Abstract

This research aimed to examine shortcomings such as low efficiency and unstable coal release of 2313 large inclined-angle comprehensively released working faces in 230 mining areas of a mine in Shandong. Through the study of the actual working conditions of the large inclined-angle comprehensive release working face, it is concluded that the mining efficiency of the large inclined-angle coal seam is mainly related to the sequence of coal release, the step distance of the coal release, the distance between the end faces, the mining height, the working resistance of the hydraulic bracket and other factors. Taking ZF5600/16.5/26 hydraulic support as an example, simulation software was used to study the influencing factors of coal release efficiency, and the most efficient coal release method was found through the control variable method, so as to improve the mining recovery efficiency of the overall working face of the large inclined-angle coal seam, and after optimizing the working conditions of the hydraulic support, the top coal recovery efficiency was increased by 14.3% compared with the previous one after the actual statistics of the field situation.

1. Introduction

In recent years, many scholars have studied the coal release characteristics of hydraulic support in the process of integrated mining.

Through numerical simulation of the comprehensive mining process, Vakili and N E [1] classified the coal release characteristics using multi factor statistical methods. N. E. and B U [2] conducted numerical simulations on the role of supports in the process of top coal release, and it was found that the thickness of the top coal is one of the key factors affecting the characteristics of coal release. Wei Weijie and Wang Jiachen [3] used the PFC2D system to study the relationship between the hydraulic support structure of top coal and the efficiency of top coal release. They systematically investigated the effects of the inclination angle α of the shield beam, the length ratio RL of the shield beam to the tail beam, and the rotation angle β of the tail beam on the top coal release rate, release body, and top coal boundary. They found that the inclination angle of the shield beam and the rotation angle of the tail beam have a significant impact on the efficiency of top coal release, and the ideal inclination angle of the shield beam should be 55°. Jing Yi Cheng, Yi Dong Zhang et al. [4] studied the load and operating characteristics of hydraulic supports and found that the resistance of the supports is generally higher when the working face propulsion speed is slow. They proposed techniques to control the stability of hydraulic supports, such as appropriately increasing the propulsion speed, controlling the mining height, and increasing the support resistance. Wang Shuai, Zhang Chunhua, and others [5] used the top coal mining method to study the motion relationship between the top coal and the roof. They established a numerical model of the top coal movement and coal rock interface development in longwall top coal mining faces using PFC2D, and found that reasonable coal mining timing and step spacing are crucial for achieving high recovery rates.

The stress and migration laws of coal and rock masses in steeply inclined coal seams are complex, and they are considered difficult to mine [6,7,8,9]. As the core equipment of the fully mechanized mining face, hydraulic supports are affected by the inclination angle of the working face in the application of large angle coal seams, resulting in low efficiency and poor stability of the coal drawing equipment [10,11,12]. Large-angle thick coal seam caving mining is an efficient coal mining method that improves the efficiency of coal seam mining while reducing the amount of roadway excavation, greatly reducing the mining cost of high-angle coal seams. In the process of using the top coal caving mining method in steeply inclined coal seams, improving the efficiency of hydraulic support for coal extraction has always been a research direction in the mining of steeply inclined coal seams. Research has shown that the mining efficiency of steeply inclined coal seams is mainly related to factors such as coal wall stability, coal discharge sequence, coal discharge step distance, end face distance, hydraulic support working resistance, and mining height [13,14]. In order to achieve more efficient mining and improve the coal mining efficiency of the working face, simulation software is used to study the influencing factors of coal mining efficiency [15,16], analyze and summarize the impact and laws of each factor on coal mining efficiency, and find the most effective coal mining method by summarizing and analyzing the research results, in order to improve the overall mining and extraction rate of large-angle coal seams [17,18,19,20].

This paper takes the ZF5600/16.5/26 (Shandong Yankuang Group) low-level-roof coal discharge hydraulic support as an example, improves the coal discharge efficiency of the hydraulic support as the research goal, and adopts a method combining simulation and field experiment to study the coal discharge characteristics of a large inclined-angle comprehensive coal discharge working face.

2. Influence of Different Factors on the Coal Release Characteristics of a Large Inclined Working Face

There are many factors affecting the coal-releasing efficiency of hydraulic support, and the coal-releasing sequence of the working face, the coal-releasing step distance, end face distance, the working resistance of hydraulic support and the mining height will all affect the coal-releasing efficiency of the hydraulic support. In order to achieve more efficient mining of coal seams in a large inclined-angle working face and to improve the coal-releasing efficiency of hydraulic support, simulation software is used to study the influencing factors of coal-releasing efficiency and to analyze and summarize the influence of each factor on the mining efficiency of coal seams, as well as the role of the law. By summarizing and analyzing the results of the study, the most efficient method for coal release is found, and the optimal coal release process parameters of the large inclined-angle working face under study are determined, so as to improve the mining and recovery efficiency of the large inclined-angle coal seam working face as a whole.

2.1. Influence of the Sequence of Coal Release at the Working Face on the Effect of Coal Release

2.1.1. Simulation Analysis of Upward Coal Release on the Large Inclined-Angle Complex Working Face

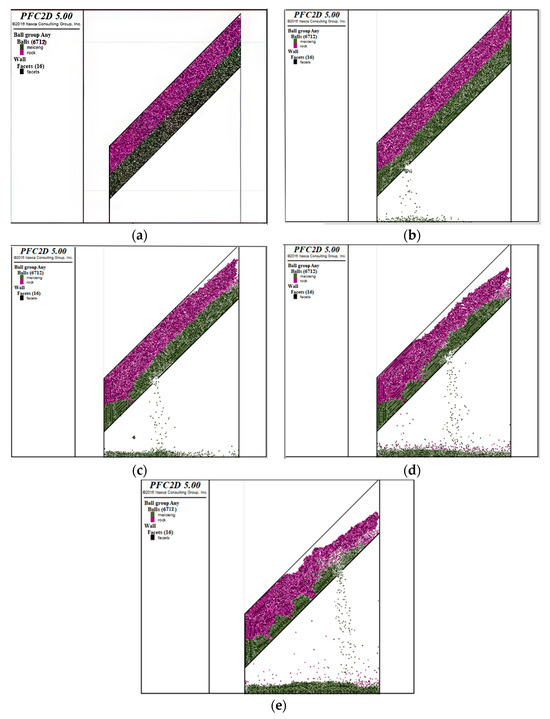

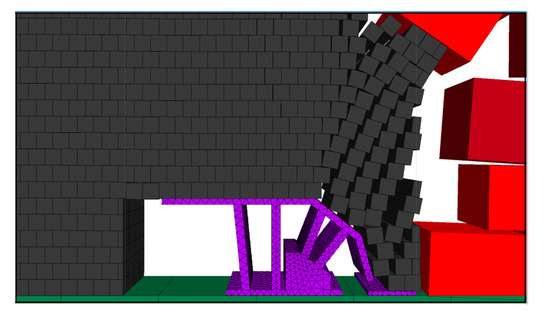

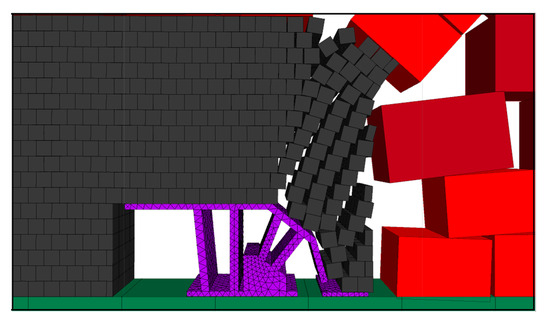

In order to ensure the accuracy and persuasiveness of the experiment, a wall model of the large inclination working face with an inclination angle of 45° was constructed in PFC2D (version 5.0) software and the contact intrinsic model was set up; the simulation results of the upward coal release are shown in Figure 1.

Figure 1.

Simulation of upward coal release on the large inclined working face. (a) Coal preparation. (b) Upstream coal discharge opening 1. (c) Upstream coal discharge opening 2. (d) Upstream coal discharge opening 3. (e) Upstream coal discharge opening 4.

Upon examination of the figure, it is evident that the FISH function has been utilized to statistically determine the top coal discharge rate and the gangue content within the coal body. Calculations reveal that when employing the upward coal release method in the large inclined-angle comprehensive discharge working face, the top coal release rate achieves a notable 84.7%, while the gangue content rate within the coal body is a relatively low 2.38%. Observing the pattern of gangue accumulation illustrated in Figure 1, it becomes apparent that the upward coal release method results in a more thorough fragmentation of the top coal in the upper regions of the working face, leading to an increased rate of top coal release. However, this method also predisposes the operation to the risk of top coal leakage and compromises the stability of the overlying strata.

2.1.2. Simulation Analysis of Downward Coal Release from Large Inclined Workings

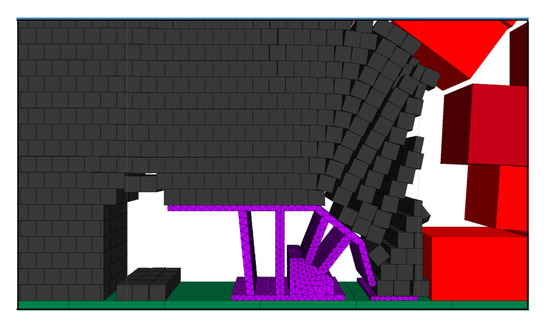

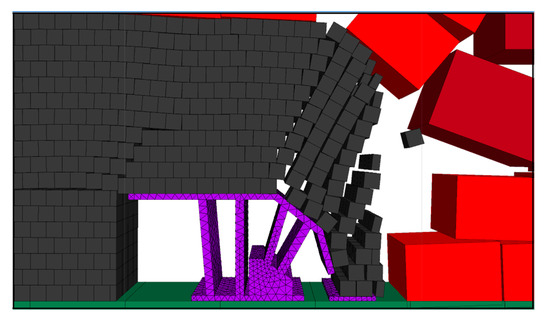

The order of opening at the bottom edge of WALL was changed to simulate and analyze the downward coal release from a large inclined working face.

Utilizing the FISH function for calculation, it was determined that when the large inclination-angle comprehensive discharge working face employs the downward coal discharge method, the top coal discharge rate reaches 80.5%, while the gangue content rate within the coal body is 3.25%. As depicted in Figure 2, the pattern of gangue accumulation indicates that when the downward coal discharge method is used, there is a preference for discharging the top coal from the working face. This means that the gangue, situated in the upper part of the working face, tends to move downward during the coal discharge process. The downward movement of the gangue not only impedes the subsequent discharge of the top coal but also contributes to an increased rate of gangue content within the coal body. However, it is important to note that the downward coal release method enhances the overall stability of the overlying coal rock across the working face.

Figure 2.

Simulation of downward coal release from large inclination working face. (a) Coal preparation. (b) Downward coal discharge method opening 1. (c) Downward coal discharge method opening 2. (d) Downward coal discharge method opening 3. (e) Downward coal discharge method opening 4.

The following can be seen from the above analysis:

- (1)

- In terms of both the quantity and quality of coal released, the upward coal release method achieves a top-coal release rate of 84.7%, with a coal body gangue content rate of 2.38%. In contrast, the downward coal release method yields a top-coal release rate of 80.5% and a coal body gangue content rate of 3.25%. This comparison reveals that the upward coal release method surpasses the downward method by 4.2% in terms of top-coal release rate, while also demonstrating a 0.87% reduction in the coal body gangue content rate.

- (2)

- Analyzing the movement of coal and rock bodies during the coal releasing process, it is observed that the upward coal releasing method is prone to causing top coal leakage, which consequently results in compromised stability of the overlying rock strata. Conversely, the downward coal release method significantly enhances the overall stability of the overlying coal rock across the entire working face.

2.2. Influence of Different Coal Releasing Steps on the Effect of Coal Releasing

Based on the specific physical parameters of coal rock shown in Table 1, a simulation model was established to simulate the effect of different coal release step distances on coal release efficiency. Rhino and 3DEC were used for joint simulation. Simulation analysis and research were conducted on the coal release efficiency of hydraulic supports under three different coal release step distances: one mining and one release (0.6 m), two mining and one release (1.2 m), and three mining and one release (1.8 m). Among them, for a step distance of 0.6 m, a smaller step distance can more evenly release the stress of the coal seam, which is usually used for thinner coal seams or situations that require fine operation. For a step spacing of 1.2 m, this is a common medium step spacing, suitable for most coal seams. It strikes a balance between efficiency and stability. For a step distance of 1.8 m, a larger step distance is suitable for thicker coal seams or high-yield operating environments. Although it can improve production efficiency, it may increase the pressure and maintenance costs of the bracket, and it is necessary to ensure that the support system can withstand this step distance.

Table 1.

Physical and mechanical parameters of the coal seam.

2.2.1. Experimental Model Establishment

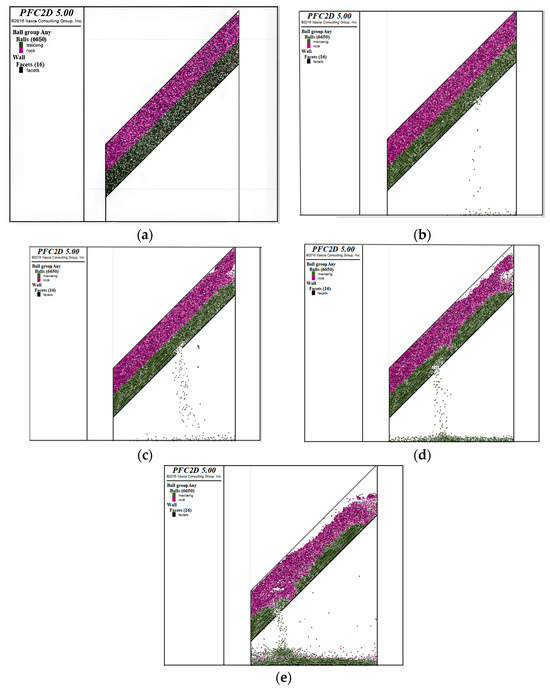

Rhino was used to establish the equal scale ZF5600/16.5/26 low-level-roof coal hydraulic support and a scraper conveyor three-dimensional model and it was then imported into 3DEC as shown in Figure 3, below.

Figure 3.

Model of hydraulic support and scraper conveyor.

In 3DEC (version 7.0) software, using command flow, a numerical model of the working face is established based on the physical and mechanical parameters of the coal and rock layers obtained from research, and according to the position and distribution of the rock layers in the model. Based on the physical and mechanical properties of each coal rock mass in the actual working face obtained from the research, values can be assigned to the physical parameters of the coal rock mass according to the position and distribution of the rock mass in the model. Model boundary conditions and gravity acceleration can be set and equivalent stress applied above the model to simulate burial depth. After calculating the excavation range, the hydraulic support model can be imported to achieve coupling between the hydraulic support and the coal rock mass. The coupling model between hydraulic support and coal rock mass is shown in Figure 4. By modifying the code to change the model structure, the coal discharge efficiency of hydraulic supports can be analyzed and studied under different coal discharge step distances.

Figure 4.

Coupling model between hydraulic support and coal rock mass.

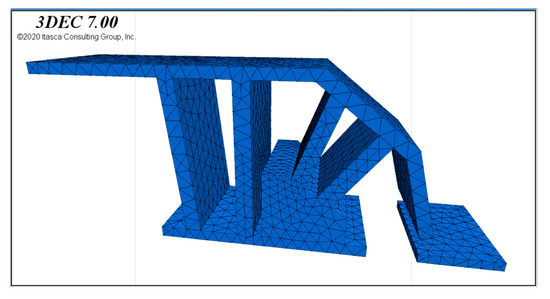

2.2.2. Simulation Analysis of Coal Release Effect of One Mining and One Release

Keeping the distance between the end faces, mining height, and working resistance constant, the coal discharge efficiency of hydraulic supports under different end face distances is studied by controlling the hanging distance of the top coal. The coal discharge effect of the hydraulic support is shown in Figure 5.

Figure 5.

Hydraulic support for the one mining and one coal release effect.

As illustrated in Figure 4, the limited overhang of the top coal results in a slower collapse rate of the coal body under the influence of gravity, cohesion and friction. When the coal release step distance is set at 0.6 m, the length of the hydraulic support’s cover beam plays a significant role. Most of the top coal accumulates on top of the cover beam, with only a minor fraction of the fragmented coal body falling onto the scraper conveyor. This leads to a reduced top-coal recovery rate and a slower coal release process.

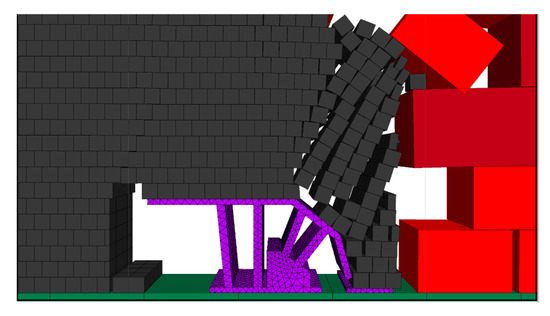

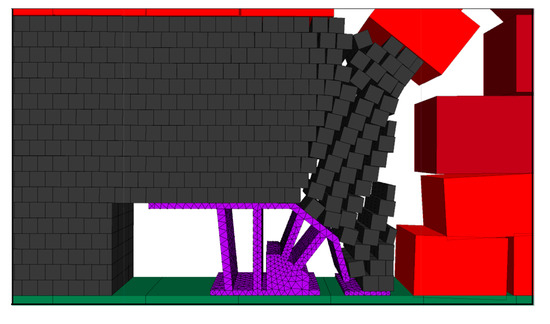

2.2.3. Simulation Analysis of the Coal Release Effect of Two Mining and One Release

The top coal suspension distance was expanded, and the effect of coal release with hydraulic support when the step distance of the coal release is 1.2 m was simulated. The effect of two mining and one coal release of hydraulic support is shown in Figure 6.

Figure 6.

Hydraulic support for two mining and one coal release effect.

By implementing the two mining and one releasing approach, there is a notable increase in the top coal suspension break, which in turn elevates the coal releasing rate compared to the one mining and one releasing method. This technique results in the majority of the top coal, which collapses under the influence of gravity, being concentrated directly above the scraper conveyor. Consequently, this method achieves a higher top-coal recovery rate, signifying its effectiveness in improving the efficiency of the coal extraction process.

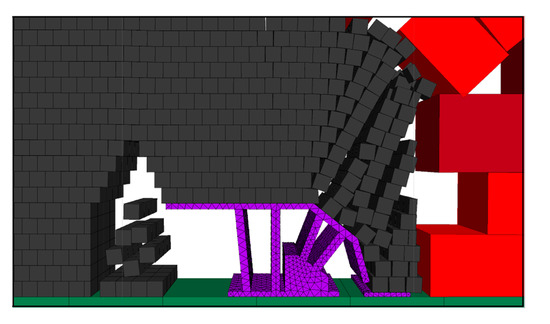

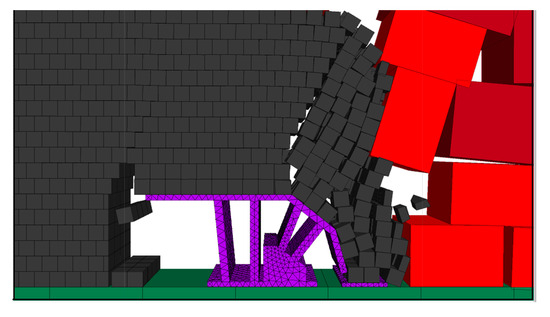

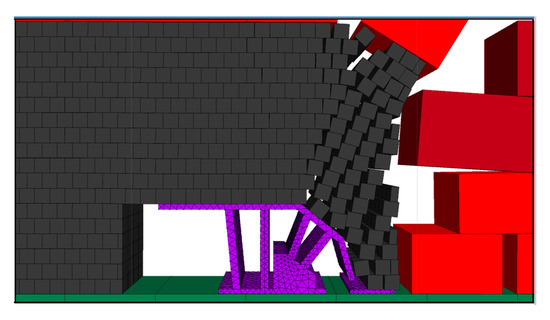

2.2.4. Simulation Analysis of the Effect of Three Mining and One Discharging Coal

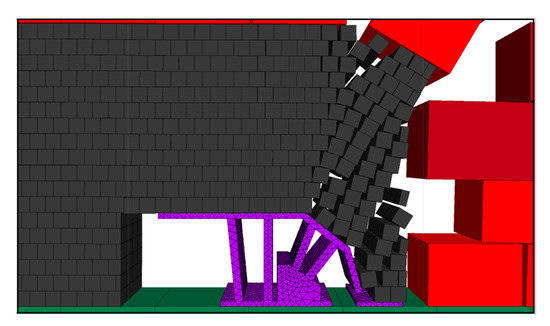

The effect of three mining and one coal release with hydraulic support is shown in Figure 7.

Figure 7.

Hydraulic support for three mining and one release coal release effect.

Utilizing the three mining and one releasing method accelerates the collapse of the coal body due to the increased overhang of the top coal. This larger overhang results in the top coal sliding down along the hydraulic support cover beam as it falls. However, the extended release step distance causes a significant portion of the dislodged top coal to fall behind the scraper conveyor. This coal cannot be effectively transported out of the working face, leading to a diminished top coal recovery rate and, ultimately, a waste of valuable resources.

In conclusion, when evaluating the three distinct coal releasing steps for the ZF5600/16.5/26 large inclination hydraulic support, the two mining and one releasing method proves to be the most effective. Specifically, with a coal releasing step of 1.2 m, this approach achieves the highest top-coal recovery rate and the quickest coal releasing rate across the working face. Thus, the adoption of the two mining and one releasing method is deemed the most rational and efficient strategy for coal extraction in this context.

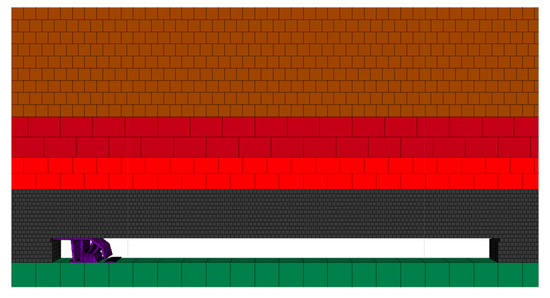

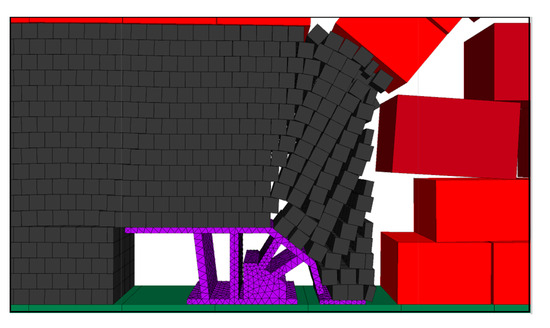

2.3. Influence of Different Release End-Face Distances on the Effect of Coal Release

In order to maintain the stability of the top plate of the hydraulic support working face, the coal mining step distance, mining height, and working resistance remained unchanged, and four different end-face distances of 0.25 m, 0.75 m, 1.25 m, and 1.5 m were taken to study the influence of different end-face distances on the stability of the roof during the coal discharge process of hydraulic supports, as shown in Figure 8, Figure 9, Figure 10 and Figure 11.

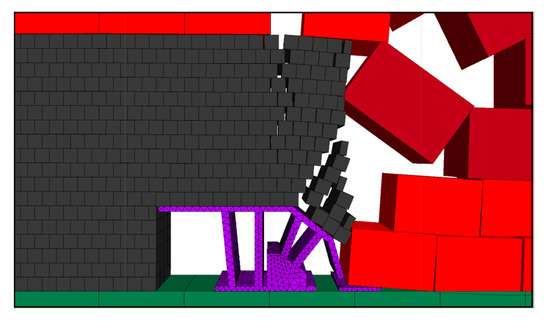

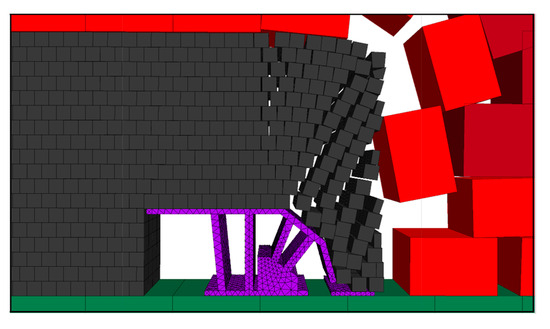

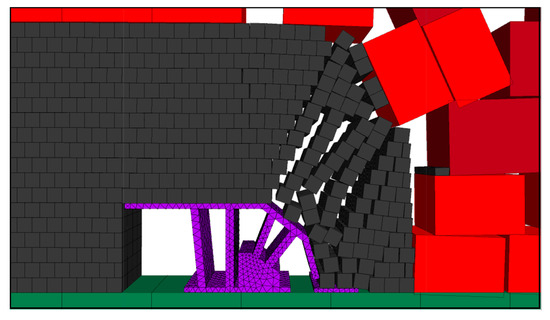

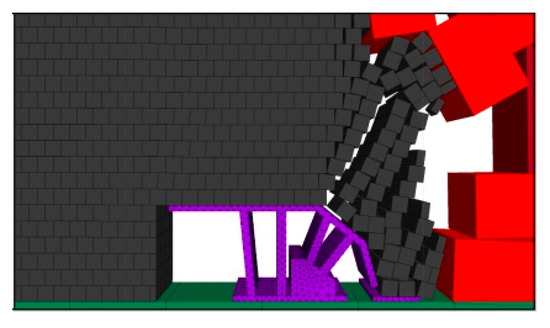

Figure 8.

Top plate condition at 0.25 m end-face distance.

Figure 9.

Top plate condition at 0.75 m end-face distance.

Figure 10.

Top plate condition at 1.25 m end-face distance.

Figure 11.

Top plate condition at 1.5 m end-face distance.

As illustrated in Figure 8, Figure 9, Figure 10 and Figure 11, when the end face distance is maintained below 0.75 m, the top coal situated in front of the hydraulic support roof beam benefits from the effects of friction and cohesion. This results in enhanced stability under the hydraulic support, effectively preventing any top coal from falling at the end face position. Consequently, the overall stability of the working face is significantly strengthened. It is observed that a smaller end-face distance correlates with improved top coal stability and a reduced likelihood of falling incidents, thereby reinforcing the stability of the working environment.

At a face distance of 1.25 m, there is an observable increase in the roof overhang range. This expansion leads to the coal body collapsing downward, primarily due to gravitational forces, which in turn triggers the occurrence of top coal falling at the face. As the distance between the end faces continues to increase, both the height and the extent of the fallen material at the face also progressively increase.

When the face distance extends to 1.5 m, the severity of the falling phenomenon escalates. The falling height can reach up to 5.6 m, significantly compromising the stability of the roof plate. Under these conditions, the face becomes uncontrollable, posing potential risks to the mining operation.

In summary, through comparative analysis, the stability of the roof plate in the process of coal release under different end face distance can be obtained. When the end face distance is less than 0.75 m, the hydraulic support of the large inclination comprehensive release working face does not experience the top-coal falling phenomenon in the process of coal release, and the stability of the working face is stronger. Therefore, in the process of coal release, the end face distance should be controlled within 0.75 m.

2.4. Influence of Different Mining Heights on the Effect of Coal Release

Based on the characteristics of the ZF5600/16.5/26 large inclination hydraulic support, the coal discharge efficiency of the hydraulic support was studied at three different mining heights of 1.9 m, 2.3 m, and 2.6 m, while keeping the coal mining step distance, end face distance, and working resistance constant. In order to better compare and analyze the coal release effect of hydraulic supports at different mining heights, the model’s operating steps at three mining heights were controlled at 100,000 steps. The coal release effects at different mining heights are shown in Figure 12, Figure 13 and Figure 14.

Figure 12.

The effect of hydraulic support coal release when the mining height is 1.9 m.

Figure 13.

The effect of hydraulic support coal release when the mining height is 2.3 m.

Figure 14.

The effect of hydraulic support coal release when the mining height is 2.6 m.

Figure 12, Figure 13 and Figure 14 show a comparative analysis of the coal release characteristics of hydraulic support under different mining heights. From the effect of coal rock body collapse under different mining heights in the figure, it can be seen that with the increase in mining height, the thickness of the top coal of the hydraulic support decreases, and the stability of the overlying coal rock layer decreases, so the higher the mining height, the faster the collapse rate of the overlying coal rock body of the hydraulic support. From the perspective of coal release effect, the lower the mining height, the smaller the falling distance of the top coal, and the collapsed coal body is more likely to fall above the scraper conveyor, which leads to a higher recovery rate of the coal body. Considering the high stability requirements of hydraulic support for a large inclination comprehensive discharge work face, the mining height is too big to cause the center of gravity of hydraulic support to move up, reducing the stability of hydraulic support, so the mining height of the work face should not be too big. By comprehensively analyzing the coal release efficiency of the hydraulic support and the recovery rate of the top coal, when the mining height is set at 2.3 m, the working face can show a better comprehensive performance.

2.5. Simulation of the Effect of Different Working Resistances on the Effect of Coal Release

In the actual production operation of the comprehensive workface, the reasonableness of the hydraulic support working resistance will directly determine the stability of the roof-covering rock, which in turn determines the support effect of the whole workface.

Keeping the coal mining step distance, end face distance, and mining height unchanged, the situation of the roof is shown in Figure 15 and Figure 16 when the working resistance is 3000 kN and 3300 kN.

Figure 15.

Top plate condition at a working resistance of 3000 kN.

Figure 16.

Top plate condition at a working resistance of 3300 kN.

It can be seen from Figure 15 and Figure 16, above, that when the hydraulic support working resistance is 3000 kN, the top plate sinking amount is 21.3 cm, the top coal of the working face falls seriously, and the stability of the working face is poor. When the working resistance is increased to 3300 kN, the roof sinking amount is 15.4 cm, compared with the working resistance of 3000 kN, where the roof sinking amount is reduced, the end face falling condition is eased, and the stability of the roof plate is improved with the increase in working resistance. However, the overall view of the working resistance of 3300 kN hydraulic support still cannot produce a good support effect, and the whole comprehensive release working-face roof stability is poor.

We increased the working resistance to study the stability of the working face roof. As shown in Figure 17, when the working resistance is increased to 3600 kN, the roof sinking amount is reduced to 9.3 cm, and there is no top coal falling phenomenon at the end of the working face, so the hydraulic support can have a good supporting effect on the roof. Continuing to expand the working resistance, Figure 18 shows that when the working resistance is increased to 3900 kN, the roof sinking amount is 8.75 cm; compared with the working resistance of 3600 kN, the change is not big. When the working resistance is increased to 4200 kN, as shown in Figure 19, there is still 8.51 cm of subsidence under the top plate, and the end face of the working surface has good stability.

Figure 17.

Top plate condition at a working resistance of 3600 kN.

Figure 18.

Top plate condition at a working resistance of 3900 kN.

Figure 19.

Top plate condition at a working resistance of 4200 kN.

To sum up, by analyzing the support effect of hydraulic support on the roof of the working face under different working resistances, it can be concluded that the larger the working resistance, the better the support effect of hydraulic support on the roof of the working face. When the working resistance is less than 3600 kN, the stability of the working face roof is poor, the phenomenon of top coal falling from the end of the working face occurs, and the roof sinking amount is large; the roof sinking amount is 21.3 cm when the working resistance is 3000 kN, and the roof sinking amount is 15.4 cm when the working resistance is 3300 kN. When the working resistance is increased to 3600 kN, the stability of the roof of the working face is greatly improved. At this time, the phenomenon of top coal falling from the end face disappears, and the roof sinking amount is only 9.3 cm, which can be maintained at a low level. After increasing the working resistance to 3900 kN and 4200 kN, through the comparative analysis, it can be seen that when the working resistance reaches 3600 kN and continue to increase, the stability of the working face top plate does not change obviously, the top plate sinking amount is maintained at about 8.75 cm, and there is no top-coal-falling phenomenon on the end face. Therefore, the hydraulic support working resistance should be greater than 3600 kN.

3. Optimization of the Working Conditions of Hydraulic Supports

Through the above research on the coal-releasing characteristics of ZF5600/16.5/26 hydraulic support under different working conditions, the stability and coal releasing efficiency of the hydraulic support in actual work can be improved by optimizing and improving the hydraulic support and its working conditions, through the following methods:

- ① Adopting the segmental coal releasing method for top coal recovery mining;

- ② Selecting the coal releasing step distance of hydraulic support as 1.2 m;

- ③ Making the distance between ends less than 0.75 m;

- ④ Setting the mining height of hydraulic support to 2.3 m;

- ⑤ Making the working resistance of hydraulic support more than 3600 kN.

4. Field Experiment

The experimental site was selected as the 230 mining area of a mine in Shandong, and the experimental working face was a 2313 working face, located in the western part of the mining area; the average inclination angle of the coal seam is 45°. According to the above research content, the hydraulic support adopts the two mining and one coal release method, the step distance of coal release is 1.2 m, the distance between the control hydraulic support and the end face of the working face is less than 0.75 m, the mining height of the hydraulic support is set at 2.3 m, and the working resistance of the hydraulic support is more than 3600 kN. The working face adopts the segmented coal release method, and the coal release starts when the working face advances for 10 m, and the process of coal release first adopts the upward movement when the length of coal release reaches the working face. When the length of coal release reaches 2/3 of the working face, the remaining part adopts the downward coal release method, starting from the upper end of the working face, and the transition brackets located at both ends are not involved in coal release. The underground operation of hydraulic support is shown in Figure 20.

Figure 20.

Hydraulic bracket underground site map.

A 3-month tracking and research process was conducted on the actual operation of the improved ZF5600/16.5/26 hydraulic support. By comparing the coal discharge amount with the three months before optimization, the coal discharge amount was calculated and is shown in Table 2. Feedback from the work shows that the mining operation on the working face was stable, and there was no occurrence of hydraulic support tilting or sliding during the mining process. The phenomenon of top-coal caving on the end face of the hydraulic support on the working face was greatly reduced, and the overall efficiency of top coal recovery increased by 14.3% compared to before.

Table 2.

Comparison of coal discharge in March before and after optimization.

5. Conclusions

This article studies the factors affecting the coal discharge efficiency of hydraulic supports in large-angle fully mechanized mining faces. Using 3DEC to study the influence of factors such as coal discharge step distance, end face distance and mining height on the coal discharge efficiency of hydraulic supports in actual coal discharge processes, the following conclusions have been drawn through analysis and practical application on site:

- (1)

- By using the control variable method for research and analysis, it was found that hydraulic supports have a higher top coal mining recovery rate and the best overall stability of the working face when the coal release step distance is 1.2 m, the end face distance is less than 0.75 m, the working resistance is 3600 kN, and the mining height is set to 2.3 m. Finally, based on the research content, the working conditions of the hydraulic support were optimized and improved to enhance the coal discharge efficiency of the hydraulic support.

- (2)

- An innovative segmented coal discharge method is proposed, which greatly enhances the stability of the working face while improving the efficiency of coal discharge. The improved ZF5600/16.5/26 hydraulic support, which combines simulation analysis with practical application, has good stability and support effect in the actual application process, and can better meet the support requirements of the 2313 working face.

Author Contributions

Conceptualization and methodology, L.C.; writing—original draft preparation, M.G.; investigation, R.S.; data curation, D.Z.; resources, X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vakili, A.; Hebblewhite, B.K. A new cavability assessment criterion for longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 1317–1329. [Google Scholar] [CrossRef]

- Yasitli, N.E.; Unver, B. 3D numerical modeling of longwall mining with top-coal caving. Int. J. Rock Mech. Min. Sci. 2005, 42, 219–235. [Google Scholar] [CrossRef]

- Wei, W.; Wang, J.; Zhang, J.; Wu, S.; Li, Z.; Zhang, X. Drawing mechanisms of granular top coal considering the strcture of hydraulic support in longwall top coal caving. Bull. Eng. Geol. Environ. 2023, 82, 138. [Google Scholar] [CrossRef]

- Cheng, J.-Y.; Zhang, Y.-D.; Cheng, L.; Ji, M.; Gu, W.; Gao, L.-S. Study of Loading and Running Characteristic of Hydraulic Support in Underhand Mining Face. Arch. Min. Sci. 2017, 62, 215–224. [Google Scholar] [CrossRef][Green Version]

- Wang, S.; Zhang, C.; He, F.; Yang, Y. Numerical modelling of loose top coal and roof mass movement for a re-mined seam using the top coal caving method. PLoS ONE 2023, 18, e0283883. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Cao, A.; Wang, C.; Shen, W.; Liu, Y.; Yang, Y.; Guo, W.; Bai, X. Mechanism of rock bursts in a large inclined extra-thick coal seam under the condition of upper slice mining: A case study. Geomat. Nat. Hazards Risk 2023, 14, 2184672. [Google Scholar] [CrossRef]

- Xue, C.; Cao, A.; Guo, W.; Liu, Y.; Wang, S.; Dong, J.; Gu, Y. Mechanism and Energy Evolution Characteristics of Coal Burst in Mining Thick, Deep, and Large Inclined Coal Seams: A Case Study from a Chinese Coal Mine. Geofluids 2022, 2022, 7704226. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Jiao, J.; Cao, P. Stability Mechanism and Control Technology for Fully Mechanized Caving Mining of Steeply Inclined Extra-Thick Seams with Variable Angles. Min. Metall. Explor. 2021, 38, 1047–1057. [Google Scholar]

- Fang, F.; Shu, C.; Wang, H. Physical simulation of upper protective coal layer mining with different coal seam inclinations. Energy Sci. Eng. 2020, 8, 3103–3116. [Google Scholar] [CrossRef]

- Lu, D.; Shao, Y. Application of Automatic Pulling Frame and Gangue Blocking Control System for Large Tilt Angle Working Face. Coal Min. Mach. 2024, 45, 132–135. [Google Scholar]

- Wang, C. Development of a hydraulic support with side protection device suitable for mining large angle thin coal seams. Min. Equip. 2024, 7, 150–152. [Google Scholar]

- Feng, K.; Du, Y.; Wu, Y.; Xie, P.; Hu, T. Analysis of Load Behavior and Failure Characteristics of Hydraulic Support Jack for Large Tilt Coal Seam. Coal Eng. 2024, 56, 212–218. [Google Scholar]

- Ji, Y.; Zhang, Y.; Huang, Z.; Shao, Z.; Gao, Y. Theoretical analysis of support stability in large dip angle coal seam mined with fully-mechanized top coal caving. Min. Sci. 2020, 27, 73–87. [Google Scholar]

- Ye, Q.; Wang, G.; Jia, Z.; Zheng, C.; Wang, W. Similarity simulation of mining-crack-evolution characteristics of overburden strata in deep coal mining with large dip. J. Pet. Sci. Eng. 2018, 165, 477–487. [Google Scholar] [CrossRef]

- Zhang, J. Research on the setting of coal release spacing in long-wall integrated coal removal process for thick coal seams. Shanxi Chem. Ind. 2024, 44, 207–209. [Google Scholar]

- Xi, Y. Analysis of the influence of different mining heights and coal release spacing in mining thick coal seams with large inclination angle. Shanxi Chem. Ind. 2024, 44, 171–173. [Google Scholar]

- Wang, J. Selection of various methods of coal release in working face of thick coal seam. Autom. Appl. 2024, 65, 10–11. [Google Scholar]

- Yin, J.; Xu, W.; Geng, Y. Numerical simulation of coal release mechanism based on PFC. Shaanxi Coal 2024, 43, 6–11. [Google Scholar]

- Wang, Q. Optimisation of mining height and coal release step spacing. Shanxi Chem. Ind. 2023, 43, 165–166, 169. [Google Scholar]

- Wu, H. Analysis of key technologies for comprehensive mechanized mining of steeply inclined coal seams. Min. Equip. 2023, 10, 32–33. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).