Geometric Design and Basic Feature Analysis of Double Helical Face Gears

Abstract

1. Introduction

2. Materials and Methods

2.1. Pinion and DHFG Processing Materials

2.2. Geometric Design of DHFG Transmission Device

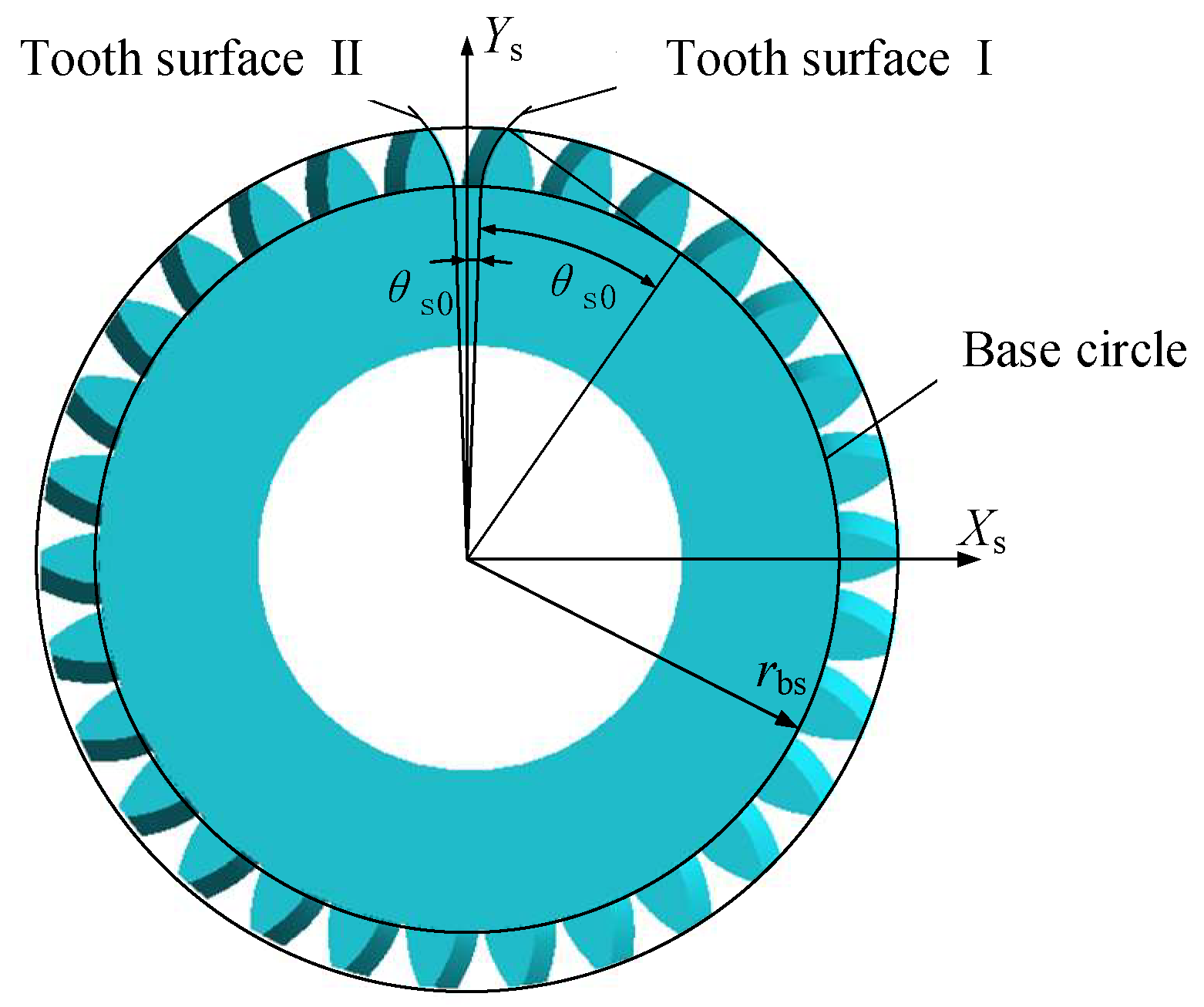

2.2.1. Pinion and Cutter Tooth Surface Equations

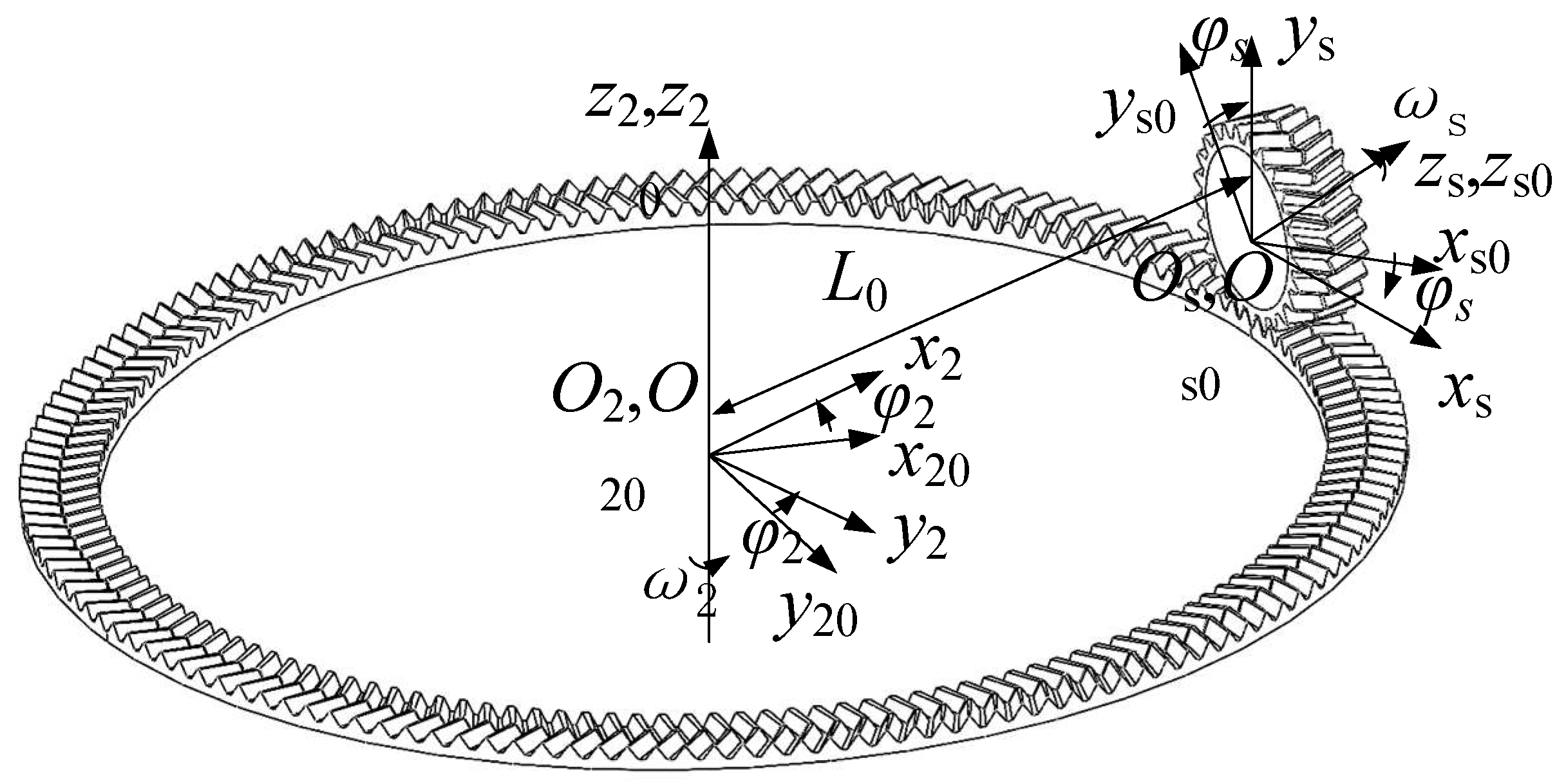

2.2.2. Establishment of a Coordinate System for the Transformation of Face Gear

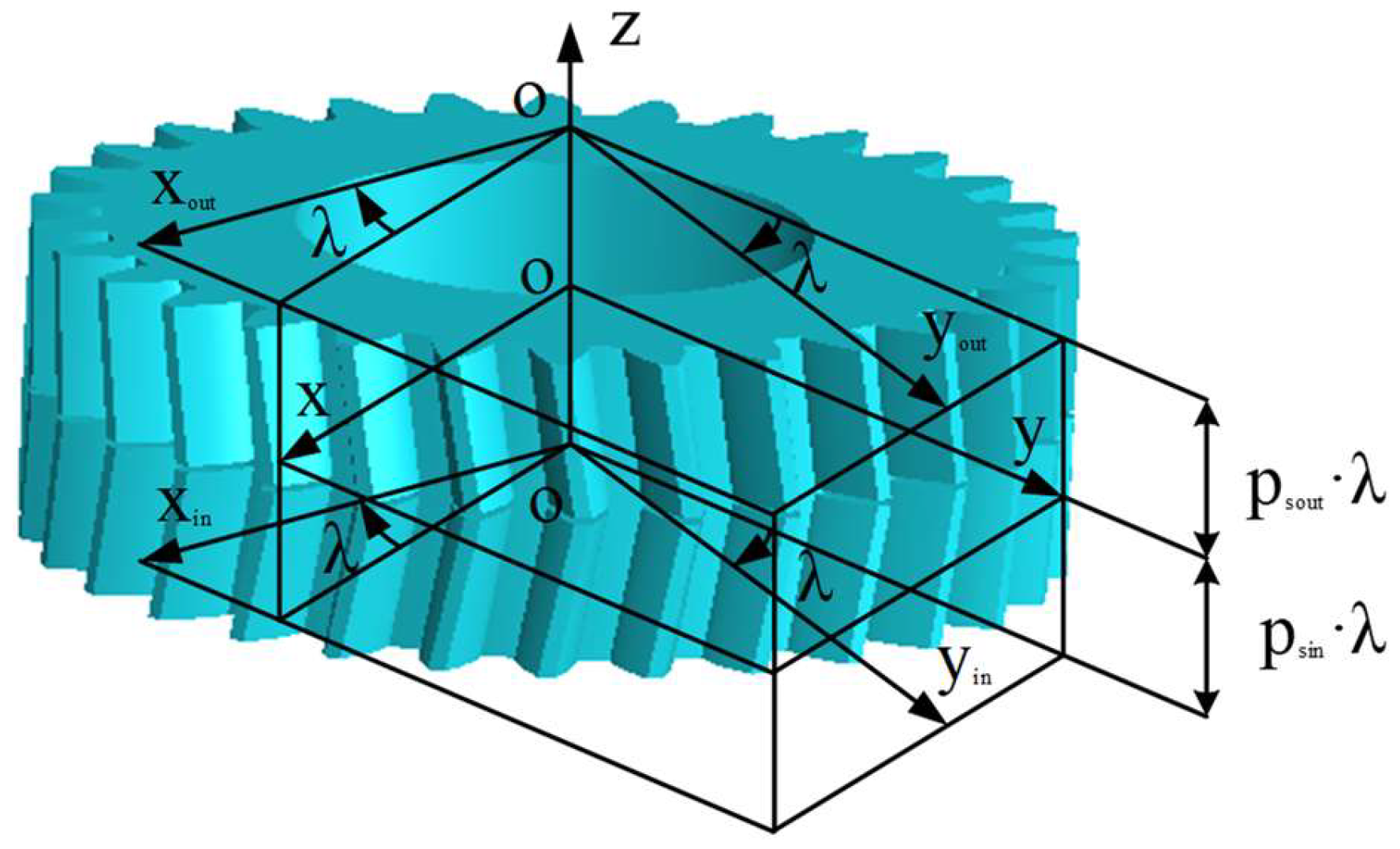

2.3. Derivation of DHFG Tooth Equation

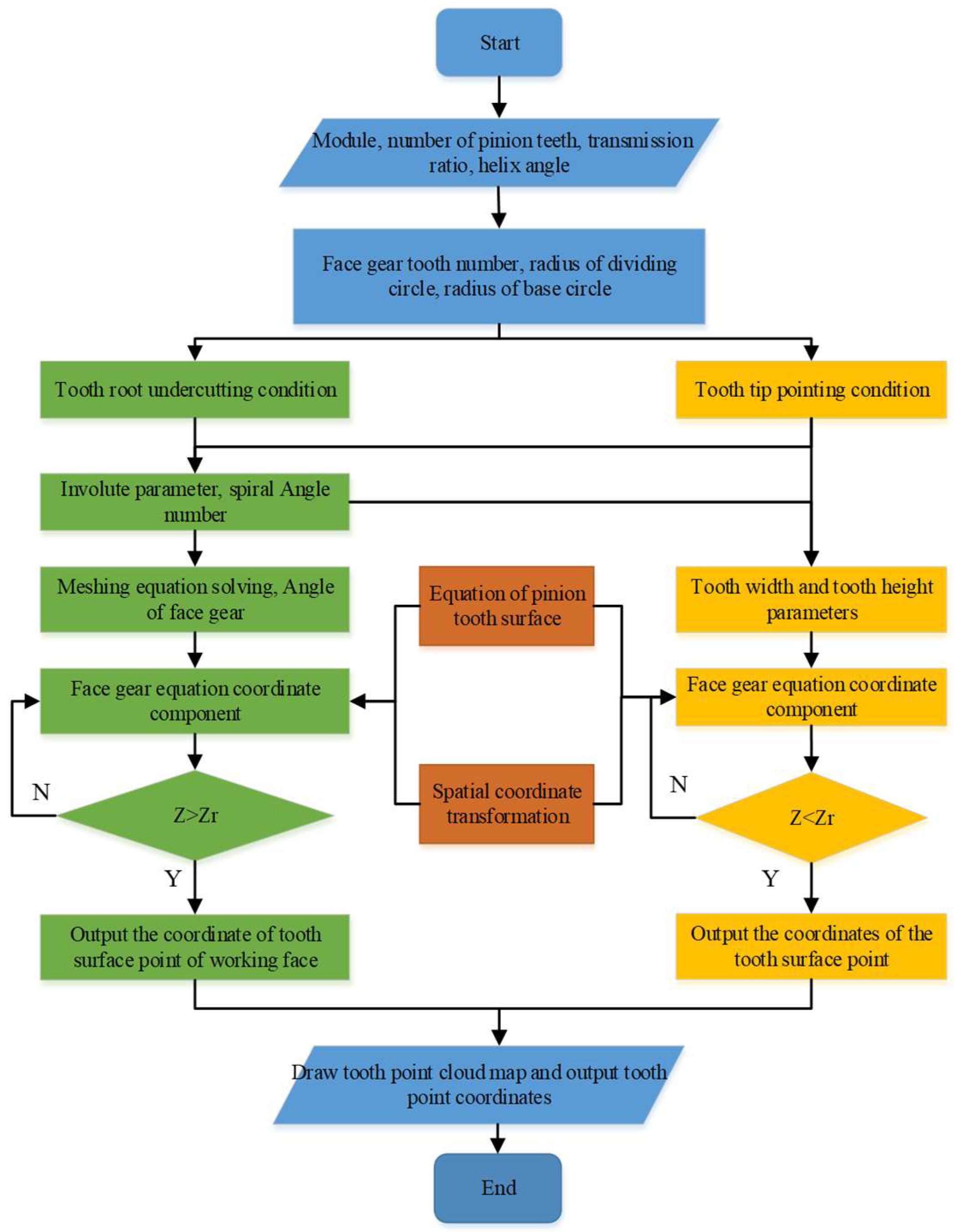

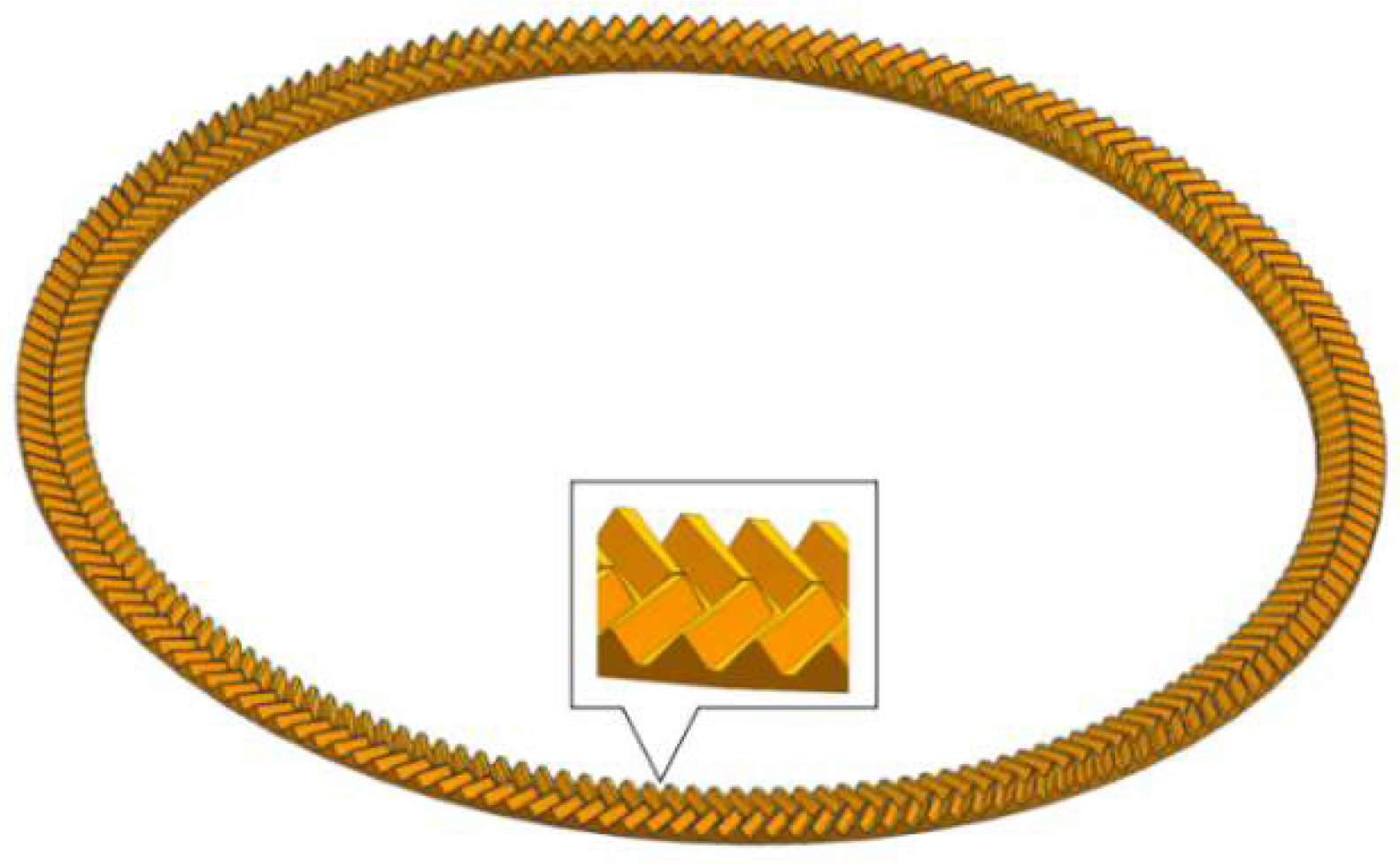

2.4. Modeling of DHFG

2.5. DHFG Loading Contact Analysis Orthogonal Experimental Design

3. Results

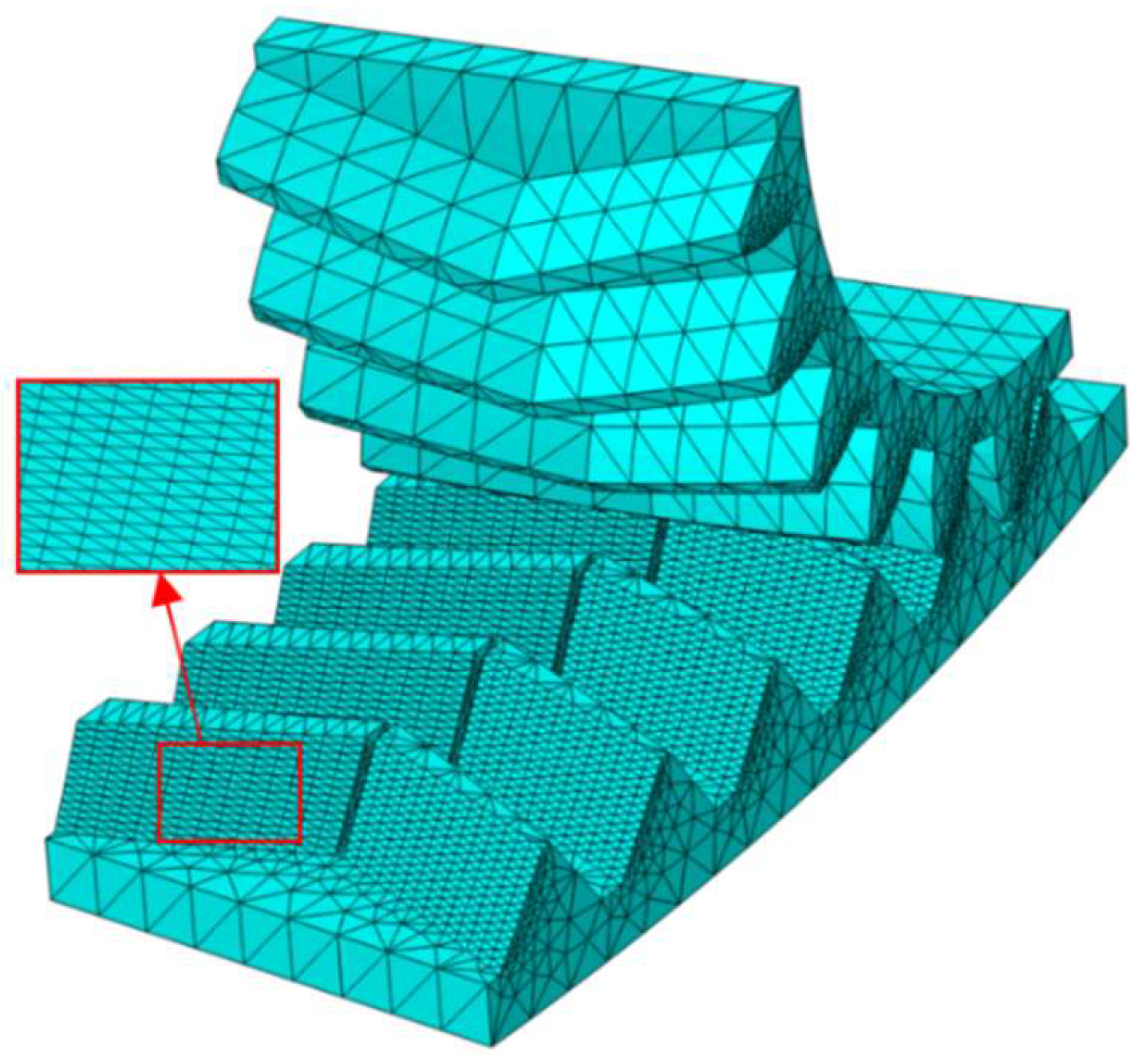

3.1. Simulation Model Simplification

3.2. Tooth Surface Contact Analysis

3.2.1. Simulation Analysis of Meshing Stiffness

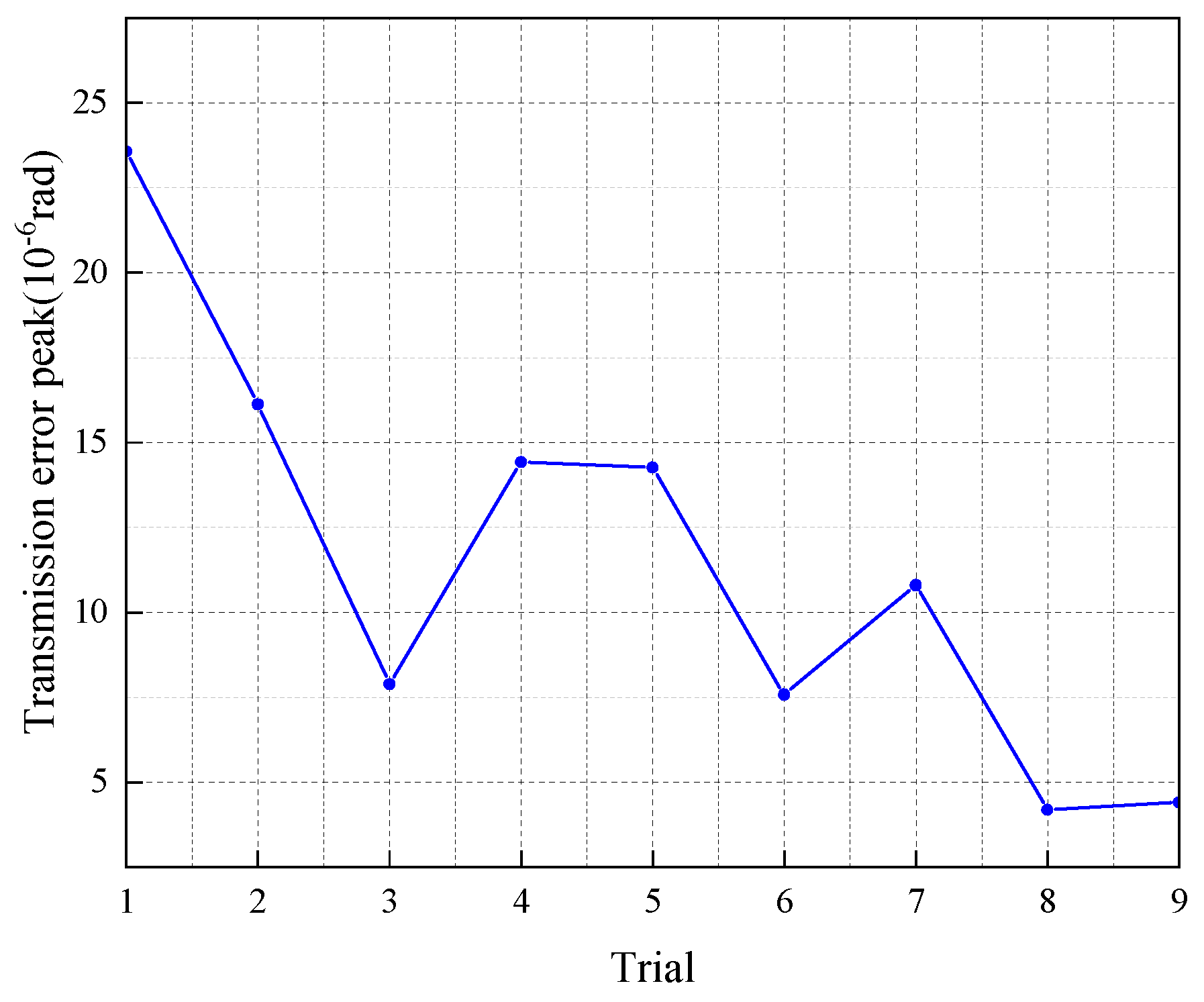

3.2.2. Transmission Error Analysis

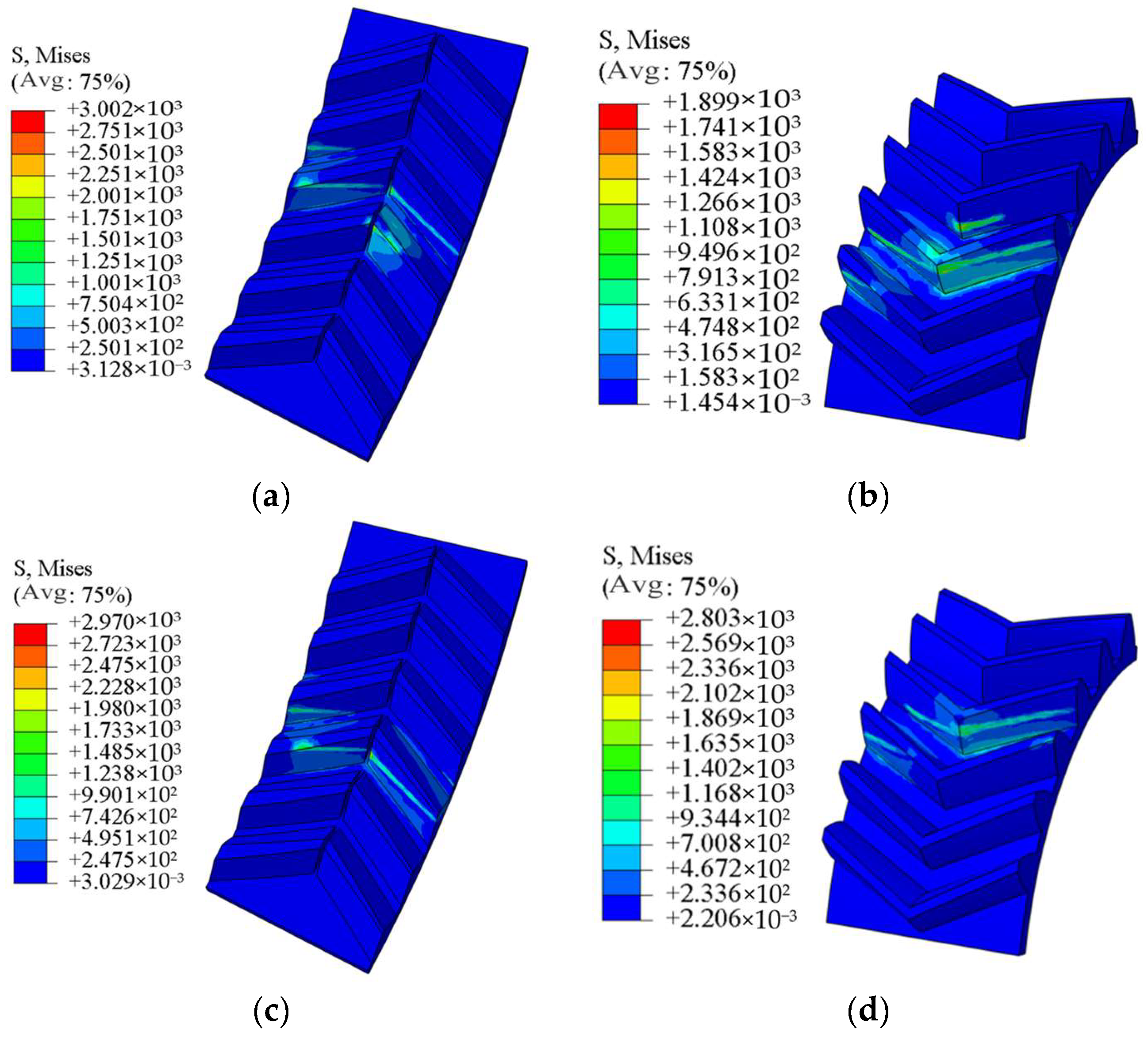

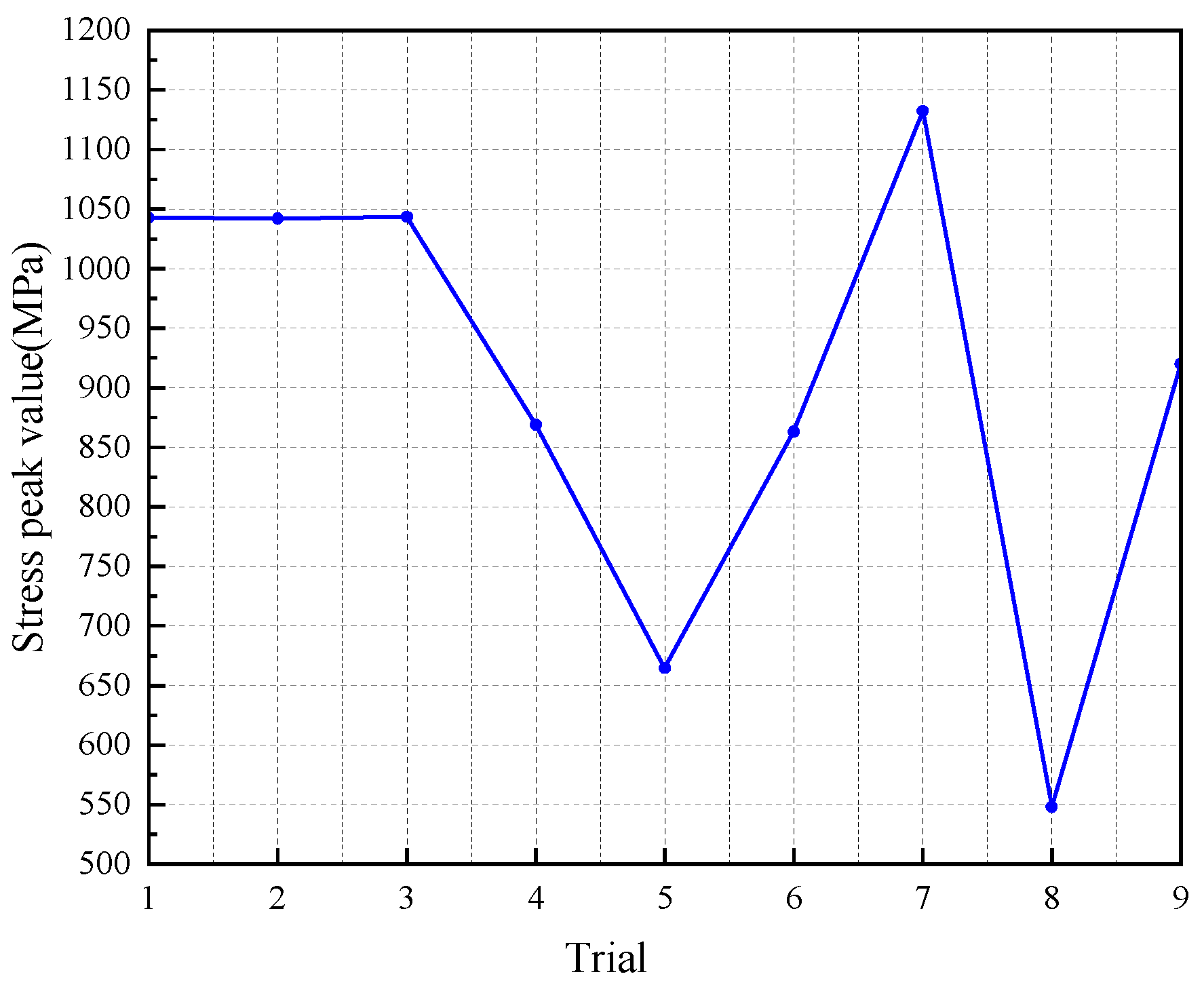

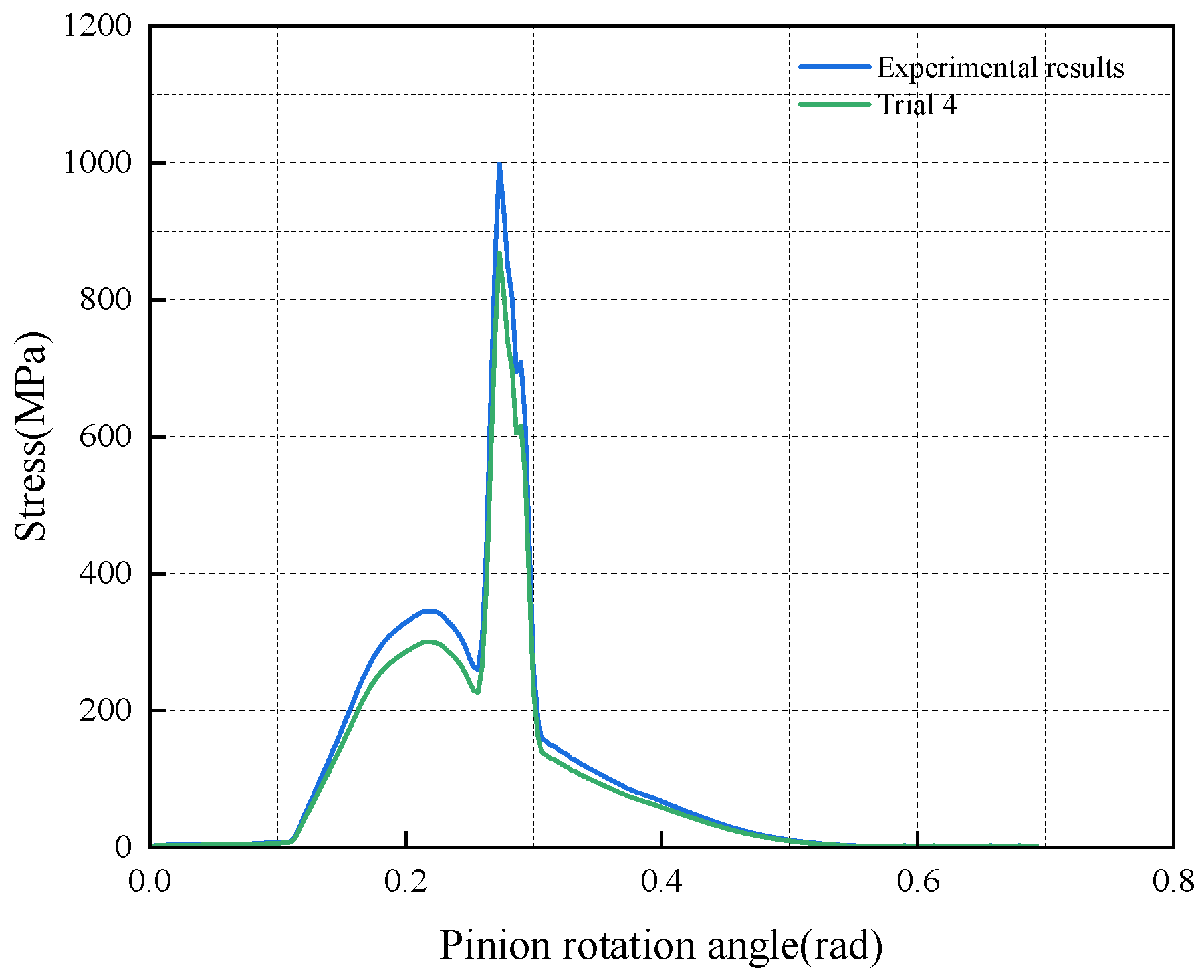

3.2.3. Simulation Analysis of Contact Stress of DHFG

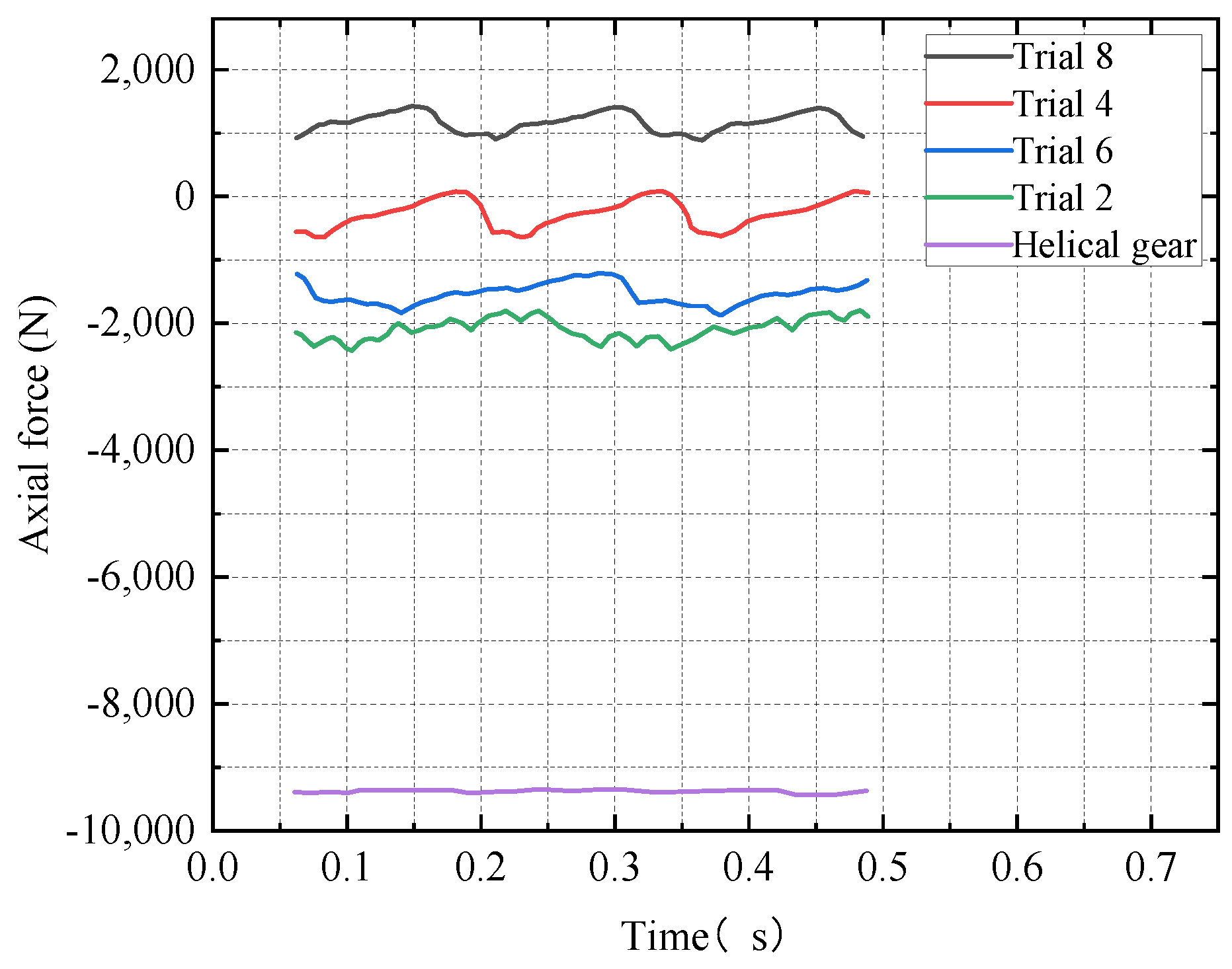

3.3. Axial Force Analysis

3.4. Trial Manufacture for Geometric Design Method Verification

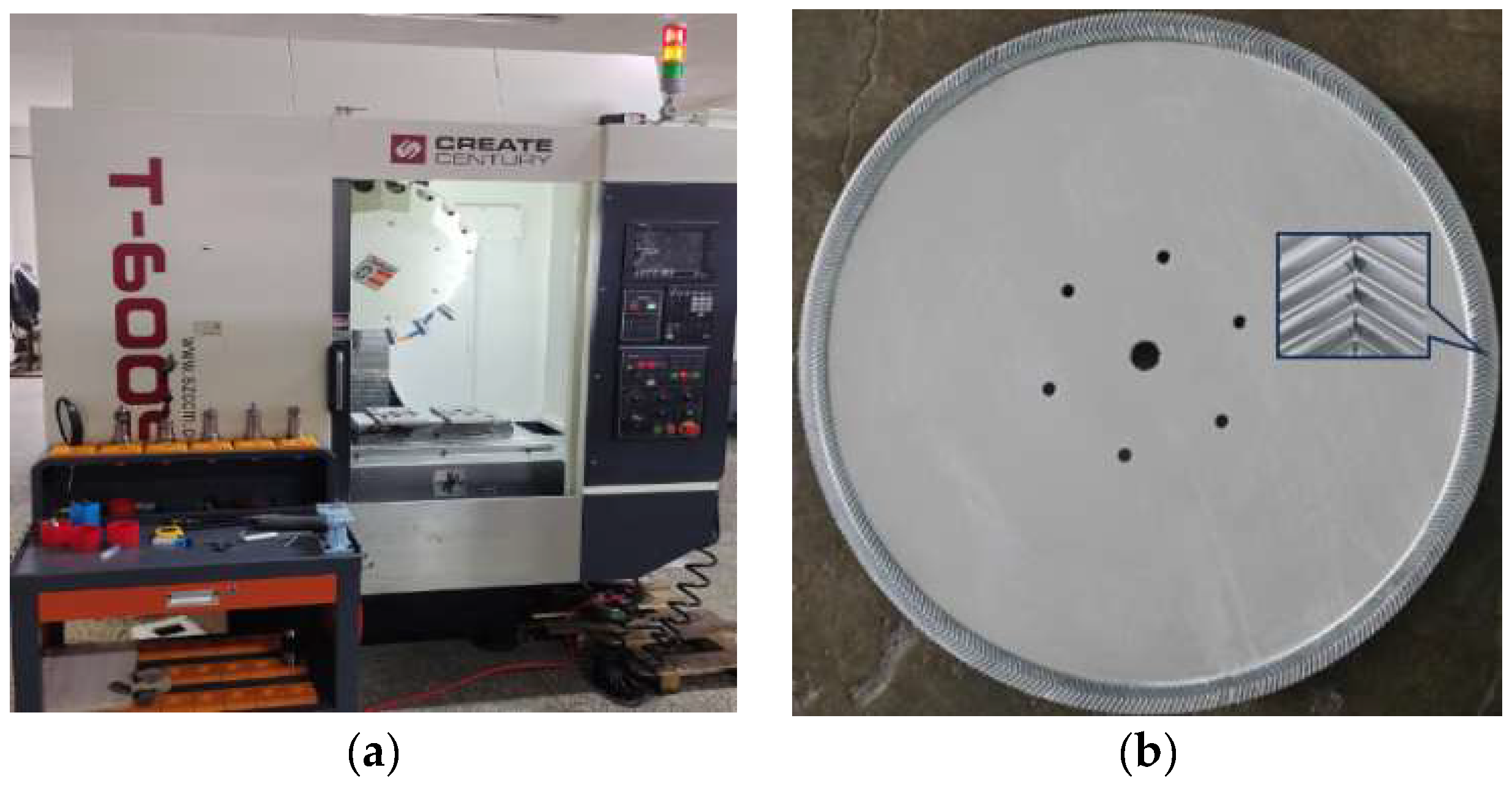

3.4.1. Experimental Study on the Machining and Manufacturing of DHFG

3.4.2. Contact Pattern Inspection of DHFG

4. Conclusions

- A robust mathematical model for the DHFG tooth surface is established based on the spatial meshing theory and coordinate transformation. Point clouds on the surface of teeth are generated through computer programs to precisely create 3D models for subsequent finite element analysis.

- The finite element analysis revealed that the designed DHFG pair exhibits favorable meshing characteristics. The actual overlap ratio fluctuated between two and three, ensuring smooth power transmission. Furthermore, the meshing stiffness results indicated a strong load-bearing capacity of the tooth surface.

- The orthogonal experimental design effectively identified the influence of key design parameters (pinion tooth count, transmission ratio, and helix angle). The results demonstrated a clear trend: increasing these parameters generally reduced the transmission error (enhancing operational smoothness and reducing vibration) and decreased maximum contact stress.

- The symmetrical double helical structure of the DHFG enables the inherent self-balancing of axial forces. Finite element analysis demonstrated a substantial reduction in axial load compared to a single helical gear. This advantage lowers the load requirements on bearings and housing, facilitating more compact and efficient transmission.

- Excellent agreement between simulation and experimental results confirms the FE model’s reliability. This, combined with the successful prototype manufacture and correlation of its contact pattern with simulations, validates the entire design-to-manufacturing process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| The base circle radius of the tool involute | |

| The angle parameter of the intersection point between the involute of the cutting tool and the base circle | |

| The angle parameter of the involute tooth surface | |

| The angle turned by the cutting tool during processing | |

| The number of teeth of the tool | |

| The pressure angle of the division circle phase of the cutting tool | |

| The involute function | |

| The helical angle of the helical motion | |

| The helical parameter | |

| The normal vector to the teeth of the tool | |

| The velocity of the tool in the coordinate system with respect to the gear of the teeth | |

| The angular velocity of the cutter | |

| The position vector of point L in the cutter coordinate system | |

| The helix angle of the base circle | |

| The pitch circle radius of the tool gear | |

| The root height of the tool gear | |

| The angular displacement of the pinion | |

| The actual angular displacement of the DHFG | |

| The theoretical angular displacement of the driven gear |

References

- Liu, H.; Zhao, J.; Tang, J. Simulation and Experimental Verification of Die Quenching Deformation of Aviation Carburized Face Gear. Materials 2023, 16, 690. [Google Scholar] [CrossRef]

- Mo, S.; Xuan, H.; Liu, W.; Zhang, W. Study on nonlinear vibration and primary resonance characteristics of helicopter face gear-planetary gear coupling transmission system. Proc. Inst. Mech. Eng. Part K-J. Multi-Body Dyn. 2023, 237, 534–550. [Google Scholar] [CrossRef]

- Chen, H.; Li, Q.; Jia, C. Research on the Design and Meshing Performance Analysis of Face Gear Meshing Nutation Reducers. Mathematics 2025, 13, 476. [Google Scholar] [CrossRef]

- Liu, D.; Wang, G. Transmission principle and geometrical model of eccentric face gear. Mech. Mach. Theory 2017, 109, 51–64. [Google Scholar] [CrossRef]

- Noritsugu, M. Research on simplification of face gear tooth surface design. J. Adv. Mech. Des. Syst. Manuf. 2024, 18, JAMDSM0006. [Google Scholar] [CrossRef]

- Wei, S.; Zhao, J. Geometric Design of a Face Gear Drive with Low Sliding Ratio. Appl. Sci. 2022, 12, 2936. [Google Scholar] [CrossRef]

- Litvin, F.L.; Fuentes, A. Gear Geometry and Applied Theory, 2nd ed.; Cambridge University Press: New York, NY, USA, 2004. [Google Scholar]

- Litvin, F.L.; Fuentes, A.; Zanzi, C. Design, generation, and stress analysis of two versions of geometry of face gear drives. Mech. Mach. Theory 2002, 37, 1179–1211. [Google Scholar] [CrossRef]

- Litvin, F.L.; Gonzalez-Perez, I.; Fuentes, A. Design, generation and stress analysis of face gear drive with helical pinion. Comput. Methods Appl. Mech. Eng. 2005, 194, 3870–3901. [Google Scholar] [CrossRef]

- Kawasaki, K.; Tsuji, I.; Gunbara, H. Geometric design of a face gear drive with a helical pinion. Mech. Sci. Technol. 2018, 32, 1653–1659. [Google Scholar] [CrossRef]

- Lin, C.; Ran, G.; Hu, Y. Compound motion characteristics analysis of eccentric herringbone curve-face gear pair. Mech. Sci. Technol. 2021, 35, 5571–5578. [Google Scholar] [CrossRef]

- Gao, L.; Feng, Z.R. Tooth surface design and undercutting research of offset orthogonal arc tooth face gear. J. Aerosp. Power 2022, 37, 869–876. [Google Scholar] [CrossRef]

- Mo, S.; Zhang, Y. Design methods and stress analysis of asymmetric offset face-gear transmission. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2022, 236, 7814–7828. [Google Scholar] [CrossRef]

- Fu, X.; Fang, Z.; Cui, Y. Modelling, design and analysis of offset, non-orthogonal and profile-shifted face gear drives. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, C.; Xu, H. Static load sharing performance of non-orthogonal and offset helical face gear dual-branch drivetrain. Adv. Mech. Eng. 2025, 17, 1–11. [Google Scholar] [CrossRef]

- Wang, J.; Dong, J.; Wang, S.; Xiao, Y. Mathematic design and computer analysis of curve-surface conjugated face gear pair. Adv. Mech. Eng 2025, 17, 1–13. [Google Scholar] [CrossRef]

- Li, Z.; Wu, H.; Zhu, R. Influence predictions of geometric parameters on face gear strength. Adv. Mech. Eng. 2015, 2015, 1–7. [Google Scholar] [CrossRef]

- Li, Z.; Fan, J.; Zhu, R. Construction of tooth modeling solutions of face gear drives with an involute pinion. Iran. J. Sci. Technol. Trans. Mech. Eng. 2018, 42, 35–39. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, R. Theoretical and experimental research on tooth root bending stress of face gear. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2024, 238, 7172–7188. [Google Scholar] [CrossRef]

- Zhu, L.; Bai, J.X. Stiffness analysis of nutation face gear considering roughness. Eng. Comput. 2023, 40, 2348–2362. [Google Scholar] [CrossRef]

- Peng, L. A new geometry definition and generation method for a face gear meshed with a spur pinion. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2022, 236, 1037–1051. [Google Scholar] [CrossRef]

- Feng, G.; Gu, Y.P. Geometric design and characteristic analysis of herringbone face gears. Tsinghua Univ. 2019, 59, 670–678. [Google Scholar] [CrossRef]

- Feng, G.; Xie, Z.F.; Zhou, M. Geometric design and analysis of face gear drive with involute helical pinion. Mech. Mach. Theory 2019, 134, 169–196. [Google Scholar] [CrossRef]

- Mo, S.; Wang, S. Machining principle and cutter design of face gear skiving. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2023, 237, 468–480. [Google Scholar] [CrossRef]

- Mo, S.; Luo, B.R. Geometry design and tooth contact analysis of non-orthogonal asymmetric helical face gear drives. Mech. Mach. Theory 2022, 173, 104831. [Google Scholar] [CrossRef]

- Bo, P.; González, D.; Kang, K.; Wu, Y.; Ma, W. 5-axis double-flank CNC machining of spiral bevel gears via custom-shaped milling tools—Part I: Modeling and simulation. Precis. Eng. 2020, 62, 204–212. [Google Scholar] [CrossRef]

- Gómez Escudero, G.; Bo, P.; González-Barrio, H.; Ortega, R.; López de Lacalle, L.N. 5-axis double-flank CNC machining of spiral bevel gears via custom-shaped tools—Part II: Physical validations and experiments. Int. J. Adv. Manuf. Technol. 2022, 119, 1647–1658. [Google Scholar] [CrossRef]

- Álvarez, A.; Calleja, A.; Ortega, N.; López de Lacalle, L.N. Spiral bevel gears face roughness prediction produced by CNC end milling centers. Materials 2018, 11, 1301. [Google Scholar] [CrossRef]

- Álvarez, A.; Calleja, A. Five-Axis Milling of Large Spiral Bevel Gears: Toolpath Definition, Finishing, and Shape Errors. Metals 2018, 8, 353. [Google Scholar] [CrossRef]

| Performance Parameters | 20CrMnTi (Pinion) | 18CrNiMo7-6 (DHFG) | Unit |

|---|---|---|---|

| Surface hardness | 60 ± 2 | 58 ± 2 | HRC |

| Core hardness | 40 ± 5 | 38 ± 5 | HRC |

| Tensile strength (Rm) | ≥1500 | ≥1200 | MPa |

| Yield strength (Rp0.2) | ≥950 | ≥850 | MPa |

| Contact fatigue strength (σ Hlim) | 1500 | 1450 | MPa |

| Bending fatigue strength (σ Flim) | 430 | 400 | MPa |

| Gear Parameter Name | Parameter Value |

|---|---|

| Number of pinion teeth | 30 |

| Tooth number of DHFG | 180 |

| Modulus (mm) | 5 |

| Pressure angle (°) | 20 |

| Tooth top height coefficient | 1 |

| Top clearance coefficient | 0.25 |

| Internal helix angle (°) | −30 |

| Outer helix angle (°) | 30 |

| Level | Number of Pinion Teeth | Transmission Ratio | Helix Angle (°) | Blank Group |

|---|---|---|---|---|

| 1 | 25 | 6 | 20 | - |

| 2 | 30 | 8 | 25 | - |

| 3 | 35 | 10 | 30 | - |

| Trial | Number of Pinion Teeth | Transmission Ratio | Helix Angle (°) | Blank Group |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 2 | 1 | 3 | 2 |

| 5 | 2 | 2 | 1 | 3 |

| 6 | 2 | 3 | 2 | 1 |

| 7 | 3 | 1 | 2 | 3 |

| 8 | 3 | 2 | 3 | 1 |

| 9 | 3 | 3 | 1 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, X.; Chen, F. Geometric Design and Basic Feature Analysis of Double Helical Face Gears. Machines 2025, 13, 912. https://doi.org/10.3390/machines13100912

Chu X, Chen F. Geometric Design and Basic Feature Analysis of Double Helical Face Gears. Machines. 2025; 13(10):912. https://doi.org/10.3390/machines13100912

Chicago/Turabian StyleChu, Xiaomeng, and Faqiang Chen. 2025. "Geometric Design and Basic Feature Analysis of Double Helical Face Gears" Machines 13, no. 10: 912. https://doi.org/10.3390/machines13100912

APA StyleChu, X., & Chen, F. (2025). Geometric Design and Basic Feature Analysis of Double Helical Face Gears. Machines, 13(10), 912. https://doi.org/10.3390/machines13100912