Enhancing Accuracy of Ultrasonic Transit-Time Flow Measurement in Hydropower Systems Under Complex Operating Conditions: A Comprehensive Review

Abstract

1. Introduction

- (1)

- To comprehensively review the fundamental principles, system architectures, and classifications of ultrasonic transit-time flow meters, highlighting their engineering adaptability in hydropower settings;

- (2)

- To critically analyze the dominant sources of measurement errors (e.g., geometric parameter deviations, transducer-induced flow disturbances, and flow-field distortions) and their coupling mechanisms;

- (3)

- To synthesize and evaluate emerging technological pathways for enhancing accuracy, including hardware innovations (e.g., transducer design), CFD-driven flow-field optimization, and multi-method collaborative calibration;

- (4)

- To identify challenges (e.g., non-axisymmetric flows, calibration–field discrepancies) and outline future research directions for high-reliability applications in large-scale hydropower systems.

2. Ultrasonic Transit-Time Flow Measurement Technology

2.1. Review Methodology

- (1)

- Literature Search: Comprehensive searches were conducted across major scientific databases, including ScienceDirect (Elsevier), SpringerLink and CNKI Data. Key search terms and their combinations encompassed “ultrasonic flow meter”, “transit-time method”, “time-of-flight”, “flow measurement error”, “measurement accuracy”, “uncertainty”, “hydropower”, “hydroelectric”, “water turbine”, “penstock”, “flow disturbance”, “installation effect”, “geometric parameter”, “error source”, “accuracy improvement”, “optimization”, “CFD”, and “multi-method calibration”, along with their Chinese equivalents. The search focused primarily on literature published from 2000 onwards to capture recent advancements, while seminal earlier works were also considered. Relevant international and national standards (e.g., IEC, GB/T) and proceedings of key conferences in fluid mechanics and hydropower engineering were also reviewed. Backward snowballing (tracking references from retrieved articles) was utilized to identify additional pertinent studies.

- (2)

- Study Selection: Inclusion criteria required studies to ① explicitly focus on ultrasonic transit-time flow measurement technology; ② investigate sources of measurement error, their mechanisms, influencing factors, and/or strategies/technologies for improving measurement accuracy; ③ be applicable or relevant to the context of hydropower/hydraulic engineering (large diameters, specific flow conditions); ④ comprise peer-reviewed journal articles, conference papers, dissertations, technical reports from reputable institutions, or standards. Studies primarily dealing with other flow meter types (e.g., electromagnetic, Doppler ultrasonic) or lacking substantive details on error analysis or optimization methods were excluded.

- (3)

- Data Extraction and Synthesis: Information pertaining to identified error sources (type, magnitude, causes), proposed optimization strategies (hardware, software, installation, calibration), experimental/simulation conditions, and main findings was extracted from the selected literature. Thematic analysis was used to identify, categorize, and synthesize recurring themes and patterns related to error mechanisms and accuracy enhancement approaches.

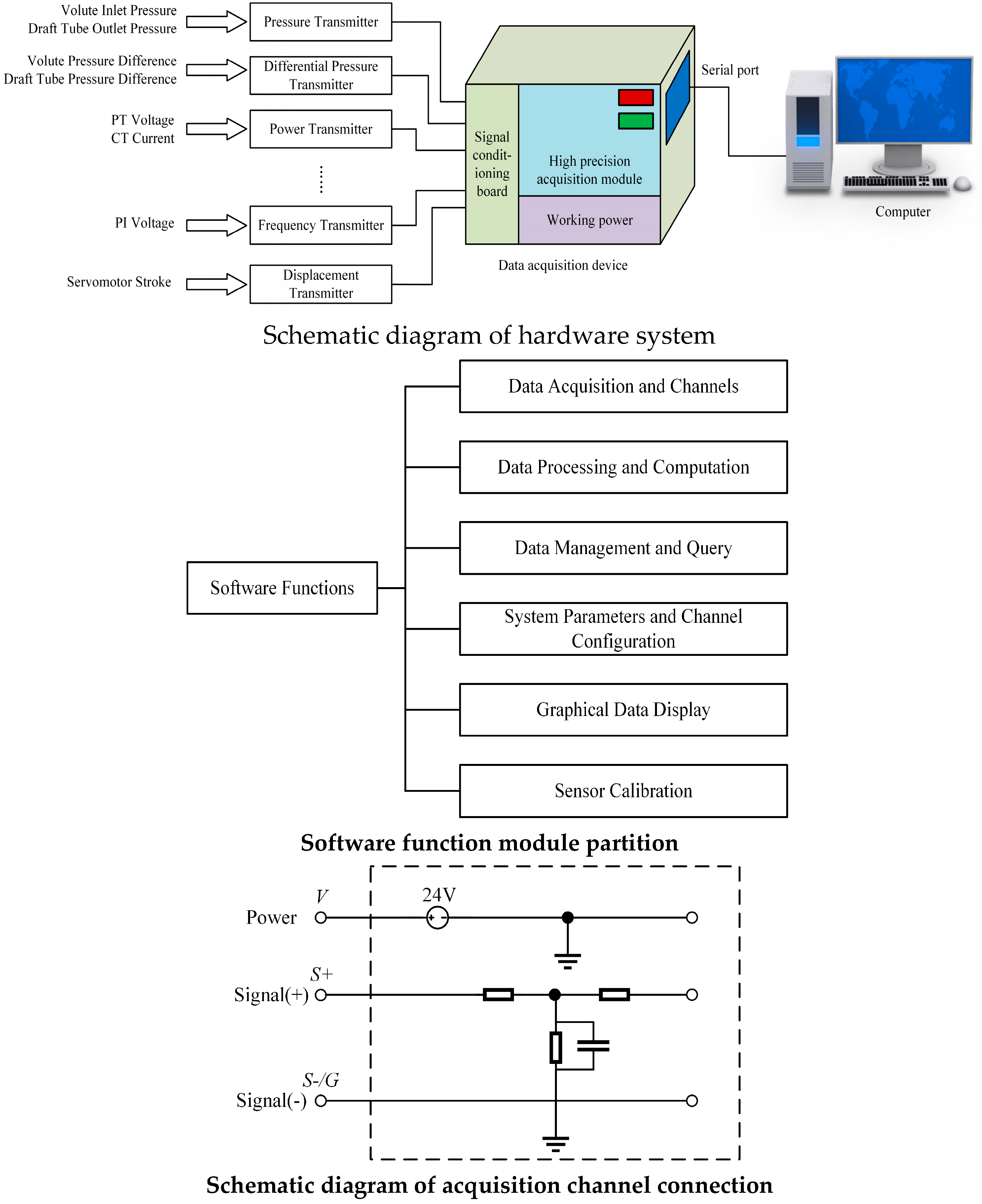

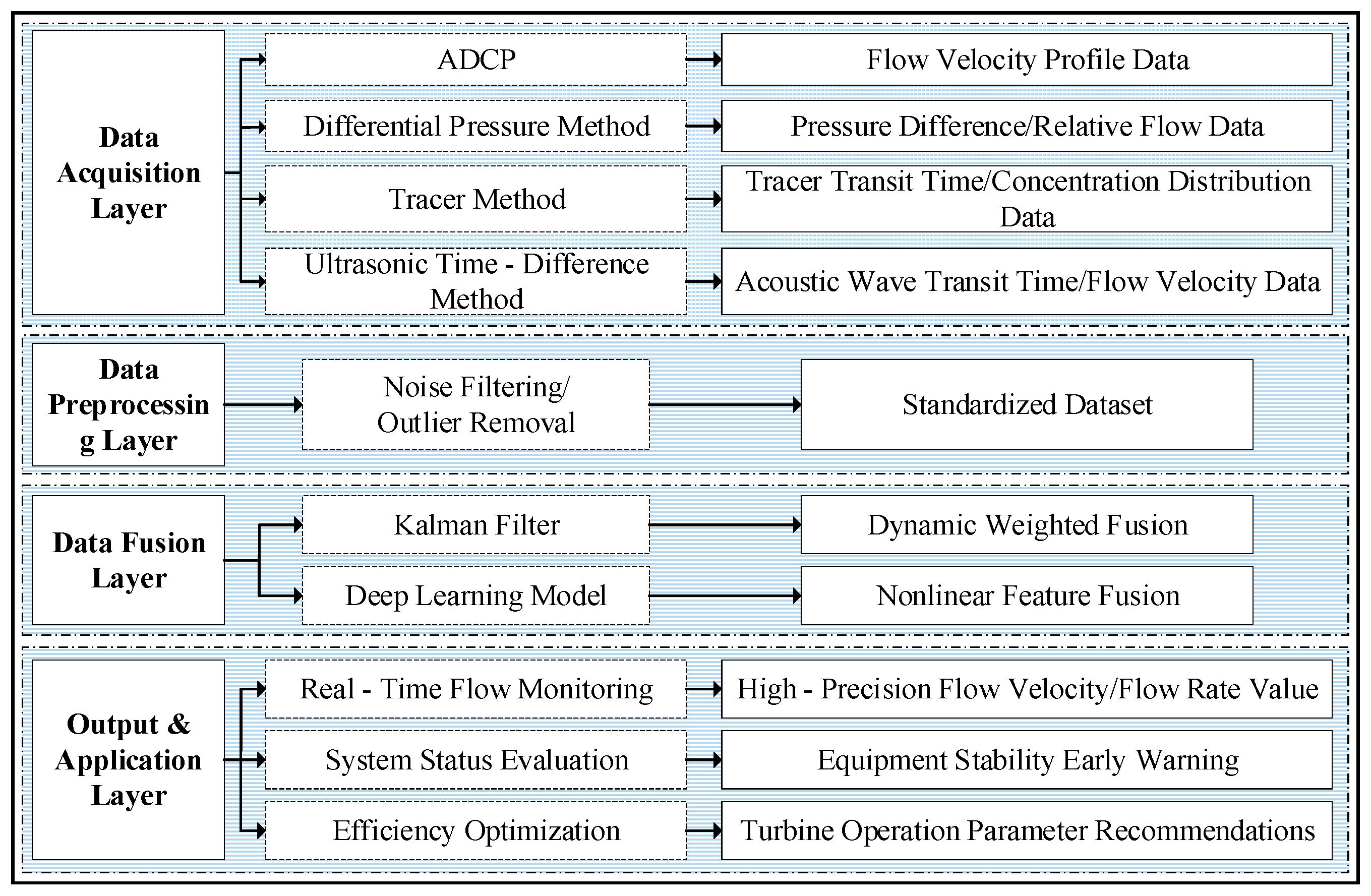

2.2. Ultrasonic Transit-Time Flow Measurement Devices

- (1)

- Single-path ultrasonic flow meters: Tang et al. [17] pioneered a flow measurement scheme employing a pair of transducers to form a single acoustic path, establishing the foundation for ultrasonic flow measurement technology. This simple design suits stable flow conditions and is well-suited for relatively stable flow conditions. Subsequently, Irving [18] introduced a flow velocity detection method based on ultrasonic phase shift, further expanding the principles of ultrasonic flow measurement. As the field advanced, the United States successfully developed the world’s first commercial ultrasonic flow meter, “MAXSON”, which implemented the “sing-around” technique in aviation fuel measurement, initiating ultrasonic engineering applications [19].

- (2)

- Multi-path ultrasonic flow meters: In 1963, Schima et al. [20] developed an ultrasonic flow meter featuring a symmetric dual-path configuration, which significantly reduced velocity-profile-induced errors. This milestone established multi-path technology’s origin. With the evolution of microprocessors and digital signal processors, multi-path configurations have progressed toward higher precision and intelligent functionality. In recent years, to address challenges such as non-axisymmetric flow fields and large-diameter pipelines, researchers have continually optimized acoustic path layouts, transducer materials, and structural designs, thereby improving the robustness and adaptability of multi-path ultrasonic flow meters [21].

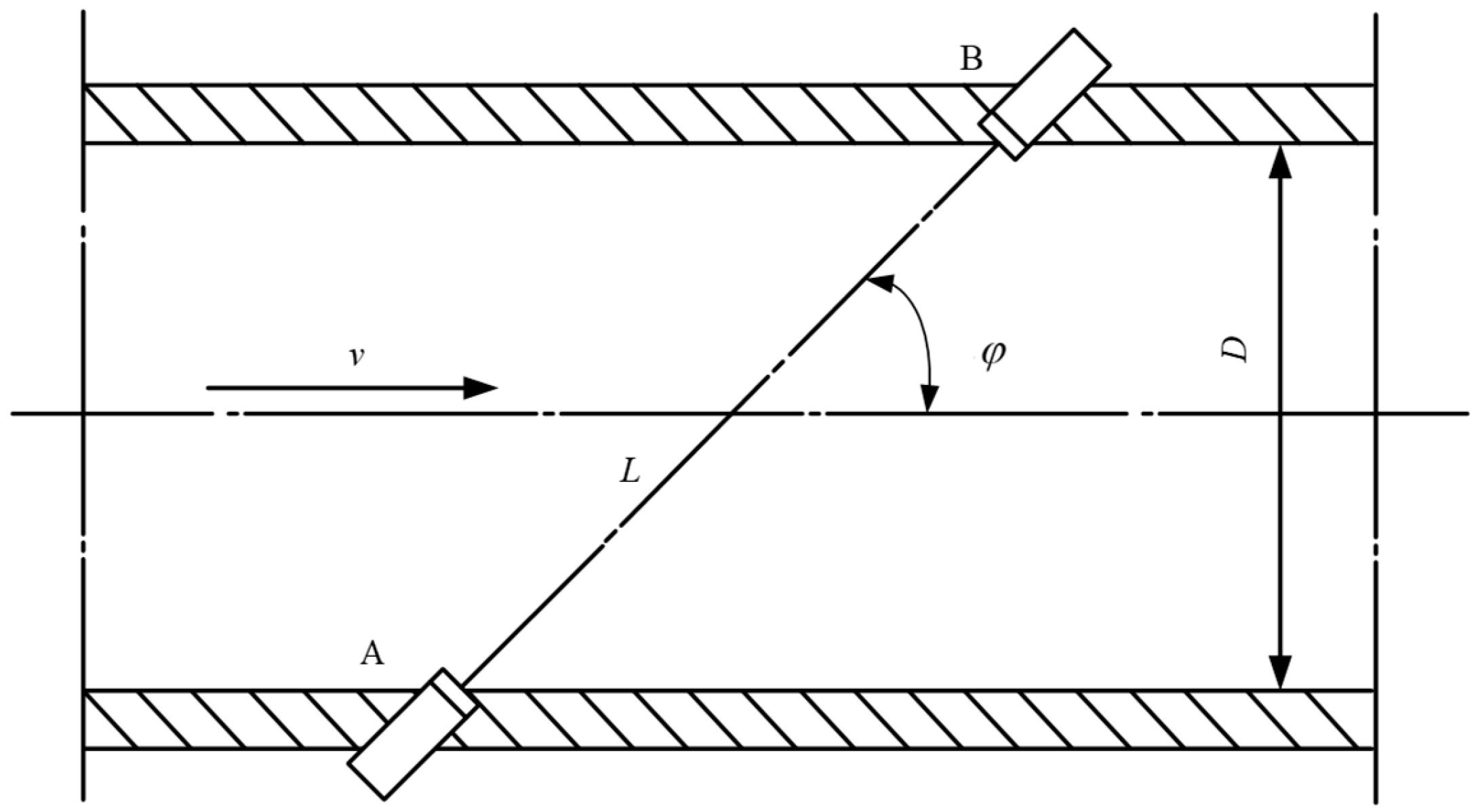

2.3. Principle of Ultrasonic Transit-Time Flow Measurement

2.4. On-Site Installation

- External clamp-on ultrasonic flow meters require a certain length of exposed pipe and support pipe diameters up to 6 m. These devices typically employ two crossed acoustic paths, allowing measurement only at the central layer of the pipe, resulting in lower accuracy. Under ideal flow conditions, measurement errors can be within 1%; however, in disturbed flow, errors may exceed 2%.

- External insertion-type ultrasonic flow meters also require an exposed pipe section and involve drilling a hole into the pipe wall. They are unsuitable for high-pressure applications (e.g., above 2 MPa).

- Internally mounted ultrasonic flow meters do not require exposed pipe segments and are capable of operating under relatively high pressure (up to 4 MPa or more). These are typically used in large-scale hydropower facilities.

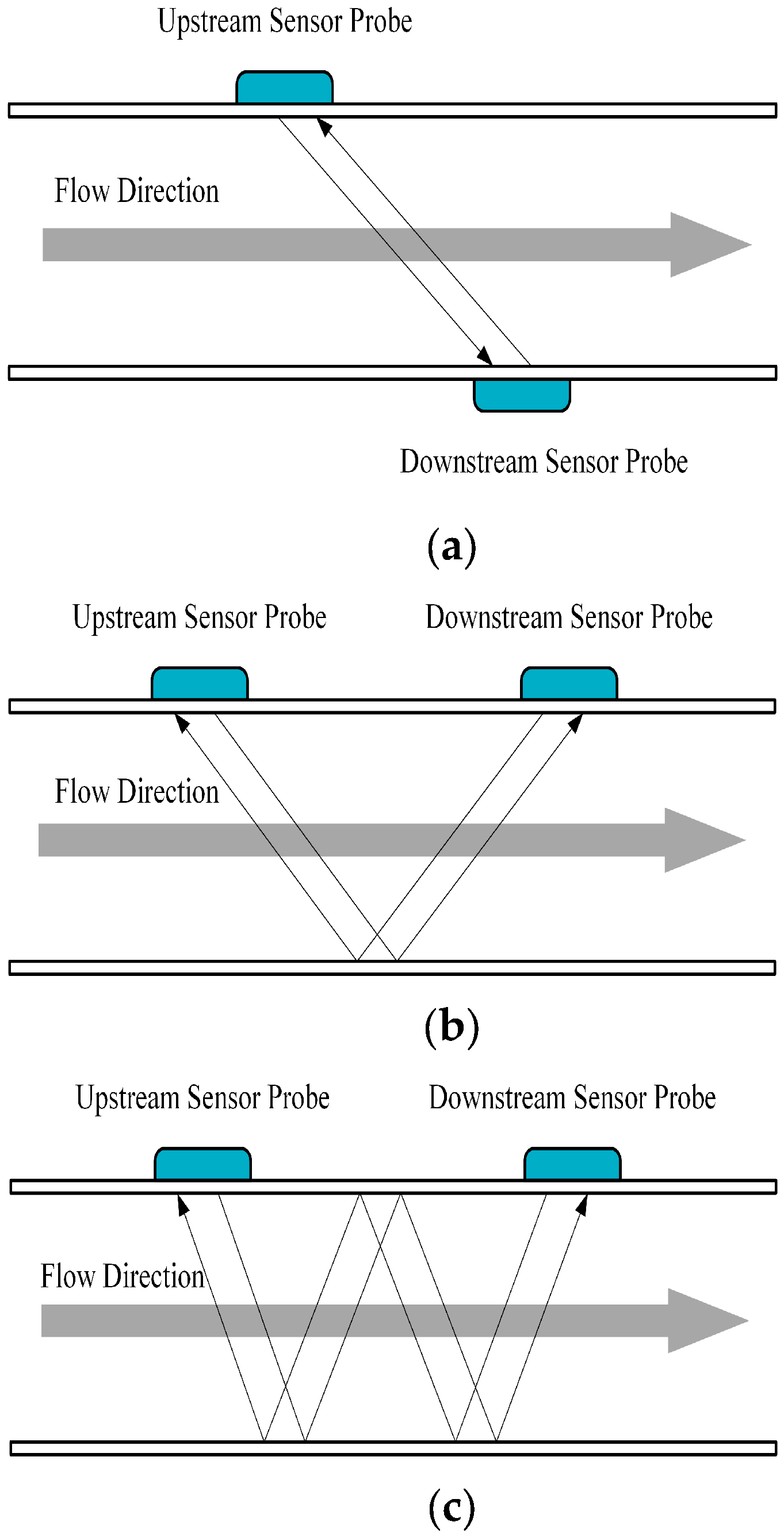

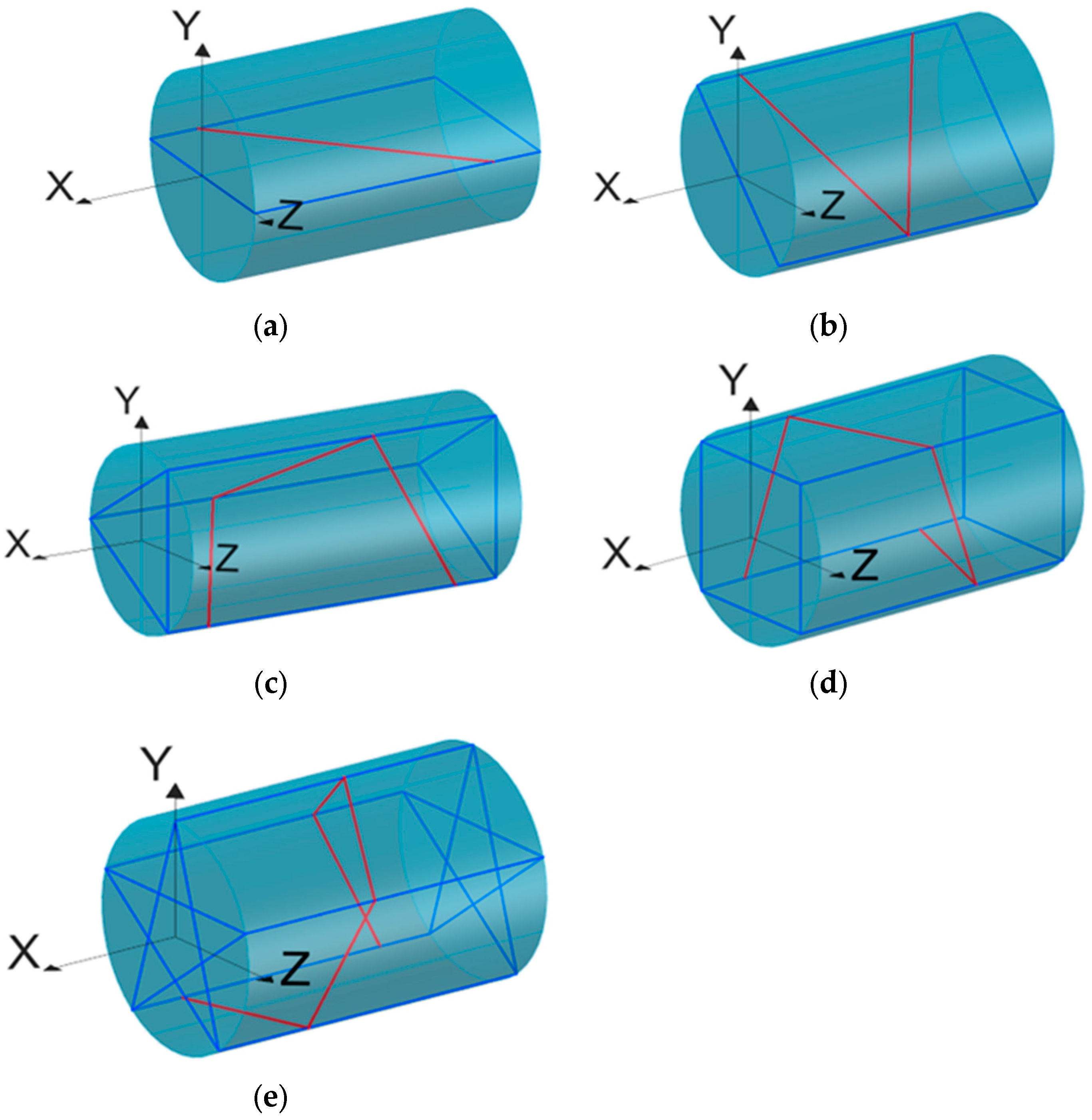

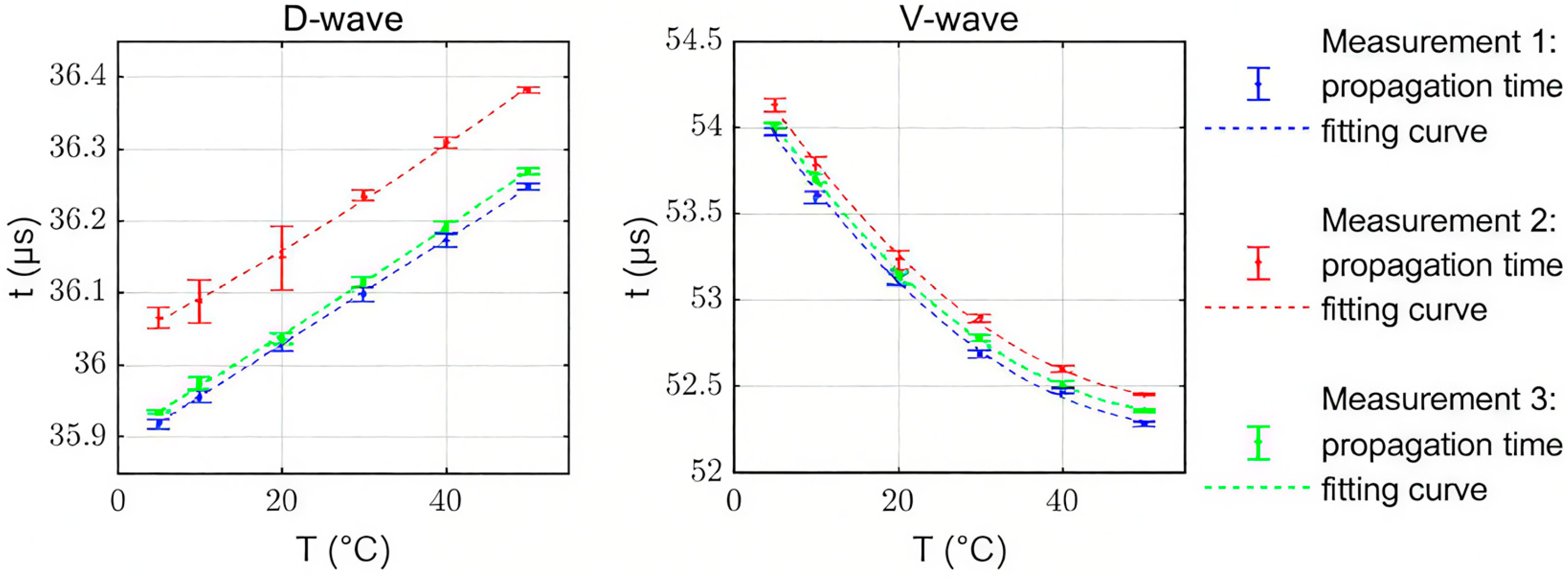

2.5. Transducer Layout

2.6. Geometric Parameter Measurement

3. Measurement Errors

3.1. Local Disturbances of the Transducer

3.2. Rectifying Effect of Flow Regulators and Calibration Differences

4. Precision Improvements

4.1. Hardware Improvements

4.2. CFD Applications

4.2.1. Flow Field Characteristic Analysis

4.2.2. Optimizing the Design of Ultrasonic Flow Meters

4.2.3. Signal Processing and Error Compensation Methods Supported by CFD

4.3. Advances in Flow Measurement Technology

5. Summary and Outlook

- (1)

- To address the objective of “comprehensively reviewing the fundamental principles, system architectures, and classifications of ultrasonic transit-time flow meters, and clarifying their engineering adaptability in hydropower scenarios,” this study systematically sorts out the core components of transit-time ultrasonic flow meters (ultrasonic transducers, signal processing units, and display systems). It categorizes and elaborates on the characteristics of single-path and multi-path configurations, as well as installation types such as clamp-on and insertion types. Combined with complex environments in hydropower engineering (e.g., penstocks, volutes), it analyzes the applicable scenarios of different types of flow meters (e.g., the advantages of multi-path configurations in non-ideal flow fields, and the flexibility of clamp-on types in large-diameter pipelines), thus defining their boundaries of engineering applications.

- (2)

- Regarding the objective of “analyzing the main sources of measurement errors and their coupling mechanisms,” this study identifies key error sources, including geometric parameter deviations (accounting for 30–50% of total uncertainty), localized flow disturbances caused by transducers (e.g., recirculation zones due to protrusions/recessions), and flow field distortions (e.g., secondary flows induced by elbows). By integrating CFD simulations and experimental data, it reveals the coupling effects of various error sources (e.g., installation deviations and flow field distortions jointly amplify measurement biases) and quantifies their impacts on measurement accuracy (e.g., transducer interference in small-diameter pipelines can lead to a −5% error).

- (3)

- For the objective of “comprehensively evaluating technological pathways for accuracy improvement,” this study systematically summarizes three core optimization methods: hardware-level improvements (PMN-PT single-crystal transducers improve sensitivity by 20%, and TDC technology enhances time measurement accuracy to ±20 ps), CFD-driven optimizations (flow field correction reduces errors in disturbed flows by ≤5%, and optimized transducer layouts reduce system errors by 15%), and multi-method collaborative calibration (the integration of ultrasonic and thermodynamic methods reduces uncertainty to ±0.8%). Through comparative analysis, it clarifies the applicable conditions and effects of different technologies.

- (4)

- Concerning the objective of “identifying challenges and proposing future directions,” this study points out the limitations of current technologies in adapting to non-axisymmetric flow fields and discrepancies between calibration and on-site conditions. Based on existing research results, it proposes that future efforts should focus on developing array-based transducers (enabling real-time reconstruction of three-dimensional flow fields), multi-physical field coupling correction models (integrating temperature, pressure, and flow velocity), and improving industry standards, thus providing a reference path for high-reliability applications in large-scale hydropower systems.

- (5)

- In the future, research should prioritize the development of array-based transducers capable of adapting to complex flow pattern variations, for real-time reconstruction of three-dimensional flow fields. Concurrently, establishing multi-physical field correction models that dynamically integrate temperature, pressure, and flow velocity is essential. Furthermore, advancing national/industry standards for ultrasonic flow measurement in hydropower applications would enhance technological consistency and facilitate broader implementation.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

References

- Wang, R.; Xiao, Q.; Chen, Y.; Liu, Y.; Wang, X. Development Trend and Exploration of Core Control System of Hydropower Units in New Power System. New Type Power Syst. 2025, 3, 33–44. [Google Scholar] [CrossRef]

- Zhang, K.; Zhou, Y. Discussion of Turbine Efficiency Testing of a Nepal Hydropower Station by Thermodynamic Method. Mech. Electr. Tech. Hydropower Stn. 2020, 43, 8–10. [Google Scholar] [CrossRef]

- Cao, D.; Zhou, Y.; Pan, L.; Liu, Y. Absolute Discharge Measurement of Bulb Turbine Based on Current-Meter Method. Water Resour. Power 2021, 39, 190–193. [Google Scholar] [CrossRef]

- Cattaert, A.E. High Pressure Pump Efficiency Determination from Temperature and Pressure Measurements. In Proceedings of the 2007 IEEE Power Engineering Society Conference and Exposition in Africa—PowerAfrica, Johannesburg, South Africa, 16–20 July 2007; pp. 1–8. [Google Scholar] [CrossRef]

- IS/IEC 41; Field Acceptance Tests to Determine the Hydraulic Performance of Hydraulic Turbines, Storage Pumps and Pump Turbines. Bureau of Indian Standards (BIS): New Delhi, India, 1991. Available online: https://archive.org/details/gov.in.is.iec.41.1991 (accessed on 27 March 2025).

- Lu, C. Field Acceptance Tests of Pump-turbine with Thermodynamics and its Discussions. Water Power 2005, 31, 59–66. [Google Scholar]

- Baidar, B.; Nicolle, J.; Gandhi, B.K.; Cervantes, M.J. Sensitivity of the Winter-Kennedy Method to Different Guide Vane Openings on an Axial Machine. Flow Meas. Instrum. 2019, 68, 101585. [Google Scholar] [CrossRef]

- Zhou, B.; Tian, T.T.; Zhu, G.; Zhao, J.B.; Liu, D.H. An Ultrasonic Testing Method for Wall Thickness of Turbine Blades. Measurement 2022, 198, 111357. [Google Scholar] [CrossRef]

- Yang, Y.X. Measurement and Energy Efficiency Analysis of Hydraulic Turbine Based on CFD and Ultrasonic Method. Master’s Thesis, Xinjiang Agricultural University, Wulumuqi, China, 2021. [Google Scholar]

- Zhang, N. The Principle and Application of Ultrasonic Flowmeter. Ind. Metrol. 2019, 29, 36–38. [Google Scholar] [CrossRef]

- GB/T 20043-2005; Field Acceptance Test to Determine the Hydraulic Performance of Hydraulic Turbine, Storage Pumps and Pump-Turbines. China Standards Press: Beijing, China, 2005. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=34BCCE2D14AC8DB07993B6235FA1F919 (accessed on 27 March 2025).

- Sanderson, M.L.; Yeung, H. Guidelines for the Use of Ultrasonic Non-Invasive Metering Techniques. Flow Meas. Instrum. 2002, 13, 125–142. [Google Scholar] [CrossRef]

- Baker, R.C. Flow Measurement Handbook: Industrial Designs, Operating Principles, Performance, and Applications; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, P.; Wang, R.; Niu, Z.; Zhang, K. Signal Processing Method of Ultrasonic Gas Flowmeter Based on Transit-Time Mathematical Characteristics. Measurement 2025, 239, 115485. [Google Scholar] [CrossRef]

- Tan, C.; Murai, Y.; Liu, W.; Tasaka, Y.; Dong, F.; Takeda, Y. Ultrasonic Doppler Technique for Application to Multiphase Flows: A Review. Int. J. Multiph. Flow 2021, 144, 103811. [Google Scholar] [CrossRef]

- Ren, R.; Wang, H.; Sun, X.; Quan, H. Design and Implementation of an Ultrasonic Flowmeter Based on the Cross-Correlation Method. Sensors 2022, 22, 7470. [Google Scholar] [CrossRef]

- Tang, X.; Xie, X.; Fan, B.; Sun, Y. A Fault-Tolerant Flow Measuring Method Based on PSO-SVM with Transit-Time Multipath Ultrasonic Gas Flowmeters. IEEE Trans. Instrum. Meas. 2018, 67, 992–1005. [Google Scholar] [CrossRef]

- Irving, W. Air Speed Indicator. U.S. Patent 2274262A, 31 May 1939. [Google Scholar]

- Raine, A.B.; Aslam, N.; Underwood, C.P.; Danaher, S. Development of an Ultrasonic Airflow Measurement Device for Ducted Air. Sensors 2015, 15, 10705–10722. [Google Scholar] [CrossRef] [PubMed]

- Schima, H.; Huber, L.; Schmallegger, H.; Drost, C.J.; Droudt, A.; Wieselthaler, G.; Losert, U. Flow Measurement at the Pump Head of Centrifugal Pumps: Comparison of Ultrasonic Transit Time and Ultrasonic Doppler Systems. Artif. Organs. 1997, 21, 808–815. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.N.; Hu, L.; Peng, X.X. A Method Combining Measurement Tool and Numerical Simulation for Calculating Acoustic Signals of Ultrasonic Flowmeter. IEEE Sens. J. 2019, 19, 11805–11813. [Google Scholar] [CrossRef]

- Marco, D.; Mauro, C.; Matteo, D. Measurement of High-Pressure Natural Gas Flow Using Ultrasonic Flowmeters. Measurement 1997, 20, 75–89. [Google Scholar] [CrossRef]

- Qu, Z.; Zhang, F.; Yang, W. The Application of Ultrasonic Wave Meter in Puding Hydropower Station. Power Syst. Big Data 2018, 21, 85–88. [Google Scholar] [CrossRef]

- Fang, W.G. Application of Plug-in Ultrasonic Flowmeter in Online Continuous Flow Replacement Situation. Water Purif. Technol. 2020, 39, 151–154. [Google Scholar] [CrossRef]

- Cascetta, F. Application of a Portable Clamp-on Ultrasonic Flowmeter in the Water Industry. Flow Meas. Instrum. 1994, 5, 191–194. [Google Scholar] [CrossRef]

- Dadashnialehi, A.; Moshiri, B. Online Monitoring of Transit-Time Ultrasonic Flowmeters Based on Fusion of Optical Observation. Measurement 2011, 44, 1028–1037. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, G.; Liu, J. Application of Ultrasonic Flowmeter in Hydropower Station. Northwest Hydropower 2021, 05, 94–97. [Google Scholar] [CrossRef]

- Yang, J. Application of Pipe Flow Meter of Multi-Path Time Difference Method in Manla Hydropower Station. Water Resour. Informatiz. 2014, 06, 47–50. [Google Scholar] [CrossRef]

- Zhang, R.; Li, G. The Application of Ultrasonic Flowmeter in Liquid Transmission Metering. J. Langfang Norm. Univ. 2003, 19, 95–97. [Google Scholar] [CrossRef]

- Qiu, S.; Xu, K. Research on the Detection Method of Pipeline Natural Gas Ultrasonic Flow Meter. China Insp. Body Lab. 2024, 32, 35–40. [Google Scholar] [CrossRef]

- Zheng, D.D.; Zhang, P.Y.; Xu, T.S. Study of Acoustic Transducer Protrusion and Recess Effects on Ultrasonic Flowmeter Measurement by Numerical Simulation. Flow Meas. Instrum. 2011, 22, 488–493. [Google Scholar] [CrossRef]

- Li, Q.; Ma, H.; Liu, H.; Li, Y. Experimental Study on Online Detection of Portable Ultrasonic Flowmeter. Metrol. Sci. Technol. 2017, 08, 46–48. [Google Scholar] [CrossRef]

- Cavuoto, G.; Romeo, R.; Lago, S.; Giuliano, A. Towards the Validation of Ultrasonic Flowmeters Operating in Hydrogen-Enriched Natural Gas Mixtures through Speed of Sound Measurements Obtained by a Clamp-On Meter. Int. J. Hydrogen Energy 2025, 105, 1178–1185. [Google Scholar] [CrossRef]

- GB/T 35717-2024; Discharge Measurement for Hydraulic Turbines, Storage Pumps and Pump-Turbines—Ultrasonic Transit-Time Method. China Standards Press: Beijing, China, 2024. Available online: https://max.book118.com/html/2025/0103/5322002023012023.shtm (accessed on 27 March 2025).

- IEC 60041:1991; Field Acceptance Tests to Determine the Hydraulic Performance of Hydraulic Turbines, Storage Pumps and Pump-Turbines. International Electrotechnical Commission (IEC): Geneva, Switzerland, 1991. Available online: https://webstore.iec.ch/en/publication/154 (accessed on 27 March 2025).

- Broquet, P.; Conti, L.; Vaterlaus, H.P. Use of Total Station Theodolite for the Installation of Ultrasonic Flowmeters in Large Diameter Penstocks. In Proceedings of the 3rd International Conference ICHEM, Lucerne, Switzerland, 10–12 July 2000. [Google Scholar]

- Stefan, B. Discussion of Installation Methods and Errors of Multipath Acoustic Discharge Measurements in Closed Conduits. In Proceedings of the 5rd International Conference ICHEM, Lucerne, Switzerland, 14–16 July 2004. [Google Scholar]

- Hu, H.; Wang, C.; Meng, T.; Cui, L. Study on Geometric Parameter Calculation Method and Uncertainty Estimation of Ultrasonic Flowmeter. Chin. J. Sci. Instrum. 2010, 31, 1583–1587. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, C.W.; Lin, J. Effects of Velocity Profiles on Measuring Accuracy of Transit-Time Ultrasonic Flowmeter. Appl. Sci. 2019, 9, 1648. [Google Scholar] [CrossRef]

- Meng, T.; Hu, H.; Wang, C.; Chen, H.; Zhuang, T. Geometric Parameter Measurement of Large Ultrasonic Flowmeter Based on Total Station. ACTA Metrol. Sin. 2010, 31, 59–62. [Google Scholar] [CrossRef]

- Hu, H.; Meng, T.; Wang, C. Theoretical Analysis of Integration Error of Ultrasonic Flowmeter in the Disturbed Flow Condition. ACTA Metrol. Sin. 2011, 32, 198–202. [Google Scholar] [CrossRef]

- Cui, H. Research and Application of Online Precision Measurement Method for Geometric Parameters of Ultrasonic Flow Measuring Device. Master’s Thesis, China Jiliang University, Hangzhou, China, 2019. [Google Scholar] [CrossRef]

- Renaldas, R. Investigation of The Flow Velocity Profile in a Metering Section of an Invasive Ultrasonic Flowmeter. Flow Meas. Instrum. 2006, 17, 201–206. [Google Scholar] [CrossRef]

- Lukács, G.; Martin, R.; Marshall, D. Faithful Least-Squares Fitting of Spheres, Cylinders, Cones and Tori for Reliable Segmentation. In Proceedings of the 15th European Conference on Computer Vision, Freiburg, Germany, 1–5 June 1998; pp. 671–686. [Google Scholar] [CrossRef]

- Zhu, W.J.; Xu, K.J.; Fang, M.; Shen, Z.W.; Tian, L. Variable Ratio Threshold and Zero-Crossing Detection-Based Signal Processing Method for Ultrasonic Gas Flow Meter. Measurement 2017, 103, 343–352. [Google Scholar] [CrossRef]

- Chen, H. Influence of the Upstream Pipe Bends on the Measurement Errors of an Ultrasonic Flowmeter. Master’s Thesis, China Jiliang University, Hangzhou, China, 2014. [Google Scholar]

- Staubli, T.; Tresch, T.; Gruber, P. A Discussion of Uncertainties and of Potential for Improvement of the Acoustic Transit Time Method; Hydro Porto: Oslo, Norway, 2004. [Google Scholar]

- Voser, A.; Bruttinch, C.; Prenat, J.; Staubli, T. Improving Acoustic Flow Measurement. Int. Water Power Dam Constr. 1996, 48, 30–34. [Google Scholar]

- Hu, Y.; Zhang, T.; Zheng, D.D. Estimation of the Influence of Ultrasonic Flowmeter Probe Installation Intrusion Length on Measurement Accuracy. J. Tianjin Univ. (Sci. Technol.) 2013, 46, 776–783. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Zheng, D.D.; Xu, T.S. Study on the Influence of Ultrasonic Probes on Flow Field and Measurement Performance of Ultrasonic Flowmeter. Exp. J. Exp. Fluid Mech. 2011, 25, 60–65. [Google Scholar]

- Zheng, D.D.; Zhao, D. Study on Mechanism of Flow Disturbance Caused by Acoustic Transducers in Flow Measurement. J. Mech. Eng. 2014, 50, 20–22. [Google Scholar] [CrossRef]

- Liu, D.; Liu, H.; Gan, M. Development and Test of Combined Standard Meter Flow Standard Device. Ind. Metrol. 2024, 34, 46–49. [Google Scholar] [CrossRef]

- Wang, B.; Cui, Y.; Liu, W. Study of Transducer Installation Effects on Ultrasonic Flow Metering Using Computational Fluid Dynamics. Adv. Mater. Res. 2013, 629, 676–681. [Google Scholar] [CrossRef]

- Goltsman, A.; Saushin, I. The Resulting Effect of Flow Pulsations on Calibration Constant of Acoustic Path in Ultrasonic Flowmeters. Sensors 2022, 22, 2815. [Google Scholar] [CrossRef]

- Martin, H.; Jacob, S.; Jerker, D. Simulation of Flow Meter Calibration Factors for Various Installation Effects. Measurement 1995, 15, 235–244. [Google Scholar] [CrossRef]

- Lin, J.Z. Turbulent Dynamics; Zhejiang University Press: Hangzhou, China, 2000. [Google Scholar]

- Hallanger, A.; Saetre, C.; Frøysa, K.E. Flow Profile Effects Due to Pipe Geometry in an Export Gas Metering Station-analysis by CFD Simulations. Flow Meas. Instrum. 2018, 61, 56–65. [Google Scholar] [CrossRef]

- Spearman, E.P.; Sattary, J.A.; Reader-Harris, M.J. Comparison of Velocity and Turbulence Profiles Downstream of Perforated Plate Flow Conditioners. Flow Meas. Instrum. 1996, 7, 181–199. [Google Scholar] [CrossRef]

- Wang, Z.; Zou, H.; Meng, T.; Han, C. Experimental Study on the Measurement Performance of Dual Channel Ultrasonic Flowmeter under Obstruction Conditions. Ind. Metrol. 2013, 23, 33–36. [Google Scholar] [CrossRef]

- Zhang, P. Research on the Adaptability of Ultrasonic Flowmeter in the Non-Ideal Flow Field. Master’s Thesis, Tianjin University, Tianjin, China, 2012. [Google Scholar]

- Smith, W.A.; Auld, B.A. Modeling 1-3 Composite Piezoelectrics: Thickness-Mode Oscillations. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1991, 38, 40–47. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F. High Performance Ferroelectric Relaxor-PbTiO3 Single Crystals: Status and Perspective. J. Appl. Phys. 2012, 111, 031301. [Google Scholar] [CrossRef]

- Sadeghi, S.; Najafabadi, M.A.; Javadi, Y. Using Ultrasonic Waves and Finite Element Method to Evaluate Through-Thickness Residual Stresses Distribution in the Friction Stir Welding of Aluminum Plates. Mater. Des. 2013, 52, 870–880. [Google Scholar] [CrossRef]

- Gururaja, T.R. Piezoelectric Composite Materials for Ultrasonic Transducer Applications. Part I: Resonant Modes of Vibration of PZT Rod-Polymer Composites. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1985, 32, 481–498. [Google Scholar] [CrossRef]

- Lynnworth, L.C. Ultrasonic Measurements for Process Control: Theory, Techniques, Applications; Academic Press: Cambridge, MA, USA, 1989. [Google Scholar]

- Willatzen, M. Ultrasonic Flowmeters: Half-Century Progress Report, 1955–2005. Ultrasonics 2006, 44, 1371–1378. [Google Scholar] [CrossRef]

- Zhang, J. A High-Resolution Time-to-Digital Converter Implemented in Field-Programmable-Gate-Arrays. IEEE Trans. Nucl. Sci. 2006, 53, 236–241. [Google Scholar] [CrossRef]

- Robert, H. Time Delay Estimation of Random Signals Using Cross-correlation with Hilbert Transform. Measurement 2019, 146, 792–799. [Google Scholar] [CrossRef]

- Balazs, T.; Attila, B.; Sándor, Z.; Gabor, V.; Gabor, P. Cross-correlation based time delay estimation for turbulent flow velocity measurements: Statistical considerations. Phys. Plasmas 2011, 18, 122304. [Google Scholar] [CrossRef]

- Manuchehri, M.S.; Setarehdan, S.K. A Robust Time Delay Estimation Method for Ultrasonic Echo Signals and Elastography. Comput. Biol. Med. 2021, 136, 104653. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Chen, D.; Fei, C.; Li, D.; Zhang, Q.; Feng, W.; Yang, Y. Optimization Design of High-Frequency Ultrasonic Transducer Based on ANFIS and Particle Swarm Optimization Algorithm. Appl. Acoust. 2022, 187, 108507. [Google Scholar] [CrossRef]

- International Electrotechnical Commission (IEC). IEC 61000-4-1: 2006—Electromagnetic Compatibility (EMC)—Part 4-1: Testing and Measurement Techniques—General Guide on the Limits of Electromagnetic Interference; IEC: Geneva, Switzerland, 2006. [Google Scholar]

- Zhang, Y. Research on Measurement Error Compensation of Multi-Channel Ultrasonic Flow Meter. New Technol. New Prod. China 2024, 22, 8–10. [Google Scholar] [CrossRef]

- Zhao, H.; Peng, L.; Stephane, S.A.; Ishikawa, H.; Shimizu, K.; Takamoto, M. CFD-Aided Investigation of Multipath Ultrasonic Gas Flow Meter Performance under Complex Flow Profile. IEEE Sens. J. 2014, 14, 897–907. [Google Scholar] [CrossRef]

- Kurniadi, D.; Trisnobudi, A. A Multi-Path Ultrasonic Transit Time Flow Meter Using a Tomography Method for Gas Flow Velocity Profile Measurement. Part. Part. Syst. Charact. 2006, 23, 330–338. [Google Scholar] [CrossRef]

- Piechota, P.; Synowiec, P.; Andruszkiewicz, A.; Wędrychowicz, W. Selection of the Relevant Turbulence Model in a CFD Simulation of a Flow Disturbed by Hydraulic Elbow—Comparative Analysis of the Simulation with Measurements Results Obtained by the Ultrasonic Flowmeter. J. Therm. Sci. 2018, 27, 413–420. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The Numerical Computation of Turbulent Flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Xia, X.X.; Li, Y.C.; Cai, F.Y. Ultrasonic Tunable Focusing by a Stretchable Phase-Reversal Fresnel Zone Plate. Appl. Phys. Lett. 2020, 117, 021904. [Google Scholar] [CrossRef]

- Alvarez-Arenas, T.E.G.; Camacho, J.; Fritsch, C. Passive Focusing Techniques for Piezoelectric Air-Coupled Ultrasonic Transducers. Ultrasonics 2016, 67, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Lu, W.; Cui, Y.; Sun, T.; Wu, C.; Xu, Y.; Li, P. Field Simulation and Measurement of Effective Radiating Area of Planar Non-Focused Therapeutic Ultrasound Transducers. Measurement 2025, 254, 117907. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, W.; Shen, P.; Wang, C.; Jiang, Y. A Fault Diagnosis Method for Ultrasonic Flow Meters Based on KPCA-CLSSA-SVM. Processes 2024, 12, 809. [Google Scholar] [CrossRef]

- Wang, W.T. Multi-Channel Gas Ultrasonic Flowmeter Flow Field Adaptability. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2011. [Google Scholar]

- Mousavi, S.F.; Hashemabadi, S.H.; Jamali, J. Calculation of Geometric Flow Profile Correction Factor for Ultrasonic Flow Meter Using Semi-3D Simulation Technique. Ultrasonics 2020, 106, 106165. [Google Scholar] [CrossRef]

- Joshi, S.G. Ultrasonic Flow Meter Using Mode Coupling Transducers. Ultrasonics 2021, 116, 106497. [Google Scholar] [CrossRef]

- Guo, S.; Xiang, N.; Li, B.; Wang, F.; Zhao, N.; Zhang, T. Integration Method of Multipath Ultrasonic Flowmeter Based on Velocity Distribution. Measurement 2023, 207, 112388. [Google Scholar] [CrossRef]

- Hon, S.F.; Kwok, K.W.; Li, H.L. Self-Focused Acoustic Ejectors for Viscous Liquids. Rev. Sci. Instrum. 2010, 81, 065102. [Google Scholar] [CrossRef]

- LeMay, G.S.; Askari, D. A New Method for Ultrasonic Detection of Peel Ply at the Bondline of Out-of-Autoclave Composite Assemblies. J. Compos. Mater. 2019, 53, 245–259. [Google Scholar] [CrossRef]

- Aeinfar, S.; Serteser, N. Parametric Study of Energy Optimization and Airflow Management in High-Rise Buildings with Double-Skin Façade Using a Genetic Algorithm and CFD. J. Build. Eng. 2025, 105, 112441. [Google Scholar] [CrossRef]

- Wang, X.; Liu, C.; Wu, G. An Acoustic Pressure-Gradient MEMS Vector Hydrophone System Based on Piezoelectric Micromachined Ultrasonic Transducer Array. Microelectron. J. 2024, 151, 106332. [Google Scholar] [CrossRef]

- Javadi, Y.; Pirzaman, H.S.; Raeisi, M.H. Ultrasonic Inspection of a Welded Stainless Steel Pipe to Evaluate Residual Stresses Through Thickness. Mater. Des. 2013, 49, 591–601. [Google Scholar] [CrossRef]

- Javadi, Y.; Pirzaman, H.S.; Raeisi, M.H. Ultrasonic Evaluation of Welding Residual Stresses in Stainless Steel Pressure Vessel. J. Press. Vessel Technol.-Trans. ASME 2013, 135, 041502. [Google Scholar] [CrossRef]

- He, X.L.; Duan, Y.X.; Fan, Q.W. Correction of Coupling Error in Contact-Type Ultrasonic Evaluation of Bolt Axial Stress. Ultrasonics 2022, 124, 106763. [Google Scholar] [CrossRef] [PubMed]

- Rincón, M.J.; Reclari, M.; Yang, X.; Abkar, M. Validating the Design Optimization of Ultrasonic Flow Meters Using Computational Fluid Dynamics and Surrogate Modelling. Int. J. Heat Fluid Flow 2023, 100, 109112. [Google Scholar] [CrossRef]

- Liang, F.; Hang, Y.; Yu, H.; Gao, J. Identification of Gas-Liquid Two-Phase Flow Patterns in a Horizontal Pipe Based on Ultrasonic Echoes and RBF Neural Network. Flow Meas. Instrum. 2021, 79, 101960. [Google Scholar] [CrossRef]

- Murai, Y.; Tasaka, Y.; Nambu, Y.; Takeda, Y.; Gonzalez, S. Ultrasonic Detection of Moving Interfaces in Gas–Liquid Two-Phase Flow. Flow Meas. Instrum. 2010, 21, 356–366. [Google Scholar] [CrossRef]

- Wang, X.F.; Tang, Z.A. Note: Ultrasonic Gas Flowmeter Based on Optimized Time-of-Flight Algorithms. Rev. Sci. Instrum. 2011, 82, 1371–1384. [Google Scholar] [CrossRef]

- Zou, Z.Y.; Hao, Y.P.; Tian, F.Y. An Ultrasonic Longitudinal Through-Transmission Method to Measure the Compressive Internal Stress in Epoxy Composite Specimens of Gas-Insulated Metal-Enclosed Switchgear. Energies 2020, 13, 1428. [Google Scholar] [CrossRef]

- Liu, L.; Li, B.; Liu, S.; Wang, K.; Gu, H. Recognition of Gas-Liquid Flow Regimes in Helically Coiled Tube Using Wire-Mesh Sensor and KNN Algorithm. Int. J. Multiph. Flow 2022, 154, 104144. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Z.; Yu, F.; Yan, T.; He, B. Computational Fluid Dynamics Driven Surrogate Model to Predict Hydrodynamic and Acoustic Properties of Propeller Boss Cap Fins. Appl. Ocean Res. 2024, 153, 104293. [Google Scholar] [CrossRef]

- Petris, G.; Cianferra, M.; Armenio, V. Full Acoustic Analogy of the Fluid-Dynamics Noise of an Immersed Cube. Ocean Eng. 2024, 300, 117433. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Peng, Z.; Guo, F. Optimized Kalman Filter Techniques for Ultrasonic Flow Measurement. J. Phys. Conf. Ser. 2024, 2897, 012039. [Google Scholar] [CrossRef]

- Safikhani, H.; Esmaeili, F.; Rezvani, S. Extracting a Smart Model for Determining Defrost Time in Household Refrigerators Using a Combination of CFD, Experimental Data, and GMDH Type Artificial Neural Network. Int. J. Refrig. 2025, 176, 52–56. [Google Scholar] [CrossRef]

- Mazzuto, G.; Ciarapica, F.E.; Ortenzi, M.; Bevilacqua, M. The Digital Twin Realization of an Ejector for Multiphase Flows. Energies 2021, 14, 5533. [Google Scholar] [CrossRef]

- Li, M.; Li, Z.; Li, C. In-use Measurement of Ultrasonic Flowmeter Based on Machine Learning. Measurement 2023, 223, 113721. [Google Scholar] [CrossRef]

- Alexander, Y.G.; Mikhail, G.G.; Yuri, G.G.; Armando, M.L. Synthetic Turbulence Modeling for Evaluation of Ultrasonic Cross-correlation Flow Measurement. Flow Meas. Instrum. 2018, 60, 134–143. [Google Scholar] [CrossRef]

- Jack, M.; Paul, L.M.J.; Douwe, M.W.; Nicolaas, J.; Michiel, A.P.P.; Martin, D.V. Exploiting Nonlinear Wave Propagation to Improve the Precision of Ultrasonic Flow Meters. Ultrasonics 2021, 116, 106476. [Google Scholar] [CrossRef]

- Landskron, J.; Dötzer, F.; Benkert, A.; Mayle, M.; Drese, K.S. Acoustic Limescale Layer and Temperature Measurement in Ultrasonic Flow Meters. Sensors 2022, 22, 6648. [Google Scholar] [CrossRef]

- Hong, L. Design of Time Difference Ultrasonic Flowmeter Based on Adaptive Kalman Filter. Master’s Thesis, Huaiyin Institute of Technology, Huai’an, China, 2024. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Yang, X.H. Fusion of Cross-correlation Method and Optical Flow Method for Flow Measurement. China Water Transp. 2023, 23, 98–100. [Google Scholar]

- Zhao, Y.; Dong, K.; Liu, G.; Liu, X.; Min, Z.; Li, Z.; Ma, X.; Gao, L. Development and Field Application of Reversible Pump Turbine Efficiency Testing Software Based on Ultrasonic Method and Spiral Case Differential Pressure Method. Water Resour. Power 2015, 33, 159–162. [Google Scholar] [CrossRef]

| Method | Main Measurement Equipment | Installation and Applicability | Suitable for Long-Term Online Monitoring | Error Range (%) | Remarks and References |

|---|---|---|---|---|---|

| Current-Meter Method | Current meter | Requires shutdown for installation; demanding construction conditions; pipeline must be dry; sensitive to water quality | No | 1.2–1.5 | Particulate matter degrades accuracy [2,3]; widely used in low-head stations. |

| Thermodynamic Method | Temperature sensors | Complex installation; measurement points must be reserved during design stage; suitable for units with head ≥ 100 m | No | 0.7–1.8 | Depends on temperature accuracy (±0.1 °C), [2,6]; validated for high-head units [2,4]. |

| Pressure–Time Method | Pressure sensors | Applicable to medium- and high-head stations; not suitable for low-head stations; not capable of continuous monitoring | No | ±1.5 | Accuracy linked to pipeline layout [2,3]; invalid for head < 50 m [2,3]. |

| Ultrasonic Method | Ultrasonic flow meter | Wide applicability; no upper limit on velocity; suitable for large diameters and high flow rates; relatively easy installation; real-time capability | Yes | <2.0 | Real-time monitoring (delay < 1 s) [2,9,10]; robust to flow disturbances. |

| Spiral Case Differential Method (W-K Method) | Pressure sensors | Requires calibration of flow coefficient K using other methods; cannot be used independently; relatively easy installation; real-time capability | Yes | 0.5–1.0 | K quality determines accuracy [2,7,9]; ideal for medium-head units. |

| Flow Velocity (m/s) | Number of Channels (n = 1) | Number of Channels (n = 2) | Number of Channels (n = 4) | |||

|---|---|---|---|---|---|---|

| S = 0.9 | S = 1.0 | S = 0.9 | S = 1.0 | S = 0.9 | S = 1.0 | |

| 0.2 | −0.463 | 0.085 | −6.529 | −6.423 | −7.228 | −7.452 |

| 0.6 | −4.397 | −2.930 | −8.536 | −7.581 | −9.320 | −8.707 |

| 1 | −5.082 | −3.429 | −8.785 | −7.775 | −9.735 | −8.928 |

| 8 | −6.802 | −4.907 | −9.620 | −8.281 | −10.527 | −9.360 |

| Flow Velocity (m/s) | Number of Channels (n = 1) | Number of Channels (n = 2) | Number of Channels (n = 4) | |||

|---|---|---|---|---|---|---|

| S = 0.9 | S = 1.0 | S = 0.9 | S = 1.0 | S = 0.9 | S = 1.0 | |

| 0.2 | 0.283 | 0.592 | −5.146 | −5.264 | −4.975 | −6.235 |

| 0.6 | −4.467 | −2.946 | −6.913 | −7.219 | −7.416 | −8.156 |

| 1 | −5.265 | −3.504 | −7.339 | −7.504 | −7.777 | −8.484 |

| 8 | −7.393 | −5.118 | −7.977 | −8.222 | −8.501 | −9.035 |

| Accuracy-Improving Technology | Reported Measurement Accuracy | Frequency-Related Findings | Flow Rate Adaptability | Key References |

|---|---|---|---|---|

| Hardware Optimization | ||||

| PZT-based transducers | ±1.5–2.0% | Suitable for typical industrial frequency ranges | Applicable to medium-to-high flow rates (≥0.5 m/s) | [22,61] |

| PMN-PT single crystals | ~20% improvement compared to PZT | Enhanced sensitivity at higher frequencies | Extended to low flow rates (≥0.1 m/s) | [62] |

| TDC signal processing | Time measurement uncertainty reduced to ±20–50 ps | Enables high-resolution time measurement | Compatible with wide flow rate ranges (0.1–10 m/s) | [67,68] |

| CFD-Driven Optimization | ||||

| Flow field correction | Error reduction ≤ 5% in disturbed flows | Not applicable (simulation-focused) | Effective for large-diameter pipes with complex flows | [74,77] |

| Transducer layout optimization | Error reduction up to 15% | Minimized signal attenuation after optimization | Improved performance in asymmetric flow fields | [81,89] |

| Multi-Method Integration | ||||

| Ultrasonic + thermodynamic method | Combined uncertainty ≤ ±0.8% | Complementary frequency responses | Suitable for high-head stations (≥100 m) | [110] |

| Digital twin (CFD + real-time monitoring) | Dynamic error correction ≤ ±0.9% | Integrates real-time signal processing | Adapts to time-varying flows (0.1–8 m/s) | [97,103] |

| Technology Category | Specific Methods | Key Findings | References |

|---|---|---|---|

| Hardware Optimization | 1. Transducer material innovation (PZT-5H/PZT-8, PMN-PT single crystals) | PMN-PT transducers improve sensitivity by ~20% compared to traditional materials. | [61,62] |

| 2. Structural design (quarter-wavelength matching layer, high-impedance backing) | Matching layers increase acoustic energy transmission efficiency from 60% to 85%. | [63,64] | |

| 3. Signal processing (TDC with 20 ps resolution, FPGA-based multi-cycle averaging) | TDC reduces timing uncertainty to ±20 ps; FPGA-based systems achieve ±50 ps | [67,68] | |

| 4. Temperature compensation (real-time thermal drift correction) | Reduces temperature-induced errors from 1.5% to 0.2%. | [71] | |

| CFD-Driven Optimization | 1. Flow field characteristic analysis (RANS/LES simulations for velocity profiles) | CFD quantifies errors from non-uniform flow (≤5% in asymmetric fields). | [74,76,77] |

| 2. Structural optimization (genetic algorithms, PSO for transducer layout) | Optimized transducer angles reduce system errors by up to 15%. | [81,89,90,91,92] | |

| 3. Error compensation (surrogate models, deep learning for flow-field correction) | CFD-based models reduce measurement errors by 20% in disturbed flow conditions. | [93,94,95,96,102] | |

| Multi-Method Integration | 1. Fusion with other measurement techniques (thermodynamic, W-K method) | Integrating ultrasonic and thermodynamic methods reduces uncertainty to ±0.8%. | [105,110] |

| 2. Data fusion algorithms (adaptive Kalman filtering, wavelet-based time delay) | Kalman filtering achieves ±0.1% precision under low signal-to-noise conditions. | [69,101] | |

| 3. Digital twin technology (coupling CFD with real-time monitoring) | Enables dynamic error correction in complex, time-varying flow fields. | [97,103] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Zhou, Y.; Xu, B.; Zhao, H.; Ye, Y. Enhancing Accuracy of Ultrasonic Transit-Time Flow Measurement in Hydropower Systems Under Complex Operating Conditions: A Comprehensive Review. Machines 2025, 13, 713. https://doi.org/10.3390/machines13080713

Li L, Zhou Y, Xu B, Zhao H, Ye Y. Enhancing Accuracy of Ultrasonic Transit-Time Flow Measurement in Hydropower Systems Under Complex Operating Conditions: A Comprehensive Review. Machines. 2025; 13(8):713. https://doi.org/10.3390/machines13080713

Chicago/Turabian StyleLi, Lin, Ye Zhou, Beibei Xu, Hongli Zhao, and Yuntao Ye. 2025. "Enhancing Accuracy of Ultrasonic Transit-Time Flow Measurement in Hydropower Systems Under Complex Operating Conditions: A Comprehensive Review" Machines 13, no. 8: 713. https://doi.org/10.3390/machines13080713

APA StyleLi, L., Zhou, Y., Xu, B., Zhao, H., & Ye, Y. (2025). Enhancing Accuracy of Ultrasonic Transit-Time Flow Measurement in Hydropower Systems Under Complex Operating Conditions: A Comprehensive Review. Machines, 13(8), 713. https://doi.org/10.3390/machines13080713