A Research Review of Rolling Bearing Turbocharger Modeling and System Characteristics

Abstract

1. Introduction

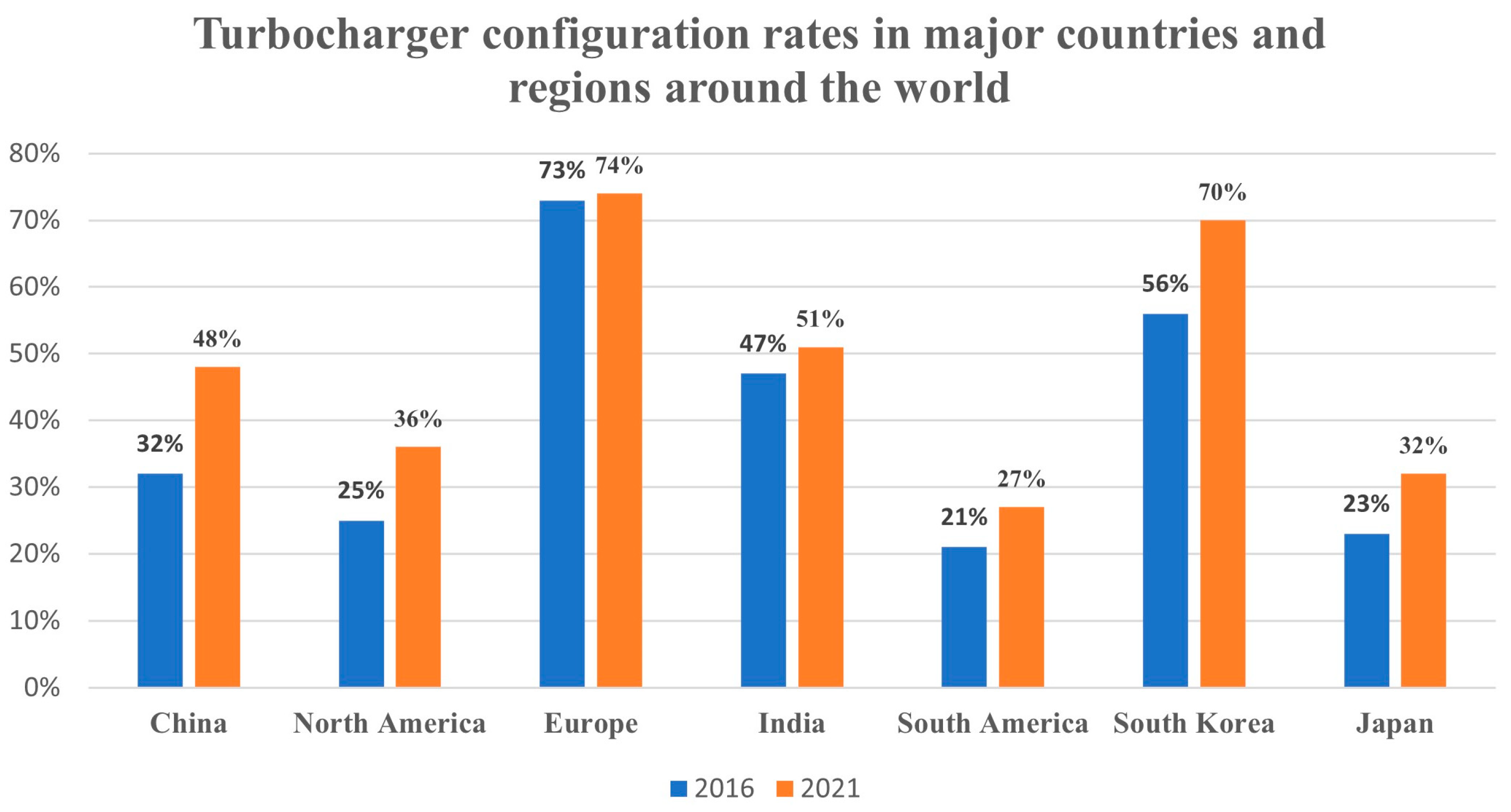

1.1. The Development and Application of Turbocharging Technology

1.2. The Development and Application of Rolling Bearing Turbochargers

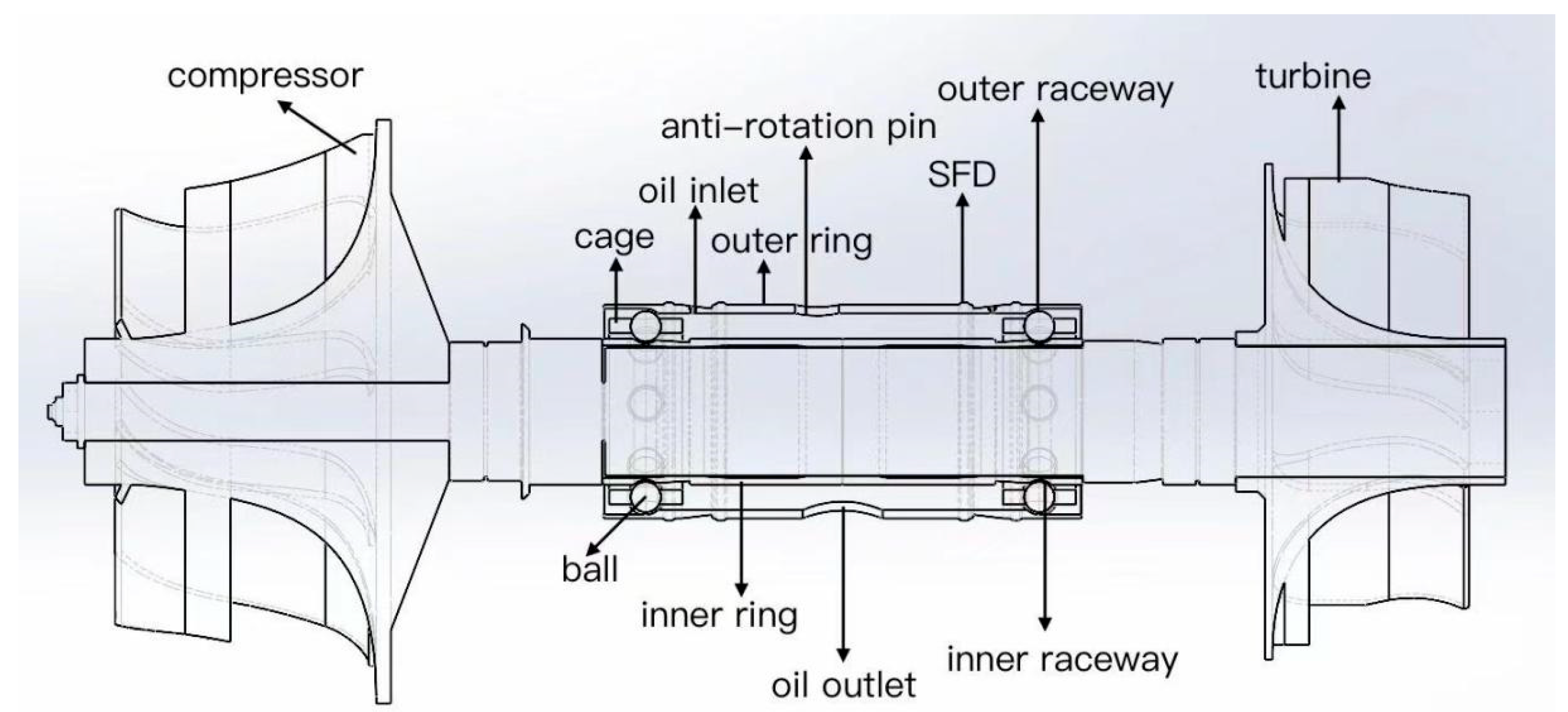

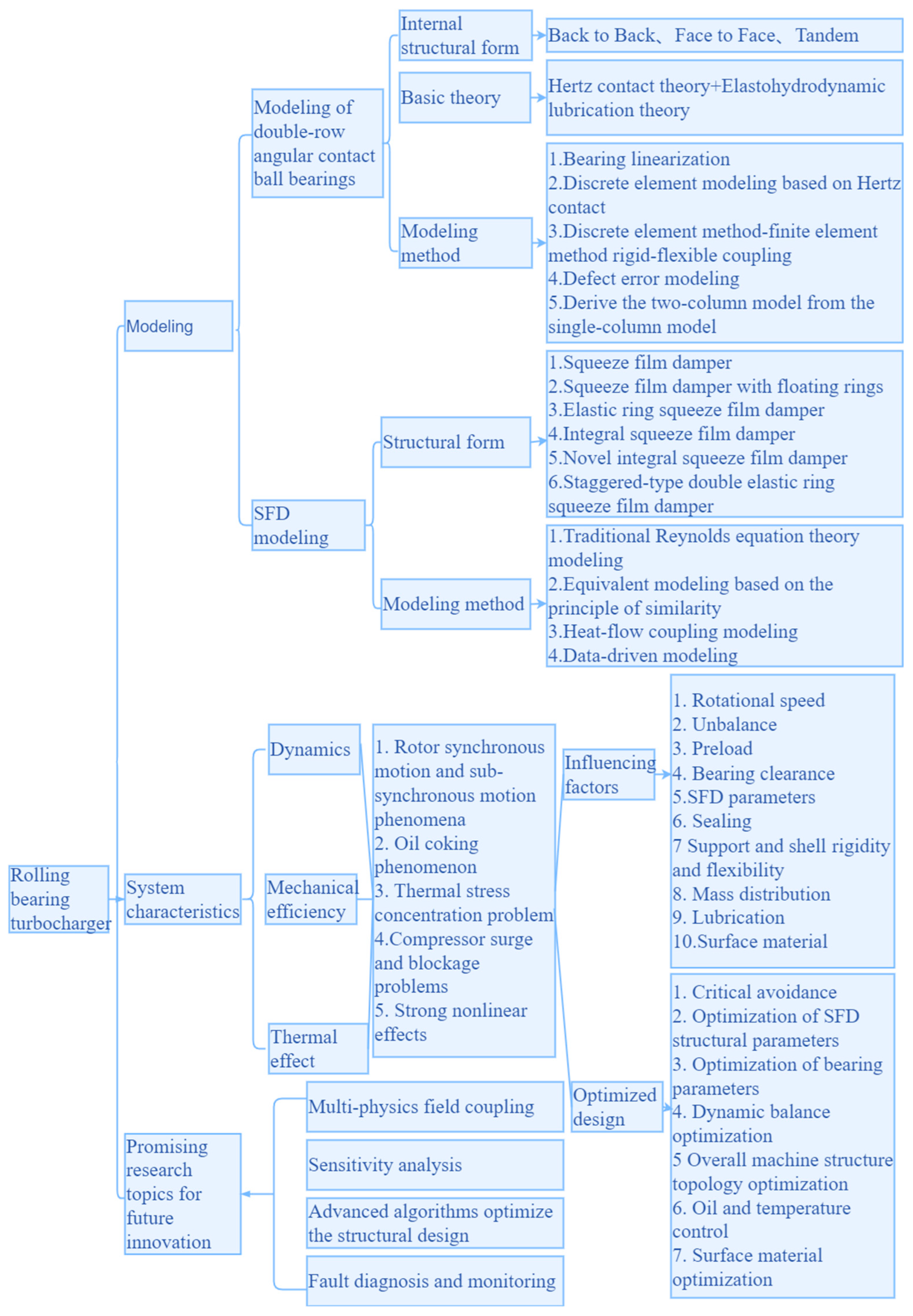

1.3. Features, Research Challenges, and Focal Topics of Rolling Bearing Turbochargers

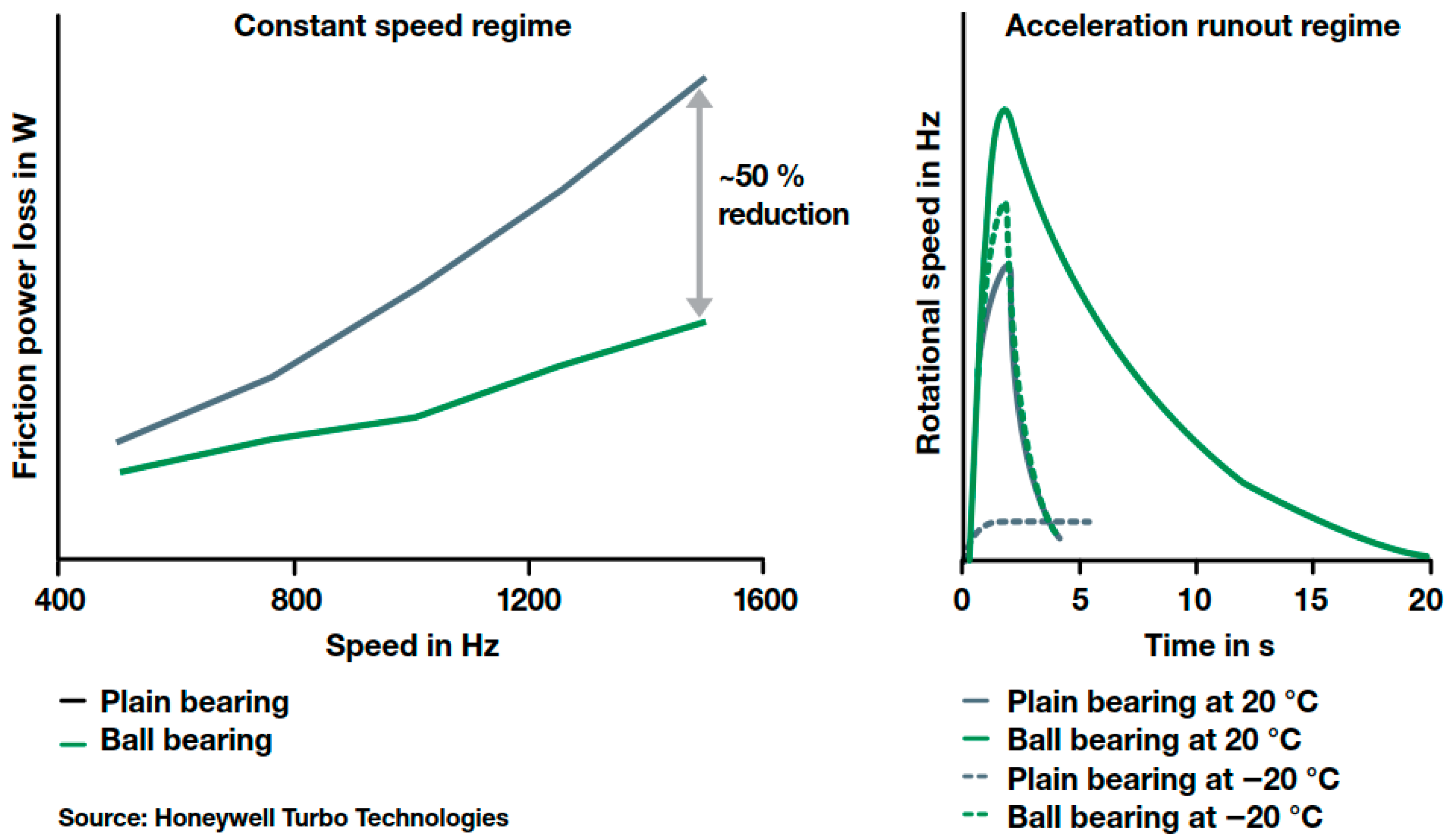

1.3.1. Features of Rolling Bearing Turbochargers

1.3.2. Research Challenges of Rolling Bearing Turbochargers

1.3.3. Focal Topics of Rolling Bearing Turbochargers

2. Modeling Study of Rolling Bearing Turbochargers

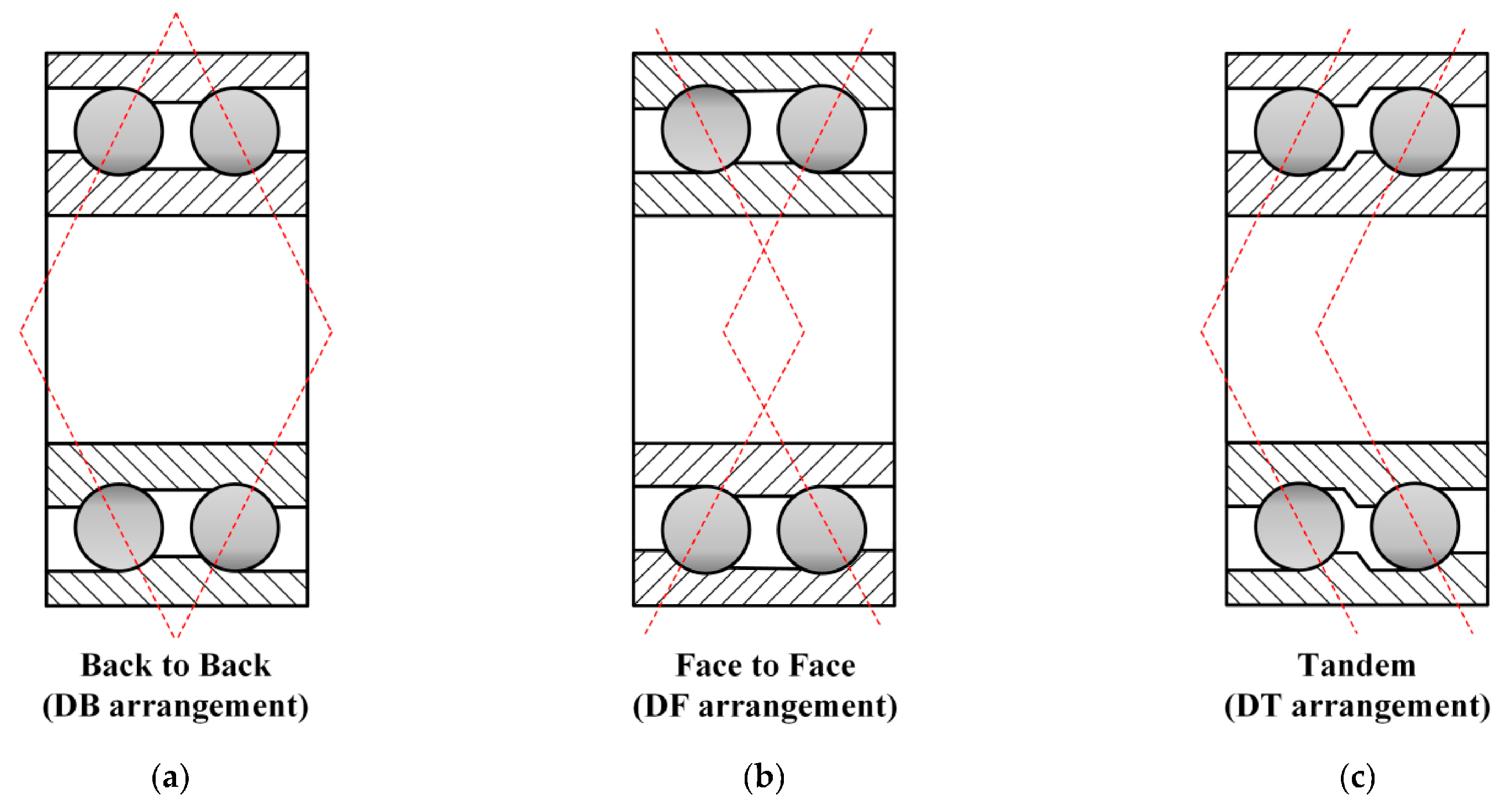

2.1. Rolling Bearing Modeling

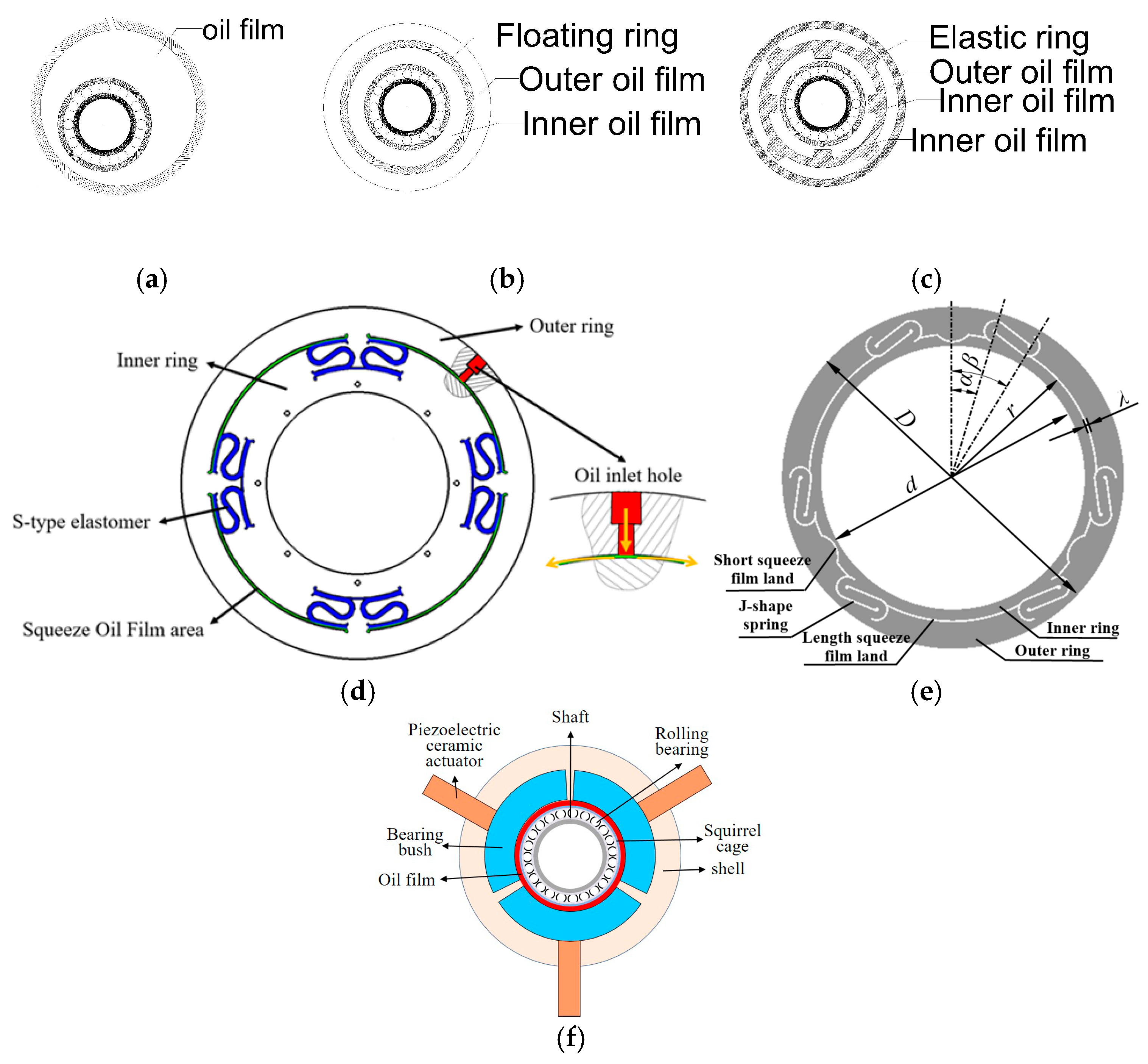

2.2. Modeling of a Squeeze Film Damper

3. Research on the Characteristics of Rolling Bearing Turbocharger Systems

3.1. Dynamics Research

3.2. Mechanical Efficiency Research

3.3. Thermal Effect Research

4. Conclusions

5. Promising Research Topics for Future Innovation

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| VGT | variable geometry turbocharger; | NISFD | novel integral squeeze film damper; |

| DN | Diameter × Nominal; | FD | finite difference; |

| PEEK | polyetheretherketone; | SVD | singular value decomposition; |

| SFD | squeeze film damper; | SDERSFD | staggered-type double elastic ring squeeze film damper; |

| REBs | rolling bearing elements; | FEM | finite element method; |

| EHD | damping of the elasto-hydrodynamic; | FRBT | floating ring bearing turbocharger; |

| EHL | elasto-hydrodynamic lubrication; | BBT | ball bearing turbocharger; |

| FSFD | SFD with floating rings; | R-K | Runge–Kutta; |

| ERSFD | elastic ring squeeze film damper; | BSFC | brake specific fuel consumption; |

| ISFD | integral squeeze film damper; | CVD | chemical vapor deposition; |

| EDM | electrical discharge machining; | CFD | computational fluid dynamics; |

| Z–G–B | Zwart–Gerber–Belamri; | RF | radio frequency; |

| DEM | Discrete Element Method; | NVH | Noise, Vibration, Harshness; |

| MBD | Multibody Dynamics; | HPO | Hunter-Prey Optimization; |

| PSO | Particle Swarm Optimization |

References

- Jin, X.; Liu, H. The impact of vehicle exhaust emissions on the environment and their control. Resour. Econom. Environ. Prot. 2015, 33, 80. [Google Scholar] [CrossRef]

- Christmann, R.; Rohi, A.; Weiske, S.; Gugau, M. VTG Turbochargers with Ball Bearings for Gasoline Engines. MTZ Worldw. 2019, 80, 18–25. [Google Scholar] [CrossRef]

- Schweizer, B. Total instability of turbocharger rotors—Physical explanation of the dynamic failure of rotors with full-floating ring bearings. J. Sound Vib. 2009, 328, 156–190. [Google Scholar]

- Schweizer, B.; Sievert, M. Nonlinear oscillations of automotive turbocharger turbines. J. Sound Vib. 2009, 321, 955–975. [Google Scholar] [CrossRef]

- Keller, R.; Scharrer, J.; Pelletti, J. Alternative Performance Turbocharger Bearing Design; No. 962500; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Koutsovasilis, P. Automotive turbocharger rotordynamics: Interaction of thrust and radial bearings in shaft motion simulation. J. Sound Vib. 2019, 455, 413–429. [Google Scholar] [CrossRef]

- Shan, R. Design and Performance Analysis of Rolling Bearing for Vehicle Turbocharger. Master’s Thesis, Henan University of Science and Technology, Luoyang, China, 2017. [Google Scholar]

- Nguyen-Schäfer, H. Rotordynamics of Automotive Turbochargers; Springer International Publishing: Cham, Switzerland, 2015; Volume 17. [Google Scholar]

- Peng, F. Turbocharging technology has great potential, and BorgWarner is accelerating its expansion into China’s electric drive market. Automob. Parts 2018, 2, 54–55. [Google Scholar] [CrossRef]

- Brouwer, M.D.; Sadeghi, F.; Lancaster, C.; Archer, J.; Donaldson, J. Whirl and friction characteristics of high speed floating ring and ball bearing turbochargers. J. Tribol. 2013, 135, 041102. [Google Scholar] [CrossRef]

- Ashtekar, A.; Tian, L.; Lancaster, C. An analytical investigation of turbocharger rotor-bearing dynamics with rolling element bearings and squeeze film dampers. In Proceedings of the 11th International Conference on Turbochargers and Turbocharging, London, UK, 13–14 May 2014; Woodhead Publishing: Oxford, UK, 2014; pp. 361–373. [Google Scholar]

- Wang, Y.; Huang, Y. Vehicle Engine Exhaust Turbocharger; National Defense Industry Press: Beijing, China, 1984. [Google Scholar]

- Wan, H.; Zhang, Z.; Fan, Y. Design of tester for rolling bearing used in automotive turbocharger. Bearing 2015, 4, 47–49+54. [Google Scholar] [CrossRef]

- Zhou, G.; Hao, S.; Zhou, P.; Ren, X.; Shang, Y.; Wang, Q. Measures on improving low-speed torque performance of turbocharged I.C. engine. Intern. Combust. Engine Powerpl. 2010, 27, 7–11. [Google Scholar]

- Onitsuka, K.; Peng, H. The potential of turbochargers to improve vehicle environmental performance. Foreign Intern. Combust. Engine 2015, 47, 57–59. [Google Scholar]

- NSK Develop New Bearing Products. Automob. Parts 2013, 8, 29. Available online: https://d.wanfangdata.com.cn/periodical/CiFQZXJpb2RpY2FsQ0hJU29scjlTMjAyNTEwMjEwOTUwNDYSDnFjbGJqMjAxMzEyMDE4GghoYjl2NGtkMQ%3D%3D (accessed on 4 November 2025).

- Schweitzer, F.; Adleff, K. Rolling bearings in turbocharger applications. MTZ Worldw. 2006, 67, 16–19. [Google Scholar] [CrossRef]

- Bearing innovation technology of SKF used for complex turbo changer. Automob. Parts 2008, 28, 44–46. Available online: https://d.wanfangdata.com.cn/periodical/CiFQZXJpb2RpY2FsQ0hJU29scjlTMjAyNTEwMjEwOTUwNDYSDnFjeXBqMjAwODAxMDE0GghqZjk3bnp6bg%3D%3D (accessed on 4 November 2025).

- Schaeffler Technologies GmbH. Rolling Bearings in Turbochargers. In Solving the Powertrain Puzzle: 10th Schaeffler Symposium April 3/4, 2014; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014; pp. 202–210. [Google Scholar]

- Bauer, K.H.; Balis, C.; Paja, D.; Davies, P.; Marsal, D. High volume series production of ball bearing turbochargers. MTZ Worldw. Emagazine 2011, 72, 48–51. [Google Scholar] [CrossRef]

- Garrett Motion. Basic Understanding the Parts of the Turbocharger; Garrett Motion Inc.: Rolle, Switzerland, 2023. [Google Scholar]

- Yang, Y. Innovation and R&D lead the way, adapting to trends to secure the future—Ningbo Weifu Tianli Turbocharging Technology Co., Ltd. deeply rooted in the turbocharger industry. Sci. Technol. Ind. China 2023, 37, 32–33. Available online: https://d.wanfangdata.com.cn/periodical/zgkjcy202307016 (accessed on 4 November 2025).

- Jebur, N.A.; Soud, W.A. A Comparative Analysis of the Performance of Ball Bearings and Journal Bearings Under Varying Rotational Speeds. J. Fail. Anal. Prev. 2025, 25, 1528–1538. [Google Scholar] [CrossRef]

- Brouwer, M.D.; Sadeghi, F. Investigation of turbocharger dynamics using a combined explicit finite and discrete element method rotor–cartridge model. J. Tribol. 2017, 139, 012201. [Google Scholar] [CrossRef]

- Tanimoto, K.; Kajihara, K.; Yanai, K. Hybrid Ceramic Ball Bearings for Turbochargers; SAE Transactions: Warrendale, PA, USA, 2000; pp. 763–775. [Google Scholar]

- Brouwer, M.D.; Shahidi, A.; Gupta, L.A.; Sadeghi, F.; Peroulis, D. Application of ball bearing cage RF temperature sensor in high speed turbocharger. In Proceedings of the 2014 IEEE Antennas and Propagation Society International Symposium (APSURSI), Memphis, TN, USA, 6–11 July 2014; IEEE: New York, NY, USA, 2014; pp. 1312–1313. [Google Scholar]

- Griffith, R.C.; Slaughter, S.E.; Mavrosakis, P.E. Applying Ball Bearings to the Series Turbochargers for the Caterpillar® Heavy-Duty on-Highway Truck Engines; No. 2007-01-4235l; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Huang, R.; Ge, X.; Ma, C. Critical speed analysis on vehicle turbocharger with ball bearings. Veh. Engine 2007, 30, 72–76. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, Y.; Chen, T. Rotor dynamics analysis for ball bearing turbocharger considering the sealed construction. Zhendong Yu Chongji (J. Vib. Shock.) 2012, 31, 153–156+182. [Google Scholar]

- Huang, R.; Zhang, W.; Xing, W.; Zhang, Y. Gas excitation’s influence on dynamic behavior of a turbocharger rotor–ball bearing system. J. Vib. Shock. 2014, 33, 140–146. [Google Scholar]

- Huang, R.; Zhang, W.; Jiang, Y.; Xing, W. Influences of acceleration on dynamic characteristics of a turbocharger’s ball bearing–rotor system. J. Vib. Shock. 2014, 33, 136–140. [Google Scholar]

- Huang, R.; Zhen, S.; Zhang, W. Influences of ball bearing stiffness on transient response of a turbocharger. J. Vib. Shock. 2016, 35, 83–87. [Google Scholar]

- Ashtekar, A.; Sadeghi, F. Experimental and analytical investigation of high speed turbocharger ball bearings. J. Eng. Gas. Turbines Power 2011, 133, 122501. [Google Scholar] [CrossRef]

- Conley, B.; Sadeghi, F. Experimental and analytical investigation of turbocharger whirl and dynamics. Tribol. Trans. 2021, 64, 239–252. [Google Scholar] [CrossRef]

- Conley, B.; Sadeghi, F.; Griffith, R.C.; McCormack, J.W. Experimental investigation of the dynamic loads in a ball bearing turbocharger. J. Tribol. 2019, 141, 111101. [Google Scholar] [CrossRef]

- Conley, B.; Sadeghi, F. Impact of whirl and axial motion on ball bearing turbocharger dynamics. Tribol. Trans. 2023, 66, 338–349. [Google Scholar] [CrossRef]

- Conley, B.B. Experimental and Analytical Investigation of Ball Bearing Turbocharger Dynamics. Ph.D. Dissertation, Purdue University Graduate School, West Lafayette, IN, USA, 2022. [Google Scholar]

- Wan, H. Design and Experiment Study of Rolling Bearings of Automobile Turbocharger. Master’s Thesis, Henan University of Science and Technology, Luoyang, China, 2015. [Google Scholar]

- Lu, D. Application of collaborative simulation technology in rotor bearing systems. In Proceedings of the 12th Joint Academic Conference on Multibody Dynamics and Control, the 7th Joint Academic Conference on Aerospace Dynamics and Control, and the 15th National Joint Academic Conference on Analytical Mechanics, Shanghai, China, 13 November 2021; p. 90. [Google Scholar] [CrossRef]

- Majer, M.; Chatterton, S.; Dassi, L.; Gheller, E.; Pennacchi, P.E.L.M.; Colonna, P.; Pini, M. Mechanical design and rotordynamic analysis of the ORCHID turbine. J. Glob. Power Propuls. Soc. 2025, 9, 45–66. [Google Scholar] [CrossRef]

- Bala Murugan, S.; Behera, R.K.; Parida, P.K. Nonlinear Dynamic Analysis of Automotive Turbocharger Rotor System. In Advances in Applied Mechanical Engineering: Select Proceedings of ICAMER 2019; Springer: Singapore, 2020; pp. 443–453. [Google Scholar]

- Fang, B.; Zhang, J.; Hong, J.; Yan, K. Research on the nonlinear stiffness characteristics of double-row angular contact ball bearings under different working conditions. Lubricants 2023, 11, 44. [Google Scholar] [CrossRef]

- Desai, A. Analytical and Experimental Investigation of Effect of Cage and Shaft Flexibility on Dynamics of Bearing Shaft Systems. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2007. [Google Scholar]

- Wensing, J.A. On the Dynamics of Ball Bearings. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1998. [Google Scholar]

- Yao, T. Modeling and Simulation Analysis of the Rigid–Flexible Coupling Multi-Body Dynamics of the Milling Machine Spindle System. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2007. [Google Scholar]

- Yao, T. Research on Multibody Contact Dynamics of Ball Bearings. Ph.D. Dissertation, Kunming University of Science and Technology, Kunming, China, 2009. [Google Scholar]

- Yao, T.; Chi, Y.; Huang, Y. Dynamic contact analysis of ball bearing. Mech. Des. Manuf. 2007, 45, 1–3. [Google Scholar] [CrossRef]

- Yao, T.; Chi, Y.; Huang, Y.; Tan, Y. Rigid and Flexible Contact Dynamics Analysis on Rolling Bearing. China Mech. Eng. 2008, 19, 1924–1928. [Google Scholar]

- Fan, R.; Yao, T.; Liu, X.; Xiong, T. Stability analysis of angular contact ball bearing cage. Mach. Des. Res. 2017, 33, 76–81. [Google Scholar]

- Zhu, K.; Zhang, S.; Luo, Z.; Luo, F. Design of double-row angular contact ball bearings and study of their life and reliability. Mech. Eng. 2024, 56, 136–141+145. [Google Scholar]

- Li, Z.; Wang, Q.; Wang, R.; Qin, B. Dynamic Characteristics Analysis of Double Row Angular Contact Ball Bearings with Different Bearing Configurations. J. Mech. Eng. 2025, 61, 220–231. [Google Scholar]

- Deng, S.; Jia, Q.; Xue, J. Principles of Rolling Bearing Design, 2nd ed.; China Standards Press: Beijing, China, 2014. [Google Scholar]

- Yao, T.Q.; Wang, L.H.; Chi, Y.L.; Huang, Y. Research on multibody contact dynamics of ball bearings. J. Aerosp. Power 2013, 28, 1624–1637. [Google Scholar]

- Deng, S.E.; Xie, P.F.; Yang, H.S.; Gao, Y.T. Flexible-body dynamics analysis on cage of high-speed angular contact ball bearing. Acta Armamentarii 2011, 32, 625. [Google Scholar]

- Deng, S.E.; Dong, X.; Cui, Y.C.; Hu, G.C. Analysis of dynamic stiffness characteristics of double-row angular contact ball bearings. Acta Armamentarii 2015, 36, 1140. [Google Scholar]

- Gunduz, A.; Dreyer, J.T.; Singh, R. Effect of bearing preloads on the modal characteristics of a shaft-bearing assembly: Experiments on double row angular contact ball bearings. Mech. Syst. Signal Process. 2012, 31, 176–195. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, X. Load calculation for double row angular contact ball bearing based on deformation coordination. Bearing 2004, 47, 1–4. [Google Scholar] [CrossRef]

- Zhuo, Y.; Zhou, X.; Yang, C. Dynamic analysis of double-row self-aligning ball bearings due to applied loads, internal clearance, surface waviness and number of balls. J. Sound Vib. 2014, 333, 6170–6189. [Google Scholar] [CrossRef]

- Cheng, C.; Wang, J. Load analysis of double row angular contact ball bearings. Mech. Sci. Technol. Aerosp. Eng. 2014, 33, 829–833. [Google Scholar]

- Liu, Y.; Yang, M.; Su, B.; Deng, S. Simulation Analysis of the Friction Power Consumption of Double Row Angular Contact Ball Bearings for Aero-engine. J. Mech. Transm. 2021, 45, 129–135. [Google Scholar]

- Saheta, V. Dynamics of Rolling Element Bearings Using Discrete Element Method. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2001. [Google Scholar]

- Cao, L. Dynamic Bearing Simulation Using Combined EFEM-DEM Method. Ph.D. Dissertation, Purdue University, West Lafayette, IN, USA, 2018. [Google Scholar]

- Ashtekar, A.; Sadeghi, F.; Stacke, L.E. A new approach to modeling surface defects in bearing dynamics simulations. J. Tribol. 2008, 130, 041103. [Google Scholar] [CrossRef]

- Ashtekar, A.; Sadeghi, F.; Stacke, L.E. Surface defects effects on bearing dynamics. Proc. Inst. Mech. Eng. Part. J. J. Eng. Tribol. 2010, 224, 25–35. [Google Scholar] [CrossRef]

- Doro, A.M.K. A Preliminary Study of the Impact of Material, Unbalanced Mass, and Bearing Type on Turbocharger Vibration Behavior Using ANSYS. Ph.D. Dissertation, Cleveland State University, Cleveland, OH, USA, 2024. [Google Scholar]

- Luo, Z.; Wang, J.; Han, Q.; Wang, D. Research progress on the dynamics of combined support rotor systems. Trans. Chin. Soc. Mech. Eng. 2021, 57, 44–60. [Google Scholar]

- Sawalem, M.; Aburwais, M. Analysis of Double-Row Ball Bearing Used in TACCHI FTC 100 Machine (case study). Int. J. Eng. Inf. Technol. (IJEIT) 2023, 11, 21–24. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Z.; Liu, H.; Liu, T.; Wang, Q. Modeling and Dynamic Analysis of Double-Row Angular Contact Ball Bearing–Rotor–Disk System. Lubricants 2024, 12, 441. [Google Scholar] [CrossRef]

- Wen, B.; Ma, S.; Fang, B.; Yan, K.; Zhang, X.; Zhang, J.; Hong, J. Quasi-dynamic modelling and performance analysis of double-row angular contact ball bearing considering overturning moment. Eur. J. Mech.-A/Solids 2025, 116, 105924. [Google Scholar] [CrossRef]

- Kim, K.; Ryu, K. Rotordynamic analysis of automotive turbochargers supported on ball bearings and squeeze film dampers in series: Effect of squeeze film damper design parameters and rotor imbalances. Tribol. Lubr. 2018, 34, 9–15. [Google Scholar]

- Gunter, E.J. Design of Oil and Air Squeeze Film Dampers for a Ball Bearing Turbocharger; Dyrobes: Charlottesville, VA, USA, 2023. [Google Scholar]

- Zhou, H.; Luo, G.; Chen, G.; Wang, F. Nonlinear dynamic analysis of a rotor supported on the ball bearings with squeeze film dampers. Mech. Sci. Technol. Aerosp. Eng. 2013, 32, 499–505. [Google Scholar]

- Zhou, H.L.; Luo, G.H.; Chen, G.; Wang, F. Analysis of the nonlinear dynamic response of a rotor supported on ball bearings with floating-ring squeeze film dampers. Mech. Mach. Theory 2013, 59, 65–77. [Google Scholar] [CrossRef]

- Brouwer, M. Dynamic Performance of Turbocharger Rotor-Bearing Systems. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2015. [Google Scholar]

- Gjika, K.; Costeux, A.; LaRue, G.; Wilson, J. Ball bearing turbocharger vibration management: Application on high speed balancer. Mech. Ind. 2020, 21, 619. [Google Scholar] [CrossRef]

- Heidari, H.; Ashkooh, M. The influence of asymmetry in centralizing spring of squeeze film damper on stability and bifurcation of rigid rotor response. Alex. Eng. J. 2016, 55, 3321–3330. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Y.; Yang, T.; Luo, Z.; Han, Q. Navigating the Dynamics of Squeeze Film Dampers: Unraveling Stiffness and Damping Using a Dual Lens of Reynolds Equation and Neural Network Models for Sensitivity Analysis and Predictive Insights. Mathematics 2024, 12, 771. [Google Scholar] [CrossRef]

- Groves, K.H.; Bonello, P. Improved identification of squeeze-film damper models for aeroengine vibration analysis. Tribol. Int. 2010, 43, 1639–1649. [Google Scholar] [CrossRef]

- Liu, Y. Modeling of a Dynamic Nonlinear Rotor System with a Squeeze Film Damper. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Wang, X.; Han, Z.; Ding, Q.; Zhang, W. Influence of fluid inertia on dynamic characteristics of elastic ring squeeze film damper-rotor system. J. Aerosp. Power 2018, 33, 2981–2990. [Google Scholar]

- He, H.; Wang, S.; Wang, L.; Ji, J.; Zhao, L. Influence of elastic ring damper on power performance of turbocharger rotor. Veh. Engine 2016, 4, 70–74. [Google Scholar]

- Nerg, J.; Jaatinen-Värri, A.; Pyrhönen, J.; Sopanen, J. Mechanical design of rotor-bearing system in a high-speed 20 kw range extender for battery electric vehicles. In Proceedings of the 12th International Conference on Vibrations in Rotating Machinery, Virtual, 14–15 October 2020; CRC Press: Boca Raton, FL, USA, 2020; pp. 511–521. [Google Scholar]

- Fan, T.; Behdinan, K. An Analytical Turbulence Model for Squeeze Film Damper Short-Bearing Analysis. Appl. Mech. 2025, 6, 48. [Google Scholar] [CrossRef]

- He, F.; Yang, T.; Ren, Y.; Zu, S.; Li, Y.; Luo, Z.; Shi, H.; Li, L.; Bai, X. Design of similarity method for rotor system with squeeze film damper. Mech. Syst. Signal Process. 2025, 240, 113423. [Google Scholar] [CrossRef]

- Luo, Z.; Sun, K.; Ge, X.; Zhou, G.; Cui, Z. Dynamic analysis of the rotor system with elastic ring squeeze film damper considering oil film temperature. Nonlinear Dyn. 2023, 111, 15981–16002. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.; Deng, S. Dynamic characteristics study of elastic ring squeeze film damper with rigid–elastic–oil coupled model. Lubricants 2023, 11, 491. [Google Scholar] [CrossRef]

- Sun, K.; Luo, Z.; Li, L.; Wu, F.; Hao, H. Mechanical and vibration characteristics investigation of the elastic ring squeeze film damper-rotor considering oil film sealing and leakage. Int. J. Non-Linear Mech. 2024, 161, 104701. [Google Scholar] [CrossRef]

- Yan, W.; Lu, J.; Pan, J.; Liu, J.; Fuyang, C.; Ye, D. Research on dynamic characteristic coefficients of integral squeeze film damper. Machines 2024, 12, 274. [Google Scholar] [CrossRef]

- Lu, Q.; Li, C.; Zhang, Y.; Fang, H.; Bin, G. Study on the vibration control method of a turboshaft engine rotor based on piezoelectric squeeze film damper oil film clearance. Mech. Sci. 2023, 14, 237–246. [Google Scholar] [CrossRef]

- Dong, H.; He, L.; Jia, X. Using integral squeeze film damper to suppress vibration of gas turbine. J. Vib. Eng. Technol. 2023, 11, 3163–3176. [Google Scholar] [CrossRef]

- Zhang, Y.; Hou, L.; Wang, S.; Zhao, K.; Zhao, L.; Li, Q. Vibration reduction characteristics analysis and experimental study of staggered-type double elastic ring squeeze film damper under complex operating conditions. Mech. Syst. Signal Process. 2025, 235, 112919. [Google Scholar] [CrossRef]

- Huang, R.; Ge, X.-B.; Ma, C.-C. Research on the critical speed of a mixed-flow turbocharger with hybrid ceramic ball bearing. J. Beijing Inst. Technol. 2009, 18, 298–303. [Google Scholar]

- Ashtekar, A.; Sadeghi, F.; Powers, G.; Mantel, K.; Griffith, R. Experimental investigation of turbocharger rotor bearing system. In Proceedings of the ASME Turbo Expo 2011: Power for Land, Sea, and Air, Vancouver, BC, Canada, 6–10 June 2011; Volume 54662, pp. 559–566. [Google Scholar]

- Zhen, S. Stiffness Characteristics of Ball Bearing Turbocharger and Influence on the Rotor Dynamic Characteristics. Master’s Thesis, Beijing Institute of Technology, Beijing, China, 2016. [Google Scholar]

- Shafiee, A.; Sadeghi, F.; Wilmer, M.G. An Integrated Finite Element and adams Modeling Approach for Analyzing Rotor-Bearing Housing Systems. J. Tribol. 2025, 147, 014303. [Google Scholar] [CrossRef]

- Li, T.; Guo, H.; Cheng, Z.; Men, R.; Li, J.; Chen, Y. Nonlinear Vibration Analysis of Turbocharger Rotor Supported on Rolling Bearing by Modified Incremental Harmonic Balance Method. Machines 2025, 13, 360. [Google Scholar] [CrossRef]

- Li, Y.; Cui, Y.; Deng, S. Research on Sudden Unbalance Response of Rigid-Elastic-Oil Coupled Ball Bearings. Lubricants 2024, 12, 161. [Google Scholar] [CrossRef]

- Huang, R.; Shang, W.T.; Zhang, W.L. Study on turbocharger transient response characteristics and its evaluation method. Chin. Intern. Combust. Engine Eng. 2014, 35, 27–35. [Google Scholar]

- Tian, X.; Mao, Y.; Xu, S.; Yao, J.; Guo, F. Heat generating analysis of high-speed hybrid ceramic ball bearing of turbocharger and efficiency. Mod. Manuf. Eng. 2011, 34, 5–9. [Google Scholar] [CrossRef]

- Zhang, N.; Burke, R.D.; Duda, T.; Brace, C.J.; Akehurst, S.; Capon, G.; Dowell, P.G.; Davies, P. Experimental and analytical investigation of implementing a ball bearing turbocharger on a production diesel engine. In Proceedings of the 11th International Conference on Turbochargers and Turbocharging, London, UK, 13–14 May 2014. [Google Scholar]

- Huang, R.; Wang, S.Q.; Wei, M.S. Mechanical loss measuring method and equipment for turbocharger. Neiranji Gongcheng/Chin. Intern. Combust. Engine Eng. 2010, 31, 92–97. [Google Scholar]

- Ozaki, M.; Yoshida, T.; Fujita, Y.; Futae, T.; Arai, T.; Yamada, Y. Development of Turbocharger for Next-generation Hybrid Electric Vehicles. Mitsubishi Heavy Ind. Tech. Rev. 2021, 58, 1. [Google Scholar]

- Faraj, S.S.; Hadi, N.H. Dynamic Stress Analysis of Turbocharger Blades under High-Velocity Impact Load. Iraqi J. Ind. Res. 2024, 11, 25–34. [Google Scholar] [CrossRef]

- An, Y.; Li, P.; Sun, C. Effect of Ball Bearing Turbo Charger on Combustion and Emissions for Heavy Duty Diesel Engine. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4778968 (accessed on 4 November 2025).

- Fasolia, V.; Hetman, M.; Staryi, A. Performance analysis of turbocharger rotor friction pairs of an automobile engine. Probl. Tribol. 2023, 28, 58–65. [Google Scholar] [CrossRef]

- Riera, P.; Macareno, L.M.; Fernandez de Bustos, I.; Aguirrebeitia, J. Hard Preloaded Duplex Ball Bearing Dynamic Model for Space Applications. Machines 2025, 13, 581. [Google Scholar] [CrossRef]

- Serrano, J.R.; Izaguirre, A.O.T.; García-Cuevas, L.M.; Usaquén, T.R.; Guillaume, M. A methodology to study oil-coking problem in small turbochargers. Int. J. Engine Res. 2020, 21, 1193–1204. [Google Scholar] [CrossRef]

- Hu, X.; Lin, J. Study on Flow Field Characteristics of High-Speed Double-Row Ball Bearings with Under-Race Lubrication. Aerospace 2025, 12, 861. [Google Scholar] [CrossRef]

- Zhou, H.; Cao, G.; Chen, X.; Zhang, Y.; Cang, Y. A study on the thermal properties of oil-film viscosity in squeeze film dampers. Lubricants 2023, 11, 163. [Google Scholar] [CrossRef]

- Tian, X.; Mao, Y.; Xu, S.; Yao, J.; Guo, F. Development of high speed hybrid ceramic bearing for tank engine turbocharger. Mech. Sci. Technol. Aerosp. Eng. 2012, 31, 1390–1394. [Google Scholar]

- Cheng, C.; Wang, J.G. Optimal design of double-row angular-contact ball bearing based on genetic algorithm. J. Mach. Des. 2015, 32, 46–50. [Google Scholar]

- Cheng, C.; Wang, J.G. Optimum Design of Double-row Angular-contact Ball Bearing with Immune Algorithm. J. Aerosp. Power 2015, 30, 2810–2816. [Google Scholar]

- Hu, Q.G.; Du, C.C.; Wu, M.Q. Optimization Design of Penalty Function Particle Swarm Optimization Algorithm for Angular Contact Ball Bearings. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2021, 40, 145–150. [Google Scholar]

- Xu, Y.; Cao, H.; Shi, J.; Pei, S.; Zhang, B.; She, K. A comprehensive multi-parameter optimization method of squeeze film damper-rotor system using hunter-prey optimization algorithm. Tribol. Int. 2024, 194, 109538. [Google Scholar] [CrossRef]

- Sharko, O.; Stepanchikov, D.; Sharko, A.; Yanenko, A. Computer diagnostics of the condition of ship rolling bearings during their operation. Sci.-Based Technol. 2024, 63, 409–418. [Google Scholar]

- Nnaji, O.E.; Nkoi, B.; Lilly, M.T.; Le-ol, A.K. Evaluating the reliability of a marine diesel engine using the Weibull distribution. J. Newviews Eng. Technol. (JNET) 2020, 2, 1–9. [Google Scholar]

- Chen, Y.; Li, J.; Chen, C. Optimization design of thin wall angular contact ball bearing based on MATLAB genetic algorithm. J. Phys. Conf. Ser. 2023, 2459, 012104. [Google Scholar] [CrossRef]

| Modeling Method | Applicability | Advantages | Limitations |

|---|---|---|---|

| Bearing linearization | Emphasize the overall machine analysis and the situation where the influence of bearings accounts for a small proportion. | Quickly solve the natural frequency of the rotor and evaluate the stiffness and damping of the bearings. | Quickly solve the natural frequency of the rotor and evaluate the stiffness and damping of the bearings. |

| Discrete element modeling based on Hertz contact | Evaluation of high-speed/high-DN transient operating conditions and uneven load distributions between two trains. | The contact is physically close to the movement of the rolling elements. The internal movement of the bearing can be analyzed. | The number of parameters is large, and the step size/convergence is sensitive. |

| Discrete Element Method (DEM)-FEM rigid–flexible coupling | Consider the flexibility of some components in the bearing section; assembly pre-tightening—flexibility coupling check. | It simultaneously reflects the local contact details and the flexible transmission of the seat ring/outer ring. It is suitable for comprehensive matching of pre-tightening, load and geometry. | The modeling cost is high; the grid is sensitive to contact parameters. slow computing speed. |

| Defect error modeling | Fault mechanism and life analysis; evaluate the impact of defects on the stability and contact fatigue of bearings. | The effect of quantifiable defect size/position/amplitude on stress and load distribution; it is convenient for Noise, Vibration, Harshness (NVH)/lifespan comparison. | The actual effect of the defect structure is difficult to determine, and there is a risk of extrapolation. |

| Derive the two-column model from the single-column model | Compare the differences between double-column and single-column models; establishment of theoretical equations for two-column models with different internal configurations. | Reveal the theoretical mechanism of the uneven loading of the two columns; single-column research can provide a solid theoretical foundation. | It is necessary to carry out simultaneous pre-tightening—inner ring clearance and equivalent oil film correction. |

| Modeling Method | Applicability | Advantages | Limitations |

|---|---|---|---|

| Hertz contact theory | The basic theory of bearings is used to calculate the nonlinear force–displacement relationship of local contact between balls and grooves. Variable contact angles, preload/clearance can all be embedded. | The form is simple and naturally coupled with DEM and Multibody Dynamics (MBD). High computing efficiency; wide engineering applications. | The influences of roughness, viscoelasticity, oil film, etc., were ignored. |

| Boussinesq’s elastic half-space theory | When the flexibility of the outer ring or bearing housing is significant and needs to be elastically linked with the structure. | The contact domain influence function is clear, and a more accurate equivalent contact stiffness can be derived. | The geometric approximation and roughness matching requirements are high. The implementation of numerical values is cumbersome. Material parameter sensitivity. |

| Elastohydrodynamic lubrication theory | High-speed, high-temperature, and significantly viscous working conditions. | Reflect the influence of thermo–fluid–solid coupling on the softening and hardening of contact stiffness. | Many parameters, convergence-sensitive. |

| Deformation coordination theory | Calculate the double-column load distribution and equivalent stiffness matrix quickly. When the component is flexible, consider the impact introduced by the pre-tightening design. | Strong analytical ability and fast convergence. | Many implementations are based on quasi-static or quasi-dynamic conditions, making it difficult to directly reflect dynamic phenomena such as time-varying nonlinearity and periodic bifurcation caused by the passage of rolling elements. |

| Modeling Method | Applicability | Advantages | Limitations |

|---|---|---|---|

| Traditional Reynolds equation theory modeling (short/finite-width/long bearing theory; π/2π theory) | Engineering dimension design, theoretical derivation. | The physics is clear and highly interpretable. | There is no analytical solution, making the calculation difficult and the calculation speed slow. |

| Equivalent modeling based on the principle of similarity (Buckingham π Theory) | There are already test benches or prototypes. Cross-platform parameter transplantation. | The design rules are intuitive. Nonlinear oil film forces and structural parameters can be mapped to a small number of dimensionless groups. Reduce the full numerical solution. | There is a deviation when extrapolating the similarity criterion to extreme working conditions. Not very precise. |

| Heat-flow coupling modeling (couple the energy equation with the Reynolds equation and the viscosity-temperature equation) | The temperature increase is significant, sealing is greatly affected, and the viscosity–temperature feedback and other working conditions need to be evaluated. | It can reveal the feedback chain of “extrusion heat generation → viscosity change → cavitation/inhalation”. It has strong guidance for ERSFD/seal design. | There are many parameters and boundaries. Expensive to calculate; the requirements for parameter calibration and convergence are high. |

| Data-driven modeling (Chebyshev polynomial fitting, intelligent optimization of Hunter-Prey Optimization (HPO)/Particle Swarm Optimization (PSO)) | Multi-objective optimization Quickly calculate the oil film force; fast interpolation under complex boundaries. | Significantly reduce the cost of online batch computing; it is convenient for sensitivity and robustness optimization. | Rely on high-quality training data; there is a risk of extrapolation. Physical interpretability is relatively weak. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Zhang, Z.; Pu, J.; Xue, Q.; Li, Y.; Wang, T. A Research Review of Rolling Bearing Turbocharger Modeling and System Characteristics. Machines 2025, 13, 1066. https://doi.org/10.3390/machines13111066

Yu Z, Zhang Z, Pu J, Xue Q, Li Y, Wang T. A Research Review of Rolling Bearing Turbocharger Modeling and System Characteristics. Machines. 2025; 13(11):1066. https://doi.org/10.3390/machines13111066

Chicago/Turabian StyleYu, Zhiheng, Zhiyong Zhang, Jinrui Pu, Qi Xue, Yuanhao Li, and Tianyou Wang. 2025. "A Research Review of Rolling Bearing Turbocharger Modeling and System Characteristics" Machines 13, no. 11: 1066. https://doi.org/10.3390/machines13111066

APA StyleYu, Z., Zhang, Z., Pu, J., Xue, Q., Li, Y., & Wang, T. (2025). A Research Review of Rolling Bearing Turbocharger Modeling and System Characteristics. Machines, 13(11), 1066. https://doi.org/10.3390/machines13111066