3.1. Simulation Methodology

This work employs a CFD–DEM gas–solid two-phase flow coupling simulation approach. Using this method, the operational process of the gas-excitation sampling and delivery device, as well as the interphase interaction forces, are numerically investigated. The dynamic description of the fluid phase is based on the volumetric Navier–Stokes equation, where the fluid continuity equation is

The momentum conservation equation of fluid is

The phase transfer equation is

In these equations,

represents the cell void fraction,

represents the fluid phase density,

represents the fluid velocity vector,

p represents the pressure,

represents the momentum source term generated by the particle,

represents viscous stress tensor,

is the acceleration of gravity,

represents the computational cell volume, and

represents the drag force of the fluid relative to the particle, which can be derived with the following equation

In this equation, represents the particle diameter, represents the drag coefficient, while represents the particle velocity vector.

The description of the motion of particles follows Newton’s second law as following

In this equation, represents the mass of a single particle, represents the contact force between particles, represents the volume of a single particle, represents the moment of inertia of the particle, represents the angular velocity vector of the particles, and represents the torque applied on the particles.

To mitigate the influence of Earth’s gravity and approximate the low-gravity condition of asteroids, low-density expanded polystyrene (EPS) particles were selected as mechanically equivalent substitutes, with a simplified spherical shape to ensure consistency and controllability in both experiments and simulations. To ensure consistency between the simulated particle parameters and the experimental materials, both intrinsic material properties and fundamental contact parameters of the foam balls must first be established.

The key intrinsic parameters of the material include Poisson’s ratio, shear modulus, and density, which are characteristic of the material itself and can be obtained from the literature and technical manuals. Since the density of EPS foam balls typically falls within a range, it is determined by the expansion ratio of polystyrene particles during molding, generally between . For this study, 4 mm foam balls were selected and screened using a sieve. Given that polystyrene is hydrophobic, the density of the foam balls was measured via the drainage method, yielding a value of 36.6 .

German scholars Eriksson and Tränk summarized the relationship between the elastic modulus and density of EPS materials in 1991 [

33].

The elastic modulus of the EPS material is calculated to be

E = 14.28 MPa using Equation (

7).

The basic contact parameters mainly include the collision recovery coefficient, static friction coefficient, and rolling friction coefficient, which are further divided into particle-to-geometry contact parameters. The shape and humidity of materials usually have a significant impact on such parameters, and there are no manuals or relevant literature available for reference. Therefore, it is usually necessary to calibrate these parameters through “virtual experiments”.

The definition of the recovery coefficient is the ratio of forward and backward velocities, which can be converted into a relationship of height without considering air resistance.

In this equation, is the velocity before the collision, is the velocity after the collision, is the height before falling, and is the maximum height of the rebound after the collision.

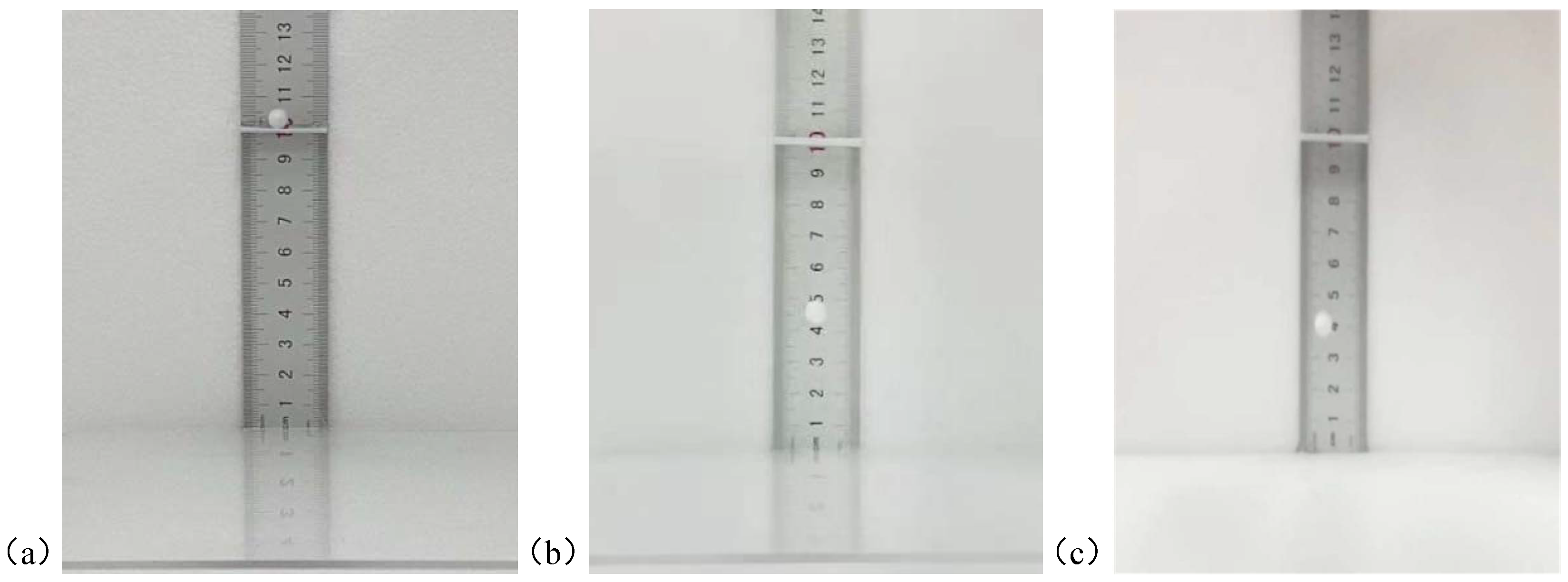

The measurement experiment of the foam ball recovery coefficient is shown in

Figure 2. For

Figure 2a, the initial height of the foam ball is set to

= 10 cm. According to the bounce height of foam ball in

Figure 2b, the recovery coefficient of foam ball and geometry can be calculated as

= 0.636. According to the bounce height of the foam balls in

Figure 2c, the recovery coefficient between foam balls is

= 0.604.

The static friction coefficient between the EPS material and the wall is 0.60 by measuring the minimum inclination angle of the EPS material foam block sliding on the geometric material. By measuring the minimum inclination angle of the EPS foam ball material to roll with the geometric material, the rolling friction coefficient between the EPS material and the wall surface was determined to be 0.075.

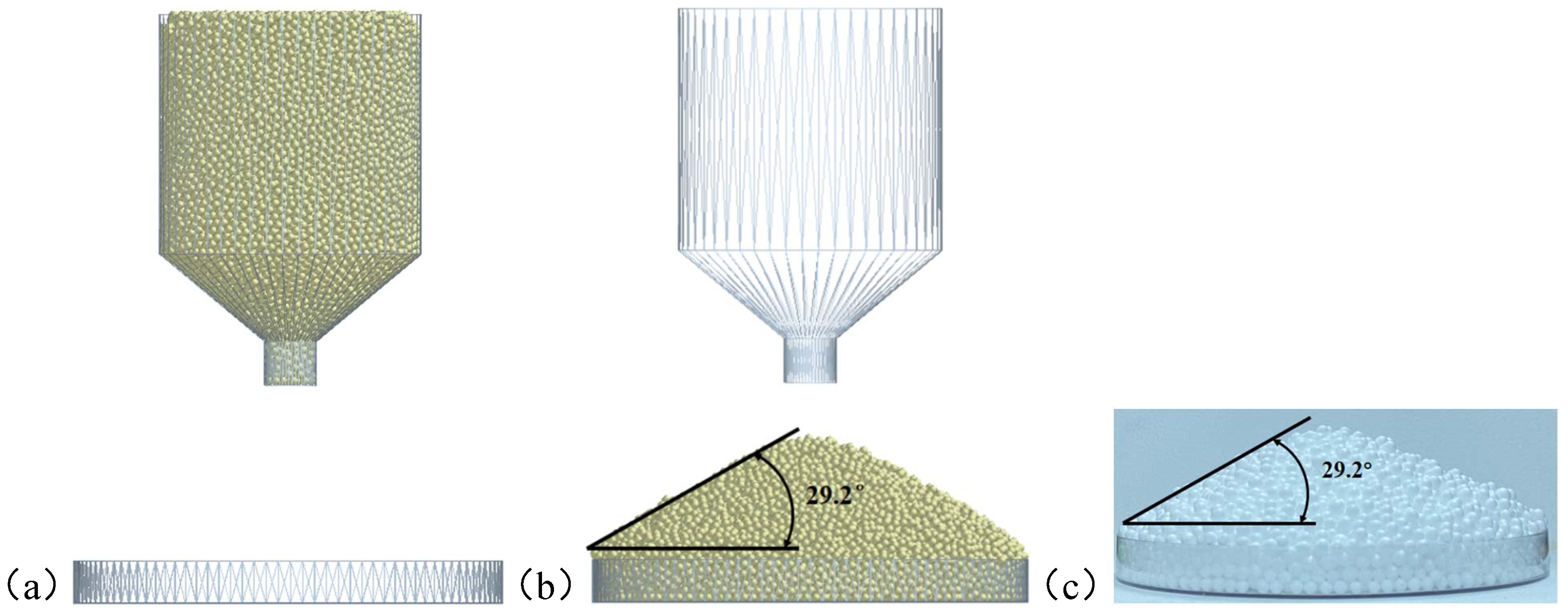

It is difficult to directly measure the particle-to-particle static friction coefficient and rolling friction coefficient. In engineering, the angle between the surface of a stable cone pile formed by the free accumulation of bulk materials under gravity and the horizontal plane, known as the accumulation angle, is measured and compared with the particle-to-particle static friction coefficient and rolling friction coefficient in EDEM simulation software to determine the particle-to-particle contact parameters. In order to measure the static friction coefficient and rolling friction coefficient between particles, virtual calibration experiments were conducted as shown in

Figure 3.

Figure 3a represents the initial state of the calibration experiment. The particles are stacked through free blanking in the particle factory filled with 4 mm foam balls. This article sets the static friction coefficients between particles to 0.3, 0.4, 0.5, and 0.6, and sets the rolling friction coefficients between particles to 0.02, 0.03, 0.04, and 0.05. A total of 16 virtual calibration experiments were conducted. By comparing with the accumulation angle of the actual foam ball particles in

Figure 3c of 29.2°, it is finally determined that the static friction coefficient between particles is 0.5, and the rolling friction coefficient between particles is 0.03.

The other detailed simulation parameters are shown in

Table 1.

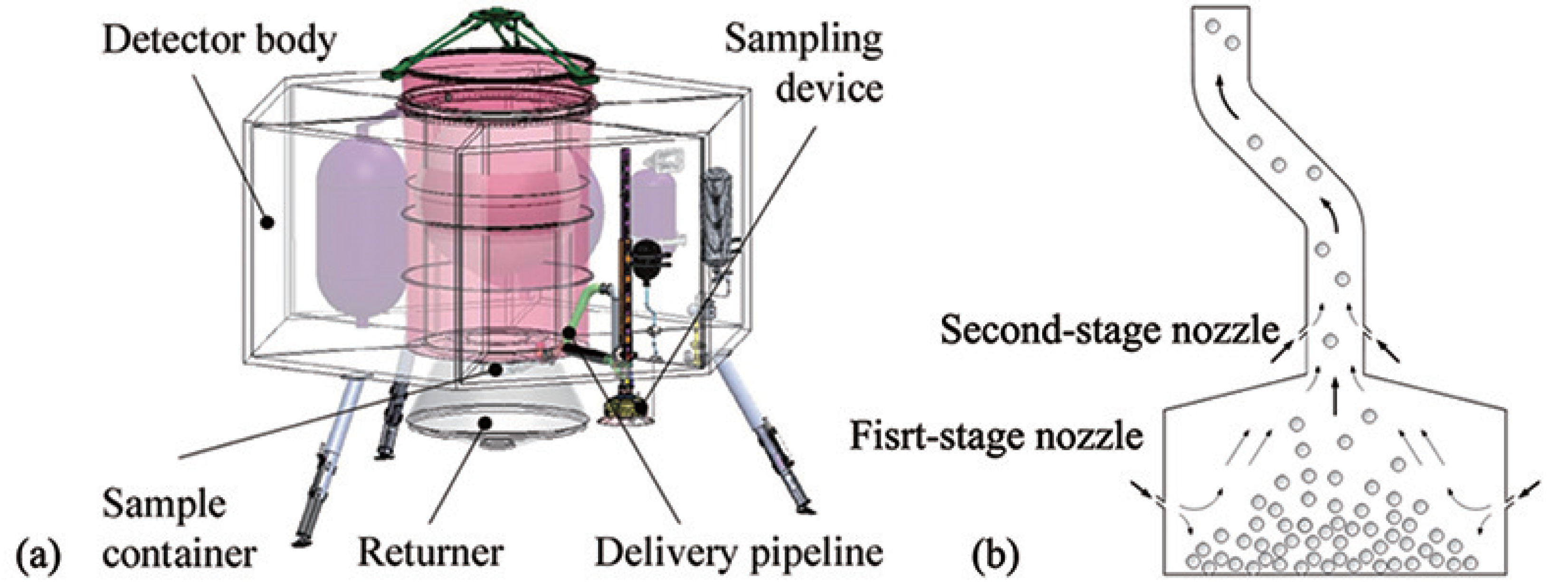

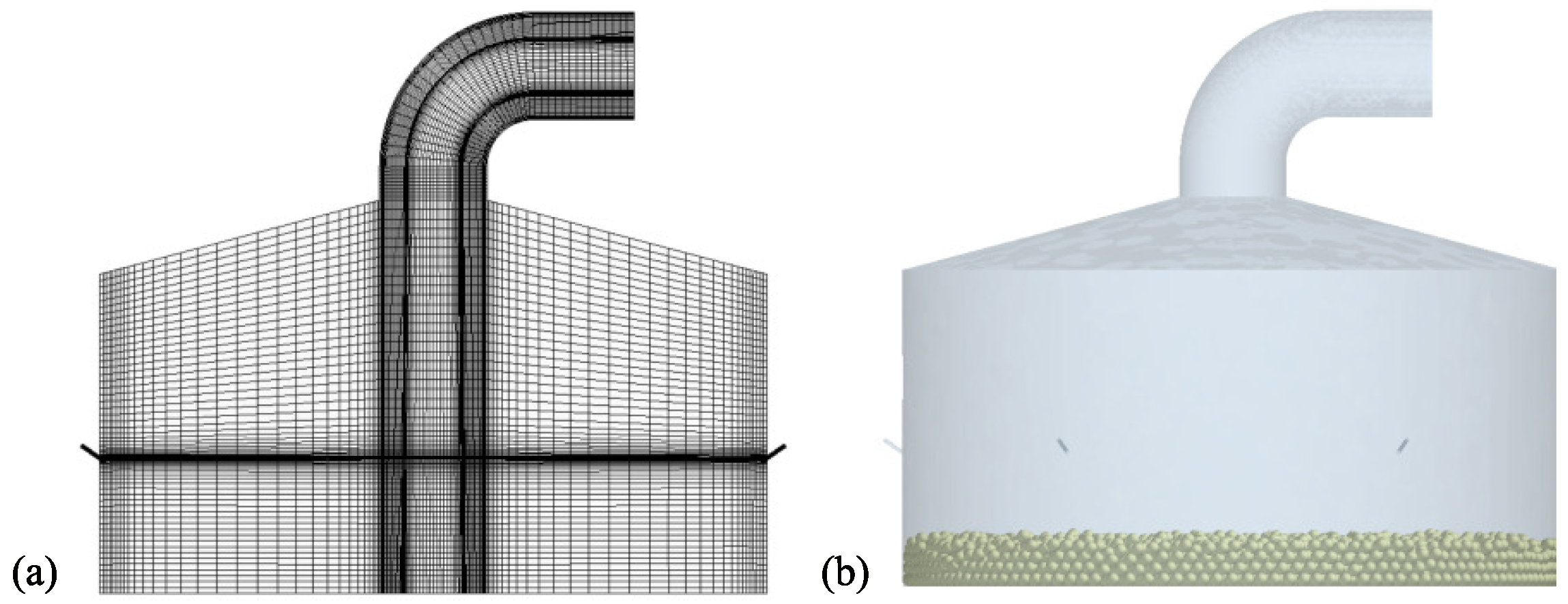

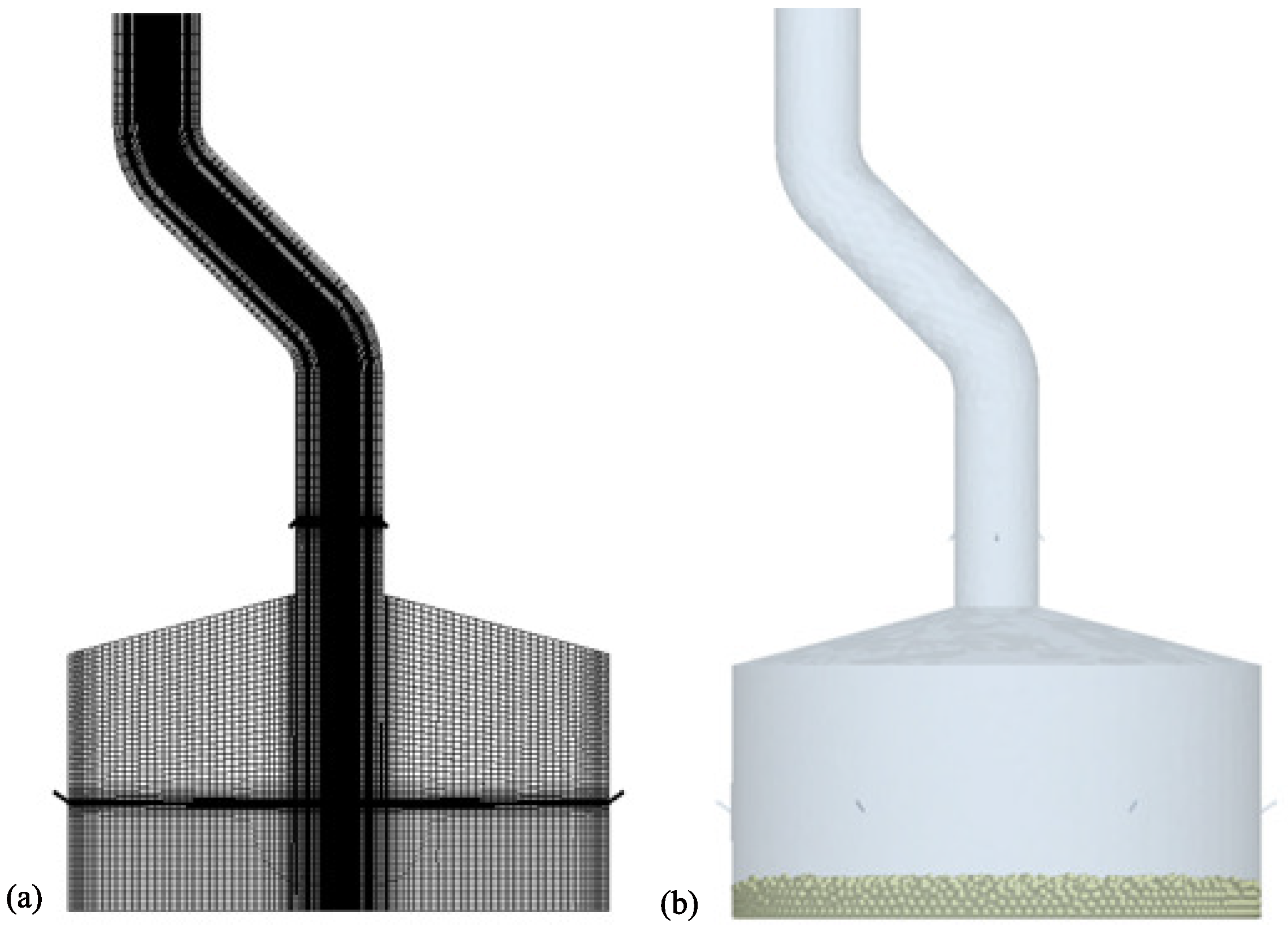

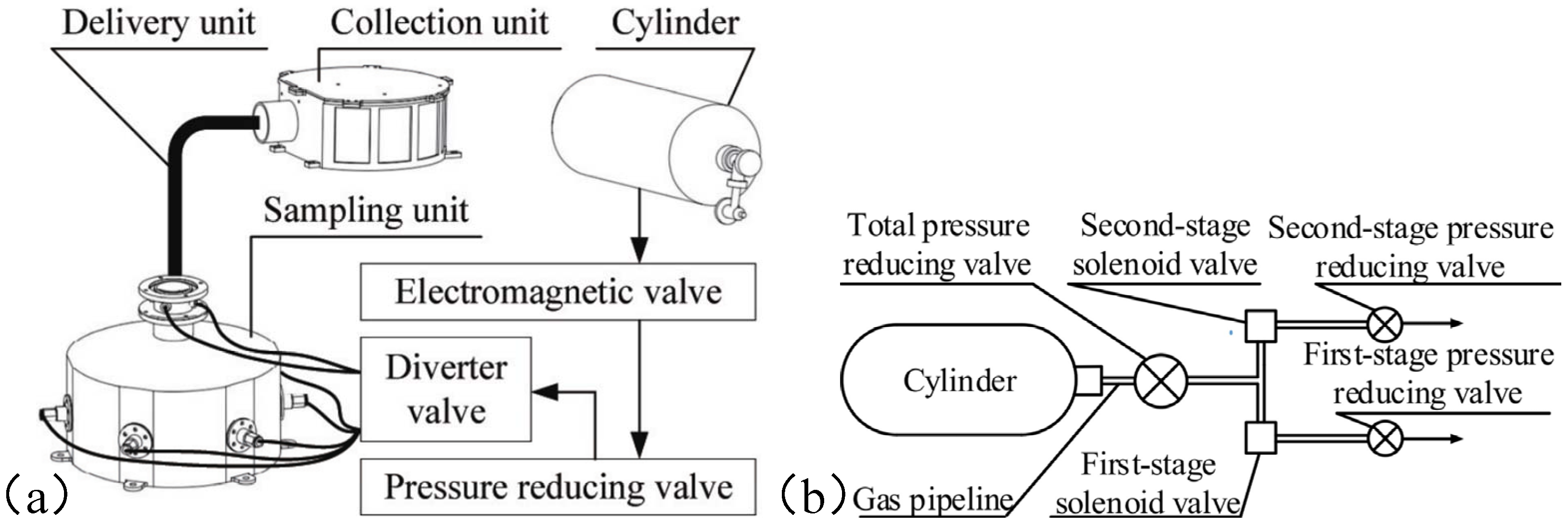

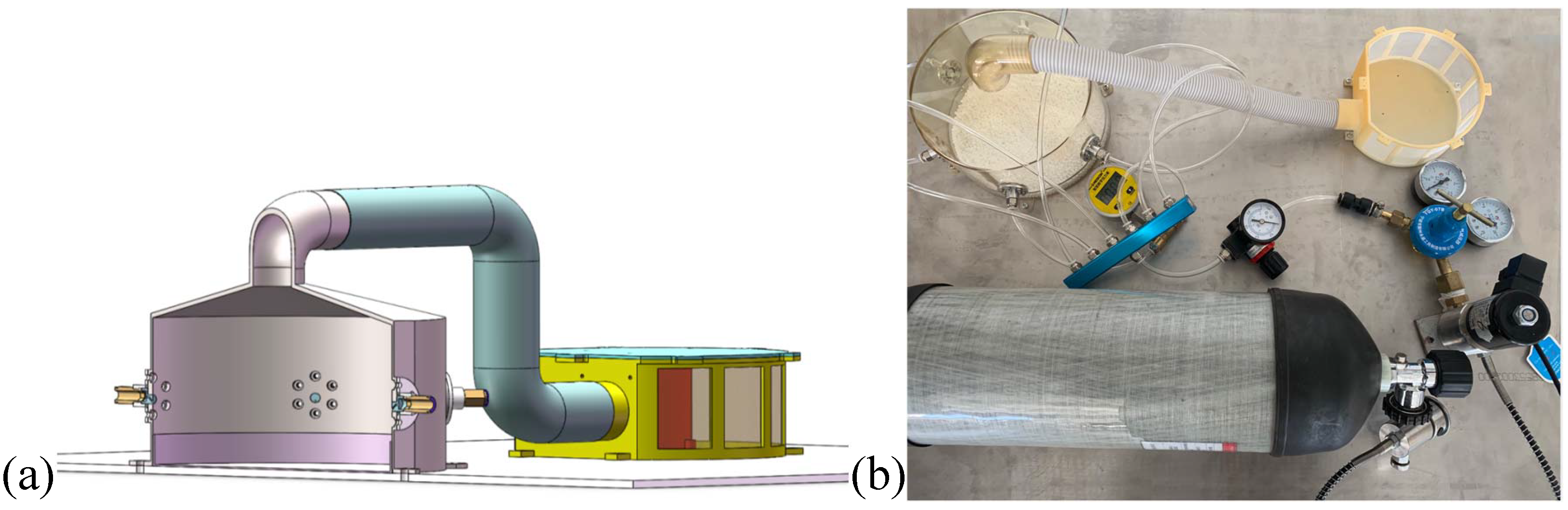

The sampling unit adopts a cylindrical hollow hood design, which forms a sealed space when brought into contact with the asteroid surface. In this configuration, six first-stage gas nozzles, each with a diameter of 1 mm, are installed at the lower section of the hood wall and are uniformly arranged symmetrically along the circumference. These nozzles eject high-pressure gas downward at a specified angle, mobilizing the asteroid regolith particles and directing them toward the hood outlet to accomplish the sampling process. The CFD–DEM gas–solid two-phase flow coupling model of the first-stage gas-excitation unit is illustrated in

Figure 4.

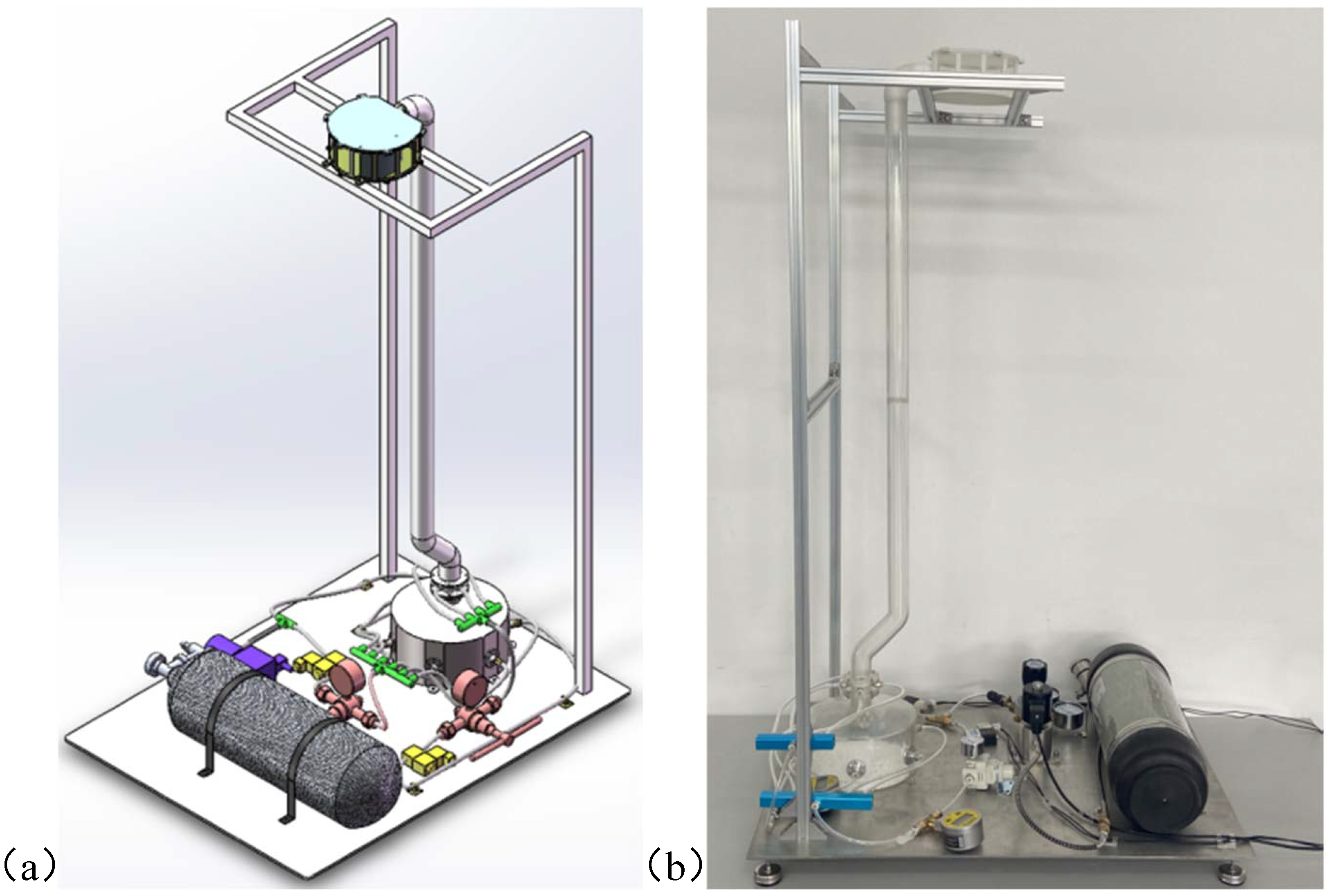

Building upon the first-stage gas-excitation sampling device, a two-stage integrated gas-excitation sampling and delivery system is developed. The outlet of the sampling hood is connected to a vertical sample-conveying pipeline with a height of 880 mm. At the junction between the hood and the pipeline, four second-stage nozzles, each with an upward inclination and a diameter of 1.2 mm, are installed. In this design, the first-stage nozzles eject downward gas to dislodge and transport regolith particles toward the hood–pipeline junction, while the second-stage nozzles eject gas obliquely upward to convey the particles through the pipeline into the sample container, thereby completing the entire sampling and delivery process. The simulation model of the two-stage integrated gas-excitation sampling and delivery device is shown in

Figure 5.

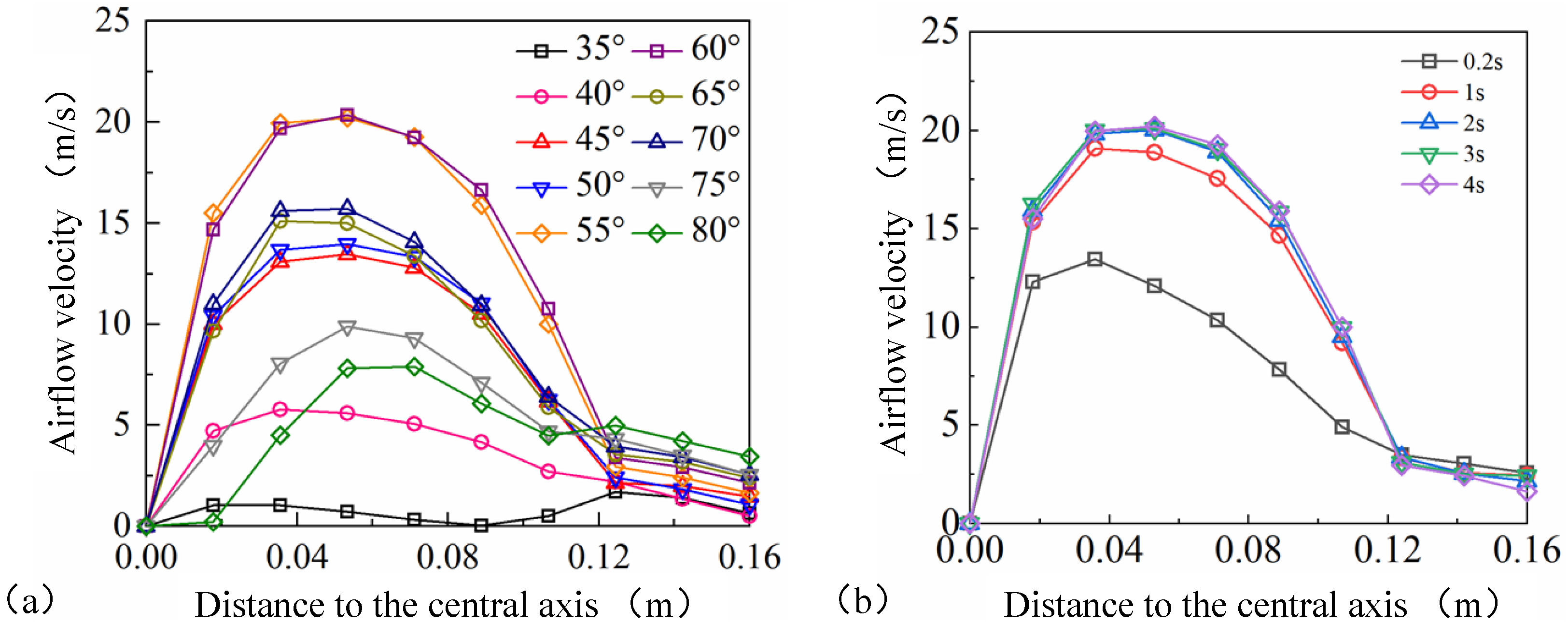

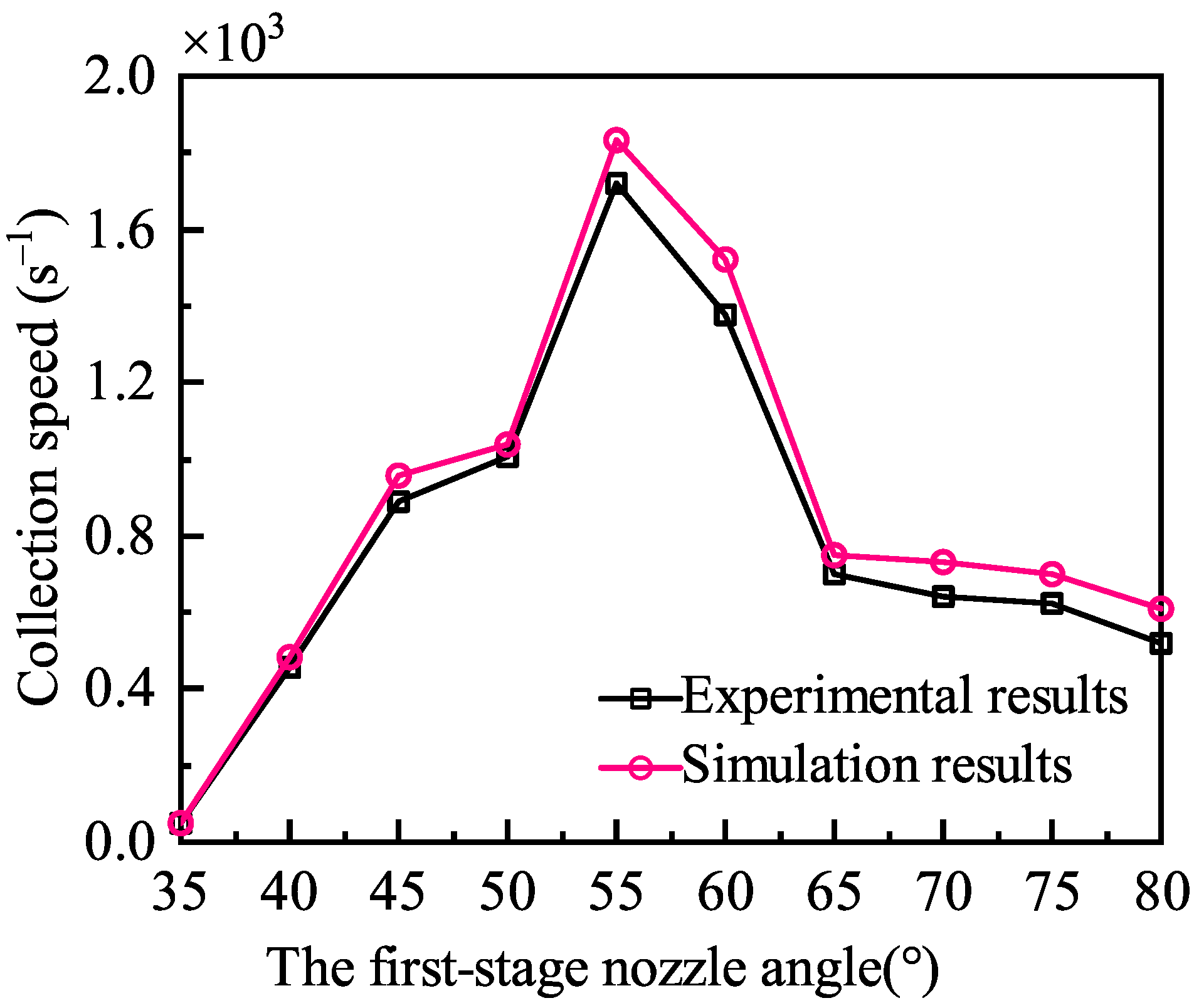

3.2. Simulation Results of the First-Stage Gas-Excitation Sampling in the Earth’s Environment

In this simulation, the nozzle angle is defined as the angle between the central axis of the nozzle and the wall of the sampling hood. The nozzle angle was varied within a range of 35°–80° with an increment of 5°. The inlet pressure of the nozzle was set to 0.1 MPa, while the outlet pressure at the pipeline was maintained at 0 MPa. Gravity was modeled at 9.81

, consistent with terrestrial conditions, and the total simulation duration was 10 s. The corresponding results are summarized in

Table 2.

The sampling simulation results show that all 7500 particles in the particle bed have been collected before the simulation time reaches 10 s at the first-stage gas nozzle angles of 45°, 50°, 55°, and 60°. The collection rate of each angle is calculated according to the actual sampling time. The average collection rate of the 55° nozzle is 1834

, in which situation the sampling effect is the best in the simulation. In the next step, the vertical component data of the airflow velocity was extracted at each point of the central axis, and a curve was drawn to study the influence of the air blowing angle on the velocity component, which is shown in

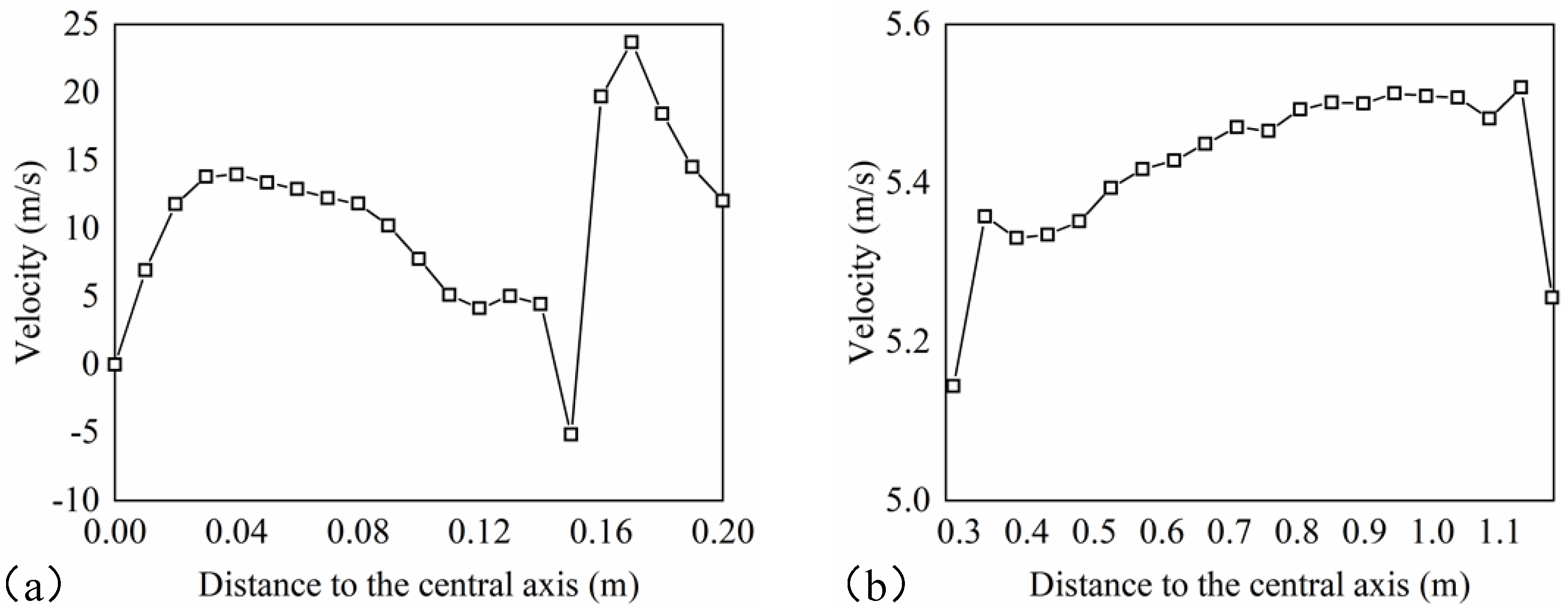

Figure 6. In

Figure 6a, at the bottom center of the sampling hood, namely the zero point of the central axis, the airflow velocity is 0 since it has not entered the nozzle air blowing range. As it moves up the central axis, the airflow speed increases rapidly. When the angle of the nozzle jet gases is in a different direction, the airflow focal point is different; the maximum airflow speed point on the central axis is shown in different places in this diagram. When the first-stage nozzle angle stays at 35° and 40°, the air velocity on the center axis about 0.035 m from the bottom of the sampling hood obtains the biggest airflow velocity components. When the nozzles were set within an angle of 45° to 75°, the nozzle air velocity points are shown in the center with a distance of about 0.05 m. At the angle of 55° and 60°, maximum airflow speed can reach more than 20

, which is the most beneficial to collecting the sample particles. The air velocity biggest point of the nozzle with an angle of 80° is higher, which stays at 0.07 m. As the distance from the bottom of the sample cover increases, the influence of the nozzle on the vertical component of the flow velocity is weakened, and the flow velocity decreases. At the outlet of the sampling hood, namely the central axis at 0.12 m, the flow velocity at each nozzle angle gradually approaches 0.

Figure 6b shows that for a nozzle angle of 55°, the airflow velocity tends to stabilize after 1 s of the sampling task.

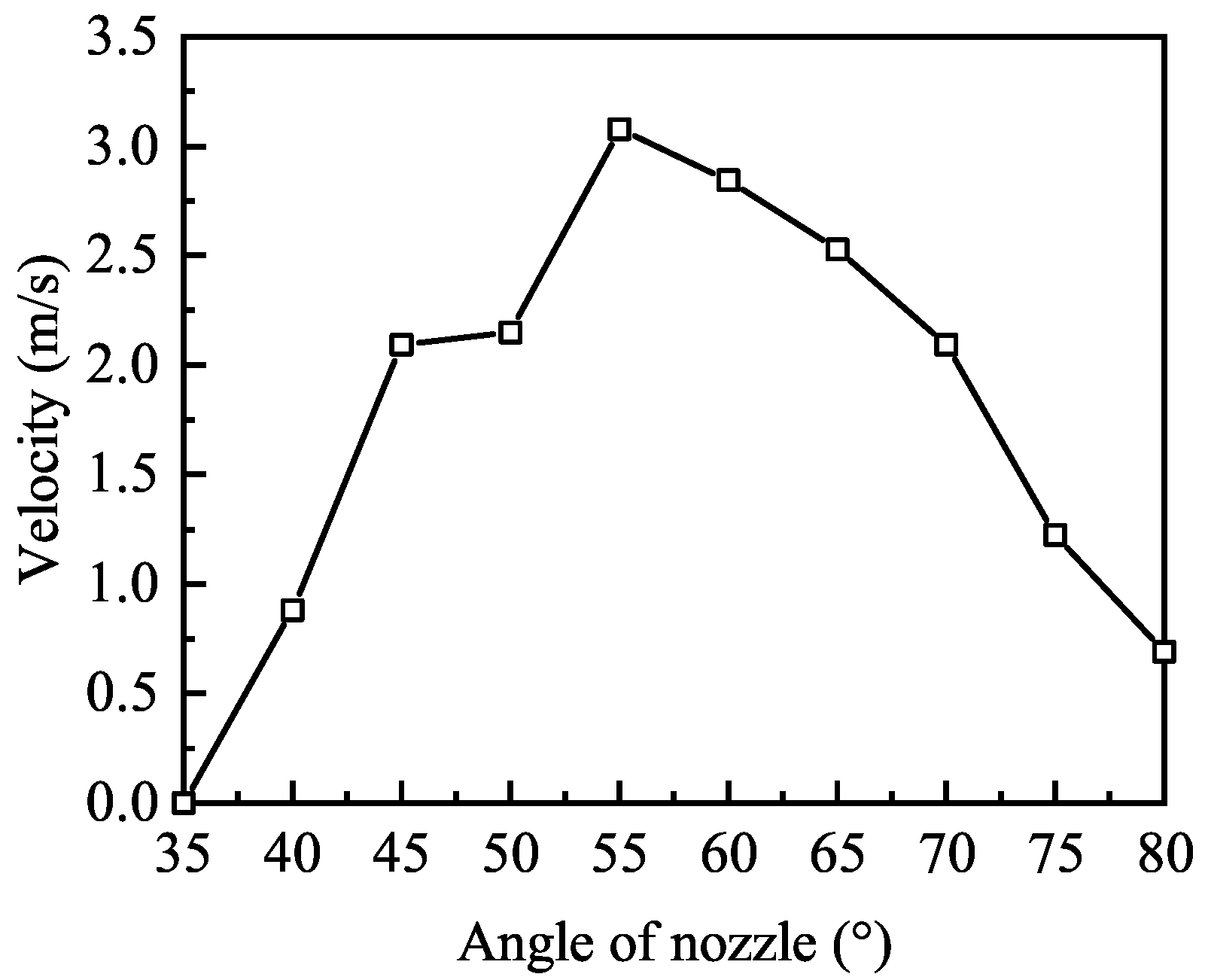

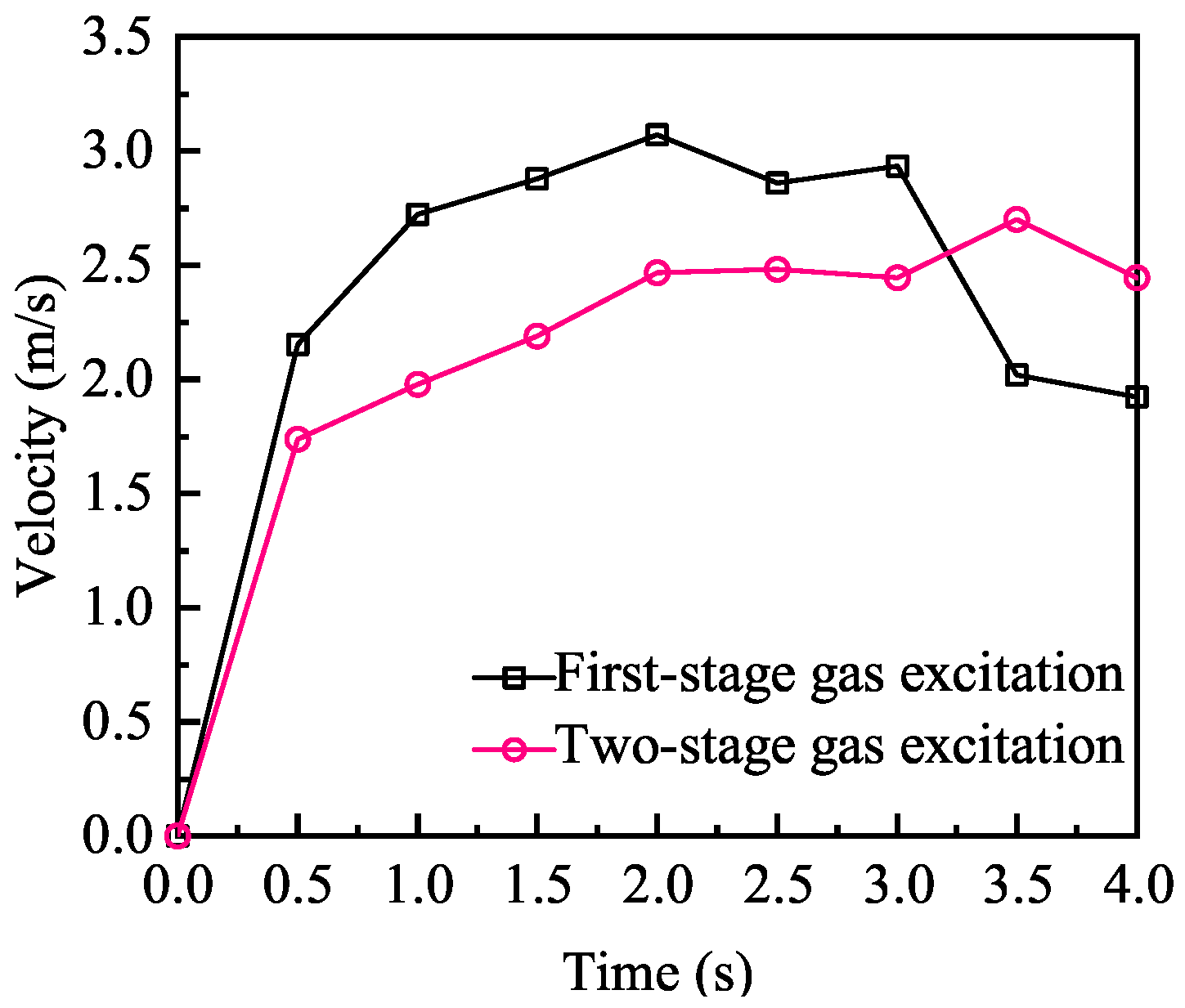

The average vertical velocity of particles along the central axis of the sampling device was extracted from the EDEM software (2025.1) to investigate the effect of the first-stage gas nozzle angle on particle motion. As illustrated in

Figure 7, a clear correlation is observed between particle velocity and nozzle inlet angle. When the inlet angle lies within the range of 35°–55°, the particle velocity increases with the angle. At angles below 35°, particles are almost unable to accelerate. When the angle reaches 55°, the vertical velocity attains its maximum, with an average value of 3

. Beyond this point, as the angle increases from 55° to 80°, the particle velocity decreases progressively.

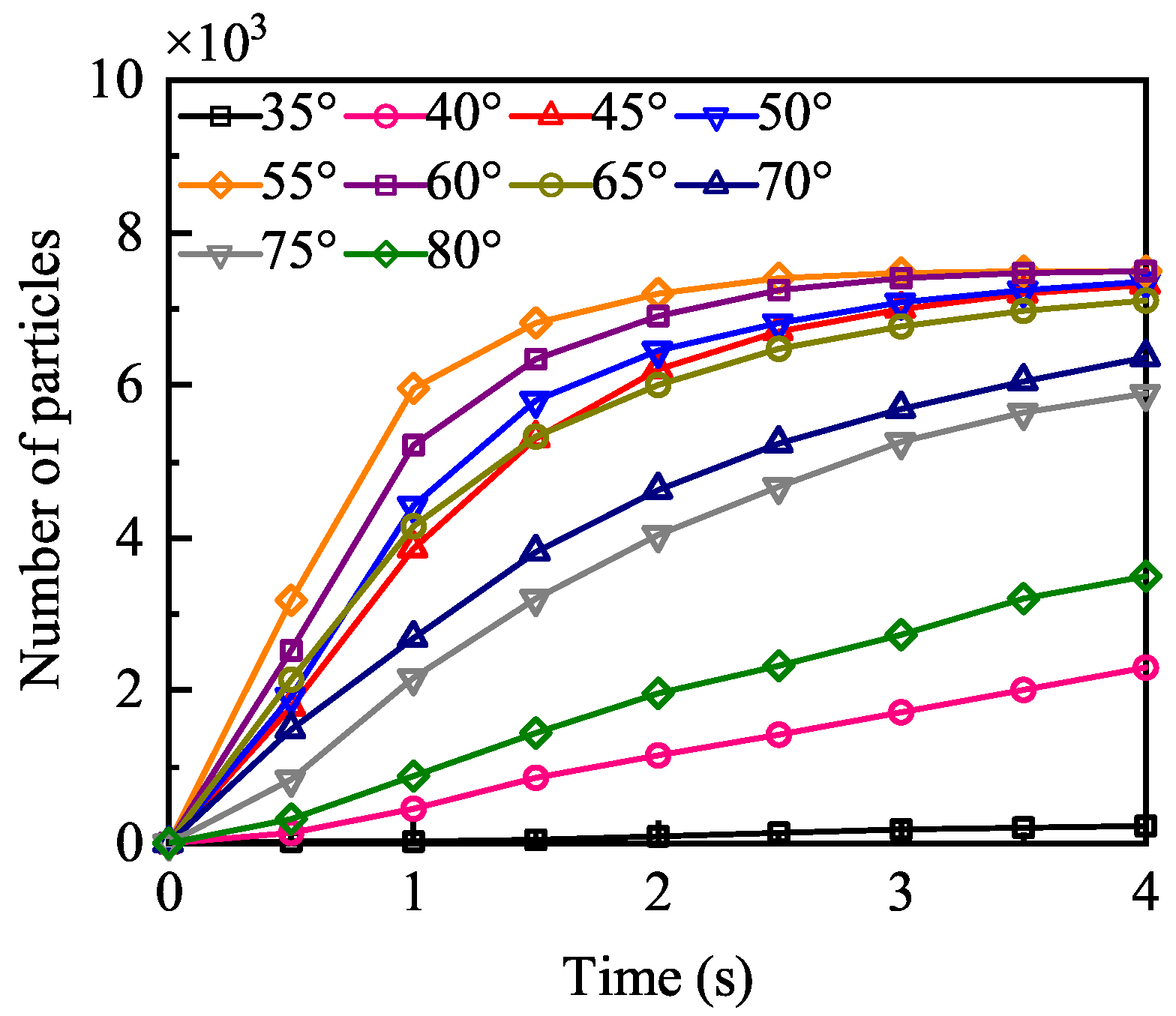

Since the first-stage gas-excitation sampling device with the angle of 55° completed the collection of all sample particles at 4.09 s, the sampling process of 4 s before each nozzle angle was selected for analysis. The comparison of the influence of the first-stage gas nozzle angle on particle collection efficiency is shown in

Figure 8. The particle bed was initially affected by the airflow before 1s, and the particle collection volume increased rapidly. The collection rate of the 55° sampling device was the fastest, and 80% of the particle collection was completed at the first second. After 1 s, the collection rate of the nozzle angles of 45°, 50°, 55°, 60°, and 65° continue to decrease and the total particles collected in these sampling devices slowly approach 7500. The sampling device with 55° firstly collects all the particles. The collection rate of the nozzle angles of 35°, 40°, 70°, 75° and 80° are basically unchanged in the first 4s and the number of the particles collected is small.

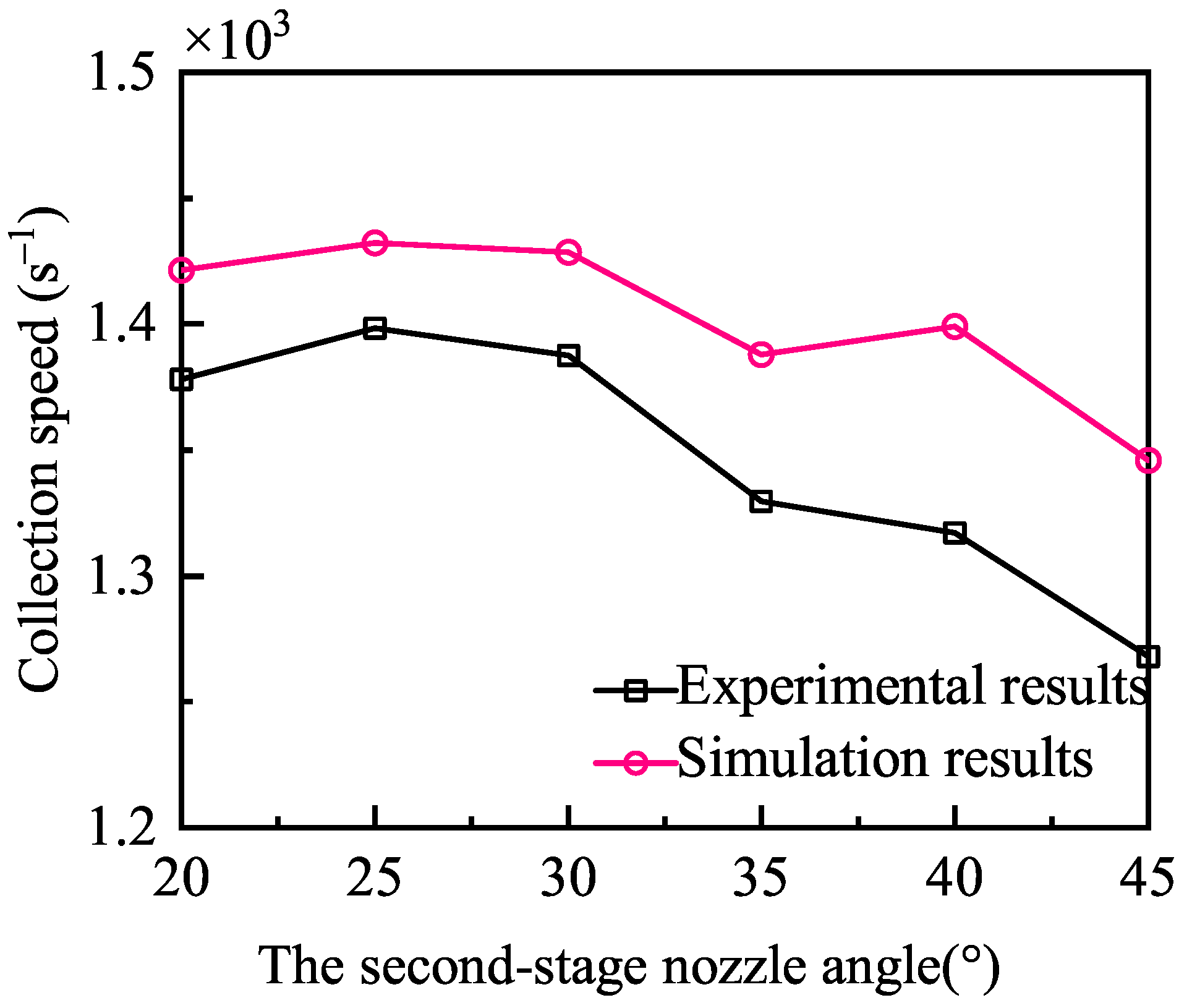

3.3. Simulation Results of the Two-Stage Gas-Excitation Sampling in the Earth’s Environment

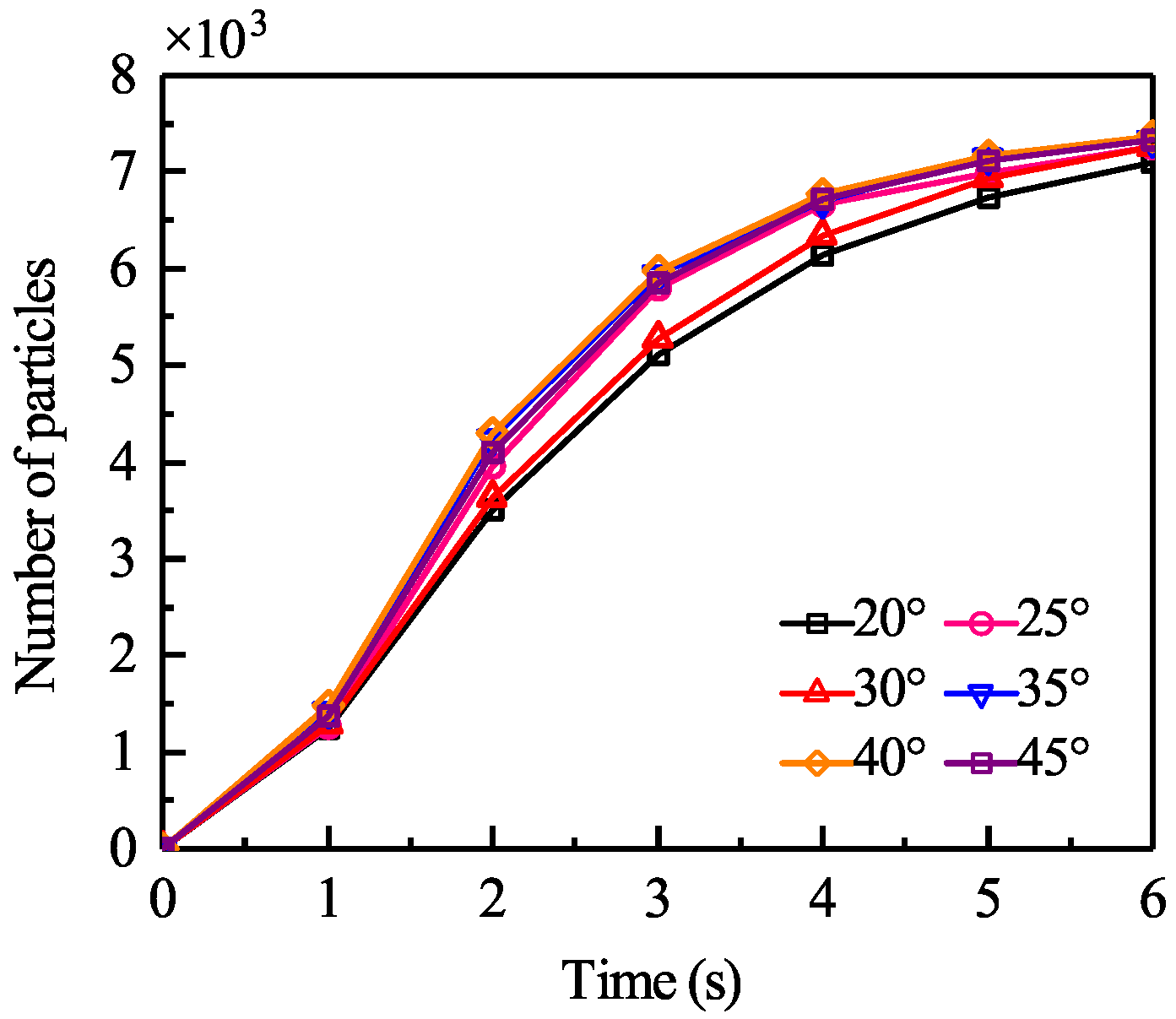

The CFD–DEM coupled simulation was established to examine the effect of the second-stage nozzle angle on delivery efficiency and the overall performance of the sample collection device. The second-stage nozzle angle was varied from 20° to 45° with an increment of 5°. This angle is defined as the inclination between the nozzle’s central axis and the pipeline wall. The inlet pressure of both the first- and second-stage nozzles was set at 0.1 MPa, while the outlet pressure of the pipeline was maintained at 0 MPa. The total simulation time was 10 s. Since the two-stage gas-excitation sampling and delivery device was able to collect nearly all particles within 10 s across all tested angles, direct comparison of collection efficiency over the full simulation was not feasible. Therefore, the simulation results at 6 s were selected for comparative analysis, as presented in

Table 3. The results indicate that a second-stage nozzle angle of 40° yields the highest collection rate and provides the most effective sample delivery. To validate the rationality of this optimal angle, the simulation outcomes were further post-processed and analyzed using Fluent and EDEM software (2025.1).

The second-stage nozzle angle of 40° was selected to analyze the vertical component of airflow velocity along the central axis of the sampling device. The section from the bottom of the sampling hood to the pipeline corner, spanning 0–1.18 m, is shown in

Figure 9, with 0–0.12 m corresponding to the sampling hood. In this region, the airflow distribution and excitation effect are similar to those of the first-stage unit, both reaching a peak vertical velocity at 0.035 m. However, due to the obstructive influence of the reverse flow generated by the second-stage nozzle, the vertical velocity at each point along the hood’s central axis decreases, with the maximum velocity at 0.035 m reduced from 20 m/s (first-stage only) to 14 m/s. The subsequent 0.12–0.2 m section corresponds to the sample delivery pipeline, where the second-stage nozzle is located at 0.14 m. At 0.15 m, turbulence induces a negative velocity of –5 m/s, which impedes sample transport. Between 0.16 m and 0.2 m, the airflow converges to form a positive velocity field favorable for particle delivery, reaching a maximum of 23.7 m/s at 0.17 m. Beyond this region, in the 0.28–1.18 m section of the pipeline (excluding the corner effect), the vertical velocity component along the central axis remains nearly uniform and minimally influenced by distance from the nozzle. This ensures a stable aerodynamic force to support efficient sample delivery.

As shown in

Figure 10, comparing the average velocity of particles with the first-stage gas-excitation effect and the two-stage gas-excitation combination is conducted individually, because the first-stage gas-excitation sampling device is not installed in vertical gas pipelines, the particle moving distance is short, and there is no second-stage nozzle to generate convection, so the average velocity is higher in the first 3 s. After the process of 3 s, the number of particles that remained in the sampling hood decreases; the particles collide with the walls and the number of collisions is increased while the average velocity decreases. The airflow velocity in the sample pipe of the two-stage combined gas-excitation sampling and sample delivery device is evenly distributed. The average particle velocity is relatively stable, and the particle velocity is higher than that of the first-stage gas-excitation at the later stage of the simulation.

The variation in particle collection with time for different second-stage nozzle angles in the two-stage gas-excitation sampling and delivery device is presented in

Figure 11. While the total number of collected particles differs only slightly among the tested angles, collection performance at 25° and 30° is relatively poor compared with the other cases, whereas the device with a nozzle angle of 40° achieves the highest particle yield. At the initial stage of the simulation, sample particles are strongly accelerated by the high-pressure gas, leading to a rapid increase in both particle velocity and collection quantity. For the 40° configuration, approximately 90% of the final collected amount is achieved within the first 4 s. Beyond this point, the accumulation rate gradually decreases, and the growth of total collected particles slows as the simulation progresses. At the end of the simulation, the device with a second-stage nozzle angle of 40° successfully collects a total of 7370 particles.

3.4. Simulation Results of the Two-Stage Gas-Excitation Sampling in the Asteroid Environment

Due to the significant differences between the vacuum and microgravity conditions on the asteroid surface and the terrestrial environment, the CFD–DEM coupled simulation method was employed to numerically model the sample collection process in the asteroid environment after determining the optimal structural parameters of the device. A two-stage combined gas-excitation sampling and delivery device was selected, with the environmental parameters set to absolute vacuum and gravitational acceleration set to one ten-thousandth of that on Earth. Prototype particles corresponding to the asteroid environment were adopted, and simulation results such as airflow velocity and collected particle number were analyzed to functionally validate and evaluate the performance of the gas-excitation-based sampling and delivery device.

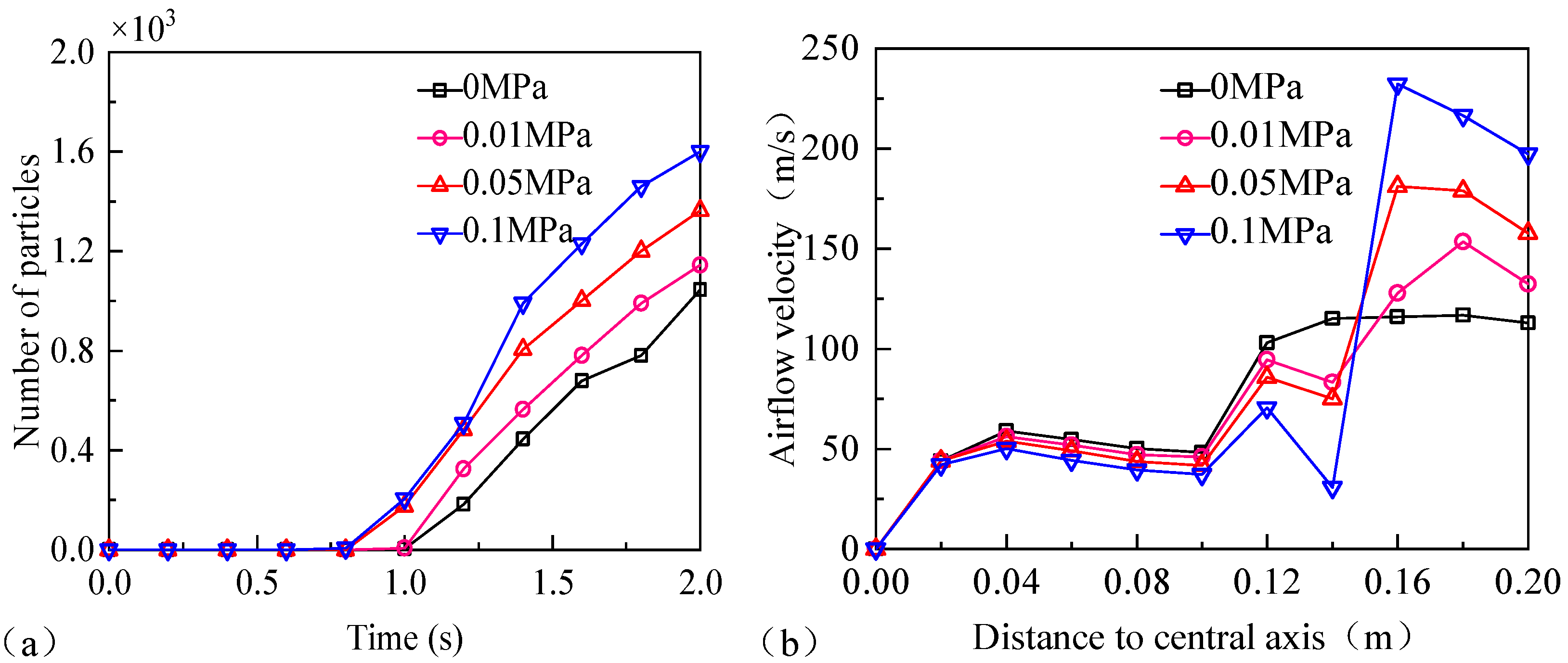

Based on the preliminary simulation results, the inlet angle of the first-stage nozzle was set to 55°, and that of the second-stage nozzle was set to 40°. The particle bed contained 7500 spherical particles with a diameter of 4 mm. According to the parameters of the Hayabusa mission asteroids, the simulation conditions under the asteroid environment were defined, as summarized in

Table 4. Four simulation cases were established, with the second-stage inlet pressure set to 0 MPa, 0.01 MPa, 0.05 MPa, and 0.1 MPa, respectively. The reference pressure in Fluent was set to 0 Pa, and the coupling simulation time was set to 2 s.

The simulation results are shown in

Figure 12. As illustrated in

Figure 12a, under the condition that the first-stage gas pressure is set to 0.1 MPa, the second-stage gas pressure of 0.01 MPa achieves the best collection performance, with a total of 1364 particles collected within 2 s. During the period of 0–0.6 s, no particles pass through the sample delivery pipeline. In the time range of 0.8–1 s, the number of collected particles increases proportionally with the second-stage gas pressure, where 0.1 MPa enables the earliest particle collection and yields higher particle counts than the other pressure levels. After 1 s, although the second-stage nozzle accelerates the airflow, the negative airflow generated in the opposite direction hinders the sampling efficiency, and the hindrance effect becomes more pronounced with higher pressures. At 0.05 MPa and 0.1 MPa, the inhibitory effect outweighs the driving effect, resulting in a lower total number of collected particles compared to 0 MPa. This indicates that inappropriate settings of the second-stage nozzle pressure can significantly reduce collection efficiency. As shown in

Figure 12b, the section from 0 m to 0.12 m corresponds to the sampling hood region. Due to the negative airflow induced by the second-stage nozzle, the airflow velocity components along the central axis at 0.01 MPa, 0.05 MPa, and 0.1 MPa are lower than those at 0 MPa. At 0.12 m, at the interface between the sampling hood and the sample pipeline, the flow cross-section decreases and the airflow velocity increases. At 0.14 m, where the second-stage nozzle is installed, turbulence occurs at 0.1 MPa, causing a sharp velocity drop. At 0.01 MPa and 0.05 MPa, the velocity decreases slightly, while at 0 MPa it remains nearly stable. In the section from 0.14 m to 0.2 m, the airflow converges to generate higher velocity, and the positive contribution of the second-stage nozzle pressure becomes evident. Within the pipeline, the velocity components increase with the gas pressure.

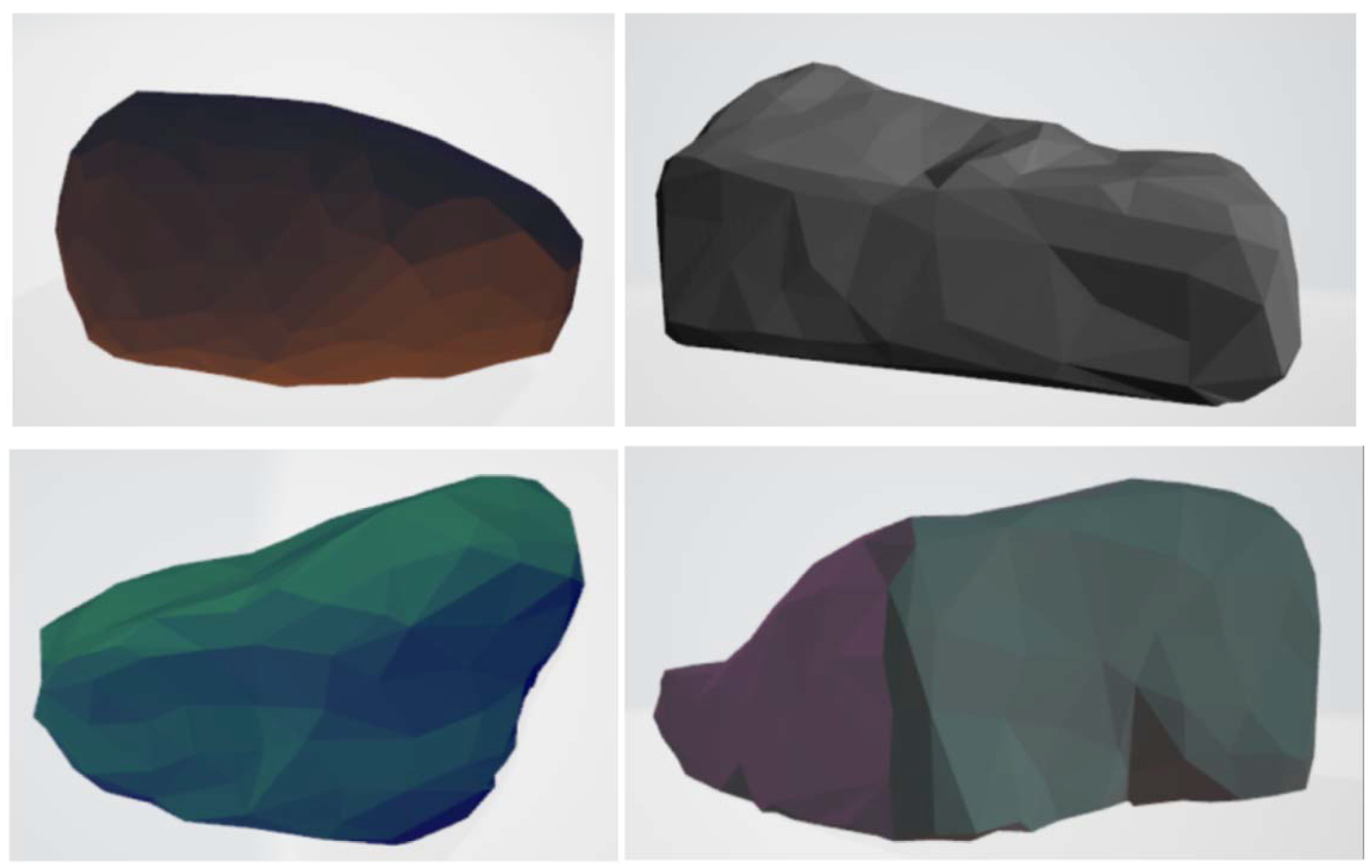

Comprehensive analysis indicates that applying a secondary gas pressure generates a small portion of negative airflow, which reduces the airflow velocity inside the sampling hood. When the pressure is excessively high, turbulence may also occur locally at the secondary nozzle, further impairing the collection efficiency. Meanwhile, the application of secondary pressure enhances the airflow velocity within the sample pipeline, which is beneficial for sample delivery. Therefore, an appropriate pressure ratio between the first-stage and second-stage inlets should be selected to ensure that the driving effect outweighs the hindrance. According to the simulation results, when the first-stage inlet pressure is set to 0.1 MPa, a second-stage pressure of 0.01 MPa is favorable for increasing the total number of collected samples. In reality, asteroid particles exhibit irregular shapes, similar to terrestrial gravel. To capture this characteristic, four types of irregular gravel models were established to simulate the actual particle geometry, as illustrated in

Figure 13. The maximum dimension of each particle model was set to 4 mm to satisfy mesh calculation requirements. The model was filled with spherical particles to fit the boundaries, while other physical parameters were kept consistent with those of prototype particles under asteroid conditions.

As shown in

Figure 14, an irregular particle bed was constructed in EDEM. Based on the optimized nozzle pressure and structural parameters discussed previously, CFD–DEM coupled simulations were performed on the irregular particle bed with a simulation time of 2 s, yielding a total sampling amount of 1288 particles. Overall, the above results demonstrate that the proposed gas-excitation-based sampling scheme possesses strong collection capability for asteroid regolith with varying particle sizes and shapes.