Friction Stir Channeling in Heat Sink Applications: Innovative Manufacturing Approaches and Performance Evaluation

Abstract

1. Introduction

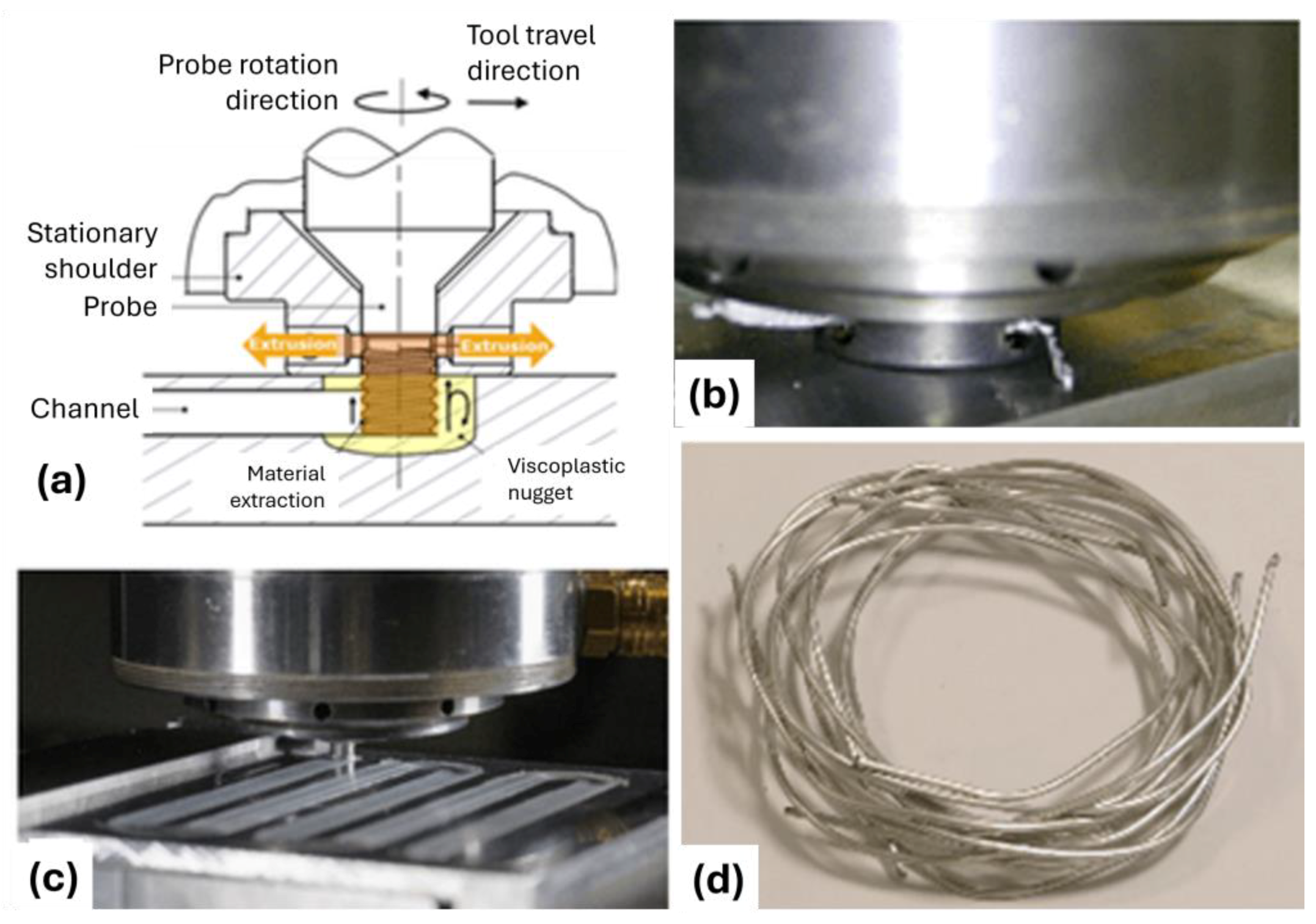

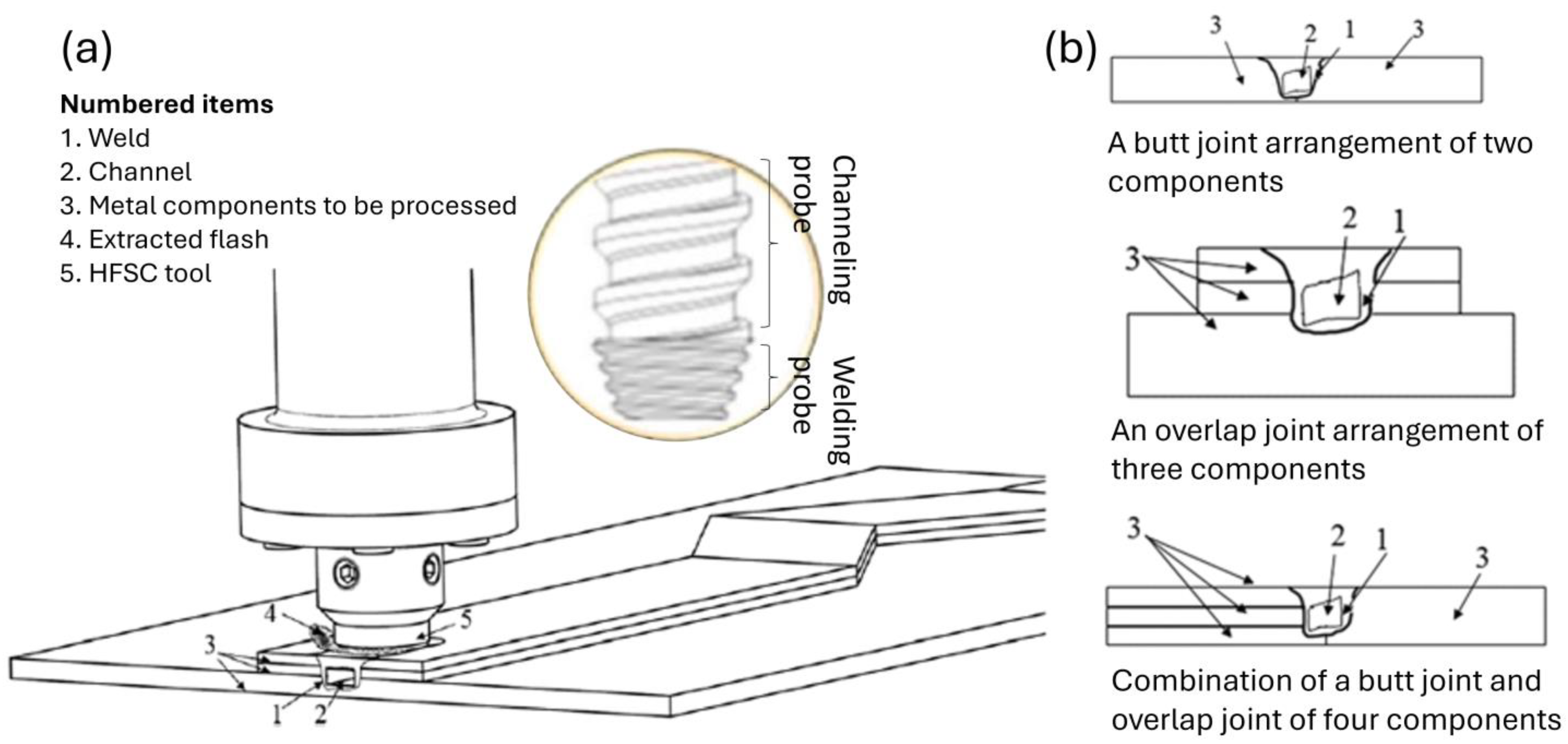

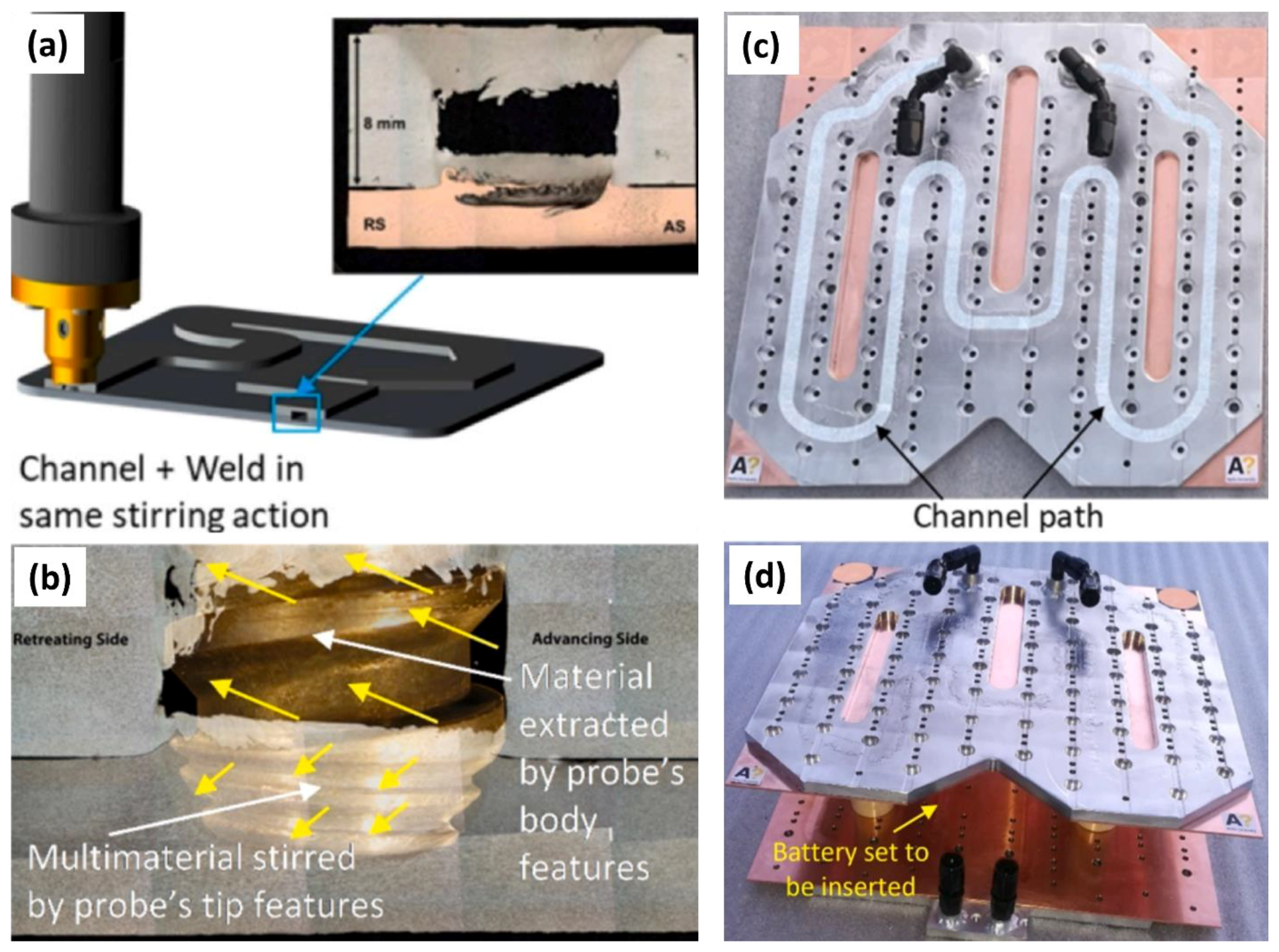

2. Friction Stir Channeling Process

3. Advances in Friction Stir Channeling Concepts and Tool Design Innovations

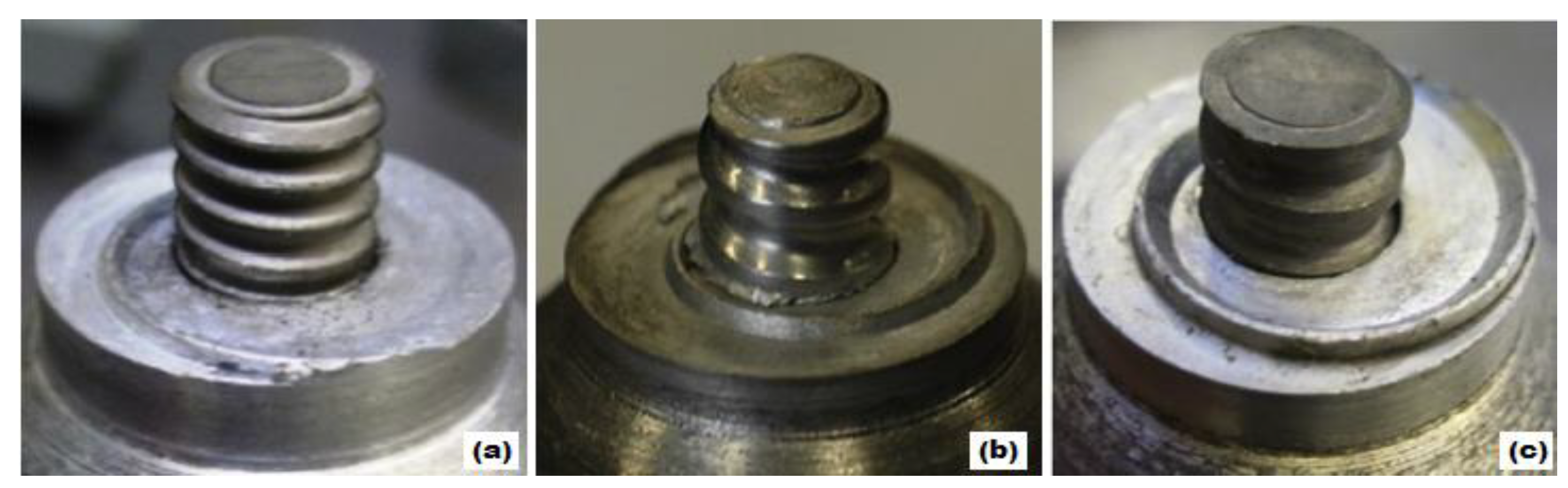

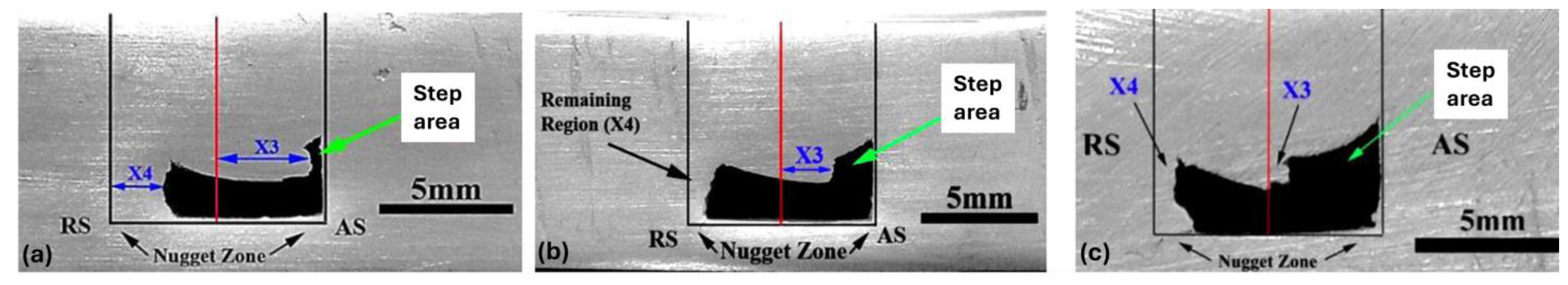

4. Formation of Integral Closed Channels

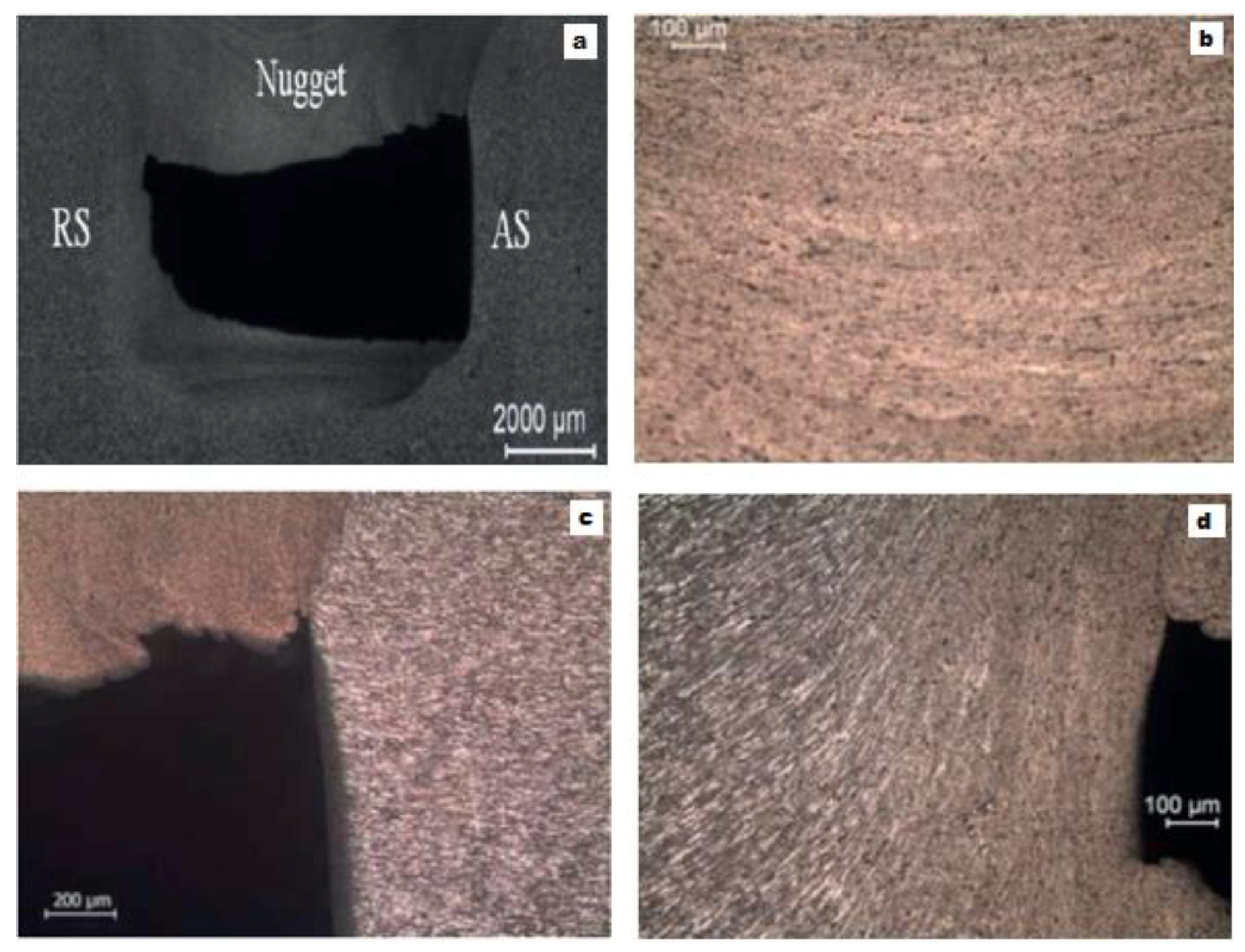

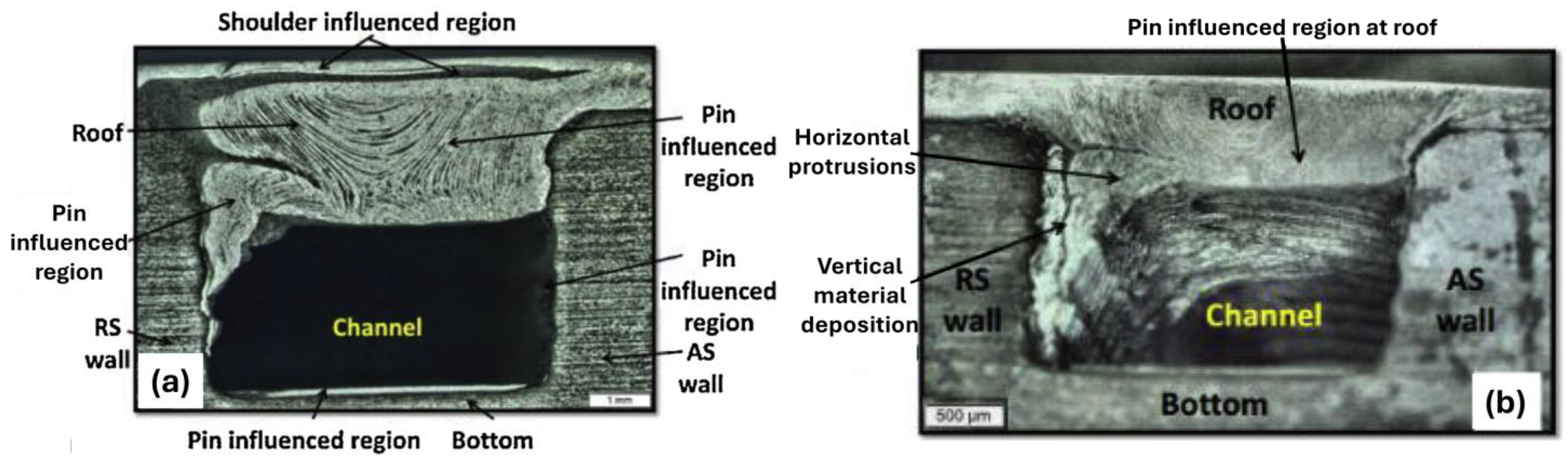

4.1. Formation of Nugget, TMAZ, and HAZ

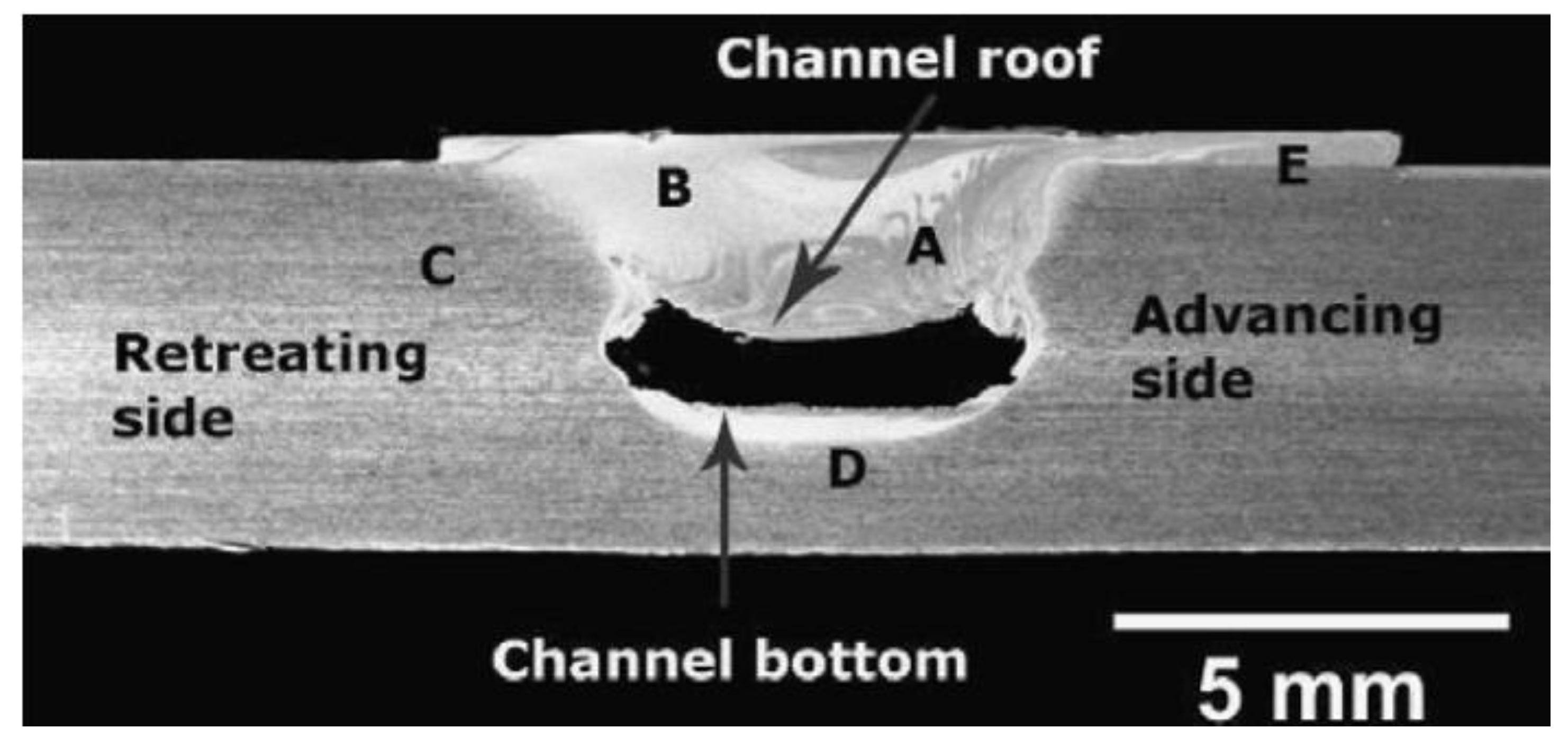

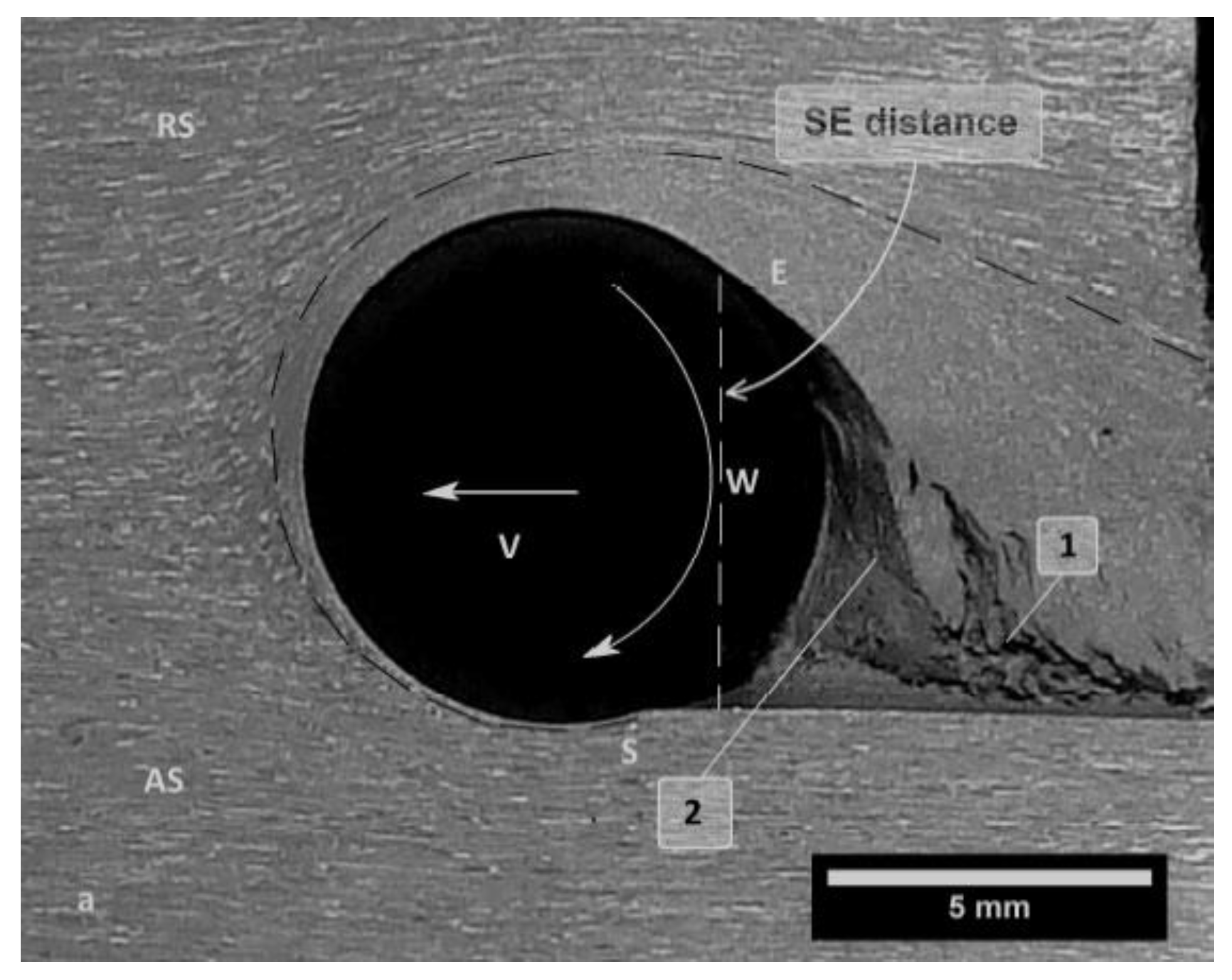

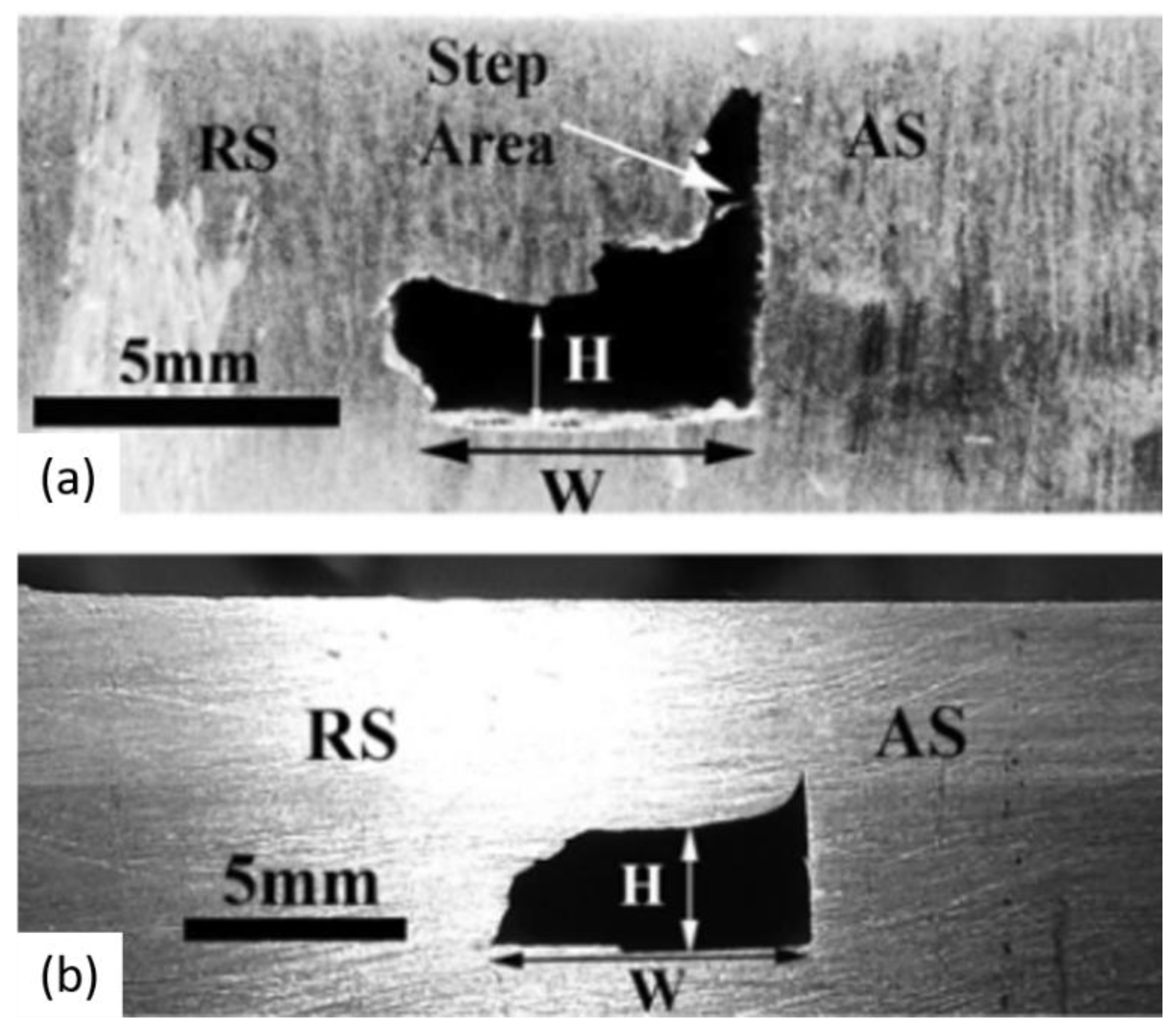

4.2. Effect of Material Flow on Channel Formation

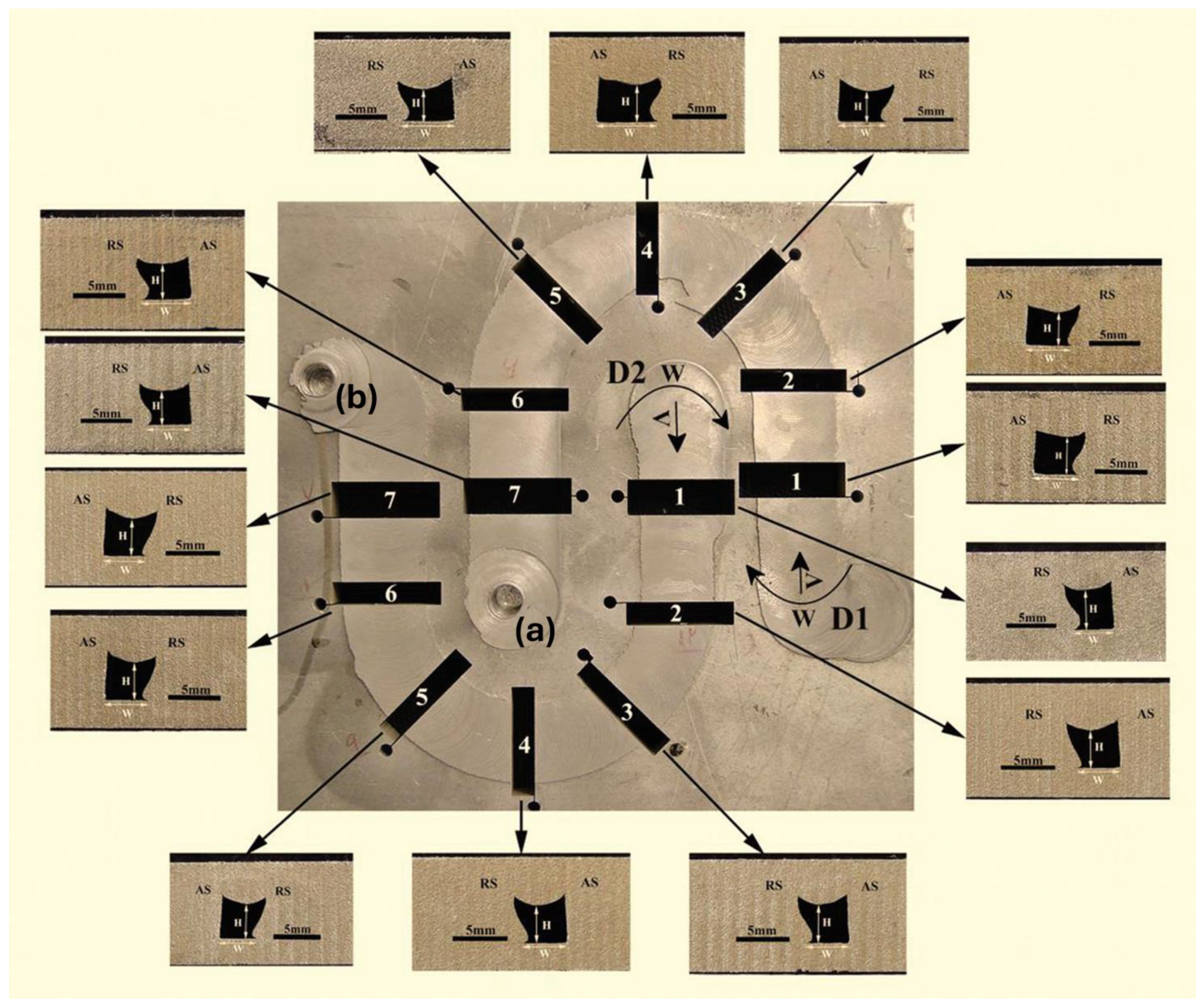

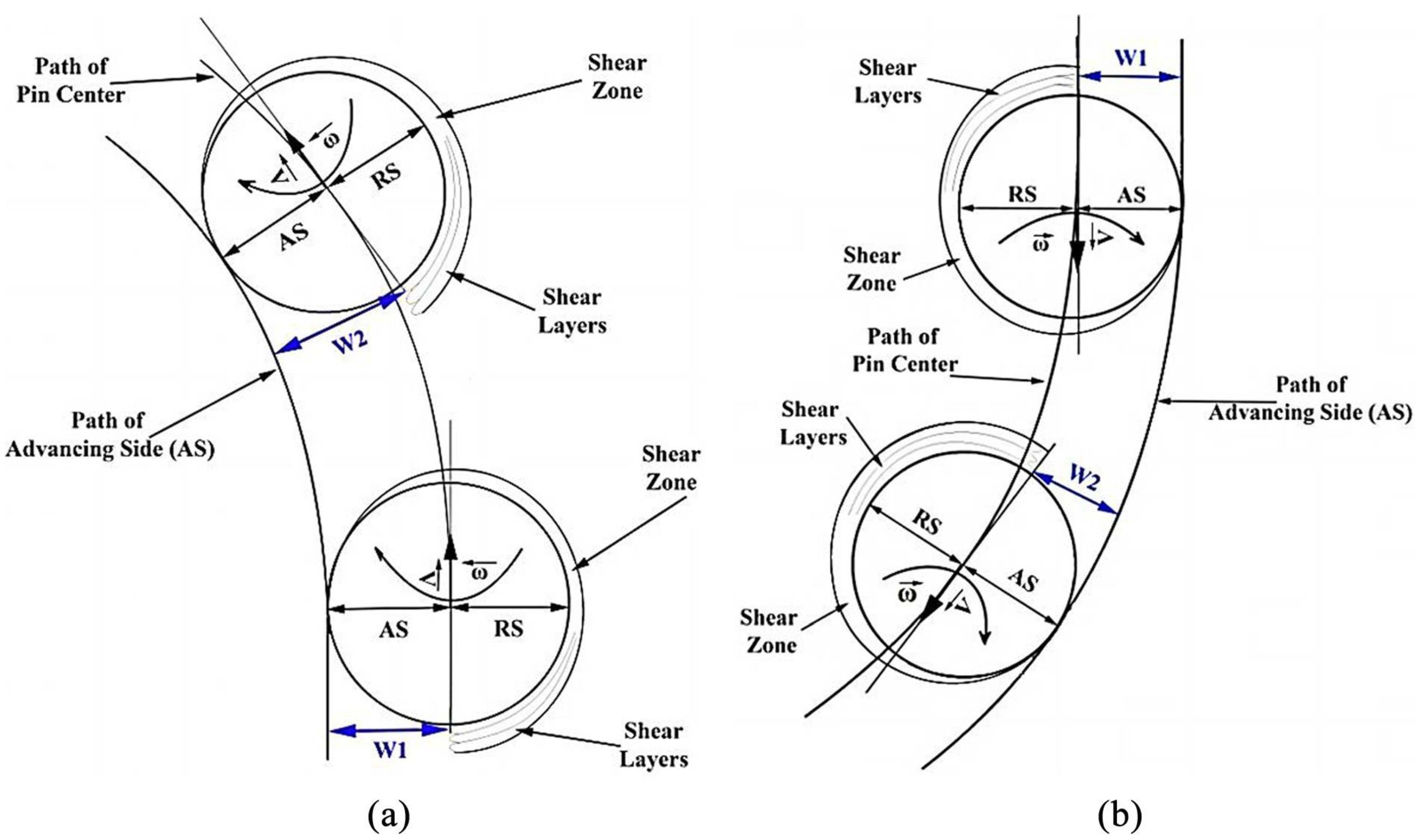

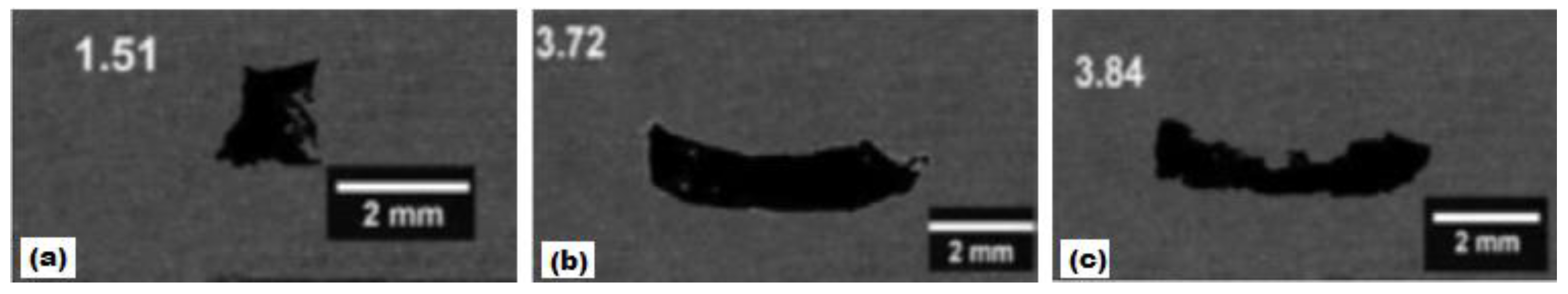

4.3. Material Flow along the Curved Path

5. Processing Parameters

5.1. Tool Rotational Speed and Traverse Speed

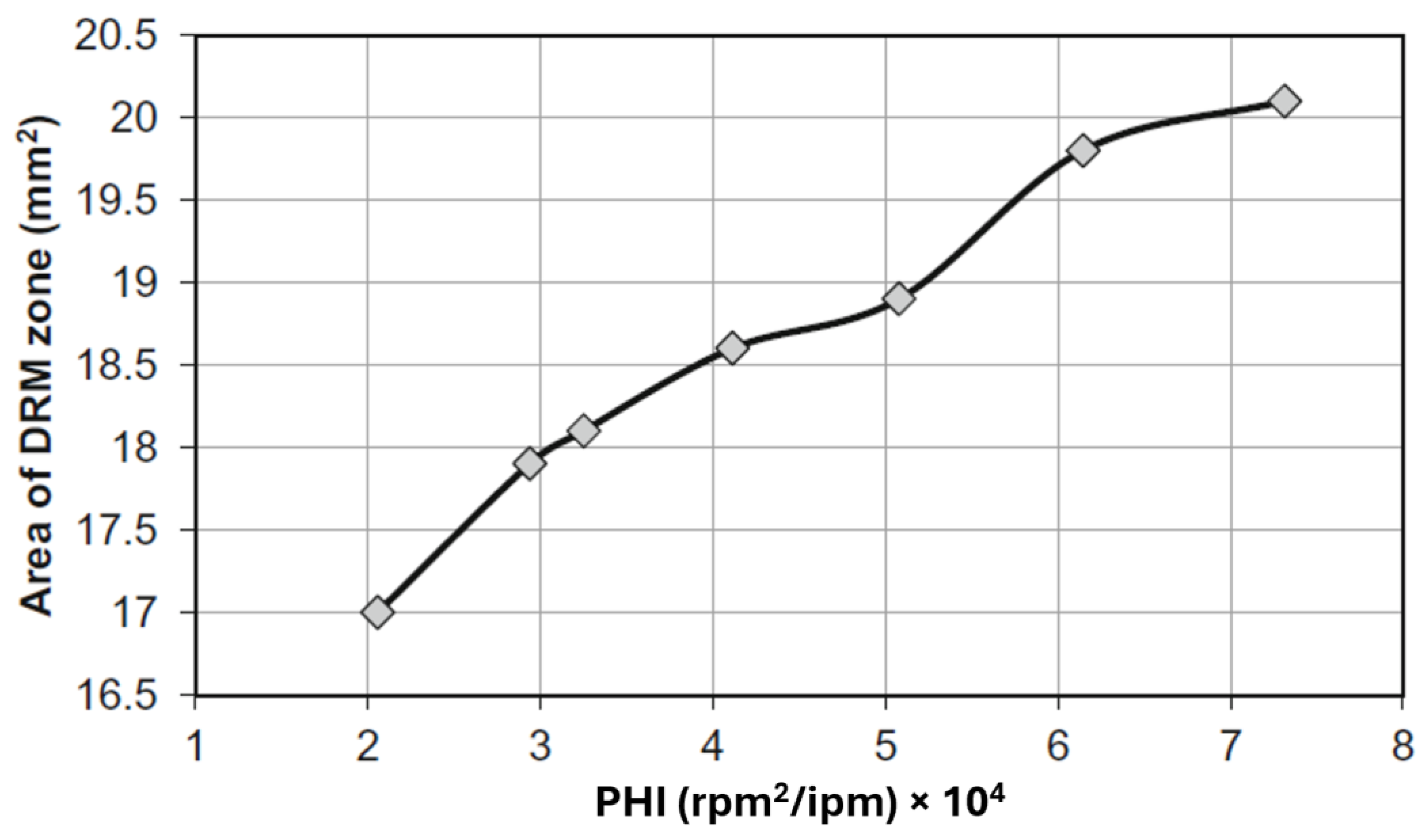

5.1.1. Dynamic Recrystallization Zone

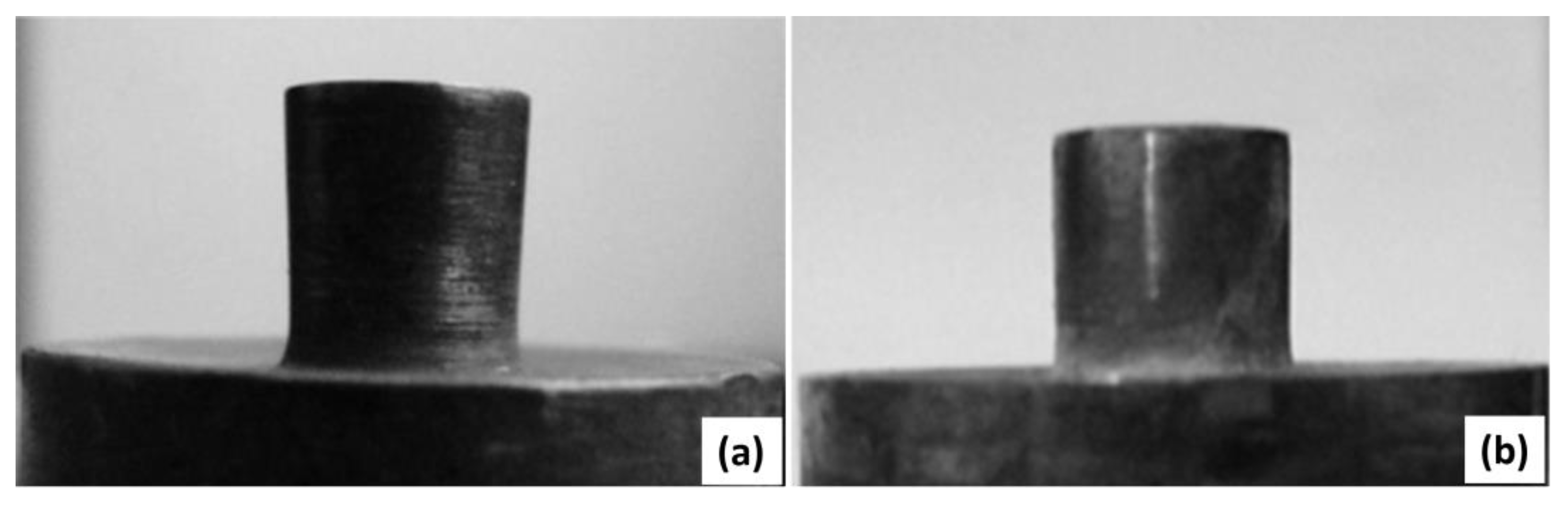

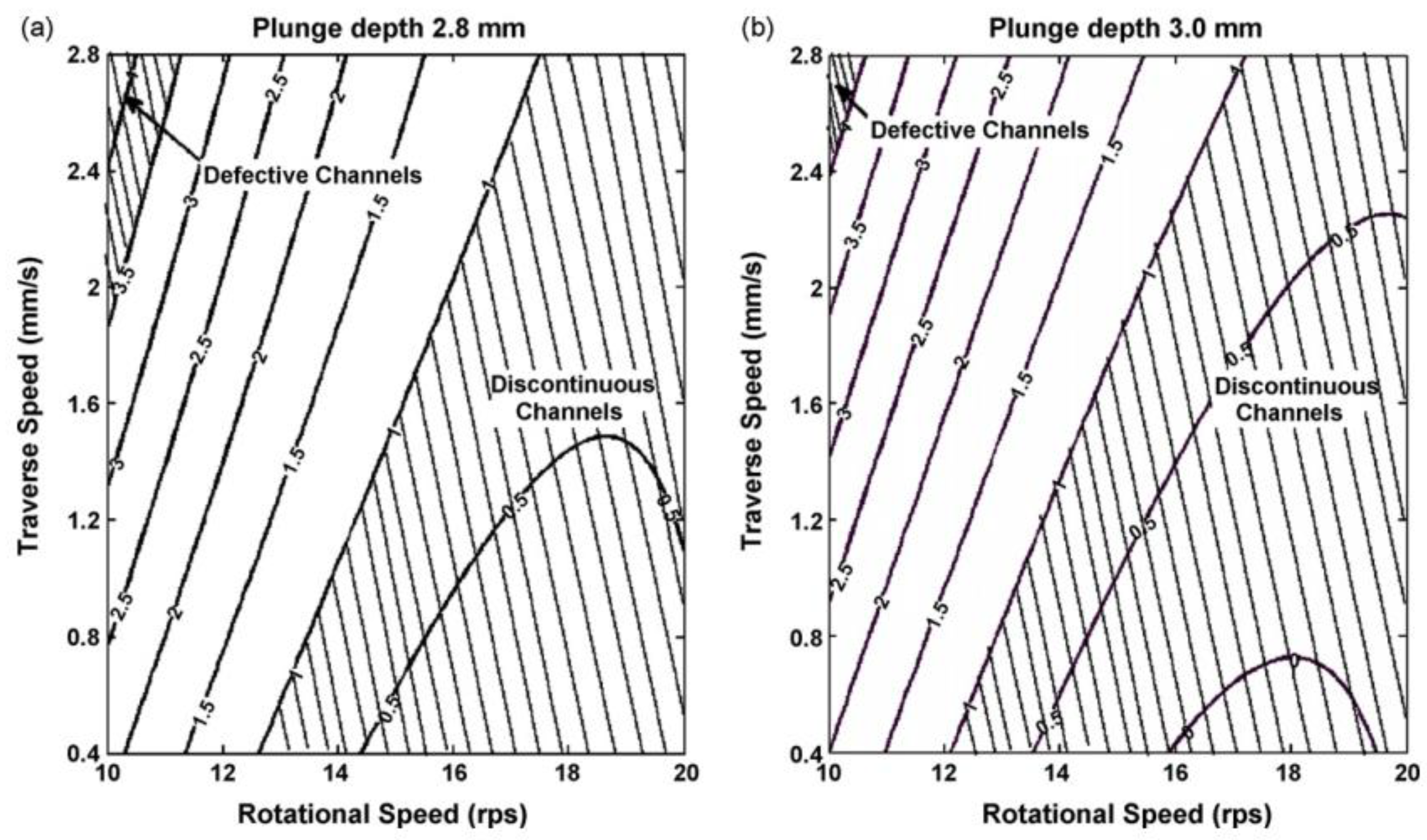

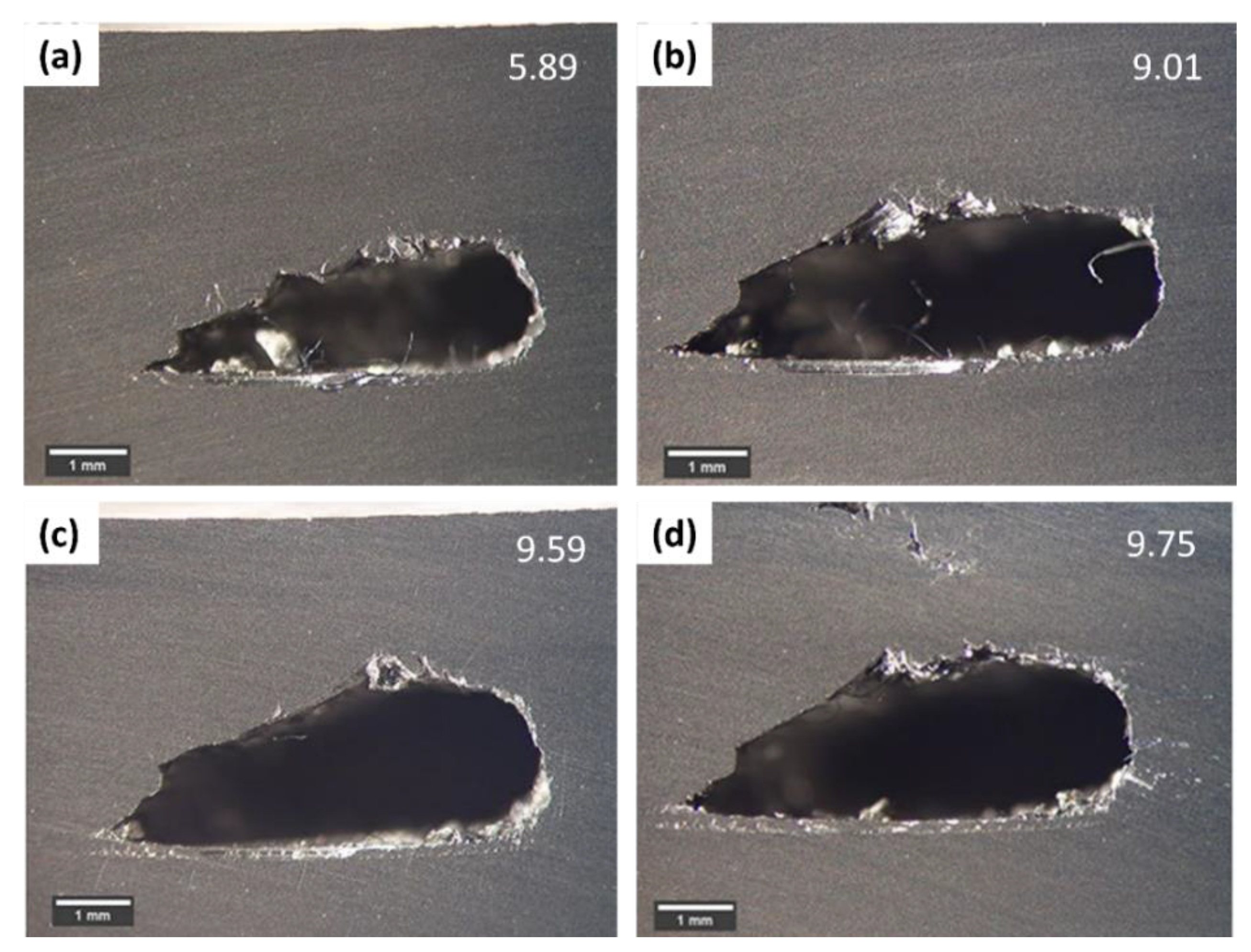

5.1.2. Channel Shape and Size

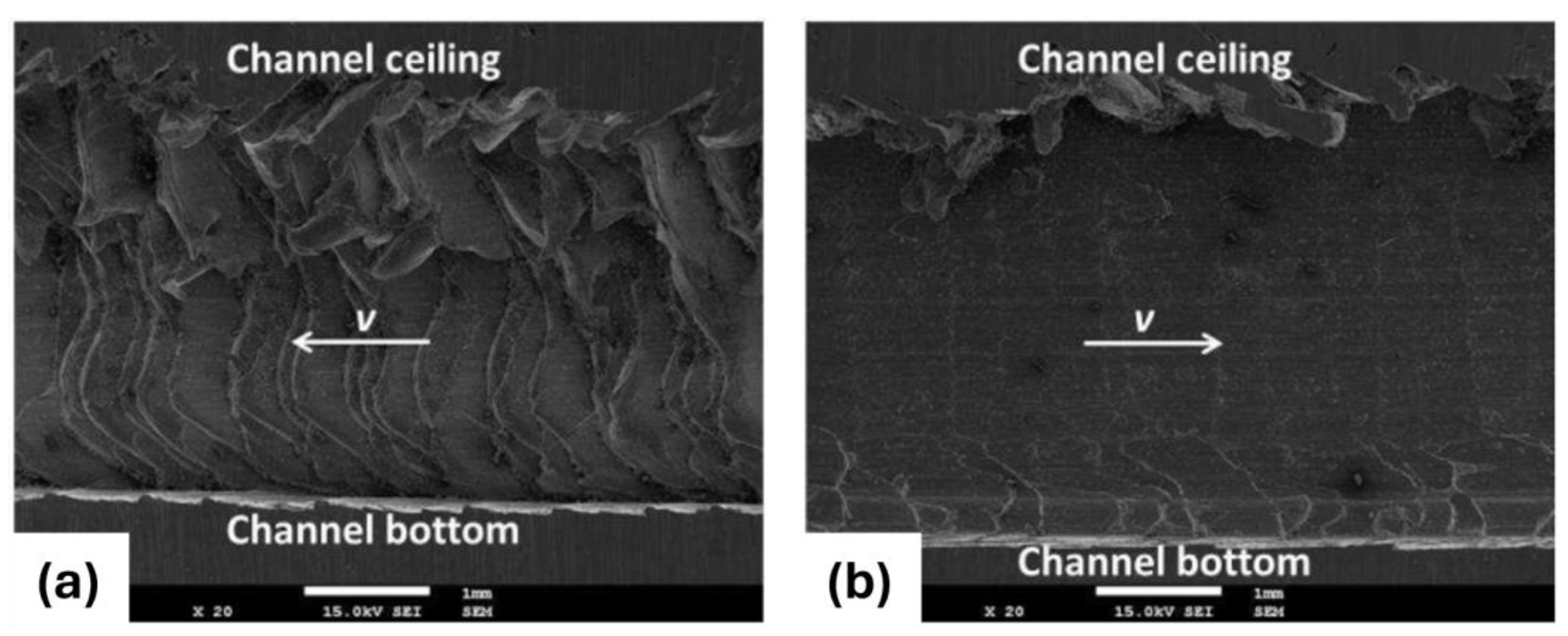

5.1.3. Surface Roughness of Channel Walls

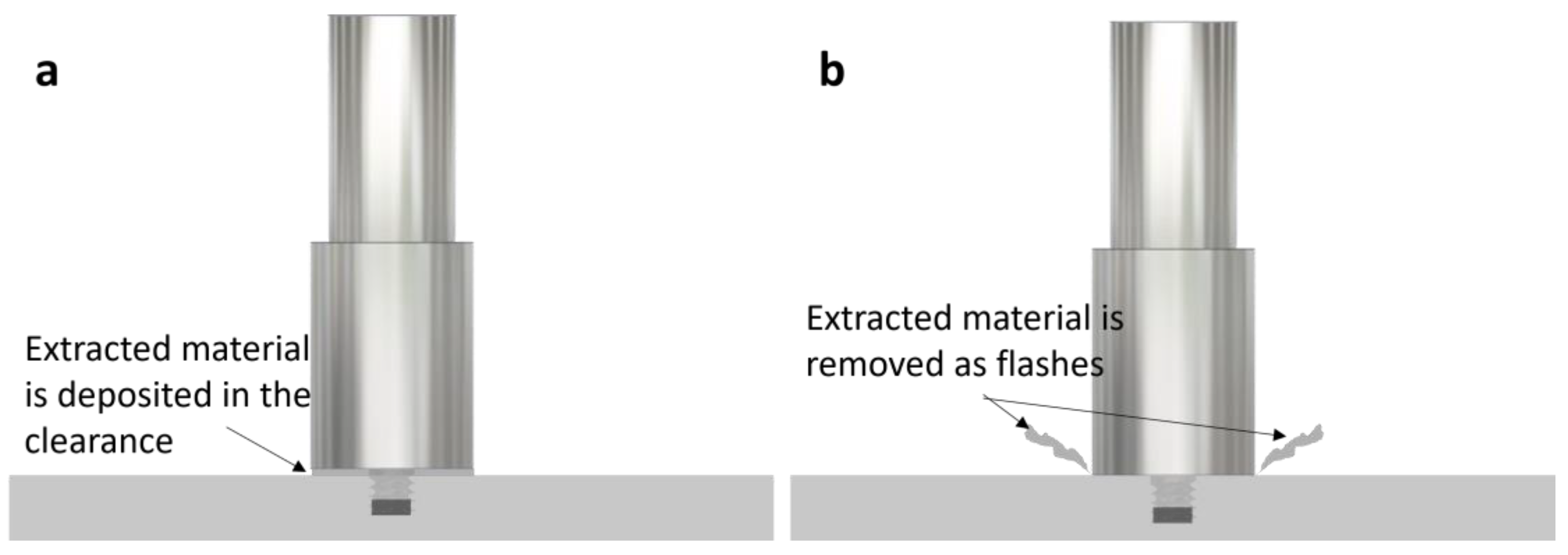

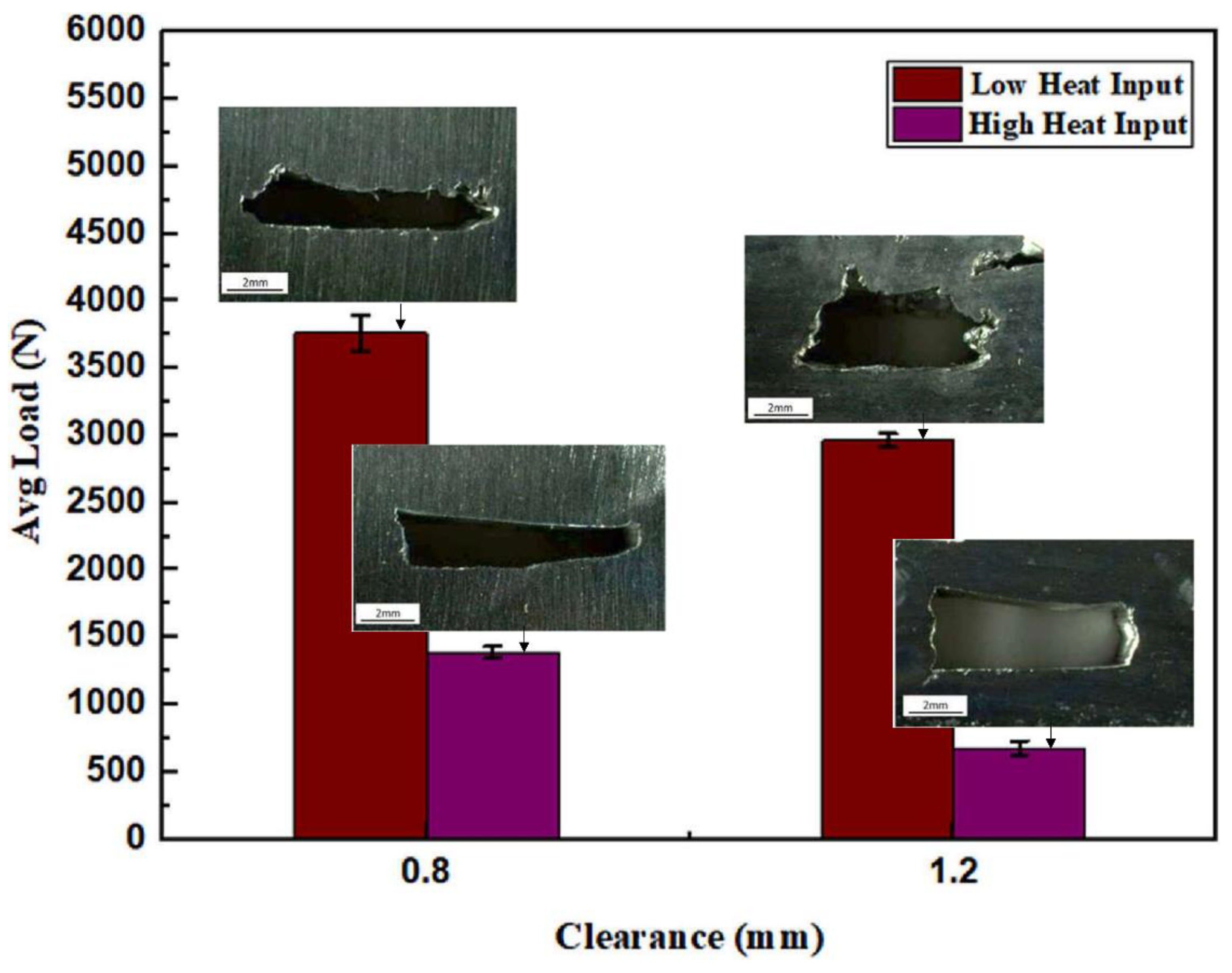

5.1.4. Tool Shoulder—Workpiece Clearance

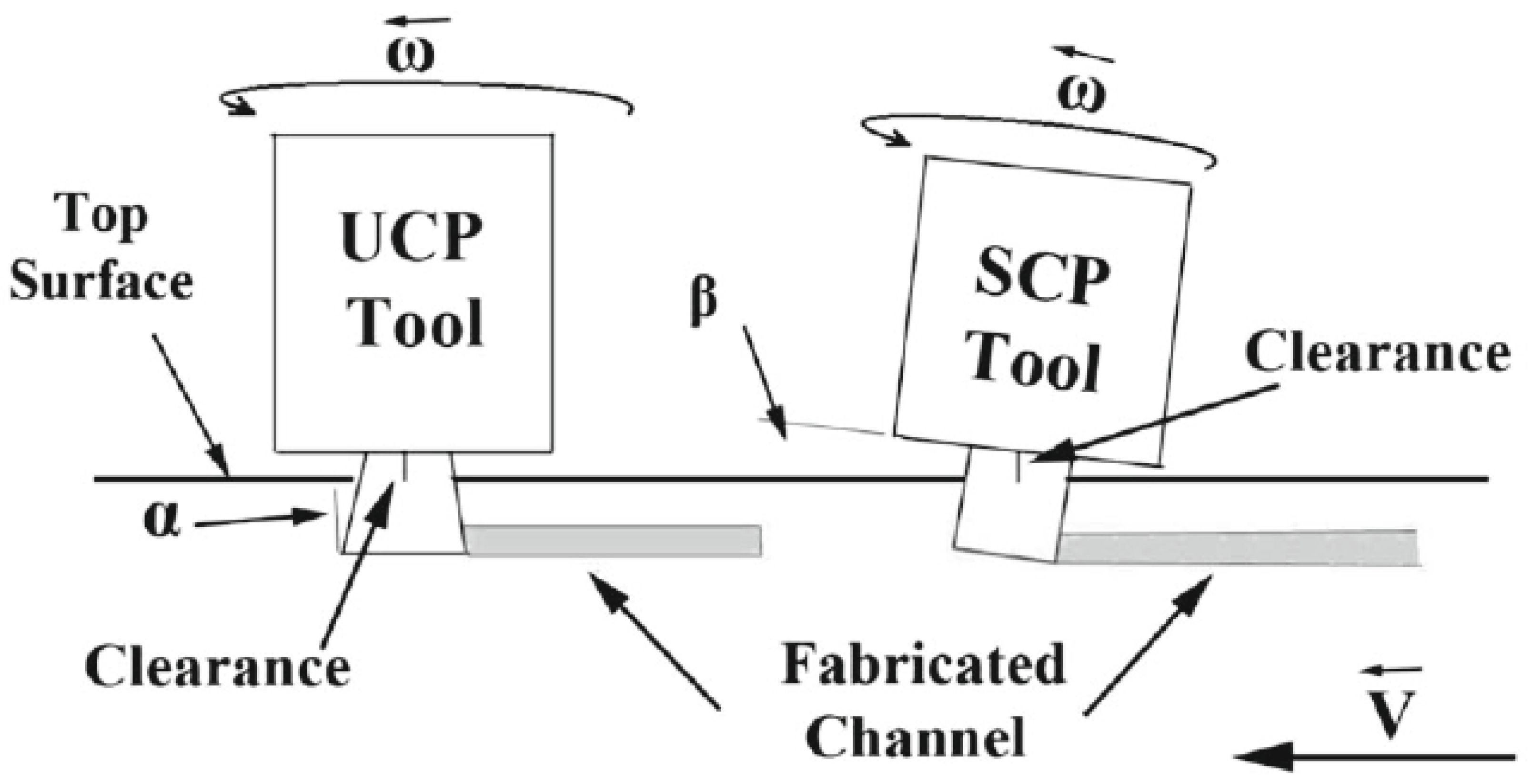

5.2. Tool Tilt Angle

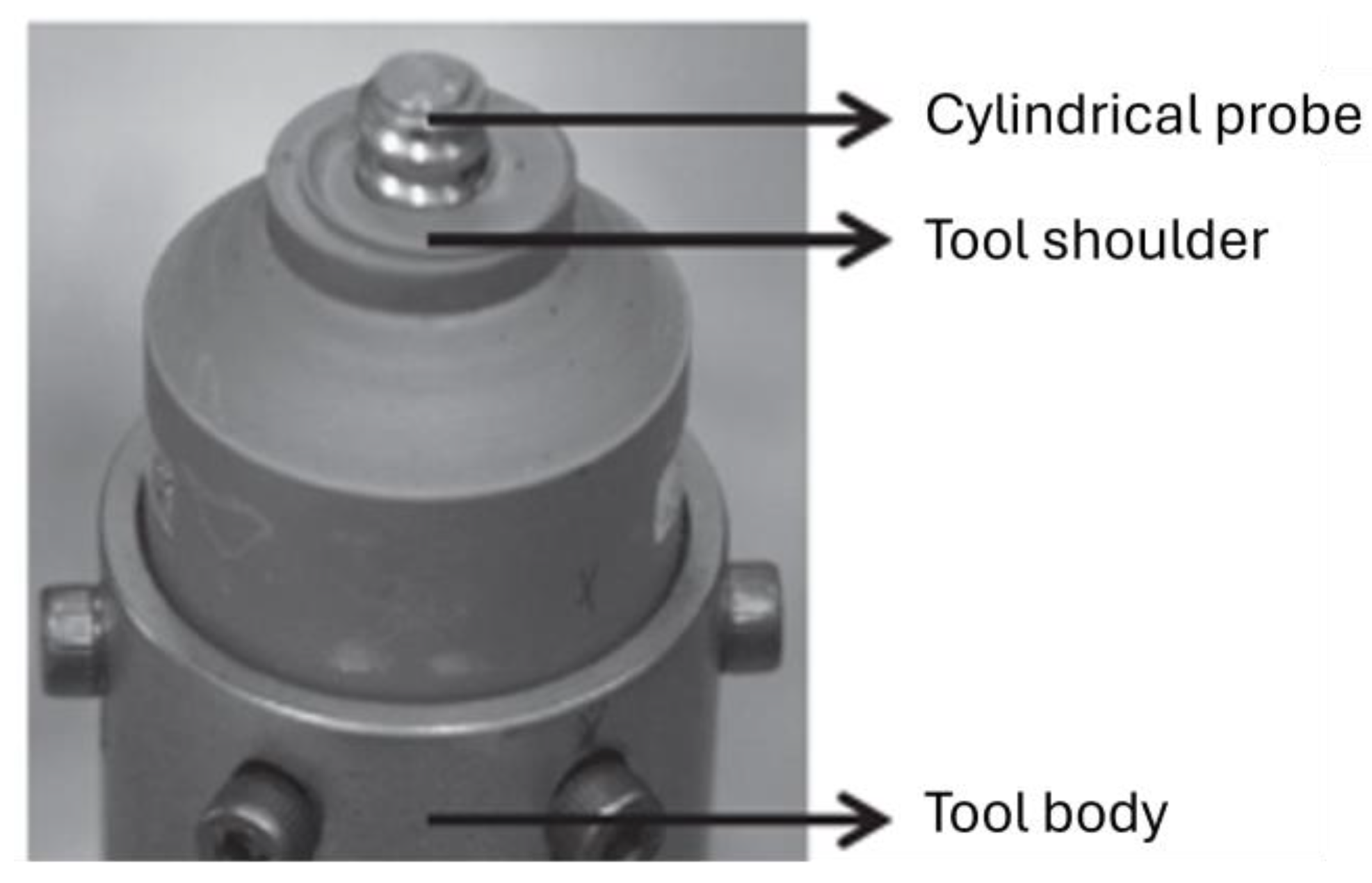

5.3. Tool Geometry

5.3.1. Depth of Cut, Thread Angle, and Pitch

5.3.2. Upward Conical Pin Tool

6. Mechanical Properties

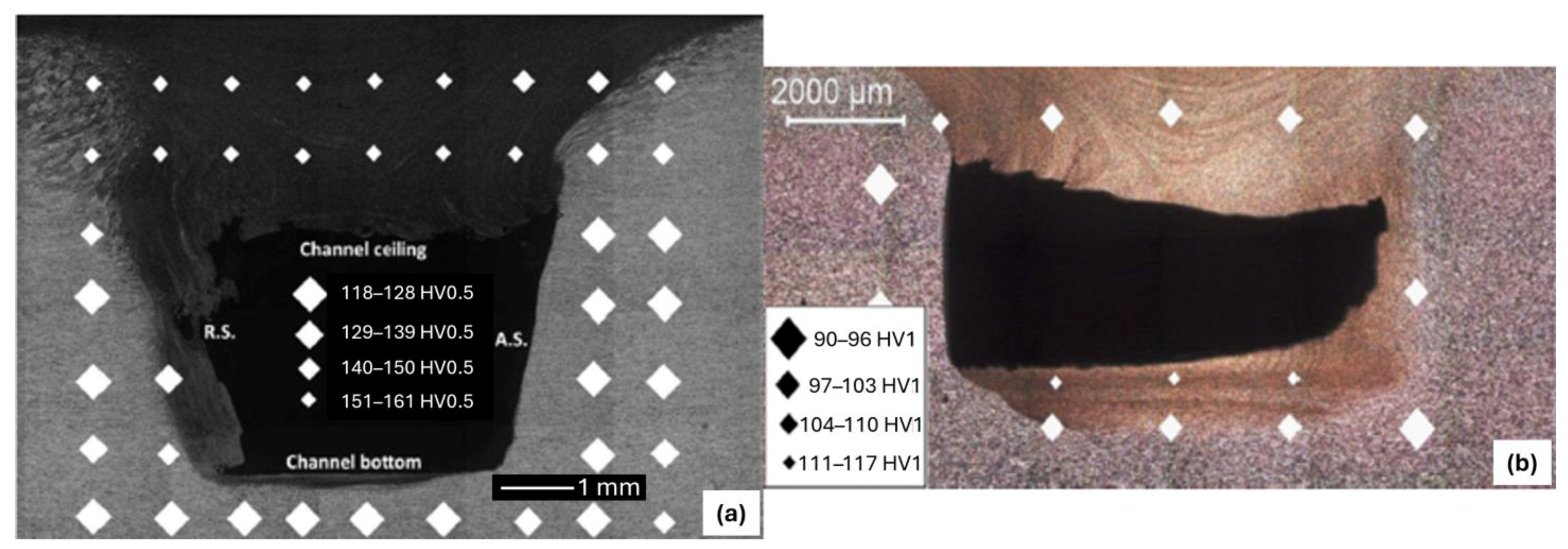

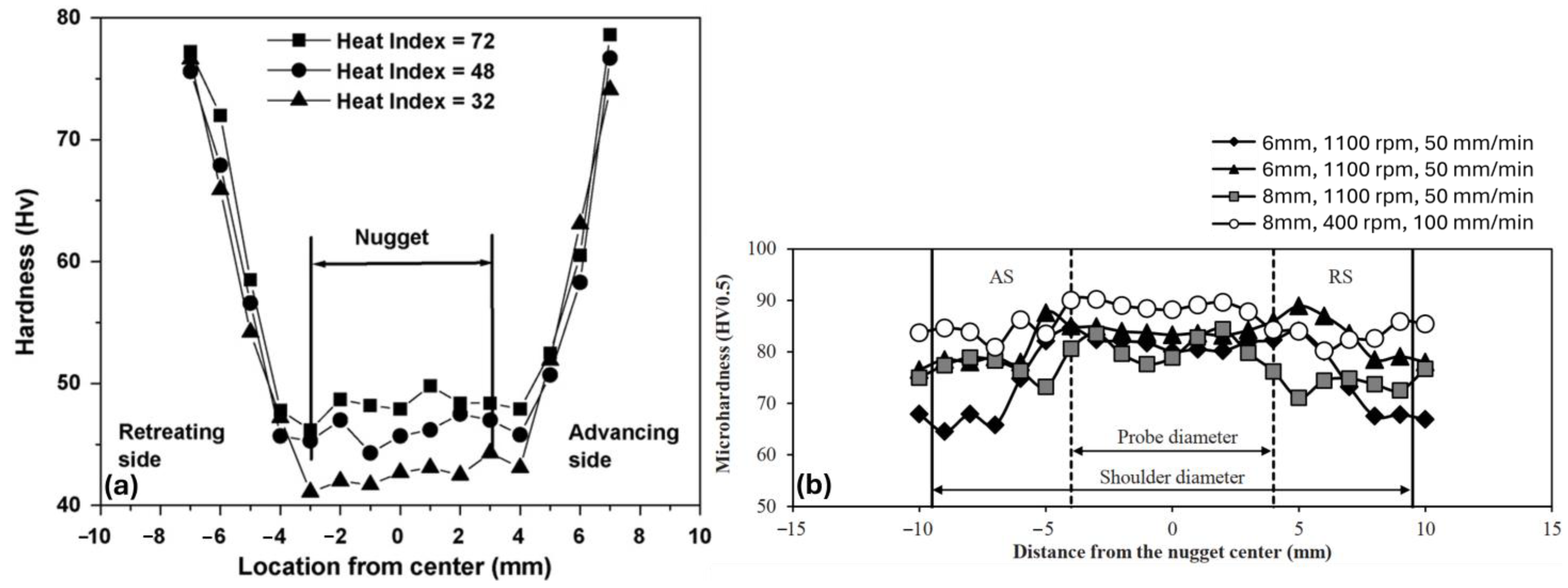

6.1. Hardness

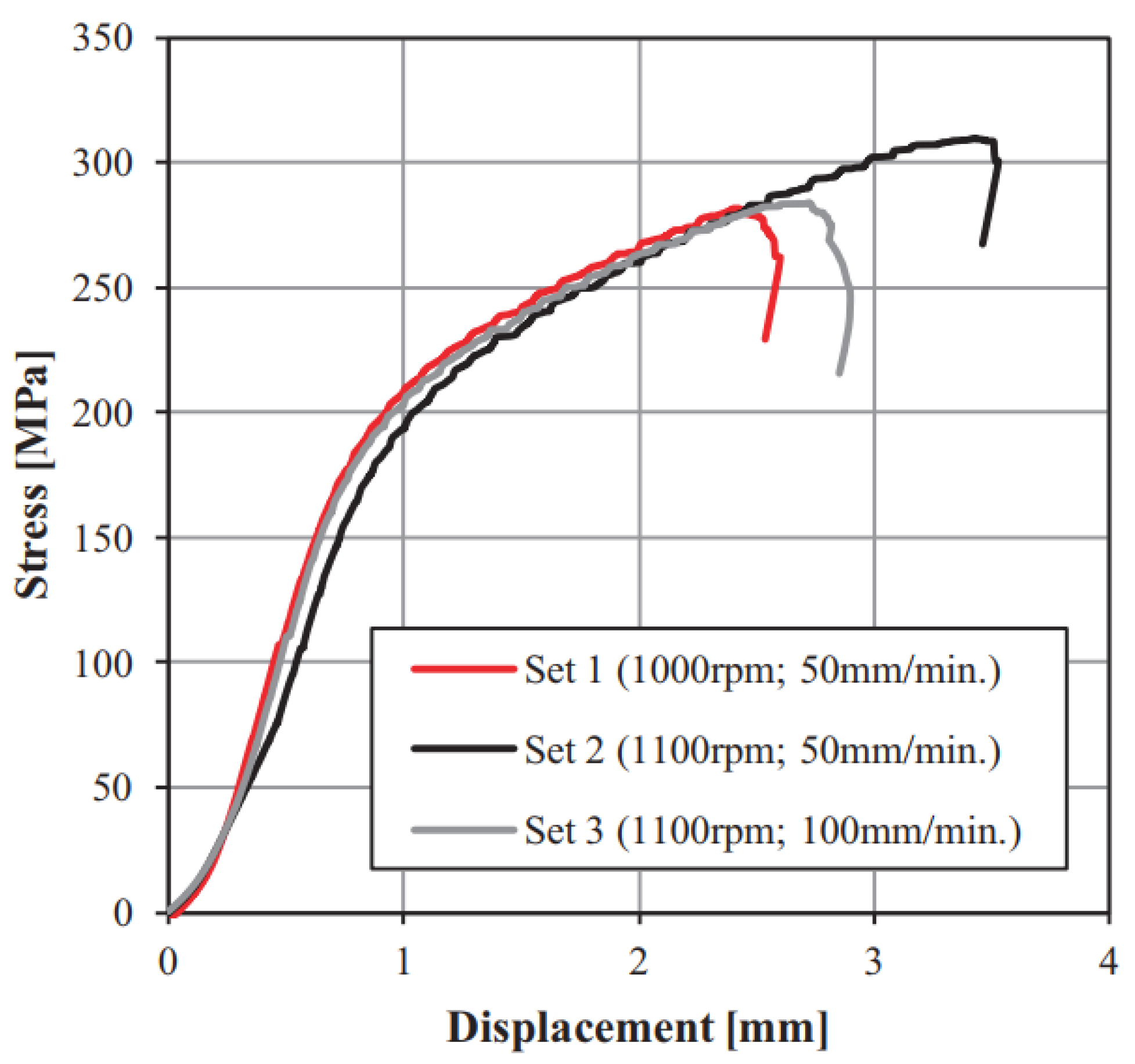

6.2. Tensile Strength

6.3. Bending Strength

6.4. Fatigue Strength

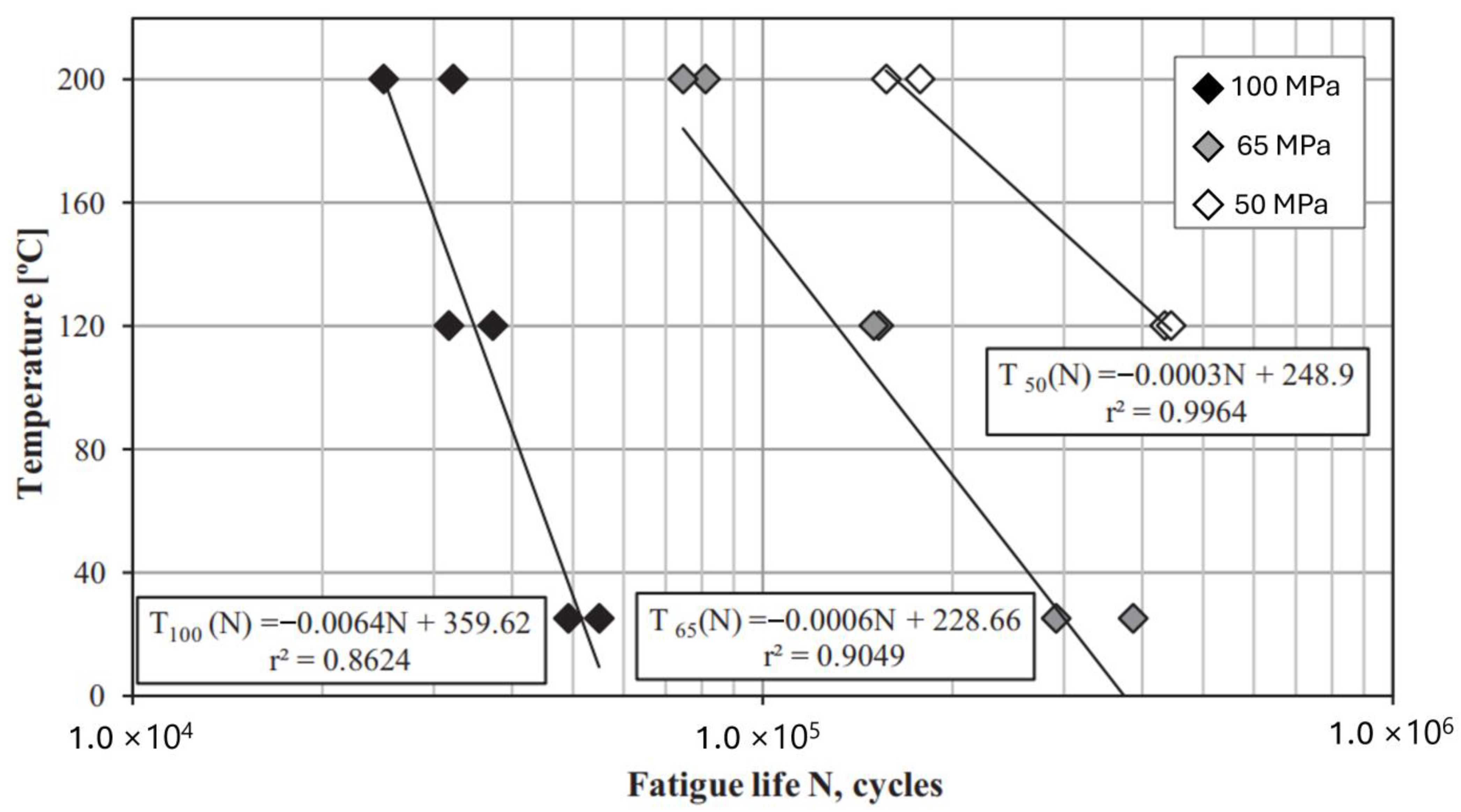

6.4.1. Four-Point Bend Fatigue Test

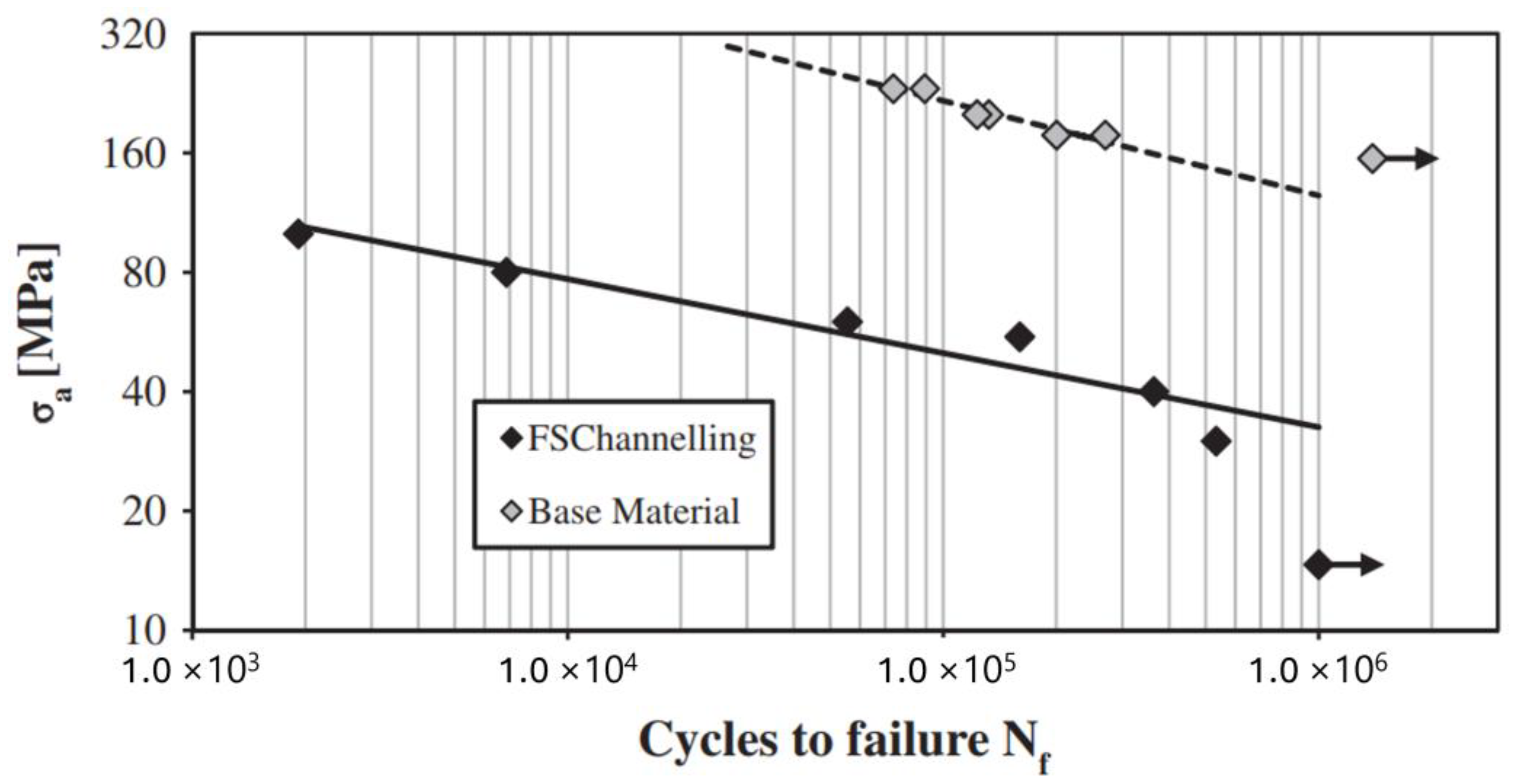

6.4.2. Uniaxial and Biaxial Tests

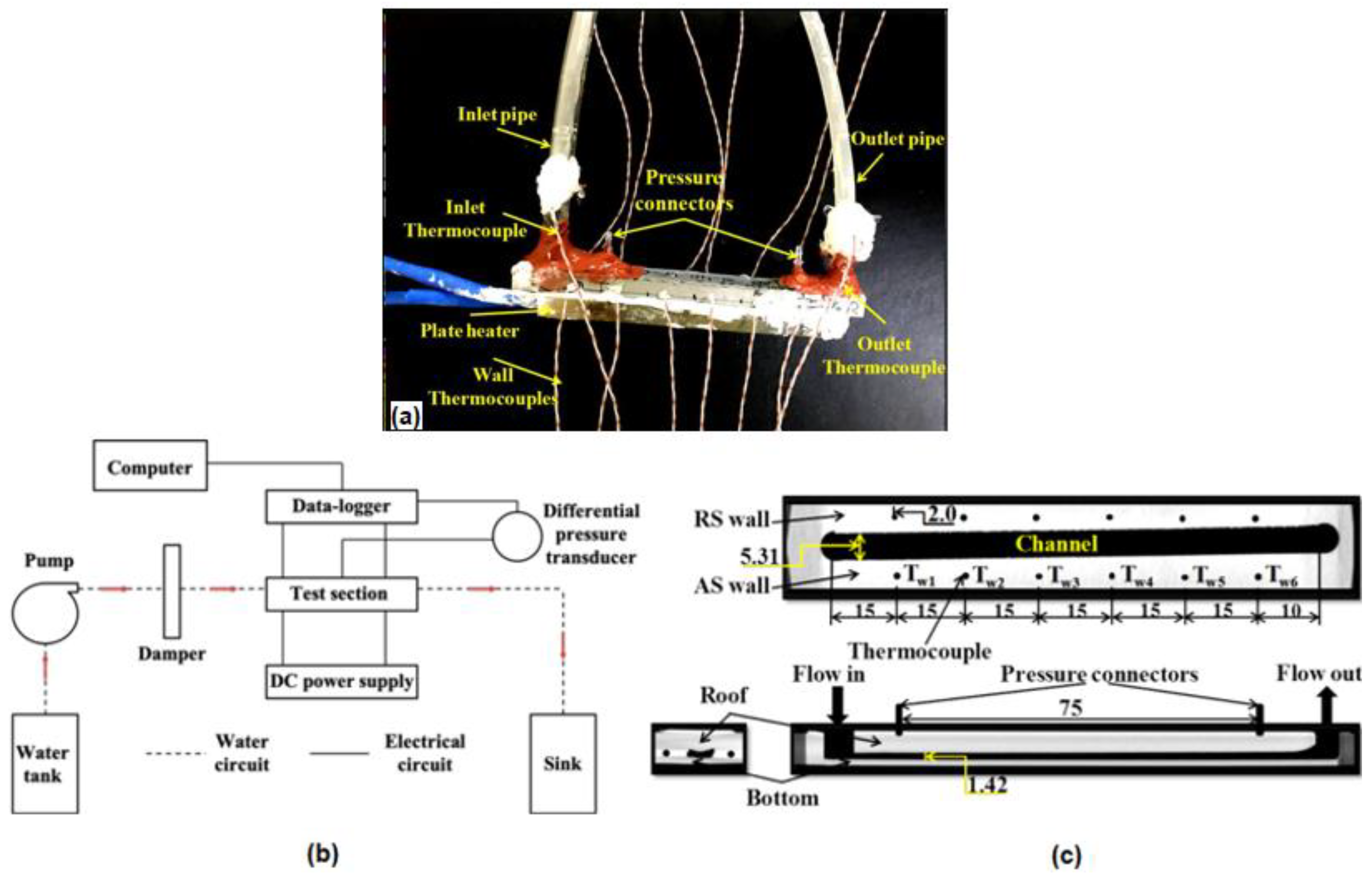

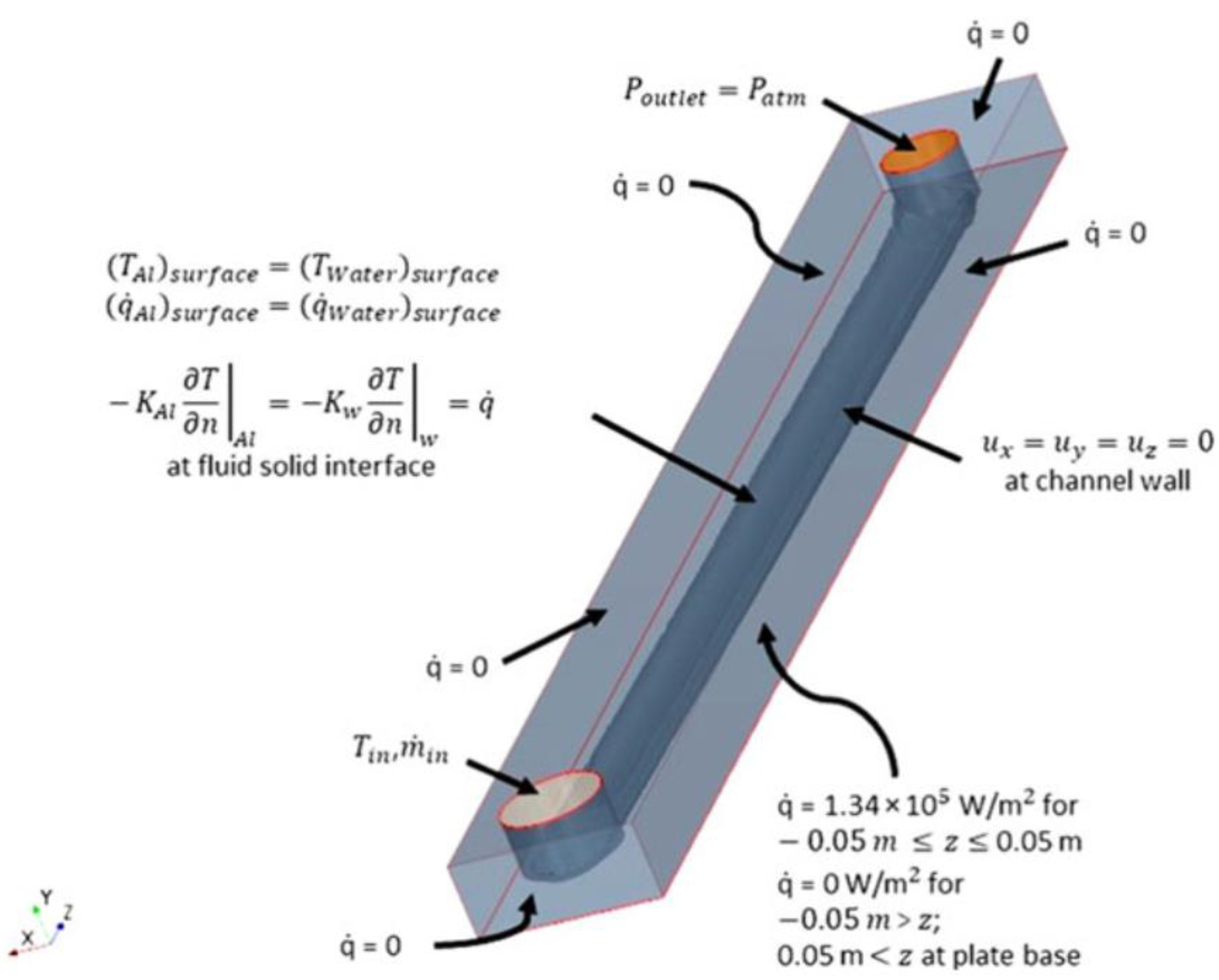

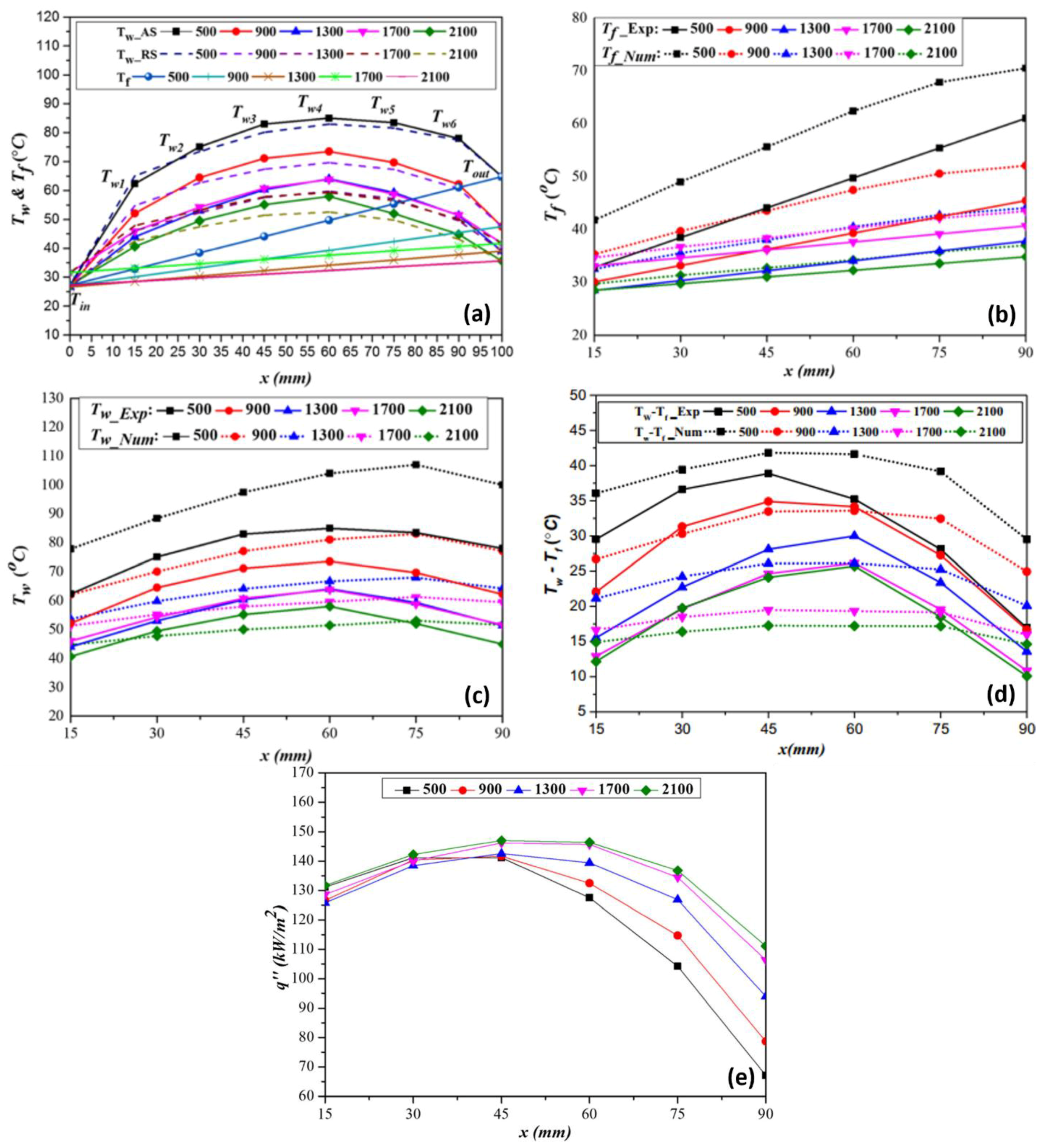

7. Channel Performance

8. Future Scope

Conclusions

- Channels are formed due to upward-rotational material flow, with the tool pin geometry being a critical factor in directing the material flow toward the channel formation.

- Material flow is not consistent along the path geometry. In serpentine profiles, larger channels are created when the advancing side (AS) is on the inner curve, attributed to increased upward material flow and fewer shear layers.

- Processing Parameters such as tool rotation speed, traverse speed, and tilt angle govern the channel shape, size, and integrity. Higher tool rotation speeds combined with lower traverse speeds enhance heat generation, promoting material flow due to increased material softening. Optimal channels are produced within a specific range of tool traverse and rotational speeds.

- Severe plastic deformation at elevated temperatures in the nugget zone leads to dynamic recrystallization, increasing the hardness of strain-hardenable alloys. At high temperatures, precipitate dissolution causes a significant drop in nugget zone hardness.

- FSC specimens exhibit lower fatigue strength than the parent metal, with fatigue strength further decreasing at higher temperatures. Regardless of channel size, specimens with a thicker closing layer show a longer crack propagation period.

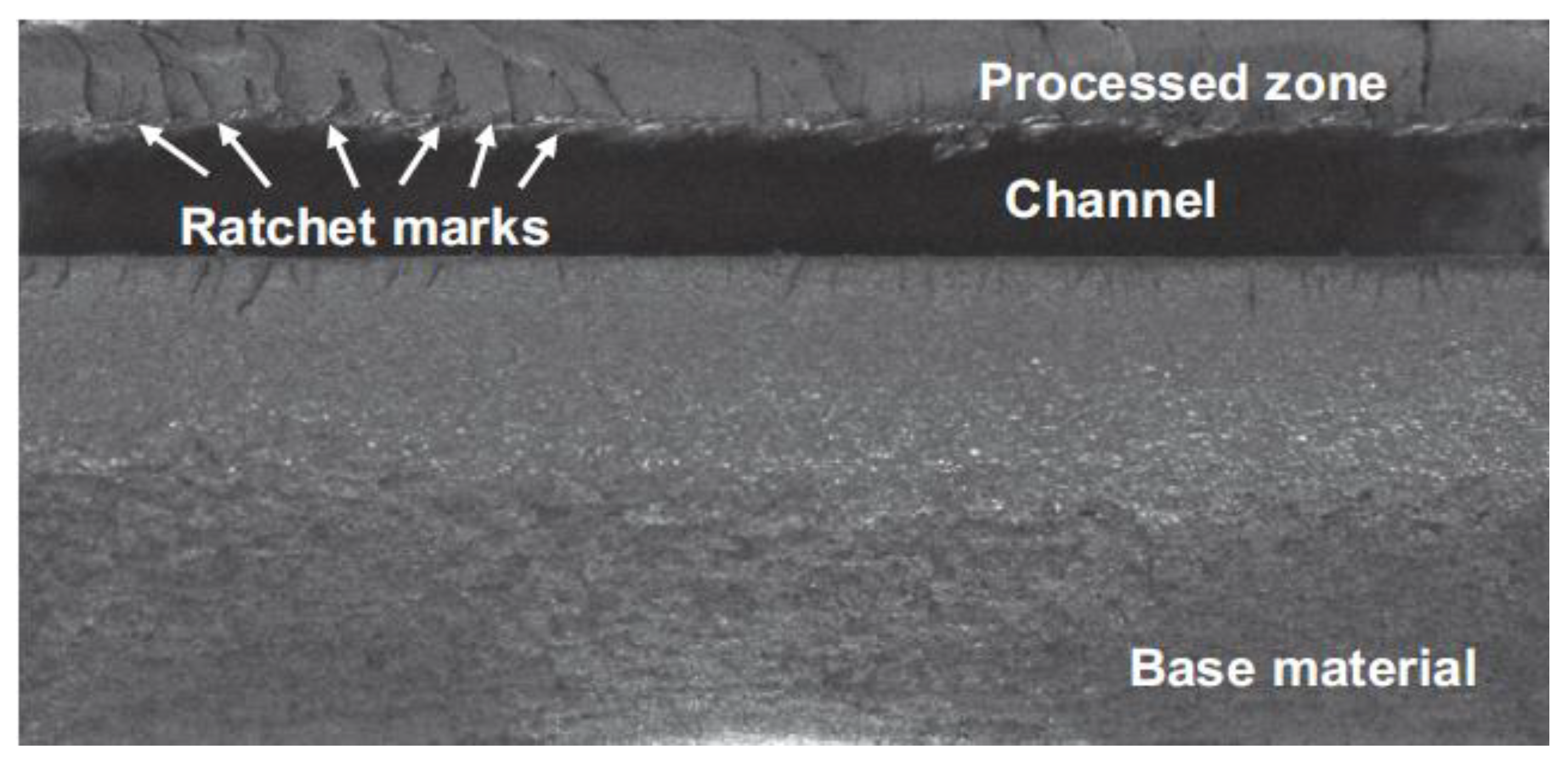

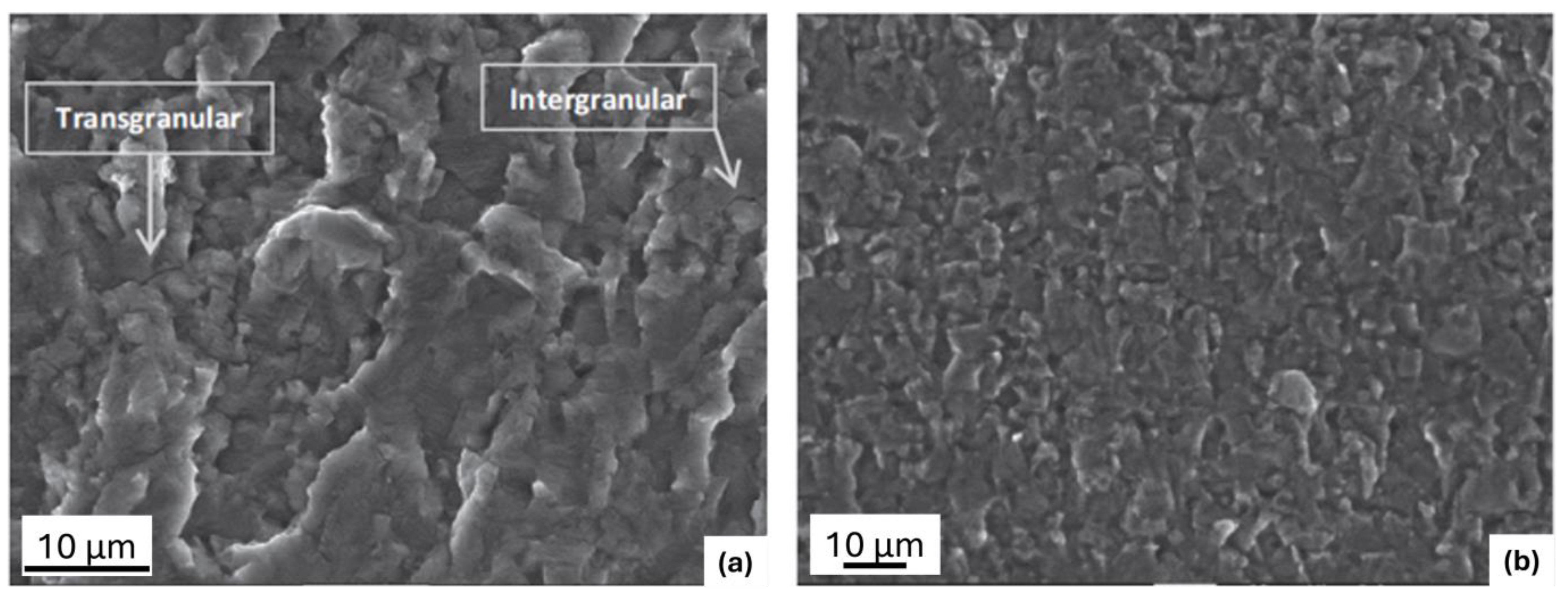

- A distinct interface separates fine equiaxed grains in the nugget zone from coarse grains in the TMAZ. The corner at the nugget zone-TMAZ interface on the AS amplifies stress concentration, initiating the cracks that propagate upward through the interface.

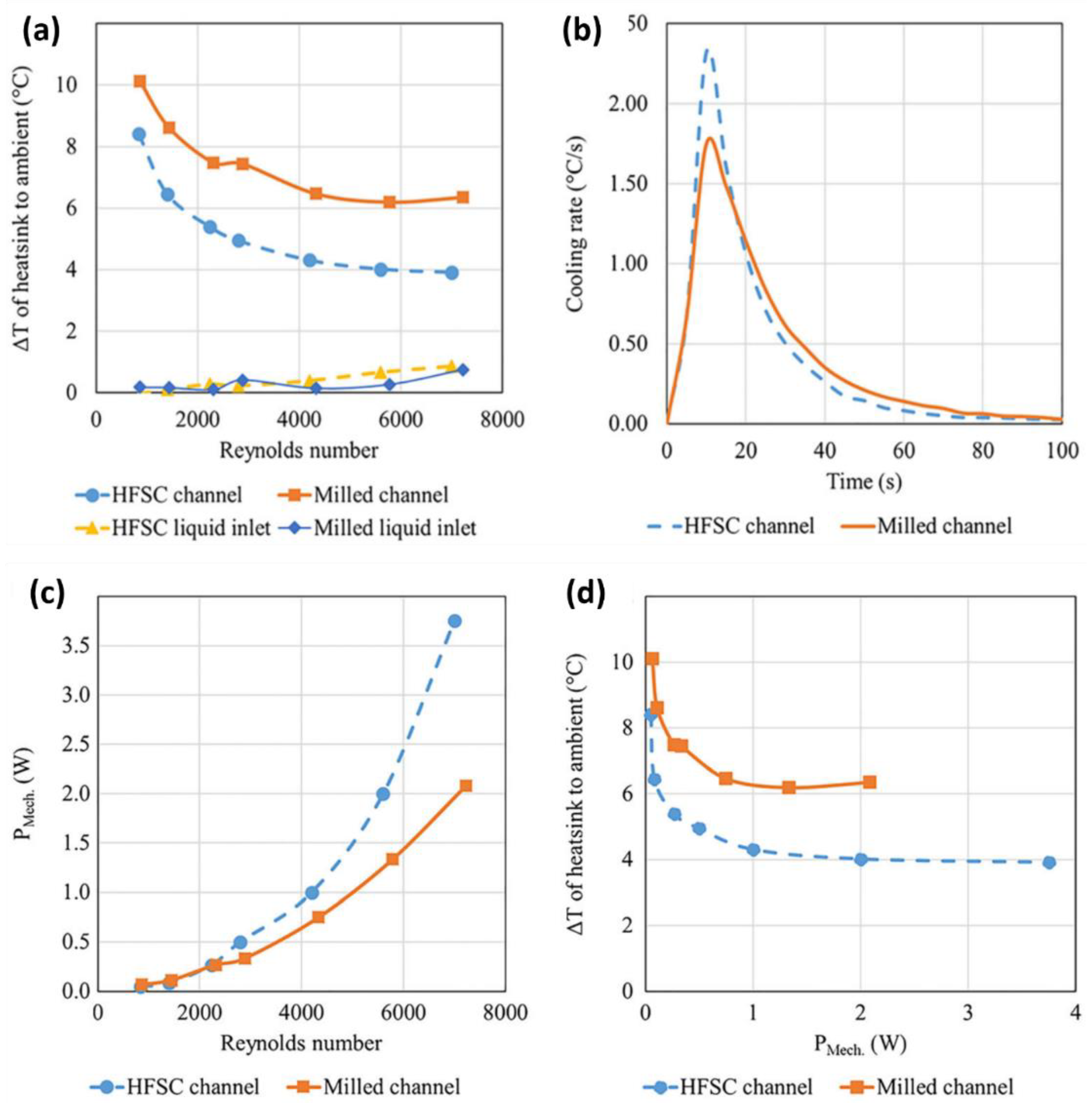

- Higher surface roughness increases surface area and creates turbulent flow at low Reynolds numbers, enhancing heat transfer in friction stir channels.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ambrose, H.; Kendall, A.; Lozano, M.; Wachche, S.; Fulton, L. Trends in life cycle greenhouse gas emissions of future light duty electric vehicles. Transp. Res. Part D Transp. Environ. 2020, 81, 102287. [Google Scholar] [CrossRef]

- Electric Vehicle Database. Available online: https://ev-database.org/car/1405/Tesla-Model-S-Plaid (accessed on 14 July 2024).

- Rao, Z.; Wang, S. A review of power battery thermal energy management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Lu, M.; Zhang, X.; Ji, J.; Xu, X.; Zhang, Y. Research progress on power battery cooling technology for electric vehicles. J. Energy Storage 2020, 27, 101155. [Google Scholar] [CrossRef]

- Lyu, Y.; Siddique, A.; Majid, S.; Biglarbegian, M.; Gadsden, S.; Mahmud, S. Electric vehicle battery thermal management system with thermoelectric cooling. Energy Rep. 2019, 5, 822–827. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1. [Google Scholar] [CrossRef]

- Pesaran, A. Battery thermal models for hybrid vehicle simulations. J. Power Sources 2002, 110, 377–382. [Google Scholar] [CrossRef]

- Hamed, M.M.; El-Tayeb, A.; Moukhtar, I.; El Dein, A.; Abdelhameed, E.H. A review on recent key technologies of lithium-ion battery thermal management: External cooling systems. Results Eng. 2022, 16, 100703. [Google Scholar] [CrossRef]

- Benabdelaziz, K.; Lebrouhi, B.; Maftah, A.; Maaroufi, M. Novel external cooling solution for electric vehicle battery pack. Energy Rep. 2020, 6, 262–272. [Google Scholar] [CrossRef]

- Panchal, S.; Khasow, R.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal design and simulation of mini-channel cold plate for water cooled large sized prismatic lithium-ion battery. Appl. Therm. Eng. 2017, 122, 80–90. [Google Scholar] [CrossRef]

- Ye, B.; Rubel, R.H.; Li, H. Design and optimization of cooling plate for battery module of an electric vehicle. Appl. Sci. 2019, 9, 754. [Google Scholar] [CrossRef]

- Huang, Y.; Mei, P.; Lu, Y.; Huang, R.; Yu, X.; Chen, Z.; Roskilly, A.P. A novel approach for Lithium-ion battery thermal management with streamline shape mini channel cooling plates. Appl. Therm. Eng. 2019, 157, 113623. [Google Scholar] [CrossRef]

- Balasubramanian, N. Friction Stir Channeling: An Innovative Technique for Heat Exchanger Manufacturing; Missouri University of Science and Technology: Rolla, MO, USA, 2008. [Google Scholar]

- Mei, F.; Parida, P.R.; Jiang, J.; Meng, W.J.; Ekkad, S.V. Fabrication, assembly, and testing of Cu- and Al-based microchannel heat exchangers. J. Microelectromech. Syst. 2008, 17, 869–881. [Google Scholar] [CrossRef]

- Collins, I.L.; Weibel, J.A.; Pan, L.; Garimella, S.V. A permeable-membrane microchannel heat sink made by additive manufacturing. Int. J. Heat Mass Transf. 2019, 131, 1174–1183. [Google Scholar] [CrossRef]

- Narendran, G.; Mallikarjuna, B.; Nagesha, B.K.; Gnanasekaran, N. Experimental investigation on additive manufactured single and curved double layered microchannel heat sink with nanofluids. Heat Mass Transf. Und Stoffuebertragung 2023, 59, 1311–1332. [Google Scholar] [CrossRef]

- Kempers, R.; Colenbrander, J.; Tan, W.; Chen, R.; Robinson, A. Experimental characterization of a hybrid impinging microjet-microchannel heat sink fabricated using high-volume metal additive manufacturing. Int. J. Thermofluids 2020, 5–6, 100029. [Google Scholar] [CrossRef]

- Mehta, K.P.; Vilaça, P. A review on friction stir-based channeling. Crit. Rev. Solid State Mater. Sci. 2021, 47, 1–45. [Google Scholar] [CrossRef]

- Sarkar, P.; Pal, S.K.; Bhattacharya, A.; Shollock, B. The influence of shoulder-workpiece clearance on channel formation during friction stir channeling at low and high heat inputs. J. Manuf. Process 2023, 101, 701–713. [Google Scholar] [CrossRef]

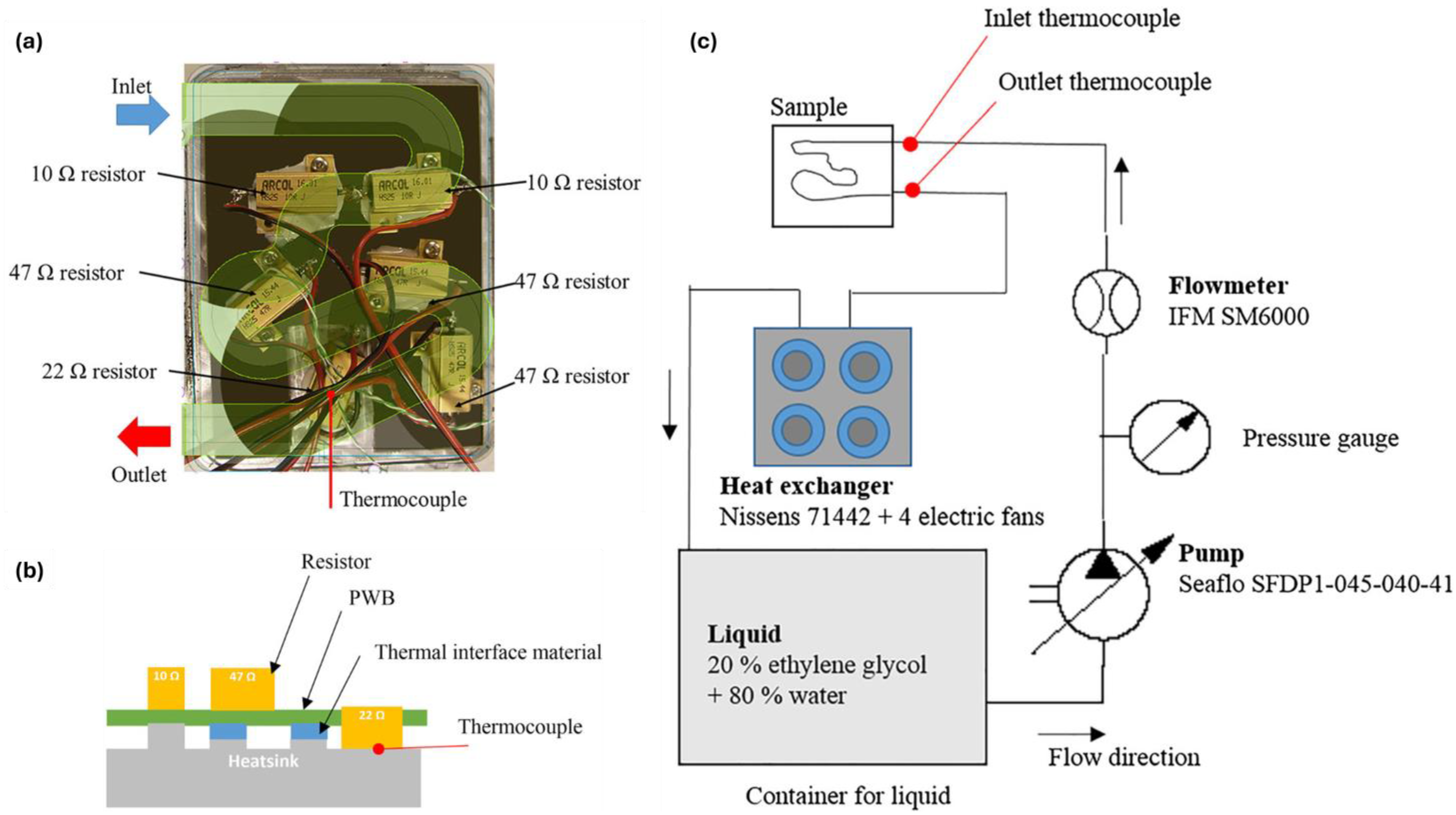

- Karvinen, H.; Nordal, D.; Galkin, T.; Vilaça, P. Application of hybrid friction stir channeling technique to improve the cooling efficiency of electronic components. Weld. World 2018, 62, 497–509. [Google Scholar] [CrossRef]

- Balasubramanian, N.; Mishra, R.; Krishnamurthy, K. Friction stir channeling: Characterization of the channels. J. Mater. Process Technol. 2009, 209, 3696–3704. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Godet, M. The third-body approach: A mechanical view of wear. Wear 1984, 100, 437–452. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V.; Vilaça, P. Characterisation of fatigue fracture surfaces of friction stir channelling specimens tested at different temperatures. Eng. Fail. Anal. 2015, 56, 204–215. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.; Robson, J.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join. Process. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Ranjan, A.; Kuriachen, B. Recent research progress in solid state friction-stir welding of aluminium–magnesium alloys: A critical review. J. Mater. Res. Technol. 2020, 9, 6217–6256. [Google Scholar] [CrossRef]

- Balasubramanian, N.; Mishra, R.S.; Krishnamurthy, K. Development of a mechanistic model for friction stir channeling. J. Manuf. Sci. Eng. Trans. ASME 2010, 132, 054504. [Google Scholar] [CrossRef]

- Vidal, C. Development and Mechanical Characterization of a New Manufacturing Technology: Friction Stir Channelling. Ph.D. Dissertation, Universidade De Lisboa, Lisbon, Portugal, 2014. [Google Scholar]

- Vidal, C.; Infante, V.; Vilaça, P. Fatigue behaviour at elevated temperature of friction stir channelling solid plates of AA5083-H111 aluminium alloy. Int. J. Fatigue 2014, 62, 85–92. [Google Scholar] [CrossRef]

- Vidal, C.; Baptista, R.; Infante, V. Experimental and numerical investigation on the fatigue behaviour of friction stirred channel plates. Eng. Fail. Anal. 2019, 103, 57–69. [Google Scholar] [CrossRef]

- Filgueiras, M.; Ferraz, S.; Pedro, D.; Vilaça, S. Friction Stir Channeling Industrial Applications Prototype Design and Production May 2012 Agradecimentos. Master’s Thesis, Technical Universty of Lisboa, Lisbon, Portugal, 2012. [Google Scholar]

- Rashidi, A.; Mostafapour, A.; Salahi, S.; Rezazadeh, V. modified friction stir channeling: A novel technique for fabrication of friction stir channel. Appl. Mech. Mater. 2013, 302, 365–370. [Google Scholar] [CrossRef]

- Rashidi, A.; Mostafapour, A. Influence of tool pin geometry and moving paths of tool on channel formation mechanism in modified friction stir channeling technique. Int. J. Adv. Manuf. Technol. 2015, 80, 1087–1096. [Google Scholar] [CrossRef]

- Rashidi, A.; Mostafapour, A. Influence of machine parameters on material flow behavior during channeling in modified friction stir channeling. Int. J. Mater. Form. 2014, 9, 1–8. [Google Scholar] [CrossRef]

- Gandra, J. Coreflow: A Sub-Surface Machining Process. Available online: https://www.twi-global.com/media-and-events/insights/coreflow-a-sub-surface-machining-process (accessed on 22 September 2020).

- Karvinen, H.; Mehta, K.P.; Vilaça, P. Novel manufacturing of multi-material component by hybrid friction stir channeling. CIRP J. Manuf. Sci. Technol. 2023, 45, 271–284. [Google Scholar] [CrossRef]

- Nordal, D. Design, Development and Analysis of Tools for Hybrid Friction Stir Channeling. Master’s Thesis, Aalto University, Espoo, Finland, 2017. [Google Scholar]

- Yan, F.; Zhang, Y.; Fu, X.; Li, Q.; Gao, J. A new calculating method of frictional heat and its application during friction stir welding. Appl. Therm. Eng. 2019, 153, 250–263. [Google Scholar] [CrossRef]

- Chiumenti, M.; Cervera, M.; de Saracibar, C.A.; Dialami, N. Numerical modeling of friction stir welding processes. Comput. Methods Appl. Mech. Eng. 2013, 254, 353–369. [Google Scholar] [CrossRef]

- Mahesh, V.P.; Patel, S.; Gumaste, A.; Arora, A. Joining of Polymer Matrix Composites Through Friction Stir Processes. Encycl. Mater. Compos. 2021, 3, 352–379. [Google Scholar]

- Sun, Z.; Wu, C.; Kumar, S. Determination of heat generation by correlating the interfacial friction stress with temperature in friction stir welding. J. Manuf. Process. 2018, 31, 801–811. [Google Scholar] [CrossRef]

- Andrade, D.; Leitão, C.; Rodrigues, D. Influence of base material characteristics and process parameters on frictional heat generation during Friction Stir Spot Welding of steels. J. Manuf. Process. 2019, 43, 98–104. [Google Scholar] [CrossRef]

- Tang, W.; Guo, X.; McCLURE, J.C.; Murr, L.E.; Nunes, A. Heat input and temperature distribution in friction stir welding. J. Mater. Process. Manuf. Sci. 1998, 7, 163–172. [Google Scholar] [CrossRef]

- Silva, A.C.F.; De Backer, J.; Bolmsjö, G. Temperature measurements during friction stir welding. Int. J. Adv. Manuf. Technol. 2017, 88, 2899–2908. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Forces and temperature variation during friction stir welding of aluminum alloy AA6082-T6. Int. J. Adv. Manuf. Technol. 2018, 99, 337–346. [Google Scholar] [CrossRef]

- Murr, L.E.; Liu, G.; McClure, J.C. Dynamic recrystallization in friction-stir welding of aluminium alloy 1100. J. Mater. Sci. Lett. 1997, 16, 1801–1803. [Google Scholar] [CrossRef]

- Jata, K.; Semiatin, S. Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scr. Mater. 2000, 43, 743–749. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G. Continuous dynamic recrystallization phenomena modelling in friction stir welding of aluminium alloys: A neural-network-based approach. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 857–864. [Google Scholar] [CrossRef]

- McNelley, T.; Swaminathan, S.; Su, J. Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr. Mater. 2007, 58, 349–354. [Google Scholar] [CrossRef]

- Singh, A.K.; Kaushik, L.; Pawar, S.; Singh, J.; Das, H.; Mondal, M.; Hong, S.-T.; Choi, S.-H. Unraveling the heterogeneous evolution of the microstructure and texture in the thermomechanically affected zone of commercially pure titanium during friction stir processing. Int. J. Mech. Sci. 2023, 239, 107894. [Google Scholar] [CrossRef]

- Mahmoudiniya, M.; Kestens, L.A. Microstructural development and texture evolution in the stir zone and thermomechanically affected zone of a ferrite-martensite steel friction stir weld. Mater. Charact. 2021, 175, 111053. [Google Scholar] [CrossRef]

- Donatus, U.; Thompson, G.; Momoh, M.; Maledi, N.; Tsai, I.-L.; Ferreira, R.O.; Liu, Z. Variations in stir zone and thermomechanically affected zone of dissimilar friction stir weld of AA5083 and AA6082 alloys. Trans. Nonferrous Met. Soc. China 2018, 28, 2410–2418. [Google Scholar] [CrossRef]

- Pandya, S.; Mishra, R.S.; Arora, A. Channel formation during friction stir channeling process—A material flow study using X-Ray micro-computed tomography and optical microscopy. J. Manuf. Process. 2019, 41, 48–55. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V.; Vilaça, P. Effect of microstructure on the fatigue behavior of a friction stirred channel aluminium alloy. Procedia Eng. 2013, 66, 264–273. [Google Scholar] [CrossRef]

- Fonda, R.; Reynolds, A.; Feng, C.R.; Knipling, K.; Rowenhorst, D. Material flow in friction stir welds. Met. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 44, 337–344. [Google Scholar] [CrossRef]

- Lorrain, O.; Favier, V.; Zahrouni, H.; Lawrjaniec, D. Understanding the material flow path of friction stir welding process using unthreaded tools. J. Mater. Process Technol. 2009, 210, 603–609. [Google Scholar] [CrossRef]

- Liu, F.; Nelson, T. In-situ material flow pattern around probe during friction stir welding of austenitic stainless steel. Mater. Des. 2016, 110, 354–364. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, W.; Choo, H.; Feng, Z. Transient heat and material flow modeling of friction stir processing of magnesium alloy using threaded tool. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2011, 43, 724–737. [Google Scholar] [CrossRef]

- Gerlich, A.; Su, P.; Yamamoto, M.; North, T.H. Material flow and intermixing during dissimilar friction stir welding. Sci. Technol. Weld. Join. 2008, 13, 254–264. [Google Scholar] [CrossRef]

- Galvão, I.; Leal, R.M.; Loureiro, A.; Rodrigues, D.M. Material flow in heterogeneous friction stir welding of aluminium and copper thin sheets. Sci. Technol. Weld. Join. 2010, 15, 654–660. [Google Scholar] [CrossRef]

- Gratecap, F.; Girard, M.; Marya, S.; Racineux, G. Exploring material flow in friction stir welding: Tool eccentricity and formation of banded structures. Int. J. Mater. Form. 2011, 5, 99–107. [Google Scholar] [CrossRef]

- Seidel, T.U.; Reynolds, A.P. Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2001, 32, 2879–2884. [Google Scholar] [CrossRef]

- Chen, Z.; Pasang, T.; Qi, Y. Shear flow and formation of Nugget zone during friction stir welding of aluminium alloy 5083-O. Mater. Sci. Eng. A 2008, 474, 312–316. [Google Scholar] [CrossRef]

- Wang, T.; Komarasamy, M.; Liu, K.; Mishra, R.S. Friction stir butt welding of strain-hardened aluminum alloy with high strength steel. Mater. Sci. Eng. A 2018, 737, 85–89. [Google Scholar] [CrossRef]

- Zeng, X.H.; Xue, P.; Wang, D.; Ni, D.R.; Xiao, B.L.; Wang, K.S.; Ma, Z.Y. Material flow and void defect formation in friction stir welding of aluminium alloys. Sci. Technol. Weld. Join. 2018, 23, 677–686. [Google Scholar] [CrossRef]

- Coelho, R.S.; Kostka, A.; dos Santos, J.; Pyzalla, A.R. EBSD technique visualization of material flow in aluminum to steel friction-stir dissimilar welding. Adv. Eng. Mater. 2008, 10, 1127–1133. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, S.; Chen, K.; Ni, J. Material flow visualization of dissimilar friction STIR welding process using nano-computed tomography. J. Manuf. Sci. Eng. Trans. ASME 2018, 140, 111010. [Google Scholar] [CrossRef]

- Rashidi, A.; Mostafapour, A.; Rezazadeh, V.; Salahi, S. Channel formation in modified friction stir channeling. Appl. Mech. Mater. 2013, 302, 371–376. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V.; Vilaça, P. Fatigue assessment of friction stir channels. Int. J. Fatigue 2014, 62, 77–84. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V.; Vilaça, P. Metallographic characterization of friction stir channels. Mater. Sci. Forum 2013, 730–732, 817–822. [Google Scholar] [CrossRef]

- Snyder, B.; Li, K.; Wirtz, R. Heat transfer enhancement in a serpentine channel. Int. J. Heat Mass Transf. 1993, 36, 2965–2976. [Google Scholar] [CrossRef]

- Rashidi, A.; Mostafapour, A. Influence of tool geometry on the channel formation along the linear and non-linear channeling using modified friction stir channeling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 231, 1438–1447. [Google Scholar] [CrossRef]

- Yu, P.; Wu, C.; Shi, L. Analysis and characterization of dynamic recrystallization and grain structure evolution in friction stir welding of aluminum plates. Acta Mater. 2021, 207, 116692. [Google Scholar] [CrossRef]

- Abbasi, M.; Bagheri, B.; Sharifi, F. Simulation and experimental study of dynamic recrystallization process during friction stir vibration welding of magnesium alloys. Trans. Nonferrous Met. Soc. China 2021, 31, 2626–2650. [Google Scholar] [CrossRef]

- Hu, Y.; Niu, Y.; Zhao, Y.; Yang, W.; Ma, X.; Li, J. Friction stir welding of CoCrNi medium-entropy alloy: Recrystallization behaviour and strengthening mechanism. Mater. Sci. Eng. A 2022, 848, 143361. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V.; Vilaça, P. Metallographic and morphological characterization of sub-surface friction stirred channels produced on AA5083-H111. Int. J. Adv. Manuf. Technol. 2019, 105, 2215–2235. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, K.; Pandey, S. Process forces and heat input as function of process parameters in AA5083 friction stir welds. Trans. Nonferrous Met. Soc. China 2012, 22, 288–298. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Influences of tool pin profile and axial force on the formation of friction stir processing zone in AA6061 aluminium alloy. Int. J. Adv. Manuf. Technol. 2008, 38, 285–295. [Google Scholar] [CrossRef]

- Kim, Y.; Fujii, H.; Tsumura, T.; Komazaki, T.; Nakata, K. Three defect types in friction stir welding of aluminum die casting alloy. Mater. Sci. Eng. A 2006, 415, 250–254. [Google Scholar] [CrossRef]

- Papantoniou, I.; Karmiris-Obratański, P.; Manolakos, D. Investigation of process parameters and tool design on friction stir channeling (FSC) of AA5083 monolithic plates and microstructural characterization. Int. J. Adv. Manuf. Technol. 2022, 121, 981–992. [Google Scholar] [CrossRef]

- Balasubramanian, N.; Mishra, R.; Krishnamurthy, K. Process forces during friction stir channeling in an aluminum alloy. J. Mater. Process Technol. 2010, 211, 305–311. [Google Scholar] [CrossRef]

- Vidal, C.; Ferreira, P.M.; Ferreira, F.B.; Buinho, M.; Silva, T.T.; Santos, T.G. Improving the stability of the friction stir channelling technology via a cooled copper backing plate. Int. J. Adv. Manuf. Technol. 2023, 129, 525–546. [Google Scholar] [CrossRef]

- Gungor, B.; Kaluc, E.; Taban, E.; Sik, A. Mechanical, fatigue and microstructural properties of friction stir welded 5083-H111 and 6082-T651 aluminum alloys. Mater. Des. 2014, 56, 84–90. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction stir welding of similar and dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Emamikhah, A.; Kazerooni, A.; Rakhshkhorshid, M. A Mechanical and Microstructural Study on Friction Stir Welding of 5083 Aluminum Alloy Based on Optimal Values of the Response Surface Method. J. Mater. Eng. Perform. 2022, 31, 9448–9461. [Google Scholar] [CrossRef]

- Gholami, S.; Emadoddin, E.; Tajally, M.; Borhani, E. Friction stir processing of 7075 Al alloy and subsequent aging treatment. Trans. Nonferrous Met. Soc. China 2015, 25, 2847–2855. [Google Scholar] [CrossRef]

- Al-Fadhalah, K.J.; Almazrouee, A.I.; Aloraier, A.S. Microstructure and mechanical properties of multi-pass friction stir processed aluminum alloy 6063. Mater. Des. 2014, 53, 550–560. [Google Scholar] [CrossRef]

- Abnar, B.; Gashtiazar, S.; Javidani, M. Friction Stir Welding of Non-Heat Treatable Al Alloys. Crystals 2023, 13, 576. [Google Scholar] [CrossRef]

- Karvinen, H.; Hasani Aleni, A.; Salminen, P.; Minav, T.; Vilaça, P. Thermal Efficiency and Material Properties of Friction Stir Channelling Applied to Aluminium Alloy AA5083. Energies 2019, 12, 1549. [Google Scholar] [CrossRef]

- Kandasamy, R.; Ho, J.Y.; Liu, P.; Wong, T.N.; Toh, K.C.; Chua, S.J. Two-phase spray cooling for high ambient temperature data centers: Evaluation of system performance. Appl. Energy 2022, 305, 117816. [Google Scholar] [CrossRef]

- Ling, L.; Zhang, Q.; Yu, Y.; Liao, S. A state-of-the-art review on the application of heat pipe system in data centers. Appl. Therm. Eng. 2021, 199, 117618. [Google Scholar] [CrossRef]

- Zhang, Q.; Meng, Z.; Hong, X.; Zhan, Y.; Liu, J.; Dong, J.; Bai, T.; Niu, J.; Deen, M.J. A survey on data center cooling systems: Technology, power consumption modeling and control strategy optimization. J. Syst. Arch. 2021, 119, 102253. [Google Scholar] [CrossRef]

- Mozafari, M.; Lee, A.; Mohammadpour, J. Thermal management of single and multiple PCMs based heat sinks for electronics cooling. Therm. Sci. Eng. Prog. 2021, 23, 100919. [Google Scholar] [CrossRef]

- Meng, B.; Wan, M.; Zhao, R.; Zou, Z.; Liu, H. Micromanufacturing technologies of compact heat exchangers for hypersonic precooled airbreathing propulsion: A review. Chin. J. Aeronaut. 2021, 34, 79–103. [Google Scholar] [CrossRef]

- Yan, B.; Wang, C.; Li, L. The technology of micro heat pipe cooled reactor: A review. Ann. Nucl. Energy 2020, 135, 106948. [Google Scholar] [CrossRef]

- Cui, S.; Zhang, Y.; Bai, J.; Li, H.; Zheng, H.; Zhang, Z. Experimental study on high temperature performance of heat pipe and vapor compression compound cooling unit for communication base station. Energy Rep. 2023, 10, 4436–4446. [Google Scholar] [CrossRef]

- Mishra, R.S. Integral Channels in Metal Components and Fabrication. U.S. Patent 6923362 B2, 2 August 2005. [Google Scholar]

- Pandya, S.; Gurav, S.; Hedau, G.; Saha, S.K.; Arora, A. Effect of axial conduction in integral rough friction stir channels: Experimental thermo-hydraulic characteristics analyses. Heat Mass Transf. Und Stoffuebertragung 2020, 56, 1725–1738. [Google Scholar] [CrossRef]

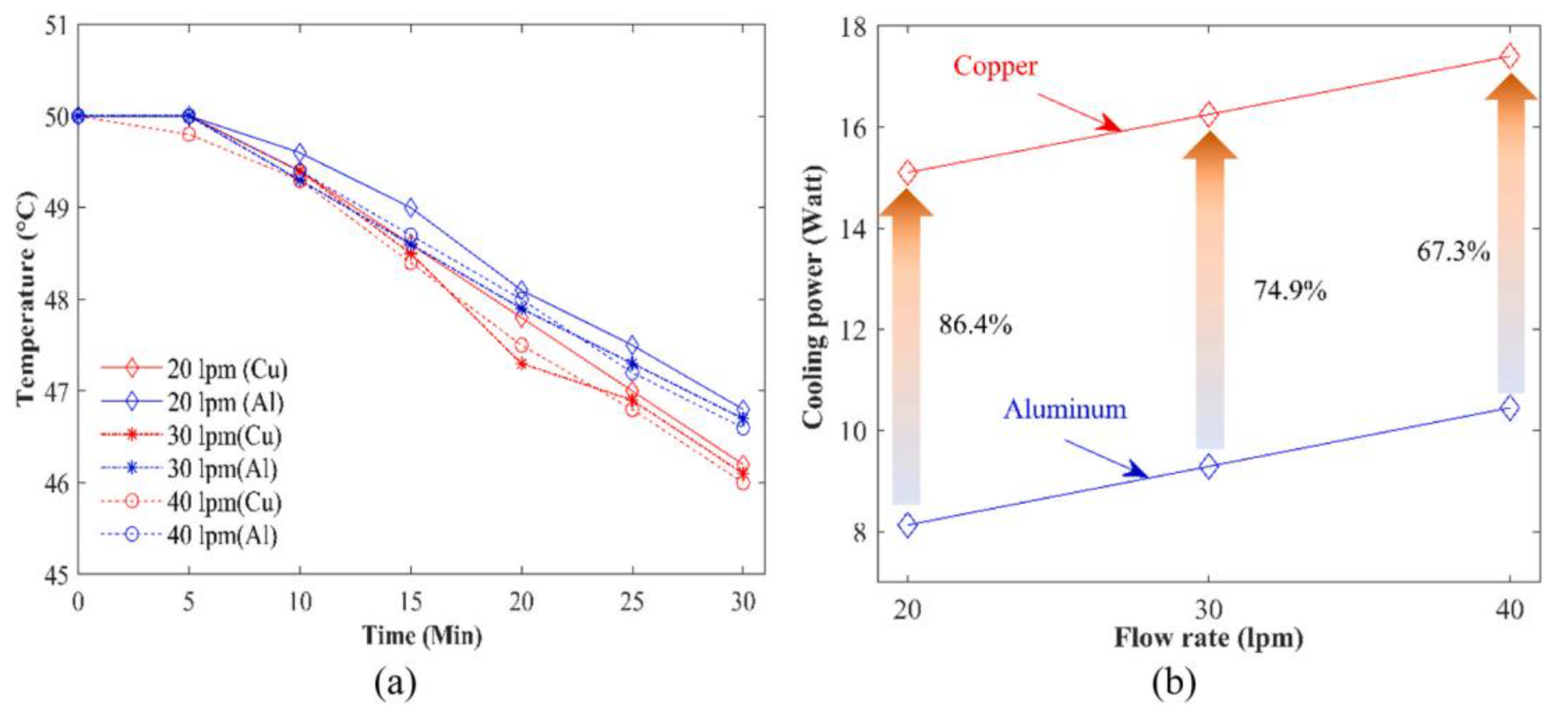

- Pandya, M.; Patel, N.P.; Mehta, K.P. Channel formation characteristics under the influence of tool design and comparative analysis on friction stir channeling between copper and aluminum materials. CIRP J. Manuf. Sci. Technol. 2024, 49, 128–149. [Google Scholar] [CrossRef]

| Primary FSC | FSC with Scroll Shoulder | FSC with Tilted Tool-Pin | FSC with Stationary Shoulder | ||

|---|---|---|---|---|---|

| Pin | Threaded pin | Threaded pin | Unthreaded cylindrical pin | Unthreaded upward conical pin | Threaded pin |

| Shoulder | Flat shoulder | Shoulder having scroll/scrolls | Flat shoulder | Flat shoulder | Stationary shoulder with vents |

| Shoulder—Workpiece interface | Clearance | No clearance | Clearance | Clearance | No clearance |

| Tool orientation | No tilt angle | No tilt angle | Tilt angle | No tilt angle | No tilt angle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, S.; Arora, A. Friction Stir Channeling in Heat Sink Applications: Innovative Manufacturing Approaches and Performance Evaluation. Machines 2024, 12, 494. https://doi.org/10.3390/machines12070494

Patel S, Arora A. Friction Stir Channeling in Heat Sink Applications: Innovative Manufacturing Approaches and Performance Evaluation. Machines. 2024; 12(7):494. https://doi.org/10.3390/machines12070494

Chicago/Turabian StylePatel, Sooraj, and Amit Arora. 2024. "Friction Stir Channeling in Heat Sink Applications: Innovative Manufacturing Approaches and Performance Evaluation" Machines 12, no. 7: 494. https://doi.org/10.3390/machines12070494

APA StylePatel, S., & Arora, A. (2024). Friction Stir Channeling in Heat Sink Applications: Innovative Manufacturing Approaches and Performance Evaluation. Machines, 12(7), 494. https://doi.org/10.3390/machines12070494