Current Status of Research on Hybrid Ceramic Ball Bearings

Abstract

1. Introduction

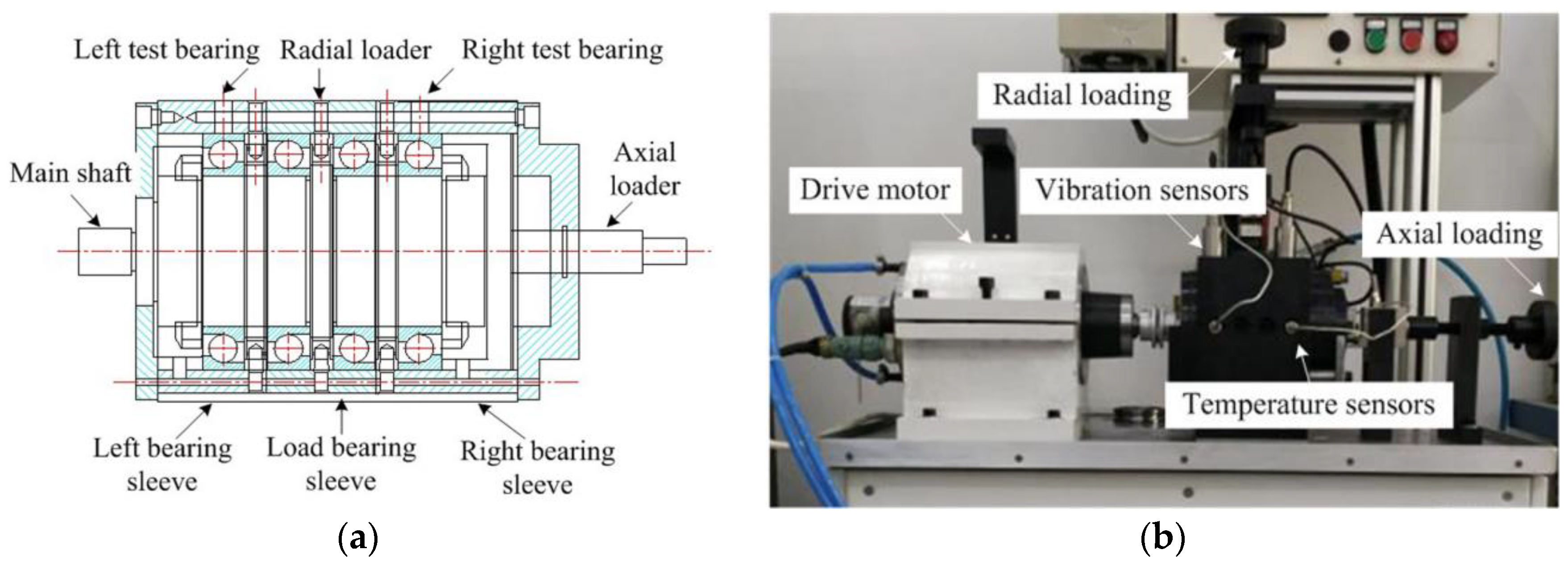

2. The Study on the Lifetime of Hybrid Ceramic Ball Bearings

2.1. Life Prediction

2.2. Surface Cracks in Ceramic Balls

2.3. Fatigue and Wear of Hybrid Ceramic Ball Bearings

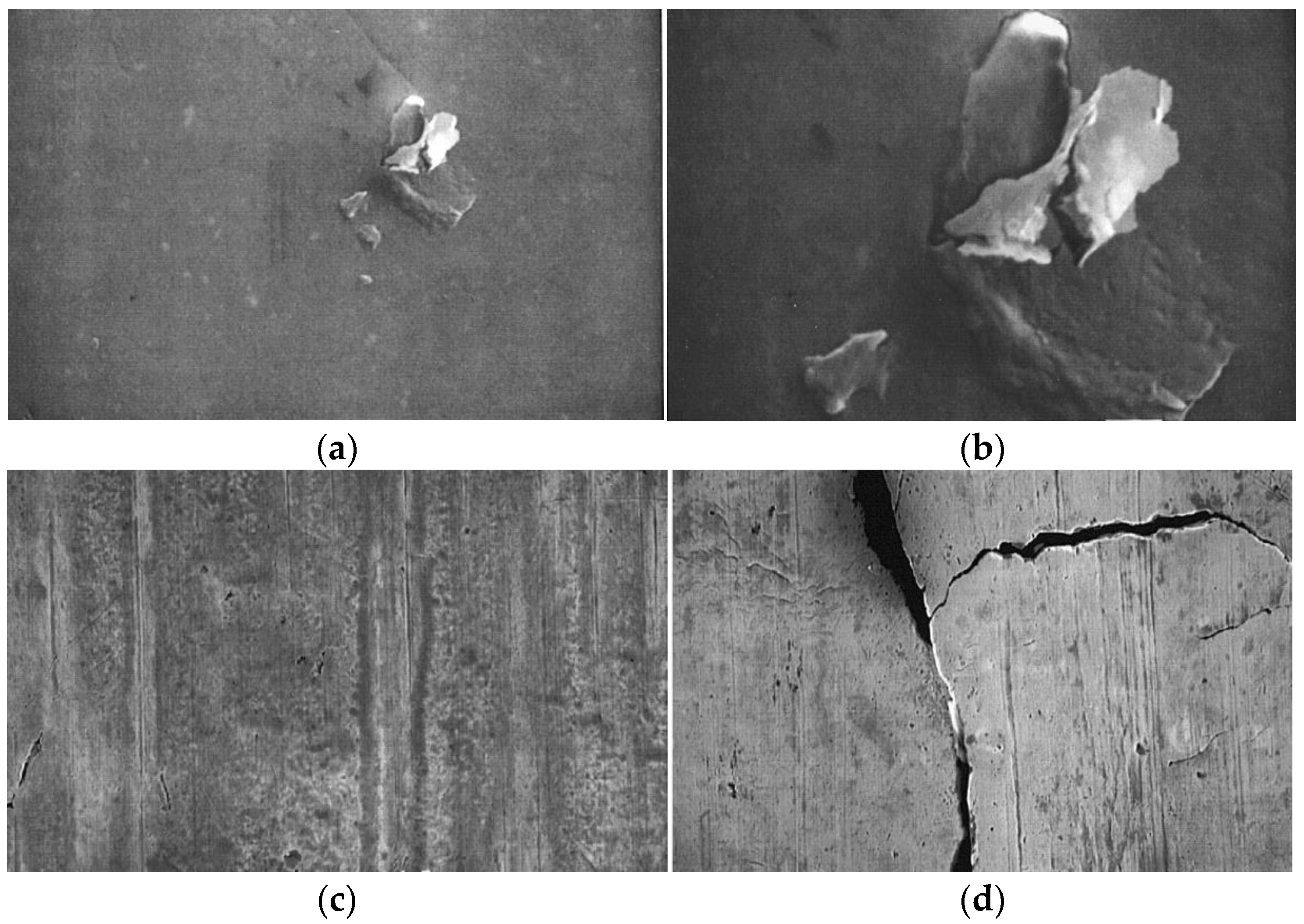

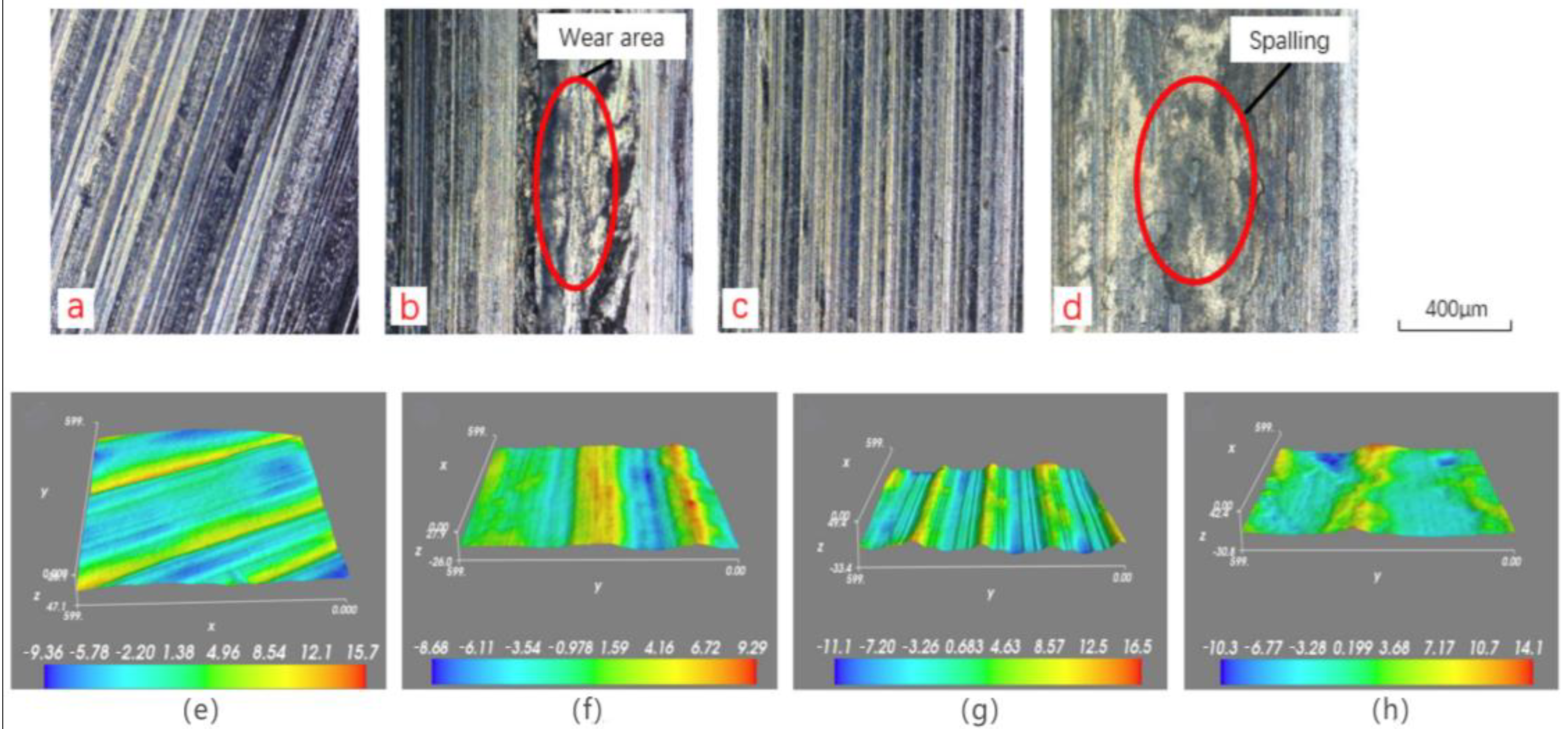

2.3.1. Contact Fatigue Spalling of Hybrid Ceramic Ball Bearings

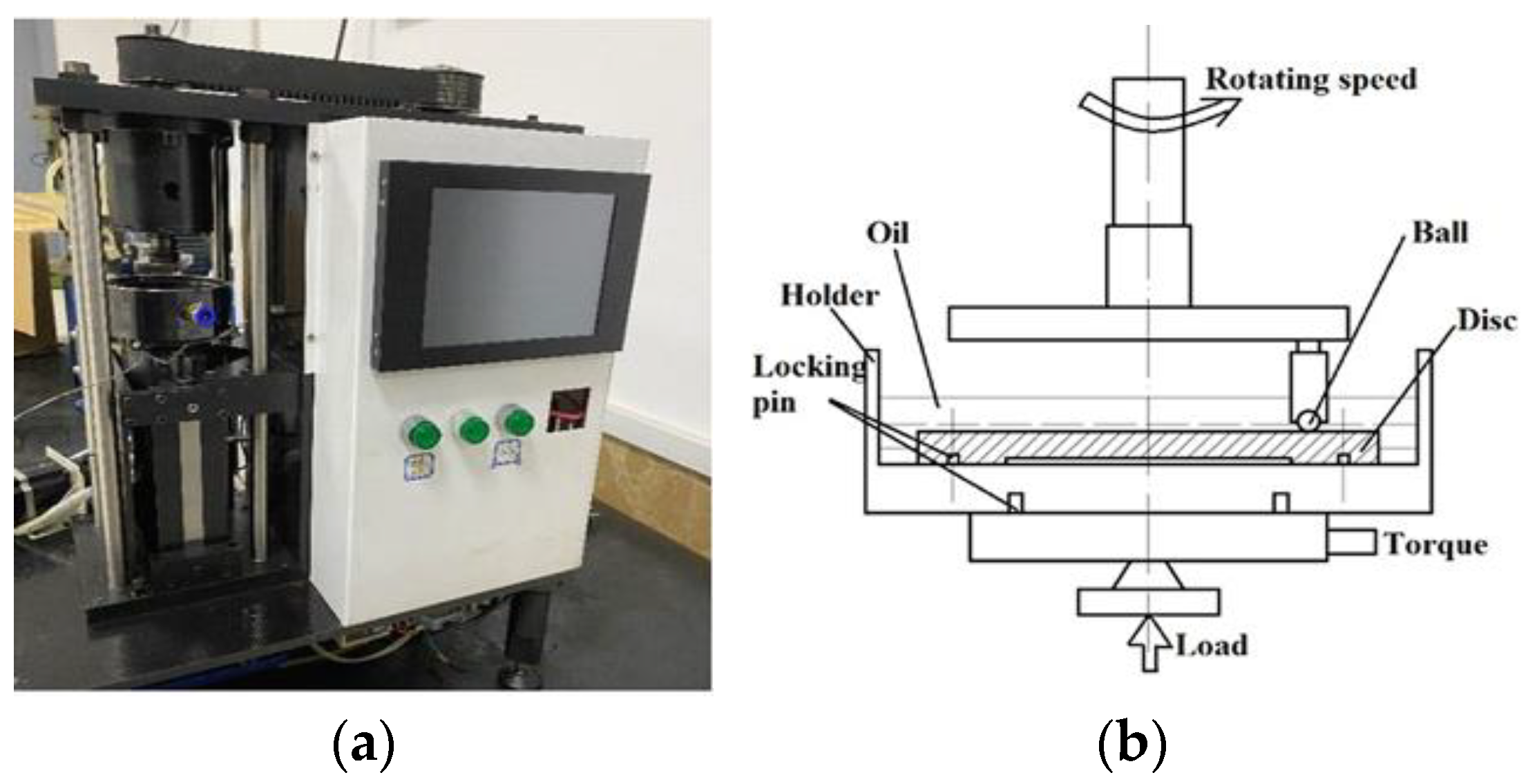

2.3.2. Wear of Hybrid Ceramic Ball Bearings

2.3.3. The Influence of Porosity in Ceramic Balls on Fatigue Failure and Wear in Hybrid Ceramic Bearings

2.4. Analysis of Spalling Failures in Hybrid Ceramic Balls

3. Hybrid Ceramic Ball Bearing Analysis Method

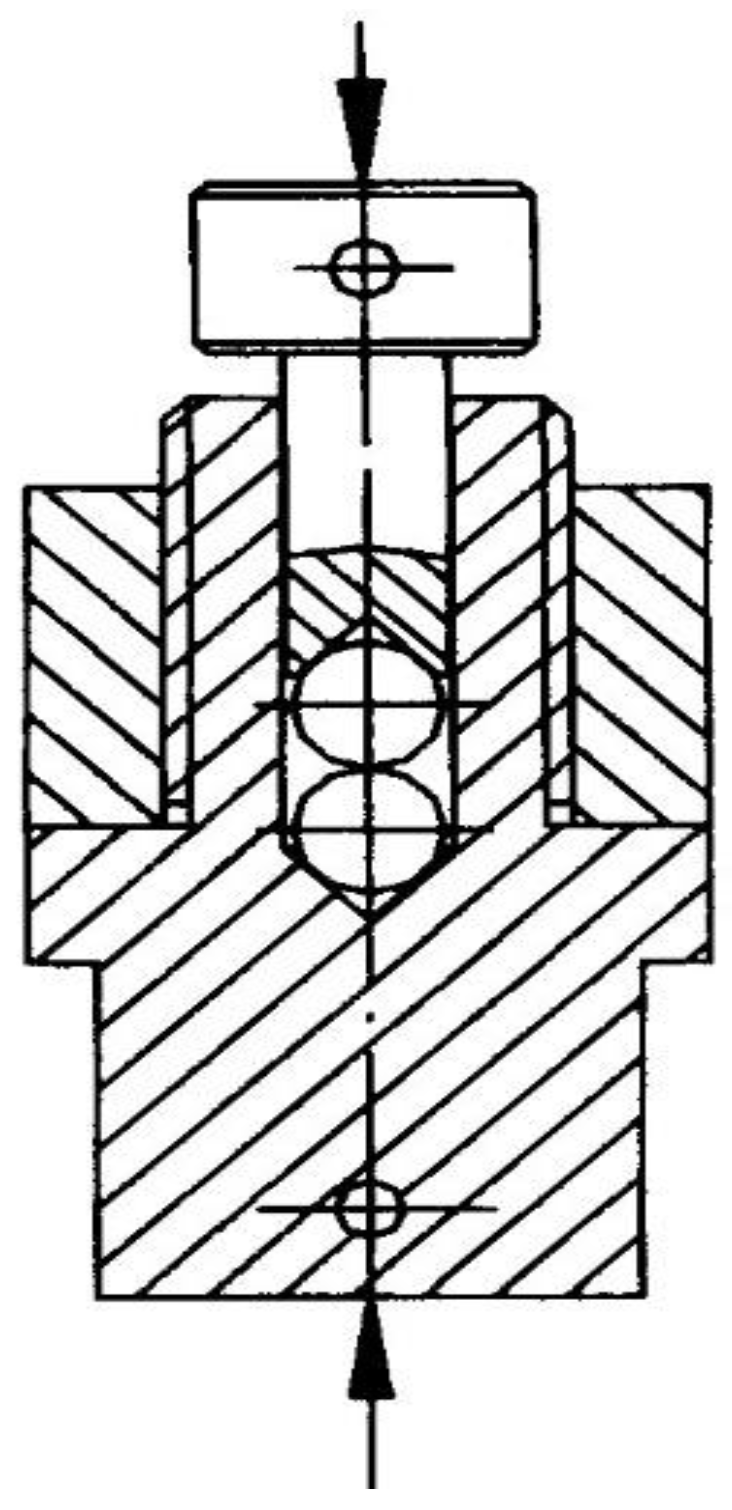

3.1. Analysis of Hybrid Ceramic Ball Bearings Based on Finite Element Software

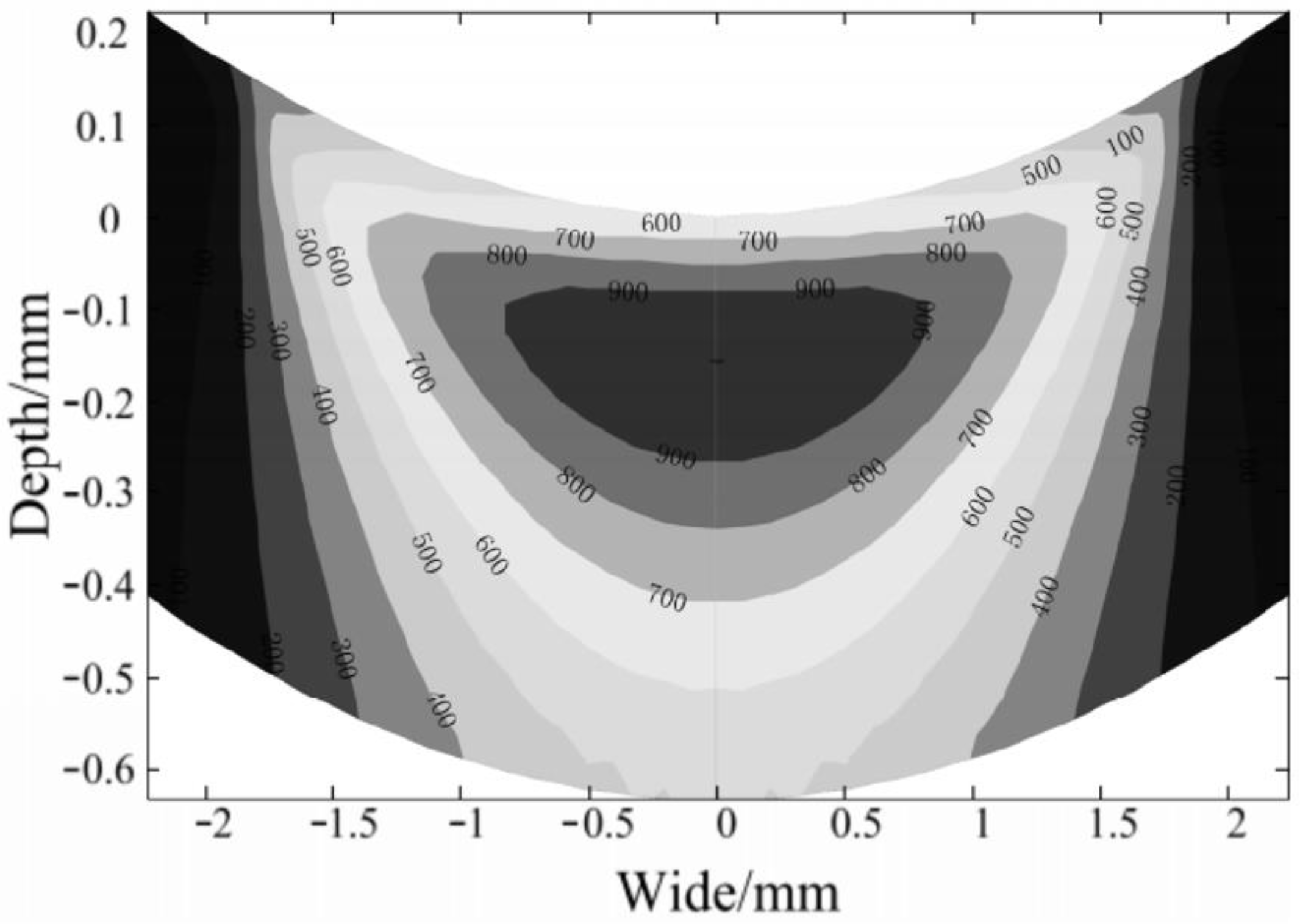

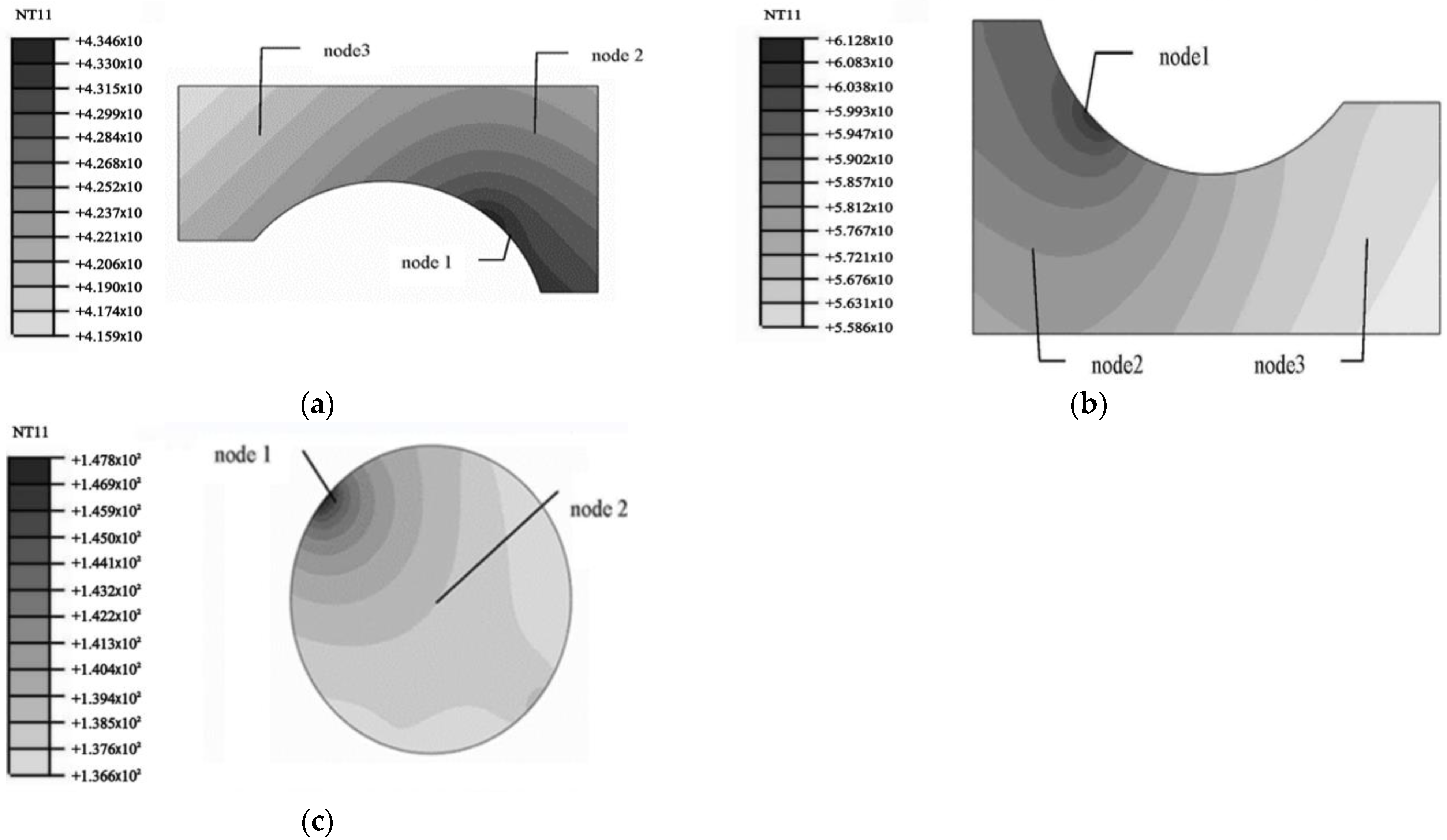

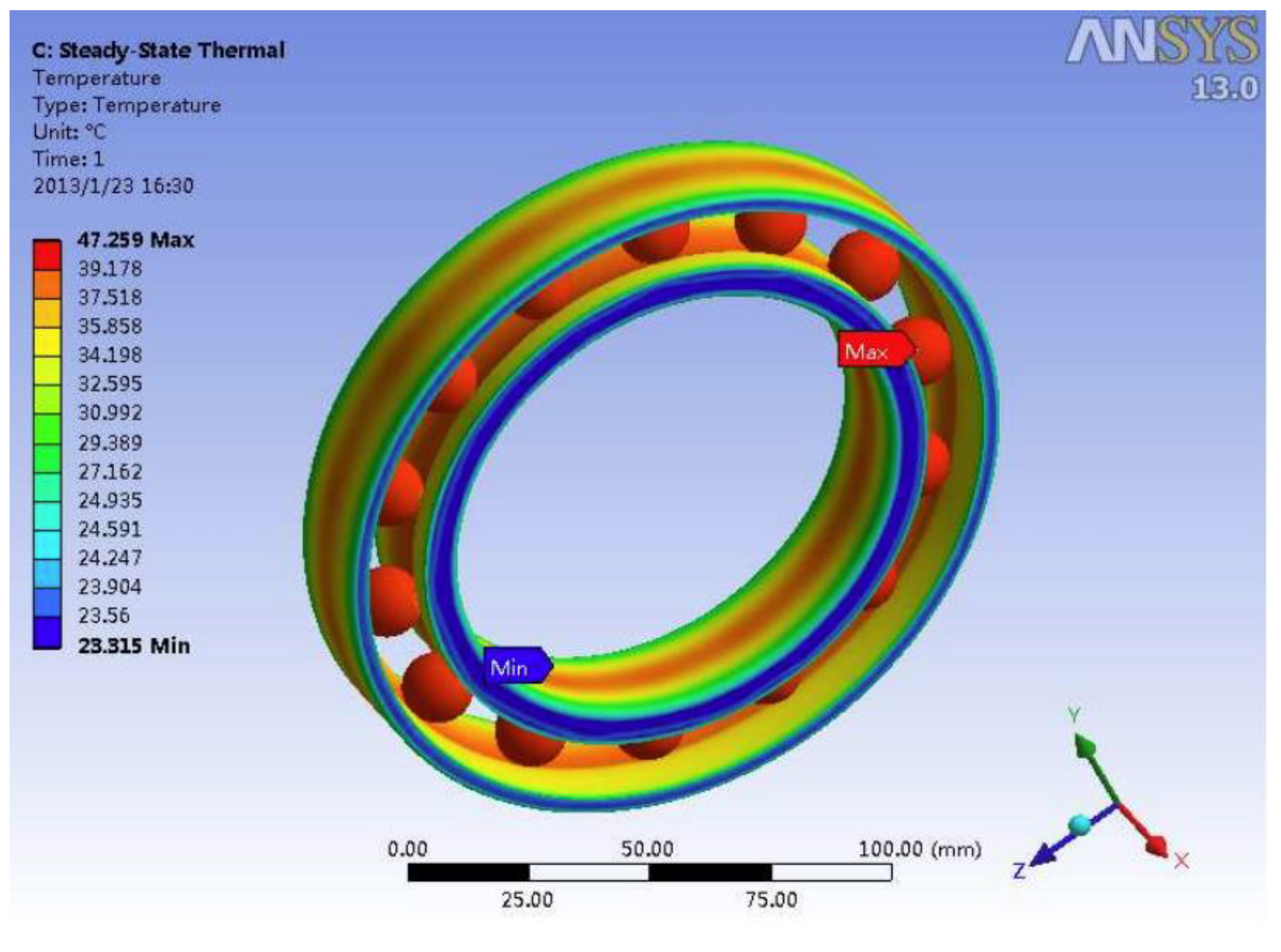

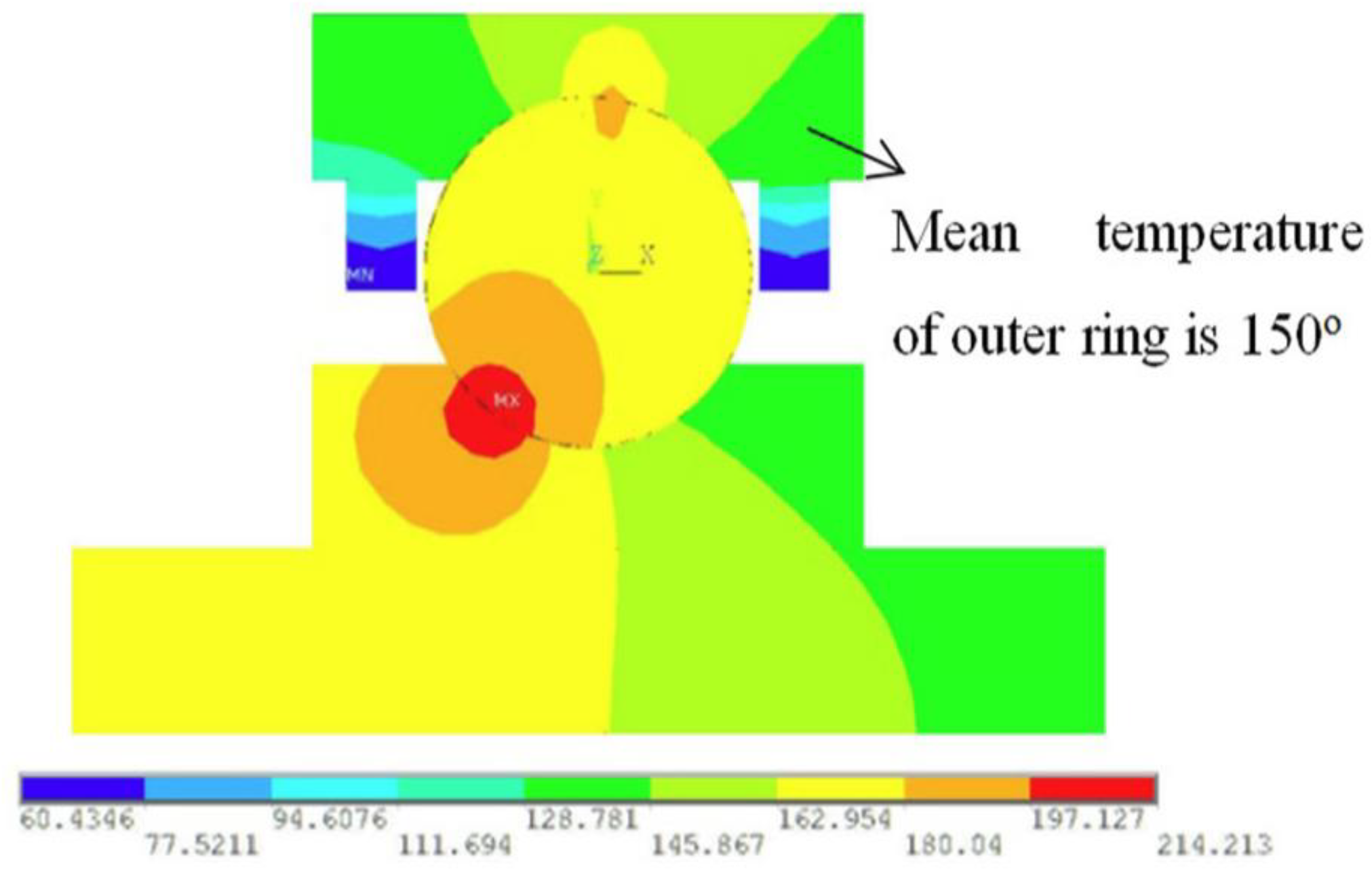

3.1.1. Analysis Based on Ansys Software

3.1.2. Analysis Based on Abaqus Software

3.2. Methods for Analyzing the Performance of Hybrid Ceramic Ball Bearings

3.2.1. Static Analysis

3.2.2. Quasi-Static Analysis

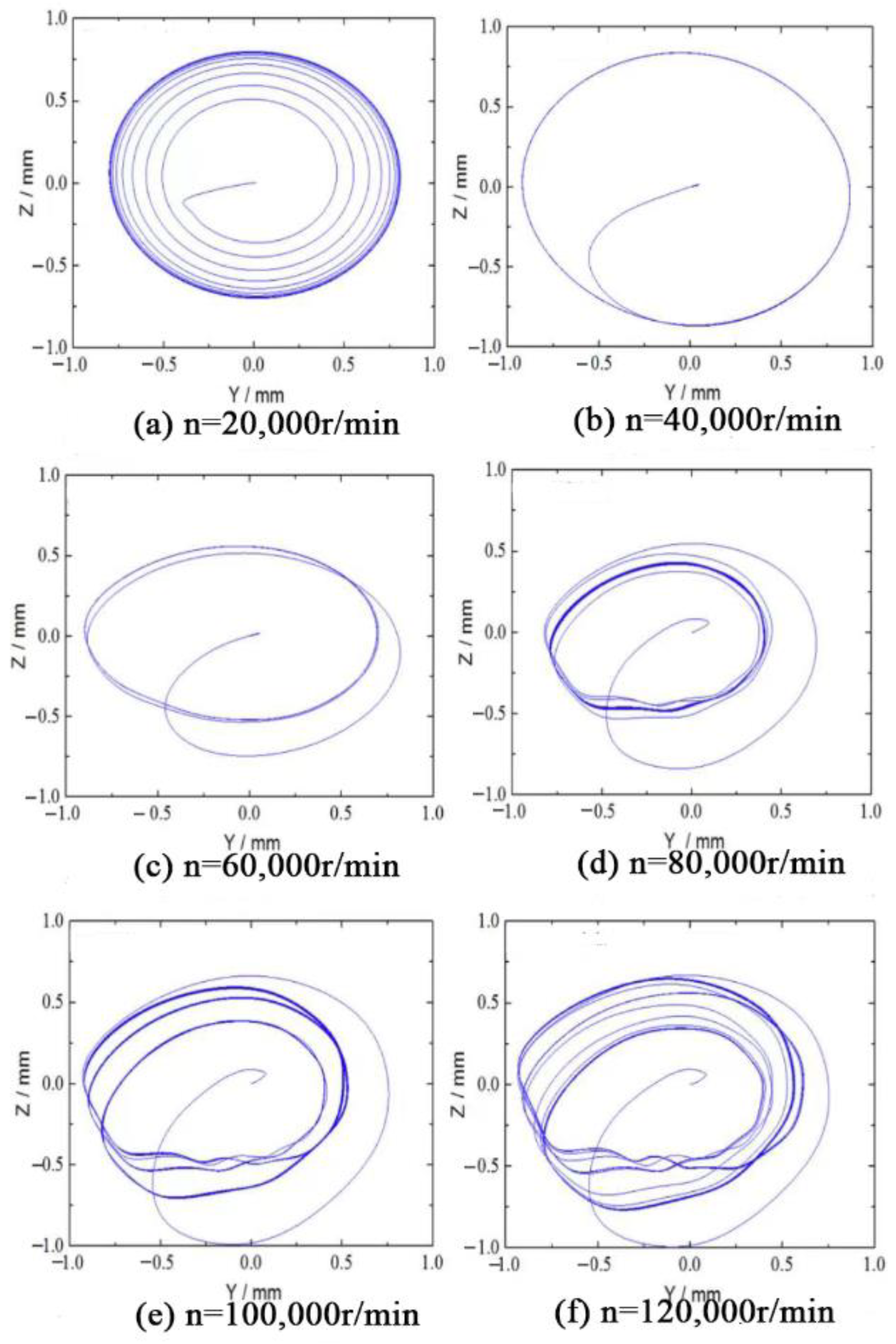

3.2.3. Dynamic Analysis

3.3. Other Analysis and Testing Methods

4. Research on Temperature and Lubrication of Hybrid Ceramic Ball Bearings

4.1. Thermal Analysis of Hybrid Ceramic Ball Bearings

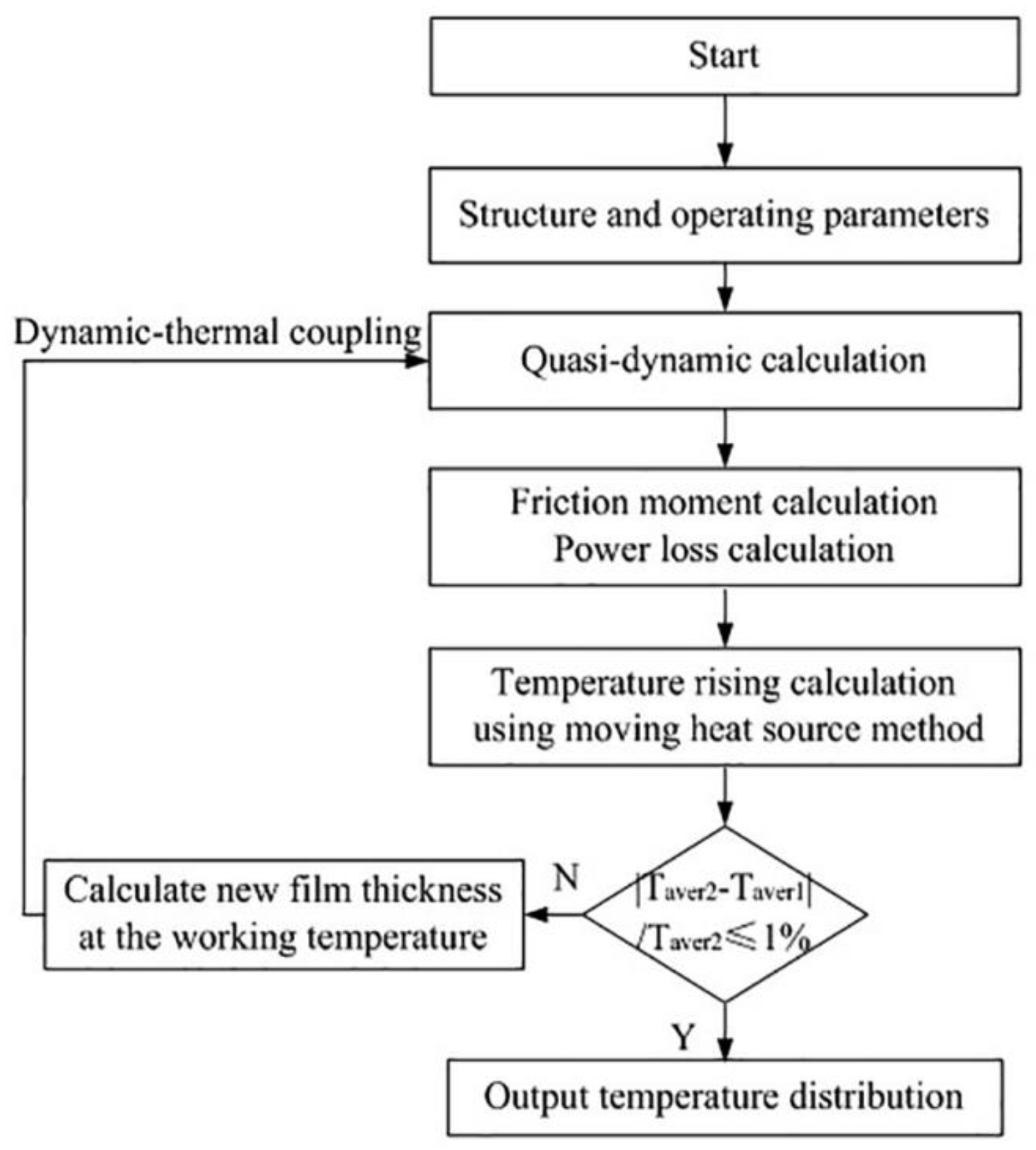

4.1.1. Research on Heat Generation in Hybrid Ceramic Ball Bearings

4.1.2. Research on Temperature Distribution of Hybrid Ceramic Ball Bearings

4.2. Research on Lubrication of Hybrid Ceramic Ball Bearing

4.2.1. Oil Lubrication

- (1)

- Friction and wear performance of hybrid ceramic ball bearings under oil-starved conditions: Through experiments and simulation analysis, study the friction coefficient, wear rate, and other performance parameters of hybrid ceramic ball bearings under oil-starved conditions to understand the impact of lubrication status on performance.

- (2)

- Temperature rise and heat dissipation performance of hybrid ceramic ball bearings under oil-starved conditions: Study the temperature rise pattern and heat dissipation performance of bearings under oil-starved conditions to understand the impact of insufficient lubrication on the thermal stability of hybrid ceramic ball bearings.

- (3)

- Fatigue life of hybrid ceramic ball bearings under oil-starved conditions: Through accelerated life tests and other methods, study the fatigue life and failure mechanisms of bearings under oil-starved conditions to assess their reliability in practical applications.

- (4)

- Lubrication system design for hybrid ceramic ball bearings under oil-starved conditions: Optimize the design and operating parameters of the lubrication system for oil-starved conditions to ensure that the bearings maintain stable performance even when oil starved.

4.2.2. Grease Lubrication

4.2.3. Self-Lubrication

4.2.4. Special Lubricants

4.3. Outer Ring Direct Cooling Technology

5. Discussion

- (1)

- The firing and processing of ceramic balls are extremely difficult, which easily leads to surface crack defects. Surface cracks are difficult to detect in large-scale production processes [23]. Therefore, rapid and reliable nondestructive testing is an important technology for manufacturing high-reliability hybrid ceramic ball bearings.

- (2)

- The brittleness of early ceramic materials has always been one of the most direct factors affecting the failure modes and impact resistance of hybrid ceramic ball bearings. Although the comprehensive performance of ceramic bearings has been greatly improved through hot isostatic pressing sintering technology, their low toughness, high hardness, and moderate flexural strength remain fatal weaknesses of ceramic materials [27]. However, it is not always the case that the less impurities there are, the better. Silicon nitride ceramics with low impurity content have better porosity and higher hardness, while those with high impurity content have better toughness. Controlling the impurity content of ceramic materials is the key to producing high-quality silicon nitride ceramic balls [108]. In the future, more high-quality ceramic blank materials should be obtained through process optimization.

- (3)

- The high elastic modulus and hardness of silicon nitride in hybrid ceramic ball bearings lead to increased stress on the raceway due to the relatively small contact area between the ball and the raceway. This can result in a sharp rise in heat generation under heavy loads and high rotation speeds. It is essential to focus on developing effective lubrication methods to prevent fatigue spalling and ensure the longevity of hybrid ceramic ball bearings.

- (4)

- The surface fatigue spalling mechanism in hybrid ceramic ball bearings differs from traditional steel bearings, with ceramic particles generated by spalling being pressed into the raceway, causing irreversible damage in the form of micro-pits [33]. Therefore, it is necessary to reduce the hardness of the ceramic balls and apply surface treatments to the steel raceways to minimize the hardness difference between them. In addition, understanding the failure mechanisms of hybrid ceramic balls is also very important.

- (5)

- The development of hybrid ceramic ball bearings is severely restricted due to their high costs in both R&D and production, the limited market demand, and the high requirement for reliability.

6. Conclusions

- (1)

- Currently, the longevity of hybrid ceramic ball bearings is primarily determined using SKF’s GBLM general bearing life model. While these bearings typically last two times longer than standard all-steel bearings, issues such as double-impact vibration from surface cracks and fatigue spalling prevent hybrid ceramic ball bearings from reaching their full potential lifetime.

- (2)

- Various studies have delved into the mechanical and kinematic performance of hybrid ceramic ball bearings, highlighting their ability to achieve much higher limit speeds compared to all-steel bearings and showcasing superior stability.

- (3)

- Research on the temperature field of hybrid ceramic balls is currently limited, with a focus on thermal analysis. Findings suggest that hybrid ceramic ball bearings are best suited for high-speed and light-load applications, showing improved performance and greater resilience under high-temperature conditions.

- (4)

- For hybrid ceramic ball bearings, in high-speed conditions, oil lubrication offers superior performance with reduced resistance and provides a certain degree of prevention against abrasive wear. At medium to low speeds, grease lubrication can effectively mitigate fatigue failure. However, irrespective of the lubrication method used, the primary goal is to lower bearing temperature and mitigate surface fatigue spalling in hybrid ceramic ball bearings. Scholars are encouraged to concentrate on lubrication studies for these bearings, conducting thorough research into lubrication technology. This research is crucial for enhancing bearing performance and longevity, ultimately contributing to advancements in high-end equipment manufacturing and offering vital support to aerospace, manufacturing equipment, and related industries.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taylor, K.M.; Sibley, L.B. Development of a ceramic rolling contact bearing for high temperature use. Wear 1963, 6, 226–240. [Google Scholar] [CrossRef]

- Harris, T.A. On the Effectiveness of Hollow Balls in High-Speed Thrust Bearings. ASLE Trans. 1968, 11, 290–294. [Google Scholar] [CrossRef]

- Scott, D.B.; Blackwell, J.L. Hot pressed silicon nitride as a rolling bearing material—a preliminary assessment. Wear 1973, 24, 61–67. [Google Scholar] [CrossRef]

- Parker, R.J.; Zaretsky, E.V. Fatigue life of highspeed ball bearings with silicon nitride balls. J. Lubr. Technol. 1975, 97, 350–355. [Google Scholar] [CrossRef]

- Aramaki, H.; Shoda, Y.; Morishita, Y.; Sawamoto, T. The performances of ball bearings with silicon nitride ceramic balls in highspeed spindles for machine tools. J. Tribol. 1988, 110, 693–698. [Google Scholar] [CrossRef]

- Rhoads, M.; Bashyam, M.; Crecelius, W. Large engine hybrid ceramic bearings. In Proceedings of the ASME 1994 International Gas Turbine and Aeroengine Congress and Exposition, The Hague, The Netherlands, 13–16 June 1994. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, H.; Wu, Y.H.; Fu, D.W. Research on high-speed Performance and tests of the hybrid ceramic ball bearings. J. Shenyang Jianzhu Univ. 1998, 2, 76–79. (In Chinese) [Google Scholar]

- Jiang, X.; Liu, H.Z. Selection of hybrid ceramic ball bearing. J. Xi’an Univ. Technol. 2012, 28, 33–38. [Google Scholar] [CrossRef]

- Huang, R.; Zhen, S.S.; Zhang, W.L. Influences of ball bearing stiffness on transient response of a turbocharger. J. Vib. Shock. 2016, 35, 83–87+94. [Google Scholar] [CrossRef]

- Wang, L.; Wood, R.J.K.; Powrie, H.E.G.; Streit, E.; Care, I. Performance Evaluation of Hybrid (Ceramic on Steel) Bearings with Advanced Aircraft Engine Oils for Lubrication. In Proceedings of the ASME Turbo Expo 2004, Vienna, Austria, 14–17 June 2004. [Google Scholar] [CrossRef]

- Wang, L.Q.; Jia, H.X.; Zheng, D.Z.; Ye, Z.H. Advances in High-reliability Ceramic Rolling Element Bearing Technology. Aeroengines 2013, 39, 6–13. (In Chinese) [Google Scholar]

- Goepfert, O.; Ampuero, J.; Pahud, P.; Boving, H.J. Surface Roughness Evolution of Ball Bearing Components. Tribol. Trans. 2000, 43, 275–280. [Google Scholar] [CrossRef]

- O’brien, M.J.; Presser, N.; Robinson, E.Y. Failure analysis of three Si3N4 balls used in hybrid bearings. Eng. Failure Anal. 2003, 10, 453–473. [Google Scholar] [CrossRef]

- Zhou, J.L.; Wu, G.Q.; Liu, X.Y. Tensile Stress Life Model for Rolling Contact Fatigue of Silicon Nitride Ceramic Balls. J. Mech. Eng. 2008, 44, 6. (In Chinese) [Google Scholar] [CrossRef]

- Cheng, Z.M.; Zhou, J.L.; Lu, P.P. Life Prediction of Si3N4 Ceramic Balls Based on Tensile Stress Life Model. Bearing 2014, 12, 41–43. [Google Scholar] [CrossRef]

- Deutsch, J.; He, M.; He, D. Remaining Useful Life Prediction of Hybrid Ceramic Bearings Using an Integrated Deep Learning and Particle Filter Approach. Appl. Sci. 2017, 7, 649. [Google Scholar] [CrossRef]

- Wang, C.H.; Yu, W.; Ren, C.Z. An accurate method for calculating the contact subsurface stress field of hybrid ceramic ball Bearing. Solid. State Phenom. 2011, 175, 215–218. [Google Scholar] [CrossRef]

- Gupta, P.K.; Zaretsky, E.V. Life Model Enhancement for Hybrid Ball Bearings. Tribol. Trans. 2019, 62, 1129–1141. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Gabelli, A. Application of a rolling bearing life model with surface and subsurface survival to hybrid bearing cases. J. Mech. Eng. Sci. 2019, 233, 5491–5498. [Google Scholar] [CrossRef]

- Vieillard, C.; Kadin, Y.; Morales-Espejel, G.E.; Gabelli, A. An experimental and theoretical study of surface rolling contact fatigue damage progression in hybrid bearings with artificial dents. Wear 2016, 364–365, 211–223. [Google Scholar] [CrossRef]

- Brizmer, V.; Gabelli, A.; Vieillard, C.; Morales-Espejel, G.E. An experimental and theoretical study of hybrid bearing micropitting performance under reduced lubrication. Tribol. Trans. 2015, 58, 829–835. [Google Scholar] [CrossRef]

- Gabelli, Antonio and Guillermo Enrique Morales-Espejel. A model for hybrid bearing life with surface and subsurface survival. Wear 2019, 422–423, 223–234. [Google Scholar] [CrossRef]

- Wang, Y.; Hadfield, M. Life prediction for surface crack-initiated contact fatigue of silicon nitride bearing balls. Tribol. Interface Eng. Ser. 2003, 41, 349–358. [Google Scholar] [CrossRef]

- Tsai, Y.L.; Mecholsky Jr, J.J.; Chin, H.A. Finite Element Analysis of the Stress Distribution in Silicon Nitride Bearing Balls. Ceram. Eng. Sci. Proc. 1998, 19, 185–192. [Google Scholar] [CrossRef]

- Sun, J.G.; Koehl, E.R.; Steckenrider, S.; Vieillard, C.; Bayer, T. Nondestructive Inspection of Ceramic Bearing Balls Using Phased Array Ultrasonics. Ceram. Eng. Sci. Proc. 2009, 30, 233–240. [Google Scholar] [CrossRef]

- Seimert, M.; Gühmann, C. Vibration based diagnostic of cracks in hybrid ball bearings. Measurement 2017, 108, 201–206. [Google Scholar] [CrossRef]

- Li, Y.L. Research Status of Hybrid Ceramic Bearing Life. Theory Pract. New Ind. 2014, 1, 503–507. [Google Scholar] [CrossRef]

- Mitchell, D.J.; Mecholsky, J.J.; Adair, J.H. All-steel and Si3N4-steel hybrid rolling contact fatigue under contaminated conditions. Wear 2000, 239, 176–188. [Google Scholar] [CrossRef]

- Hadfield, M.; Stolarski, T.A.; Cundill, R.T.; Horton, S.A. Failure modes of pre-cracked ceramic elements under rolling contact. Wear 1993, 69, 69–75. [Google Scholar] [CrossRef]

- Hadfield, M.; Stolarski, T.A.; Cundill, R.T.; Horton, S.A. Failure modes of ceramic elements with ring-crack defects. Tribol. Int. 1993, 26, 157–164. [Google Scholar] [CrossRef]

- Chiu, Y.P.; Pearson, P.K.; Dezzani, M.M.; Daverio, H. Fatigue life and performance testing of hybrid ceramic ball bearings. Lubr. Eng. 1996, 52, 198–204. [Google Scholar]

- Gu, L.; Wang, L.; Jin, Y.; Li, X. Fatigue behavior of hybrid ceramic ball bearings in liquid nitrogen. Tribol. Trans. 2003, 46, 494–498. [Google Scholar] [CrossRef]

- Zhang, X.C.; Wu, D.; Xia, Z.F.; Li, Y.F.; Wang, J.Q.; Han, E.H. Characteristics and mechanism of surface damage of hybrid ceramic ball bearings for high-precision machine tool. Eng. Failure. Anal. 2022, 142, 106784. [Google Scholar] [CrossRef]

- Zhang, X.C.; Wu, D.; Xia, Z.F.; Li, Y.F.; Wang, J.Q.; Han, E.H. Study on surface fatigue and metamorphic layer of raceway of hybrid ceramic ball bearing in high-speed spindle for machine tool. Eng. Failure. Anal. 2022, 143, 106928. [Google Scholar] [CrossRef]

- Zhang, X.C.; Wu, D.; Xia, Z.F.; Li, Y.F.; Wang, J.Q.; Han, E.H. Comparative study on surface contact fatigue of machine tool bearing raceways with different rolling elements: Two failure bearings case studies. Tribol. Lett. 2023, 71, 55. [Google Scholar] [CrossRef]

- Ghezzi, I.; Komba, E.H.; Tonazzi, D.; Bouscharain, N.; Jeune, G.L.; Coudert, J.B.; Massi, F. Damage evolution and contact surfaces analysis of high-loaded oscillating hybrid bearings. Wear 2018, 406–407, 1–12. [Google Scholar] [CrossRef]

- Stelmakh, A.U.; Kostunik, R.E.; Radzievskiy, V.A.; Maystrenko, A.L.; Sokhan’, S.V.; Kulich, V.G. Rolling Friction of Hybrid Ceramic–Steel Pairs under Different Lubrication Conditions. J. Frict. Wear 2020, 41, 432–442. [Google Scholar] [CrossRef]

- Pessolano Filos, I.; Sesana, R.; Di Biase, M.; Lupoi, R. New Abrasive Coatings: Abraded Volume Measurements in Ceramic Ball Production. J. Manuf. Mater. Process. 2021, 5, 81. [Google Scholar] [CrossRef]

- Wang, W.; Wong, P.L.; He, F.; Wan, G.T.Y. Experimental Study of the Smoothing Effect of a Ceramic Rolling Element on a Bearing Raceway in Contaminated Lubrication. Tribol. Lett. 2007, 28, 89–97. [Google Scholar] [CrossRef]

- Thoma, K.; Rohr, L.; Rehmann, H.; Roos, S.; Michler, J. Materials failure mechanisms of hybrid ball bearings with silicon nitride balls. Tribol. Int. 2004, 37, 463–471. [Google Scholar] [CrossRef]

- Yan, H.P.; Lang, S.; Qin, Z.Y. Simulation Analysis of Vibration Characteristics of Hybrid Ceramic Ball Bearing. (In Chinese) Mach. Tool. Hydraul. 2023, 51, 172–177. [Google Scholar] [CrossRef]

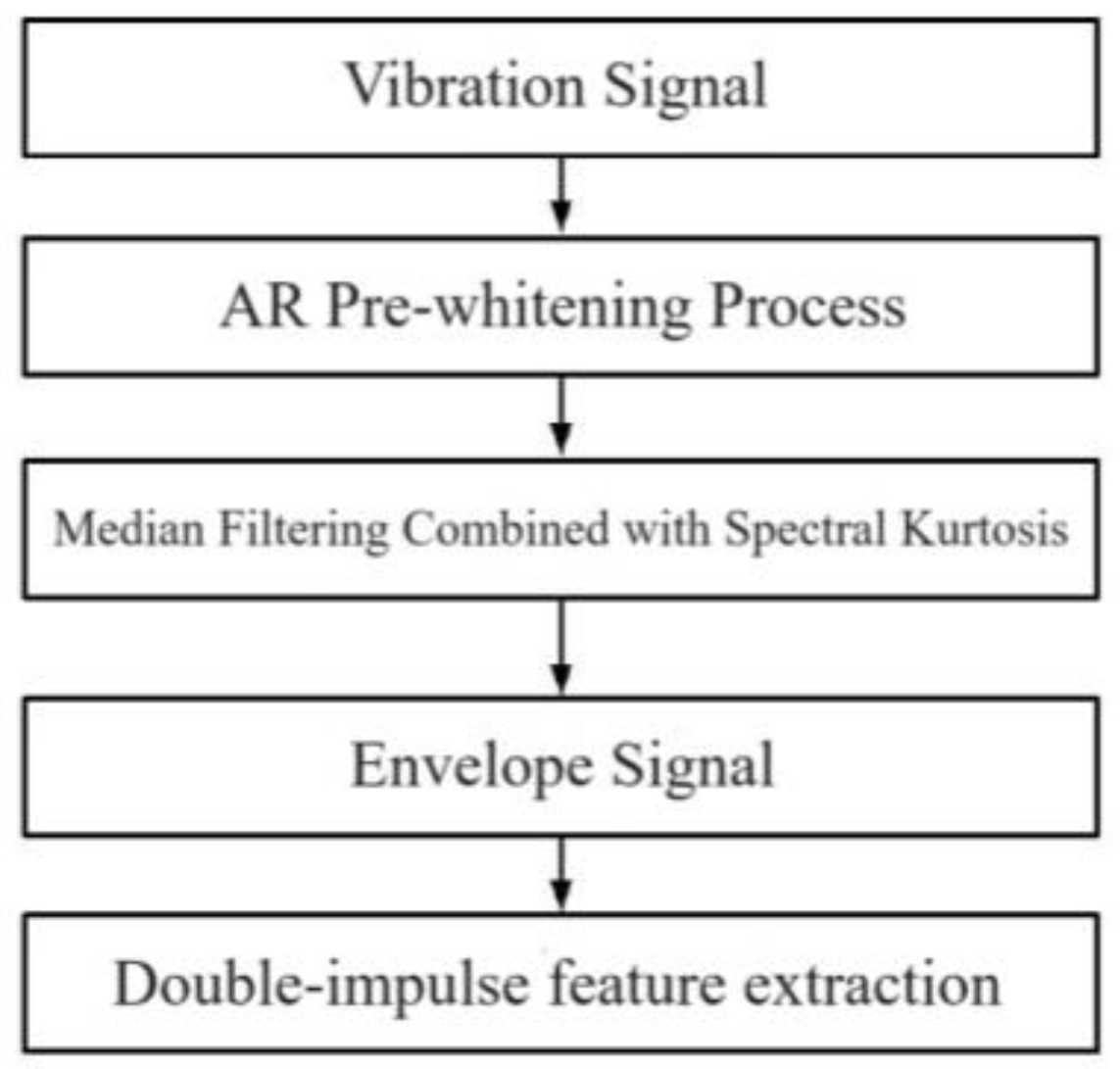

- Kong, Y.B.; Guo, Y.; Wu, X. Double-impulse feature extraction of faulty hybrid ceramic ball bearings based on EEMD. J. Vib. Shock. 2016, 35, 17–22. (In Chinese) [Google Scholar] [CrossRef]

- Lu, Y.X.; Guo, Y. Double-impulse feature extraction of faulty hybrid ceramic ball bearings based on DTCWPT. Vib. Proced 2017, 14, 51–56. [Google Scholar] [CrossRef]

- Kang, W.; Guo, Y.; Wu, X. Spall size estimation of faulty hybrid ceramic ball bearings without a speed meter based on double impulses. J. Vib. Shock. 2017, 36, 6. [Google Scholar] [CrossRef]

- Guo, Y.; Sun, S.; Wu, X.; Na, J.; Fung, R.F. Experimental investigation on double-impulse phenomenon of hybrid ceramic ball bearing with outer race spall. Mech. Syst. Signal Process 2016, 113, 189–198. [Google Scholar] [CrossRef]

- Shi, H.T.; Bai, X.T.; Zhang, K.; Liu, Z.M. Spalling Localization on the Outer Ring of Hybrid Ceramic Ball Bearings Based on the Sound Signals. IEEE Access 2019, 7, 134621–134634. [Google Scholar] [CrossRef]

- Xu, Q.; Ren, C.Z.; Chen, J.J. Three-dimensional FEM Analysis of interface and Contact Stress of Hybrid Ceramic Ball Bearing. Mach. Tool. Hydraul. 2003, 2, 203–204+206. (In Chinese) [Google Scholar]

- Wu, Z.Y.; Ren, C.Z.; Xu, Q. Three-dimensional Finite Element Analysis of Contact Problem in Optimal Design of Hybrid Ceramic Ball Bearings. J. Mech. Des. 2004, 5, 47–49. [Google Scholar] [CrossRef]

- Shen, H.K.; Zhang, C.; Zheng, J.H. Contact Analysis of Angular Contact Hybrid Ceramic Ball Bearing Based on ANSYS. Modul. Mach. Tool. Autom. 2011, 1, 33–34+38. (In Chinese) [Google Scholar]

- Guo, B.; Han, Y.Q.; Lei, W.J.; Wei, H.B.; Li, F.Z. Finite Element Analysis of Hybrid Ceramic Ball Bearing Contact. Key Eng. Mater. 2011, 474–476, 2064–2070. [Google Scholar] [CrossRef]

- Li, Q.Z.; Zhu, Q.; Li, D.J. Optimization Design of Curvature Radius of Silicon Nitride Hybrid Ceramic Ball Bearing based on Contact Stress. J. Mech. Transm. 2017, 41, 100–104. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zhou, G.; Zhang, D.Z.; Zhou, N.N. Research on dynamic performance and operating stability of ceramic ball bearings for space use. In Proceedings of the Third International Conference on Mechanical Design and Simulation, Xi’an, China, 16 June 2023. [Google Scholar] [CrossRef]

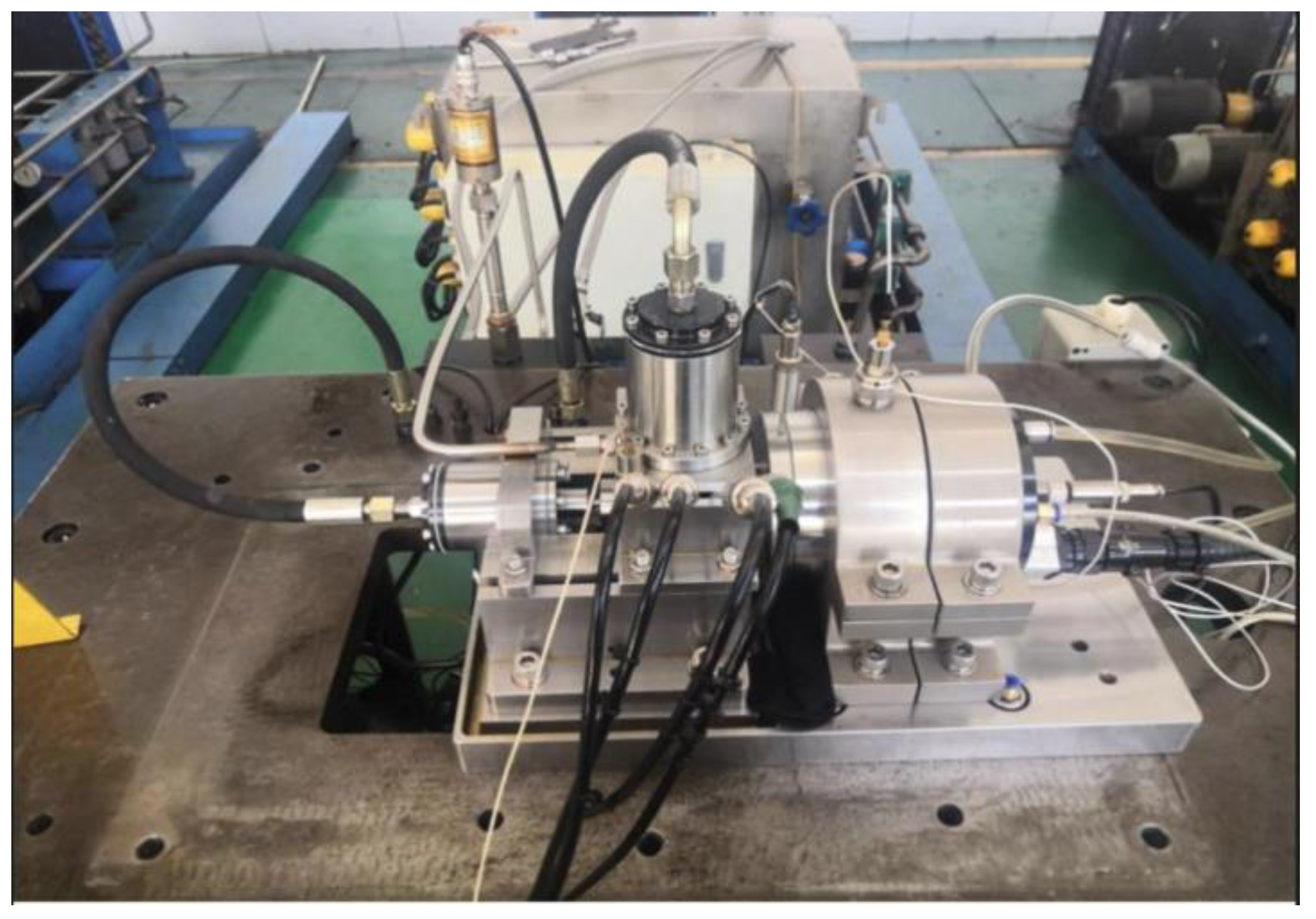

- Chen, Z.X.; Long, W.S.; Song, L.; Li, X.L. Experiment and simulation analysis of tribological and dynamic characteristics in aeroengine hybrid ceramic bearing. Aircr. Eng. Aerosp. Technol. 2023, 95, 1694–1705. [Google Scholar] [CrossRef]

- Liu, S.C.; Xu, H.L.; Yu, W.; Song, X.D. Static Analysis of Hybrid Ceramic Angular Contact Ball Bearing. J. Intell. Manuf. 2013, Z1, 76–79. (In Chinese) [Google Scholar]

- Chen, J.J.; Ren, C.Z.; Xu, Y.S. Numerical Solution of Contact Stress and Deformation of Hybrid Ceramic Ball Bearing. J. Mech. Des. 2004, 1, 10–12. [Google Scholar] [CrossRef]

- Wei, Y.G.; Xu, K.; Yao, J.C.; Li, D.J.; Lv, H.T. Influence of Radial Clearance on Load Distribution and Contact Stress of All—Steel and Ceramic Ball Bearings. Bearing 2023, 11, 27–34. [Google Scholar] [CrossRef]

- Yuan, W.; Xiong, W.L.; Huang, H.W. Comparative research on the performance of the high-speed precision ceramic ball bearing and steel ball bearing. Machinery 2003, 30, 33–36. (In Chinese) [Google Scholar]

- Jones, A.B. A General Theory for Elastically Constrained Ball and Radial Roller Bearings Under Arbitrary Load and Speed Conditions. J. Basic. Eng. 1960, 82, 309–320. [Google Scholar] [CrossRef]

- Liu, C.H.; Gu, J.M.; Dong, X.Y. Performance Analysis and Experiments of Hybrid Bearing for Micro-Satellite Attitude Control Momentum Wheel. J. Astronaut. 2007, 2, 427–431. (In Chinese) [Google Scholar]

- Xu, Y.Z.; Jiang, S.Y. Study on Dynamic Characteristics of High-Speed Angular Contact Ceramic Ball Bearing. J. Southeast. Univ. 2004, 3, 319–323. (In Chinese) [Google Scholar]

- He, Q.; Liu, H.Z.; Zhang, Y.B.; Ye, J.; Niu, Q.P. The characteristics of hybrid ceramic ball bearing for high-speed spindle. In Proceedings of the 2009 IEEE International Conference on Mechatronics and Automation, Changchun, China, 4–7 August 2009. [Google Scholar] [CrossRef]

- Tian, X.L.; Xu, S.; Yao, J.M. Effects on capability of ultra-high-speed angular contact ceramic ball bearing by ball diameter and its capabilities and optimal design of parameters. J. Mech. Des. 2011, 28, 29–33. [Google Scholar] [CrossRef]

- Lavrentyev, Y.L. Determining the Optimal Sphere of Application of Hybrid Rolling Bearings. Her. Bauman Mosc. State Tech. Univ. Mech. Eng. 2018, 1, 57–65. [Google Scholar] [CrossRef]

- Gärtner, M.; Brecher, C.; Neus, S.; Eckel, H.-M.; Bartelt, A.; Hoppert, M.; Ilkhani, M.R. The Friction of Radially Loaded Hybrid Spindle Bearings under High Speeds. Machines 2023, 11, 649. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, X.; Han, Q.P.; Zhu, R.; Lv, H.Y. Analysis of Preload of Hybrid Bearings for Micro Turbine. Bearing 2024, in press. Available online: http://kns.cnki.net/kcms/detail/41.1148.TH.20231227.1608.004.html (accessed on 15 June 2024).

- Zheng, Y.W.; Liu, G.P.; Zhao, B.H.; Hao, D.Q.; Chen, H.Q. Performance analysis and test research of high temperature and high-speed hybrid ceramic ball bearings. J. Aerosp. Power 2024. in press Available online: https://doi.org/10.13224/j.cnki.jasp.20210402 (accessed on 15 June 2024).

- TAKEBAYASHI, H. Bearings for Extreme Special Environments (3)-basic performance of ceramic (silicon nitride) bearings. KOYO Eng. J. 2001, 158, 53–60. [Google Scholar]

- TAKEBAYASHI, H. Bearings for Extreme Special Environment (4)-Application of Ceramic Bearings. KOYO Eng. J. 2002, 160, 56–64. [Google Scholar]

- Gu, L.; Wang, L.Q.; Li, X.J.; Qi, L.L. Load-bearing properties of silicon nitride bearing balls under ultra-low temperature. J. Harbin Inst. Tech. 2002, 2, 148–151. (In Chinese) [Google Scholar]

- Gu, L.; Wang, L.Q.; Qi, L.L. Performance of hybrid ceramic bearing at cryogenic and high-speed condition. J. Harbin Inst. Tech. 2004, 2, 157–159. (In Chinese) [Google Scholar]

- Grigorescu, R.; Giovanola, J.H. Some aspects of power losses in high-speed hybrid bearings. Tribol. Interface Eng. Ser. 2002, 40, 481–488. [Google Scholar] [CrossRef]

- Fan, Y.Q.; Zhang, Z.H.; Liu, P.D.; Ma, Y. High-speed Performance Analysis of Hybrid Ceramic Angular Contact Ball Bearing. Bearing 2012, 3, 20–22. (In Chinese) [Google Scholar] [CrossRef]

- Wang, B.; Guo, Y.B.; Zhang, Z.; Yi, X.H.; Wang, D.G. Investigation of cryogenic friction and wear properties of Invar 36 alloy against Si3N4 ceramic balls. Wear 2023, 518–519, 2046–2048. [Google Scholar] [CrossRef]

- Slaney, F.D. Hybrid ceramic bearing development for gas turbine engines. In Proceedings of the ASME 1994 International Gas Turbine and Aeroengine Congress and Exposition, The Hague, The Netherlands, 13–16 June 1994. [Google Scholar] [CrossRef]

- Shoda, Y.; Ijuin, S.; Aramaki, H.; Yui, H.; Toma, K. The Performance of a Hybrid Ceramic Ball Bearing Under High-Speed Conditions with the Under-Race Lubrication Method. Tribol. Trans. 1997, 40, 676–684. [Google Scholar] [CrossRef]

- Cento, P.; Dareing, D.W. Ceramic Materials in Hybrid Ball Bearings. Tribol. Trans. 1999, 42, 707–714. [Google Scholar] [CrossRef]

- Tian, X.L.; Mao, Y.T.; Xu, S.; Yao, J.K.; Guo, F. Heat generating analysis of high-speed hybrid ceramic ball bearing of turbocharger and efficiency. Mod. Manuf. Eng. 2011, 9, 5–9. [Google Scholar] [CrossRef]

- Takeuchi, Y.R.; Davis, S.E.; Eby, M.A. Steel and Hybrid Spacecraft Ball-Bearing Thermal Conductance Comparisons. In Proceedings of the Symposium on Rolling Element Bearings, Anaheim, CA, USA, 13–14 April 2011. [Google Scholar] [CrossRef]

- Lavrentyev, Y.L.; Petrov, N.I.; Nozhnitsky, Y.A. Empirical correlation of heat generation in hybrid ball bearings, depending on the operational conditions in the aero-engine rotor supports. J. Phys. Conf. Ser. 2021, 1777, 012046. [Google Scholar] [CrossRef]

- Lavrentyev, Y.; Petrov, N.; Nozhnitsky, Y. Determination of the Area of Rational Use of Hybrid Bearings with Steel Rings and Ceramic Rolling Elements in High-Speed Aircraft Engines. In Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference and Exposition, Volume 9A: Structures and Dynamics—Aerodynamics Excitation and Damping; Bearing and Seal Dynamics; Emerging Methods in Design and Engineering, Virtual, Online, 7–11 June 2021. [Google Scholar] [CrossRef]

- Nozhnitsky, Y.A.; Petrov, N.I.; Lavrentyev, Y.L. Hybrid rolling bearings for aircraft engines (review). Aviat. Engines 2019, 2, 63–76. [Google Scholar] [CrossRef]

- Cao, Y. Finite-Element Analysis for Temperature Field of Hybrid Ceramic Angular Contact Ball Bearings. Master’s Thesis, Tianjin University, Tianjin, China, 2008. [Google Scholar] [CrossRef]

- Wang, P.; Lei, C.L.; Zhou, B.C.; Zhao, W.P. Finite Element Analysis for Thermal Characteristics of High-Speed Angular Contact Ball Bearing. Appl. Mech. Mater. 2013, 397–400, 126–130. [Google Scholar] [CrossRef]

- Cui, L.; Zhang, H.S. Limiting speeds of high-speed ball bearings considering prevention of skidding and overheating conditions. Adv. Mech. Eng. 2019, 11, 1–11. [Google Scholar] [CrossRef]

- Schrader, S.; Pfaffenberger, E. Performance of Hybrid Ball Bearings in Oil and Jet Fuel. Tribol. Trans. 1992, 35, 389–396. [Google Scholar] [CrossRef]

- Wang, L.; Wood, R.J.K.; Harvey, T.J.; Morris, S.; Powrie, H.E.G.; Care, I. Wear performance of oil lubricated silicon nitride sliding against various bearing steels. Wear 2003, 255, 657–668. [Google Scholar] [CrossRef]

- Jeng, Y.R.; Huang, P.Y. Temperature rise of hybrid ceramic and steel ball bearings with oil-mist lubrication. Lubr. Eng. 2000, 12, 56. [Google Scholar]

- Paleu, V.; Damian, I.; Stirbu, C. Friction Torque Measurement in Partial Hybrid S-C Angular Contact Ball Bearings. Appl. Mech. Mater. 2014, 658, 339–344. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Mao, H.B. Investigation of the High-Speed Rolling Bearing Temperature Rise with Oil-Air Lubrication. J. Tribol. 2011, 133, 655–664. [Google Scholar] [CrossRef]

- Wang, J. Experimental Research on Oil-air Lubrication and Preload for Hybrid Ceramic Ball Bearing. J. Yanshan Univ. 2004, 1, 92–94. (In Chinese) [Google Scholar]

- Dotsenko, V.; Gnytko, O.; Koveza, Y.; Kuznetsova, A. Experimental Determination of Power Losses in Steel and Hybrid Rolling Bearings. Cioboată, D.D. In Proceedings of the International Conference on Reliable Systems Engineering, Bucharest, Romania, 7–8 September 2023. [Google Scholar] [CrossRef]

- Zhu, P.J. Analysis of Thermal Mixed Lubrication of Angular Contact Ball Bearing in High-Speed Railway Gearboxs. Master’s Thesis, Qingdao University of Technology, Qingdao, China, June 2023. [Google Scholar]

- Lugt, P.M.; Zoelen, M.T.V.; Vieillard, C.; Berens, F.; Meaney, P. Grease Performance in Ball and Roller Bearings for All-Steel and Hybrid Bearings. Tribol. Trans. 2021, 65, 1–13. [Google Scholar] [CrossRef]

- Zheng, D.; Le, G.; Wang, T.; Wang, L. Performance and Failure Modes of Grease Lubricated Hybrid Ceramic Bearing in High Speed and High Temperature Condition. In Proceedings of the ASME/STLE 2012 International Joint Tribology Conference, ASME/STLE 2012 International Joint Tribology Conference, Denver, CO, USA, 7–10 October 2012. [Google Scholar] [CrossRef]

- Wei, W.X.; Su, Y.F.; Fan, H.Z.; Song, J.J.; Zhang, Y.S.; Hu, L.T. Rolling Friction, Wear Characteristics and Damage Behaviors of Si3N4 Ceramic Bearing Balls. Tribology 2024, 44, 1–10. [Google Scholar] [CrossRef]

- Li, S.S.; Huang, X.; Li, D.J.; Zhou, P.; Chen, B. Early Failure Experiments for High-speed Hybrid Ceramic Ball Spindle Bearings with Grease Lubrication. Bearing 2011, 11, 30–33. [Google Scholar] [CrossRef]

- Wu, C.; Liu, Z.; Zhao, H.J.; Yang, H.D.; Li, X.L.; Ni, J. Effect of the grease thickener on tribological properties of Si3N4/GCr15 contact interface and the performance in hybrid ceramic ball bearing. Ceram. Int. 2023, 49, 16857–16867. [Google Scholar] [CrossRef]

- Gibson, H.; Munafo, P. Lubrication of Space Shuttle Main Engine Turbopump Bearings. Lubr. Eng. 2001, 57, 10. [Google Scholar] [CrossRef]

- Nosaka, M.; Kikuchi, M.; Oike, M.; Kawai, N. Tribo-Characteristics of Cryogenic Hybrid Ceramic Ball Bearings for Rocket Turbopumps: Bearing Wear and Transfer Film. ASLE Trans. 1999, 42, 106–115. [Google Scholar] [CrossRef]

- Nosaka, M.; Takada, S.; Yoshida, M.; Kikuchi, M.; Nakamura, S. Improvement of Durability of Hybrid Ceramic Ball Bearings in Liquid Hydrogen at 3Million DN (120,000 rpm). Tribol. Online 2010, 5, 60–70. [Google Scholar] [CrossRef]

- Nosaka, M. Cryogenic Tribology of High-Speed Bearings and Shaft Seals in Liquid Hydrogen. Tribol. Online 2011, 6, 133–141. [Google Scholar] [CrossRef]

- Liu, F.; Lin, B.; Wang, Z.B. Design on Hybrid Ceramic Bearing Based on Water Based Fluid with Controllable Viscosity. Key Eng. Mater. 2010, 443, 731–735. [Google Scholar] [CrossRef]

- Lu, D.; Liu, K.J.; Zhao, W.H.; Lu, B.H. Thermal Characteristics of Water-Lubricated Ceramic Hydrostatic Hydrodynamic Hybrid Bearings. Tribol. Lett. 2016, 63, 23. [Google Scholar] [CrossRef]

- Xiong, X.Z.; Xu, H. Study on the Friction Characteristic of a Water-Lubricated Hybrid Bearing. Adv. Mater. Res. 2013, 816–817, 289–293. [Google Scholar] [CrossRef]

- Wu, C.; Han, Y.; Zhao, H.; Zheng, C.; Li, X.; Ni, J. Effect of choline chloride/multiple diols deep eutectic solvents on the friction and vibration performance of Si3N4/GCr15 hybrid ceramic ball bearings. Tribol. Int. 2024, 198, 109845. [Google Scholar] [CrossRef]

- Gloeckner, P.; Martin, M.; Flouros, M. Comparison of Power Losses and Temperatures between an All-Steel and a Direct Outer Ring–Cooled, Hybrid 133-mm-Bore Ball Bearing at Very High Speeds. Tribol. Trans. 2017, 60, 1148–1158. [Google Scholar] [CrossRef]

- Flouros, M.; Gloeckner, P.; Hirschmann, M.; Martin, M.; Cottier, F.; Papailia, D. Experimental and Numerical Investigation of the Outer Ring Cooling Concept in a Hybrid and in an All-Steel Ball Bearing Used in Aero-Engines by the Introduction of a Helical Duct. Aerospace 2018, 5, 23. [Google Scholar] [CrossRef]

- Yu, Q.; Ma, Y.; Xu, M.; Yang, W.H. Effect of Si3N4 Raw Materials on Performances of Ceramic Balls. Bearing 2019, 5, 23–25. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, B.; Lu, C.; Li, C. Current Status of Research on Hybrid Ceramic Ball Bearings. Machines 2024, 12, 510. https://doi.org/10.3390/machines12080510

Su B, Lu C, Li C. Current Status of Research on Hybrid Ceramic Ball Bearings. Machines. 2024; 12(8):510. https://doi.org/10.3390/machines12080510

Chicago/Turabian StyleSu, Bing, Chunhao Lu, and Chenghui Li. 2024. "Current Status of Research on Hybrid Ceramic Ball Bearings" Machines 12, no. 8: 510. https://doi.org/10.3390/machines12080510

APA StyleSu, B., Lu, C., & Li, C. (2024). Current Status of Research on Hybrid Ceramic Ball Bearings. Machines, 12(8), 510. https://doi.org/10.3390/machines12080510