1. Introduction

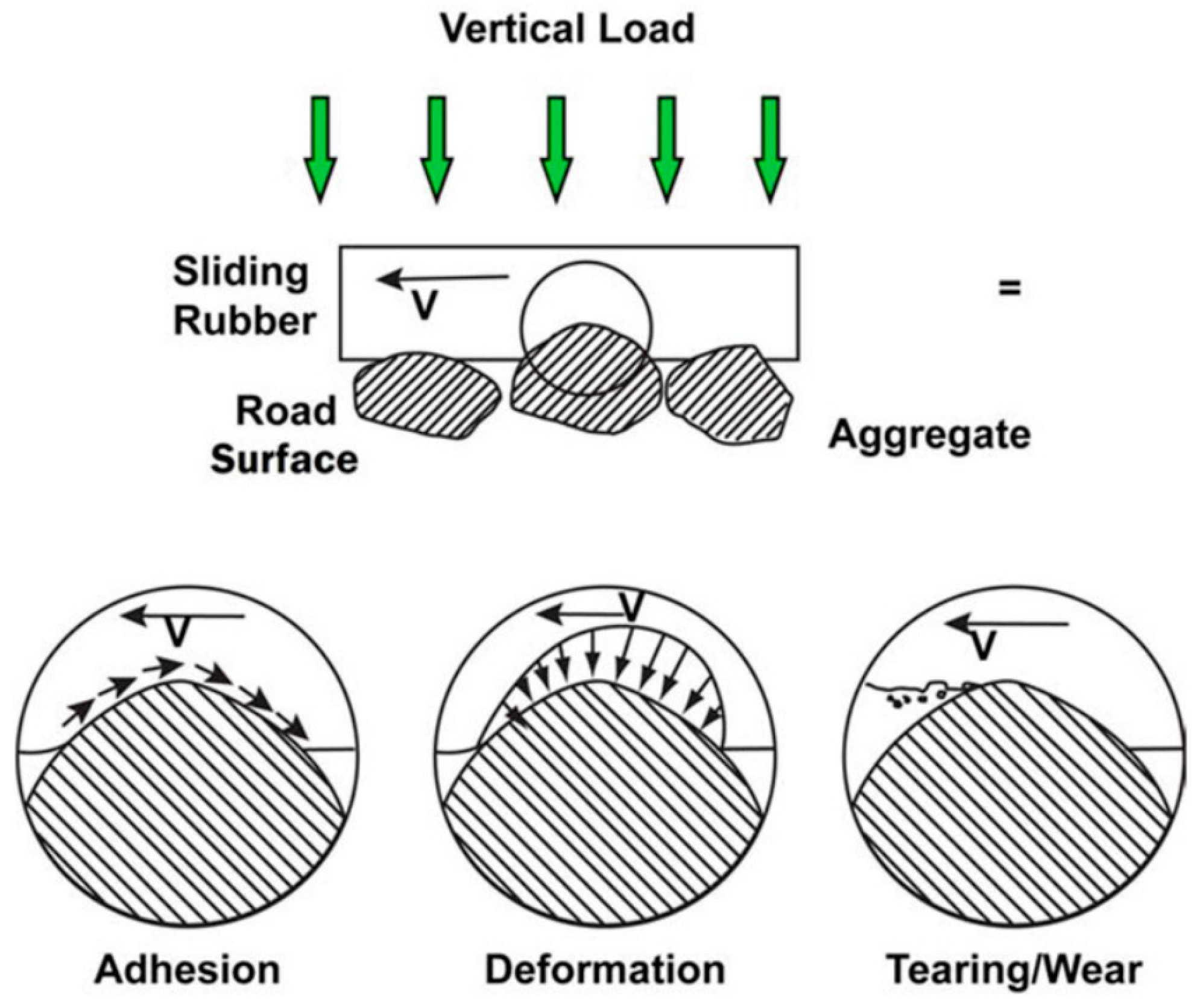

The tire rubber wear phenomenon is defined as the result of energy dissipation into friction. Energy dissipation is largely characterized by tire adhesion and hysteresis. In general, there are three components to rubber friction: adhesion, deformation, and abrasion, as in

Figure 1 [

1]. Adhesion is present when two sliding surfaces slide on one another with some pressure. Hysteresis, on the other hand, is a material characteristic that defines the response of a deformed subject returning to its normal state from compression or expansion [

2,

3]. For viscoelastic tire materials, the hysteresis wear occurs from the material being penetrated by the asperities of the road onto the tire, whilst developing high and low deformation areas. When the tire slides at any point over a surface in this fashion, the rubber creates a pressure hysteresis in the tire. This is generally a mild type of wear; however, depending on the material and material-dependent properties like temperature, the process can be exponential.

Experimental-based methodologies to estimate tire wear involve quantitative measuring tools such as sensor data. The data is then used to relate to tire-road frictional data to estimate a wear model. Khaleghian et al. [

4] describe the experimental approach in three steps: obtaining wear-related parameters, correlating the data through wear-related formulations, and estimating the tire wear.

In 2002, Grosch [

5] developed an abrasion testing machine for empirical tire wear simulations. Grosch’s experimental procedure uses a sample piece of a tire attached to a mount that rolls over an abrasive disc. This machine is titled the Grosch machine, or the Laboratory Abrasion and Skid Tester (LAT) 100. In this test, the lateral force at a given slip angle is observed.

Simulated tire wear approaches are the analysis of tire wear using theoretical, mathematical, or computer-aided simulated models. DaSilva et al. [

6] used a similar approach of formulating wear with abrasion, like in Grosch’s work, but theoretically in the form of the bicycle model. This tire wear model was an estimation using only steady-state cornering maneuvers and a 2-degree-of-freedom bicycle model. In this model, any lateral load transfer was negligible, and no tire suspension characteristics were considered. Additionally, the model is only valid for low lateral accelerations.

In 2011, Chang et al. [

7] developed a Finite Element Analysis (FEA) tire wear model with a programmed subroutine using the Archard wear model. This model was a simple sliding abrasion relationship between two surfaces. This study analyzed the wear using Archard’s wear model under straight free rolling and driven conditions and estimated tire wear as a function of mass and depth. In 2014, Zang et al. [

8] combined FEA tire wear testing and neural network tools to estimate tire wear. In this study, an FEA tire model using the Neo-Hookean tread material equipped with constant shear and unconditional stability is used in several varying simulations. This analysis looks at a particular material type, and the neural network is trained for input variables of inflation pressure, speed, load, and different vibrational frequencies of the tire. In 2017, Wu et al. [

9] researched a semi-empirical model of wear using FEA and the LAT100 wear test machine. This model uses the LAT100 with a rubber specimen, but simulates a rolling tire on a wheel within FEA. This study showed that the wear rate is exponential to the friction energy rate. In similar studies, it was also noticed in tire wear simulation that footprint frictional energy dissipation is the main cause of tire wear [

10,

11]. In 2013, Dumitriu et al. [

12] worked on an FEA friction model using Coulomb’s law, which yielded results that agreed with experimental data. Konde et al. [

13] did similar research for an aircraft tire, also using Coulomb’s law, which yielded agreeable results with experiments. In 2015, Alroqi et al. [

14] developed a tire model that uses a mass-spring-damper system to measure vertical loads for a tire wear model. This model also implemented Archard’s wear theory depending on tire normal load, hardness and slip ratio. This model uses a generic load model alongside a simplified wear model for a tire that is mostly locked and sliding on asphalt. In 2021, Hartung et al. [

15] developed a tire wear model on the block level. This study looked at the tire wear of a portioned block of tire rubber pressed and sliding over a track. This model also used Archard’s wear theory to simulate the tire block wear using Coulomb’s law. In 2022, Li et al. [

16] developed a finite element tire model capable of simulating tire wear using Archard’s wear theory. This tire was limited in validation as it was only statically tested against experimental results. The wear simulation implementation also lacks temperature and hardness modeling using constant values from varying literature. In 2023, Zhang et al. [

17] did similar research, developing a tire wear model using finite element models, studying the impact of cornering. However, similar limitations were seen with temperature, material hardness, and overall tire validation against experimental results.

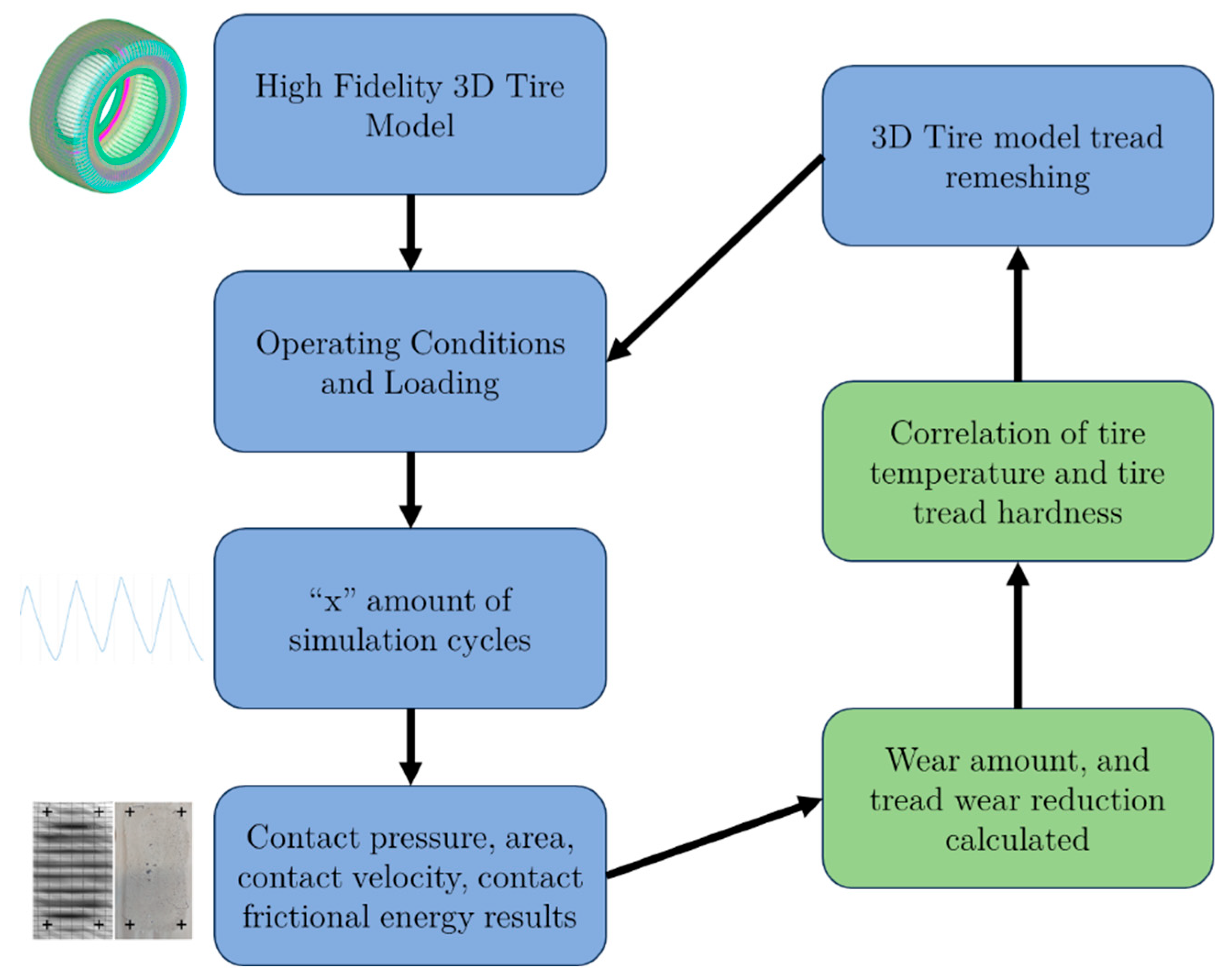

This study aims to advance the work in tire wear modeling by developing a wear model process using the finite element method and MATLAB R2025a. The model incorporates a high-fidelity tire model that was comprehensively validated against experimental results. This should yield a highly accurate friction dissipation energy rate at its contact patch within the simulation. Following this, a modified Archard’s wear theory is used, incorporating a temperature-dependent hardness model and a velocity-dependent friction model. By utilizing in-house tire modeling, material testing, and custom tire wear testing, an agreeable wear test method is proposed. This research provides insight into the clear gaps in the current body of literature for tire wear simulation. The novel wear model presented in this research uses a highly validated tire model in both static and dynamic domains. Also, the tire wear model incorporates a tread hardness-temperature correlation for dynamic tire maneuvering. The model simulates the tread wear for a dynamic rolling tire through acceleration and deceleration procedures and is validated against controlled experimental tests. The insights provided from this body of work will contribute to the understanding of tire wear mechanics and support the development of tire wear measurement methods.

2. Experimental Testing

This section outlines the experimental setup for acquiring physical data on the R25B tire wear model. The dynamometer, vehicle setup, tire setup, specifications, and data acquisition are comprehensively presented.

2.1. Dynamometer and Vehicle Setup

The vehicle used in this study is the Formula Society of Automotive Engineers (FSAE) F22 Ontario Tech University (OTU) race car. The F22 is an all-electric race car that was custom-designed and built at OTU in Oshawa, Canada for FSAE competition. This vehicle is equipped with a 400 V battery pack, a 5.76 kWh capacity, and a max output power of 80 kW. The battery powers the EMRAX 208 High Voltage (HV) motor that has a peak torque rating of 150 Nm and a continuous torque rating of 90 Nm. This vehicle was chosen for this wear study as all information and data sets regarding the F22 are well documented, including some tire data. Furthermore, being an engineering development vehicle, it was additionally equipped with data acquisition tools to measure all aspects of vehicle performance. Additionally, the electric motor power delivery of the vehicle made it very capable of controlled and consistent tire tests.

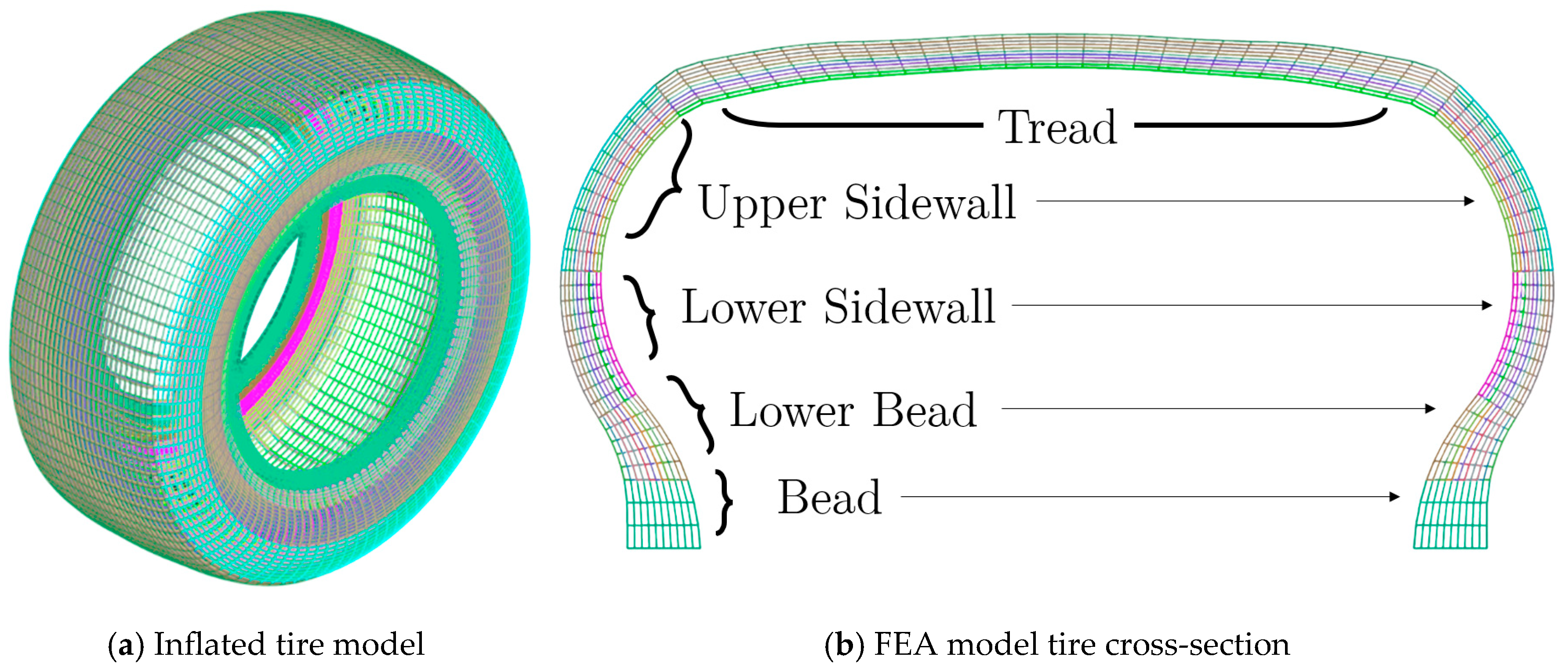

The 18.0X6.0-10 Hoosier R25B tires were set on 10-inch rims, and their tire data was available through the Calspan Corporation and FSAE Tire Test Consortium (TTC). Since the test was completed on a full vehicle setup, the acceleration data and tire wear data would prove useful for analysis on the vehicle’s actual dynamics for performance and future work.

Before wear testing, the vehicle needed to be mechanically conditioned and set up for the required experiments. The vehicle and wheel setup were calibrated for weight and alignment as seen in

Figure 2. This was required for high-accuracy measurements for pretest measurements, post-test measurements, and the creation of virtual sensors. The alignment process consisted of using a rigid fixture referenced from the chassis of the vehicle to 4 datum points outside the perimeter of the wheels and centered at the wheel center. Using a string to link each of the datums on each side of the vehicle, a measurement can be taken at the fore and aft points on each of the wheel rims about its center. Using these measurements, the toe angle of each wheel could be adjusted and set. The corner weights were set using precision scales on each wheel, placed on pads leveled to the floor. By adjusting the pre-load on the springs and the push rods, the ride height and corner weights were set to the desired target for testing.

Once this was completed, the vehicle was ready to be strapped onto the dynamometer. The dynamometer used was a Mustang MD-AWD-500 series chassis dynamometer. This dynamometer is used for a vast variety of vehicle testing, including tire testing. The system is capable of handling AWD drive systems, but for this test, it was used in single axle mode. The rear wheels were placed onto the single-axle dynamometer steel drum. The steel drum was manufactured with a knurled pattern to maintain grip. The drum was also painted yellow, whose importance will be discussed later in the

Section 4.

The Mustang MD-AWD-500 series chassis dyno uses an internal drive system. It can achieve a max horsepower (hp) of 3000 hp and a max absorption of 1800 hp. The MD-AWD-500 is equipped with an air-cooled eddy current power absorber (MDK-250) loading device and uses a closed-loop strain gauge dynamic load cell for torque measurements. It is rated for 2000 lbs. of inertia in the 2-wheel drive mode and 3625 lbs. in the all-wheel drive mode. The knurled steel drum is precision-machined and dynamically balanced. The dimensions are 370.675 mm in diameter, with a face length of 939 mm, inner track width of 609 mm, and outer track width of 2489.20 mm.

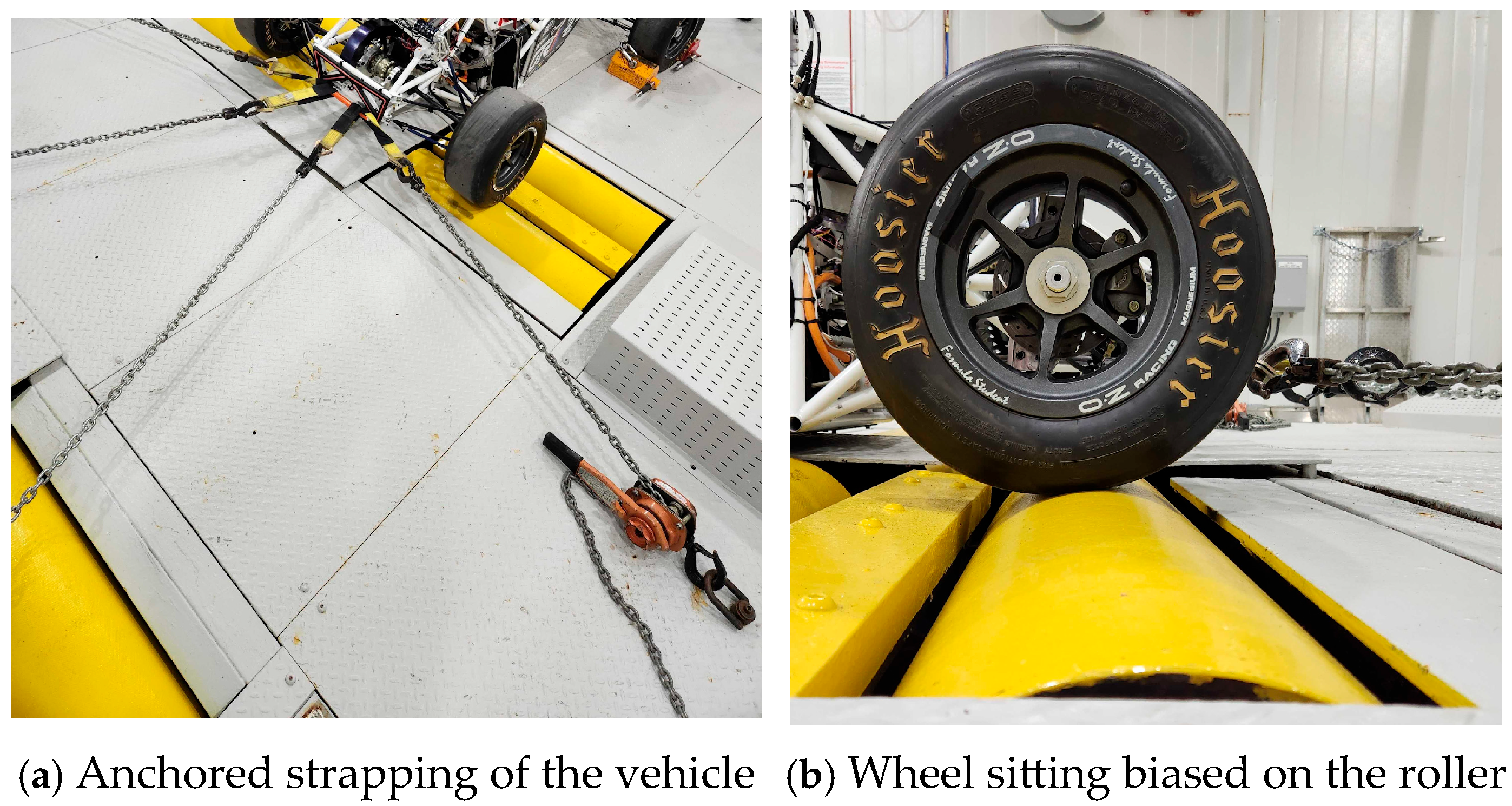

The vehicle was strapped to the dyno in six opposite directions, all pulling from the unsprung mass. The vehicle was set up so that the rear wheels were biased on the front face of the rollers so the vehicle would roll off and away from the rollers in an unsafe event, as seen in

Figure 3a,b.

To operate the vehicle, the signals that were otherwise coming from the analog sensors of the driver interface, a bypass were bypassed through a Controller Area Network (CAN) communication. The CAN communication was fed to the motor’s inverter for standardized throttle input profile requests. All operators were placed at a safe distance from the vehicle using this remote setup. Other safety items were also in place, such as an e-stop used to shut down the HV interlock and remove the tractive system voltage from the surrounding environment. To apply a constant road load, the MD-AWD-500 user interface was used to throttle the resistance of the dyno drum. To finish up setting the vehicle on the dyno, a strap loading was used to apply a controlled vertical force on the tires.

Data acquisition was performed through a combination of the systems on the F22 and a separate apparatus used to measure tire slip. All data was collected through CAN communication and a CAN logger on board F22 from CSS Electronics. This allowed the ability to obtain data that was time synchronized, aiding in data validity and usability. Virtual sensors were any data that could be modeled by a combination of other real sensor data, vehicle known values, a mathematical model, and/or a physics model.

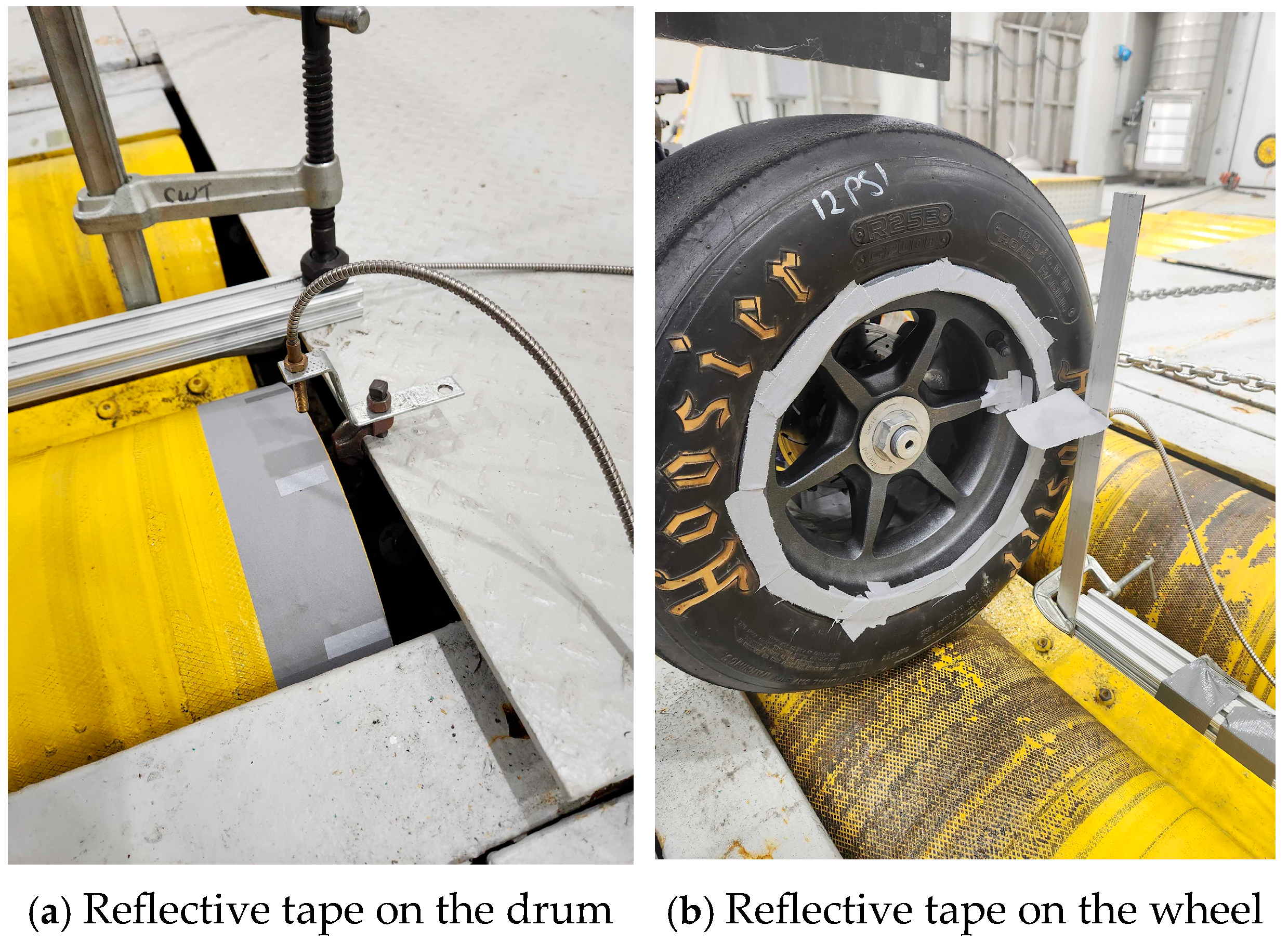

Most of the data related to tire forces were calculated using the outputs from the vehicle motor inverter. Using its calculated torque measurement, various tire parameters and forces would be displayed. The inverter was also able to provide motor speed, which can be used to calculate wheel speed. For additional measurements, the accurate speed of the road and wheel is required. To do this, a CSS digital to CAN module was used along with a reflective pulse sensor to calculate dynamometer drum speed and wheel speed, as in

Figure 4. Comparing these relative speeds can be used to determine the slip between the wheel and the road. This could then be used to determine the friction coefficient of the tire and road and monitor any excessive slip.

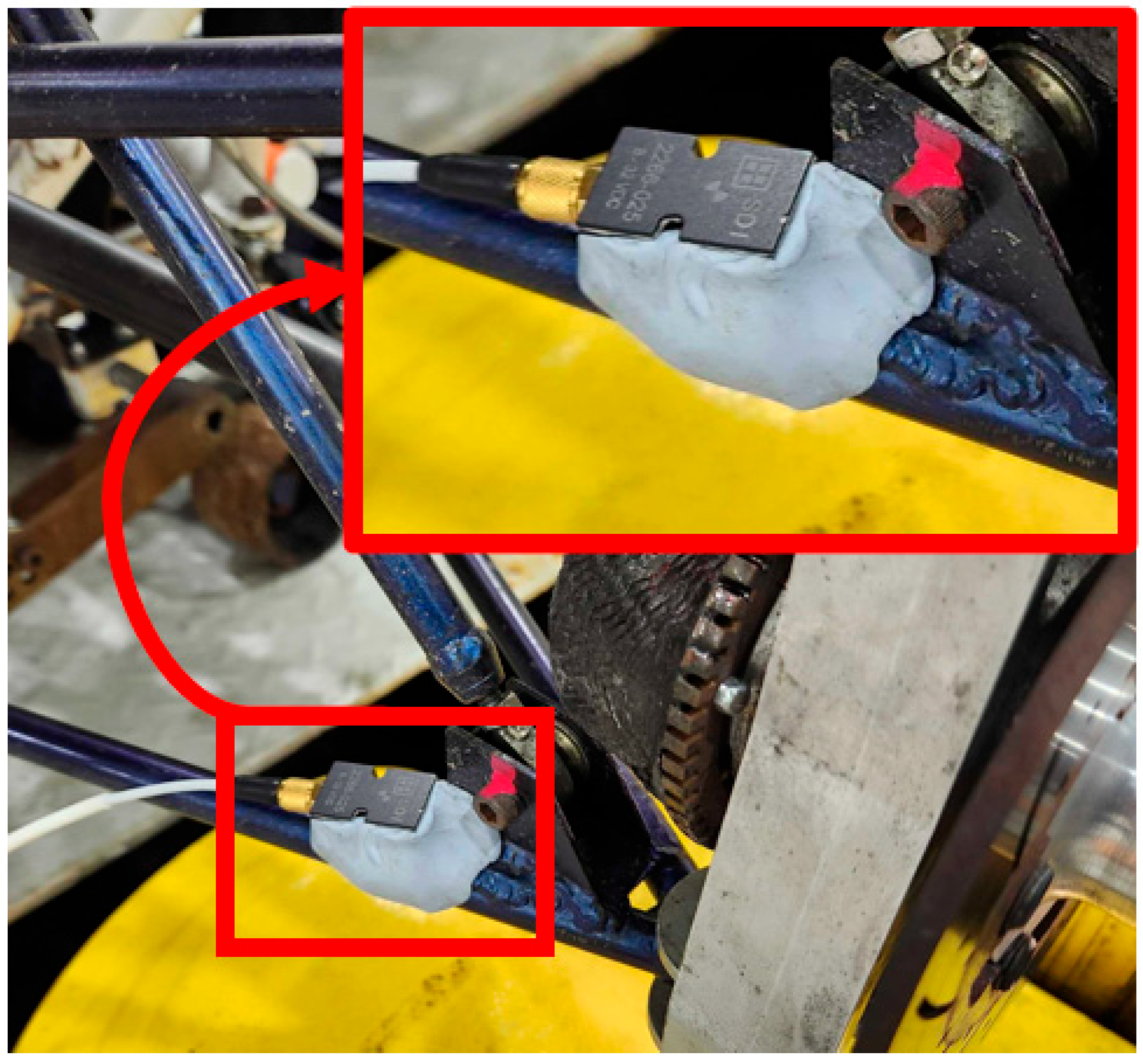

Vertical loading was a static measurement based on the pretest data, and then adding the additional force calculated via the suspension spring compression. Due to the vehicle not moving on a course, this was sufficient for data collection. Despite this, an accelerometer was also placed at the end of the control arm nearest to the upright and collected vibrational data. This allowed for compensation due to any additional forces introduced by any phenomena like wheel hop related to the kinematic characteristics of the suspension during acceleration, and any imbalance in the driveline. This can be seen in

Figure 5.

At the end of every test, the tire was weighed on a high-precision scale with an accuracy of 0.01 g to calculate the tire wear over time. Using a datum weight taken before the test, the amount of tire compound that was shed during testing could also be determined to calculate tire degradation. At the end of testing, the data were presented as a time series for post-processing in Excel and MATLAB R2025a.

2.2. Wear Experiment Setup

The wear experiment on the dynamometer consisted of three sets of acceleration-deceleration tests. Each test lasted 900 s (15 min), with a predefined testing profile. Between each 900-s set, the batteries were required to charge for approximately an hour. Each experimental Wear Test (WT) in this work will be noted as: Wear Test 1 (WT1), Wear Test 2 (WT2), and Wear Test 3 (WT3). Each wear test used the same testing profile, where one acceleration-deceleration cycle is completed in approximately 60 s. The torqued wheel speed of the tire on the dynamometer is recorded and used as input in the simulations to retain accuracy.

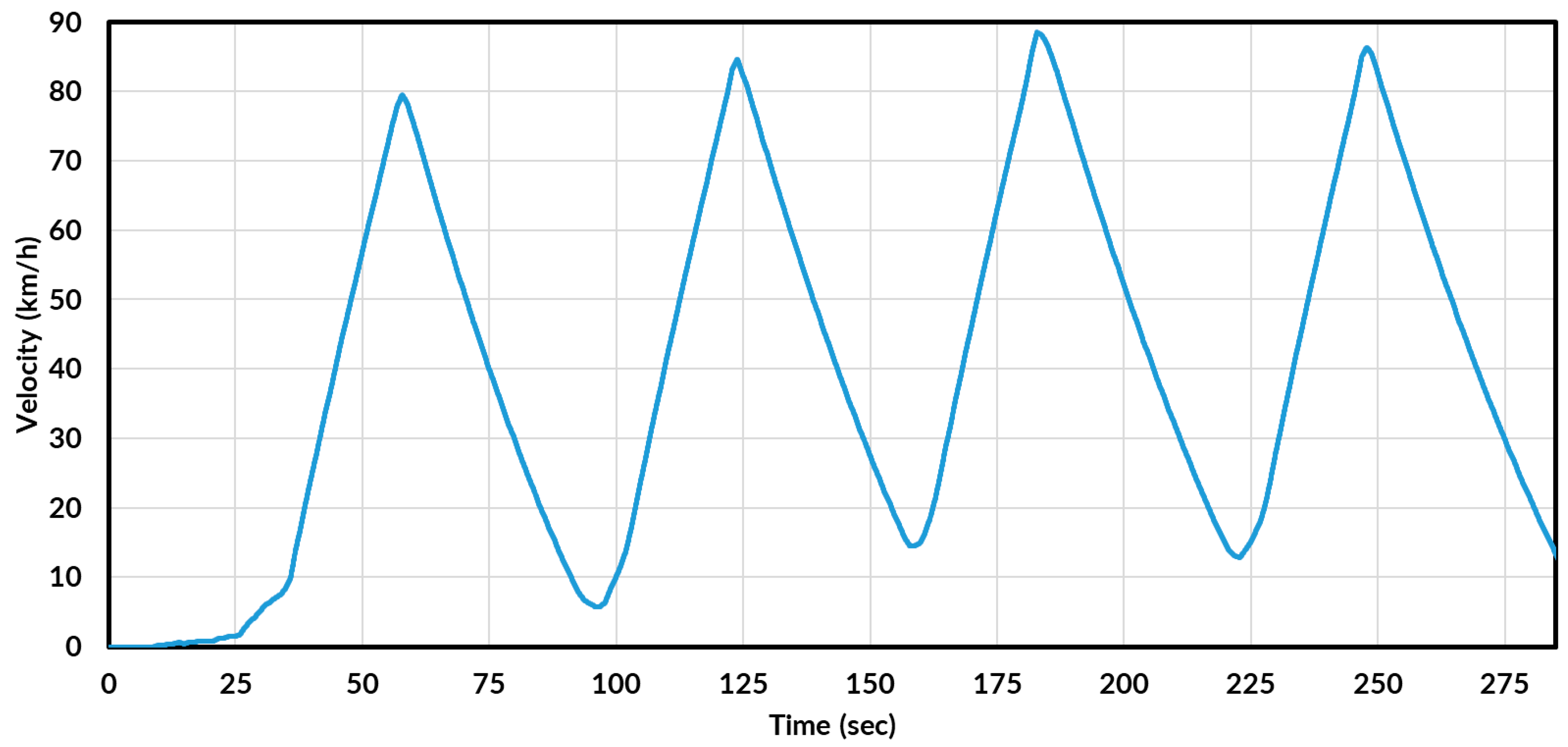

The strapped-down tire load on the dynamometer was measured to be 220 lbs., inflated to 12 psi, and was set up for 0-degree toe, slip angle and inclination angle. The tire was accelerated to approximately 85 km/h longitudinal velocity and decelerated to 15 km/h. This acceleration profile was a common acceleration profile for the FSAE vehicle and was also used to test the limitations of the battery onboard. The experimental velocity output for the WT tire can be seen in

Figure 6 for the first 300 s.

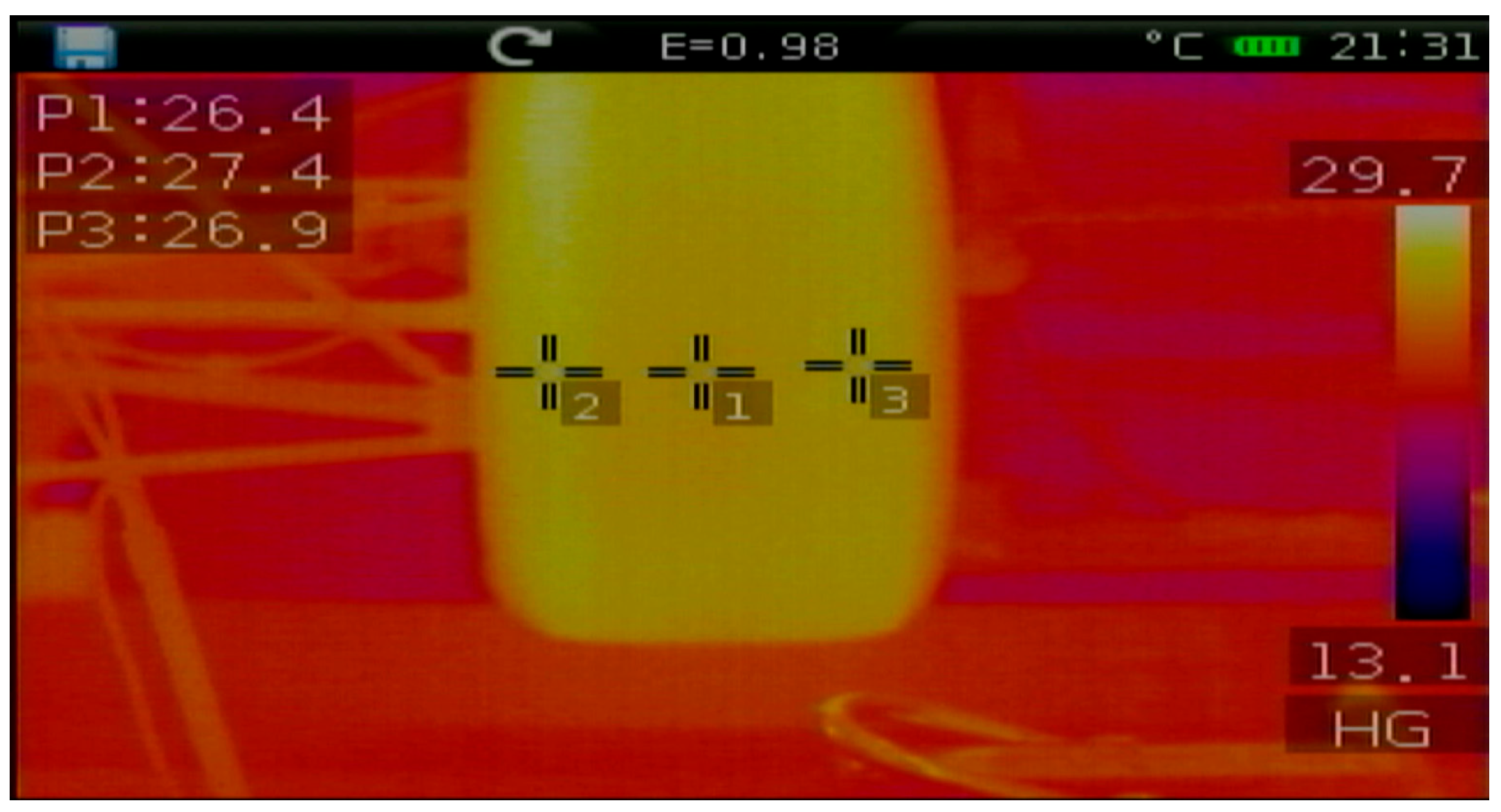

An infrared thermal camera was used to determine the tread temperature of the tire as it rotates on the dynamometer drum. Three measurements of the tire temperature along its width were recorded.

Figure 7 shows the tire thermal measurements in °C, where P1 indicates the central tread surface temperature, P2 indicates the inside tire temperature closest to the vehicle chassis, and P3 indicates the outermost tire surface temperature.

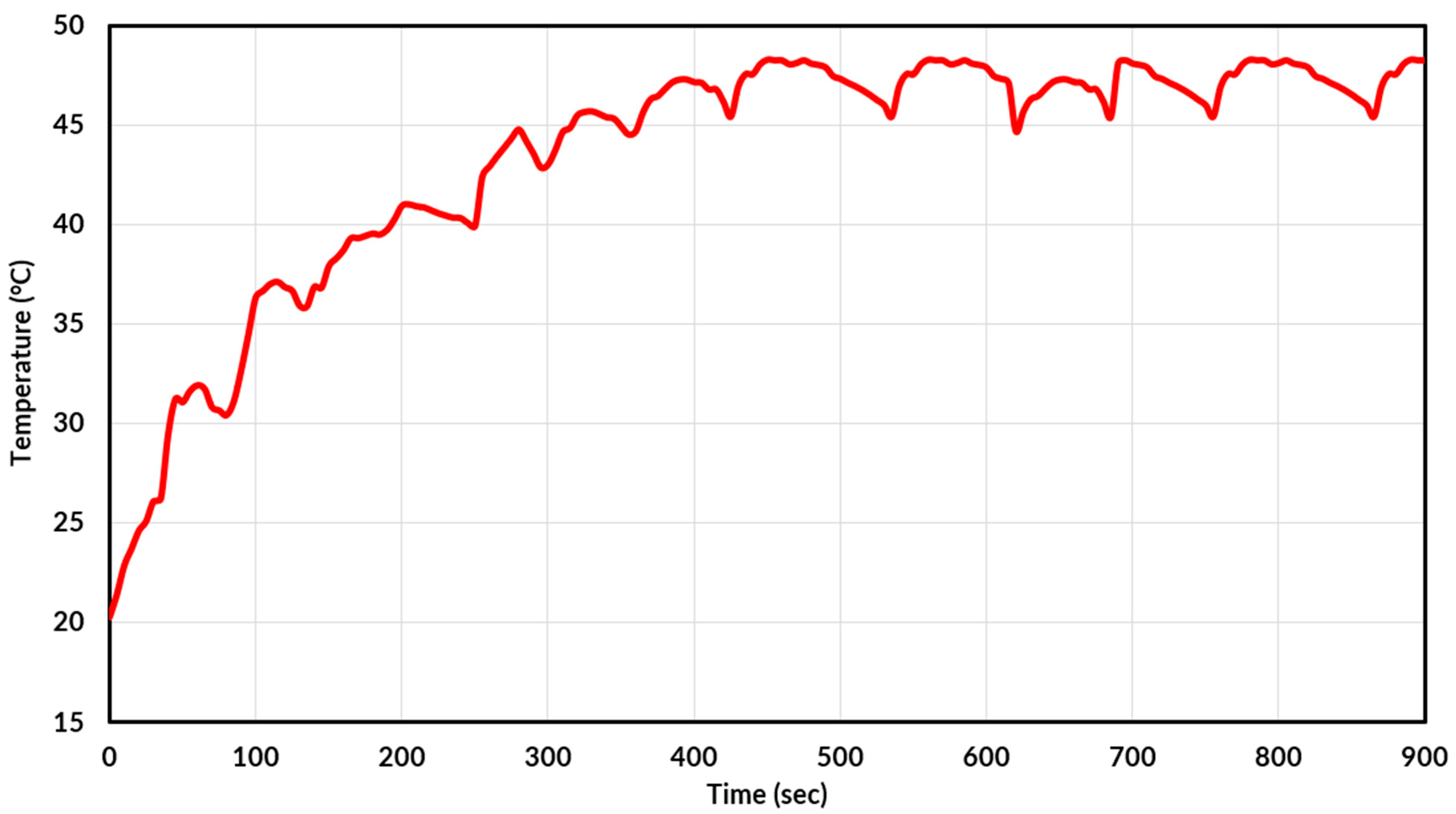

With these measurements, the tread temperature during the tire’s transient acceleration and deceleration loading can be measured. The average tire temperature, which was used for the tread-hardness correlation over time, can be seen in

Figure 8. The tread temperature can be seen to follow the velocity profile, where wheel speed and temperature increase together. However, after the first cycle, the temperature is seen to lag behind the wheel speed due to the viscoelastic behaviour of the tire, as also seen in the supporting literature [

18]. This is due to the heat in tires being generated from both internal hysteresis and friction at the contact patch. From this heat, the dissipation through conduction, convection, and radiation does not happen instantaneously, leading to temperature drag. At approximately 400 s into the WT runs, the temperature saturates at 51 °C. This temperature relationship is later used in correlation to a tread hardness model for the R25B tire.

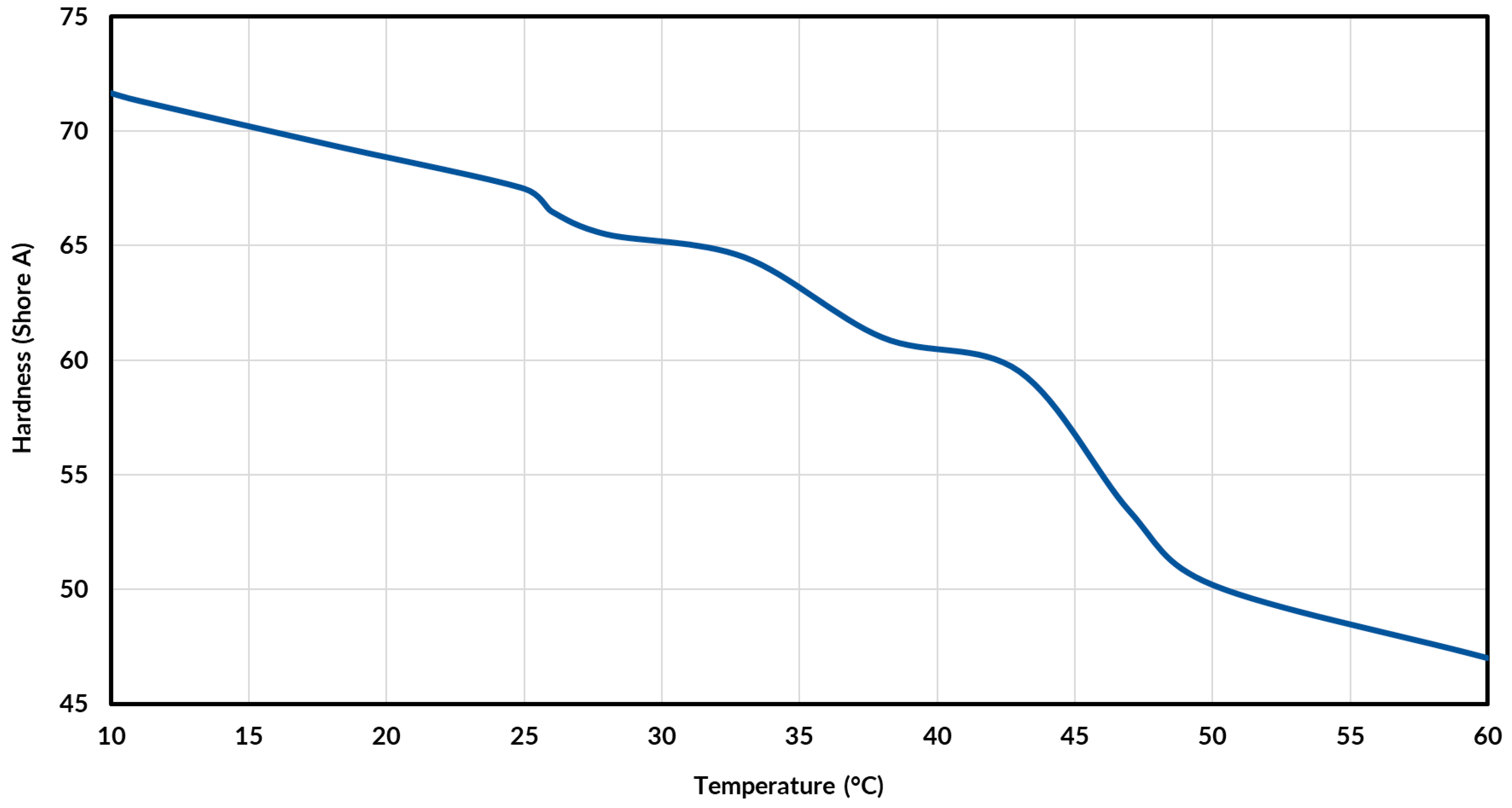

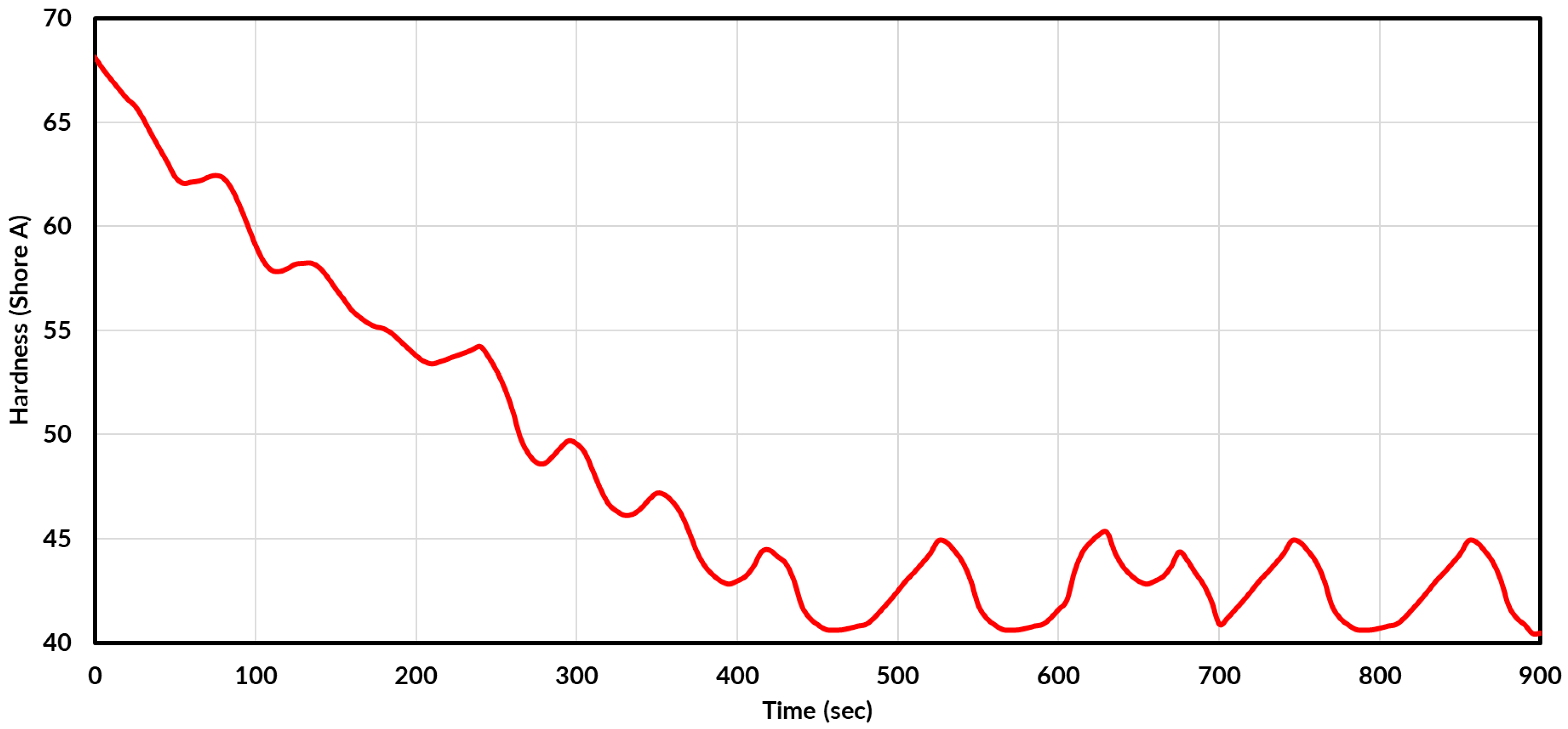

The Shore A hardness durometer was used to measure the hardness of the tread rubber at varying temperatures. The tire was placed into an AES ZBD-908 laboratory oven, heating the tread up to 60 °C. More specifically, the tire tread portion was evenly heated within the oven to closely replicate the tread surface temperature experienced in testing. As the tire cooled to 10 °C, the Shore A durometer was placed against the tire tread to determine its hardness as it cooled. The Shore A hardness can be seen to decrease non-linearly as temperature increases in

Figure 9. As tire temperature increases, the tread rubber becomes soft and pliable, hence the decrease in hardness. The same trend for tire rubber can be seen in the literature [

19].

When combining the temperature readings of the tire in

Figure 8 and the hardness relationship in

Figure 9, the tire’s hardness relative to time and, therefore, velocity can be determined. This is shown in

Figure 10, where the hardness of the tread decreases with the WTs acceleration-declaration cycles over time. The hardness can be seen to decrease non-linearly over time, in similar oscillations to those of

Figure 8. Then the hardness saturates at approximately 42 Shore A, as temperature saturates at 51 °C. These trends are expected, as the hardness relationship is dependent on the temperature relationship and therefore shares similar oscillations and patterns. This hardness model is then used later in the wear model discussed in the

Section 4.

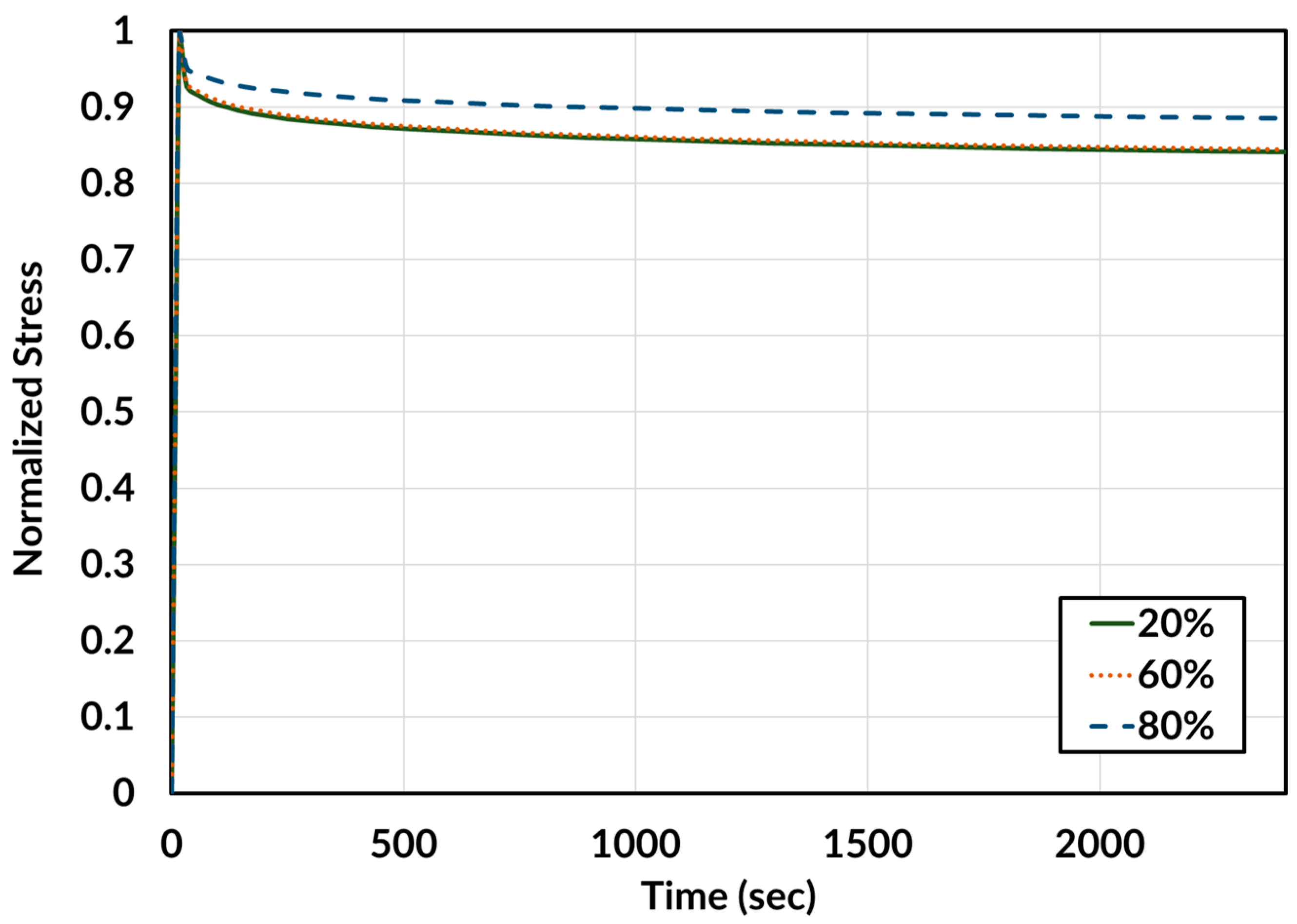

4. Simulation Results and Validation

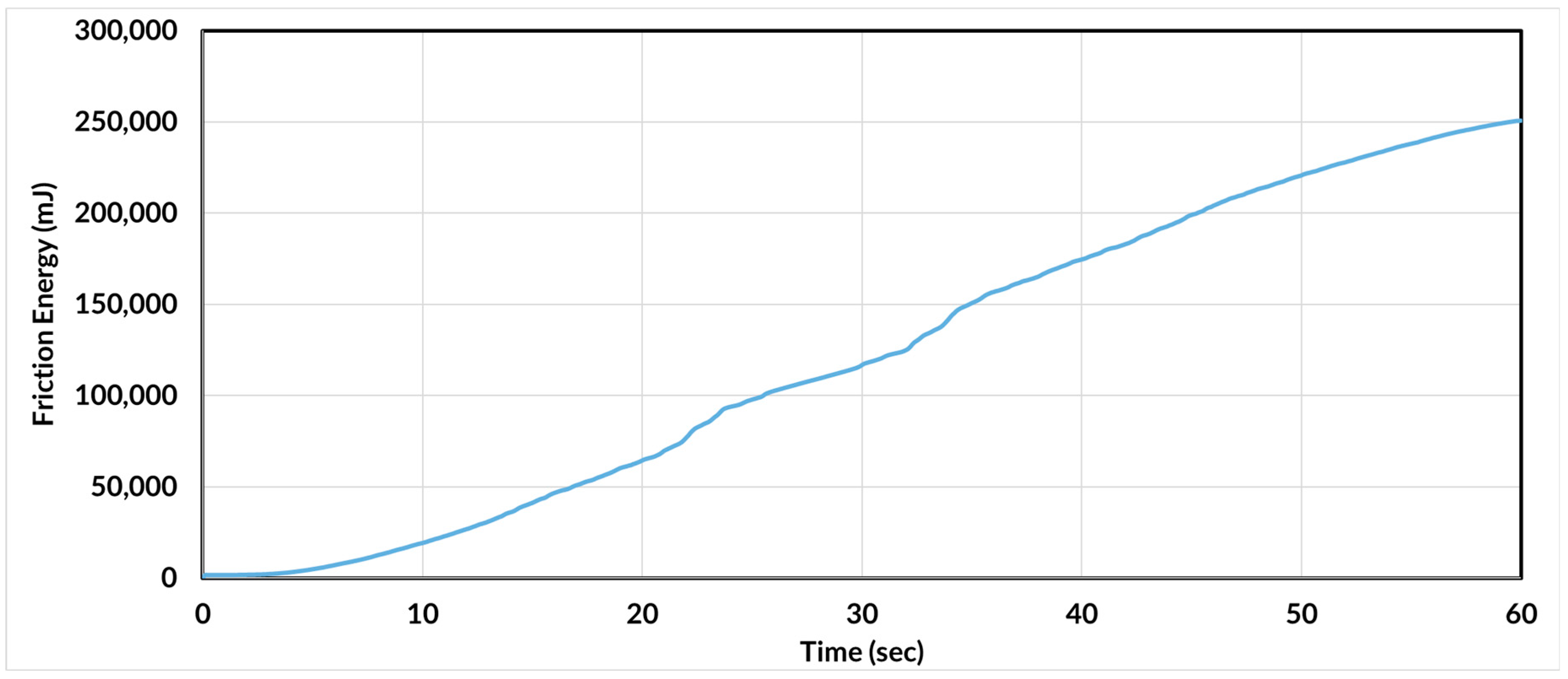

Generally, the friction energy dissipated at the tire contact can be seen to follow an exponential trend, as in

Figure 17. This shows the friction energy rate for the reference tire simulation model with no wear, hence a datum. The friction energy can be seen to increase slightly exponentially during acceleration up to 30 s. As the tire decelerates, the friction energy continues to increase; however, it saturates at the 30 s mark, and saturates further near the end of deceleration at 60 s.

To replicate the tire wear from experiments, 12 wear reductions in the tire tread were simulated according to the implemented wear process. The simulated tire in each wear step lasted for 180 s to 225 s, depending on wear rate. Each wear step reduced the radius by approximately 0.001 mm, corresponding to a volume reduction of approximately 250 mm

3 each step. This was found to produce a wear model that was more than sufficient to accurately capture the wear of this model. However, it should be noted that more aggressive and instantaneous tire wear will require more wear steps to accurately capture the mass loss phenomena. Each wear step is a reduction of approximately 0.001 mm for the outer tread layer within the FEA tire model. In terms of volumetric losses, outer tread elemental volume is clearly presented in

Table 2. For clarity, as aforementioned, the ablation is dependent on the friction energy dissipation, tread hardness and speed. Additional considerations for ablation are the nodes connecting the sidewall to the central tread portion. When reducing the tread layer, the connecting nodes and consequent elements are affected towards the sidewall.

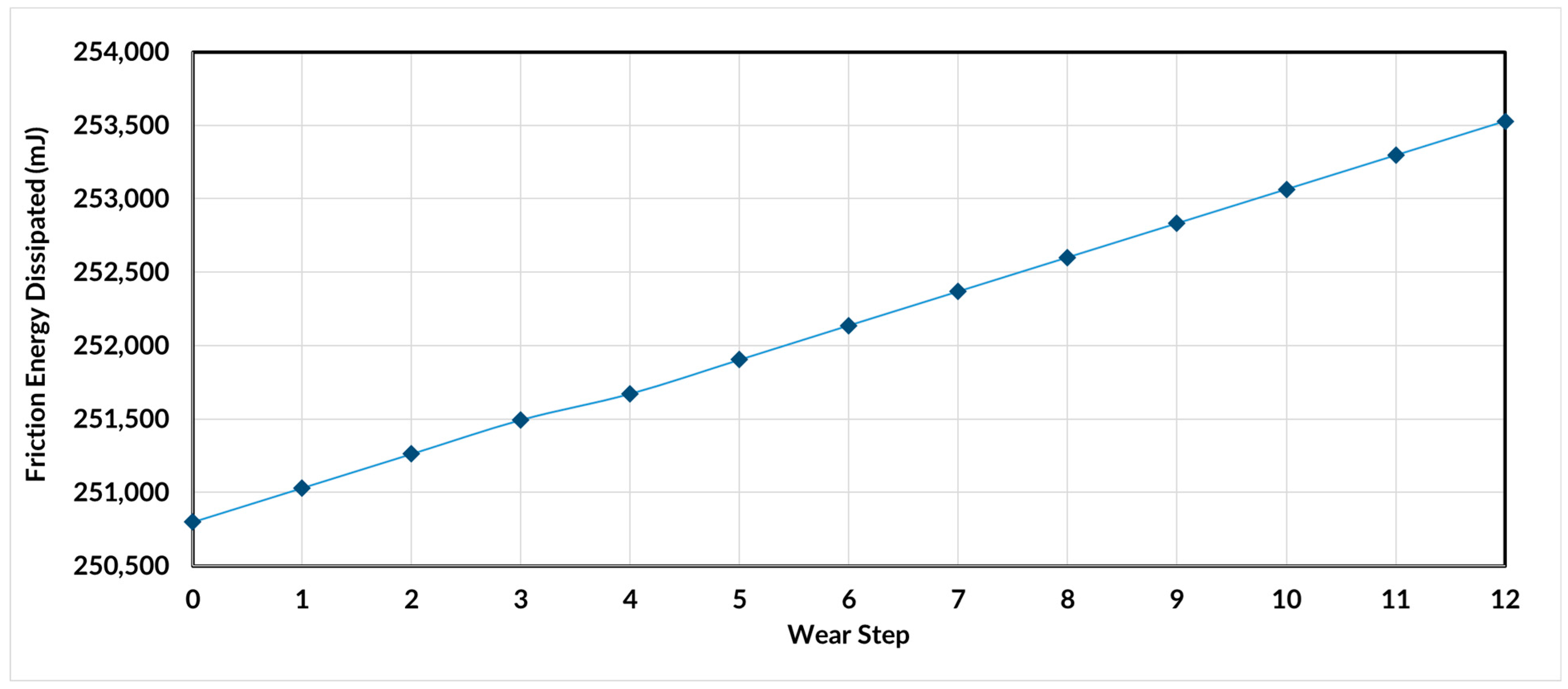

Figure 18 presents the friction energy dissipation difference of the datum or reference tire model with each worn tire model, denoted as ‘Step 1’, ‘Step 2’, and so on. When comparing the dissipated friction energy of different wear step tire models to the reference datum plane, wear step 12 shows the largest difference of 2728.031 mJ. For clarity, the difference between the reference energy rate and the step 1 model energy rate is minuscule, in that it is presented closest to 0 mJ. However, the reference energy rate is heavily different when the model reaches wear step 12, showing a difference of 2728.031 mJ at the end of a cycle. It is observed in simulation that each wear step tire model increases linearly in friction energy dissipation per cycle, with the exception of wear step 4. In step 4, the slightest of changes for the connecting nodes between the tread and sidewall altered the linearity of friction energy dissipation for a cycle. This is more clearly noticed in

Figure 19, where there is a very small dip in friction energy for the otherwise linear trend.

Figure 19 shows the friction energy for the span or an acceleration-deceleration cycle for every wear step model. This suggests that for the wear amount of the tire, the friction energy linearly increases with every wear step. The general pattern of this is as expected, due to the tire maintaining the same speed with a reduced tread, there will be a slight increase in rolling resistance for the wear occurring.

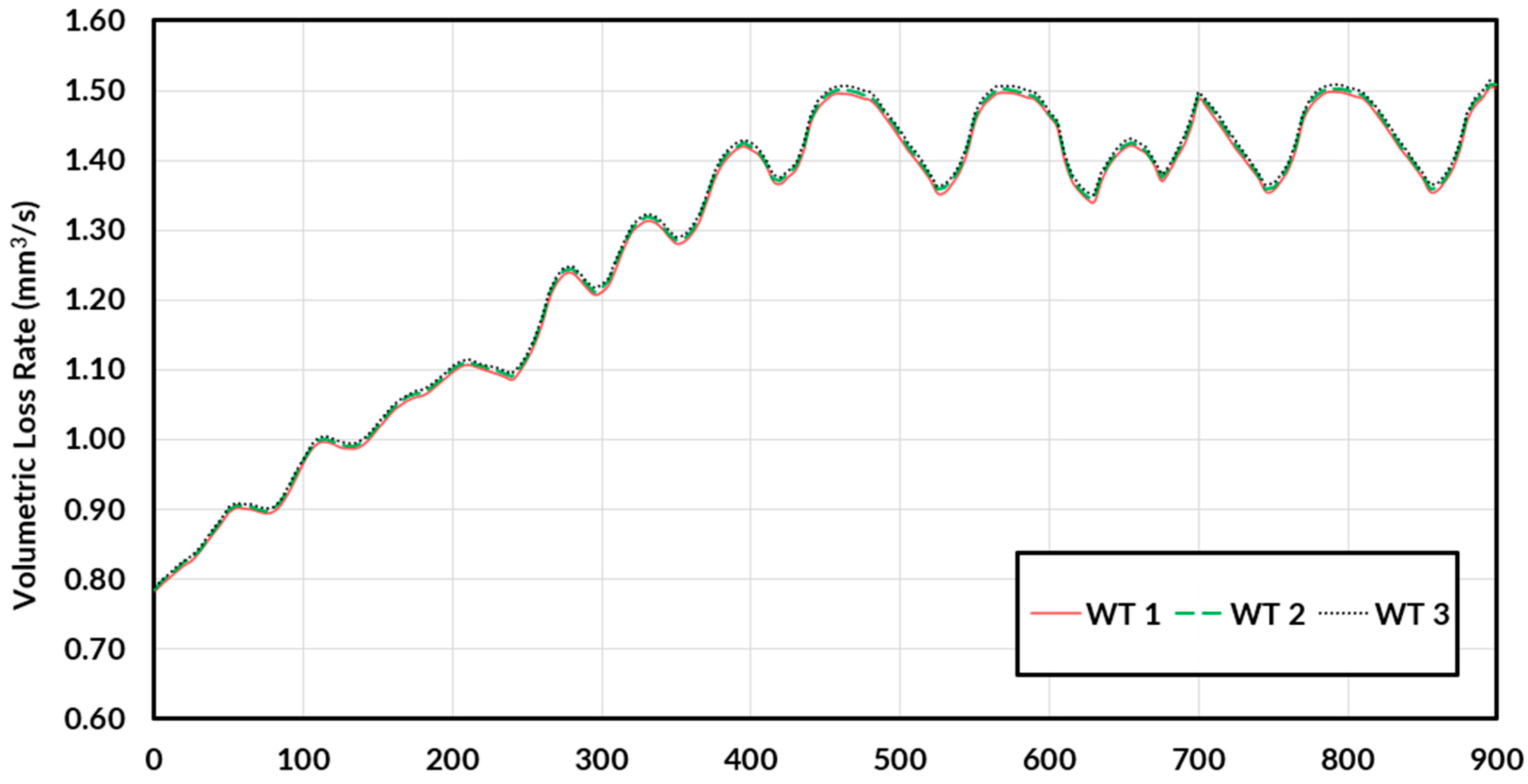

Using the modified Archard’s wear equation, the volumetric loss rate,

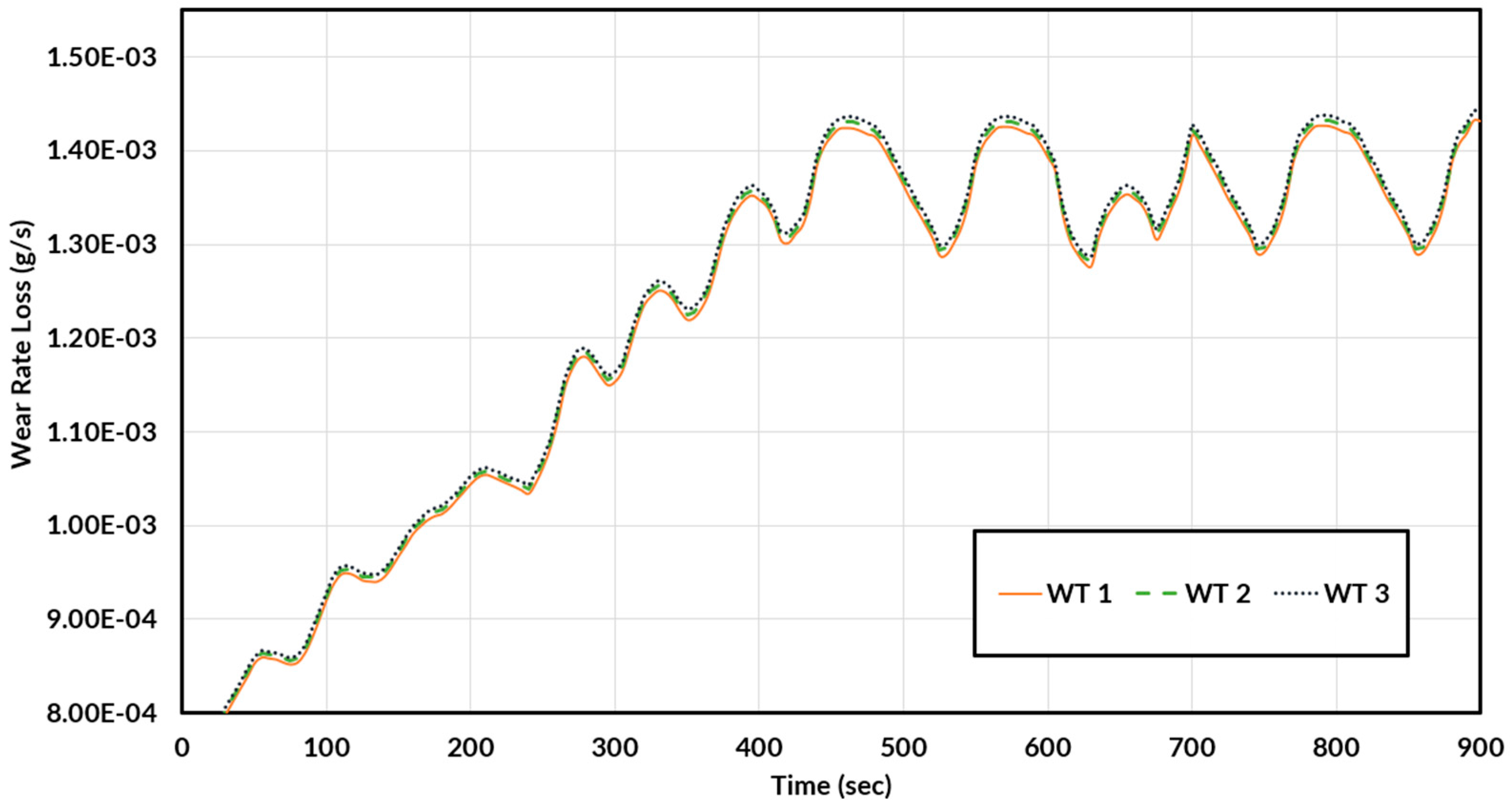

was determined for the full 900-s simulation as seen in

Figure 20. Each 900-s simulation can be seen through WT 1, WT 2, and WT 3 with their respective

values. WT 1 underwent 5 wear steps, WT2 and WT3 underwent 4 wear steps each, where each wear step varied the friction energy rate slightly. Due to Archard’s wear theory, the increasing friction energy rate yields a slightly higher volumetric loss rate as they are directly correlated. Therefore, while the

can be seen to be quite similar in linear regions, but it can also differ at its peaks after accelerating for varying WT. As the tire wore more over time, a higher

can be observed when comparing WT 1, WT 2 and WT 3. The difference was observed to be more prominent in later times for each wear step as the first 200 s showed very similar results between WTs. A major factor that determines the

is the tire’s thermal generation at the tread. The hardness value in the wear theory used was determined using a temperature-hardness correlation from

Figure 8 and

Figure 9. The temperature of the tread surface as determined by the experimental thermal measurements, can be seen to contribute to the general trend of

with time in an inverse relationship.

Figure 21 presents the tread wear rate loss between each WT. This is the result of the product between

and tread rubber density, 953,228.8 g/m

3. In post-processing for calculating

, a time step of 5 s was used. For every 5 s, a wear rate loss is determined as seen in

Figure 21. When taking the product of the instantaneous wear loss rate in its time span, the wear mass value can be predicted.

When looking at the actual tire wear mass over time from simulation as presented in

Figure 22, each WT shows a slight exponential increase of tire wear with time, heavily influenced by the temperature increase of the tire tread and slightly correlated by the difference in friction energy. Between the WTs, the differences at the beginning show negligible wear differences; however, the wear differences are more apparent after accumulating some temperature at the tread compound. Alike

, the wear mass difference can be seen to be more apparent later in the simulation. As it is difficult to show the variation between the simulated WTs, the total mass loss can be seen clearly in

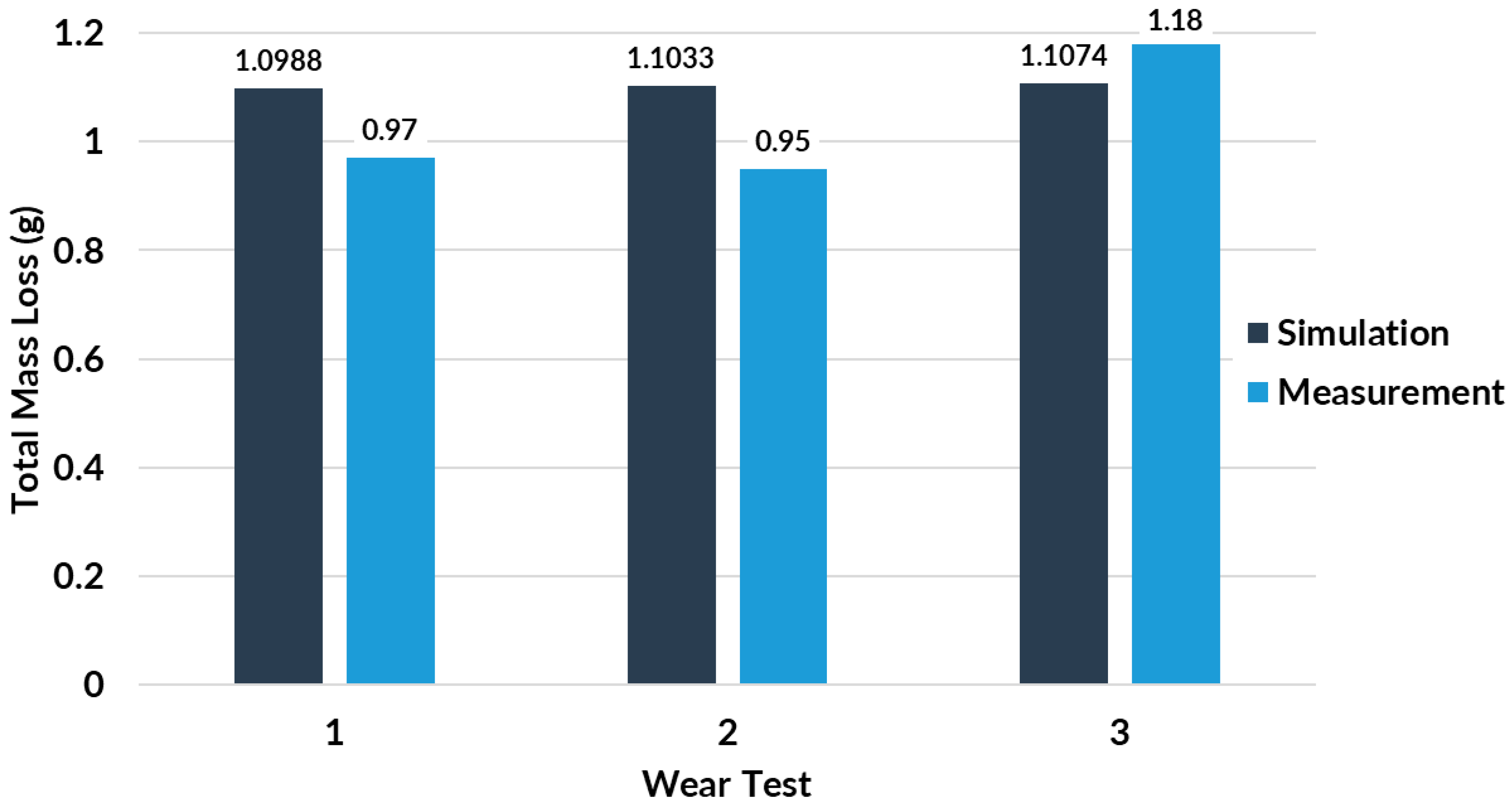

Figure 23.

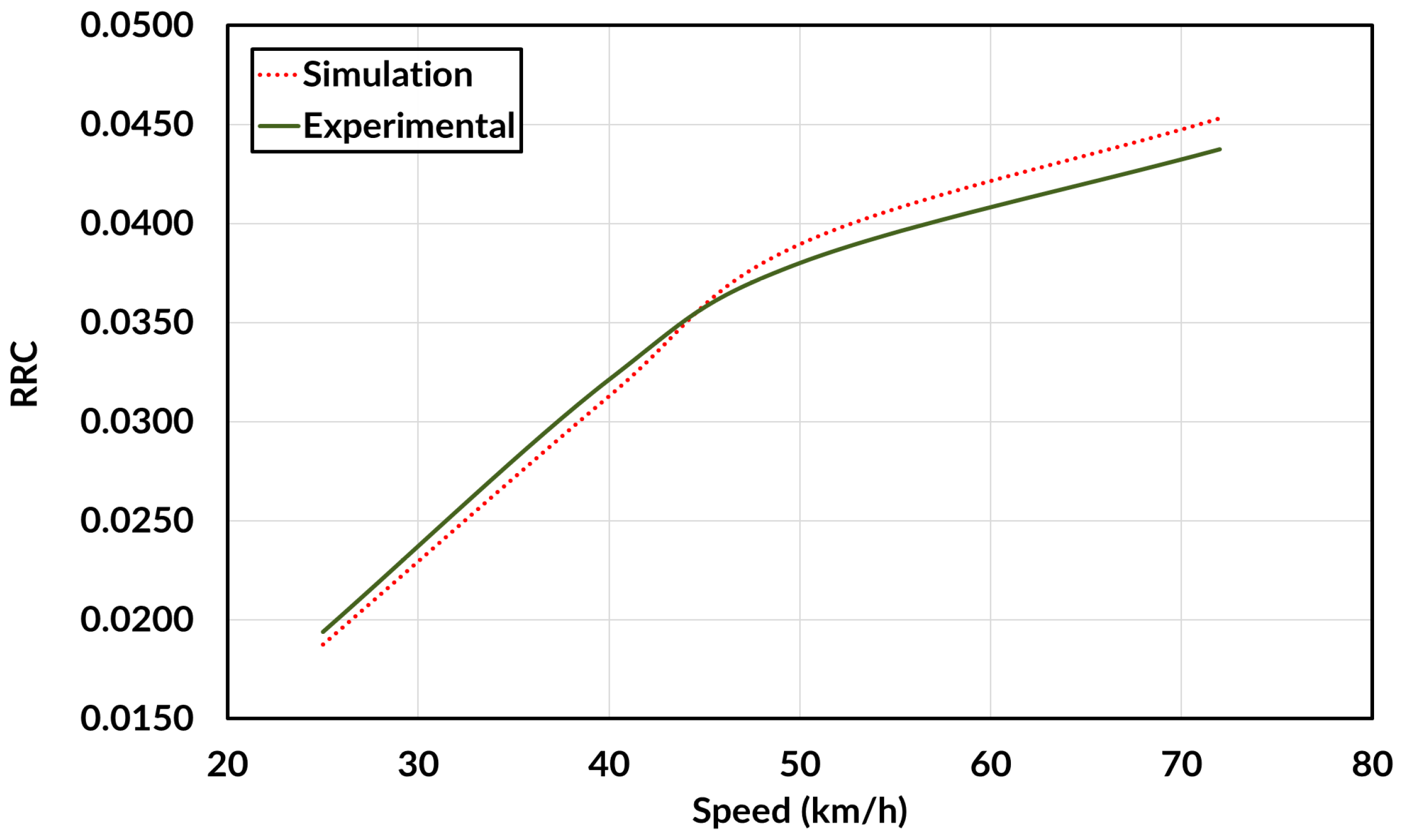

The tire wear mass for WT 1, which includes 5 wear steps, was found to be 1.0988 g, WT 2, including 4 wear steps, was found to be 1.1033 g and WT3, including 4 wear steps was 1.10741 g. WT 1 and WT 2 differed by 0.00454 g, and WT2 and WT 3 differed by 0.00407 g of tire wear loss. In experimental measurement, there is no distinct trend between the mass loss per WT. Between WT 1 and WT 2, there was only a 0.02 g difference in mass loss, however, a 0.23 g difference can be seen between WT 2 and WT3, which may suggest a mass loss increase correlation with wear.

A total wear loss of 2.95983 g was seen between the WT simulations with an estimated wear coefficient of

. The experimental tests yielded a wear mass loss of 3.10 g, resulting in a 4.5216% error, which shows agreement between measurements and simulation. Between WT 1 and WT 2, the total mass loss can be seen to differ from experimental measurements. However, including WT 3, the trends do show an overall increase of total mass loss with each progressing WT. The small difference between WT 1 and WT 2 in the experimental tests may be attributed to temperature changes between the garage door opening. Where the outdoor ambient temperature and the dynamometer area inside the facility may have caused a slight difference in mass measurement. Additionally, there was a significant accumulation of paint from the steel roller by the end of WT 3 in experiments that may have contributed to the significant increase in mass by WT 3. In the experiment, as the tire wore more, the tread surface may have increased in roughness. In parallel with significant temperature changes over time, the tire tread was seen to accumulate more paint as the wear tests continued. The paint on the tire can be seen in

Figure 24.

The wear model can be seen to be heavily influenced by temperature and tread surface hardness, and for the wear amount simulated, slightly influenced by friction energy rate. This work suggests that there is an exponential increase in wear mass loss over time that is dependent on the friction energy rate, and therefore tread hardness, contact area, contact pressure and speed. As this study shows slight increases in friction dissipation rates and mass loss for a moderate amount of tire wear; the data suggests a more significant, exponential difference were the tire to show excessive wear. For future work, other velocity profiles can be used to observe the impact of varying maneuvers to tire wear using the same model. This model can also be implemented for other tires provided that an adequate FEA model is developed, and tread hardness for varying temperatures are obtained. Following this, for more instantaneous wear applications a mesh sensitivity analysis will be required. High acceleration loads will deform the elements at the contact patch in more extreme manners compared to those found in this study.