The Development of a Predictive Maintenance System for Gearboxes Through a Statistical Diagnostic Analysis of Lubricating Oil and Artificial Intelligence

Abstract

1. Introduction

2. Materials and Methods

2.1. Creation of Condition Monitoring Report Database

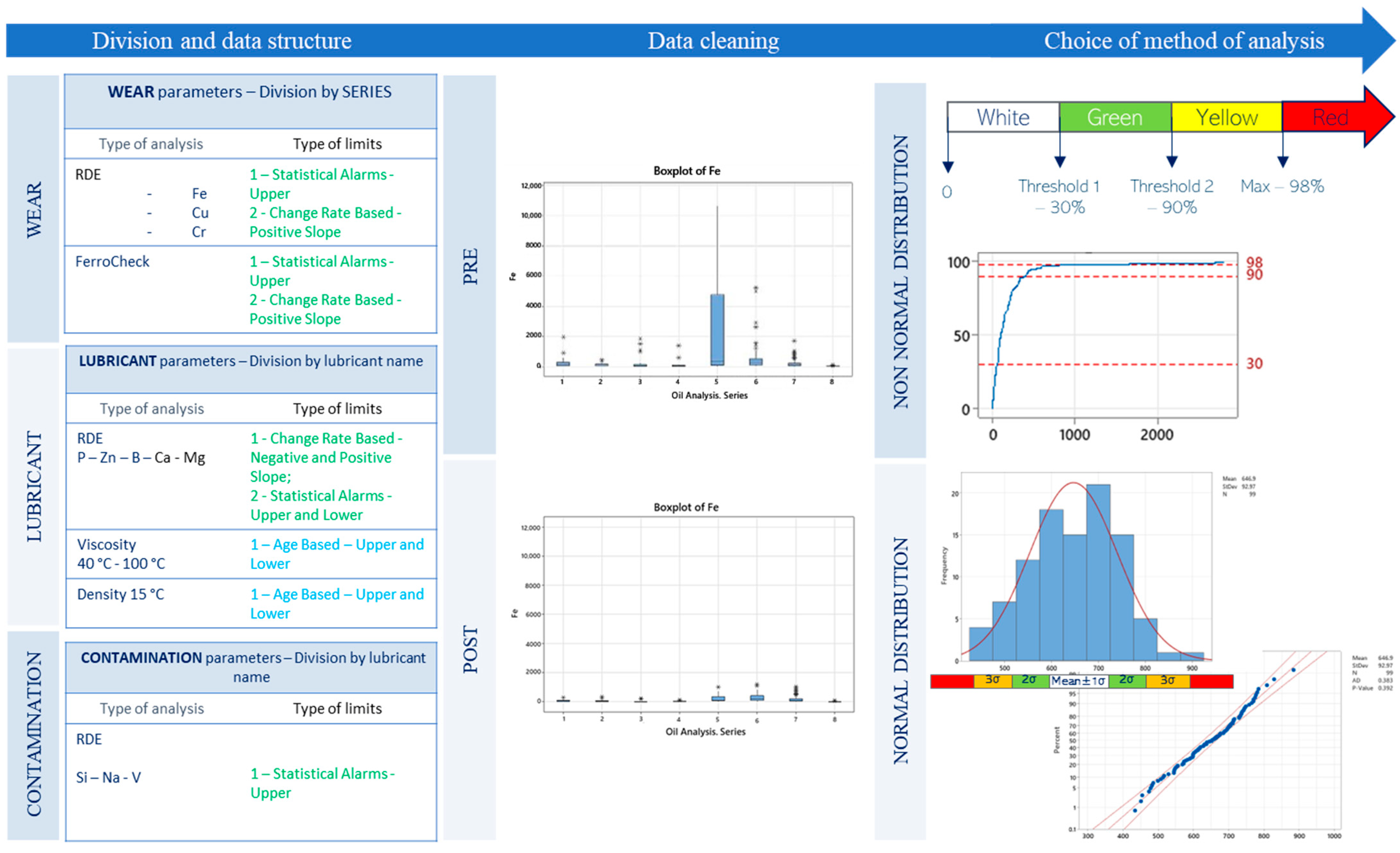

2.2. Selection of Critical Oil Measurements

- Analysis ID: This is required to identify each sample analyzed uniquely. Its function is essential to ensuring the traceability and correct association of data with the respective machines and operating conditions.

- Gearbox series: This identifies the series to which the reducer belongs. This information is particularly important because reducers from different series can be made of different materials and lead, at the time of analysis, to misinterpretations when, for example, wear is analyzed.

- Gearbox serial number: The serial number identifies the gearbox. Making an analogy with the world of medicine, we can say that it represents the name and surname of the reducer.

- The date of sampling in which the oil was removed from the reducer: This is one of the most important pieces of information because it allows us to study the history of gearboxes. In fact, oil analyses are often based on comparisons with historical data. An incorrect date can alter the trend of parameters over time, leading to wrong assessments on oil degradation or machine wear.

- The type of oil: Each lubricant has different chemical–physical characteristics that affect the performance of the oil itself and therefore of the machine. Without knowing the type of oil, it is difficult to determine whether the values are normal or if the correct oil has been used.

- Hours of oil usage: This indicates the time of use of the oil since the last significant change or top-up. This is crucial for assessing lubricant degradation and component wear. In fact, an abnormal increase in contaminants or wear metals compared to operating hours may indicate an imminent mechanical problem.

- Machine hours: This parameter indicates the total operating time of the machine.

- Refueling: This refers to the addition of oil in the system to compensate for leakage, evaporation, or natural consumption during operation. This parameter is important because it impacts oil quality and machinery condition diagnosis.

2.3. Definition of Diagnostic Limits

- Change rate-based: Rate-of-change alarms are generally set up to measure properties that vary as the oil is used. The rate is typically calculated as a function of machine hours or oil hours and corresponds to the slope of the line of ppm with respect to hours. For example, in the case of wear elements, the total ppm value will be divided by machine hours to give an indication of how many ppm/hour were generated by the system during its operation, while in the case of additives, the values will be divided by oil hours. This consideration is fundamental because some parameters may be below absolute levels yet still exceed the rate of increase, which could lead to early wear.

- Statistical alarms: Statistical limits are the most important and simple. This provides a sufficient amount of data to be representative of the machine and oil. The approach involves generating a standard mean and distribution from the available data and comparing these with the values from the sample under analysis. The ASTM D7720 standard [26] provides guidelines on how to set limits and their level of attention. In particular, there are four levels of attention: white, green, yellow, and red. The document describes two main methods for establishing and updating alarm limits: statistical process control (SPC) and cumulative technique. SPC is based on statistics to assess control limits in data that follow a normal distribution. Limits are calculated based on standard deviation from the population average of the data: if the value is within a standard deviation from the average, it is considered normal (white). If it falls outside of a standard deviation from the mean but is within two deviation standards, is considered a warning (green). If the result exceeds two standard deviations, the value is considered in a critical alarm because it is higher or lower, depending on the cases, to 95% of the population. If the value exceeds three standard deviations, the situation is really critical, as the value exceeds about 99% percentile of the population. However, this approach is applicable to a normal distribution. In case of non-normal distribution, the standards propose to use the technique of cumulative distribution. Unlike SPC, cumulative distribution is not based on an assumed statistical model but sorts the data according to actual observed values, creating a percentage distribution. The resulting curve represents the cumulative probability, which indicates the percentage of data below a given value. This technique is suitable for data with non-Gaussian distributions, such as oil contamination, wear and chemical degradation. ASTM D7720 describes different types of cumulative distributions, depending on the nature of the data.

- Goal-based limits: Targets apply to the control of parameters such as contamination, viscosity, and density. A goal-based limit is set with a specific objective, not necessarily related to the aging of the oil, but rather to maintaining optimal conditions to improve machine performance. In summary, the goal-based limit is an ideal value to maintain to maximize the performance and reliability of the machine.

- Aging limits: Another type of limit or proactive alarm concerns the progressive aging of a lubricant [3]. In fact, all lubricants are subject to aging, and therefore, the chemical–physical characteristics can deteriorate more or less slowly. For example, imagine having a lubricant for an industrial gearbox with a nominal viscosity of 320 cSt at 40 °C. To ensure optimal performance and reduce the risk of wear or malfunction, an acceptability range of about 10% around the nominal value is established. The objective of aging limits is to keep the lubricant in ideal conditions, intervening when significant variations occur that could compromise the protection and efficiency of the machinery. If the values are close to the limits, corrective actions such as an oil change, filtration, or more in-depth analysis can be taken to identify the causes of the change.

2.4. Application of Artificial Intelligence Model

2.4.1. Pre-Processing

- Result: Represents a single oil analysis entry, including fields such as ID, sampling date, lubricant and machine hours, diagnosis, and elemental concentrations.

- GearboxInfo: Encapsulates information specific to the gearbox, such as the serial number.

- GearboxResult: Aggregates analysis results for a given gearbox, linking a GearboxInfo instance to a chronologically ordered list of Result entries.

2.4.2. The Development of the Application for Automated Diagnostics

- columns_wear: includes parameters related to component wear (e.g., operating hours, metal concentrations, machine ID, date, and diagnosis).

- columns_oil: contains characteristics of the lubricant, such as oil type, density, viscosity, and other chemical–physical properties.

- columns_contamination: collects data on the presence of contaminants (e.g., silicon, sodium, vanadium, etc.).

- Wear: absolute limits and normalized limits per operating hour (PPM/h);

- Lubrication: thresholds for additives, density, and viscosity—both absolute and normalized;

- Contamination: acceptable thresholds for external elements.

- Wear analysis: The function filters only entries related to operating gearboxes, excluding new oil samples. The gearbox series is then identified, and using the get_relevant_data function, historical data (from other gearboxes of the same series) are separated from the current data. These are then formatted in Markdown and incorporated into the prompt alongside the relevant reference limits.

- Oil analysis: The system selects the row corresponding to the gearbox under examination and identifies the type of lubricant used. It then accesses a folder containing PDF files with technical specifications and new oil samples. These documents are read using the PyMuPDF library and integrated into the prompt together with current and historical data, as well as applicable limits.

- Contamination analysis: Similarly, the function selects data related to contamination and accesses the relevant PDF files. The data are enriched with the gearbox series and oil type, which are critical for an accurate evaluation.

2.4.3. Prompt Engineering

- 1.

- Wear analysis

- Ongoing Analysis Prompt: This prompt instructs the model to generate a diagnosis on the presence of wear particles in the lubricant under analysis, using the chemical data available in the database. Specifically, the model must fill in the Diagnosis column by focusing solely on parameters related to wear debris, excluding all other lubricant aspects. To do so, it analyzes the concentrations of elements such as iron (Fe), aluminum (Al), and chromium (Cr), comparing them with historical data. After generating the diagnosis, the model must also provide an explanation for the observed wear level. In summary, this prompt explains how to read the data and how to produce a focused analysis.

- Historical Data Prompt: This prompt guides the model in formulating a diagnosis by analyzing similar gear units, with a particular focus on wear. The model must consider diagnoses previously made by an expert on reducers from the same group, reviewing historical analysis values to identify recurring trends or anomalies. However, it must ignore any parts of the historical diagnoses that are unrelated to the data available in the current analysis.

- Limit Prompt: This prompt instructs the model on how to interpret wear thresholds, both in terms of absolute values (ppm) and in terms of time-based variation (ppm/hour), to assess the condition of the gear unit.

- 2.

- Lubricant property analysis

- Ongoing Analysis Prompt: This prompt guides the model in completing the Diagnosis column based on current database values. The focus is exclusively on additives, viscosity, and density. The chemical elements phosphorus (P), zinc (Zn), boron (B), calcium (Ca), and magnesium (Mg) represent the concentrations of additives in the lubricant. In addition to generating a diagnosis, the model must provide an explanation for the observed additive values.

- Historical Data Prompt: As in the previous section, this prompt helps the model build the diagnosis by leveraging historical expert evaluations of similar oils. Each dataset represents the oil test history of a specific gear unit. The model must analyze these series to identify trends and significant variations. It must also compare the chemical and physical properties in the technical specifications with those observed in new oil analyses. The model should ensure consistency with the lubricant’s evolution over time.

- Limit Prompt: This prompt instructs the model to interpret both absolute and incremental limits for additives. For viscosity and density, it only needs to evaluate whether values fall within defined acceptable ranges. If the oil name is not found in the limits database, the model should not produce any assessment related to limits, thus avoiding misleading or inaccurate evaluations.

- 3.

- Contamination analysis

- Ongoing Analysis Prompt: This prompt instructs the model to assess oil contamination. It must evaluate the presence of elements such as silicon (Si), sodium (Na), and vanadium (V) and suggest potential causes for contamination.

- Historical Data Prompt: The model must focus on three key aspects: oil contamination, viscosity, and density. It should compare the oil composition with the analysis of fresh oil, as well as evaluate viscosity and density values against the specifications provided by the manufacturer.

- Limit Prompt: This prompt explains how the model should interpret values of silicon, sodium, and vanadium in the analysis, comparing them against reference thresholds. If the lubricant under analysis is not listed in the predefined limits, the model must refrain from drawing any conclusions based on those thresholds.

- 4.

- Sample conditions and final evaluation

- Sample Reception Prompt: This is written manually for each sample as reception conditions vary. It provides the model with details about the sample’s arrival state.

- Integration Prompt: This prompt instructs the model to integrate the results obtained from the previous sections and propose any additional analyses that may help further clarify the equipment’s condition.

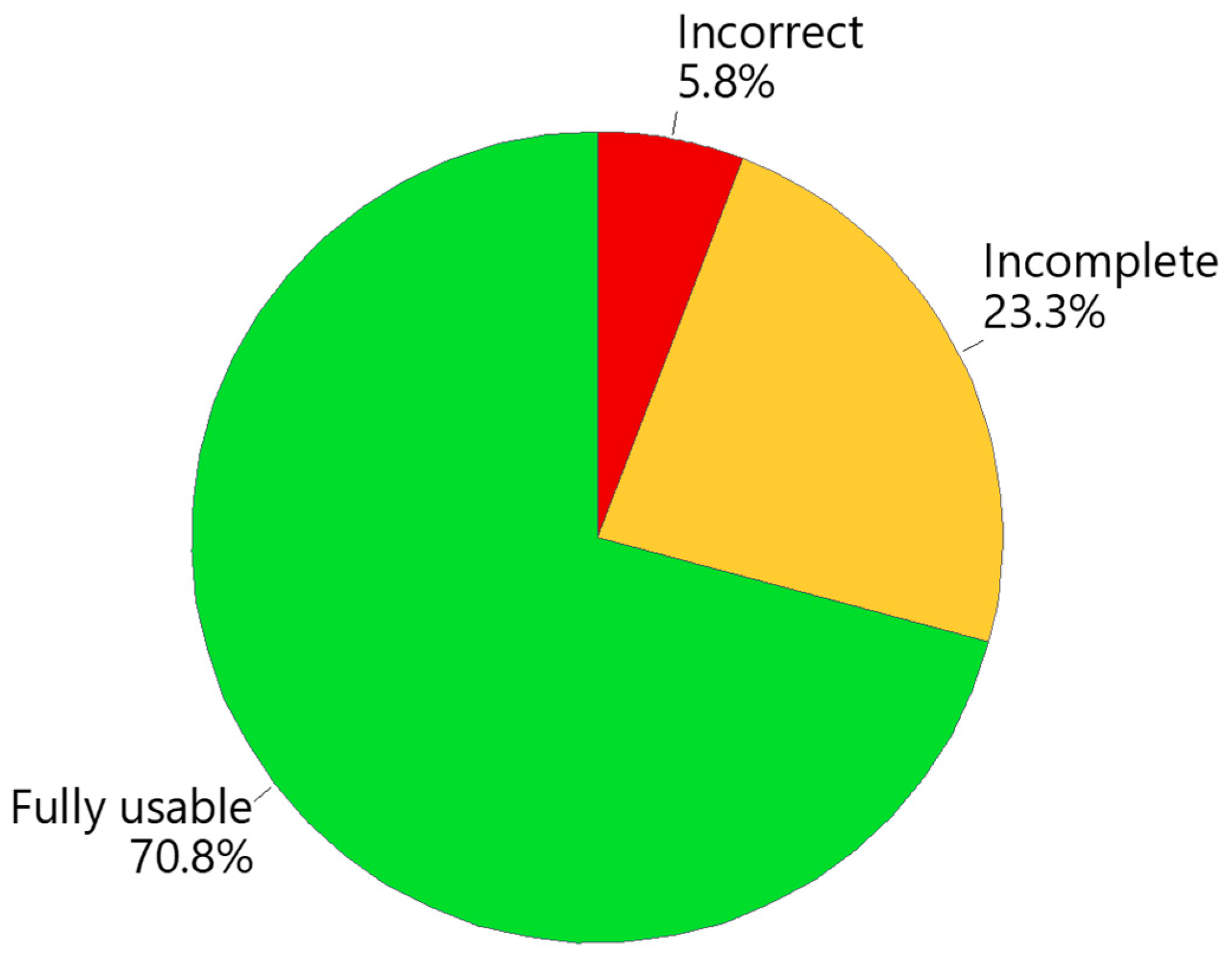

3. Results and Discussion

- Class 1—Irrelevant Comments (points 0): Includes all diagnoses in which the model generates content completely unrelated to the topic. These comments are considered unusable and excluded from operational evaluation.

- Class 2—Partially Incorrect Comments (points 1–3): Includes diagnoses that contain significant inaccuracies, such as the misinterpretation of limit values or inconsistent assessments. While occasionally partially useful, these comments require thorough revision.

- Class 3—Usable but Incomplete Comments (points 4–6): Refers to diagnoses that are generally correct but lack completeness. The comments often omit important aspects that a human expert would consider, but they still remain usable as a basis for analysis.

- Class 4—Fully Usable Comments (points 7–9): Includes diagnoses that are fully consistent with the expert-validated master version, both in terms of content and argumentation. These comments can be directly used in the decision-making process.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhat, J.S.; Sonawane, B.U. Condition Monitoring of Worm Gearbox through Oil Analysis. In Recent Trends in Engineering Design; Parey, A., Kumar, R., Singh, M., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Wakiru, J.M.; Pintelon, L.; Muchiri, P.N.; Chemweno, P.K. A review on lubricant condition monitoring information analysis for maintenance decision support. Mech. Syst. Signal Process. 2019, 118, 108–132. [Google Scholar] [CrossRef]

- Fitch, J.; Troyer, D. Oil Analysis Basics, 2nd ed.; Noria Corporation: Tulsa, OK, USA, 2010. [Google Scholar]

- del Álamo, J.R.; Duran, M.J.; Muñoz, F.J. Analysis of the Gearbox Oil Maintenance Procedures in Wind Energy. Energies 2020, 13, 3414. [Google Scholar] [CrossRef]

- Yan, S.; Kong, Z.; Liu, H.; Li, B.; Fan, M.; Zhang, X. Oil Change Interval Evaluation of Gearbox Used in Heavy-Duty Truck E-Axle with Oil Analysis Data. Lubricants 2022, 10, 252. [Google Scholar] [CrossRef]

- ISO 17359:2018; Condition Monitoring and Diagnostics of Machines—General Guidelines. ISO: Geneva, Switzerland, 2018.

- Abbasi, T.; Lim, K.H.; Soomro, T.A.; Ismail, I.; Ali, A. Condition Based Maintenance of Oil and Gas Equipment: A Review. In Proceedings of the 2020 3rd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 29–30 January 2020; pp. 1–9. [Google Scholar] [CrossRef]

- Mobley, R.K. An Introduction to Predictive Maintenance, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2002. [Google Scholar]

- Asadi, S.Y.; Schenck, T.; May, G. Integrated Oil Condition Monitoring and Predictive Maintenance Using Lubricant Analysis in Industrial Gearboxes. J. Mach. Eng. 2021, 21, 60–74. [Google Scholar]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Bindra, S.; Jain, R. Artificial Intelligence in Medical Science: A Review. Ir. J. Med. Sci. (1971-) 2023, 193, 1419–1429. [Google Scholar] [CrossRef] [PubMed]

- Weng, Y.; Wu, J.; Kelly, T.; Johnson, W. Comprehensive Overview of Artificial Intelligence Applications in Modern Industries. arXiv 2024, arXiv:2409.13059. [Google Scholar] [CrossRef]

- Singh, V.; Gangsar, P.; Porwal, R.; Atulkar, A. Artificial Intelligence Application in Fault Diagnostics of Rotating Industrial Machines: A State-of-the-Art Review. J. Intell. Manuf. 2021, 34, 931–960. [Google Scholar] [CrossRef]

- Giorgetti, A.; Arcidiacono, G.; Ciappi, A.; Barbieri, R.; Citti, P. HNCR model following robust approach. Qual. Reliab. Eng. Int. 2018, 34, 1271–1288. [Google Scholar] [CrossRef]

- Giorgetti, A.; Rolli, F.; La Battaglia, V.; Marini, S.; Arcidiacono, G. Axiomatic Design Using Multi-criteria Decision Making for Material Selection in Mechanical Design: Application in Different Scenarios. In Proceedings of the 15th International Conference on Axiomatic Design 2023, Eindhoven, The Netherlands, 31 May–2 June 2023. [Google Scholar] [CrossRef]

- Aliyu, R.; Mokhtar, A.A.; Hussin, H. Prognostic Health Management of Pumps Using Artificial Intelligence in the Oil and Gas Sector: A Review. Appl. Sci. 2022, 12, 11691. [Google Scholar] [CrossRef]

- Habbal, A.; Ali, M.K.; Abuzaraida, M.A. Artificial Intelligence Trust, Risk and Security Management (AI TRiSM): Frameworks, Applications, Challenges and Future Research Directions. Expert Syst. Appl. 2023, 240, 122442. [Google Scholar] [CrossRef]

- Sounderajah, V.; Ashrafian, H.; Rose, S.; Shah, N.H.; Ghassemi, M.; Golub, R.; Kahn, C.E.; Esteva, A.; Karthikesalingam, A.; Mateen, B.; et al. A Quality Assessment Tool for Artificial Intelligence-Centered Diagnostic Test Accuracy Studies: QUADAS-AI. Nat. Med. 2021, 27, 1663–1665. [Google Scholar] [CrossRef]

- Hanna, M.; Pantanowitz, L.; Jackson, B.; Palmer, O.; Visweswaran, S.; Pantanowitz, J.; Deebajah, M.; Rashidi, H. Ethical and Bias Considerations in Artificial Intelligence (AI)/Machine Learning. Mod. Pathol. 2025, 38, 100686. [Google Scholar] [CrossRef]

- Abdelwanis, M.; Alarafati, H.K.; Tammam, M.M.S.; Simsekler, M.C.E. Exploring the Risks of Automation Bias in Healthcare Artificial Intelligence Applications: A Bowtie Analysis. J. Saf. Sci. Resil. 2024, 5, 460–469. [Google Scholar] [CrossRef]

- Cunha, B.Z.; Droz, C.; Zine, A.-M.; Foulard, S.; Ichchou, M. A Review of Machine Learning Methods Applied to Structural Dynamics and Vibroacoustic. Mech. Syst. Signal Process. 2023, 200, 110535. [Google Scholar] [CrossRef]

- Mey, O.; Neudeck, W.; Schneider, A.; Enge-Rosenblatt, O. Machine Learning-Based Unbalance Detection of a Rotating Shaft Using Vibration Data. In Proceedings of the International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020. [Google Scholar] [CrossRef]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A.V. Fault Diagnosis Using eXplainable AI: A Transfer Learning-Based Approach for Rotating Machinery Exploiting Augmented Synthetic Data. Expert Syst. Appl. 2023, 232, 120860. [Google Scholar] [CrossRef]

- Cardoso, D.; Ferreira, L. Application of Predictive Maintenance Concepts Using Artificial Intelligence Tools. Appl. Sci. 2020, 11, 18. [Google Scholar] [CrossRef]

- Scaife, A.D. Improve Predictive Maintenance through the Application of Artificial Intelligence: A Systematic Review. Results Eng. 2023, 21, 101645. [Google Scholar] [CrossRef]

- ASTM D7720-11; Standard Guide for Statistically Evaluating Measurand Alarm Limits. ASTM International: West Conshohocken, PA, USA, 2011.

- Han, M.K.; Jian, J.P. Data Mining: Concepts and Techniques, 3rd ed.; Morgan Kaufmann: Waltham, MA, USA, 2011. [Google Scholar]

- Dasu, T.; Johnson, T. Exploratory Data Mining and Data Cleaning; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Pyle, D. Data Preparation for Data Mining; Morgan Kaufmann: Waltham, MA, USA, 1999. [Google Scholar]

- Fernández-Feal, M.; Fernández-Feal, M.; Sánchez-Fernández, L.; Pérez-Prado, J. Study of Metal Concentration in Lubricating Oil with Predictive Purposes. Curr. J. Appl. Sci. Technol. 2018, 27, 1–12. [Google Scholar] [CrossRef]

- Mathura, S. Lubrication Degradation Mechanisms; CRC Press eBooks: Boca Raton, FL, USA, 2020. [Google Scholar] [CrossRef]

- La Battaglia, V.; Mussi, V.; Marini, S.; Giorgetti, A. Investigation of Damage Caused by Chlorine-Contaminated Fuel in Standard Vehicle Components. Eng. Proc. 2025, 85, 8. [Google Scholar] [CrossRef]

- Shi, J.; Han, C.; Chen, L.; Jin, W. Investigating wear-induced health-instability dynamics in spur gear systems with installation error. Nonlinear Dyn. 2025, 1–22. [Google Scholar] [CrossRef]

- Mao, Y.; Tong, J.; Chin, Z.Y.; Borghesani, P.; Peng, Z. Transmission-error- and vibration-based condition monitoring of gear wear with contaminated lubricant. Wear 2023, 523, 204760. [Google Scholar] [CrossRef]

- Wang, Z.; Xue, X.; Yin, H.; Jiang, Z.; Li, Y. Research Progress on Monitoring and Separating Suspension Particles for Lubricating Oil. Complexity 2018, 2018, 9356451. [Google Scholar] [CrossRef]

- Sondhiya, O.P.; Gupta, A.K. Wear Debris Analysis of Automotive Engine Lubricating Oil Using by Ferrography. Int. J. Eng. Innov. Technol. 2012, 2, 46–47. [Google Scholar]

- Jaech, A.; Kalai, A.; Lerer, A.; Richardson, A.; El-Kishky, A.; Low, A.; Helyar, A.; Madry, A.; Beutel, A.; Carney, A. Openai o1 system card. arXiv 2024, arXiv:2412.16720. [Google Scholar] [CrossRef]

- Jegham, N.; Abdelatti, M.; Hendawi, A. Visual Reasoning Evaluation of Grok, Deepseek Janus, Gemini, Qwen, Mistral, and ChatGPT. arXiv 2025, arXiv:2502.16428. [Google Scholar] [CrossRef]

- Bagnato, S.; Boccagni, C.; Bonavita, J. Assessing the Accuracy of ChatGPT in Answering Questions About Prolonged Disorders of Consciousness. Brain Sci. 2025, 15, 392. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, Z.; Langrené, N.; Zhu, S. Unleashing the Potential of Prompt Engineering for Large Language Models. Patterns 2025, 6, 101260. [Google Scholar] [CrossRef]

- Ye, Q.; Axmed, M.; Pryzant, R.; Khani, F. Prompt Engineering A Prompt Engineer. arXiv 2023, arXiv:2311.05661. [Google Scholar] [CrossRef]

- Oppenlaender, J.; Linder, R.; Silvennoinen, J. Prompting AI Art: An Investigation into the Creative Skill of Prompt Engineering. Int. J. Hum.-Comput. Interact. 2024, 1–23. [Google Scholar] [CrossRef]

| Scale | Synthetical Meaning | Class |

|---|---|---|

| 0 | The comment provided may lead to a misdiagnosis. | 1—Unusable and misleading. |

| 1-2-3 | The comment may lead to a partially wrong diagnosis (e.g., incorrect processing limits). | 2—Comment not usable. |

| 4-5-6 | The comment provided is consistent with the application but not exhaustive. | 3—Usable after revision. |

| 7-8-9 | The comment provided is comparable to the master provided. | 4—Usable as is. |

| Diagnoses # | AI Diagnosis | Master Diagnosis |

|---|---|---|

| 1 | The presence of ferromagnetic particulates (FeC) and spectrometric particulates (Fe and Cu) above threshold 1 but below threshold 2. It is recommended to continue sampling to monitor the trend. | Evidence of iron and ferromagnetic particulates. |

| 2 | Viscosity is acceptable for the specified grade. The presence of an abnormal additive compared to the new lubricant, and possible contamination with other lubricants. It is recommended to continue sampling to monitor the trend. | Viscosity is acceptable for the specified grade. |

| 3 | The sample has levels of magnesium, boron and barium compared to the reference lubricant, suggesting possible contamination with other lubricant or additive. In addition, sodium and vanadium values indicate potential counts. We recommend to check that the lubricant used is the one specified. | The fluid is probably contaminated with other lubricant. |

| 4 | The sampling method is different to the standard indicated. This could affect the significance of the sample being analyzed. The presence of ferromagnetic particles and wear metals above threshold 1 but below threshold 2 indicate the abnormal wear of the internal components. In addition, the high presence of additives such as magnesium and boron suggests possible contamination or mixing with other lubricant. It is recommended to check the lubricant used, check the condition of internal components and monitor the trend of metals in subsequent analyses. Additional analysis: FT-IR, Karl–Fischer, or analytical microscopy. | The sampling methods are different to the standard indicated. This could affect the significance of the sample being analyzed. The presence of ferrous and ferromagnetic spectrometric particulates is evident. The fluid is probably contaminated by other lubricant. Viscosity is acceptable for the specified grade. It is recommended to continue sampling to monitor the trend. Additional analysis: Karl–Fischer or analytical microscopy. |

| Diagnoses ID | Score | |||

|---|---|---|---|---|

| Section Wear | Section Lubricant | Section Contamination | Sample Conditions and Final Evaluation | |

| 1 | 6 | 8 | 9 | 8 |

| 2 | 7 | 9 | 8 | 5 |

| 3 | 7 | 7 | 7 | 6 |

| 4 | 8 | 6 | 7 | 5 |

| 5 | 7 | 8 | 6 | 7 |

| 6 | 2 | 2 | 5 | 2 |

| 7 | 8 | 6 | 7 | 8 |

| 8 | 7 | 7 | 6 | 6 |

| 9 | 8 | 9 | 7 | 8 |

| 10 | 9 | 8 | 9 | 7 |

| 11 | 6 | 7 | 8 | 7 |

| 12 | 8 | 6 | 6 | 8 |

| 13 | 8 | 7 | 6 | 8 |

| 14 | 6 | 7 | 7 | 8 |

| 15 | 9 | 8 | 8 | 8 |

| 16 | 8 | 8 | 8 | 7 |

| 17 | 8 | 8 | 8 | 7 |

| 18 | 8 | 8 | 8 | 7 |

| 19 | 8 | 8 | 5 | 5 |

| 20 | 5 | 8 | 5 | 8 |

| 21 | 6 | 6 | 6 | 6 |

| 22 | 8 | 9 | 9 | 8 |

| 23 | 8 | 8 | 9 | 8 |

| 24 | 8 | 8 | 3 | 3 |

| 25 | 8 | 8 | 8 | 8 |

| 26 | 8 | 8 | 8 | 5 |

| 27 | 8 | 8 | 6 | 8 |

| 28 | 8 | 8 | 9 | 8 |

| 29 | 8 | 8 | 8 | 6 |

| 30 | 3 | 5 | 3 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rigolli, D.; Pompei, L.; Manfredini, M.; Vignoli, M.; La Battaglia, V.; Giorgetti, A. The Development of a Predictive Maintenance System for Gearboxes Through a Statistical Diagnostic Analysis of Lubricating Oil and Artificial Intelligence. Machines 2025, 13, 693. https://doi.org/10.3390/machines13080693

Rigolli D, Pompei L, Manfredini M, Vignoli M, La Battaglia V, Giorgetti A. The Development of a Predictive Maintenance System for Gearboxes Through a Statistical Diagnostic Analysis of Lubricating Oil and Artificial Intelligence. Machines. 2025; 13(8):693. https://doi.org/10.3390/machines13080693

Chicago/Turabian StyleRigolli, Diego, Lorenzo Pompei, Massimo Manfredini, Massimiliano Vignoli, Vincenzo La Battaglia, and Alessandro Giorgetti. 2025. "The Development of a Predictive Maintenance System for Gearboxes Through a Statistical Diagnostic Analysis of Lubricating Oil and Artificial Intelligence" Machines 13, no. 8: 693. https://doi.org/10.3390/machines13080693

APA StyleRigolli, D., Pompei, L., Manfredini, M., Vignoli, M., La Battaglia, V., & Giorgetti, A. (2025). The Development of a Predictive Maintenance System for Gearboxes Through a Statistical Diagnostic Analysis of Lubricating Oil and Artificial Intelligence. Machines, 13(8), 693. https://doi.org/10.3390/machines13080693