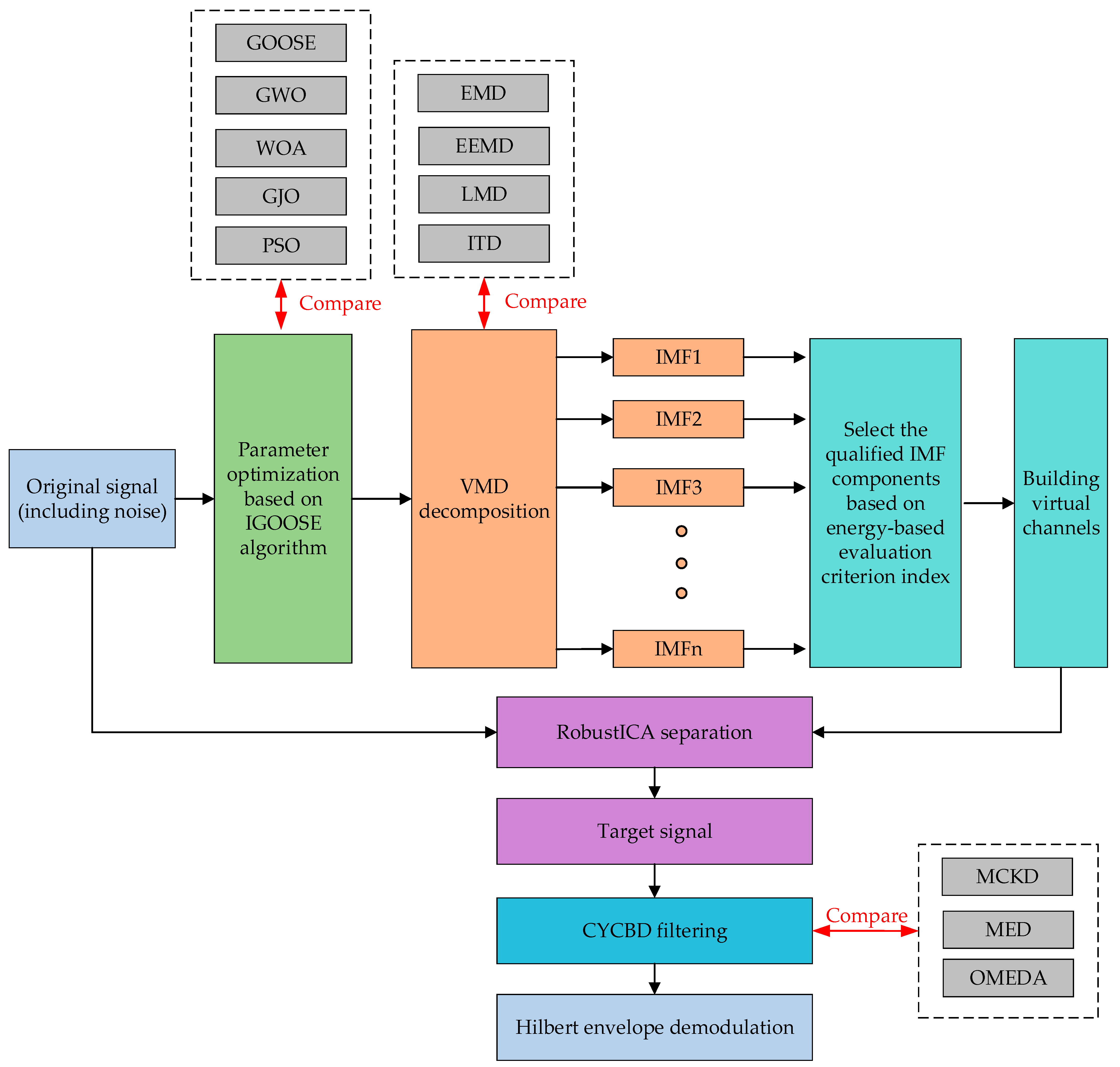

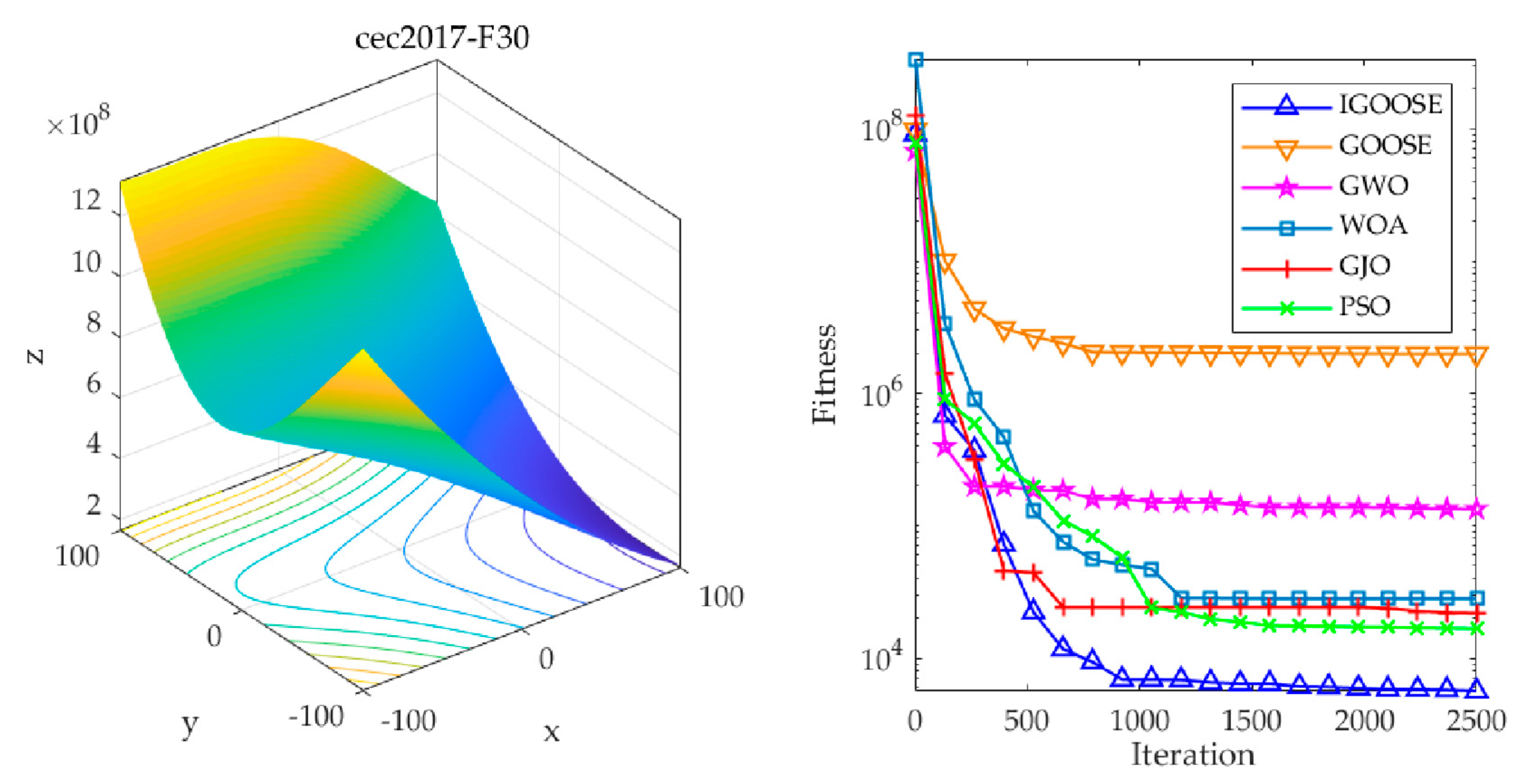

4.1. Analysis of Optimization Performance of IGOOSE

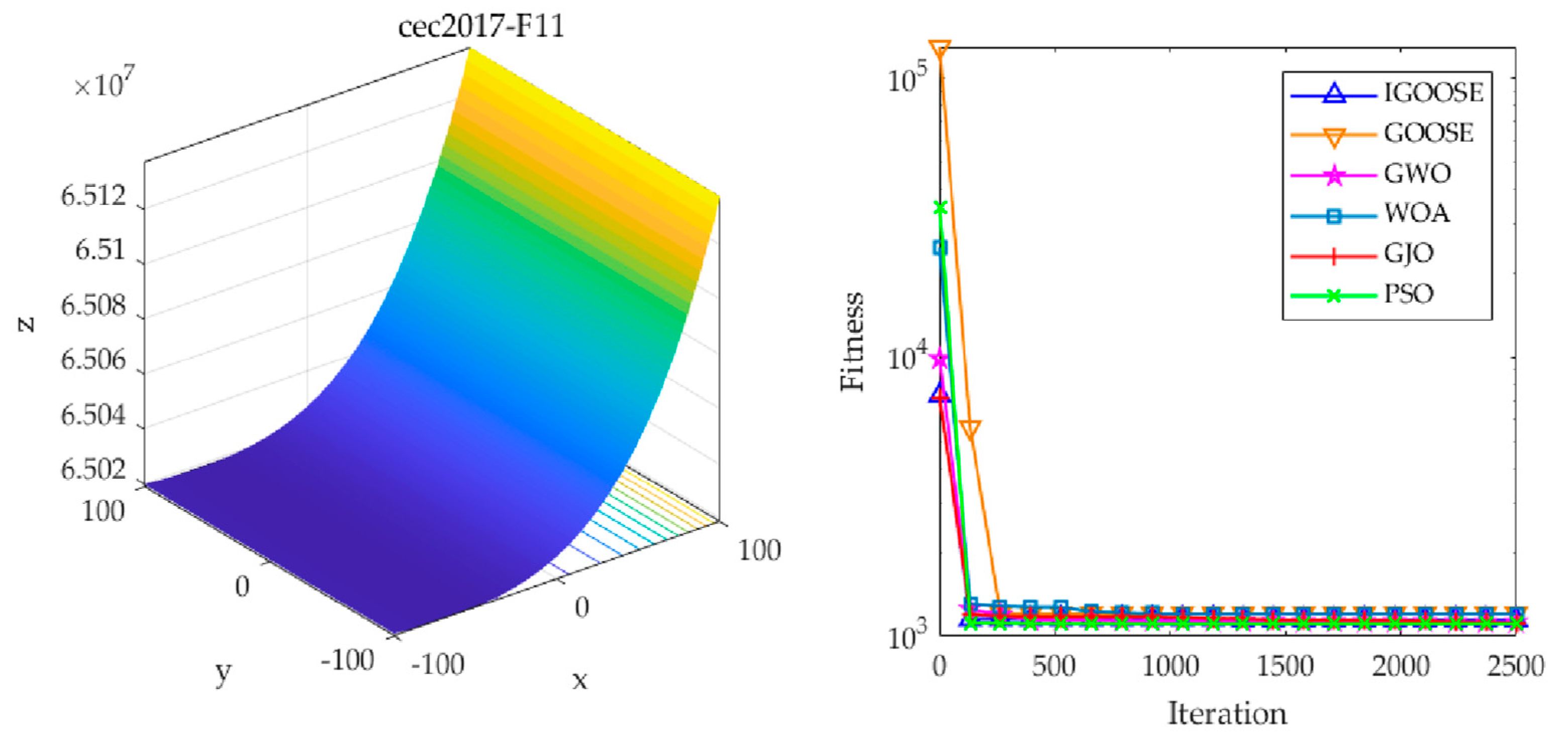

To evaluate the optimization performance of the IGOOSE, this study designed comparative experiments by subjecting the IGOOSE, alongside the GOOSE, the emerging Grey Wolf Optimizer (GWO), Whale Optimization Algorithm (WOA), Golden Jackal Optimization (GJO), and the widely recognized Particle Swarm Optimization (PSO) [

29,

30,

31,

32], to optimization tests on three benchmark functions under the CEC2017 dataset. During the experiments, the parameter settings of each algorithm were meticulously configured following standard procedures and are detailed in

Table 1 to ensure the objectivity of experimental results. By analyzing the convergence curves of these algorithms, this study not only quantified their performance in terms of convergence speed and accuracy but also delved into their strategies and effectiveness in exploring and exploiting the search space while avoiding local optima. As illustrated in

Figure 5,

Figure 6 and

Figure 7, these charts visually present the fitness trends of each algorithm on the three complex test functions: F2, F11, and F30.

The experimental results indicate that the IGOOSE, with its unique optimization strategies, exhibits significant advantages in convergence speed, stability, and global search capability. In particular, its improved optimization mechanism effectively accelerates the convergence process and significantly reduces the final optimal fitness value, demonstrating the efficiency and accuracy of the algorithm in solving complex optimization problems. Furthermore, the IGOOSE demonstrates robust capabilities in escaping local optima, enabling it to effectively jump out of local extrema regions and comprehensively search the solution space for better global solutions.

To enhance the robustness of the experimental results, this study further conducted replication experiments under controlled experimental conditions, specifically setting the maximum number of iterations to 2500. Specifically, each algorithm was independently executed 30 times to eliminate the potential influence of randomness introduced by a single run. Based on this, the standard deviation (Std) and average value (Avg) of each experiment were calculated and recorded as quantitative indicators to evaluate the optimization performance of the algorithms, as detailed in

Table 2. Through a comprehensive examination and comparative analysis of the data, it can be clearly observed that the IGOOSE exhibits relatively superior performance in both the standard deviation and average value dimensions compared to other optimization algorithms under comparison. Specifically, its lower standard deviation reflects the stability and reliability of the algorithm’s results, while the relatively lower average value demonstrates the advantages of the IGOOSE in terms of solution efficiency and accuracy.

4.2. Simulation Verification

To ensure the uniqueness of our validation approach, this study employs synthetic signals tailored specifically to mimic the characteristics of rolling bearing vibrations. The formulation for these custom-generated signals is elaborated as follows:

In the aforementioned equation, we define a carrier frequency, fn = 3000 Hz, and a damping factor, ξ = 0.1. The signal is sampled at a frequency fs = 20,000 Hz, with t representing individual sampling instants within a period T = 0.01 s. The total number of samples acquired is N = 4096, and the characteristic failure frequency under investigation is denoted as f0 = 100 Hz.

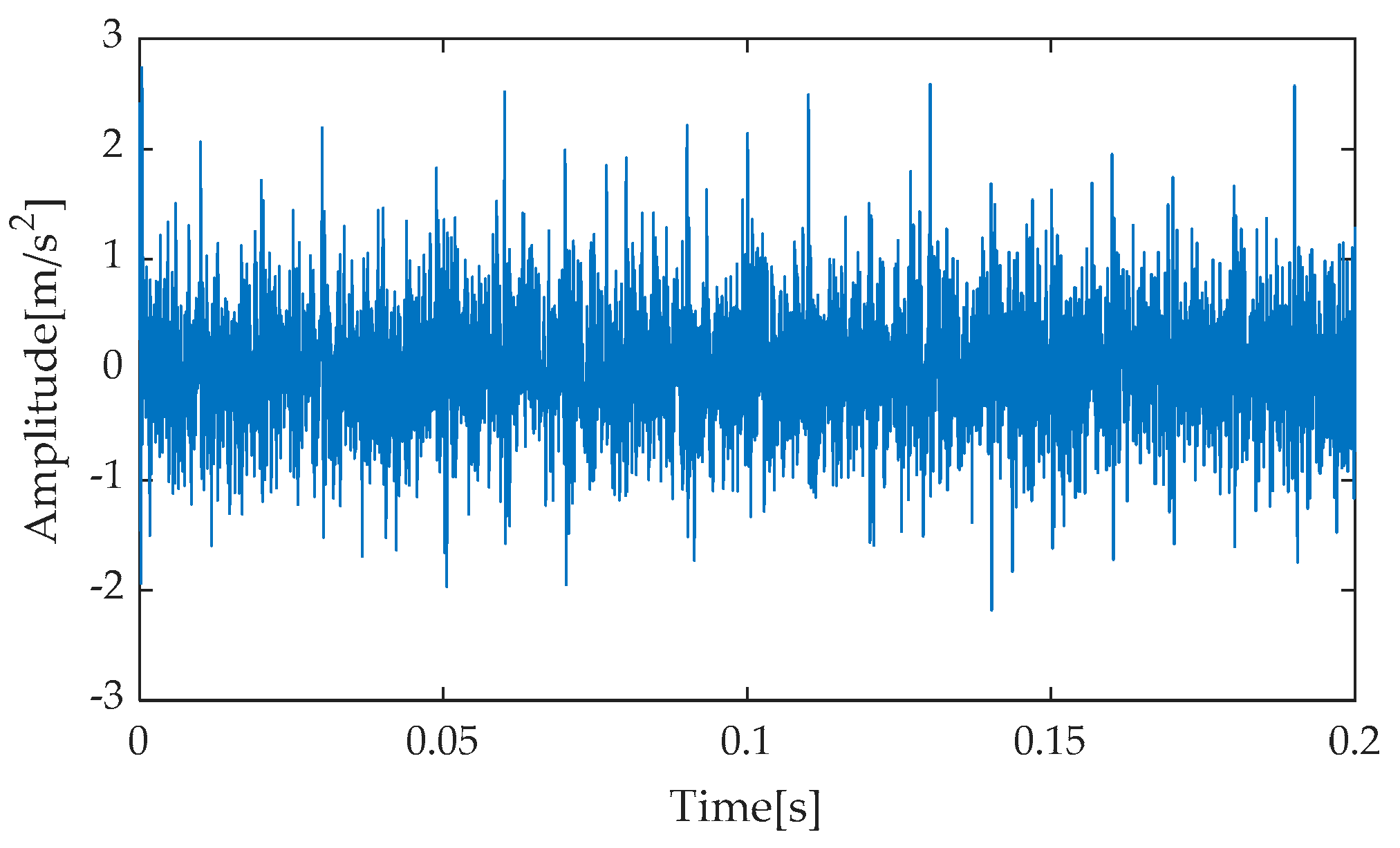

In this experiment, to simulate potential bearing faults in real-world scenarios, noise with a signal-to-noise ratio (SNR) of −7 dB was introduced into the simulated signal. This step aimed to mimic signal interference caused by environmental factors or inherent equipment issues under actual operating conditions. The simulation and analysis were conducted using the MATLAB R2023b software platform, with the objective of observing and analyzing signal characteristics against a strong noise background.

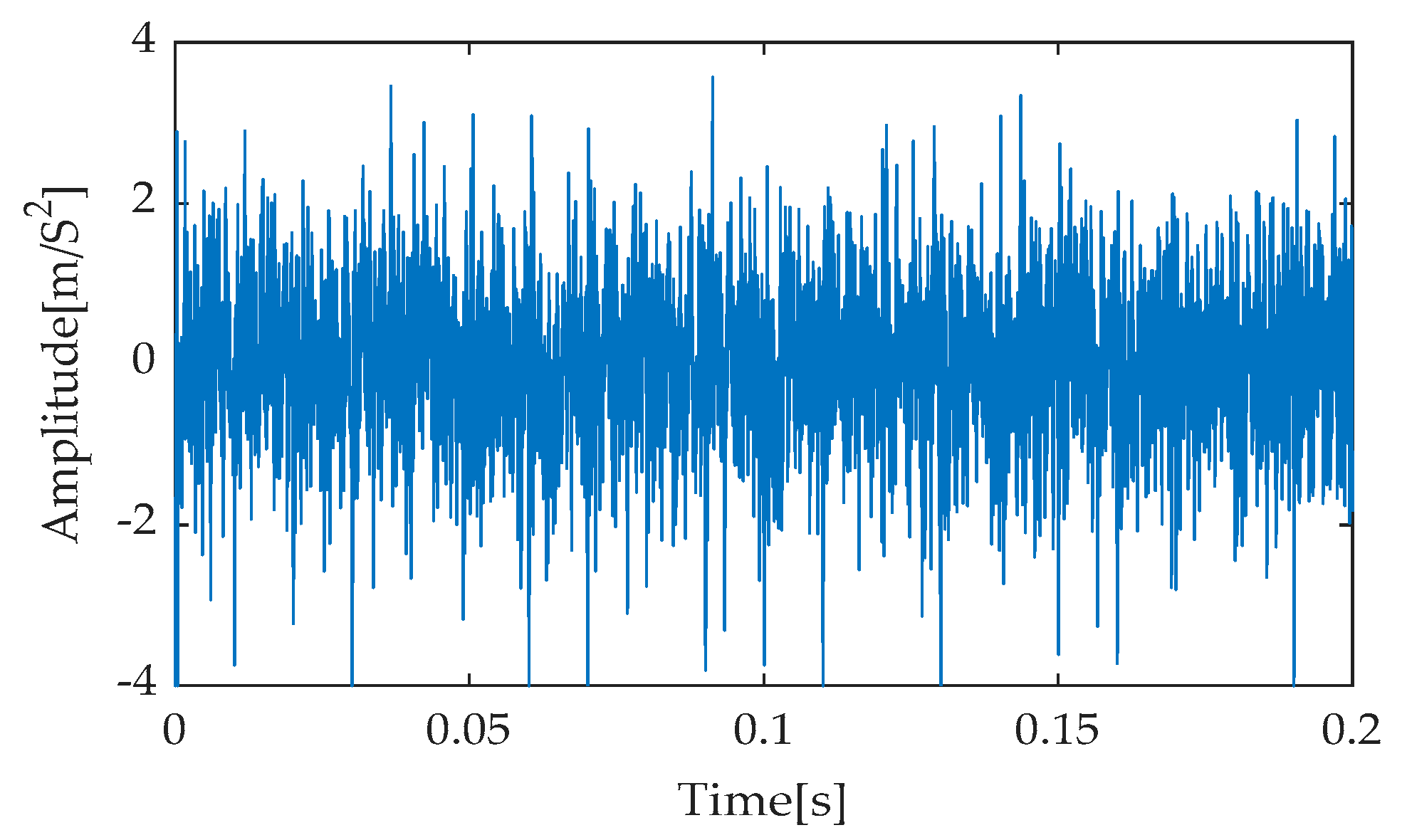

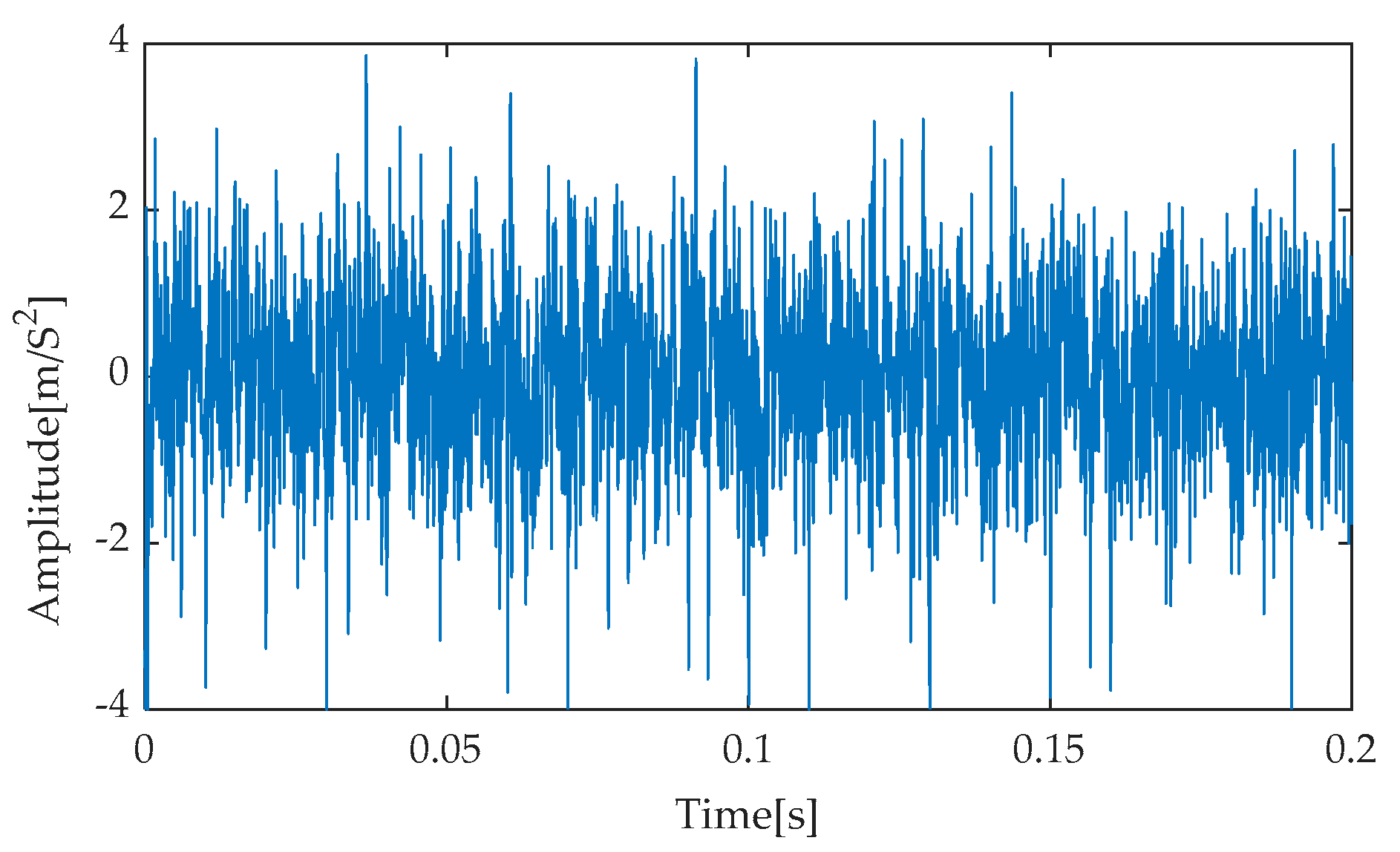

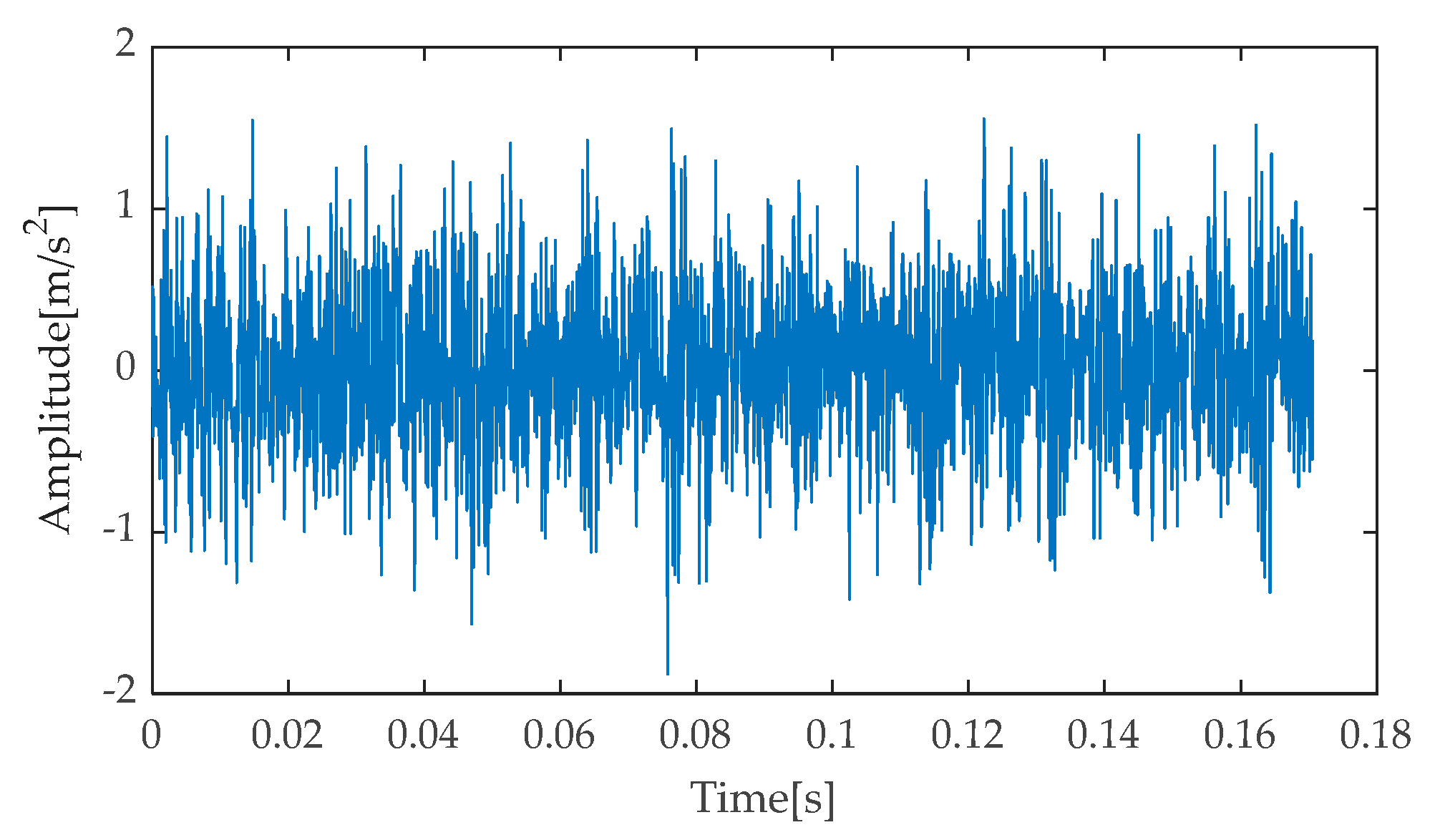

Figure 8 presents the time–domain waveform of the original, noise-free simulated signal, serving as a benchmark for comparison with subsequent processing results. Subsequently, after incorporating noise with an SNR of −7 dB into the simulated signal, the resulting noisy simulated signal’s time–domain waveform is depicted in

Figure 9. As evident from

Figure 9, the strong background noise significantly overwhelms the periodic features originally present in the simulated signal, rendering it extremely challenging to directly extract useful fault information from the time–domain waveform. Consequently, further processing and analysis of the noisy signal are necessary.

Given the significant interference posed by noise on signals, this study introduces an IGOOSE strategy to optimize the critical parameters of VMD, specifically the selection of the number of modal components K and the penalty factor a. This optimization process aims to lay a solid foundation for subsequent signal decomposition by precisely configuring the initialization parameters of VMD. In implementing the IGOOSE algorithm, an Energy-Based Evaluation Criterion Index (EECI) proposed in this paper is designed and adopted as the fitness function to automatically search and optimize the VMD parameters, ensuring optimal decomposition results. During the initialization phase of IGOOSE, meticulous optimization operations are focused on the two crucial parameters in VMD: the number of modal components and the penalty factor. Specifically, the search range for the number of decomposition components is set to [2, 10], while the penalty factor is searched within the interval [100, 5000], ensuring that the algorithm explores within a reasonable parameter space. Additionally, in IGOOSE, a population size of 30 and a maximum number of iterations of 30 are configured to promote stable convergence and efficient execution of the algorithm.

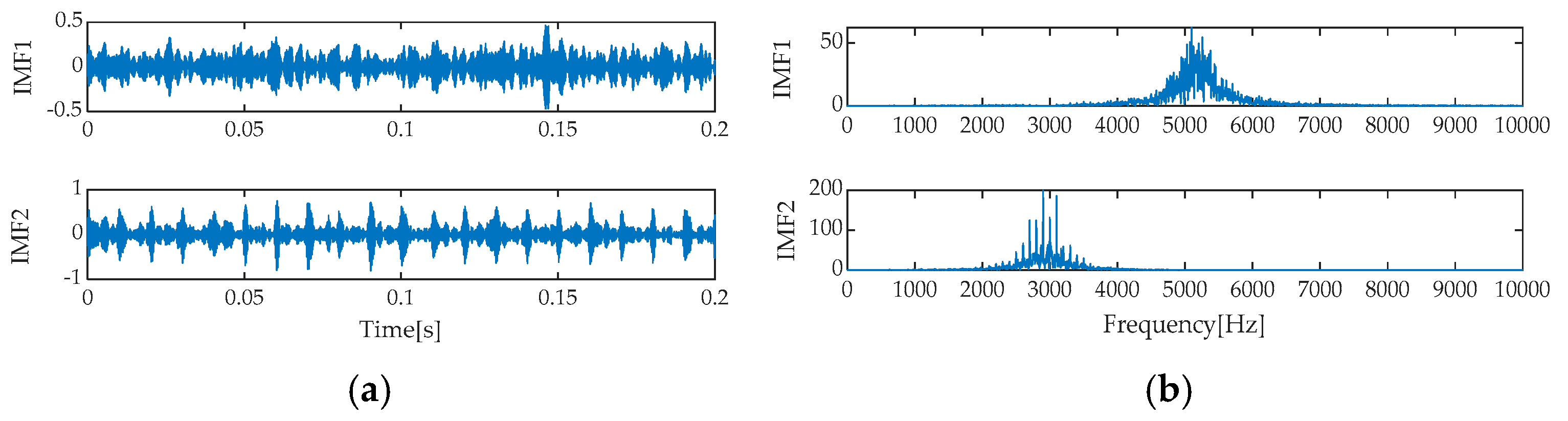

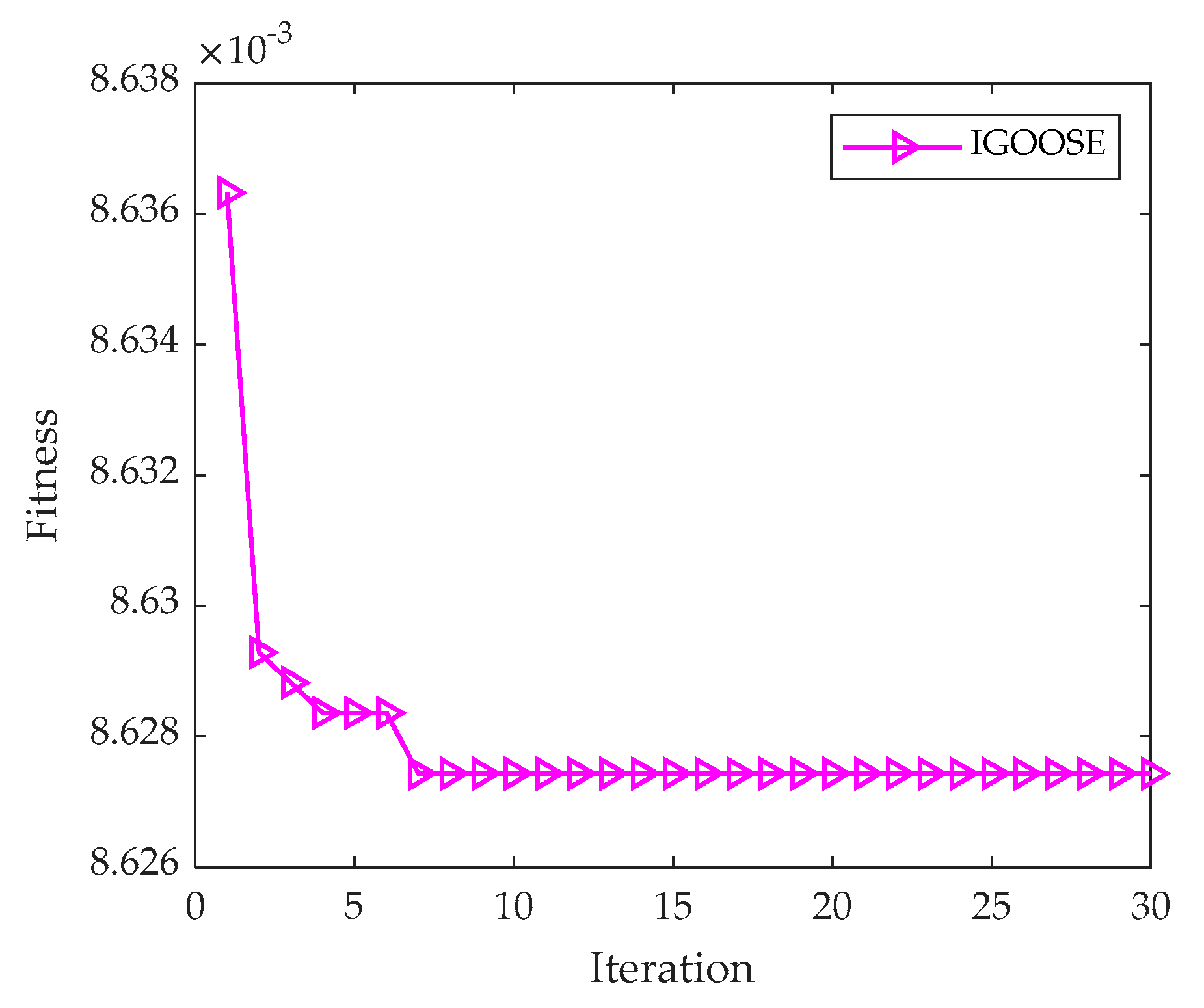

As depicted in

Figure 10, the fitness curve variation of IGOOSE visually illustrates the rapid convergence of the algorithm to the optimal solution. Upon reaching the optimal fitness value, the experiment determines the optimal number of decomposition components to be 2 and the optimal penalty factor to be 4237. These optimized parameters are then applied to the VMD model for effective decomposition of the noisy simulated signal. To comprehensively evaluate the effectiveness of the IGOOSE-VMD method, this study also conducted parallel comparative experiments using Empirical Mode Decomposition (EMD), Ensemble Empirical Mode Decomposition (EEMD), Local Mean Decomposition (LMD), and Intrinsic Time-Scale Decomposition (ITD).

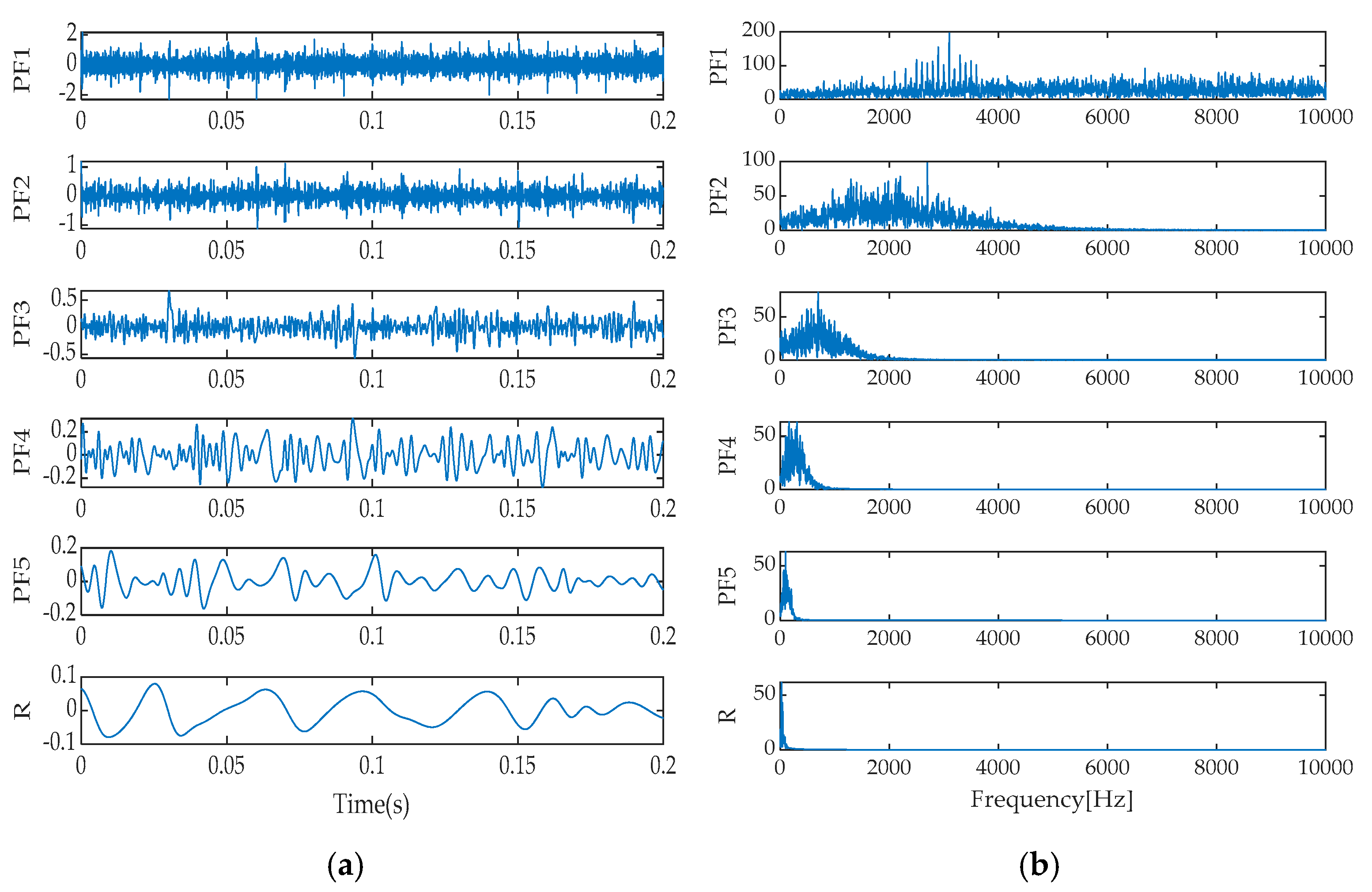

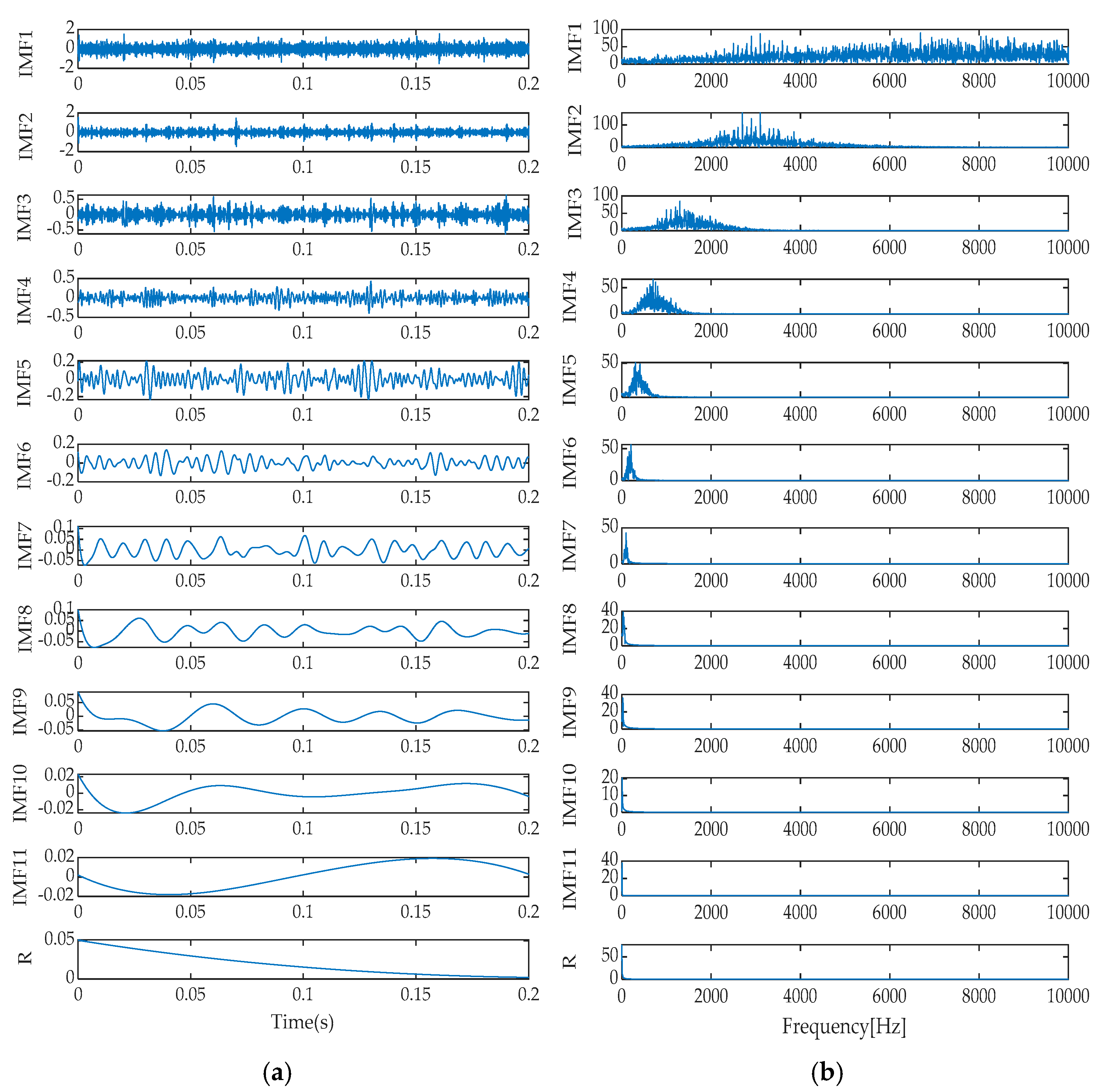

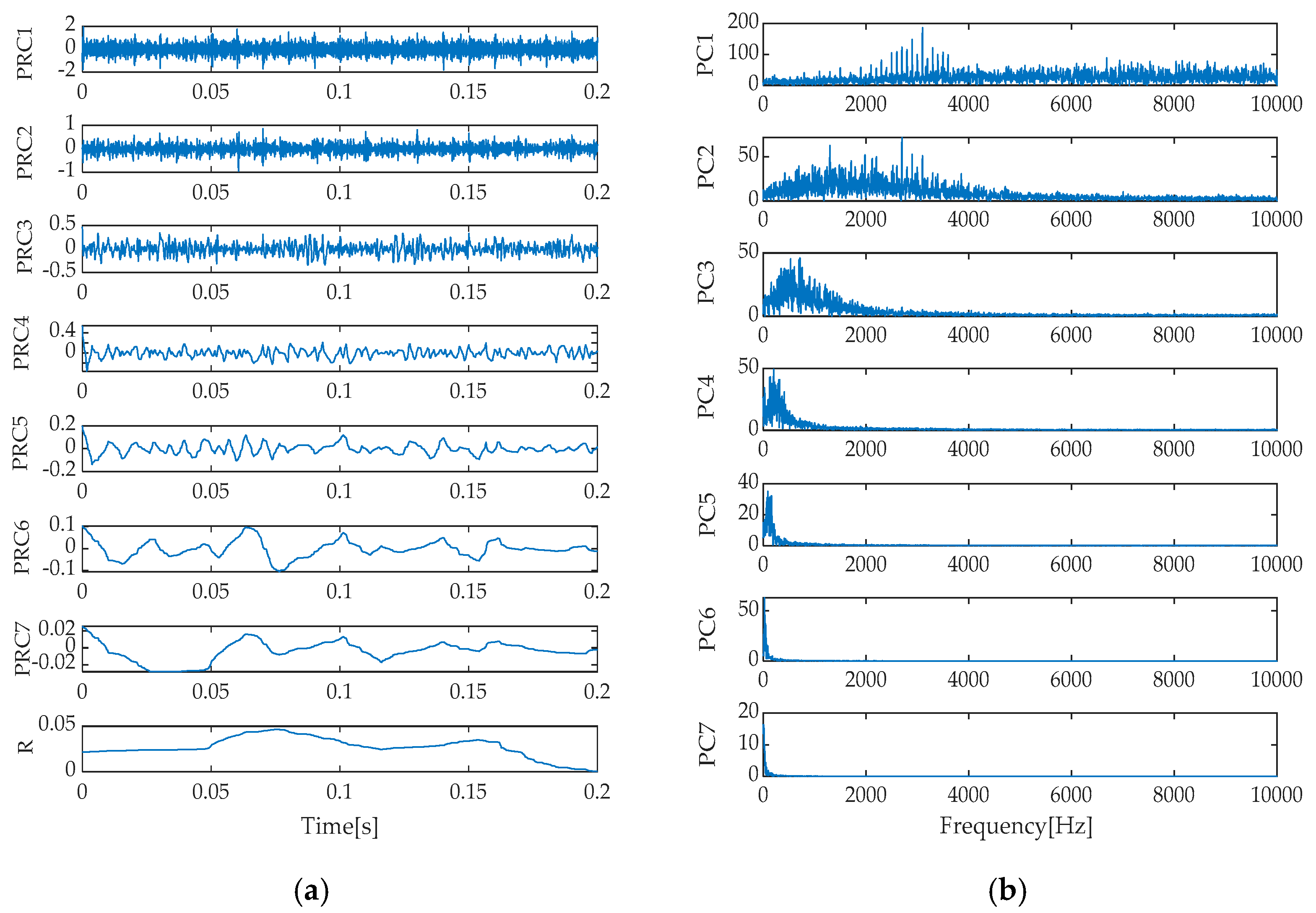

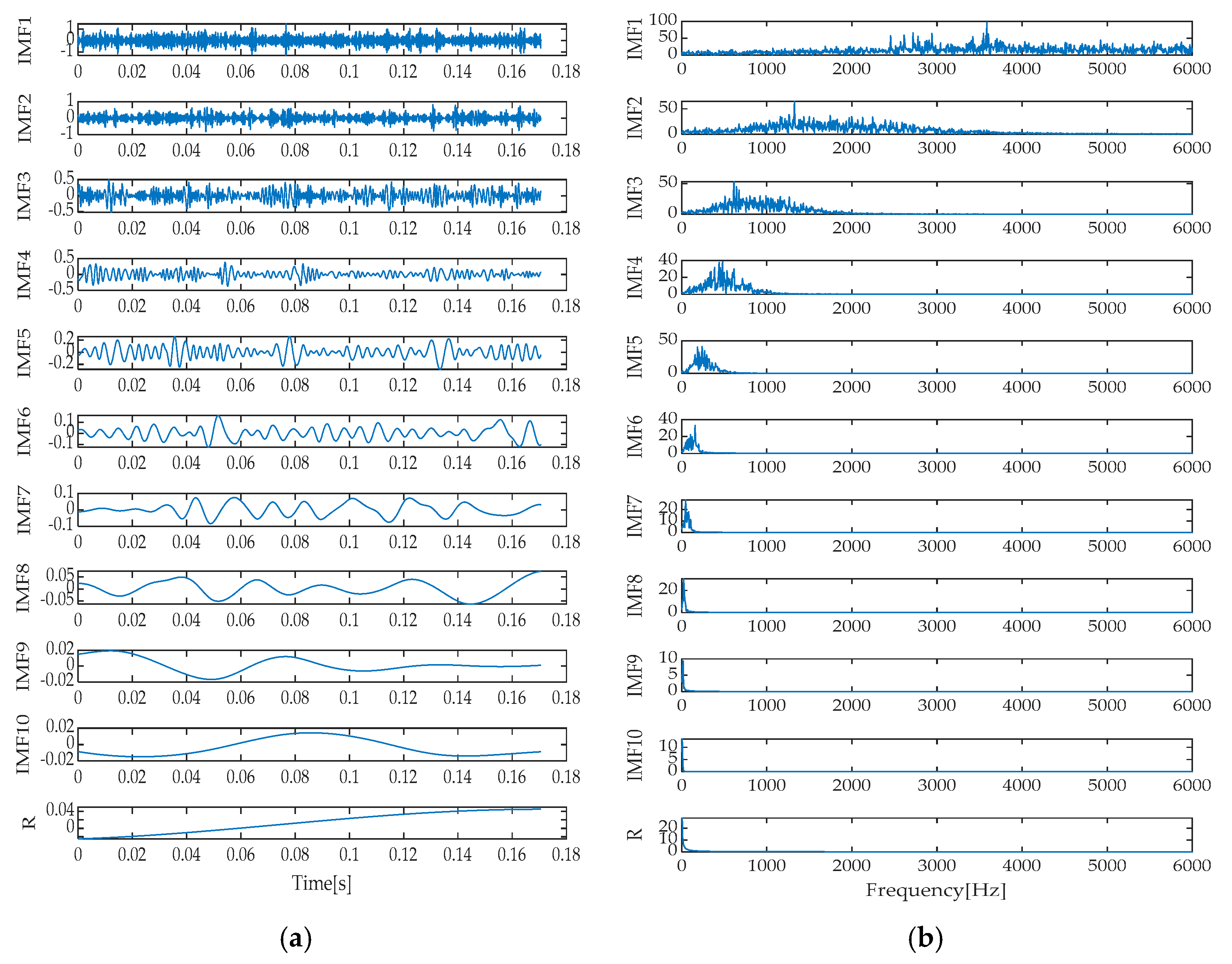

Figure 11,

Figure 12,

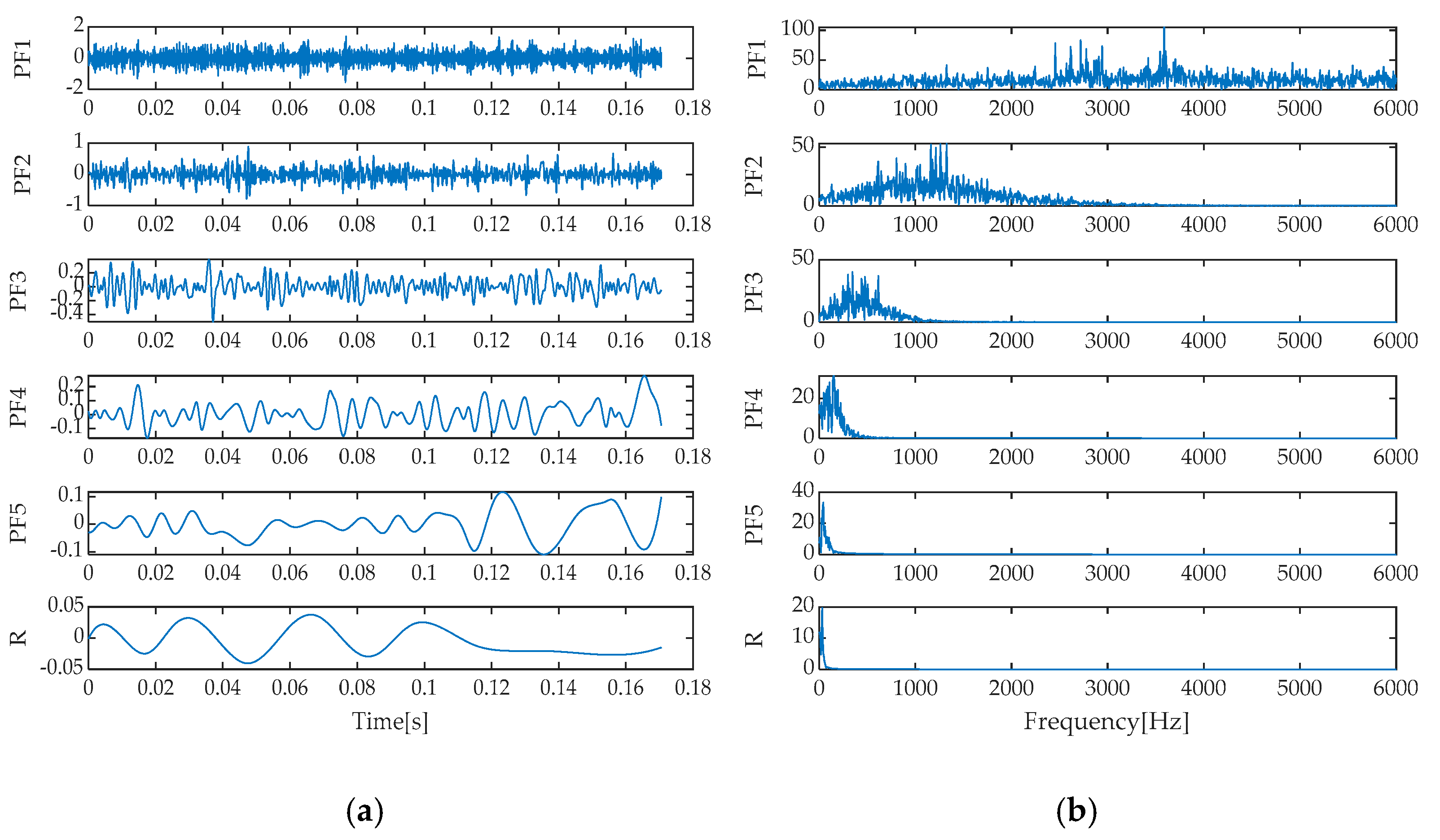

Figure 13,

Figure 14 and

Figure 15 showcase the signal decomposition results obtained using IGOOSE-VMD, EMD, LMD, EEMD, and ITD, respectively, providing intuitive visual references for subsequent performance comparisons and in-depth analysis.

Upon a thorough analysis of the decomposition effects presented in

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15, we can clearly observe the differences in performance among various signal decomposition methods. Specifically, after processing the signal using the IGOOSE-VMD method, two signal components were successfully separated, with their spectral characteristics exhibiting excellent separation and no overlap, ensuring uniformity and clarity in the spectral distribution. In contrast, the EMD method yielded 11 signal components and 1 residual component. Its time–domain representation distinctly identifies the presence of mode mixing, which is further corroborated in the frequency spectrum, particularly between IMF1, IMF2, and IMF3 components, where significant spectral overlap affects the purity and effectiveness of signal decomposition. Moving on to the EEMD method, although designed to alleviate the mode mixing issue of EMD, in this experiment, it also produced 11 signal components and 1 residual component, with similar mode mixing phenomena visible in the time–domain plot as EMD, failing to significantly improve the signal decomposition outcome.

Additionally, the frequency spectra of the individual signal components exhibited spectral overlap, indicating that EEMD’s improvement is limited in handling complex, noisy signals. As for the LMD method, it decomposed the signal into five signal components and one residual component. Modal mixing was effectively suppressed in the time–domain plot. However, a certain degree of spectral overlap still existed between PF1 and PF3 components in the frequency spectrum, suggesting that while maintaining signal independence, further optimization of LMD’s spectral separation capability is needed. Finally, the ITD method decomposed the signal into seven signal components and one residual component, with signs of mode mixing reappearing in its time–domain representation. Meanwhile, notable spectral overlap between PRC1 and PRC3 components in the frequency spectrum indicates that ITD also faces challenges in mode separation and spectral clarity when dealing with complex signals. In summary, different signal decomposition methods exhibit their respective advantages and limitations when processing the same signal. Among them, IGOOSE-VMD performs relatively better in spectral separation.

To precisely select the most suitable signal components from the decomposition results of various signal time–frequency analysis methods, this study introduces the proposed

EECI as the core evaluation criterion. Firstly, the

EECI values of each signal component under each method were meticulously calculated and tabulated in

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7 for analysis. As evident from

Table 3, the IMF1 component obtained from the IGOOSE-VMD method possesses the smallest

EECI value, significantly indicating that the energy of the signal damage characteristic frequency is highly concentrated in this component, making the damage feature particularly prominent. Therefore, IMF1 was chosen for reconstructing the observed signal channel, while the remaining components were allocated to the reconstruction of the noise signal channel. Similarly,

Table 4 reveals that after EMD decomposition, IMF2 exhibits the smallest

EECI value, implying its excellence in capturing signal damage characteristics with energy concentrated at the damage characteristic frequency. Consequently, IMF2 was selected as the basis for reconstructing the observed signal channel, and the rest of the components were utilized for the noise channel reconstruction. Further analysis of

Table 5 shows that the EEMD method also highlights the superiority of IMF2 in terms of

EECI, further confirming its effectiveness in representing signal damage characteristics. Thus, IMF2 was designated as the core for reconstructing the observed signal channel, while the other components aided in constructing the noise signal channel.

In

Table 6, the application of the LMD method indicates that PF1 has the smallest EECI value, demonstrating its high focus of energy distribution on the signal damage characteristic frequency, resulting in clear damage features. Hence, PF1 was utilized for reconstructing the observed signal channel, while the other components contributed to the reconstruction of the noise signal channel. Lastly, from

Table 7, it is evident that the PRC1 component obtained from the ITD method possesses the smallest

EECI value, which also proves the high concentration of energy on the signal damage characteristic in this component. Therefore, PRC1 was chosen as the key component for reconstructing the observed signal channel, and the remaining components were used to build the noise signal channel. Based on the above screening, this study further employed the RobustICA algorithm to effectively separate the signal from noise. Specifically, the proposed method was compared with traditional methods such as EMD-RobustICA, EEMD-RobustICA, LMD-RobustICA, and ITD-RobustICA in terms of noise reduction effects (as shown in

Figure 16,

Figure 17,

Figure 18,

Figure 19 and

Figure 20).

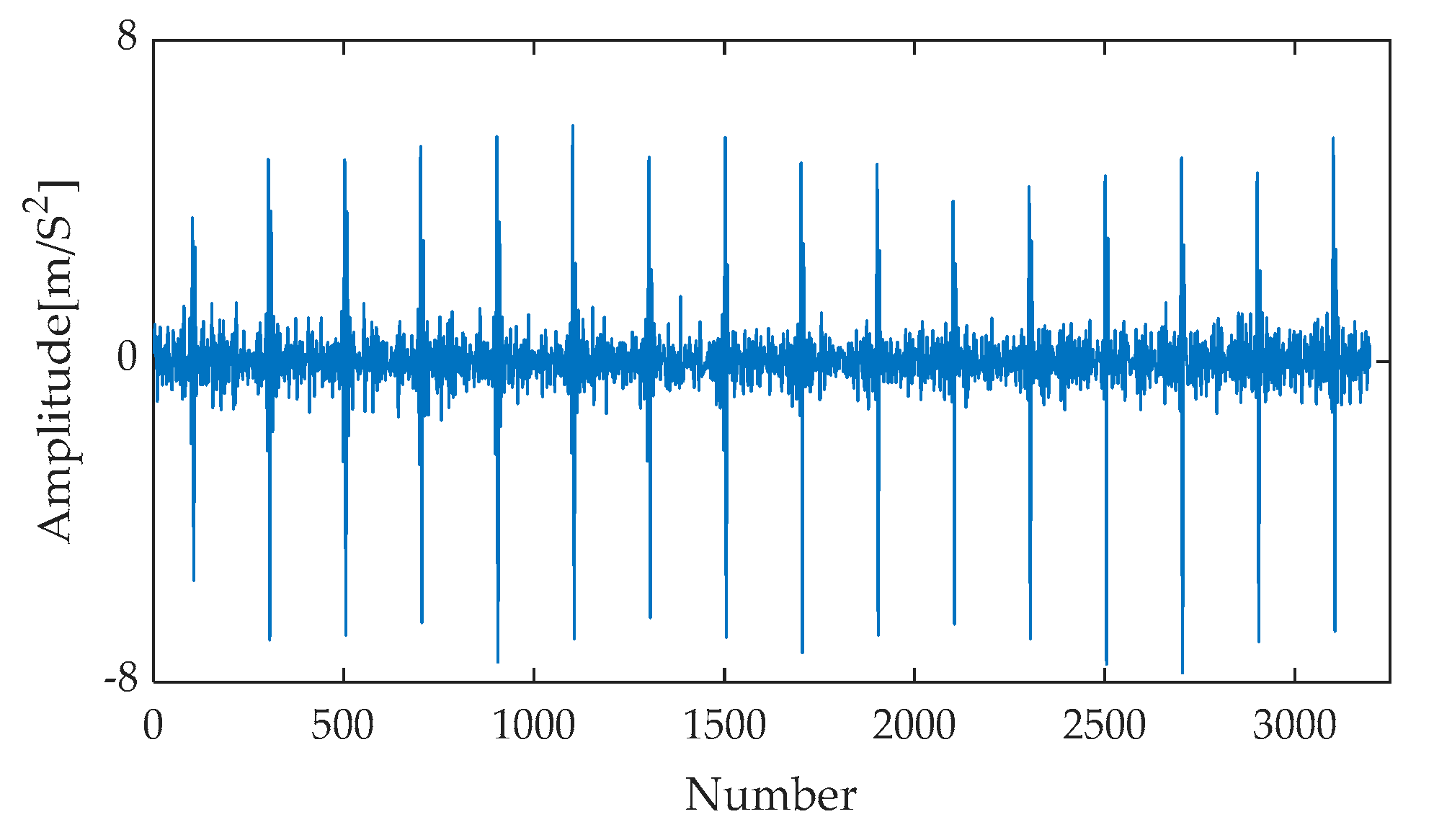

Figure 16,

Figure 17,

Figure 18,

Figure 19 and

Figure 20 present the time–domain waveforms obtained after applying different noise reduction methods. Upon careful analysis, it is evident that the proposed IGOOSE-VMD-RobustICA method significantly enhances the visibility and clarity of the periodic impulsive components in the signal post-denoising. In contrast, while traditional methods such as EMD-RobustICA, EEMD-RobustICA, LMD-RobustICA, and ITD-RobustICA can also observe impulsive components to some extent after noise reduction, these components are often obscured by larger irrelevant noise peaks, leading to less clear waveforms.

Following the RobustICA noise reduction process, to comprehensively and deeply quantify the noise reduction performance of each method, the experimental analysis selected three indicators: cross-correlation coefficient, kurtosis, and mean absolute error (MAE) for a comprehensive analysis. These indicators not only reflect the similarity between the denoised signal and the original signal but also embody the sharpness of the signal waveform and the overall impact of noise reduction processing on signal errors. Specifically,

Table 8 details the specific values of each evaluation indicator after applying different noise reduction methods. Notably, the IGOOSE-VMD-RobustICA method demonstrates significant advantages in both cross-correlation coefficient and kurtosis. Its cross-correlation coefficient reaches 0.649, indicating a high degree of similarity between the denoised signal and the original signal. The kurtosis value of 5.097 further reveals the effective enhancement in the clarity and sharpness of the impulsive components in the signal. Although this method slightly lags behind the EMD-RobustICA method in terms of MAE, the difference is relatively small. Further observation of the evaluation results for other methods reveals that, regardless of EMD-RobustICA, EEMD-RobustICA, LMD-RobustICA, or ITD-RobustICA, their performance in cross-correlation coefficient and kurtosis falls short of the IGOOSE-VMD-RobustICA method. While these traditional methods can reduce noise to a certain extent, they exhibit notable deficiencies in preserving signal characteristics and enhancing signal clarity.

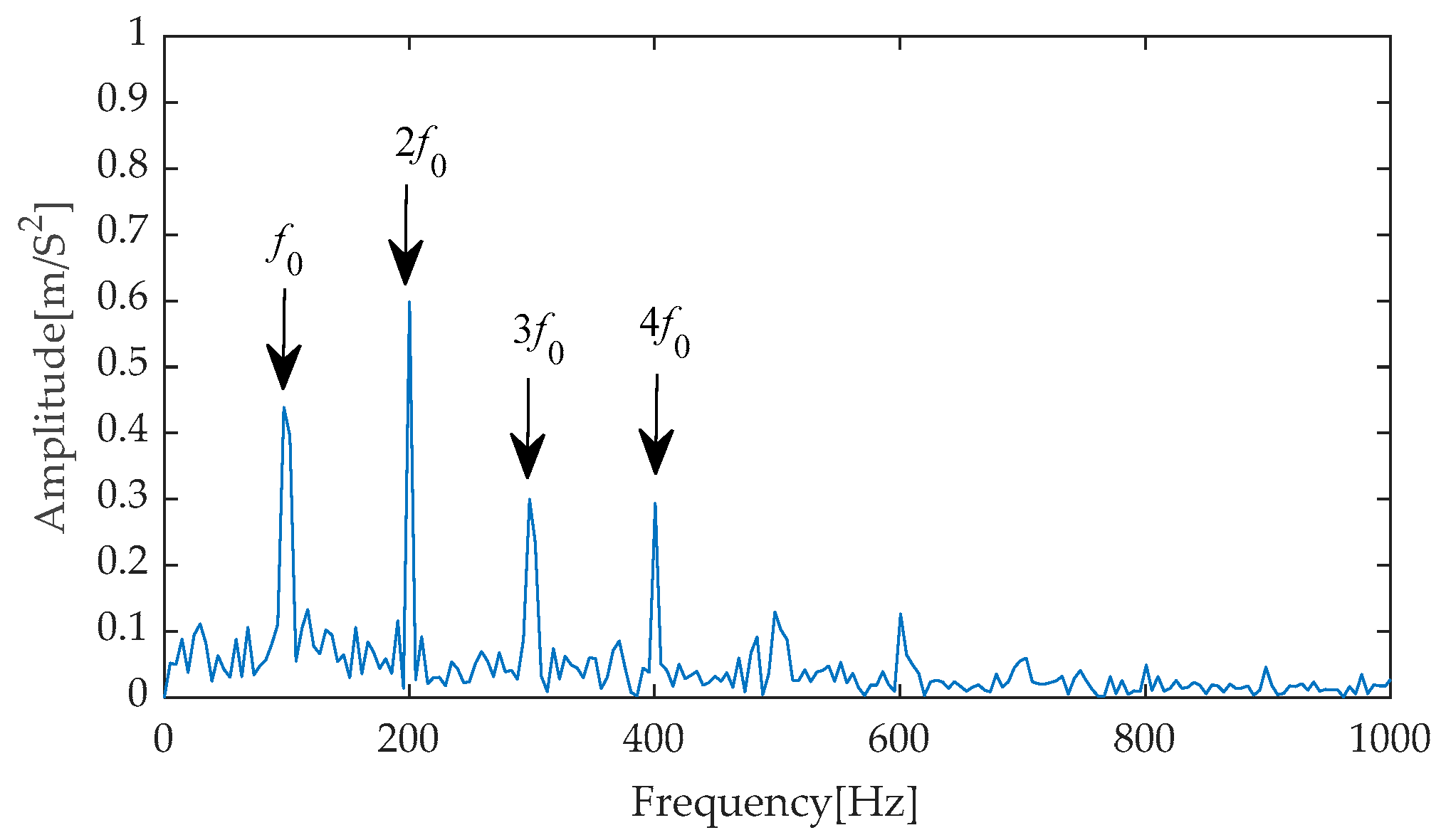

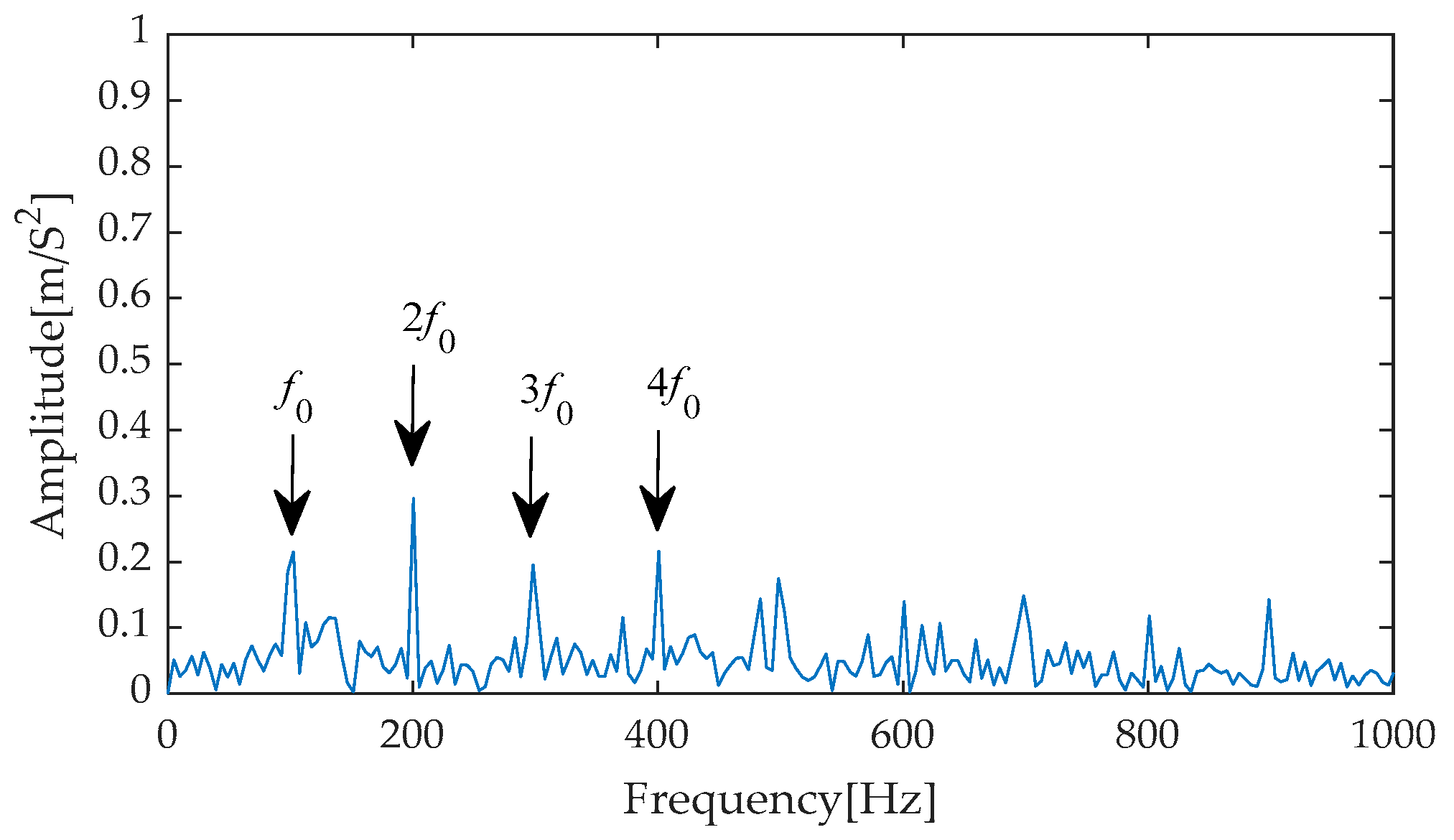

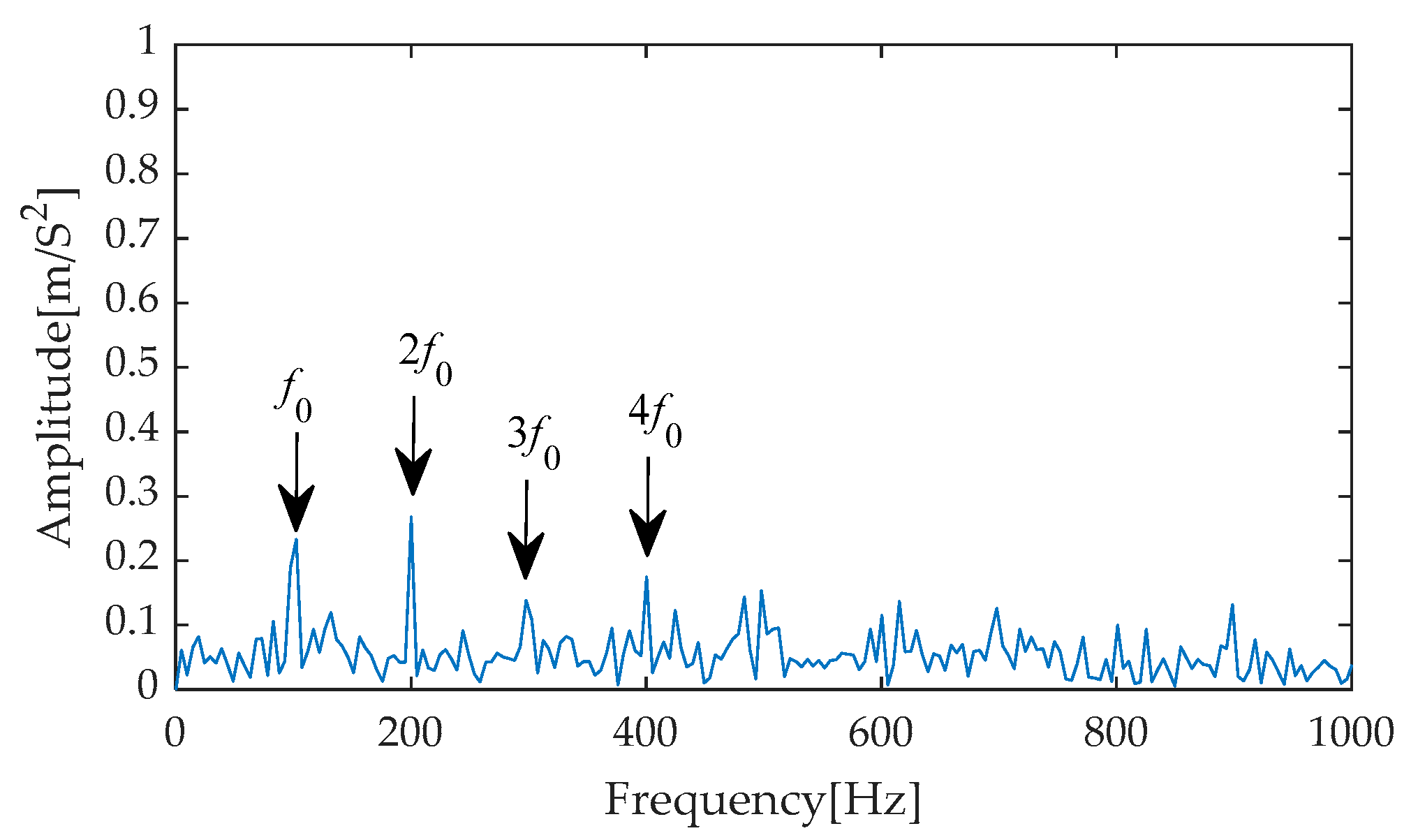

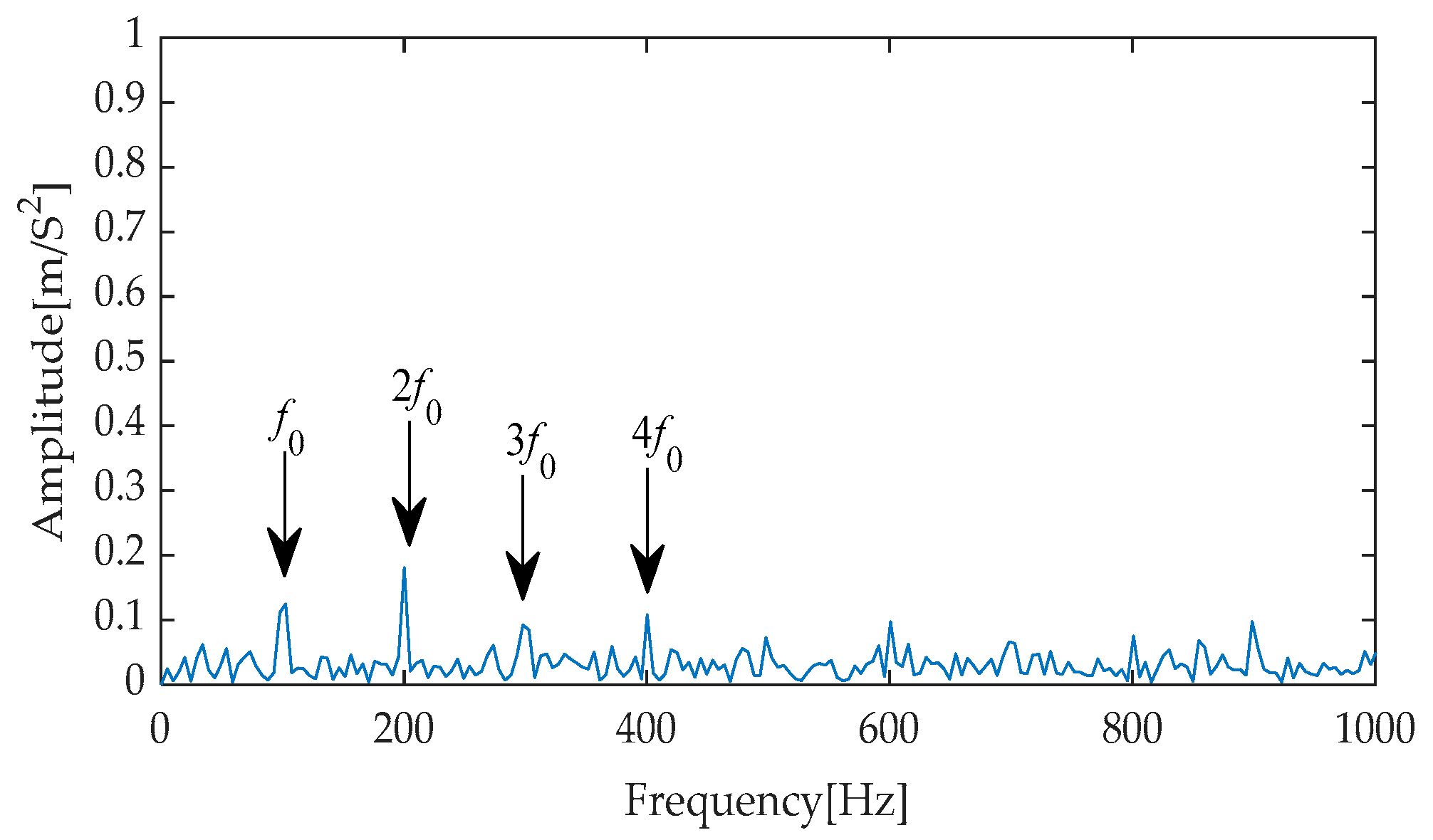

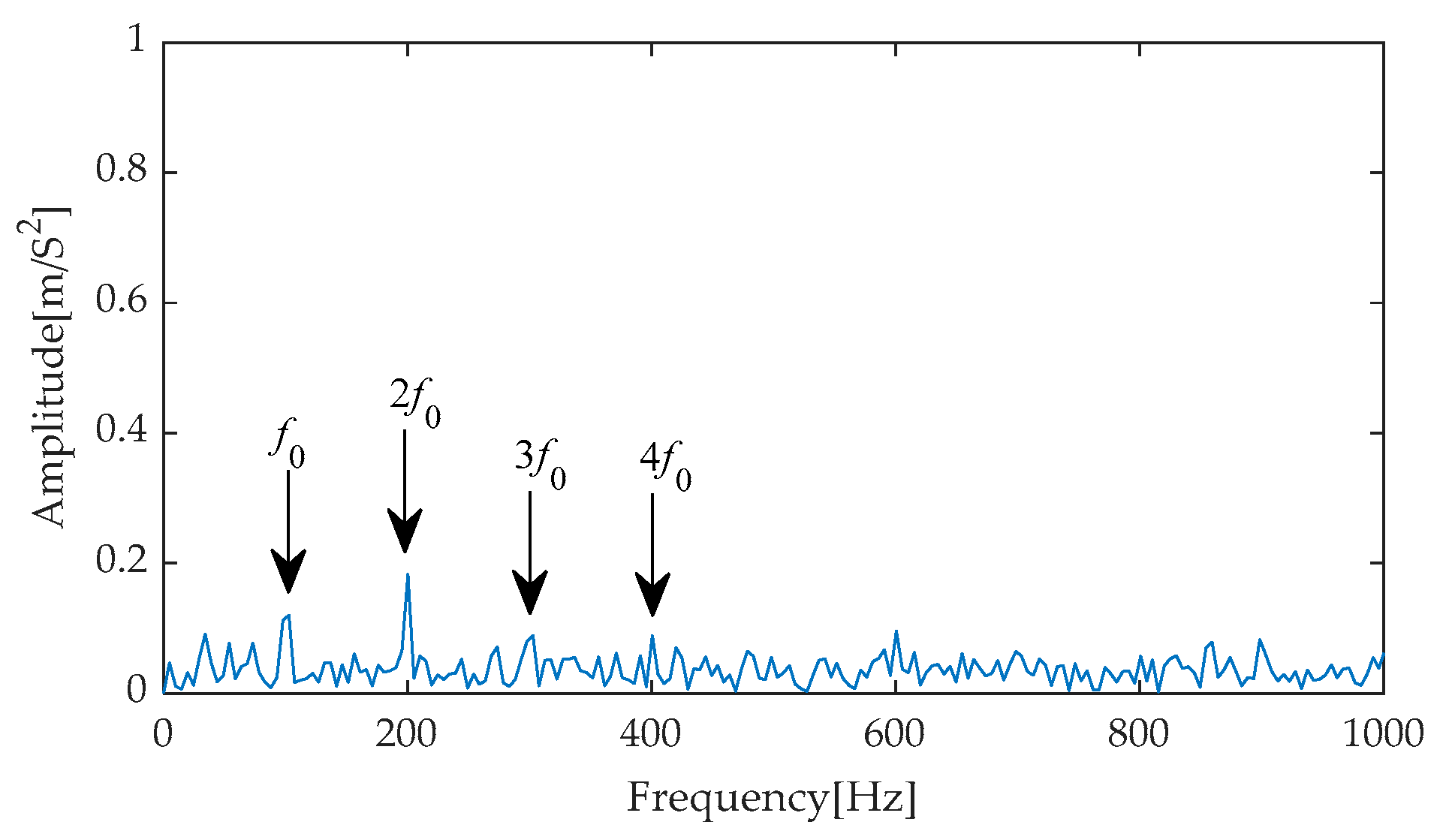

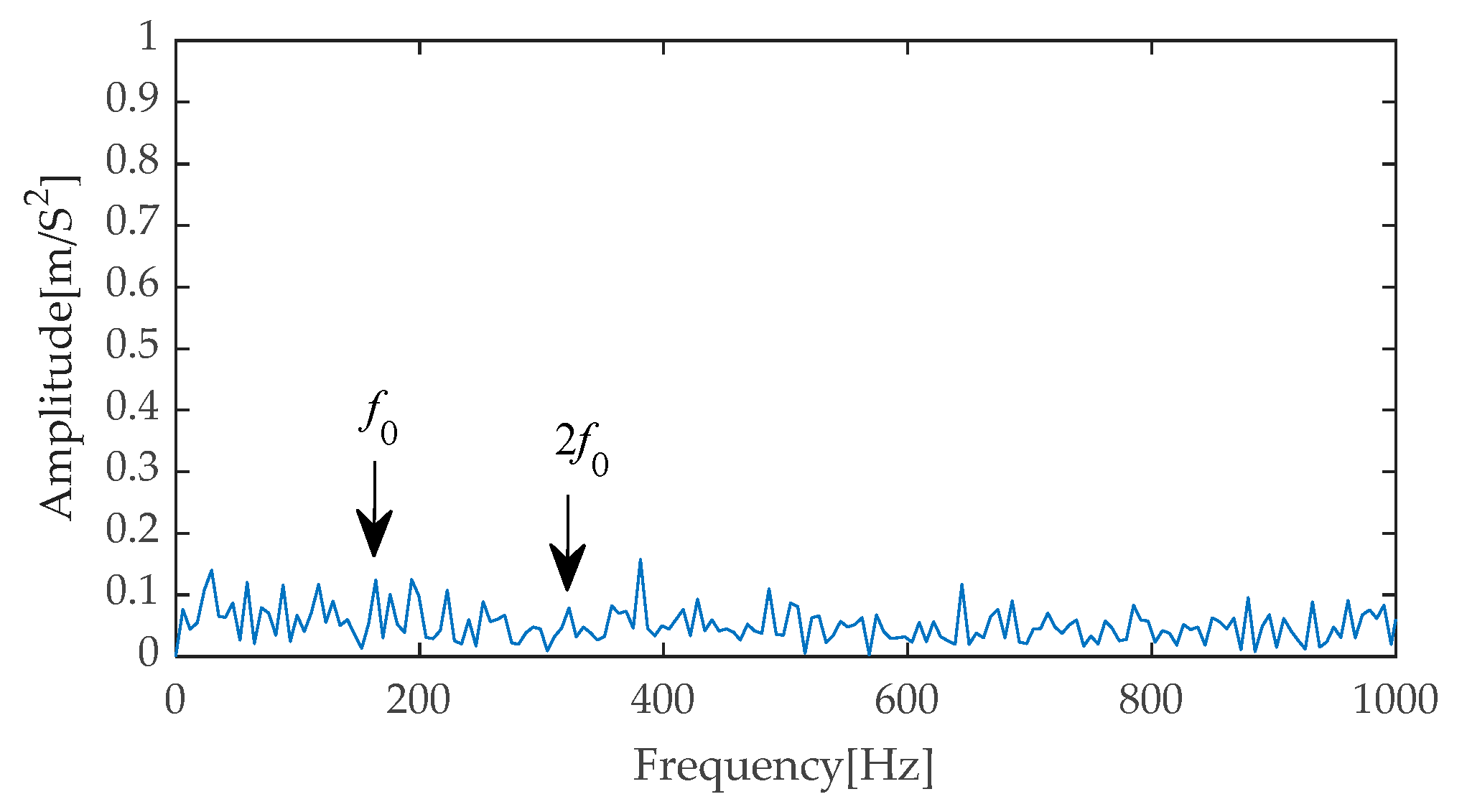

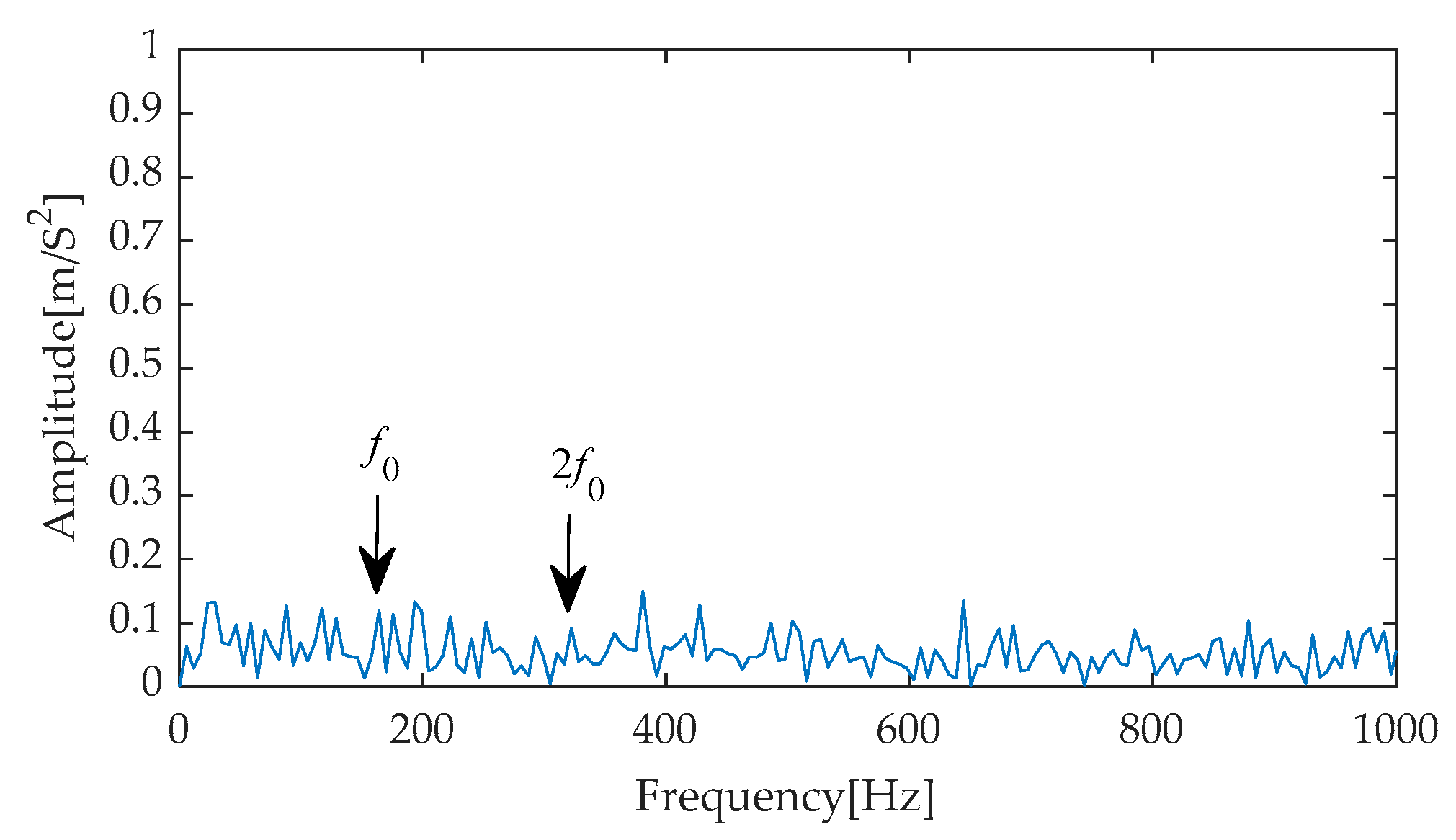

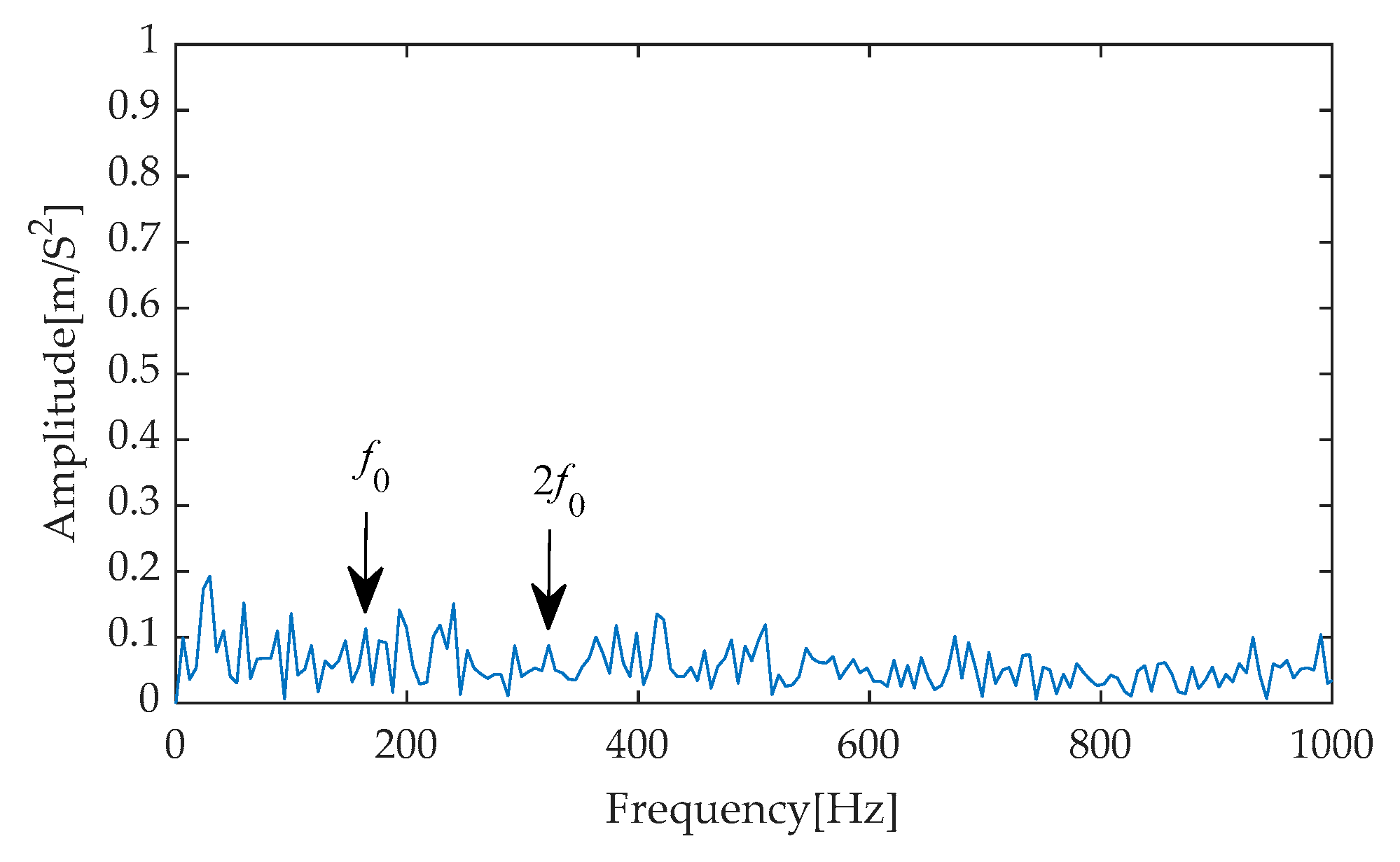

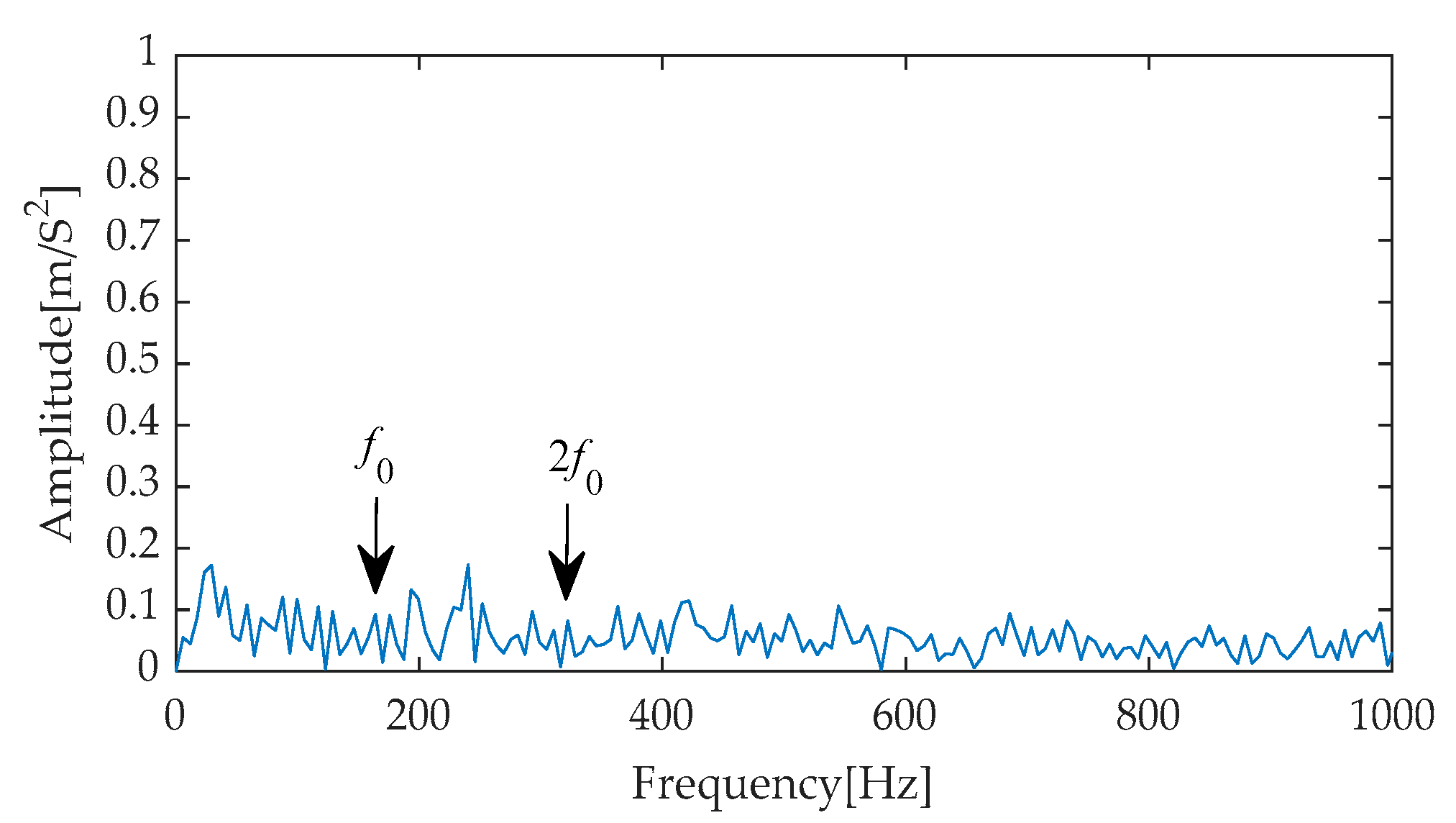

Furthermore, to precisely extract fault characteristics, Hilbert envelope demodulation was implemented on the results of effective signal-noise separation achieved through the aforementioned diverse methods. The resulting envelope spectra (as shown in

Figure 21,

Figure 22,

Figure 23,

Figure 24 and

Figure 25) comprehensively display the frequency components under different processing methods, with notable changes particularly evident from the first to the fourth harmonics of the fault characteristics. Through comparative analysis, it can be observed that while methods such as EMD-RobustICA, EEMD-RobustICA, LMD-RobustICA, and ITD-RobustICA can reveal the existence of the first to the fourth harmonics of fault characteristics, the amplitudes of these frequency components are relatively low. Notably, in the envelope spectra of LMD-RobustICA and ITD-RobustICA, the amplitudes of fault frequencies are similar to those of background noise or irrelevant interference components, posing a significant challenge to the accuracy of fault diagnosis and increasing the risk of misdiagnosis or missed diagnoses.

In contrast, the envelope spectrum obtained using the IGOOSE-VMD-RobustICA method exhibits superior performance. Specifically, this method not only significantly enhances the amplitudes of the first to the fourth harmonics of fault characteristics, making them stand out among numerous frequency components and thereby more intuitively indicating the occurrence of faults, but also effectively reduces the interference from irrelevant components near the fault frequencies, greatly improving the clarity and accuracy of fault diagnosis. Subsequently, the signal denoised by the IGOOSE-VMD-RobustICA method is input into the CYCBD filter to further enhance the periodic impulsive characteristics in the signal.

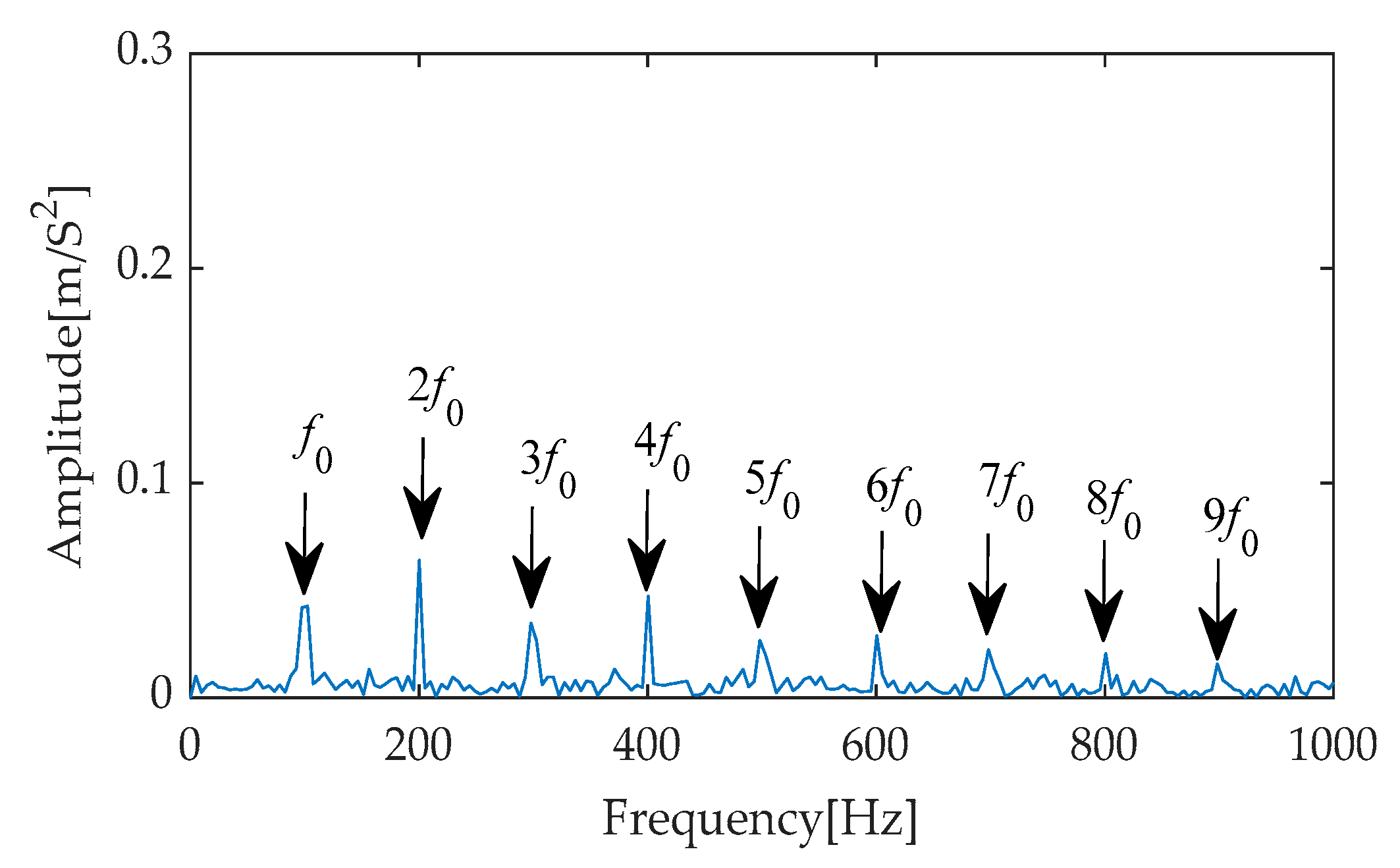

After the refinement of the original signal through the CYCBD filter, the experimental results yielded its time–domain waveform (as shown in

Figure 26) and the corresponding envelope spectrum (as shown in

Figure 27). In the time–domain waveform of

Figure 26, the periodic impulse components within the signal are effectively extracted by the filter, becoming exceptionally clear with significantly enhanced amplitudes. Further observation of the envelope spectrum in

Figure 27 reveals that within the crucial frequency range of 0 to 1000 Hz, the fault characteristic frequency and its second to ninth harmonics stand out prominently with extremely high amplitudes. This pronounced frequency distribution characteristic not only validates the effectiveness of the filter but also provides compelling evidence indicating the presence of a fault within the bearing system.

To comprehensively evaluate the effectiveness of different deconvolution methods in signal filtering, this study employed the signal denoised by the IGOOSE-VMD-RobustICA method and further processed it using three deconvolution techniques: Maximum Correlated Kurtosis Deconvolution (MCKD), Minimum Entropy Deconvolution (MED), and Optimal Minimum Entropy Deconvolution Adjusted (OMEDA) for in-depth filtering. To further analyze the filtering effects, the processed signals underwent Hilbert envelope analysis to generate envelope spectrums, with the results presented in

Figure 28,

Figure 29 and

Figure 30. Upon careful examination of these envelope spectra, it becomes evident that the amplitudes of irrelevant interference components are significantly reduced after filtering with MCKD, MED, and OMEDA. Specifically, within the frequency range of 0 Hz to 1000 Hz, these methods can clearly identify and extract the fundamental frequency of the fault characteristic frequency along with its first to ninth harmonics, demonstrating their proficiency in complex signal analysis. However, it is noteworthy that despite the unique features and respective advantages of MCKD, MED, and OMEDA, when compared to the CYCBD method, they yield relatively lower amplitudes in extracting the fault characteristic frequencies. This further underscores the superiority of the CYCBD method in enhancing the amplitudes of fault characteristic frequencies.

4.3. Experimental Verification

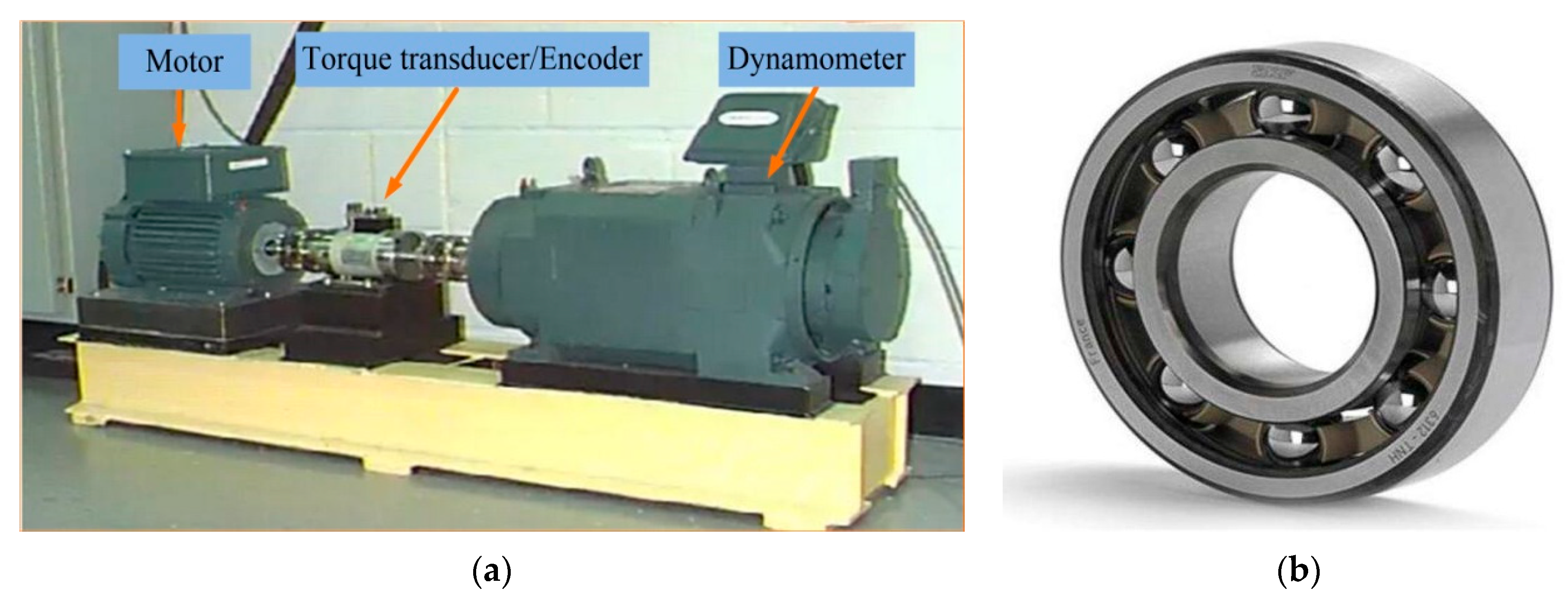

To validate the practical effectiveness of the proposed method, experiments were conducted using the publicly available bearing dataset from the renowned Case Western Reserve University for in-depth analysis.

Figure 31 illustrates the overall architecture and components of the rolling bearing fault monitoring setup [

33,

34]. The core components of this experimental framework encompass the motor system, torque sensor devices, among others, which collaborate to establish a foundation of high precision and robustness for the experimental process. The experiments focused on a specific bearing model, namely the SKF6205 series, where single-point defects with a defined diameter were artificially introduced to critical locations of the bearings using advanced electrical discharge machining techniques, aiming to accurately simulate fault modes that may occur under actual operating conditions.

In terms of experimental parameter configuration, a sampling frequency of 12 kHz was meticulously selected as the standard for data acquisition, while the equipment was maintained at a constant rotational speed of 1797 revolutions per minute to ensure consistency and accuracy in data collection. Under these conditions, representative vibration signals were collected from the preset faults on the bearing inner race, with the intention of thoroughly analyzing the fault characteristics through these data.

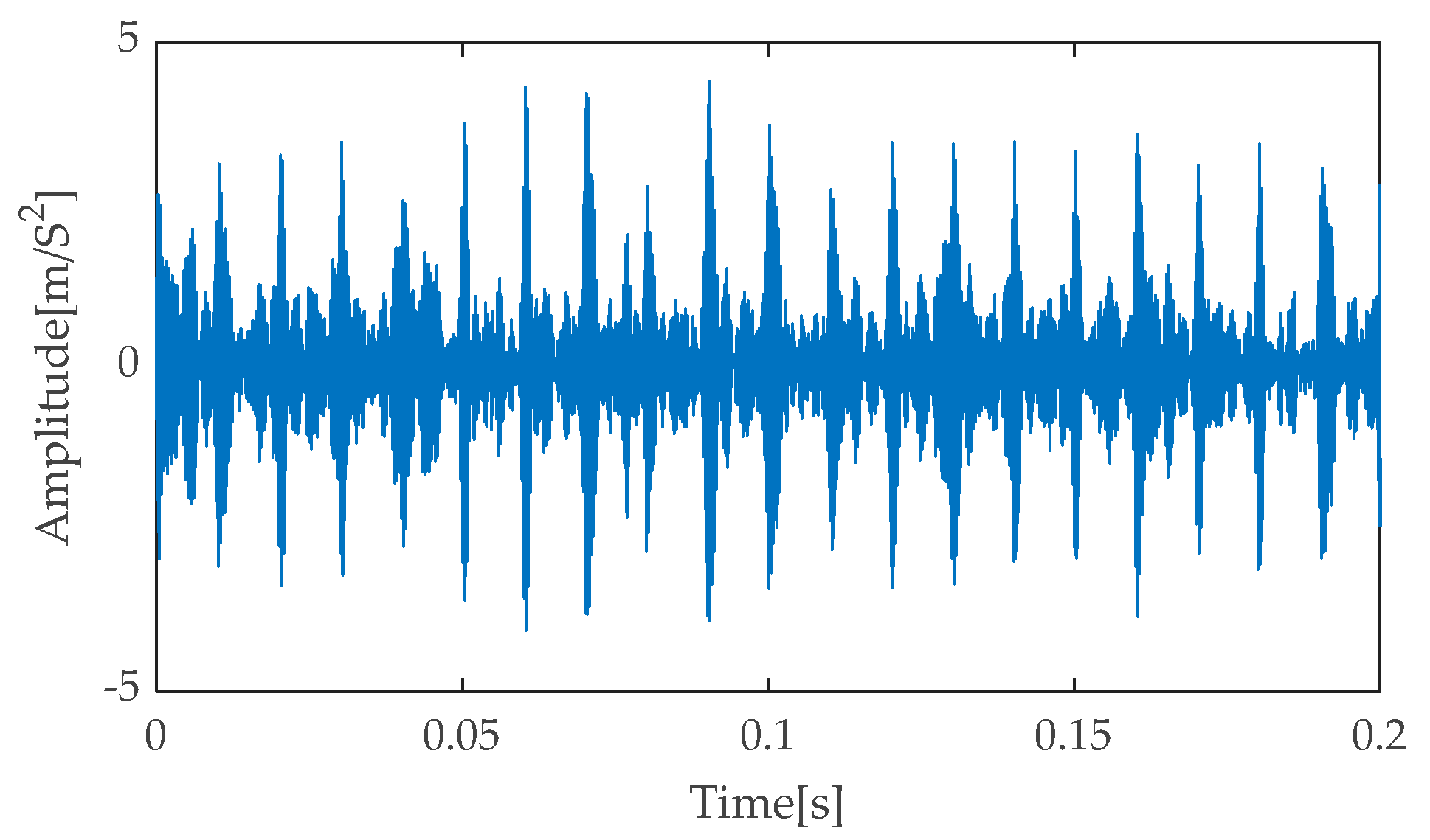

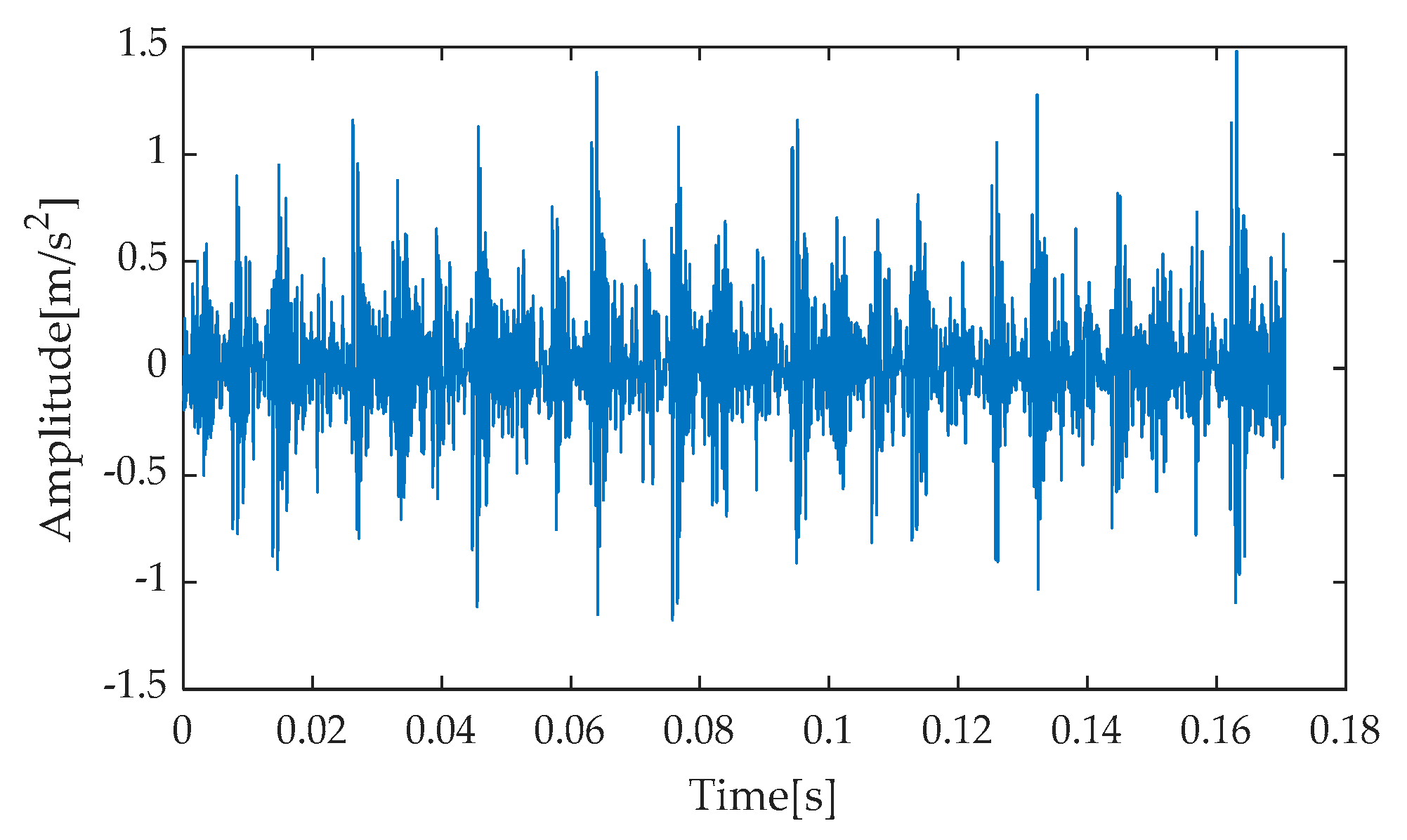

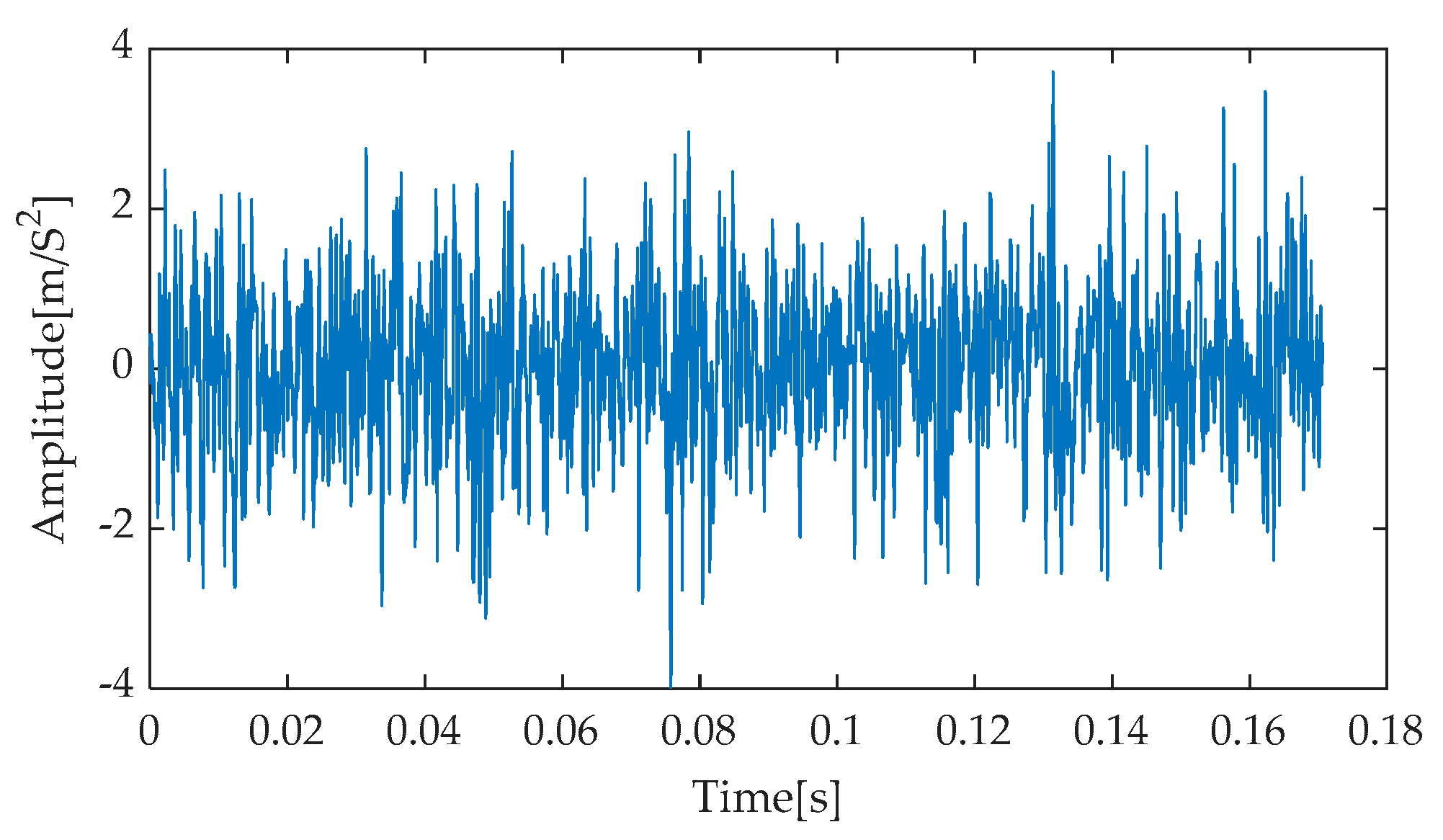

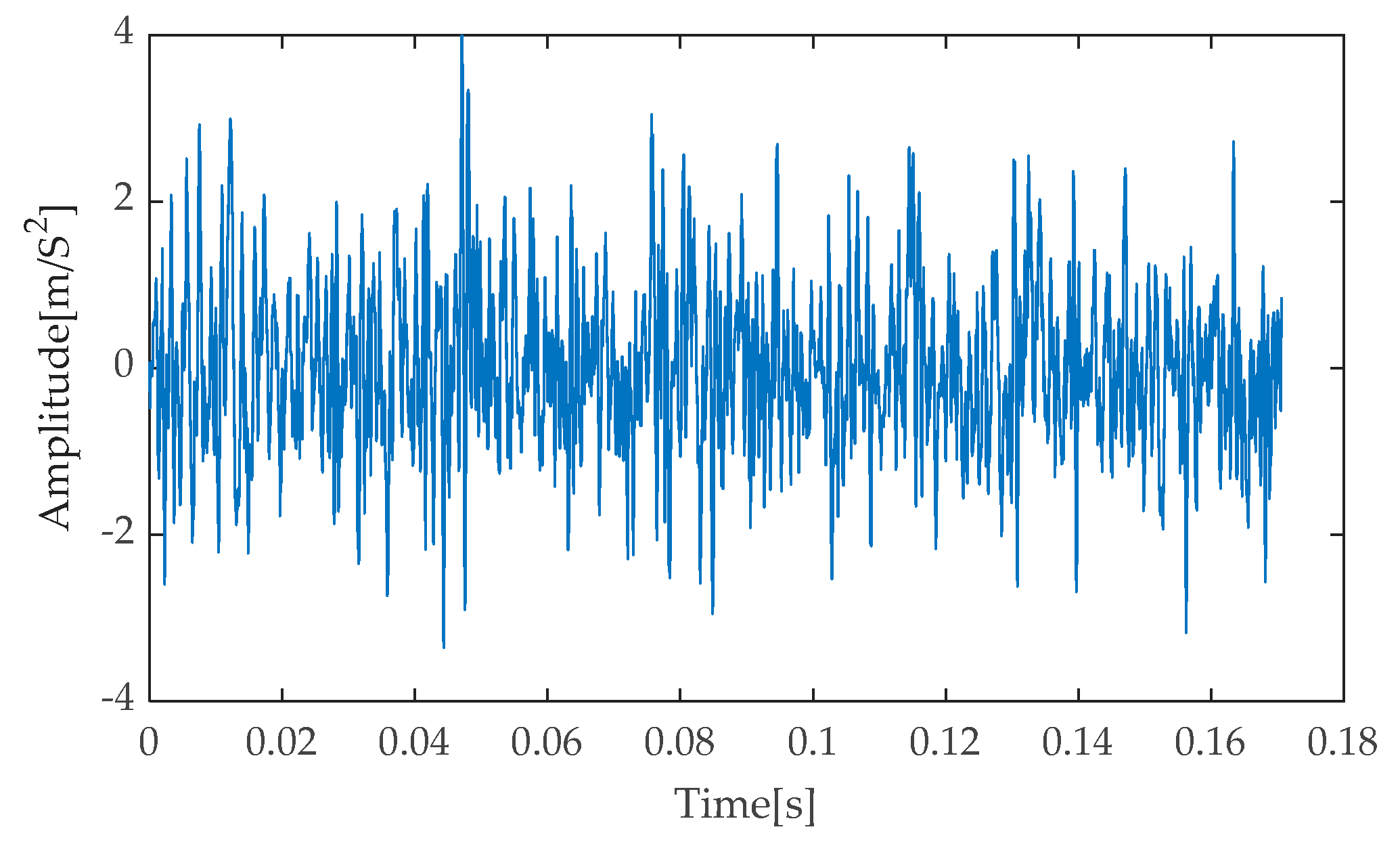

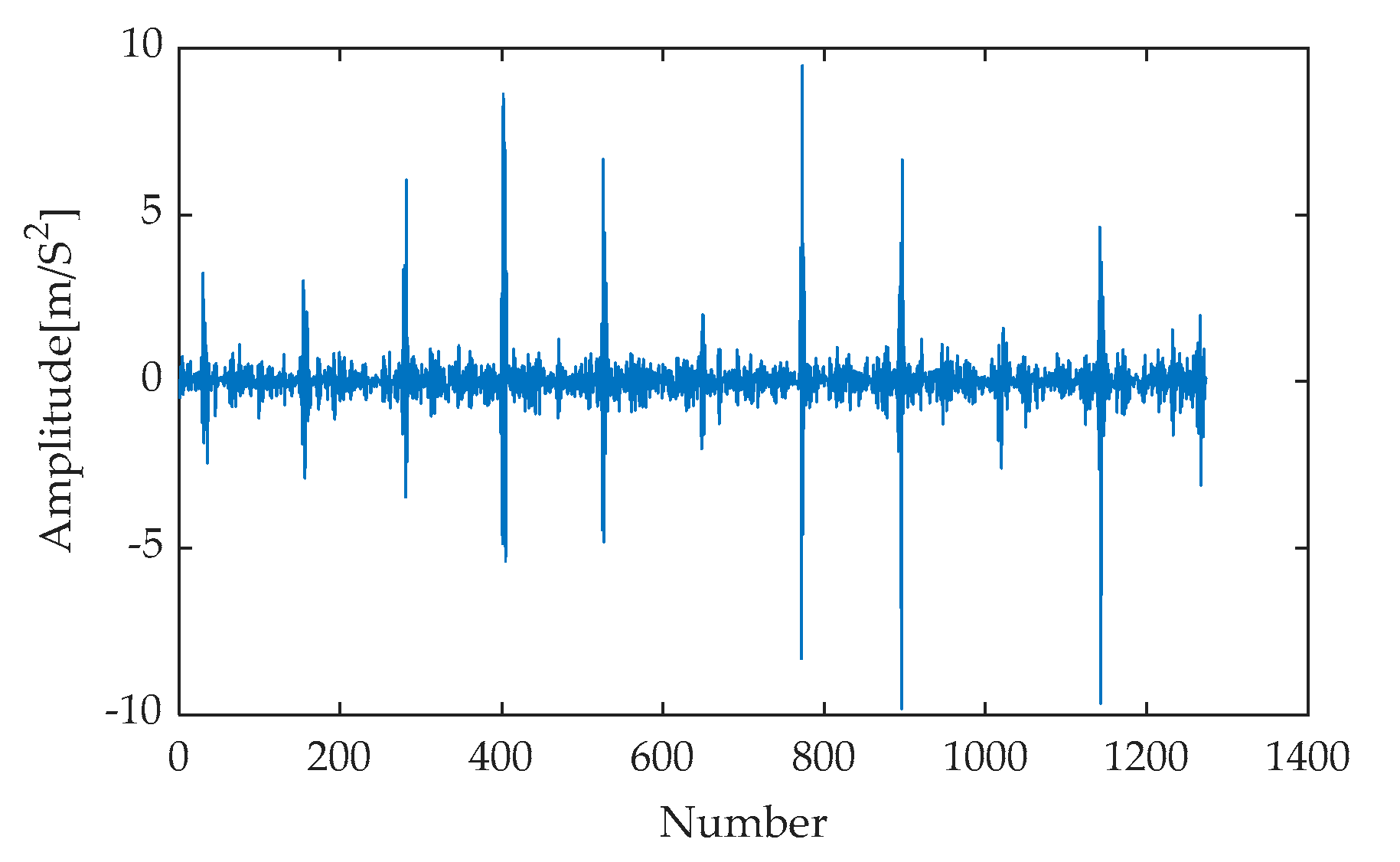

For the collected fault data, the time–domain waveform of the rolling bearing inner race fault is extracted, and the specific results are presented in

Figure 32. Upon close examination of this waveform, it can be discerned that the noise interference is relatively weak. To further validate the practicality and robustness of the method proposed in this paper, noise with a signal-to-noise ratio (SNR) of −3 dB was introduced into the pure inner race fault signal, constructing a composite signal. The time–domain representation of this composite signal is shown in

Figure 33. Observing

Figure 33, it becomes evident that the introduction of noise significantly impacts the clarity of the original inner race fault signal, particularly making the distinctive impact features more subtle and difficult to identify against the noise background. This experimental design aims to simulate the complex signal environment under real operating conditions to comprehensively evaluate the performance of the proposed method.

Given the significant impact of noise interference in signal analysis, this study first optimizes the key parameters of VMD through the IGOOSE to fine-tune its core parameters—specifically, the number of decomposition components and the penalty factor. The goal is to strengthen the initial conditions of VMD through optimal parameter configuration, laying a solid foundation for subsequent signal analysis. In the implementation strategy of the IGOOSE, the EECI proposed in this paper is adopted as the fitness function to achieve automatic search and optimization of VMD parameters, ensuring the efficiency and precision of the decomposition process. During the initialization phase of the IGOOSE, the search ranges for the critical VMD parameters are experimentally set as follows: the search interval for the number of decomposition components is set to [2, 10], and the search space for the penalty factor is determined to be [100, 5000], ensuring that the algorithm can conduct a comprehensive exploration within a reasonable parameter domain. Furthermore, the population size is set to 30 individuals, and the maximum number of iterations is limited to 30, aiming to balance the convergence speed and computational efficiency of the algorithm.

Figure 34 illustrates the fitness evolution curve of the IGOOSE, clearly reflecting the dynamic process of the algorithm rapidly approaching and locking onto the optimal solution. Ultimately, the experiments determined the optimal number of decomposition components to be 7, and the optimal value of the penalty factor was set at 739. These optimized parameters were then input into the VMD model for high-quality decomposition of the noisy simulation signals. To comprehensively validate the superiority of the IGOOSE-VMD method, this study employed the same evaluation framework as in the simulation signal experiments and introduced comparative analysis methods such as EMD, EEMD, LMD, and ITD.

Figure 35,

Figure 36,

Figure 37,

Figure 38 and

Figure 39 visually present the decomposition results of each method, providing rich data support for subsequent performance comparisons and in-depth analysis.

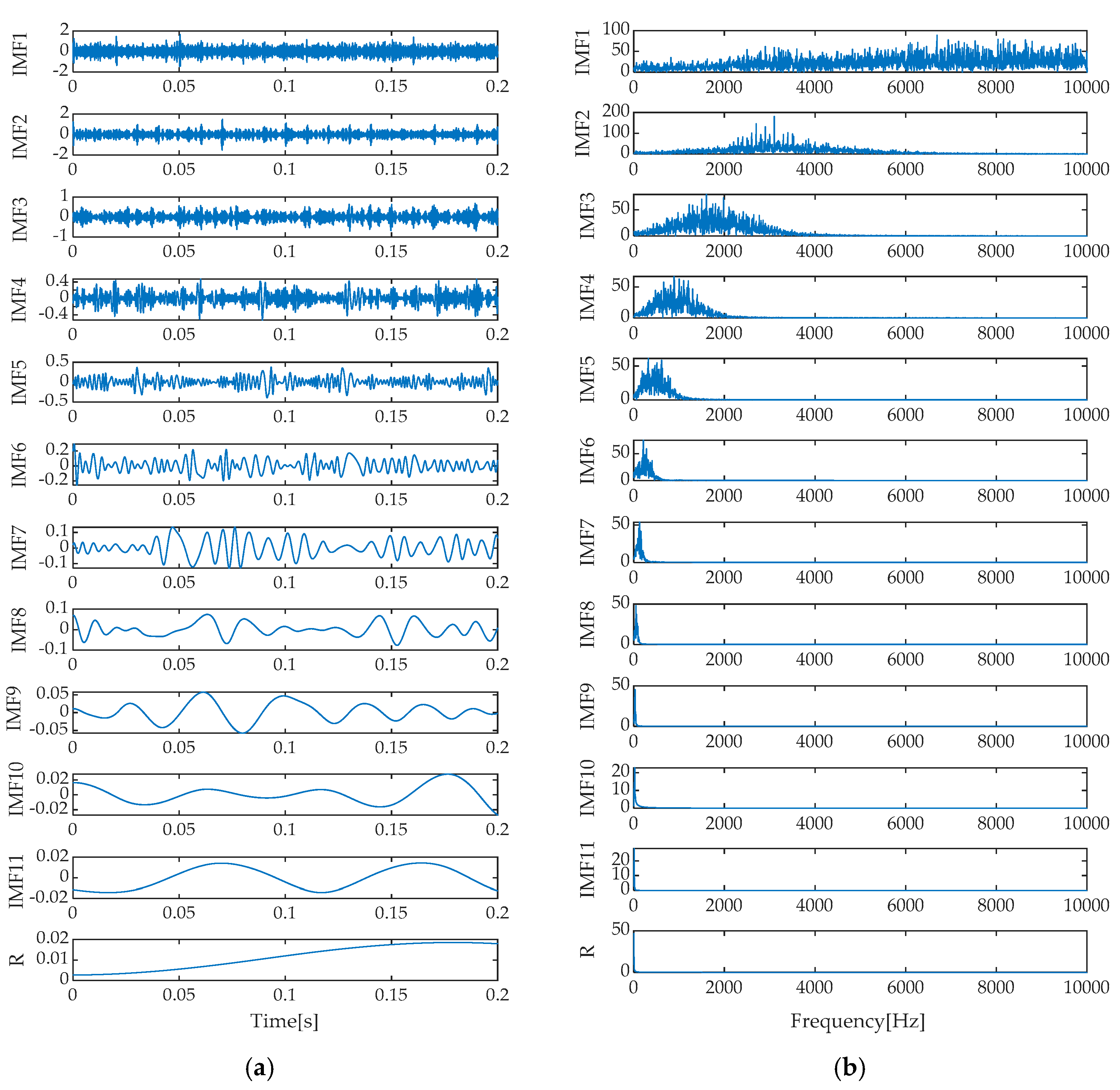

Upon meticulous analysis of the decomposition results presented in

Figure 35,

Figure 36,

Figure 37,

Figure 38 and

Figure 39, we can clearly contrast the performance differences among various signal decomposition techniques. Specifically, when applying the IGOOSE-VMD method for signal decomposition, seven independent signal components were successfully extracted, exhibiting excellent separation performance in their spectral characteristics. The boundaries between spectra are distinct and free from overlap, ensuring the purity and clarity of spectral information. In contrast, the EMD method produced a combination of 10 signal components and 1 residual component. By observing its time–domain waveform, we can identify significant modal mixing, which is further confirmed in the corresponding frequency spectrum, particularly among IMF1, IMF2, and IMF3 components, where spectral overlap is particularly prominent.

As an improvement over EMD, the EEMD method aims to mitigate modal mixing. However, in our experiments, its output still included 10 signal components and 1 residual term, and the modal mixing issue in the time domain remained largely unresolved. Spectral overlap was also observed in the frequency spectrum, indicating that EEMD’s improvement is limited in decomposing signals under complex noise environments. The LMD method demonstrated different decomposition characteristics, yielding five signal components and one residual term. From a time–domain perspective, LMD effectively suppressed modal mixing, but at the spectral level, some degree of spectral overlap was still visible among PF1 to PF3 components. Finally, the ITD method decomposed the signal into seven signal components and one residual term. Modal mixing reappeared in its time–domain representation, and spectral overlap between PRC1 and PRC3 components was also evident in the frequency spectrum.

To accurately identify and extract the most suitable signal components among various time–frequency analysis techniques, this study also employs the proposed E

ECI as an assessment criterion. During the experiments, the E

ECI values of each signal component under each time–frequency decomposition method were systematically calculated, and the detailed data were organized in

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13 for further analysis. From the exhaustive data in

Table 9, it can be intuitively inferred that the IMF4 component decomposed by the IGOOSE-VMD method exhibits the lowest E

ECI value, strongly suggesting that the energy of the signal damage characteristic frequency within this component is highly concentrated, and the damage characteristics are particularly prominent. Consequently, this study decides to adopt the IMF4 signal component as the basis for reconstructing the observation signal channel, while assigning the remaining components to the reconstruction system of the noise signal channel. Similarly, the data in

Table 10 reveals the significant advantage of the IMF1 component decomposed by the EMD method in terms of E

ECI, indicating that its energy is efficiently concentrated at the damage characteristic frequency, demonstrating an exceptional ability to capture signal damage. Therefore, IMF1 is selected as the core for reconstructing the observation signal channel, while the remaining components contribute to the reconstruction of the noise channel. Upon further examination of

Table 11, the EEMD method also highlights the leading position of the IMF1 component in E

ECI values. Therefore, IMF1 is chosen as the foundation for reconstructing the observation signal channel, with the remaining components aiding in the reconstruction of the noise signal channel. In the application analysis of the LMD method (as shown in

Table 12), the PF1 component stands out with the lowest EECI value. Based on this, PF1 is designated as the primary component for reconstructing the observation signal channel, while the other components contribute to the construction of the noise signal channel. Finally, the data in

Table 13 indicates that the PRC3 component decomposed by the ITD method possesses the smallest E

ECI value, which also verifies the high degree of energy concentration on the signal damage characteristic of this component. Therefore, PRC3 is identified as the crucial element for reconstructing the observation signal channel, and the remaining components are utilized in the construction of the noise signal channel. Based on these selection results, this study employs the same comparison criteria as in the simulation experiments to conduct an in-depth comparative analysis of the noise reduction performance between the proposed method and traditional methods such as EMD-RobustICA, EEMD-RobustICA, LMD-RobustICA, and ITD-RobustICA, aiming to comprehensively evaluate and validate the effectiveness of the proposed method.

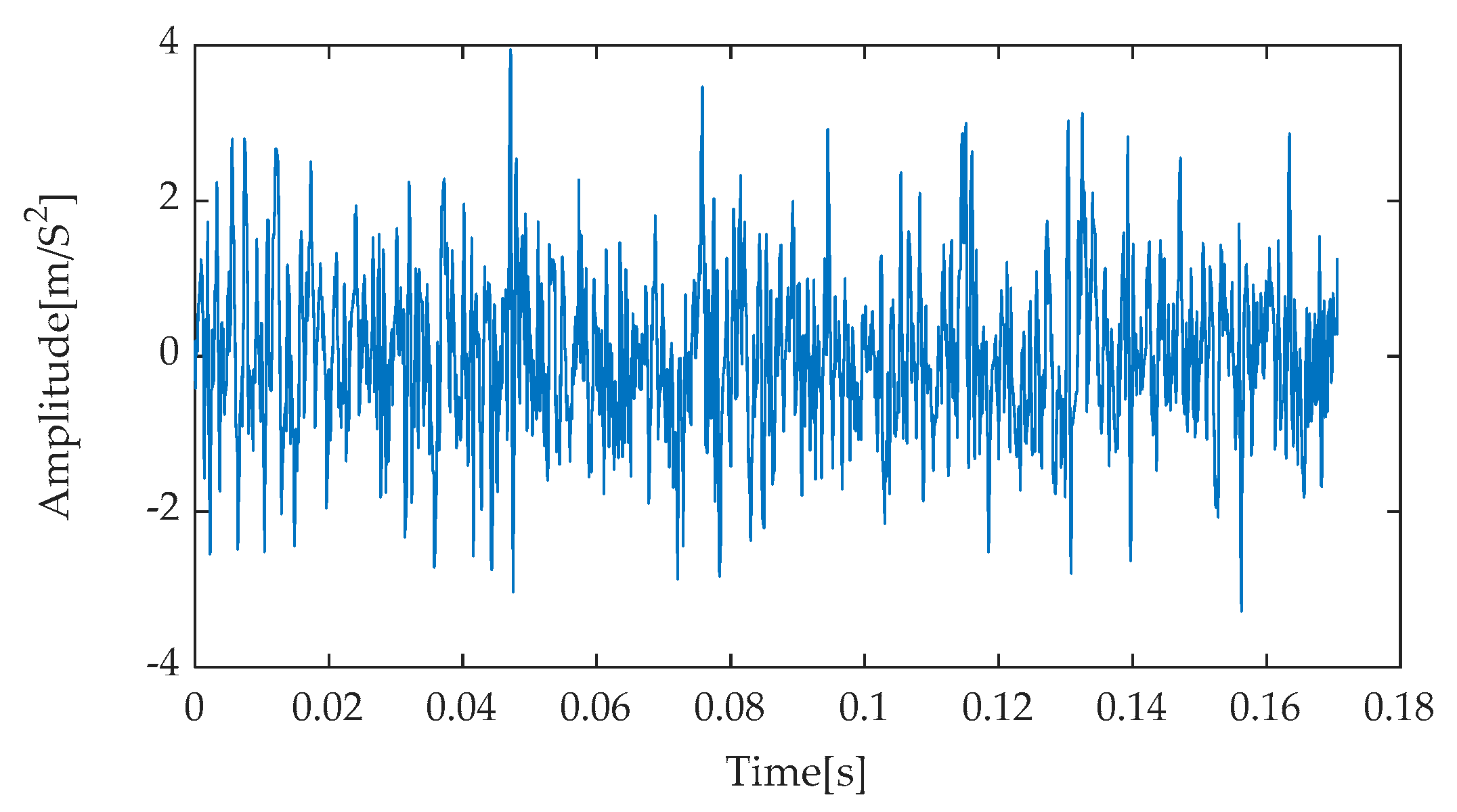

During the thorough examination of the experimental results,

Figure 40,

Figure 41,

Figure 42,

Figure 43 and

Figure 44 visually present the time–domain waveform characteristics after noise reduction using various methods. Through meticulous comparison and analysis of these waveforms, the IGOOSE-VMD-RobustICA method proposed in this paper demonstrates its unique superiority. Specifically, the processed signal exhibits a clearer waveform profile with prominently enhanced periodic impulse components, showcasing a high degree of clarity and discriminability. This characteristic is crucial for subsequent signal analysis and feature extraction. In contrast, traditional methods such as EMD-RobustICA, EEMD-RobustICA, LMD-RobustICA, and ITD-RobustICA, though capable of suppressing noise to some extent and revealing impulse components within the signal, are limited by higher background noise levels in the presentation of these components. Specifically, in the waveforms after noise reduction using these traditional methods, the impulse components are often surrounded or interfered with by more significant noise peaks that are not directly related to the signal characteristics, leading to a decrease in overall waveform clarity and affecting the accurate capture of the signal’s true characteristics.

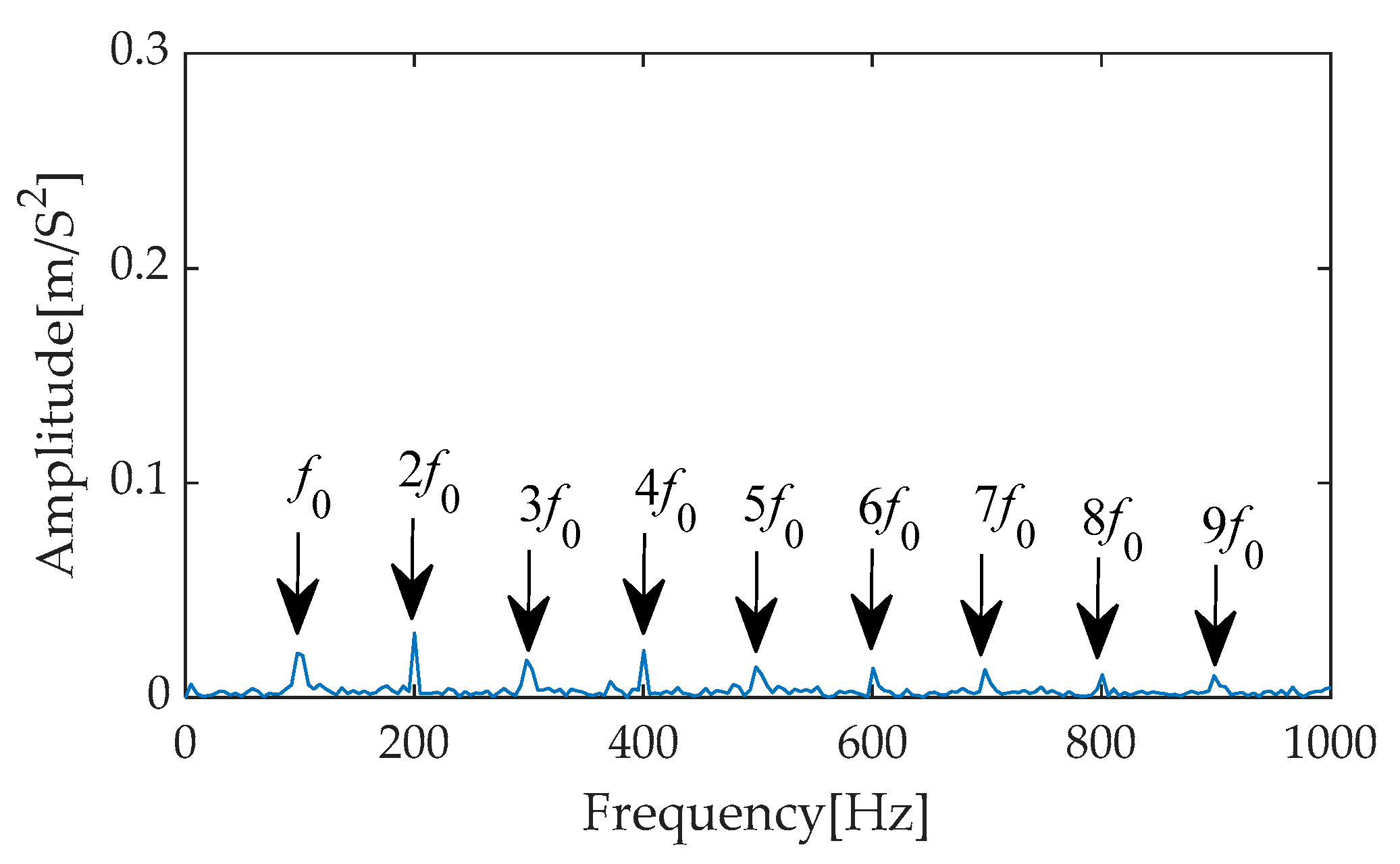

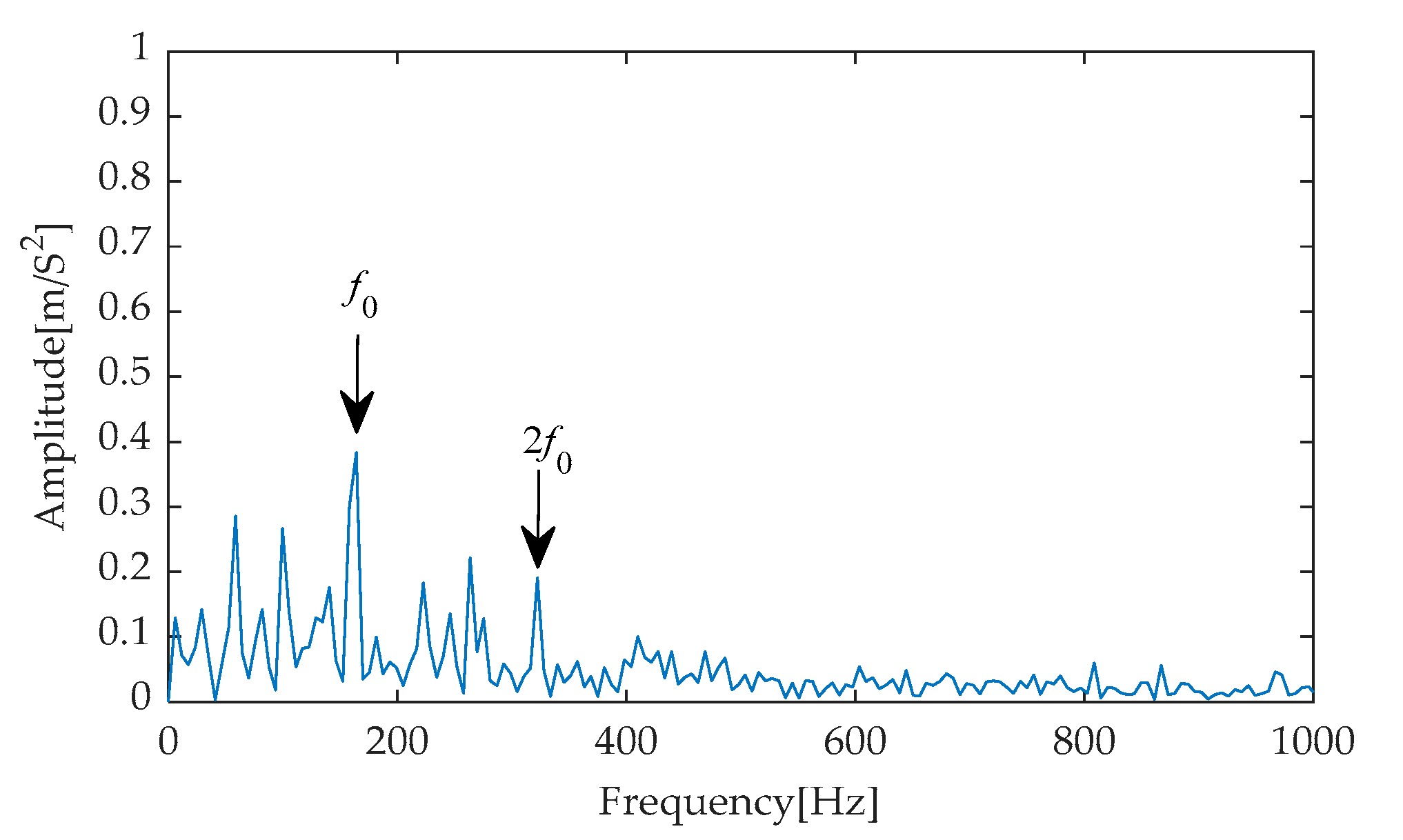

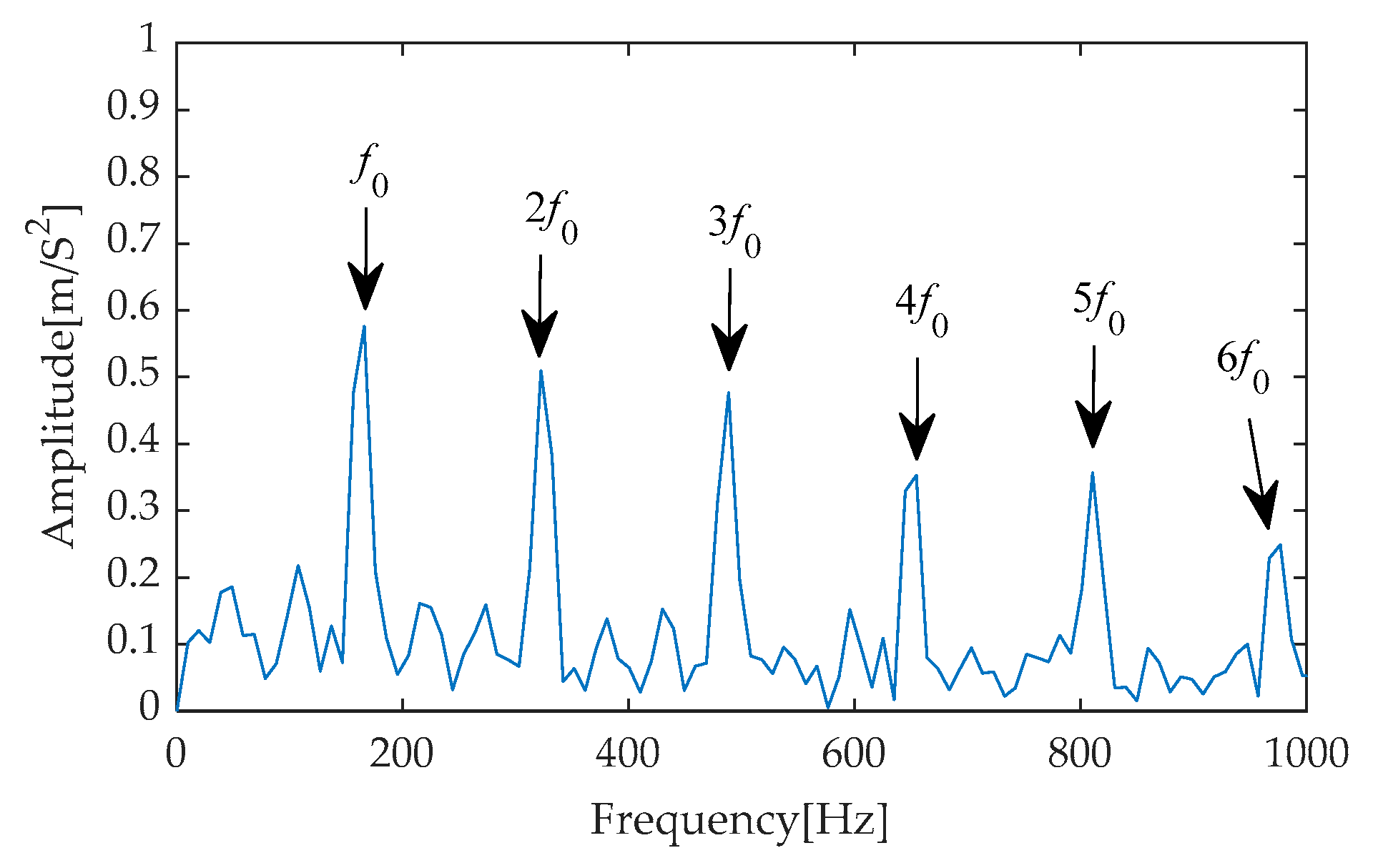

In the subsequent stage of the experiment, we performed Hilbert envelope demodulation on the time–domain signals obtained after separating signals from noise through the aforementioned methods, aiming to precisely extract fault features. The resulting envelope spectra (

Figure 45,

Figure 46,

Figure 47,

Figure 48 and

Figure 49) provided us with intuitive analytical evidence. Specifically,

Figure 45 exhibits the envelope spectrum processed by the method proposed in this paper, where multiple prominent high-amplitude peaks are clearly visible, particularly the first and second harmonics of the fault characteristic frequency, which are distinctly outlined with prominent amplitudes. Notably, the amplitudes of unrelated interference components in the background remain at a low level, effectively reducing the disturbance to the identification of fault characteristics. In contrast,

Figure 46,

Figure 47,

Figure 48 and

Figure 49 present the envelope spectra obtained using traditional methods such as EMD-RobustICA, EEMD-RobustICA, LMD-RobustICA, and ITD-RobustICA, respectively. Although these methods can also capture the first and second harmonics of the fault characteristic frequency, their amplitudes appear relatively weaker and are surrounded by numerous unrelated interference waveforms with similar amplitudes, undoubtedly increasing the difficulty of fault feature identification and potentially leading to misinterpretation or omission in subsequent fault diagnosis. The aforementioned comparative analysis demonstrates that the method proposed in this paper exhibits superior performance in fault feature extraction, with more significant extraction effects, contributing to improved accuracy and reliability in fault diagnosis. To further enhance the periodic impulse characteristics in the signal, the denoised signal was input into the designed CYCBD filter, aiming to further highlight the crucial fault information within the signal.

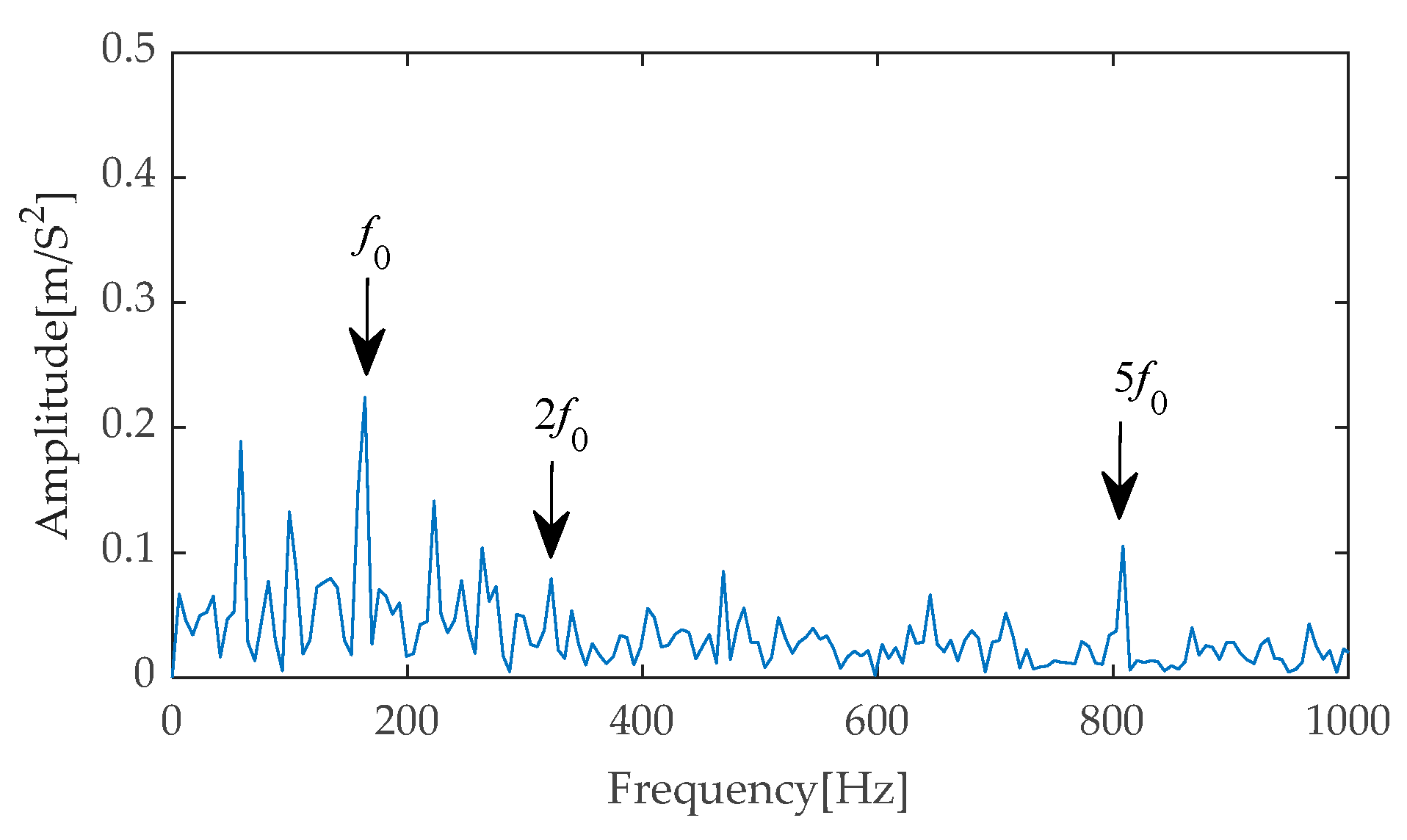

By inputting the signal processed by IGOOSE-VMD-RobustICA into the CYCBD filter for filtering, the experiment obtained an optimized time–domain waveform signal, as shown in

Figure 50. In the depiction of the time–domain waveform in

Figure 50, the filter successfully highlights the periodic impulse components within the signal, making them visually prominent and significantly amplifying their amplitudes, thereby demonstrating the effectiveness of the filtering process in enhancing signal characteristics. Subsequently, Hilbert envelope demodulation was performed on the filtered signal, and the corresponding envelope spectrum analysis is presented in

Figure 51. The experiment focused on an in-depth analysis within the frequency range of 0 to 1000 Hz. Within this range, the fault characteristic frequency and its multiples (specifically, the second to sixth harmonics) are prominently displayed with extremely high amplitudes, forming a clearly distinguishable frequency distribution pattern. This phenomenon not only validates the excellent performance of the CYCBD filter in extracting and enhancing fault features but also strongly supports the conclusion that there is a fault in the inner race of the bearing system.

To comprehensively and laterally evaluate the filtering performance of the CYCBD method, this study further selected signals denoised by the IGOOSE-VMD-RobustICA algorithm as the analysis subjects. Subsequently, three deconvolution techniques, namely MCKD, MED, and OMEDA, were applied to these signals for in-depth filtering. To refine the assessment of filtering effects, Hilbert envelope analysis was conducted on the signals processed by each method, and corresponding envelope spectra were plotted, as shown in

Figure 52,

Figure 53 and

Figure 54. Through meticulous analysis of these envelope spectra, it is observed that the MCKD, MED, and OMEDA methods are all capable of effectively extracting multiple harmonic components of the bearing inner race fault characteristic frequency. Specifically, within the frequency range of 0 Hz to 1000 Hz, the MCKD successfully identifies and extracts the first, second, and fifth harmonics of the inner race fault characteristic frequency; the MED similarly captures these harmonic components; whereas the OMEDA extends the detection range further, additionally extracting the third harmonic. These findings demonstrate the efficacy of these deconvolution techniques in fault feature extraction. However, compared to the CYCBD, while the aforementioned methods can identify similar fault characteristic frequencies, they exhibit relatively lower amplitudes in the extracted fault characteristic frequencies, and the envelope spectra still contain a certain degree of non-target component interference.