Towards a Framework for the Industrial Recommissioning of Residual Energy (IRRE): How to Systematically Evaluate and Reclaim Waste Energy in Manufacturing

Abstract

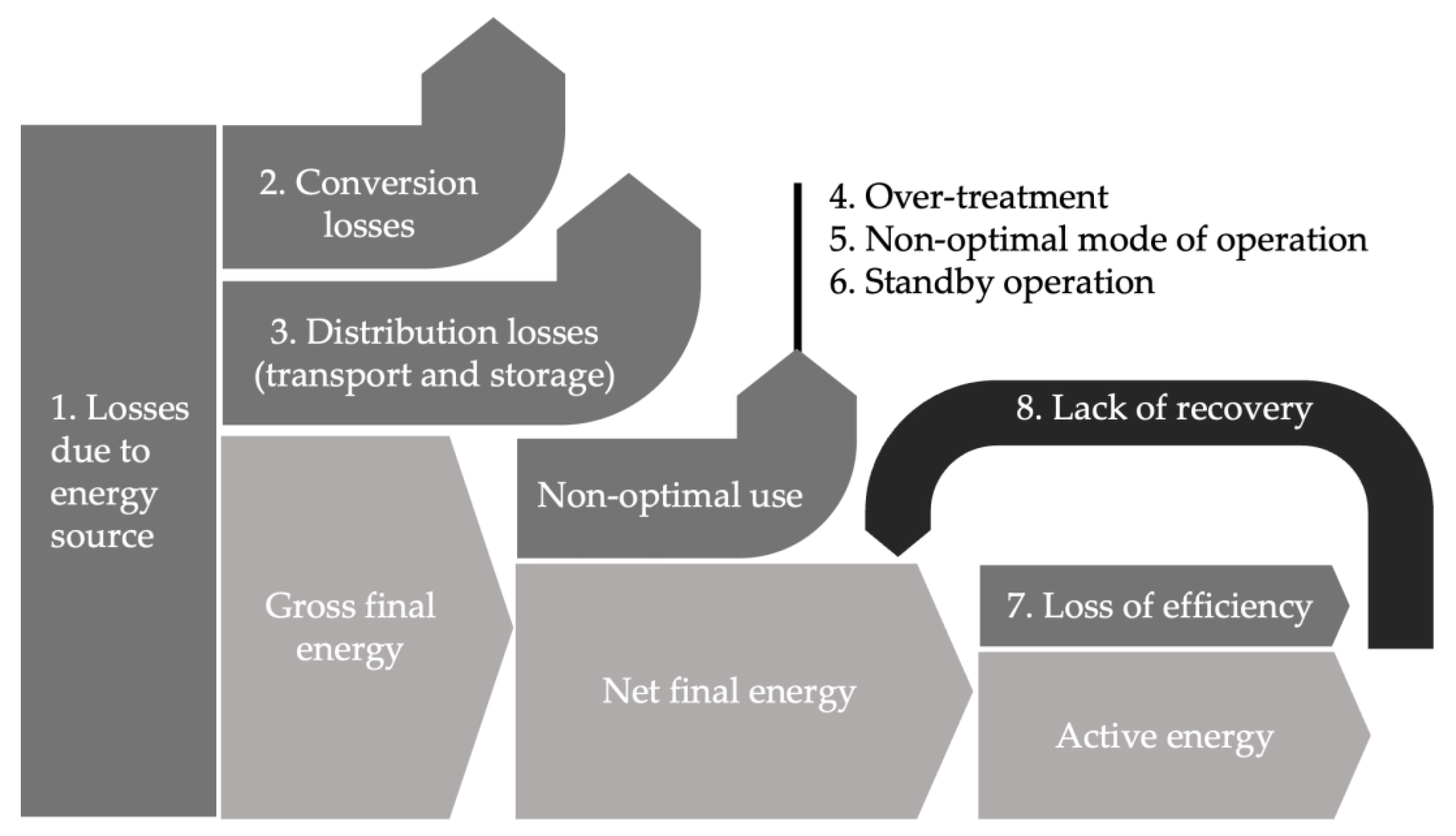

1. Introduction

2. Methods

2.1. Adapted PRISMA Approach for a Systematic Literature Review

2.2. Applied Design Science Research for the Development of a Structured Framework for the Industrial Recommissioning of Residual Energy (IRRE)

3. The Energy Conversion Overview (ECO) Table

| From/to ↱ | Chemical (C) | Thermal (T) | Mechanical (M) | Electrical (E) |

|---|---|---|---|---|

| Chemical (C) | Not applicable | Combustion reaction | Internal combustion engine | Fuel cell |

| Efficiency: | 51% to 99% 3 | 11% to 37% 8 | 70% to 100% 11 | |

| Thermal (T) | Endothermic process | Heat exchanger | Not applicable | Thermoelectric cooling |

| Efficiency: | 19% to 90% 1 | 15% up to 95% 4 | 25% to 90% 12 | |

| Mechanical (M) | Not applicable | Friction | Gears | Generator |

| Efficiency: | 35% to 45% 5 | 81% to 99% 9 | 60% to 92% 13 | |

| Electrical (E) | Electrolysis | Resistance heating | Electric motor | Electric transformer |

| Efficiency: | 60% to 95% 2 | 98.5% to 100% 6 | 70% to 96% 10 | 96% to 99.75% 14 |

| Electro- magnetic (EM) | Not applicable | Solar absorption | Not applicable | Photovoltaic cells |

| Efficiency: | 50% to 96% 7 | 20% to 49% 15 |

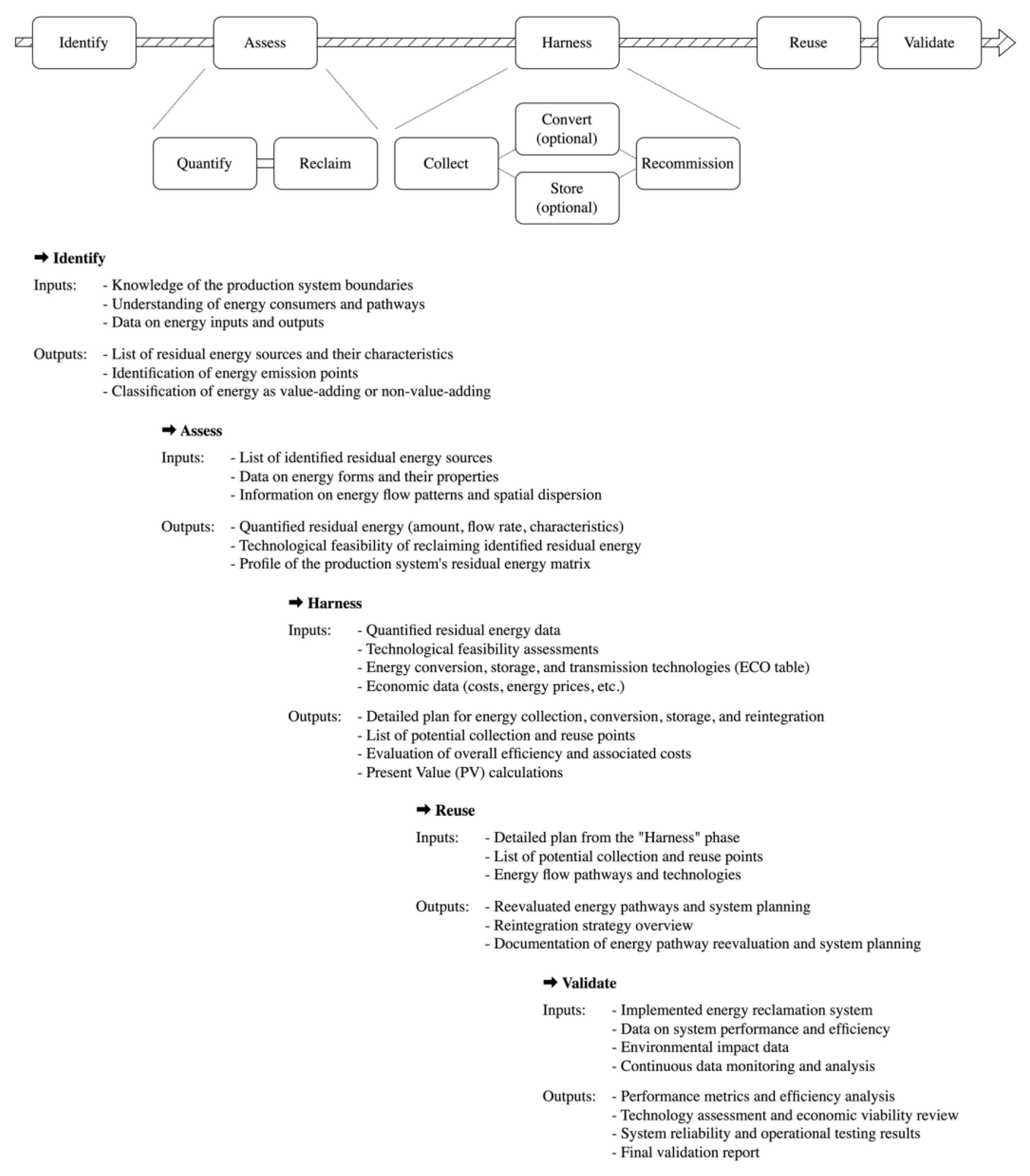

4. The Framework for the Industrial Recommissioning of Residual Energy (IRRE)

4.1. Identify

4.2. Assess

4.3. Harness

4.4. Reuse

4.5. Validate

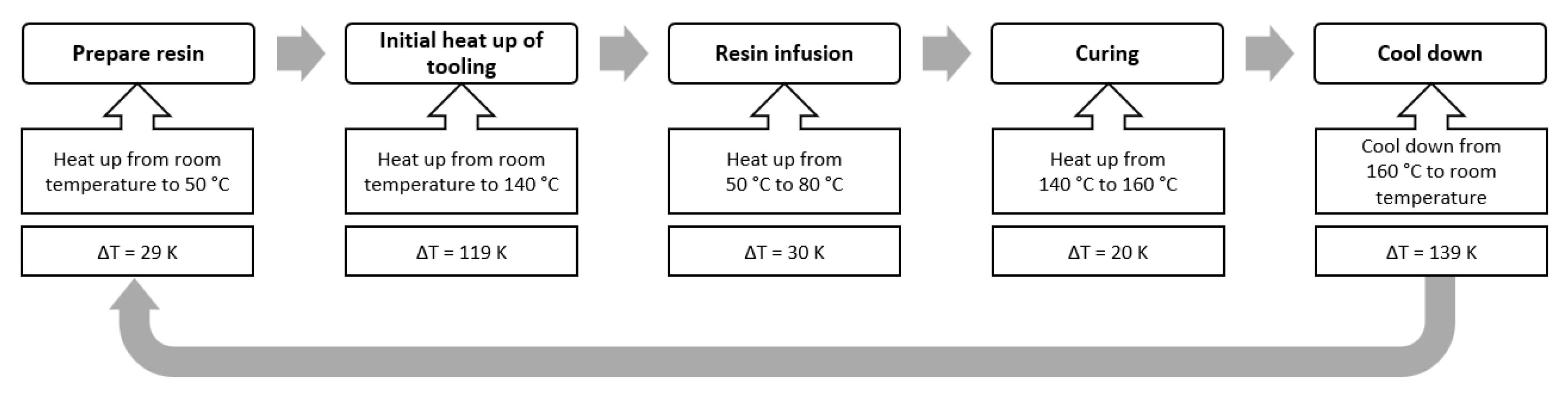

5. Application of the IRRE Framework in Large-Aircraft Carbon Fiber Manufacturing

5.1. Identify

5.2. Assess

5.2.1. Quantify

5.2.2. Reclaim

5.3. Harness

5.3.1. Collect

5.3.2. Recommission

5.4. Reuse

5.5. Validate

6. Discussion

7. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sangwan, K.S.; Kumar, R.; Herrmann, C.; Poonia, V.; Kulshrestha, R. Modelling and Simultaneous Optimization of Environmental, Economic, and Technological Factors in Machining. Int. J. Interact. Des. Manuf. 2023, 18, 859–877. [Google Scholar] [CrossRef]

- Erlach, K.; Westkämper, E.; Fraunhofer-Institut für Produktionstechnik und Automatisierung (Eds.) Energiewertstrom: Der Weg zur Energieeffizienten Fabrik; Fraunhofer Verl: Stuttgart, Germany, 2009; ISBN 978-3-8396-0010-8. [Google Scholar]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A Review on Energy Saving Strategies in Industrial Sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Herrmann, C.; Thiede, S. Process Chain Simulation to Foster Energy Efficiency in Manufacturing. CIRP J. Manuf. Sci. Technol. 2009, 1, 221–229. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards Energy and Resource Efficient Manufacturing: A Processes and Systems Approach. CIRP Ann. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Jimoh, A.A.; Findlay, R.D.; Poloujadoff, M. Stray Losses in Induction Machines: Part I, Definition, Origin and Measurement. IEEE Trans. Power Appar. Syst. 1985, PAS-104, 1500–1505. [Google Scholar] [CrossRef]

- Erlach, K. Energiewertstrom—Steigerung der Energieeffizienz in der Produktion. In Handbuch Ressourcenorientierte Produktion; Neugebauer, R., Ed.; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2013; pp. 41–63. ISBN 978-3-446-43008-2. [Google Scholar]

- International Energy Agency Energy Statistics Data Browser. Available online: https://www.iea.org/data-and-statistics/data-tools/energy-statistics-data-browser (accessed on 11 June 2024).

- Adomat, V.; Kober, C.; Ahanpanjeh, M.; Wulfsberg, J.P. A Linear Programming Model for Renewable Energy Aware Discrete Production Planning and Control. In Proceedings of the Conference on Production Systems and Logistics: CPSL 2023-1, Hannover, Germany, 28 February–3 March 2023. [Google Scholar] [CrossRef]

- Adomat, V.; Trautwein, D.; Eckhoff, J.; Wulfsberg, J.P. Redesigning Industrial Composite Production Planning and Control for Energy Awareness. Procedia CIRP 2023, 119, 582–588. [Google Scholar] [CrossRef]

- Xia, B.; Ding, T.; Xiao, J. Life Cycle Assessment of Concrete Structures with Reuse and Recycling Strategies: A Novel Framework and Case Study. Waste Manag. 2020, 105, 268–278. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Gupta, M.K. Towards Zero Waste Manufacturing: A Multidisciplinary Review. J. Clean. Prod. 2017, 168, 1230–1243. [Google Scholar] [CrossRef]

- Zaman, A.U. A Comprehensive Review of the Development of Zero Waste Management: Lessons Learned and Guidelines. J. Clean. Prod. 2015, 91, 12–25. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Milani, A.S.; Fakhrhoseini, S.M.; Date, A.; Shabani, B.; Atkiss, S.; Ramakrishna, S.; Fox, B.; Jazar, R.N. Improving Energy Efficiency of Carbon Fiber Manufacturing through Waste Heat Recovery: A Circular Economy Approach with Machine Learning. Energy 2021, 225, 120113. [Google Scholar] [CrossRef]

- Oró, E.; Depoorter, V.; Garcia, A.; Salom, J. Energy Efficiency and Renewable Energy Integration in Data Centres. Strategies and modelling review. Renew. Sustain. Energy Rev. 2015, 42, 429–445. [Google Scholar] [CrossRef]

- Huang, P.; Copertaro, B.; Zhang, X.; Shen, J.; Löfgren, I.; Rönnelid, M.; Fahlen, J.; Andersson, D.; Svanfeldt, M. A Review of Data Centers as Prosumers in District Energy Systems: Renewable Energy Integration and Waste Heat Reuse for District Heating. Appl. Energy 2020, 258, 114109. [Google Scholar] [CrossRef]

- Werkneh, A.A.; Beyene, H.D.; Osunkunle, A.A. Recent Advances in Brewery Wastewater Treatment; Approaches for Water Reuse and Energy Recovery: A Review. Environ. Sustain. 2019, 2, 199–209. [Google Scholar] [CrossRef]

- Neugebauer, R.; Putz, M.; Keller, C.; Fälsch, S. Reducing Energy Demands of Printing Machines by Energy Reuse Options and Optimization. In Leveraging Technology for a Sustainable World; Dornfeld, D.A., Linke, B.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 107–112. ISBN 978-3-642-29068-8. [Google Scholar]

- Ja’fari, M.; Khan, M.I.; Al-Ghamdi, S.G.; Jaworski, A.J.; Asfand, F. Waste Heat Recovery in Iron and Steel Industry Using Organic Rankine Cycles. Chem. Eng. J. 2023, 477, 146925. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste Heat Recovery Technologies and Applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial Waste Heat Recovery Technologies: An Economic Analysis of Heat Transformation Technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Geng, D.; Evans, S. A Literature Review of Energy Waste in the Manufacturing Industry. Comput. Ind. Eng. 2022, 173, 108713. [Google Scholar] [CrossRef]

- Rethlefsen, M.L.; Kirtley, S.; Waffenschmidt, S.; Ayala, A.P.; Moher, D.; Page, M.J.; Koffel, J.B.; PRISMA-S Group; Blunt, H.; Brigham, T.; et al. PRISMA-S: An Extension to the PRISMA Statement for Reporting Literature Searches in Systematic Reviews. Syst. Rev. 2021, 10, 39. [Google Scholar] [CrossRef]

- Snyder, H. Literature Review as a Research Methodology: An Overview and Guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Kober, C.; Adomat, V.; Ahanpanjeh, M.; Fette, M.; Wulfsberg, J.P. Digital Twin Fidelity Requirements Model for Manufacturing. In Proceedings of the Conference on Production Systems and Logistics, Hannover, Germany, 17–20 May 2022. [Google Scholar] [CrossRef]

- Wieringa, R.J. What Is Design Science? In Design Science Methodology for Information Systems and Software Engineering; Springer: Berlin/Heidelberg, Germany, 2014; pp. 3–11. ISBN 978-3-662-43838-1. [Google Scholar]

- Wieringa, R.J. The Design Cycle. In Design Science Methodology for Information Systems and Software Engineering; Springer: Berlin/Heidelberg, Germany, 2014; pp. 27–34. ISBN 978-3-662-43838-1. [Google Scholar]

- Wieringa, R.J. Implementation Evaluation and Problem Investigation. In Design Science Methodology for Information Systems and Software Engineering; Springer: Berlin/Heidelberg, Germany, 2014; pp. 41–49. ISBN 978-3-662-43838-1. [Google Scholar]

- Zhang, S.; Zhang, L.; Wei, H.; Jing, J.; Zhou, X.; Zhang, X. Field Testing and Performance Analyses of Ground Source Heat Pump Systems for Residential Applications in Hot Summer and Cold Winter Area in China. Energy Build. 2016, 133, 615–627. [Google Scholar] [CrossRef]

- Hailu, G. Energy Systems in Buildings. In Energy Services Fundamentals and Financing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 181–209. ISBN 978-0-12-820592-1. [Google Scholar]

- Pashchenko, D. How to Choose Endothermic Process for Thermochemical Waste-Heat Recuperation? Int. J. Hydrogen Energy 2020, 45, 18772–18781. [Google Scholar] [CrossRef]

- Riera, J.A.; Lima, R.M.; Knio, O.M. A Review of Hydrogen Production and Supply Chain Modeling and Optimization. Int. J. Hydrogen Energy 2023, 48, 13731–13755. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Dewil, R.; Vanierschot, M.; Baeyens, J.; Deng, Y. Water Splitting by MnOx/Na2CO3 Reversible Redox Reactions. Sustainability 2022, 14, 7597. [Google Scholar] [CrossRef]

- Dincer, I.; AlZahrani, A.A. 4.25 Electrolyzers. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 985–1025. ISBN 978-0-12-814925-6. [Google Scholar]

- Tanneberger, T.; Schimek, S.; Paschereit, C.O.; Stathopoulos, P. Combustion Efficiency Measurements and Burner Characterization in a Hydrogen-Oxyfuel Combustor. Int. J. Hydrogen Energy 2019, 44, 29752–29764. [Google Scholar] [CrossRef]

- Qin, X.; Wang, D.; Jin, Z.; Wang, J.; Zhang, G.; Li, H. A Comprehensive Investigation on the Effect of Internal Heat Exchanger Based on a Novel Evaluation Method in the Transcritical CO2 Heat Pump System. Renew. Energy 2021, 178, 574–586. [Google Scholar] [CrossRef]

- Allahyarzadeh-Bidgoli, A.; Dezan, D.J.; Yanagihara, J.I. COP Optimization of Propane Pre-Cooling Cycle by Optimal Fin Design of Heat Exchangers: Efficiency and Sustainability Improvement. J. Clean. Prod. 2020, 271, 122585. [Google Scholar] [CrossRef]

- Zhu, G.; Chow, T.-T.; Maisotsenko, V.S.; Wen, T. Maisotsenko Power Cycle Technologies: Research, Development and Future Needs. Appl. Therm. Eng. 2023, 223, 120023. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, Y. A Calculation Method for Friction Coefficient and Meshing Efficiency of Plastic Line Gear Pair under Dry Friction Conditions. Friction 2021, 9, 1420–1435. [Google Scholar] [CrossRef]

- Dincer, I. 1.7 Energy and Exergy Efficiencies. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 265–339. ISBN 978-0-12-814925-6. [Google Scholar]

- Rosen, M.; Farsi, A. Energy and Exergy Methods. In Sustainable Energy Technologies for Seawater Desalination; Elsevier: Amsterdam, The Netherlands, 2022; pp. 133–160. ISBN 978-0-323-99872-7. [Google Scholar]

- Wu, F.; Shi, P.; Yi, Z.; Li, H.; Yi, Y. Ultra-Broadband Solar Absorber and High-Efficiency Thermal Emitter from UV to Mid-Infrared Spectrum. Micromachines 2023, 14, 985. [Google Scholar] [CrossRef]

- Almasri, R.A.; Abu-Hamdeh, N.H.; Esmaeil, K.K.; Suyambazhahan, S. Thermal Solar Sorption Cooling Systems—A Review of Principle, Technology, and Applications. Alex. Eng. J. 2022, 61, 367–402. [Google Scholar] [CrossRef]

- Albatayneh, A.; Assaf, M.N.; Alterman, D.; Jaradat, M. Comparison of the Overall Energy Efficiency for Internal Combustion Engine Vehicles and Electric Vehicles. Environ. Clim. Technol. 2020, 24, 669–680. [Google Scholar] [CrossRef]

- Ruiz-Ponce, G.; Arjona, M.A.; Hernandez, C.; Escarela-Perez, R. A Review of Magnetic Gear Technologies Used in Mechanical Power Transmission. Energies 2023, 16, 1721. [Google Scholar] [CrossRef]

- Demirel, Y. 5.2 Energy Conservation. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 45–90. ISBN 978-0-12-814925-6. [Google Scholar]

- Li, X. Thermodynamic Performance of Fuel Cells and Comparison with Heat Engines. In Advances in Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2007; Volume 1, pp. 1–46. ISBN 978-0-08-045394-1. [Google Scholar]

- Arshad, A.; Ali, H.M.; Habib, A.; Bashir, M.A.; Jabbal, M.; Yan, Y. Energy and Exergy Analysis of Fuel Cells: A Review. Therm. Sci. Eng. Prog. 2019, 9, 308–321. [Google Scholar] [CrossRef]

- Mitsushima, S.; Gollas, B.; Hacker, V. Introduction. In Fuel Cells and Hydrogen; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–13. ISBN 978-0-12-811459-9. [Google Scholar]

- Iqbal, F.; Gull, M.N.; Rizwan, H.M.; Amir, D.; Saleem, A.; Haq, S.U.; Cheema, T.A. Uncovering the Cooling Potential by Water Circulation on the Hot Side of a Peltier Module. Eng. Proc. 2023, 45, 34. [Google Scholar] [CrossRef]

- Blum, T.; Carrigan, S.; Platzek, D.; Kornadt, O. Evaluation of the Energy Efficiency of an Active Thermoelectric Façade. Energy Build. 2023, 292, 113128. [Google Scholar] [CrossRef]

- Bravo, R.R.D.S.; Gama, A.T.D.C.; Oliveira, A.A.M.; De Negri, V.J. Component Sizing and Sensitivity Analysis of Design Parameters of a Hydraulic-Pneumatic Regenerative Braking System for Heavy Duty Vehicles. Energy 2023, 264, 126021. [Google Scholar] [CrossRef]

- Palomba, I.; Wehrle, E.; Carabin, G.; Vidoni, R. Minimization of the Energy Consumption in Industrial Robots through Regenerative Drives and Optimally Designed Compliant Elements. Appl. Sci. 2020, 10, 7475. [Google Scholar] [CrossRef]

- Targosz, R.; Fassbinder, S.; Baggini, A. Power Transformers. In Electrical Energy Efficiency; Sumper, A., Baggini, A., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 21–69. ISBN 978-0-470-97551-0. [Google Scholar]

- Almora, O.; Baran, D.; Bazan, G.C.; Cabrera, C.I.; Erten-Ela, S.; Forberich, K.; Guo, F.; Hauch, J.; Ho-Baillie, A.W.Y.; Jacobsson, T.J.; et al. Device Performance of Emerging Photovoltaic Materials (Version 3). Adv. Energy Mater. 2023, 13, 2203313. [Google Scholar] [CrossRef]

- Allouhi, A.; Rehman, S.; Buker, M.S.; Said, Z. Recent Technical Approaches for Improving Energy Efficiency and Sustainability of PV and PV-T Systems: A Comprehensive Review. Sustain. Energy Technol. Assess. 2023, 56, 103026. [Google Scholar] [CrossRef]

- Soga, T. Fundamentals of Solar Cell. In Nanostructured Materials for Solar Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2006; pp. 3–43. ISBN 978-0-444-52844-5. [Google Scholar]

- Amin, N. Principle of Photovoltaics. In Comprehensive Guide on Organic and Inorganic Solar Cells; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–23. ISBN 978-0-323-85529-7. [Google Scholar]

- Hayashiya, H.; Watanabe, Y.; Fukasawa, Y.; Miyagawa, T.; Egami, A.; Iwagami, T.; Kikuchi, S.; Yoshizumi, H. Cost Impacts of High Efficiency Power Supply Technologies in Railway Power Supply-Traction and Station. In Proceedings of the 2012 15th International Power Electronics and Motion Control Conference (EPE/PEMC), Novi Sad, Serbia, 4–6 September 2012; pp. LS3e.4-1–LS3e.4-6. [Google Scholar]

- Li, J.; Aierken, A.; Liu, Y.; Zhuang, Y.; Yang, X.; Mo, J.H.; Fan, R.K.; Chen, Q.Y.; Zhang, S.Y.; Huang, Y.M.; et al. A Brief Review of High Efficiency III-V Solar Cells for Space Application. Front. Phys. 2021, 8, 631925. [Google Scholar] [CrossRef]

- Al-Ghussain, L.; Samu, R.; Taylan, O.; Fahrioglu, M. Sizing Renewable Energy Systems with Energy Storage Systems in Microgrids for Maximum Cost-Efficient Utilization of Renewable Energy Resources. Sustain. Cities Soc. 2020, 55, 102059. [Google Scholar] [CrossRef]

- Mauri, F.; Garetti, M.; Gandelli, A. A Structured Approach to Process Improvement in Manufacturing Systems. Prod. Plan. Control 2010, 21, 695–717. [Google Scholar] [CrossRef]

- Eckhoff, J.; Adomat, V.; Fette, M. Energieoptimierte Produktionsplanung: Am Beispiel Der Faserverbundkunststoffverarbeitenden Luftfahrtindustrie. Z. Wirtsch. Fabr. 2023, 118, 133–137. [Google Scholar] [CrossRef]

- Tillman, A.-M.; Ekvall, T.; Baumann, H.; Rydberg, T. Choice of System Boundaries in Life Cycle Assessment. J. Clean. Prod. 1994, 2, 21–29. [Google Scholar] [CrossRef]

- Guzhev, D.A. Methodology for Calculating the Net Present Value of Investment Project, Taking into Account the Variability of Determining the Cash Flow of Capital Investments. Financ. Credit 2022, 28, 2016–2031. [Google Scholar] [CrossRef]

- Yescombe, E.R.; Farquharson, E. Cash Flow and Investment Analysis. In Public-Private Partnerships for Infrastructure; Elsevier: Amsterdam, The Netherlands, 2018; pp. 25–34. ISBN 978-0-08-100766-2. [Google Scholar]

- Adomat, V.; Ehrhardt, J.; Kober, C.; Ahanpanjeh, M.; Wulfsberg, J.P. A Machine Learning Approach for Revenue Management in Cloud Manufacturing. Procedia CIRP 2023, 118, 342–347. [Google Scholar] [CrossRef]

- Gerring, J. What Is a Case Study and What Is It Good For? Am. Polit. Sci. Rev. 2004, 98, 341–354. [Google Scholar] [CrossRef]

- Adomat, V.; Ahanpanjeh, M.; Kober, C.; Fette, M.; Wulfsberg, J.P. Interdisziplinäre Forschungsperspektiven auf die Digitalisierung in der Leichtbauproduktion und Anwendungsmöglichkeiten in der LaiLa Modellfabrik. In Forschungsaktivitäten im Zentrum für Digitalisierungs- und Technologieforschung der Bundeswehr dtec.bw; openHSU: Hamburg, Germany, 2022; Volume 1. [Google Scholar] [CrossRef]

- Santa, J.F.; Vanegas-Jaramillo, J.D.; Patiño, I.D. Mechanical Characterization of Composites Manufactured by RTM Process: Effect of Fiber Content, Strain Rate and Orientation. Lat. Am. J. Solids Struct. 2016, 13, 344–364. [Google Scholar] [CrossRef][Green Version]

- Joven, R.; Das, R.; Ahmed, A.; Roozbehjavan, P.; Minaie, B. Thermal Properties of Carbon Fiber-Epoxy Composites with Different Fabric Weaves. In Proceedings of the International SAMPE Technical Conference 2012, Charleston, SC, USA, 22 October 2012. [Google Scholar]

| Variable | Definition | Unit |

|---|---|---|

| PV | Present value | [€] |

| t | Period | unitless |

| Φ(t) | Residual energy emission power per period | [W] |

| ηtrans/store/convert | Efficiency of transmission, storage, and conversion system | [%] |

| i, j, k | Individual transmission, storage, and conversion system | unitless |

| n, m, o | Number of transmission, storage, and conversion systems | unitless |

| pt | Principal energy price per unit per period | [€/Ws] |

| Ct | Recurring and non-recurring cost of energyreclamation implementation and operation per period | [€] |

| q | Number of periods per year | unitless |

| rannual | Annual internal interest rate | [%] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eckhoff, J.; Adomat, V.; Kober, C.; Fette, M.; Weidner, R.; Wulfsberg, J.P. Towards a Framework for the Industrial Recommissioning of Residual Energy (IRRE): How to Systematically Evaluate and Reclaim Waste Energy in Manufacturing. Machines 2024, 12, 594. https://doi.org/10.3390/machines12090594

Eckhoff J, Adomat V, Kober C, Fette M, Weidner R, Wulfsberg JP. Towards a Framework for the Industrial Recommissioning of Residual Energy (IRRE): How to Systematically Evaluate and Reclaim Waste Energy in Manufacturing. Machines. 2024; 12(9):594. https://doi.org/10.3390/machines12090594

Chicago/Turabian StyleEckhoff, Jannis, Vincent Adomat, Christian Kober, Marc Fette, Robert Weidner, and Jens P. Wulfsberg. 2024. "Towards a Framework for the Industrial Recommissioning of Residual Energy (IRRE): How to Systematically Evaluate and Reclaim Waste Energy in Manufacturing" Machines 12, no. 9: 594. https://doi.org/10.3390/machines12090594

APA StyleEckhoff, J., Adomat, V., Kober, C., Fette, M., Weidner, R., & Wulfsberg, J. P. (2024). Towards a Framework for the Industrial Recommissioning of Residual Energy (IRRE): How to Systematically Evaluate and Reclaim Waste Energy in Manufacturing. Machines, 12(9), 594. https://doi.org/10.3390/machines12090594