Stability Analysis and Static–Dynamic Characterization of Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valves

Abstract

1. Introduction

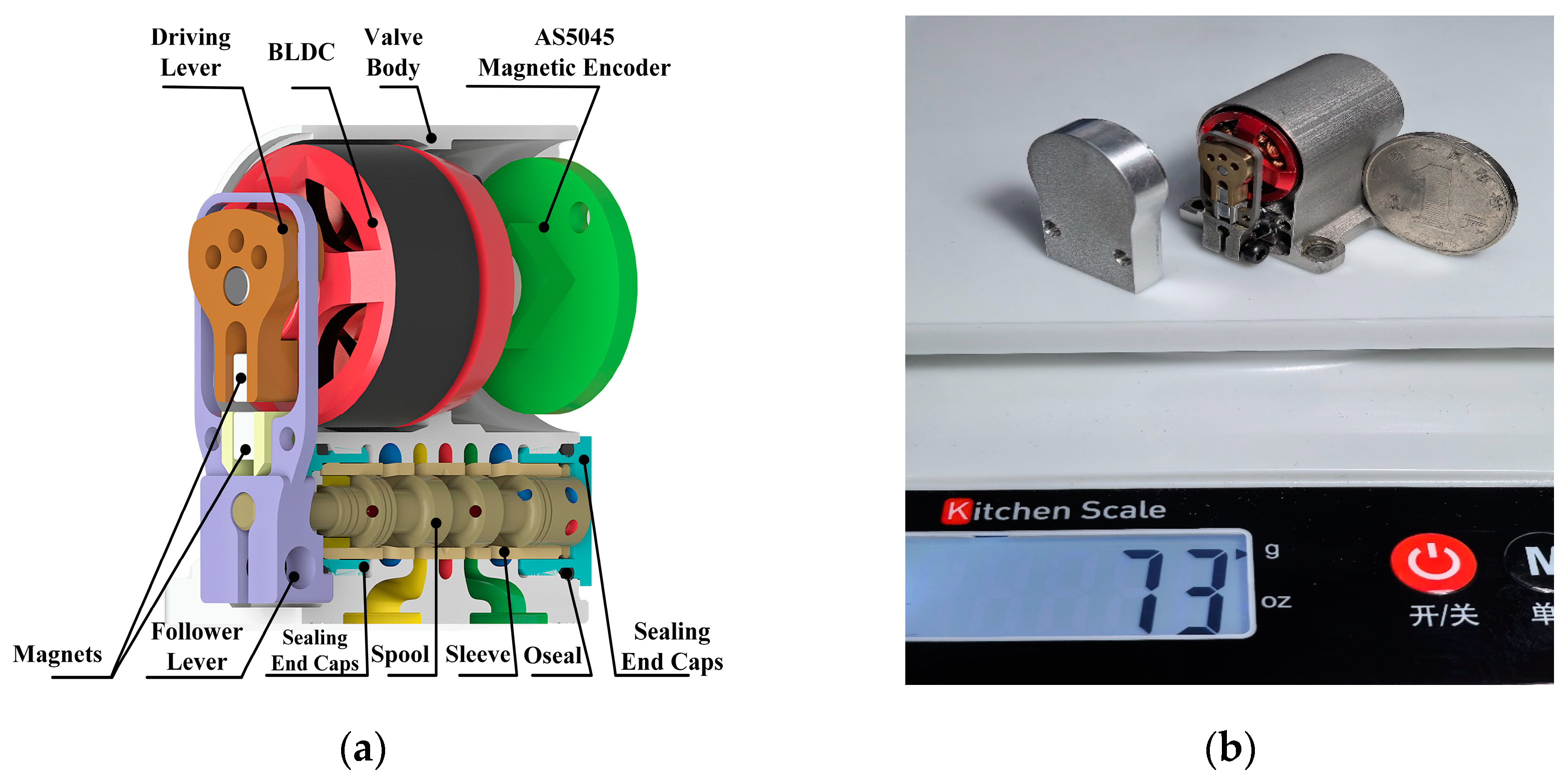

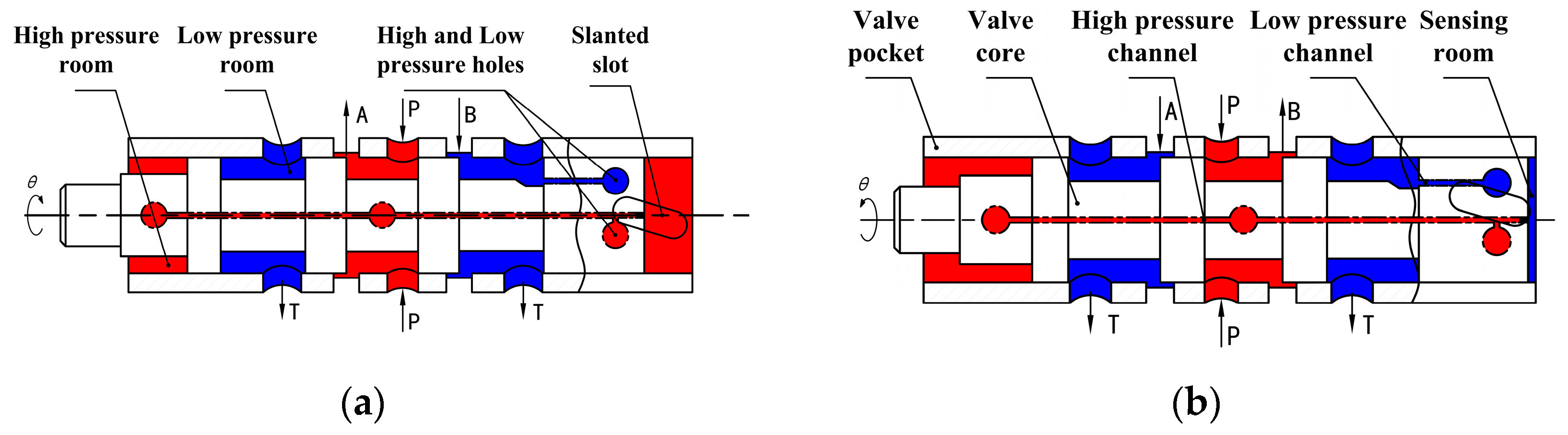

2. Structure and Working Principle of the 2D Servo Valve

3. Stability Analysis of Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valve

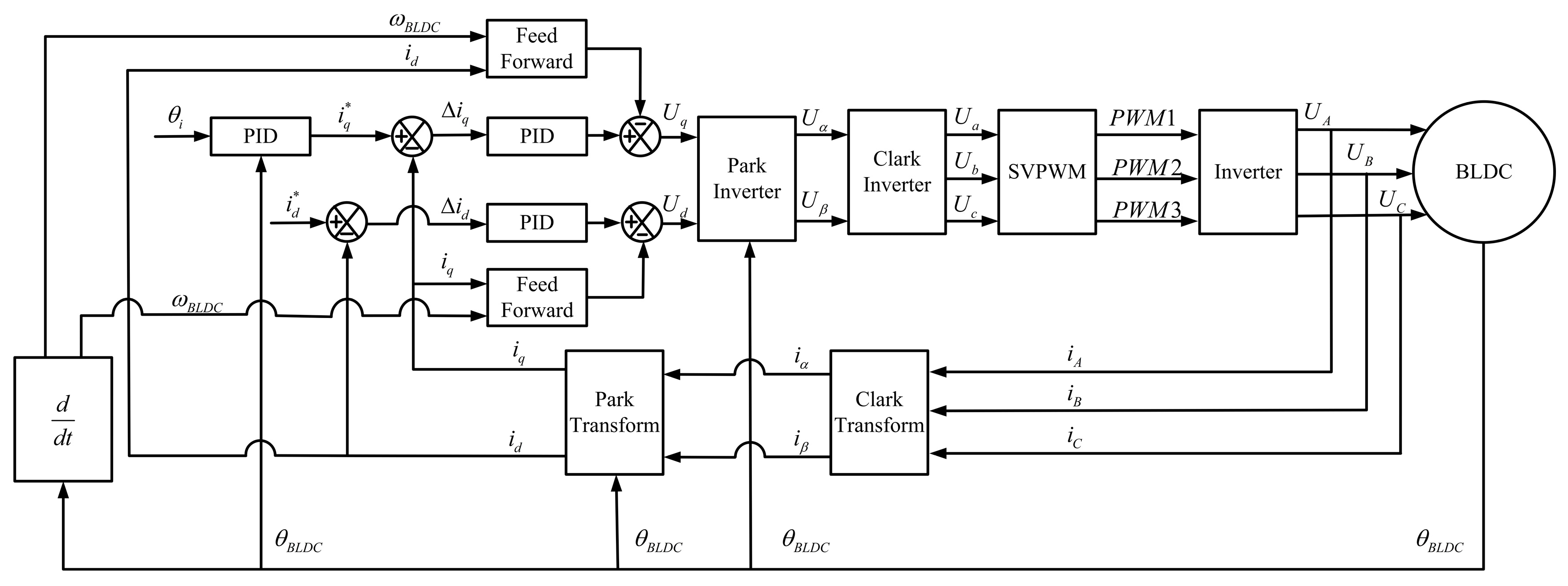

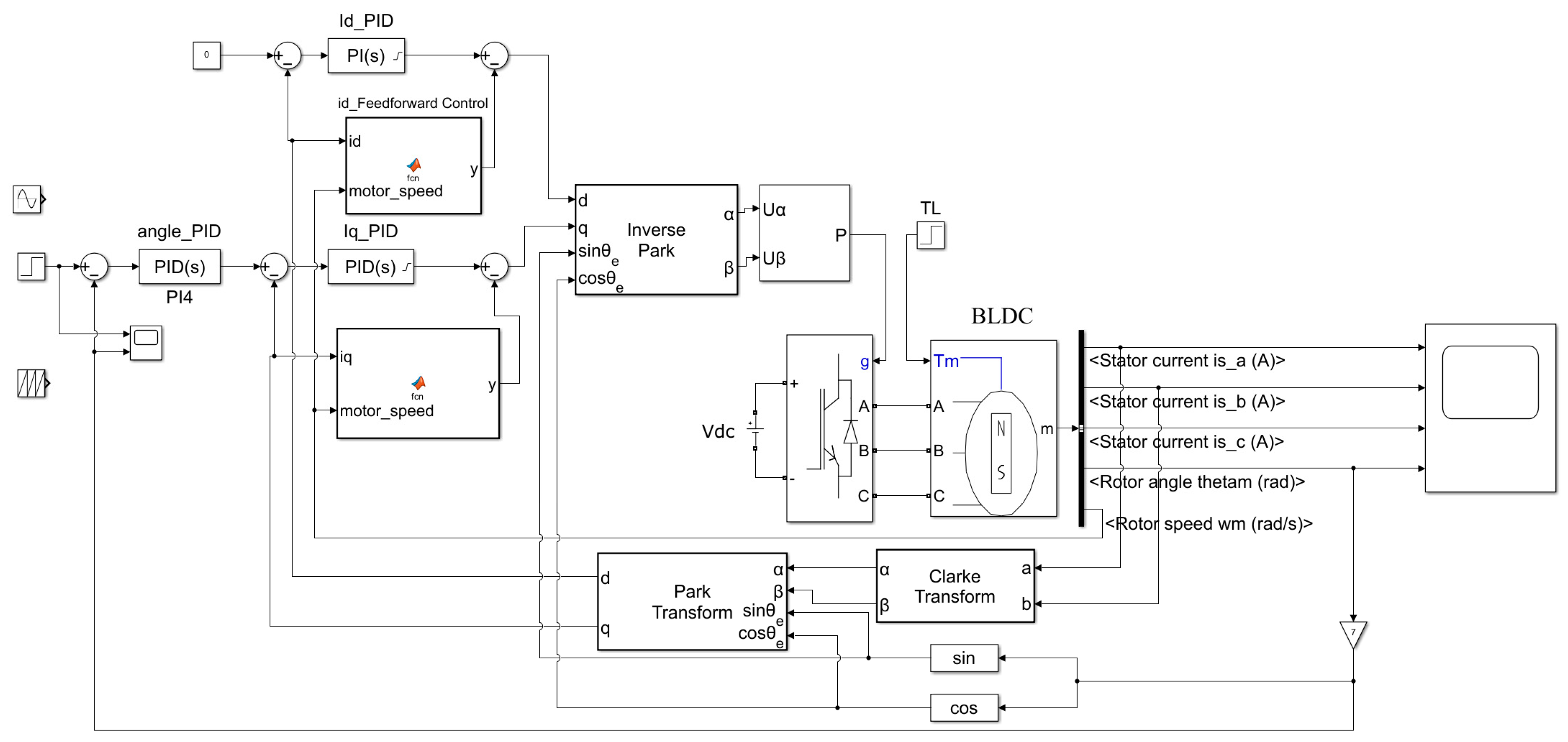

3.1. Stability Analysis of Electro-Mechanical Converter Control Algorithm

3.1.1. Mathematical Model of Electro-Mechanical Converter

3.1.2. Control Strategies for Electro-Mechanical Converters

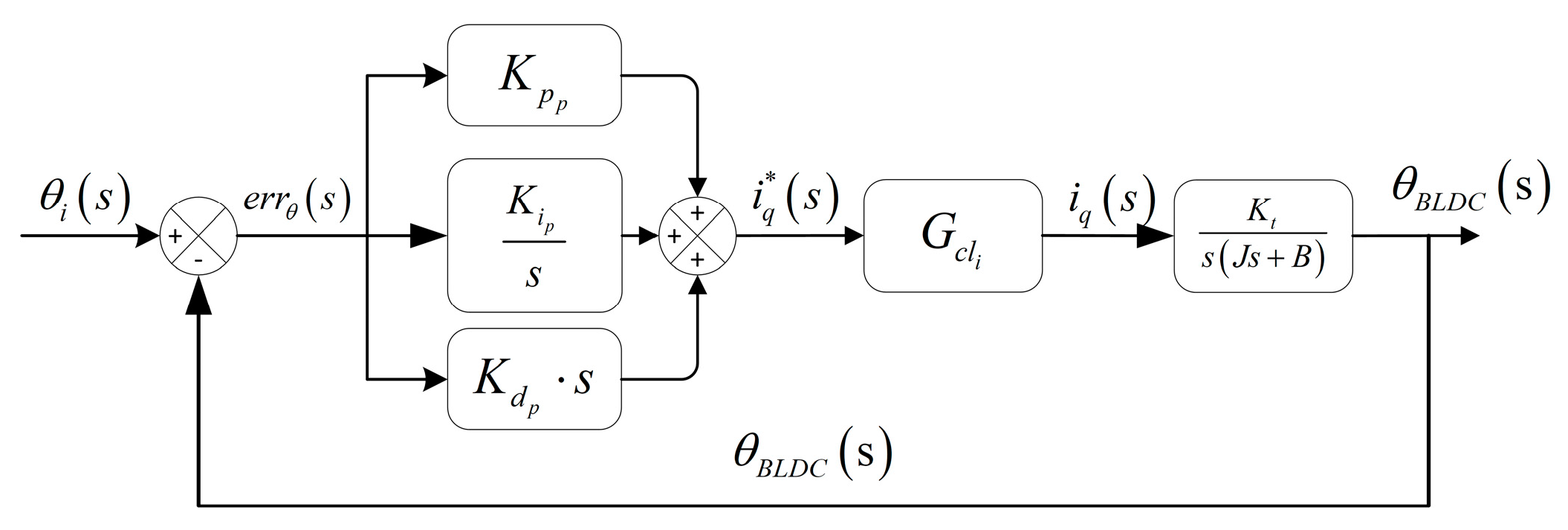

3.1.3. Transfer Functions of Electro-Mechanical Converters

3.1.4. Stability Analysis of Electro-Mechanical Converters

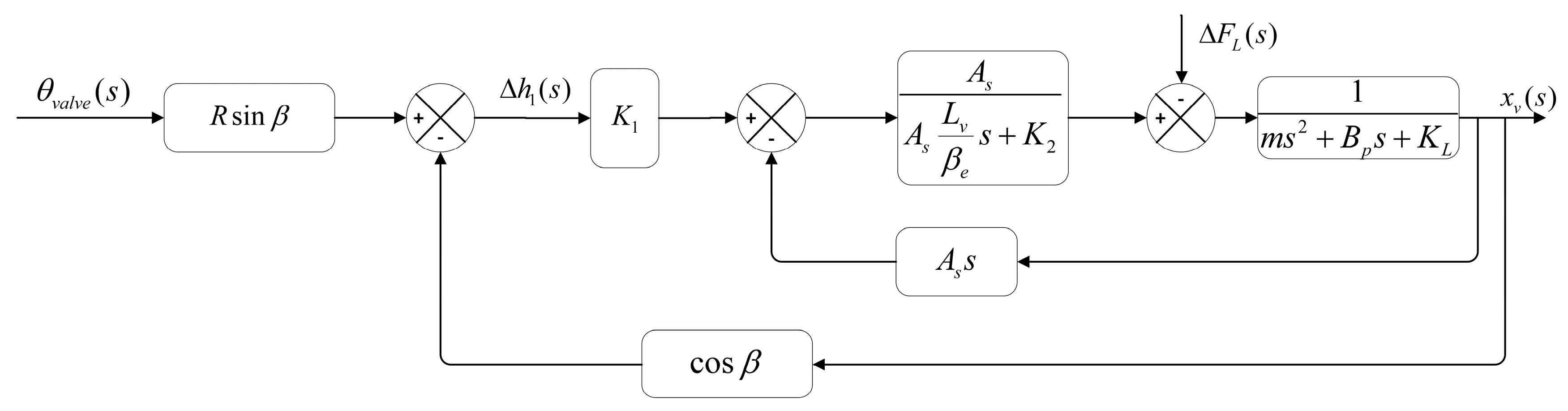

3.2. Stability Analysis of 2D Servo Screw Mechanism

3.2.1. Mathematical Model of 2D Servo Screw Mechanism

3.2.2. Stability Analysis of the 2D Servo Screw Mechanism

4. Combined Dynamic and Static Characteristic Simulation Analysis of the Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valve

4.1. Simulation Model of the Electro-Mechanical Converter

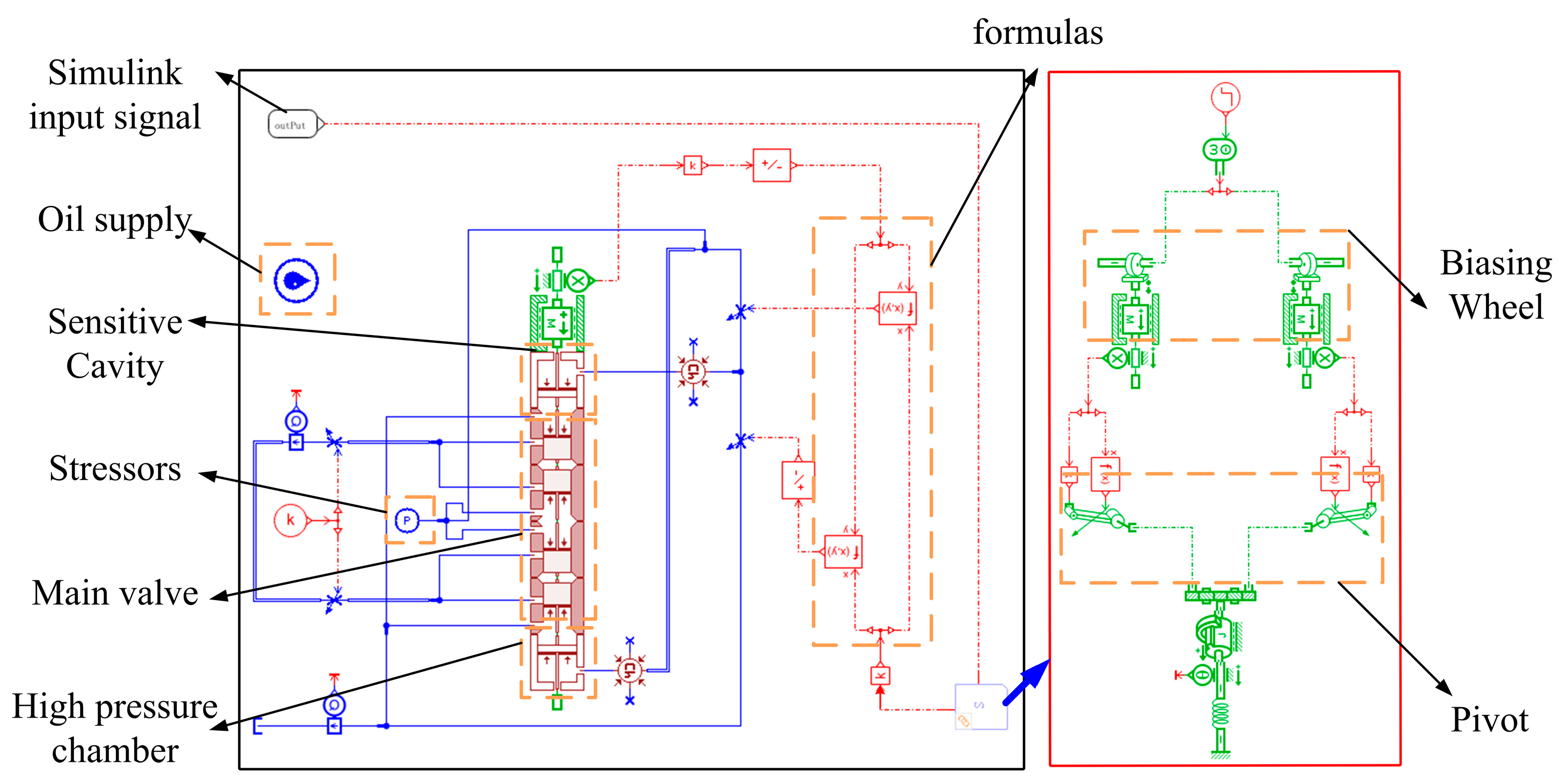

4.2. Combined Simulation Mode

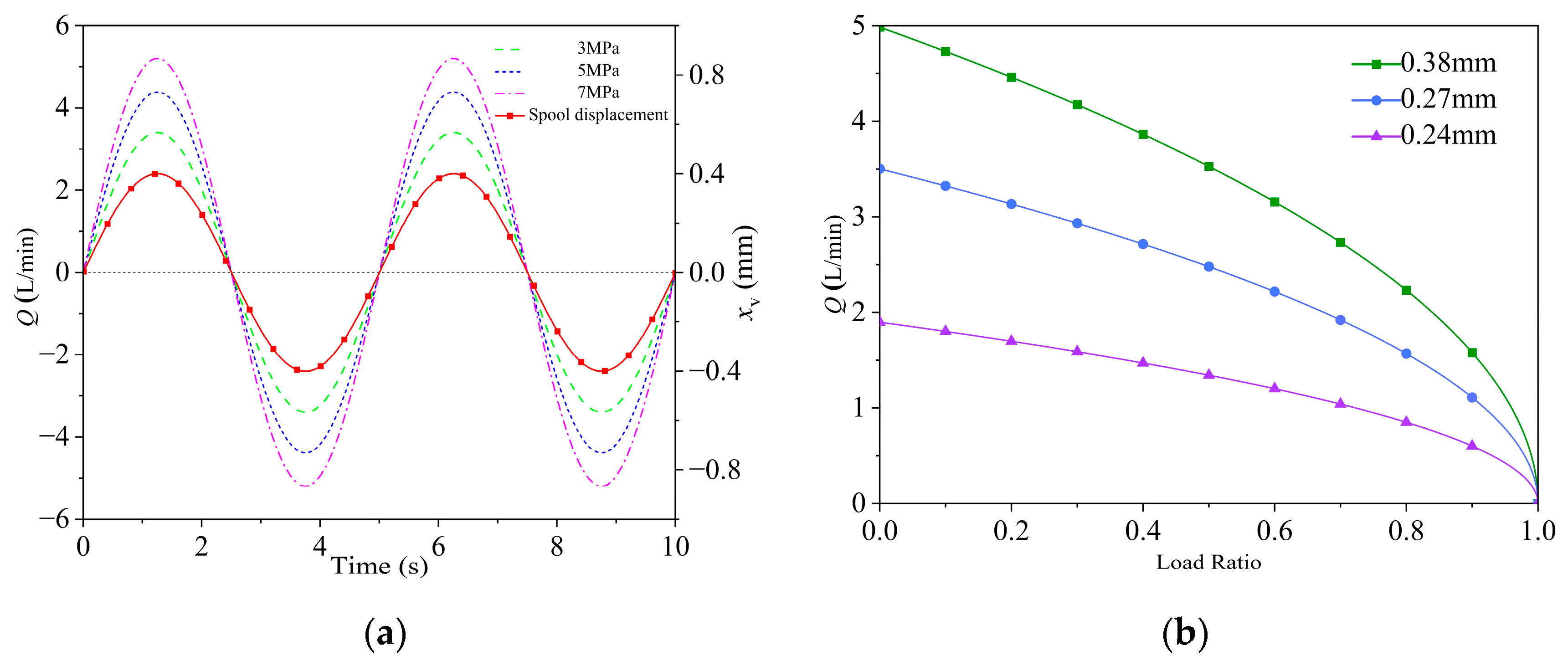

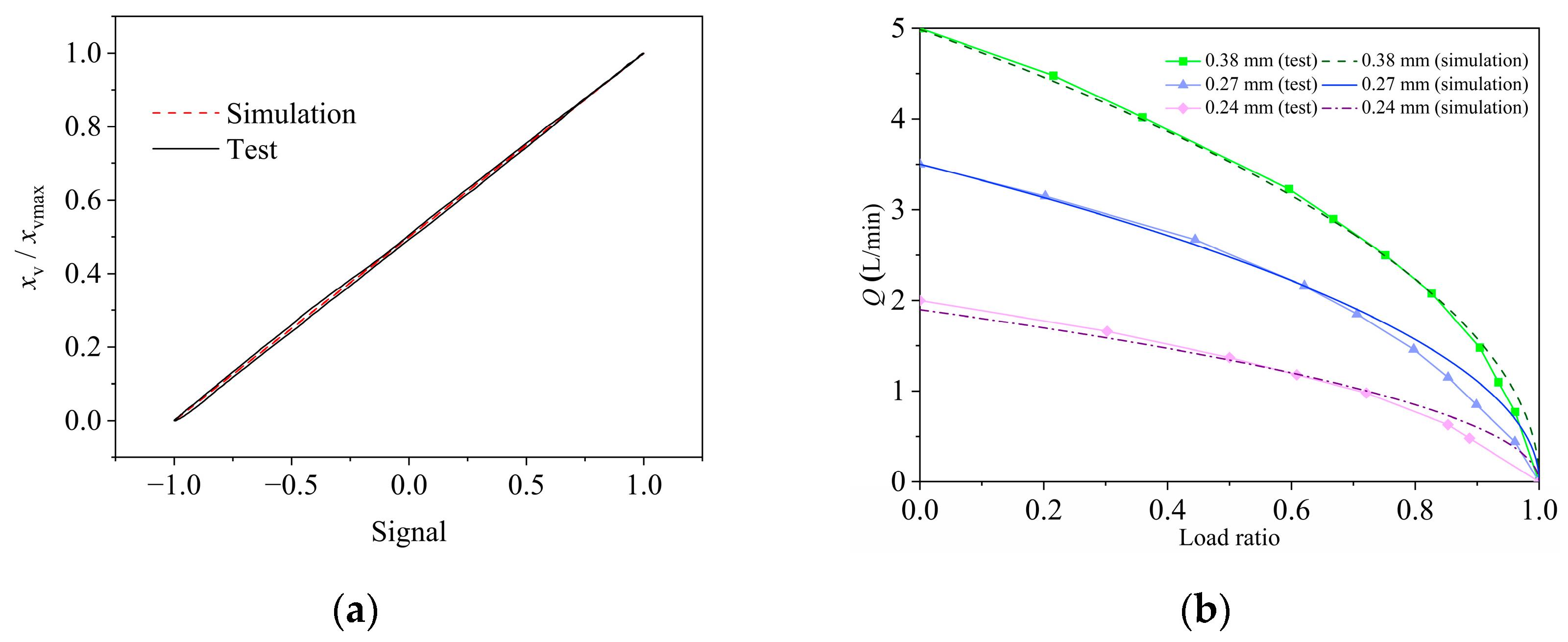

4.3. Static Characteristic Simulation Analysis

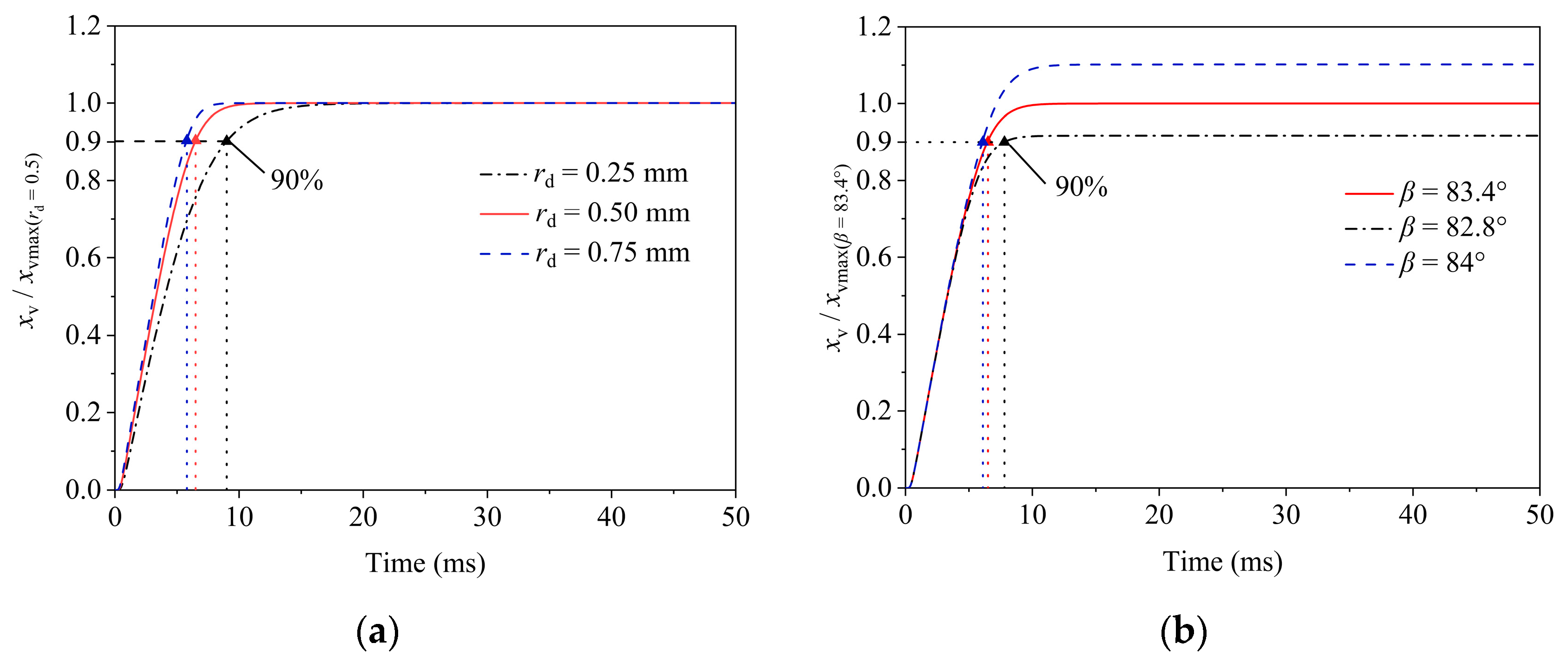

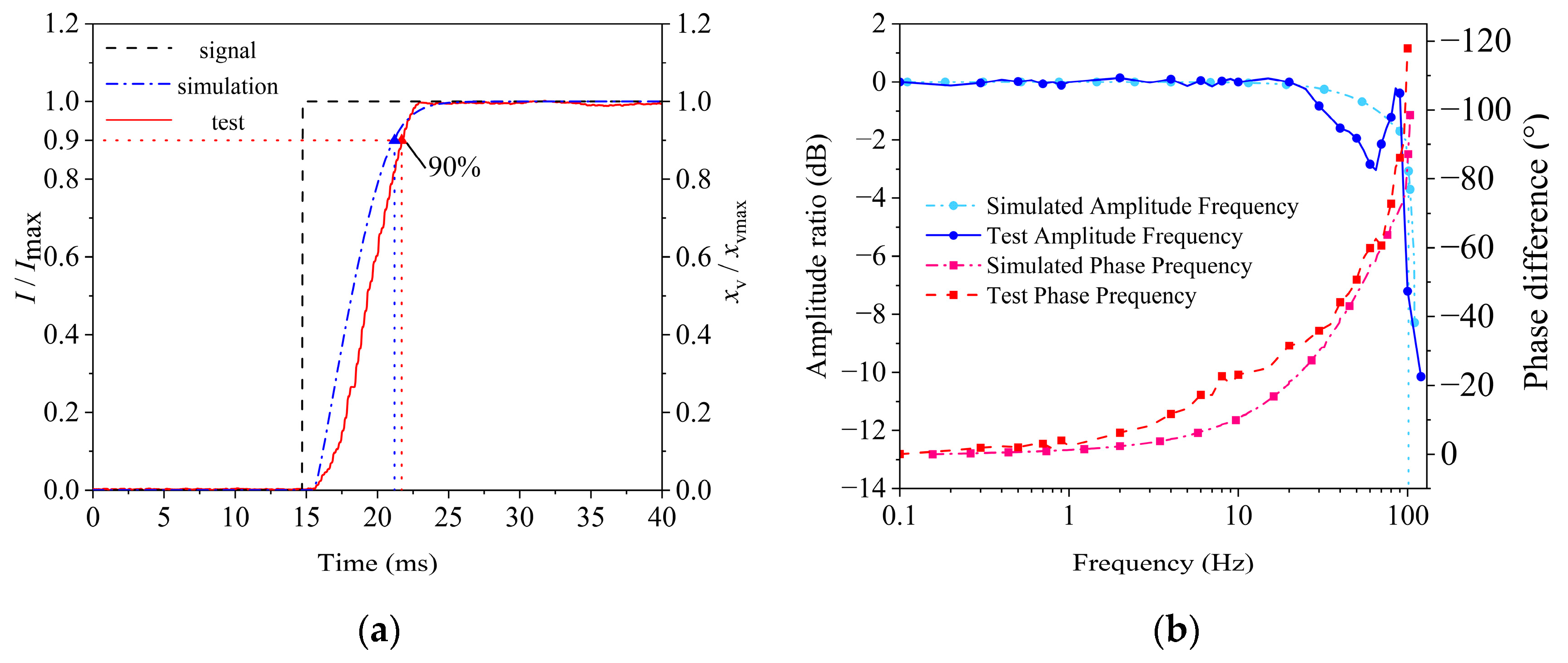

4.4. Dynamic Characteristic Simulation Analysis

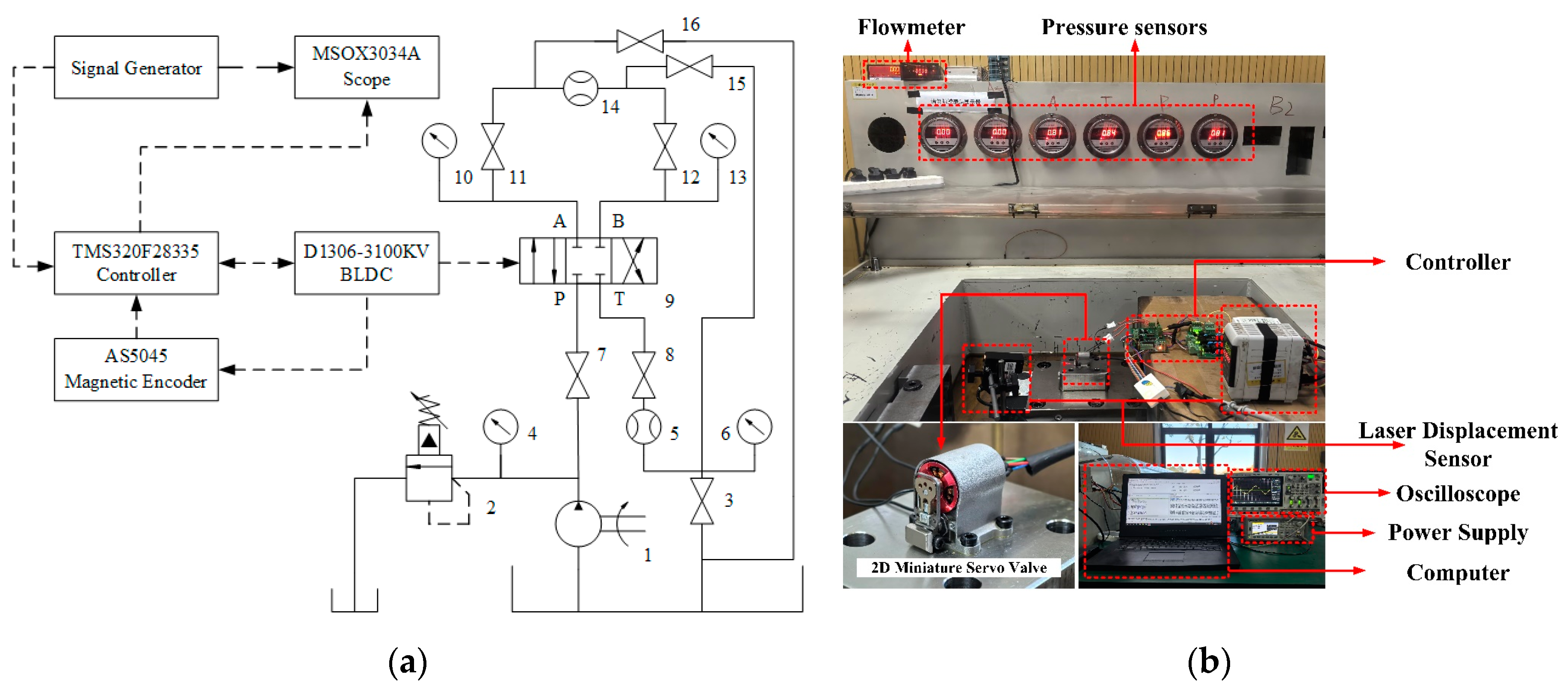

5. Experimental Research

5.1. Test Bench

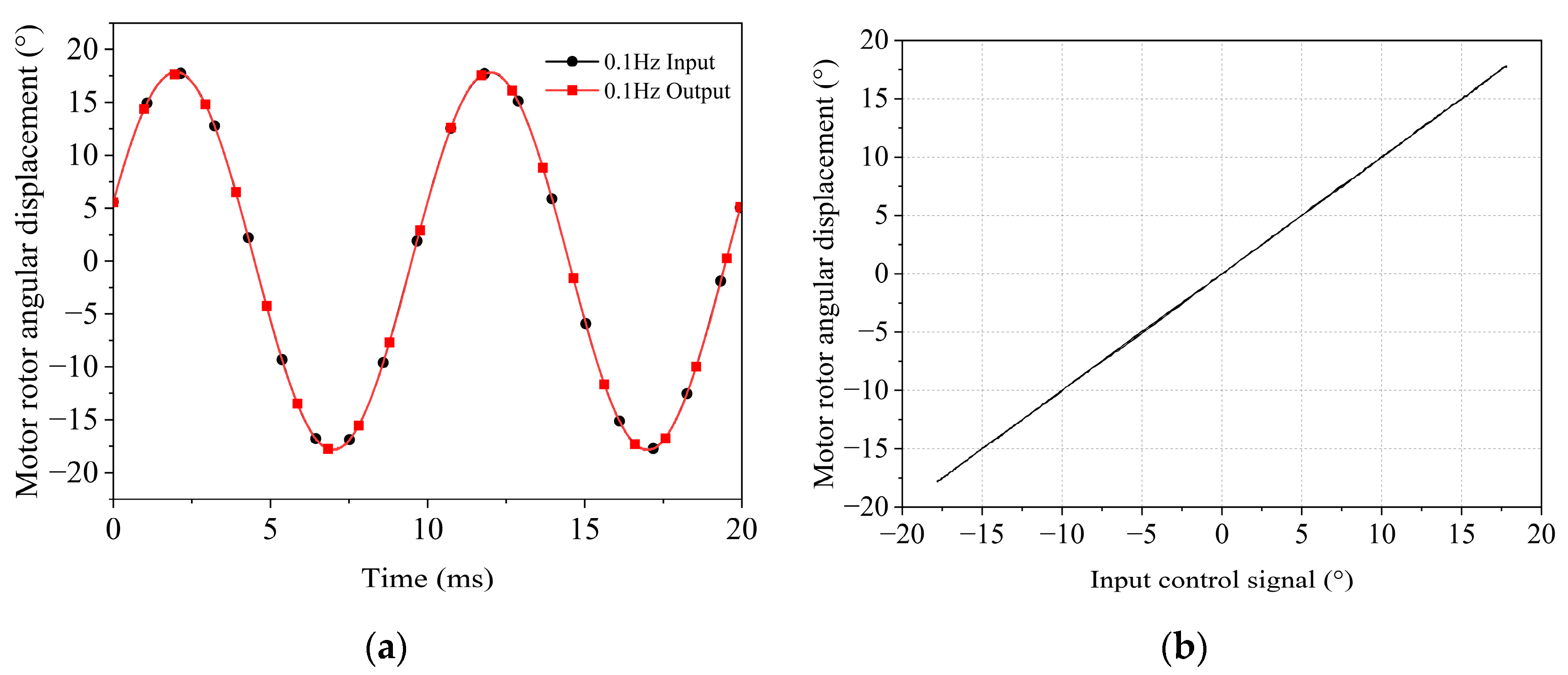

5.2. Dynamic and Static Characteristics of the Electro-Mechanical Converter

5.2.1. Static Characteristics of the Electro-Mechanical Converter

5.2.2. Dynamic Characteristics of the Electro-Mechanical Converter

5.3. Static Characteristics of the Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valve

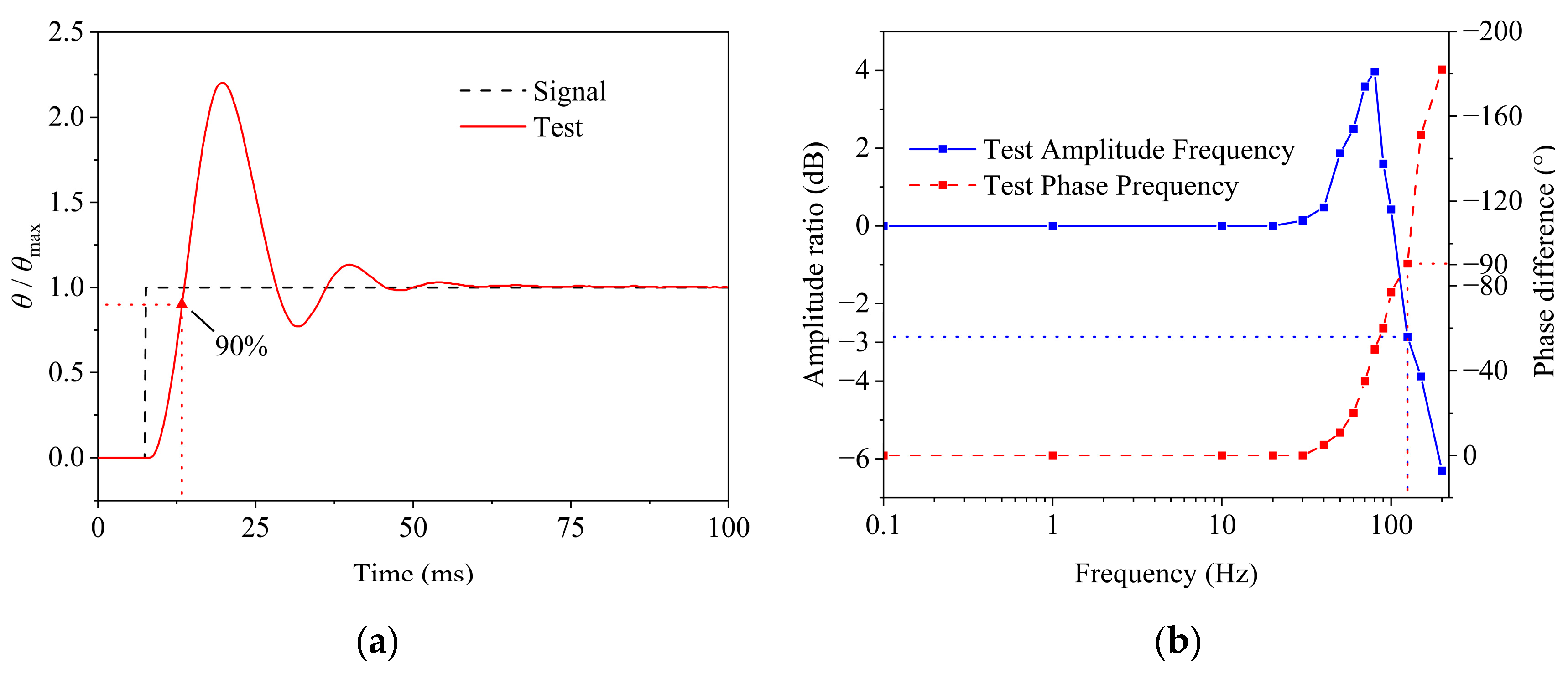

5.4. Dynamic Characteristics of the Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valve

6. Conclusions

- (1)

- This paper innovatively proposes a subminiature two-dimensional (2D) electro-hydraulic servo valve based on the servo helical mechanism, which realizes the integration of the pilot stage and the power stage by coupling the spool rotation and axial displacement double-degree-of-freedom motions and significantly improves the figure-of-merit-weight ratio. Meanwhile, a high-power-density brushless DC motor (BLDC) was adopted as the electro-mechanical converter to further reduce the volume and mass. Aiming at the special working conditions of the electro-mechanical converter with a small corner oscillation, a position–current double closed-loop PID control algorithm was designed on the basis of the FOC. The valve body was fabricated via binder jetting (BJ) additive manufacturing to reduce mass. The prototype dimensions were 31.7 mm × 29.3 mm × 31 mm, with a mass of 73 g.

- (2)

- A mathematical model of the electro-mechanical converter was developed, along with its control algorithm and transfer function. Stability conditions were derived using the Routh–Hurwitz criterion, showing that increasing the proportional gain, derivative gain, and damping coefficient or reducing the rotational inertia and integral gain, enhanced system stability, providing a theoretical basis for PID controller design. For the 2D servo spiral mechanism, mathematical modeling and transfer function derivation were performed. Stability analysis via the Routh–Hurwitz criterion indicated that increasing the inclination angle of the helical groove and high-pressure port radius improved stability, guiding structural design.

- (3)

- Co-simulation of the 2D servo valve was conducted using AMESim and Matlab/Simulink. The results indicate that under no-load conditions, the flow rate positively correlated with the system pressure, while under load, the flow rate negatively correlated with the load pressure ratio and exhibited nonlinear decay. The step response was overdamped with no overshoot or oscillation. Simulations also revealed that increasing the high-pressure port radius enhanced the response speed, whereas the inclination angle of the helical groove minimally affected the response speed but significantly altered steady-state flow.

- (4)

- An experimental platform was constructed to evaluate the dynamic and static performance of the 2D servo valve. The results demonstrated that the electro-mechanical converter had a response time of 5.6 ms, a −3 dB magnitude bandwidth of 130 Hz, and a phase bandwidth of 125 Hz; at 7 MPa, the valve achieved a maximum no-load flow rate of 5 L/min with 4.80% hysteresis and 2.54% linearity. The system step response time was 7.5 ms, with a −3 dB magnitude bandwidth of 90 Hz and a phase bandwidth of 95 Hz. The experimental data confirm the valve’s excellent dynamic–static performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Parameter | Value |

| Electro-mechanical converter winding terminal voltage | |

| Three-phase winding resistance | |

| Stator phase winding current | |

| Winding inductance constant | |

| Winding mutual inductance constant | |

| Electro-mechanical converter electromagnetic torque | |

| Three-phase stator reverse electromotive force | |

| Rotor angular velocity | |

| Load torque | |

| Electro-mechanical converter moment of inertia | |

| Damping factor | |

| Electro-mechanical converter rotor electrical angle | |

| Electro-mechanical converter internal resistance | |

| Straight-axis inductors | |

| Cross-axis inductors | |

| Permanent magnet chain | |

| Polar logarithm | |

| Position closed-loop proportional gain coefficient | |

| Position closed-loop integral gain coefficient | |

| Position closed-loop differential gain coefficient | |

| Flow into sensitive cavities | |

| Leakage flow from high-pressure orifice to spiral groove | |

| Flow out of the sensitive cavity | |

| Leakage flow from spiral groove to low-pressure hole | |

| Sensitive cavity spool area | |

| Spool displacement | |

| Sensitive cavity volume | |

| Volumetric modulus of elasticity of the oil | |

| Sensitive cavity pressure | |

| System pressure | |

| Height of the overlap area of the high-pressure small hole and the servo spiral groove | |

| Clearance from spiral groove to high-(low-) pressure hole | |

| Spool shoulder radius | |

| Spiral groove angle of rise | |

| Spool angle | |

| Height of the overlap area between the low-voltage small hole and the servo spiral groove | |

| High-(low-) pressure hole radius | |

| Flow rate trimming factor | |

| Overlap area of high-pressure holes and servo helix grooves | |

| Fluid density | |

| Overlap area between low-pressure hole and spiral groove | |

| Heavy mass of spool | |

| Equivalent to the total viscosity coefficient on the valve spool | |

| Load acting on the spool |

References

- Yang, W.; Li, R.; Xu, J.; Xiao, G.; Yuan, W.; Sun, Y.; Zhang, Q. CFD-based axial steady-state hydrodynamic study and structural optimization of miniature switching valve. Flow Meas. Instrum. 2024, 100, 102744. [Google Scholar] [CrossRef]

- Simic, M.; Herakovic, N. Reduction of the flow forces in a small hydraulic seat valve as alternative approach to improve the valve characteristics. Energy Convers. Manag. 2015, 89, 708–718. [Google Scholar] [CrossRef]

- Bai, Y.; Yao, J.; Hu, J.; Feng, G. Output feedback active disturbance rejection control of an electro-hydraulic servo system based on command filter. Chin. J. Aeronaut. 2025, 38, 103169. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, L.; Zhuo, Y.; Wang, M.; He, C.; Zhang, C.; Xie, G. Mechanical Characteristics and Miniaturization Design of the Electromagnetic Valve Used in Drilling Robots. Processes 2024, 12, 1685. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Fan, Q. Adaptive learning and sliding mode control for a magnetic microrobot precision tracking with uncertainties. IEEE Robot. Autom. Lett. 2023, 8, 7767–7774. [Google Scholar] [CrossRef]

- Liu, Q.; Ghodrat, S.; Huisman, G.; Jansen, K.M.B. Shape Memory Alloy Actuators for Haptic Wearables: A Review. Mater. Des. 2023, 233, 112264. [Google Scholar] [CrossRef]

- Lisowski, E.; Filo, G.; Pluskowski, P.; Rajda, J. Flow analysis of a novel, three-way cartridge flow control valve. Appl. Sci. 2023, 13, 3719. [Google Scholar] [CrossRef]

- Xu, C.; Ren, Y.; Tang, H.; Lu, L.; Huang, Y.; Ruan, J. Investigation on a novel high frequency two-dimensional (2D) rotary valve variable mechanism for fluid pulse-width-modulation application. J. Mech. Sci. Technol. 2023, 37, 757–765. [Google Scholar] [CrossRef]

- Qun, F.; Zeng, H. Developing Process, Research Actuality and Trend of Electrohydraulic Servo valve. Mach. Tools Hydraul. 2007, 35, 162–165. [Google Scholar]

- Prsic, D.; Fragassa, C.; Nedic, N.; Pavlovic, A. Describing function of the pneumatic flapper-nozzle valve. Mech. Syst. Signal Process. 2019, 124, 696–714. [Google Scholar] [CrossRef]

- Yan, H.; Wang, F.-J.; Li, C.-C.; Huang, J. Research on the jet characteristics of the deflector–jet mechanism of the servo valve. Chin. Phys. B 2017, 26, 044701. [Google Scholar] [CrossRef]

- Li, C.; Yin, Y.; Wang, M.; Wang, F. Influence of high temperature on couples matching and characteristics of jet pipe electrohydraulic servovalve. J. Mech. Eng. 2018, 54, 251–261. [Google Scholar] [CrossRef]

- Chu, Y.; Yuan, Z.; He, X.; Dong, Z. Model construction and performance degradation characteristics of a deflector jet pressure servo valve under the condition of oil contamination. Int. J. Aerosp. Eng. 2021, 2021, 8840084. [Google Scholar] [CrossRef]

- Zhao, R.; Liao, Y.; Lian, Z.; Li, R.; Guo, Y. Research on the performance of a novel electro-hydraulic proportional directional valve with position-feedback groove. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 1930–1944. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, M.; Xu, B. Design and experimental research of a miniature digital hydraulic valve. Micromachines 2018, 9, 283. [Google Scholar] [CrossRef]

- Obayashi, H.; Akagi, T.; Dohta, S.; Kobayashi, W.; Matsui, Y.; Shimooka, S.; Shinohara, T.; Aliff, M. Development of portable rehabilitation device driven by low-cost servo valve using tap water. Int. J. Mech. Eng. Robot. Res. 2020, 9, 353–359. [Google Scholar] [CrossRef]

- Yan, L. Multi-Parameter Comprehensive Influence Mechanism and Experimental Research on Zero Position Characteristics of Jet Disk Servo Valve. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Bai, J. Research on Control Key Technology of Resonant Electro-Hydraulic High-Frequency Fatigue Testing Machine. Ph.D. Thesis, Zhejiang University of Technology, Harbin, China, 2013. [Google Scholar]

- Bing, M.; Qiong, L. Torque-angle Characteristics of Permanent Magnet Torque Motor with Single-phase Excitation. Mech. Sci. Technol. Aerosp. Eng. 2018, 37, 532–536. [Google Scholar] [CrossRef]

- Yu, Y.; Ke, S.; Jin, K. Structural parameters optimization for a proportional solenoid. Int. J. Simul. Model. 2020, 19, 689–700. [Google Scholar] [CrossRef]

- Yokota, S.; Hiramoto, K. An ultra high-speed electrohydraulic servo valve by making use of a multilayered piezoelectric device (PZT). Compensation of the hysteresis by introducing a software algorithm. Nihon Kikai Gakkai Ronbunshu B Hen/Trans. Jpn. Soc. Mech. Eng. Part B 1991, 57, 182–187. [Google Scholar] [CrossRef][Green Version]

- Zhou, X.; Wu, S.; Wang, X.; Wang, Z.; Zhu, Q.; Sun, J.; Huang, P.; Wang, X.; Huang, W.; Lu, Q. Review on piezoelectric actuators: Materials, classifications, applications, and recent trends. Front. Mech. Eng. 2024, 19, 6. [Google Scholar] [CrossRef]

- Sheng, L. Research of Key Technologies of Digital Control for 2D Servo Valve. Ph.D. Thesis, Zhejiang University of Technology, Harbin, China, 2012. [Google Scholar]

- Mohanraj, D.; Aruldavid, R.; Verma, R.; Sathiyasekar, K.; Barnawi, A.B.; Chokkalingam, B.; Mihet-Popa, L. A review of BLDC motor: State of art, advanced control techniques, and applications. IEEE Access 2022, 10, 54833–54869. [Google Scholar] [CrossRef]

- Ruan, J.; Burton, R.; Ukrainetz, P. An Investigation into the Characteristics of a Two Dimensional “2D” Flow Control Valve. J. Dyn. Syst. Meas. Control 2002, 124, 214–220. [Google Scholar] [CrossRef]

- Zhao, C.; Cai, J.; Zhang, B.; Qu, X. Key technology of binder jet 3D printing. J. Mater. Eng. 2023, 51, 14–26. [Google Scholar]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder Jet 3D Printing—Process Parameters, Materials, Properties, Modeling, and Challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L.; Dong, Z.; Yang, Z.; Li, T. Research on Low-cost Tungsten Powder Printing Process Using Binder Jet 3D Printing. Mater. Her. 2024, 38, 387–390. [Google Scholar]

- Wang, H.; Chau, K.; Liu, W.; Goetz, S.M. Design and control of wireless permanent-magnet brushless DC motors. IEEE Trans. Energy Convers. 2023, 38, 2969–2979. [Google Scholar] [CrossRef]

- Skuric, A.; Bank, H.S.; Unger, R.; Williams, O.; González-Reyes, D. SimpleFOC: A field oriented control (FOC) library for controlling brushless direct current (BLDC) and stepper motors. J. Open Source Softw. 2022, 7, 4232.123. [Google Scholar] [CrossRef]

- Hussein, T.A.; Mohammed, L.A. Detailed Simulink implementation for induction motor control based on space vector pulse width modulation SVPWM. Indones. J. Electr. Eng. Comput. Sci. 2021, 22, 1251–1262. [Google Scholar]

| Pole Pairs | Mass/kg | Resistance/Ω | Direct Axis Inductance Ld/μH | Quadrature Axis Inductance Lq/μH | Flux Linkage Coefficient /Wb | Rotational Inertia J/g·cm2 |

|---|---|---|---|---|---|---|

| 6 | 0.015 | 0.157 | 5.424 | 19.5 | 0.0007728 | 3.57 |

| Module | Parameters | Value |

|---|---|---|

| Master valve | Spool diameter/mm | 4.5 |

| Spool mass/g | 2 | |

| Inclination angle of slanting groove/° | 83.4 | |

| High-pressure hole diameter/mm | 1 | |

| Spool displacement/mm | ±0.9 | |

| Flow rate coefficient | 0.62 | |

| Offset distance /mm | 1.8 | |

| Fluids | Fluid density/(kg×m−3) | 860 |

| Bulk modulus of elasticity/MPa | 700 | |

| Fluid system pressure/MPa | 7 |

| Component | Model Number | Parameters |

|---|---|---|

| Flow meter | A350-AO | 0–40.00 L/min |

| Oscillograph | MSO-X 3054A | Maximum sampling frequency: 500 MHz |

| Laser displacement sensor | LK-G150 | 650 nm |

| Signal generators | 33660A |

| Manufacturer | Series Model | Linearity | Mass | Bandwidth |

|---|---|---|---|---|

| MOOG | MOOG73 | <±7 | 1180 | >80 |

| REXRITH | 4WS2EM | <±10 | 800 | >80 |

| PARKER | BD062 | <±10 | 2100 | >18 |

| This article | 2D servo valve | 2.54 | 73 | 90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, L.; Dai, Q.; Song, Z.; Zhu, C.; Li, S. Stability Analysis and Static–Dynamic Characterization of Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valves. Machines 2025, 13, 388. https://doi.org/10.3390/machines13050388

Pan L, Dai Q, Song Z, Zhu C, Li S. Stability Analysis and Static–Dynamic Characterization of Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valves. Machines. 2025; 13(5):388. https://doi.org/10.3390/machines13050388

Chicago/Turabian StylePan, Lei, Quanchao Dai, Zhankai Song, Chengtao Zhu, and Sheng Li. 2025. "Stability Analysis and Static–Dynamic Characterization of Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valves" Machines 13, no. 5: 388. https://doi.org/10.3390/machines13050388

APA StylePan, L., Dai, Q., Song, Z., Zhu, C., & Li, S. (2025). Stability Analysis and Static–Dynamic Characterization of Subminiature Two-Dimensional (2D) Electro-Hydraulic Servo Valves. Machines, 13(5), 388. https://doi.org/10.3390/machines13050388