Investigation of Single Grain Grinding of Titanium Alloy Using Diamond Abrasive Grain with Positive Rake Angle

Abstract

1. Introduction

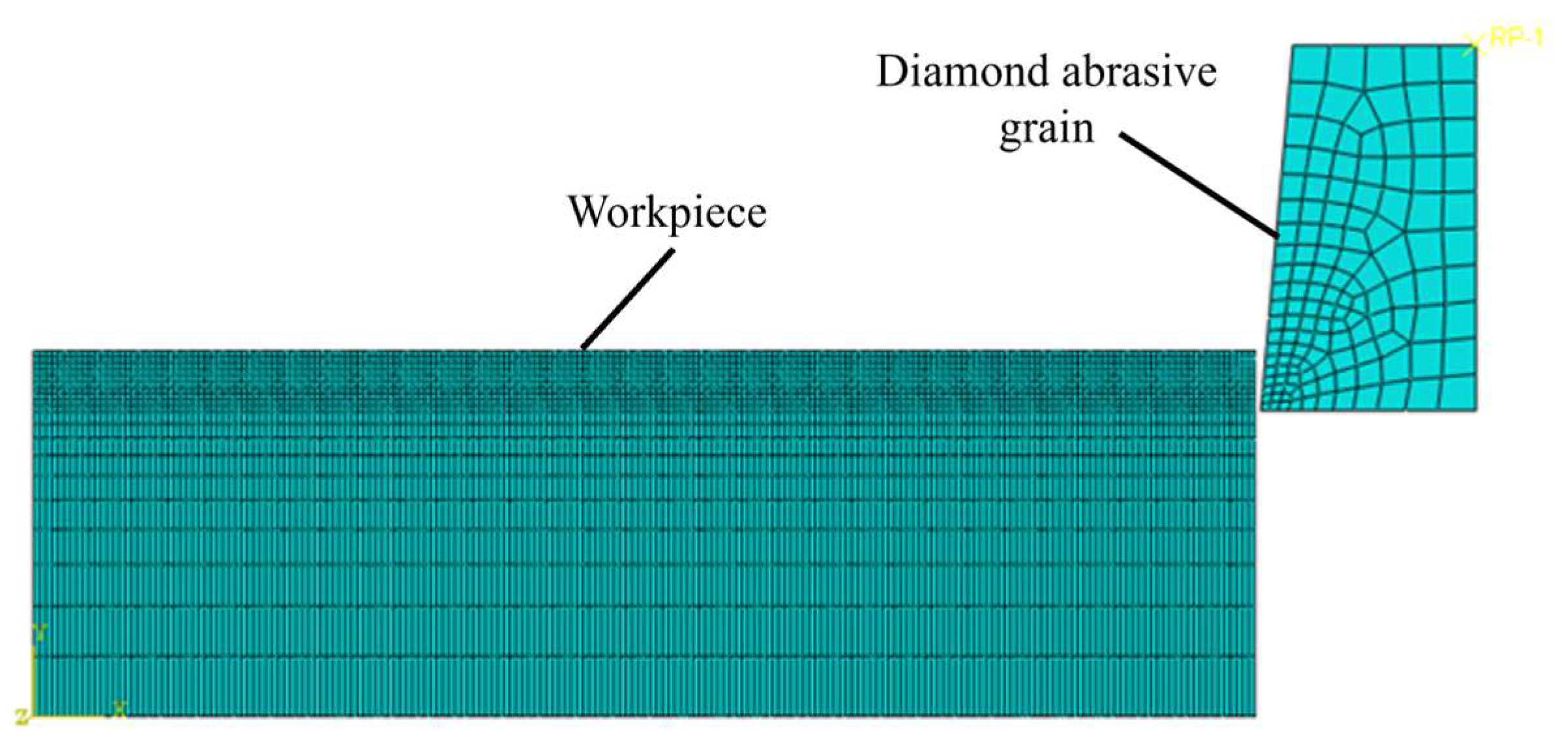

2. Finite Element Model

2.1. Material Constitutive Modeling

2.2. Material Failure Criterion

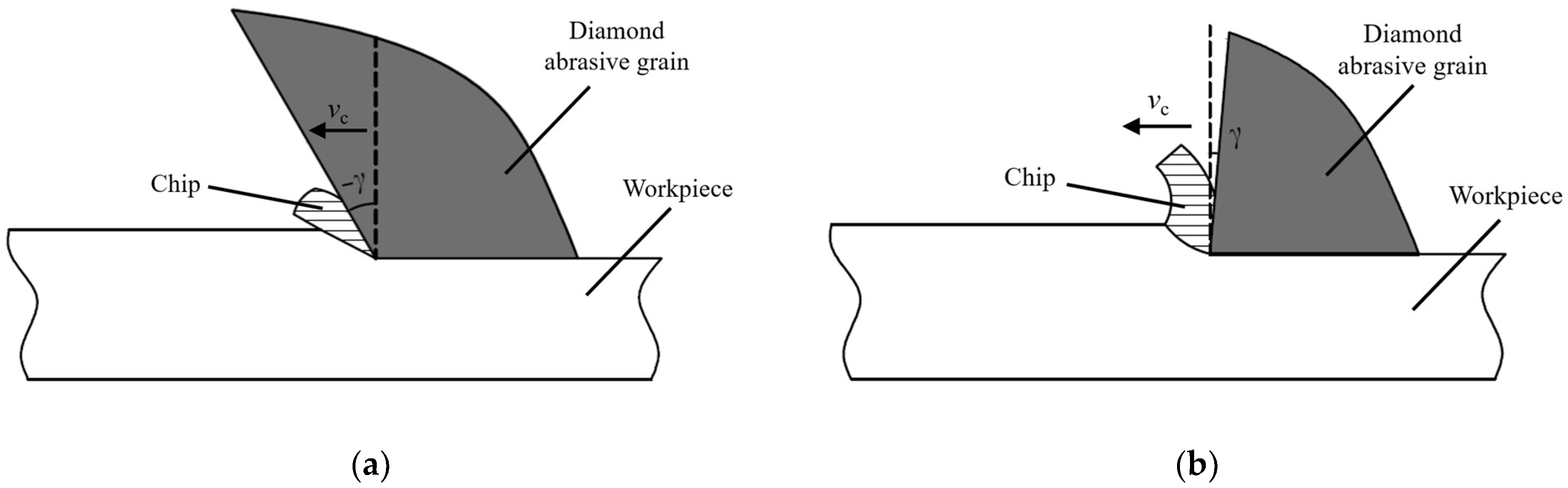

2.3. Geometric Model and Simulation Parameters

3. Simulation Results

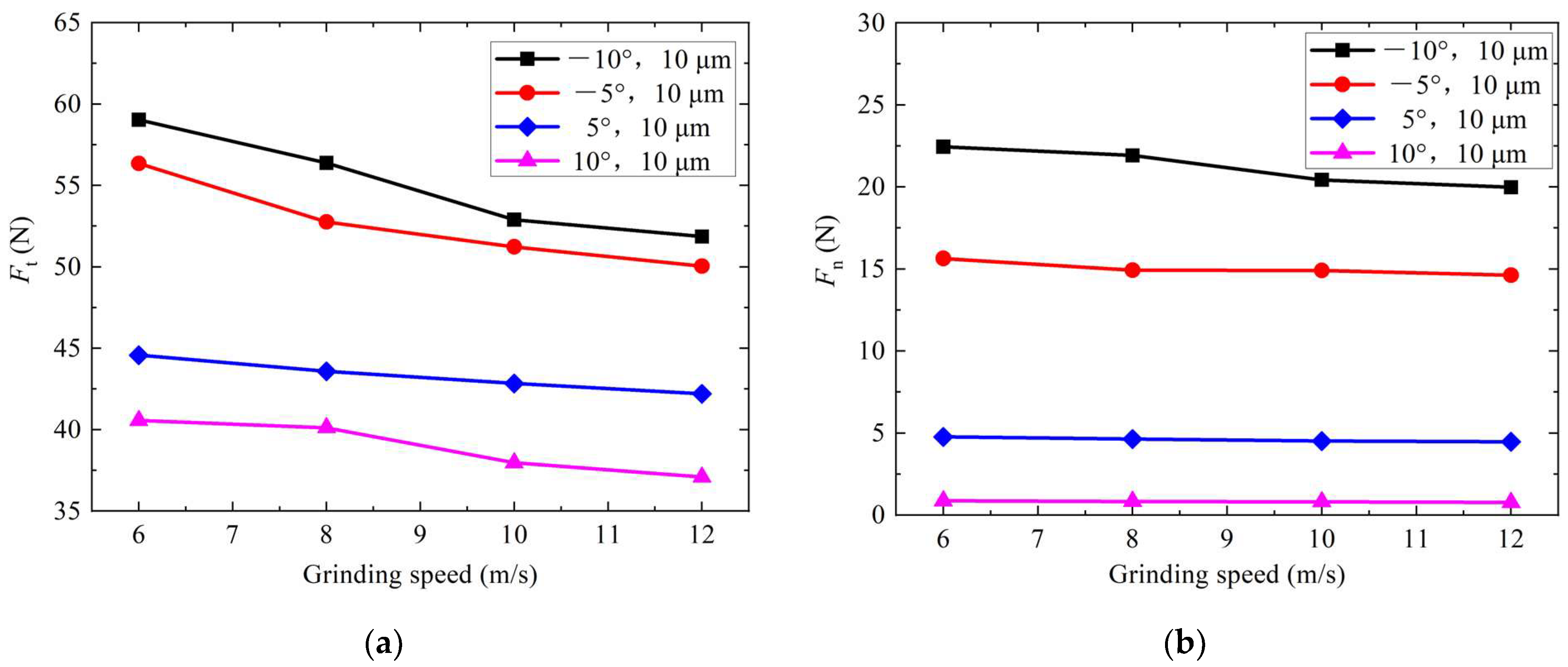

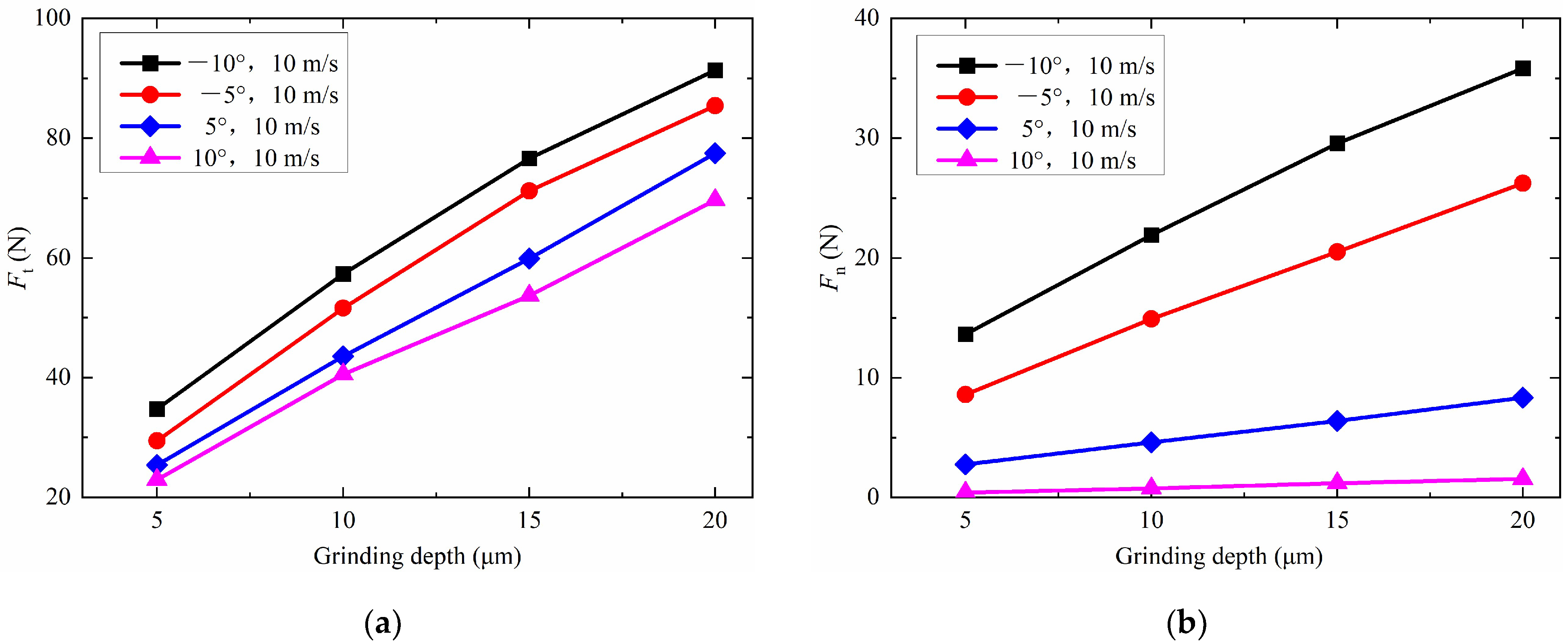

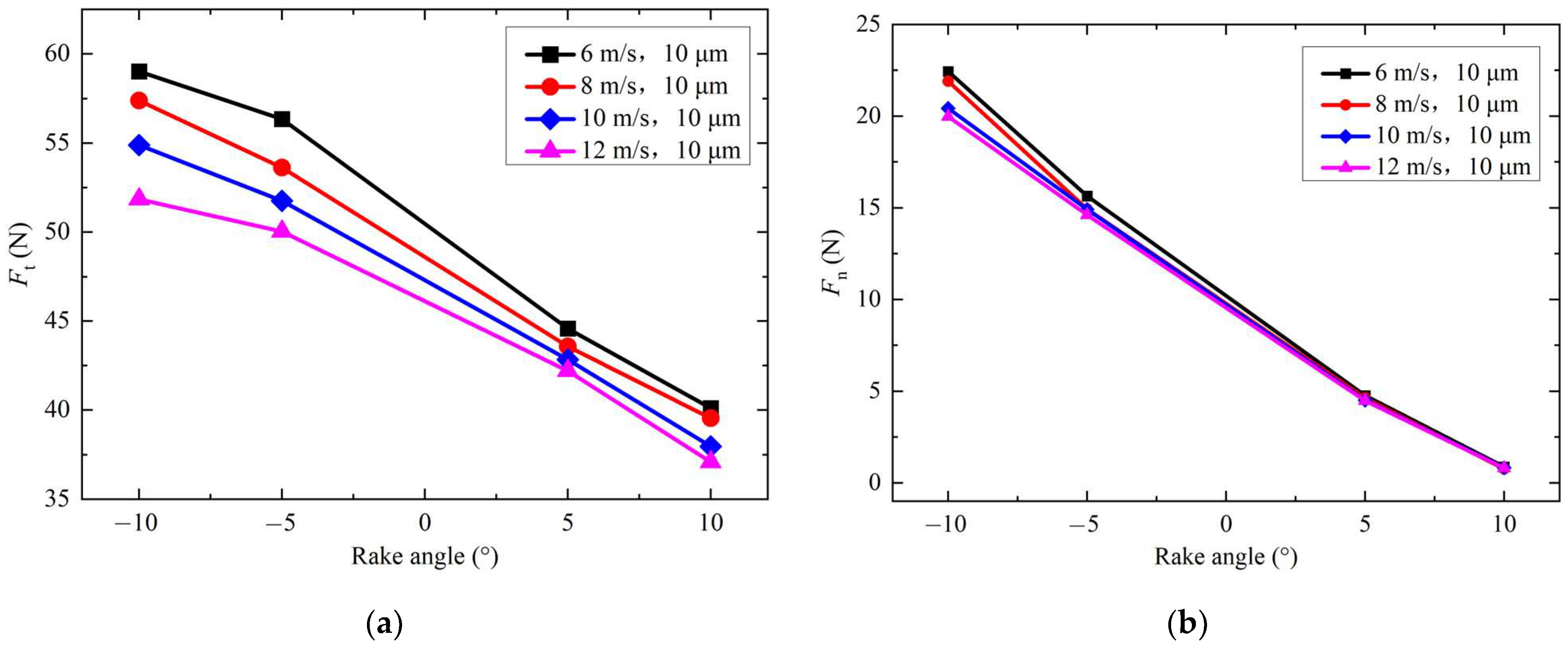

3.1. Grinding Force

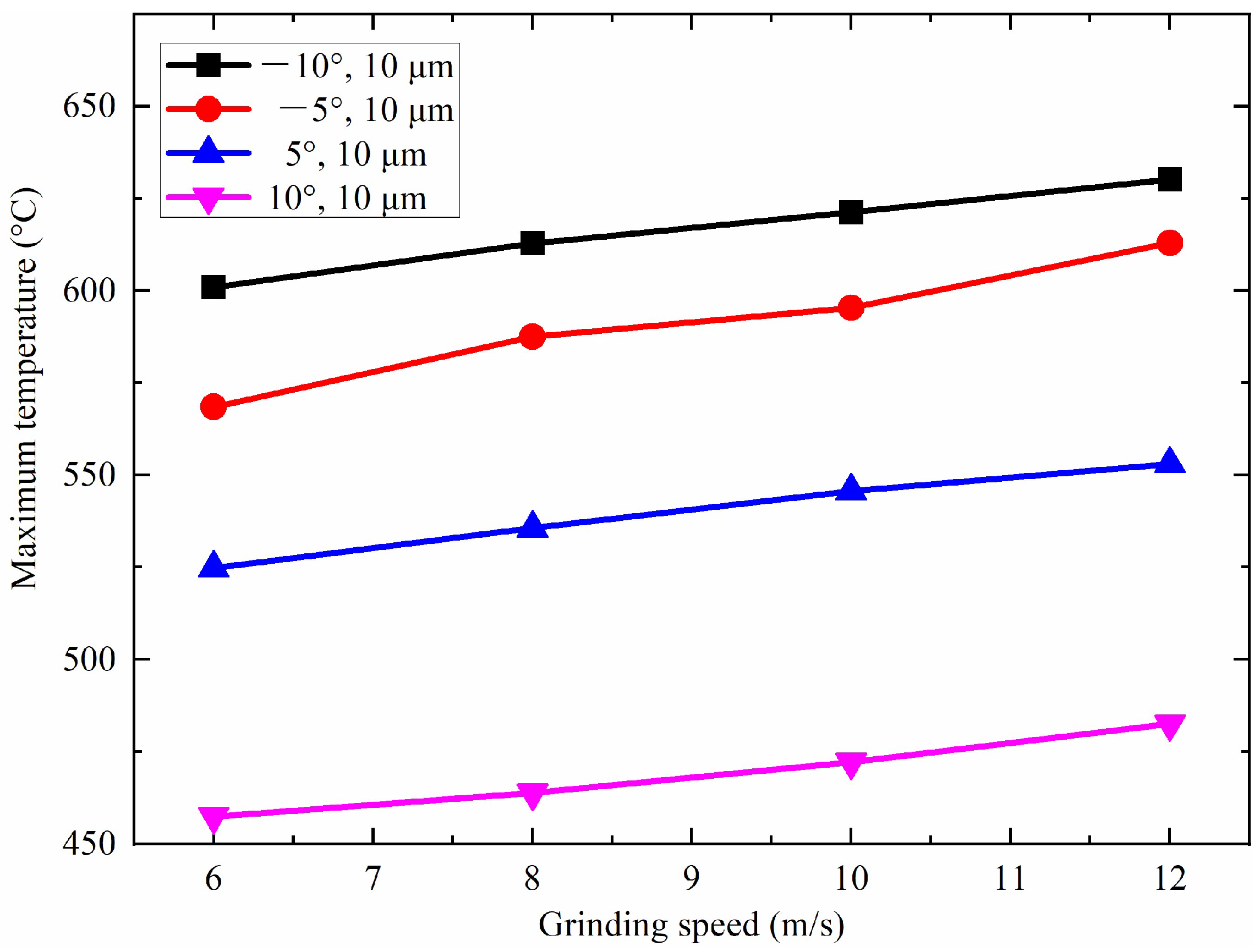

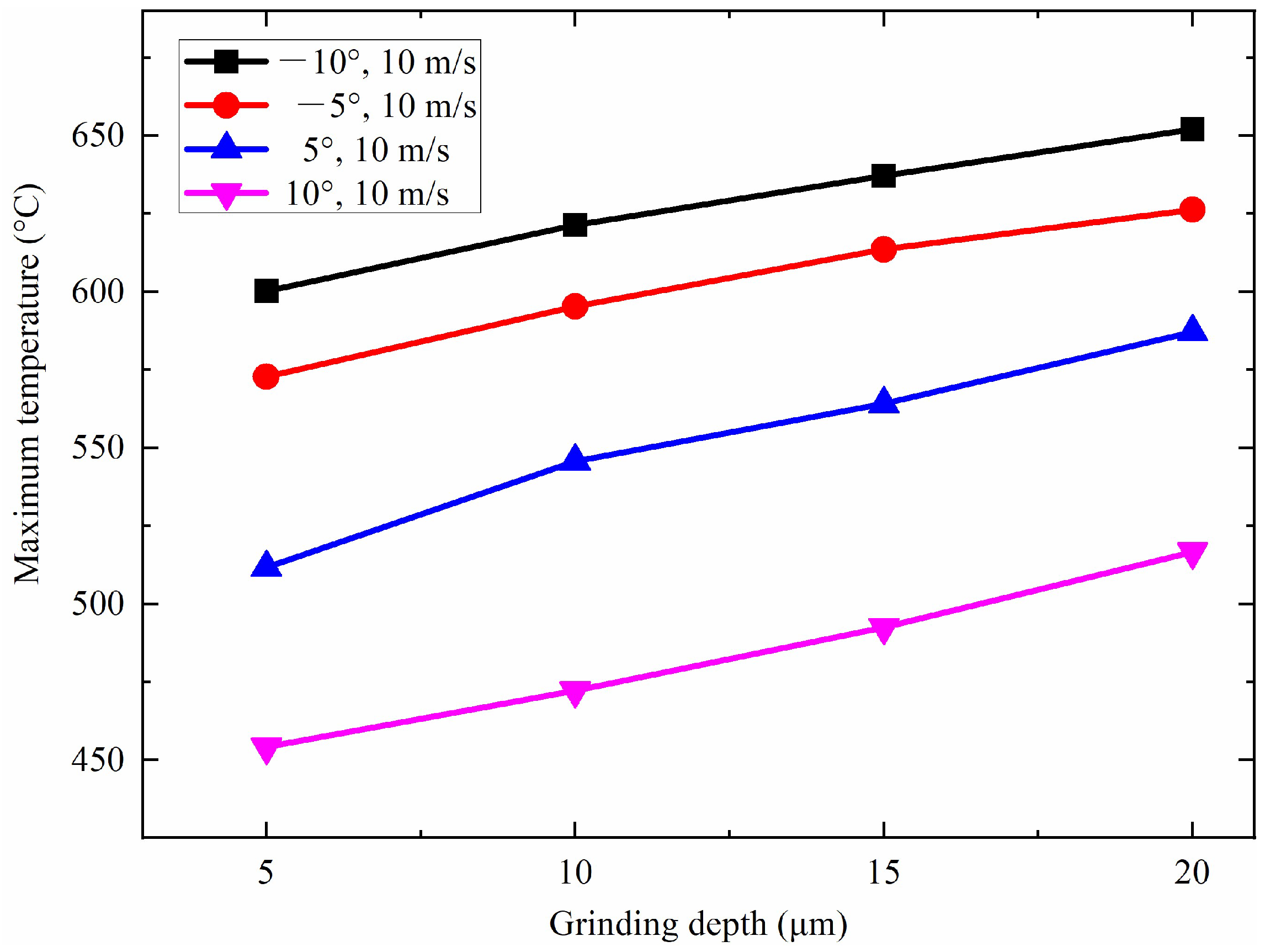

3.2. Grinding Temperature

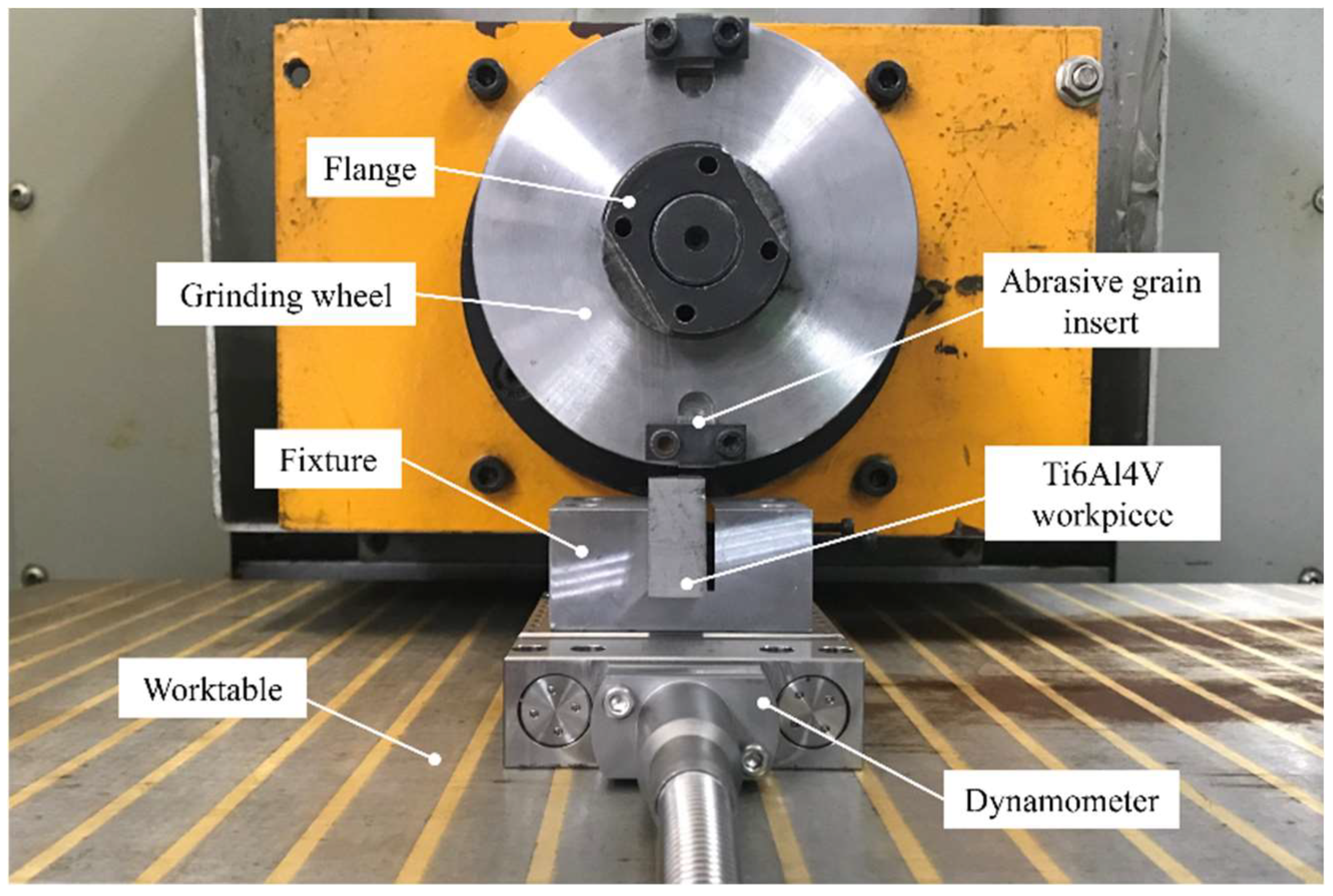

4. Experimental Setup and Scheme

5. Results and Discussion

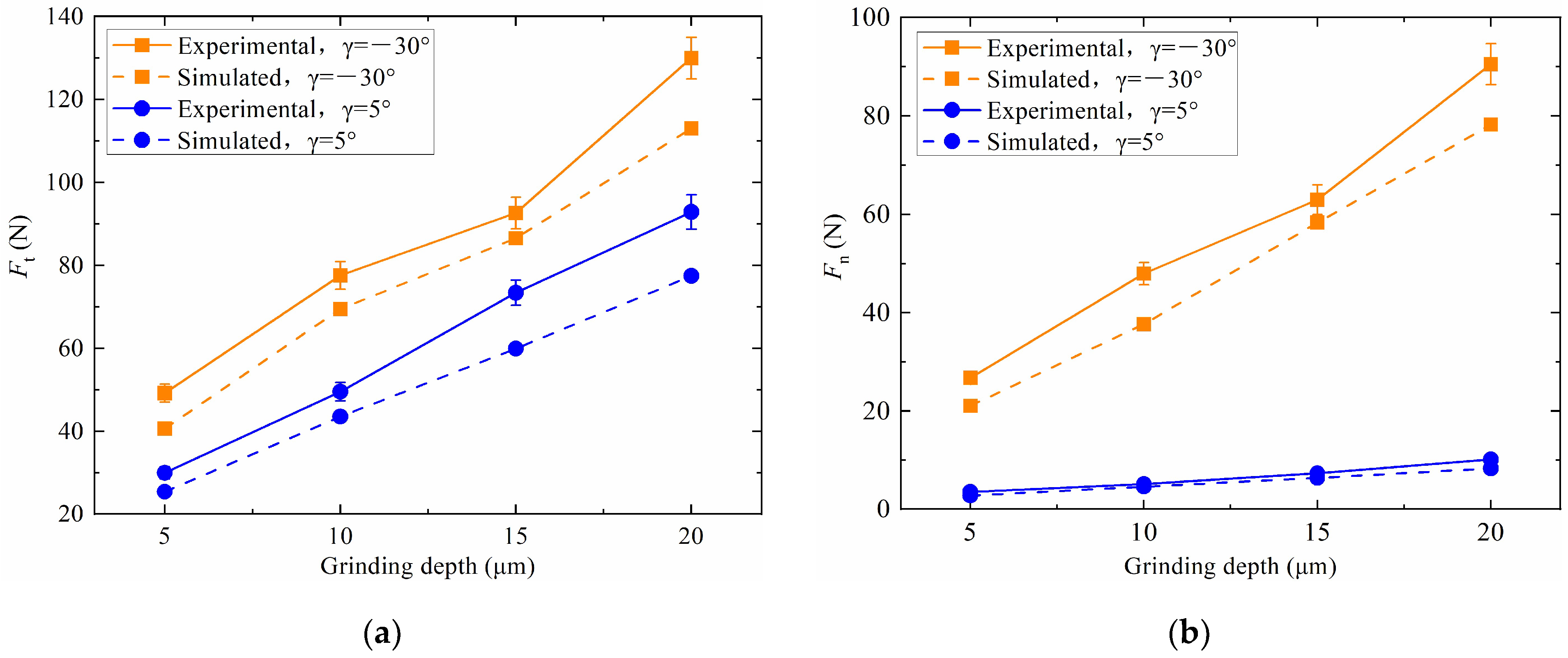

5.1. Grinding Force

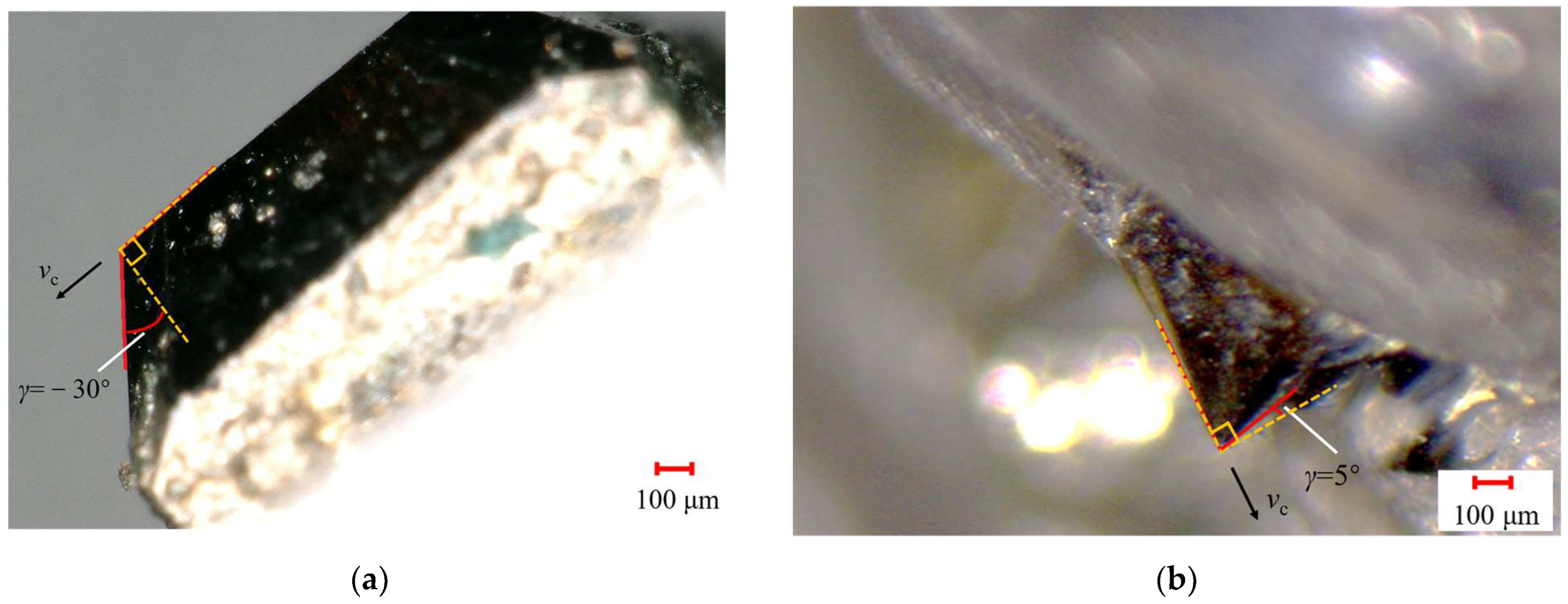

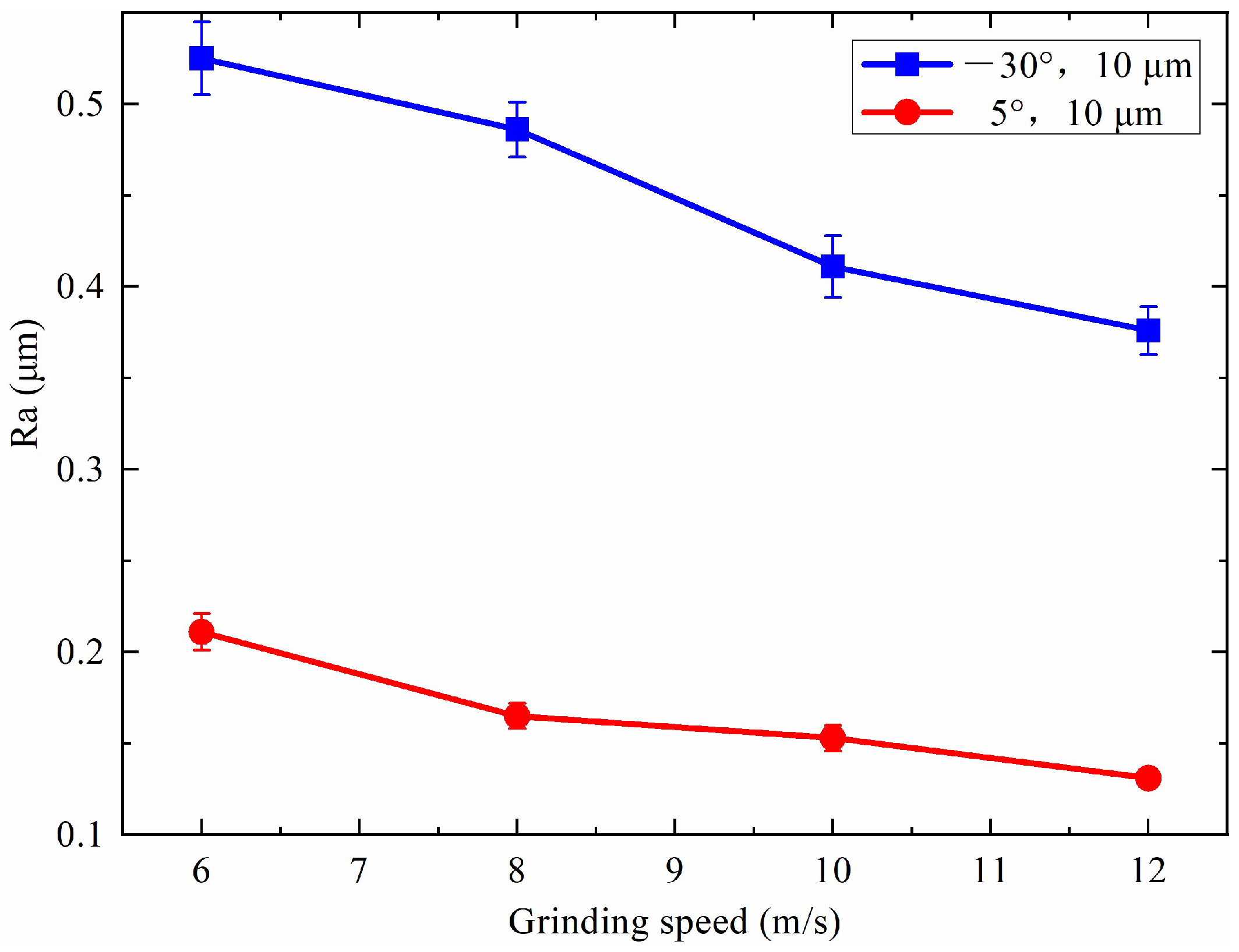

5.2. Surface Morphology and Surface Roughness

6. Conclusions

- In single diamond grain grinding, both tangential and normal grinding forces slightly decline as the grinding speed is increased, regardless of PRA or NRA. With the increment in grinding depth, the grinding forces gradually rise. When the rake angle is varied from −30° to 5°, the tangential grinding forces decrease by 25–41% and the normal forces decrease by 81–89%.

- In the grinding with both PRA and NRA single diamond abrasive grains, there is a gradual increase in the maximum temperature within the grinding zone correlating with increases in both grinding speed and depth. When the rake angle of the diamond grain transitions from negative to positive, the maximum grinding temperature significantly decreases.

- After the single grain grinding process, the roughness of the workpiece surface exhibits a decrease as the grinding speed rises and shows an increase in response to a greater grinding depth. Compared to NRA single grain grinding, PRA single diamond grain grinding skips the friction and ploughing stages, directly cutting into the material without inducing severe compressive sliding deformation, resulting in shallower grinding traces and fewer processing defects. The surface roughness in single grain grinding with a PRA were reduced by 58% to 66%, indicating that a diamond abrasive grain with a PRA can effectively improve the surface integrity after grinding for hard-to-machine materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, H.; Li, X.; Mu, D.; Lawn, B.R. Science and Art of Ductile Grinding of Brittle Solids. Int. J. Mach. Tools Manuf. 2021, 161, 103675. [Google Scholar] [CrossRef]

- Zeng, K.; Wu, X.; Jiang, F.; Shen, J.; Zhu, L.; Li, L. A Comprehensive Review on the Cutting and Abrasive Machining of Cemented Carbide Materials. J. Manuf. Process. 2023, 108, 335–358. [Google Scholar] [CrossRef]

- Wu, D.; Liu, S.; Wang, H. High Surface Integrity Machining of Typical Aviation Difficult-to-Machine Material Blade. Int. J. Adv. Manuf. Technol. 2023, 129, 2861–2873. [Google Scholar] [CrossRef]

- Khanna, N.; Zadafiya, K.; Patel, T.; Kaynak, Y.; Rahman Rashid, R.A.; Vafadar, A. Review on Machining of Additively Manufactured Nickel and Titanium Alloys. J. Mater. Res. Technol. 2021, 15, 3192–3221. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Ding, W.; An, Q.; Liu, B.; Li, H.N.; Said, Z.; Sharma, S.; Li, R.; et al. Comparative Assessment of Force, Temperature, and Wheel Wear in Sustainable Grinding Aerospace Alloy Using Biolubricant. Front. Mech. Eng. 2023, 18, 3. [Google Scholar] [CrossRef]

- Fang, N. Tool-Chip Friction in Machining with a Large Negative Rake Angle Tool. Wear 2005, 258, 890–897. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Mia, M.; Gupta, M.K.; Machado, A.R.; Tomaz, Í.V.; Sarikaya, M.; Wojciechowski, S.; Mikolajczyk, T.; Kaplonek, W. Improvement of Machinability of Ti and Its Alloys Using Cooling-Lubrication Techniques: A Review and Future Prospect. J. Mater. Res. Technol. 2021, 11, 719–753. [Google Scholar] [CrossRef]

- Liao, Z.; la Monaca, A.; Murray, J.; Speidel, A.; Ushmaev, D.; Clare, A.; Axinte, D.; M’Saoubi, R. Surface Integrity in Metal Machining—Part I: Fundamentals of Surface Characteristics and Formation Mechanisms. Int. J. Mach. Tools Manuf. 2021, 162, 103687. [Google Scholar] [CrossRef]

- Axinte, D.; Butler-Smith, P.; Akgun, C.; Kolluru, K. On the Influence of Single Grit Micro-Geometry on Grinding Behavior of Ductile and Brittle Materials. Int. J. Mach. Tools Manuf. 2013, 74, 12–18. [Google Scholar] [CrossRef]

- Wei, C.; He, C.; Chen, G.; Sun, Y.; Ren, C. Material Removal Mechanism and Corresponding Models in the Grinding Process: A Critical Review. J. Manuf. Process. 2023, 103, 354–392. [Google Scholar] [CrossRef]

- Anderson, D.; Warkentin, A.; Bauer, R. Experimental and Numerical Investigations of Single Abrasive-Grain Cutting. Int. J. Mach. Tools Manuf. 2011, 51, 898–910. [Google Scholar] [CrossRef]

- Anderson, D.; Warkentin, A.; Bauer, R. Comparison of Spherical and Truncated Cone Geometries for Single Abrasive-Grain Cutting. J. Mater. Process. Technol. 2012, 212, 1946–1953. [Google Scholar] [CrossRef]

- Liu, W.; Deng, Z.; Wan, L.; Zhao, X.; Pi, Z. Simulation and experiment study for silicon nitride cutting with single diamond grain. Chin. J. Mech. Eng.-En. 2015, 51, 191–198. [Google Scholar] [CrossRef]

- Dai, C.; Ding, W.; Xu, J.; Fu, Y.; Yu, T. Influence of Grain Wear on Material Removal Behavior during Grinding Nickel-Based Superalloy with a Single Diamond Grain. Int. J. Mach. Tools Manuf. 2017, 113, 49–58. [Google Scholar] [CrossRef]

- Fu, D.; Ding, W.; Miao, Q.; Xu, J. Simulation Research on the Grinding Forces and Stresses Distribution in Single-Grain Surface Grinding of Ti-6Al-4V Alloy When Considering the Actual Cutting-Depth Variation. Int. J. Adv. Manuf. Technol. 2017, 91, 3591–3602. [Google Scholar] [CrossRef]

- Yin, G.; Gong, Y.; Li, Y.; Song, J.; Zhou, Y. Modeling and Evaluation in Grinding of SiCp/Al Composites with Single Diamond Grain. Int. J. Mech. Sci. 2019, 163, 105137. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Cui, X.; Said, Z.; Sharma, S.; Liu, M.; Gao, T.; Zhou, Z.; Wang, X.; Li, C. Mechanical Behavior and Modeling of Grinding Force: A Comparative Analysis. J. Manuf. Process. 2023, 102, 921–954. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.; Meng, B.; Liu, L.; Rao, X. Material Removal Mechanism and Grinding Force Modelling of Ultrasonic Vibration Assisted Grinding for SiC Ceramics. Ceram. Int. 2017, 43, 2981–2993. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, B.; Zhao, Q.; Li, H.N.; Jackson, M.J.; Linke, B.S.; Luo, X. Modelling of Grinding Mechanics: A Review. Chin. J. Aeronaut. 2023, 36, 25–39. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M. A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Kong, J.; Zhang, T.; Du, D.; Wang, F.; Jiang, F.; Huang, W. The Development of FEM Based Model of Orthogonal Cutting for Pure Iron. J. Manuf. Process. 2021, 64, 674–683. [Google Scholar] [CrossRef]

- Mao, C.; Lu, J.; Zhao, Z.; Yin, L.; Hu, Y.; Bi, Z. Simulation and Experiment of Cutting Characteristics for Single CBN-WC-10Co Fiber. Precis. Eng. 2018, 52, 170–182. [Google Scholar] [CrossRef]

- Kacalak, W.; Lipiński, D.; Bałasz, B.; Rypina; Tandecka, K.; Szafraniec, F. Performance Evaluation of the Grinding Wheel with Aggregates of Grains in Grinding of Ti-6Al-4V Titanium Alloy. Int. J. Adv. Manuf. Technol. 2018, 94, 301–314. [Google Scholar] [CrossRef]

- Eberle, G.; Dold, C.; Wegener, K. Laser Fabrication of Diamond Micro-Cutting Tool-Related Geometries Using a High-Numerical Aperture Micro-Scanning System. Int. J. Adv. Manuf. Technol. 2015, 81, 1117–1125. [Google Scholar] [CrossRef]

- Konov, V.I. Laser in Micro and Nanoprocessing of Diamond Materials. Laser Photonics Rev. 2012, 6, 739–766. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Janulewicz, K.A. Structural Transformation of Monocrystalline Diamond Driven by Ultrashort Laser Pulses. Diam. Relat. Mater. 2016, 70, 194–200. [Google Scholar] [CrossRef]

- Setti, D.; Sinha, M.K.; Ghosh, S.; Venkateswara Rao, P. Performance Evaluation of Ti-6Al-4V Grinding Using Chip Formation and Coefficient of Friction under the Influence of Nanofluids. Int. J. Mach. Tools Manuf. 2015, 88, 237–248. [Google Scholar] [CrossRef]

- Yin, J.; Chen, G.; Xiong, B.; Zhu, Z.C.; Jin, M. Femtosecond Pulsed Laser Fabrication of a Novel SCD Grinding Tool with Positive Rake Angle. Appl. Phys. A Mater. Sci. Process. 2018, 124, 859. [Google Scholar] [CrossRef]

| A (MPa) | B (MPa) | C | m | n |

|---|---|---|---|---|

| 875 | 793 | 0.01 | 0.71 | 0.386 |

| Density (kg•m−3) | Young’s Modulus (GPa) | Poisson’s Ratio | Specific Heat (J/(kg•K)) | Linear Expansion Coefficient (K−1) | Thermal Conductivity (W/(m•K)) |

|---|---|---|---|---|---|

| 3.5 × 103 | 9.6 × 102 | 0.2 | 508 | 1.18 × 10−6 | 2000 |

| D1 | D2 | D3 | D4 | D5 |

|---|---|---|---|---|

| −0.09 | 0.25 | −0.5 | 0.014 | 3.87 |

| Density (kg•m−3) | Hardness (HRC) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation | Poisson’s Ratio | Linear Expansion Coefficient (K−1) | Inelastic Thermal Coefficient |

|---|---|---|---|---|---|---|---|

| 4450 | 36 | 900 | 112 | 10% | 0.35 | 9.5 × 10−6 | 0.9 |

| Temperature (K) | Thermal Conductivity (W/(m•K)) | Specific Heat (J/(kg•K)) |

|---|---|---|

| 300 | 6.8 | 611 |

| 373 | 7.4 | 624 |

| 473 | 8.7 | 653 |

| 573 | 9.8 | 674 |

| 673 | 10.3 | 691 |

| 773 | 11.8 | 703 |

| Process Parameters | Value |

|---|---|

| Grinding speed vs. (m/s) | 6, 8, 10, 12 |

| Grinding depth ap (μm) | 5, 10, 15, 20 |

| Feed speed vw (mm/s) | 2 |

| Rake angle γ (°) | 5, −30 |

| Grinding time (min) | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Sun, R.; Ming, C.; Chen, C.; Zeng, S. Investigation of Single Grain Grinding of Titanium Alloy Using Diamond Abrasive Grain with Positive Rake Angle. Machines 2024, 12, 451. https://doi.org/10.3390/machines12070451

Yin J, Sun R, Ming C, Chen C, Zeng S. Investigation of Single Grain Grinding of Titanium Alloy Using Diamond Abrasive Grain with Positive Rake Angle. Machines. 2024; 12(7):451. https://doi.org/10.3390/machines12070451

Chicago/Turabian StyleYin, Jiu, Rushui Sun, Chuanbo Ming, Chang Chen, and Shuai Zeng. 2024. "Investigation of Single Grain Grinding of Titanium Alloy Using Diamond Abrasive Grain with Positive Rake Angle" Machines 12, no. 7: 451. https://doi.org/10.3390/machines12070451

APA StyleYin, J., Sun, R., Ming, C., Chen, C., & Zeng, S. (2024). Investigation of Single Grain Grinding of Titanium Alloy Using Diamond Abrasive Grain with Positive Rake Angle. Machines, 12(7), 451. https://doi.org/10.3390/machines12070451