1. Introduction

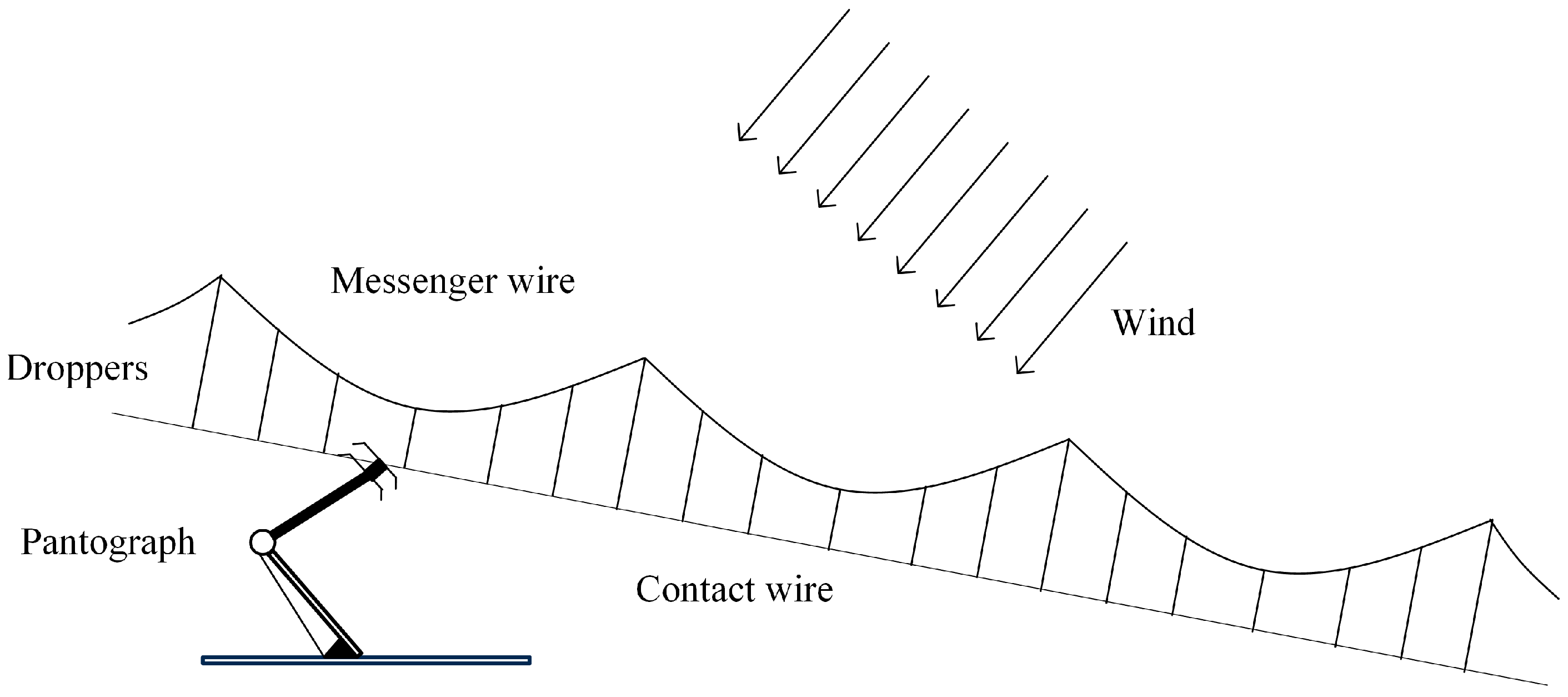

As a critical component of electrified railways, the stable contact of the pantograph-catenary system ensures the operational reliability of railway systems. However, with the increasing frequency of extreme weather events worldwide, crosswinds acting on overhead contact lines have become more intense, thereby compromising the stability of the pantograph-catenary system (As illustrated in

Figure 1). Statistical data reveal numerous instances of wind-induced train service suspensions. For example, Train L656 on the Lanzhou-Xinjiang Railway was forced to stop due to strong winds, causing a cascading delay of nearly 7.5 h for subsequent trains. Improving the dynamic response characteristics of the pantograph-catenary system under crosswind conditions is essential for enhancing the operational stability of electrified railways and effectively mitigating the risks of service interruptions caused by routine crosswinds.

Extensive research has been conducted by scholars worldwide on the contact performance of pantograph-catenary systems under crosswind conditions. Some scholars have investigated the effects of crosswind speed, angle of attack, and turbulence intensity on the pantograph-catenary system by establishing wind field models. The results demonstrate that these factors exacerbate the vibration of the catenary, significantly impairing the current collection stability of the system and posing a serious threat to train operational safety [

1,

2,

3,

4]. Luo et al. [

5] established a pantograph-catenary coupled system using the absolute nodal coordinate formulation (ANCF) and relevant standards, demonstrating that contact force fluctuations intensify with increasing wind speed. Niu and Zhou [

6] examined crosswind effects on pantograph heads during tunnel entry and exit, identifying stronger dynamic responses during exit phases. Daocharoenporn and Mongkolwongrojn [

7] employed multibody system (MBS) dynamics to simulate wear mechanisms, correlating increased wind speed with elevated contact wire wear and separation rates. Li et al. [

8] analyzed lateral displacement under crosswind effects using a proposed prediction model and conducted a contact stability analysis. Xie and Zhi [

9] used sensor arrays to collect measurement-point data and examined wind effects on the catenary through wind tunnel experiments. Numerical simulations revealed significant displacement of the catenary under wind loads, adversely affecting the contact stability of the coupled pantograph-catenary system. Pan et al. [

10] evaluated dropper fatigue life via MATLAB R2023a, linking crosswinds to accelerated wear. Duan et al. [

11] characterized contact wires with varying wear levels under wind loads and proposed design improvements. Chen et al. [

12] established wind fields to analyze fluctuation velocities, demonstrating that pulsation intensity is proportional to contact wire impacts. Based on the aforementioned findings, it can be concluded that crosswinds exert significant adverse effects on the operational stability of pantograph-catenary systems.

Compared with studies investigating the current collection performance of pantograph-catenary systems under crosswinds, relatively limited research has focused on maintaining and improving such performance under crosswind conditions. Song et al. [

13] developed a nonlinear catenary model and a multibody dynamic pantograph model, and proposed a control strategy using a PD controller with different actuator configurations. The reliability of the approach was validated under strong wind conditions. Addressing stochastic wind fields, Song et al. [

14] introduced an active pantograph control strategy based on PD sliding-mode surfaces, which effectively suppresses contact force fluctuations by reducing the pantograph head’s mechanical impedance. Ren et al. [

15] applied sliding-mode control to a three-mass pantograph model under pulsating wind loads, achieving significant vibration suppression and a reduced standard deviation of contact forces. For transitional windbreak wall zones, Zhang et al. [

16] proposed a localized optimization approach to counteract train yaw effects. Dong et al. [

17] enhanced catenary performance by installing porous wind barriers on top of embankment windbreak walls. Their parametric study on porosity ratios revealed that optimal porosity configurations can effectively minimize conductor displacement. However, these studies predominantly rely on infrastructure-based methodologies and conventional control strategies.

In recent years, an increasing number of studies have applied advanced control strategies to nonlinear systems, such as state-filtering-based disturbance rejection control [

18] and multi-layer neural control strategies [

19]. However, due to issues such as potential high-frequency noise in the pantograph–catenary system itself and substantial computational demands, these methods exhibit certain limitations. Neural network-based PID control has been widely applied in the field of active suspension systems. Some studies have introduced disturbances to simulate road unevenness and utilized neural network PID controllers to optimize suspension performance [

20,

21]. Duan et al. [

22] employed an improved neural network PID strategy to enhance the performance of a passive suspension model under various road conditions. Liu et al. [

23] optimized vehicle performance indicators using a proposed BP-PID control method and validated its superiority through comparison with conventional PID approaches. Effendi et al. [

24] developed a PID tuning method based on a backpropagation neural network combined with a genetic algorithm to improve ride comfort, demonstrating its effectiveness through computed metrics and relevant evaluation standards. However, research on the application of neural network PID control to pantograph-catenary systems under crosswind conditions remains relatively limited.

As evidenced by the aforementioned research, while active control methods represent an effective approach for improving the current collection performance of pantograph-catenary systems under crosswind conditions, current studies still exhibit certain limitations. Firstly, the catenary models employed are often oversimplified; secondly, existing active control strategies tend to be overly complex, making them difficult to implement in practical pantograph systems. To better enhance the current collection quality of high-speed railway pantograph-catenary systems under crosswind effects, this paper adopts an offline and online combined neural network-based PID strategy within the MATLAB environment for system control. Owing to the hybrid offline-online nature of the proposed method, a feedback structure is utilized in this study. Given that PID control is most likely to be implemented in practical pantograph-catenary applications and considering the inherent capabilities of Radial Basis Function (RBF) networks, the proposed framework employs a PID controller with RBF-based algorithm parameter adjustment.

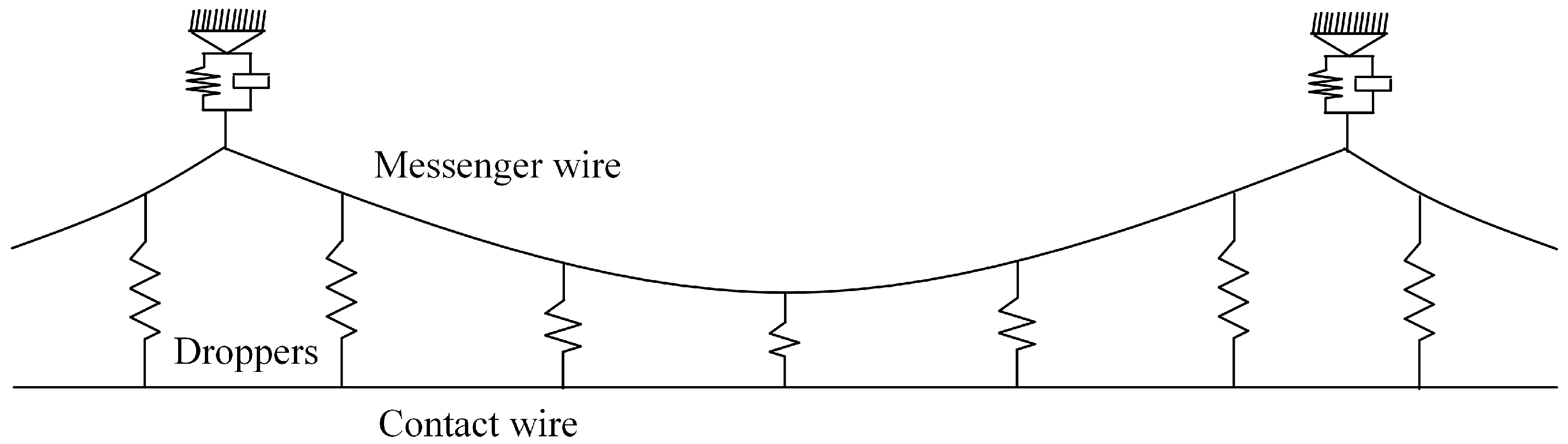

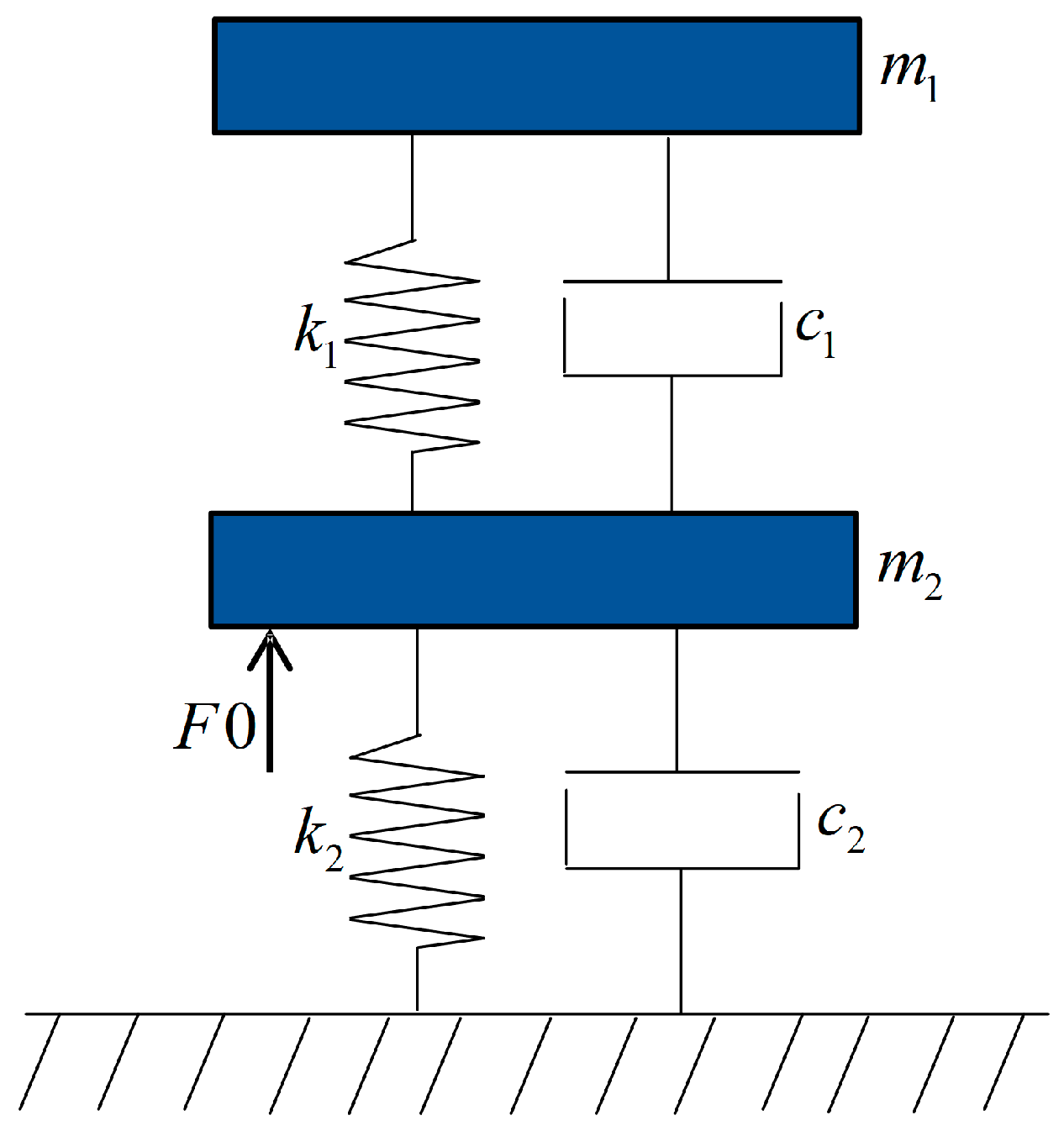

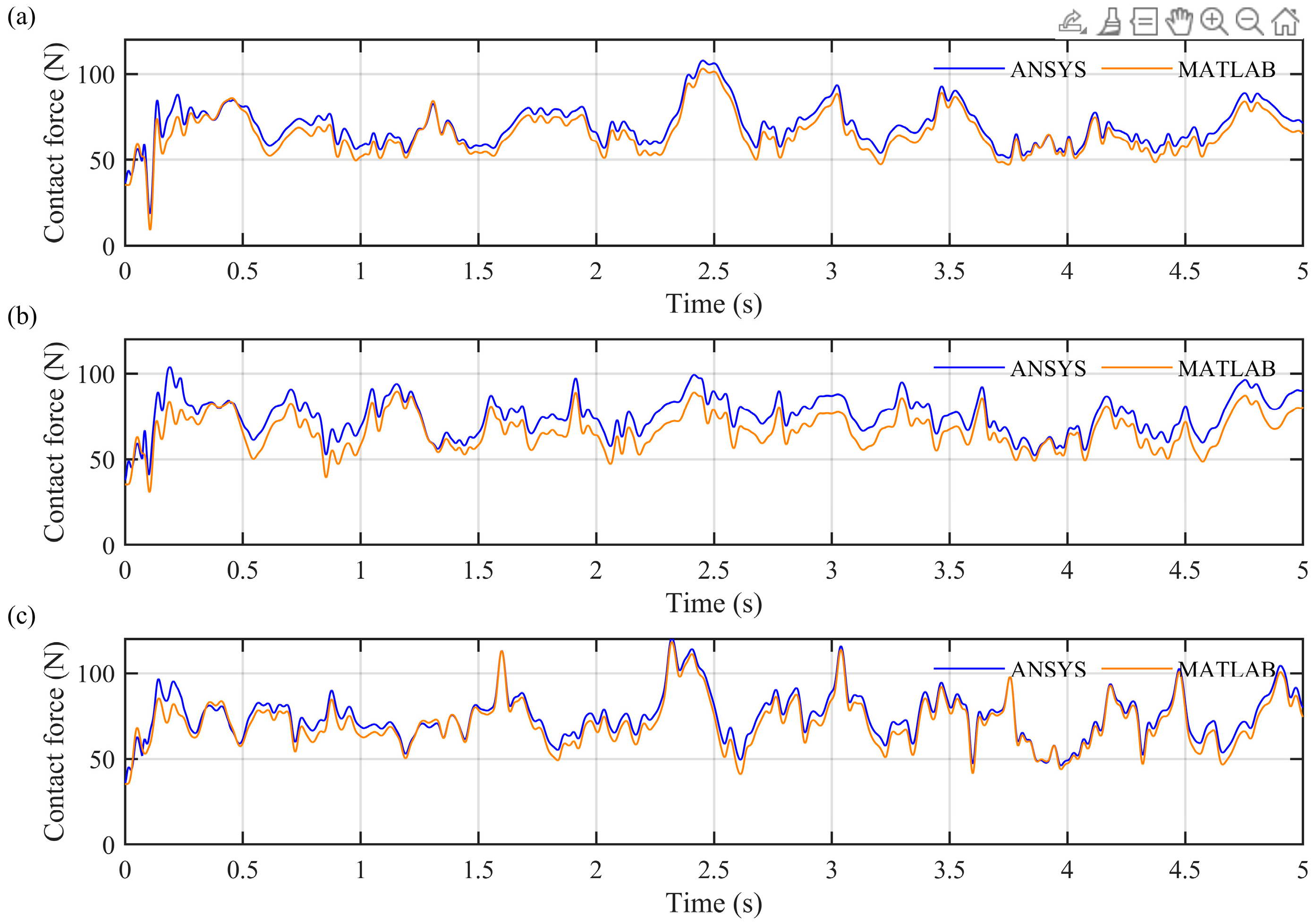

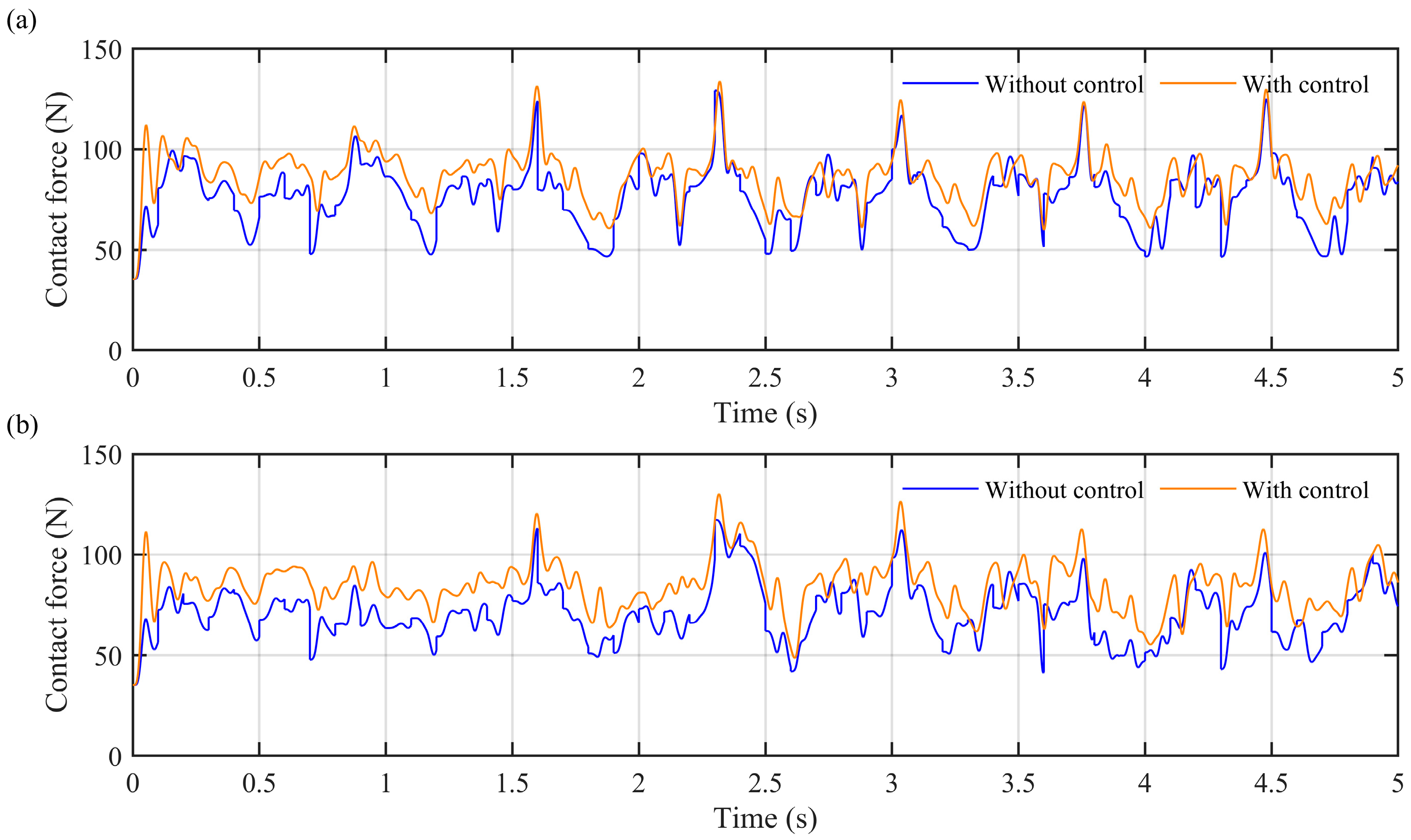

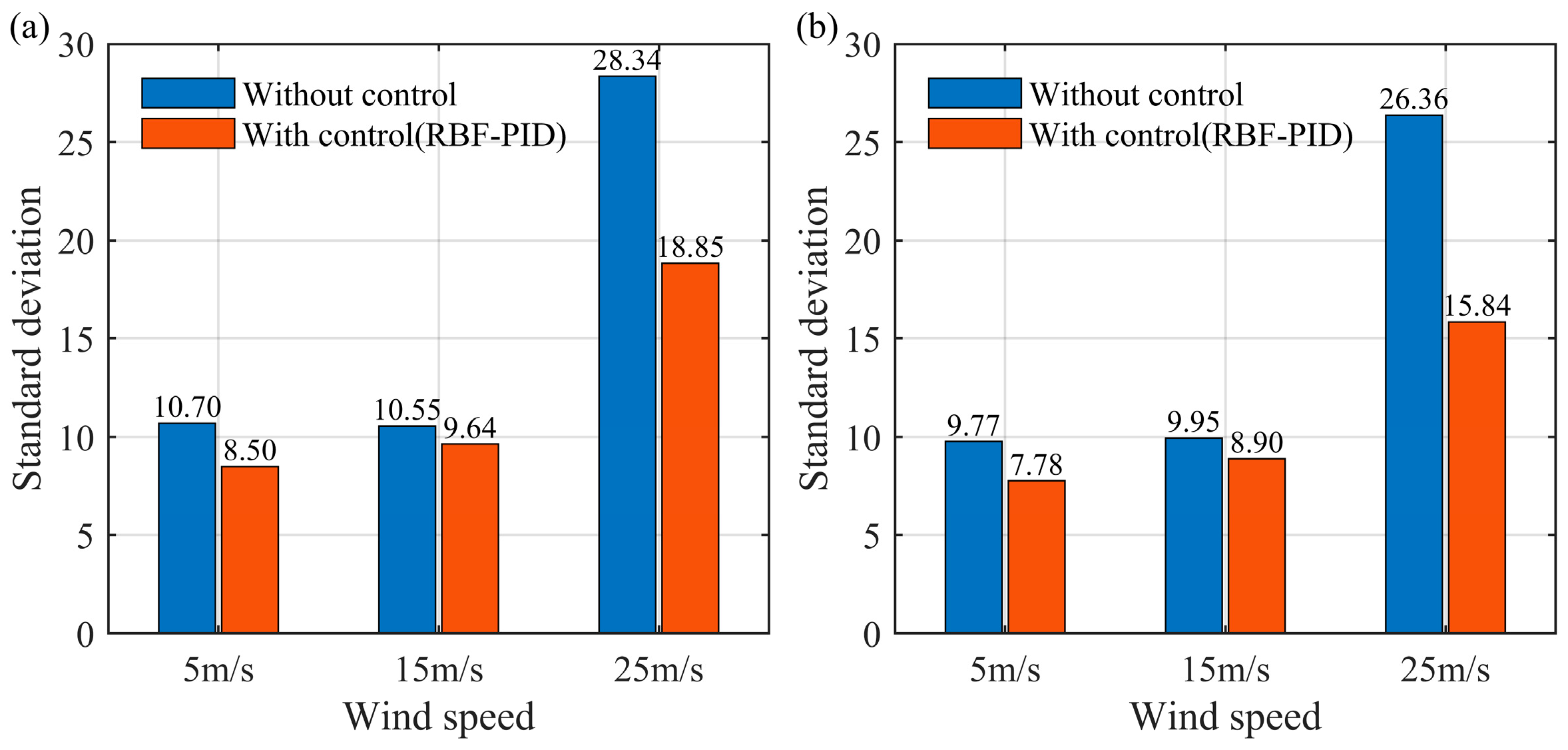

This study proposes a neural network-based PID control approach for the pantograph-catenary system to optimize current collection quality under crosswind disturbances. First, models of the pantograph, catenary, and crosswind are established. A simplified stitched catenary model is formulated using the Lagrange equation, while the pantograph is modeled as a two-mass block system. The coupling relationship between the pantograph and catenary is then established via the penalty function method, forming a complete pantograph-catenary system into which the crosswind effect is incorporated. Subsequently, the contact quality is optimized using a neural network PID method, with contact force selected as the feedback variable and the output lifting force controlled through the proposed strategy. By selecting appropriate initial values for the proportional-integral-derivative (PID) controller and initializing learning rates as well as weight coefficients, effective system control is achieved with favorable results.

Section 2 develops the pantograph–catenary interaction model based on the derived dynamic equations, incorporating crosswind models at varying wind speeds;

Section 3 constructs the neural network PID control framework;

Section 4 analyzes the control outcomes, with comparative validation demonstrating the effectiveness of the proposed method;

Section 5 presents the conclusions.

5. Conclusions

This study presents a neural network PID-based active control strategy for pantograph-catenary systems operating under crosswind conditions, effectively overcoming the inadequate performance of traditional PID controllers in complex, time-varying environments. A pantograph-catenary interaction model under crosswind was established using a truncated beam approach within the MATLAB simulation environment, incorporating crosswind effects modeled via wind spectra. A nonlinear neural network PID controller was designed and integrated into this dynamic system. The results indicate that the RBF-PID controller effectively enhances the dynamic response characteristics of the pantograph-catenary system, significantly suppresses contact force fluctuations, and nearly eliminates the offline phenomenon under crosswind disturbances. Compared with conventional PID controllers, the neural network PID approach ensures more stable and reliable current collection. Robustness analyses further demonstrate that the controller consistently maintains high performance despite variations in pantograph parameters, indicating strong adaptability to practical engineering applications. For real-world implementation, it is feasible to embed micro-actuators within the pantograph head to enable real-time control adjustment, thereby improving adaptability to changing catenary conditions and enhancing current collection stability. While certain engineering challenges-such as high-voltage insulation, spatial constraints, and equipment reliability-remain to be addressed, ongoing advances in materials science, micro-actuation, and embedded control technology are accelerating progress toward practical deployment of active pantograph control. Overall, the method proposed in this study not only provides a solid theoretical foundation and technical guidance for improving the stability of pantograph-catenary systems under wind conditions, but also offers novel insights and references for the intelligent and adaptive control of high-speed rail systems under complex external disturbances.