A Novel Ground-to-Elevated Mobile Manipulator Base System for High-Altitude Operations

Abstract

1. Introduction

- (1)

- For the mobile base designed in this study, it is essential to thoroughly consider the feasibility of manufacturing and transportation, as well as the flexibility of adjustment and adaptation in practical applications. This ensures that its mobility and adaptability are superior to those of fixed tracks when addressing diverse work sites and task requirements.

- (2)

- Accurate pose estimation of robots at high altitudes serves as the foundation for flexible operations in elevated environments. However, existing height estimation methods exhibit certain limitations. For instance, the accuracy of height measurement using LiDAR is constrained [15]. Additionally, in the actual scene described in this paper, the measured plane is uneven and subject to strong vibrations caused by movement, which makes the measurement data unreliable. When using RTK (real-time kinematic) devices for height estimation, there is a problem of insufficient accuracy [16]. The utilization of infrared ranging sensors also presents disadvantages, such as interference from strong environmental light and a limited measurement range [17].

- (3)

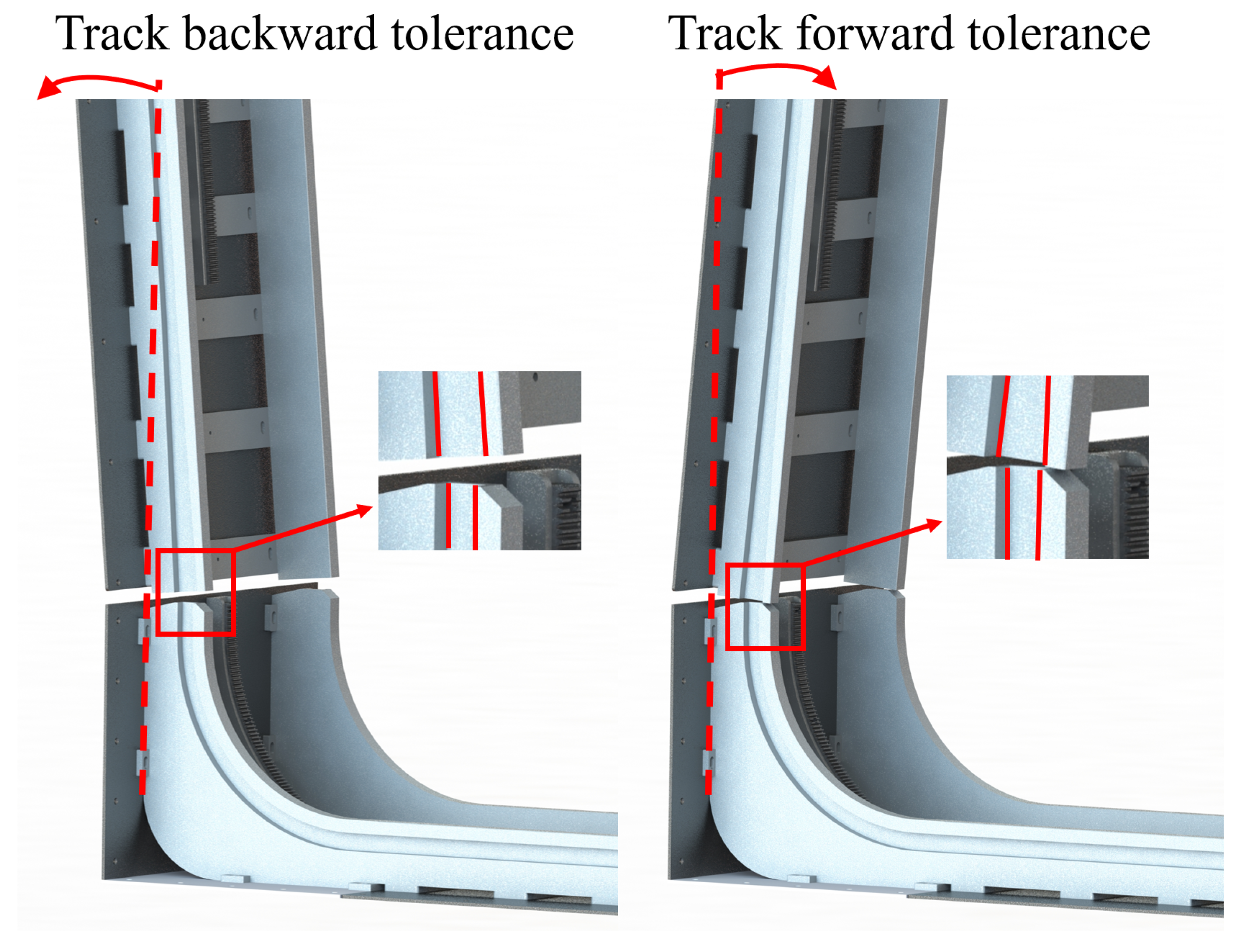

- In the climbing drive section of our base configuration, we implement a rigidly connected independent drive motor architecture. However, when encountering curved tracks with substantial curvature variations, the robot’s posture remains in a continuous dynamic state. Furthermore, the designed foldable track includes sections with missing racks, presenting a significant challenge for the smooth and seamless passage of the compliant drive gear through the curved and suspended segments of the track.

- (4)

- These compound mobile operation robots are primarily designed for outdoor environments [18,19]. The conventional localization method used is RTK for absolute pose estimation [20], but the accuracy of RTK devices significantly decreases when encountering strong electromagnetic interference [21]. Additionally, the mechanical track in this paper has a small allowable pose error when entering the track in order to closely match the robot body. It is difficult to meet the positioning accuracy requirements solely relying on RTK [22,23,24]. Simultaneously, for the stability of outdoor work, adaptability to harsh environments should also be considered, such as working stability under strong electromagnetic interference and adverse weather conditions.

- We present a new design for mobile manipulators, along with an innovative design for mechanical gear-tracks.

- We introduce a robot navigation algorithm that is based on the fusion of multi-sensor information and localization techniques. This algorithm significantly enhances the adaptability and accuracy of localization systems within complex outdoor environments.

- We outline a methodology for robot localization and for ensuring smooth operation on the track. This methodology addresses the challenges associated with pose estimation in a compound robot mobile base for work-at-height operations and effectively enhances the stability and smoothness of robot movement on both curved and suspended tracks.

- A series of empirical tests were conducted in real-world environments to validate the proposed robot mobile base system and methodology.

2. Design

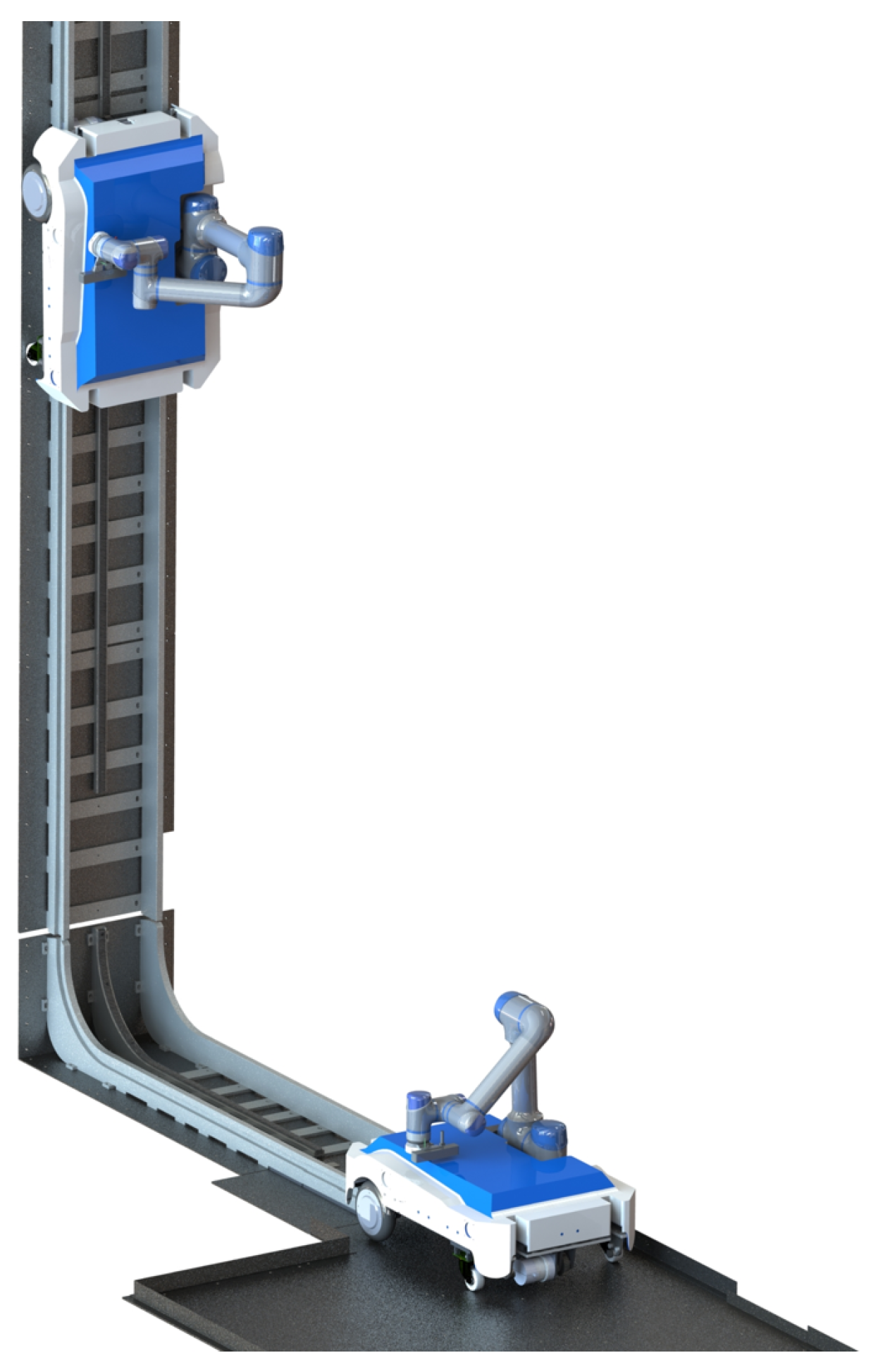

2.1. Robot General Design

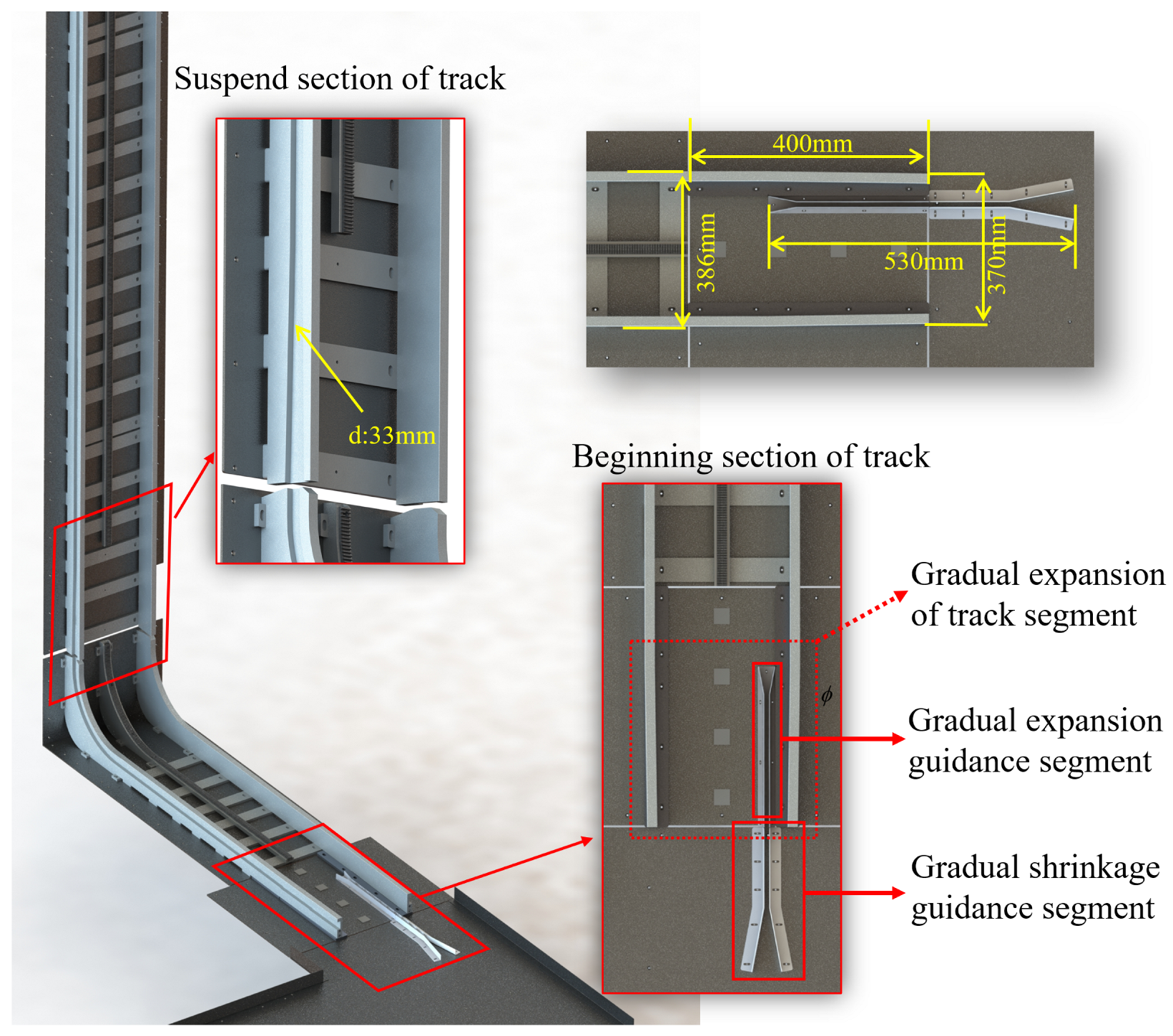

2.2. Gear-Track and Gear-Climbing Mechanism Design

2.2.1. Gear-Track Mechanism Design

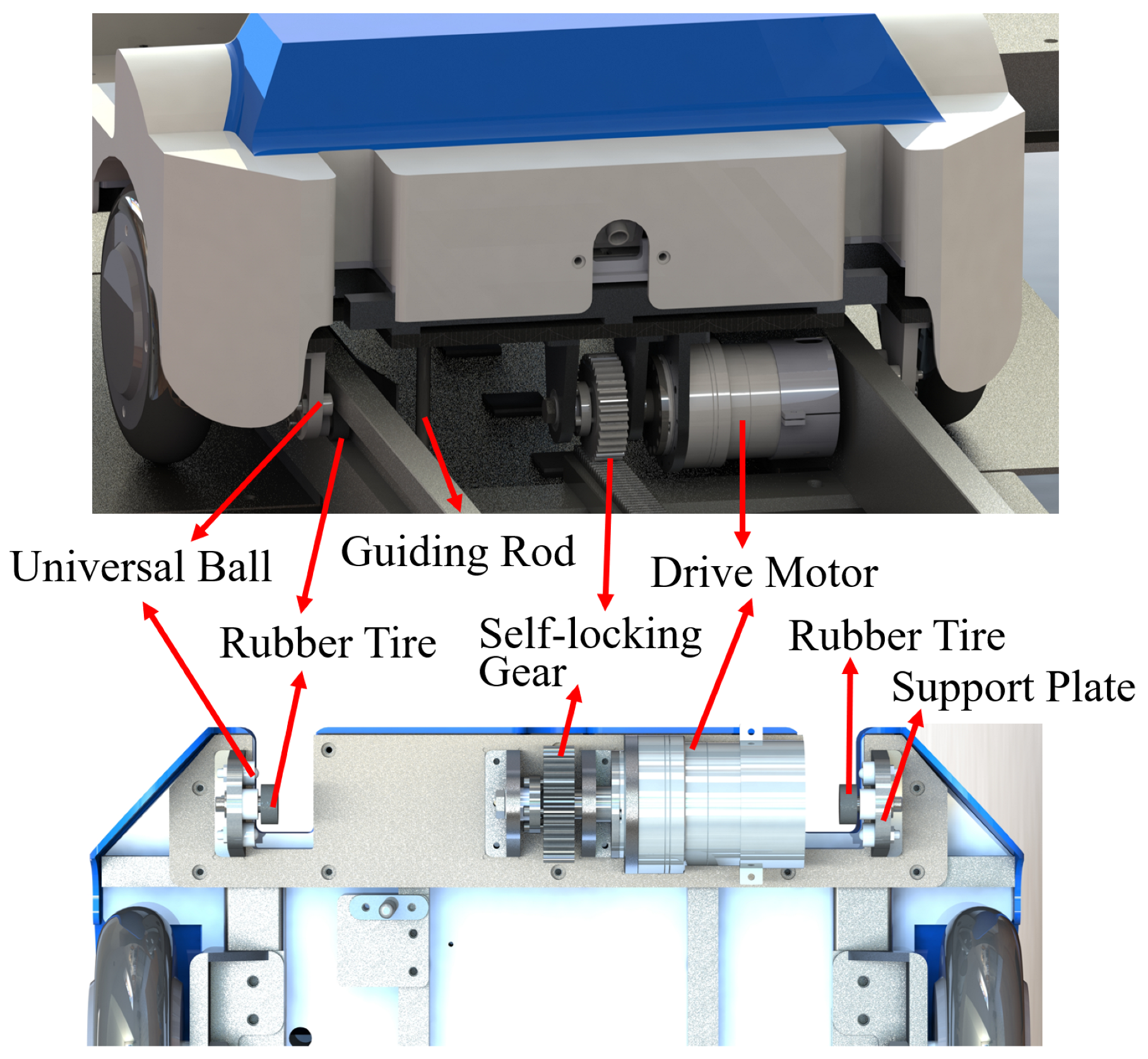

2.2.2. Gear-Climbing Mechanism Design

- It must possess the capability to autonomously enter the mechanical track from an open ground.

- It must incorporate a mechanical limiting mechanism to ensure stable movement on the track.

- The entire climbing process must maintain continuous power.

- The base moves smoothly along the track, primarily utilizing the track guidance mechanism and the track drive mechanism. Upon reaching the track’s starting place, the base employs the guide rod located at its base to initiate entry into the track through the progressively narrowing guide section. Following this, the rubber tires of the front guidance mechanism engage with the gradually widening track section.

- When the base fully enters the track, the track guiding mechanisms installed on both sides of the front and rear drive motors constrain the base to the guide rail. Each set of track guiding mechanisms comprises a rubber tire, a universal ball, and a support plate, ensuring that the base moves only in a direction parallel to the guide rail. Figure 7 below illustrates the constraint method.

- As illustrated in Figure 5, a gap exists in the rack of the mechanical gear-track, resulting in a power loss issue for the base when the gear is suspended at this point. To ensure continuous and stable climbing power for the base, independent and complete drive gears have been installed at both the front and rear of the base. When one gear is suspended and loses power transmission due to the interruption of the rack, the other gear can continue to provide power. Taking the drive motor mechanism on one side as an example, it primarily consists of a drive motor, support components, bearings, a shaft, and a self-locking gear, and the composition of this mechanism is depicted in Figure 8.

3. Localization and Control Methods

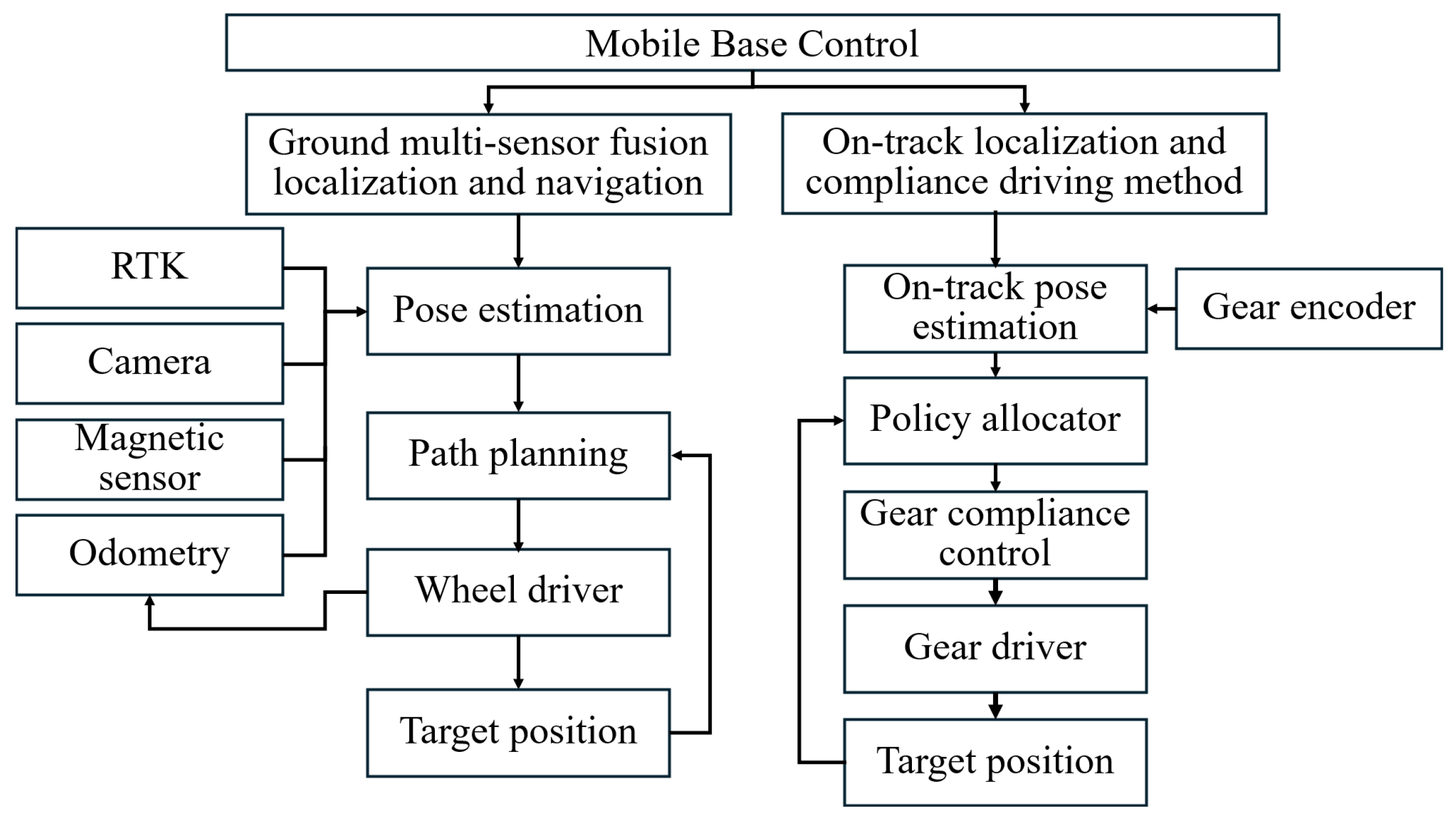

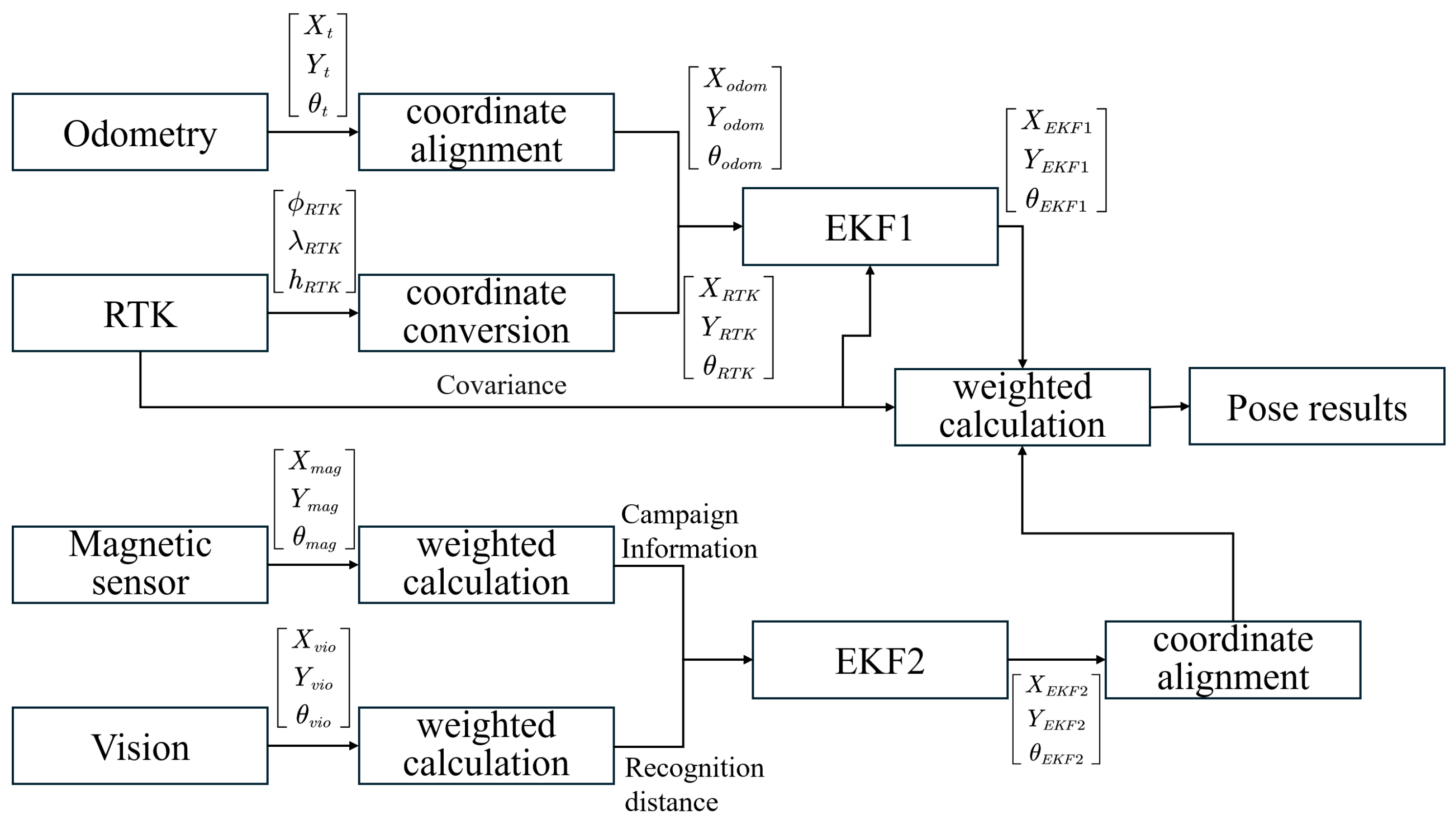

3.1. Localization and Control Framework

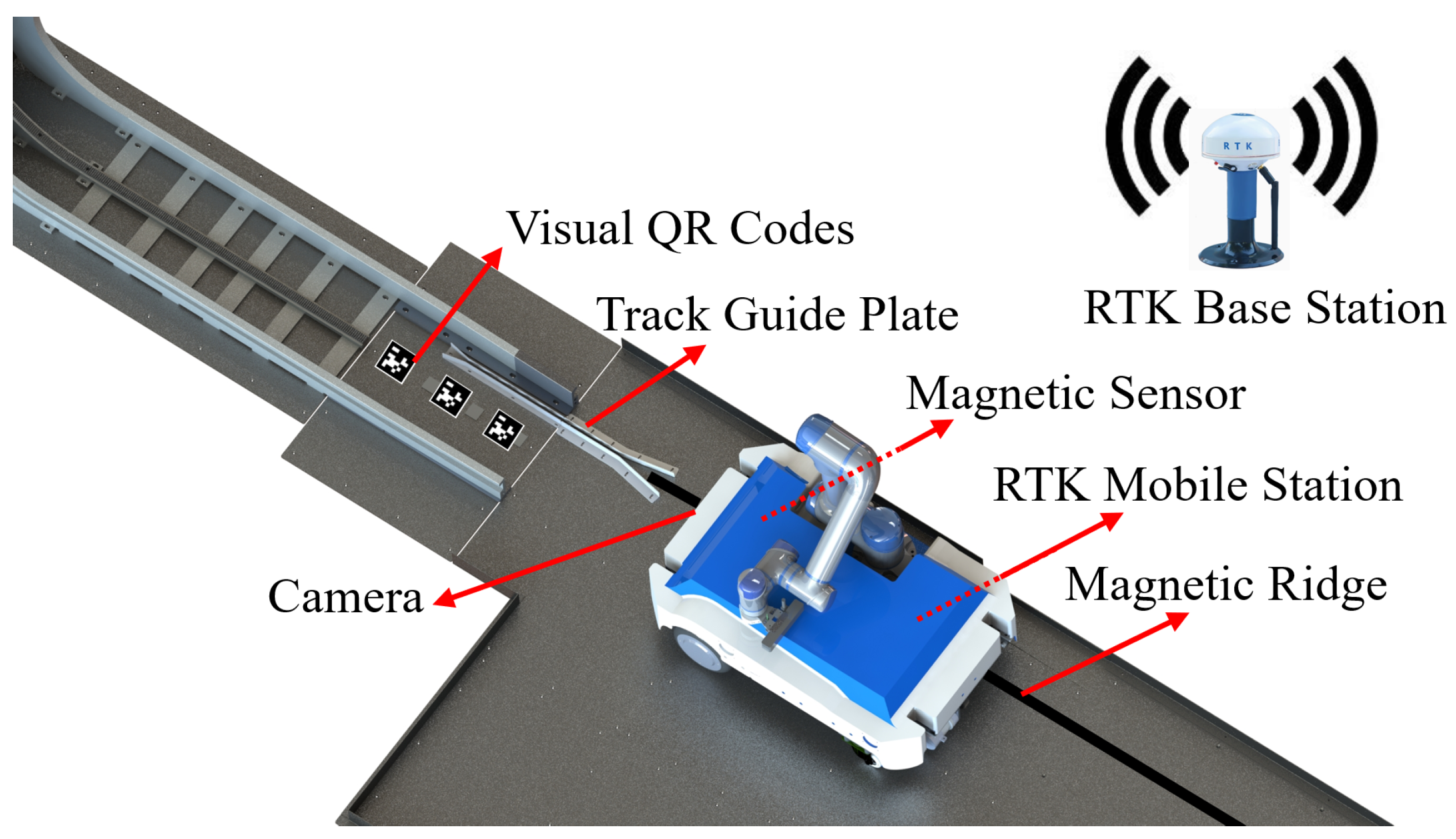

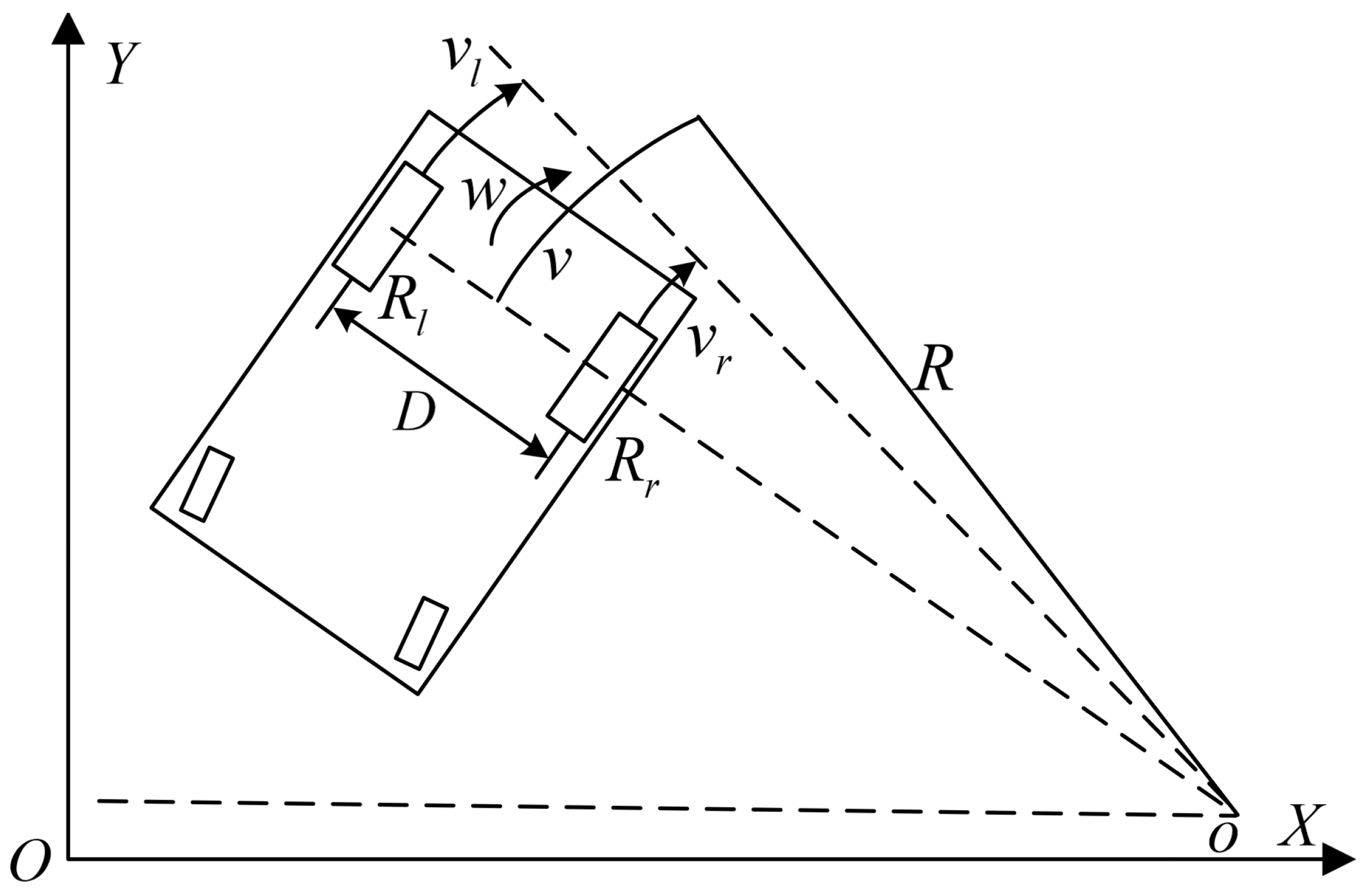

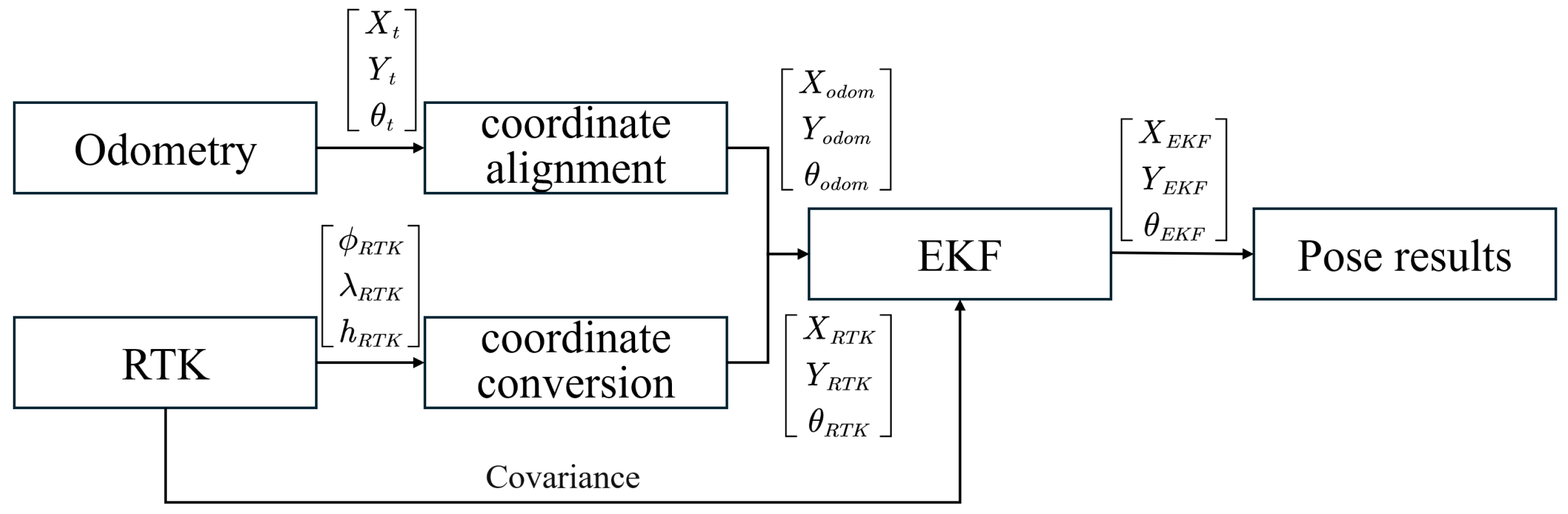

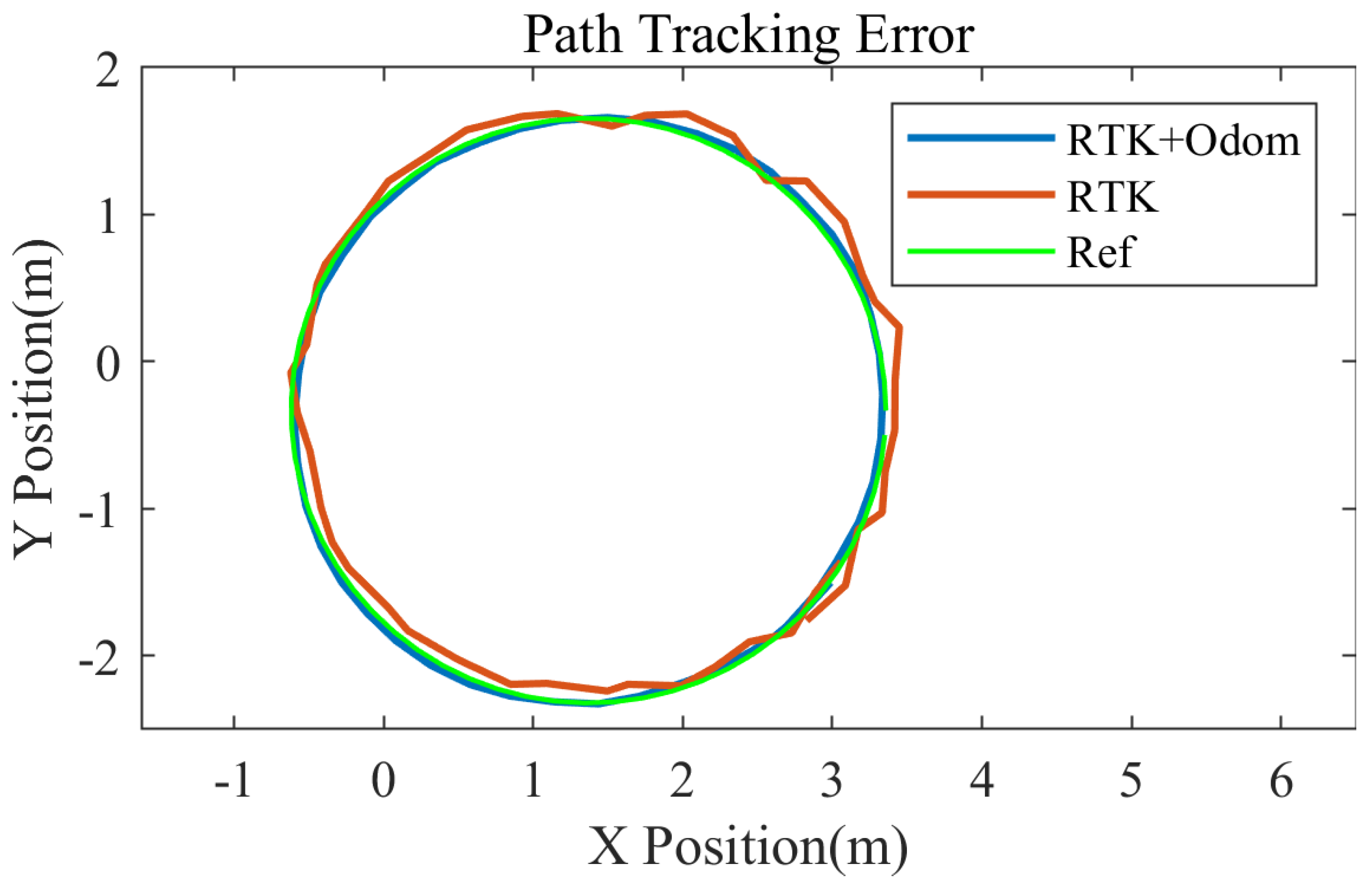

3.2. Ground Multi-Sensor Fusion Localization and Navigation Methods

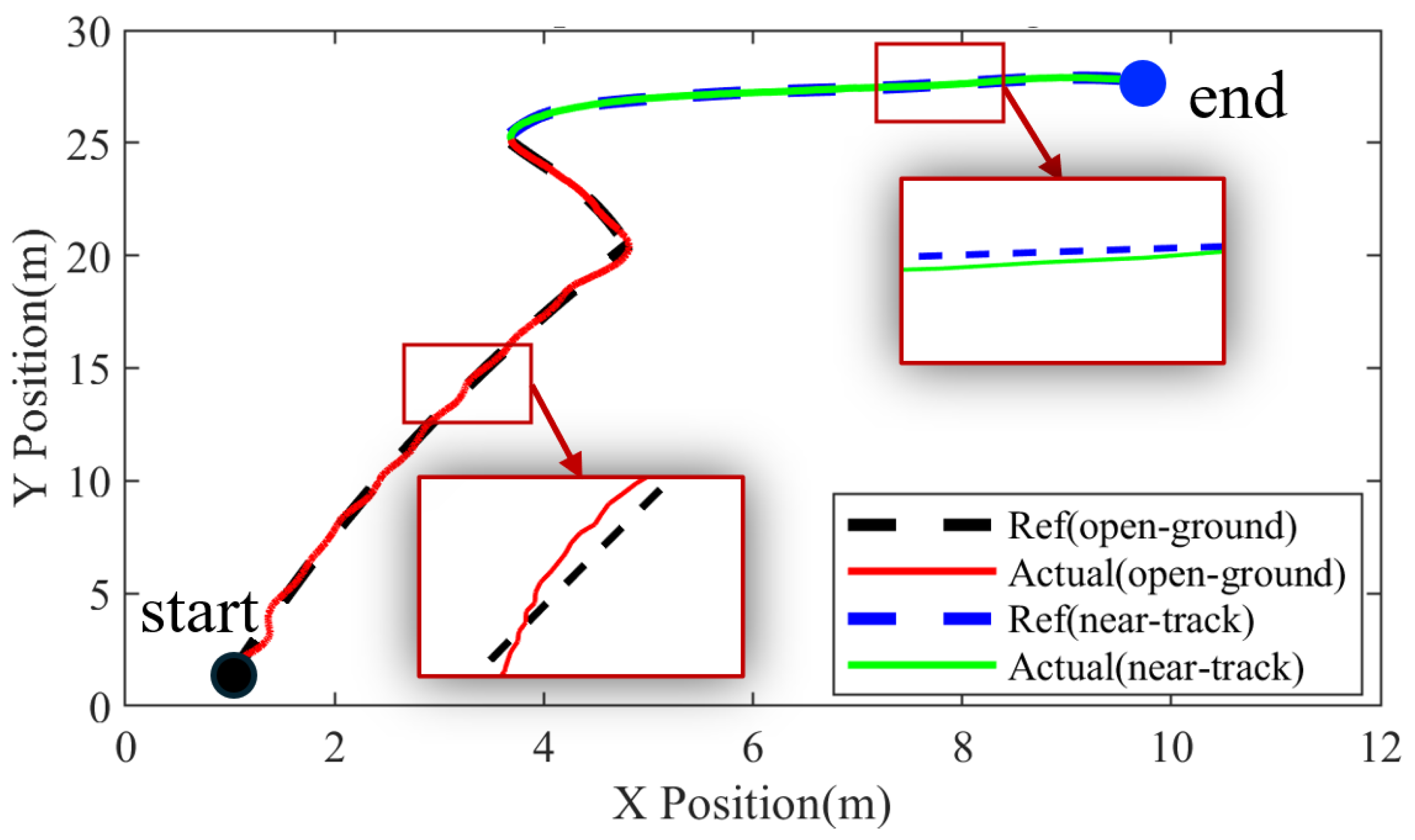

3.2.1. Methods for Open Ground

- State predictionThe pose of the mobile robot at the moment can be expressed asIn Equation (5), represents the state variable at time . denotes the control input to the system at time , while represents the motion noise at time . Finally, represents the relationship between the state variables and .Prediction of the pose estimate at the moment from the robot motion model:where is the estimated value of the positional attitude at the moment predicted by the motion model, and is the predicted value of the positional attitude at the moment k.The covariance matrix of the a priori estimates of the predicted state vector isIn Equation (7), and represent the covariance matrices of the pose and process noise , respectively. and represent the Jacobian matrices of the motion model and the Jacobian matrix of the process noise, respectively.

- State update.At time , the observation model for the localization information provided by RTK can be obtained as follows:In Equation (8), represents the system observation at time , represents the observation noise at time , and represents the pose values calculated by RTK.

- (1)

- Calculate the Kalman gain as follows:where represents the Kalman gain at time ; represents the Jacobian matrix of the measurement model, which is known to be the identity matrix according to the observation model; and represents the covariance matrix of the observation noise, provided by the RTK pose conversion package.In Equation (10), is the observed noise variance of the pose and attitude of the RTK output, respectively.

- (2)

- A posteriori of the state variables.

- (3)

- Update the covariance matrix to be the posterior estimate covariance matrix of the state variables:In the equation, is the third-order unit matrix.

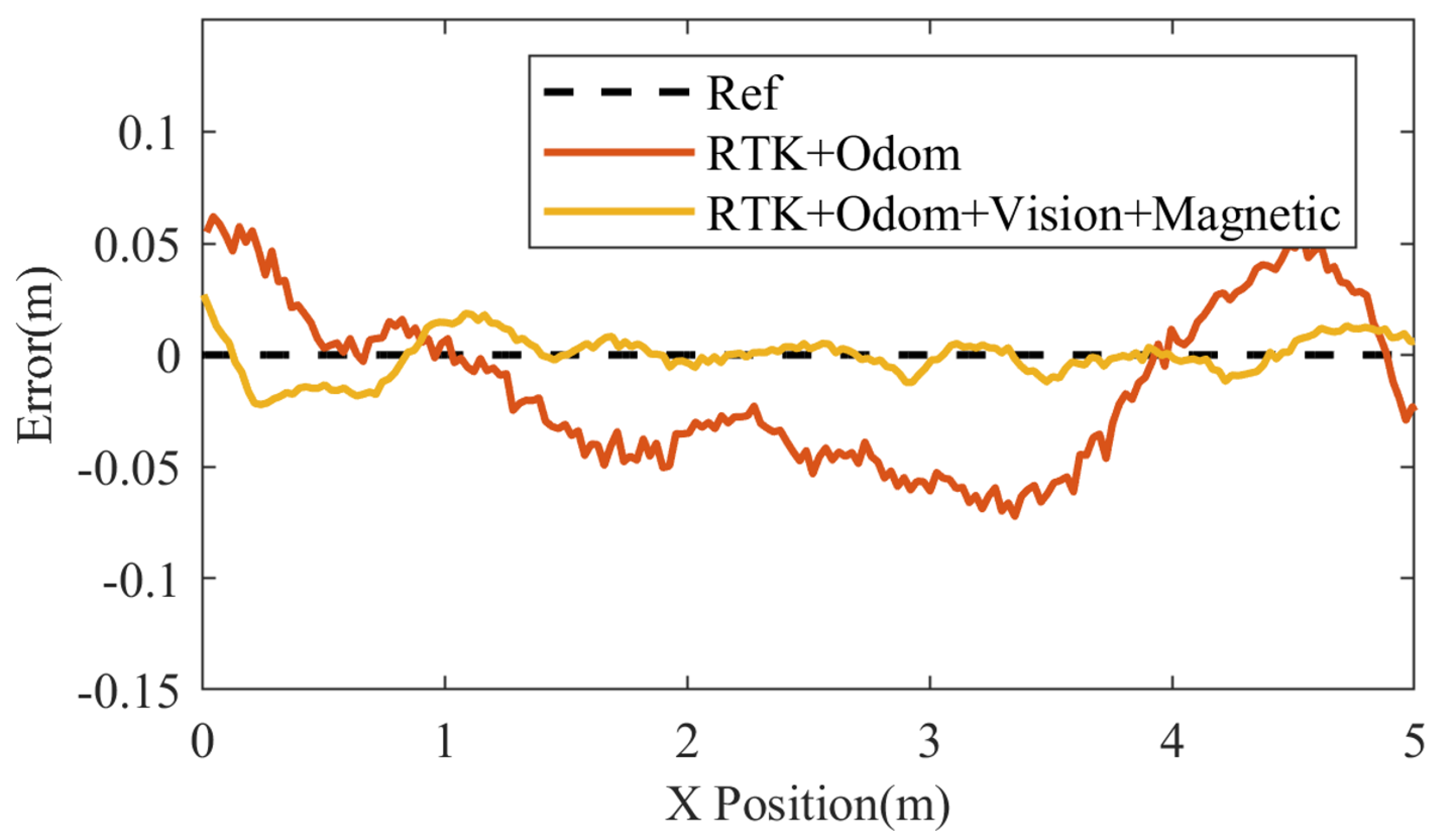

3.2.2. Method for Near-Track Areas

3.3. On-Track Localization and Compliance Driving Method

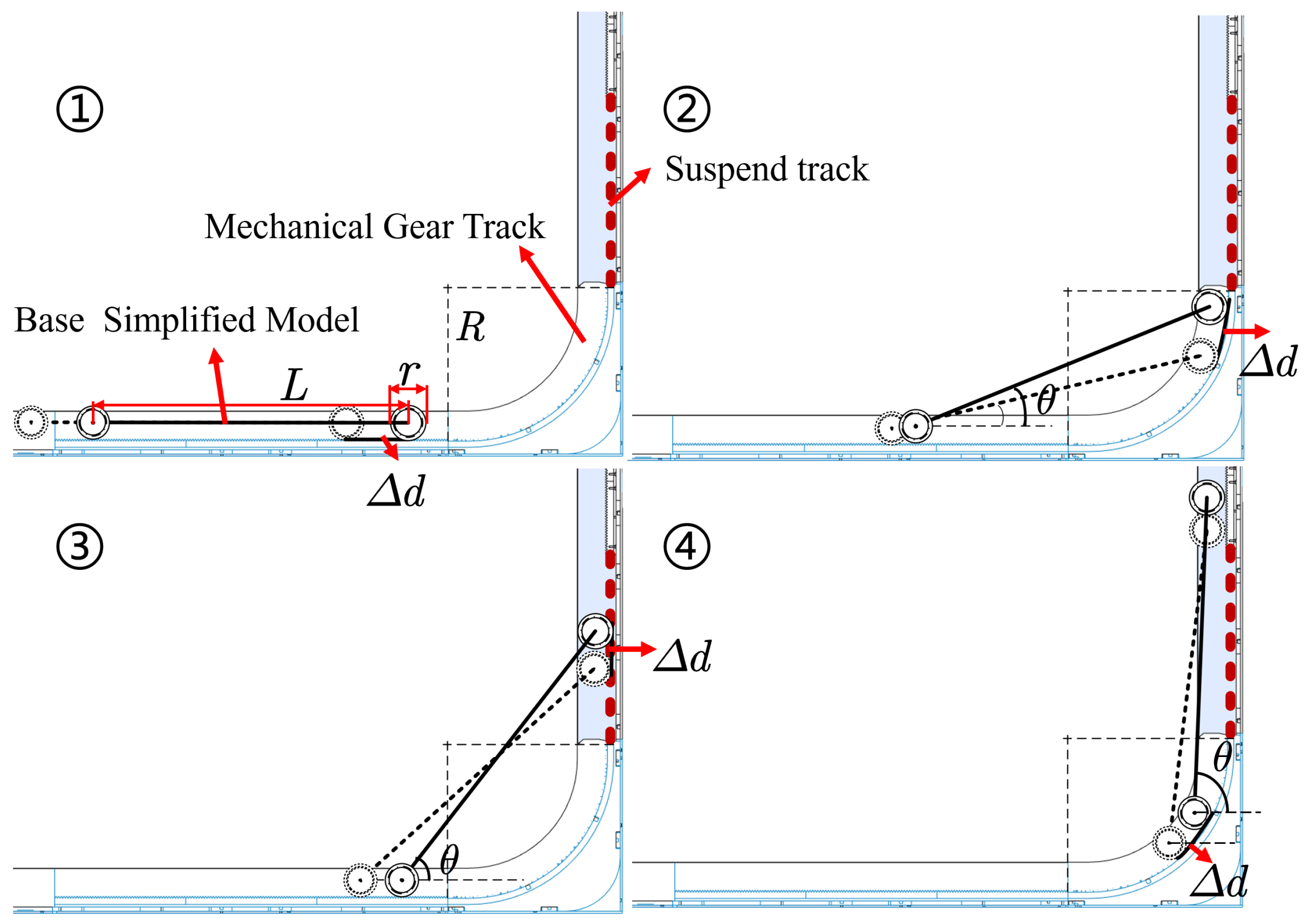

- When the robot enters the gear-track from the horizontal plane without entering the curved track, its current pose can be simply represented asIn this context, the base pitch angle is denoted as , the distance that the center of mass of the base moves forward relative to the starting point of the rack is denoted as y, and the elevation height of the base center of mass is denoted as z. The arc length traversed by the gear during the time interval is denoted as . The pose information for the first three stages is recorded to facilitate the calculation of poses in the subsequent stage, with the pitch angles designated as and the positions as .

- Subsequently, the front drive gear enters the curved track. Due to constraints in mechanical design, the rear drive gear remains on the horizontal track. At this point, considering the continuity of motion and neglecting the minor distance discrepancies caused by the bending of the rack, let the diameter of the drive gear be denoted as r and the spacing between the two drive gears as L. The designed curved track is effectively a segment of a circle with a radius denoted as R. Thus, denoting the variable as , the following relationship can be established:and it can be concluded that the current pose is

- As the front gear traverses the curved track, the rear gear remains on the horizontal track, thereby yielding the following result:and it can be concluded that the current pose is

- As the front gear traverses the suspended segment of the track, the rear gear will move onto the curved track. Similarly, by neglecting the minor distance differences caused by the slight deformation of the rack due to bending, the following result can be obtained:and it can be concluded that the current pose is

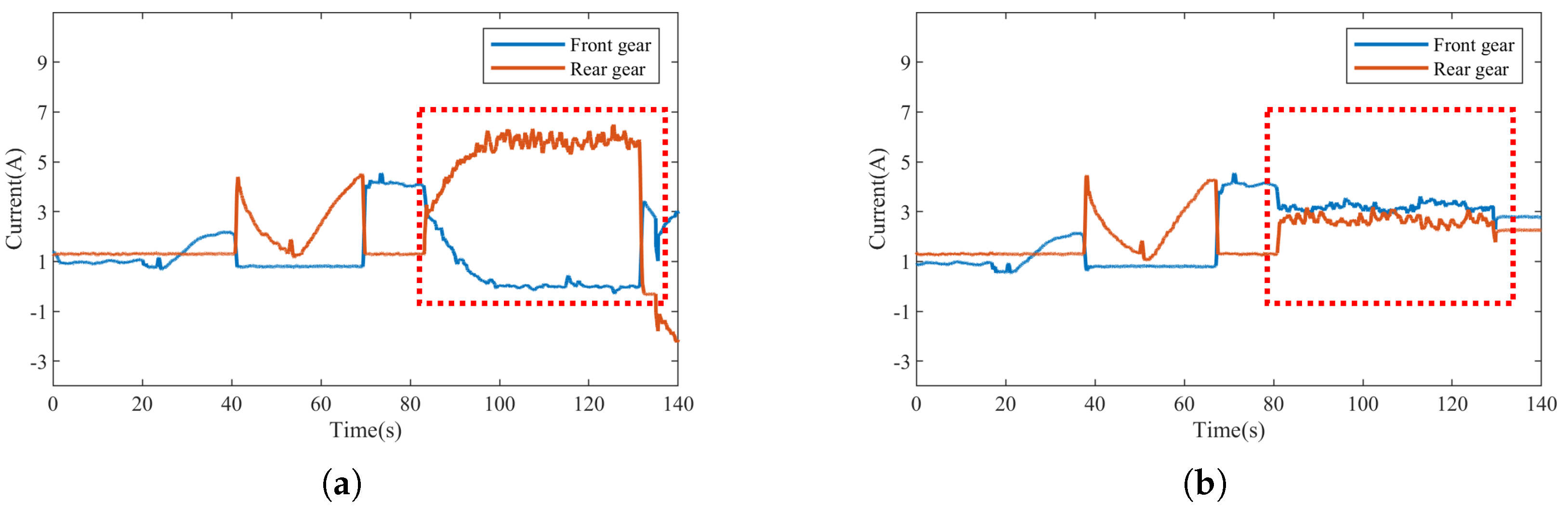

- When the robot begins to ascend at a level where the front gear can still provide effective driving force, the front gear operates at a constant speed while the rear gear adjusts its torque through an adaptive controller. This adjustment is made in real-time, based on the curvature of the curve and the current speed of the robot, thereby altering the driving current of the rear gear.

- When the front gear of the robot transitions to a suspended state and loses driving force, the rear gear provides the necessary driving force. During this period, the front gear will undergo a process of transitioning from suspension to contact with the rack. The adaptive controller adjusts the driving current of the front gear in real-time based on the distribution of the interruption points in the track and the current speed of the robot to match the driving speed of the rear gear.

- Ultimately, the front gear will continuously operate on a vertical track, while the rear gear will experience a process of transitioning from suspension to contact with the rack. It is essential to monitor the control current of the front driving gear at a constant speed to ensure the rear driving gear matches this current appropriately.

- In the final ascent motion, both driving gears are positioned on the vertical track, and the driving current of the rear gear is adjusted in real-time to match that of the front gear, ensuring coordinated and stable rotation, thereby achieving a steady state of ascent.

4. Experiments and Conclusions

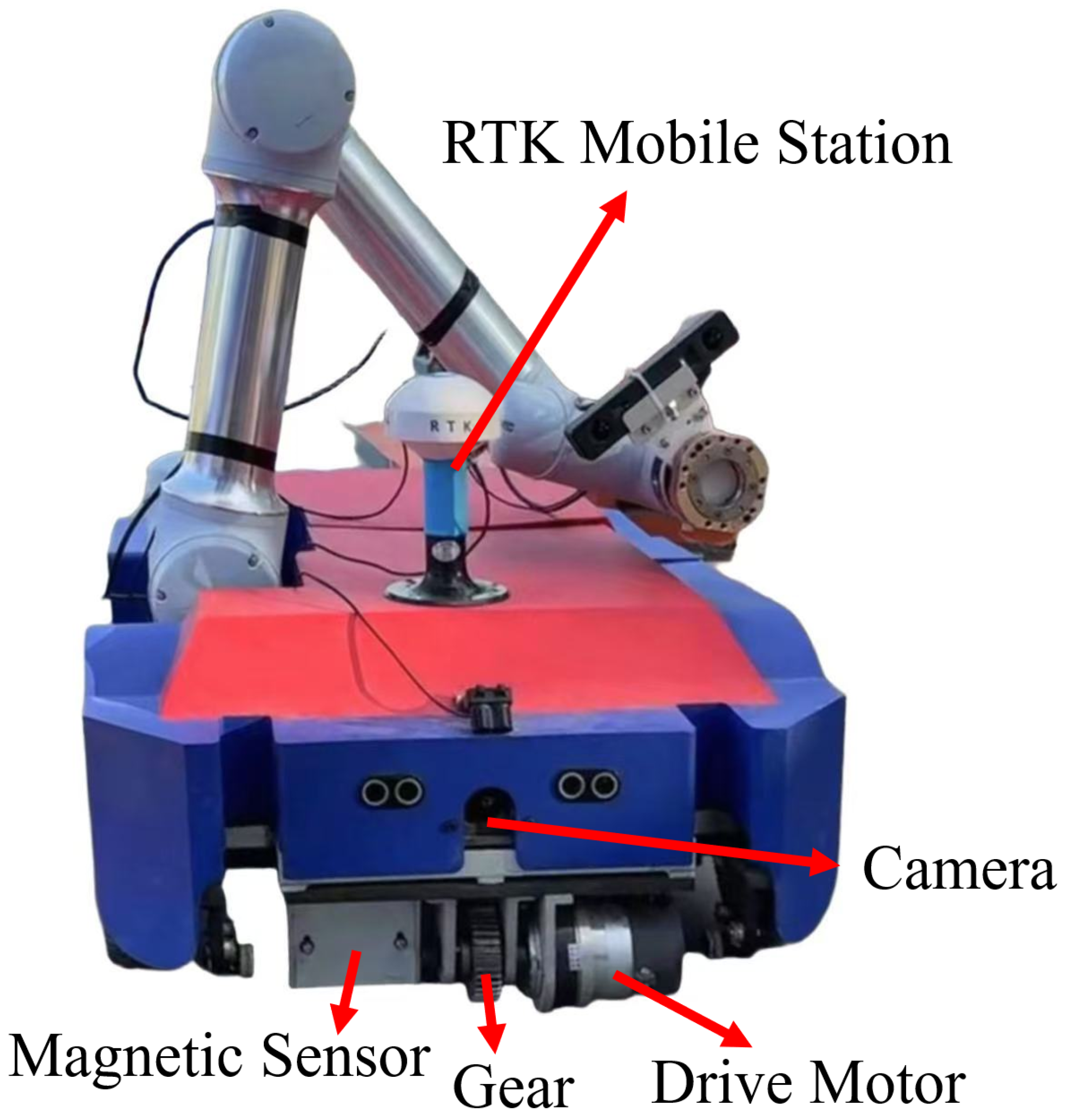

4.1. Experimental Hardware Composition

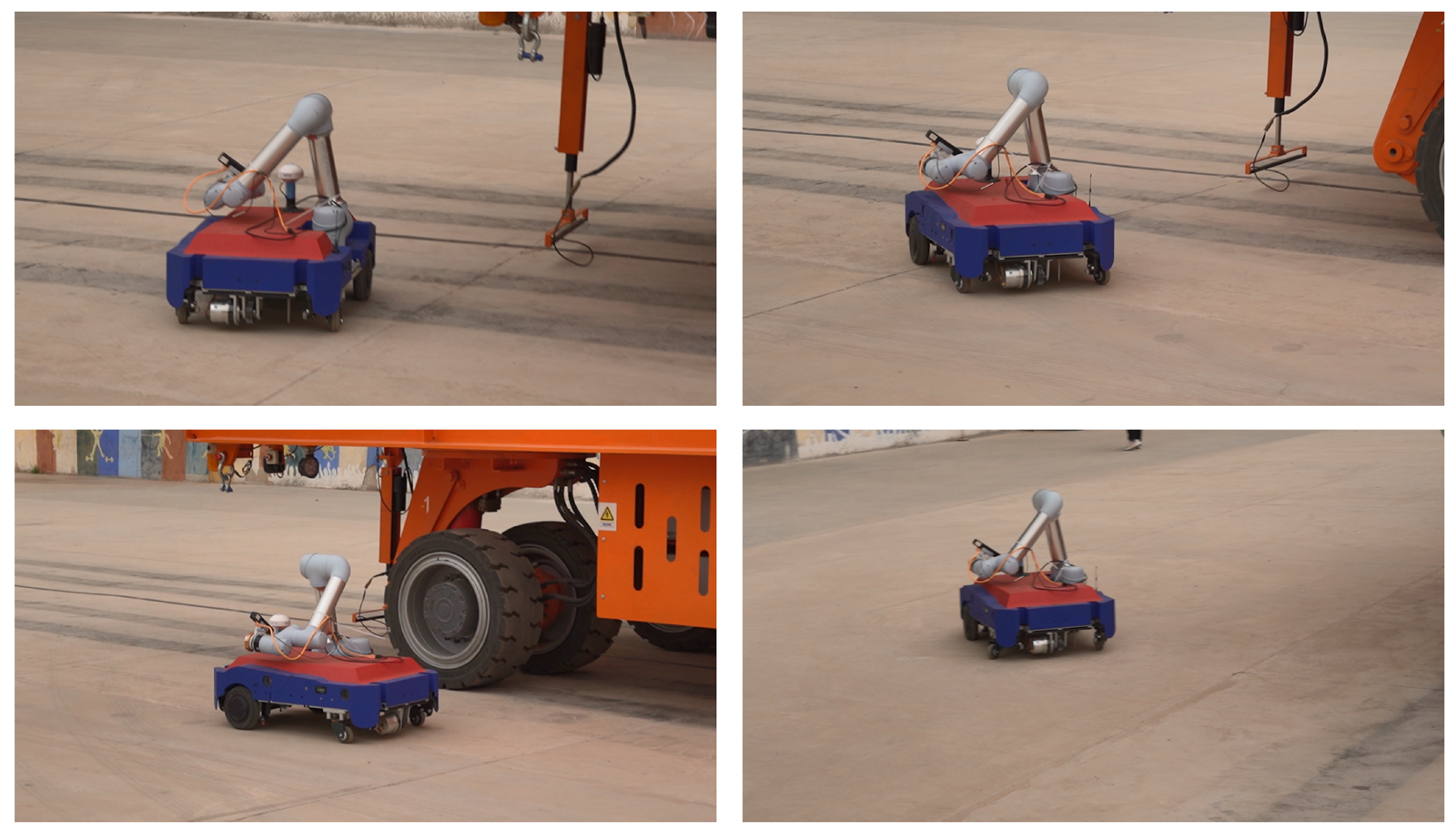

4.2. Ground Navigation Experiments

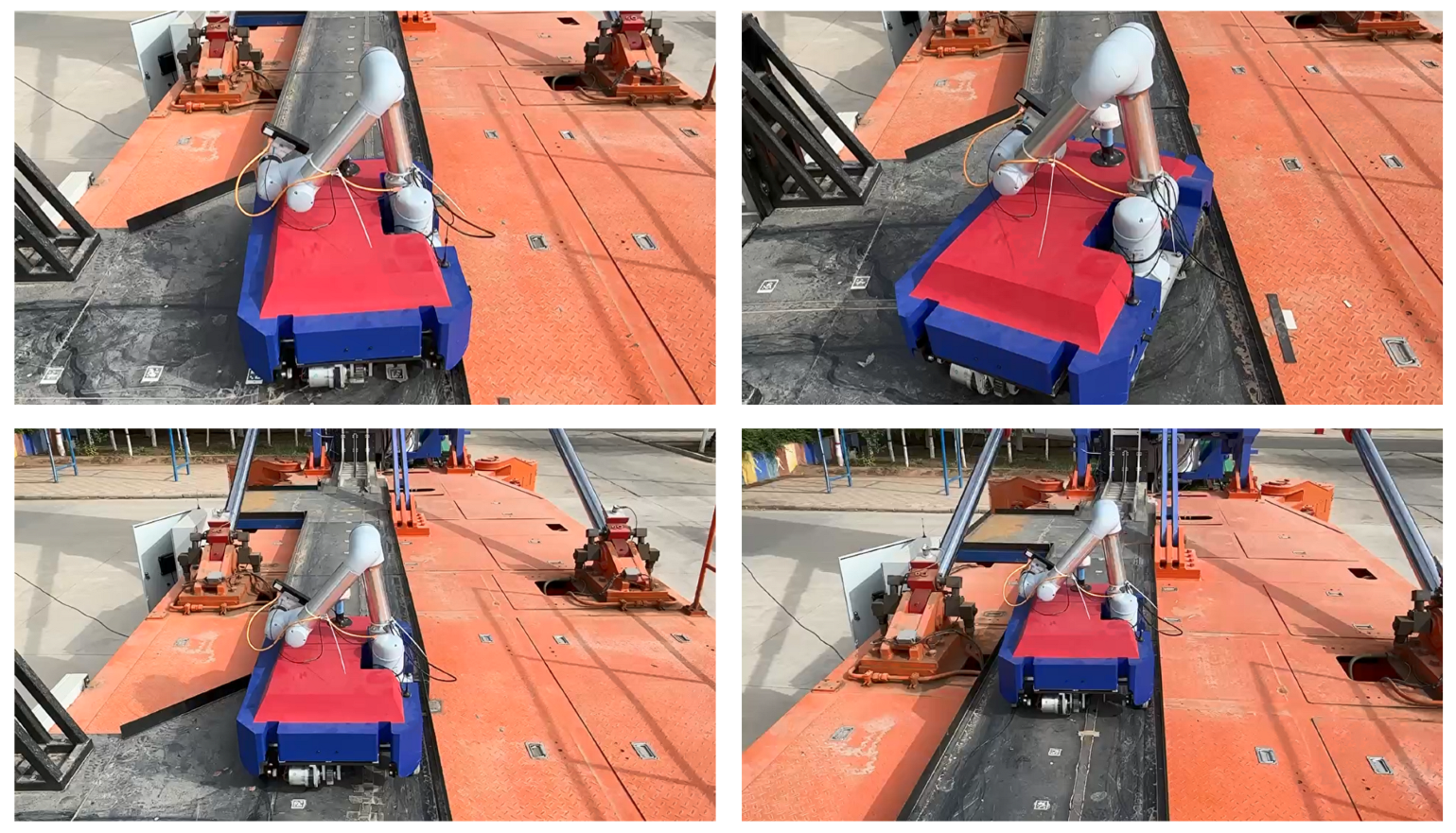

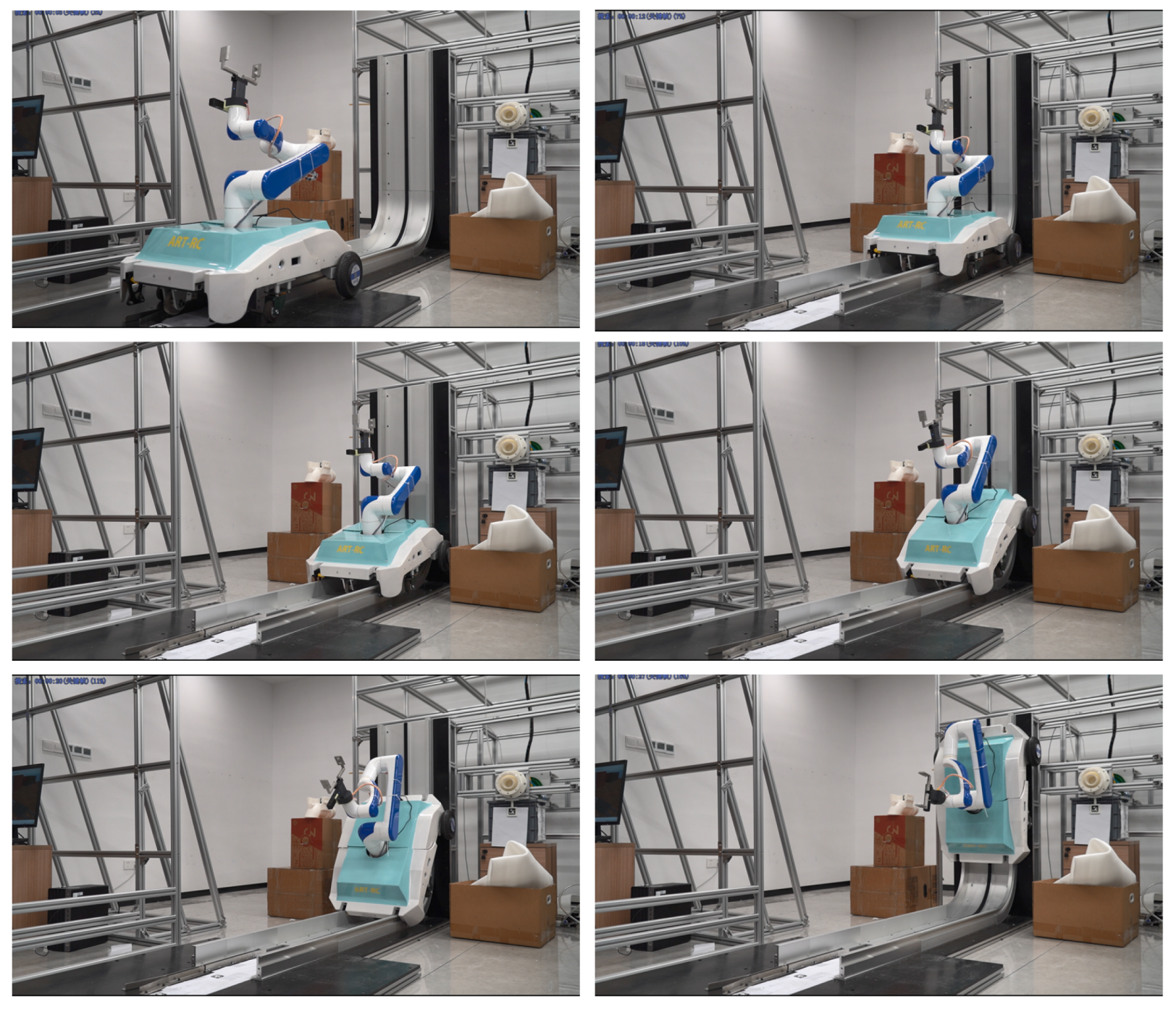

4.3. Gear-Track Climbing Experiments

4.4. Complete Tasks’ Experiments

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sandakalum, T.; Ang, M.H., Jr. Motion planning for mobile manipulators—A systematic review. Machines 2022, 10, 97. [Google Scholar] [CrossRef]

- Sun, F.; Chen, Y.; Wu, Y.; Li, L.; Ren, X. Motion planning and cooperative manipulation for mobile robots with dual arms. IEEE Trans. Emerg. Top. Comput. Intell. 2022, 6, 1345–1356. [Google Scholar]

- Honerkamp, D.; Büchner, M.; Despinoy, F.; Welschehold, T.; Valada, A. Language-grounded dynamic scene graphs for interactive object search with mobile manipulation. IEEE Robot. Autom. Lett. 2024, 9, 8298–8305. [Google Scholar] [CrossRef]

- Ding, L.; Xing, H.; Torabi, A.; Mehr, J.K.; Sharifi, M.; Gao, H.; Mushahwar, V.K.; Tavakoli, M. Intelligent assistance for older adults via an admittance-controlled wheeled mobile manipulator with task-dependent end-effectors. Mechatronics 2022, 85, 102821. [Google Scholar]

- Thakar, S.; Malhan, R.K.; Bhatt, P.M.; Gupta, S.K. Area-coverage planning for spray-based surface disinfection with a mobile manipulator. Robot. Auton. Syst. 2022, 147, 103920. [Google Scholar]

- Piyapunsutti, S.; De Guzman, E.L.; Chaichaowarat, R. Navigating Mobile Manipulator Robot for Restaurant Application Using Open-Source Software. In Proceedings of the 2023 IEEE International Conference on Robotics and Biomimetics (ROBIO), Koh Samui, Thailand, 4–9 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Tadakuma, K.; Tadakuma, R.; Nagatani, K.; Yoshida, K.; Peters, S.; Udengaard, M.; Iagnemma, K. Crawler vehicle with circular cross-section unit to realize sideways motion. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 2422–2428. [Google Scholar]

- Tadakuma, K.; Tadakuma, R.; Kinoshita, H.; Nagatani, K.; Yoshida, K.; Udengaard, M.; Iagnemma, K. Mechanical design of cylindrical track for sideways motion. In Proceedings of the 2008 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 5–8 August 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 161–167. [Google Scholar]

- Ernits, R.M.; Hoppe, N.; Kuznetsov, I.; Uriarte, C.; Freitag, M. A new omnidirectional track drive system for off-road vehicles. In Proceedings of the XXII International Conference on Material Handling, Constructions and Logistics, Belgrade, Serbia, 4–6 October 2017. [Google Scholar]

- Fiedeń, M.; Bałchanowski, J. A mobile robot with omnidirectional tracks—Design and experimental research. Appl. Sci. 2021, 11, 11778. [Google Scholar] [CrossRef]

- Xiao, Y.; Yan, Y.; Yu, Y.; Wang, B.; Liang, Y. Research on pose adaptive correction method of indoor rail mounted inspection robot in GIS Substation. Energy Rep. 2022, 8, 696–705. [Google Scholar]

- Masuda, N.; Khalil, M.M.; Toda, S.; Takayama, K.; Kanada, A.; Mashimo, T. A Suspended Pollination Robot with a Flexible Multi-Degrees-of-Freedom Manipulator for Self-Pollinated Plants. IEEE Access 2024, 12, 142449–142458. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, Y.; Liu, X.; Wang, B.; Zhang, L.; Nie, Z. Research on motion planning system for wall-climbing mobile manipulator for large steel structures welding operation. Ind. Robot. Int. J. Robot. Res. Appl. 2024, 52, 73–83. [Google Scholar]

- Liu, Y.; Wang, H.; Hu, C.; Zhou, Q.; Li, P. A Spiny Climbing Robot with Dual-Rail Mechanism. Biomimetics 2023, 8, 14. [Google Scholar] [CrossRef] [PubMed]

- Ganz, S.; Käber, Y.; Adler, P. Measuring tree height with remote sensing—A comparison of photogrammetric and LiDAR data with different field measurements. Forests 2019, 10, 694. [Google Scholar] [CrossRef]

- Kim, H.; Hyun, C.U.; Park, H.D.; Cha, J. Image mapping accuracy evaluation using UAV with standalone, differential (RTK), and PPP GNSS positioning techniques in an abandoned mine site. Sensors 2023, 23, 5858. [Google Scholar] [CrossRef] [PubMed]

- Rix, B.; Nebeling, A.; Raab, T. Distance measurement using near infrared sensors. In Proceedings of the Energy Consumption and Autonomous Driving: Proceedings of the 3rd CESA Automotive Electronics Congress, Paris, France, 3–4 December 2014; Springer: Berlin/Heidelberg, Germany, 2016; pp. 177–189. [Google Scholar]

- Štibinger, P.; Broughton, G.; Majer, F.; Rozsypálek, Z.; Wang, A.; Jindal, K.; Zhou, A.; Thakur, D.; Loianno, G.; Krajník, T.; et al. Mobile manipulator for autonomous localization, grasping and precise placement of construction material in a semi-structured environment. IEEE Robot. Autom. Lett. 2021, 6, 2595–2602. [Google Scholar]

- Basiri, M.; Gonçalves, J.; Rosa, J.; Bettencourt, R.; Vale, A.; Lima, P.U. A multipurpose mobile manipulator for autonomous firefighting and construction of outdoor structures. Field Robot. 2021, 1, 102–126. [Google Scholar]

- Pastor, F.; Ruiz-Ruiz, F.J.; Gómez-de Gabriel, J.M.; García-Cerezo, A.J. Autonomous wristband placement in a moving hand for victims in search and rescue scenarios with a mobile manipulator. IEEE Robot. Autom. Lett. 2022, 7, 11871–11878. [Google Scholar] [CrossRef]

- Cui, B.; Zhang, J.; Wei, X.; Cui, X.; Sun, Z.; Zhao, Y.; Liu, Y. Improved Information Fusion for Agricultural Machinery Navigation Based on Context-Constrained Kalman Filter and Dual-Antenna RTK. In Proceedings of the Actuators, Wiesbaden, Germany, 13–14 June 2024; MDPI: Basel, Switzerland, 2024; Volume 13, p. 160. [Google Scholar]

- Woo, H.J.; Yoon, B.J.; Cho, B.G.; Kim, J.H. Research into navigation algorithm for unmanned ground vehicle using real time kinemtatic (RTK)-GPS. In Proceedings of the 2009 ICCAS-SICE, Fukuoka, Japan, 18–21 August 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 2425–2428. [Google Scholar]

- Feng, Y.; Wang, J. GPS RTK performance characteristics and analysis. Positioning 2008, 1, 1–8. [Google Scholar] [CrossRef]

- Valente, D.S.M.; Momin, A.; Grift, T.; Hansen, A. Accuracy and precision evaluation of two low-cost RTK global navigation satellite systems. Comput. Electron. Agric. 2020, 168, 105142. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Gong, C.; Fan, L.; Liu, G.; Zheng, Y.; Shen, T.; Suo, X. A Novel Ground-to-Elevated Mobile Manipulator Base System for High-Altitude Operations. Machines 2025, 13, 288. https://doi.org/10.3390/machines13040288

Wu H, Gong C, Fan L, Liu G, Zheng Y, Shen T, Suo X. A Novel Ground-to-Elevated Mobile Manipulator Base System for High-Altitude Operations. Machines. 2025; 13(4):288. https://doi.org/10.3390/machines13040288

Chicago/Turabian StyleWu, Hongjia, Chengzhang Gong, Li Fan, Guoan Liu, Yonghuang Zheng, Tingzheng Shen, and Xiangbo Suo. 2025. "A Novel Ground-to-Elevated Mobile Manipulator Base System for High-Altitude Operations" Machines 13, no. 4: 288. https://doi.org/10.3390/machines13040288

APA StyleWu, H., Gong, C., Fan, L., Liu, G., Zheng, Y., Shen, T., & Suo, X. (2025). A Novel Ground-to-Elevated Mobile Manipulator Base System for High-Altitude Operations. Machines, 13(4), 288. https://doi.org/10.3390/machines13040288