An Autonomous Mobile Measurement Method for Key Feature Points in Complex Aircraft Assembly Scenes

Abstract

1. Introduction

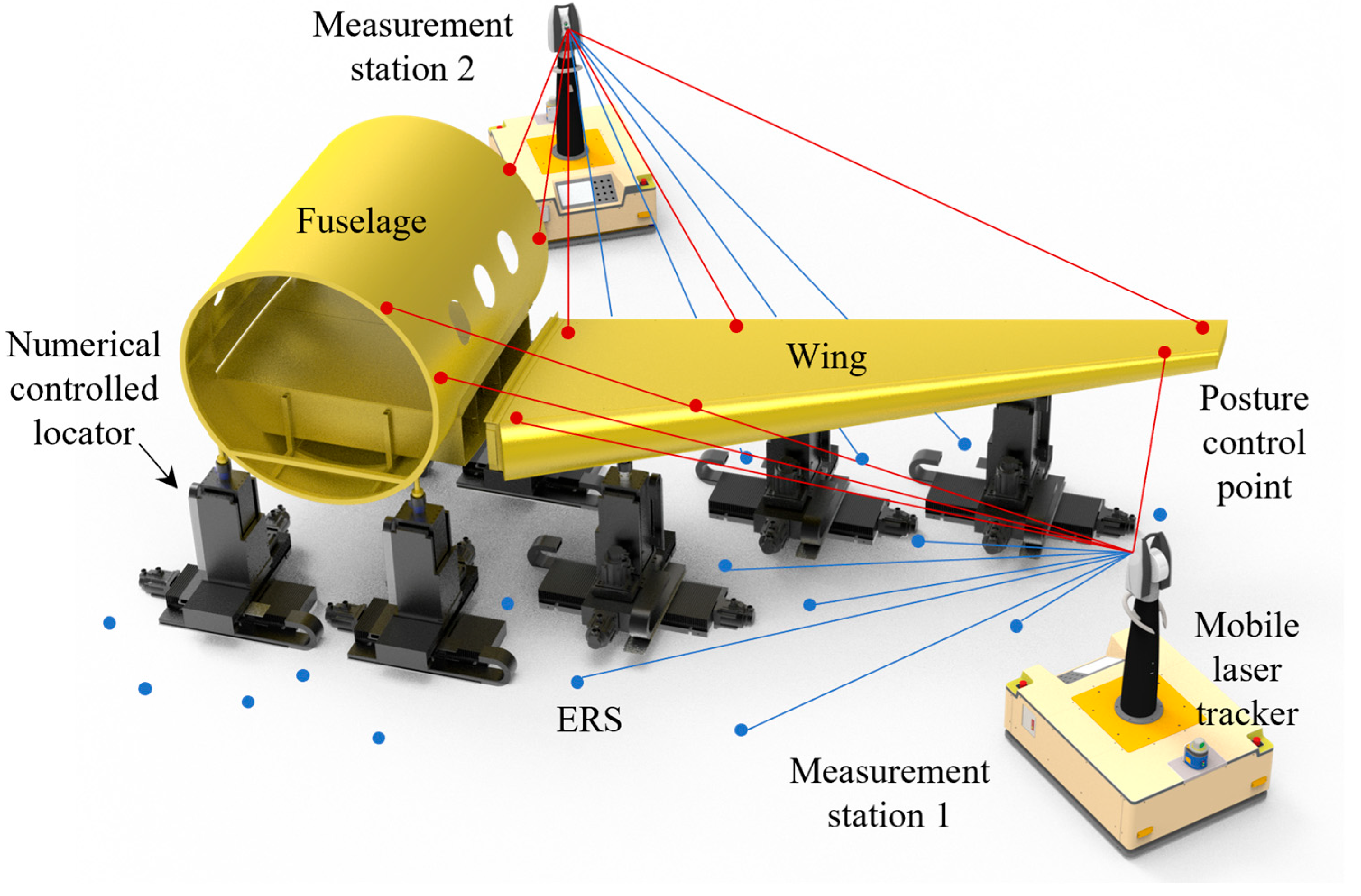

1.1. Background

1.2. Related Work

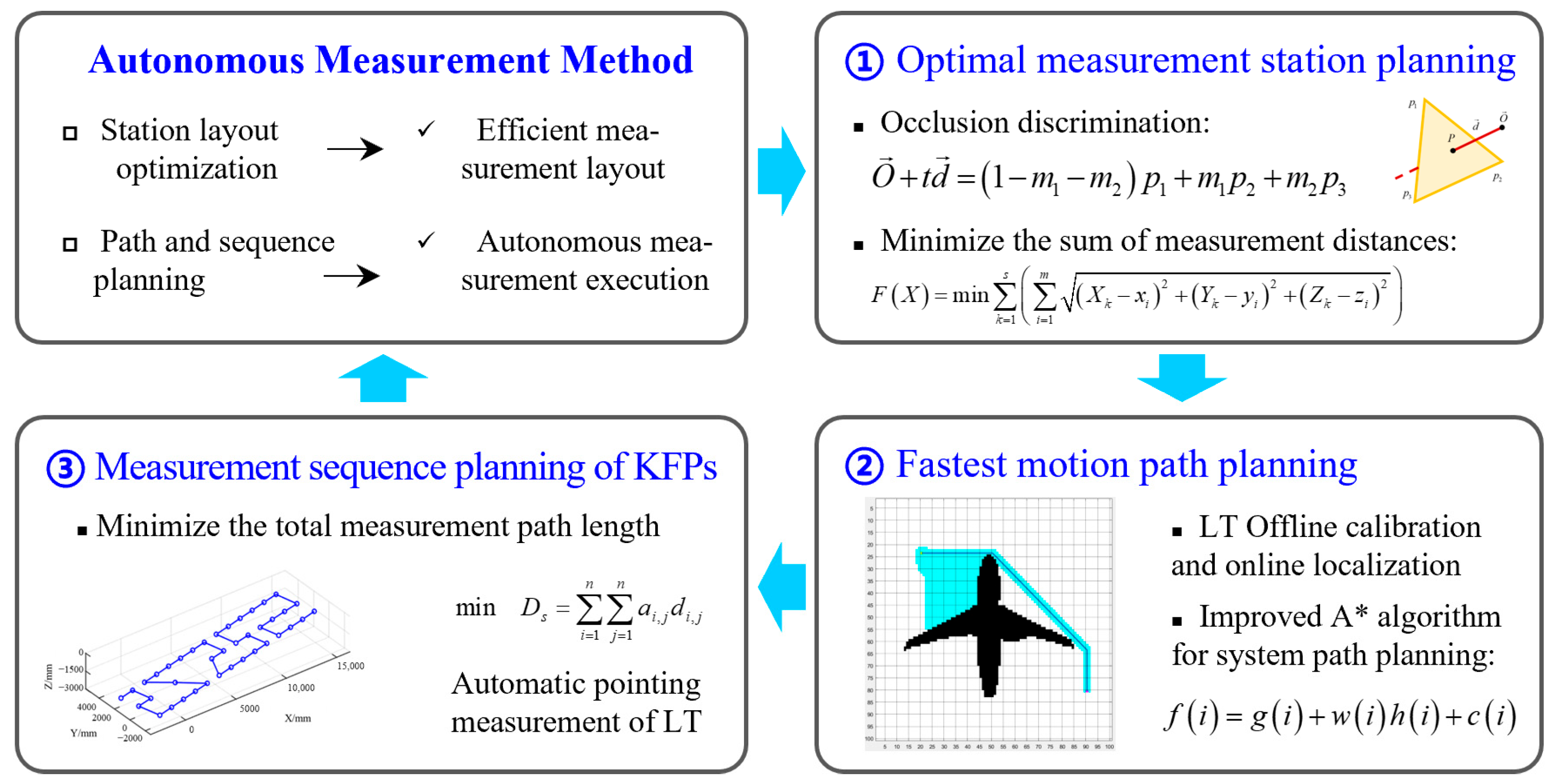

2. Methodology

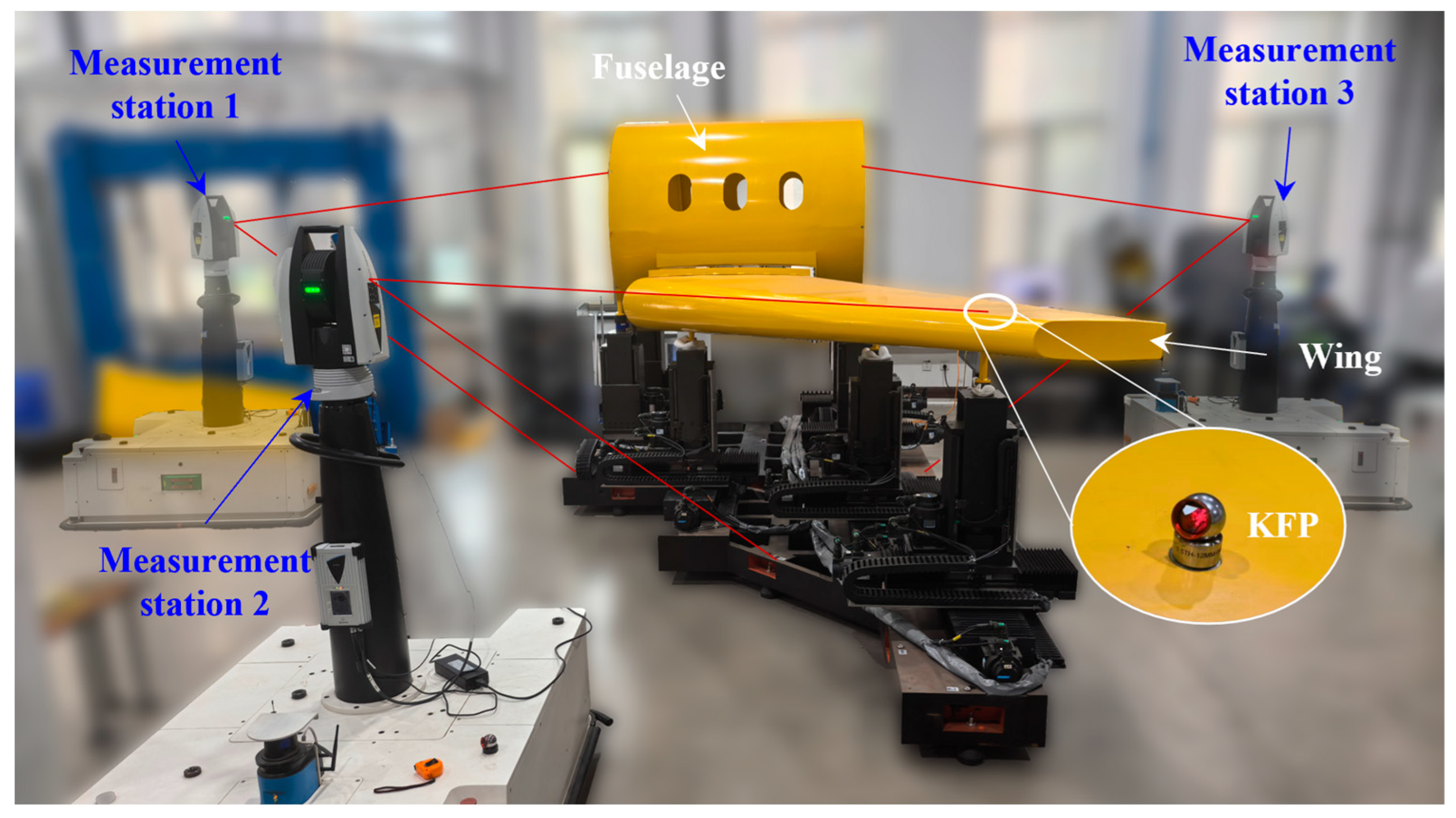

2.1. Overall Architecture of the Proposed Method

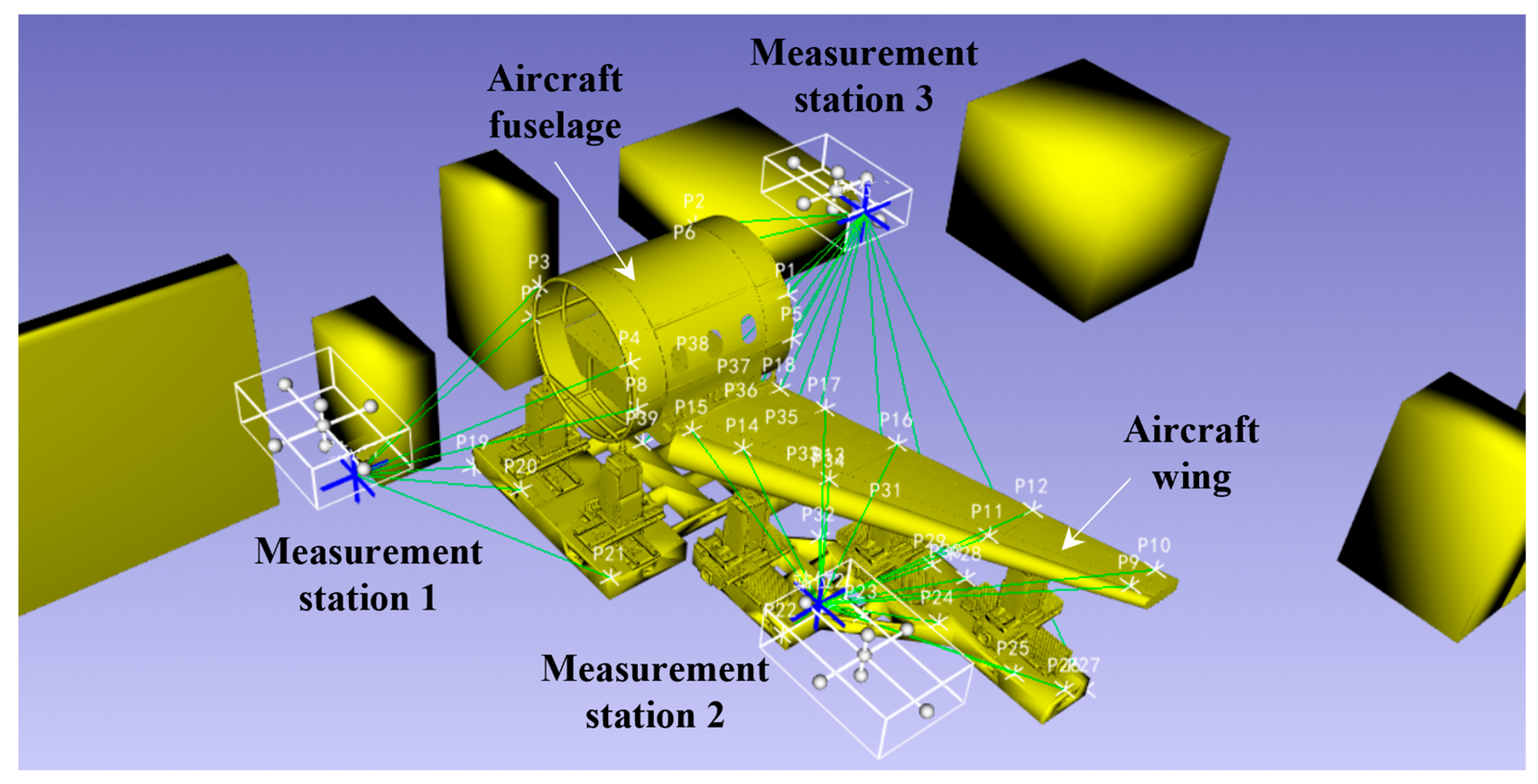

2.2. Measurement Station Planning Considering Line-of-Sight Occlusion

- (1)

- A single measurement station should cover as many measurement points as possible: that is, under the premise of satisfying measurement requirements, the number of stations should be minimized to reduce coordinate transformation errors, while fewer station transitions can also improve measurement efficiency.

- (2)

- The vertical angle range for single-point measurement is 0~145°, and the distance range is within 10 m: this corresponds to the effective measurement range of the LT, where the measurement distance can be user-defined according to the LT performance and accuracy requirements.

- (3)

- The total distance between each measurement station and its corresponding measurement points should be minimized as much as possible.

- (4)

- Occlusion determination should be performed during the planning process to ensure measurement accessibility and full coverage. If any point proves non-measurable under the current layout, the station count is incremented and the layout is re-planned; when defining the feasible region for each additional station, priority is given to guaranteeing line-of-sight access to the previously occluded point.

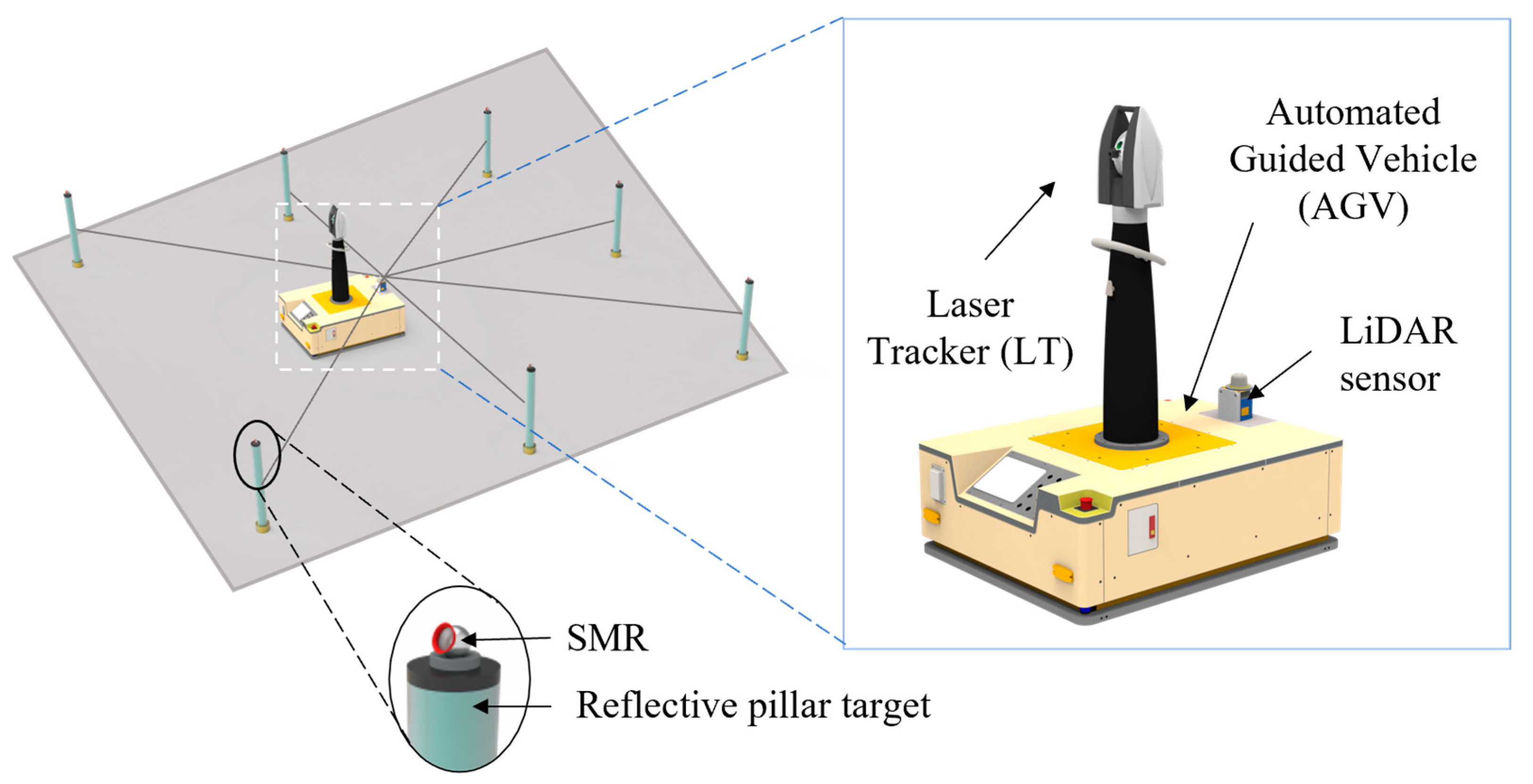

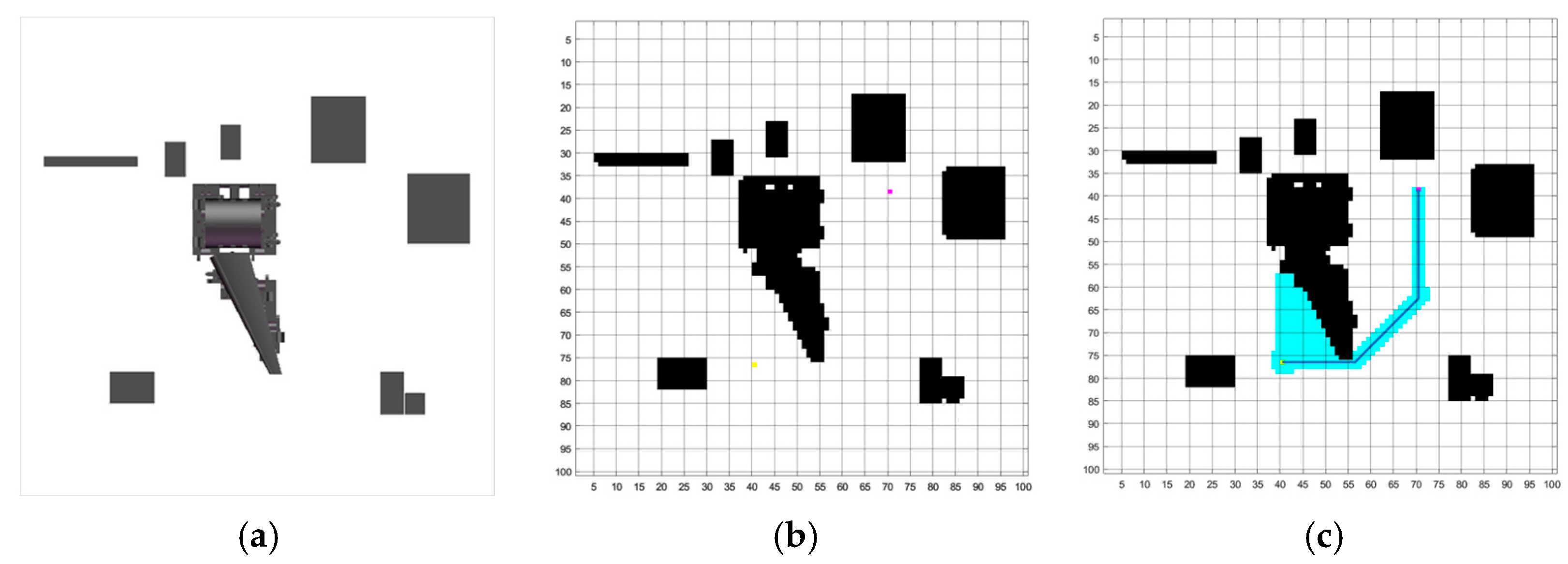

2.3. Localization of the Measurement System and Mobile Path Planning

- (1)

- Construct the two-dimensional map coordinate system.

- (2)

- Measure the two-dimensional equivalent centers of the reflective pillar targets using the laser tracker.

- (3)

- Calibration between the map coordinate system and the onboard LT coordinate system.

- (4)

- Calibration between the onboard LT coordinate system and the AGV coordinate system.

| Algorithm 1: Path Planning Based on the Shortest Running Time | |

| Input: start, goal | |

| Output: Path and its total cost | |

| 1 | open ← {start}, closed ← |

| 2 | g ← 0, h = h(start), c = 0, f[start] = g + h + c |

| 3 | while open ≠ do |

| 4 | n ← node in open with minimal f |

| 5 | if n = goal then return reconstruct-path (parent, n), f[n] |

| 6 | end if |

| 7 | for all neighbor v of n do |

| 8 | g′ ← g[n] + cost (n, v) |

| 9 | h′ ← h(v) |

| 10 | if closed = then c′ ← 0 |

| 11 | else c′ ← turn (parent[n], n, v) |

| 12 | end if |

| 13 | f′ ← g′ + h′ + c′ |

| 14 | if v open then |

| 15 | if f′ < f[v] then update g, h, f, parent[v] |

| 16 | else insert v into open with g′, h′, f′, parent[v] |

| 17 | end if |

| 18 | end for |

| 19 | move n from open to closed |

| 20 | end while |

| 21 | Return path and its total cost |

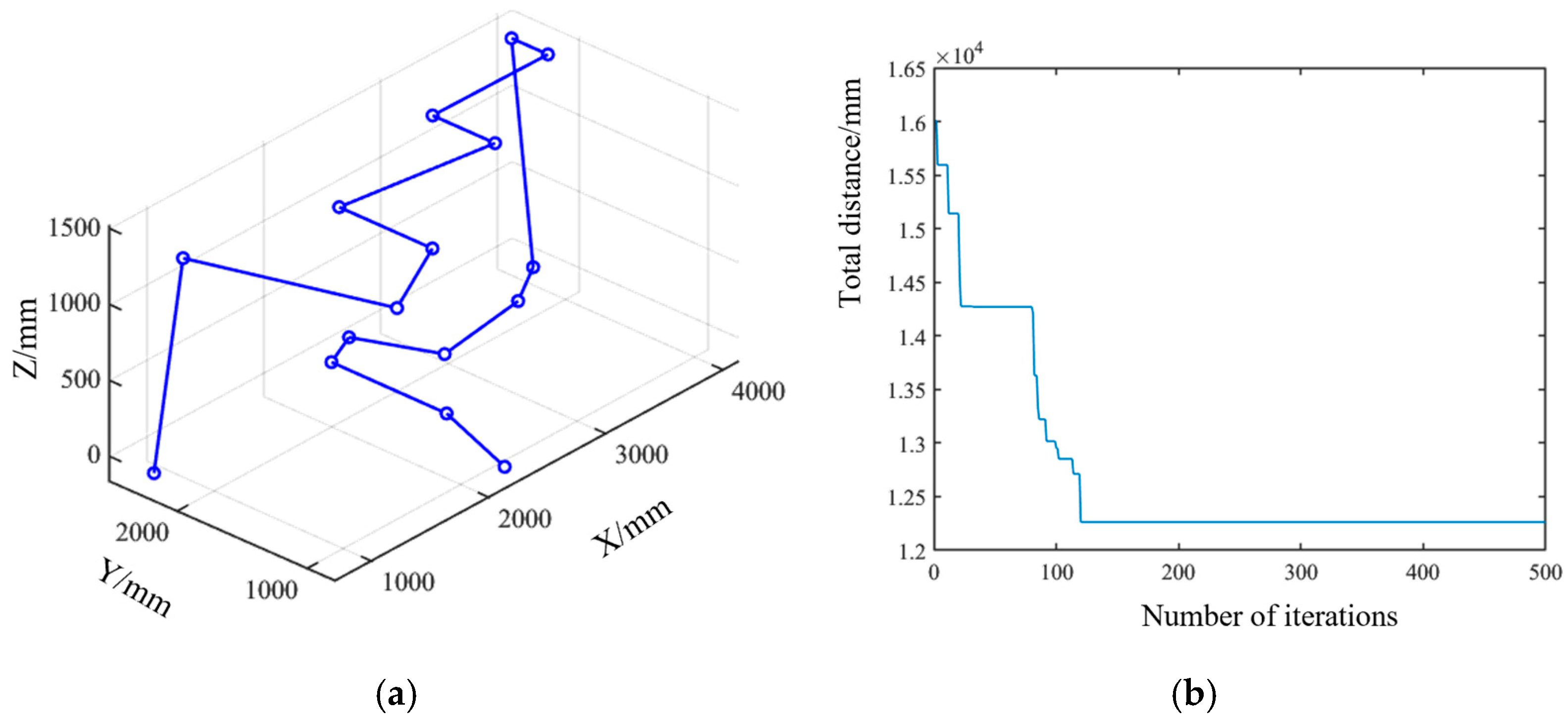

2.4. Measurement Sequence Planning of Discrete KFPs

- (1)

- Population initialization based on a combination of the nearest-neighbor method and the random method. Assume the number of measurement points is and the population size is To avoid excessive duplicate individuals during initialization, one measurement point is selected as the first point in the sequence, and the nearest-neighbor method is applied to generate one sequence (i.e., one individual). By taking each measurement point as the first point and performing sorting once, individuals are generated in total. The remaining − individuals are then generated using the random method, thereby completing the initialization of all individuals in the population.

- (2)

- Offspring generation based on order crossover. A portion of the measurement point sequence is copied from one parent to the offspring, and then the remaining measurement points are copied from the second parent to the offspring while preserving their relative order from the second parent.

- (3)

- Generate offspring through mutation. A combined mutation operation consisting of inversion, insertion, and swapping is employed. Specifically, inversion reverses the order of measurement points between two randomly selected positions. Insertion moves the measurement point at position to immediately follow position . Swapping exchanges the measurement points at positions and .

- (4)

- Design the fitness function. The total distance of each measurement point sequence is calculated, and the reciprocal of the total distance is taken as the fitness function. The smaller the total distance, the better the fitness value.

- (5)

- Select suitable individuals to retain as parents. The roulette wheel method is employed for selection.

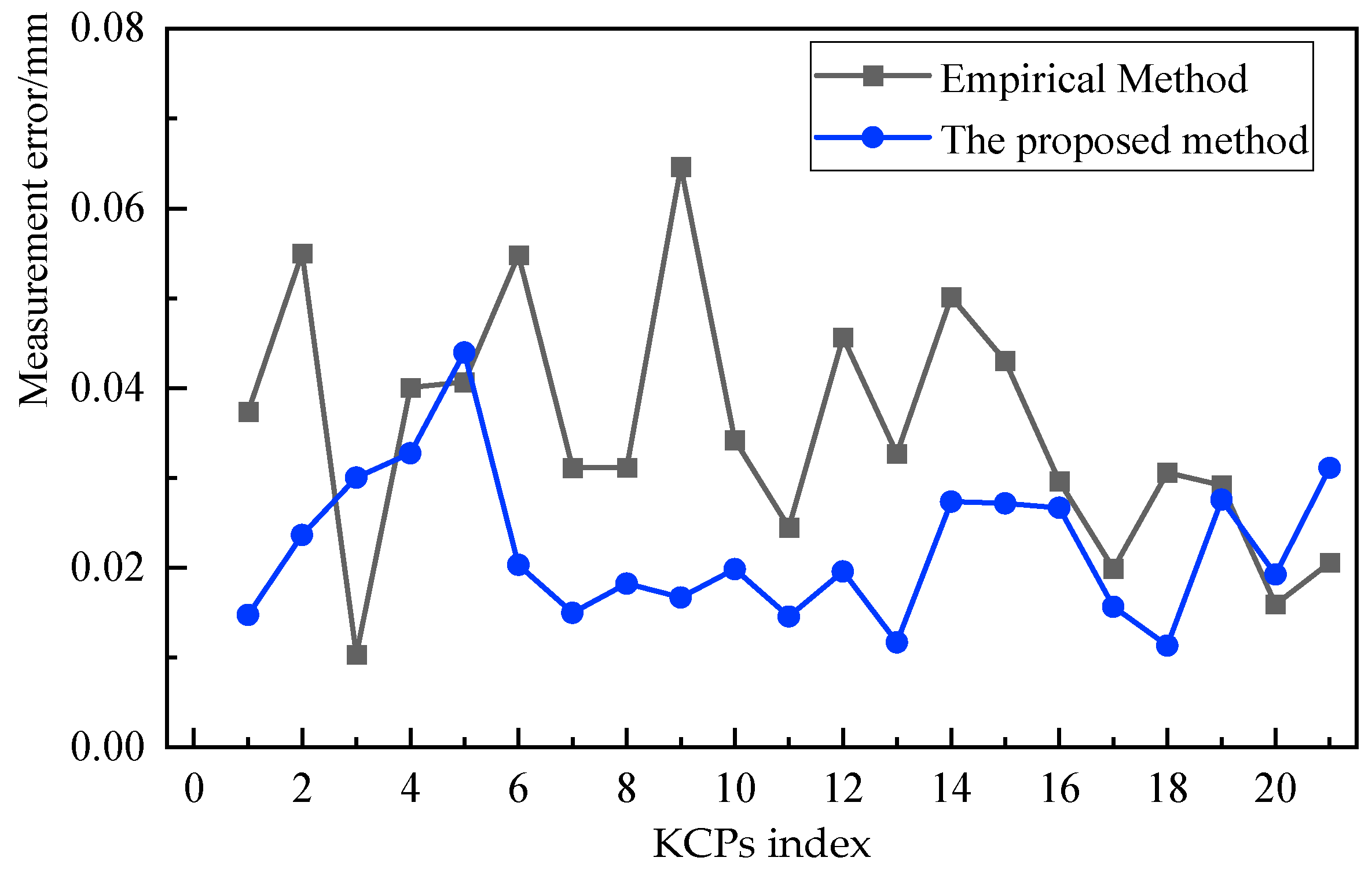

3. Experimental Validation and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, T.; Huang, X.; Li, S.; Hou, G. Multi-Source Error Coupling and Tolerance Optimization for Improving the Precision of Automated Assembly of Aircraft Components. Machines 2025, 13, 736. [Google Scholar] [CrossRef]

- Gai, Y.; Zhang, J.; Guo, J.; Shi, X.; Wu, D.; Chen, K. Construction and Uncertainty Evaluation of Large-Scale Measurement System of Laser Trackers in Aircraft Assembly. Measurement 2020, 165, 108144. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Lu, H.; Liu, R.; Gao, C.; Chen, Q.; Zhang, Y. Workspace-Based Hybrid Force Position Posture Alignment for High Quality Aircraft Assembly of Large-Scale Components. Chin. J. Aeronaut. 2025, 103414. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Chen, H.; Xie, Q.; Zhang, K.; Wang, J. Combined Measurement Based Wing-Fuselage Assembly Coordination via Multiconstraint Optimization. IEEE Trans. Instrum. Meas. 2022, 71, 1–16. [Google Scholar] [CrossRef]

- Chu, W.; Li, G.; Li, S.; Huang, X. Posture Adjustment Method of Large Aircraft Components Based on Multiple Numerical Control Positioners. Int. J. Adv. Manuf. Technol. 2023, 126, 2159–2174. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, H.; Zhao, B.; Wang, S.; Xue, Y. Docking Pose Analytical Calculation Method for Large Components Based on Draw-Wire Displacement Sensors. Measurement 2025, 242, 116072. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, W.; Zhang, Y.; Li, J.; Sun, S.; Cui, J.; Zeng, T. Accurate Construction Method of Sensor Measurement Network System for In-Situ Manufacturing of Large Aerospace Component. IEEE Trans. Instrum. Meas. 2023, 72, 1–11. [Google Scholar] [CrossRef]

- Zhehan, C.; Fuzhou, D.; Xiaoqing, T. Research on Uncertainty in Measurement Assisted Alignment in Aircraft Assembly. Chin. J. Aeronaut. 2013, 26, 1568–1576. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, W.; Zhang, Y.; Xing, H.; Li, J.; Liu, S.; Zhang, L. An Accurate Calibration Method of Large-Scale Reference System. IEEE Trans. Instrum. Meas. 2020, 69, 6957–6967. [Google Scholar] [CrossRef]

- Brillinger, C.; Susemihl, H.; Ehmke, F.; Staude, T.; Deutmarg, K.; Klemstein, M.; Boehlmann, C.; Hintze, W.; Wollnack, J. Mobile Laser Trackers for Aircraft Manufacturing: Increasing Accuracy and Productivity of Robotic Applications for Large Parts; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Sheng, Y.; Wang, Y.; Liu, S.; Wang, C.; Xi, J. Large-Scale Measurement Layout Optimization Method Based on Laser Multilateration. Machines 2022, 10, 988. [Google Scholar] [CrossRef]

- Zou, L.; Luo, C.; Zhang, G.; Zhang, Q.; He, Y. Method of High-Precision Measurement Station Optimization and Layout Deviation Compensation for Laser Tracker. IEEE Trans. Instrum. Meas. 2025, 74, 1–13. [Google Scholar] [CrossRef]

- Xu, S.; Huang, X.; Li, S.; Hou, G. The Research on Spatial Accuracy-Driven Adaptive Measurement Station Planning for Laser Trackers Based on Monte Carlo Simulations and GA-BP Neural Networks. Meas. Sci. Technol. 2025, 36, 065007. [Google Scholar] [CrossRef]

- Zhou, S.; Cheng, G.; Meng, Q.; Lin, H.; Du, Z.; Wang, F. Development of Multi-Sensor Information Fusion and AGV Navigation System. In Proceedings of the 2020 IEEE 4th Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 12–14 June 2020; Volume 1, pp. 2043–2046. [Google Scholar]

- Verde, P.; Díez-González, J.; Álvarez, R.; Perez, H. Characterization of AGV Localization System in Industrial Scenarios Using UWB Technology. IEEE Trans. Instrum. Meas. 2023, 72, 1–13. [Google Scholar] [CrossRef]

- Wang, S.-Y.; Li, C.-M.; Liong, S.-T.; Sheng, Y.-T.; Huang, Y.-C.; Liong, G.-B.; Gan, Y.-S. AGV Indoor Localization: A High Fidelity Positioning and Map Building Solution Based on Drawstring Displacement Sensors. J. Ambient. Intell. Hum. Comput. 2024, 15, 2277–2293. [Google Scholar] [CrossRef]

- Chung, M.-A.; Lin, C.-W. An Improved Localization of Mobile Robotic System Based on AMCL Algorithm. IEEE Sens. J. 2022, 22, 900–908. [Google Scholar] [CrossRef]

- Ren, J.; Li, W.; Ou, J.; Shi, J.; Jia, K.; Hou, M.; Zhou, J.; Huang, P.; Fu, Z.; Liu, J.; et al. ALEL-AMCL: An Artificial Landmark Enhanced Localization of Mobile Robotic System Based on AMCL Algorithm. Meas. Sci. Technol. 2025, 36, 056311. [Google Scholar] [CrossRef]

- Xu, T. Recent Advances in Rapidly-Exploring Random Tree: A Review. Heliyon 2024, 10, e32451. [Google Scholar] [CrossRef] [PubMed]

- Agirrebeitia, J.; Avilés, R.; de Bustos, I.F.; Ajuria, G. A New APF Strategy for Path Planning in Environments with Obstacles. Mech. Mach. Theory 2005, 40, 645–658. [Google Scholar] [CrossRef]

- Warren, C.W. Fast Path Planning Using Modified A* Method. In Proceedings of the 1993 IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; Volume 2, pp. 662–667. [Google Scholar]

- Kabir, R.; Watanobe, Y.; Islam, M.R.; Naruse, K. Enhanced Robot Motion Block of A-Star Algorithm for Robotic Path Planning. Sensors 2024, 24, 1422. [Google Scholar] [CrossRef] [PubMed]

- Martins, O.O.; Adekunle, A.A.; Olaniyan, O.M.; Bolaji, B.O. An Improved Multi-Objective a-Star Algorithm for Path Planning in a Large Workspace: Design, Implementation, and Evaluation. Sci. Afr. 2022, 15, e01068. [Google Scholar] [CrossRef]

- Wang, X.; Lu, J.; Ke, F.; Wang, X.; Wang, W. Research on AGV Task Path Planning Based on Improved A* Algorithm. Virtual Real. Intell. Hardw. 2023, 5, 249–265. [Google Scholar] [CrossRef]

- Brunton, S.L.; Nathan Kutz, J.; Manohar, K.; Aravkin, A.Y.; Morgansen, K.; Klemisch, J.; Goebel, N.; Buttrick, J.; Poskin, J.; Blom-Schieber, A.W.; et al. Data-Driven Aerospace Engineering: Reframing the Industry with Machine Learning. AIAA J. 2021, 59, 2820–2847. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, W.; Yu, R.; Zhang, Y. Motion Planning for Mobile Robots—Focusing on Deep Reinforcement Learning: A Systematic Review. IEEE Access 2021, 9, 69061–69081. [Google Scholar] [CrossRef]

- Zhu, Y.; Wan Hasan, W.Z.; Harun Ramli, H.R.; Norsahperi, N.M.H.; Mohd Kassim, M.S.; Yao, Y. Deep Reinforcement Learning of Mobile Robot Navigation in Dynamic Environment: A Review. Sensors 2025, 25, 3394. [Google Scholar] [CrossRef]

- Deng, Z.; Huang, X.; Li, S.; Xing, H. On-Line Calibration and Uncertainties Evaluation of Spherical Joint Positions on Large Aircraft Component for Zero-Clearance Posture Alignment. Robot. Comput.-Integr. Manuf. 2019, 56, 38–54. [Google Scholar] [CrossRef]

- Wu, D.; Du, F. A Multi-Constraints Based Pose Coordination Model for Large Volume Components Assembly. Chin. J. Aeronaut. 2020, 33, 1329–1337. [Google Scholar] [CrossRef]

| Station Name | Reference Position of Station | Measurement Tasks | ||

|---|---|---|---|---|

| X/mm | Y/mm | Z/mm | ||

| Station 1 | −422.352 | −1669.265 | 1371.717 | p3, p4, p7, p8, p15, p19, p20, p21, p22, p39 |

| Station 2 | 4060.940 | −85.044 | 1482.281 | p5, p9, p10, p11, p12, p13, p14, p16, p23, p24, p25, p26, p27, p28, p29, p34 |

| Station 3 | −633.645 | 3843.305 | 1319.160 | p1, p2, p6, p17, p18, p30, p31, p32, p33, p35, p36, p37, p38 |

| Point Name | X/mm | Y/mm | Z/mm |

|---|---|---|---|

| P5 | 699.000 | 1947.190 | 1555.386 |

| P9 | 694.081 | 362.078 | 1552.166 |

| P10 | 4060.566 | 2248.582 | 1357.038 |

| ⋮ | ⋮ | ⋮ | ⋮ |

| P28 | 2584.708 | 2388.403 | 38.779 |

| P29 | 2303.704 | 2270.357 | 37.910 |

| P34 | 923.443 | 2394.333 | −159.615 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Gao, C.; Sun, S.; Guan, X.; Shi, Y.; Liu, W.; Lu, Y. An Autonomous Mobile Measurement Method for Key Feature Points in Complex Aircraft Assembly Scenes. Machines 2025, 13, 892. https://doi.org/10.3390/machines13100892

Zhang Y, Gao C, Sun S, Guan X, Shi Y, Liu W, Lu Y. An Autonomous Mobile Measurement Method for Key Feature Points in Complex Aircraft Assembly Scenes. Machines. 2025; 13(10):892. https://doi.org/10.3390/machines13100892

Chicago/Turabian StyleZhang, Yang, Changyong Gao, Shouquan Sun, Xiao Guan, Yanjun Shi, Wei Liu, and Yongkang Lu. 2025. "An Autonomous Mobile Measurement Method for Key Feature Points in Complex Aircraft Assembly Scenes" Machines 13, no. 10: 892. https://doi.org/10.3390/machines13100892

APA StyleZhang, Y., Gao, C., Sun, S., Guan, X., Shi, Y., Liu, W., & Lu, Y. (2025). An Autonomous Mobile Measurement Method for Key Feature Points in Complex Aircraft Assembly Scenes. Machines, 13(10), 892. https://doi.org/10.3390/machines13100892