Hypotheses in Opportunistic Maintenance Modeling: A Critical and Systematic Literature Review

Abstract

1. Introduction

2. Conceptual Background

- Modeling and formulation of target system and logistic support. This step is crucial for developing decision rules and/or optimizing maintenance planning. The quality of modeling and formulation can impact the optimality of an established maintenance schedule [28,30,31]. In the context of opportunistic maintenance, this phase requires explicitly modeling the dependencies between components and logistic resources to identify where potential maintenance opportunities may arise.

- Development of appropriate maintenance strategies. The objective is to construct decision rules for the selection of maintenance actions based on the level of dysfunction of the components/system while planning these actions per the specifications/constraints related to the maintained system and its support system. Here, opportunistic criteria such as component age, degradation level, remaining useful life or marginal cost savings are introduced to guide the decision of whether to extend a maintenance intervention to other components when an opportunity occurs.

- Evaluation and optimization of the maintenance strategies developed which aim firstly at evaluating the maintenance schedules provided by such a maintenance strategy defined according to one or more performance criteria (e.g., cost criterion, availability, security, etc.) then secondly, to determine an optimal maintenance planning according to one or more objective functions (e.g., minimize the total cost, maximize availability, etc.). In this phase, opportunistic criteria are assessed against the chosen objectives to determine the conditions under which opportunistic interventions provide the best trade-off between cost, reliability and availability.

2.1. Dependence Modeling and Integration in Maintenance-Optimization Process

- Stochastic dependencies mean that the state of one component can impact the failure process of other components. Stochastic dependencies are classically classified into several subclasses as follows [1,32,33,34]:

- Load sharing with which the failure of one component accelerates the rate of degradation of other components [38];

- Common-cause dependence exists when the processes of several components are simultaneously impacted by the same cause. For example, a common-cause dependence model was introduced in [39] where the external impact (shock/operating condition) simultaneously affects the processes of two components;

- Structural dependencies: This type of dependency exists when different components physically form a part and the execution of maintenance on one component (i) physically implies an intervention on other components [11,32,45]; (ii) positively or negatively impacts the degradation process of other components [38,46]. Recently, another type of structural dependency was introduced in [47,48]: the failure or maintenance execution of one component implies a shutdown of other components. This type of dependency can be identified in series-parallel structures.

- Economic dependence which represents the sharing of preparation tasks (machine opening, spare part transportation, etc.) and/or system downtime between different maintenance activities. In that way, the cost of joint execution of several maintenance actions is either cheaper (positive dependence) or more expensive (negative dependence) than when they are separately performed [49].

- Geographical dependence exists when the maintained system is composed of several production sites located far apart from each other, and maintenance teams are not located at production sites [1]. Therefore, to perform maintenance actions of a given production site, a maintenance team needs to travel to the production site. As a consequence, the total distance/time of the joint maintenance group of several components in different sites may be smaller than the total distance/time of each individual component.

- Resources dependence means that executing the maintenance of several components requires the same maintenance resources (spare parts, maintenance tools, maintenance skills, etc.) [15];

- Human errors. Some specific errors of maintenance technicians may have important impact on the quality of executed maintenance actions, leading to an increase in the degradation/reliability process of a reduction of performance of maintained components/systems [13]. The human error may depend on different factors such as the technician skill and state, the characteristics of maintained components/system, maintenance tools, workload, variations in the environment, etc.

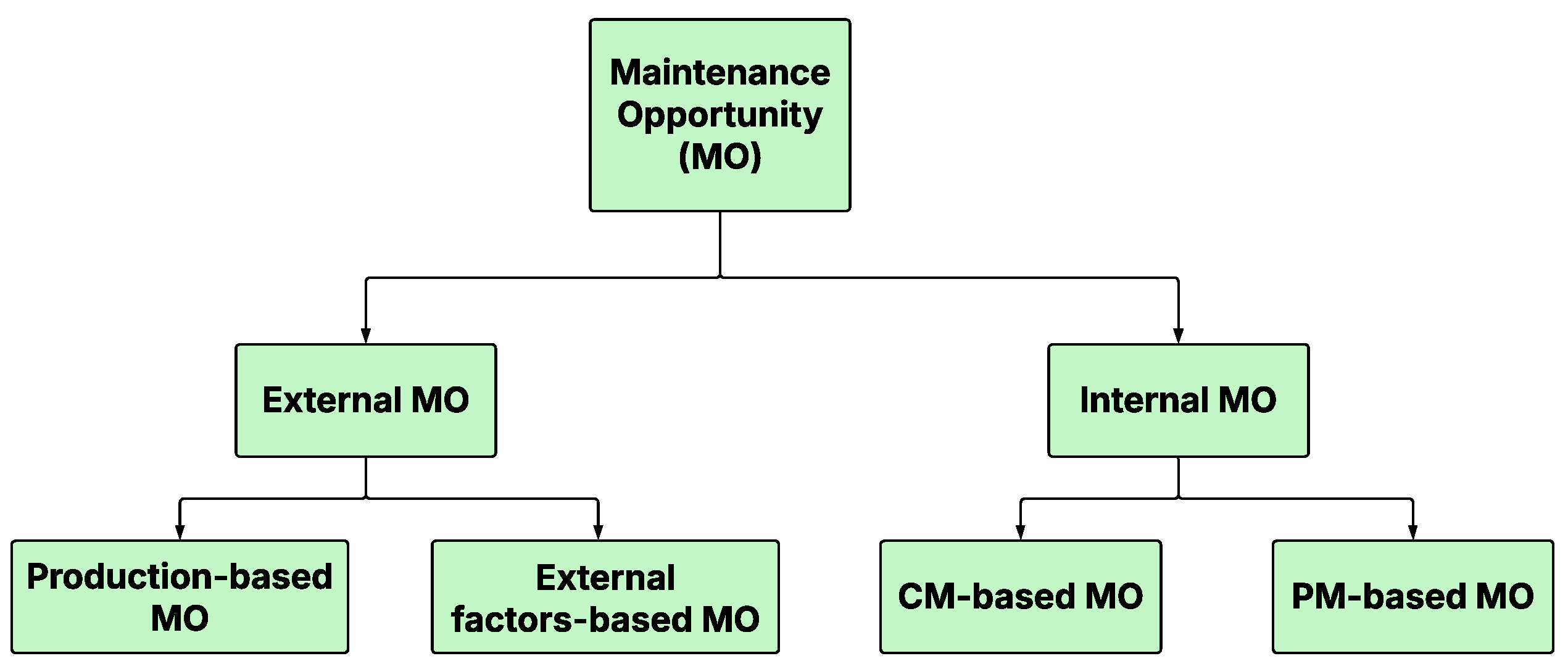

2.2. Definition and Classification of Maintenance Opportunities

2.3. Maintenance Grouping vs. Opportunistic Maintenance

3. Methodology of the Systematic Review and Overview of the Results

- Defining the research questions

- Identifying the search process, including search phrases and databases

- Establishing inclusion and exclusion criteria, a set of rules that allows selecting the literature entries that are included in the review

- Determining quality assessment criteria to assess the relevance of the selected papers to answer the research questions

- Collecting the data, including procuring the papers, reading and curating a database regarding their contents

- Analyzing the data and providing an insightful and critical review of the literature entries.

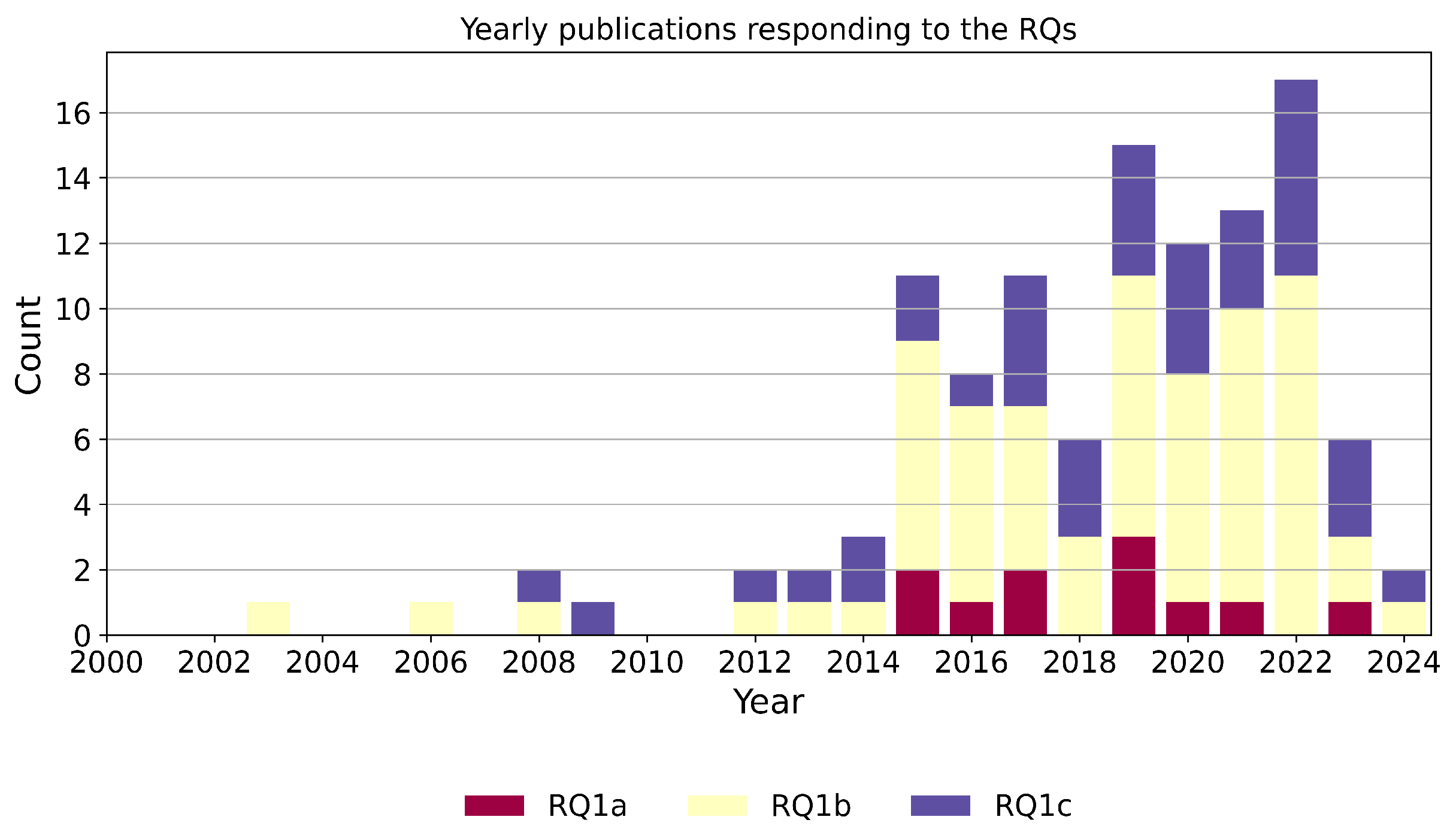

3.1. Research Questions

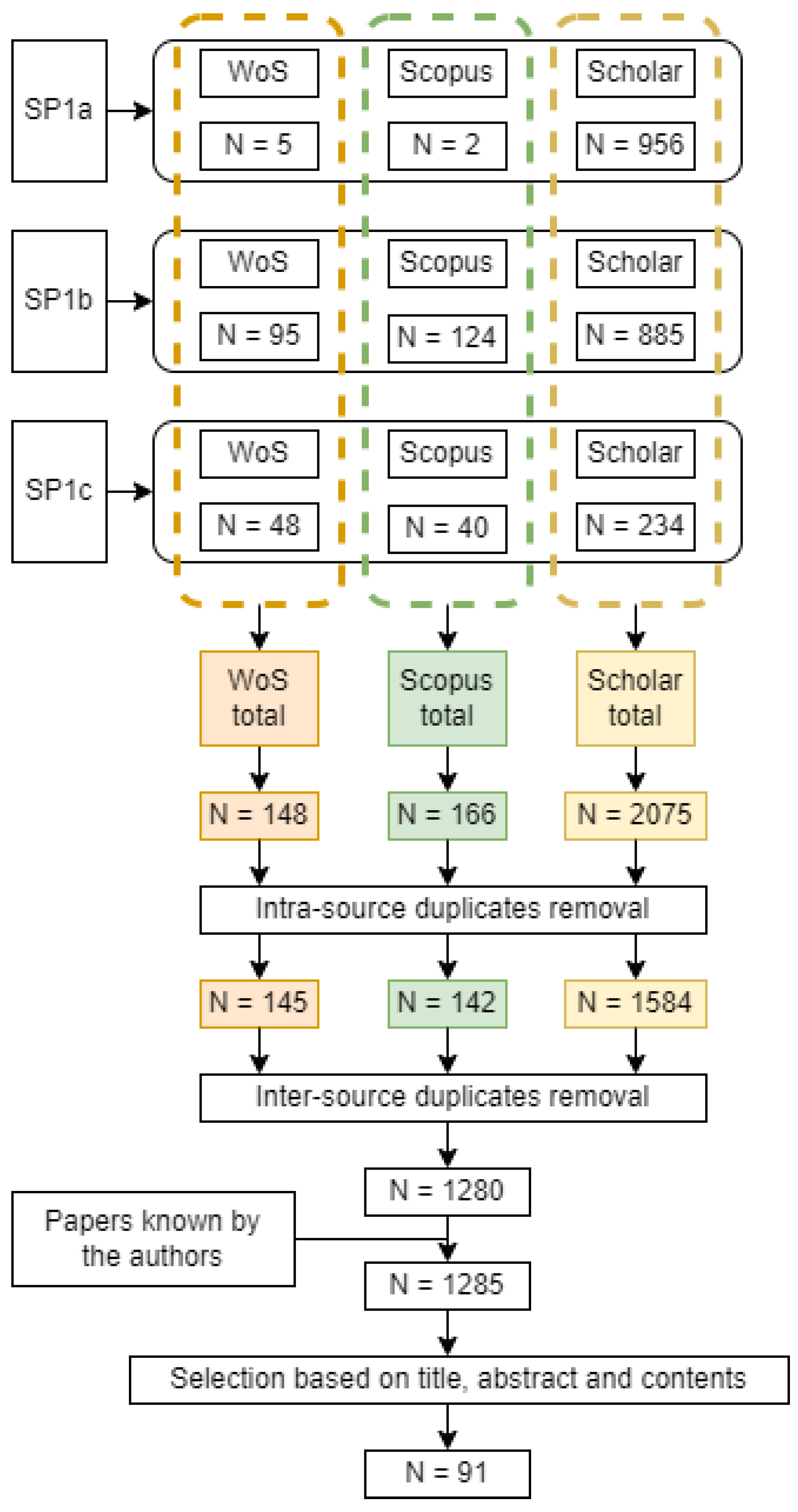

3.2. Search Process

3.3. Inclusion Criteria

- The publication is written either in French or in English.

- The publication addresses opportunistic maintenance through modeling, simulating or reviewing publications that include modeling and simulating.

- The publication describes how the workers’ skills, dependencies or resource constraints are taken into account in opportunistic maintenance modeling.

3.4. Exclusion Criteria

- Publications that only respond to RQ1b should not be limited to economic dependency

- Publications should not have been published before year 2000.

3.5. Quality Assessment

3.6. Research Process and Results

4. In-Depth Analysis for Maintenance Modeling

4.1. Human Factors in Opportunistic Maintenance Modeling

- Skill type hypotheses, where different failure modes require specific skill sets for maintenance;

- Human error hypotheses, describing situations where the maintenance is affected by human errors that are defined by their impact and probability of occurrence;

- Skill level hypotheses, under which the workers’ proficiency in their skills needs to exceed a given level in order for them to accomplish their maintenance tasks.

4.2. Dependencies in Opportunistic Maintenance Modeling

4.2.1. Stochastic Dependencies

- Type I: the failure of a component instantaneously induces a probability p of failure of the dependent component.

- Type II: the failure of component A induces a probability of instantaneous failure p on component B, whereas the failure of component B induces a shock on component A, modifying its failure rate, instead of inducing a probability of instantaneous failure.

- Type III: The failure of either component induces a shock on the other component, modifying its failure rate.

- Type IV: The current state of degradation (typically modeled through stochastic processes) of a component influences the degradation process, or the failure rate of another component.

4.2.2. Structural Dependencies

- Type A: Must maintain jointly: two components must always be maintained simultaneously.

- Type B: Must remove to maintain: the structural dependence comes from topological considerations in the machine that is maintained, which requires disassembling one or more components to access other components.

- Type C: Can only be maintained if parent component is being maintained: a component can only be maintained in the eventuality a given other component is maintained as well.

- Type D: The failure of a component impacts the overall system performance such as a production flow restriction.

4.2.3. Geographical Dependencies

- Weather geographical dependencies: the maintenance actions are weather-dependent and are subject to seasonal and punctual schedule variations.

- Distance geographical dependencies: the assets that need maintenance are geographically distributed and require time and resources to be addressed.

- Travelling Repairman Problem (TRP), in which the assets to be visited have all failed.

- Vehicle Routing Problem, which is a variant of the TRP with several travelling agents.

- Travelling Maintainer Problem, in which the visited assets have not yet failed.

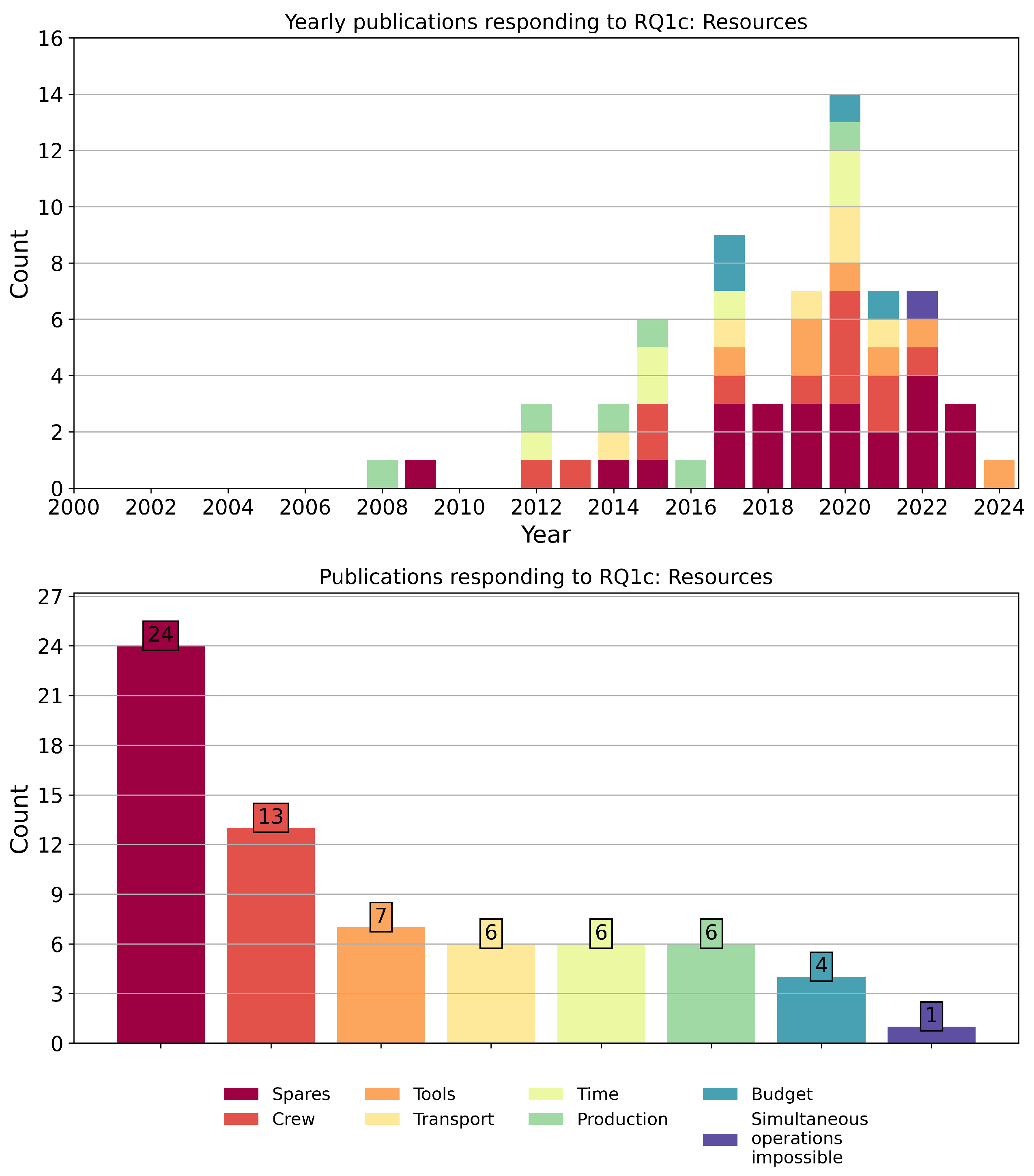

4.3. Resource Constraints in Opportunistic Maintenance Modeling

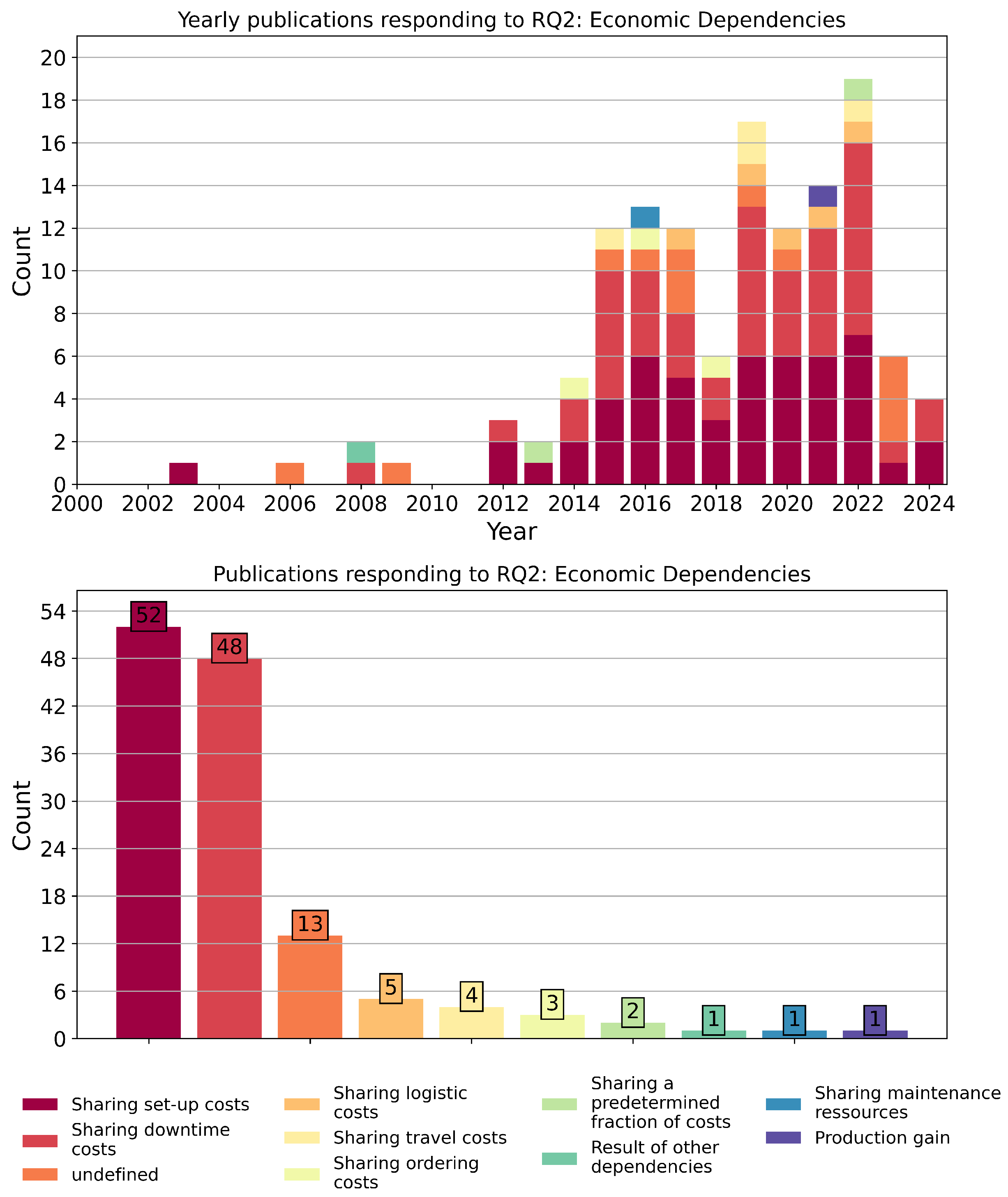

4.4. Modeling Economic Dependencies

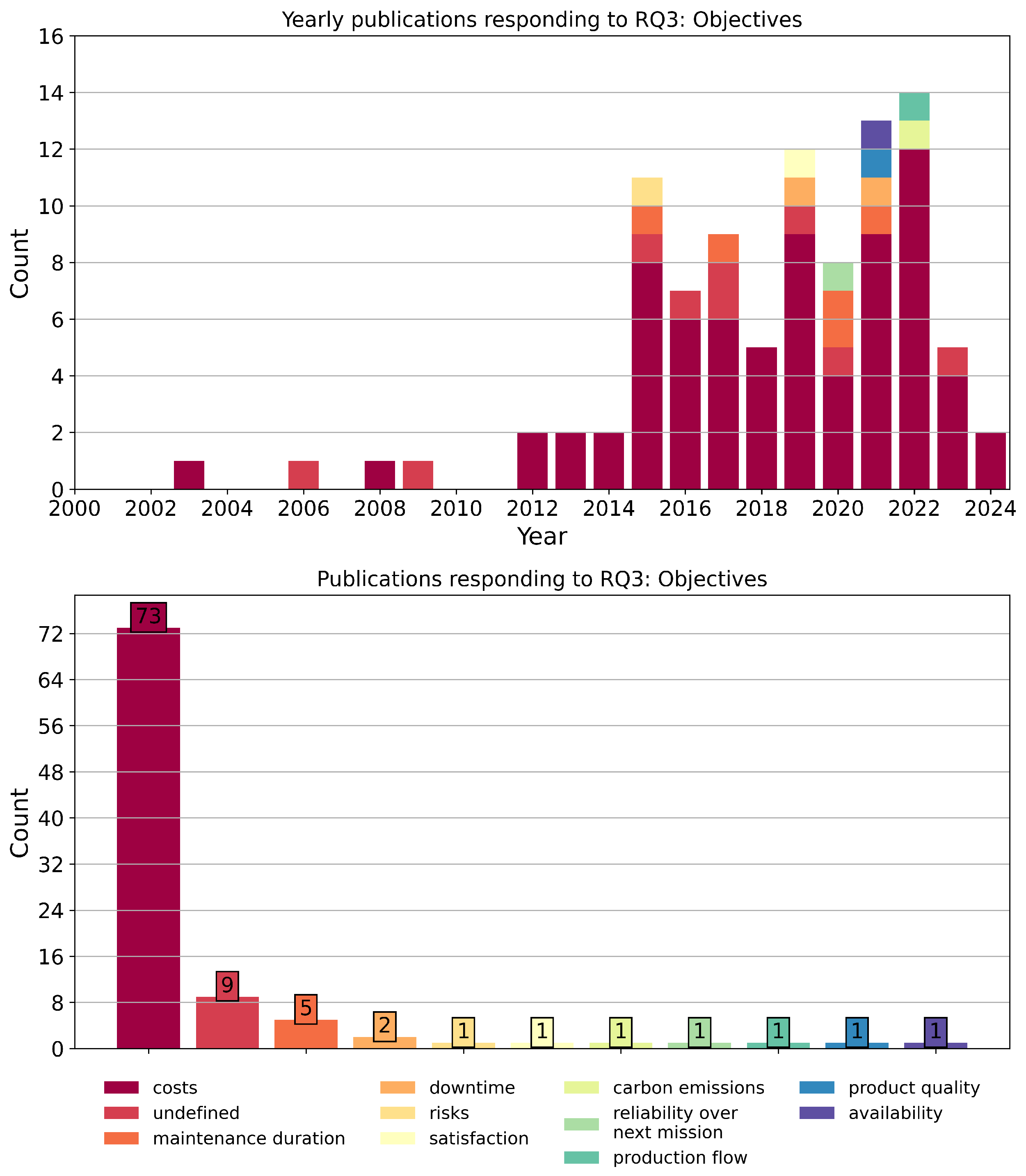

4.5. Optimization Objectives

5. Discussion and Future Research Directions

5.1. Human Factors in Opportunistic Maintenance

5.2. Predictive Analytics for Opportunistic Maintenance

- Data quality and availability: PA models often require high-quality, relevant data to make accurate predictions [143]. However, industrial data may be noisy, incomplete or not completely representative of all failure modes, which can limit the effectiveness of PA models [144]. Further, drifts may exist in the industrial data, which requires specific methodologies for adaptation of PA models [145]. Likewise, the sensors themselves evolve, are replaced or their number is increased over time, with the inherent complexity in PA model development [146]. The strong dependence of PA models on data could therefore be seen as creating potential resource constraints on data. In this case, the lack of data, data contamination, unexpected drifts and other phenomena could hinder the accuracy of PA models.

- Complexity of opportunistic maintenance scheduling: opportunistic maintenance scheduling is a complex task because it involves balancing multiple factors, such as the cost of downtime, and the availability of maintenance tools, resources and the criticality of different components in industrial systems [5]. Therefore, developing PA models that can handle this complexity requires careful design and significant computational power;

- Real-time decision making: In some specific industrial applications, opportunistic maintenance decisions need to be made in real time, especially in dynamic environments like manufacturing or transportation. This requires PA models to be fast and reliable, and to align correctly with existing maintenance-management systems [143]. For example, a major difficulty in this context is the necessary tradeoff between the latency of the prediction, energy consumption and prediction accuracy, leading the recent literature to either oppose or merge the concepts of cloud computing and edge computing in search of balanced performances with respect to these indicators [147].

5.3. Sustainability in Opportunistic Maintenance

6. Conclusions

- The current hypotheses regarding workers’ skills, dependencies and resource constraints have been identified:

- -

- Human factors are seldom represented in the identified literature, and mainly by dividing the workforce by skill types. Human errors and the separation of skill levels are also mentioned.

- -

- Dependencies (other than economic) to be split into three large families—stochastic, structural and geographic—each of them being categorized into subtypes, all in relation to real effects.

- -

- Resource constraints to be mainly concerned with spare parts, but also to cover multiple other hypotheses more sporadically invoked in the literature.

- In papers modeling other dependencies, the economic dependency is mostly represented as a sharing of set-up costs or downtime costs between maintenance operations. Other marginal models have been identified.

- In papers modeling dependencies that are not limited to the economic, the optimization objectives are almost exclusively costs and marginally maintenance duration. Other objectives are anecdotal, including the environmental impact of maintenance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Olde Keizer, M.C.; Flapper, S.D.P.; Teunter, R.H. Condition-Based Maintenance Policies for Systems with Multiple Dependent Components: A Review. Eur. J. Oper. Res. 2017, 261, 405–420. [Google Scholar] [CrossRef]

- de Jonge, B.; Scarf, P. A Review on Maintenance Optimization. Eur. J. Oper. Res. 2020, 285, 805–824. [Google Scholar] [CrossRef]

- Vu, H.C.; Do, P.; Fouladirad, M.; Grall, A. Dynamic Opportunistic Maintenance Planning for Multi-Component Redundant Systems with Various Types of Opportunities. Reliab. Eng. Syst. Saf. 2020, 198, 106854. [Google Scholar] [CrossRef]

- EN 13306:2017; Maintenance—Maintenance Terminology. CEN: Bruxelles, Belgium, 2017.

- Ab-Samat, H.; Kamaruddin, S. Opportunistic Maintenance (OM) as a New Advancement in Maintenance Approaches: A Review. J. Qual. Maint. Eng. 2014, 20, 98–121. [Google Scholar] [CrossRef]

- Van Horenbeek, A.; Pintelon, L.; Muchiri, P. Maintenance Optimization Models and Criteria. Int. J. Syst. Assur. Eng. Manag. 2010, 1, 189–200. [Google Scholar] [CrossRef]

- Iung, B.; Do, P.; Levrat, E.; Voisin, A. Opportunistic Maintenance Based on Multi-Dependent Components of Manufacturing System. CIRP Ann. 2016, 65, 401–404. [Google Scholar] [CrossRef]

- Dekker, R. Applications of Maintenance Optimization Models: A Review and Analysis. Reliab. Eng. Syst. Saf. 1996, 51, 229–240. [Google Scholar] [CrossRef]

- Van Horenbeek, A.; Buré, J.; Cattrysse, D.; Pintelon, L.; Vansteenwegen, P. Joint Maintenance and Inventory Optimization Systems: A Review. Int. J. Prod. Econ. 2013, 143, 499–508. [Google Scholar] [CrossRef]

- Zeng, Z.; Barros, A.; Coit, D. Dependent Failure Behavior Modeling for Risk and Reliability: A Systematic and Critical Literature Review. Reliab. Eng. Syst. Saf. 2023, 239, 109515. [Google Scholar] [CrossRef]

- Nicolai, R.P.; Dekker, R. Optimal Maintenance of Multi-component Systems: A Review. In Complex System Maintenance Handbook; Springer: London, UK, 2008; pp. 263–286. [Google Scholar] [CrossRef]

- Nowakowski, T.; Werbińska-Wojciechowska, S. On Problems of Multicomponent System Maintenance Modeling. Int. J. Autom. Comput. 2009, 6, 364–378. [Google Scholar] [CrossRef]

- Shafiee, M. Maintenance Logistics Organization for Offshore Wind Energy: Current Progress and Future Perspectives. Renew. Energy 2015, 77, 182–193. [Google Scholar] [CrossRef]

- Wang, R.; Chen, N. A Survey of Condition-Based Maintenance Modeling of Multi-Component Systems. In Proceedings of the 2016 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bali, Indonesia, 4–7 December 2016; pp. 1664–1668. [Google Scholar] [CrossRef]

- Alaswad, S.; Xiang, Y. A Review on Condition-Based Maintenance Optimization Models for Stochastically Deteriorating System. Reliab. Eng. Syst. Saf. 2017, 157, 54–63. [Google Scholar] [CrossRef]

- Chin, H.H.; Varbanov, P.S.; Klemeš, J.J.; Benjamin, M.F.D.; Tan, R.R. Asset Maintenance Optimisation Approaches in the Chemical and Process Industries—A Review. Chem. Eng. Res. Des. 2020, 164, 162–194. [Google Scholar] [CrossRef]

- Sedghi, M.; Kauppila, O.; Bergquist, B.; Vanhatalo, E.; Kulahci, M. A Taxonomy of Railway Track Maintenance Planning and Scheduling: A Review and Research Trends. Reliab. Eng. Syst. Saf. 2021, 215, 107827. [Google Scholar] [CrossRef]

- Tusar, M.I.H.; Sarker, B.R. Spare Parts Control Strategies for Offshore Wind Farms: A Critical Review and Comparative Study. Wind Eng. 2022, 46, 1629–1656. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, C.; Tang, T. A Review of Sustainable Maintenance Strategies for Single Component and Multicomponent Equipment. Sustainability 2022, 14, 2992. [Google Scholar] [CrossRef]

- Scarf, P.; Syntetos, A.; Teunter, R. Joint Maintenance and Spare-Parts Inventory Models: A Review and Discussion of Practical Stock-Keeping Rules. IMA J. Manag. Math. 2023, 35, 83–109. [Google Scholar] [CrossRef]

- Shadi, M.R.; Mirshekali, H.; Shaker, H.R. Explainable Artificial Intelligence for Energy Systems Maintenance: A Review on Concepts, Current Techniques, Challenges, and Prospects. Renew. Sustain. Energy Rev. 2025, 216, 115668. [Google Scholar] [CrossRef]

- Abbas, Y.; Martinetti, A. Design for an Integrated Knowledge Management Policy for Railway Maintenance: An Industrial Synopsis. Procedia CIRP 2023, 119, 521–526. [Google Scholar] [CrossRef]

- Cárcel-Carrasco, J.; Gómez-Gómez, C. Qualitative Analysis of the Perception of Company Managers in Knowledge Management in the Maintenance Activity in the Era of Industry 4.0. Processes 2021, 9, 121. [Google Scholar] [CrossRef]

- Wang, H. A Survey of Maintenance Policies of Deteriorating Systems. Eur. J. Oper. Res. 2002, 139, 469–489. [Google Scholar] [CrossRef]

- Kitchenham, B. Procedures for Performing a Systematic Reviews; Technical Report; Keele University: Keele, Staffs, UK, 2004. [Google Scholar]

- Kitchenham, B.; Pearl Brereton, O.; Budgen, D.; Turner, M.; Bailey, J.; Linkman, S. Systematic Literature Reviews in Software Engineering—A Systematic Literature Review. Inf. Softw. Technol. 2009, 51, 7–15. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, R.; Kamaruddin, S. An Overview of Time-Based and Condition-Based Maintenance in Industrial Application. Comput. Ind. Eng. 2012, 63, 135–149. [Google Scholar] [CrossRef]

- Do, P. Contribution au Développement de Modèles d’aide à La Décision en Maintenance Pour des Systèmes à Dépendances Multiples: Vers une Maintenance Prescriptive; Habilitation to Supervise Research; Université de Lorraine: Nancy, France, 2019. [Google Scholar]

- Friederich, J.; Lazarova-Molnar, S. Reliability Assessment of Manufacturing Systems: A Comprehensive Overview, Challenges and Opportunities. J. Manuf. Syst. 2024, 72, 38–58. [Google Scholar] [CrossRef]

- Mo, R.; Zhou, H.; Yin, H.; Si, X. A Survey on Few-Shot Learning for Remaining Useful Life Prediction. Reliab. Eng. Syst. Saf. 2025, 257, 110850. [Google Scholar] [CrossRef]

- Dekker, R.; Wildeman, R.E.; Van Der Duyn Schouten, F.A. A Review of Multi-Component Maintenance Models with Economic Dependence. Math. Methods Oper. Res. 1997, 45, 411–435. [Google Scholar] [CrossRef]

- Do, P.; Barros, A.; Berenguer, C.; Bouvard, K.; Brissaud, F. Dynamic Grouping Maintenance with Time Limited Opportunities. Reliab. Eng. Syst. Saf. 2013, 120, 51–59. [Google Scholar] [CrossRef]

- Hong, H.; Zhou, W.; Zhang, S.; Ye, W. Optimal Condition-Based Maintenance Decisions for Systems with Dependent Stochastic Degradation of Components. Reliab. Eng. Syst. Saf. 2014, 121, 276–288. [Google Scholar] [CrossRef]

- Scarf, P.; Deara, M. Block Replacement Policies for a Two-Component System with Failure Dependence. Nav. Res. Logist. 2003, 50, 70–87. [Google Scholar] [CrossRef]

- Golmakani, H.R.; Moakedi, H. Periodic Inspection Optimization Model for a Two-Component Repairable System with Failure Interaction. Comput. Ind. Eng. 2012, 63, 540–545. [Google Scholar] [CrossRef]

- Zhang, N.; Fouladirad, M.; Barros, A. Warranty Analysis of a Two-Component System with Type I Stochastic Dependence. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2018, 232, 274–283. [Google Scholar] [CrossRef]

- Marseguerra, M.; Zio, E.; Podofillini, L. Condition-Based Maintenance Optimization by Means of Genetic Algorithms and Monte Carlo Simulation. Reliab. Eng. Syst. Saf. 2002, 77, 151–165. [Google Scholar] [CrossRef]

- Mercier, S.; Pham, H.H. A Random Shock Model with Mixed Effect, Including Competing Soft and Sudden Failures, and Dependence. Methodol. Comput. Appl. Probab. 2016, 18, 377–400. [Google Scholar] [CrossRef]

- Assaf, R.; Do, P.; Nefti-Meziani, S.; Scarf, P. Wear Rate–State Interactions within a Multi-Component System: A Study of a Gearbox-Accelerated Life Testing Platform. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2018, 232, 425–434. [Google Scholar] [CrossRef]

- Bian, L.; Gebraeel, N. Stochastic Framework for Partially Degradation Systems with Continuous Component Degradation-rate-interactions. Nav. Res. Logist. (NRL) 2014, 61, 286–303. [Google Scholar] [CrossRef]

- Bian, L.; Gebraeel, N. Stochastic Modeling and Real-Time Prognostics for Multi-Component Systems with Degradation Rate Interactions. IIE Trans. 2014, 46, 470–482. [Google Scholar] [CrossRef]

- Rasmekomen, N.; Parlikad, A.K. Condition-Based Maintenance of Multi-Component Systems with Degradation State-Rate Interactions. Reliab. Eng. Syst. Saf. 2016, 148, 1–10. [Google Scholar] [CrossRef]

- Zhang, N.; Fouladirad, M.; Barros, A.; Zhang, J. Condition-Based Maintenance for a K-out-of-N Deteriorating System under Periodic Inspection with Failure Dependence. Eur. J. Oper. Res. 2020, 287, 159–167. [Google Scholar] [CrossRef]

- Thomas, L. A Survey of Maintenance and Replacement Models for Maintainability and Reliability of Multi-Item Systems. Reliab. Eng. 1986, 16, 297–309. [Google Scholar] [CrossRef]

- Do, P.; Barros, A.; Berenguer, C. Importance Measure on Finite Time Horizon and Application to Markovian Multistate Production Systems. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2008, 222, 449–461. [Google Scholar] [CrossRef]

- Nguyen, K.A.; Do, P.; Grall, A. Multi-Level Predictive Maintenance for Multi-Component Systems. Reliab. Eng. Syst. Saf. 2015, 144, 83–94. [Google Scholar] [CrossRef]

- Camci, F. System Maintenance Scheduling with Prognostics Information Using Genetic Algorithm. IEEE Trans. Reliab. 2009, 58, 539–552. [Google Scholar] [CrossRef]

- Vu, H.C.; Do, P.; Barros, A.; Berenguer, C. Maintenance Planning and Dynamic Grouping for Multi-Component Systems with Positive and Negative Economic Dependencies. IMA J. Manag. Math. 2015, 26, 145–170. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, Y.; Peng, R.; Ma, X. Opportunistic Maintenance of Production Systems Subject to Random Wait Time and Multiple Control Limits. J. Manuf. Syst. 2018, 47, 12–34. [Google Scholar] [CrossRef]

- Cavalcante, C.; Lopes, R.; Scarf, P. A General Inspection and Opportunistic Replacement Policy for One-Component Systems of Variable Quality. Eur. J. Oper. Res. 2018, 266, 911–919. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, Y.; Peng, R.; Ma, X. Hybrid Preventive Maintenance of Competing Failures under Random Environment. Reliab. Eng. Syst. Saf. 2018, 174, 130–140. [Google Scholar] [CrossRef]

- Truong Ba, H.; Cholette, M.; Borghesani, P.; Zhou, Y.; Ma, L. Opportunistic Maintenance Considering Non-Homogenous Opportunity Arrivals and Stochastic Opportunity Durations. Reliab. Eng. Syst. Saf. 2017, 160, 151–161. [Google Scholar] [CrossRef]

- Li, H.; Deloux, E.; Dieulle, L. A Condition-Based Maintenance Policy for Multi-Component Systems with Lévy Copulas Dependence. Reliab. Eng. Syst. Saf. 2016, 149, 44–55. [Google Scholar] [CrossRef]

- Ait Mokhtar, E.H.; Chateauneuf, A.; Laggoune, R. Condition Based Opportunistic Preventive Maintenance Policy for Utility Systems with Both Economic and Structural Dependencies—Application to a Gas Supply Network. Int. J. Press. Vessel. Pip. 2018, 165, 214–223. [Google Scholar] [CrossRef]

- Lu, B.; Zhou, X. Opportunistic Preventive Maintenance Scheduling for Serial-Parallel Multistage Manufacturing Systems with Multiple Streams of Deterioration. Reliab. Eng. Syst. Saf. 2017, 168, 116–127. [Google Scholar] [CrossRef]

- Zhou, X.; Shi, K. Capacity Failure Rate Based Opportunistic Maintenance Modeling for Series-Parallel Multi-Station Manufacturing Systems. Reliab. Eng. Syst. Saf. 2019, 181, 46–53. [Google Scholar] [CrossRef]

- Huynh, K.T.; Barros, A.; Berenguer, C. A Reliability-Based Opportunistic Predictive Maintenance Model for k-out-of-n Deteriorating Systems. Chem. Eng. Trans. 2013, 33, 493–498. [Google Scholar] [CrossRef]

- Radner, R.; Jorgenson, D.W. Opportunistic Replacement of a Single Part in the Presence of Several Monitored Parts. Manag. Sci. 1963, 10, 70–84. [Google Scholar] [CrossRef]

- Sarker, B.R.; Faiz, T.I. Minimizing Maintenance Cost for Offshore Wind Turbines Following Multi-Level Opportunistic Preventive Strategy. Renew. Energy 2016, 85, 104–113. [Google Scholar] [CrossRef]

- Wildeman, R.E.; Dekker, R. Dynamic Influences in Multi-Component Maintenance. Qual. Reliab. Eng. Int. 1997, 13, 199–207. [Google Scholar] [CrossRef]

- Agergaard, J.K.; Sigsgaard, K.V.; Mortensen, N.H.; Ge, J.; Hansen, K.B.; Khalid, W. Standardising Maintenance Jobs to Improve Grouping Decision Making. In Proceedings of the Design Society, Gothenburg, Sweden, 16–20 August 2021; Volume 1, pp. 2701–2710. [Google Scholar] [CrossRef]

- Harzing, A.W. Publish or Perish, 2007. Available online: https://harzing.com/resources/publish-or-perish (accessed on 8 August 2025).

- Dinh, D.H.; Do, P.; Iung, B. Degradation Modeling and Reliability Assessment for a Multi-Component System with Structural Dependence. Comput. Ind. Eng. 2020, 144, 106443. [Google Scholar] [CrossRef]

- Oakley, J.L.; Wilson, K.J.; Philipson, P. A Condition-Based Maintenance Policy for Continuously Monitored Multi-Component Systems with Economic and Stochastic Dependence. Reliab. Eng. Syst. Saf. 2022, 222, 108321. [Google Scholar] [CrossRef]

- Okoh, P. Maintenance Grouping Optimization for the Management of Risk in Offshore Riser System. Process Saf. Environ. Prot. 2015, 98, 33–39. [Google Scholar] [CrossRef]

- Chang, F.; Zhou, G.; Cheng, W.; Zhang, C.; Tian, C. A Service-Oriented Multi-Player Maintenance Grouping Strategy for Complex Multi-Component System Based on Game Theory. Adv. Eng. Inform. 2019, 42, 100970. [Google Scholar] [CrossRef]

- Aizpurua, J.; Catterson, V.; Papadopoulos, Y.; Chiacchio, F.; D’Urso, D. Supporting Group Maintenance through Prognostics-Enhanced Dynamic Dependability Prediction. Reliab. Eng. Syst. Saf. 2017, 168, 171–188. [Google Scholar] [CrossRef]

- Viveros, P.; Mena, R.; Zio, E.; Miqueles, L.; Kristjanpoller, F. Integrated Planning Framework for Preventive Maintenance Grouping: A Case Study for a Conveyor System in the Chilean Mining Industry. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2021, 237, 1011–1028. [Google Scholar] [CrossRef]

- Si, G.; Xia, T.; Zhu, Y.; Du, S.; Xi, L. Triple-Level Opportunistic Maintenance Policy for Leasehold Service Network of Multi-Location Production Lines. Reliab. Eng. Syst. Saf. 2019, 190, 106519. [Google Scholar] [CrossRef]

- Liu, G.; Chen, S.; Ho, T.; Ran, X.; Mao, B.; Lan, Z. Optimum Opportunistic Maintenance Schedule over Variable Horizons Considering Multi-Stage Degradation and Dynamic Strategy. Reliab. Eng. Syst. Saf. 2022, 225, 108572. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, Y.; Ma, Y.; Lin, C. A Novel Opportunistic Maintenance Strategy for Systems with Dependent Main and Auxiliary Components. IMA J. Manag. Math. 2021, 32, 69–90. [Google Scholar] [CrossRef]

- Sheikhalishahi, M.; Azadeh, A.; Pintelon, L. Dynamic Maintenance Planning Approach by Considering Grouping Strategy and Human Factors. Process Saf. Environ. Prot. 2017, 107, 289–298. [Google Scholar] [CrossRef]

- Vijayan, V.; Chaturvedi, S.K. Multi-Component Maintenance Grouping Optimization Based on Stochastic Dependency. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2021, 235, 293–305. [Google Scholar] [CrossRef]

- Geng, J.; Azarian, M.; Pecht, M. Opportunistic Maintenance for Multi-Component Systems Considering Structural Dependence and Economic Dependence. J. Syst. Eng. Electron. 2015, 26, 493–501. [Google Scholar] [CrossRef]

- Dinh, D.H.; Do, P.; Iung, B. Multi-Level Opportunistic Predictive Maintenance for Multi-Component Systems with Economic Dependence and Assembly/Disassembly Impacts. Reliab. Eng. Syst. Saf. 2022, 217, 108055. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Z.; Xia, T.; Hsieh, M.; Li, J. Integrated Structural Dependence and Stochastic Dependence for Opportunistic Maintenance of Wind Turbines by Considering Carbon Emissions. Energies 2022, 15, 625. [Google Scholar] [CrossRef]

- Shi, H.; Zeng, J.C. Real-Time Prediction of Remaining Useful Life and Preventive Opportunistic Maintenance Strategy for Multi-Component Systems Considering Stochastic Dependence. Comput. Ind. Eng. 2016, 93, 192–204. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Chen, J.; Liu, Y. A Condition-Based Maintenance Policy for Multi-Component Systems Subject to Stochastic and Economic Dependencies. Reliab. Eng. Syst. Saf. 2022, 219, 108174. [Google Scholar] [CrossRef]

- Do, P.; Assaf, R.; Scarf, P.; Iung, B. Modeling and Application of Condition-Based Maintenance for a Two-Component System with Stochastic and Economic Dependencies. Reliab. Eng. Syst. Saf. 2019, 182, 86–97. [Google Scholar] [CrossRef]

- Dao, C.D.; Zuo, M.J. Selective Maintenance of Multi-State Systems with Structural Dependence. Reliab. Eng. Syst. Saf. 2017, 159, 184–195. [Google Scholar] [CrossRef]

- Zhu, M.; Zhou, X. Hypergraph-Based Joint Optimization of Spare Part Provision and Maintenance Scheduling for Serial-Parallel Multi-Station Manufacturing Systems. Reliab. Eng. Syst. Saf. 2022, 225, 108619. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zeng, J.C. Joint Optimization of Condition-Based Opportunistic Maintenance and Spare Parts Provisioning Policy in Multiunit Systems. Eur. J. Oper. Res. 2017, 262, 479–498. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zeng, J.C.; Gan, J. Joint Optimization of Condition-Based Maintenance and Spare Part Inventory for Two-Component System. J. Ind. Prod. Eng. 2018, 35, 394–420. [Google Scholar] [CrossRef]

- Zhang, X.H.; Liao, H.; Zeng, J.C.; Shi, G.; Zhao, B. Optimal Condition-based Opportunistic Maintenance and Spare Parts Provisioning for a Two-unit System Using a State Space Partitioning Approach. Reliab. Eng. Syst. Saf. 2021, 209, 107451. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, W.; Yang, T.; Guo, S. Opportunistic Maintenance Strategy for Wind Turbines Considering Weather Conditions and Spare Parts Inventory Management. Renew. Energy 2019, 133, 703–711. [Google Scholar] [CrossRef]

- Koochaki, J.; Bokhorst, J.A.; Wortmann, H.; Klingenberg, W. The Influence of Condition-Based Maintenance on Workforce Planning and Maintenance Scheduling. Int. J. Prod. Res. 2013, 51, 2339–2351. [Google Scholar] [CrossRef]

- Xu, J.; Liang, Z.; Li, Y.F.; Wang, K. Generalized Condition-Based Maintenance Optimization for Multi-Component Systems Considering Stochastic Dependency and Imperfect Maintenance. Reliab. Eng. Syst. Saf. 2021, 211, 107592. [Google Scholar] [CrossRef]

- Li, H.; Zhu, W.; Dieulle, L.; Deloux, E. Condition-Based Maintenance Strategies for Stochastically Dependent Systems Using Nested Lévy Copulas. Reliab. Eng. Syst. Saf. 2022, 217, 108038. [Google Scholar] [CrossRef]

- Do, P.; Vu, H.C.; Barros, A.; Berenguer, C. Maintenance Grouping for Multi-Component Systems with Availability Constraints and Limited Maintenance Teams. Reliab. Eng. Syst. Saf. 2015, 142, 56–67. [Google Scholar] [CrossRef]

- Sheikhalishahi, M.; Pintelon, L.; Azadeh, A. An Integrated Approach for Maintenance Planning by Considering Human Factors: Application to a Petrochemical Plant. Process Saf. Environ. Prot. 2017, 109, 400–409. [Google Scholar] [CrossRef]

- Liu, B.; Pandey, M.D.; Wang, X.; Zhao, X. A Finite-Horizon Condition-Based Maintenance Policy for a Two-Unit System with Dependent Degradation Processes. Eur. J. Oper. Res. 2021, 295, 705–717. [Google Scholar] [CrossRef]

- Urbani, M.; Brunelli, M.; Punkka, A. An Approach for Bi-Objective Maintenance Scheduling on a Networked System with Limited Resources. Eur. J. Oper. Res. 2023, 305, 101–113. [Google Scholar] [CrossRef]

- Zhu, W.; Castanier, B.; Bettayeb, B. A Dynamic Programming-Based Maintenance Model of Offshore Wind Turbine Considering Logistic Delay and Weather Condition. Reliab. Eng. Syst. Saf. 2019, 190, 106512. [Google Scholar] [CrossRef]

- Si, G.; Xia, T.; Pan, E.; Xi, L. Service-Oriented Global Optimization Integrating Maintenance Grouping and Technician Routing for Multi-Location Multi-Unit Production Systems. IISE Trans. 2022, 54, 894–907. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, Y.; Ma, X. Group Maintenance Scheduling for Two-Component Systems with Failure Interaction. Appl. Math. Model. 2019, 71, 118–137. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, X.; Song, Y.; Qiu, Q. Joint Optimization of Condition-Based Maintenance and Spares Inventory for a Series–Parallel System with Two Failure Modes. Comput. Ind. Eng. 2022, 168, 108094. [Google Scholar] [CrossRef]

- Yang, L.; Peng, R.; Li, G.; Lee, C.G. Operations Management of Wind Farms Integrating Multiple Impacts of Wind Conditions and Resource Constraints. Energy Convers. Manag. 2020, 205, 112162. [Google Scholar] [CrossRef]

- Zequeira, R.I.; Valdes, J.E.; Berenguer, C. Optimal Buffer Inventory and Opportunistic Preventive Maintenance under Random Production Capacity Availability. Int. J. Prod. Econ. 2008, 111, 686–696. [Google Scholar] [CrossRef]

- Nguyen, K.A.; Do, P.; Grall, A. Joint Predictive Maintenance and Inventory Strategy for Multi-Component Systems Using Birnbaum’s Structural Importance. Reliab. Eng. Syst. Saf. 2017, 168, 249–261. [Google Scholar] [CrossRef]

- Vu, H.C.; Do, P.; Barros, A.; Berenguer, C. Maintenance Grouping Strategy for Multi-Component Systems with Dynamic Contexts. Reliab. Eng. Syst. Saf. 2014, 132, 233–249. [Google Scholar] [CrossRef]

- Dinh, D.H.; Do, P.; Iung, B. Maintenance Optimisation for Multi-Component System with Structural Dependence: Application to Machine Tool Sub-System. CIRP Ann. 2020, 69, 417–420. [Google Scholar] [CrossRef]

- Chang, F.; Zhou, G.; Zhang, C.; Xiao, Z.; Wang, C. A Service-Oriented Dynamic Multi-Level Maintenance Grouping Strategy Based on Prediction Information of Multi-Component Systems. J. Manuf. Syst. 2019, 53, 49–61. [Google Scholar] [CrossRef]

- Van Horenbeek, A.; Pintelon, L. A Dynamic Predictive Maintenance Policy for Complex Multi-Component Systems. Reliab. Eng. Syst. Saf. 2013, 120, 39–50. [Google Scholar] [CrossRef]

- Cui, L.; Li, H. Opportunistic Maintenance for Multi-component Shock Models. Math. Methods Oper. Res. 2006, 63, 493–511. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, L.; Liang, W. Opportunistic Predictive Maintenance for Complex Multi-Component Systems Based on DBN-HAZOP Model. Process Saf. Environ. Prot. 2012, 90, 376–388. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, K.; Xi, L.; Lee, J. Preventive Maintenance Modeling for Multi-Component Systems with Considering Stochastic Failures and Disassembly Sequence. Reliab. Eng. Syst. Saf. 2015, 142, 231–237. [Google Scholar] [CrossRef]

- Camci, F. Maintenance Scheduling of Geographically Distributed Assets with Prognostics Information. Eur. J. Oper. Res. 2015, 245, 506–516. [Google Scholar] [CrossRef]

- Jafari, L.; Makis, V. Joint Optimization of Lot-Sizing and Maintenance Policy for a Partially Observable Two-Unit System. Int. J. Adv. Manuf. Technol. 2016, 87, 1621–1639. [Google Scholar] [CrossRef]

- Nguyen, H.S.H.; Do, P.; Vu, H.C.; Iung, B. Dynamic Maintenance Grouping and Routing for Geographically Dispersed Production Systems. Reliab. Eng. Syst. Saf. 2019, 185, 392–404. [Google Scholar] [CrossRef]

- Wakiru, J.M.; Pintelon, L.; Muchiri, P.; Chemweno, P. Integrated Maintenance Policies for Performance Improvement of a Multi-Unit Repairable, One Product Manufacturing System. Prod. Plan. Control 2021, 32, 347–367. [Google Scholar] [CrossRef]

- Qiu, S.; Ming, X.; Sallak, M.; Lu, J. Joint Optimization of Production and Condition-Based Maintenance Scheduling for Make-to-Order Manufacturing Systems. Comput. Ind. Eng. 2021, 162, 107753. [Google Scholar] [CrossRef]

- Manco, P.; Rinaldi, M.; Caterino, M.; Fera, M.; Macchiaroli, R. Maintenance Management for Geographically Distributed Assets: A Criticality-Based Approach. Reliab. Eng. Syst. Saf. 2022, 218, 108148. [Google Scholar] [CrossRef]

- Dinh, D.H.; Do, P.; Iung, B.; Nguyen, P.T.N. Reliability Modeling and Opportunistic Maintenance Optimization for a Multicomponent System with Structural Dependence. Reliab. Eng. Syst. Saf. 2024, 241, 109708. [Google Scholar] [CrossRef]

- Zhu, M.; Zhou, X. Hybrid Opportunistic Maintenance Policy for Serial-Parallel Multi-Station Manufacturing Systems with Spare Part Overlap. Reliab. Eng. Syst. Saf. 2023, 236, 109304. [Google Scholar] [CrossRef]

- Zhu, M.; Zhou, X. Hierarchical-Clustering-Based Joint Optimization of Spare Part Provision and Maintenance Scheduling for Serial-Parallel Multi-Station Manufacturing Systems. Int. J. Prod. Econ. 2023, 264, 108971. [Google Scholar] [CrossRef]

- Einabadi, B.; Mahmoodjanloo, M.; Baboli, A.; Rother, E. Dynamic Predictive and Preventive Maintenance Planning with Failure Risk and Opportunistic Grouping Considerations: A Case Study in the Automotive Industry. J. Manuf. Syst. 2023, 69, 292–310. [Google Scholar] [CrossRef]

- Boujarif, A.; Coit, D.; Jouini, O.; Zeng, Z.; Heidsieck, R. Opportunistic Maintenance of Multi-Component Systems Under Structure and Economic Dependencies: A Healthcare System Case Study. In Proceedings of the 12th International Conference on Operations Research and Enterprise Systems, Lisbon, Portugal, 19–21 February 2023; pp. 158–166. [Google Scholar] [CrossRef]

- Ma, W.N.; Li, H.; Yang, Z.Y.; Hu, Q.W. Maintenance Optimization for Two-Component Series Systems with Degradation Dependence. IEEE Access 2021, 9, 48174–48184. [Google Scholar] [CrossRef]

- Zhou, X.; Mao, W. Maintenance Modeling for Hot Rolling Production Lines with Constraint of Auxiliary Resources. Comput. Ind. Eng. 2024, 188, 109938. [Google Scholar] [CrossRef]

- Ghamlouch, H.; Grall, A. Opportunistic Maintenance Strategy for a Train Fleet under Safety Constraints and Inter-System Dependencies. In Proceedings of the Safety and Reliability—Safe Societies in a Changing World, Trondheim, Norway, 17–21 June 2018; pp. 579–586. [Google Scholar] [CrossRef]

- Li, Z.; Chen, X.; Li, J.; Huang, X. Opportunistic Group Maintenance Optimization of Multi-unit System Considering Dependency. In Proceedings of the 2020 6th International Conference on Control, Automation and Robotics (ICCAR), Singapore, 20–23 April 2020; pp. 33–38. [Google Scholar] [CrossRef]

- Do, P.; Scarf, P.; Iung, B. Condition-Based Maintenance for a Two-Component System with Dependencies. IFAC-PapersOnLine 2015, 48, 946–951. [Google Scholar] [CrossRef]

- Nguyen, K.A.; Do, P.; Grall, A. A Joint Predictive Maintenance and Spare Parts Provisioning Policy for Multi-component Systems Using RUL Prediction and Importance Measure. In Proceedings of the European Conference of the Prognostics and Health Management Society 2014, Nantes, France, 8–10 July 2014; p. 12. [Google Scholar]

- Si, G.; Xia, T.; Zhang, K.; Wang, D.; Pan, E.; Xi, L. Technician Collaboration and Routing Optimization in Global Maintenance Scheduling for Multi-Center Service Networks. IEEE Trans. Autom. Sci. Eng. 2022, 19, 1542–1554. [Google Scholar] [CrossRef]

- Do, P.; Vu, H.C.; Barros, A.; Berenguer, C. Grouping Maintenance Strategy with Availability Constraint under Limited Repairmen. In Proceedings of the SAFEPROCESS 2012—8th IFAC Symposium on Fault Detection, Supervision and Safety for Technical Processes, Mexico City, Mexico, 16–18 April 2012; Volume 45, pp. 486–491. [Google Scholar] [CrossRef]

- Wu, Q.; Lv, C.; Zhou, D.; Wang, Y.; Yu, D. Study on Multi-Event Opportunistic Maintenance Decision-Making Model Based on Condition. In Proceedings of the 2016 IEEE International Conference on Prognostics and Health Management (ICPHM), Ottawa, ON, Canada, 20–22 June 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Salari, N.; Makis, V.; Abbou, A. Joint Optimization of Maintenance and Spare Parts Provisioning for Multi-Unit Systems. In Proceedings of the 2018 Industrial and Systems Engineering Research Conference, Orlando, FL, USA, 19–22 May 2018; p. 7. [Google Scholar]

- Werbińska-Wojciechowska, S. Preventive Maintenance Models for Technical Systems. In Technical System Maintenance; Springer International Publishing: Cham, Switzerland, 2019; pp. 21–100. [Google Scholar] [CrossRef]

- Do, P.; Assaf, R.; Scarf, P. Opportunistic Maintenance Policies for Multi-Components Systems. In Multicriteria and Optimization Models for Risk, Reliability, and Maintenance Decision Analysis; de Almeida, A.T., Ekenberg, L., Scarf, P., Zio, E., Zuo, M.J., Eds.; Springer International Publishing: Cham, Switzerland, 2022; Volume 321, pp. 403–422. [Google Scholar] [CrossRef]

- Li, H. Condition-Based Maintenance Policies for Multi-Component Systems Considering Stochastic Dependences. Ph.D. Thesis, Université de Technologie de Troyes, Troyes, France, 2016. [Google Scholar]

- Nguyen, H.S.H. Développement d’une Stratégie de Regroupement Dynamique d’actions de Maintenance Pour Un Système de Production Géographiquement Dispersé. Ph.D. Thesis, Université de Lorraine, Nancy, France, 2019. [Google Scholar]

- Alghanmi, S. Opportunistic Maintenance Optimization Based on Stochastic Dependence for Multi-Component System Exposed to Different Failure Modes. Ph.D. Thesis, University of Akron, Akron, OH, USA, 2018. [Google Scholar]

- Dinh, D.H. Opportunistic Predictive Maintenance for Multi-Component Systems with Multiple Dependences. Ph.D. Thesis, Université de Lorraine, Nancy, France, 2021. [Google Scholar]

- Murthy, D.N.P.; Nguyen, D.G. Study of Two-component System with Failure Interaction. Nav. Res. Logist. Q. 1985, 32, 239–247. [Google Scholar] [CrossRef]

- Peña, C.; Romero, D.; Noguez, J. Workforce Learning Curves for Human-Based Assembly Operations: A State-of-the-Art Review. Appl. Sci. 2022, 12, 9608. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable Operations: Their Impact on the Triple Bottom Line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Nunes, P.; Santos, J.; Rocha, E. Challenges in Predictive Maintenance—A Review. CIRP J. Manuf. Sci. Technol. 2023, 40, 53–67. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.F.; Coit, D.W. Deep Reinforcement Learning for Dynamic Opportunistic Maintenance of Multi-Component Systems with Load Sharing. IEEE Trans. Reliab. 2023, 72, 863–877. [Google Scholar] [CrossRef]

- Kuhnle, A.; Jakubik, J.; Lanza, G. Reinforcement Learning for Opportunistic Maintenance Optimization. Prod. Eng. 2019, 13, 33–41. [Google Scholar] [CrossRef]

- Valet, A.; Altenmüller, T.; Waschneck, B.; May, M.C.; Kuhnle, A.; Lanza, G. Opportunistic Maintenance Scheduling with Deep Reinforcement Learning. J. Manuf. Syst. 2022, 64, 518–534. [Google Scholar] [CrossRef]

- Nassehi, A.; Zhong, R.Y.; Li, X.; Epureanu, B.I. Review of Machine Learning Technologies and Artificial Intelligence in Modern Manufacturing Systems. In Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Elsevier: Amsterdam, The Netherlands, 2022; pp. 317–348. [Google Scholar] [CrossRef]

- Deng, W.; Nguyen, K.T.; Gogu, C.; Medjaher, K.; Morio, J. Enhancing Prognostics for Sparse Labeled Data Using Advanced Contrastive Self-Supervised Learning with Downstream Integration. Eng. Appl. Artif. Intell. 2024, 138, 109268. [Google Scholar] [CrossRef]

- Zhou, H.; Yin, H.; Zhao, D.; Cai, L. Incremental Learning and Conditional Drift Adaptation for Nonstationary Industrial Process Fault Diagnosis. IEEE Trans. Ind. Inform. 2023, 19, 5935–5944. [Google Scholar] [CrossRef]

- Zhou, H.; Yin, H.; Qin, Y.; Yuen, C. Industrial Fault Diagnosis with Incremental Learning Capability Under Varying Sensory Data. IEEE Trans. Syst. Man Cybern. Syst. 2025, 55, 1322–1333. [Google Scholar] [CrossRef]

- Sathupadi, K.; Achar, S.; Bhaskaran, S.V.; Faruqui, N.; Abdullah-Al-Wadud, M.; Uddin, J. Edge-Cloud Synergy for AI-Enhanced Sensor Network Data: A Real-Time Predictive Maintenance Framework. Sensors 2024, 24, 7918. [Google Scholar] [CrossRef] [PubMed]

- Independent Group of Scientists appointed by the Secretary-General. Global Sustainable Development Report 2019: The Future Is Now—Science for Achieving Sustainable Development. Technical Report, United Nations, New York, 2019. Available online: https://pure.iiasa.ac.at/id/eprint/16067/1/24797GSDR_report_2019.pdf (accessed on 3 March 2025).

- Franciosi, C.; Voisin, A.; Miranda, S.; Riemma, S.; Iung, B. Measuring Maintenance Impacts on Sustainability of Manufacturing Industries: From a Systematic Literature Review to a Framework Proposal. J. Clean. Prod. 2020, 260, 121065. [Google Scholar] [CrossRef]

- Sénéchal, O. Research Directions for Integrating the Triple Bottom Line in Maintenance Dashboards. J. Clean. Prod. 2017, 142, 331–342. [Google Scholar] [CrossRef]

- Sénéchal, O.; Trentesaux, D. A Framework to Help Decision Makers to Be Environmentally Aware during the Maintenance of Cyber Physical Systems. Environ. Impact Assess. Rev. 2019, 77, 11–22. [Google Scholar] [CrossRef]

- Hennequin, S.; Ramirez Restrepo, L.M. Fuzzy Model of a Joint Maintenance and Production Control under Sustainability Constraints. IFAC-PapersOnLine 2016, 49, 1216–1221. [Google Scholar] [CrossRef]

- Saihi, A.; Ben-Daya, M.; As’ad, R.A. Maintenance and Sustainability: A Systematic Review of Modeling-Based Literature. J. Qual. Maint. Eng. 2023, 29, 155–187. [Google Scholar] [CrossRef]

| Year | Paper | Topic | Limitations |

|---|---|---|---|

| 1996 | [8] | Maintenance optimization models | Does not cover resources or dependant failure modes |

| 2008 | [11] | Maintenance of multi-component systems | The human factor is not considered beyond economic dependency |

| 2009 | [12] | Multicomponent system maintenance | Does not cover resources or human factor |

| 2010 | [6] | Objective function of maintenance optimization | Does not cover resources or dependant failure modes |

| 2013 | [9] | Maintenance and inventory optimization | Does not cover resources different than inventory |

| 2014 | [5] | Opportunistic maintenance, objective function | Mentions but does not analyze the modeling of dependent failures or resource limitations |

| 2015 | [13] | Maintenance logistics for offshore wind farms | Limited to weather constraints and resource dependence |

| 2016 | [14] | Condition-based maintenance | Does not cover resources or human factor |

| 2017 | [15] | Condition-based maintenance | Limited to condition-based maintenance, limited analysis of dependencies |

| 2017 | [1] | Condition-based maintenance | Limited to condition-based maintenance, limited analysis of human factor |

| 2020 | [16] | Maintenance in the chemical industry | Does not cover dependent failure modes |

| 2020 | [2] | Maintenance optimization and assumption | Does not cover resources different than inventory |

| 2021 | [17] | Railway track maintenance | Limited to railway applications, found no article related to structural and stochastic dependencies |

| 2022 | [18] | Spare parts management for offshore wind farms | Specific scope, does not cover dependencies |

| 2022 | [19] | Sustainable maintenance strategies | No mention of the optimization objectives, limited analysis of dependencies |

| 2023 | [20] | Maintenance and spare-parts inventory | Does not cover dependent failure modes |

| 2023 | [10] | Dependent failures modeling | Limited to the risk and reliability points of view, does not cover resource limitations |

| 2025 | [21] | Performances of explainable artificial intelligence models in maintenance | Does not address opportunistic maintenance or hypotheses in maintenance modeling |

| Opportunistic Maintenance | Workers’ Skills | Dependences | Resource Constraints |

|---|---|---|---|

| opportunist* maintenanc* | skill* | dependenc* | resource* constraint* |

| dynamic grouping* | expertise | spare part* | |

| inventory | |||

| logistic support |

| Publication Type | Number Reviewed | Refs. |

|---|---|---|

| Original research: Journal papers | 64 | [3,7,35,47,49,54,55,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120] |

| Original research: Conference papers | 9 | [62,121,122,123,124,125,126,127,128] |

| Book chapter | 2 | [129,130] |

| Review papers | 12 | [1,2,11,12,13,14,15,16,17,18,19,20] |

| Theses | 4 | [131,132,133,134] |

| Total | 91 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Equeter, L.; Do, P.; Colantonio, L.; Tiberi, L.A.; Dehombreux, P.; Iung, B. Hypotheses in Opportunistic Maintenance Modeling: A Critical and Systematic Literature Review. Machines 2025, 13, 947. https://doi.org/10.3390/machines13100947

Equeter L, Do P, Colantonio L, Tiberi LA, Dehombreux P, Iung B. Hypotheses in Opportunistic Maintenance Modeling: A Critical and Systematic Literature Review. Machines. 2025; 13(10):947. https://doi.org/10.3390/machines13100947

Chicago/Turabian StyleEqueter, Lucas, Phuc Do, Lorenzo Colantonio, Luca A. Tiberi, Pierre Dehombreux, and Benoît Iung. 2025. "Hypotheses in Opportunistic Maintenance Modeling: A Critical and Systematic Literature Review" Machines 13, no. 10: 947. https://doi.org/10.3390/machines13100947

APA StyleEqueter, L., Do, P., Colantonio, L., Tiberi, L. A., Dehombreux, P., & Iung, B. (2025). Hypotheses in Opportunistic Maintenance Modeling: A Critical and Systematic Literature Review. Machines, 13(10), 947. https://doi.org/10.3390/machines13100947