Current Status and Trends of Wall-Climbing Robots Research

Abstract

1. Introduction

- The physical principles, scalability, and implementation mechanisms of various attachment methods used in wall-climbing robots are examined. Their applicability and limitations are evaluated in relation to robot size and structural design.

- The design of motion and attachment mechanisms under specific attachment methods is systematically analyzed. The compatibility between motion styles and attachment methods is discussed, offering practical guidance for mechanism design in both inspection-oriented and operation-oriented task scenarios.

- Common localization and path planning methods for wall-climbing robots are summarized and categorized. A comparative analysis of graph search-based algorithms, sampling/randomized algorithms, and feedback-based planning methods is conducted to clarify strategy selection under different environmental complexities and task requirements.

- Future development trends of wall-climbing robots are outlined, including the diversification of motion mechanisms, the hybridization of attachment systems, and advancements in intelligent localization and path planning in complex and dynamic environments.

2. Research Related to Wall-Climbing Robots

2.1. Negative Pressure Adhesion

2.1.1. Adhesion Principles and Their Scalability

2.1.2. Locomotion and Adhesion Mechanism Design

- Negative Pressure Adhesion with Suction Cups

- 2.

- Centrifugal Fan Negative Pressure Adhesion

- 3.

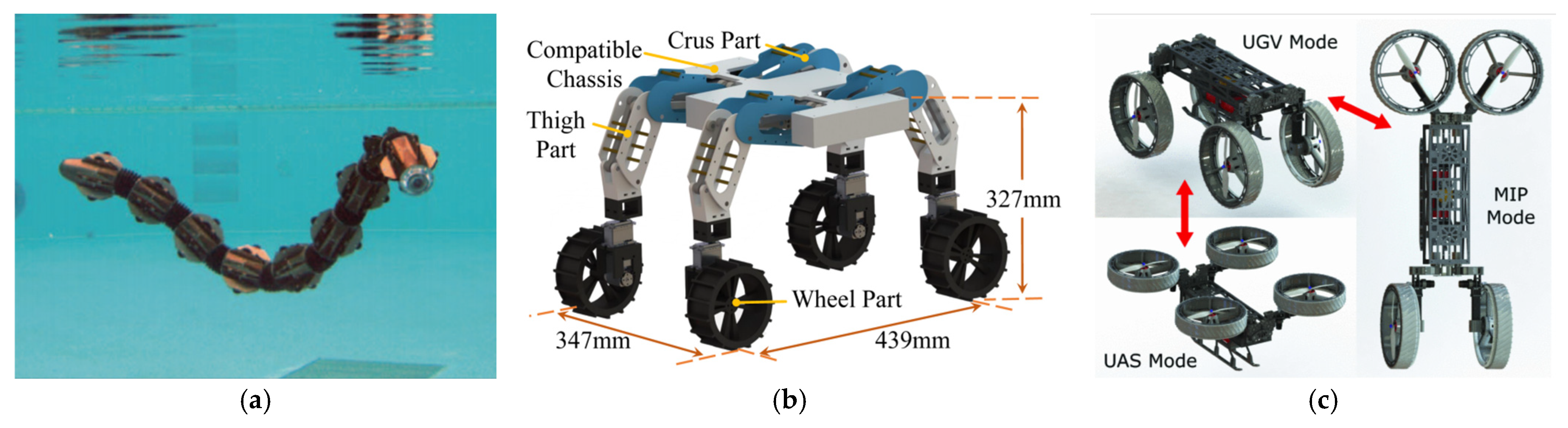

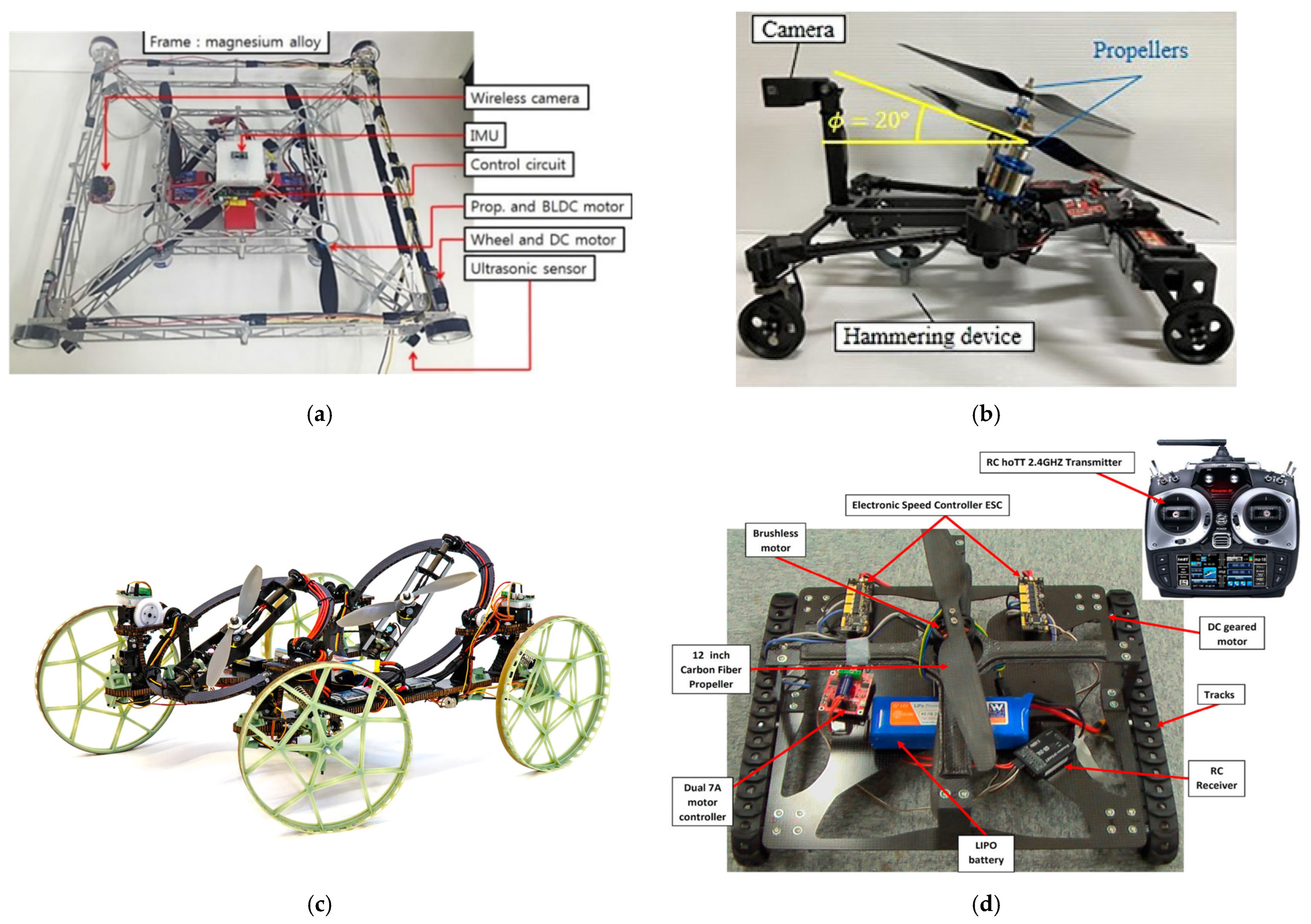

- Propeller Thrust Adhesion

2.1.3. Mechanism Adaptability Analysis and Its Applications

2.2. Magnetic Adhesion

2.2.1. Adhesion Principles and Their Scalability

2.2.2. Locomotion and Adhesion Mechanism Design

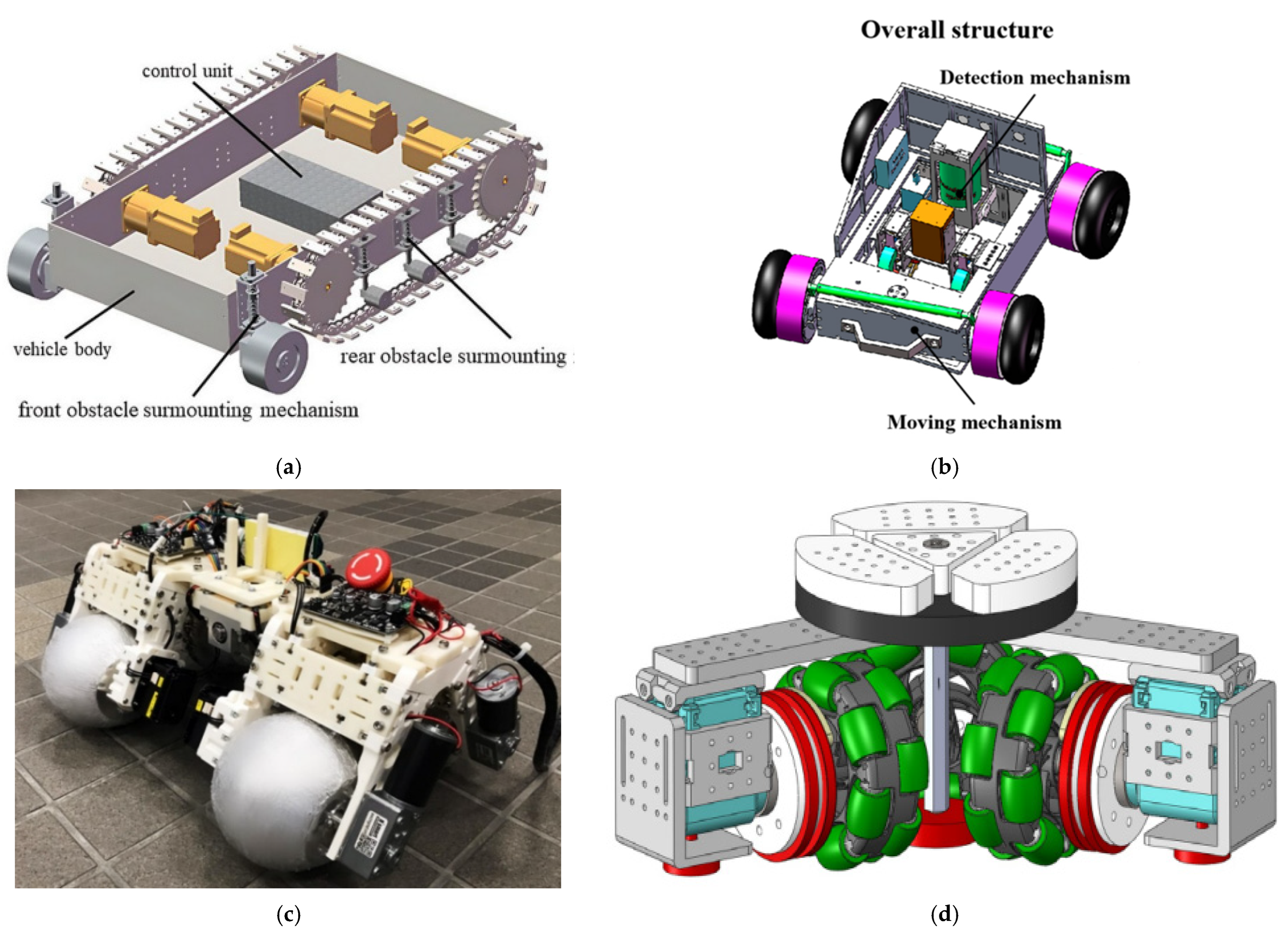

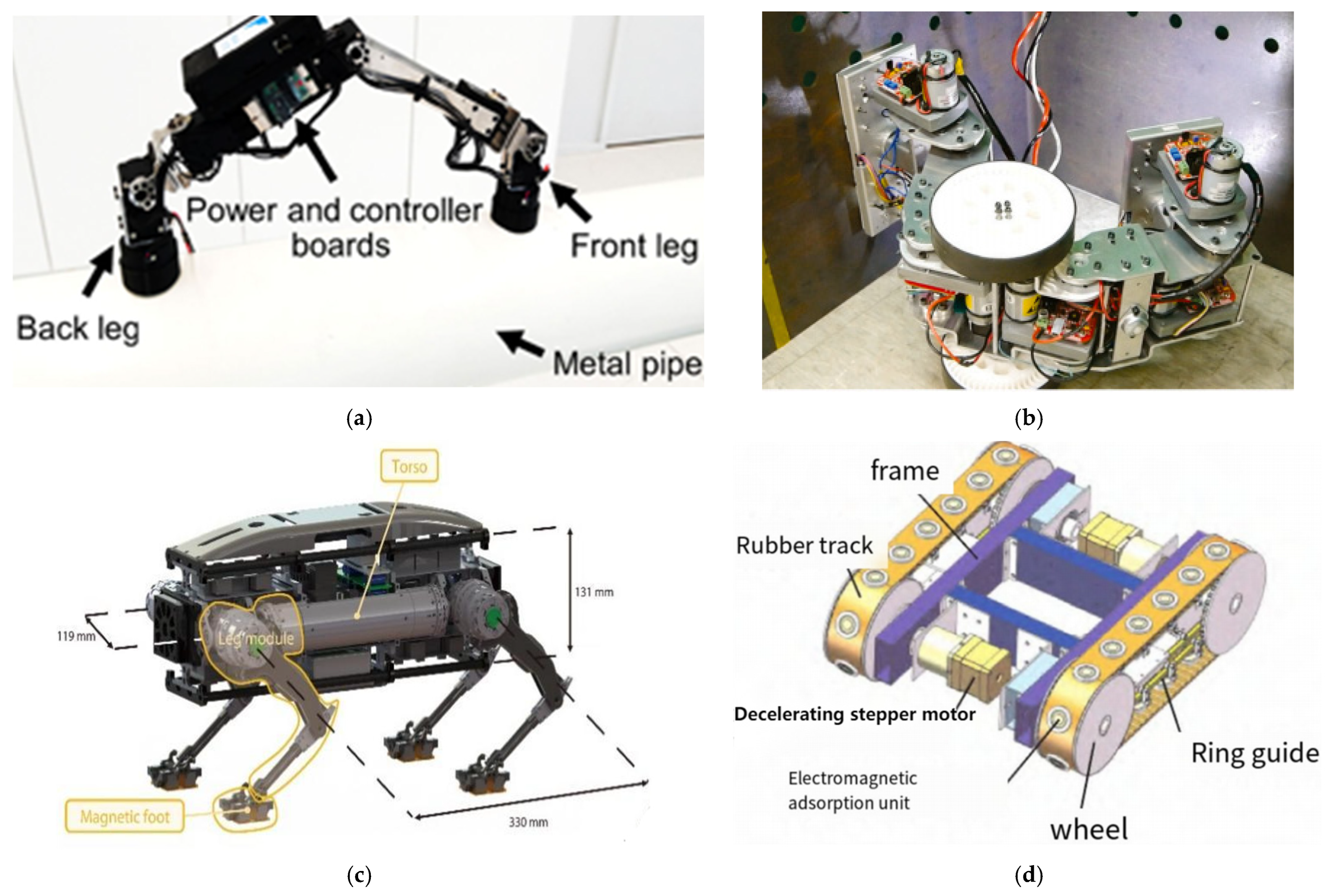

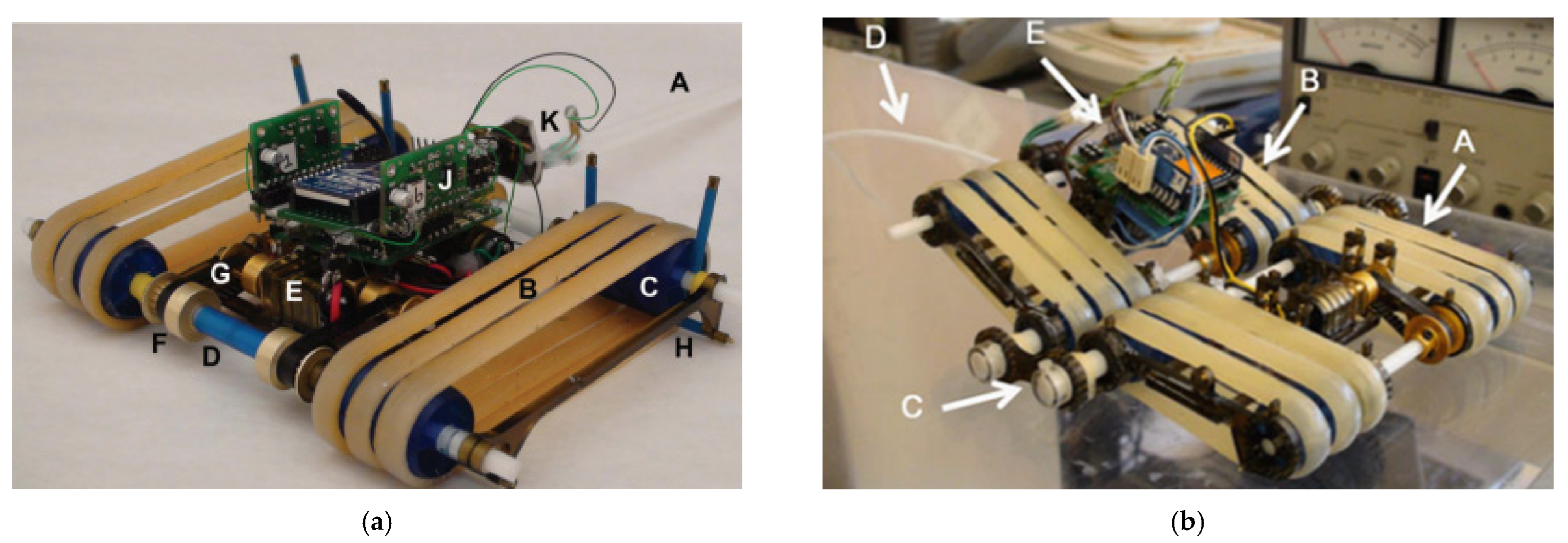

- Permanent Magnetic Adhesion

- 2.

- Electromagnetic Adhesion

2.2.3. Mechanism Adaptability Analysis and Its Applications

2.3. Electrostatic Adhesion

2.3.1. Adhesion Principles and Their Scalability

2.3.2. Locomotion and Adhesion Mechanism Design

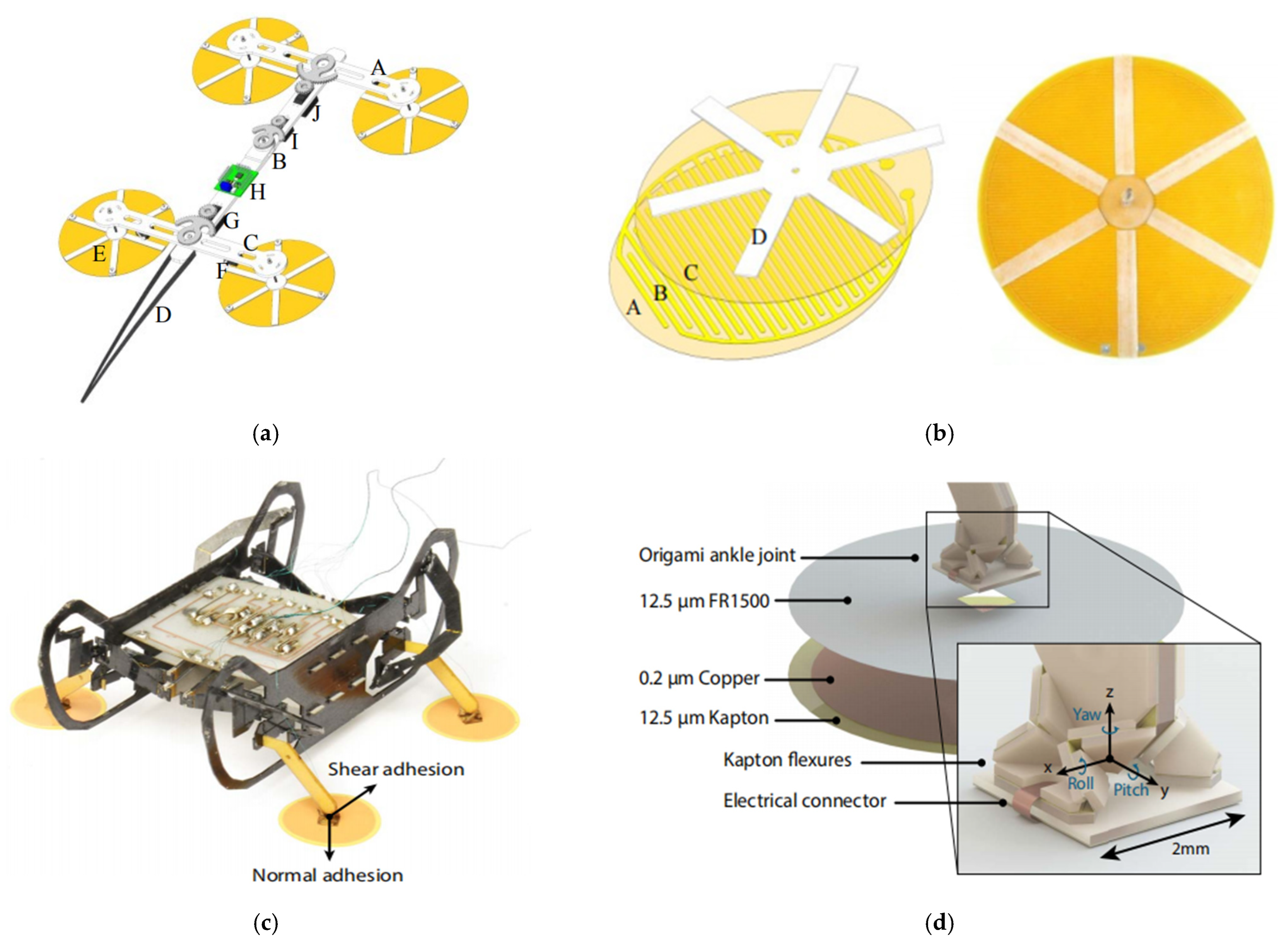

- Static Foot Pad Adhesion

- Electrostatic footpads, which generate adhesion through electrostatic forces.

- Flexible actuators, which drive the deformation and coordinated movement of the robot body.

- 2.

- Electrostatic Panel Adhesion Mechanism

2.3.3. Mechanism Adaptability Analysis and Its Applications

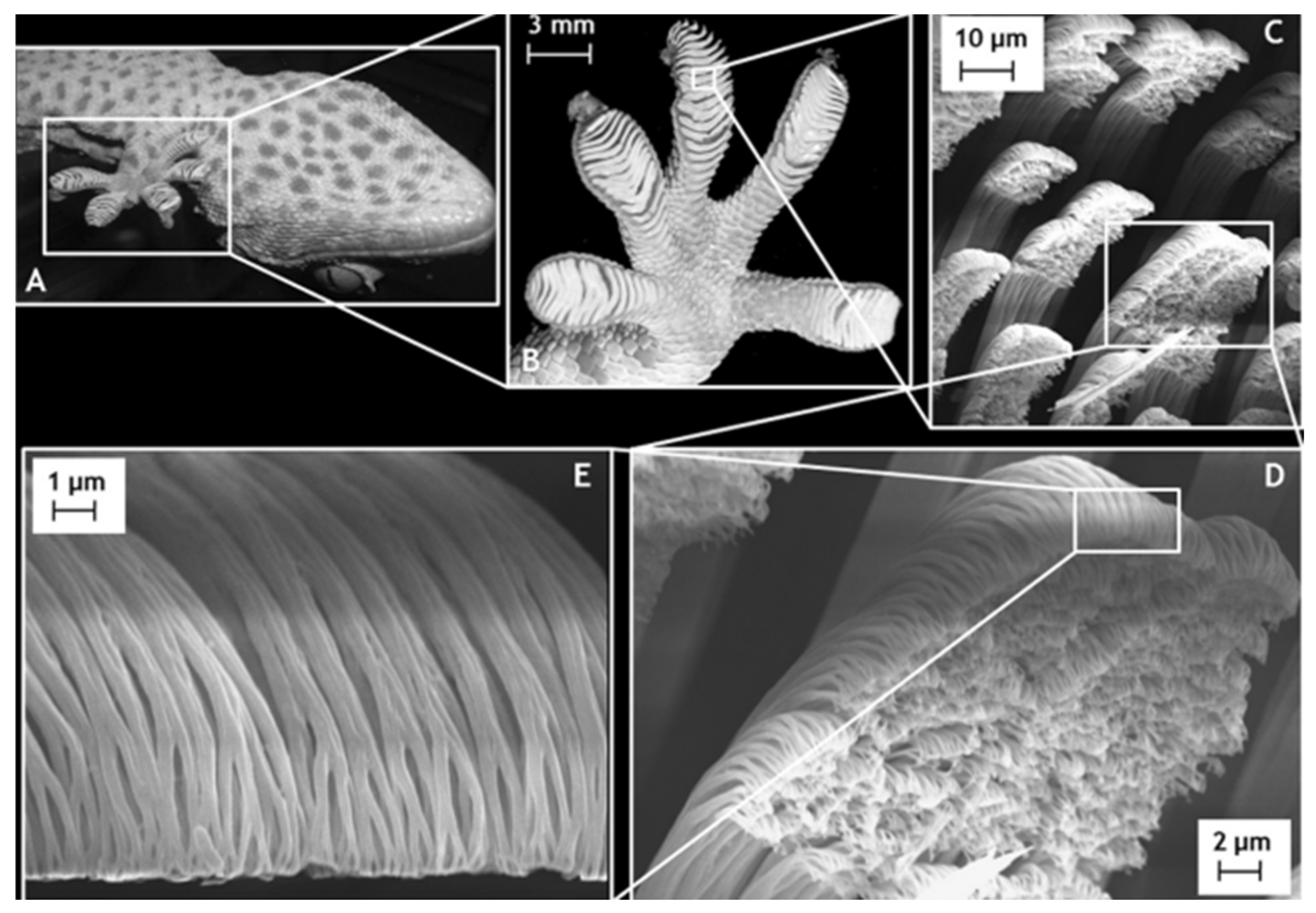

2.4. Dry Adhesion

2.4.1. Adhesion Principles and Their Scalability

- Microscopic hypothesis: detachment occurs when the shaft of the setae reaches a critical angle relative to the substrate, causing the adhesive contact to fail.

- Macroscopic hypothesis: detachment occurs when the gecko’s toes hyperextend and peel away from the surface similarly to duct tape being pulled off.

2.4.2. Locomotion and Adhesion Mechanism Design

2.4.3. Mechanism Adaptability Analysis and Its Applications

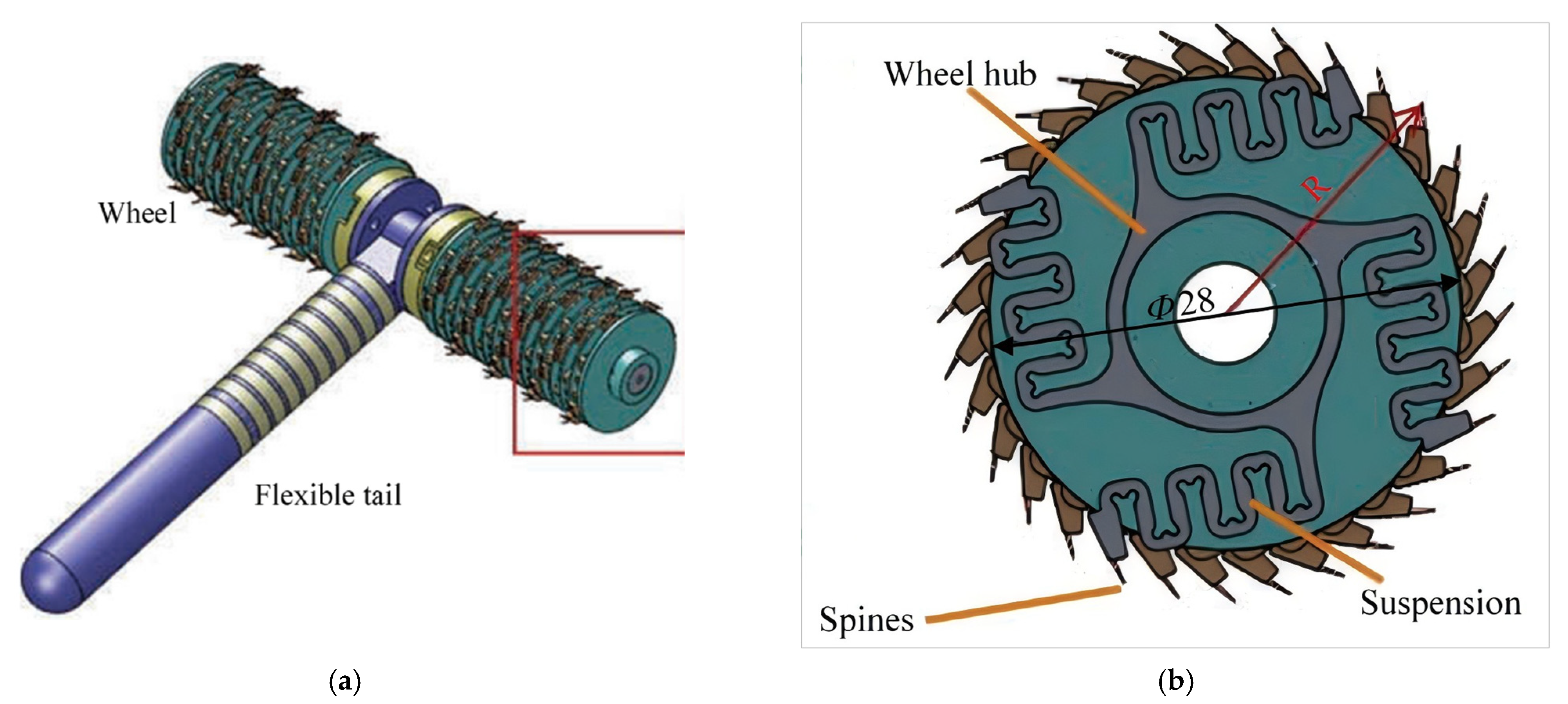

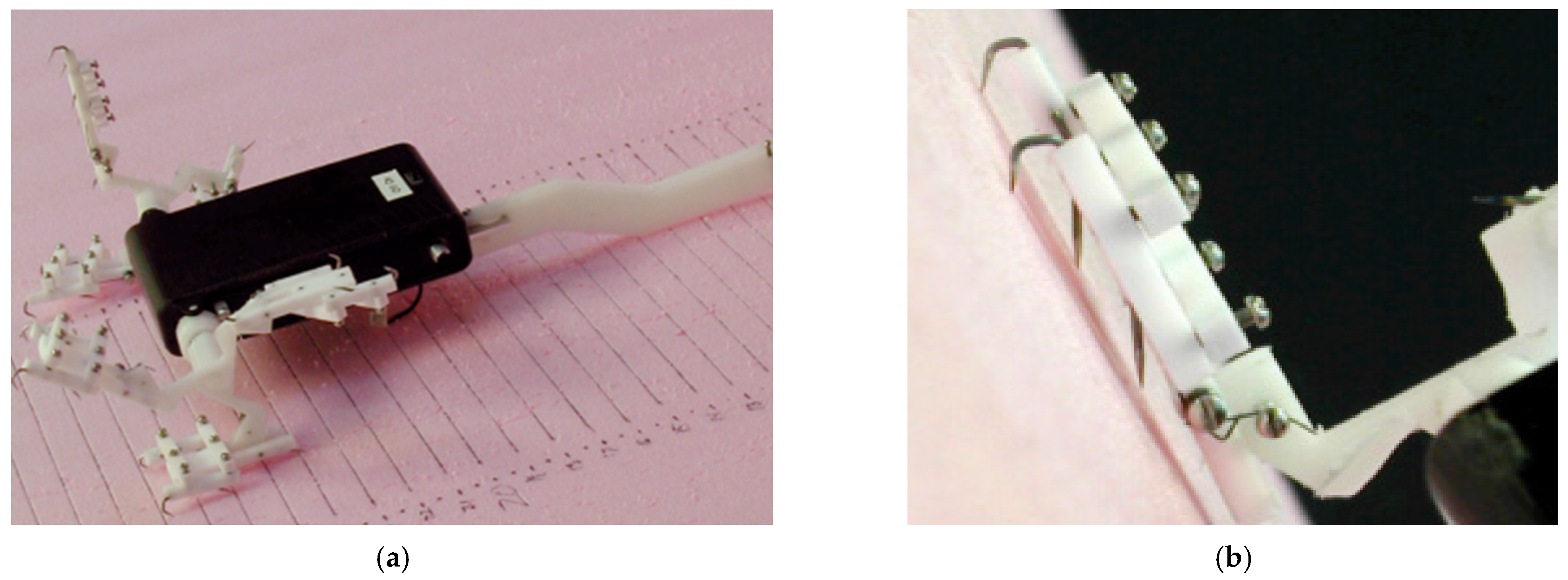

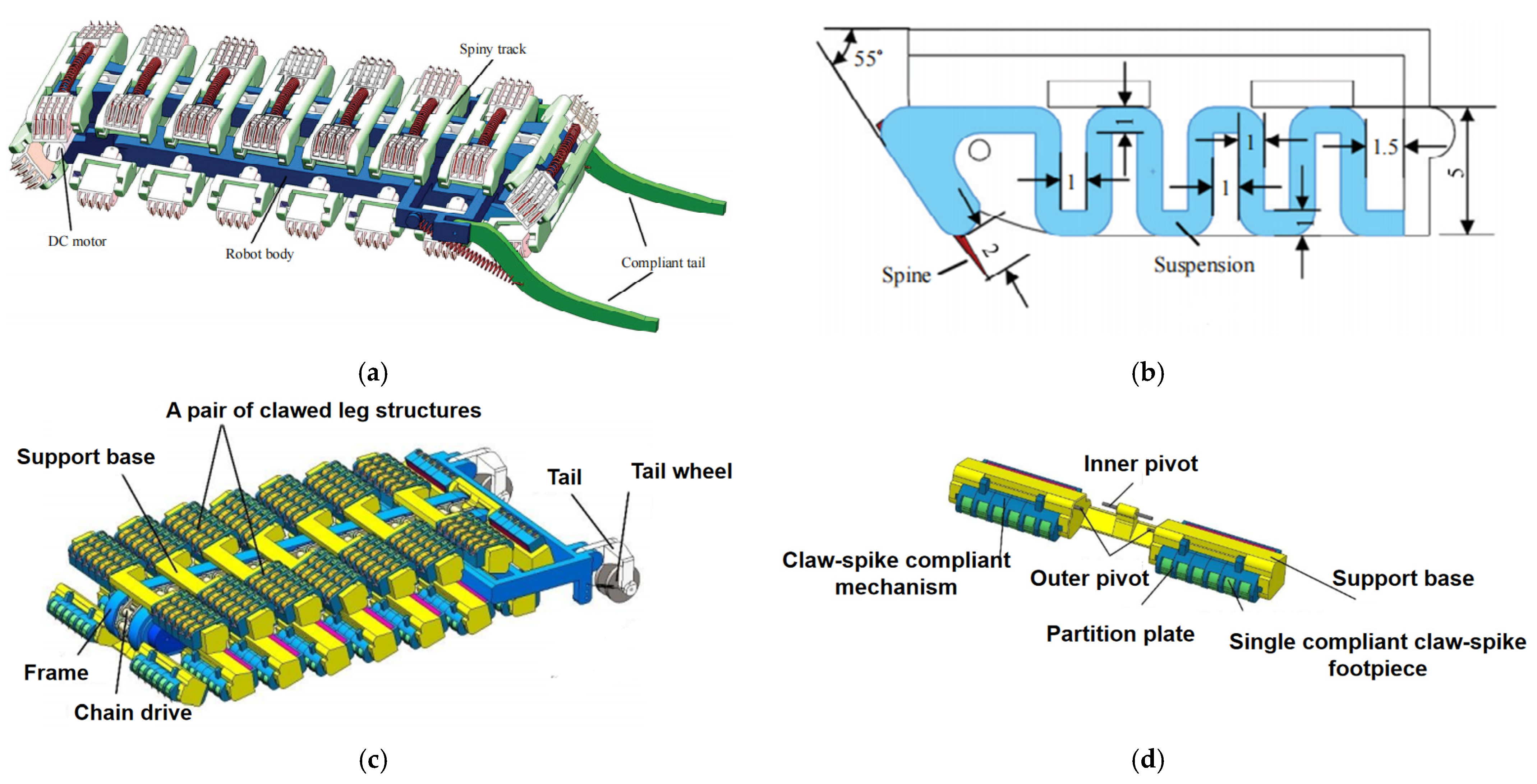

2.5. Claw-Based Attachment

2.5.1. Adhesion Principles and Their Scalability

2.5.2. Locomotion and Adhesion Mechanism Design

2.5.3. Mechanism Adaptability Analysis and Its Applications

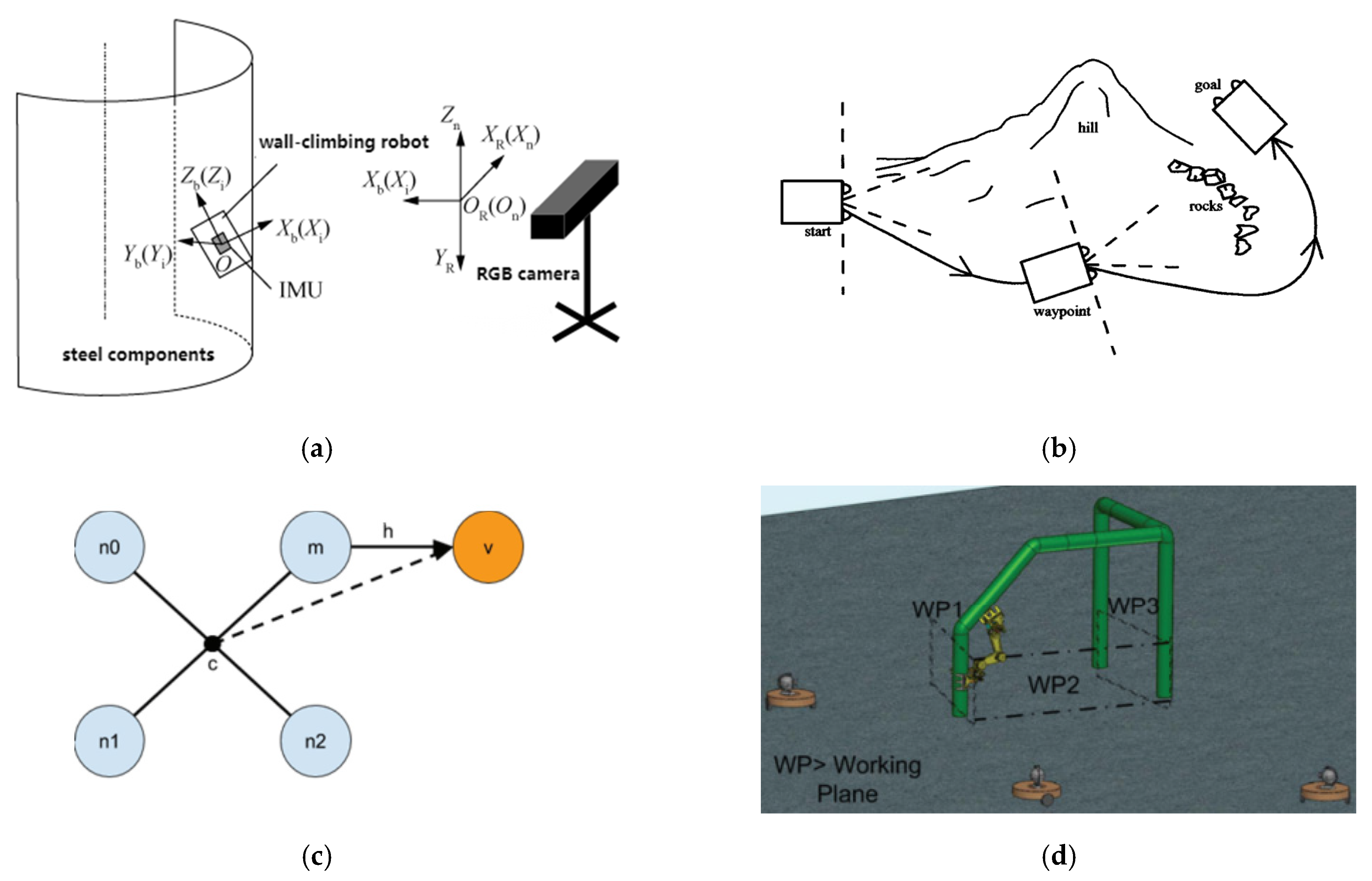

3. Localization and Path Planning Methods for Wall-Climbing Robots

3.1. Overview

3.2. Classification and Principles of Localization Methods

3.2.1. Localization Methods Based on External Measurements

3.2.2. Localization Methods Based on Onboard Sensors

3.2.3. Multi-Robot Cooperative Localization Methods

3.2.4. Comparison of Climbing Robot Localization Methods

3.3. Path Planning for Wall-Climbing Robots

3.3.1. Graph Search Algorithms

3.3.2. Sampling-Based/Randomized Algorithms

3.3.3. Feedback-Based Planning Algorithms

3.3.4. Comparison of Path Planning Methods for Wall-Climbing Robots

- Graph search algorithms, such as A* and Dijkstra, perform well in structured environments (e.g., wind turbine towers, factory outer walls), offering high path determinism and clear navigation for tracked or wheeled wall-climbing robots. These methods are particularly suitable for “inspection-type” tasks. However, their adaptability is limited when facing sudden environmental changes or dynamic obstacles.

- Sampling/randomized algorithms, such as RRT and PRM, are more suitable for legged or bio-inspired robots with high degrees of freedom and multiple constraints. On discontinuous surfaces like steep rock walls, these methods can quickly generate feasible foot placement and posture coordination paths. Nevertheless, traditional RRT also suffers from non-optimality and lack of path smoothness.

- Feedback-based planning algorithms, such as Artificial Potential Field (APF) and D*, are suitable for highly dynamic environments where real-time responsiveness is essential. They allow rapid path adjustment during execution when faced with moving obstacles or environmental disturbances, thus improving the overall planning efficiency. However, these methods are often prone to issues such as local minima and typically require integration with global planning methods to ensure stability.

4. Key Technologies and Development Direction

4.1. Diversification of the Motion Mechanism

4.2. Hybridization of Attachment Method

- Negative pressure adhesion offers broad surface adaptability, but requires high wall airtightness.

- Magnetic adhesion provides strong holding force, but is limited to ferromagnetic surfaces.

- Electrostatic adhesion features a simple structure and is suitable for lightweight designs, yet its performance is significantly affected by environmental humidity.

- Dry adhesion is adaptable to various environments, but its load capacity is limited, and the fabrication of adhesive footpads is often complex and costly.

- Claw-spike attachment relies on mechanical interlocking with the surface, consuming little energy, but potentially damaging the wall.

4.3. Intelligent Positioning and Navigation

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalra, L.P.; Gu, J.; Meng, M. A Wall Climbing Robot for Oil Tank Inspection. In Proceedings of the 2006 IEEE International Conference on Robotics and Biomimetics, Kunming, China, 17–20 December 2006; IEEE: New York, NY, USA, 2006; pp. 1523–1528. [Google Scholar]

- Yi, Z.; Gong, Y.; Wang, Z.; Liu, Q. Development of a Wall Climbing Robot for Ship Rust Removal. In Proceedings of the 2009 International Conference on Mechatronics and Automation, Changchun, China, 9–12 August 2009; IEEE: New York, NY, USA, 2009; pp. 4610–4615. [Google Scholar]

- Yi, Z.; Mi, S.; Feng, B.; Liu, Q. A Large Surface Spraying Technical Analysis of Ship Shell with Wall Climbing Robot in China. Available online: https://ssrn.com/abstract=4674023 (accessed on 5 June 2025).

- Sattar, T.P. Wall Climbing Crawlers for Nondestructive Testing; American Society for Nondestructive Testing: Columbus, OH, USA, 2000. [Google Scholar]

- Berns, K.; Hillenbrand, C. A Climbing Robot Based on Under Pressure Adhesion for the Inspection of Concrete Walls. In Proceedings of the ISR 2004—35th International Symposium on Robotics, Paris, France, 23–26 March 2004; pp. 1–6. [Google Scholar]

- Eich, M.; Vögele, T. Design and Control of a Lightweight Magnetic Climbing Robot for Vessel Inspection. In Proceedings of the 2011 19th Mediterranean Conference on Control & Automation (MED), Corfu, Greece, 20–23 June 2011; IEEE: New York, NY, USA, 2011; pp. 1200–1205. [Google Scholar]

- Liu, R.; Chen, R.; Shen, H.; Ma, L.; Feng, J. Wall Climbing Robot Using Electrostatic Adhesion Force Generated by Flexible Interdigital Electrodes. Int. J. Adv. Robot. Syst. 2013, 10, 36. [Google Scholar] [CrossRef]

- Liu, Y.; Shin, M.; Jeong, K.; Park, Y. Dry Adhesion Optimization Design for a Wall-Climbing Robot Based on Experiment. In Proceedings of the 2014 11th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Kuala Lumpur, Malaysia, 12–15 November 2014; IEEE: New York, NY, USA, 2014; pp. 216–219. [Google Scholar]

- Hawkes, E.W.; Ulmen, J.; Esparza, N.; Spenko, M.; Cutkosky, M.R. Scaling Walls: Applying Dry Adhesives to the Real World. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; IEEE: New York, NY, USA, 2011; pp. 5100–5106. [Google Scholar]

- Liu, Y.; Lim, B.; Lee, J.W.; Park, S. Steerable Dry-Adhesive Linkage-Type Wall-Climbing Robot. Mech. Mach. Theory 2020, 153, 103987. [Google Scholar] [CrossRef]

- Miyake, T.; Ishihara, H.; Yoshimura, M. Basic Studies on Wet Adhesion System for Wall Climbing Robots. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), San Diego, CA, USA, 29 October–2 November 2007; IEEE: New York, NY, USA, 2007; pp. 1920–1925. [Google Scholar]

- Xu, F.; Wang, B.; Shen, J.; Zhao, H.; Li, M. Design and Realization of the Claw Gripper System of a Climbing Robot. J. Intell. Robot. Syst. 2018, 89, 301–317. [Google Scholar] [CrossRef]

- Li, M.; Mao, A.; Guan, Q.; Saiz, E. Nature-Inspired Adhesive Systems. Chem. Soc. Rev. 2024, 53, 8240–8305. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Yang, C.; Zhang, R.; He, X. A Novel Worm-Inspired Wall Climbing Robot with Sucker-Microspine Composite Structure. In Proceedings of the 2018 3rd International Conference on Advanced Robotics and Mechatronics (ICARM), Singapore, 18–20 July 2018; IEEE: New York, NY, USA, 2018; pp. 744–749. [Google Scholar]

- Simões, S. High-Performance Advanced Composites in Multifunctional Material Design: State of the Art, Challenges, and Future Directions. Materials 2024, 17, 5997. [Google Scholar] [CrossRef]

- Rich, S.I.; Wood, R.J.; Majidi, C. Untethered Soft Robotics. Nat. Electron. 2018, 1, 102–112. [Google Scholar] [CrossRef]

- Pukánszky, B.; Fekete, E. Adhesion and Surface Modification. In Mineral Fillers in Thermoplastics I: Raw Materials and Processing; Springer: Berlin/Heidelberg, Germany, 1999; pp. 109–153. [Google Scholar]

- Guangqing, C.; Lei, Z.; Jinze, X.; Zhu, J. Analysis and Future Prospects of Adsorption Techniques Employed by Wall-Climbing. Int. J. Adv. Robot. Syst. 2024, 21, 17298806241279611. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, Y.; Zhang, P. Review of Advancements in Wall Climbing Robot Techniques. Frankl. Open 2024, 8, 100148. [Google Scholar] [CrossRef]

- Brusell, A.; Andrikopoulos, G.; Nikolakopoulos, G. Novel Considerations on the Negative Pressure Adhesion of Electric Ducted Fans: An Experimental Study. In Proceedings of the 2017 25th Mediterranean Conference on Control and Automation (MED), Valletta, Malta, 3–6 July 2017; IEEE: New York, NY, USA, 2017; pp. 1404–1409. [Google Scholar]

- Fang, Y.; Wang, S.; Bi, Q.; Zhang, L. Design and Technical Development of Wall-Climbing Robots: A Review. J. Bionic Eng. 2022, 19, 877–901. [Google Scholar] [CrossRef]

- Kang, T.; Kim, H.; Choi, H. Realtime Perception with Infrared Scanner for Navigation of Quadruped Walking and Climbing Robot. In Proceedings of the 2004 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Sendai, Japan, 28 September–2 October 2004; IEEE: New York, NY, USA, 2004; Volume 3, pp. 2550–2555. [Google Scholar]

- Xue, C.; Du, Q.; Ma, W.; Geng, Y. Research on Motion Control of Bionic Sucker Inchworm Robot Based on MPC. IEEE Access 2023, 11, 92943–92958. [Google Scholar] [CrossRef]

- Shi, X.; Xu, L.; Xu, H.; Yang, X.; Feng, B. A 6-DOF Humanoid Wall-Climbing Robot with Flexible Adsorption Feet Based on Negative Pressure Suction. Mechatronics 2022, 87, 102889. [Google Scholar] [CrossRef]

- Guan, Y.; Zhu, H.; Wu, W.; Li, Y. A Modular Biped Wall-Climbing Robot with High Mobility and Manipulating Function. IEEE/ASME Trans. Mechatron. 2012, 18, 1787–1798. [Google Scholar] [CrossRef]

- Ito, K.; Yoshizawa, K. Uraraka VI: Multi-Legged Robot with Suckers to Climb Walls and Pipes. Artif. Life Robot. 2022, 27, 834–841. [Google Scholar] [CrossRef]

- Shang, J.; Sattar, T.; Chen, S.; Bridge, B. Design of a Climbing Robot for Inspecting Aircraft Wings and Fuselage. Ind. Robot 2007, 34, 495–502. [Google Scholar] [CrossRef]

- Rosyid, A.; Stefanini, C.; El-Khasawneh, B. A Reconfigurable Parallel Robot for On-Structure Machining of Large Structures. Robotics 2022, 11, 110. [Google Scholar] [CrossRef]

- Rosyid, A.; Stefanini, C.; El-Khasawneh, B. A novel walking parallel robot for on-structure three-axis machining of large structures. J. Mech. Robot. 2023, 15, 061016. [Google Scholar] [CrossRef]

- Rosyid, A.; El-Khasawneh, B. A Large-Scale Suction-Based Climbing Parallel Robot for Wall Painting Application. In Proceedings of the 2024 IEEE International Conference on Robotics and Automation (ICRA), Yokohama, Japan, 13–17 May 2024; IEEE: New York, NY, USA, 2024. [Google Scholar]

- Ge, D.; Ren, C.; Matsuno, T.; Ma, S. Guide Rail Design for a Passive Suction Cup Based Wall-Climbing Robot. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; IEEE: New York, NY, USA, 2016; pp. 5776–5781. [Google Scholar]

- Lee, G.; Kim, H.; Seo, K.; Kim, J.; Kim, H.S. MultiTrack: A Multi-Linked Track Robot with Suction Adhesion for Climbing and Transition. Robot. Auton. Syst. 2015, 72, 207–216. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Z.; Cheng, S.; Li, C. Optimized Design of the Main Structure of a Wall-Climbing Robot for Bridge Detection Based on Negative Pressure Adhesion. J. South China Univ. Technol. (Nat. Sci. Ed.) 2023, 51, 21–33. [Google Scholar] [CrossRef]

- Yang, L.; Li, B.; Feng, J.; Yang, G.; Chang, Y.; Jiang, B.; Xiao, J. Automated Wall-Climbing Robot for Concrete Construction Inspection. J. Field Robot. 2023, 40, 110–129. [Google Scholar] [CrossRef]

- Longo, D.; Muscato, G. The Alicia/sup 3/Climbing Robot: A Three-Module Robot for Automatic Wall Inspection. IEEE Robot. Autom. Mag. 2006, 13, 42–50. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, S.; Cui, D.; Bi, Q.; Jiang, R.; Yan, C. Design and Optimization of Wall-Climbing Robot Impeller by Genetic Algorithm Based on Computational Fluid Dynamics and Kriging Model. Sci. Rep. 2022, 12, 9571. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Chang, Y.; Song, Y.; Lin, S.; Jing, F. Design and Analysis of a Negative Pressure Wall-Climbing Robot with an Omnidirectional Characteristic for Cylindrical Wall. Robotica 2024, 42, 2226–2242. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, C. Development of an Underwater Cleaning Robot with Vortex Suction Mechanism. In Proceedings of the 2022 3rd International Conference on Robotics Systems and Vehicle Technology, Singapore, 22–24 July 2022. [Google Scholar]

- Tang, Q.; Du, Y.; Ding, M.; Zhang, S.; Zhao, Q.; Hu, S.; Wang, G. Study on the Performance of Vortex Suction Cup for an Underwater Inspection Robot. Ocean Eng. 2024, 300, 117462. [Google Scholar] [CrossRef]

- Shin, J.U.; Kim, D.; Kim, J.H.; Myung, H. Micro-Aerial Vehicle Type Wall-Climbing Robot Mechanism for Structural Health Monitoring. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2013; SPIE: Bellingham, WA, USA, 2013; Volume 8692, pp. 363–369. [Google Scholar]

- Nishimura, Y.; Mochiyama, H.; Yamaguchi, T. Propeller-Type Wall-Climbing Robot for Visual and Hammering Inspection of Concrete Surfaces. IEEE Access 2024, 12, 70963–70972. [Google Scholar] [CrossRef]

- Liang, P.; Gao, X.; Zhang, Q.; Gao, R.; Li, M.; Xu, Y.; Zhu, W. Design and Stability Analysis of a Wall-Climbing Robot Using Propulsive Force of Propeller. Symmetry 2020, 13, 37. [Google Scholar] [CrossRef]

- Alkalla, M.G.; Fanni, M.A.; Mohamed, A.F.; Hashimoto, S.; Sawada, H.; Miwa, T.; Hamed, A. EJBot-II: An Optimized Skid-Steering Propeller-Type Climbing Robot with Transition Mechanism. Adv. Robot. 2019, 33, 1042–1059. [Google Scholar] [CrossRef]

- Vega-Heredia, M.; Mohan, R.E.; Wen, T.Y.; Siti’Aisyah, J.; Vengadesh, A.; Ghanta, S.; Vinu, S. Design and Modelling of a Modular Window Cleaning Robot. Autom. Constr. 2019, 103, 268–278. [Google Scholar] [CrossRef]

- Kawasaki, K.; Motegi, Y.; Zhao, M.; Okada, K.; Inaba, M. Dual Connected Bi-Copter with New Wall Trace Locomotion Feasibility That Can Fly at Arbitrary Tilt Angle. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; IEEE: New York, NY, USA, 2015; pp. 524–531. [Google Scholar]

- Wu, M.; Pan, G.; Zhang, T.; Chen, S.; Zhuang, F.; Yan-zheng, Z. Design and Optimal Research of a Non-Contact Adjustable Magnetic Adhesion Mechanism for a Wall-Climbing Welding Robot. Int. J. Adv. Robot. Syst. 2013, 10, 63. [Google Scholar] [CrossRef]

- Kratt, K.; Badilita, V.; Burger, T.; Korvink, J.G.; Wallrabe, U. A Fully MEMS-Compatible Process for 3D High Aspect Ratio Micro Coils Obtained with an Automatic Wire Bonder. J. Micromech. Microeng. 2009, 20, 015021. [Google Scholar] [CrossRef]

- Sun, J.; Tao, Z.; Li, H.; Zhu, K.; Wang, D.; Wu, H.; Xu, T. A MEMS Voice Coil Motor with a 3D Solenoid Coil. In Proceedings of the 2021 IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 25–29 April 2021; IEEE: New York, NY, USA, 2021; pp. 1745–1748. [Google Scholar]

- Cai, J.; He, K.; Fang, H.; Chen, H.; Hu, S.; Zhou, W. The Design of Permanent-Magnetic Wheeled Wall-Climbing Robot. In Proceedings of the 2017 IEEE International Conference on Information and Automation (ICIA), Macau, China, 18–20 July 2017; IEEE: New York, NY, USA, 2017; pp. 604–608. [Google Scholar]

- Xu, M.; Xue, S.; Wang, Q.; He, S.; Deng, R.; Li, Z.; Li, R. Design and Analysis of Wheel-Tracked Composite Magnetic Adhesion Wall-Climbing Robot. Ind. Robot Int. J. Robot. Res. Appl. 2024, 52, 94–105. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, M.; Jiao, S.; Sun, L.; Li, M. Design and Optimization of the Wall Climbing Robot for Magnetic Particle Detection of Ship Welds. J. Mar. Sci. Eng. 2024, 12, 610. [Google Scholar] [CrossRef]

- Eto, H.; Asada, H.H. Development of a Wheeled Wall-Climbing Robot with a Shape-Adaptive Magnetic Adhesion Mechanism. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; IEEE: New York, NY, USA, 2020; pp. 9329–9335. [Google Scholar]

- Tavakoli, M.; Viegas, C.; Marques, L.; Pires, J.N.; De Almeida, A.T. OmniClimbers: Omni-directional Magnetic Wheeled Climbing Robots for Inspection of Ferromagnetic Structures. Robot. Auton. Syst. 2013, 61, 997–1007. [Google Scholar] [CrossRef]

- Zhang, Y.; Guan, E.; Li, P.; Zhao, Y. An Automated Nondestructive Testing System for the Surface of Pressure Pipeline Welds. J. Field Robot. 2023, 40, 1927–1944. [Google Scholar] [CrossRef]

- Park, C.; Bae, J.; Ryu, S.; Lee, J.; Seo, T. R-track: Separable Modular Climbing Robot Design for Wall-to-Wall Transition. IEEE Robot. Autom. Lett. 2021, 6, 1036–1042. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, Y.; Bi, X.; Yan, C.; Dong, Y. Optimum Design of Magnetic Adhesion Structure and Machine Performance Test for Sand Blasting and Rust-Removing Wall-Climbing Robot. J. China Univ. Pet. 2020, 44, 94–99. [Google Scholar]

- Hu, J.; Han, X.; Tao, Y.; Feng, S. A Magnetic Crawler Wall-Climbing Robot with Capacity of High Payload on the Convex Surface. Robot. Auton. Syst. 2022, 148, 103907. [Google Scholar] [CrossRef]

- Park, G.; Rodrigue, H. Soft Climbing Robot with Magnetic Feet for Multimodal Locomotion. Sci. Rep. 2023, 13, 8377. [Google Scholar] [CrossRef]

- Khan, M.B.; Chuthong, T.; Do, C.D.; Thor, M.; Billeschou, P.; Larsen, J.C.; Manoonpong, P. iCrawl: An Inchworm-Inspired Crawling Robot. IEEE Access 2020, 8, 200655–200668. [Google Scholar] [CrossRef]

- Lin, T.H.; Putranto, A.; Chen, P.H.; Teng, Y.Z.; Chen, L. High-Mobility Inchworm Climbing Robot for Steel Bridge Inspection. Autom. Constr. 2023, 152, 104905. [Google Scholar] [CrossRef]

- Hong, S.; Um, Y.; Park, J.; Park, H.W. Agile and Versatile Climbing on Ferromagnetic Surfaces with a Quadrupedal Robot. Sci. Robot. 2022, 7, eadd1017. [Google Scholar] [CrossRef]

- Hong, X.; Chen, Y. Development of Innovative Wall-Climbing Robot with Electromagnetic Absorption. Mech. Sci. Technol. 2021, 40, 337–343. [Google Scholar]

- Tarapongnivat, K.; Janna, R.; Nantareekurn, W.; Ausrivong, W.; Srisuchinnawong, A.; Asawalertsak, N.; Manoonpong, P. Hybrid Omnidirectional Wheeled Climbing Robot with an Electromagnet for Inspection. In Proceedings of the Climbing and Walking Robots Conference, Florianópolis, Brazil, 2–4 October 2023; Springer: Cham, Switzerland, 2023; pp. 82–87. [Google Scholar]

- Peidró, A.; Tavakoli, M.; Marín, J.M.; Reinoso, Ó. Design of Compact Switchable Magnetic Grippers for the HyReCRo Structure-Climbing Robot. Mechatronics 2019, 59, 199–212. [Google Scholar] [CrossRef]

- Wang, B.; Li, P.; Li, P.; Zhang, L.; Guan, E.; Liu, X.; Zhao, Y. Development of a Wheeled Wall-Climbing Robot with an Internal Corner Wall Adaptive Magnetic Adhesion Mechanism. J. Field Robot. 2024, 42, 97–114. [Google Scholar] [CrossRef]

- Wang, G.; Li, W.; Che, H. Design and Analysis of Anti-Overturning Mechanism for Magnetic Wall-Climbing Robot. J. Mech. Sci. Technol. 2024, 38, 379–387. [Google Scholar] [CrossRef]

- Song, W.; Jiang, H.; Wang, T.; Ji, D.; Zhu, S. Design of Permanent Magnetic Wheel-Type Adhesion-Locomotion System for Water-Jetting Wall-Climbing Robot. Adv. Mech. Eng. 2018, 10, 1687814018787378. [Google Scholar] [CrossRef]

- Guerrero, J.M.; De Vicuna, L.G.; Uceda, J. Uninterruptible Power Supply Systems Provide Protection. IEEE Ind. Electron. Mag. 2007, 1, 28–38. [Google Scholar] [CrossRef]

- Shi, J.; Xu, Y.; Liao, M.; Guo, S.; Li, Y.; Ren, L.; Tang, Y. Integrated Design Method for Superconducting Magnetic Energy Storage Considering the High Frequency Pulse Width Modulation Pulse Voltage on Magnet. Appl. Energy 2019, 248, 1–17. [Google Scholar] [CrossRef]

- Shi, B.; Agnihotri, M.V.; Chen, S.H.; Black, R.; Singer, S.J. Polarization charge: Theory and applications to aqueous interfaces. J. Chem. Phys. 2016, 144, 164702. [Google Scholar] [CrossRef]

- Feng, P.X.L.; Young, D.J.; Zorman, C.A. MEMS/NEMS Devices and Applications. In Springer Handbook of Nanotechnology, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 395–429. [Google Scholar]

- Cao, J.; Qin, L.; Liu, J.; Ren, Q.; Foo, C.C.; Wang, H.; Zhu, J. Untethered Soft Robot Capable of Stable Locomotion Using Soft Electrostatic Actuators. Extreme Mech. Lett. 2018, 21, 9–16. [Google Scholar] [CrossRef]

- Qin, L.; Liang, X.; Huang, H.; Chui, C.K.; Yeow, R.C.H.; Zhu, J. A Versatile Soft Crawling Robot with Rapid Locomotion. Soft Robot. 2019, 6, 455–467. [Google Scholar] [CrossRef]

- Hu, Q.; Li, J.; Dong, E.; Sun, D. Soft Scalable Crawling Robots Enabled by Programmable Origami and Electrostatic Adhesion. IEEE Robot. Autom. Lett. 2023, 8, 2365–2372. [Google Scholar] [CrossRef]

- Gu, G.; Zou, J.; Zhao, R.; Zhao, X.; Zhu, X. Soft Wall-Climbing Robots. Sci. Robot. 2018, 3, eaat2874. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Liu, R.; Chen, J.; Zhang, J. A Gecko Inspired Wall-Climbing Robot Based on Electrostatic Adhesion Mechanism. In Proceedings of the 2013 IEEE International Conference on Robotics and Biomimetics (ROBIO), Shenzhen, China, 12–14 December 2013; IEEE: New York, NY, USA, 2013; pp. 396–401. [Google Scholar]

- De Rivaz, S.D.; Goldberg, B.; Doshi, N.; Jayaram, K.; Zhou, J.; Wood, R.J. Inverted and Vertical Climbing of a Quadrupedal Microrobot Using Electroadhesion. Sci. Robot. 2018, 3, eaau3038. [Google Scholar] [CrossRef]

- Yamamoto, A.; Nakashima, T.; Higuchi, T. Wall Climbing Mechanisms Using Electrostatic Attraction Generated by Flexible Electrodes. In Proceedings of the 2007 International Symposium on Micro-NanoMechatronics and Human Science, Nagoya, Japan, 11–14 November 2007; IEEE: New York, NY, USA, 2007; pp. 389–394. [Google Scholar]

- Wang, L. Research on a Tracked Wall-Climbing Robot Based on a Bionic Compliant Claw-Spike Structure. Master’s Thesis, South China University of Technology, Guangzhou, China, 2012. [Google Scholar]

- Prahlad, H.; Pelrine, R.; Stanford, S.; Marlow, J.; Kornbluh, R. Electroadhesive Robots—Wall Climbing Robots Enabled by a Novel, Robust, and Electrically Controllable Adhesion Technology. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; IEEE: New York, NY, USA, 2008; pp. 3028–3033. [Google Scholar]

- Chen, R.; Liu, R.; Shen, H. Design of a Double-Tracked Wall Climbing Robot Based on Electrostatic Adhesion Mechanism. In Proceedings of the 2013 IEEE Workshop on Advanced Robotics and Its Social Impacts, Tokyo, Japan, 7–9 November 2013; IEEE: New York, NY, USA, 2013; pp. 212–217. [Google Scholar]

- Wang, H.; Yamamoto, A. Analyses and Solutions for the Buckling of Thin and Flexible Electrostatic Inchworm Climbing Robots. IEEE Trans. Robot. 2017, 33, 889–900. [Google Scholar] [CrossRef]

- Wang, H.; Yamamoto, A.; Higuchi, T. Electrostatic-motor-driven electroadhesive robot. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Algarve, Portugal, 7–12 October 2012; IEEE: New York, NY, USA, 2012; pp. 914–919. [Google Scholar]

- Fang, G.; Cheng, J. Advances in climbing robots for vertical structures in the past decade: A review. Biomimetics 2023, 8, 47. [Google Scholar] [CrossRef]

- Mao, J.B.; Qin, L.; Zhang, W.X.; Xie, L.; Wang, Y. Modeling and analysis of electrostatic adhesion force for climbing robot on dielectric wall materials. Eur. Phys. J. Appl. Phys. 2015, 69, 11003. [Google Scholar] [CrossRef]

- Pugno, N.M.; Lepore, E. Living Tokay Geckos display adhesion times following Weibull statistics. J. Adhes. 2008, 84, 947–960. [Google Scholar] [CrossRef]

- Bullock, J.M.R.; Drechsler, P.; Federle, W. Comparison of smooth and hairy attachment pads in insects: Friction, adhesion and mechanisms for direction-dependence. J. Exp. Biol. 2008, 211, 3333–3343. [Google Scholar] [CrossRef]

- Guo, C.; Sun, J.R.; Ge, Y.B.; Wang, W.; Wang, D.; Dai, Z. Biomechanism of adhesion in gecko setae. Sci. China Life Sci. 2012, 55, 181–187. [Google Scholar] [CrossRef]

- Persson, B.N.J. On the mechanism of adhesion in biological systems. J. Chem. Phys. 2003, 118, 7614–7621. [Google Scholar] [CrossRef]

- Huber, G.; Gorb, S.N.; Hosoda, N.; Spolenak, R.; Arzt, E. Influence of surface roughness on gecko adhesion. Acta Biomater. 2007, 3, 607–610. [Google Scholar] [CrossRef]

- Pugno, N.M.; Lepore, E. Observation of optimal gecko’s adhesion on nanorough surfaces. Biosystems 2008, 94, 218–222. [Google Scholar] [CrossRef] [PubMed]

- Autumn, K.; Dittmore, A.; Santos, D.; Spenko, M.; Cutkosky, M. Frictional adhesion: A new angle on gecko attachment. J. Exp. Biol. 2006, 209, 3569–3579. [Google Scholar] [CrossRef]

- Israelachvili, J.N. Intermolecular and Surface Forces, 3rd ed.; Academic Press: London, UK, 2011. [Google Scholar]

- Haomachai, W.; Shao, D.; Wang, W.; Ji, A.; Dai, Z.; Manoonpong, P. Lateral undulation of the bendable body of a gecko-inspired robot for energy-efficient inclined surface climbing. IEEE Robot. Autom. Lett. 2021, 6, 7917–7924. [Google Scholar] [CrossRef]

- Duan, J.; Wang, B.; Ji, B.; Sun, W.; Wang, Z.; Dai, Z. Control Strategy of Stable Climbing Mechanics for Gecko-Inspired Robot on Vertical Arc Surface. IEEE Instrum. Meas. Mag. 2023, 26, 48–56. [Google Scholar] [CrossRef]

- Menon, C.; Li, Y.; Sameoto, D.; Martens, C. Abigaille-I: Towards the development of a spider-inspired climbing robot for space use. In Proceedings of the 2008 2nd IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics, Scottsdale, AZ, USA, 19–22 October 2008; IEEE: New York, NY, USA, 2008; pp. 384–389. [Google Scholar]

- Hawkes, E.W.; Christensen, D.L.; Cutkosky, M.R. Vertical dry adhesive climbing with a 100× bodyweight payload. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; IEEE: New York, NY, USA, 2015; pp. 3762–3769. [Google Scholar]

- Dai, Z.; Zhang, H.; Li, H. Biomimetics of gecko locomotion: From biology to engineering. In Proceedings of the 2009 ASME/IFToMM International Conference on Reconfigurable Mechanisms and Robots, London, UK, 22–24 June 2009; IEEE: New York, NY, USA, 2009; pp. 464–468. [Google Scholar]

- Xiao, J.; Hao, L.; Xu, H.; Zhang, X.; Li, X.; Li, Z. MST-Q: Micro suction tape quadruped robot with high payload capacity. IEEE Robot. Autom. Lett. 2023, 8, 7304–7311. [Google Scholar] [CrossRef]

- Custodio, J.A.; Wang, Y. A spoke-wheel based wall-climbing robot. In Proceedings of the 2008 IEEE Conference on Robotics, Automation and Mechatronics, Chengdu, China, 21–24 September 2008; IEEE: New York, NY, USA, 2008; pp. 456–461. [Google Scholar]

- Gorb, S.N.; Sinha, M.; Peressadko, A.; Daltorio, K.A.; Quinn, R.D. Insects did it first: A micropatterned adhesive tape for robotic applications. Bioinspir. Biomim. 2007, 2, S117. [Google Scholar] [CrossRef]

- Murphy, M.P.; Sitti, M. Waalbot: An agile small-scale wall-climbing robot utilizing dry elastomer adhesives. IEEE/ASME Trans. Mechatron. 2007, 12, 330–338. [Google Scholar] [CrossRef]

- Daltorio, K.A.; Gorb, S.; Peressadko, A.; Horchler, A.D.; Ritzmann, R.E.; Quinn, R.D. A robot that climbs walls using micro-structured polymer feet. In Climbing and Walking Robots, Proceedings of the 8th International Conference on Climbing and Walking Robots and the Support Technologies for Mobile Machines (CLAWAR 2005), London, UK, 13–15 September 2005; Springer: Berlin/Heidelberg, Germany, 2006; pp. 131–138. [Google Scholar]

- Unver, O.; Sitti, M. Tankbot: A palm-size, tank-like climbing robot using soft elastomer adhesive treads. Int. J. Robot. Res. 2010, 29, 1761–1777. [Google Scholar] [CrossRef]

- Seo, T.; Sitti, M. Tank-like module-based climbing robot using passive compliant joints. IEEE/ASME Trans. Mechatron. 2012, 18, 397–408. [Google Scholar] [CrossRef]

- Krahn, J.; Liu, Y.; Sadeghi, A.; Menon, C. A tailless timing belt climbing platform utilizing dry adhesives with mushroom caps. Smart Mater. Struct. 2011, 20, 115021. [Google Scholar] [CrossRef]

- Autumn, K.; Sitti, M.; Liang, Y.A.; Peattie, A.M.; Hansen, W.R.; Sponberg, S. Evidence for van der Waals adhesion in gecko setae. Proc. Natl. Acad. Sci. USA 2002, 99, 12252–12256. [Google Scholar] [CrossRef] [PubMed]

- Huber, G.; Mantz, H.; Spolenak, R.; Spolenak, R.; Mecke, K.; Jacobs, K.; Gorb, S.N.; Arzt, E. Evidence for capillarity contributions to gecko adhesion from single spatula nanomechanical measurements. Proc. Natl. Acad. Sci. USA 2005, 102, 16293–16296. [Google Scholar] [CrossRef]

- Dai, Z.D.; Hui, C.; Stanislav, G. Effect of surface roughness on the adhesive properties of polyurethane. Mocaxue Xuebao (Tribol.) 2003, 23, 245–249. [Google Scholar]

- Turnbull, G.; Chari, S.; Li, Z.; Yang, Z.; Alam, C.M.; Clemente, C.J.; Alam, P. The influence of claw morphology on gripping efficiency. Biol. Open 2023, 12, bio059874. [Google Scholar] [CrossRef]

- Xu, F.; Meng, F.; Jiang, Q.; Peng, G. Grappling claws for a robot to climb rough wall surfaces: Mechanical design, grasping algorithm, and experiments. Robot. Auton. Syst. 2020, 128, 103501. [Google Scholar] [CrossRef]

- Chen, D.L.; Zhang, Q.; Liu, S.Z. Design and realization of a flexible claw of rough wall climbing robot. Adv. Mater. Res. 2011, 328, 388–392. [Google Scholar] [CrossRef]

- Jiang, Q.; Xu, F. Grasping claws of bionic climbing robot for rough wall surface: Modeling and analysis. Appl. Sci. 2017, 8, 14. [Google Scholar] [CrossRef]

- Saunders, A.; Goldman, D.I.; Full, R.J.; Buehler, M. The rise climbing robot: Body and leg design. In Unmanned Systems Technology VIII; SPIE: Bellingham, WA, USA, 2006; Volume 6230, pp. 401–413. [Google Scholar]

- Haynes, G.C.; Khripin, A.; Lynch, G.; Amory, J.; Saunders, A.; Rizzi, A.A.; Koditschek, D.E. Rapid pole climbing with a quadrupedal robot. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; IEEE: New York, NY, USA, 2009; pp. 2767–2772. [Google Scholar]

- Kim, S.; Asbeck, A.T.; Cutkosky, M.R.; Provancher, W.R. SpinybotII: Climbing hard walls with compliant microspines. In Proceedings of the 12th International Conference on Advanced Robotics, Hong Kong, China, 20–22 May 2024; IEEE: New York, NY, USA, 2005; pp. 601–606. [Google Scholar]

- Asbeck, A.T.; Kim, S.; Cutkosky, M.R.; Provancher, W.R.; Lanzetta, M. Scaling hard vertical surfaces with compliant microspine arrays. Int. J. Robot. Res. 2006, 25, 1165–1179. [Google Scholar] [CrossRef]

- Parness, A. Science objectives and rover design for a limbed comet rover mission concept. In Proceedings of the 2017 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2017; IEEE: New York, NY, USA, 2017; pp. 1–7. [Google Scholar]

- Parness, A.; Abcouwer, N.; Fuller, C.; Wiltsie, N.; Nash, J.; Kennedy, B. LEMUR 3: A limbed climbing robot for extreme terrain mobility in space. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation, Singapore, 29 May–3 June 2017; IEEE: New York, NY, USA, 2017; pp. 5467–5473. [Google Scholar]

- Nadan, P.; Backus, S.; Johnson, A.M. LORIS: A lightweight free-climbing robot for extreme terrain exploration. In Proceedings of the 2024 IEEE International Conference on Robotics and Automation, Yokohama, Japan, 13–17 May 2024; IEEE: New York, NY, USA, 2024; pp. 18480–18486. [Google Scholar]

- Sintov, A.; Avramovich, T.; Shapiro, A. Design and motion planning of an autonomous climbing robot with claws. Robot. Auton. Syst. 2011, 59, 1008–1019. [Google Scholar] [CrossRef]

- Parness, A. Anchoring foot mechanisms for sampling and mobility in microgravity. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; IEEE: New York, NY, USA, 2011; pp. 6596–6599. [Google Scholar]

- Li, R.; Wu, C.; Yan, S.; Li, C.; Gong, X.; Lee, C.H.; Shou, M. A spiny claws climbing robot based on self-sensing soles. IEEE Robot. Autom. Lett. 2024, 9, 10906–10913. [Google Scholar] [CrossRef]

- Zi, P.; Xu, K.; Chen, J.; Wang, C.; Zhang, T.; Luo, Y.; Ding, X. Intelligent rock-climbing robot capable of multimodal locomotion and hybrid bioinspired attachment. Adv. Sci. 2024, 11, 2309058. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhao, J.; Guo, J.; Wu, H.; Liu, Z. A wheeled wall-climbing robot with bio-inspired spine mechanisms. J. Bionic Eng. 2015, 12, 17–28. [Google Scholar] [CrossRef]

- Daltorio, K.A.; Wei, T.E.; Horchler, A.D.; Southard, L.; Wile, G.D.; Quinn, R.D.; Ritzmann, R.E. Mini-whegs TM climbs steep surfaces using insect-inspired attachment mechanisms. Int. J. Robot. Res. 2009, 28, 285–302. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Niu, F.; Li, P.; Li, Y.; Mei, T. A track-type inverted climbing robot with bio-inspired spiny grippers. J. Bionic Eng. 2020, 17, 920–931. [Google Scholar] [CrossRef]

- Wang, L. Research on Tracked Wall-Climbing Robot Based on Bionic Compliant Claw Structure. Ph.D. Thesis, Xi’an University of Technology, Xi’an, China, 2021. [Google Scholar]

- Zhang, W.; Ding, Y.; Chen, Y.; Sun, Z. Autonomous positioning for wall climbing robots based on a combination of an external camera and a robot-mounted inertial measurement unit. J. Tsinghua Univ. (Sci. Technol.) 2022, 62, 1524–1531. [Google Scholar]

- Zhang, W.; Huang, T.; Sun, Z. Localization of wall climbing robot on cylinder-shaped steel. In Mechatronics and Automation Technology; IOS Press: Amsterdam, The Netherlands, 2022; pp. 292–303. [Google Scholar]

- Enjikalayil, A.R.; Veerajagadheswar, P.; Lin, N.H.; Kumaran, S.; Vishaal, S.R.; Mohan, R.E. Sparrow: A magnetic climbing robot for autonomous thickness measurement in ship hull maintenance. J. Mar. Sci. Eng. 2020, 8, 469. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, S.; Song, W.; Li, C.; Shi, H. Path planning for wall-climbing robot in volume measurement of vertical tank. Robot 2024, 46, 36–44. [Google Scholar] [CrossRef]

- Nazemzadeh, P.; Fontanelli, D.; Macii, D.; Palopoli, L. Indoor localization of mobile robots through QR code detection and dead reckoning data fusion. IEEE/ASME Trans. Mechatron. 2017, 22, 2588–2599. [Google Scholar] [CrossRef]

- Gu, Z.; Gong, Z.; Tao, B.; Yin, Z.; Ding, H. Global localization based on tether and visual-inertial odometry with adsorption constraints for climbing robots. IEEE Trans. Ind. Inform. 2022, 19, 6762–6772. [Google Scholar] [CrossRef]

- Seraji, H.; Howard, A. Behavior-based robot navigation on challenging terrain: A fuzzy logic approach. IEEE Trans. Robot. Autom. 2002, 18, 308–321. [Google Scholar] [CrossRef]

- Yang, L.; Yang, G.; Liu, Z.; Chang, Y.; Jiang, B.; Awad, Y.; Xiao, J. Wall-climbing robot for visual and GPR inspection. In Proceedings of the 2018 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; IEEE: New York, NY, USA, 2018; pp. 1004–1009. [Google Scholar]

- Zhang, W.; Huang, T.; Sun, Z. An autonomous localisation method of wall-climbing robots on large steel components with IMU and fixed RGB-D camera. J. Navig. 2024, 77, 469–484. [Google Scholar] [CrossRef]

- Yang, L.; Li, B.; Yang, G.; Chang, Y.; Liu, Z.; Jiang, B.; Xiaol, J. Deep neural network based visual inspection with 3D metric measurement of concrete defects using wall-climbing robot. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 4–8 November 2019; IEEE: New York, NY, USA, 2019; pp. 2849–2854. [Google Scholar]

- Ismail, H.; Roy, R.; Sheu, L.J.; Chieng, W.H.; Tang, L.C. Exploration-based SLAM (e-SLAM) for the indoor mobile robot using LiDAR. Sensors 2022, 22, 1689. [Google Scholar] [CrossRef] [PubMed]

- Seçkin, A.Ç.; Karpuz, C.; Özek, A. Feature matching based positioning algorithm for swarm robotics. Comput. Electr. Eng. 2018, 67, 807–818. [Google Scholar] [CrossRef]

- Cotera, P.; Velazquez, M.; Cruz, D.; Medina, L.; Bandala, M. Indoor robot positioning using an enhanced trilateration algorithm. Int. J. Adv. Robot. Syst. 2016, 13, 110. [Google Scholar] [CrossRef]

- Reina, G.; Vargas, A.; Nagatani, K.; Yoshida, K. Adaptive Kalman filtering for GPS-based mobile robot localization. In Proceedings of the 2007 IEEE International Workshop on Safety, Security and Rescue Robotics, Rome, Italy, 27–29 September 2007; IEEE: New York, NY, USA, 2007; pp. 1–6. [Google Scholar]

- Morad, S.; Kalita, H.; Thangavelautham, J. Planning and navigation of climbing robots in low-gravity environments. In Proceedings of the 2018 IEEE/ION Position, Location and Navigation Symposium (PLANS), Monterey, CA, USA, 23–26 April 2018; IEEE: New York, NY, USA, 2018; pp. 1302–1310. [Google Scholar]

- Tavakoli, M.; Cabrita, G.; Faria, R.; Marques, L.; de Almeida, A.T. Cooperative multi-agent mapping of three-dimensional structures for pipeline inspection applications. Int. J. Robot. Res. 2012, 31, 1489–1503. [Google Scholar] [CrossRef]

- Kurazume, R.; Hirose, S. An experimental study of a cooperative positioning system. Auton. Robot. 2000, 8, 43–52. [Google Scholar] [CrossRef]

- An, X.; Wu, C.; Lin, Y.; Lin, M.; Yoshinaga, T.; Ji, Y. Multi-robot systems and cooperative object transport: Communications, platforms, and challenges. IEEE Open J. Comput. Soc. 2023, 4, 23–36. [Google Scholar] [CrossRef]

- Sukop, M.; Šmídl, V.; Prokeš, A. Simple ultrasonic-based localization system for mobile robots. Appl. Sci. 2024, 14, 3625. [Google Scholar] [CrossRef]

- Dubey, A.C.; Subramanian, V.A.; Kumar, V.J. Low energy ultrasonic single beacon localization for testing of scaled model vehicle. Ocean. Syst. Eng. 2019, 9, 391–407. [Google Scholar]

- Huang, L. Review on LiDAR-based SLAM techniques. In Proceedings of the 2021 International Conference on Signal Processing and Machine Learning (CONF-SPML), Beijing, China, 18–20 August 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Khan, M.U.; Zaidi, S.A.A.; Ishtiaq, A.; Bukhari, S.U.R.; Samer, S.; Farman, A. A comparative survey of LiDAR-SLAM and LiDAR-based sensor technologies. In Proceedings of the 2021 Mohammad Ali Jinnah University International Conference on Computing (MAJICC), Karachi, Pakistan, 15–17 July 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Wang, C.; Cheng, C.; Yang, D.; Pan, G.; Zhang, F. Path planning in localization uncertainty environment based on Dijkstra method. Front. Neurorobot. 2022, 16, 821991. [Google Scholar]

- Zhou, X.; Yan, J.; Yan, M.; Mao, K.; Yang, R.; Liu, W. Path planning of rail-mounted logistics robots based on the improved Dijkstra algorithm. Appl. Sci. 2023, 13, 9955. [Google Scholar] [CrossRef]

- Alshammrei, S.; Boubaker, S.; Kolsi, L. Improved Dijkstra algorithm for mobile robot path planning and obstacle avoidance. Comput. Model. Eng. Sci. 2022, 72, 5939–5954. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, W.; Chen, A. Path planning for the mobile robot: A review. Symmetry 2018, 10, 450. [Google Scholar] [CrossRef]

- Guo, J.; Huo, X.; Guo, S.; Xu, J. A path planning method for the spherical amphibious robot based on improved A-star algorithm. In Proceedings of the 2021 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 8–11 August 2021; IEEE: New York, NY, USA, 2021; pp. 1274–1279. [Google Scholar]

- Naderi, K.; Rajamäki, J.; Hämäläinen, P. Discovering and synthesizing humanoid climbing movements. ACM Trans. Graph. (TOG) 2017, 36, 1–11. [Google Scholar] [CrossRef]

- Zhang, R.; Latombe, J.C. Capuchin: A free-climbing robot. Int. J. Adv. Robot. Syst. 2013, 10, 194. [Google Scholar] [CrossRef]

- Zhu, H.; Lu, J.; Gu, S.; Wei, S.; Guan, Y. Planning three-dimensional collision-free optimized climbing path for biped wall-climbing robots. IEEE/ASME Trans. Mechatron. 2020, 26, 2712–2723. [Google Scholar] [CrossRef]

- Core, M.G.; Moore, J.D.; Zinn, C. Supporting constructive learning with a feedback planner. In Proceedings of the AAAI Fall Symposium on Building Dialogue Systems for Tutorial Applications, North Falmouth, MA, USA, 3–5 November 2000; pp. 1–9. [Google Scholar]

- Reist, P.; Preiswerk, P.; Tedrake, R. Feedback-motion-planning with simulation-based LQR-trees. Int. J. Robot. Res. 2016, 35, 1393–1416. [Google Scholar] [CrossRef]

- Koenig, S.; Likhachev, M. D* lite. In Proceedings of the Eighteenth National Conference on Artificial Intelligence, Edmonton, AB, Canada, 28 July–1 August 2002; pp. 476–483. [Google Scholar]

- Zuo, L.; Guo, Q.; Xu, X.; Fu, H. A hierarchical path planning approach based on A⁎ and least-squares policy iteration for mobile robots. Neurocomputing 2015, 170, 257–266. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Ding, W.; Wang, X.; Sun, Q. Robust path planning for quadruped robots in dynamic and challenging environment. In Proceedings of the 2024 China Automation Congress (CAC), Qingdao, China, 1–3 November 2024; IEEE: New York, NY, USA, 2024; pp. 6711–6715. [Google Scholar]

- Meng, X.; Fang, X. A UGV path planning algorithm based on improved A* with improved artificial potential field. Electronics 2024, 13, 972. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, H.; Bhatt, V.; Nikolaidis, S.; Li, J. Guidance graph optimization for lifelong multi-agent path finding. arXiv 2024, arXiv:2402.01446. [Google Scholar]

- Hirose, S.; Yamada, H. Snake-like robots [tutorial]. IEEE Robot. Autom. Mag. 2009, 16, 88–98. [Google Scholar] [CrossRef]

- Peng, Y.; Nabae, H.; Funabora, Y.; Suzumori, K. Controlling a peristaltic robot inspired by inchworms. Biomim. Intell. Robot. 2024, 4, 100146. [Google Scholar] [CrossRef]

- Tadakuma, K.; Tadakuma, R.; Maruyama, A.; Rohmer, E.; Nagatani, K.; Yoshida, K.; Kaneko, M. Mechanical design of the wheel-leg hybrid mobile robot to realize a large wheel diameter. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; IEEE: New York, NY, USA, 2010; pp. 3358–3365. [Google Scholar]

- Kim, Y.S.; Jung, G.P.; Kim, H.; Cho, K.J.; Chu, C.N. Wheel transformer: A wheel-leg hybrid robot with passive transformable wheels. IEEE Trans. Robot. 2014, 30, 1487–1498. [Google Scholar] [CrossRef]

- Dethe, R.D.; Jaju, S.B. Developments in wall climbing robots: A review. Int. J. Eng. Res. Gen. Sci. 2014, 2, 33–42. [Google Scholar]

- Ma, J.; Zhu, M.; Zhang, T.; Capello, E.; Yue, X. Flexibility and granular terrain adaptability of a linkage-based wheel-legged robot: LinkWheg. IEEE/ASME Trans. Mechatron. 2025; in press. [Google Scholar]

- Sihite, E.; Ramezani, A.; Gharib, M. Dynamic modeling of wing-assisted inclined running with a morphing multi-modal robot. In Proceedings of the 2024 IEEE International Conference on Robotics and Automation (ICRA), Yokohama, Japan, 13–17 May 2024; IEEE: New York, NY, USA, 2024; pp. 2339–2345. [Google Scholar]

- Wang, X.; Lin, A.; Yuan, W.; Hu, H.; Cheng, G.; Ding, J. Design of an actuator with bionic claw hook–suction cup hybrid structure for soft robot. Bioinspir. Biomim. 2024, 19, 036021. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Xu, J.; Liu, X.; Zhang, Q.; Cong, Q.; Chen, T.; Liu, C. Advanced bionic attachment equipment inspired by the attachment performance of aquatic organisms: A review. Biomimetics 2023, 8, 85. [Google Scholar] [CrossRef]

- Liu, J.; Xu, L.; Xu, J.; Liu, L.; Cheng, G.; Chen, S.; Liang, X. Analysis and optimization of the wall-climbing robot with an adsorption system and adhesive belts. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420926409. [Google Scholar] [CrossRef]

- Wainwright, D.K.; Kleinteich, T.; Kleinteich, A.; Gorb, S.N.; Summers, A.P. Stick tight: Suction adhesion on irregular surfaces in the northern clingfish. Biol. Lett. 2013, 9, 20130234. [Google Scholar] [CrossRef]

- Hou, J.; Wright, E.; Bonser, R.H.C.; Jeronimidis, G. Development of biomimetic squid-inspired suckers. J. Bionic Eng. 2012, 9, 484–493. [Google Scholar] [CrossRef]

- Flammang, B. Functional morphology of the remora adhesive disc. FASEB J. 2015, 29, 865–869. [Google Scholar] [CrossRef]

- Xi, P.; Cong, Q.; Xu, J.; Qiu, K. Design, experiment and adsorption mechanism analysis of bionic sucker based on octopus sucker. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2019, 233, 1250–1261. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; Gu, J.; Shen, Y. Proposed wall climbing robot with permanent magnetic tracks for inspecting oil tanks. In Proceedings of the IEEE International Conference on Mechatronics and Automation, Niagara Falls, ON, Canada, 29 July–1 August 2005; IEEE: New York, NY, USA, 2005; Volume 4, pp. 2072–2077. [Google Scholar]

- Wang, J.; Chortos, A. Control strategies for soft robot systems. Adv. Intell. Syst. 2022, 4, 2100165. [Google Scholar] [CrossRef]

- Zhong, Z.; Xu, M.; Xiao, J.; Lu, H. Design and control of an omnidirectional mobile wall-climbing robot. Appl. Sci. 2021, 11, 11065. [Google Scholar] [CrossRef]

- Fateh, M.M.; Arab, A. Robust control of a wheeled mobile robot by voltage control strategy. Nonlinear Dyn. 2015, 79, 335–348. [Google Scholar] [CrossRef]

- Fang, X.; Wang, C.; Nguyen, T.M.; Xie, L. Graph optimization approach to range-based localization. IEEE Trans. Syst. Man Cybern. Syst. 2020, 51, 6830–6841. [Google Scholar] [CrossRef]

| Category | Equipment Used | Advantages | Disadvantages | Typical Application Scenarios |

|---|---|---|---|---|

| External Camera-Based Localization [129,133] | RGB-D Camera | High accuracy; robust against internal sensor noise | Limited by field of view, lighting, and weather conditions | Indoor structural inspection, laboratory environments |

| Wireless Beacon/Ultrasonic-Based [131,147,148] | Beacons + Sensors | Good obstacle penetration; real-time performance | Complex spatial deployment; medium localization accuracy | Tank inspection, in-pipe inspection |

| Onboard Camera + IMU [135,136] | IMU + Camera | Easy to integrate; adaptable to dynamic environments | Odometry cumulative error | Small multifunctional robots, field inspections |

| LiDAR-Based SLAM [139,149,150] | LiDAR | Strong mapping capabilities; high adaptability to complex environments | Expensive equipment; high power consumption | Large-scale structure inspection, long-duration autonomous tasks |

| Multi-Robot Cooperative Localization [143,144] | Multiple robots/Tethered system | Improved overall reliability and environmental adaptability | Complex algorithms; high communication requirements | Steep terrain, space exploration (e.g., crater navigation) |

| Method Type | Representative Algorithms | Advantages | Limitations | Typical Application Scenarios |

|---|---|---|---|---|

| Graph Search [151,152,153,154,155,156,157] | Dijkstra, A*, A*-Prune | Globally optimal, well-established, explainable | Not suitable for high-dimensional spaces; rigid path execution; requires full map | Ship hull inspection, inner tank scanning |

| Sampling-Based [157,158] | RRT, RRT*, PRM | Adapts to high DoF and discontinuous/complex terrain | Non-optimal paths; requires smoothing | Rock wall climbing, facade skeleton traversal |

| Feedback-Based [159,160,161,162,163] | APF, D*, IJ-APF | Real-time, responsive to dynamic obstacles, lightweight | Prone to local minima; lacks global optimality | Pipeline inspection, steel structure obstacle avoidance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, S.; Wei, Z.; Guo, J.; Ding, Y.; Liu, J.; Song, A. Current Status and Trends of Wall-Climbing Robots Research. Machines 2025, 13, 521. https://doi.org/10.3390/machines13060521

Lou S, Wei Z, Guo J, Ding Y, Liu J, Song A. Current Status and Trends of Wall-Climbing Robots Research. Machines. 2025; 13(6):521. https://doi.org/10.3390/machines13060521

Chicago/Turabian StyleLou, Shengjie, Zhong Wei, Jinlin Guo, Yu Ding, Jia Liu, and Aiguo Song. 2025. "Current Status and Trends of Wall-Climbing Robots Research" Machines 13, no. 6: 521. https://doi.org/10.3390/machines13060521

APA StyleLou, S., Wei, Z., Guo, J., Ding, Y., Liu, J., & Song, A. (2025). Current Status and Trends of Wall-Climbing Robots Research. Machines, 13(6), 521. https://doi.org/10.3390/machines13060521