Metamodel-Based Digital Twin Architecture with ROS Integration for Heterogeneous Model Unification in Robot Shaping Processes

Abstract

1. Introduction

- (1)

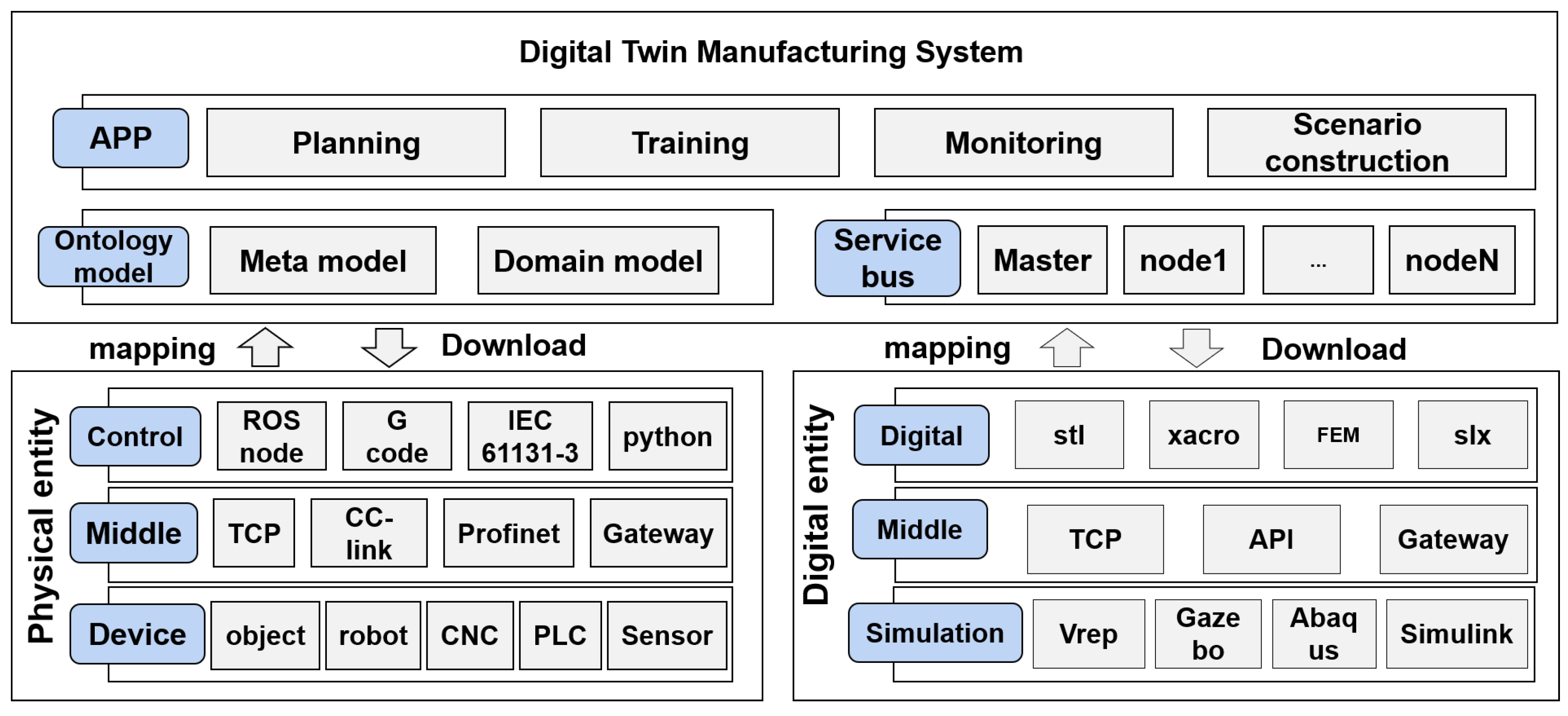

- We propose a novel digital twin implementation architecture for precision manufacturing that encapsulates both physical and virtual systems, enabling the unified design and programming of a shaping system digital twin within a single environment.

- (2)

- Building upon this architecture, we develop a metamodel-based digital twin operation mechanism and establish a unified simulation environment through ontology-driven configuration. This approach allows subsystems to achieve rapid integration, while ROS serves as the execution platform for virtual–real fusion, thereby supporting the construction of executable robot manufacturing digital twin scenarios.

2. Precision Manufacturing Mode Based on Digital Twins

3. Digital Twin Implementation Architecture

3.1. The Overall Architecture

3.2. Ontology Model Design

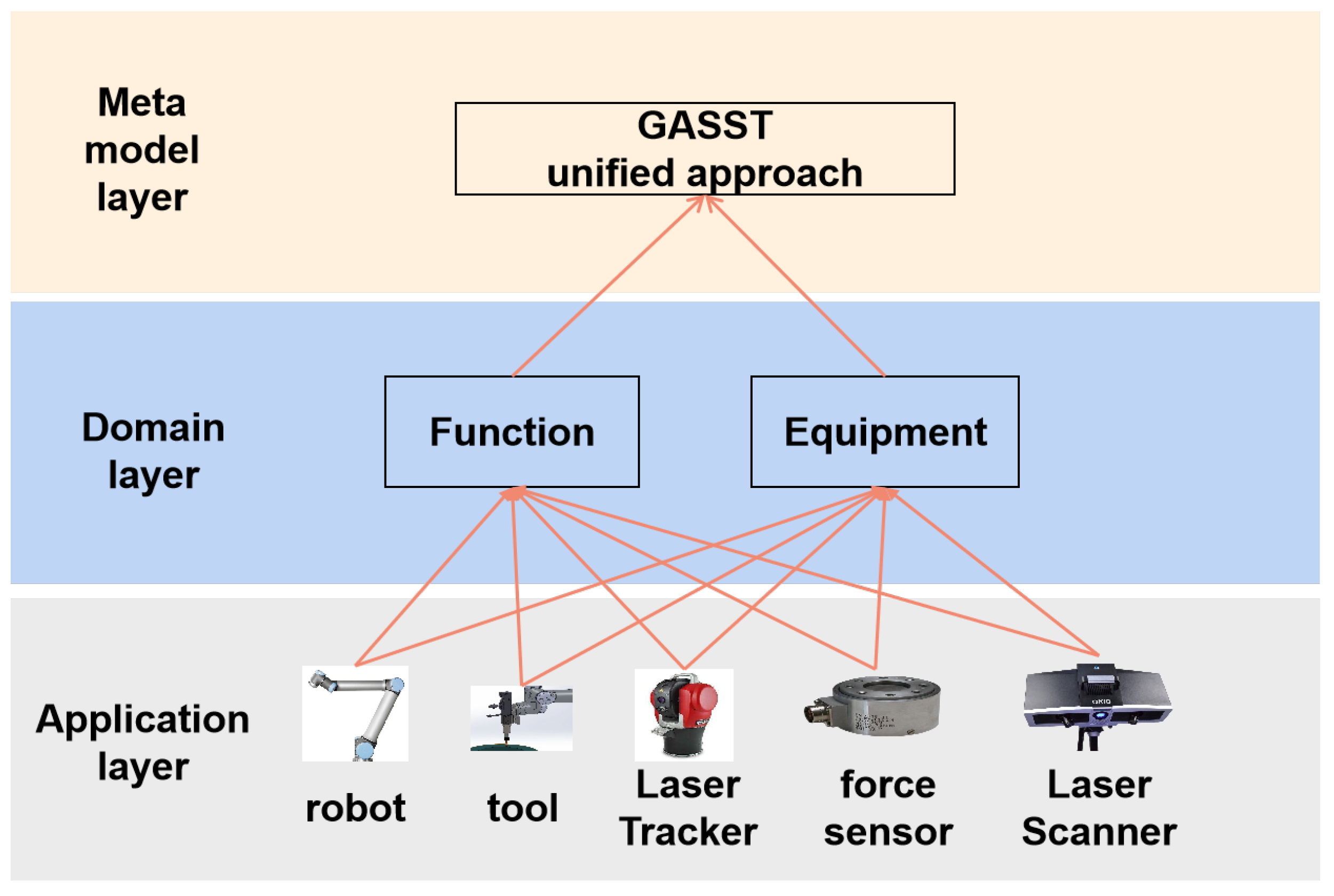

3.2.1. Ontological Structure

3.2.2. Metal Model Ontology

3.2.3. Domain Ontology

- (1)

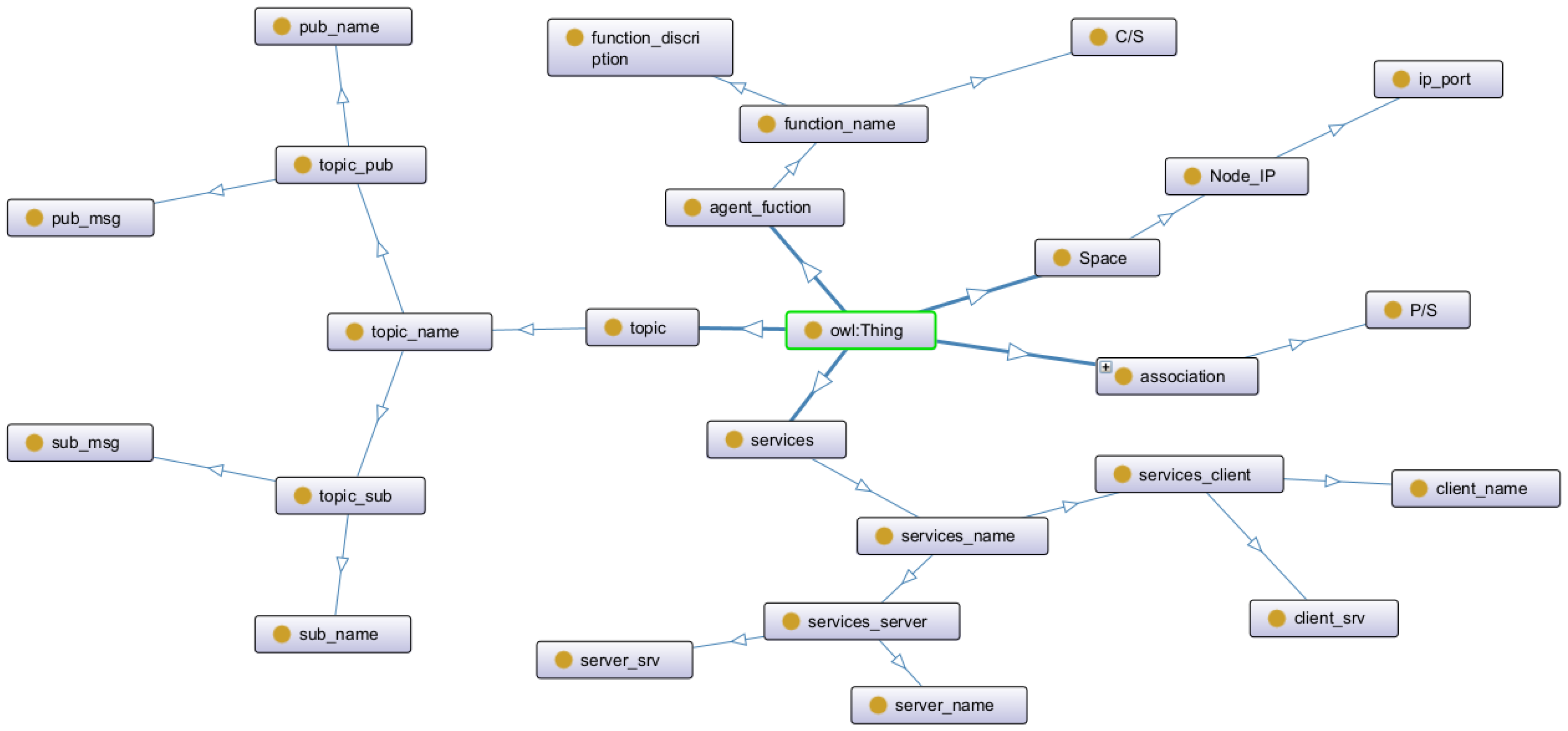

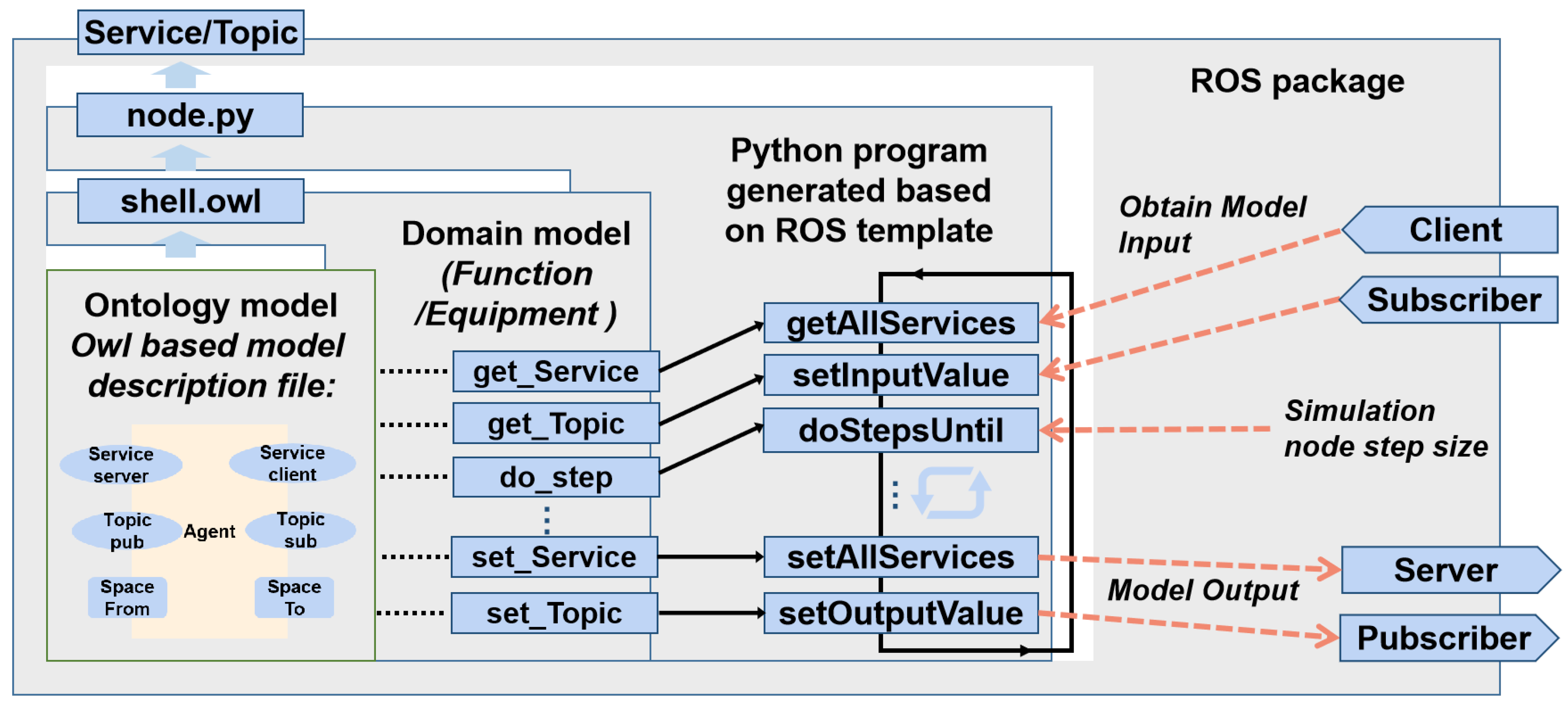

- Function ontology—The function ontology is used to characterize the model or method in the system, which is expanded based on the metamodel architecture; the services of the function ontology correspond to an srv file and the source program for the function; the topic corresponds to an msg file, the data format of the topic, and the source program for the function, with the physical equipment to be deployed by the ontology and the call relationship of the corresponding services and topics. Figure 5 depicts the function ontology model.

- (2)

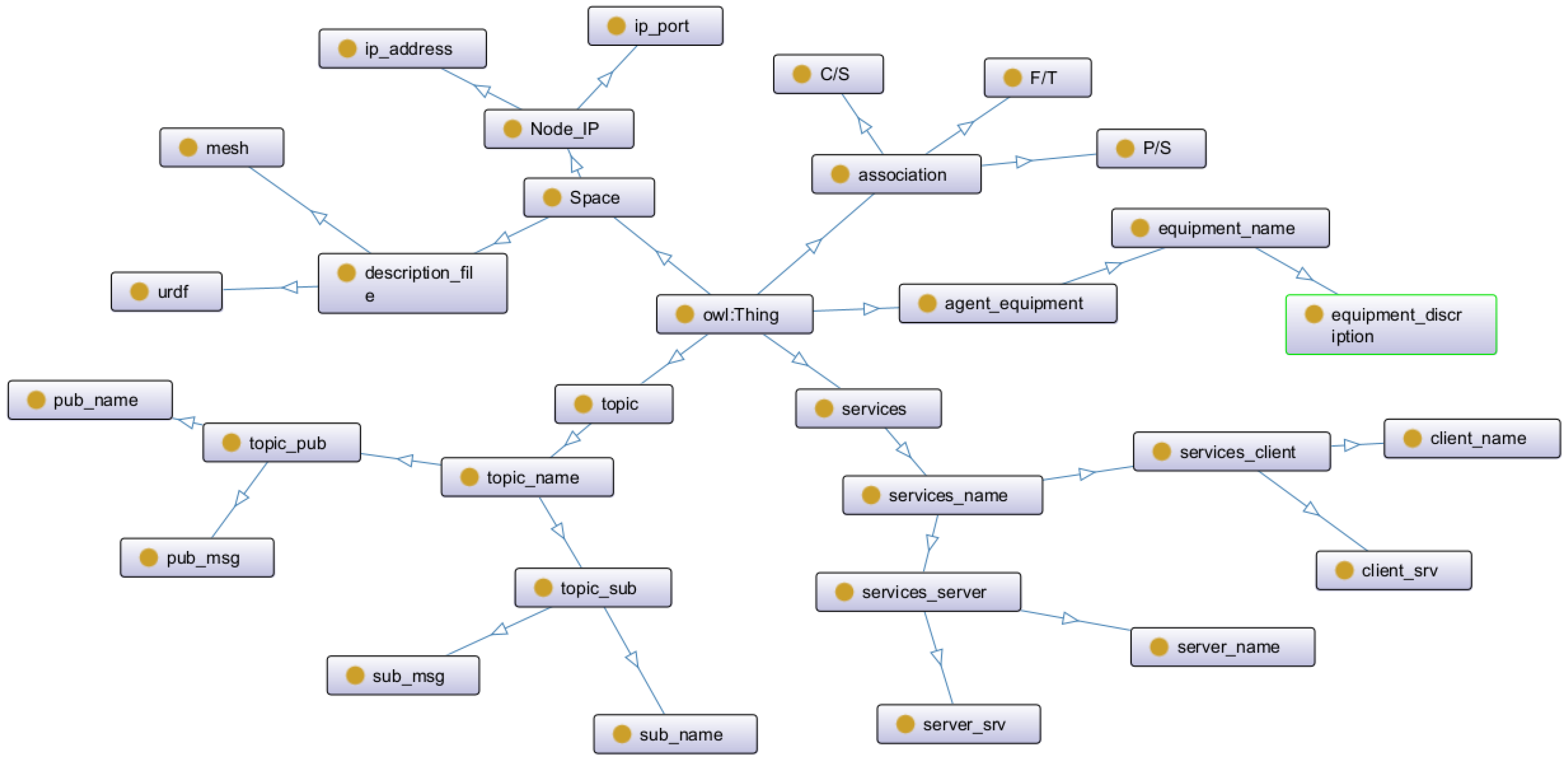

- Equipment ontology—This is the collection of equipment categories in the robot shaping system. Unlike the method model, the device ontology adds the spatial relationship of the device and the 3D description file of the device for the subsequent digital twin simulation. At the same time, most of the services provided by the equipment body are network services packaged on the basis of the hardware drive, such as the position control service of the robot. Figure 6 shows the device ontology model.

4. Application Layer Design

- (1)

- Model configuration—Based on the GASSTA specification, entities and algorithms in the system are used as agents, and all agents can be used to generate multiple OWL files. Model instantiation is implemented by using the parameter configuration. The configuration parameters provide detailed information on the processed part, including a detailed description of the processed part; design documents, such as a 3D model; material attribute information, such as Poisson’s ratio, strength, and specific heat; and process requirements, such as machining accuracy, safety constraints, and other information.

- (2)

- Model arrangement—The actual business process and data flow are realized through correlation between the models, using a line representation with arrows. C/S between services represents the service flow in the collaborative simulation scenario. The arrow root node represents the service provider, and the arrow terminal indicates the service user. P/S between topics represents the information flow in the collaborative simulation scenario. The root node of the arrow represents the topic provider, and the arrow terminal represents the topic user. The translation between spatial attributes represents the positional relationship between physical entity models in the collaborative simulation scenario. The shaping system is finally characterized in the form of graphs, and the corresponding system files are generated.

- (3)

- Code generation—The choreographed scenario model generates executable programs for the target environment by association.

- (4)

- Model deployment—The arranged system file contains the interaction between services, topics, spaces, and other information between agents. The code parses the graph information and generates the corresponding program in the form of a functional package according to the ROS node template. After parsing the file, the deployment tool is deployed to the node device according to the IP address, and then, the running scheduling logic is controlled through the master node. Finally, they participate in the simulation process in the form of a ROS node service or topic.

4.1. Code Generation

4.2. Operation Process of DTMS

- (1)

- Configuration stage-scene construction—All solid objects in the agent in the graph provide the corresponding URDF model, which can be built in the simulation environment; subobjects provide operational packages that can be run as nodes in ROS.

- (2)

- Configuration stage-parameter configuration—Based on the design information, the static information of the digital twin simulation includes the solid initial pose; material attribute information, such as Poisson ratio, strength, specific heat, etc.; and process requirements, such as machining accuracy, safety constraints, and other information.

- (3)

- Initialization stage-scene initialization—The specific location of the entity object is determined by the space attribute, and the location relationship of the entity object is described by translation.

- (4)

- Initialization phase-service registration and initialization—The specific functions of the entity are published in a service manner.

- (5)

- Digital twin simulation stage-workflow operation—According to the specific workflow of the task model reasoning, the processing process of the robot shaping system is simulated through the service calling sequence of the ontology model.

- (6)

- Digital twin simulation stage-single-step calculation—The specific simulation step is determined according to the initialization information, the multidisciplinary simulation is integrated by the agent model, and the simulation is calculated according to the specific solver or executable program.

- (7)

- Digital twin simulation stage-simulation results—The resulting data of the simulation are stored uniformly according to the ontology model.

- (1)

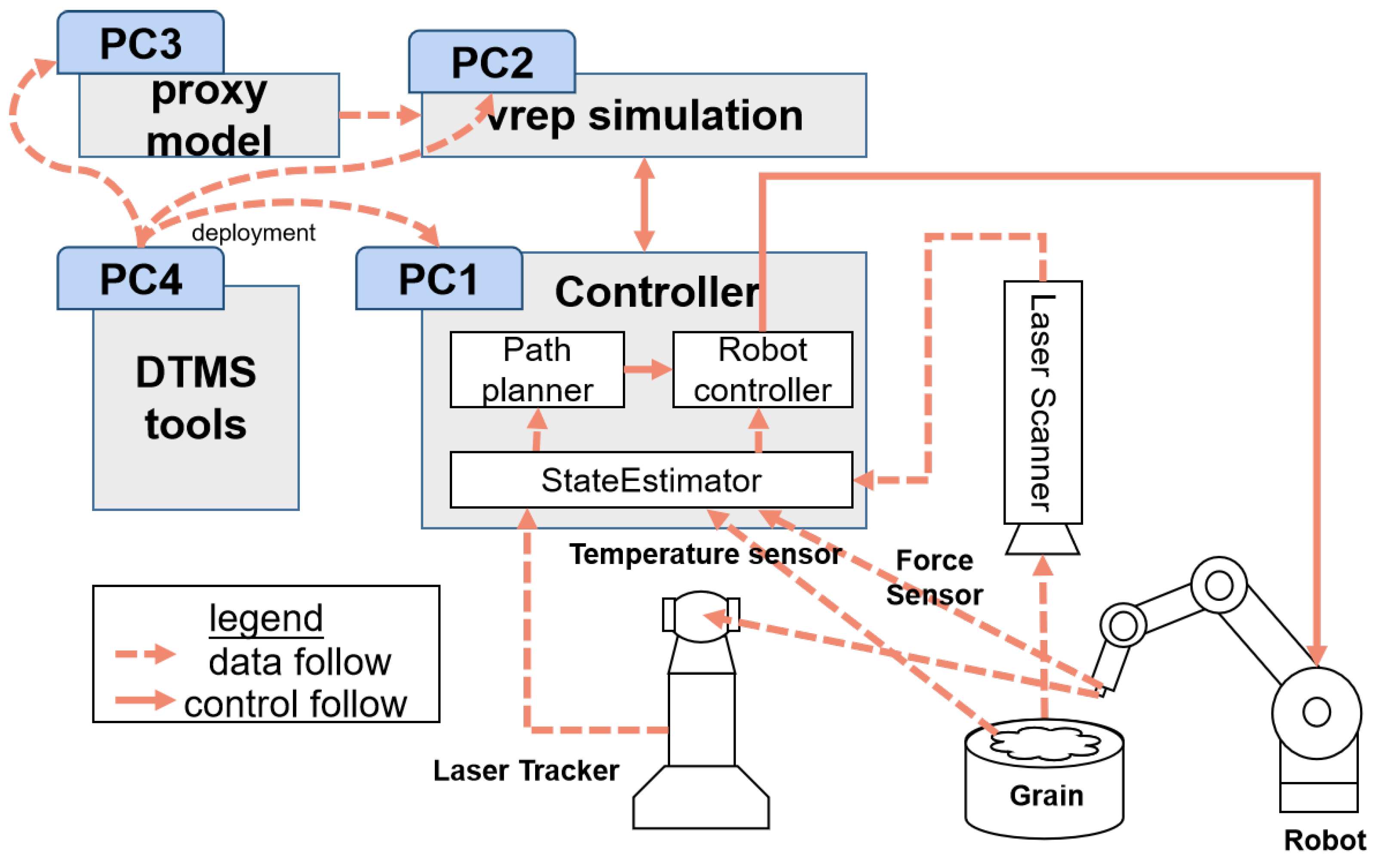

- A unified semantic modeling method is adopted to establish the ontology model of multiple agents, which integrates the physical model and the digital model of each piece of physical equipment into the process of solid propellant grain shaping.

- (2)

- The ontology model is transformed into nodes under the ROS architecture, and each environment of the digital twin is connected through service combination, and data interaction between subsystems is realized through topics.

5. Digital Twin Simulation Verification of the Shaping System

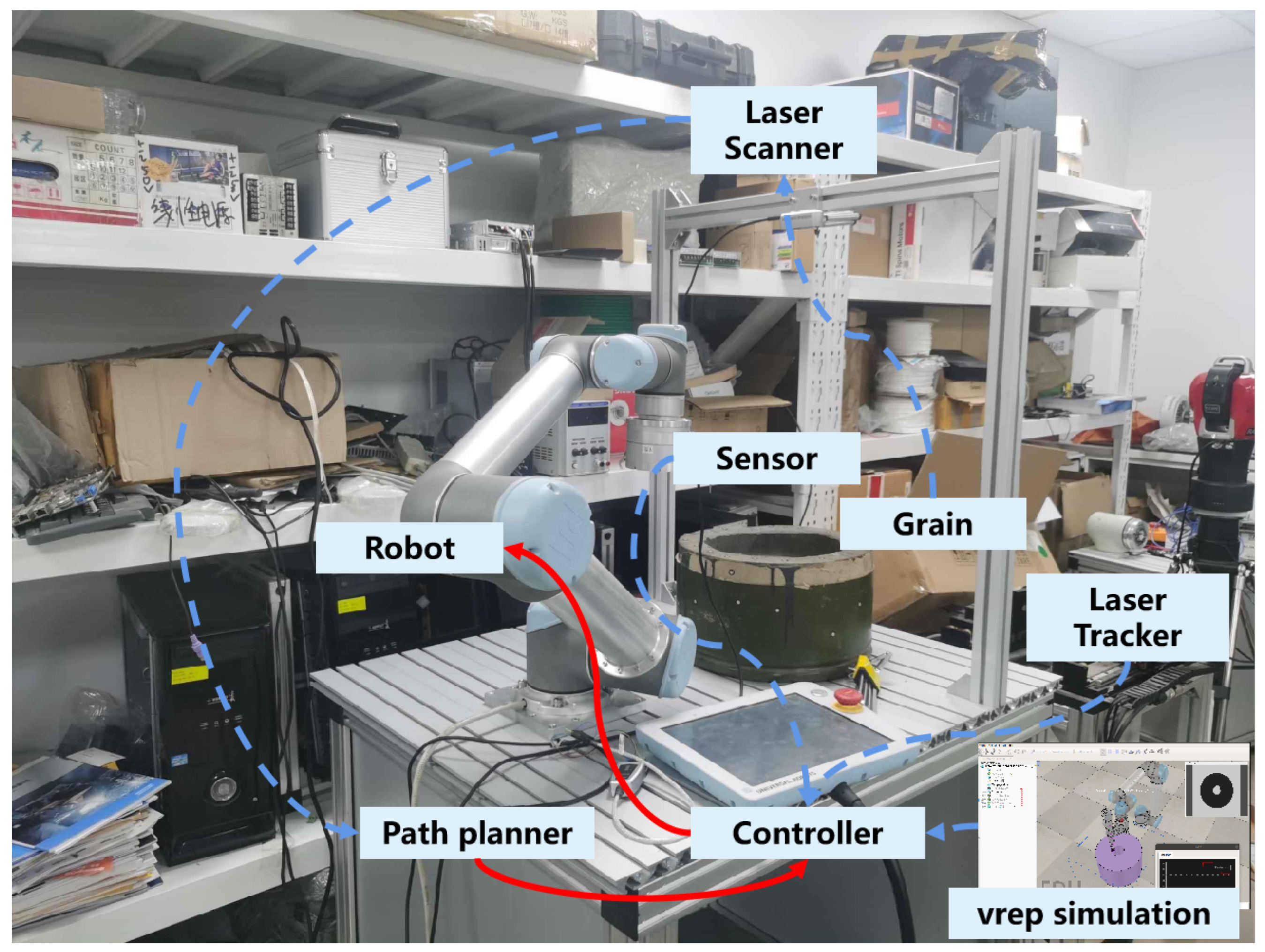

5.1. The Robot Shaping System

5.2. Ontology Model Design of the Robot Shaping Scene

5.3. Digital Twin Simulation and Deployment of the System

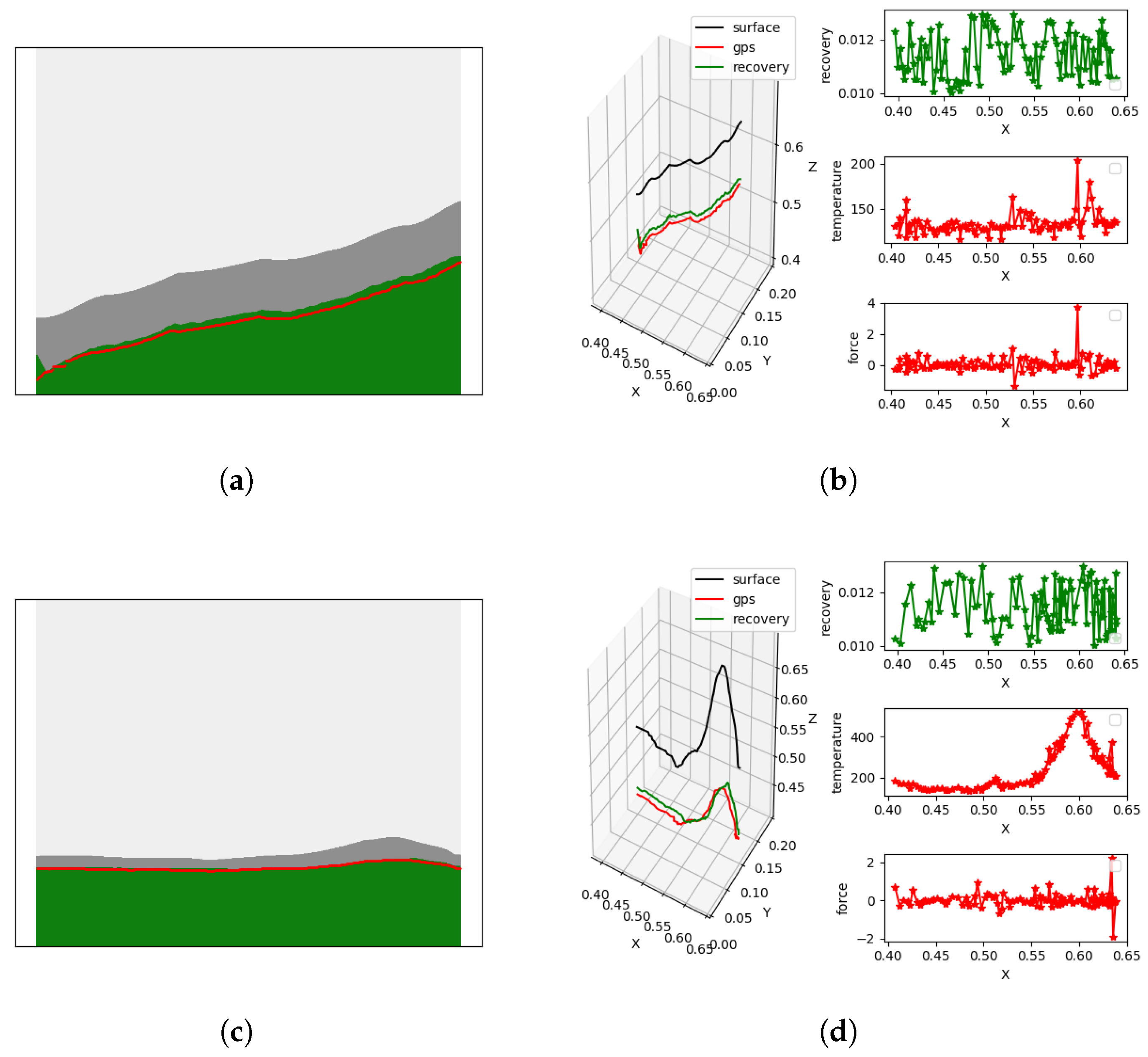

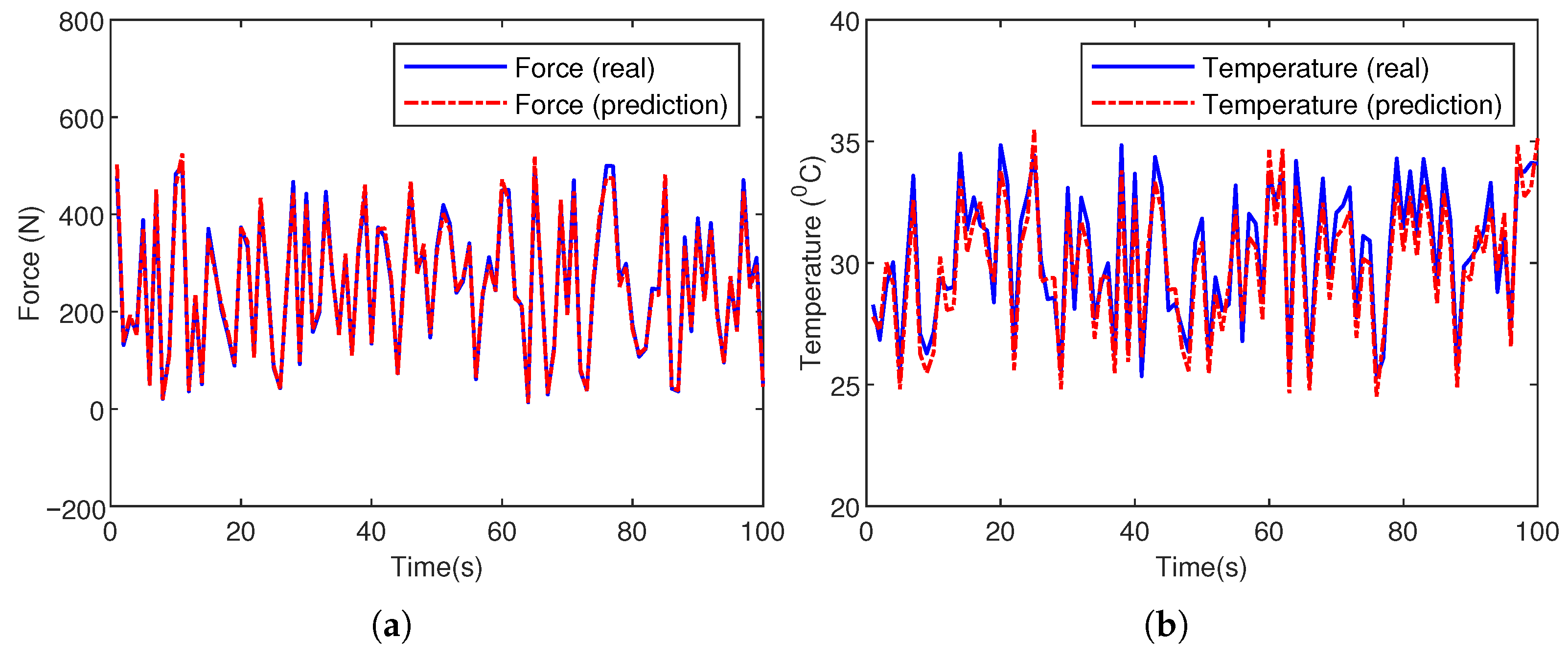

5.4. Analysis of the Simulation Results

5.5. Analysis of the Physical Experiment Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Urrea, C.; Kern, J. Recent Advances and Challenges in Industrial Robotics: A Systematic Review of Technological Trends and Emerging Applications. Processes 2025, 13, 832. [Google Scholar] [CrossRef]

- Ji, W.; Wang, L. Industrial robotic machining: A review. Int. J. Adv. Manuf. Technol. 2019, 103, 1239–1255. [Google Scholar] [CrossRef]

- Makulavičius, M.; Petkevičius, S.; Rožėnė, J.; Dzedzickis, A.; Bučinskas, V. Industrial robots in mechanical machining: Perspectives and limitations. Robotics 2023, 12, 160. [Google Scholar] [CrossRef]

- Liu, D.; Liu, Z.; Zhao, J.; Song, Q.; Ren, X.; Ma, H. Tool wear monitoring through online measured cutting force and cutting temperature during face milling Inconel 718. Int. J. Adv. Manuf. Technol. 2022, 122, 729–740. [Google Scholar] [CrossRef]

- Wu, M.; Guo, Z.; Qian, J.; Reynaerts, D. Multi-Ion-Based Modelling and Experimental Investigations on Consistent and High-Throughput Generation of a Micro Cavity Array by Mask Electrolyte Jet Machining. Micromachines 2022, 13, 2165. [Google Scholar]

- Wu, M.; Arshad, M.H.; Saxena, K.K.; Qian, J.; Reynaerts, D. Profile prediction in ECM using machine learning. Procedia CIRP 2022, 113, 410–416. [Google Scholar] [CrossRef]

- Wu, M.; Yao, Z.; Verbeke, M.; Karsmakers, P.; Gorissen, B.; Reynaerts, D. Data-driven models with physical interpretability for real-time cavity profile prediction in electrochemical machining processes. Eng. Appl. Artif. Intell. 2025, 160, 111807. [Google Scholar] [CrossRef]

- Chen, G.; Zhu, J.; Zhao, Y.; Hao, Y.; Yang, C.; Shi, Q. Digital twin modeling for temperature field during friction stir welding. J. Manuf. Process. 2021, 64, 898–906. [Google Scholar] [CrossRef]

- Zhang, Q.; Shen, S.; Li, H.; Cao, W.; Tang, W.; Jiang, J.; Deng, M.; Zhang, Y.; Gu, B.; Wu, K.; et al. Digital twin-driven intelligent production line for automotive MEMS pressure sensors. Adv. Eng. Inform. 2022, 54, 101779. [Google Scholar] [CrossRef]

- Saren, Q.; Zhang, Z.; Xiong, J.; Chen, X.; Zhu, D.; Wu, W.; Jin, X.; Shang, K. An accuracy and performance-oriented accurate digital twin modeling method for precision microstructures. J. Intell. Manuf. 2024, 35, 2887–2911. [Google Scholar] [CrossRef]

- Huang, Z.; Fey, M.; Liu, C.; Beysel, E.; Xu, X.; Brecher, C. Hybrid learning-based digital twin for manufacturing process: Modeling framework and implementation. Robot. Comput.-Integr. Manuf. 2023, 82, 102545. [Google Scholar] [CrossRef]

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Giannoulis, C.; Michalos, G.; Makris, S. Digital twin for adaptation of robots’ behavior in flexible robotic assembly lines. Procedia Manuf. 2019, 28, 121–126. [Google Scholar] [CrossRef]

- Kampa, A. Modeling and simulation of a digital twin of a production system for industry 4.0 with Work-in-Process synchronization. Appl. Sci. 2023, 13, 12261. [Google Scholar] [CrossRef]

- Matulis, M.; Harvey, C. A robot arm digital twin utilising reinforcement learning. Comput. Graph. 2021, 95, 106–114. [Google Scholar] [CrossRef]

- Saavedra Sueldo, C.; Perez Colo, I.; De Paula, M.; Villar, S.A.; Acosta, G.G. ROS-based architecture for fast digital twin development of smart manufacturing robotized systems. Ann. Oper. Res. 2023, 322, 75–99. [Google Scholar] [CrossRef]

- Lu, J.; Yang, Z.; Zheng, X.; Wang, J.; Dimitris, K. Exploring the concept of Cognitive Digital Twin from model-based systems engineering perspective. Int. J. Adv. Manuf. Technol. 2022, 121, 5835–5854. [Google Scholar] [CrossRef]

- Asif, M.E.; Rastegarpanah, A.; Stolkin, R. Robotic disassembly for end-of-life products focusing on task and motion planning: A comprehensive survey. J. Manuf. Syst. 2024, 77, 483–524. [Google Scholar] [CrossRef]

- Vazirpanah, M.; Attarzadeh-Niaki, S.H.; Salimi-Badr, A. Ros-based co-simulation for formal cyber-physical robotic system design. In Proceedings of the 2022 27th International Computer Conference, Computer Society of Iran (CSICC), Tehran, Iran, 23–24 February 2022; pp. 1–5. [Google Scholar]

- Li, Y.; Chen, J.; Hu, Z.; Zhang, H.; Lu, J.; Kiritsis, D. Co-simulation of complex engineered systems enabled by a cognitive twin architecture. Int. J. Prod. Res. 2022, 60, 7588–7609. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Wang, P.; Law, J.; Calinescu, R.; Mihaylova, L. A deep learning-enhanced Digital Twin framework for improving safety and reliability in human–robot collaborative manufacturing. Robot. Comput.-Integr. Manuf. 2024, 85, 102608. [Google Scholar] [CrossRef]

- Rakhtala, S.M.; Ghayebi, R. Real time control and fabrication of a soft robotic glove by two parallel sensors with MBD approach. Med. Eng. Phys. 2022, 100, 103743. [Google Scholar] [CrossRef] [PubMed]

- Gan, J.; Zhou, Z.; Yu, A.; Ellis, D.; Attwood, R.; Chen, W. Co-simulation of multibody dynamics and discrete element method for hydraulic excavators. Powder Technol. 2023, 414, 118001. [Google Scholar] [CrossRef]

- Huynh, H.N.; Assadi, H.; Rivière-Lorphèvre, E.; Verlinden, O.; Ahmadi, K. Modelling the dynamics of industrial robots for milling operations. Robot. Comput.-Integr. Manuf. 2020, 61, 101852. [Google Scholar] [CrossRef]

| 1 | Configuration process |

| 2 | Create functional packages, and each agent corresponds to one or more functional packages. |

| 3 | Create the msg folder, and import the msg file that originates from the ontology model. |

| 4 | Modify the CMakeLists.txt document. |

| 5 | Modify the package.xml |

| 6 | Generate pub files and sub files based on the template. |

| 7 | Compile and configure the environment variables. |

| Agent | Call the Service | Subscribe to the Topic | Render Services | Post a Topic |

|---|---|---|---|---|

| V-rep_node | Formal simulation | Deformation quantity | Location control service | Robot cartesian data |

| Force simulation | Contact force | Photo service | Robot joint data | |

| Temperature simulation | Temperature scale | Position reading service | Point cloud data | |

| Robot control | Joint control | |||

| Plan | Photo service | Point cloud data | Planning services | Planning trajectory |

| Contact force | ||||

| Temperature scale | ||||

| Planning services | Planning trajectory | Robot control | Joint control | |

| Robot control | Location services | Robot Cartesian | ||

| Position reading service | Robot joint value | |||

| Laser tracker data | Robot tcp data | |||

| State estimator | Temperature-sensor data | Temperature scale | ||

| Force sensor | Contact force | |||

| Temperature agent | Temperature simulation | Temperature scale | ||

| Force agent | Force simulation | Contact force | ||

| Formal agent | Formal simulation | Deformation quantity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Zeng, P.; Wu, Q.; Zhang, H. Metamodel-Based Digital Twin Architecture with ROS Integration for Heterogeneous Model Unification in Robot Shaping Processes. Machines 2025, 13, 898. https://doi.org/10.3390/machines13100898

Li Q, Zeng P, Wu Q, Zhang H. Metamodel-Based Digital Twin Architecture with ROS Integration for Heterogeneous Model Unification in Robot Shaping Processes. Machines. 2025; 13(10):898. https://doi.org/10.3390/machines13100898

Chicago/Turabian StyleLi, Qingxin, Peng Zeng, Qiankun Wu, and Hualiang Zhang. 2025. "Metamodel-Based Digital Twin Architecture with ROS Integration for Heterogeneous Model Unification in Robot Shaping Processes" Machines 13, no. 10: 898. https://doi.org/10.3390/machines13100898

APA StyleLi, Q., Zeng, P., Wu, Q., & Zhang, H. (2025). Metamodel-Based Digital Twin Architecture with ROS Integration for Heterogeneous Model Unification in Robot Shaping Processes. Machines, 13(10), 898. https://doi.org/10.3390/machines13100898