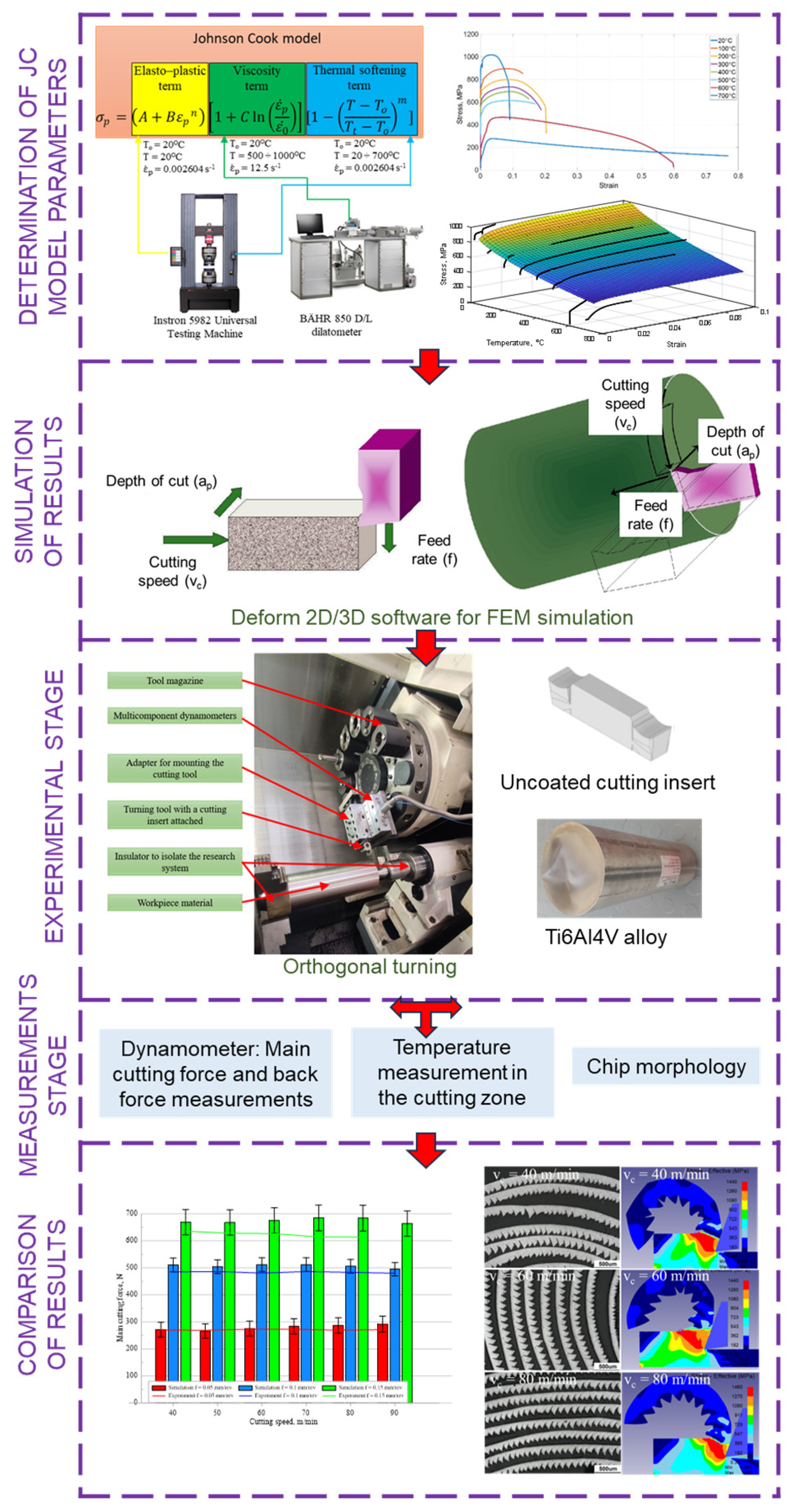

Determination and Verification of the Johnson–Cook Constitutive Model Parameters in the Precision Machining of Ti6Al4V Alloy

Abstract

1. Introduction

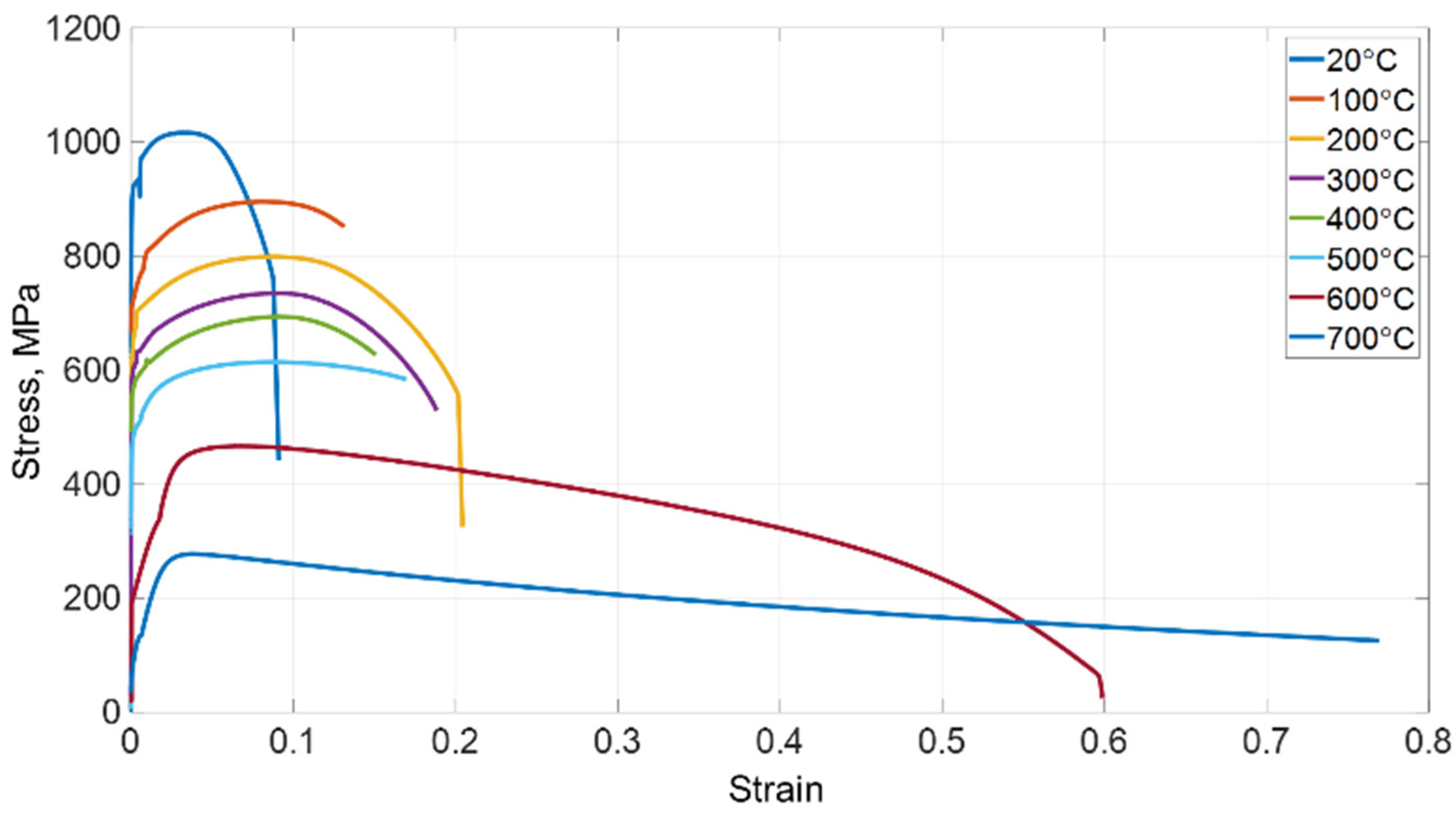

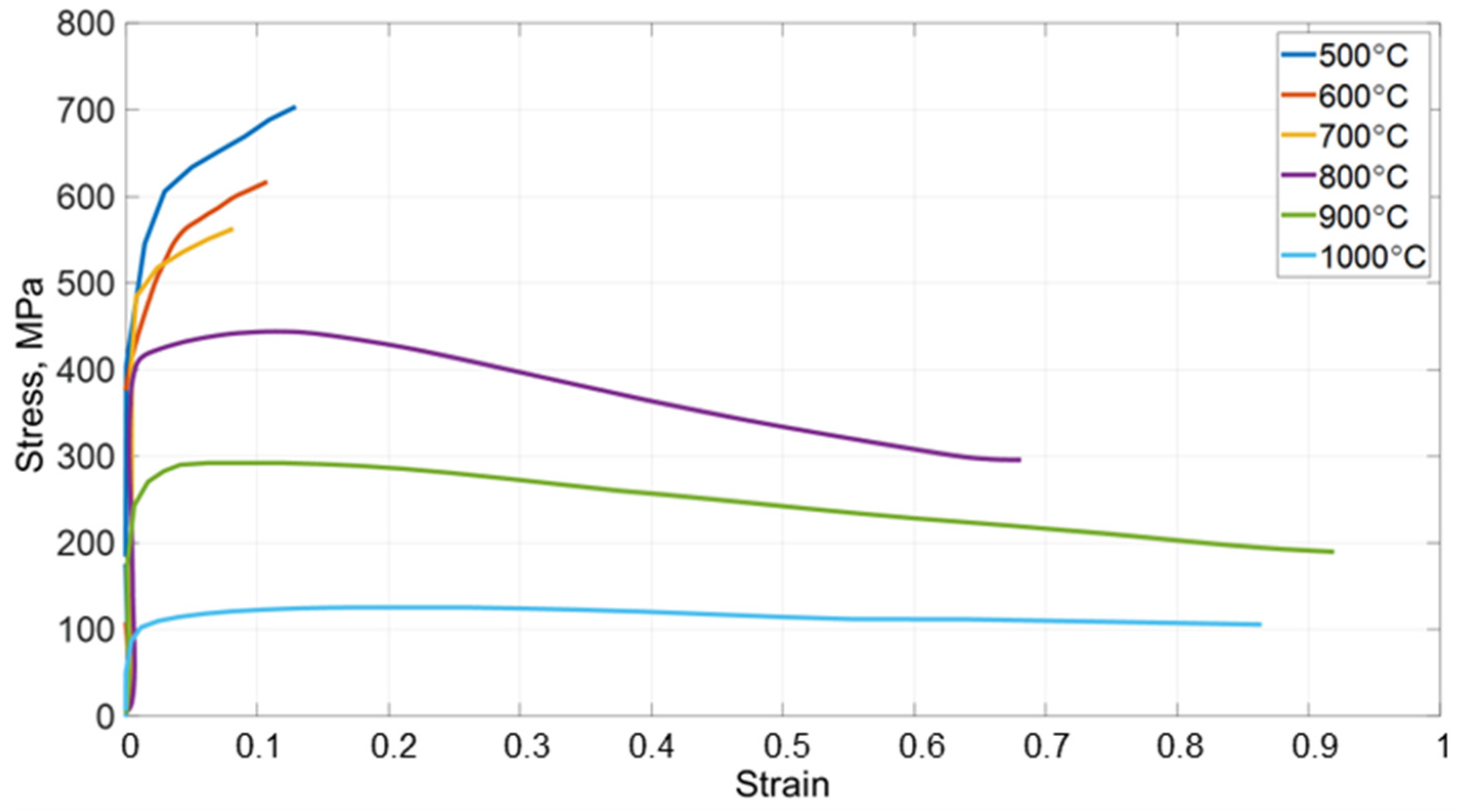

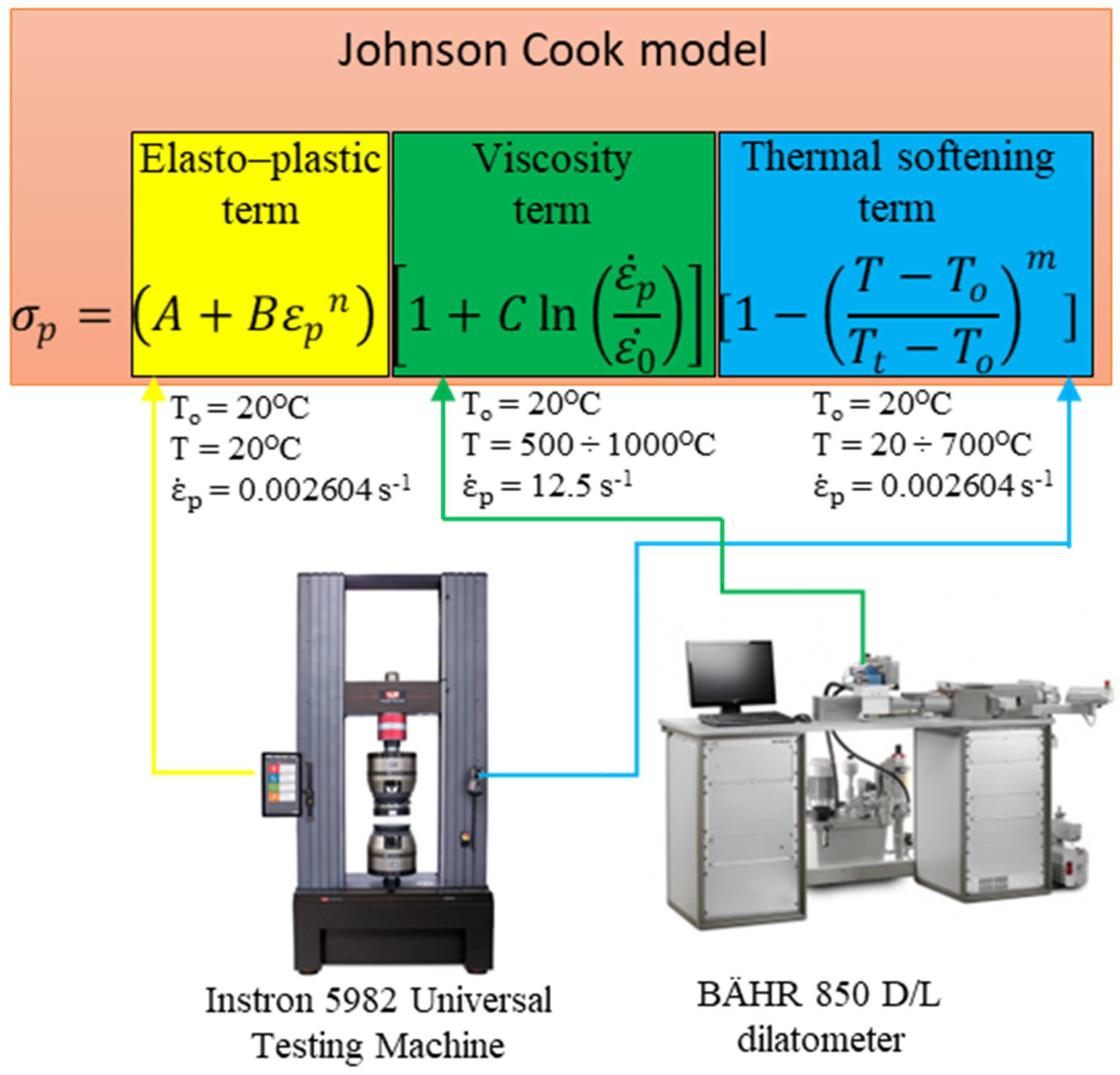

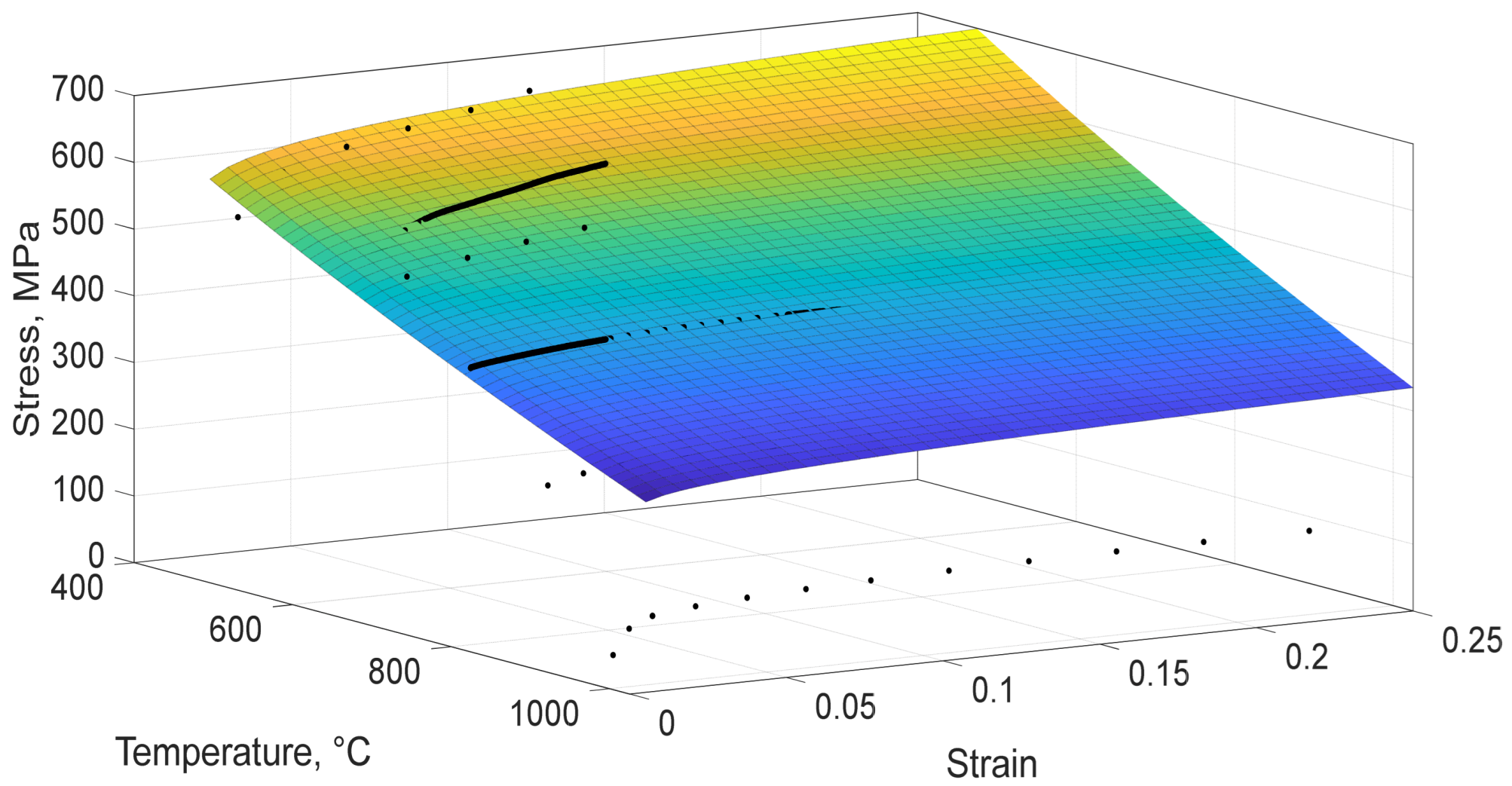

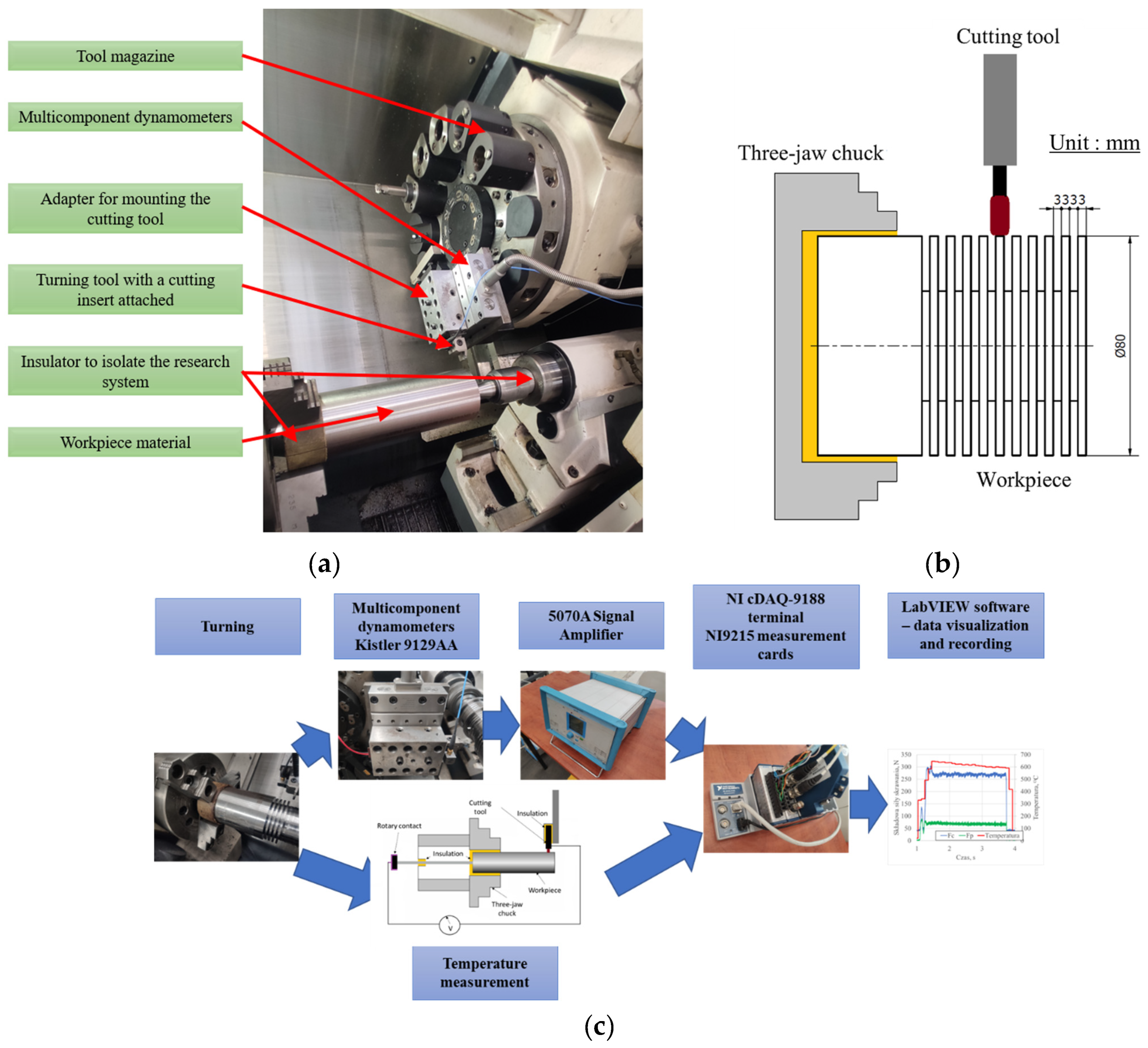

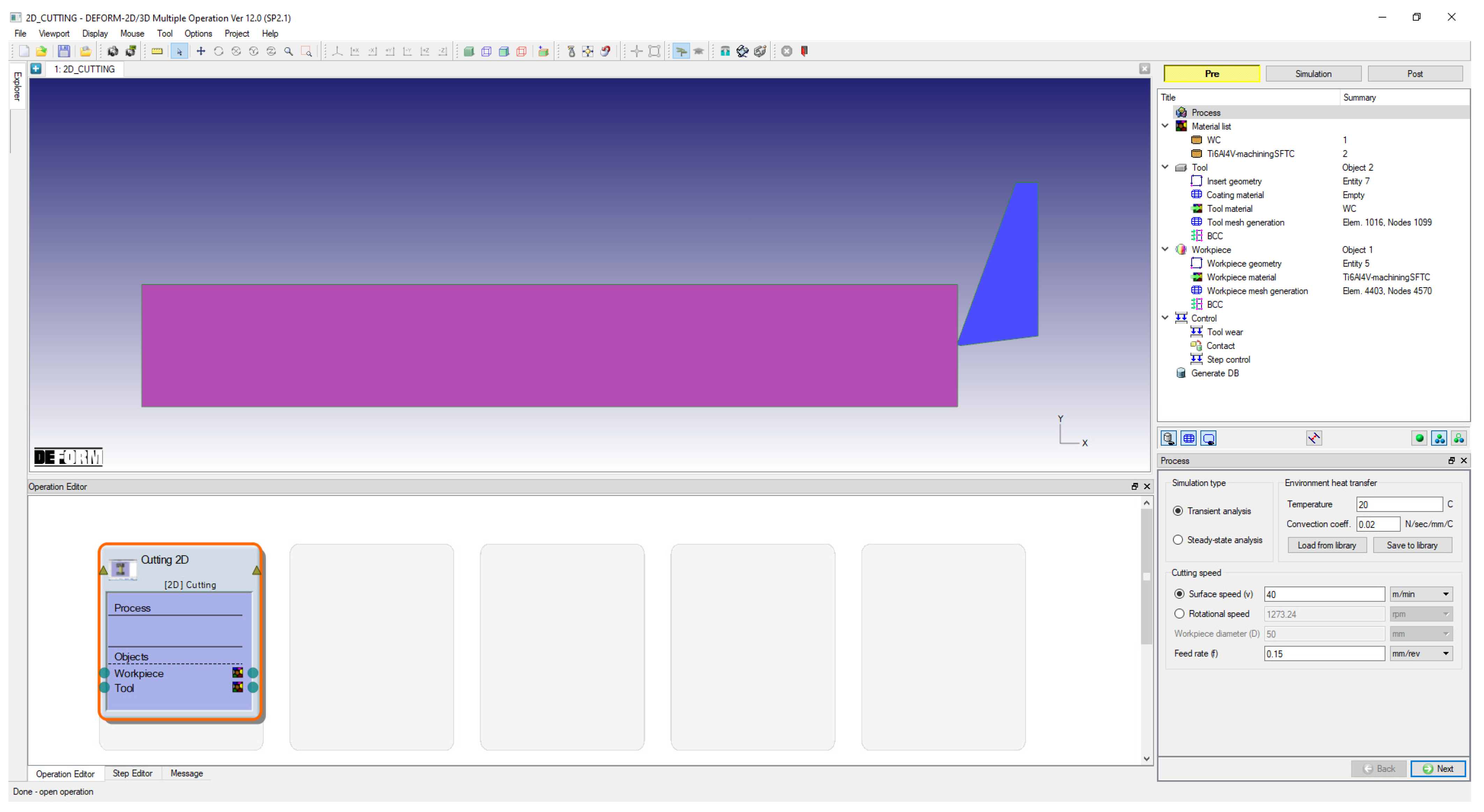

2. Methodology for Identifying the Parameters of Constitutive Equations

3. Experimental and Simulation Approach

- Orthogonal rake angle γo = 20°;

- Normal clearance angle αo = 7°.

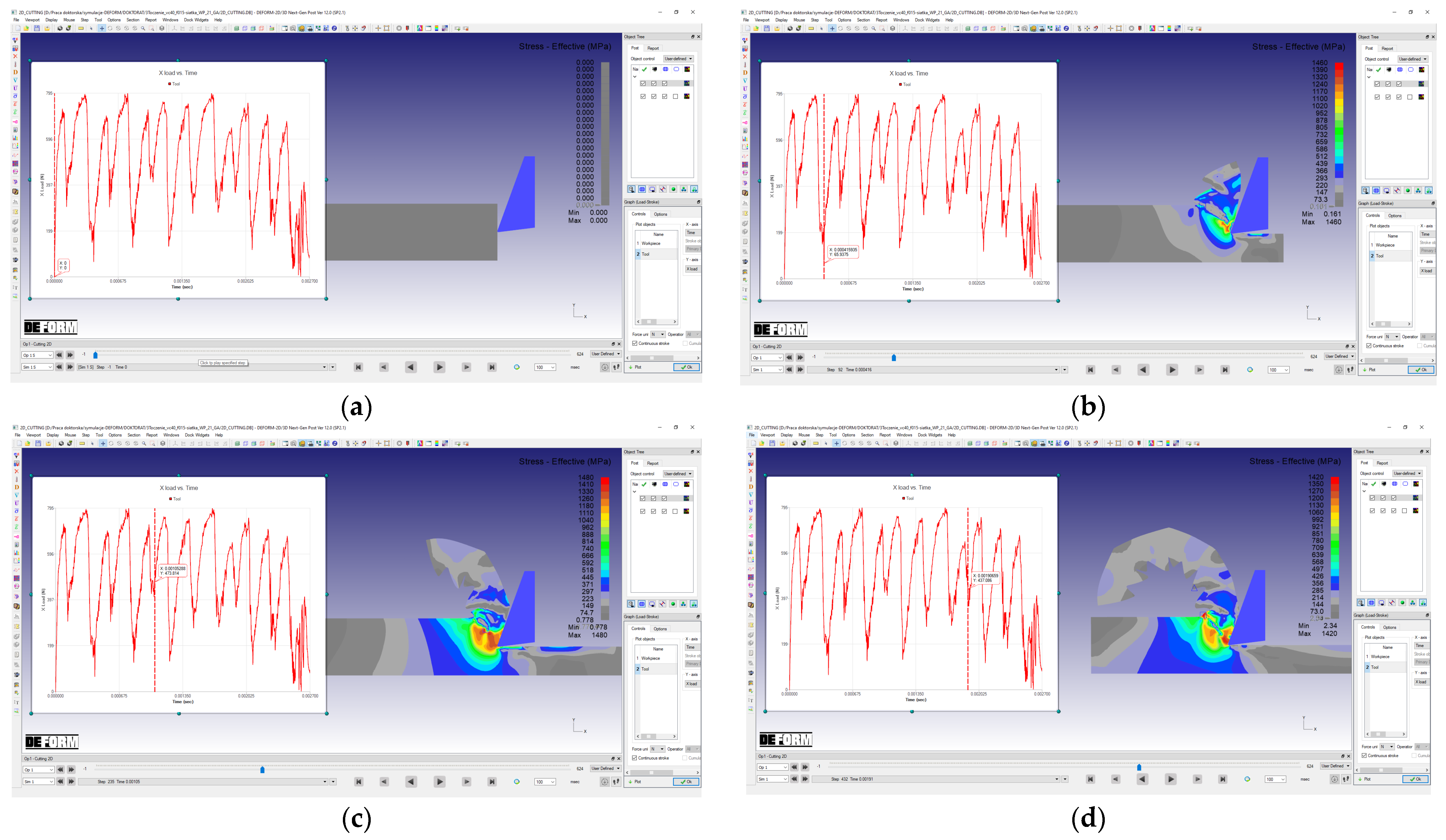

4. Results and Discussion

4.1. Chip Characteristics

4.2. Cutting Forces

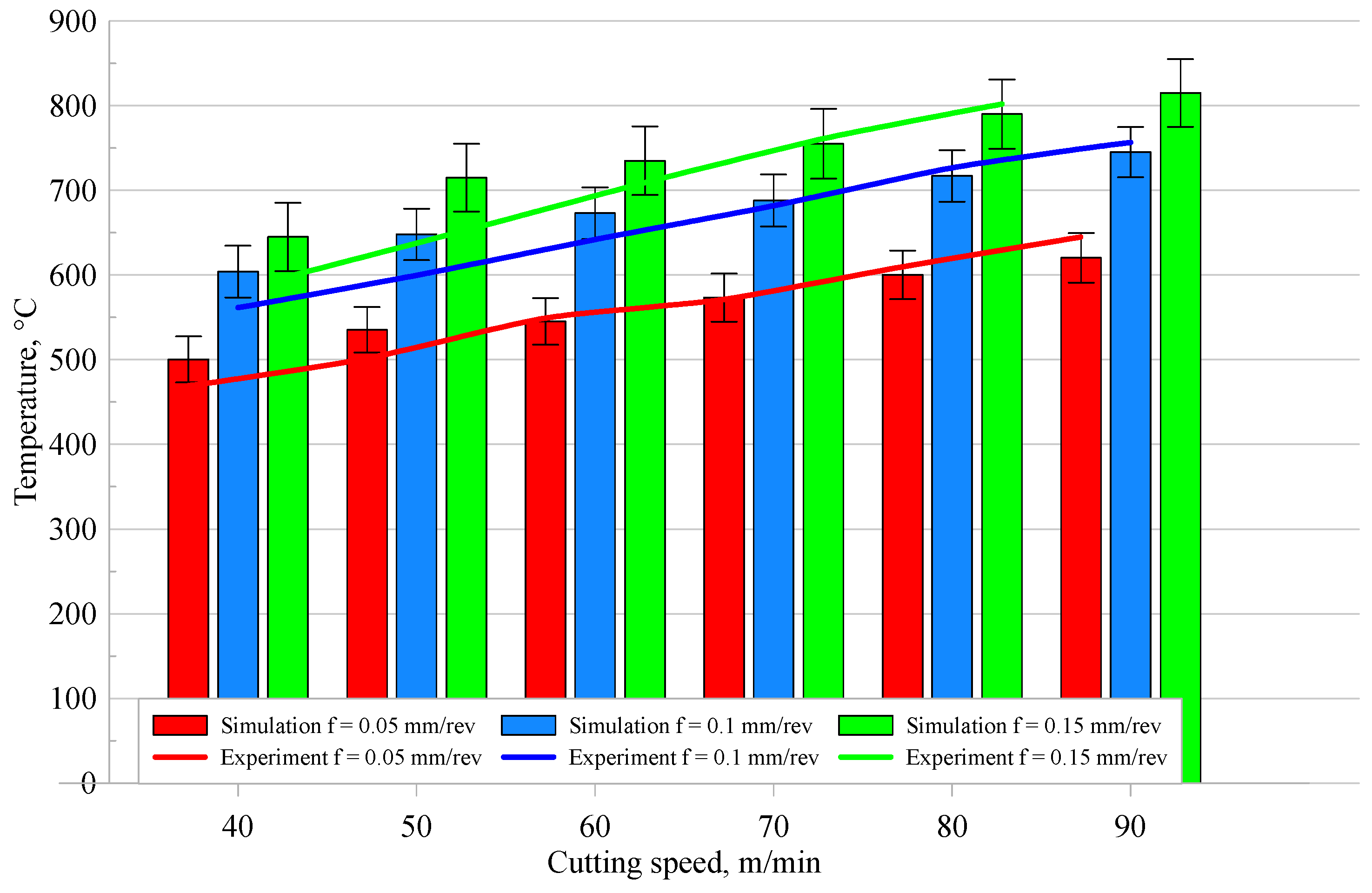

4.3. Temperature in the Cutting Zone

5. Conclusions

- It is possible to determine the material constants of the Johnson–Cook model based on strength tests in a simple way using the analytical method. The fit of the obtained curves of the mathematical model to the experimental tests is at a good level, and the differences in the curves for different temperatures do not exceed 8% (R2 = 0.9782).

- The material constants determined by the Johnson–Cook model can be successfully used in FEM modeling of the cutting process of the Ti6Al4V titanium alloy for the adopted range of technological parameter values.

- The material constants of the JC model allowed for very good agreement between the FEM simulation results and the experimental results.

- The best match between FEM simulation results and experimental tests was found for the temperature in the cutting zone, where the differences did not exceed 40 °C (4%).

- It was also noticed that, with the increase in the feed rate and cutting speed, the match between the simulation and experimental results deteriorated. The reason for this could be a significant increase in the strain rate and temperature for which no strength tests were conducted and were not included in the determination of the material constants of the Johnson–Cook model.

- Conducting the whole range of both simulation and experimental studies raises the question, “To what extent do individual values of material constants affect the change in stress–strain curves as well as the results of FEM simulations?” Therefore, in the future, the authors will attempt to evaluate the effect of changing individual parameters of the Johnson–Cook material model on the results of numerical simulations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mourtzis, D.; Doukas, M.; Bernidaki, D. Simulation in Manufacturing: Review and Challenges. Procedia CIRP 2014, 25, 213–229. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I.S. Recent Advances in Modelling of Metal Machining Processes. CIRP Ann. 2013, 62, 695–718. [Google Scholar] [CrossRef]

- Zindani, D.; Kumar, K. A Brief Review on Cryogenics in Machining Process. SN Appl. Sci. 2020, 2, 1107. [Google Scholar] [CrossRef]

- Komanduri, R.; Hou, Z.-B. On Thermoplastic Shear Instability in the Machining of a Titanium Alloy (Ti-6Al-4V). Metall. Mater. Trans. A 2002, 33, 2995–3010. [Google Scholar] [CrossRef]

- Binali, R. Parametric Optimization of Cutting Force and Temperature in Finite Element Milling of AISI P20 Steel. J. Mater. Mechatron. A 2023, 4, 244–256. [Google Scholar] [CrossRef]

- Binali, R.; Yaldız, S.; Neşeli, S. Investigation of Power Consumption in the Machining of S960QL Steel by Finite Elements Method. Eur. J. Tech. 2022, 12, 43–48. [Google Scholar] [CrossRef]

- Osorio-Pinzon, J.C.; Abolghasem, S.; Casas-Rodriguez, J.P. Predicting the Johnson Cook Constitutive Model Constants Using Temperature Rise Distribution in Plane Strain Machining. Int. J. Adv. Manuf. Technol. 2019, 105, 279–294. [Google Scholar] [CrossRef]

- Bergs, T.; Hardt, M.; Schraknepper, D. Determination of Johnson-Cook Material Model Parameters for AISI 1045 from Orthogonal Cutting Tests Using the Downhill-Simplex Algorithm. Procedia Manuf. 2020, 48, 541–552. [Google Scholar] [CrossRef]

- Cheng, C.; Mahnken, R. A Modified Zerilli–Armstrong Model as the Asymmetric Visco-Plastic Part of a Multi-Mechanism Model for Cutting Simulations. Arch. Appl. Mech. 2021, 91, 3869–3888. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Ren, X.-W.; Xiao, Z.-B.; Zhang, X.-Y.; Huang, Y.-C. Flow Stress Prediction of Hastelloy C-276 Alloy Using Modified Zerilli−Armstrong, Johnson−Cook and Arrhenius-Type Constitutive Models. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2020, 30, 3031–3042. [Google Scholar] [CrossRef]

- Johnson, G.R. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, Netherlands, 19–21 April 1983. [Google Scholar]

- Wang, Z.; Cao, Y.; Gorbachev, S.; Kuzin, V.; He, W.; Guo, J. Research on Conventional and High-Speed Machining Cutting Force of 7075-T6 Aluminum Alloy Based on Finite Element Modeling and Simulation. Metals 2022, 12, 1395. [Google Scholar] [CrossRef]

- Ning, J.; Liang, S.Y. Model-Driven Determination of Johnson-Cook Material Constants Using Temperature and Force Measurements. Int. J. Adv. Manuf. Technol. 2018, 97, 1053–1060. [Google Scholar] [CrossRef]

- Binali, R.; Yaldız, S.; Neşeli, S. Finite Element Analysis and Statistical Investigation of S960ql Structure Steel Machinability with Milling Method. J. Brazilian Soc. Mech. Sci. Eng. 2024, 46, 260. [Google Scholar] [CrossRef]

- Banerjee, A.; Dhar, S.; Acharyya, S.; Datta, D.; Dhar, S.; Acharyya, S.; Datta, D.; Nayak, N.; Banerjee, A.; Dhar, S.; et al. Determination of Johnson Cook Material and Failure Model Constants and Numerical Modelling of Charpy Impact Test of Armour Steel. Mater. Sci. Eng. A 2015, 640, 200–209. [Google Scholar] [CrossRef]

- Cao, Y.; Zhen, Y.; Song, M.; Yi, H.; Li, F.; Li, X. Determination of Johnson–Cook Parameters and Evaluation of Charpy Impact Test Performance for X80 Pipeline Steel. Int. J. Mech. Sci. 2020, 179, 105627. [Google Scholar] [CrossRef]

- Cowper, G.R.; Symonds, P.S. Strain-Hardening and Strain-Rate Effects in the Impact Loading of Cantilever Beams; Division of Applied Mathematics, Brown University: Providence, RI, USA, 1957. [Google Scholar]

- Grzesik, W.; Niesłony, P.; Laskowski, P. Determination of Material Constitutive Laws for Inconel 718 Superalloy Under Different Strain Rates and Working Temperatures. J. Mater. Eng. Perform. 2017, 26, 5705–5714. [Google Scholar] [CrossRef]

- Farahani, H.K.; Ketabchi, M.; Zangeneh, S. Determination of Johnson–Cook Plasticity Model Parameters for Inconel718. J. Mater. Eng. Perform. 2017, 26, 5284–5293. [Google Scholar] [CrossRef]

- Karkalos, N.E.; Markopoulos, A.P. Determination of Johnson-Cook Material Model Parameters by an Optimization Approach Using the Fireworks Algorithm. Procedia Manuf. 2018, 22, 107–113. [Google Scholar] [CrossRef]

- Löschner, P.; Jarosz, K.; Niesłony, P. Optimization of Johnson–Cook Constitutive Model Parameters. J. Mach. Eng. 2019, 19, 66–73. [Google Scholar] [CrossRef]

- Shrot, A.; Bäker, M. Determination of Johnson-Cook Parameters from Machining Simulations. Comput. Mater. Sci. 2012, 52, 298–304. [Google Scholar] [CrossRef]

- Niesłony, P.; Habrat, W. Metodyka Wyznaczania Temperatury w Strefie Skrawania Podczas Toczenia i Frezowania Stopu Ti6Al4V. Mechanik 2015, 88, 71–81. [Google Scholar] [CrossRef][Green Version]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 9788578110796. [Google Scholar]

- Bindu, B.; Vinod, B. Measurement of Cutting Forces in CNC Turning Centers: A Review. Int. J. Mech. Eng. 2015, 3, 77–87. [Google Scholar]

- Liang, Q.; Zhang, D.; Coppola, G.; Mao, J.; Sun, W.; Wang, Y.; Ge, Y. Design and Analysis of a Sensor System for Cutting Force Measurement in Machining Processes. Sensors 2016, 16, 70. [Google Scholar] [CrossRef] [PubMed]

- Mia, M.; Dhar, N.R. Effect of High Pressure Coolant Jet on Cutting Temperature, Tool Wear and Surface Finish in Turning Hardened (HRC 48) Steel. J. Mech. Eng. 2015, 45, 1–6. [Google Scholar] [CrossRef][Green Version]

| A | B | C | n | m |

|---|---|---|---|---|

| 775.2 | 440.3 | 0.01483 | 0.1668 | 0.6269 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Löschner, P.; Gupta, M.K.; Niesłony, P.; Korkmaz, M.E.; Jamil, M. Determination and Verification of the Johnson–Cook Constitutive Model Parameters in the Precision Machining of Ti6Al4V Alloy. Machines 2024, 12, 709. https://doi.org/10.3390/machines12100709

Löschner P, Gupta MK, Niesłony P, Korkmaz ME, Jamil M. Determination and Verification of the Johnson–Cook Constitutive Model Parameters in the Precision Machining of Ti6Al4V Alloy. Machines. 2024; 12(10):709. https://doi.org/10.3390/machines12100709

Chicago/Turabian StyleLöschner, Piotr, Munish Kumar Gupta, Piotr Niesłony, Mehmet Erdi Korkmaz, and Muhammad Jamil. 2024. "Determination and Verification of the Johnson–Cook Constitutive Model Parameters in the Precision Machining of Ti6Al4V Alloy" Machines 12, no. 10: 709. https://doi.org/10.3390/machines12100709

APA StyleLöschner, P., Gupta, M. K., Niesłony, P., Korkmaz, M. E., & Jamil, M. (2024). Determination and Verification of the Johnson–Cook Constitutive Model Parameters in the Precision Machining of Ti6Al4V Alloy. Machines, 12(10), 709. https://doi.org/10.3390/machines12100709