A Generic Modeling Method of Multi-Modal/Multi-Layer Digital Twins for the Remote Monitoring and Intelligent Maintenance of Industrial Equipment

Abstract

1. Introduction

2. Literature Review

2.1. The Methods for DT Modeling

2.2. The Methods for Modeling the Working Flows and Operation Mechanisms in DT

2.3. The Methods for Building Intelligent DT Models

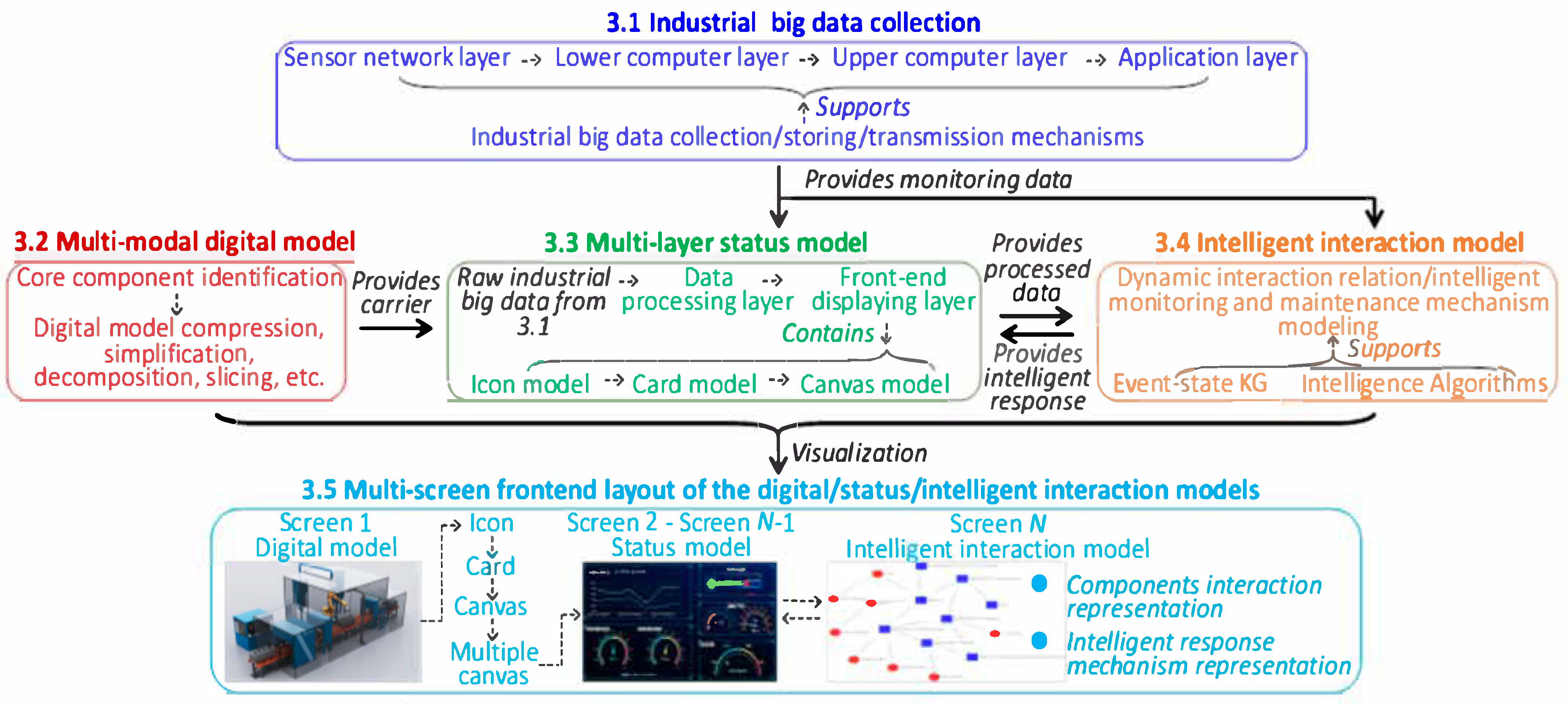

3. The Generic DT Modeling Method

- Industrial big data collection, which provides a data basis for the DT

- Digital/Status/Intelligent interaction models of the object equipment, which are the core for representing the monitoring data, and the dynamic operation/maintenance workflow and mechanisms of the DT

- Multi-screen-based front-end layout of the DT

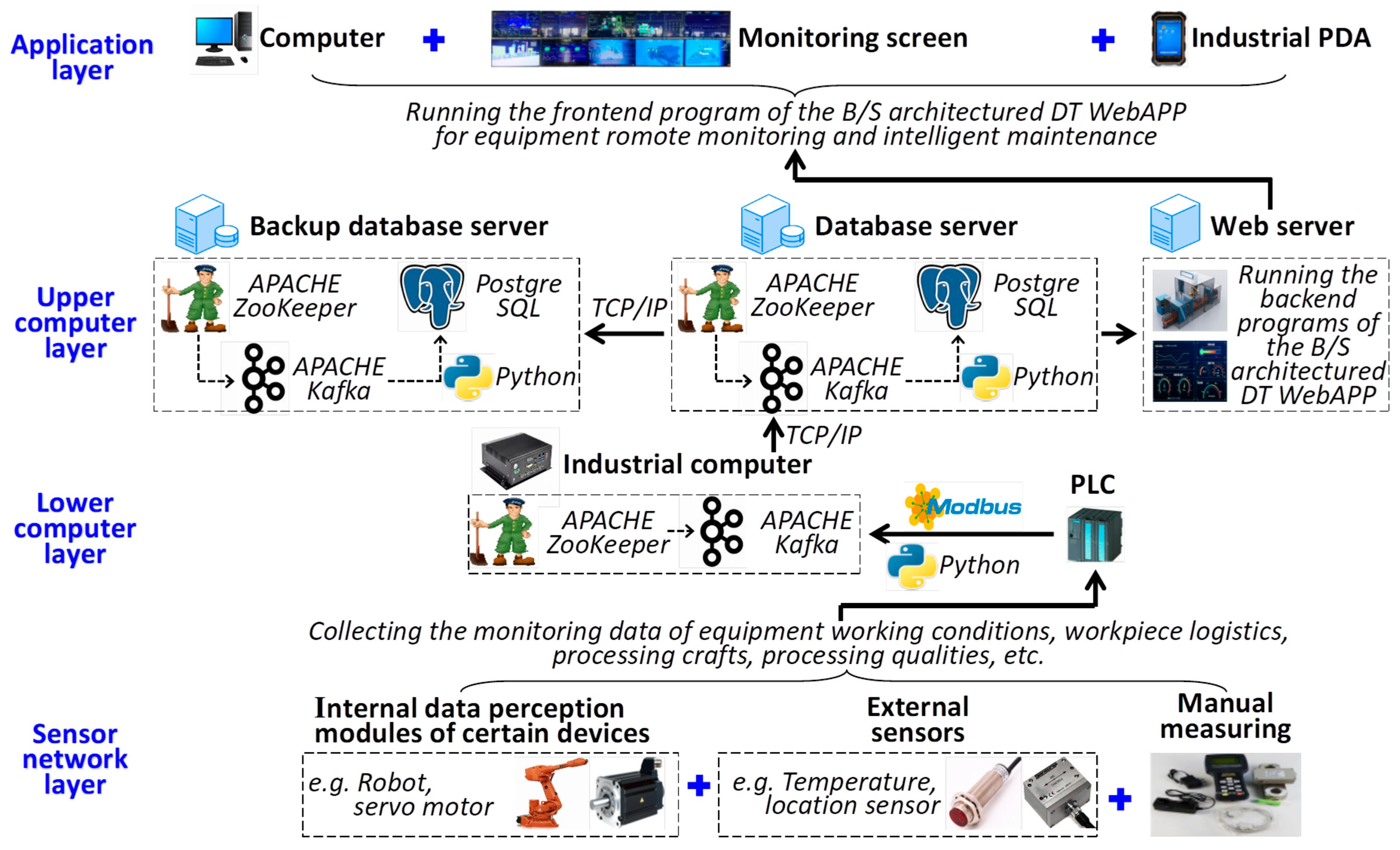

3.1. Industrial Big Data Collection for Equipment Remote Monitoring and Intelligent Maintenance

3.1.1. Sensor Network Layer

3.1.2. Lower Computer Layer

3.1.3. Upper Computer Layer

3.1.4. Application Layer

3.2. Multi-Modal Digital Model

3.2.1. Non-Modular Configurable Digital Models

- Overall model: It represents the digital model of the entire equipment, and it can be separated into (1) Simplified 3D models, which are compressed from the original 3D CAD models (such as .gltf or .draco files compressed through SolidWorks Visualize software); (2) 2D image of the Simplified 3D model; (3) 2D schematic diagram, which is further simplified from 2D image model and can be loaded even faster in the front-end DT software program;

- Key partial model: It represents only part of the entire equipment that is important for the monitoring and maintenance tasks. It can be further separated into (1) Simplified partial 3D model, which is also the compressed and simplified version of the original 3D CAD model of the object equipment; (2) Simplified partial 2D model, which can be either the surface image or cross-section image of the object equipment.

3.2.2. Modular Configurable Digital Models

- Simplified 3D configuration model: This subtype is also built from compressing and simplifying the original 3D CAD model of the object equipment, but with separated and configurable modules.

- Simplified 2D configuration model: As the name suggests, this subtype is similar to the previous one but with (1) simplified 2D images or (2) simplified 2D schematic diagrams. It is worth mentioning that the simplified 2D schematic diagram is actually the traditional configuration user interface front-end of SCADA software [38], which was established before the concept of DT.

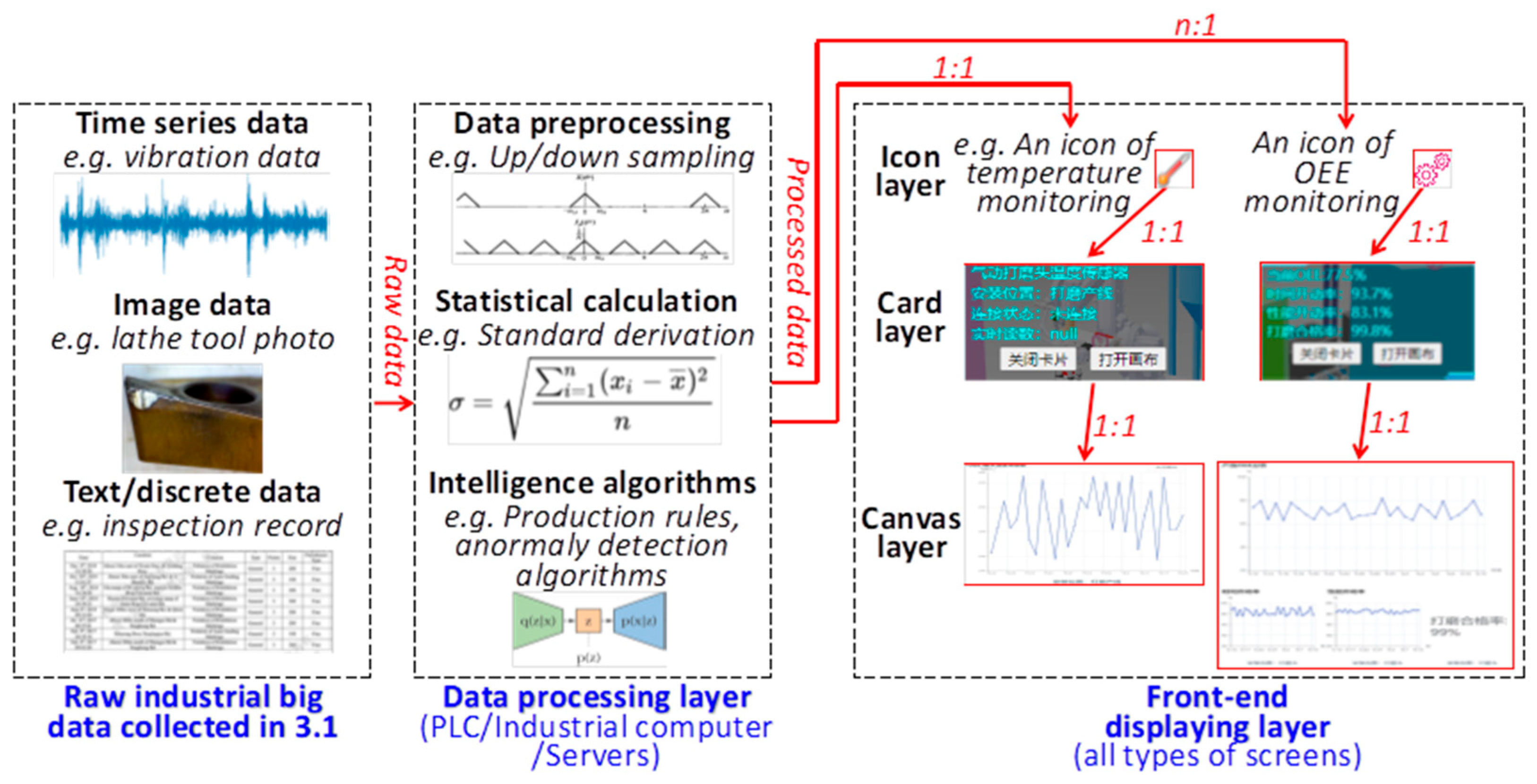

3.3. Multi-Layer Status Model

- Data preprocessing. It includes data cleaning, data format unifying, up/down sampling, etc., and all the functions are for providing processed data more easily for extracting valuable information from raw data.

- Statistical calculation. It indicates using statistical calculation to extract certain features of the preprocessed data, such as standard deviations, peak values, and more complicated features, such as continuously increasing by 7 points in statistical process quality control algorithms.

- Intelligent algorithms. It indicates applying different types of intelligent algorithms to extract monitoring and maintenance-related information from the preprocessed data. For example, production rule-based reasoning can be used for basic working condition separation, and deep learning-based anomaly detection algorithms can be used for providing early alarms of working conditions/processing crafts/processing quality anomalies.

- Icon layer. It is a kind of icon, each of which represents a source for data collection, and the position where the icon was placed in the digital model indicates the position of the corresponding sensor placed on the equipment.

- Card layer. By clicking an icon on the digital model, the corresponding card layer of the icon would be displayed in a pop-up window. The card would display an abstract of the corresponding data source and the sensor. For example, in Figure 4, the icon of a thermometer in the front-end interface of a DT program can be placed at the corresponding position of the thermometer on the real equipment. By clicking on the icon, the name/type/location/real-time temperature data of the thermometer would pop up in the front-end interface.

- Canvas layer. It would pop up after clicking on the card and present more detailed descriptions of the monitoring data and the sensor. For example, the historical time series temperature data collected by the thermometer would be displayed in the canvas, and further functions such as anomaly alarm, short-term future temperature prediction, and control/optimization suggestions can also be contained in the canvas. It is worth mentioning that one icon model always corresponds to one card model, and one card model always corresponds to one canvas model. However, one icon model could correspond to one or multiple data sources. For example, a temperature icon model corresponds to a thermometer, while the overall equipment effectiveness (OEE) icon model corresponds to time activation rate data, performance rate data, and qualified product rate data.

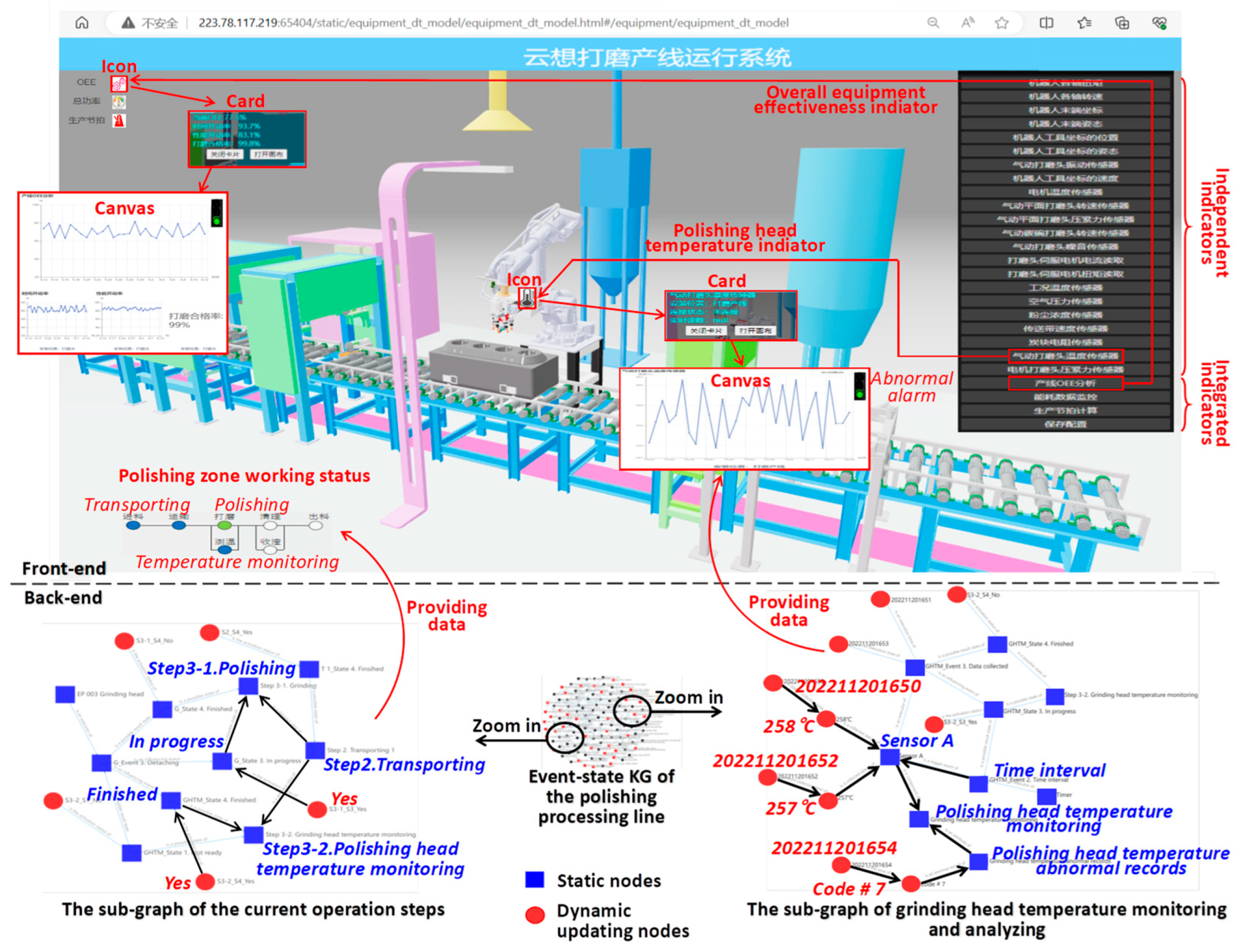

3.4. Event-State Knowledge Graph-Based Intelligent Interaction Model

3.4.1. The Nodes in the Event-State KG

- A component node represents the component in the original physical system, sensor network, or status model of the equipment (e.g., in Figure 5, Visual detection module A is a component).

- A step node represents a step during the operation process of the equipment (e.g., Step 3.1 Polishing).

- A state node represents a possible state of a step node, which can be Not ready→ Ready→ In progress →Finished. It is worth mentioning how many states for step can be determined according to the real situation.

- A yes/no node indicates which one of the possible states of a step node is currently activated (e.g., Yes → Not ready → Step 3.1 Polishing indicates that the state of Not ready is currently activated, which means Step 3.1 Polishing is currently Not ready).

- An event node represents an event that can trigger the updating of the state nodes (e.g., Ready → In position → Not ready indicates that the occurrence of In position would trigger the state changing of the event node from Not ready to Ready).

- The datum node stores one piece of monitoring data collected by a sensor component (e.g., Datum 1 → Sensor A).

- An algorithm node represents an algorithm model (e.g., an anomaly detection (AD) algorithm model) that can process the data collected from a sensor (e.g., Sensor A → AD algorithm).

- A calculation result node represents the calculation or analysis result of an algorithm node (e.g., Calculation result 1 → AD algorithm).

- A time node records the time of the incident of an event or the time when a piece of monitoring data was collected (e.g., Time 1 → Datum 1).

3.4.2. The Links in the Event-State KG

- A link that starts from step A to step B indicates that step A is the previous step of step B (e.g., Step 2. Transporting 1 → Step 3.1 Polishing).

- A link that starts from component A to component B indicates that component A is a sub-component of component B (e.g., Polishing head → Robot).

- A link starts from a state node to a step node indicates that the state is one of the possible states of the step (e.g., Not ready → Step 3.1 Polishing).

- A link starts from a Yes/No node to a state node indicates that the state is currently activated/inactivated (e.g., “Yes → Not ready → Step 3.1 Polishing” indicates that Step 3.1 Polishing is currently not ready).

- A link starts from a component node to an event node indicates that the component is the executor or the trigger of the event (e.g., “Timer → Time interval passed” indicates that the timer emits a signal at regular intervals, and it triggers the occurrence of the event of “Time interval passed”).

- A link starts from an event node to a component node indicates that if the event occurred the component would be triggered to execute its function (e.g., “Time interval passed → Sensor A” indicates that for each time the event of “Time interval passed” Sensor A would collect a piece of monitoring datum).

- A link that starts from a datum node to a component node indicates that the datum recorded in the datum node was collected by the component. In addition, a component may have collected several pieces of data and therefore be connected with several datum nodes (e.g., Datum 1 → Sensor A ← Datum2).

- A link that starts from a time node to a datum node indicates that the datum was collected at the time (e.g., Time 1 → Datum 1)

- A link that starts from a time node to an event node indicates that the event occurred at that time. In addition, an event may occur several times and therefore be connected with several time nodes (e.g., Time 1 → Datum collected ← Time 2).

- A link starts from a component node to an algorithm node indicates that the data collected by the component would be sent to the algorithm model as input (e.g., Sensor A → AD algorithm).

- A link starts from an algorithm node to an event node indicates that every time the algorithm generates a new calculation result, the event would occur (AD algorithm → New analysis result generated).

- A link that starts from a calculation result node to an algorithm node indicates that the former records the newest calculation result of the latter (e.g., Calculation result 1 → AD algorithm).

- A link starts from a calculation result node to an event node indicates that the updating of the calculation result would trigger the occurrence of the event (Calculation result 1→ Front-end alarm updated).

3.4.3. The Dynamic Automatic Updating Mechanisms of the Event-State KG

- The state-changing mechanism of a step node is triggered by the state(s) changing of another (other) step node(s). It represents the working flow during the operation and maintenance of the object equipment. An example of the state-changing mechanism of Step 4 Transporting 2 triggered by the state-changing of its two previous steps (i.e., Step 3.1 Polishing and Step 3.2 Polishing head temperature monitoring) can be represented with the pseudocode below.

Assume that currently both Step 3.1 Polishing and Step 3.2 Polishing head temperature monitoring are in the state of In progress, and Step 4 Transporting 2 is in the state of Not ready. If the current states of Steps 3.1 and 3.2 have been updated to Finished The current state of Step 4 would be automatically updated to Ready Else The current state of Step 4 remains Not ready - The state-changing mechanism of a step node is triggered by the occurrence of an event. For example, in Figure 5, the links of Yes → Not ready → Step 3.1 Polishing indicate that Not ready is a possible state of Step 3.1 Polishing, and currently Not ready is activated, i.e., Step 3.1 Polishing is currently not ready. The links of No → Ready → Step 3.1 Polishing indicate that Ready is another possible state of Step 3.1 Polishing, and currently Ready is not activated. The links of Ready → In position → Not ready indicate that In position is the event that could trigger the state changing from Not ready to Ready for Step 3.1 Polishing, and the trigger mechanism can be realized with the pseudocode below.

Assume that currently Step 3.1 is not ready If the event of In position occurred The current state of Step 3.1 would be automatically updated from Not ready to Ready Else The current state of Step 3.1 remains as Not ready - The state-changing mechanism within a step node. It guarantees that for each step node, only one of its two states (i.e., Yes or No) can be activated at the same time. Assuming that a step node has several states, then the mechanism can be represented with the pseudocode below.

For all the state nodes of step node n If state i is currently activated The rest state node would be inactivated - Monitoring data recording mechanism. It supports the automatic updating of data nodes. An example pseudocode for recording the monitoring data collected by Sensor A is listed below.

For each time the event of the Time interval has occurred A new piece of monitoring data would be collected by Sensor A, and the new datum would be recorded in a newly generated datum node linked to Sensor A The time when the new datum was collected would be recorded in a newly generated time node linked to the newly generated datum node - Algorithm operation mechanism. It realizes the operation of the algorithm node for updating the monitoring/maintenance-related contents of the event-state KG. Here, a deep learning-based AD algorithm for predicting equipment anomaly according to the monitoring data from Sensor A is listed below as an example. It is worth mentioning that the mechanism here mainly defines how to integrate AI models into the event-state KG. How to build or train the AI models is not the focus of the event-state KG.

For each time a new piece of monitoring data has been collected by the sensor connected to the AD algorithm node The trained AD model represented by the AD algorithm node would run with the new datum as input The Calculation result 1 linked to the AD algorithm would be updated according to the new output

3.5. Multi-Screen Front-End Layout of the Digital/Status/Intelligent Interaction Models

4. Case Study

4.1. A DT with Configurable Module-Based Digital/Status Models but a Weak Intelligent Interaction Model

4.1.1. Constructing the Configurable Modules of the Digital Model of the Processing Line DT

- Polishing devices: Top surface polishing, Side surface polishing, Bottom surface polishing.

- Robot body: IRB 5710, IRB 6700, IRB 7600.

- Dust control devices: Dust cover, Vacuum cleaner, Dust collector.

- Sensors: Thermometer, Vibrating sensor, Pressure sensor, Position sensor, etc.

- Auxiliary devices: Centering mechanism, Clamping mechanism, Conveyor belt, Control cabinet, etc.

4.1.2. Configuring the Digital and Status Model of the DT

4.2. A DT with Static 3D Digital Model, Multi-Layer Status Model, and Strong Intelligent Interaction Model

4.3. A DT with Weak Digital Model but Strong Status/Intelligent Interaction Models Represented with Split Screen

- Robot 1/2—Current: displaying the current data of the six axes of Robot 1/2.

- Overall equipment effectiveness: displaying the OEE calculation result and its factors of the processing line, including Qualification rate, Time activation rate, and Performance efficiency. The monitoring object in this subarea can be constantly scrolling among integrated indicators, e.g., OEE, Overall energy consumption, and Production tact.

- Polishing head compression force/rotation speed: including the compression force/rotation speed data of polishing heads 1 and 2.

- Polishing head temperature: the temperature of a monitoring point on the polishing head body.

- Dust cap temperature/pressure/dust concentration: the temperature, air pressure (should be negative pressure), and dust concentration inside the dust cap.

- Processing line overall status: indicating whether the core functional components of the processing line are working or halting, and the position of the carbon block currently being processed. As the customer prepared only one screen for the DT, the digital model is displayed in a subarea of the screen. However, the customers can click on the digital model for an enlarged view similar to the case in Section 4.2.

- Abnormal records: logs recording abnormal alarms.

5. Discussion and Conclusions

5.1. Characteristics and Contributions

5.1.1. From a Methodology Perspective

5.1.2. From a Technique Perspective

5.2. Issue Worth Further Exploration

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Toothman, M.F.; Braun, B.; Bury, S.J.; Moyne, J.; Tilbury, D.M.; Ye, Y.; Barton, K. A digital twin framework for prognostics and health management. Comput. Ind. 2023, 150, 103948. [Google Scholar] [CrossRef]

- Hossain, R.; Ahmed, F.; Kobayashi, K.; Koric, S.; Abueidda, D.; Alam, S.B. Virtual sensing-enabled digital twin framework for real-time monitoring of nuclear systems leveraging deep neural operators. NPJ Mater. Degrad. 2025, 9, 21. [Google Scholar] [CrossRef]

- Leng, J.; Zhu, X.; Huang, Z.; Xu, K.; Liu, Z.; Liu, Q.; Chen, X. ManUChain II: Blockchained smart contract system as the digital twin of decentralized autonomous manufacturing toward resilience in industry 5.0. IEEE Trans. Syst. Man Cybern. Syst. 2023, 53, 4715–4728. [Google Scholar] [CrossRef]

- Bai, L.; Zhang, J.; Yan, J.; López de Lacalle, L.N.; Muñoa, J. Cutting Model Integrated Digital Twin–based Process Monitoring in Small-batch Machining. Int J. Adv. Manuf. Technol. 2025, 136, 109–121. [Google Scholar] [CrossRef]

- Willard, J.; Jia, X.; Xu, S.; Steinbach, M.; Kumar, V. Integrating scientific knowledge with machine learning for engineering and environmental systems. ACM Comput. Surv. 2022, 55, 1–37. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Yuan, Y.; Zhang, S.; Hu, W.; Ma, J.; Tan, J. Digital-twin-enabled online wrinkling monitoring of metal tube bending manufacturing: A multi-fidelity approach using forward-convolution-GAN. Appl. Soft Comput. 2025, 171, 112684. [Google Scholar] [CrossRef]

- Liu, C.; Chen, Y.; Xu, X.; Che, W. Domain generalization-based damage detection of composite structures powered by structural digital twin. Compos. Sci. Technol. 2024, 258, 110908. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, C.; Li, Z.; Ding, K.; Wang, C. Knowledge-driven digital twin manufacturing cell towards intelligent Manufacturing. Int. J. Prod. Res. 2019, 58, 1034–1051. [Google Scholar] [CrossRef]

- Cao, Q.; Giustozzi, F.; Zanni-Merk, C.; Bertrand, F.; Reich, C. Smart condition monitoring for industry 4.0 manufacturing processes: An ontology-based approach. Cybern. Syst. 2019, 50, 82–96. [Google Scholar] [CrossRef]

- Piltan, F.; Kim, J.-M. Bearing anomaly recognition using an intelligent digital twin integrated with machine learning. Appl. Sci. 2021, 11, 4602. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Ponciroli, R.; Bruck, P.; Esselman, T.C.; Rigatti, J.A.; Vilim, R.B. A digital twin approach to system-level fault detection and diagnosis for improved equipment health monitoring. Ann. Nucl. Energy 2022, 170, 109002. [Google Scholar] [CrossRef]

- VanDerHorn, E.; Wang, Z.; Mahadevan, S. Towards a digital twin approach for vessel-specific fatigue damage monitoring and prognosis. Reliab. Eng. Syst. Saf. 2021, 219, 108222. [Google Scholar] [CrossRef]

- Klein, C.; Wolters, F.; Reitenbach, S.; Schönweitz, D. Integration of 3D-CFD Component Simulation Into Overall Engine Performance Analysis for Engine Condition Monitoring Purposes. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Li, W.; Rentemeister, M.; Badeda, J.; Jöst, D.; Schulte, D.; Sauer, D.U. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557. [Google Scholar] [CrossRef]

- Li, T.; Liao, Z.; Cai, Y. Reprint of: Physical modeling for digital twin of continuous damping control damper. J. Manuf. Process. 2023, 100, 55–63. [Google Scholar] [CrossRef]

- Brandtstaedter, H.; Ludwig, C.; Hubner, L.; Tsouchnika, E.; Jungiewicz, A.; Wever, U. Digital Twins For Large Electric Drive Trains. In Proceedings of the 2018 Petroleum and Chemical Industry Conference Europe, Antwerp, Belgium, 5–7 June 2018. [Google Scholar]

- Papacharalampopoulos, A. Investigating data-driven systems as digital twins: Numerical behavior of Ho–Kalman method for order estimation. Processes 2020, 8, 431. [Google Scholar] [CrossRef]

- Wang, J.; Fei, Z.; Chang, Q.; Li, S. Energy saving operation of manufacturing system based on dynamic adaptive fuzzy reasoning Petri net. Energies 2019, 12, 2216. [Google Scholar] [CrossRef]

- He, B.; Cao, X.; Hua, Y. Data fusion-based sustainable digital twin system of intelligent detection robotics. J. Clean. Prod. 2020, 280, 124181. [Google Scholar] [CrossRef]

- Magargle, R.; Johnson, L.; Mandloi, P.; Davoudabadi, P.; Kesarkar, O.; Krishnaswamy, S.; Batteh, J.; Pitchaikani, A. A Simulation-Based Digital Twin for Model-Driven Health Monitoring and Predictive Maintenance of an Automotive Braking System. In Proceedings of the Linköping Electronic Conference Proceedings, Prague, Czech Republic, 15–17 May 2017. [Google Scholar]

- Kapteyn, M.G.; Knezevic, D.J.; Willcox, K. Toward Predictive Digital Twins via Component-Based Reduced-Order Models and Interpretable Machine Learning. In Proceedings of the AIAA SCITECH 2020 Forum, Orlando, Florida, 6–10 January 2020. [Google Scholar]

- Pawar, S.; Ahmed, S.E.; San, O.; Rasheed, A. Hybrid analysis and modeling for next generation of digital twins. J. Phys. Conf. Ser. 2021, 2018, 012031. [Google Scholar] [CrossRef]

- Kapteyn, M.G.; Willcox, K.E. Predictive Digital Twins: Where Dynamic Data-Driven Learning Meets Physics-Based Modeling. In Dynamic Data Driven Applications Systems; Darema, F., Blasch, E., Ravela, S., Aved, A., Eds.; Springer: Cham, Switzerland, 2020; Volume 12312, pp. 3–7. [Google Scholar]

- Liu, Z.; Meyendorf, N.; Mrad, N. The role of data fusion in predictive maintenance using digital twins. AIP Conf. Proc. 2025, 1949, 020023. [Google Scholar]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital twins and cyber–physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Kritzler, M.; Funk, M.; Michahelles, F.; Rohde, W. The Virtual Twin: Controlling Smart Factories Using A Spatially-Correct Augmented Reality Representation. In Proceedings of the Seventh International Conference on the Internet of Things, Linz, Austria, 22–25 October 2017. [Google Scholar]

- Botkina, D.; Hedlind, M.; Olsson, B.; Henser, J.; Lundholm, T. Digital twin of a cutting tool. Procedia CIRP 2018, 72, 215–218. [Google Scholar] [CrossRef]

- Scaglioni, B.; Ferretti, G. Towards digital twins through object-oriented modelling: A machine tool case study. IFAC-PapersOnLine 2018, 51, 613–618. [Google Scholar] [CrossRef]

- Chhetri, S.R.; Faezi, S.; Canedo, A.; Faruque, M.A.A. QUILT: Quality Inference From Living Digital Twins In IoT-Enabled Manufacturing Systems. In Proceedings of the International Conference on Internet of Things Design and Implementation, Montreal, QC, Canada, 15–18 April 2017. [Google Scholar]

- Zhang, Z.; Jiang, J.; Cheng, X. Research On Digital Twin Model Of Energy Equipment. In Proceedings of the IEEE 2nd International Conference on Power, Electronics and Computer Applications, Shenyang, China, 21–23 January 2022. [Google Scholar]

- Ayani, M.; Ganebäck, M.; Ng, A.H.C. Digital twin: Applying emulation for machine reconditioning. Procedia CIRP 2018, 72, 243–248. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhang, C.; Wei, Y. Digital twin for CNC machine tool: Modeling and using strategy. J. Ambient Intell. Humaniz. Comput. 2018, 10, 1129–1140. [Google Scholar] [CrossRef]

- Fan, Y.; Yao, W. Research On 3D Visualization Logistics Intelligent Scheduling System Based On Digital Twin. In Proceedings of the IEEE 2nd International Conference on Electrical Engineering, Big Data and Algorithms, Changchun, China, 24–26 February 2023. [Google Scholar]

- Xie, N.; Kou, R.; Yao, Y. Tool condition prognostic model based on digital twin system. Procedia CIRP 2020, 93, 1502–1507. [Google Scholar] [CrossRef]

- Jia, W.; Wang, W.; Zhang, Z. From simple digital twin to complex digital twin part II: Multi-scenario applications of digital twin shop floor. Adv. Eng. Inform. 2023, 56, 101915. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, G.; He, J.; Li, Z.; Cheng, W. A data- and knowledge-driven framework for digital twin manufacturing cell. Procedia CIRP 2019, 83, 345–350. [Google Scholar] [CrossRef]

- Leng, J.; Lin, Z.; Huang, Z.; Ye, R.; Liu, Q.; Chen, X. Rapid simplification of 3D geometry model of mechanisms in the digital twins-driven manufacturing system design. J. Intell. Manuf. 2023, 35, 2765–2786. [Google Scholar] [CrossRef]

- Phuyal, S.; Bista, D.; Izykowski, J.; Bista, R. Design and implementation of cost efficient SCADA system for industrial automation. Int. J. Eng. Manuf. 2020, 10, 15–28. [Google Scholar] [CrossRef]

- Yang, M.; Yang, Y.; Jiang, P. A design method for edge–cloud collaborative product service system: A dynamic event-state knowledge graph-based approach with real case study. Int. J. Prod. Res. 2023, 62, 2584–2605. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, M.; Shangguan, S.; Cao, Y.; Jiang, P. A novel method to build knowledge graph models for the configuration and operation design of smart and connected industrial products. J. Comput. Des. Eng. 2024, 11, 327–344. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, M.; Shangguan, S.; Cao, Y.; Yue, W.; Cheng, K.; Jiang, P. An industrial case study on the monitoring and maintenance service system for a robot-driven polishing service system under industry 4.0 contexts. Systems 2023, 11, 376. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhu, W.; Tao, F. Digital Twin Modeling Method for CNC Machine Tool. In Proceedings of the IEEE 15th International Conference on Networking, Sensing and Control, Zhuhai, China, 27–29 March 2018. [Google Scholar]

- Zhang, H.; Qi, Q.; Tao, F. A multi-scale modeling method for digital twin shop-floor. J. Manuf. Syst. 2022, 62, 417–428. [Google Scholar] [CrossRef]

| Items | Items | ||

|---|---|---|---|

| 1 | Robot 1-Axis 1-Current | 21 | Robot 1-Plane polishing head-Pressure |

| 2 | Robot 1-Axis 2-Current | 22 | Robot 1-Bowl polishing head-Pressure |

| 3 | Robot 1-Axis 3-Current | 23 | Robot 1-Plane polishing head-Rotate speed |

| 4 | Robot 1-Axis 4-Current | 24 | Robot 1-Bowl polishing head-Rotate speed |

| 5 | Robot 1-Axis 5-Current | 25 | Dust cap-Temperature |

| 6 | Robot 1-Axis 6-Current | 26 | Dust cap-Air pressure |

| 7 | Robot 1-Axis 1-Torque | 27 | Dust cap-Dust concentration |

| 8 | Robot 1-Axis 2-Torque | 28 | Conveyor belt-Position signal 1 |

| 9 | Robot 1-Axis 3-Torque | 29 | Conveyor belt-Position signal 2 |

| 10 | Robot 1-Axis 4-Torque | 30 | Conveyor belt-Position signal 3 |

| 11 | Robot 1-Axis 5-Torque | 31 | Conveyor belt-Position signal 4 |

| 12 | Robot 1-Axis 6-Torque | 32 | Conveyor belt-Position signal 5 |

| 13 | Robot 1-Axis 1-Rotate speed | 33 | Robot 1-on/off state |

| 14 | Robot 1-Axis 2-Rotate speed | 34 | Conveyor belt-on/off state |

| 15 | Robot 1-Axis 3-Rotate speed | 35 | Robot 1-Plane polishing head-on/off-state |

| 16 | Robot 1-Axis 4-Rotate speed | 36 | Robot 1-Bowl polishing head-on/off-state |

| 17 | Robot 1-Axis 5-Rotate speed | 37 | Robot 1-Visual module-on/off state |

| 18 | Robot 1-Axis 6-Rotate speed | 38 | Vacuum cleaner-on/off state |

| 19 | Robot 1-Body temperature | 39 | Counter |

| 20 | Robot 1-Polishing head-Temperature | 40 | Power meter |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Cao, Y.; Shangguan, S.; Chen, X.; Jiang, P. A Generic Modeling Method of Multi-Modal/Multi-Layer Digital Twins for the Remote Monitoring and Intelligent Maintenance of Industrial Equipment. Machines 2025, 13, 522. https://doi.org/10.3390/machines13060522

Yang M, Cao Y, Shangguan S, Chen X, Jiang P. A Generic Modeling Method of Multi-Modal/Multi-Layer Digital Twins for the Remote Monitoring and Intelligent Maintenance of Industrial Equipment. Machines. 2025; 13(6):522. https://doi.org/10.3390/machines13060522

Chicago/Turabian StyleYang, Maolin, Yifan Cao, Siwei Shangguan, Xin Chen, and Pingyu Jiang. 2025. "A Generic Modeling Method of Multi-Modal/Multi-Layer Digital Twins for the Remote Monitoring and Intelligent Maintenance of Industrial Equipment" Machines 13, no. 6: 522. https://doi.org/10.3390/machines13060522

APA StyleYang, M., Cao, Y., Shangguan, S., Chen, X., & Jiang, P. (2025). A Generic Modeling Method of Multi-Modal/Multi-Layer Digital Twins for the Remote Monitoring and Intelligent Maintenance of Industrial Equipment. Machines, 13(6), 522. https://doi.org/10.3390/machines13060522