Optimization of Hybrid Machining of Nomex Honeycomb Structures: Effect of the CZ10 Tool and Ultrasonic Vibrations on the Cutting Process

Abstract

1. Introduction

2. Study Material and Cutting Tool

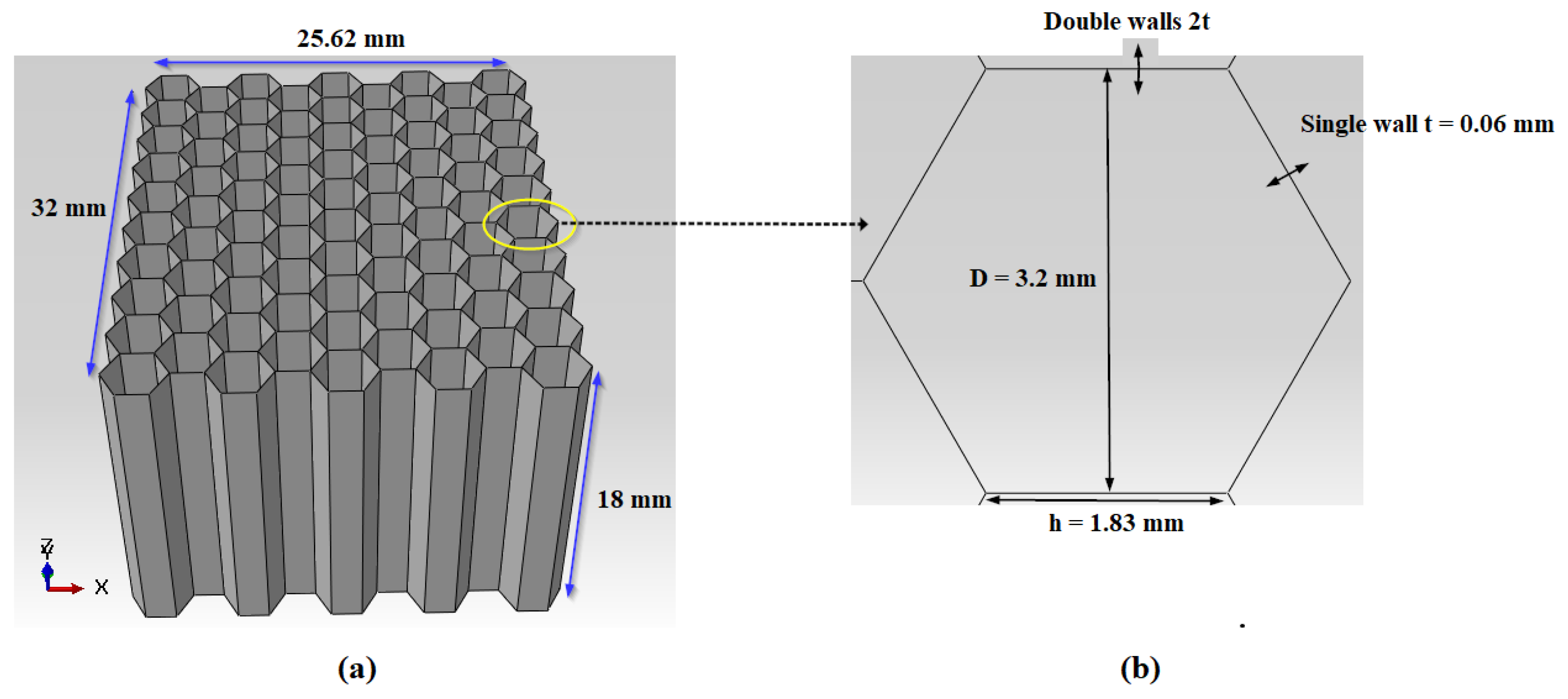

2.1. Material and Structure Studied

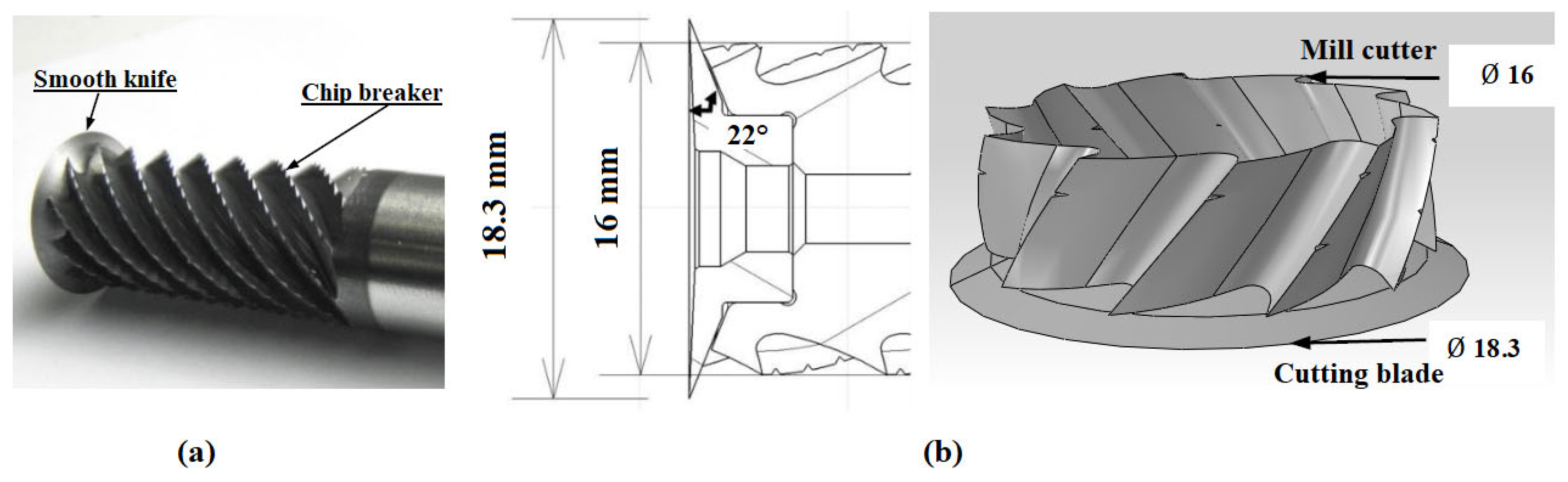

2.2. Cutting Tool Design

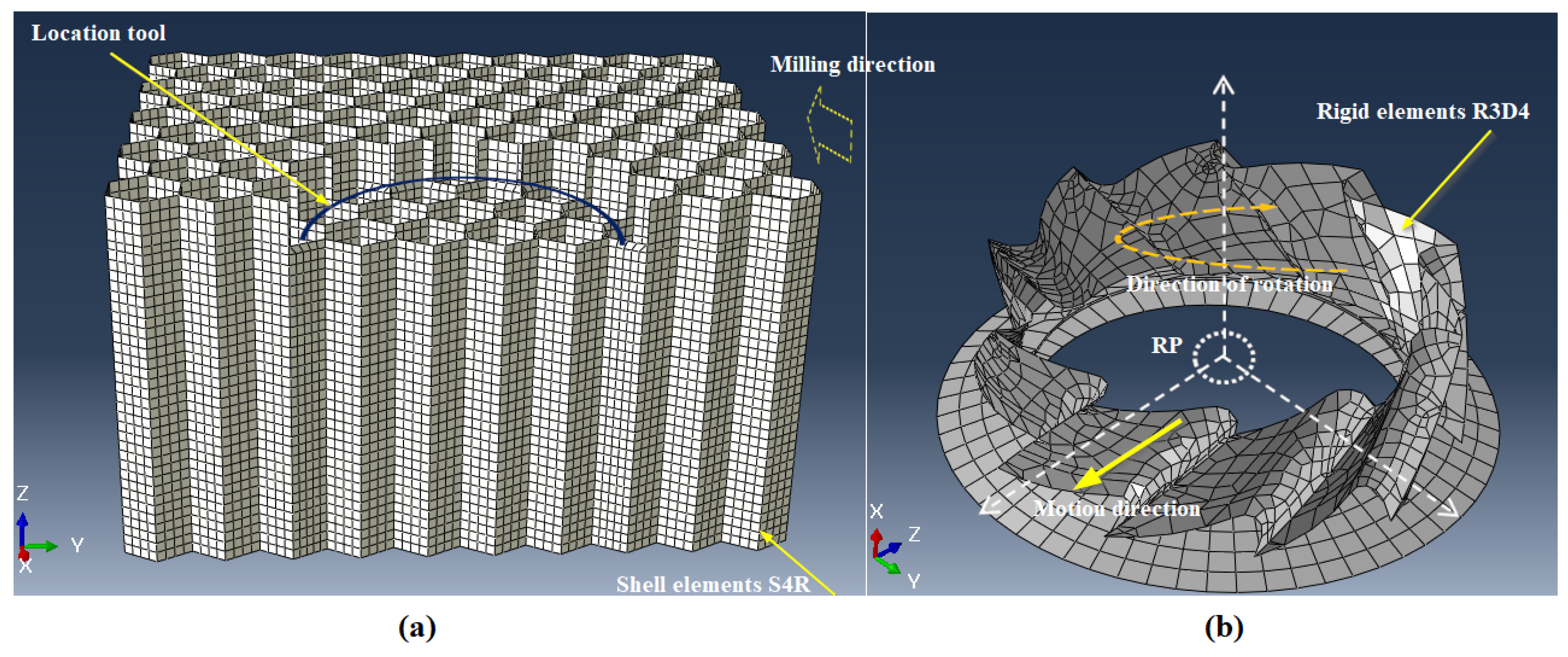

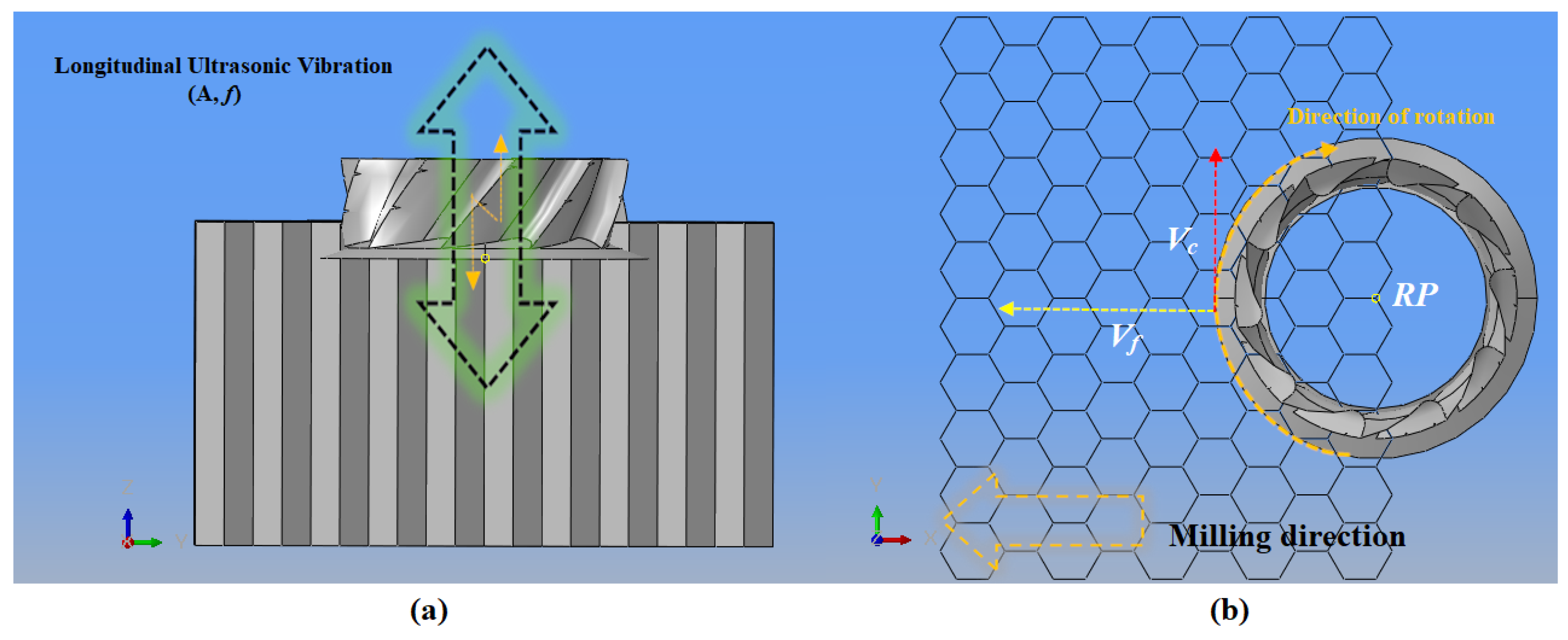

3. Description of the Numerical Model

4. Material Properties, Degradation and Failure Criteria

5. Results and Discussions

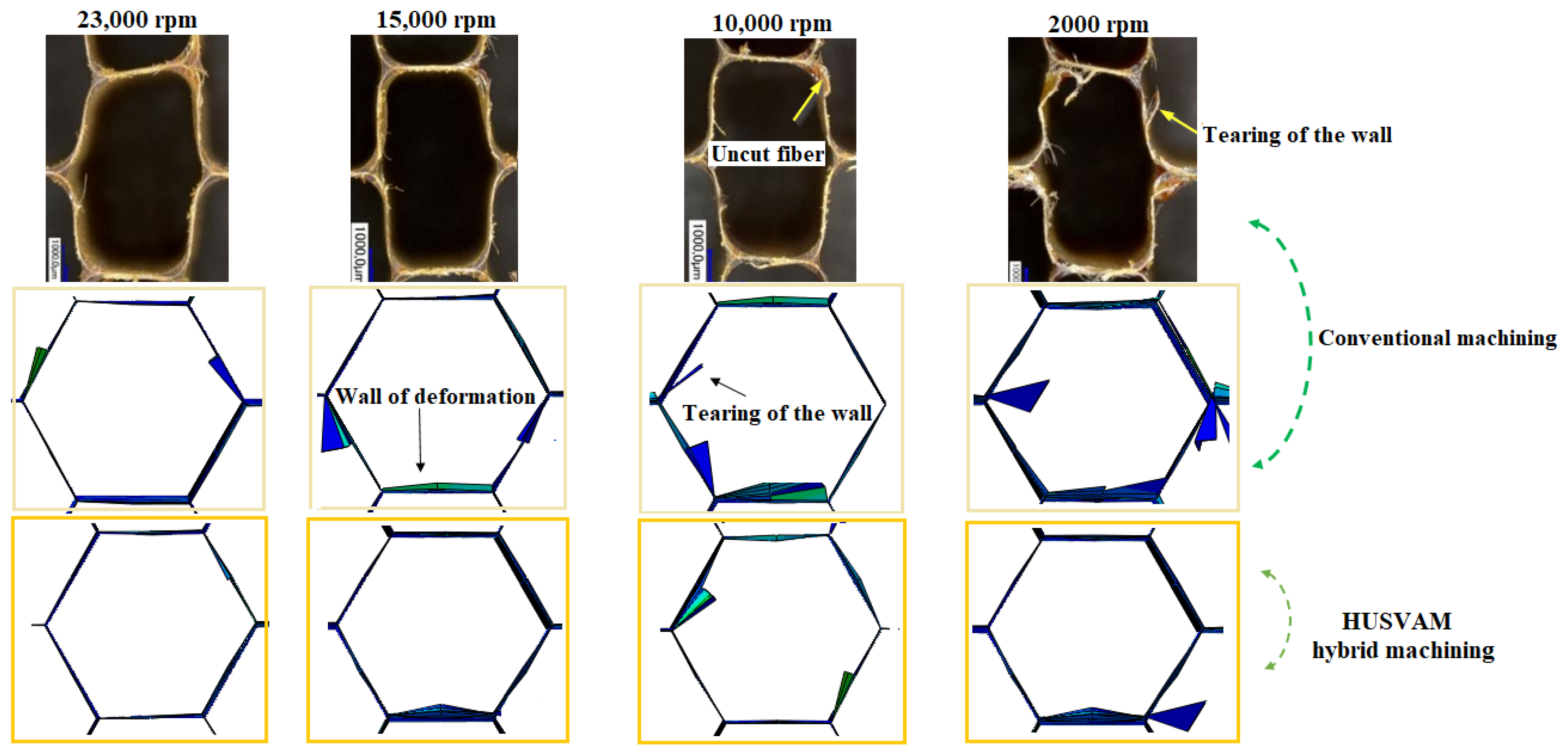

5.1. Validation of the Numerical Model for Hybrid Machining by Ultrasonic Vibrations: Study of Surface Defects as a Function of Rotation Speed

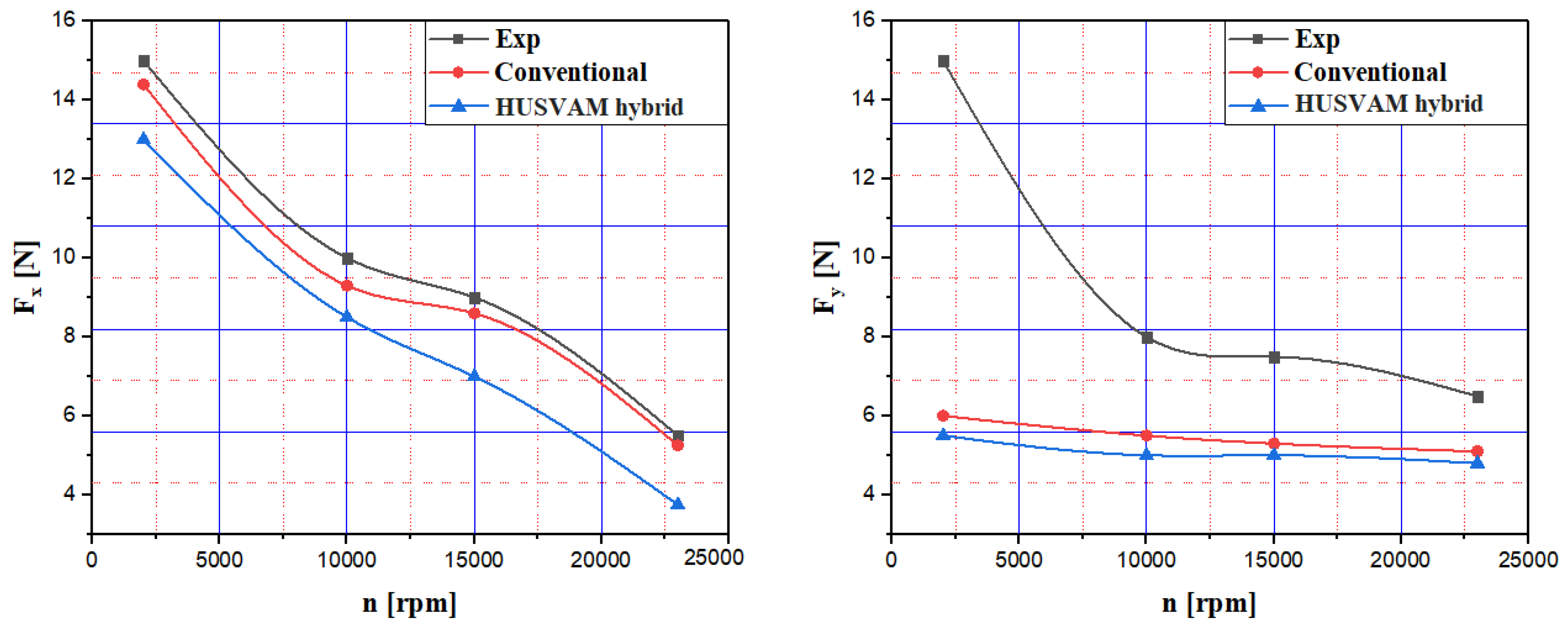

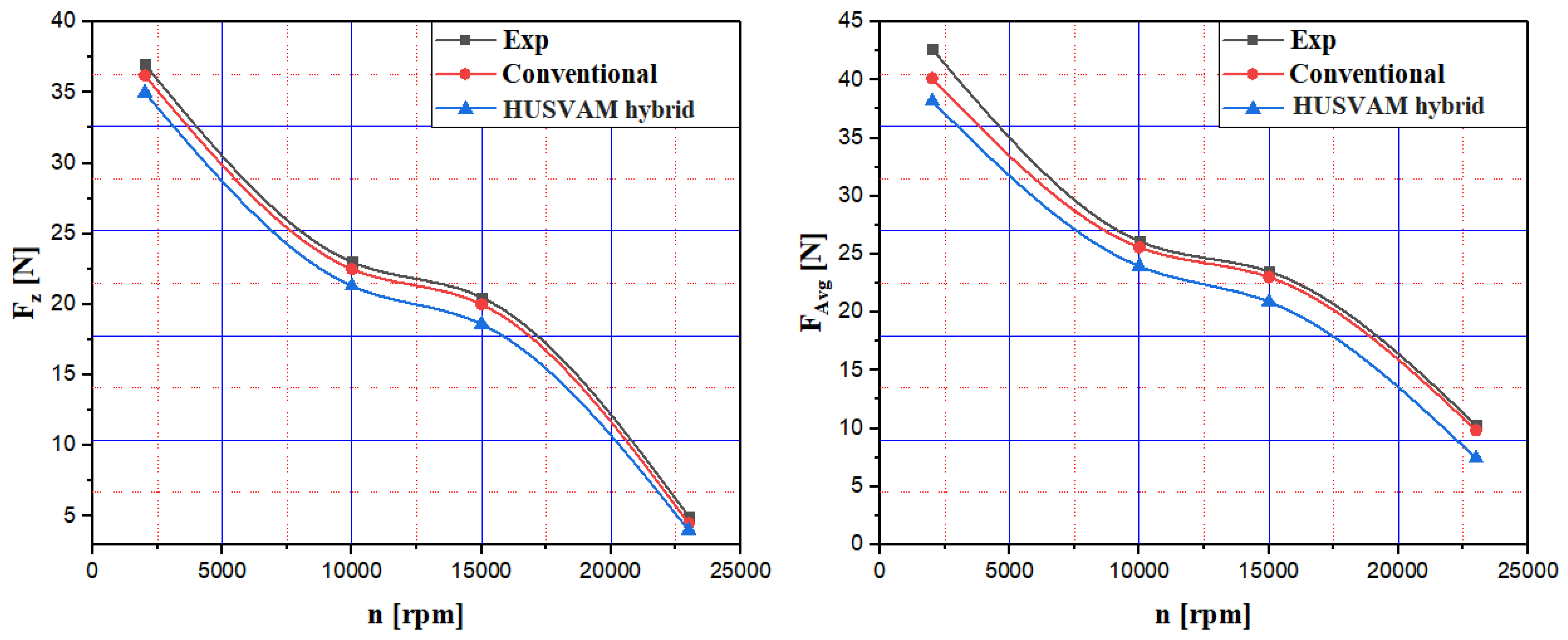

5.2. Comparison of Conventional and Hybrid HUSVAM Machining: Influence of Rotation Speed on Cutting Force and Its Components

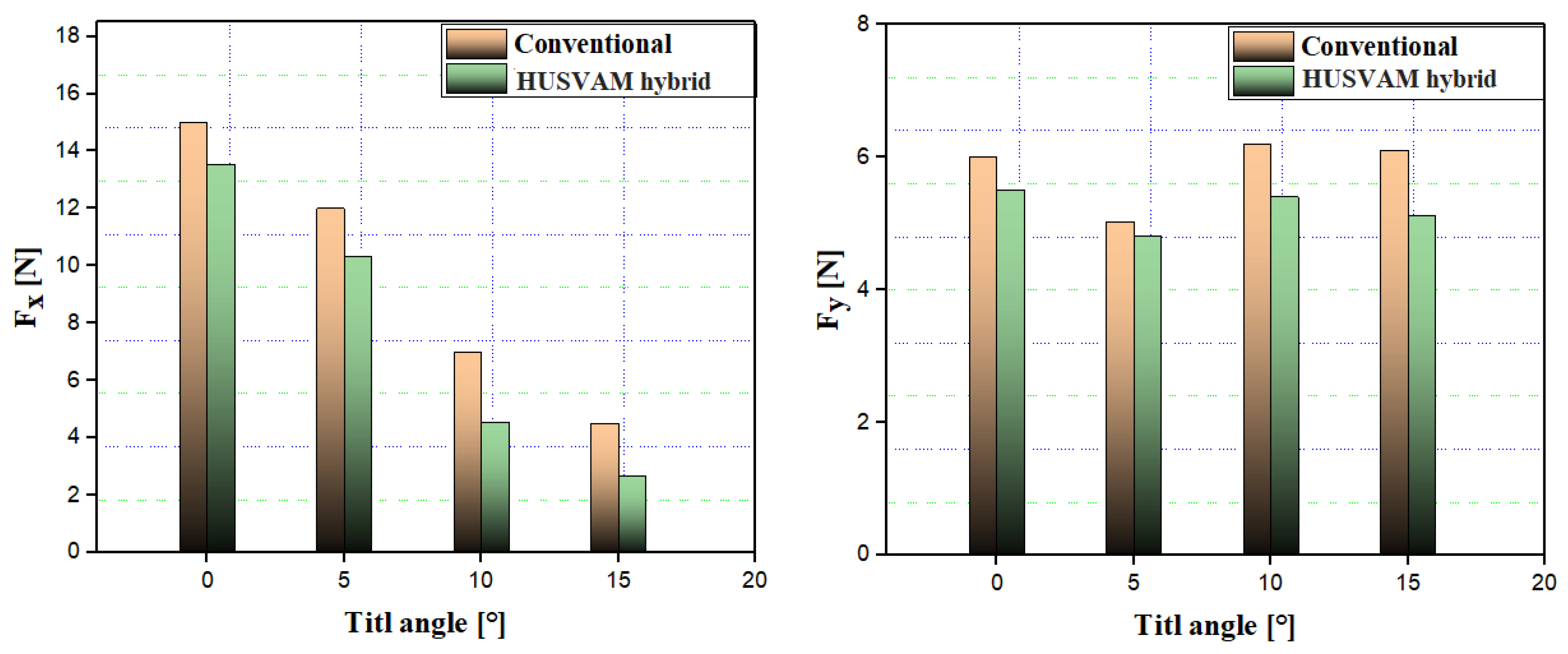

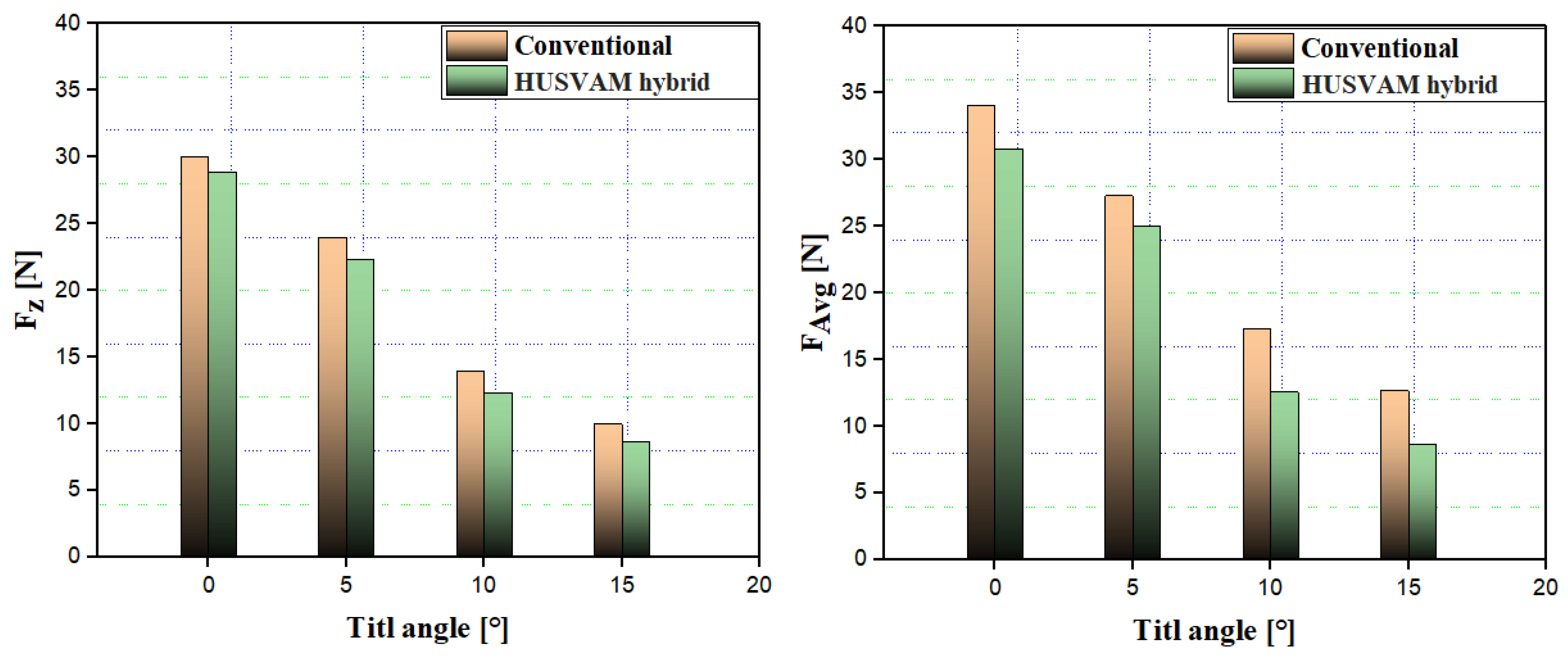

5.3. Analysis of the Impact of the Inclination Angle on the Cutting Force, Comparing Conventional and Hybrid Ultrasonic Vibration Machining

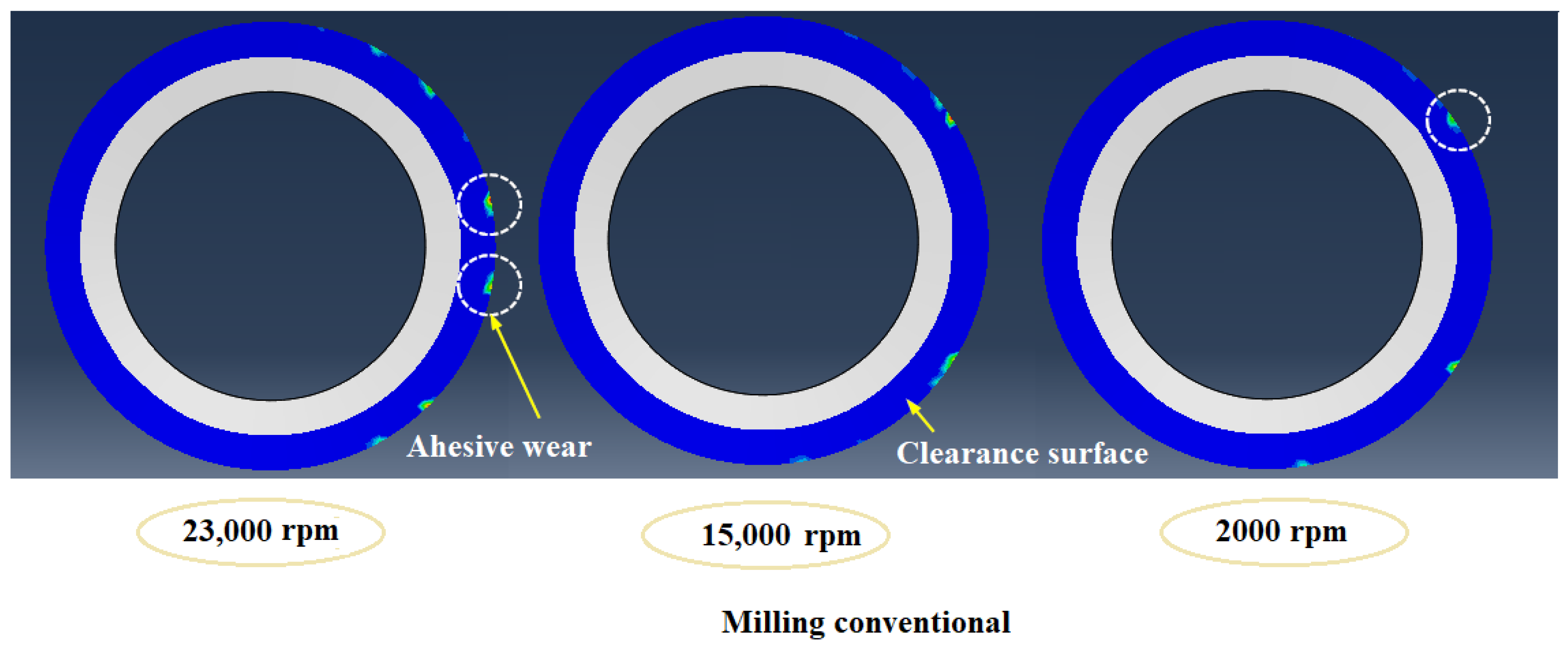

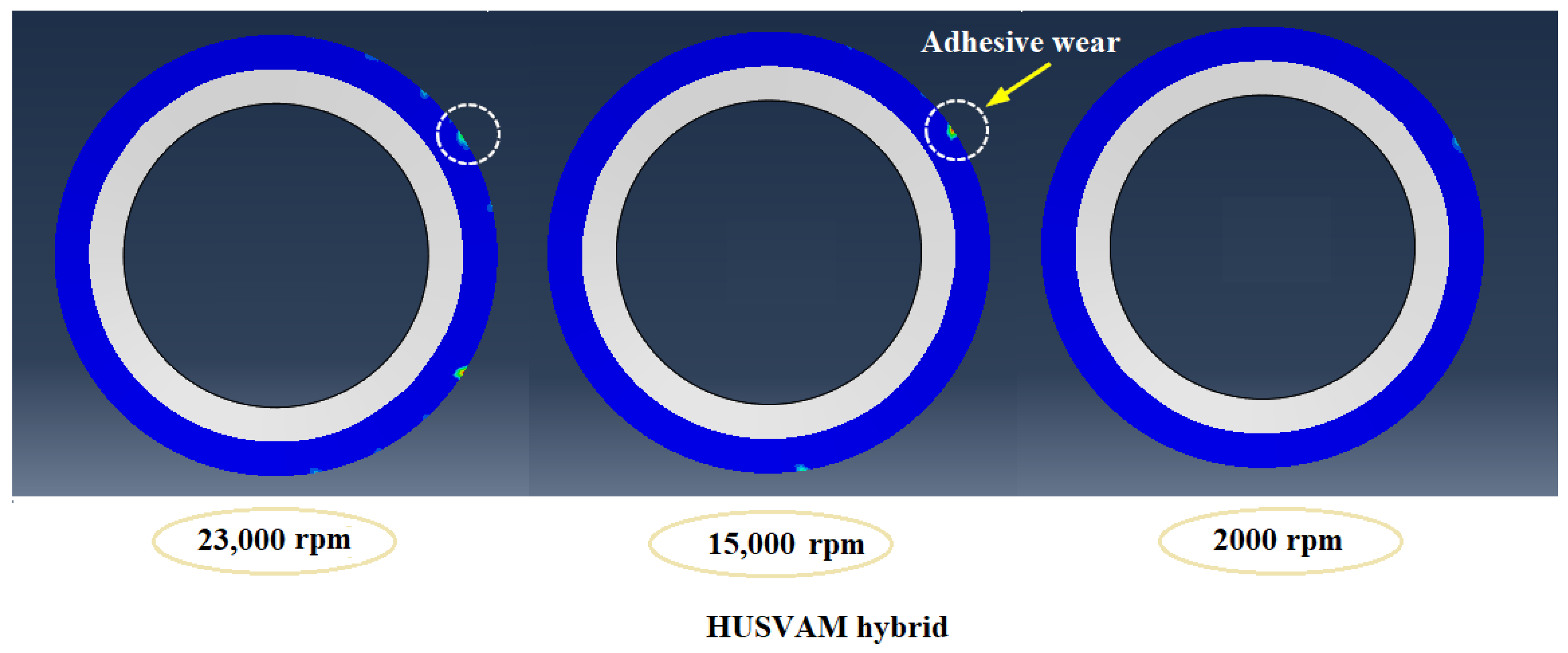

5.4. Study of Wear According to the Sticking of the Circular Knife in Conventional and Hybrid Milling Assisted by Ultrasonic Vibrations, According to the Rotation Speed

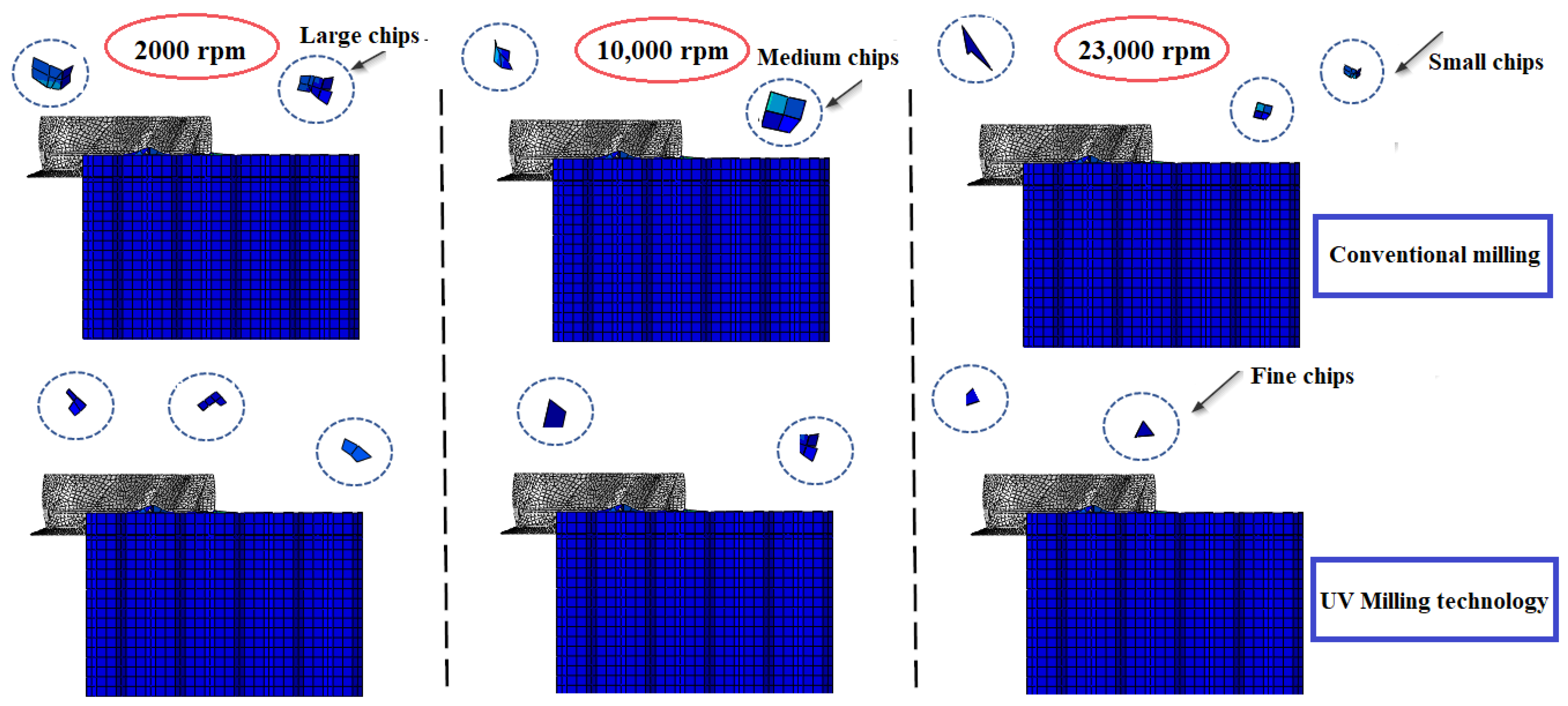

5.5. Study of Chip Formation in Conventional and Hybrid Milling Assisted by Ultrasonic Vibrations, According to Different Rotation Speeds

6. Conclusions

- The hybrid process assisted by HUSVAM ultrasonic vibrations of the Nomex honeycomb structure can significantly reduce the cutting force and its three components, ranging from 12% to 35%, especially for the crushing force Fx, thus improving process efficiency.

- The hybrid process assisted by ultrasonic vibrations reduces defects typical of conventional milling, such as tearing and wall deformation, while promoting a cleaner and more consistent machined surface, even at low rotational speeds.

- The ability of ultrasonic vibrations to reduce contact between the tool clearance surface and the material limits sticking wear, especially at lower cutting speeds. This allows for better process control and greater efficiency.

- At low rotational speeds, ultrasonic-vibration-assisted hybrid milling minimizes sticking wear and reduces cutting forces, resulting in cleaner cutting and improved tool durability, unlike conventional milling, which generates deformations and uncut fibers.

- By combining HUSVAM technology with the CZ10 combination cutting tool, the overall efficiency of the milling process is significantly optimized, providing a more durable, precise and high-performance solution, which is perfectly suited to the rigorous requirements of the aerospace industry.

- This study identified the significant impact of rotational speed and tilt angle on the performance of ultrasonic vibration-assisted hybrid milling, particularly in terms of reducing cutting forces and improving surface quality. These results provide a solid basis for guiding future multi-criteria optimization to define optimal cutting parameters suited to industrial requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviation and Nomenclature

| HUSVAM | Hybrid ultrasonic-vibration-assisted machining |

| FEM | Finite element method |

| FAvg | Average cutting force |

| Fx | Cutting force in X direction |

| Fy | Cutting force in Y direction |

| Fz | Cutting force in Z direction |

| Vc | Cutting speed |

| Vf | Feed rate |

| n | Spindle speed |

| α | Inclination angle |

| εf | Equivalent strain at failure |

| ∆ε | Increment of equivalent plastic strain |

| d | Damage coefficient |

| σ | Stress |

| τ | Shear stress |

| f | Vibration frequency |

| A | Vibration amplitude |

References

- Li, Z.; Ma, J. Experimental Study on Mechanical Properties of the Sandwich Composite Structure Reinforced by Basalt Fiber and Nomex Honeycomb. Materials 2020, 13, 1870. [Google Scholar] [CrossRef] [PubMed]

- Zaharia, S.M.; Pop, M.A.; Semenescu, A.; Florea, B.; Chivu, O.R. Mechanical Properties and Fatigue Performances on Sandwich Structures with CFRP Skin and Nomex Honeycomb Core. Mater. Plast. 2017, 54, 67–72. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yang, S. Advanced honeycomb designs for improving mechanical properties: A review. Compos. Part B Eng. 2021, 227, 109393. [Google Scholar] [CrossRef]

- Li, L.; Song, J.; Lei, Z.; Kang, A.; Wang, Z.; Men, R.; Ma, Y. Effects of ambient humidity and thermal aging on properties of Nomex insulation in mining dry-type transformer. High Volt. 2020, 6, 71–81. [Google Scholar] [CrossRef]

- Wei, X.; Xiong, J.; Wang, J.; Xu, W. New advances in fiber-reinforced composite honeycomb materials. Sci. China Technol. Sci. 2020, 63, 1348–1370. [Google Scholar] [CrossRef]

- Ranga, C.; Kumar, A.; Chandel, R. Influence of electrical and thermal ageing on the mineral insulating oil performance for power transformer applications. Insight-Non-Destr. Test. Cond. Monit. 2020, 62, 222–231. [Google Scholar] [CrossRef]

- Klocke, F.; Soo, S.L.; Karpuschewski, B.; Webster, J.A.; Novovic, D.; Elfizy, A.; Axinte, D.A.; Tönissen, S. Abrasive machining of advanced aerospace alloys and composites. CIRP Ann. 2015, 64, 581–604. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, P.; Xie, S.; Feng, Z.; Wang, D. Mechanical performance and energy absorption properties of structures combining two Nomex honeycombs. Compos. Struct. 2018, 185, 524–536. [Google Scholar] [CrossRef]

- Roy, R.; Park, S.-J.; Kweon, J.-H.; Choi, J.-H. Characterization of Nomex honeycomb core constituent material mechanical properties. Compos. Struct. 2014, 117, 255–266. [Google Scholar] [CrossRef]

- Liu, L.; Wang, H.; Guan, Z. Experimental and numerical study on the mechanical response of Nomex honeycomb core under transverse loading. Compos. Struct. 2015, 121, 304–314. [Google Scholar] [CrossRef]

- Zarrouk, T.; Salhi, J.-E.; Nouari, M.; Bouali, A. Enhancing the Machining Performance of Nomex Honeycomb Composites Using Rotary Ultrasonic Machining: A Finite Element Analysis Approach. Materials 2024, 17, 2044. [Google Scholar] [CrossRef] [PubMed]

- Mughal, K.H.; Qureshi, M.A.M.; Jamil, M.F.; Ahmad, S.; Khalid, F.A.; Qaiser, A.A.; Maqbool, A.; Raza, S.F.; Zhang, J. Investigation of hybrid ultrasonic machining process of Nomex honeycomb composite using a toothed disc cutter. Ultrasonics 2024, 141, 107343. [Google Scholar] [CrossRef] [PubMed]

- Zarrouk, T.; Nouari, M.; Salhi, J.-E.; Essaouini, H.; Abbadi, M.; Abbadi, A.; Lahlaouti, M.L. In-Depth Analysis of the Processing of Nomex Honeycomb Composites: Problems, Techniques and Perspectives. Machines 2024, 12, 561. [Google Scholar] [CrossRef]

- Liao, Y.; Chen, Y.; Lin, H. Feasibility study of the ultrasonic vibration assisted drilling of Inconel superalloy. Int. J. Mach. Tools Manuf. 2007, 47, 1988–1996. [Google Scholar] [CrossRef]

- Razfar, M.R.; Sarvi, P.; Zarchi, M.M.A. Experimental investigation of the surface roughness in ultrasonic-assisted milling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1615–1620. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, Y.; Gu, J.; Lu, D.; Ji, Y.; Nomura, M. Fundamental Machining Characteristics of the In-base-plane Ultrasonic Elliptical Vibration Assisted Turning of Inconel 718. Procedia CIRP 2016, 42, 858–862. [Google Scholar] [CrossRef]

- Zarrouk, T.; Salhi, J.-E.; Atlati, S.; Nouari, M.; Salhi, M.; Salhi, N. Modeling and numerical simulation of the chip formation process when machining Nomex. Environ. Sci. Pollut. Res. 2021, 29, 98–105. [Google Scholar] [CrossRef]

- Xiang, D.; Wu, B.; Yao, Y.; Liu, Z.; Feng, H. Ultrasonic longitudinal-torsional vibration-assisted cutting of Nomex® honeycomb-core composites. Int. J. Adv. Manuf. Technol. 2018, 100, 1521–1530. [Google Scholar] [CrossRef]

- Kang, D.; Zou, P.; Wu, H.; Duan, J.; Wang, W. Study on ultrasonic vibration–assisted cutting of Nomex honeycomb cores. Int. J. Adv. Manuf. Technol. 2019, 104, 979–992. [Google Scholar] [CrossRef]

- Cui, R.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z. A Path Planning Method for V-Shaped Robotic Cutting of Nomex Honeycomb by Straight Blade Tool. IEEE Access 2020, 8, 162763–162774. [Google Scholar] [CrossRef]

- Zarrouk, T.; Nouari, M.; Bouali, H. Numerical Modeling and Optimization of Nomex Honeycomb Core Milling: Influence of Longitudinal and Longitudinal–Torsional Ultrasonic Vibrations. Machines 2025, 13, 99. [Google Scholar] [CrossRef]

- Ahmad, S.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z. Experimental study on rotary ultrasonic machining (RUM) characteristics of Nomex honeycomb composites (NHCs) by circular knife cutting tools. J. Manuf. Process. 2020, 58, 524–535. [Google Scholar] [CrossRef]

- Yu, H.; Hu, X.; Kong, L.; Yu, B. Process path planning based on efficiency model for ultrasonic cutting curved surface of honeycomb composite parts. Adv. Mech. Eng. 2019, 11, 1687814019884176. [Google Scholar] [CrossRef]

- Xu, Q.; Bao, Y.; Wang, Y.-Q.; Gao, H. Investigation on damage reduction method by varying cutting angles in the cutting process of rectangular Nomex honeycomb core. J. Manuf. Process. 2021, 68, 1803–1813. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, R.; Qin, Y.; Meng, Q.; Dong, Z. Effects of inclination angles of disc cutter on machining quality of Nomex honeycomb core in ultrasonic cutting. Front. Mech. Eng. 2021, 16, 285–297. [Google Scholar] [CrossRef]

- Liu, G.; Yang, J.; Zhang, L.; Gao, Q.; Qian, L.; Zhang, R. Surface Quality Experimental Study on Rotary Ultrasonic Machining of Honeycomb Composites with a Circular Knife Cutting Tool. Crystals 2022, 12, 725. [Google Scholar] [CrossRef]

- Jaafar, M. Étude Expérimentale et Simulation Numérique de L’usinage des Matériaux en nids D’abeilles: Application au Fraisage des Structures Nomex® et Aluminium. Ph.D. Thesis, Université de Lorraine, Metz, France, 2018. [Google Scholar]

- Foo, C.C.; Chai, G.B.; Seah, L.K. Mechanical properties of Nomex material and Nomex honeycomb structure. Compos. Struct. 2007, 80, 588–594. [Google Scholar] [CrossRef]

- Jenarthanan, M.; Jeyapaul, R. Optimisation of machining parameters on milling of GFRP composites by desirability function analysis using Taguchi method. Int. J. Eng. Sci. Technol. 2018, 5, 22–36. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beldi, O.; Zarrouk, T.; Abbadi, A.; Nouari, M.; Salhi, J.-E.; Abbadi, M.; Barboucha, M. Optimization of Hybrid Machining of Nomex Honeycomb Structures: Effect of the CZ10 Tool and Ultrasonic Vibrations on the Cutting Process. Machines 2025, 13, 515. https://doi.org/10.3390/machines13060515

Beldi O, Zarrouk T, Abbadi A, Nouari M, Salhi J-E, Abbadi M, Barboucha M. Optimization of Hybrid Machining of Nomex Honeycomb Structures: Effect of the CZ10 Tool and Ultrasonic Vibrations on the Cutting Process. Machines. 2025; 13(6):515. https://doi.org/10.3390/machines13060515

Chicago/Turabian StyleBeldi, Oussama, Tarik Zarrouk, Ahmed Abbadi, Mohammed Nouari, Jamal-Eddine Salhi, Mohammed Abbadi, and Mohamed Barboucha. 2025. "Optimization of Hybrid Machining of Nomex Honeycomb Structures: Effect of the CZ10 Tool and Ultrasonic Vibrations on the Cutting Process" Machines 13, no. 6: 515. https://doi.org/10.3390/machines13060515

APA StyleBeldi, O., Zarrouk, T., Abbadi, A., Nouari, M., Salhi, J.-E., Abbadi, M., & Barboucha, M. (2025). Optimization of Hybrid Machining of Nomex Honeycomb Structures: Effect of the CZ10 Tool and Ultrasonic Vibrations on the Cutting Process. Machines, 13(6), 515. https://doi.org/10.3390/machines13060515