Effects of Roller End/Rib Curvature Ratio on Friction and Accuracy in Tapered Roller Bearings

Abstract

1. Introduction

2. Materials and Methods

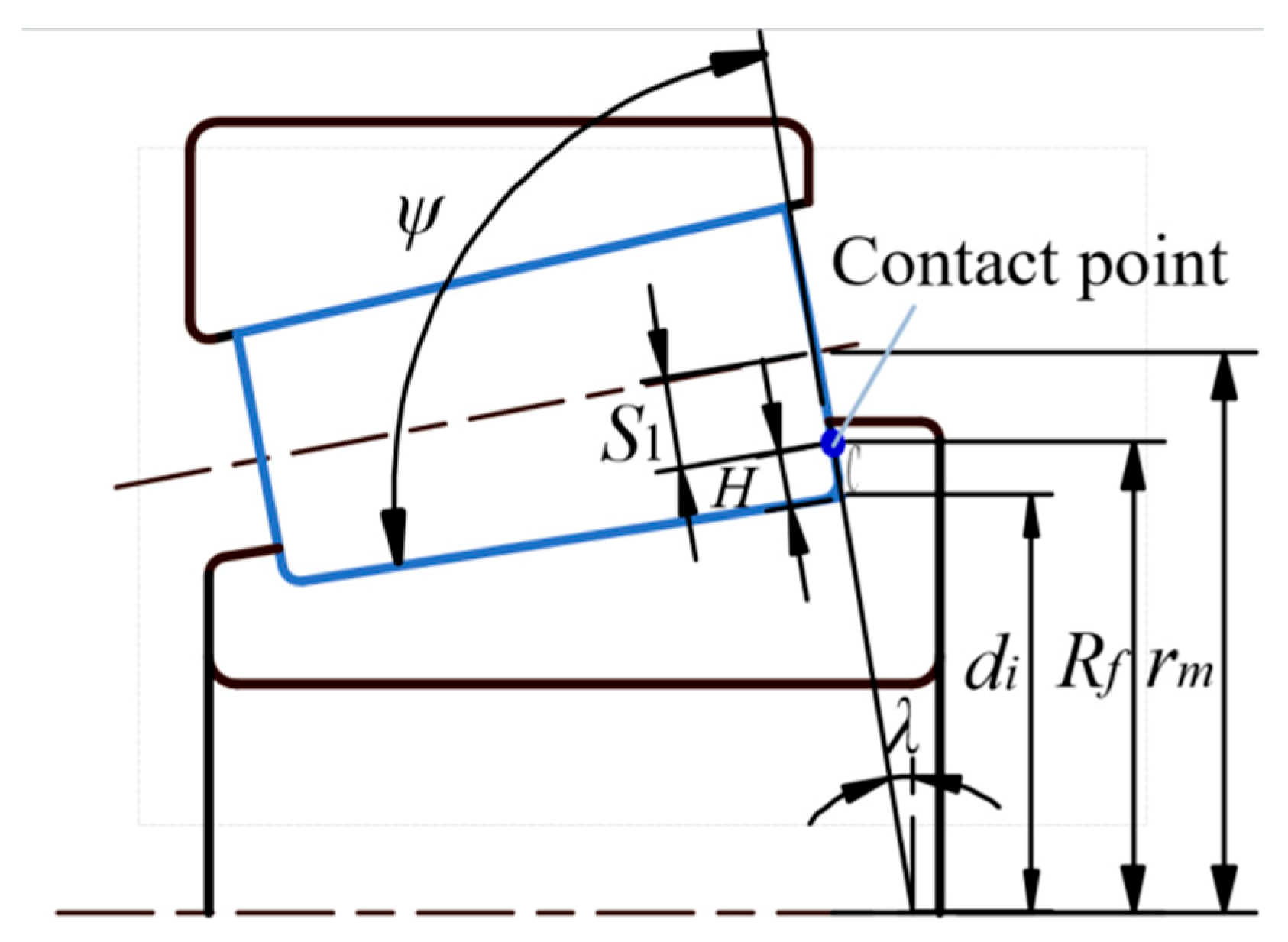

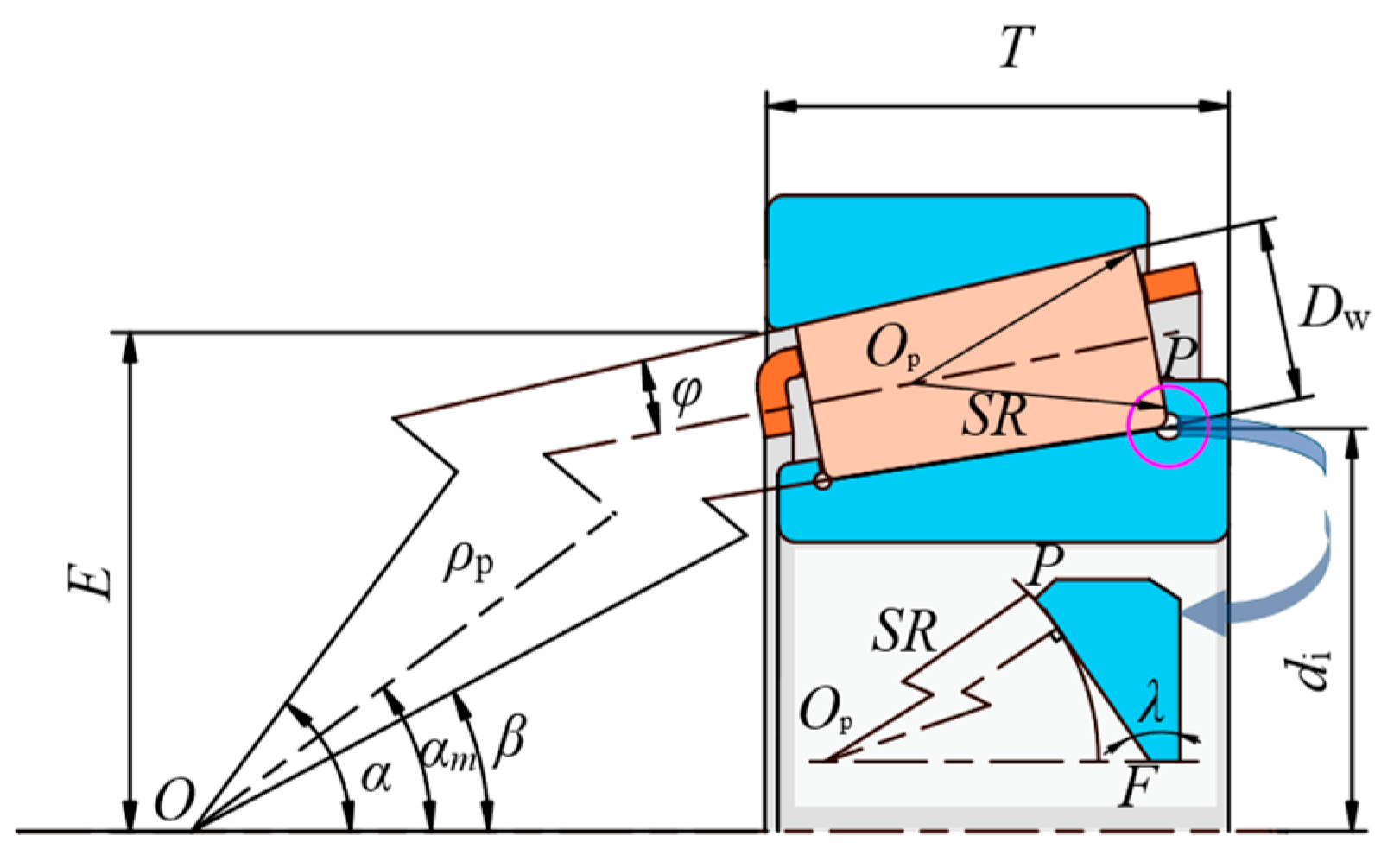

2.1. Geometric Relationship

2.2. Contact Modeling

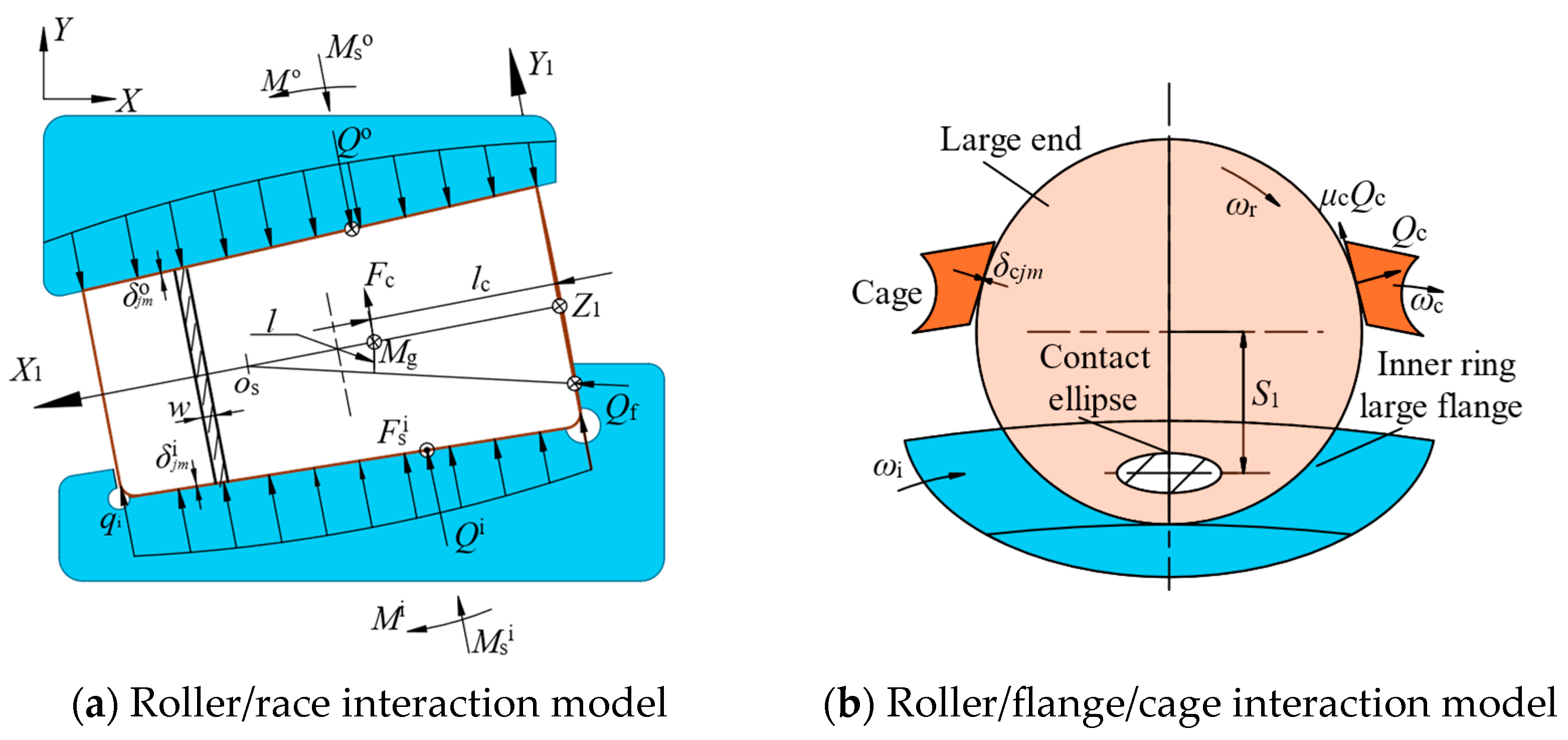

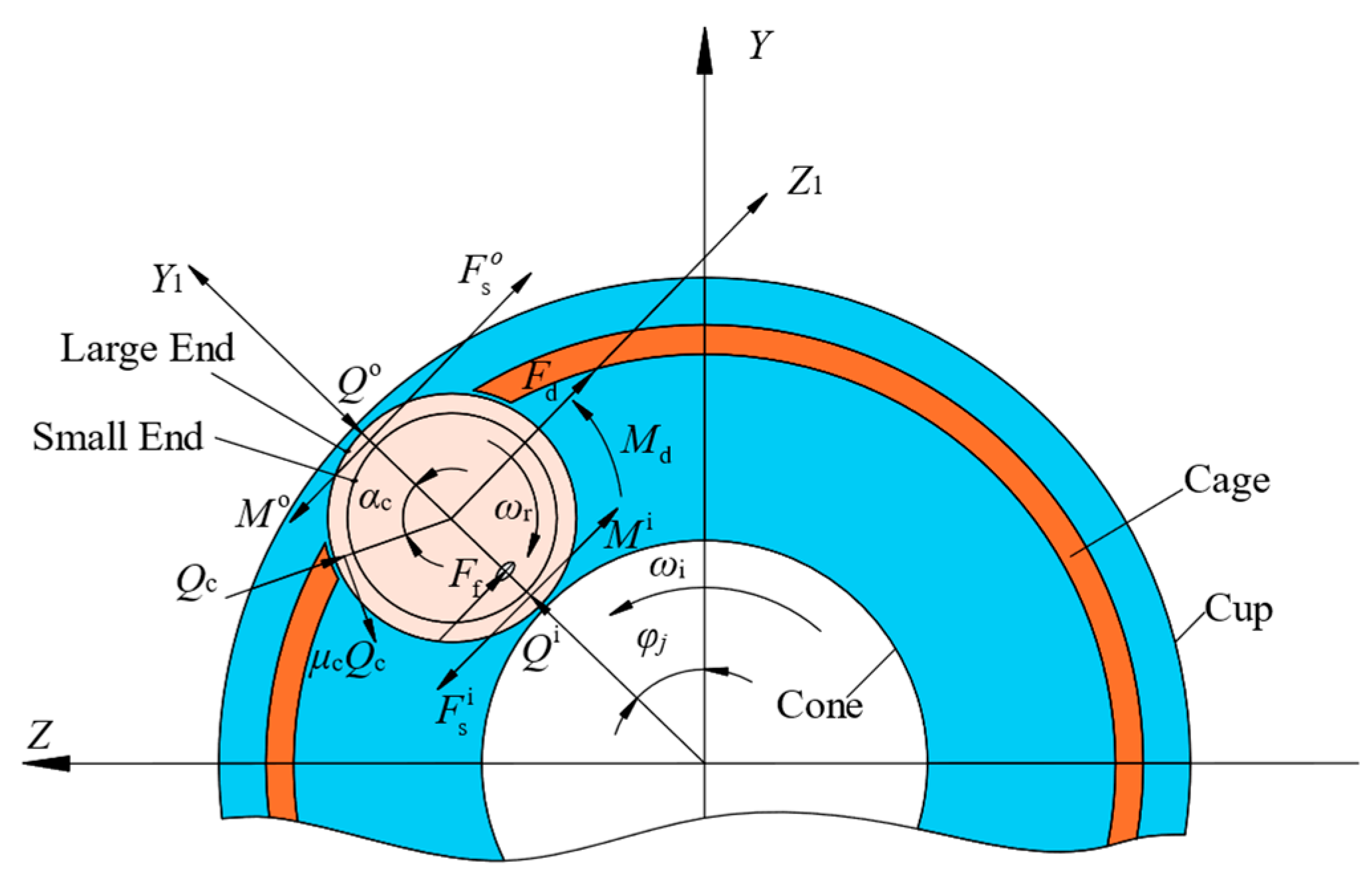

2.2.1. Roller/Race Contact Model

2.2.2. Roller Large End/Inner Ring Back Face Rib Contact Model

2.2.3. Roller/Cage Contact Model

2.3. Traction Coefficient

2.4. Damping Considerations

2.5. Bearing Friction Torque

2.6. Dynamic Differential Equations

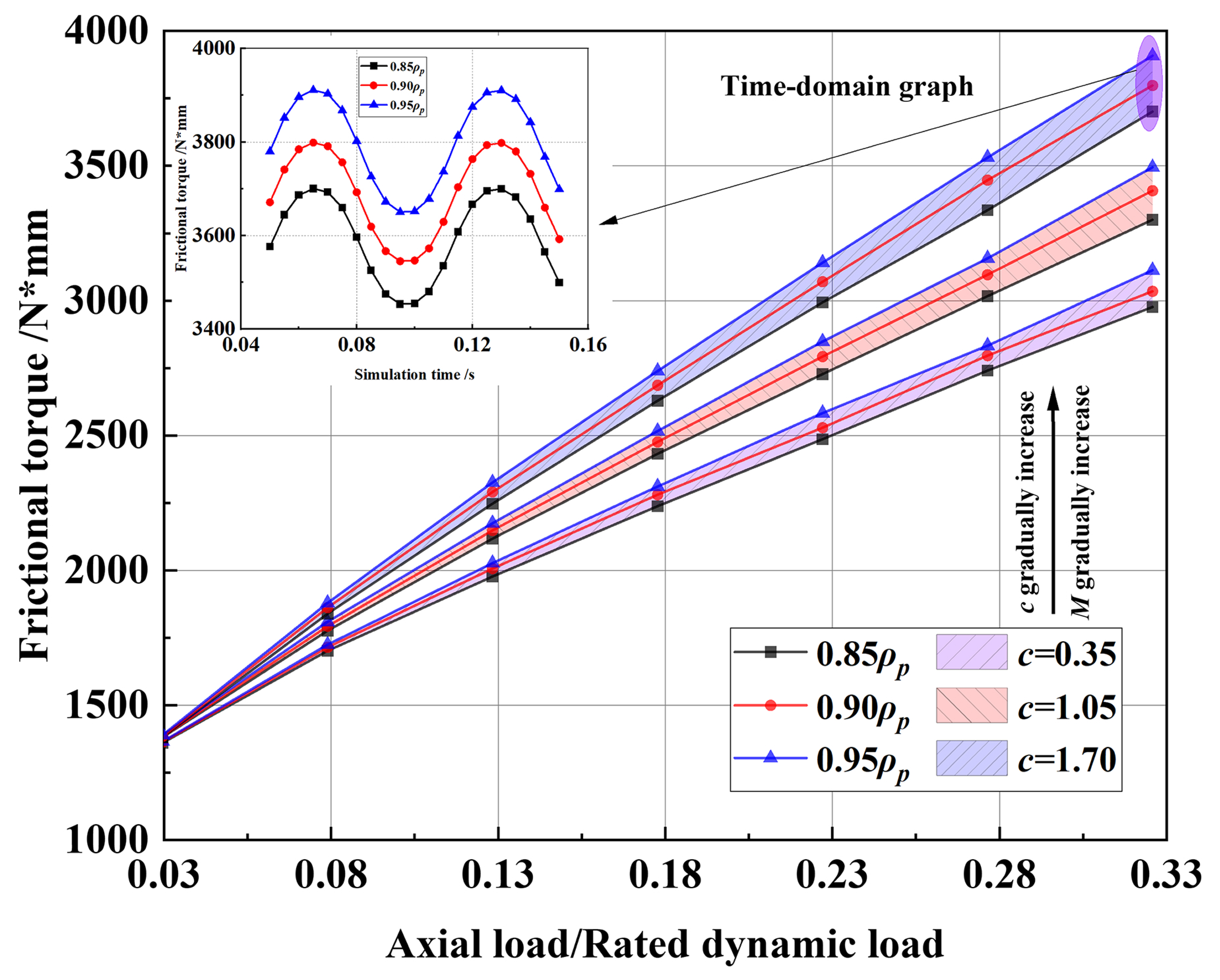

3. Result Analysis

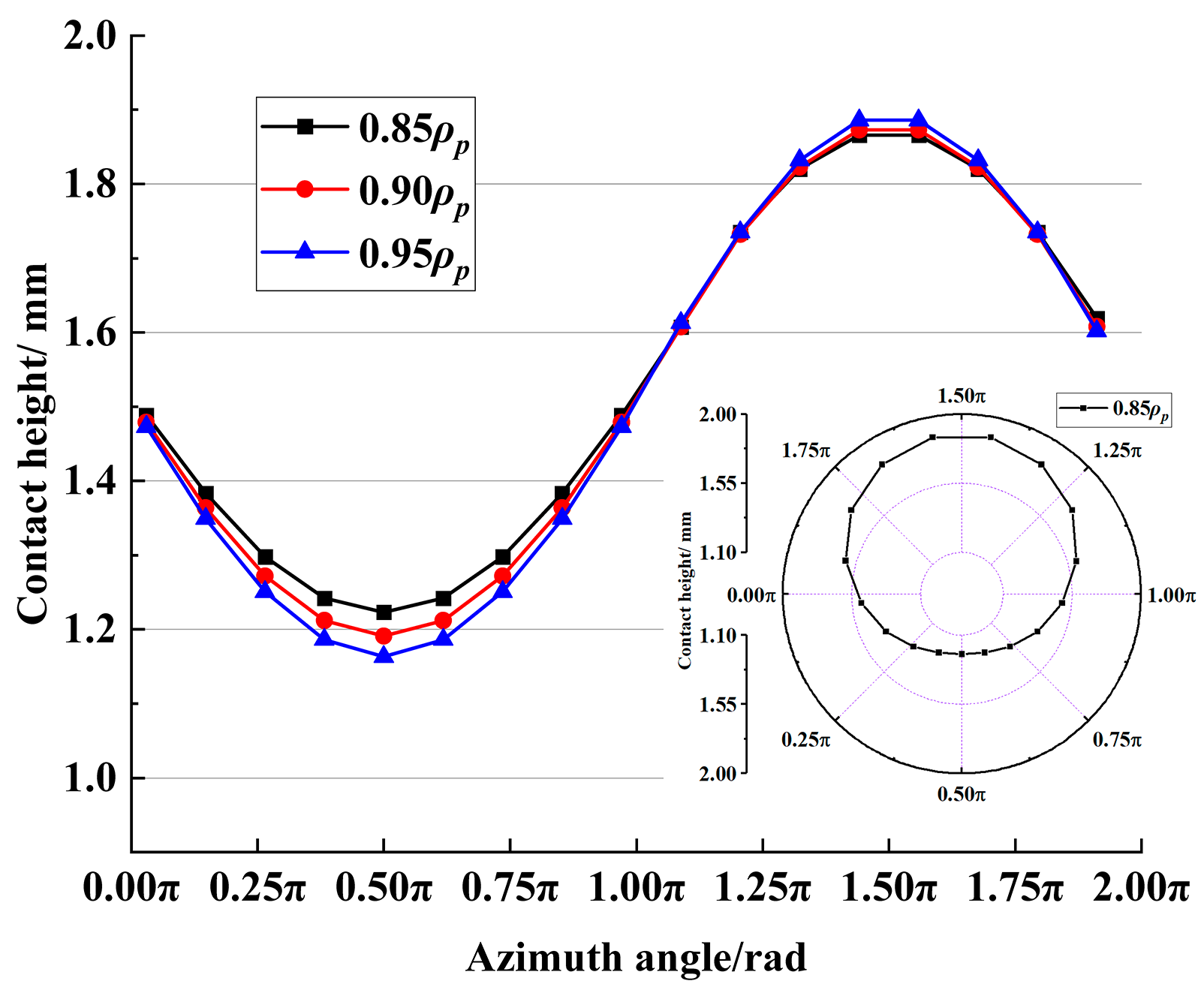

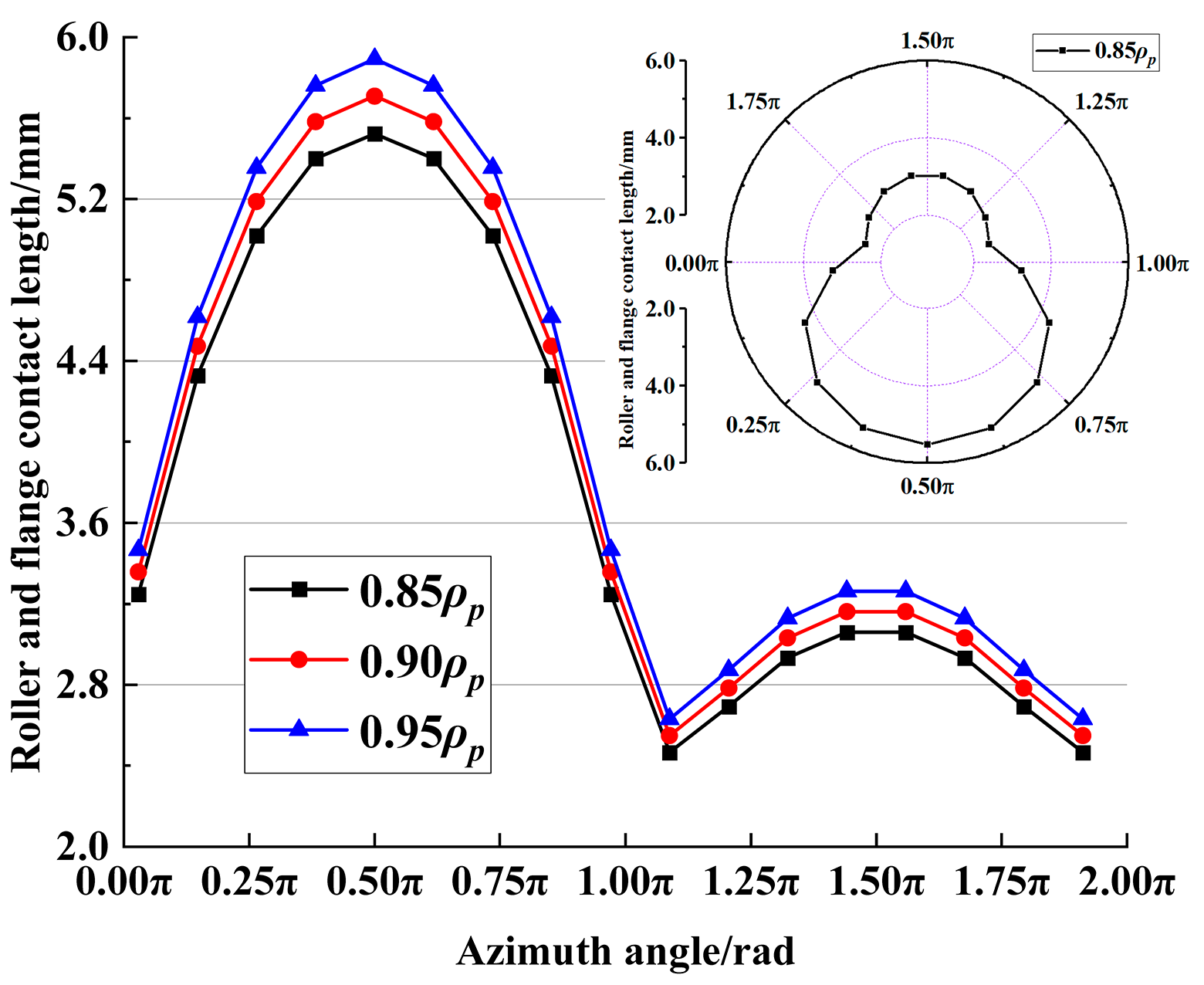

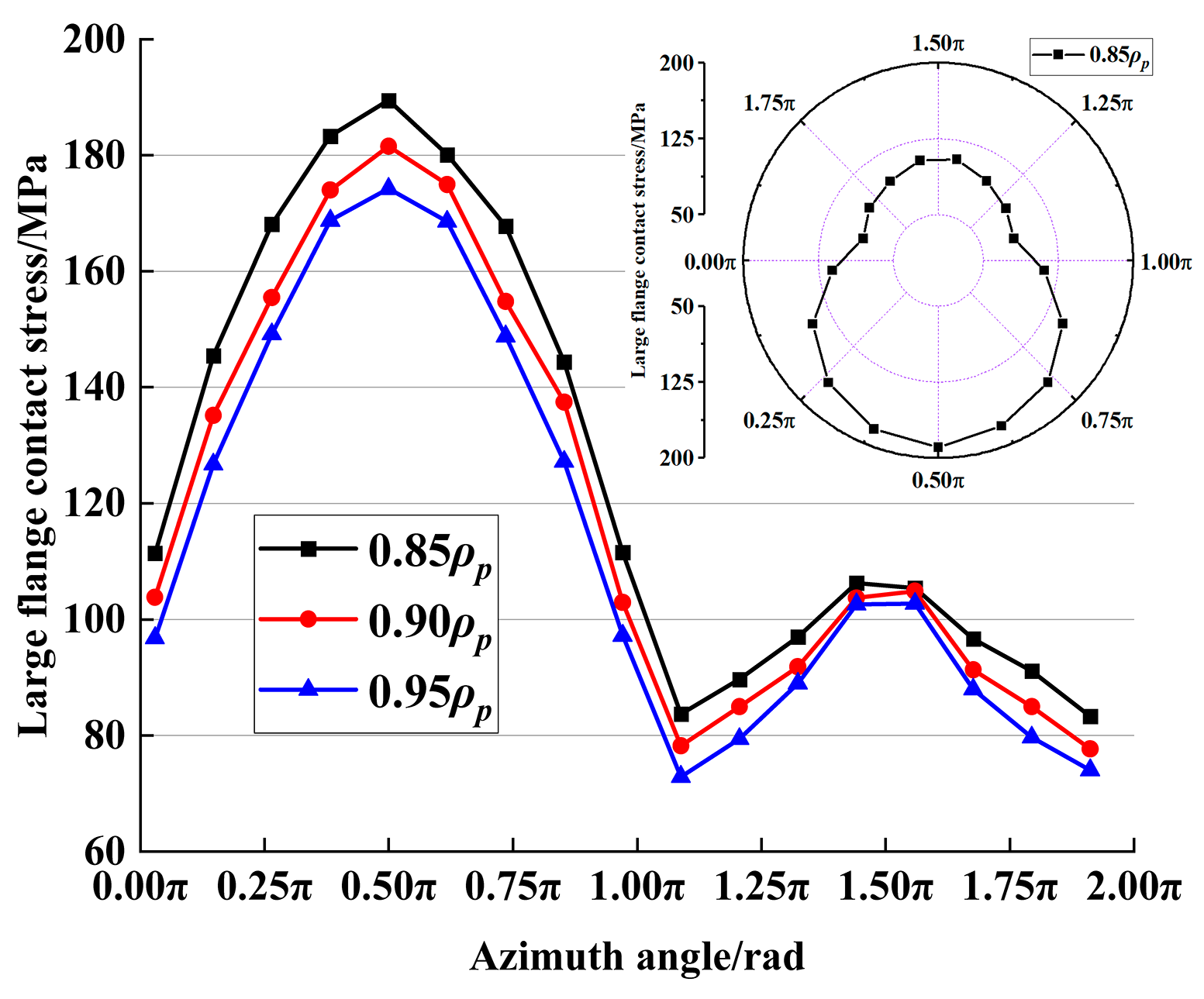

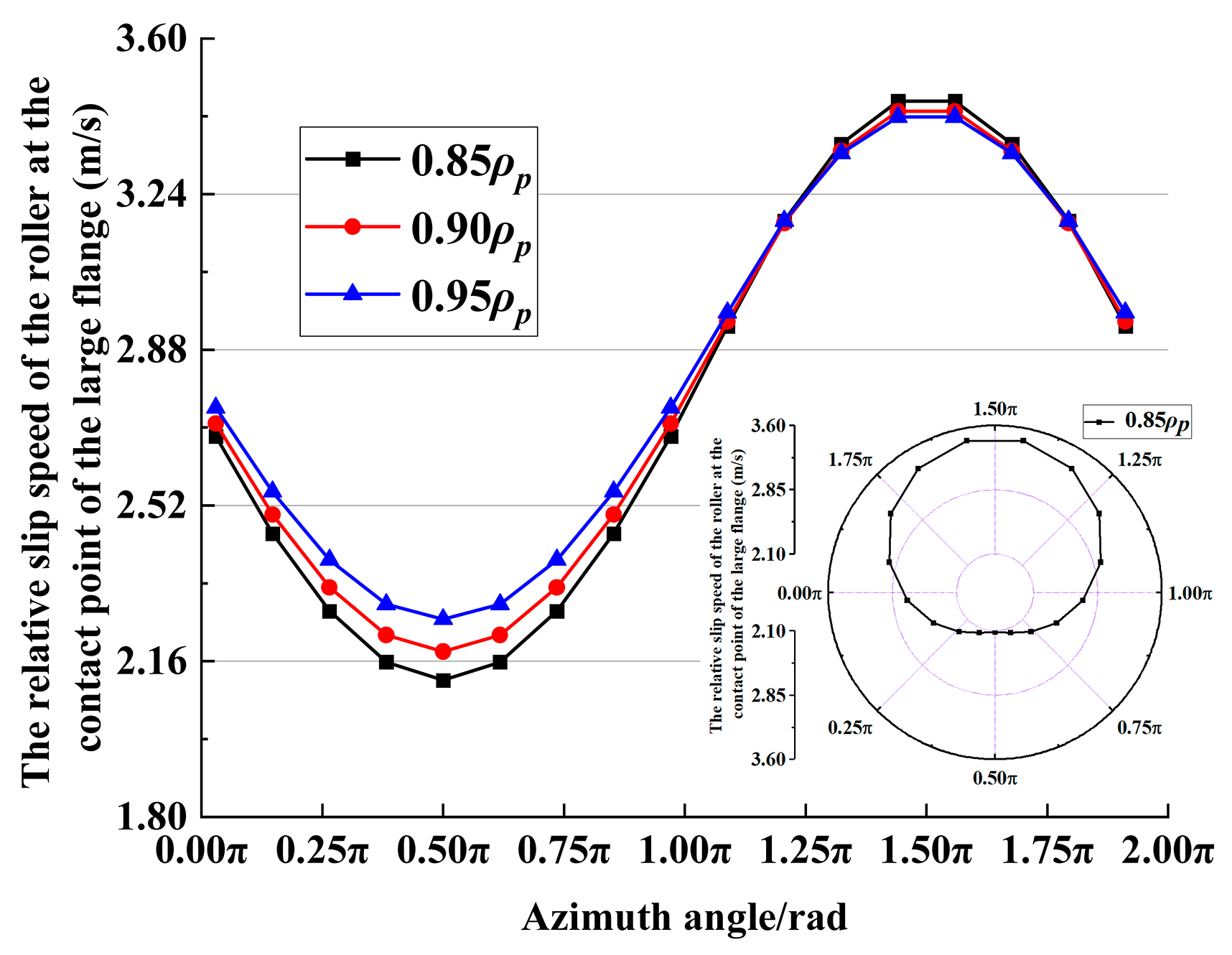

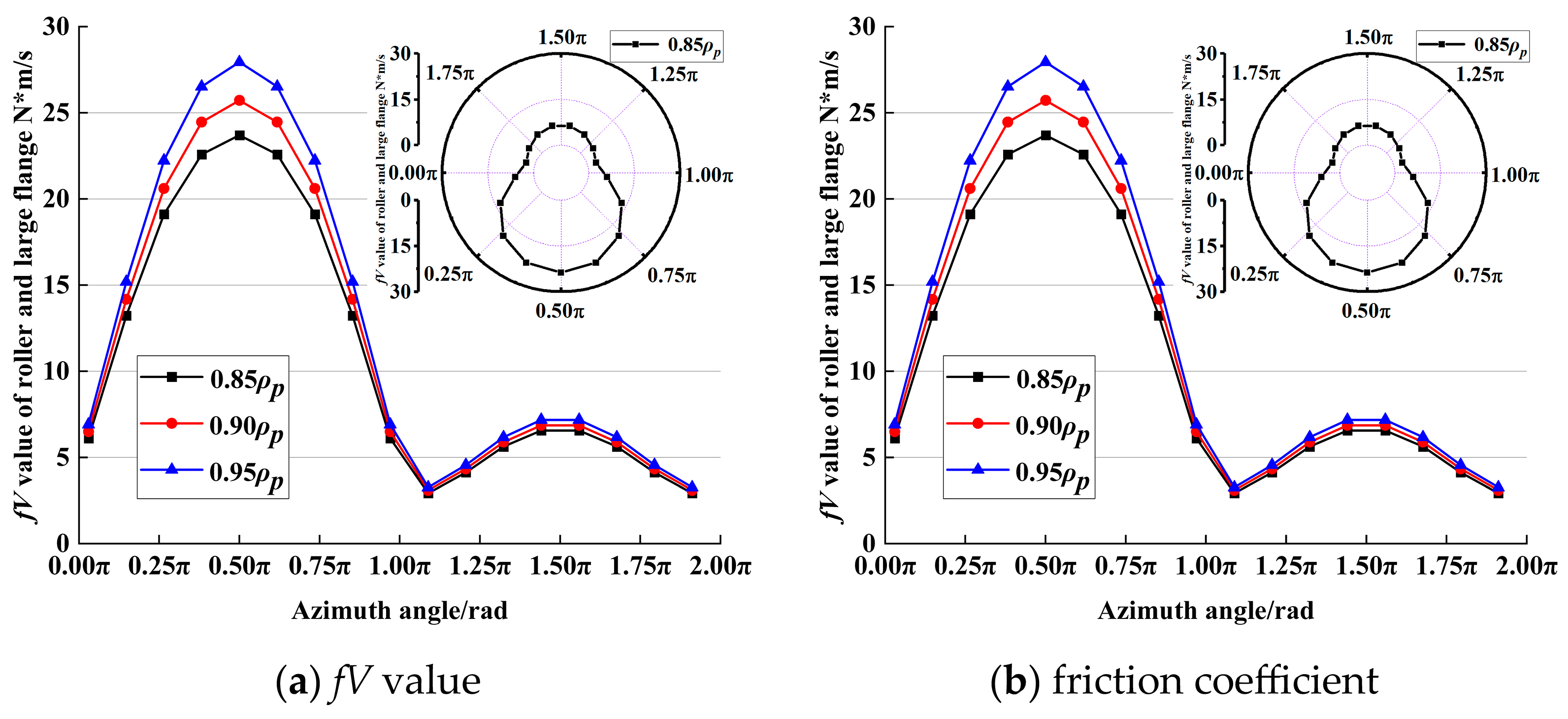

3.1. Contact State Analysis

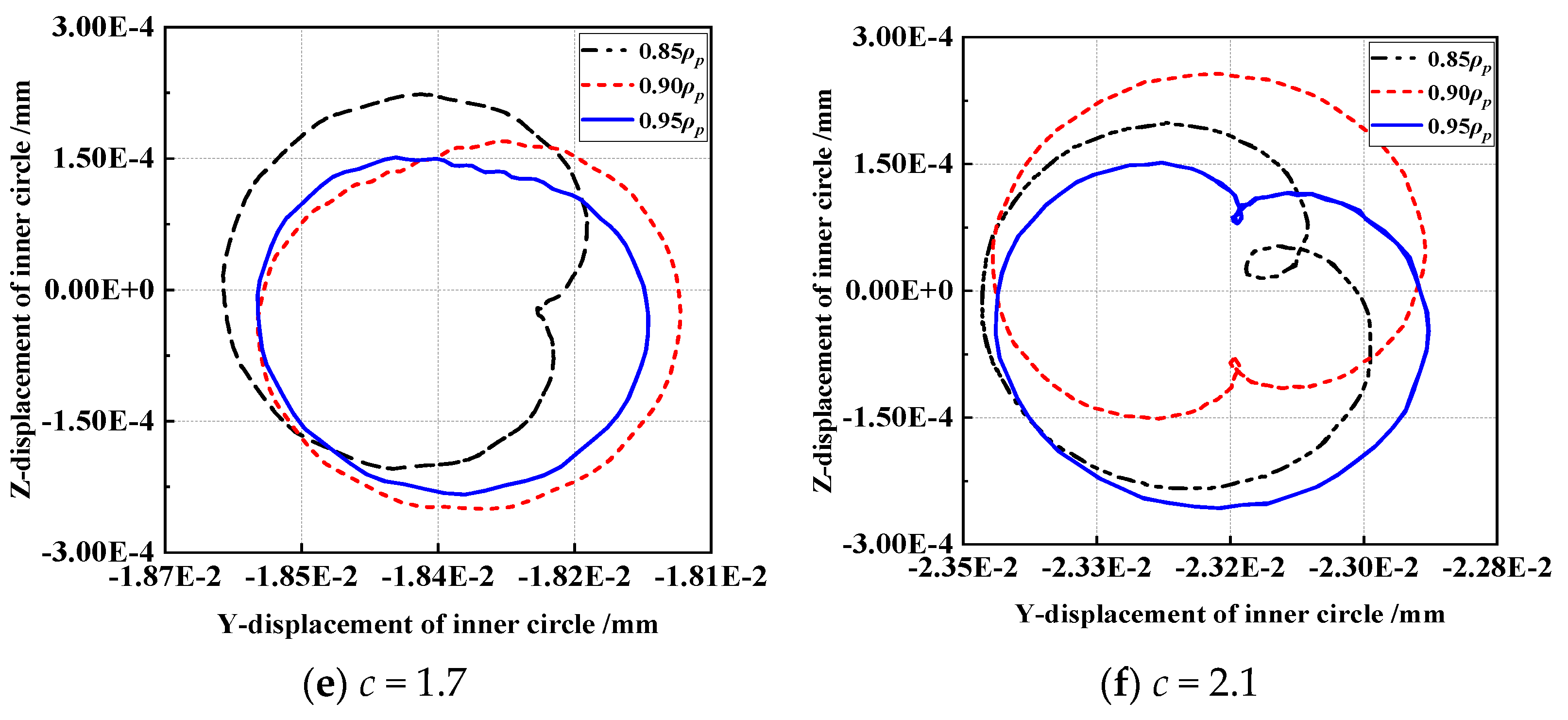

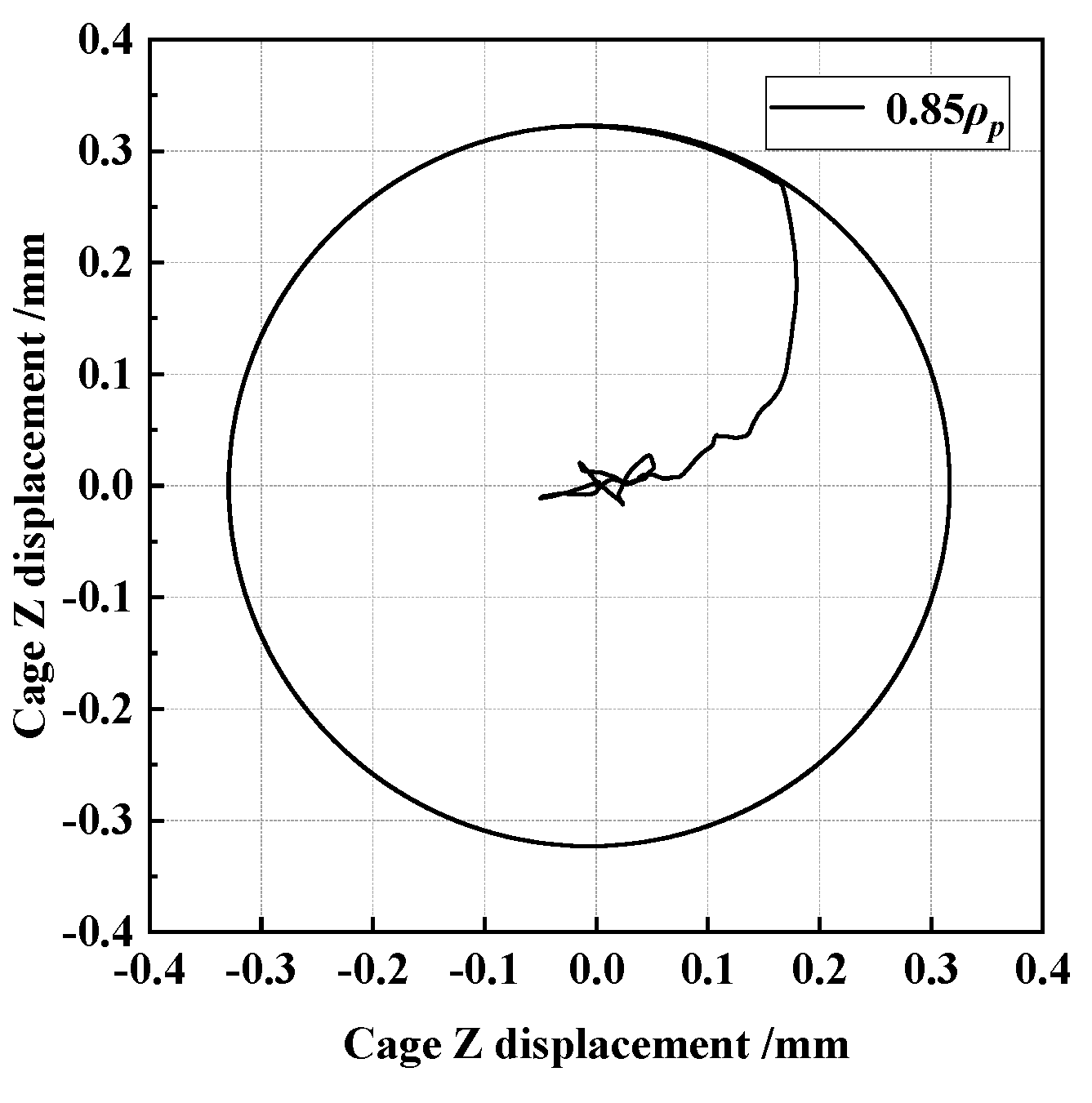

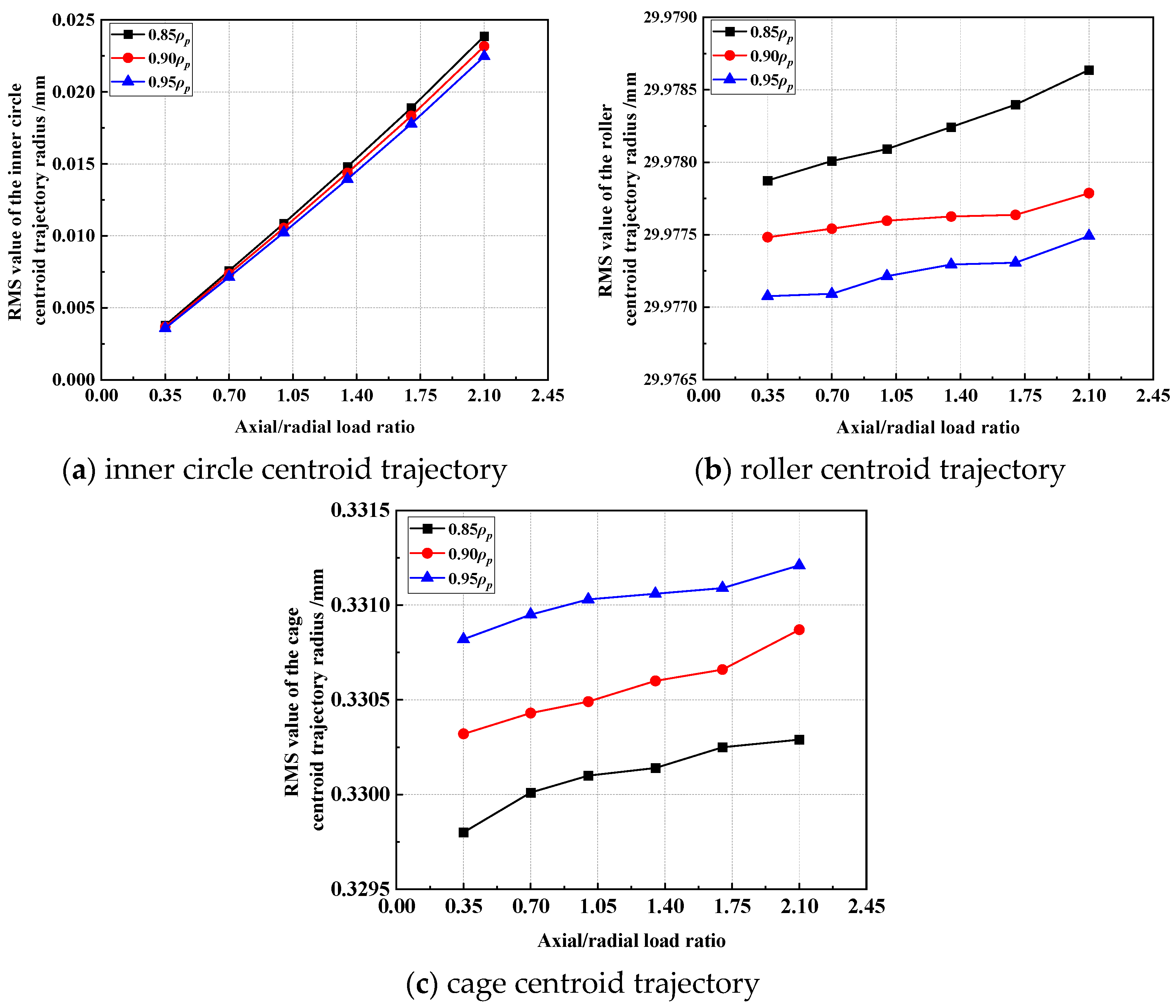

3.2. Analysis of Running Accuracy

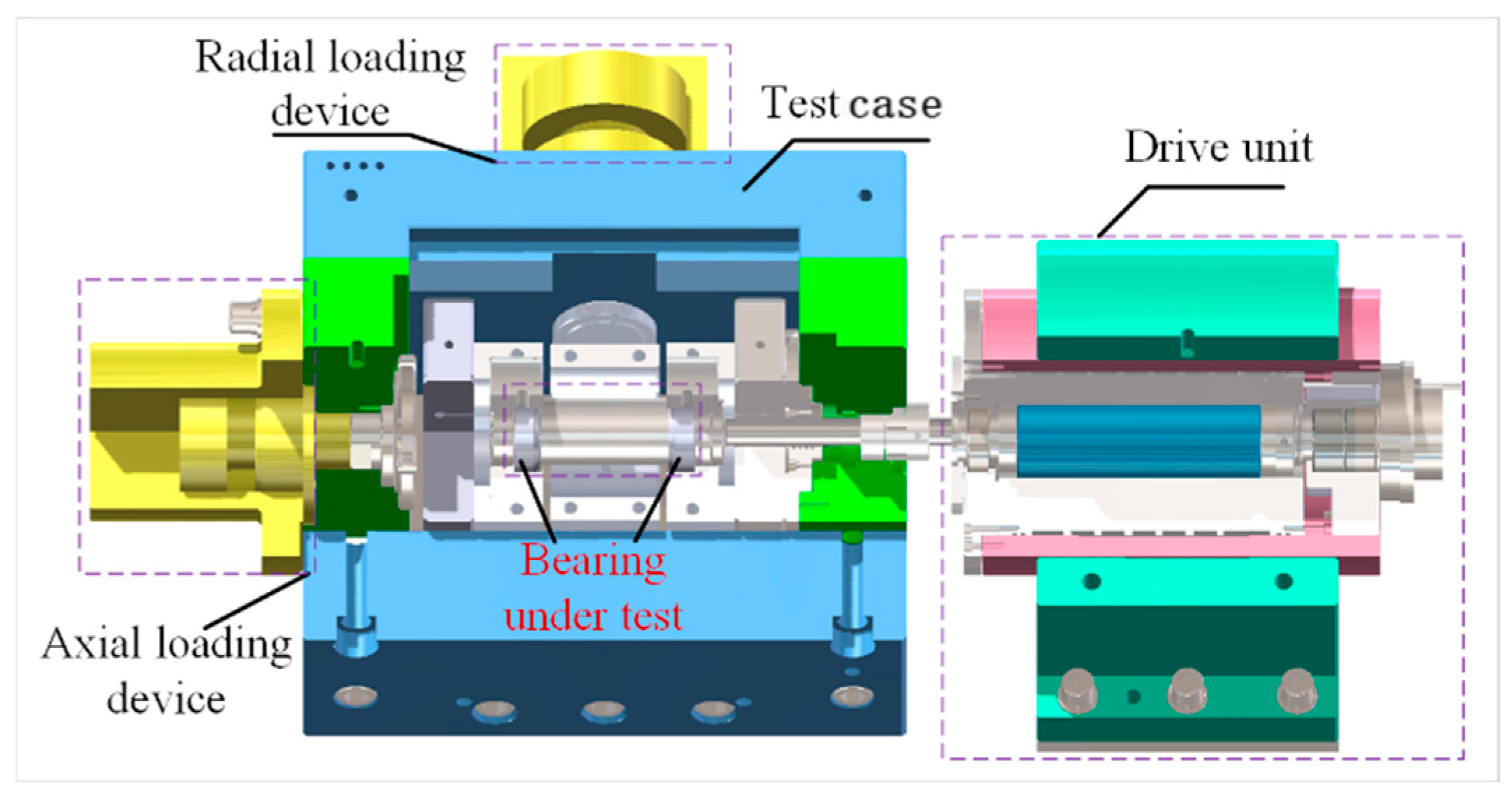

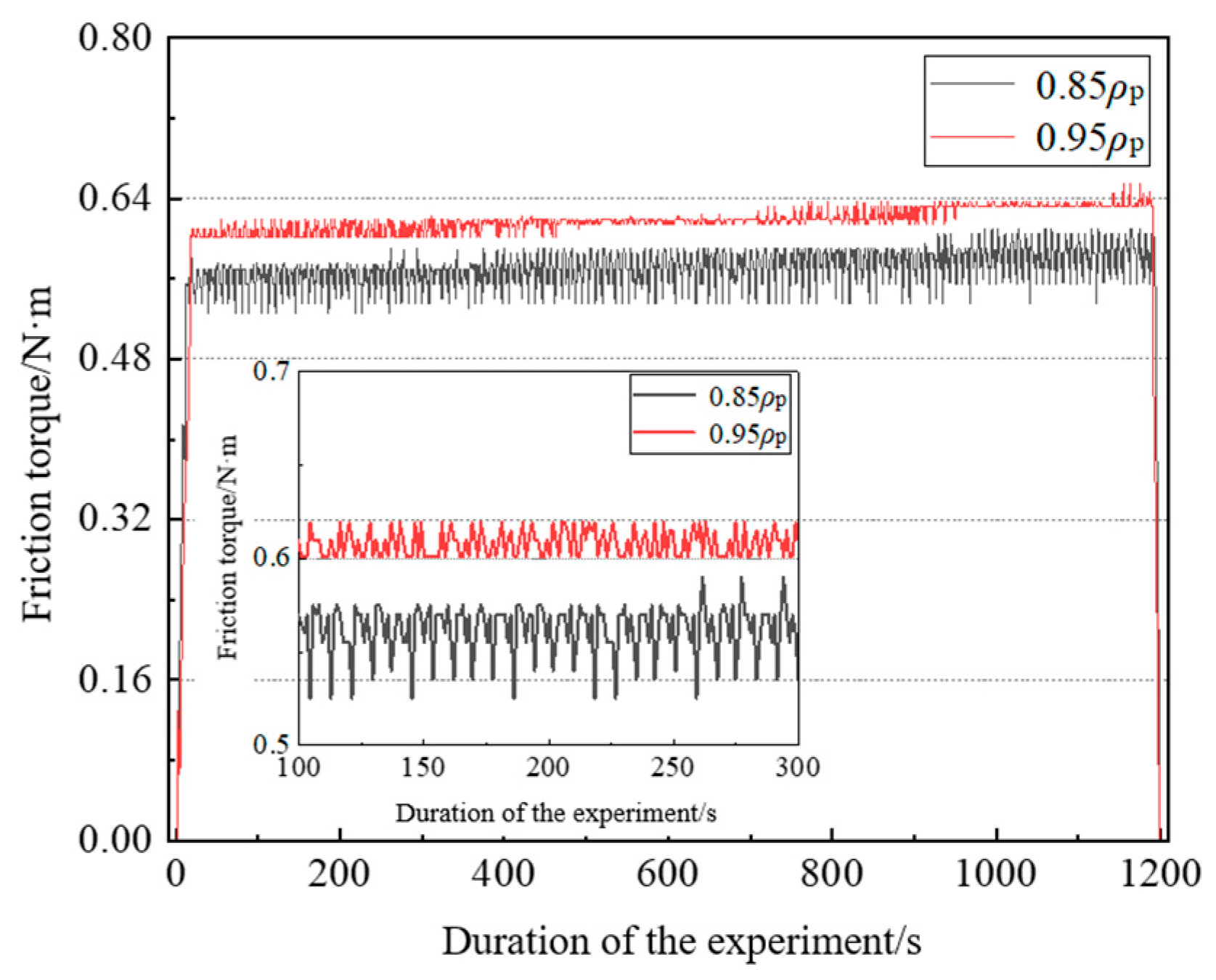

4. Test Verification

5. Conclusions

- (1)

- The larger SR makes the contact stress, contact height, and PV value of the contact area between the base surface of the roller ball and the large flange smaller, but the relative sliding speed and fV value between the roller ball base and the contact area of the large flange is higher, and the final bearing friction torque increases with the increase of SR.

- (2)

- The increase of the SR value can increase the running accuracy of the bearing to a certain extent; it is recommended to select a larger value under high radial load conditions.

- (3)

- When SR is 0.85ρp, the friction torque is small; when SR is 0.95ρp, the bearing running accuracy is high. When SR is 0.90ρp, the bearing friction torque and running accuracy can be balanced.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Roller Large End/Inner Ring Back Face Rib Contact Model

Appendix B. Sliding Speed of Large Flange

Appendix C

Appendix C.1. Dynamic Differential Equations of Roller

Appendix C.2. Cage Equilibrium

References

- Eugenio, D. Optimal design of tapered roller bearings for maximum rating life under combined loads. Mech. Ind. 2017, 18, 112. [Google Scholar]

- Lostado-Lorza, R.; Escribano-Garcia, R.; Fernandez-Martinez, R.; Illera-Cueva, M.; Mac Donald, B.J. Using the finite element method and data mining techniques as an alternative method to determine the maximum load capacity in tapered roller bearings. J. Appl. Log. 2017, 24, 4–14. [Google Scholar] [CrossRef]

- Kalyan, M.; Tiwari, R.; Ahmad, M.S. Multi-objective optimization in geometric design of tapered roller bearings based on fatigue, wear and thermal considerations through genetic algorithms. Sādhanā 2020, 45, 142. [Google Scholar] [CrossRef]

- Tiwari, R.; Sunil, K.K.; Reddy, R.S. An Optimal Design Methodology of Tapered Roller Bearings Using Genetic Algorithms. Int. J. Comput. Methods Eng. Sci. Mech. 2012, 13, 108–127. [Google Scholar] [CrossRef]

- Alberto, P.; Nicolas, F.; Philippe, V.; Morales-Espejel, G.E. Influence of spin on film thickness in elastohydrodynamic starved point contacts. Tribol. Int. 2021, 156, 106825. [Google Scholar] [CrossRef]

- Pan, C.; Shao, R.; Cao, Y. Recent Patents on Rolling Bearing Lubrication Device. Recent Pat. Eng. 2024, 18, 74–91. [Google Scholar] [CrossRef]

- Sven, W.; Max, M.; Marcel, B.; Stahl, T.; Wartzack, S. Geometrical Optimization of the EHL Roller Face/Rib Contact for Energy Efficiency in Tapered Roller Bearings. Lubricants 2021, 9, 67. [Google Scholar] [CrossRef]

- Pan, C.; Zhang, J.; Li, S. Review of Research on Dynamic Characteristics of Rolling Bearing Cages. Recent Pat. Eng. 2024, 19, 91–111. [Google Scholar] [CrossRef]

- Majdoub, F.; Mevel, B. Kinematic equilibrium of rollers in tapered roller bearings. Tribol. Trans. 2019, 62, 567–579. [Google Scholar] [CrossRef]

- Deng, S.E.; Hu, G.C.; Dong, X. Research on Power Consumption Characteristics of Double-row Tapered Roller Bearings. Acta Armamentarii 2014, 35, 1888–1907. [Google Scholar]

- Deng, S.; Gu, J.; Cui, Y.; Zhang, W. Dynamic analysis of a tapered roller bearing. Ind. Lubr. Tribol. 2018, 70, 191–200. [Google Scholar] [CrossRef]

- Wu, Z.H.; Xu, Y.Q.; Deng, S.E. Analysis of Dynamic Characteristics of Grease-Lubricated Tapered Roller Bearings. Shock. Vib. 2018, 2018, 7183042. [Google Scholar] [CrossRef]

- Wingertszahn, P.; Koch, O.; Maccioni, L.; Concli, F.; Sauer, B. Predicting Friction of Tapered Roller Bearings with Detailed Multi-Body Simulation Models. Lubricants 2023, 11, 369. [Google Scholar] [CrossRef]

- Manjunath, M.; Fauconnier, D.; Ost, W.; De Baets, P. Experimental Analysis of Rolling Torque and Thermal Inlet Shear Heating in Tapered Roller Bearings. Machines 2023, 11, 801. [Google Scholar] [CrossRef]

- Ibryaeva, O.; Sinitsin, V.; Sakovskaya, V.; Eremeeva, V. A novel hybrid method for fault diagnosis of two rolling bearings mounted on the same shaft. Meas. Sens. 2021, 18, 100210. [Google Scholar] [CrossRef]

- Fujiwara, H.; Tsujimoto, T.; Yamauchi, K. Optimized Radius of Roller Large End Face in Tapered Roller Bearings (Machine Elements, Design and Manufacturing). JSMET 2009, 75, 2319–2326. [Google Scholar] [CrossRef][Green Version]

- Li, X.; Liu, J.; Huang, S.; Pan, G. Friction moment calculation method for tapered roller bearings under combined loads. Sci. China Technol. Sci. 2024, 67, 2565–2578. [Google Scholar] [CrossRef]

- Liu, X.; Long, T.; Li, X.; Guo, F. Thermal EHL analysis of the inner ring rib and roller end in tapered roller bearings with the Carreau model. Front. Manuf. Technol. 2023, 2, 1029860. [Google Scholar] [CrossRef]

- Cai, G.; Hou, Y.; Wang, X.; Sun, S.; Zhang, Y.; Wang, N. A measurement method for friction torque between rollers and raceways of tapered roller bearings under radial heavy load conditions. Tribol. Int. 2024, 200, 110071. [Google Scholar] [CrossRef]

- Majdoub, F.; Saunier, L.; Sidoroff-Coicaud, C.; Mevel, B. Experimental and numerical roller skew in tapered roller bearings. Tribol. Int. 2020, 145, 106142. [Google Scholar] [CrossRef]

- Lostado, R.; García, E.R.; Martinez, F.R. Optimization of operating conditions for a double-row tapered roller bearing. Int. J. Mech. Mater. Des. 2016, 12, 353–373. [Google Scholar] [CrossRef]

- Klecher, R.J. High Speed Cylindrical Roller Bearing Analysis, SKF Program “CYBEAN”; NASA-CR-159460; NASA: Washington, DC, USA, 1978; Volume I–II.

- Wang, Y.S.; Yang, B.Y.; Wang, L.Q. Investigation into the traction coefficient in elastohydrodynamic lubrication. TriboTest 2004, 11, 113–124. [Google Scholar] [CrossRef]

- Friskney, B.; Mohammadpour, M.; Theodossiades, S.; Craig, C.; Rapson, G. Effects of transmission shaft flexibility on rolling element bearing tribodynamics in a high-performance transmission. Mech. Mach. Theory 2021, 165, 104440. [Google Scholar] [CrossRef]

- Vigliani, A.; Cavallaro, P.S.; Venturini, S. Modelling and Experimental Testing of Passive Magnetic Bearings for Power Loss Reduction. Appl. Sci. 2025, 15, 4149. [Google Scholar] [CrossRef]

- Deng, S.E.; Jia, Q.Y.; Xue, J.X. Design Principle of Rolling Bearings, 2nd ed.; China Standard Press: Beijing, China, 2014. [Google Scholar]

- Wang, Y.; Wang, H.; Cui, Y.; Li, C.; Deng, S. Research on the thermal characteristics of large span double row tapered roller bearing. Acta Armamentarii 2024, 45, 1285. [Google Scholar] [CrossRef]

- Korolev, V.A.; Korolev, A.A.; Krehel, R. Mathematical simulation and analysis of rolling contact fatigue damage in rolling bearings. Int. J. Adv. Manuf. Technol. 2017, 89, 661–664. [Google Scholar] [CrossRef]

| Argument | Numerical Value |

|---|---|

| Inside diameter/Outside diameter (mm) | 40.0/80.0 |

| Bearing width (mm) | 24.75 |

| Inner circle width (mm) | 23.0 |

| Outer circle width (mm) | 19.0 |

| Radius of the sphere base (mm) | 144.0 |

| Large flange Angle | 89°28′55″ |

| Large rib height (mm) | 2.706 |

| Roller small/big end diameter (mm) | 9.46/10.63 |

| Contact angle between roller and inner circle/outer circle/large rib | 10/14/87 |

| Number of rollers | 17 |

| Rated dynamic load | 81.1 kN |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Li, G. Effects of Roller End/Rib Curvature Ratio on Friction and Accuracy in Tapered Roller Bearings. Machines 2025, 13, 910. https://doi.org/10.3390/machines13100910

Zhang W, Li G. Effects of Roller End/Rib Curvature Ratio on Friction and Accuracy in Tapered Roller Bearings. Machines. 2025; 13(10):910. https://doi.org/10.3390/machines13100910

Chicago/Turabian StyleZhang, Wenhu, and Gang Li. 2025. "Effects of Roller End/Rib Curvature Ratio on Friction and Accuracy in Tapered Roller Bearings" Machines 13, no. 10: 910. https://doi.org/10.3390/machines13100910

APA StyleZhang, W., & Li, G. (2025). Effects of Roller End/Rib Curvature Ratio on Friction and Accuracy in Tapered Roller Bearings. Machines, 13(10), 910. https://doi.org/10.3390/machines13100910