2.1. Structural Design of Birotor Machines

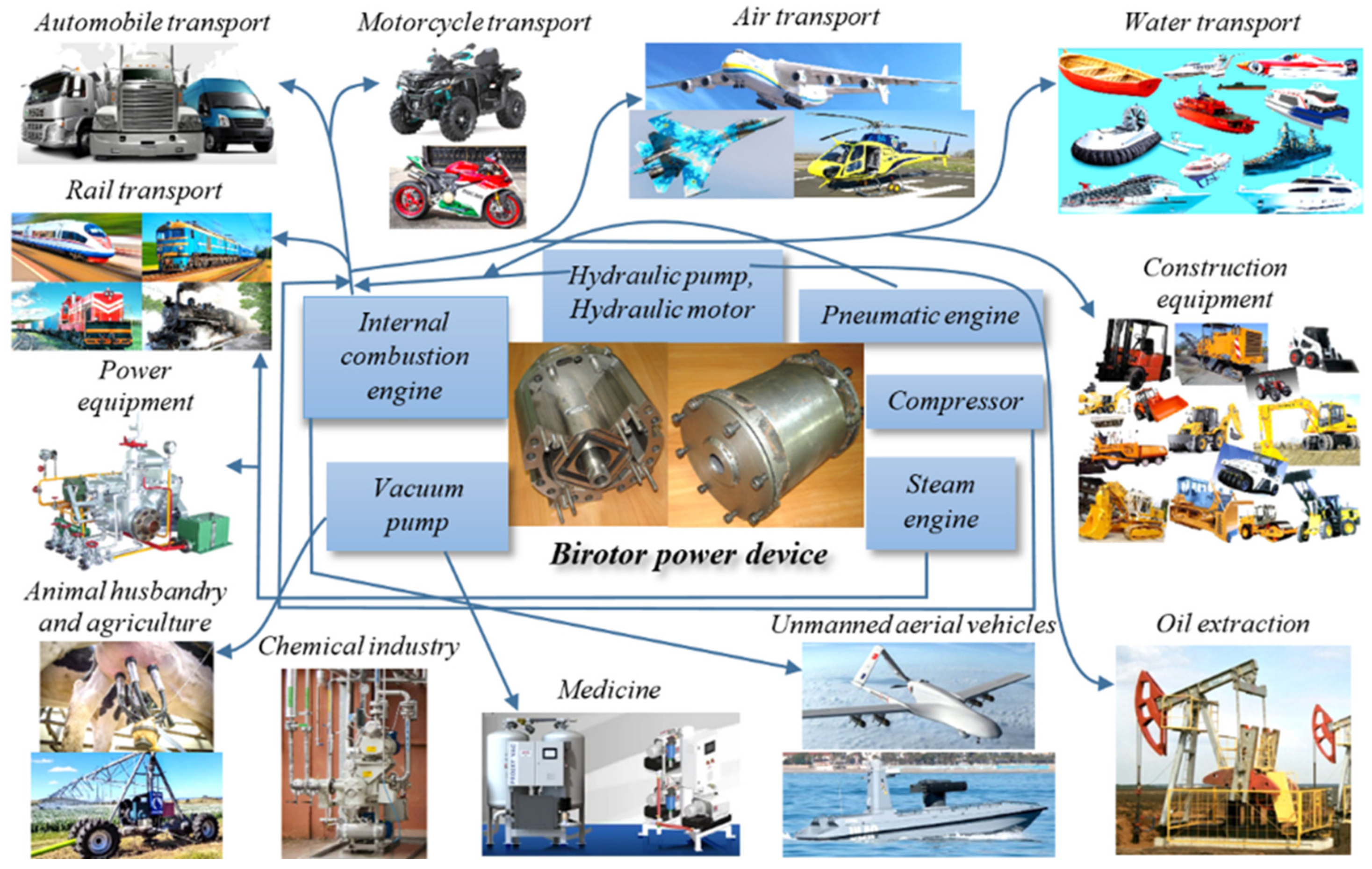

The aim of this article is to highlight promising directions for the application of birotor machines (BM) (

Figure 1) as components of technical systems across various sectors of the national economy under modern transport conditions. Scientific and engineering research conducted by the authors in the development of BM has demonstrated [

1,

2,

7,

10] that, due to their structural design, these machines combine the advantages of both piston and rotary volumetric machines. These advantages include:

reliable sealing of working chambers (ensuring high durability),

excellent dynamic balance (resulting in low vibration levels),

minimal requirements for material quality,

compact size and low weight,

ease of manufacturing,

low production cost,

high maintainability, and

no need for additional balancing mechanisms.

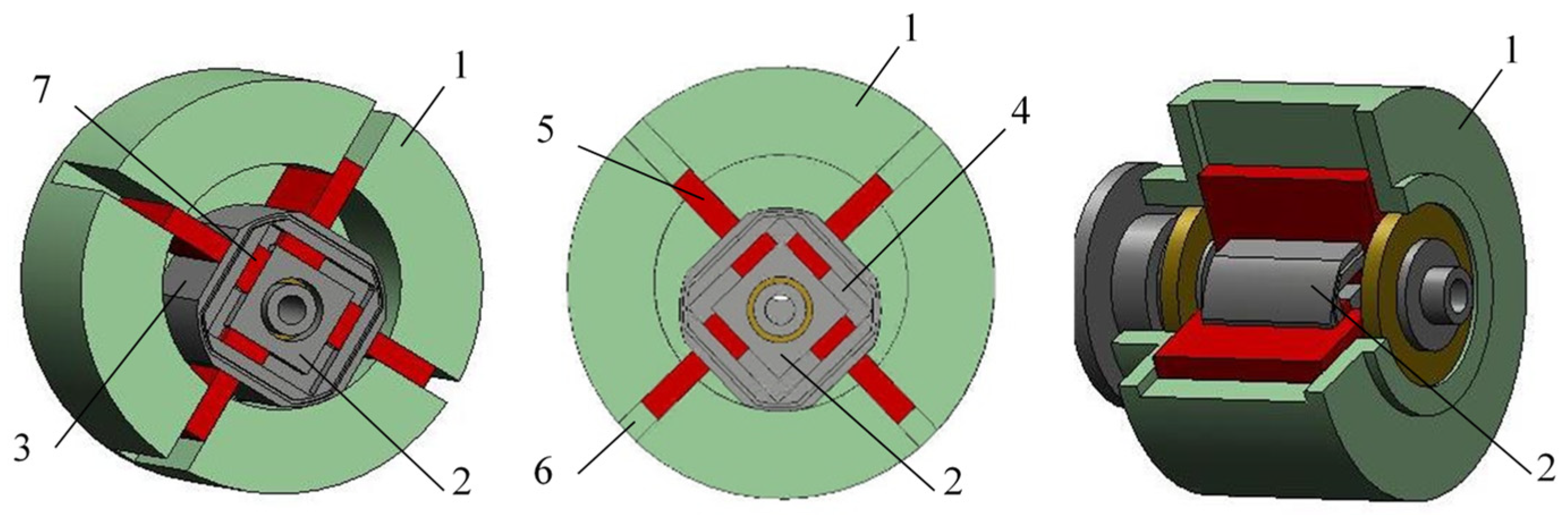

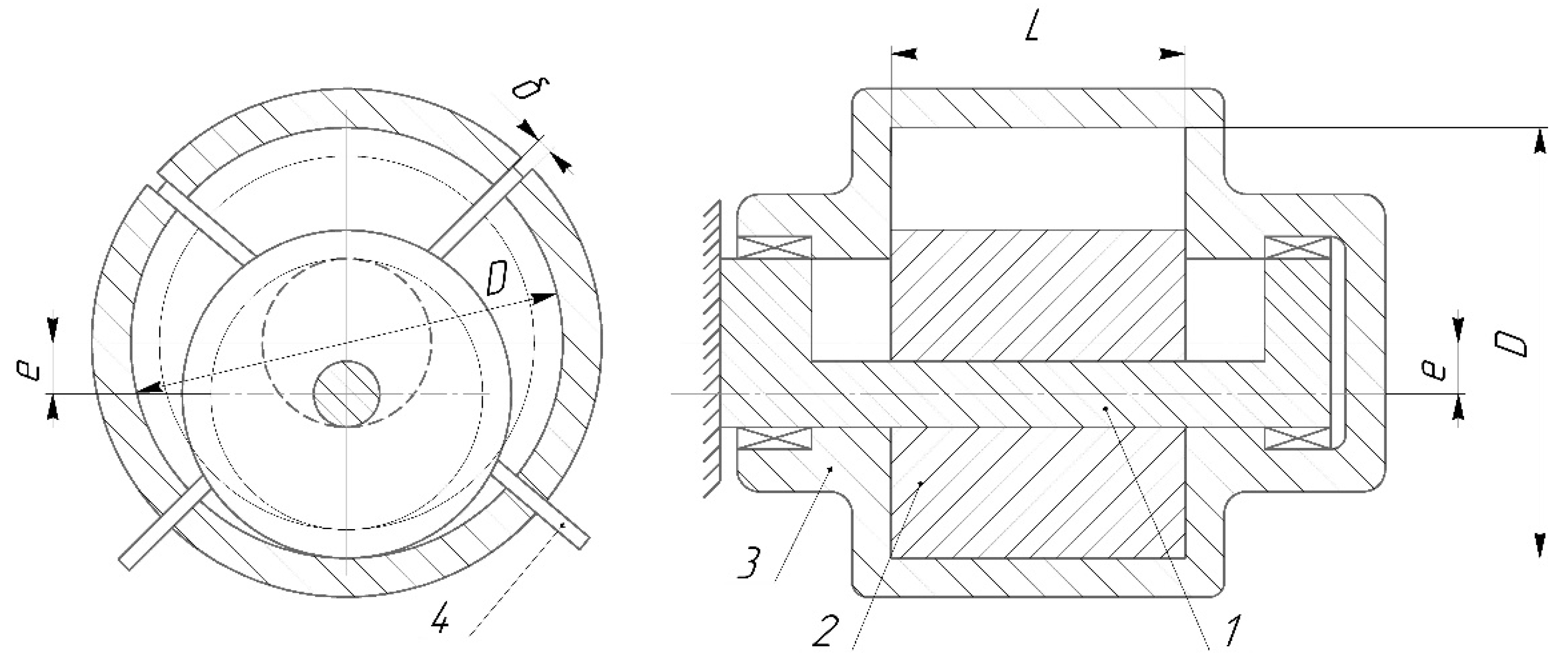

A birotor machine (

Figure 2) features a mechanism in which an axis with two eccentric journals—offset relative to each other—remains stationary. Each journal serves as the rotational axis for the housing (1) and the rotor (2), respectively. The housing is a cylindrical shell enclosed at both ends with side covers. The rotor, located inside the housing, has flat end faces (3) and parallel grooves (4) on its ends. The cavity between the housing and the rotor is divided into sealed working chambers by shutters (5), which are installed in radial grooves (6) of the housing and connected to the rotor via sliders (7). Torque is extracted from the rotating housing. For the BM to operate, a minimum of two shutters is required, while the maximum number is theoretically unlimited.

Such a birotor machine can be configured to operate as a four-stroke or two-stroke internal combustion engine, a hydraulic supercharger (pump), a hydraulic motor, a high-pressure fuel pump, a pneumatic supercharger (compressor), a pneumatic or steam motor, or a vacuum pump.

Research has demonstrated that birotor machines (BM) can be effectively utilized as hydraulic superchargers (pumps) [

5] or hydraulic motors, achieving efficiencies up to 96%. These machines are suitable for integration into hydraulic drive systems across a wide range of applications, including water, sea, and river transport; road and railway vehicles; construction and lifting equipment; agricultural machinery; ground vehicle transmissions; and hydraulic systems in aircraft and rotorcraft.

Currently, axial-piston and radial-piston devices are commonly used as hydraulic pumps and motors. However, these conventional systems are highly complex, heavy, bulky, expensive, and difficult to repair. For instance, the axial-piston hydraulic machine MH-250/100 (M+S Hydraulic PLC, Kazanlak, Bulgaria), used in diesel locomotives to drive radiator cooling fans, weighs 79 kg and has dimensions of 470 × 220 × 152 mm (volume: 0.16 m3). In contrast, a rotary hydraulic machine with equivalent performance weighs only 21 kg and measures 190 × 190 × 186 mm (volume: 0.067 m3).

Moreover, axial-piston machines cannot be repaired in standard depot conditions and require specialized aircraft repair facilities. In comparison, BM-type hydraulic machines are significantly easier to maintain and can be serviced directly within the depot, offering a practical and cost-effective alternative.

The integration of birotor machines (BM) as components of vehicle hydraulic transmissions—specifically as hydraulic pumps and motors—eliminates the need for complex and costly mechanical systems such as clutches, gearboxes, differentials, and cardan shafts. Hydraulic systems allow for flexible placement of the power unit with a hydraulic pump anywhere within the vehicle, transmitting torque to hydraulic motors or motor-wheels via fluid through pipelines and hoses. Due to their compact size and low weight, BM-based hydraulic transmission systems represent a highly promising direction for future development.

The use of BM as compressors [

14,

15,

16,

17,

18,

19], in place of conventional piston compressors commonly used in vehicles, offers significant advantages. These include a 3–5-fold reduction in weight and dimensions, and a 2–3-fold decrease in cost. Research conducted by the authors has shown that piston compressors suffer from several drawbacks: large mass and volume, high vibration levels, and excessive power consumption. These issues stem from the inherent design of crank mechanisms, which involve reciprocating motion of heavy components, leading to substantial inertial loads and imbalance. Reducing vibration in such systems is a complex engineering challenge, often requiring major design modifications aimed at balancing these inertial forces.

In contrast, rotary compressors—such as birotor compressors (BC)—offer superior performance in terms of weight, size, and vibration characteristics. For example,

Table 1 presents specifications of existing piston compressors [

18,

19,

20,

21] used in rolling stock, while

Table 2 outlines projected specifications for BCs intended for air supply systems in the same applications.

A working prototype of a BC for subway cars has already been developed. It features a working volume of 456 cm

3, delivers a pressure of 0.8 MPa (8 atmospheres), and achieves a flow rate of 0.43 m

3/min at 1500 rpm. The unit weighs 32 kg and has dimensions of 220 × 228 × 325 mm. In comparison, the currently used piston compressor ЭK-4 weighs 130 kg and measures 520 × 583 × 465 mm. Bench testing has been completed, and design documentation for an improved version of the compressor has been prepared [

4,

9].

These findings underscore the importance of continued research and development aimed at reducing the vibration, weight, size, and energy consumption of reciprocating compressors.

2.2. Birotor Machines in Internal Combustion Engines Design

BM technology is also relevant for use in internal combustion engines (ICE), both two-stroke and four-stroke, particularly for compact autonomous power units in various sectors: marine (especially sea transport), aviation, land transport, and portable mechanical tool systems [

5,

8]. This approach can reduce weight and size by 3–5 times, lower costs by 2–4 times, and improve reliability, efficiency, and service life.

Structurally, ICEs based on birotor energy devices differ from conventional designs by employing simultaneous rotation of both the housing and the rotor. This enables centripetal movement of the working mixture and cooling air, efficient unidirectional slit scavenging, and effective sealing of working chambers—all without the need for a traditional ignition system.

It is important to note that birotor internal combustion engines (BRICE) offer several advantages over conventional rotary and piston internal combustion engines, including:

Simplicity of design—due to the use of geometrically simple components.

High manufacturability—components can be produced without the need for specialized equipment.

Compact dimensions—BRICE units are 3–4 times smaller than equivalent piston-type engines.

Low material consumption and weight—resulting in lighter and more efficient systems.

High reliability and durability—achieved through the use of simple rotational motion of many components on rolling bearings and reliable sealing elements, each of which moves slowly during one engine revolution—significantly less than the rotor circumference.

Simplified ignition system—no distributor is required, unlike in conventional rotary engines.

Self-cooling capability—eliminating the need for an additional cooling system, which is standard in traditional rotary engines.

Excellent maintainability—heavily loaded components can be easily replaced as modular blocks during maintenance.

Significantly lower weight-to-power ratio—compared to piston engines.

Environmental friendliness—due to superior sealing of working chambers, which reduces the risk of harmful emissions.

Low production cost and capital investment—making BRICE an economically attractive solution.

In addition to the previously mentioned advantages, it is important to emphasize that in the BRICE, all moving components perform purely rotational motion around their respective axes. This design feature allows for an increase in engine speed without a corresponding increase in engine weight. Moreover, the reduced mass of the rotating parts enables the engine to accelerate more rapidly to higher initial speeds, which enhances its efficiency during dynamic operation.

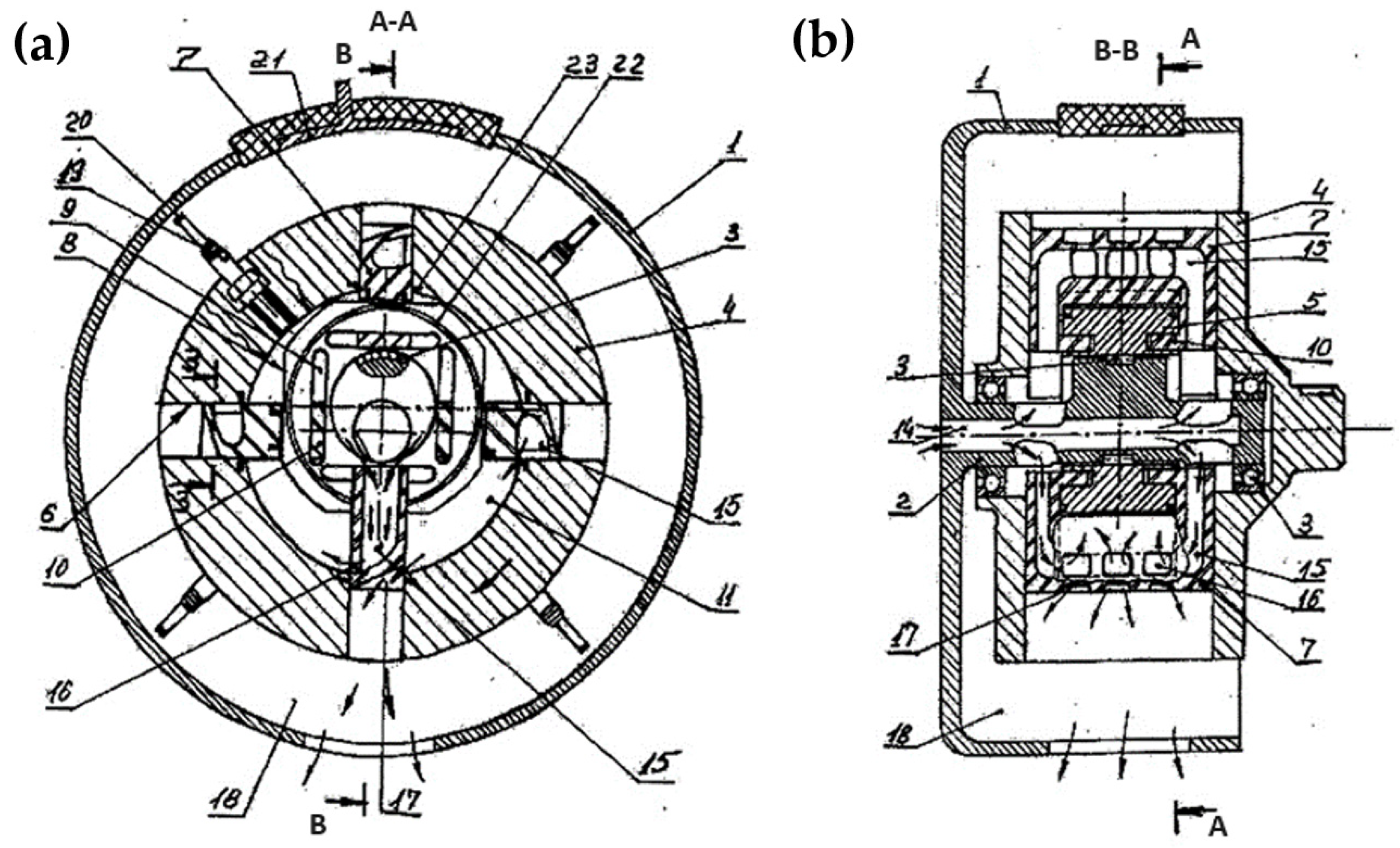

Figure 3 illustrates the general layout of a two-stroke BRICE. The engine consists of a cylindrical block with an integrated eccentric axis. On the eccentric journals of this axis, rotation supports are mounted, which carry the housing. Inside the housing, a rotor is positioned. The housing contains radial grooves in which sliders are installed with the ability to move radially. On the outer surface of the rotor, flat faces are formed in the areas where it contacts the sliders, and tangentially aligned rectangular grooves are machined parallel to these faces. Sliders, which are integrated with the shutters, are able to slide tangentially within these grooves. The space between the housing and the rotor forms sealed working volumes.

Within the eccentric axis, a receiver is integrated, which connects to intake manifolds leading into internal cavities within the shutters. These manifolds are further connected to intake ports located on one of the shutter walls. Exhaust ports are positioned at the ends of the shutters and are connected via the radial grooves to an exhaust manifold situated between the housing and the block. Each working volume is equipped with a spark plug, which is connected to a current-collecting brush. An electrically insulated current supply segment is mounted on the block in the ignition zone. Sealing of the working volumes is ensured by spring-loaded sealing rings and plates. Additionally, splines in the radial grooves engage with corresponding spline grooves in the shutters to maintain alignment and sealing integrity.

The BRICE operates on a two-stroke cycle. A supercharger injects the working mixture into the receiver, from where it flows through the intake manifolds and intake ports into the working volumes. Within these volumes, the mixture is compressed and ignited by the spark plugs. As the housing and rotor rotate synchronously, the exhaust ports open, allowing combustion gases to be expelled into the exhaust manifold. The intake and exhaust ports open and close periodically at the edges of the housing. Electrical current is supplied from the insulated segment on the block to the spark plugs via the brushes. The sealing of the working volumes is maintained by the spring-loaded sealing elements and the spline-guided movement of the shutters.

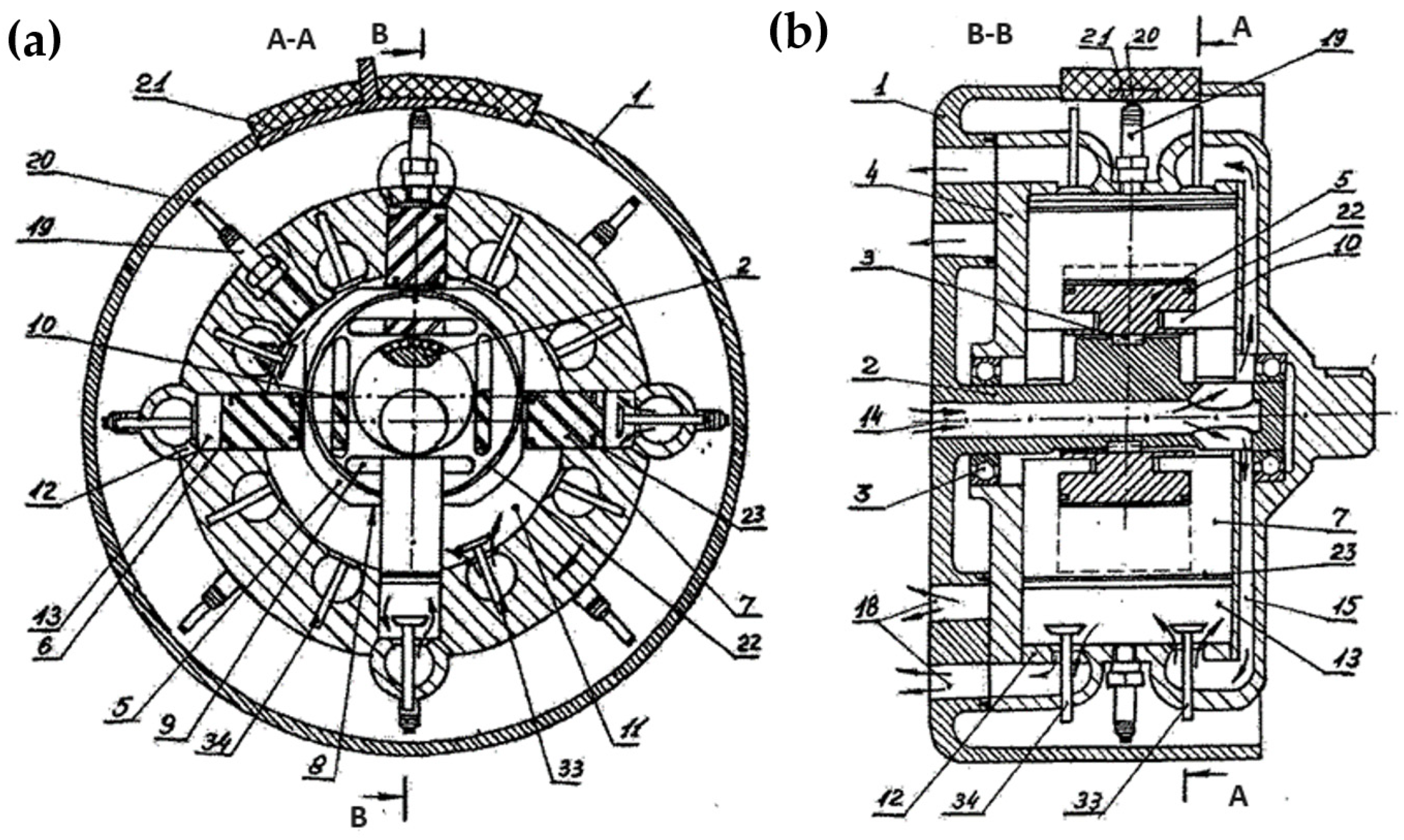

Figure 4 shows the general view of a four-stroke BRICE, which contains: a cylindrical block 1 with an eccentric axis 2 made together with it, on the eccentric necks of which a housing 4 is installed on the rotation supports 3, in the inner volume of which the rotor 5 is located.

The engine consists of a cylindrical block with an integrally formed eccentric axis. On the eccentric journals of this axis, a housing is mounted via rotation supports, and within its internal volume, a rotor is positioned.

Inside the housing, radial grooves are machined to accommodate sliders capable of radial movement. Where these sliders contact the rotor, flat faces are formed on its outer surface, and tangentially aligned rectangular grooves are positioned parallel to these faces. Within these grooves, tangentially sliding sliders are installed, which are structurally integrated with the shutters. The space between the housing and the rotor forms the primary working volumes. The radial grooves of the housing are sealed externally with plugs, which also define secondary working volumes.

A receiver is integrated within the eccentric axis and connects to intake manifolds located in one of the housing walls. Intake valves are installed in both the primary and secondary working volumes, allowing the working mixture to enter. Exhaust valves are also present in these volumes and connect to exhaust manifolds embedded in the block. Each working volume contains a spark plug equipped with a current-collecting brush, and an electrically insulated current supply segment is mounted on the block in the ignition zone. Sealing of the working volumes is ensured by spring-loaded sealing rings and plates.

The engine operates on a four-stroke cycle. As the housing rotates, the working mixture is drawn into the working volumes through the receiver, intake manifolds, and intake valves, where it is compressed and ignited by the spark plugs. As rotation continues, the exhaust valves open, allowing combustion gases to be expelled into the exhaust manifolds. The timely opening and closing of the intake and exhaust valves is controlled by a gas distribution mechanism.

Electrical current is supplied from the insulated segment on the block to the spark plugs via the current-collecting brushes. Synchronization of the housing and rotor rotation is achieved through the sliders, which move radially within the radial grooves and tangentially within the grooves of the rotor. The edges of the shutters move with slight clearance along the flat faces of the rotor, and sealing is maintained by spring-loaded plates.

Torque is transmitted from the pressure of the combusted mixture in the primary working volumes through the shutters, which press against the radial grooves of the housing, from which the engine’s output torque is extracted. In the secondary working volumes, force is transmitted via the tangential component of pressure acting on the walls of the radial grooves.

A key challenge in the development of BRICE lies in the optimal selection of its design parameters to minimize weight and size. One promising approach is the use of mathematical experiment planning methods, which enable the construction and analysis of generalized mathematical models (GMM) [

12].

As an example, the results of computational studies are presented below to determine the key design parameters of birotor compressors. These compressors are designed to match the performance and outlet pressure characteristics of existing compressor models used in modern railway rolling stock (e.g., KT-7, ПK-3.5, BB-1.5/9, ЭK-7Б, ЭK-4) [

3,

4,

5,

6,

7,

8,

9].

The primary design parameters of birotor compressors include (see

Figure 5):

D—diameter of the rotating housing,

L—length of the compressor cylinder (longitudinal dimension of the working chambers),

e—eccentricity (distance between the rotational axes of the housing and the rotor),

δ—thickness of the shutters,

z—number of shutters (i.e., number of working chambers),

n—rotational speed.

In evaluating the performance of birotor compressors (BC) for various applications, it is advisable to consider the following indicators:

Actual volumetric flow rate Q,

Total internal volume of the compressor VΣ, and

Shaft power N (i.e., the required power input from the electric drive).

The actual volumetric performance

Q of the birotor compressor is determined using the following formula:

where

l—is the length of the shutter;

λ—feed rate (it is accepted

λ = 0.53)

The values of the total structural volume

VΣ of the new BC are determined by the formula

where are

Dmax,

Lmax—the maximum dimensions of the BC structure (accepted:

Dmax = 2.667,

Lmax = 3.6). It is advisable to determine the power on the shaft of a new BC (as a rotary machine) using the formula for isothermal gas compression

where are

T—intake air temperature (accepted in research

T = 293 K);

R—gas constant (for air R = 29.27 kGm/(kg∙deg));

ping,

psuc—injection and suction pressure;

γ—air density at intake (at

t = 20 °C is

γ = 1.16 kg/m

3);

ηis—isothermal efficiency (accepted

ηis = 0.55).

It should be noted that the following were chosen as parameters that directly affect the values of the indicators: the diameter of the moving body D, the length of the compressor cylinder L and the frequency of rotation of the BC shaft n. At the same time, the experience of exploratory studies of the BC mechanical system showed that it is advisable to accept eccentricity in the calculations e = 0.12 D, the thickness of the shutters δ = e, and the number of dampers (the number of working chambers of the compressor) z = 4. As it was mentioned above, it is advisable to choose the rational values of the design parameters of the BC based on the analysis of universal GMM, which can be used for any given types of electric motors with the corresponding rotation frequencies n. As the controlled performance indicators of BC were chosen: relative performance of BC; VΣ—total constructive volume of BC; —relative power on the BC shaft.

Thus, the next stage of work involved conducting research in the direction of obtaining the sought-after generalized mathematical models of the species , and using the methods of mathematical planning of the experiment according to the following sequence.

The formation of initial data for conducting research is carried out in the form of specified intervals of variation of controlled variables (factors of the mathematical plan): D = 100…380 mm, L = 70…270 mm.

The transition from the actual values of the D, L variables to their normalized xq parameters is carried out according to the following formula

where

q—the current value of the variable under consideration (

D,

L), in the given interval of variation;

qin—the initial (zero) level of the variable

where

qmax,

qmin—respectively, the maximum and minimum values of the variable (limits of the given interval of variation); Δ

q—the step of varying the variable

where

k—the number of whole sections into which the intervals of variation of controlled variables are divided (

k = 2).

The transition to normalized parameters

xD,

xL determines the relationship with the actual values of the controlled variables

D,

L (

Table 3), which allows you to draw up a mathematical plan, having the appropriate planning matrix.

- 3.

Based on the planning matrix (

Table 4), a second-order orthogonal experimental design was developed for two controlled variables, each varied at three levels.

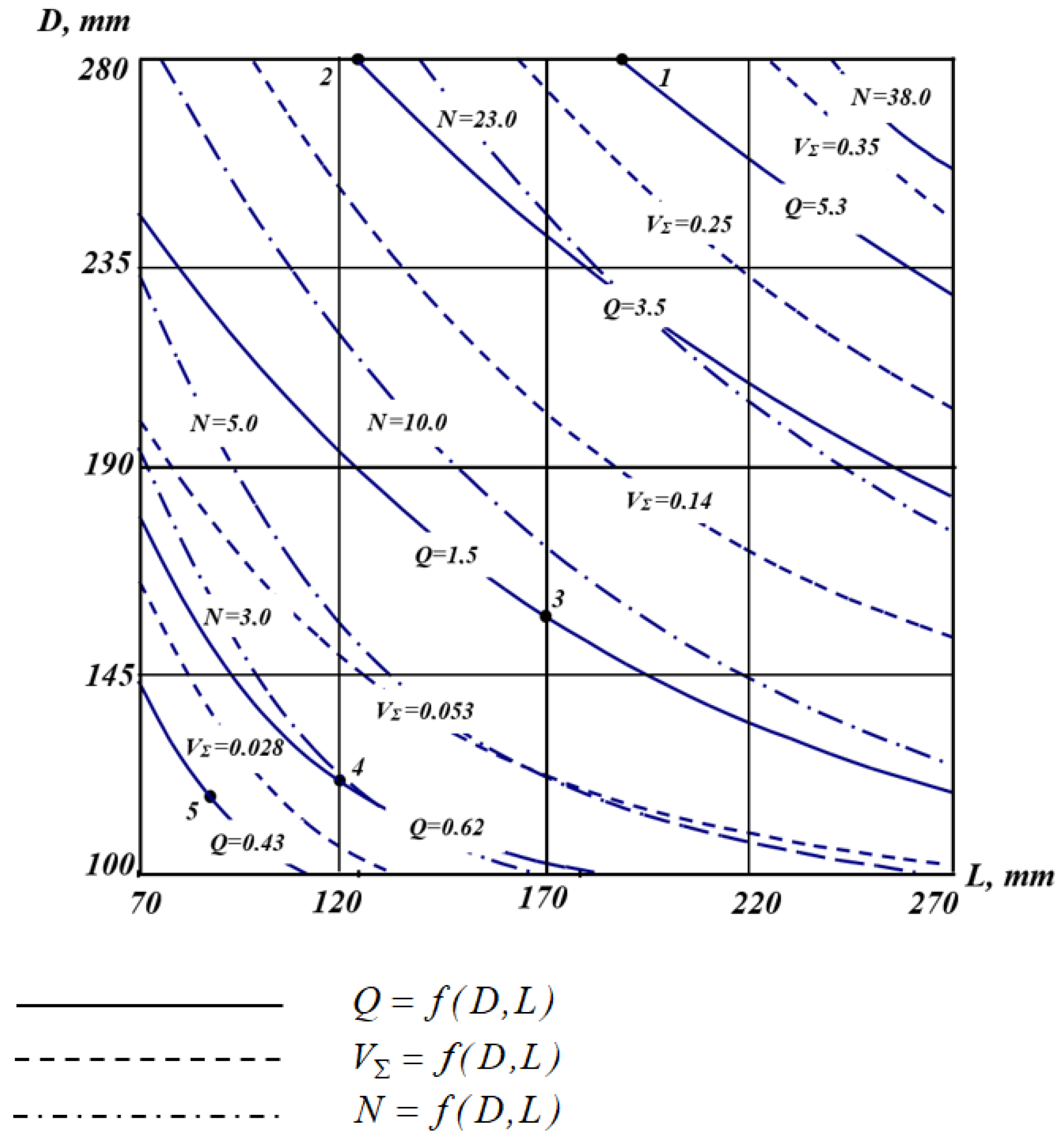

Figure 6 provides a graphical representation of this second-order orthogonal plan, corresponding to the mode designations in

Table 4. This design enables a systematic and statistically robust investigation of the influence of key parameters on the performance of birotor compressors.

Below in

Table 5 is given the orthogonal mathematical plan of the second order for three variables varying on three levels, compiled using the planning matrix (

Table 4). For each mode of the mathematical plan, the values of the monitored indicators are calculated using the developed mathematical dependencies—relative productivity

, of the total design volume of the compressor V

Σ and relative power on the BC shaft

.

- 4.

With the use of a mathematical plan in the form of polynomials of the second degree, the sought GMM are formed

where

Y—controlled indicator; ai—GMM coefficients, the numerical values of which are determined by the formula

where

Yj—the value of indicator

Y for j is the mode of the mathematical plan;

αj—vector of numbers of the corresponding coefficient;

βi—multiplier at

αj;

m—the number of modes of the mathematical plan (for the mathematical plan according to

Table 4 m = 9).

Numerical values

αj and

βj for the mathematical plan given in

Table 4 are presented in

Table 6.

The adequacy check of the obtained mathematical model can be performed by the value of the mean square deviation of the σ of the experimental

Yj and

Yj.calc obtained according to the composite model (7)

where k—the number of coefficients ai of the generalized mathematical model (

k = 6).

The transition from the obtained in the normalized parameters of the GMM of the Y = f(xD, xL) type to the models in the real values of the Y = f(D, L) is performed by substituting in the GMM (7) the ratios for the found according to Formula (4).

Below are the GMM for the controlled indicators in the real values of the variables, obtained for the mathematical plan according to

Table 5.

The values of root mean square deviations for the obtained GMM testify to their adequacy and suitability for use in further studies on the determination of geometric parameters of mechanical systems of BC for wind supply systems of modern rolling stock.

It should be noted that in order to make a justified choice of the rational values of the BC parameters for the preliminary task of the type of electric motor with the nominal frequency of rotation of the n, GMM (10) and (12) are reduced to the form

The last stage of research involves the analysis of GMM (14–17) to determine the values of the main geometric parameters of new BC, which at a given frequency of rotation of the shaft in terms of their performance correspond to existing designs of compressors (functional prototypes) used in modern rolling stock (

Table 1).

Points 1, 2, 3, 4, 5 correspond to the parameters of working BC cameras (D, L), which ensure the performance of functional prototypes. For the convenience of comparing the indicators of BC and prototypes according to mass-dimensional indicators and power consumption per drive, along with isolines of fixed productivity values Q = f(D, L) are drawn isolines VΣ = f(D, L) and N = f(D, L). In this case, the visible points on the graph (1, 2, 3, 4, 5) were selected on the corresponding isolines to reach the lowest value of the constructive volume of the BC VΣ.

Figure 7 presents an auxiliary graph on which the isolines of fixed productivity values Q (corresponding to the productivity of the functional prototypes shown in

Table 7), total volumes

VΣ and required power

N with the GMM (14–17) are illustrated for birotor compressor shaft rotation frequency

n = 1500 rpm.

A sensitivity analysis was carried out to assess the influence of geometric parameters D, L, and eccentricity e on volumetric efficiency and shaft power. The analysis revealed that variations in D have the strongest effect on flow rate, whereas L predominantly affects energy consumption. These dependencies define the operational boundaries of the model and confirm its adequacy for engineering design.

Predicted characteristics, parameters of working chambers and mass-dimensional parameters of new generation compressors for improving the systems of modern traction and rolling stock are presented above in

Table 2.

To summarize the methodology and facilitate the interpretation of the results,

Figure 8 presents a simplified flowchart of the GMM construction and validation process. The diagram outlines the main workflow from input parameters to optimization and prototype validation.