Digital Twins for Defect Detection in FDM 3D Printing Process

Abstract

1. Introduction

2. Materials and Methods

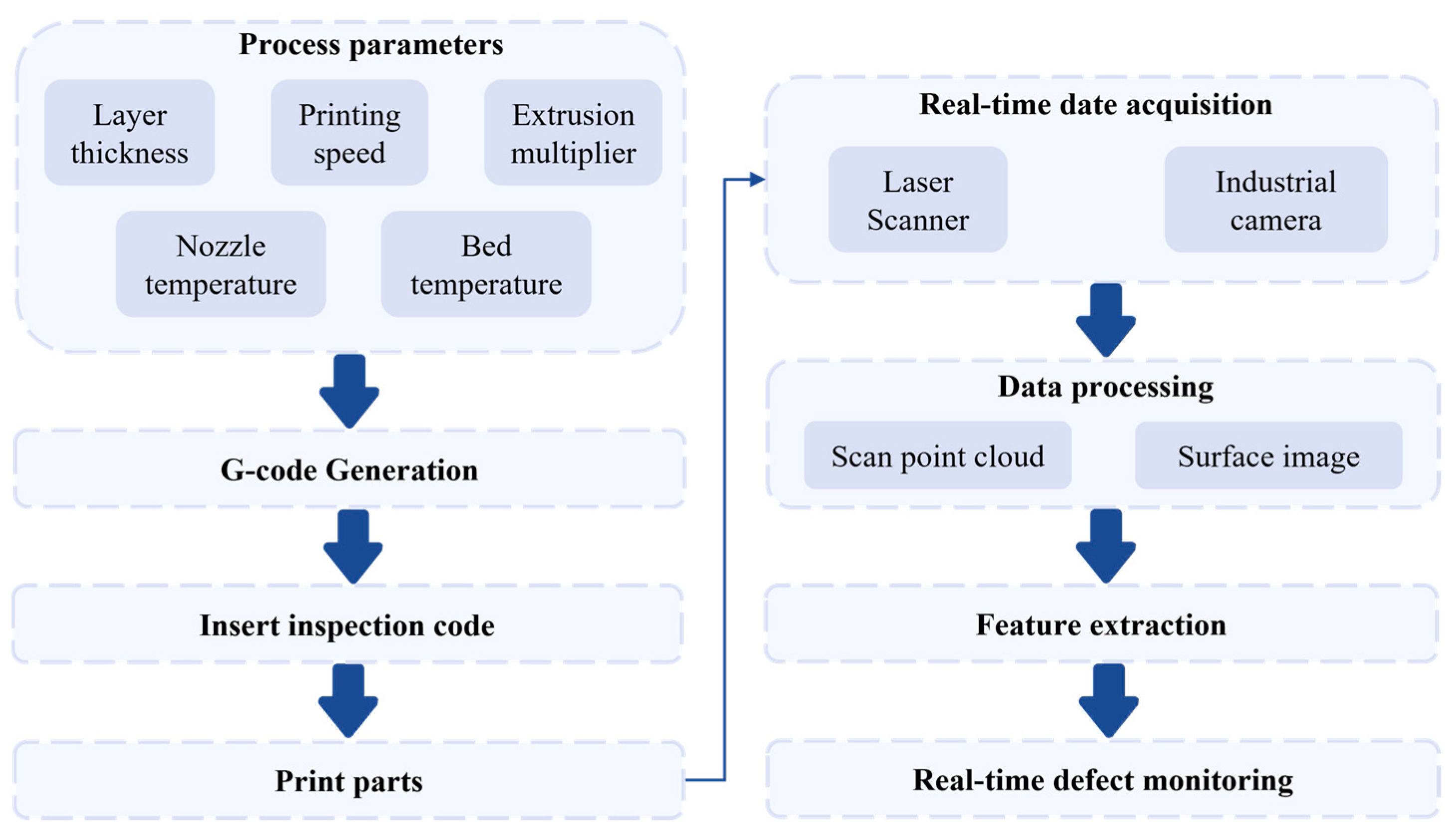

2.1. Research Methodology

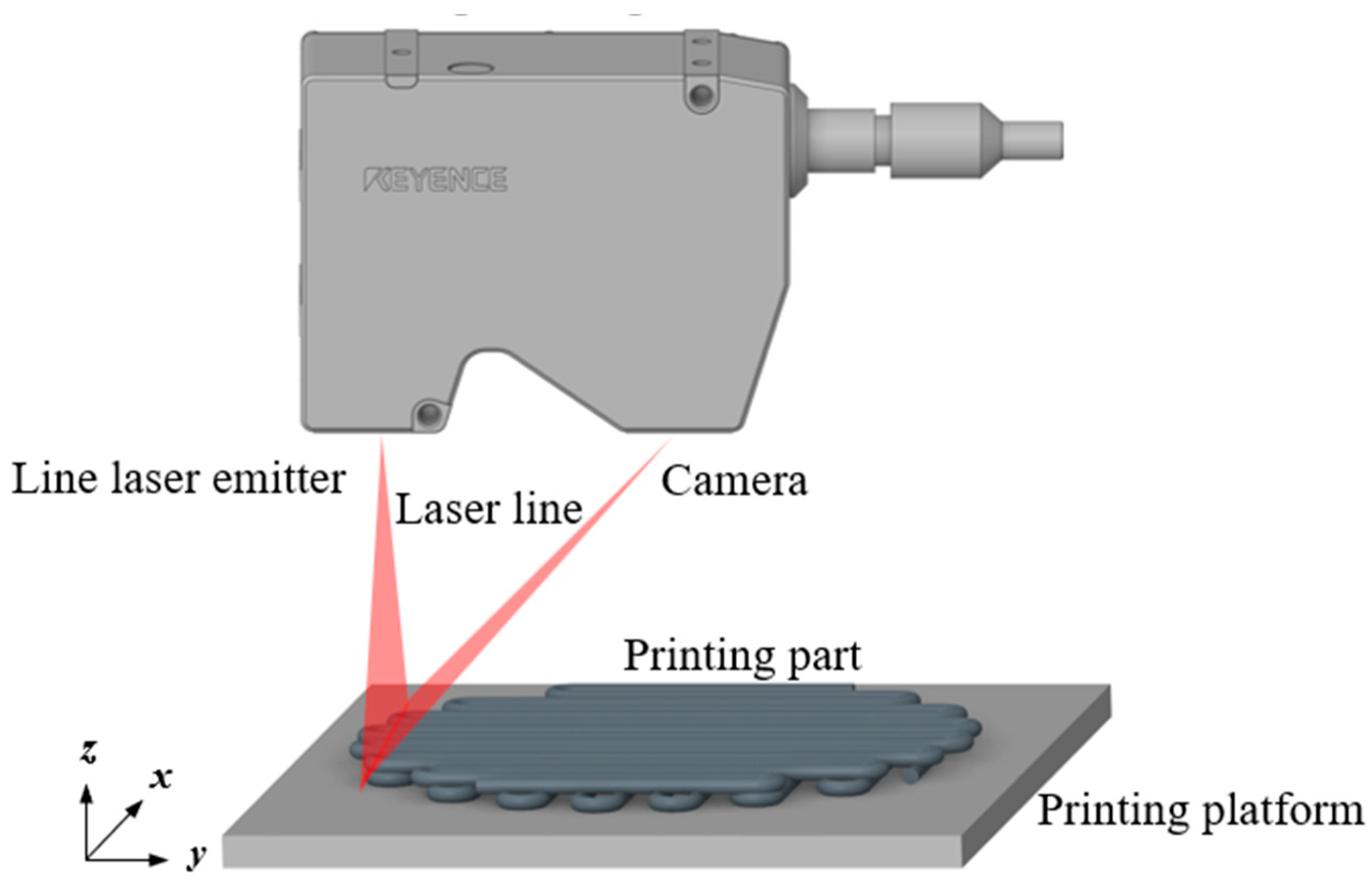

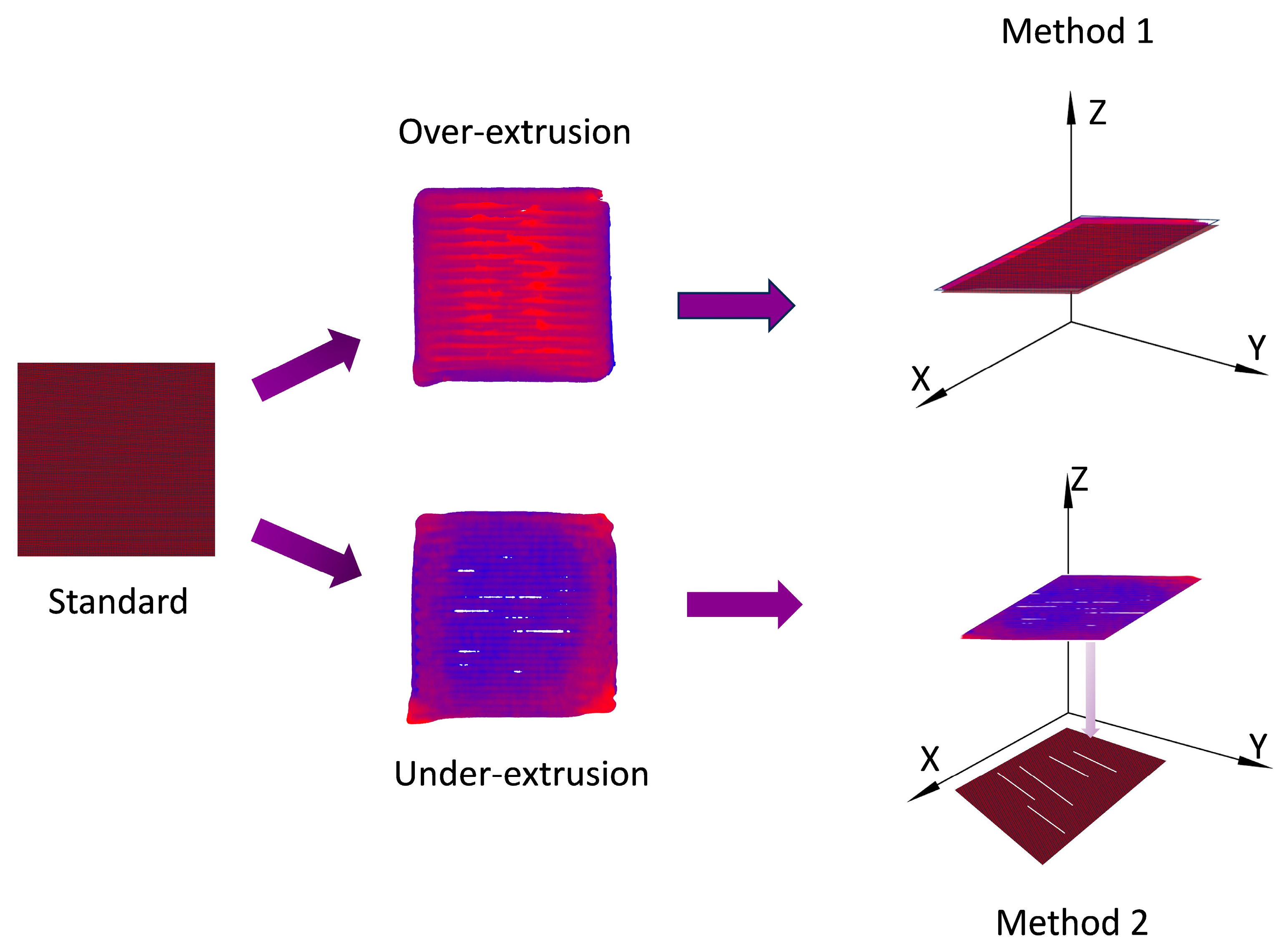

2.2. Data Processing

2.3. Parameter Settings

2.4. Defect Detection and Defect Portion Quantification

3. Results and Discussion

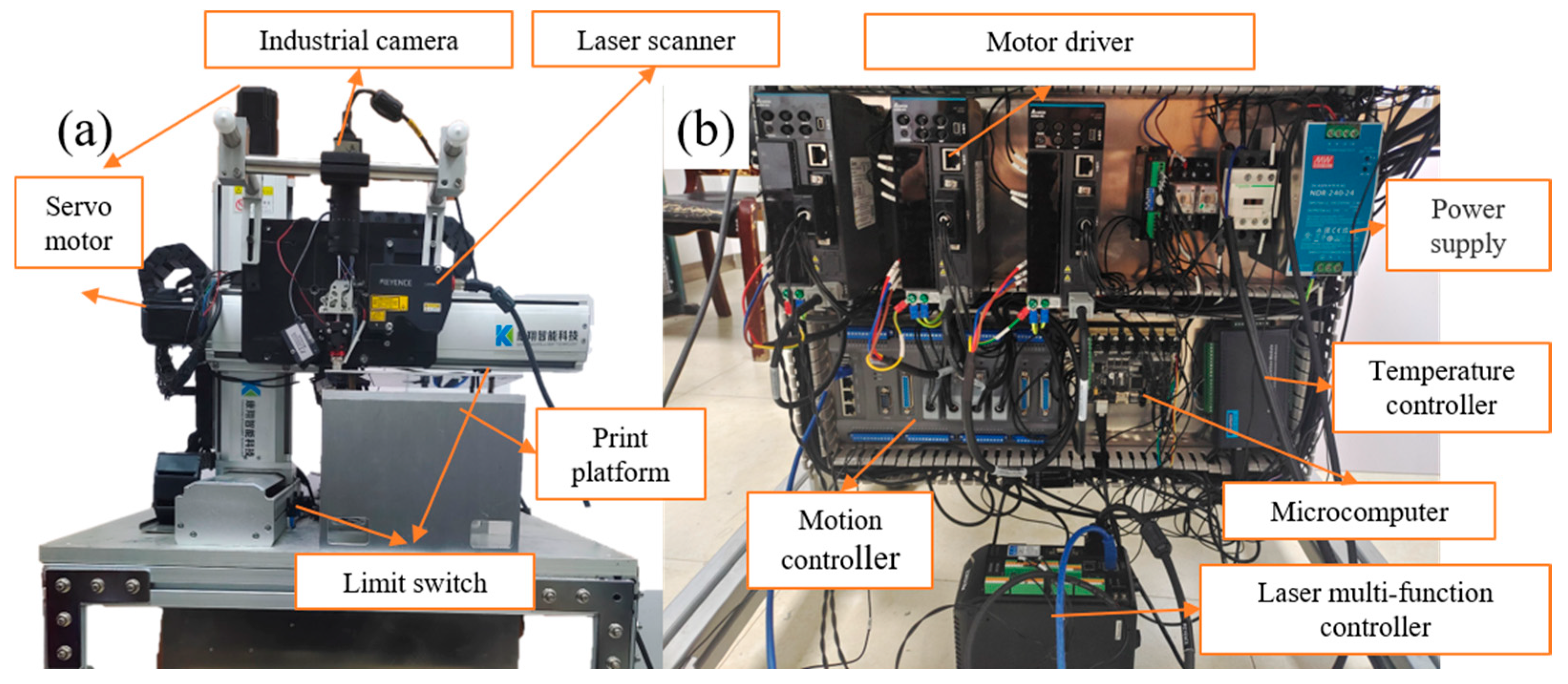

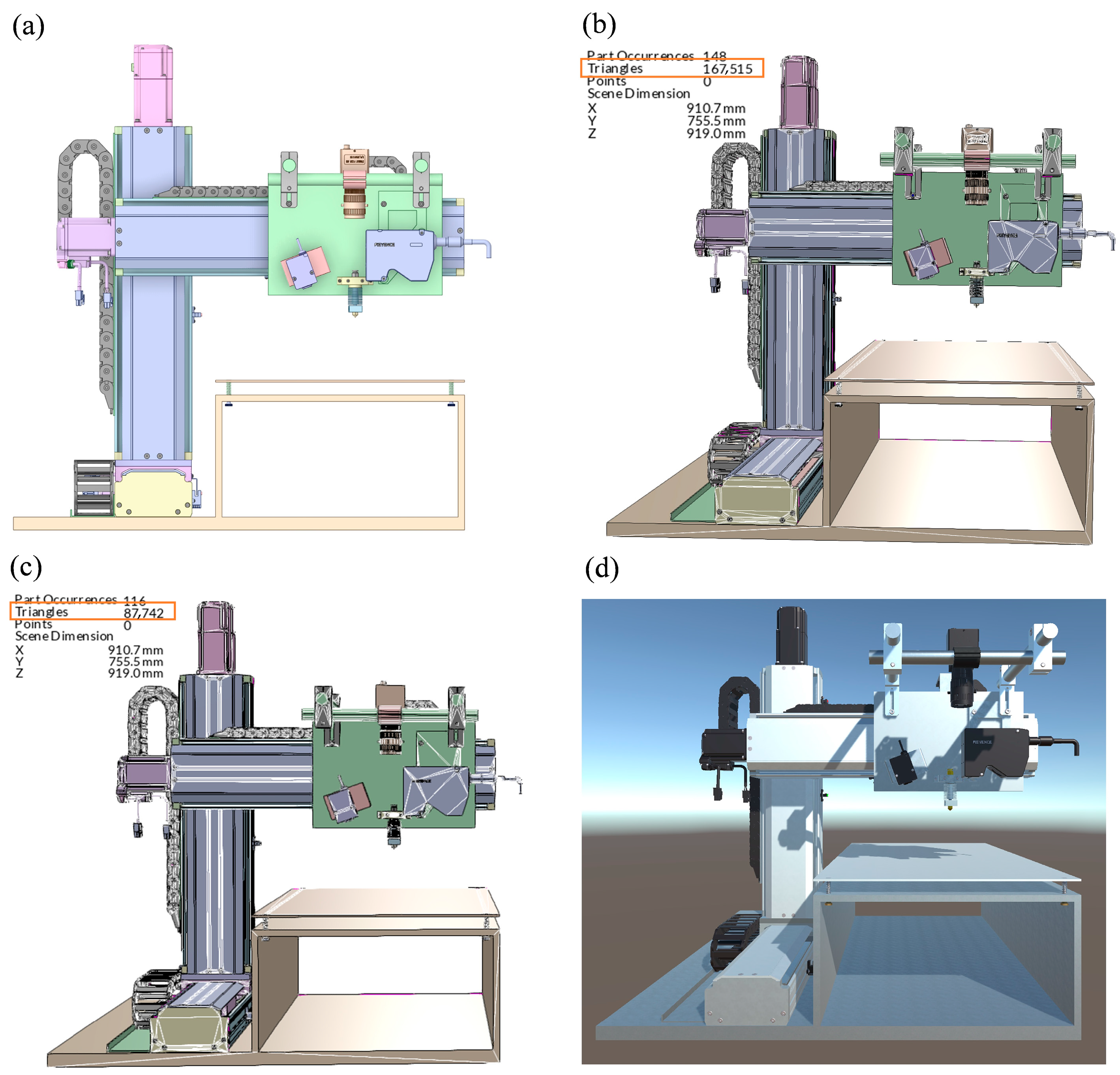

3.1. Experimental Apparatus

3.2. The Digital Twin GUI

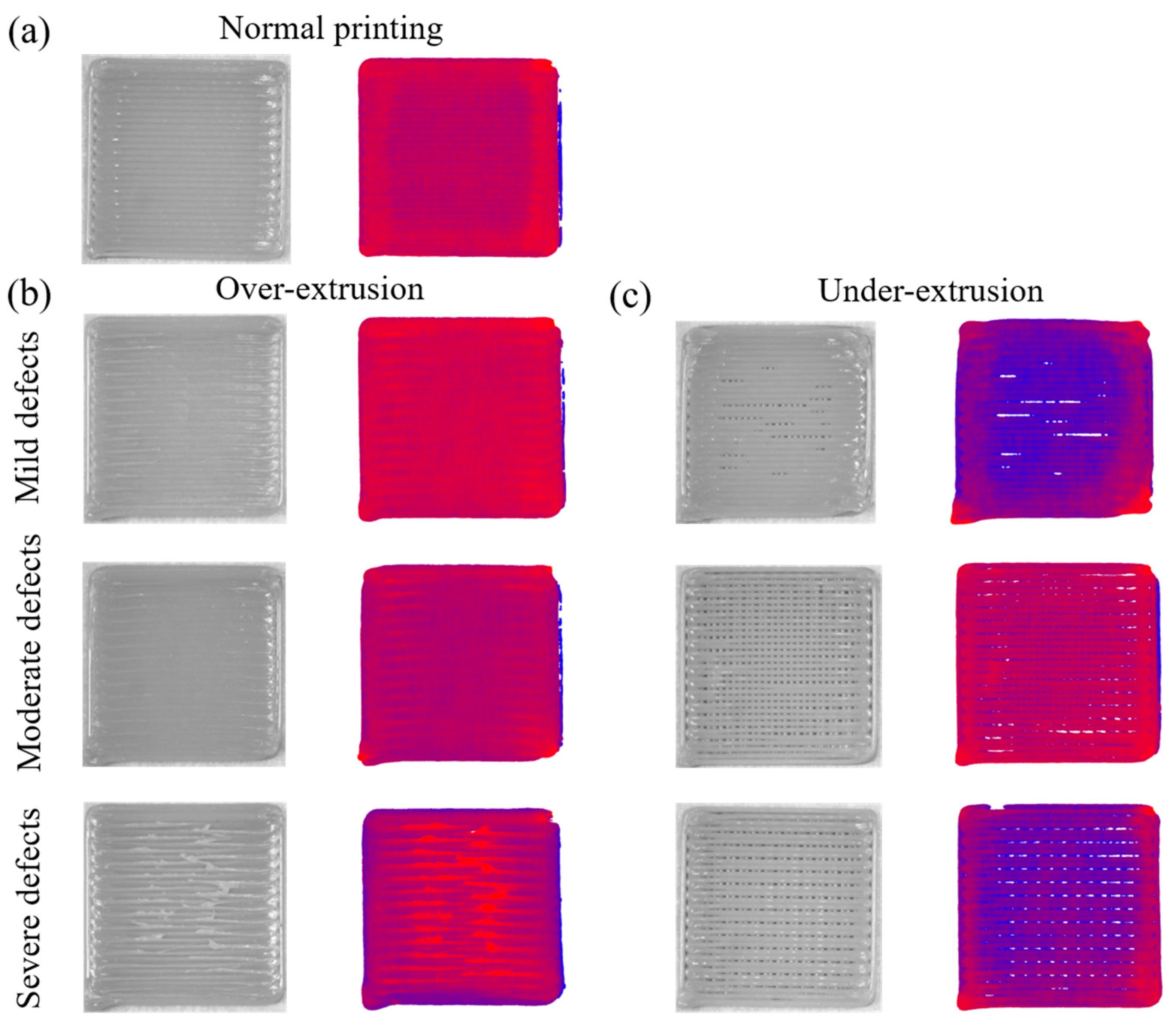

3.3. Defect Detection

4. Discussion

5. Conclusions

- The proposed DT system allows for the real-time acquisition of point cloud and image data during the printing process, enabling synchronized virtual–physical interaction through a Unity3D and Qt-based integrated system.

- A “defect percentage” indicator based on point cloud analysis was developed to quantitatively assess surface defects, allowing for classification into over-extrusion and under-extrusion types with varying severity levels, providing a practical tool for real-time quality evaluation in AM.

- Experimental validation shows that the system effectively detects and classifies defects during the printing process, reducing the reliance on offline inspection and laying the foundation for intelligent, self-correcting AM systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- du Plessis, A.; Razavi, N.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and applications of additively manufactured metallic cellular materials: A review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Tan, C.; Li, R.; Su, J.; Du, D.; Du, Y.; Attard, B.; Chew, Y.; Zhang, H.; Lavernia, E.J.; Fautrelle, Y.; et al. Review on field assisted metal additive manufacturing. Int. J. Mach. Tools Manuf. 2023, 189, 104032. [Google Scholar] [CrossRef]

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for sustainable additive manufacturing: A review. Sustain. Mater. Technol. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Cano-Vicent, A.; Tambuwala, M.M.; Hassan, S.S.; Barh, D.; Aljabali, A.A.; Birkett, M.; Arjunan, A.; Serrano-Aroca, Á. Fused deposition modelling: Current status, methodology, applications and future prospects. Addit. Manuf. 2021, 47, 102378. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.; Ahn, S.-H. Systematic deep transfer learning method based on a small image dataset for spaghetti-shape defect monitoring of fused deposition modeling. J. Manuf. Syst. 2022, 65, 439–451. [Google Scholar] [CrossRef]

- Brion, D.A.J.; Shen, M.; Pattinson, S.W. Automated recognition and correction of warp deformation in extrusion additive manufacturing. Addit. Manuf. 2022, 56, 102838. [Google Scholar] [CrossRef]

- Brion, D.A.J.; Pattinson, S.W. Quantitative and real-time control of 3D printing material flow through deep learning. Adv. Intell. Syst. 2022, 4, 2200153. [Google Scholar] [CrossRef]

- Brion, D.A.J.; Pattinson, S.W. Generalisable 3D printing error detection and correction via multi-head neural networks. Nat. Commun. 2022, 13, 4654. [Google Scholar] [CrossRef]

- Tan, L.; Huang, T.; Liu, J.; Li, Q.; Wu, X. Deep adversarial learning system for fault diagnosis in fused deposition modeling with imbalanced data. Comput. Ind. Eng. 2023, 176, 108887. [Google Scholar] [CrossRef]

- Fu, Y.; Downey, A.R.J.; Yuan, L.; Huang, H.-T. Real-time structural validation for material extrusion additive manufacturing. Addit. Manuf. 2023, 65, 103409. [Google Scholar] [CrossRef]

- AbouelNour, Y.; Gupta, N. In-situ monitoring of sub-surface and internal defects in additive manufacturing: A review. Mater. Des. 2022, 222, 111063. [Google Scholar] [CrossRef]

- Westphal, E.; Seitz, H. Machine learning for the intelligent analysis of 3D printing conditions using environmental sensor data to support quality assurance. Addit. Manuf. 2022, 50, 102535. [Google Scholar] [CrossRef]

- Wu, D.; Wei, Y.; Terpenny, J. Predictive modelling of surface roughness in fused deposition modelling using data fusion. Int. J. Prod. Res. 2018, 57, 3992–4006. [Google Scholar] [CrossRef]

- Liu, C.; Law, A.C.C.; Roberson, D.; Kong, Z. Image analysis-based closed loop quality control for additive manufacturing with fused filament fabrication. J. Manuf. Syst. 2019, 51, 75–86. [Google Scholar] [CrossRef]

- Gardner, J.M.; Hunt, K.A.; Ebel, A.B.; Rose, E.S.; Zylich, S.C.; Jensen, B.D.; Wise, K.E.; Siochi, E.J.; Sauti, G. Machines as craftsmen: Localized parameter setting optimization for fused filament fabrication 3D printing. Adv. Mater. Technol. 2019, 4, 1800653. [Google Scholar] [CrossRef]

- Lu, L.; Hou, J.; Yuan, S.; Yao, X.; Li, Y.; Zhu, J. Deep learning-assisted real-time defect detection and closed-loop adjustment for additive manufacturing of continuous fiber-reinforced polymer composites. Robot. Comput. Integr. Manuf. 2023, 79, 102431. [Google Scholar] [CrossRef]

- AbouelNour, Y.; Gupta, N. Assisted defect detection by in-process monitoring of additive manufacturing using optical imaging and infrared thermography. Addit. Manuf. 2023, 67, 103483. [Google Scholar] [CrossRef]

- Petsiuk, A.; Pearce, J.M. Towards smart monitored AM: Open source in-situ layer-wise 3D printing image anomaly detection using histograms of oriented gradients and a physics-based rendering engine. Addit. Manuf. 2022, 52, 102690. [Google Scholar] [CrossRef]

- Hossain, R.-E.N.; Lewis, J.; Moore, A.L. In situ infrared temperature sensing for real-time defect detection in additive manufacturing. Addit. Manuf. 2021, 47, 102328. [Google Scholar] [CrossRef]

- Lu, L.; Yuan, S.; Yao, X.; Li, Y.; Zhu, J.; Zhang, W. In-situ process evaluation for continuous fiber composite additive manufacturing using multisensing and correlation analysis. Addit. Manuf. 2023, 74, 103721. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Barnard, A.; DebRoy, T.; Matthews, M.J.; Ladani, L.; Gu, D. Towards developing multiscale-multiphysics models and their surrogates for digital twins of metal additive manufacturing. Addit. Manuf. 2021, 46, 102089. [Google Scholar] [CrossRef]

- Su, S.; Nassehi, A.; Hicks, B.; Ross, J. Characterisation and evaluation of identicality for digital twins for the manufacturing domain. J. Manuf. Syst. 2023, 71, 224–237. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, D.; Tao, B.; Jiang, G.; Sun, Y.; Kong, J.; Tong, X.; Zhao, G.; Chen, B. Genetic Algorithm-Based Trajectory Optimization for Digital Twin Robots. Front. Bioeng. Biotechnol. 2021, 9, 793782. [Google Scholar] [CrossRef]

- Yavari, R.; Riensche, A.; Tekerek, E.; Jacquemetton, L.; Halliday, H.; Vandever, M.; Tenequer, A.; Perumal, V.; Kontsos, A.; Smoqi, Z.; et al. Digitally twinned additive manufacturing: Detecting flaws in laser powder bed fusion by combining thermal simulations with in-situ meltpool sensor data. Mater. Des. 2021, 211, 110167. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. A digital twin for rapid qualification of 3D printed metallic components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

- Phua, A.; Davies, C.H.J.; Delaney, G.W. A digital twin hierarchy for metal additive manufacturing. Comput. Ind. 2022, 140, 103667. [Google Scholar] [CrossRef]

- Moretti, M.; Rossi, A.; Senin, N. In-process monitoring of part geometry in fused filament fabrication using computer vision and digital twins. Addit. Manuf. 2021, 37, 101609. [Google Scholar] [CrossRef]

- Rachmawati, S.M.; Putra, M.A.P.; Lee, J.M.; Kim, D.S. Digital twin-enabled 3D printer fault detection for smart additive manufacturing. Eng. Appl. Artif. Intell. 2023, 124, 106430. [Google Scholar] [CrossRef]

- Zheng, P.; Sivabalan, A.S. A generic tri-model-based approach for product-level digital twin development in a smart manufacturing environment. Robot. Comput. Integr. Manuf. 2020, 64, 101958. [Google Scholar] [CrossRef]

- Su, S.; Hicks, B.; Nassehi, A. Investigating the influence of fidelity on the capability of a digital twin to detect material extrusion failures. J. Intell. Manuf. 2023, 35, 2263–2276. [Google Scholar] [CrossRef]

- Chen, L.; Bi, G.; Yao, X.; Tan, C.; Su, J.; Ng, N.P.H.; Chew, Y.; Liu, K.; Moon, S.K. Multisensor fusion-based digital twin for localized quality prediction in robotic laser-directed energy deposition. Robot. Comput. Integr. Manuf. 2023, 84, 102581. [Google Scholar] [CrossRef]

- Yi, L.; Glatt, M.; Ehmsen, S.; Duan, W.; Aurich, J.C. Process monitoring of economic and environmental performance of a material extrusion printer using an augmented reality-based digital twin. Addit. Manuf. 2021, 48, 102388. [Google Scholar] [CrossRef]

- Pantelidakis, M.; Mykoniatis, K.; Liu, J.; Harris, G. A digital twin ecosystem for additive manufacturing using a real-time development platform. Int. J. Adv. Manuf. Technol. 2022, 120, 6547–6563. [Google Scholar] [CrossRef]

- Corradini, F.; Silvestri, M. Design and testing of a digital twin for monitoring and quality assessment of material extrusion process. Addit. Manuf. 2022, 51, 102633. [Google Scholar] [CrossRef]

- Roach, D.J.; Rohskopf, A.; Leguizamon, S.; Appelhans, L.; Cook, A.W. Invertible neural networks for real-time control of extrusion additive manufacturing. Addit. Manuf. 2023, 74, 103742. [Google Scholar] [CrossRef]

- Rusu, R.B.; Marton, Z.C.; Blodow, N.; Dolha, M.; Beetz, M. Towards 3D point cloud based object maps for household environments. Robot. Auton. Syst. 2008, 56, 927–941. [Google Scholar] [CrossRef]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for Point-Cloud Shape Detection, Proceedings of the Computer Graphics Forum; Wiley: Hoboken, NJ, USA, 2007; pp. 214–226. [Google Scholar]

| Parameters | Setting |

|---|---|

| Material | PLA |

| Extruder diameter | 0.4 |

| Infill density (%) | 100 |

| Infill pattern | Gird |

| Layer thickness (mm) | 0.32 |

| Bed temperature (°C) | 50 |

| Nozzle temperature (°C) | 205 |

| Environment temperature (°C) | 25 |

| Parameters | Setting |

|---|---|

| Extrusion multiplier | 1.2/1/0.8/0.6 |

| Print speed (mm/s) | 20/40/60 |

| Print Quality | Defect Portion |

|---|---|

| Normal printing | <1% |

| Mild defect | 1–5% |

| Moderate defect | 5–15% |

| Severe defect | >15% |

| Parameters | Defect Portion | Defect |

|---|---|---|

| EM1.2PS20 | 81.5 | Severe over-extrusion |

| EM1.2PS40 | 81.63 | Severe over-extrusion |

| EM1.2PS60 | 81.74 | Severe over-extrusion |

| EM1PS20 | 0.03 | Normal printing |

| EM1PS40 | 1.11 | Mild over-extrusion |

| EM1PS60 | 13 | Moderate over-extrusion |

| EM0.8PS20 | 1.05 | Mild under-extrusion |

| EM0.8PS40 | 2.12 | Mild under-extrusion |

| EM0.8PS60 | 4.17 | Mild under-extrusion |

| EM0.6PS20 | 11.32 | Moderate under-extrusion |

| EM0.6PS40 | 16.43 | Severe under-extrusion |

| EM0.6PS60 | 13.52 | Moderate under-extrusion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Lu, S.; Zhang, Y.; Zhang, L.; Song, Z.; Liu, H.; Liu, Q.; Ren, L. Digital Twins for Defect Detection in FDM 3D Printing Process. Machines 2025, 13, 448. https://doi.org/10.3390/machines13060448

Xu C, Lu S, Zhang Y, Zhang L, Song Z, Liu H, Liu Q, Ren L. Digital Twins for Defect Detection in FDM 3D Printing Process. Machines. 2025; 13(6):448. https://doi.org/10.3390/machines13060448

Chicago/Turabian StyleXu, Chao, Shengbin Lu, Yulin Zhang, Lu Zhang, Zhengyi Song, Huili Liu, Qingping Liu, and Luquan Ren. 2025. "Digital Twins for Defect Detection in FDM 3D Printing Process" Machines 13, no. 6: 448. https://doi.org/10.3390/machines13060448

APA StyleXu, C., Lu, S., Zhang, Y., Zhang, L., Song, Z., Liu, H., Liu, Q., & Ren, L. (2025). Digital Twins for Defect Detection in FDM 3D Printing Process. Machines, 13(6), 448. https://doi.org/10.3390/machines13060448