Numerical and Experimental Study on Deicing of Wind Turbine Blades by Electric Heating Under Complex Flow Field

Abstract

1. Introduction

2. Calculation Method

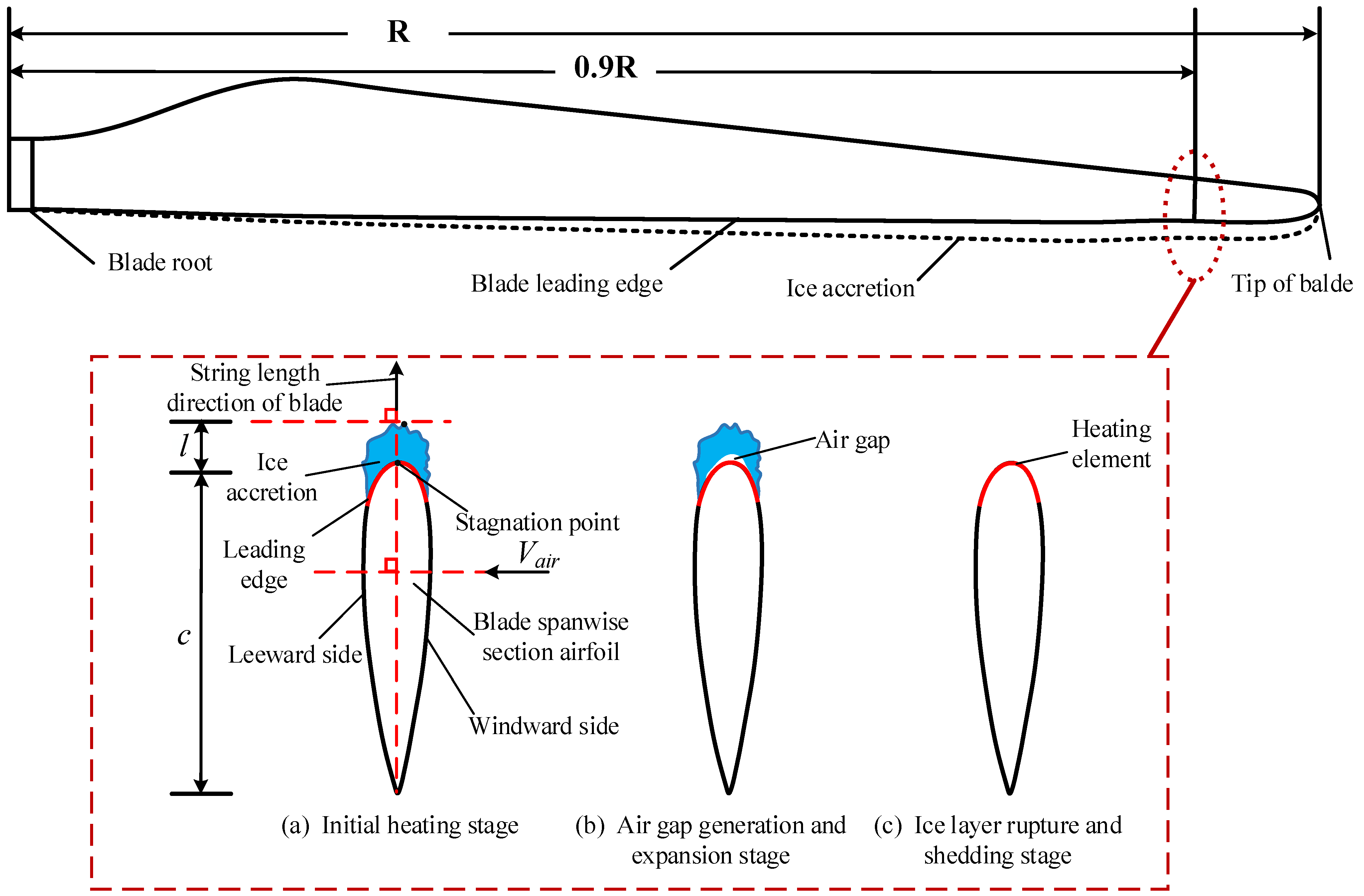

2.1. Physical Process

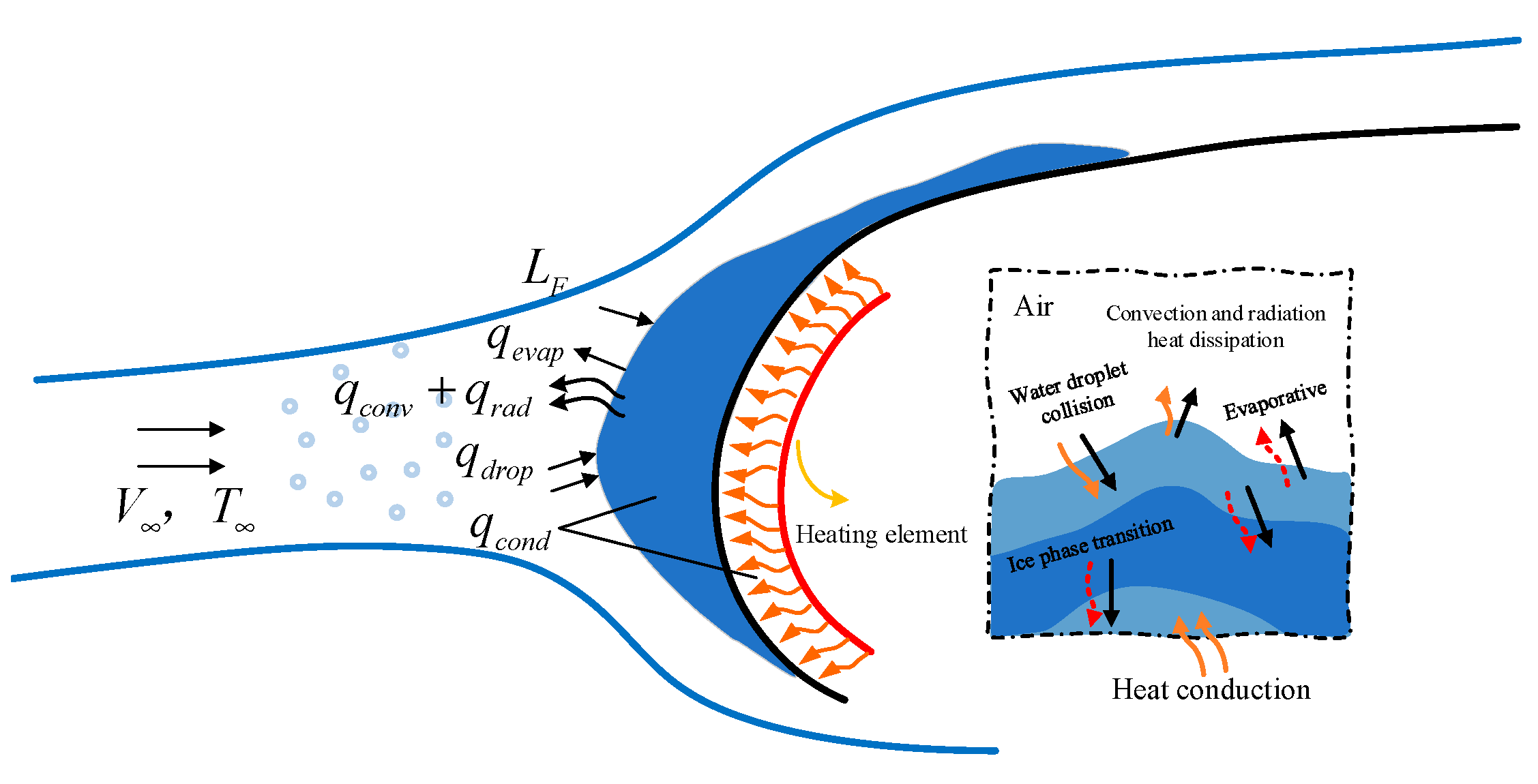

2.2. Heat Balance Process

2.3. Air Flow Field

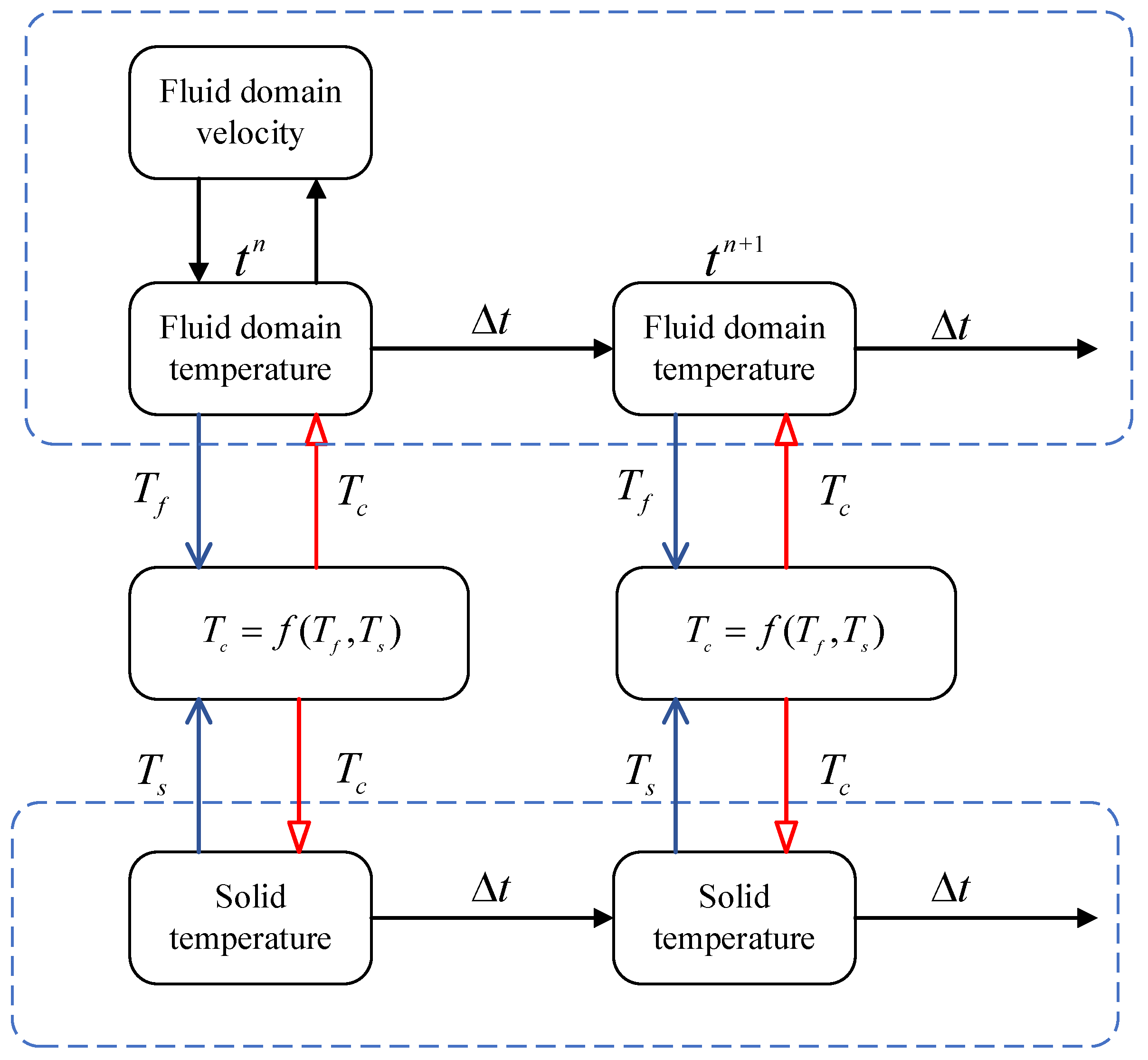

2.4. Coupling Calculation Method

- (1)

- Initialization: Set the initial temperature field and velocity field of the fluid domain and the solid domain. The boundary of the flow field is adopted as non-slip adiabatic boundary.

- (2)

- Interface coupling: According to the heat flux continuity of the coupled interface, the temperature of the coupled interface is calculated and applied to the temperature field calculation of the fluid domain and the solid domain as the coupling boundary condition. The calculation formula is as follows:where, , and , represent the temperature and thermal conductivity coefficient and temperature at the coupling interface of the solid domain and the flow field domain, respectively; and represent the distance between the flow field domain and the center of the first layer grid cell of the solid domain from the interface.

- (3)

- Iterative update: According to the same time step, iteratively solve and update the temperature field in the fluid domain and the solid domain until the maximum iteration time or convergence standard is reached.

3. Computational Implementation

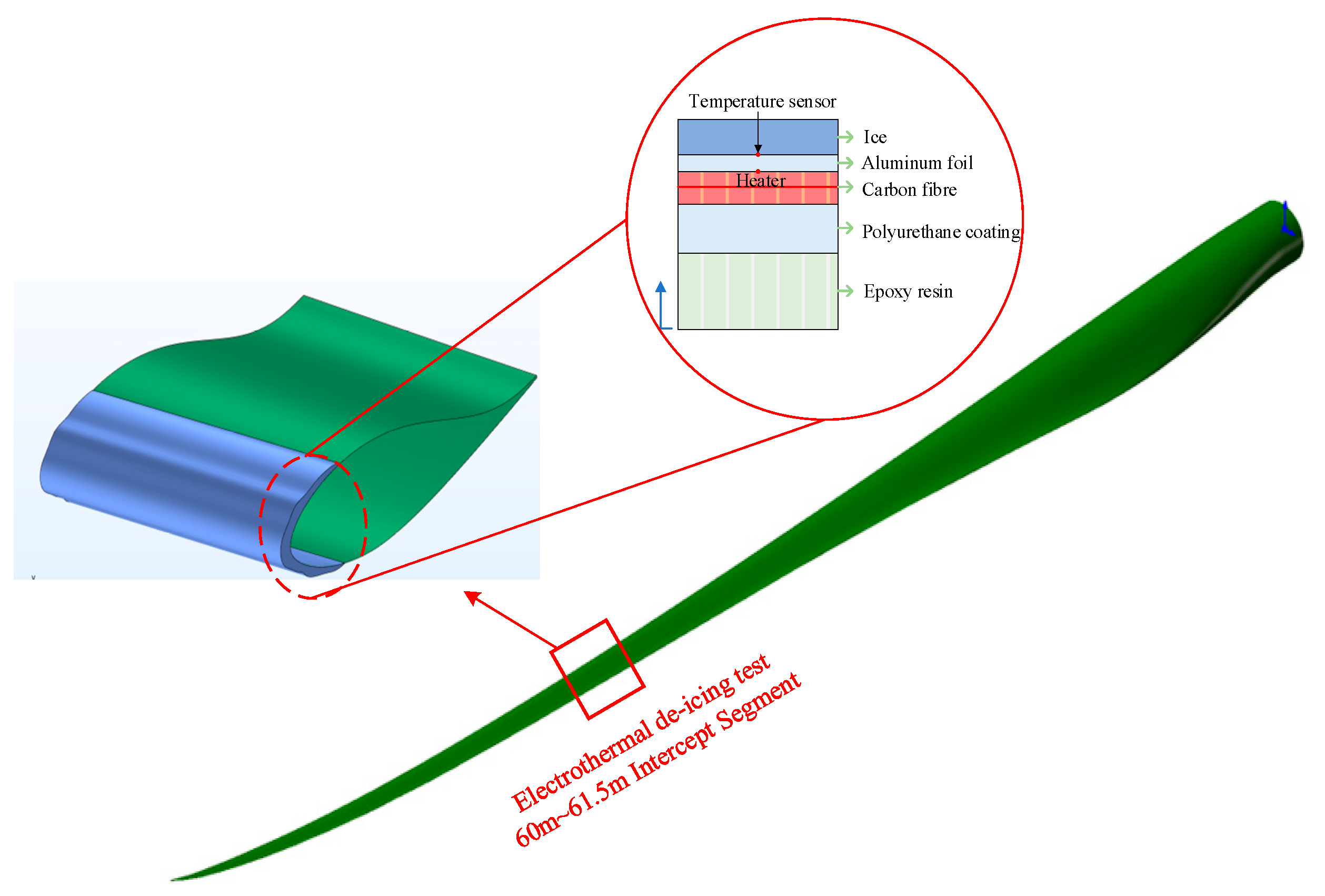

3.1. Geometric Model

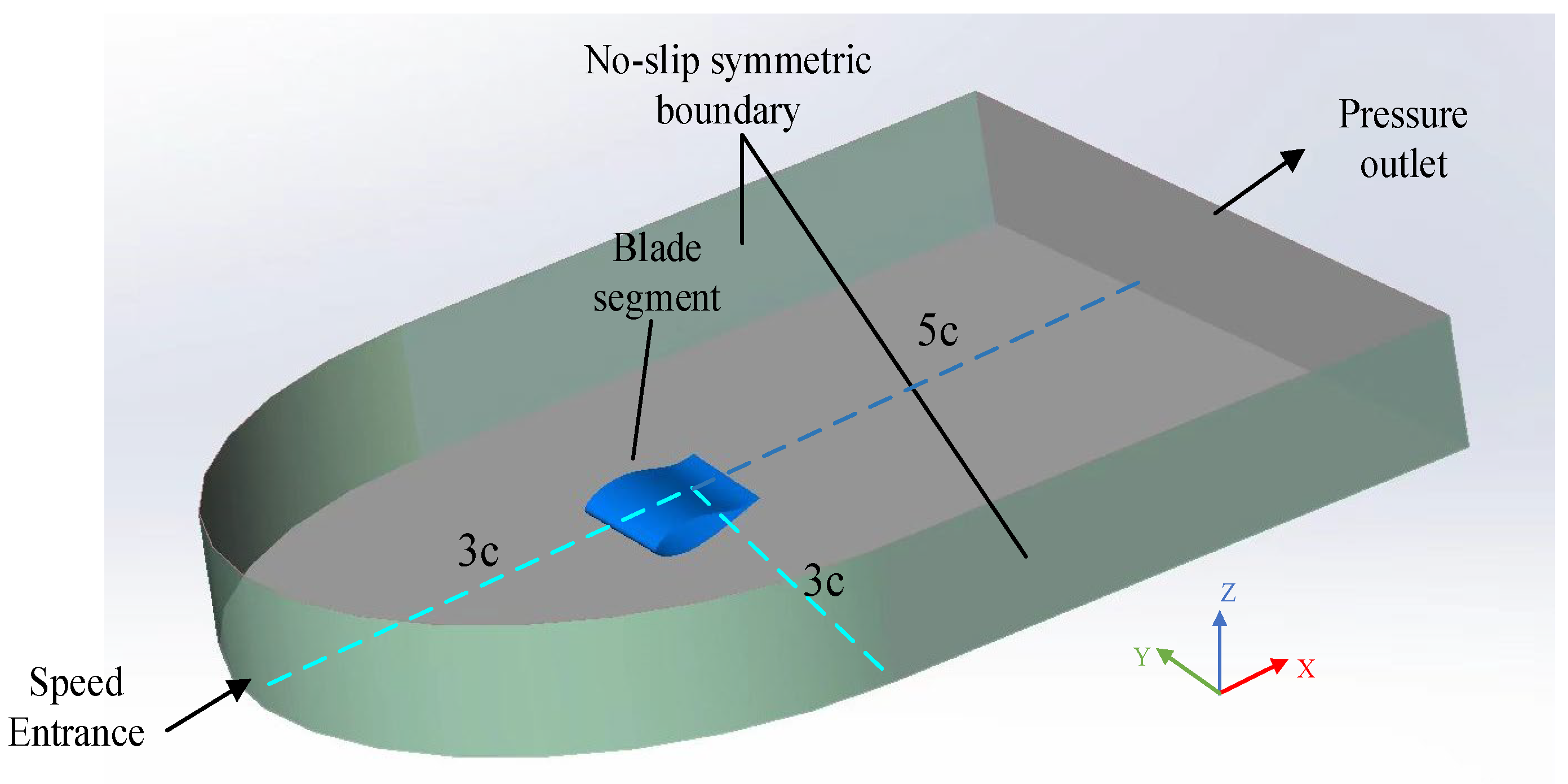

3.2. Computational Domain Selection and Boundary Conditions

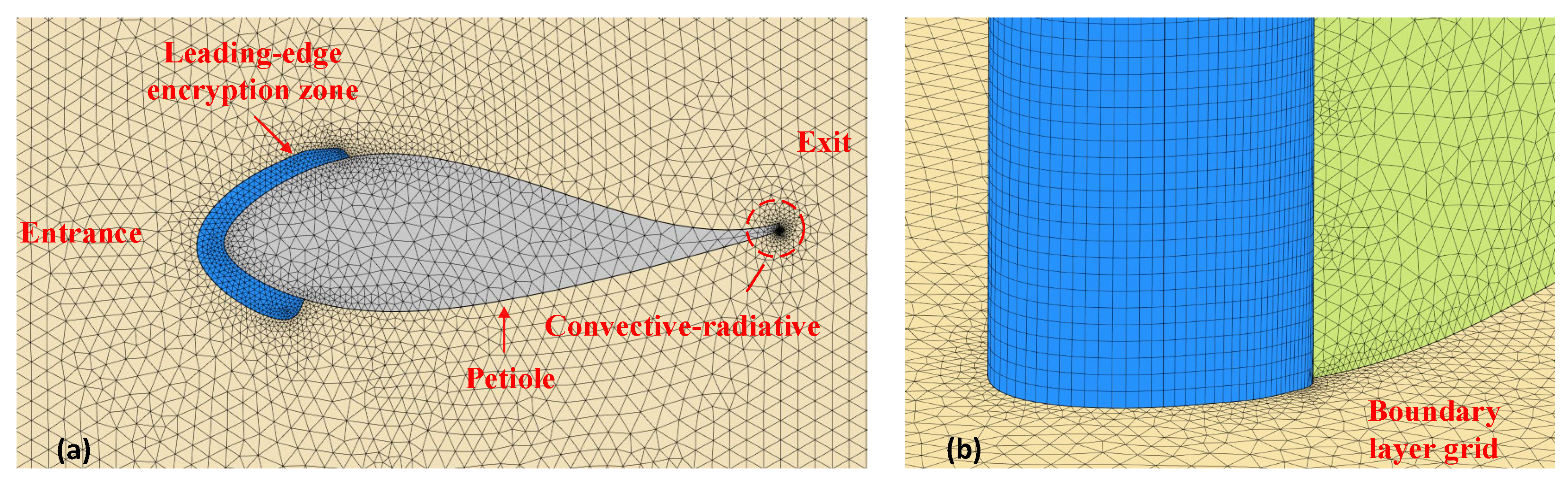

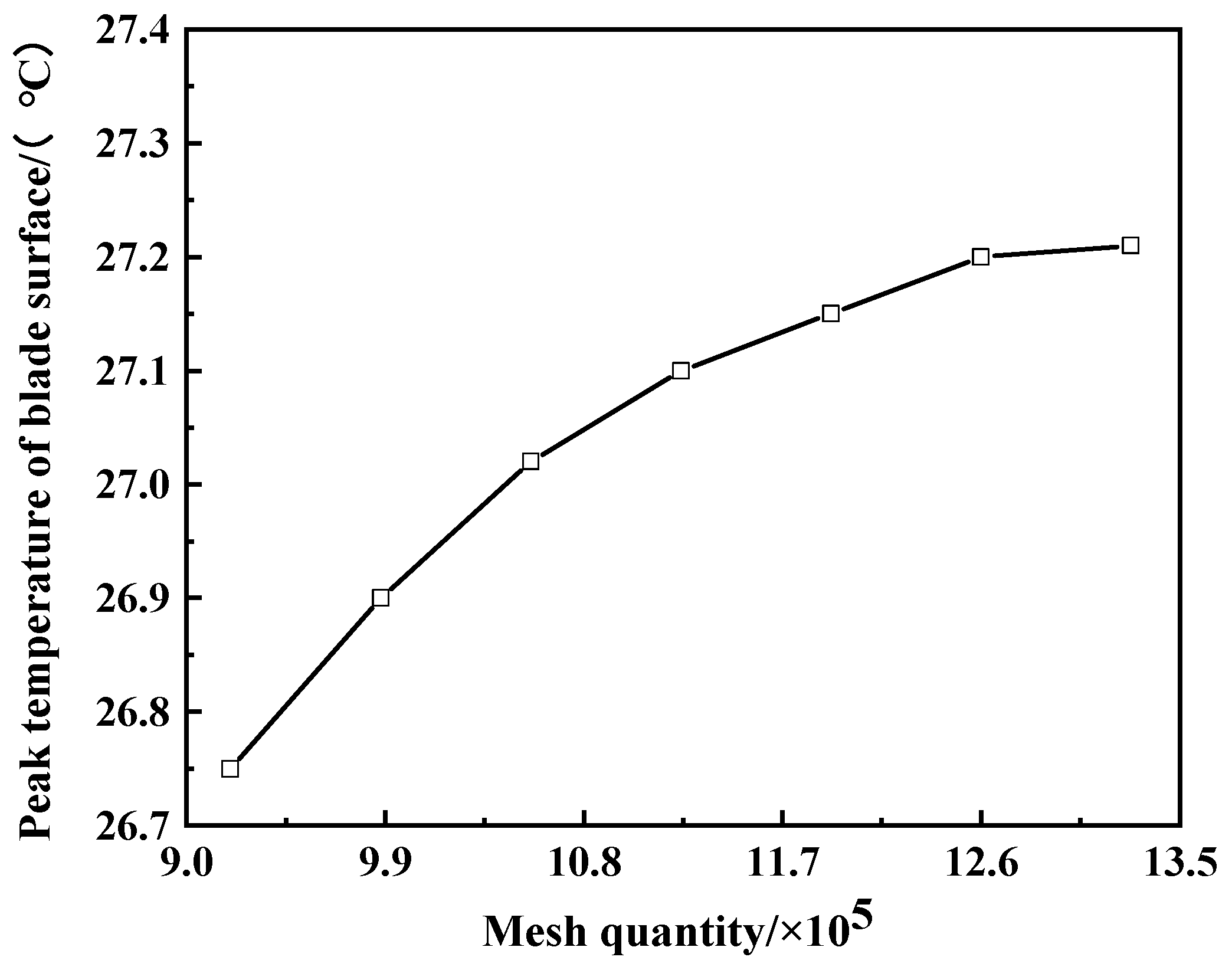

3.3. Mesh Generation and Independence Verification

- Grid encryption is implemented in the ice-water phase transition area and ice-covering interface;

- Layered mesh is used and encrypted near the wall of the fluid domain, and the height of the first layer mesh meets y+ < 1, so as to meet the wall resolution requirements of a SST turbulence model.

4. Results and Discussion

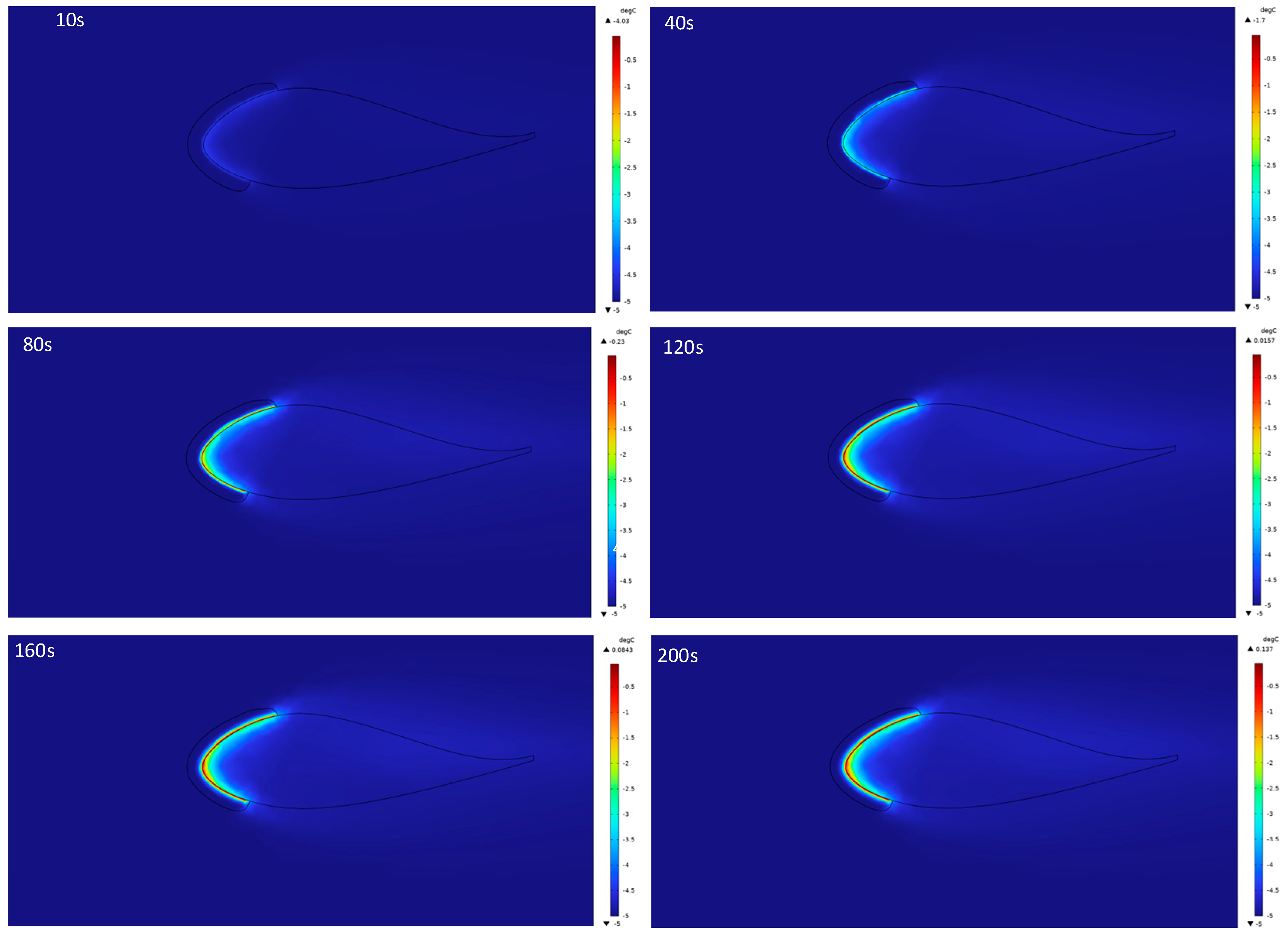

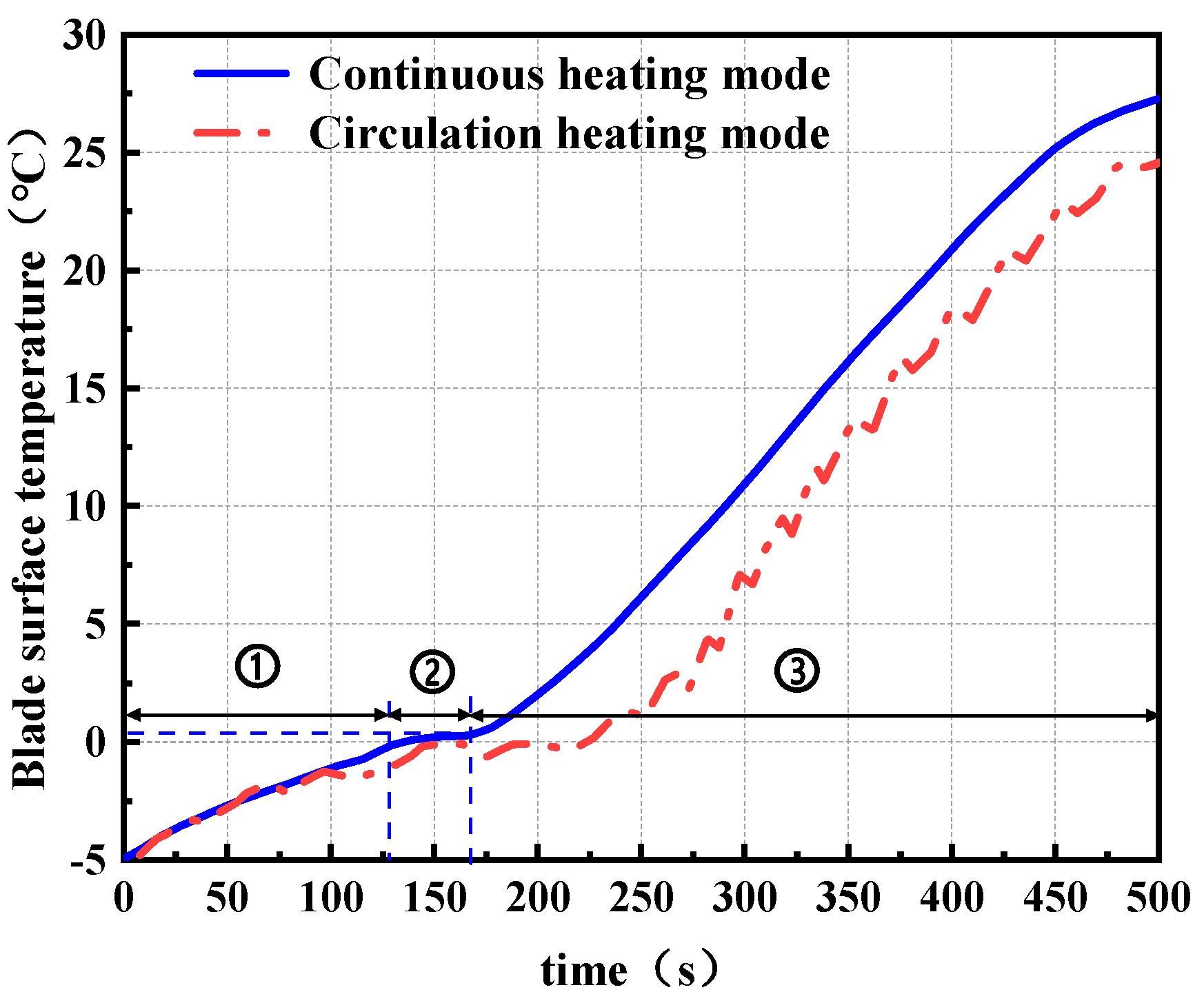

4.1. Temperature Field Development

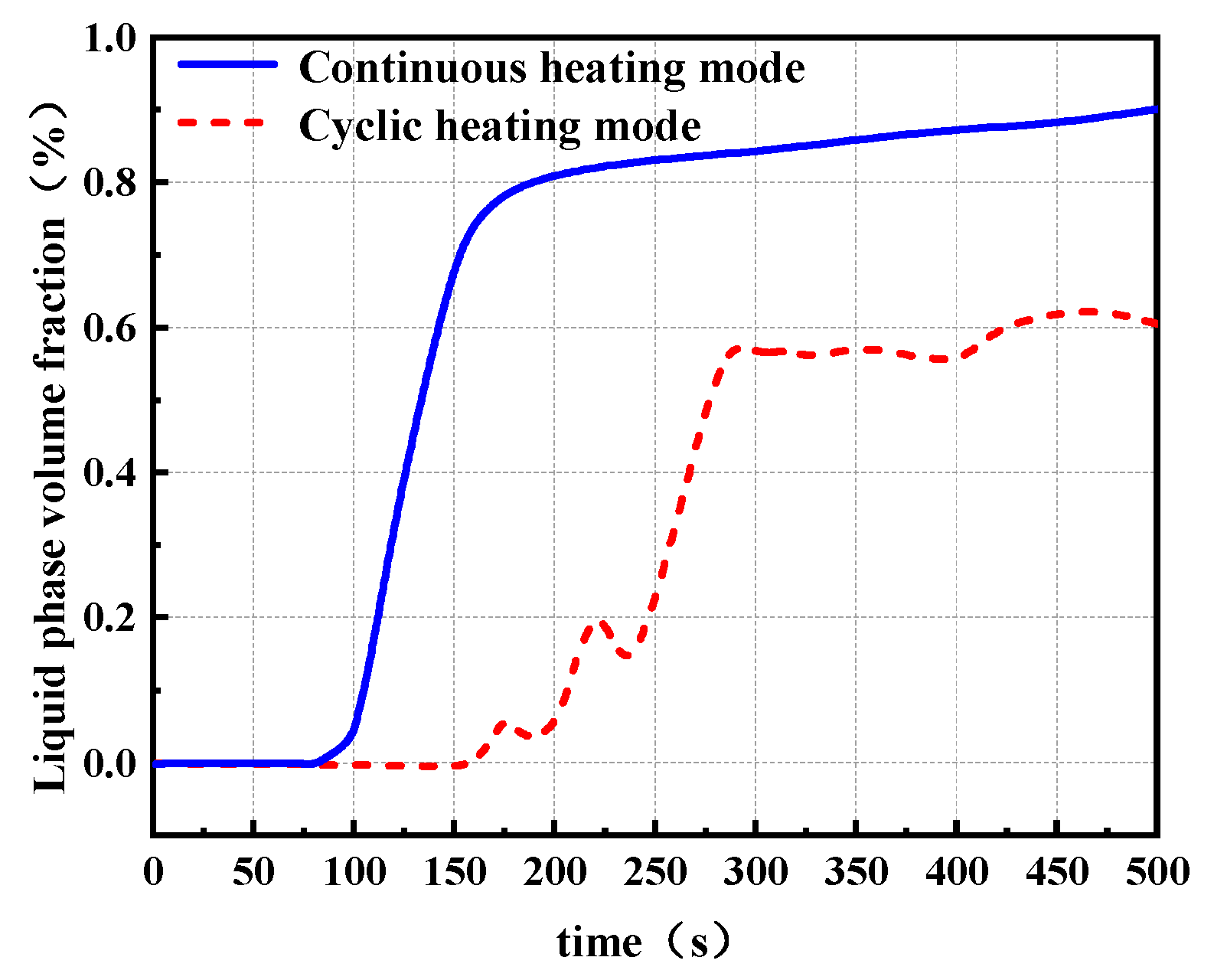

4.2. Phase Change Field Development

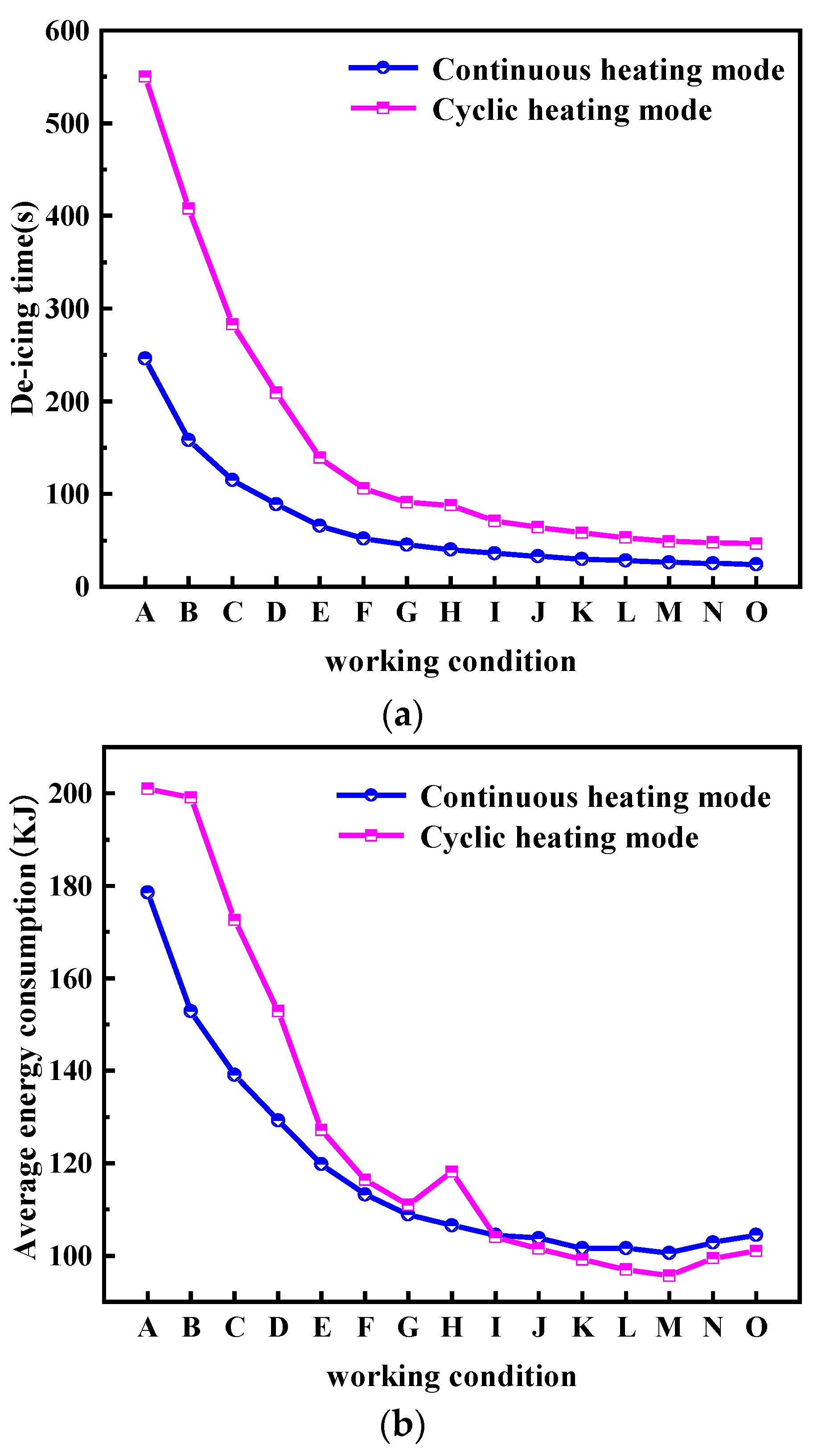

4.3. Evaluation of Deicing Efficiency

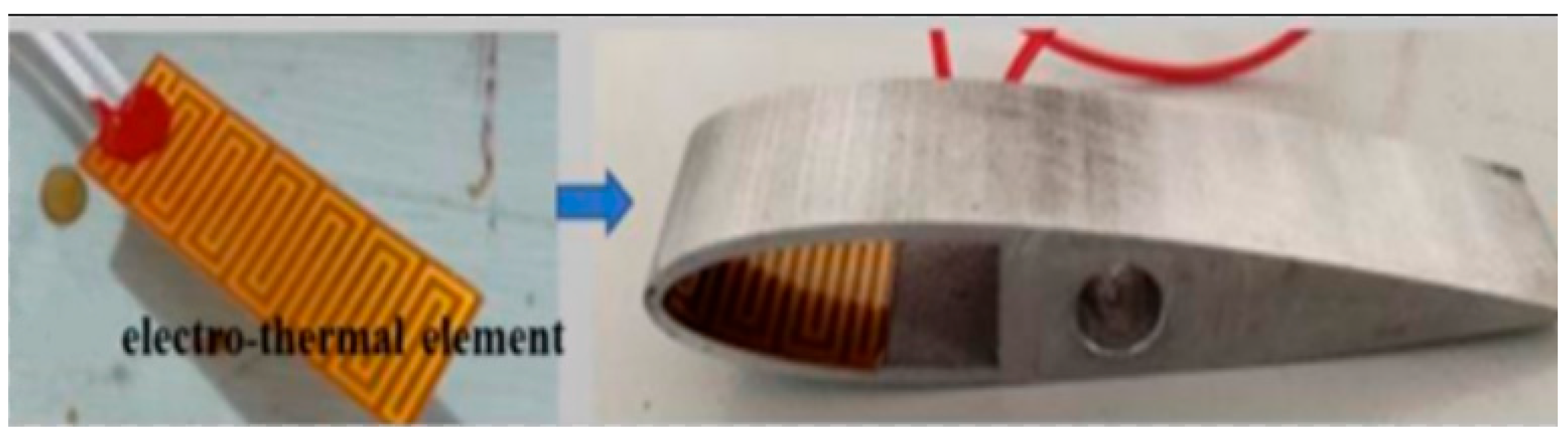

5. Experimental Research

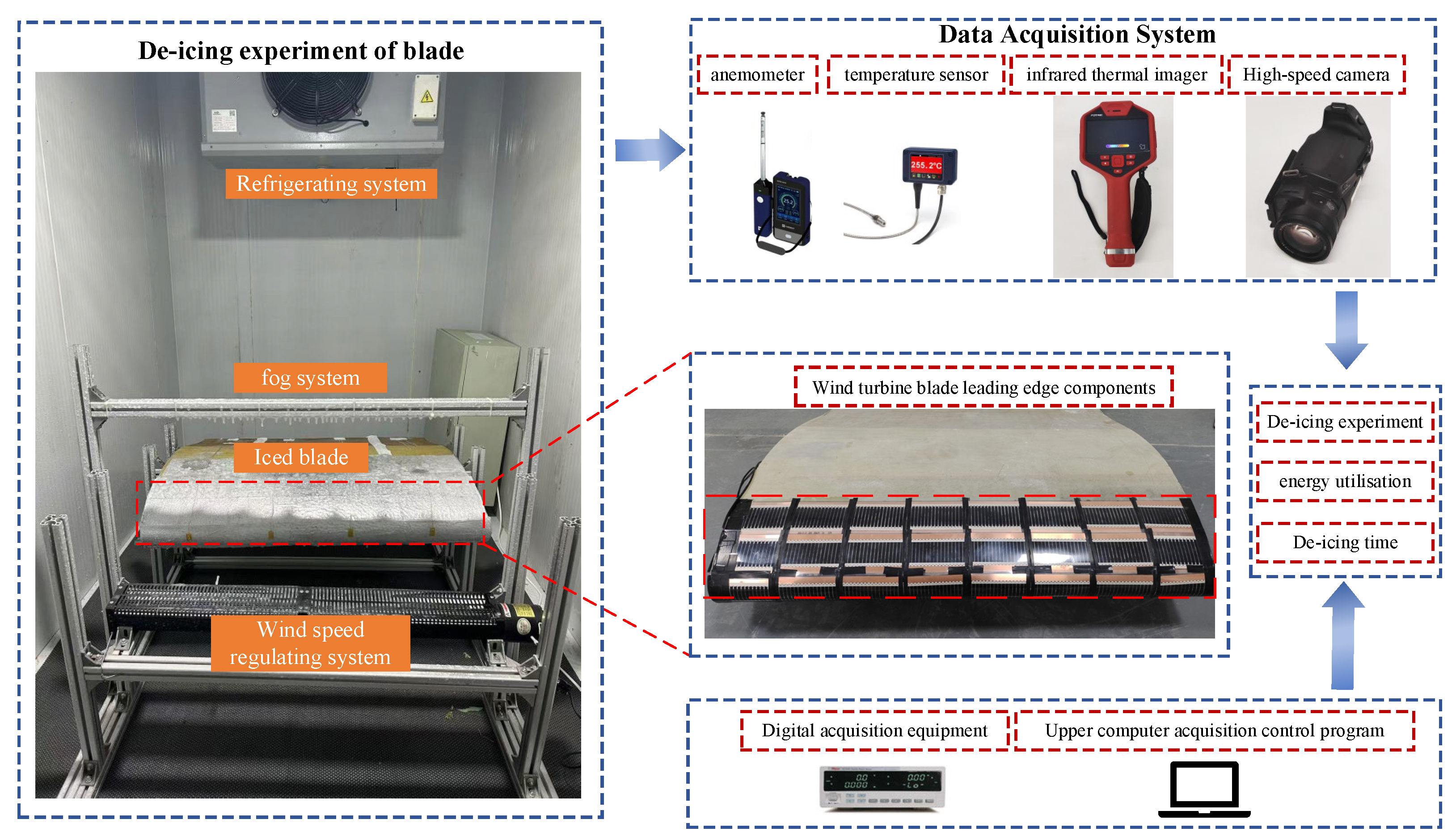

5.1. Experimental Platform Construction and Experimental Method

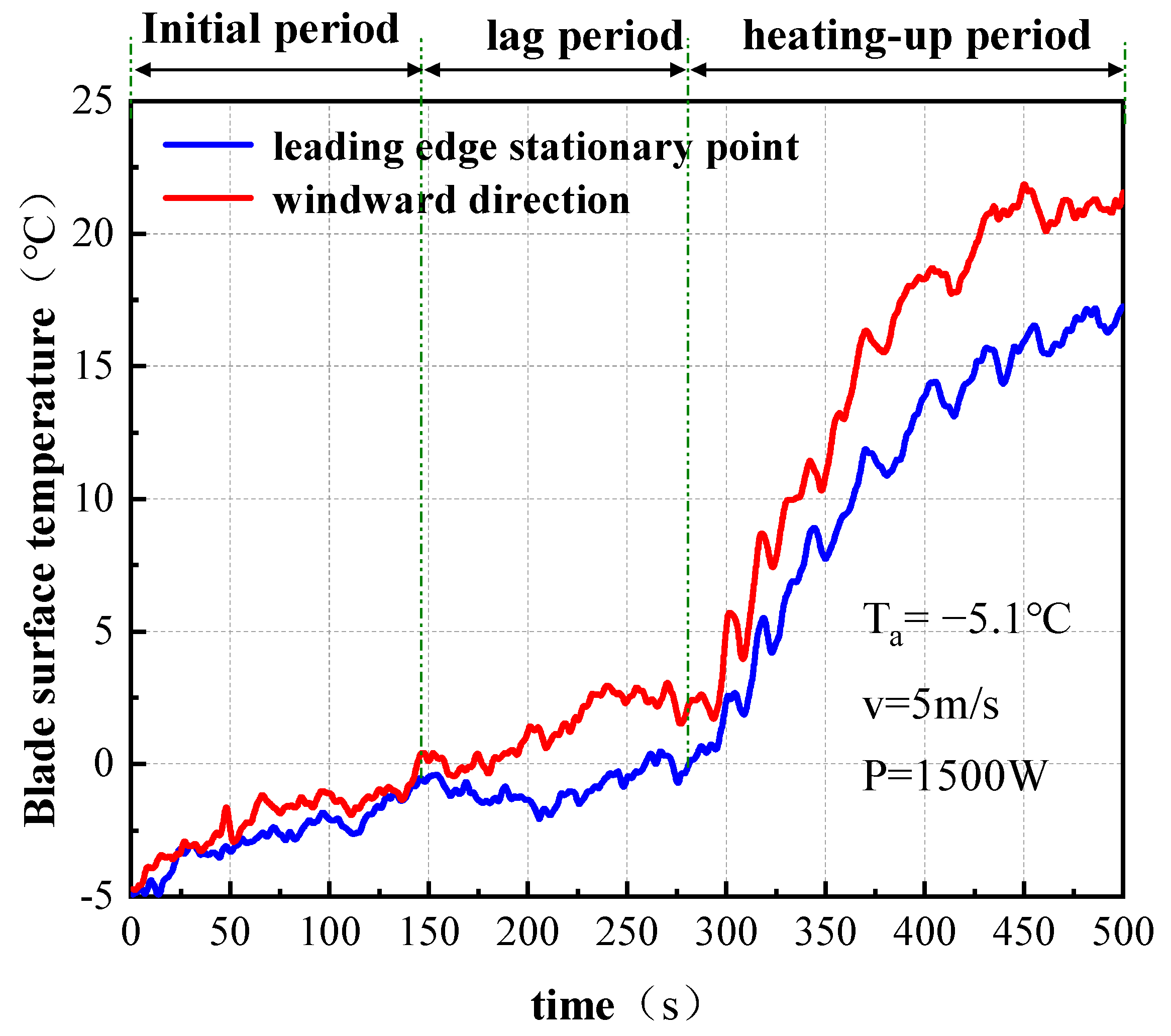

5.2. Experimental Result

6. Conclusions

- (1)

- The numerical model of deicing by electric heating under a complex flow field can effectively simulate the evolution of the leaf surface temperature field and ice layer phase transition. The results show that the deicing process can be divided into three typical stages: initial warming period, phase transition stagnation period, and rapid warming period, which has strong physical consistency and engineering guiding significance.

- (2)

- The enthalpy-pore method was used to effectively capture the evolution law of liquid phase water volume fraction inside the ice sheet. The results show that with the advance of the heating process, the solid–liquid phase change occurs first in a local area and an air gap is formed, and the formation and expansion of the air gap will significantly change the heat transfer path, which is the key factor for the intensification of the phase transition process and the continuous rise of blade surface temperature.

- (3)

- The deicing efficiency evaluation shows that there are significant differences between the two heating modes in terms of thermal response characteristics and energy efficiency. Among them, continuous heating mode has more advantages in heating rate and deicing efficiency, which is suitable for rapid deicing in extreme climates. The circulating heating mode has a good energy consumption control potential in the middle and high power range, and is suitable for the operation condition sensitive to energy consumption.

- (4)

- The deicing experiment by electric heating was carried out under artificial ice-covering laboratory conditions. The experimental results were in good agreement with the predicted trend, and the maximum temperature difference of the blade surface was within a reasonable range, which further verified the reliability of the numerical calculation method.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Wind Energy Council. GWEC’s Global Wind Report 2024. Available online: https://www.gwec.net/reports/globalwindreport/2024 (accessed on 18 May 2025).

- Martinez, A.; Iglesias, G. Global wind energy resources decline under climate change. Energy 2024, 288, 129765. [Google Scholar] [CrossRef]

- Battisti, L. Wind Turbines in Cold Climates; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Rasmussen, F.; Hansen, M.H.; Thomsen, K.; Larsen, T.J.; Bertagnolio, F.; Johansen, J.; Madsen, H.A.; Bak, C.; Hansen, A.M. Present status of aeroelasticity of wind turbines. Wind. Energy 2003, 6, 213–228. [Google Scholar] [CrossRef]

- Seifert, H.; Westerhellweg, A. Risk analysis of ice throw from wind turbines. Boreas 2003, 6, 2006. [Google Scholar]

- Homola, C.M.; Nicklasson, J.P.; Sundsbø, A.P. Ice sensors for wind turbines. Cold Reg. Sci. Technol. 2006, 46, 125–131. [Google Scholar] [CrossRef]

- Hochart, C.; Fortin, G.; Perron, J.; Ilinca, A. Icing simulation of wind turbine blades. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, Nevada, USA, 8–11 January 2007; Volume 1373. [Google Scholar]

- Lamraoui, F.; Fortin, G.; Benoit, R.; Perron, J.; Masson, C. Atmospheric icing impact on wind turbine production. Cold Reg. Sci. Technol. 2014, 117, 10036–10049. [Google Scholar] [CrossRef]

- Pourbagian, M.; Habashi, W.G. Aero-thermal optimization of in-flight electro-thermal ice protection systems in transient de-icing mode. Int. J. Heat FluidFlow 2015, 54, 167–182. [Google Scholar] [CrossRef]

- Sabatier, J.; Lanusse, P.; Feytout, B.; Gracia, S. CRONE control based anti-icing/deicing system for wind turbine blades. Control. Eng. Pract. 2016, 56, 200–209. [Google Scholar] [CrossRef]

- Fakorede, O.; Feger, Z.; Ibrahim, H.; Ilinca, A.; Perron, J.; Masson, C. Ice protection systems for wind turbines in cold climate: Characteristics, comparisons and analysis. Renew. Sustain. Energy Rev. 2016, 65, 662–675. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, X.; Hu, C.; Chen, J.; Du, Z. Wind turbines ice distribution and load response under icing conditions. Renew. Energy 2017, 113, 608–619. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Lei, Y. An effect assessment and prediction method of ultrasonic de-icing for composite wind turbine blades. Renew. Energy 2018, 118, 1015–1023. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, X. Design Research and Experimental Verification of the Electro-Impulse De-Icing System for Wind Turbine Blades in the Xuefeng Mountain Natural Icing Station. IEEE Access 2020, 8, 28915–28924. [Google Scholar] [CrossRef]

- Makkonen, L.; Laakso, T.; Marjaniemi, M.; Finstad, K.J. Modeling and prevention of ice accretion on wind turbines. Wind. Eng. 2001, 25, 3–21. [Google Scholar] [CrossRef]

- Battisti, L.; Fedrizzi, R. 2D numerical simulation of a wind turbine de-icing system, using cycled heating. Wind. Eng. 2007, 31, 33–42. [Google Scholar] [CrossRef]

- Villalpando, F.; Reggio, M.; Ilinca, A. Prediction of ice accretion and anti-icing heating power on wind turbine blades using standard commercial software. Energy 2016, 114, 1041–1052. [Google Scholar] [CrossRef]

- Hochart, C.; Fortin, G.; Perron, J.; Ilinca, A. Wind turbine performance under icing conditions. Wind. Energy 2008, 11, 319–333. [Google Scholar] [CrossRef]

- Yiqiang, H.; Jose, P. Surface Roughness and Heat Transfer Improved Predictions for Aircraft Ice-Accretion Modeling. AIAA J. 2017, 55, 1318–1331. [Google Scholar]

- Barber, S. The Impact of Ice Formation on Wind Turbine Performance and Aerodynamics. J. Sol. Energy Eng. 2011, 133, 174. [Google Scholar] [CrossRef]

- Bose, N. Icing on a small horizontal-axis wind turbine-Part 1: Glaze ice profiles. J. Wind. Eng. Ind. Aerodyn. 1992, 45, 75–85. [Google Scholar] [CrossRef]

- Mayer, C.; Ilinca, A.; Fortin, G.; Perron, J. Wind tunnel study of electro-thermal de-icing of wind turbine blades. Int. J. Offshore Polar Eng. 2007, 17, 174. [Google Scholar]

- Shu, L.; Qiu, G.; Hu, Q.; Jiang, X.; Wang, P.; Xia, H. Numerical Model and Field Experimental Investigation of Threshold Heat Flux of Wind Turbine De-icing. Proc. CSEE 2018, 38, 3997–4003+4041. [Google Scholar]

- Shu, L.; Qiu, G.; Hu, Q.; Jiang, X.; McClure, G.; Liu, Y. Numerical and experimental investigation of threshold de-icing heat flux of wind turbine. J. Wind. Eng. Ind. Aerodyn. 2018, 174, 296–302. [Google Scholar] [CrossRef]

- Shu, L.; Liang, J.; Hu, Q.; Jiang, X.; Ren, X.; Qiu, G. Sudy on SmallWind Turbine lcing and Its Performance. Cold Reg. Sci. Technol. 2017, 134, 11–19. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, Y.; Li, Y.; Tagawa, K.; Zhao, B. A wind tunnel experimental study on the icing characteristics of a cylinder rotating around a vertical axis. Appl. Sci. 2021, 11, 10383. [Google Scholar] [CrossRef]

- Li, X.; Chi, H.; Li, Y.; Xu, Z.; Guo, W.; Feng, F. An experimental study on blade surface de-Icing characteristics for wind turbines in rime ice condition by electro-thermal heating. Coatings 2024, 14, 94. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, D.; Gao, W.; Li, A. Development of de-icing method with combined excitation of ultrasonic guided waves and different types of low-frequency vibrations. Appl. Acoust. 2024, 221, 110034. [Google Scholar] [CrossRef]

- Li, P.; Kang, Y.; Song, Y.; He, X. Transient simulation and analysis of wing electrothermal ice protection system. J. Eng. 2018, 13, 438–445. [Google Scholar]

| Heating Mode | Va (m/s) | Ta (°C) | Peak Temperature (°C) | Deicing Time (s) | ||

|---|---|---|---|---|---|---|

| Simulation | Experimental | Simulation | Experimental | |||

| continuous heating | 5.0 | −4.9 | 27.2 | 24.3 | 115 | 132 |

| cyclic heating | 5.0 | −5.1 | 24.5 | 21.1 | 283 | 302 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yang, P.; Huang, X.; Zhang, L.; Wang, J. Numerical and Experimental Study on Deicing of Wind Turbine Blades by Electric Heating Under Complex Flow Field. Machines 2025, 13, 483. https://doi.org/10.3390/machines13060483

Li J, Yang P, Huang X, Zhang L, Wang J. Numerical and Experimental Study on Deicing of Wind Turbine Blades by Electric Heating Under Complex Flow Field. Machines. 2025; 13(6):483. https://doi.org/10.3390/machines13060483

Chicago/Turabian StyleLi, Jianwei, Panpan Yang, Xuemei Huang, Leian Zhang, and Jinghua Wang. 2025. "Numerical and Experimental Study on Deicing of Wind Turbine Blades by Electric Heating Under Complex Flow Field" Machines 13, no. 6: 483. https://doi.org/10.3390/machines13060483

APA StyleLi, J., Yang, P., Huang, X., Zhang, L., & Wang, J. (2025). Numerical and Experimental Study on Deicing of Wind Turbine Blades by Electric Heating Under Complex Flow Field. Machines, 13(6), 483. https://doi.org/10.3390/machines13060483