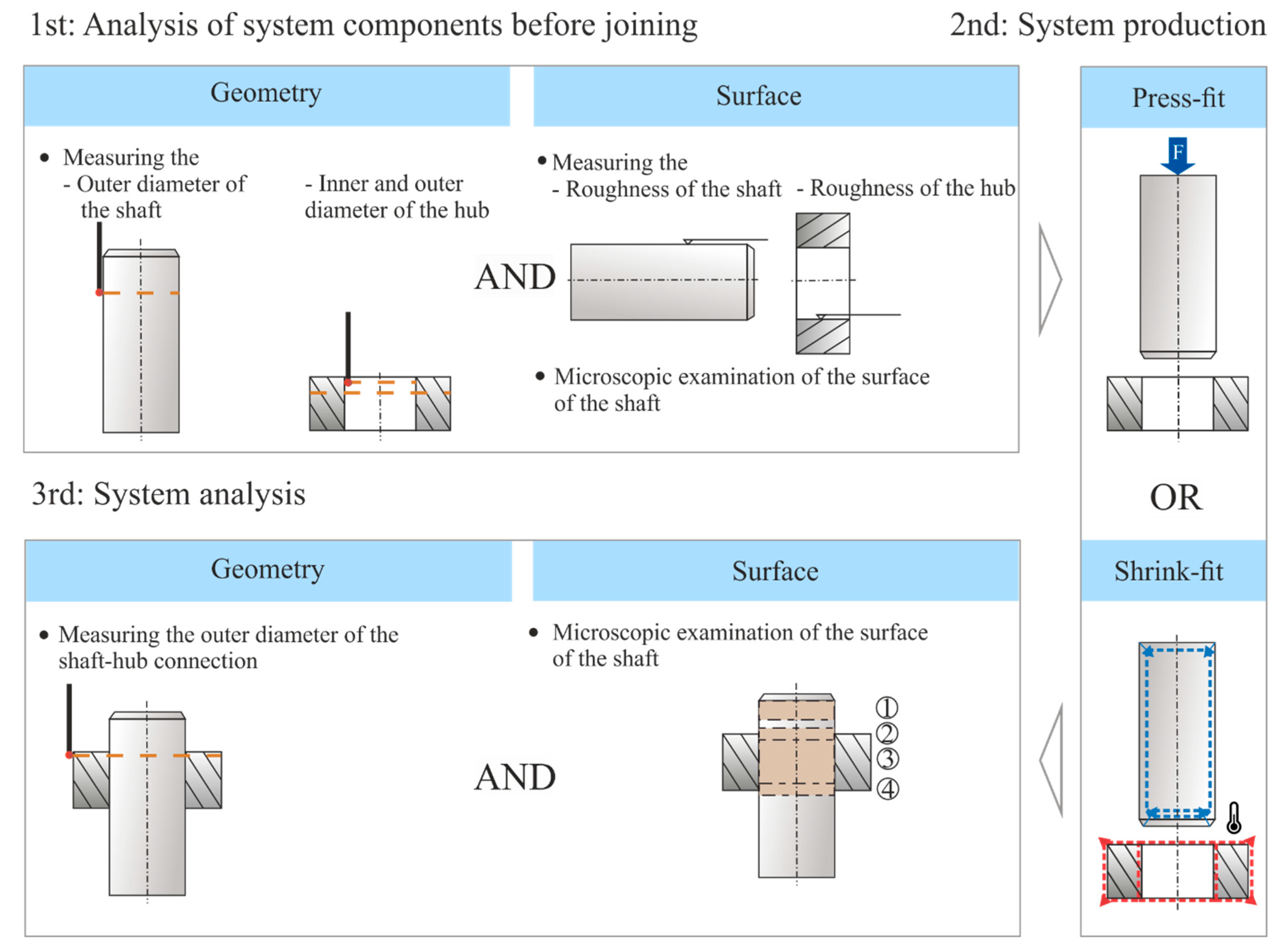

3. Test Approach

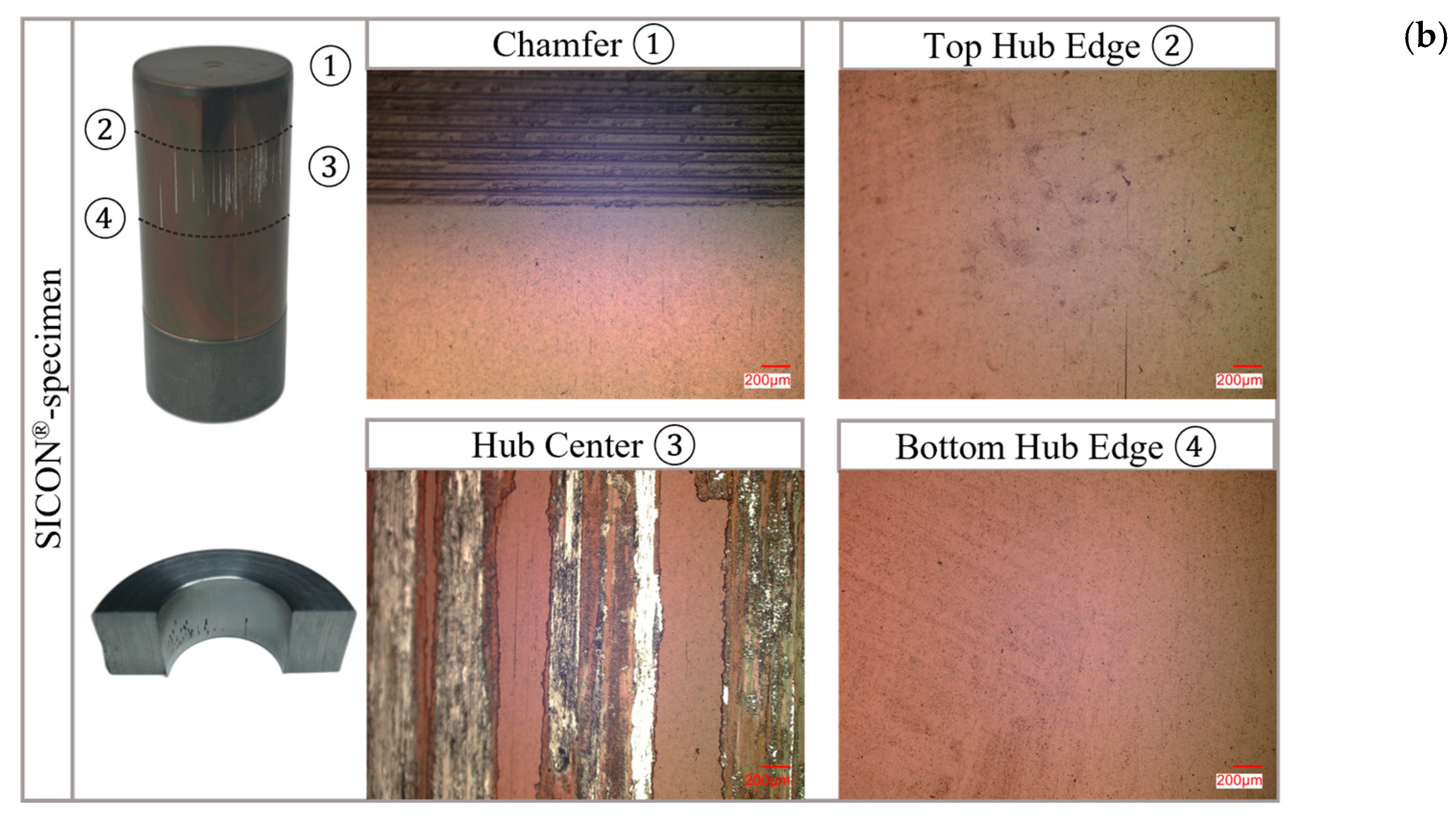

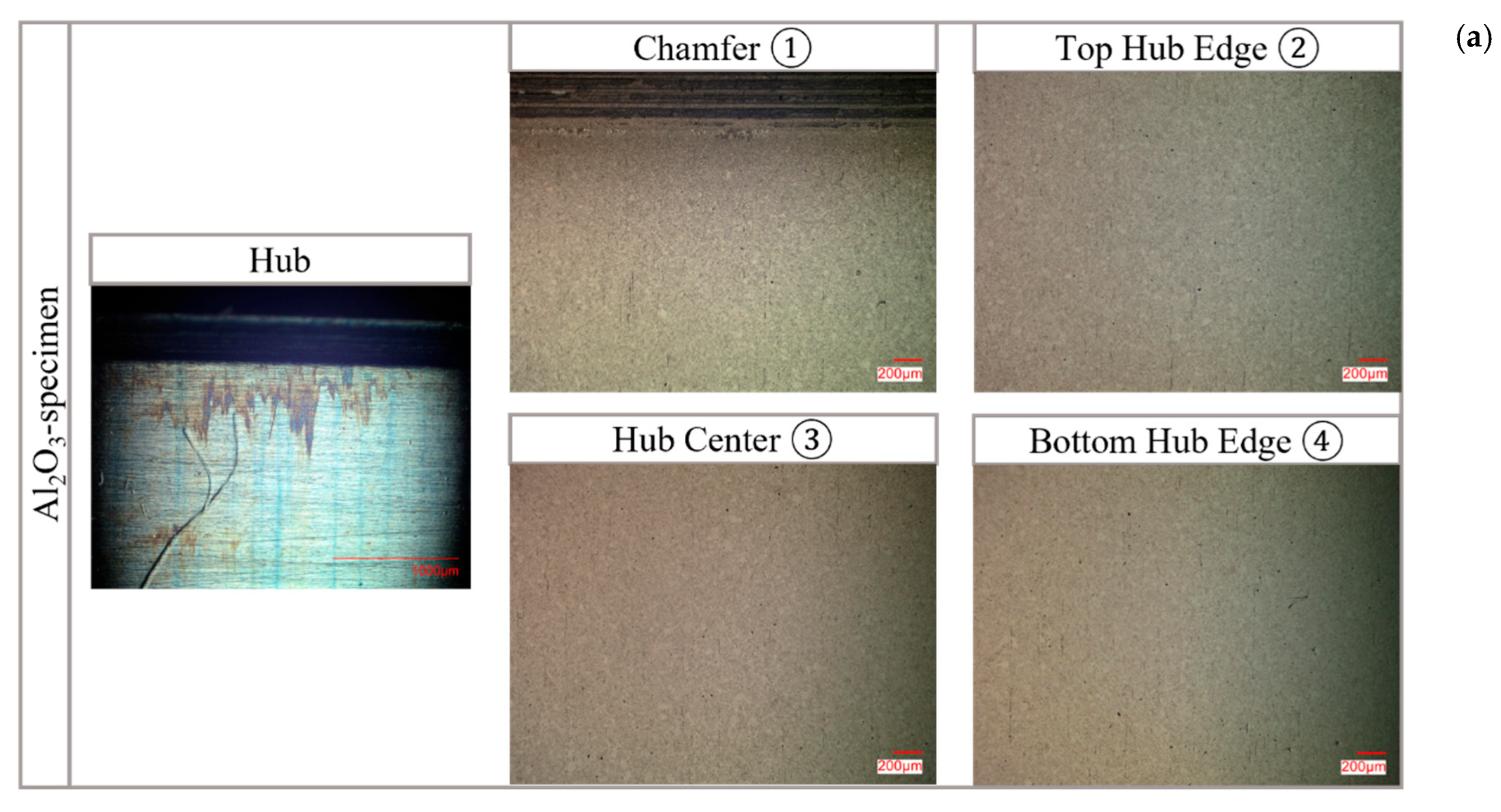

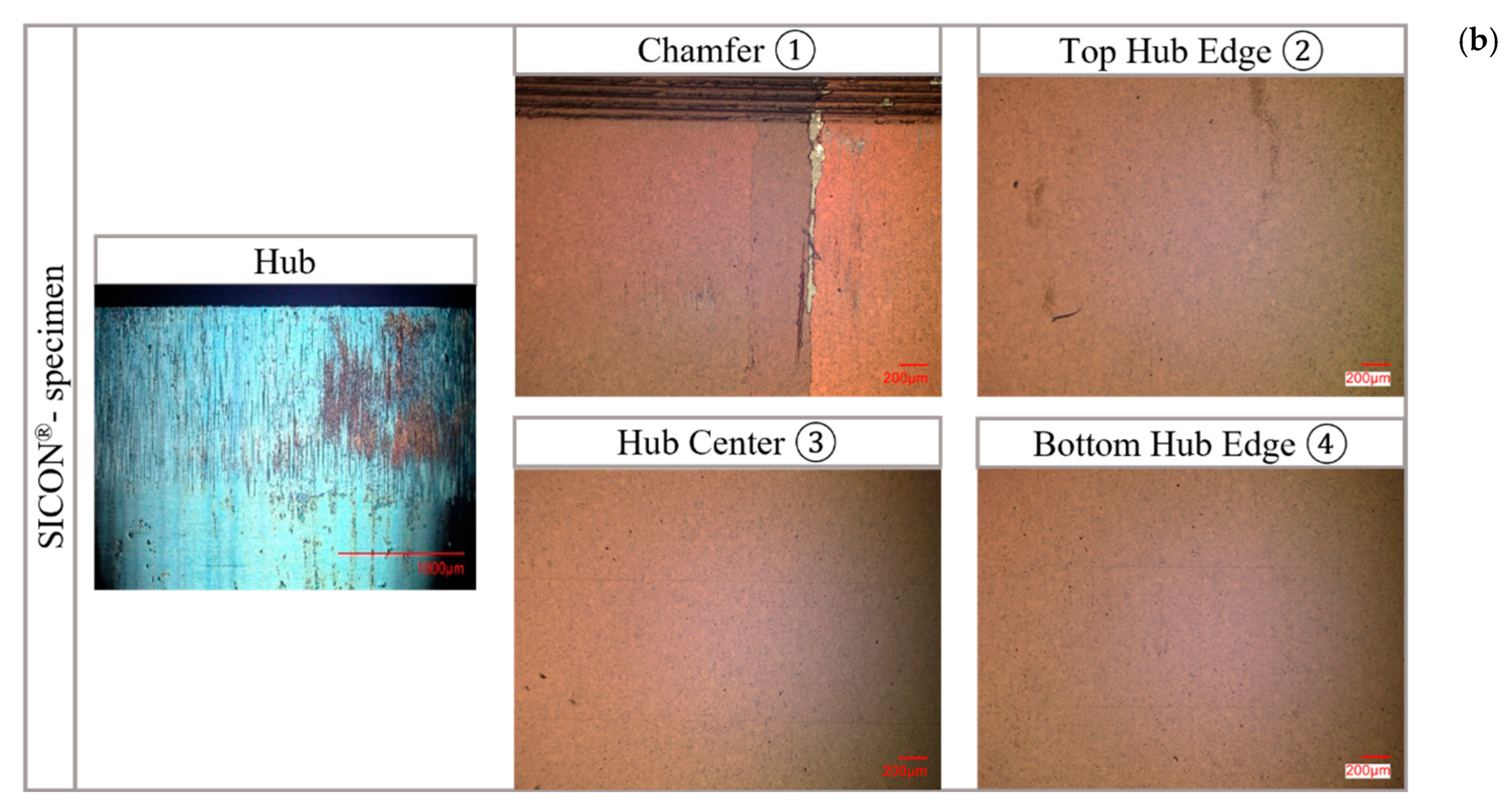

- Chamfer ①: A damaged chamfer indicates that the centering of the hub to the shaft during the joining process is insufficient and/or the joining clearance has been selected too small.

- Top Hub Edge ② and Bottom Hub Edge ④: Due to the increase in stiffness caused by the shaft protruding on both sides, the contact pressure curve shows stress increases that are constant in the circumferential direction.

- Hub Center ③: Constant contact pressure over the entire surface, which can damage the coating.

4. Results

4.1. Preferred Joining Method

4.1.1. Press-Fits

4.1.2. Shrink-Fits

4.1.3. Intermediate Summary

4.2. Maximum Temperature Difference During Joining as a Shrink-Fit

5. Discussion

5.1. Summary of Design Recommendations

5.2. Reflection on Findings

- Press-fits

- Shrink-fits

6. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SHC | Shaft-hub connection |

| COF | Static coefficient of friction |

References

- Kollmann, F.G. Welle-Nabe-Verbindungen—Gestaltung, Auslegung, Auswahl; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar] [CrossRef]

- Leidich, E. Welle-Nabe Verbindungen. In Konstruktionselemente des Maschinenbaus; Sauer, B., Ed.; Springer: Berlin, Germany, 2023; Volume 10, pp. 519–599. [Google Scholar] [CrossRef]

- Smetana, T.; Walther, V. Welle-Nabe-Verbindungen in der Elektromobilität—Automobile Verbindungstechniken im 21. Jahrhundert am Beispiel Elektrischer Fahrzeugantriebe; VDI-Berichte 2238; VDI Verlag GmbH: Düsseldorf, Germany, 2014. [Google Scholar]

- DIN 7190-1; Pressverbände-Teil 1: Berechnungsgrundlagen und Gestaltungsregeln für Zylindrische Pressverbände. DIN Media GmbH: Berlin, Germany, 2017.

- Breuning, C.; Kreimeyer, M.; Plogmeyer, M.; Pongratz, C.; Schott, A.; Bräuer, G. Untersuchung des Einsatzpotenzials Eines Multisensorischen Dünnschichtsystems zur Messung des Fugendrucks in Reibschlüssigen Welle-Nabe-Verbindungen; VDI-Berichte 2443; VDI Verlag GmbH: Düsseldorf, Germany, 2024. [Google Scholar]

- Bobzin, K.; Kalscheuer, C.; Möbius, M.P.; Hassanzadegan Aghdam, P. Thermal stability of thick α– and γ-Al2O3 coatings deposited by high-speed PVD. Surf. Coat. Technol. 2024, 447, 130411. [Google Scholar] [CrossRef]

- Horii, T.; Kirihara, S.; Miyamoto, Y. Freeform fabrication of Ti-Al alloys by 3D micro-welding. Intermetallics 2008, 16, 1245–1249. [Google Scholar] [CrossRef]

- Champi, A.; Lacerda, R.G.; Viana, G.A.; Marques, F.C. Thermal expansion dependence on the sp2 concentration of amorphous carbon and carbon nitride. J. Non-Cryst. Solids 2004, 338–340, 499–502. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Janowitz, J. Temperature measurement on tool surfaces by wear resistant PVD sensor coatings. Defect Diffus. Forum 2020, 404, 138–145. [Google Scholar] [CrossRef]

- Sperrfechter, T.; Haller, R. Elastohydrodynamic lubrication between rolling and sliding ceramic cylinders: An experimental investigation. J. Tribol. 2000, 122, 721–724. [Google Scholar] [CrossRef]

- Corbella, C.; Bialuch, I.; Kleinschmidt, M.; Bewilogua, K. Modified DLC coatings prepared in a large-scale reactor by dual microwave/pulsed-DC plasma-activated chemical vapour deposition. Thin Solid Film. 2008, 517, 1125–1130. [Google Scholar] [CrossRef]

- Emmrich, S.; Plogmeyer, M.; Bartel, D.; Herrmann, C. Development of a Thin-Film Sensor for In Situ Measurement of the Temperature Rise in Rolling Contacts with Fluid Film and Mixed Lubrication. Sensors 2021, 21, 6787. [Google Scholar] [CrossRef] [PubMed]

- Gräfensteiner, M. Gecko TP I—Analyse und Synthese Charakterisierender Kennwerte zur Funktionsgerechten Gestaltung von Wirkflächenpaaren in Reibschlüssigen Verbindungen; FVA final Report; Forschungsvereinigung Verbrennungskraftmaschinen: Frankfurt, Germany, 2014. [Google Scholar]

- Biederstedt, W. Presspassungen im Elastischen, Elastisch-Plastischen und Plastischen Verformungsbereich. Ph.D. Thesis, Hochschule Hannover-University of Applied Sciences and Arts, Hannover, Germany, 1963. [Google Scholar]

- Kalin, M.; Polajnar, M. The wetting of steel, DLC coatings, ceramics and polymers with oils and water: The importance and correlations of surface energy, surface tension, contact angle and spreading. Appl. Surf. Sci. 2014, 293, 97–108. [Google Scholar] [CrossRef]

- Tallant, D.R.; Parmeter, J.E.; Siegal, M.P.; Simpson, R.L. The thermal stability of diamond-like carbon. Diam. Relat. Mater. 1995, 4, 191–199. [Google Scholar] [CrossRef]

- Zeng, Q.; Ning, Z. High-temperature tribological properties of diamond-like carbon films: A review. Rev. Adv. Mater. Sci. 2021, 60, 276–292. [Google Scholar] [CrossRef]

- Zhang, T.F.; Wan, Z.X.; Ding, J.C.; Zhang, S.; Wang, Q.M.; Kim, K.H. Microstructure and high-temperature tribological properties of Si-doped hydrogenated diamond-like carbon films. Appl. Surf. Sci. 2018, 435, 963–973. [Google Scholar] [CrossRef]

- Dearnley, P.A.; Elwafi, A.M.; Chittenden, R.J.; Barton, D.C. Wear and Friction of Diamond like-Carbon Coated and Uncoated Steel Roller Bearings Under High Contact Pressure Oil Lubricated Rolling/Sliding Conditions. J. Tribol. 2014, 136, 021101. [Google Scholar] [CrossRef]

- Falter, J.; Herburger, D.; Binz, H.; Kreimeyer, M. An Investigation of Increased Power Transmissions Capabilities of Elastic-Plastic-Designed Press-Fit Connections Using a Detachable Joining Device. Eng 2024, 5, 1155–1172. [Google Scholar] [CrossRef]

| Fridge | Freezer | Dry Ice | Climatic Chamber | Liquid Nitrogen | |

|---|---|---|---|---|---|

| Temperature ranges | 7 °C | −15 to −22 °C | −78.4 °C [4] | −73 to 250 °C | −195.8 °C [4] |

| Al2O3 | SICON® | Steel | |

|---|---|---|---|

| μstatic with lubrication (press-fit) | 0.15 * | 0.097 * | 0.08 [14] |

| μstatic without lubrication (shrink-fit) | 0.181 * | 0.169 * | 0.12 [14] |

| Key Findings | Details |

|---|---|

| Preference for shrink-fits over press-fits |

|

| Joining temperatures |

|

| Specimen geometry |

|

| Selection of the coating |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Breuning, C.; Plogmeyer, M.; Pongratz, C.; Wagner, M.; Schott, A.; Kreimeyer, M.; Bräuer, G. Influence of Thin-Film Coatings on the Joining Process of Shaft-Hub Connections. Machines 2025, 13, 776. https://doi.org/10.3390/machines13090776

Breuning C, Plogmeyer M, Pongratz C, Wagner M, Schott A, Kreimeyer M, Bräuer G. Influence of Thin-Film Coatings on the Joining Process of Shaft-Hub Connections. Machines. 2025; 13(9):776. https://doi.org/10.3390/machines13090776

Chicago/Turabian StyleBreuning, Charlotte, Marcel Plogmeyer, Christina Pongratz, Markus Wagner, Anna Schott, Matthias Kreimeyer, and Günter Bräuer. 2025. "Influence of Thin-Film Coatings on the Joining Process of Shaft-Hub Connections" Machines 13, no. 9: 776. https://doi.org/10.3390/machines13090776

APA StyleBreuning, C., Plogmeyer, M., Pongratz, C., Wagner, M., Schott, A., Kreimeyer, M., & Bräuer, G. (2025). Influence of Thin-Film Coatings on the Joining Process of Shaft-Hub Connections. Machines, 13(9), 776. https://doi.org/10.3390/machines13090776