Solid Lubricants for the Wheel–Rail Interface: Practical Experience and Computational Estimation of Their Effects

Abstract

1. Introduction

- On the vehicle—on-board friction management systems (e.g., flange lubrication installed on a vehicle bogie);

- On the track—trackside friction management systems (e.g., stationary grease pumps installed in tight curves);

- On a special vehicle, such as the ‘lubricating tram’ in Prague or Railhead Treatment Trains (RHTTs) in Great Britain, providing rail conditioning for other vehicles running on the line.

2. Wheel–Rail Interaction in Curved Tracks

3. Modelling of the Potential Contribution of Solid Lubricants to Reducing Wheel and Rail Wear

3.1. Models and Methods

- Four wheelsets (4 × 6 DoFs);

- Two bogie frames (2 × 6 DoFs);

- Vehicle body (with seven DoFs—the additional one DoF represents its torsional flexibility);

- Eight equivalent masses of rails in the lateral direction (8 × 1 DoF) belonging to individual wheels;

- Four equivalent masses of air in the secondary suspension system (4 × 1 DoF). To reflect the real frequency-dependent dynamic behaviour of the secondary air suspension, the Gavriloski–Jovanova air spring model [44] was implemented into the MBS model, and its parameters were verified experimentally.

3.2. Simulation Scenarios

3.3. Simulation Results—General Behaviour

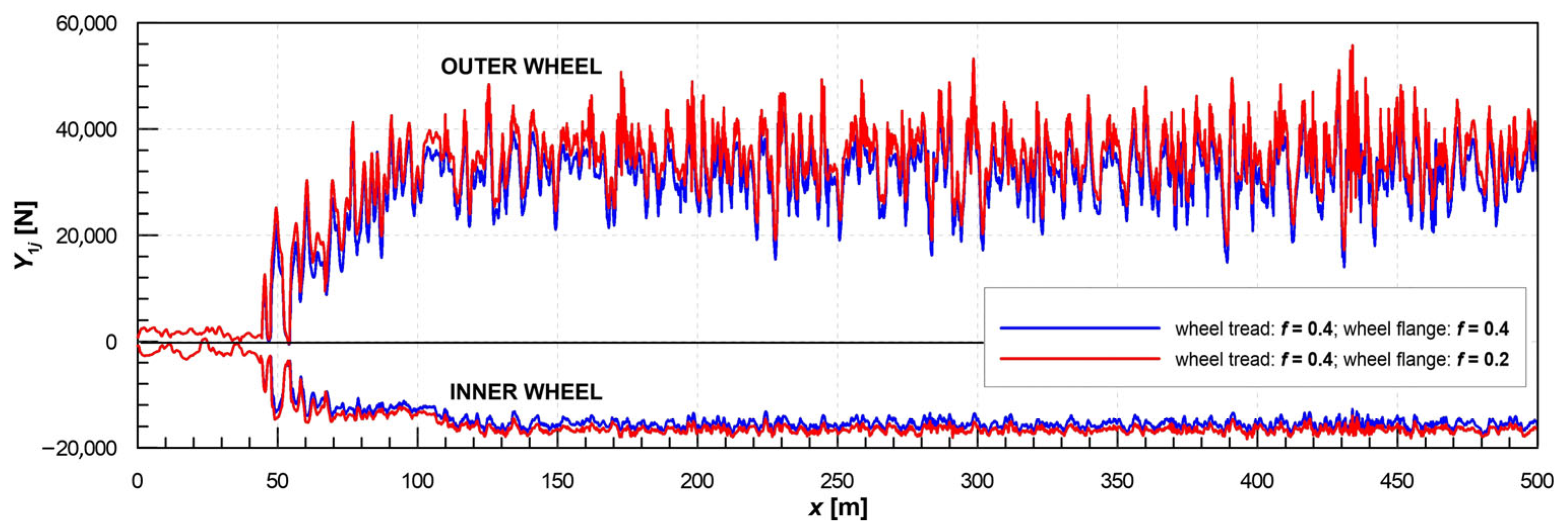

3.4. Simulation Results—Influence of Flange Lubrication

- The reduced CoF on the flange of the leading wheel significantly reduces the wear number on that wheel and has almost no influence on other wheels (as expected);

- The influence on the guiding forces (often taken as representative quantities of vehicle curving behaviour) is not the same; it is even opposite, although with a lower sensitivity: flange lubricated leading wheels experience higher guiding forces.

4. Practical Assessment of Solid Lubricant Performance

4.1. Procedure

- After mounting the test discs and setting the load, the machine runs at the required speed without lubricating the discs.

- When the coefficient of friction (CoF) reaches the initial level of 0.4, a solid lubricant sample (stick) is applied and pressed against one of the discs. If the lubricant is effective, the CoF decreases.

- After 200 s, the lubricant sample is removed without stopping the machine.

- The CoF gradually increases again. The test ends when the CoF reaches the reference dry level of 0.4.

- The lubricant sample is weighed to determine the lubricant consumption.

- Rate of CoF decrease after applying the lubricant;

- Steady CoF value during the lubrication of the discs;

- Retentivity, i.e., duration of CoF increase up to the reference dry level after the lubricant is removed.

4.2. Measured Response

4.3. Factors Influencing the Results

4.3.1. Temperature

4.3.2. Test Disc Manufacturing and Surface Quality

4.3.3. Pressure on the Lubricant Sample

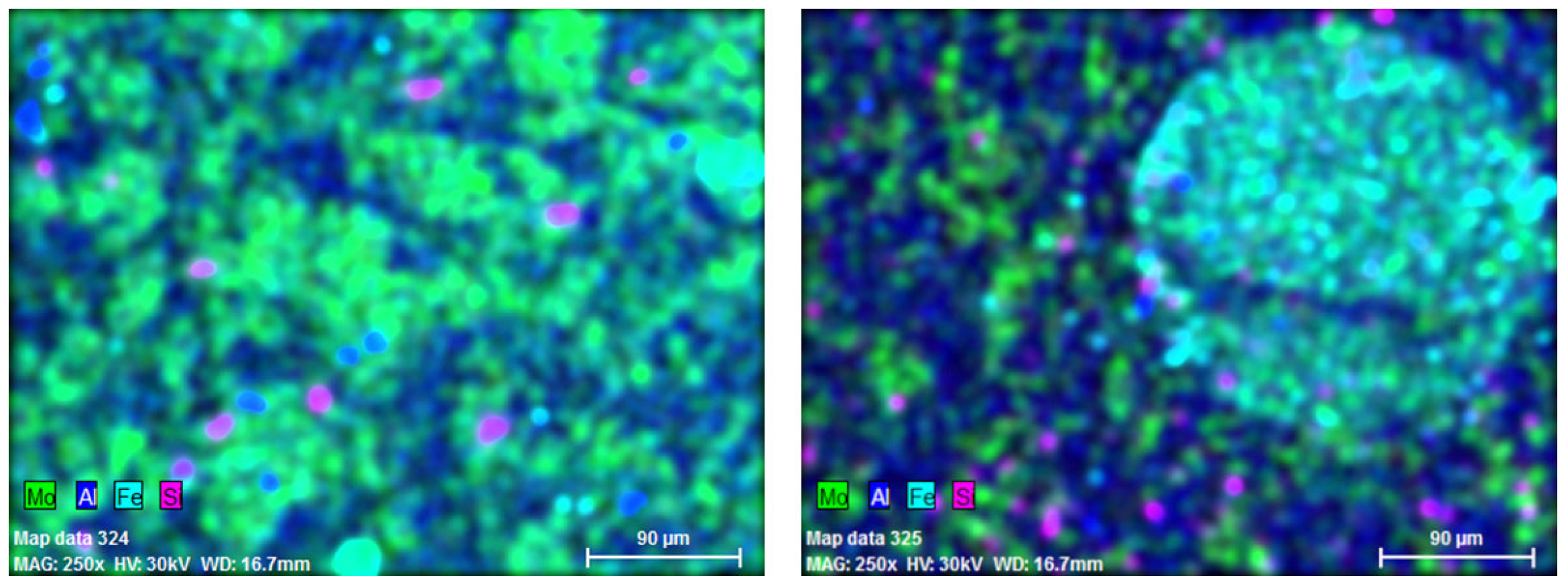

4.3.4. The Lubricant Sample and Its Application Surface

4.4. Limitations of the Current Testing Methodology and Possible Improvements

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CoF | Coefficient of friction |

| DoF | Degree of freedom |

| FM | Friction modifier |

| LCF | Low coefficient of friction |

| MBS | Multi-body simulation |

| RHTT | Railhead Treatment Trains |

| SJKV | Simulace jízdy kolejového vozidla [in Czech]—Simulation of the running of a rail vehicle |

References

- Buckley-Johnstone, L.E. Wheel/Rail Contact Tribology: Characterising Low Adhesion Mechanisms and Friction Management Products. Ph.D. Dissertation, University of Sheffield, Sheffield, UK, 2017. [Google Scholar]

- Lewis, R.; Olofsson, U. Wheel-Rail Interface Handbook; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Singh, R.K.; Shindhe, M.; Rawat, P.; Srivastava, A.K.; Singh, G.K.; Verma, R.; Bhutto, J.K.; Hussein, H.S. The Effect of Various Contaminants on the Surface Tribological Properties of Rail and Wheel Materials: An Experimental Approach. Coatings 2023, 13, 560. [Google Scholar] [CrossRef]

- Butcher, T. Understanding and Modelling Low Adhesion Risk in the Wheel-Rail Interface. Ph.D. Dissertation, University of Sheffield, Sheffield, UK, 2022. [Google Scholar]

- Galas, R. Friction Modification Within Wheel-Rail Contact. Ph.D. Dissertation, Brno University of Technology, Brno, Czech Republic, 2017. [Google Scholar]

- Chen, H.; Fukagai, S.; Sone, Y.; Ban, T.; Namura, A. Assessment of lubricant applied to wheel/rail interface in curves. Wear 2014, 314, 228–235. [Google Scholar] [CrossRef]

- Eadie, D.; Oldknow, K.; Santoro, M.; Kwan, G.; Yu, M.; Lu, X. Wayside gauge face lubrication: How much do we really understand? Proc. IMechE Part F J. Rail Rapid Transit 2012, 227, 245–253. [Google Scholar] [CrossRef]

- Fang, C.; Ding, Y.; Yan, H.; Chen, J.; Zhou, W.; Meng, X. Prediction and analysis of wheel flange wear on small curved track considering wheel-rail conformal and lubricated contact. Wear 2024, 558–559, 205569. [Google Scholar] [CrossRef]

- Rey, T.; Papin, E.; Fridrici, V.; Dassenoy, F. Experimental study of the tribological performance of a solid lubricant stick with MoS2 for wheel-rail contact. Wear 2025, 570, 205941. [Google Scholar] [CrossRef]

- EN 15427-2-1:2022; Railway Applications—Wheel/Rail Friction Management—Part 2–1: Properties and Characteristics—Flange Lubricants. European Committee for Standardization: Brussels, Belgium, 2022.

- Stock, R.; Stanlake, L.; Hardwick, C.; Yu, M.; Eadie, D.; Lewis, R. Material concepts for top of rail friction management—Classification, characterisation and application. Wear 2016, 366–367, 225–232. [Google Scholar] [CrossRef]

- Eadie, D.; Kalousek, J.; Chiddick, K.C. The role of high positive friction (HPF) modifier in the control of short pitch corrugations and related phenomena. Wear 2002, 253, 185–192. [Google Scholar] [CrossRef]

- White, B.; Lee, Z.S.; Lewis, R. Towards a Standard Approach for the Twin Disc Testing of Top-Of Rail Friction Management Products. Lubricants 2022, 2022, 124. [Google Scholar] [CrossRef]

- Omasta, M.; Machatka, M.; Smejkal, D.; Hartl, M.; Křupka, I. Influence of sanding parameters on adhesion recovery in contaminated wheel-rail contact. Wear 2015, 322–323, 218–225. [Google Scholar] [CrossRef]

- Skipper, W.A.; Chalisey, A.; Lewis, R. A review of railway sanding system research: Wheel/rail isolation, damage, and particle application. Proc. IMechE Part F J. Rail Rapid Transit 2019, 234, 567–583. [Google Scholar] [CrossRef]

- Bosso, N.; Magelli, M.; Zampieri, N. Simulation of wheel and rail profile wear: A review of numerical models. Railw. Eng. Sci. 2022, 30, 403–436. [Google Scholar] [CrossRef]

- Wang, S.; Bingguang, W.; Ren, D.; Ding, Y.; Wen, Z.; Dong, D.; Tao, G. Analysis of the causes of severe side wear of the high rail on metro curves by numerical simulation and field investigation. Proc. ImechE Part F J. Rail Rapid Transit 2024, 238, 381–393. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Spiryagin, M.; Wu, Q.; Cole, C. Wheel-rail contact wear analysis on curved lubricated track for heavy haul locomotive studies. Proc. ImechE Part F J. Rail Rapid Transit 2024, 238, 967–976. [Google Scholar] [CrossRef]

- Maya-Johnson, S.; Santa, J.F.; Toro, A. Dry and lubricated wear of rail steel under rolling contact fatigue—Wear mechanisms and crack growth. Wear 2017, 380–381, 240–250. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Wong, K.C.; Lu, X.; Cotter, J.; Eadie, D.T.; Wong, P.C.; Mitchell, K.A.R. Surface and friction characterization of MoS2 and WS2 third body thin films under simulated wheel/rail rolling–sliding contact. Wear 2008, 264, 526–534. [Google Scholar] [CrossRef]

- Cebulska, W.; Bąkowski, H.; Hadryś, D. The Influence of Selected Solid Lubricants on the Wear of the Rolling–Sliding Interface in the Wheel–Rail System According to the Standard PN-EN 15427-2-1:2022. Materials 2025, 18, 1672. [Google Scholar] [CrossRef]

- Fletcher, D.I.; Lewis, S. Creep curve measurement to support wear and adhesion modelling, using a continuously variable creep twin disc machine. Wear 2013, 298–299, 57–65. [Google Scholar] [CrossRef]

- Wu, P.; Zhang, F.; Wang, J.; Wei, L.; Huo, W. Review of wheel-rail forces measuring technology for railway vehicles. Adv. Mech. Eng. 2023, 15, 16878132231158991. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, X.; Ling, L.; Wang, K.; Zhai, W. Effect of gauge corner lubrication on wheel/rail non-Hertzian contact and rail surface damage on the curves. Acta Mech. Sin. 2022, 38, 521522. [Google Scholar] [CrossRef]

- Ye, Y.; Vuitton, J.; Sun, Y.; Hecht, M. Railway wheel profile fine-tuning system for profile recommendation. Railw. Eng. Sci. 2021, 29, 74–93. [Google Scholar] [CrossRef]

- Vollebregt, E.A.H. Detailed wheel/rail geometry processing using the planar contact approach. Veh. Syst. Dyn. 2020, 60, 1253–1291. [Google Scholar] [CrossRef]

- Stratmann, I.; Goersch, J.; Schindler, C. Overview of methods to identify the static normal wheel-rail contact. Proc. IMechE Part F J. Rail Rapid Transit 2021, 236, 783–792. [Google Scholar] [CrossRef]

- Liu, B.; Bruni, S. Comparison of wheel–rail contact models in the context of multibody system simulation: Hertzian versus non-Hertzian. Veh. Syst. Dyn. 2020, 60, 1076–1096. [Google Scholar] [CrossRef]

- Jing, L.; Zhou, X.; Wang, K. An elastic-plastic theoretical analysis model of wheel-rail rolling contact behaviour. Acta Mech. Sin. 2023, 39, 422465. [Google Scholar] [CrossRef]

- Meymand, S.Z.; Keylin, A.; Ahmadian, M. A survey of wheel–rail contact models for rail vehicles. Veh. Syst. Dyn. 2016, 54, 386–428. [Google Scholar] [CrossRef]

- Fang, C.; Jaafar, S.A.; Zhou, W.; Yan, H.; Chen, J.; Meng, X. Wheel-rail contact and friction models: A review of recent advances. Proc. IMechE Part F J. Rail Rapid Transit 2023, 237, 1245–1259. [Google Scholar] [CrossRef]

- Knothe, K.; Stichel, S. Rail Vehicle Dynamics; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Iwnicki, S.; Spiryagin, M.; Cole, C.; McSweeney, T. (Eds.) Handbook of Railway Vehicle Dynamics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Higa, D.N.; Kina, E.J.; Gay Neto, A. Wheelset-rail mechanical model for a steady-state dynamic condition and prediction of rolling contact fatigue locci. Veh. Syst. Dyn. 2020, 60, 281–308. [Google Scholar] [CrossRef]

- Pacheco, P.A.P.; Ramos, P.G.; Sá, T.L.; Santos, G.F.M.; Gay Neto, A.; Santos, A.A. Comparison between quasi-static and multibody dynamic simulations for wheel-rail contact analysis. Multibody Syst. Dyn. 2025, 63, 63–81. [Google Scholar] [CrossRef]

- Tunna, J.; Sinclair, J.; Perez, J. A Review of wheel wear and rolling contact fatigue. Proc. IMechE Part F J. Rail Rapid Transit 2007, 221, 271–289. [Google Scholar] [CrossRef]

- Wu, Q.; Bernal, E.; Spiryagin, M.; Krishna, V.; Ding, H.; Stichel, S.; Cole, C. Heavy haul rail/wheel wear and RCF assessments using 3D train models and a new wear map. Wear 2024, 538–539, 205226. [Google Scholar] [CrossRef]

- Luo, K.; Liu, X.; Yang, Y.; Cong, T.; Zhang, F.; Wang, W. Modeling the competitive relationship between wear and rolling contact fatigue of railway wheel steel. Wear 2025, 560–561, 205615. [Google Scholar] [CrossRef]

- Michálek, T.; Zelenka, J. Reduction of lateral forces between the railway vehicle and the track in small-radius curves by means of active elements. Appl. Comput. Mech. 2011, 5, 187–196. [Google Scholar]

- Michálek, T.; Zelenka, J. Simulations of dynamic behaviour of locomotive 744.001 CZ LOKO. In Proceedings of the 9th International Conference on Railway Bogies and Running Gears, Budapest, Hungary, 9–12 September 2013; BME Budapest: Budapest, Hungary, 2014; pp. 109–118. [Google Scholar]

- Michálek, T.; Kohout, M. On the problems of lateral force effects of railway vehicles in S-curves. Veh. Syst. Dyn. 2022, 60, 2739–2757. [Google Scholar] [CrossRef]

- Zelenka, J.; Michálek, T.; Kohout, M. Comparative simulations of guiding behaviour of an electric locomotive. In Proceedings of the 20th International Conference Engineering Mechanics, Svratka, Czech Republic, 12–15 May 2014; ITAM CAS: Prague, Czech Republic, 2014; pp. 740–743. [Google Scholar]

- Gavriloski, V.; Jovanova, J.; Tasevski, G.; Đidrov, M. Development of new air spring dynamic model. FME Trans. 2014, 42, 305–310. [Google Scholar] [CrossRef]

- Michálek, T.; Jeniš, F. Modelling of secondary suspension for electric multiple unit. In Proceedings of the 38th Conference with International Participation Computational Mechanics, Srní, Czech Republic, 23–25 October 2023; University of West Bohemia: Plzeň, Czech Republic, 2023; pp. 116–118. [Google Scholar]

- EN 13715:2020; Railway Applications—Wheelsets and Bogies—Wheels—Tread Profile. European Committee for Standardization: Brussels, Belgium, 2020.

- EN 13674-1:2017; Railway Applications—Track—Rail—Part 1: Vignole Railway Rails 46 kg/m and Above. European Committee for Standardization: Brussels, Belgium, 2017.

- Galas, R.; Valena, M.; Jordan, T.; Kvarda, D.; Omasta, M.; Skurka, S.; Wu, B.; Ding, H.; Wang, W.; Krupka, I.; et al. A benchmarking methodology for top-of-rail products: Carry distance and retentivity. Tribol. Int. 2024, 197, 109810. [Google Scholar] [CrossRef]

- EN 16028:2012; Railway Applications—Wheel/Rail Friction Management—Lubricants for Trainborne and Trackside Applications. European Committee for Standardization: Brussels, Belgium, 2012.

- Lewis, R.; Magel, E.; Wang, W.; Olofson, U.; Lewis, S.; Slatter, T.; Beagles, A. Towards a standard approach for the wear testing of wheel and rail materials. Proc. IMechE Part F J. Rail Rapid Transit 2017, 231, 760–774. [Google Scholar] [CrossRef]

- Gallardo-Hernandez, E.A.; Lewis, R.; Dwyer-Joyce, R.S. Temperature in a twin-disc wheel/rail contact simulation. Tribol. Int. 2006, 39, 1653–1663. [Google Scholar] [CrossRef]

- Freibauer, L. Adheze kola vozidla na dráze. In Proceedings of the 7. Vedecká Konferencia Vysokej Školy Dopravy a Spojov v Žiline, Žilina, Slovakia, 13–15 September 1983; VŠDS Žilina: Žilina, Slovakia, 1983; pp. 214–219. (In Czech) [Google Scholar]

- Buckley-Johnstone, L.E.; Trummer, G.; Voltr, P.; Six, K.; Lewis, R. Full-scale testing of low adhesion effects with small amounts of water in the wheel/rail interface. Tribol. Int. 2020, 141, 105907. [Google Scholar] [CrossRef]

- Polách, O. A Fast wheel-rail forces calculation computer code. In Proceedings of the 16th IAVSD Symposium, Vehicle System Dynamics Supplement, Pretoria, South Africa, 30 August–3 September 1999; Volume 33, pp. 728–739. [Google Scholar]

- Michálek, T.; Liberová, S.; Vágner, J.; Jaroš, P.; Šlapák, J. Stiffness characteristics of railway buffers: Requirements, testing and proposal of a new computational model. Appl. Comput. Mech. 2025, 19, 69–86. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Distance between bogie pivots | 19.0 | m |

| Bogie wheelbase | 2.40 | m |

| Nominal wheel diameter | 0.85 | m |

| Mass of driven wheelset (unsprung mass) | 1900 | kg |

| Mass of non-driven wheelset (unsprung mass) | 1700 | kg |

| Mass of bogie frame (traction bogie) | 4500 | kg |

| Mass of bogie frame (trailer bogie) | 3300 | kg |

| Mass of vehicle body | 30,000 | kg |

| Vertical stiffness of primary suspension (per axle box, traction bogie) | 650 | kN/m |

| Vertical stiffness of primary suspension (per axle box, trailer bogie) | 550 | kN/m |

| Nominal vertical stiffness of secondary suspension spring (for a load of 70 kN) | 320 | kN/m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michálek, T.; Voltr, P.; Liberová, S.; Šlapák, J. Solid Lubricants for the Wheel–Rail Interface: Practical Experience and Computational Estimation of Their Effects. Machines 2025, 13, 1041. https://doi.org/10.3390/machines13111041

Michálek T, Voltr P, Liberová S, Šlapák J. Solid Lubricants for the Wheel–Rail Interface: Practical Experience and Computational Estimation of Their Effects. Machines. 2025; 13(11):1041. https://doi.org/10.3390/machines13111041

Chicago/Turabian StyleMichálek, Tomáš, Petr Voltr, Stanislava Liberová, and Jiří Šlapák. 2025. "Solid Lubricants for the Wheel–Rail Interface: Practical Experience and Computational Estimation of Their Effects" Machines 13, no. 11: 1041. https://doi.org/10.3390/machines13111041

APA StyleMichálek, T., Voltr, P., Liberová, S., & Šlapák, J. (2025). Solid Lubricants for the Wheel–Rail Interface: Practical Experience and Computational Estimation of Their Effects. Machines, 13(11), 1041. https://doi.org/10.3390/machines13111041